Airbagit I-Beam User Manual

Typical Front

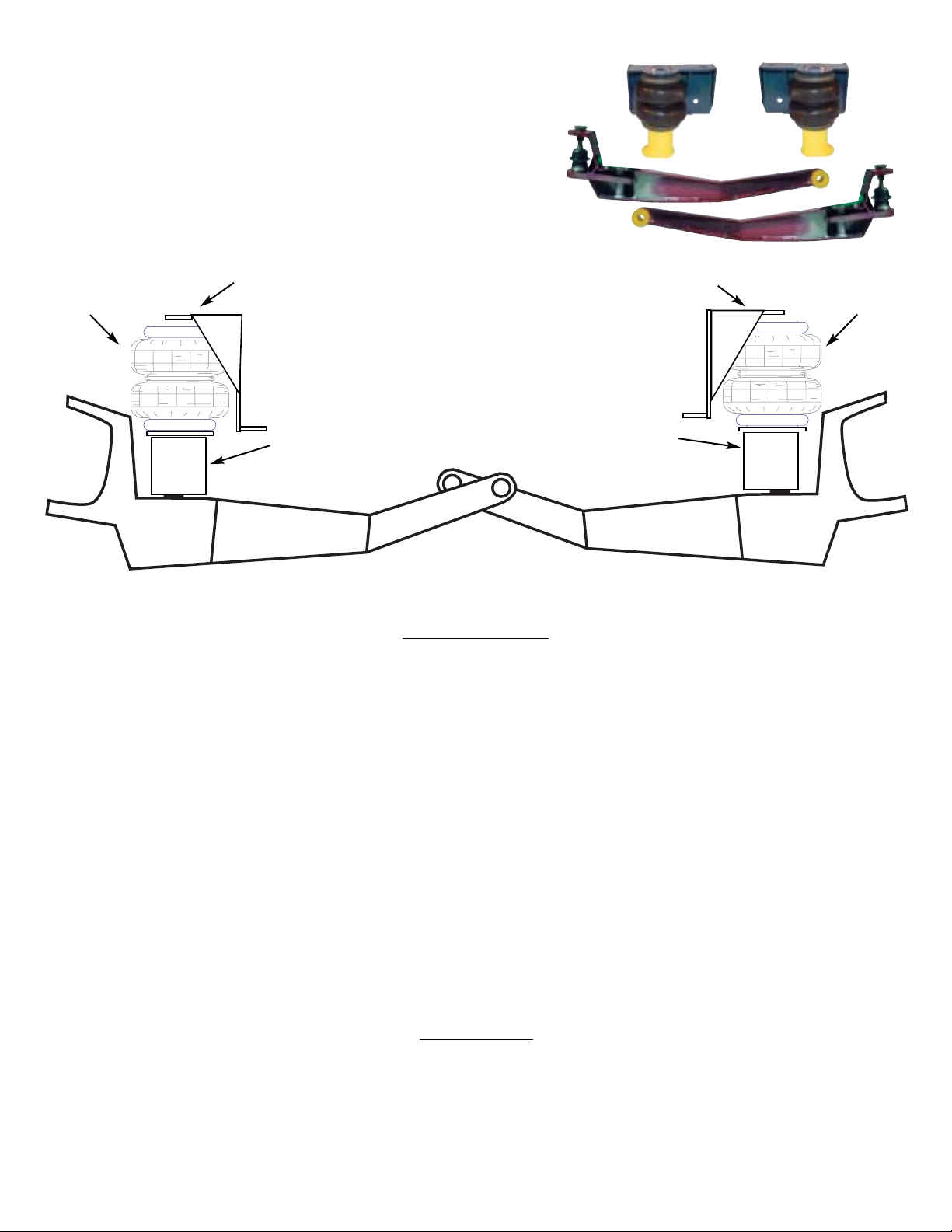

Typical Front Air Bag #3

Installation Instructions

(click on each image to purchase individual parts)

DIAGRAM #11

AIR BAG FRNT KIT 3.PDF

TOP BRACKET

AIR BAG

BOTTOM BRACKET

I-BEAM

TOP BRACKET

AIR BAG

BOTTOM BRACKET

I-BEAM

THIS IS AWELD-ON KIT. BOLT HOLES ARE FOR LOCATING PRIOR TO WELDING. THIS KIT

IS FOR USE WITH FACTORY I-BEAMS. IF YOU HAVE HAD LOWERED BEAMS INSTALLED,

YOU WILL HAVE TO USE AN OPTIONAL LOWERED BARREL.

1. REMOVE SHOCK ABSORBERS AND COIL SPRINGS.

2. REMOVE THE STOCK UPPER SPRING/SHOCK MOUNTS FROM THE FRAME. THE PASSENGER SIDE FRAME RAIL IS FLATAND THE NEW PART WILL BE INSTALLED DIRECTLY

CENTERED OVER THE SPRING PERCH MOUNT.

3. THE DRIVERS SIDE IS CURVED AND MUST BE CUT WITH A DIE GRINDER. REMOVE

JUST ENOUGH TO FIT NEW BRACKETS SNUGLY IN PLACE. TACK/WELD OR BOLT TEMPORARILY IN PLACE. WHEN YOU ARE SURE OF POSITION, THEN HAVE ACERTIFIED

WELDER APPL Y FINISHED WELDS.

DO NOT RUN AIRBAGS WITH LESS THAN 10LBS PRESSURE. NO WARRANTY ON AIR

BAGS, IT IS YOUR RESPONSIBILITY TO MAKE SURE AIRBAGS ARE CLEAR OF ANY

OBSTRUCTIONS.

IMPORT

ANT:

TACK-WELD AIRBAG BRACKETS TO FRAME MAKING SURE THAT THE BAG IS STRAIGHT

UP AND DOWN IN RELATION TO THE UPPER BAG MOUNTAND THE I-BEAM SPRING

PERCH BOLT, WHEN YOU ARE AT YOUR DESIRED RIDE HEIGHT. DO NOT USE ANY

EXISTING HOLES IN THE NEW BRACKETS AS A GUIDE. RADIUS ARMS WILL ALLOW AN

ADDITIONAL 1/2” FINAL ADJUSTMENT IF NEEDED

all FORDS WITH IBEAMS 1980 THRU 1996

and FORD RANGERS 1982 THRU 1997

INSTRUCTIONS:

Typical I-Beam

Installation Instructions

(Click on picture of part to purchase.)

OPTIONAL & RECOMMENDED

ECCENTRIC BUSHING

STOCK PARTS

NOT INCLUDED

STOCK PARTS

NOT INCLUDED

TYPICAL ASSEMBLY

STOCK PARTS

NOT INCLUDED

STOCK PARTS

NOT INCLUDED

OPTIONAL & RECOMMENDED

ECCENTRIC BUSHING

TYPICAL ASSEMBLY

STOCK PARTS

NOT INCLUDED

1. LOOSEN BOTTOM BALL JOINT NUTS AND REMOVE UPPER BALL JOINT PINCH BOLTS. REMOVE SPINDLE FROM AXLE BEAM. DO NOTHANG BRAKE ASSEMBLY BY

BRAKE LINE. PLACE JACK UNDER I-BEAM. REMOVE SHOCK AND SWAY BAR LINKS.

2. REMOVE RADIUS ARM-TO-AXLE ASSEMBLY BOLT. LOWER JACK SLOWLY. REMOVE THE COIL SPRING, AXLE PIVOT BOLT, AND I-BEAM.

3. LUBRICATE THE SPACERS AND BUSHING FACES WITH WHEEL BEARING GREASE. NOTE:DO NOT TIGHTEN AT THIS TIME. REINSTALL AXLE PIVOT BOLT. REPLACE

FRONT COIL SPRING PERCHES. INSTALL COIL SPRING. CHECK FOR PROPER SEATING. REASSEMBLE USING FACTORY TORQUE SPECS AND LUBRICATION AS OUTLINED ABOVE. TIGHTEN AXLE PIVOT BOL TS AND INSTALLSHOCKS.

4. NEXT , RELOCATE THE FACTORY ANTI SWAY BAR IF SO EQUIPPED. THE FRONT ANTI SWAY BAR IS MOUNTED ON THE BACK OF A STAMPED STEEL CROSS MEMBER

WHICH IS MOUNTED BENEATH THE RADIATOR. REMOVE THE FOUR BOLTS HOLDING THE CROSS MEMBER TO THE FRAME.

5. NOTE: IN SOME APPLICATIONS YOU WILL NEED TO FLIP AND INVERT THE STOCK END LINKS AND YOU MAY NEED TO RELOCATE THE SWAYBAR MOUNT FORWARD

1”. REMOVE THE SWAY BAR FROM THE CROSS MEMBER BY UNBOLTING THE SADDLE BRACKETS. YOU WILL NEED TO REMOUNT THE SADDLE BRACKETAS FAR

DOWN IN THE CROSS MEMBER AS FAR AS IT WILL GO. MARK THE HOLE POSITIONS AND DRILL NEW HOLES FOR THE ORIGINAL BOLTS.

6. IN ORDER TO MOUNT THE SWAY BAR TO THE ORIGINAL MOUNT ON THE SPRING PERCH. YOU MUST NOW EXCHANGE THE ANTI SWAY BAR END LINKS (MOUNTING

THE LEFT LINK TO THE RIGHT SIDE, AND THE RIGHT LINK TO THE LEFT SIDE, UPSIDE DOWN SO THAT THE ANTI SWAY BAR IS ABOVE THE ROD INSTEAD OF BELOW). IT

MAY BE NECESSARY TO SLIGHTLY GRIND THE REAR WARD INNER CORNERS SO THATTHE BAR DOES NOT RUB AGAINSTTHE PLATE.

7. TORQUE EVERY BOLTON ALL PARTS TO FACTORY SPECS AND RE-TORQUE AFTER DRIVING. PROCEED TO THE NEAREST ALIGNMENT SHOP. NOTE: FORD REPLACEMENT ADJUSTABLE ECCENTRIC BUSHINGS WILLBE NEEDED FOR ALIGNMENT TO BRING INTO FACTORYSPECS.

F-150/250/350 ONLY

1. BEFORE REPLACING THE COIL SPRING, PLACE THE ROUND DONUT WASHER ON THE CASST SPRING MOUNT.

2. BEFORE REPLACING THE NUT AND WASHER ON THE SPRING CENTER BOLT, INSERT THE URETHANE ECCENTRIC BUSHING INSIDE THE BOTTOM OF THE COIL

SPRING.

3.BEFORE INSTALLING THE STOCK SPINDLE ON TO THE I-BEAM, WE RECOMMEND GRINDING APPROXIMATLEY 3/8” OF MATERIAL OFF ON A45 DEGREE ANGLE USING

A SMALL DIE GRINDER. THIS STEP IS NECCESSARY OTHERWISSSE SOME ALIGNMENT CAMS WILL CAUSE INTERFERENCE BETWEEN THE UPPER PORTION OF THE

SPINDLE AND I BEAM.

IBEAM.PDF

DIAGRAM #13

Loading...

Loading...