Ag Spray LA5000 User Manual

CONTINUING TO

MANUFACTURE AND SELL

QUALITY SCHABEN PRODUCTS.

operation & maintenance manual

LA5000

BAKERSFIELD, CA

4450 STATE RD, 93308

877.724.2236

COLUMBUS, NE

5834 E 23RD ST, 68601

800.274.1025

VISIT US ONLINE @ WWW.AGSPRAY.COM

DOTHAN, AL

1563 S OATES ST, 36301

800.227.4098

GREENWOOD, MS

104 EASTMAN ST, 38930

800.844.4524

HOPKINSVILLE, KY

1100 NEW INDUSTRY LN, 42240

LIQUID

APPLICATOR

800.637.7172

NEWTON, KS

7000 SCHABEN CT, 67114

800.394.7662

OTHELLO, WA

81 E PINE ST, 99344

800.634.2026

TEMPE, AZ

8464 S KYRENE RD, 85284

877.974.7166

INTRODUCTION

1. Read and understand the Operators Manual and all

safety signs before using.

2. Place all controls in neutral, stop tractor engine, turn

monitor off, set park brake, remove ignition key, wait

for nozzles to stop spraying before servicing,

adjusting, or repairing.

3. Before using it in a field, be familiar with all potential

hazards: trees, rocks, ditches, gullies, etc. Plan the

spraying route to avoid hazards. Remember you are

driving a wide machine. USE CAUTION WHEN

CORNERING.

4. Keep hands, feet, hair and clothing away from all

moving and/or rotating parts.

5. Do not allow riders on the applicator or tractor during

operation or transporting.

6. Clear the area of all bystanders, especially children,

before starting or filling with water or chemical.

7. Stay away from wing pinch points when folding or

extending wings. Keep others away.

8. Stay away from power lines when extending or

folding wings. Electrocution can occur without

direct contact.

13. In case of poisoning, get immediate medical attention.

15. Do not eat in the field when side dressing.

16. Before applying pressure to the hydraulic system,

make sure all components are tight and that steel

lines, hoses and couplings are in good condition.

17. Before applying pressure to fertilizer system make

sure that all connections are tight and that all hoses

and fittings are in good condition.

18. Review safety instructions annually.

PRE-OPERATION CHECKLIST

Before operating the Applicator and each time thereafter,

the following areas should be checked off:

1. Lubricate the machine per the schedule outlined in

the “Maintenance Section”.

2. Use only a tractor of adequate power and weight to

operate the Applicator.

3. Ensure that the machine is properly attached to the

tractor. Be sure that a mechanical retainer is installed

through the drawbar pin and the safety chain is

attached to the drawbar cage. Jack is in full up

position.

4. Check the hydraulic system. Ensure that the

hydraulic reservoir in the tractor is filled to the

required specifications.

5. Inspect all hydraulic lines, hoses, fittings and couplers

for tightness. Use a clean cloth to wipe any

accumulated dirt from the couplers before

connecting to the hydraulic system of the tractor.

7. Calibrate the Applicator if it is the start of the season

or a new chemical is being used. Calibrate as

specified in rate control manual.

8. Check the condition and routing of all chemical hoses

and lines. Replace any that are damaged. Re-route

those that are rubbing pinched or crimped.

9. Check the spray pattern of each nozzle. Remove and

clean or replace any that have an unusual pattern.

10. Remove the steel mesh line filters and wash with

clean water. Reinstall.

11. Check that all connections in the electrical system are

connected and tight.

13. Before unfolding boom remove transport wing lock

pins (Figure 7) and tower cylinder Transport stop

(Figure 6) Reinstall lock pins and tower stop

before parking sprayer.

6. Check the tires and ensure that they are inflated to

the specified pressure.

1 - LA5000 LIQUID APPLICATOR OPERATION & MAINTENANCE MANUAL

PLACING IN STORAGE

At the end of the spray season, the machine should be thoroughly inspected and prepared for storage. Repair or replace

any worn or damaged components to prevent any unnecessary

down time at the beginning of the next season. Follow this

procedure:

1. Thoroughly wash the machine using a hose or a

pressure washer to remove all dirt, mud, debris or

residue.

2. Thoroughly wash the inside of the tank.

3. In climates that encounter freezing temperatures

during the storage period, the following

preparation should be done:

a. Add 10 gallons (40 liters) of a potable RV

antifreeze to the tank.

b. Run unit for 5 minutes in the spray cycle to

circulate solution to all parts of the circuit.

c. While circulating the fluid, open and close all the

valves in the system to flush all the water from

the system.

e. Flush the solution out the booms.

f. Open all disconnects and drain hoses, pumps,

filters, solenoids and tanks.

g. Remove nozzles from boom Disassemble and

wash nozzle, Spring, diaphragm and housing.

Store inside.

4. Lubricate all grease points. Make sure all grease

cavities have been filled with grease to remove

any water residue from the washing.

5. Inspect all the hydraulic hoses, couplers and fittings.

Tighten any loose fittings. Replace any hose that

is badly cut, nicked, abraded or is separating from

the crimped end of a fitting.

6. Inspect all the spray hoses and fittings. Tighten any

loose fittings. Replace any hose That is badly

cut, nicked, abraded or is separating from a fitting.

7. Touch up all paint nicks and scratches to prevent

rusting.

**STORAGE SAFETY**

1. Store unit in an area away from human activity.

2. Do not permit children to play on or around the

stored applicator.

3. Unhook and store in the transport configuration.

REMOVING FROM STORAGE

When removing from storage and preparing to use,

follow this procedure.

1. Clear the area of bystanders, especially small

children, and remove foreign objects from the

machine and the working area.

2. Check

a. Tank for cracks

b. Tank hold down hardware

c. All hardware. Tighten as required.

d. Tire pressure.

e. All sprayer and hydraulic lines, fittings and

connections. Tighten as required.

3. Lubricate all grease fittings.

4. Replace any defective parts.

5. Fill the tank with 20 gallons (75 liters) of clean water

and run for 5 minutes. Open and close all valves

several times. Flush water through the booms.

6. Repeat step 5.

7. Calibrate the pump, nozzles and sprayer before using.

8. Go through the pre-operation checklist before using.

AGSPRAY.COM 2

LIMITED WARRANTY

Ag Spray Equipment warrants to the buyer that the new machinery is free from defects in material and workmanship.

This warranty is only effective as to any new machinery which

has not been altered, changed, repaired or treated since its

delivery to the buyer, other than by Ag Spray Equipment or its

authorize dealers or employees, and does not apply to accessories, attachments, tools or parts, sold or operated with the

new machinery, if they have not been manufactured by Ag Spray

Equipment.

Ag Spray Equipment shall only be liable for defects in the materials or workmanship attributable to faulty material or bad

workmanship that can be proved by the buyer, and specifically

excludes liability for repairs arising as a result of normal wear

and tear of the new machinery or in any other manner whatsoever, and without limiting the generality of the foregoing,

excludes application or installation of parts not completed in

accordance with Ag Spray Equipment operator’s manual, specifications or printed instructions.

Written notice shall be given by registered mail, to Ag Spray

Equipment within seven (7) days after the defect shall have

become apparent or the repairs shall have become necessary,

addressed as follows: Ag Spray Equipment, 5834 East 23rd

Street, Columbus, NE 68601.

This warranty shall expire 2 years after the date of delivery of

the new machinery.

If these conditions are fulfilled, Ag Spray Equipment shall at

its own cost and at its own option either repair or replace any

defective parts provided that the buyer shall be responsible for

all expenses incurred as a result of repairs, labor, parts, transportation or any other work, unless Ag Spray Equipment has

authorized such expenses in advance.

The warranty shall not extend to any repairs, changes, alterations, or replacements made to the new equipment other than

by Ag Spray Equipment or its authorized dealers or employees.

This warranty extends only to the original owner of the new

equipment.

Rubber parts are not warranted. (including tires, hoses, grommets)

This warranty is limited to the terms stated herein and is in lieu

of any other warranties whether express or implied, and without

limiting the generality of the foregoing, excluded all warranties,

express or implied or conditions whether statutory or otherwise

as to quality and fitness for any purpose of the new equipment.

Ag Spray Equipment disclaims all liability for incidental or consequential damages.

This sprayer is subject to design changes and Ag Spray Equipment

shall not not be required to retro-fit or exchange items on previously sold units except at its own option.

OPERATING INSTRUCTIONS

1. Ensure applicator is connected securely to tractor draw bar

with clevis pin and safety chain (Figure 1).

1

3 - LA5000 LIQUID APPLICATOR OPERATION & MAINTENANCE MANUAL

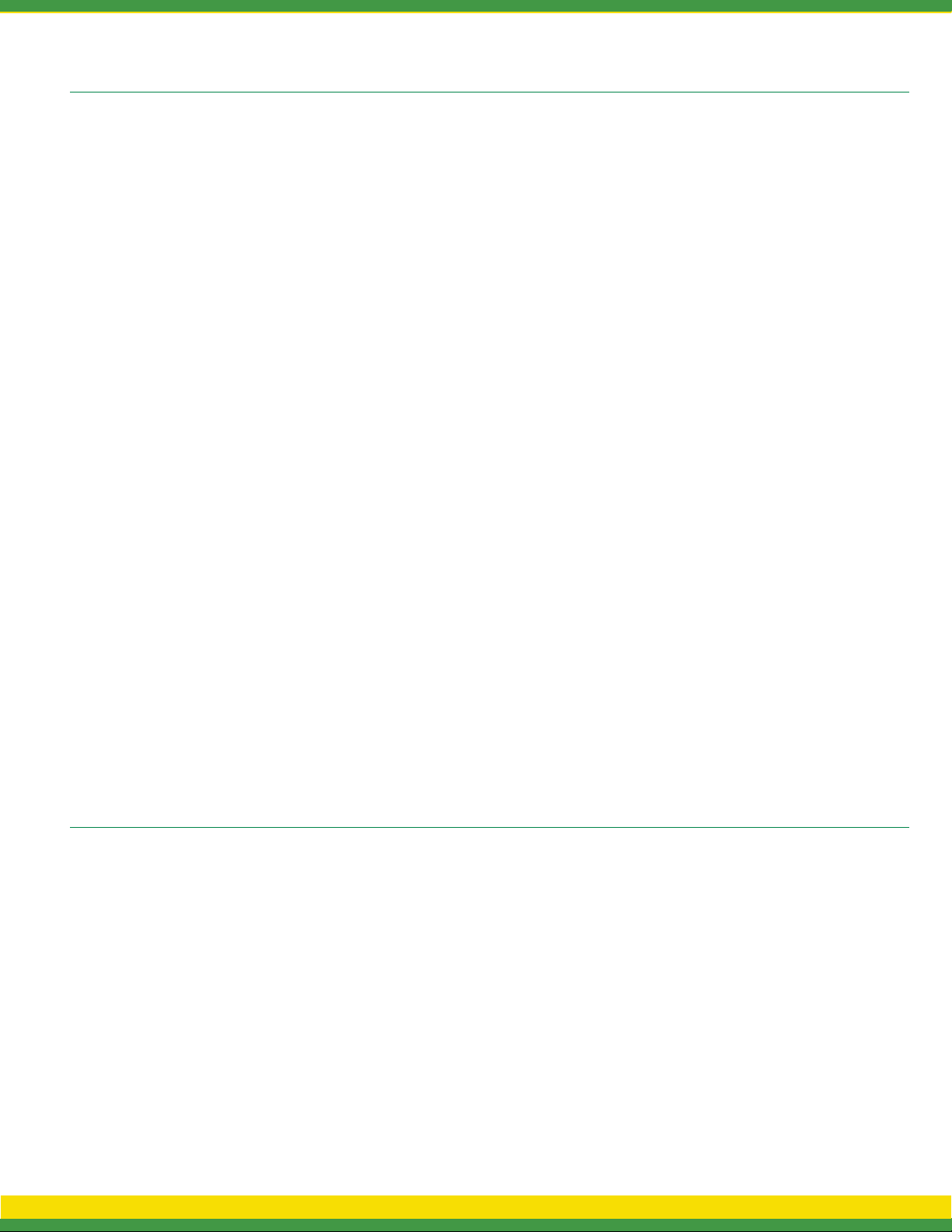

2. Connect applicator hydraulic hoses to the tractor remote

couplers. The blue hoses are for the main bar height control.

The green hoses are for the main wing fold. The yellow hoses

are for secondary wing fold on 35’ bar (Figure 2).

2

3. Connect wiring harness if using hydraulic pump with rate

control.

4. Grease Applicator (Refer to Mainentance).

8. After unfolding main wing, engage hydraulic lever in “constant

pressure.” This is necessary to allow wings to maintain

constant depth and follow uneven terrain, as well as the ability

to “gullwing” (Lift both wings evenly when turning. See #9).

5. Before road travel, install all locking collars on toolbar

cylinders and safety pins on wings.

6. Remove locking collars as needed to maintain a depth of

4 to 5 inches. Constant down pressure on main lift is not

recommended (weight of toolbar will keep unit in the ground).

Leave hydrualic selector in neutral for field operation.

7. Remove safety pins on wing cylinders. Wing cylinders remote

will run in constant while down (Figure 7).

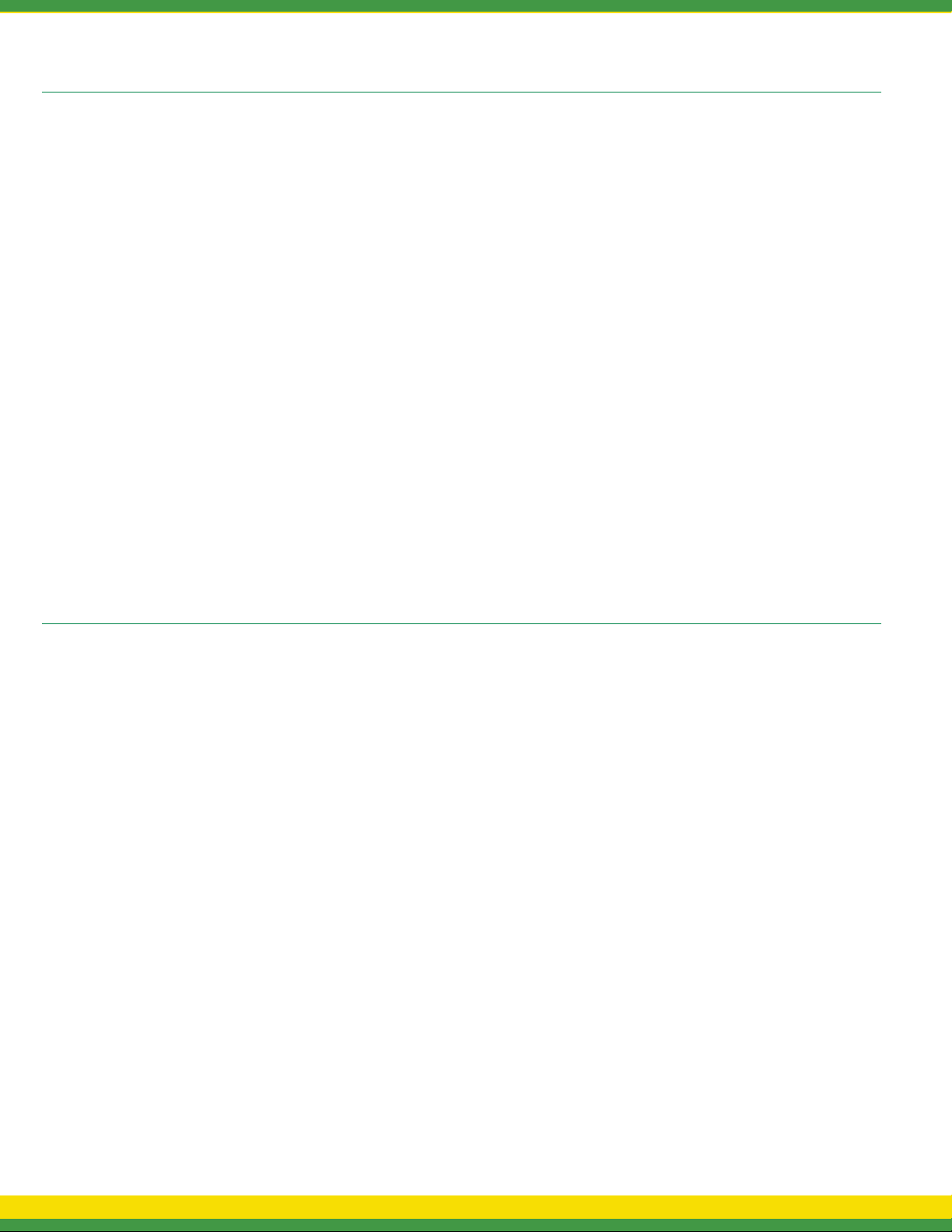

The Applicator is equipped with adjustable down pressure relief

valve on wing cylinders. The valve is preset at 800 PSI. This may

be adjusted as needed. The relief valve is located under tongue,

and requires an allen wrench to adjust (clockwise to increase

pressure and counterclockwise to decrease pressure.) (Figure 8).

6

9. Field Operation: When you come to the end of the field.

1. Lift main section

2. Pull back on main wing lever long enough to lift both

wings slightly (“gullwing”).

3. After turning, lower main section and wing section

and return wing hydraulics to constant pressure.

10. Check and clean screens as needed.

11. Pump Settings

Optional Ground Drive Pump

11a - Remove tranport pin

11b - Use John Blue pump setting slide chart. Loaded radius is

9.75 and sprocket ratio is 32 drive and 18 driven.

11c - Set pump to recommended setting.

Optional Hydraulic Drive Pump

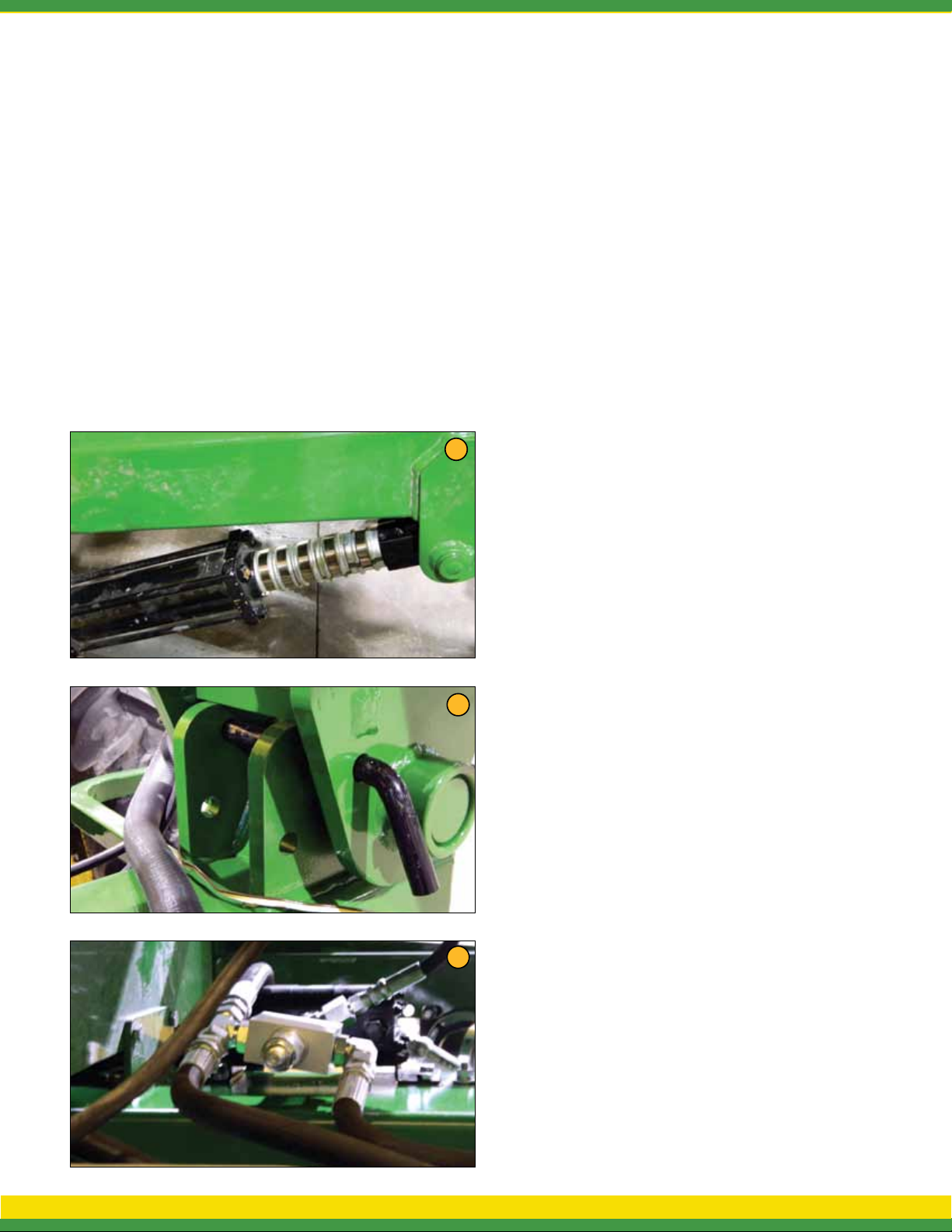

a. Hydraulic pump hoses supplied on the applicator

include (1) 1/2” line and (1) 3/4” line. The 1/2” hose

is the hydraulic supply (in/pressure) and the 3/4”

hose is the return (out/non-pressure).

NOTE: It is recommended for optimal pump performance that

the 3/4” return line connect directly to the tractor hydraulic

reservoir (not tractor SCV port). Doing so eliminates possible

back pressure restriction on the 3/4” return line. Excessive

back pressure restriction can cause hydraulic orbital motor

damage/failure.

b. Proper hydraulic pump disengagement. When shutting off

the pump, move the selector to the FLOAT position to allow

the centrifugal pump to come to a gradual stop. Standard

7

8

spool valves, which are found on all tractor hydraulic systems,

can cause potentially damaging high peak pressures in the

hydraulic system when closed, because of abrupt shutoff of

oil flow in both the supply and return lines.

c. Close and lock down the bypass adjusting screw in the

hydraulic motor (if applicable).

Switch rate controller to manual and press the “+” button on

TeeJet or “Increase” button on Raven, hold for 8 seconds. Then

press the “-” button on TeeJet or “Decrease” button on Raven for

4 seconds.

Set the tractor hydraulic flow control valve for minimum hydraulic

oil flow to the remote outlet (Tortoise position).

Start the tractor and allow the hydraulic oil to circulate for

approximately 10 to 15 minutes or until adequately warmed.

Prime the centrifugal pump with all valves open.

Open the sprayer control regulating valve and the boom shut-off

valves.

Slowly adjust the tractor hydraulic flow control valve until the

desired boom pressure is attained.

NOTE: See manufacture pump operators manual for further

setup and maintenance.

AGSPRAY.COM 4

BREAK-IN

Although there are no operational restrictions on the applicator when used for the first time, it is recommended that

the following mechanical items be checked:

A. After operating for 1/2 hour

1. Re-torque all the wheel bolts.

2. Re-torque all other fasteners and hardware.

3. Check that all electrical connections are tight.

4. Check that no fertilizer or hydraulic lines are

being pinched or crimped. Re-align as required.

5. Check that all nozzles are working properly.

Clean or replace as required.

6. Lubricate all grease fittings.

B. After 5 hours and 10 hours of operation

1. Retorque all wheel bolts, fasteners and hardware.

2. Check fertilizer and hydraulic line routing.

3. Check that all nozzles are working properly.

4. Then go to the normal servicing and maintenance

schedule as defined in the Maintenance Section.

5. Lift right hand side of machine and check main

wheel bearing for proper play (slight wobble when pulling

on top of wheel). Repeat for left hand side.

! MAINTENANCE SAFETY !

1 Review the Operator’s Manual and all safety items

before working with, maintaining or operating the

Applicator.

SERVICE AND MAINTENANCE

2. Place all controls in neutral, stop the tractor engine,

turn monitor off, set park brake, remove ignition key,

wait for nozzles to stop spraying before servicing,

adjusting, repairing or unplugging.

3. Follow good shop practices:

- Keep service area clean and dry

- Be sure electrical outlets and tools are properly

grounded

- Use adequate light for the job at hand.

4. Before applying pressure to a hydraulic system, make

sure all components are tight and that steel lines,

hoses and coupling are in good condition.

5. Before applying pressure to fertilized system, make

sure that all connection are tight and that all hoses

and fittings are in good condition.

6. Install wing lock pins and tower stops before relieving

pressure from hydraulic circuit to service Applicator.

9. Place stands or blocks under the frame before

working beneath the machine.

10. Wear safety goggles, neoprene gloves and protective

clothing when working on the Applicator filled with

active chemical.

11. Wash machine to remove all chemical residue before

working on unit. Wear appropriate protective gear at

all times.

12. Protect yourself from chemical contamination.

7. Keep hands, feet, clothing and hair away from all

moving and/or rotating parts.

8. Clear the area of bystanders, especially children,

when carrying out any maintenance and repairs or

making any adjustments or filling.

5 - LA5000 LIQUID APPLICATOR OPERATION & MAINTENANCE MANUAL

Loading...

Loading...