Owner's Manual

Boom Assemblies (with Carrier Support)

6-Row Boom Assembly

w/QJ Nozzles

8-Row Boom Assembly

w/QJ Nozzles

General Information

Thank you for purchasing this Ag Spray product. The

purpose of this manual is to assist you in operating and

maintaining your boom assembly. Please read it carefully,

as it furnishes information which will help you achieve

years of trouble-free operation.

Warranty/Parts/Service

Products are warranted for one year from date of purchase

against manufacturer or workmanship defects.

Commercial users have a 90 day warranty.

Your authorized dealer is the best source of replacement parts

and service. To obtain prompt, efficient service, always

remember to give the following information...

- Correct Part Description and/or part number.

- Model number/Serial number of your sprayer.

Part descriptions and part numbers can be obtained from the

illustrated parts list section(s) of this manual.

Whenever you need parts or repair service, contact your

distributor/dealer first. For warranty work, always take your

original sales slip, or other evidence of purchase date, to your

distributor/dealer.

Technical Specifications

Model

BA6D

•

(6 Row - 21 Ft. Wide)

Model

•

(8 Row - 28 Ft. Wide)

All Models:

•

- Adjustable Spacing Nozzles

•

- Height Adjustment

•

- 4-Way Hinge for Boom Protection

•

- Cross-Over Folding

•

- Tips/Caps/Strainers are Standard

•

- Fits all Various Carriers

•

- Square Boom Tube Construction

•

www.agspray.com

1100 New Industry Lane

Hopkinsville, KY 42240

P: 800-637-7172

F: 270-885-7392

Form No. 1916 [5008228 (11/09)] Printed in the U.S.A.

Boom Assembly

BA8D

Boom Assembly

104 Eastman Street

Greenwood, MS 38930

P: 800-844-4524

F: 662-455-4442

1563 S. Oates Street

Dothan, AL 36301

P: 800-227-4098

F: 334-673-1974

Assembly

Calibration

1. Mount the upright angles to the inside of the mounts on the

carrier, using the supplied bolts/nuts. Attach the backrack to the

upright angles using the square u-bolts & nuts. NOTE: The

backrack can be mounted in either a high or low position and the

uprights can be adjusted for desired height. Attach the UBrackets as shown in the exploded view drawing.

2. Loosen the eye-bolts and remove the 7" hinge bolt(s). Line up

the outer booms and reassemble the hinge bolt through the outer

boom yoke, the hinge casting, and the spring connector. Tighten

the eye-bolt until the spring is at the desired tension. Lock the

eye-bolt in place with the inner whiz flange locknut. The 8-Row

booms use extensions on the outer booms. Bolt on the boom

extensions using the bolts/nuts provided. (see exploded view

drawing)

3. Hook an end of each boom chain on an "S" hook attached to

the top bar tube. Place a slide clamp onto each outer boom.

Place the other end of the boom chain between the ears of the

slide clamp and secure with the bolt/nut per the exploded view.

Level the outer booms by moving the slide clamps in or out as

needed. Tighten the bolts in the slide clamps to hold the clamps

in place.

4. Attach the appropriate hose assemblies onto each of the three

boom sections. the center section has (5) nozzles with "L"

connectors on each end. Starting at the center, the nozzles

should be placed about 20 inches apart.

5. Join the designated feeder hose to each boom section and

secure in place with hose clamps.

Tip Selection

Important note:

The tips supplied as standard with this boom assembly are

number 8003VP tips. when you refer to the rate charts found in

this owners manual, you will note that they have a GPA range of

15.4 to 22 GPA (Gallons Per Acre). This is tabulated at 5 MPH,

and from 30 to 60 psi and 20 inch nozzle spacing. These rates

are based on water. Please read this tip selection section

carefully before attempting to operate your boom assembly

The selection of proper tips for the boom is determined by the

gallon per acre (GPA) requirement which is specified on the

chemical label. The following characteristics also have a

determining factor and must be considered:

Chemical labels may show application rates in gallons per

acre, gallons per 1000 square feet, or gallons per 100

square feet. You will note that the tip chart shows all 3 of

these rating systems.

Once you know how much you are going to spray, then

determine (from the tip chart) the spraying pressure (PSI),

and the spraying speed (MPH).

Determining the proper speed of the pulling vehicle can be

done by marking off 100, 200, & 300 feet. The speed chart

indicates the number of seconds it takes to travel the

distances. Set the throttle and with a running start, travel the

distances. Adjust the throttle until you travel the distances in

the number of seconds indicated by the speed chart. Once

you have reached the throttle setting needed, mark the

throttle location so you can stop and go again, returning to

the same speed.

Add water and proper amount of chemical to the tank and

drive to the starting place for spraying.

Testing the Sprayer

NOTE:

It is VERY important for you to test your sprayer with

plain water before actual spraying is attempted. This will

enable you to check the sprayer for leaks, without the

possibility of losing any expensive chemicals.

Add water to the tank & drive to the starting place for

spraying. When you are ready to spray, turn the boom valve

to the "on" position. This will start solution spraying from the

tips of the boom. The pressure will decrease slightly when the

boom is spraying. Adjust the pressure by turning the

"ON/OFF" valve lever on the bypass line valve.

Read the operating instructions and Initially begin spraying by

closing the 'bypass' valve (this is the center ON/OFF valve

located at the center port of your manifold assembly) and

opening the boom line valve (this is the 'other' valve on the

manifold). This will enable the air in the line to be eliminated

(purged) through all the tips, while building pressure. When

everything tests all right (no leaks, & good pressure), add the

desired chemicals to the mixture and water combination and

start your spraying operation. Adjust the pressure and spray

as you did in the testing procedure.

Speed of spraying (MPH)

1.

Boom nozzle spacing (specified in inches)

2.

Solution weight and conversion factor (CF)

3.

Gallons of solution to be sprayed per acre

4.

Spraying pressure

5.

Useful Formulas:

GPM - Gallons Per Minute

GPA - Gallons Per Acre

MPH - Miles Per Hour

Speed Chart

Time Required in seconds to travel a distance of:

100 Ft.

68 sec.

34

23

17 34

14

11

9.7

8.5

7.6

6.8

200 Ft.

136 sec.

Page 2

Speed in M.P.H.

(Miles per Hour)

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

Conditions of weather and terrain must be considered when

setting the sprayer. Do not spray on windy days. Protective

clothing must be worn in some cases.

Be sure to read the chemical label(s) correctly!

Suggested Minimum Spray Heights

Nozzle Height

Nozzle Type

300 Ft.

68

45

27

23

19

17

15

14

205 sec.

102

68

51

41

34

29

26

23

20

TeeJet (Flat Spray)

TeeJet (XR TeeJet)

TeeJet (XR TeeJet)

FloodJet

* Not Recommended

*** Wide angle spray tip is influenced by nozzle orientation

The critical factor is to achieve a double spray pattern overlap.

Spray

Angle

65

80

110

120

20"

Spacing

°

22"-24"

°

17"-19"

°

12"-14"

*** ***

°

30"

Spacing

33"-35"

26"-28"

16"-18"

***

40"

Spacing

NR*

NR*

NR*

Nozzle Spacing

If the nozzle spacing on your boom is different

from those tabulated, multiply the tabulated

GPA coverage by one of the following factors.

Where Tables are Based on 20" Nozzle Spacing

Other Spacing

Conversion

Factor

8"

2.5

1.67

1.43

1.25

18"10" 12" 16"14" 30"22" 24"

1.11

.91

.83

.66

Where Tables are Based on 30" Nozzle Spacing

Other Spacing

Conversion

Factor

26"

1.15

28"232"

1.07

.94

34"

.88

36"

.83

38"

.79

40"

.75

42"

.71

44"

.68

Where Tables are Based on 40" Nozzle Spacing

Other Spacing

Conversion

Factor

28"

1.43

30"

1.33

32"

1.25

34"

1.18

36"

1.11

38"

1.05

42"

.95

44"

.91

48"

.83

Spraying Solutions Other Than Water

Flow Rate

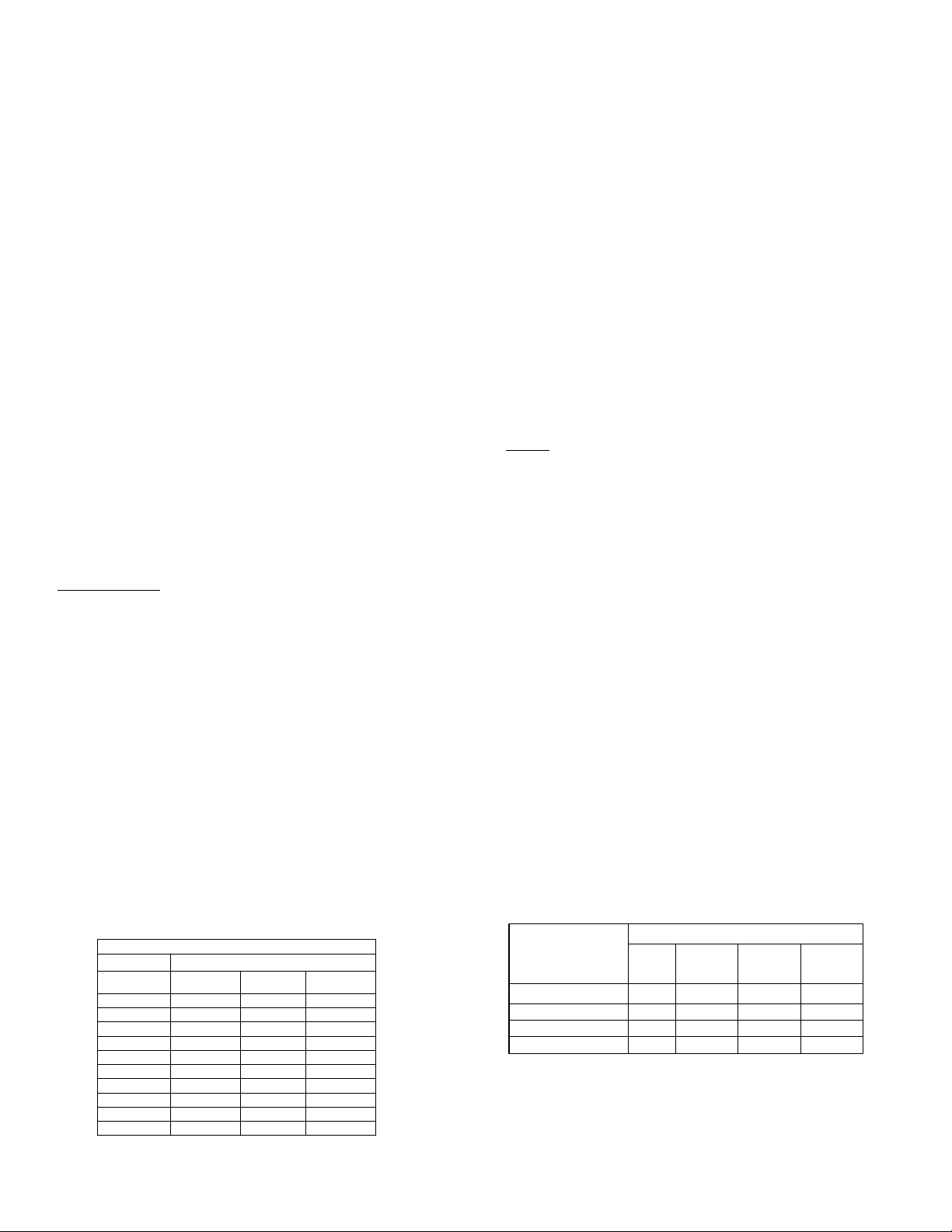

Nozzle flow rate varies with spraying pressure. In general,

the relationship between GPM and pressure is as follows:

This equation is explained by the illustration below. Simply

stated, to double the flow through a nozzle, the pressure be

increased four times.

Effect of Pressure on Volume

8002

@ 10 psi @ 40 psi

8002

Since all the tabulations are based on spraying water, which

weighs 8.34 lbs per USA gallon, conversion factors must be

used when spraying solutions which are heavier or lighter than

water. To determine the proper size nozzle for the solution to be

sprayed, first multiply the desired GPM or GPA of solution by

the rate conversion factor. Then use the new converted GPM or

GPA rate to select the proper size nozzle.

Example:

Desired application rate is 20 GPA of 28% Nitrogen.

Determine the correct nozzle size as follows:

GPA (Solution) x Conversion Factor = GPA

20 GPA (28%) x 1.13 = 22.6 GPA (Water)

The applicator should choose a nozzle size that will supply 22.6

GPA of water at the desired pressure.

Miscellaneous Conversion Factors

One Acre = 43,560 square feet = 0.405 Hectacre

One Hectacre = 2.471 Acres

One Gallon Per Acre = 9.35 Liters Per Hectacre

One Mile = 5280 Feet = 1610 Meters = 1.61 Kilometers

One Gallon = 128 Fluid Ounces = 8 Pints = 4 Quarts = 3.79

Liters = 0.83 Imperial Gallons

One Pound Per Square Inch = 0.069 bar. = 6.895 Kilo-Pascals

One Mile Per Hour = 1.609 Kilometers Per Hour

Higher pressure not only increases the flow rate of the nozzle,

but it also influences the droplet size and the rate of orifice

wear. As pressure is increased, the droplet size decreases

and the rate of orifice wear is increased.

The values given in the tabulation section of this owners

manual indicate the most commonly used pressure ranges for

the associated spray tips.

Weight of Solution

7.0 lbs per gallon

8.0 lbs per gallon

8.834 lbs per gallon (Water)

9.0 lbs per gallon

10.0 lbs per gallon

10.65 lbs per gallon (28% Nitrogen)

11.0 lbs per gallon

12.0 lbs per gallon

14.0 lbs per gallon

Specific

Gravity

.84 .92

.96 .98

1.00 1.00

1.08 1.04

1.20 1.10

1.28 1.13

1.32 1.15

1.44 1.20

1.68 1.30

Conversion

Factors

0.1 gpm 0.2 gpm

Effect of Pressure on Spray Angle

8002 8002

18"

@ 15 psi

18"

60°

23"

@ 40 psi

80°

30"

Higher pressure not only increases the flow rate of the

nozzle, but it also influences the droplet size and the rate of

orifice wear. As pressure is increased, the droplet size

decreases, and the rate of orifice wear is increased.

The values given in the tabulation section of this owner's

manual indicate the most commonly used pressure ranges

for the associated spray tips.

Spray Angle and Coverage

Depending on the nozzle type and size, the operating

pressure can have a significant effect on spray angle and

quality of spray distribution. As shown above for an 8002 flat

spray tip, lowering the pressure results in a smaller spray

angle and a significant reduction in spray coverage.

Tabulations for spray tips shown in this owner's manual are

based on spraying water. Generally, liquids more viscous

than water form relatively smaller spray angles. Whereas,

liquids with surface tensions lower than water will produce

wider spray angles. In situations where the uniformity of

spray distribution is important, be careful to operate your

spray tips within the proper pressure range.

NOTE: Suggested minimum spray heights for broadcast

spraying are based upon nozzles spraying water at the

rated spray angle.

Page 3

After Spraying

Winter Storage

After use, fill the sprayer tank part way with water. Start the

sprayer, and allow the clear water to be pumped through the

plumbing system and out through the spray nozzles.

Refill the tank about half full with plain water and use a chemical

neutralizer, such as 'Nutra-Sol', or equivalent, and repeat

cleaning instructions above. A mix of water and some detergent,

such as 'Dawn' dish soap would be a sufficient alternative.

Flush the entire sprayer with the neutralizing/cleaning agent,

then flush out one more time with plain water. Follow the

chemical manufacturer's disposal instructions of all wash or

rinsing water.

For the boom, (if applicable) remove the tips and screens from

the nozzle assemblies. Wash these items out thoroughly. Blow

the orifice clean and dry. If the orifice remains clogged, clean it

with a fine bristle (NOT WIRE) brush, or with a toothpick. Do not

damage the orifice. Water rinse and dry the tips before storing.

WARNING: Some chemicals will damage the pump valves if

allowed to soak untreated for a length of time! ALWAYS

flush the pump as instructed after each use.

Drain all water out of your sprayer, paying special attention to

the pump, handgun, and valve(s). These items are especially

prone to damage from chemicals and freezing weather.

The sprayer should be winterized before storage by pumping a

solution of RV antifreeze through the entire plumbing system.

This antifreeze solution should remain in the plumbing system

during the winter months. When spring time comes and you

are preparing your sprayer for the spray season, rinse the

entire plumbing system out, clearing the lines of the antifreeze

solution. Proper care and maintenance will prolong the life of

your sprayer.

Page 4

8.16

8.7

8.4

8.11

3

2

3

6

4

1

2

Back Rack

(w/Vertical Mounts)

5

Item NoFIMCO Part

Number

1

5006307

2

5022238

3

5038317

4

5101065

5

5101231

6

5117300

7

5275256

7.1 5022255 1

7.2 5006337 2

7.3 5006307 4

7.4 5034159 2

7.5 5034019 2

Center Rack

8

Assembly

8.1 5006054 4

8.2 5006091 4

8.3 5006142 2

8.4 5006307 8

8.5 5034074 2

8.6 5034107 2

8.7 5034159 4

8.8 5034308 4

8.9 5273315 1

8.10 5009635 1

8.11 5022256 2

8.12 5080012 2

8.13 5080011 2

8.14 5271580 2

8.15 5019097 2

8.16 5082006 2

8.4

Qty

Description

2

5/16"-18 Hex Whiz (Flange) Locknut

2

Mounting Angle

2

U-Bracket

2

Hair-Pin Cotter (0.120" Dia.)

2

Pin

2

5/16"-18 x 1" Flange Whiz Lock Screw

2

Upright Assembly

Boom Mounting Angle

1/2"-13 Hex Whiz (Flange) Locknut

5/16"-18 Hex Whiz (Flange) Locknut

Square U-Bolt, 5/16" x 1 5/16" x 1 7/8"

H.H.C.S., 1/2"-13 x 1 1/4"

1

BA6D & BA8D Boom Center Section

3/8"-16 Hex Nut

1/2"-13 Hex Locknut

Hex Jam Locknut, 1/2"

5/16"-18 Hex Whiz (Flange) Locknut

H.H.C.S., 1/2"-13 x 7"

3/8" x 4" Eyebolt, Turned, Zinc-Plated

Square U-Bolt, 5/16" x 1 5/16" x 1 7/8"

H.H.C.S., 1/2"-13 x 2 1/4"

Center Boom Weldment

Top Bar Tube (257 Boom)

End Angle (257 Boom)

Center Hinge Section

Outer Hinge Section

Spring Connector Weldment

Hinge Spring

"S" Hook

List

Price

.25

3.10

7.64

.40

3.50

.22

27.50

17.60

.30

.25

.65

.48

.25

.25

.25

.25

1.90

1.52

.65

.68

63.57

15.78

5.11

12.45

18.93

6.75

3.50

.55

8.10

7.4

8.7

7.1

8.9

8.11

8.4

7.4

7.2

7.5

8.1

8.6

8.15

8.2

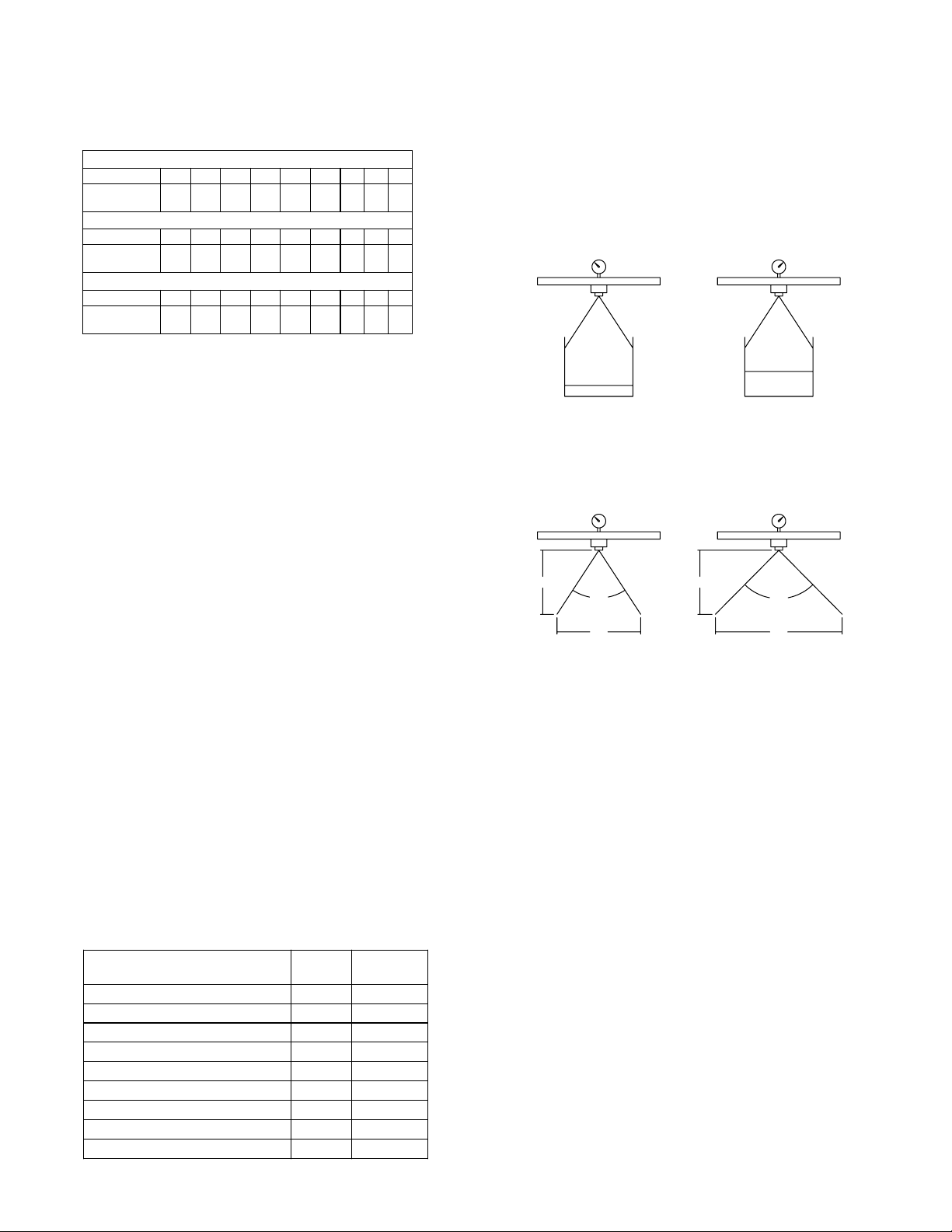

NOTE:

Mounting angles (Item 2) are used when the boom

is positioned in the "high" position. Otherwise the Ubracket (Item 3) is bolted to the top holes in the upright

angle (Item 7.1).

8.4

8.5

8.16

8.8

8.12

8.13

8.3

8.14

Center "Back Rack" Mounted

in the "High" Position

3

2

3

2

Center "Back Rack" Mounted

in the "Low" Position

Mounting Angles are NOT Used

Mounting Angles ARE Used

Page 5

18

Model: BA6D (5301957)

7

14

22

16

7

20

Item NoFIMCO Part

Number

1 5006092 4 4

2 5006259 2 2

3 5006307 2 2

4 5022238 2 2

5 5034101 4 4

6 5038317 2 2

7 5049018 2 2

8 5051085 2 2

9 5101065 2 2

10 5101231 2 2

11 5117300 2 2

12 5117307 2 2

13 5272165 13 17

14 5273313 2 2

15 5275256 2 2

16 5275736

17 5277032 1 1

18 5277033 1

19 5277034 1

20 5277035

21 5277036

Center Rack

22

Assembly

BA6D

(5301957)/QTY.

-

-

-

1 1

BA8D

(5301958)/QTY.

Components and their quantities for the 'Center Rack Assembly'

& 'Upright Assembly' are called out on Page 5.

14

Description

3/8"-16 Hex Locknut

3/8"-16 Hex Whiz (Flange) Locknut

5/16"-18 Hex Whiz (Flange) Locknut

Mounting Angle

H.H.C.S., 3/8"-16 x 1 3/4"

U-Bracket

Boom Chain (7 Ft.)

Slide Clamp

Hair-Pin Cotter (0.120" Dia.)

Pin

5/16"-18 x 1" Flange Whiz Lock Screw

3/8"-16 x 1" Whiz (Flange) Lockscrew

Vari-Quick Clamp (1 1/4" Sq. Tube)

End Boom Weldment

Upright Assembly

2

Boom Extension (for 8-Row)

1/2" QJ Center Nozzle Harness

-

1/2" QJ (LH) Nozzle Harness (BA6D)

-

1/2" QJ (RH) Nozzle Harness (BA6D)

1

1/2" QJ (LH) Nozzle Harness (BA8D)

1

1/2" QJ (RH) Nozzle Harness (BA8D)

BA6D & BA8D Boom Center Section

15

17

17

22

List

Price

.25

.25

.25

3.10

.50

7.64

3.25

8.72

.40

3.50

.22

.46

2.57

38.16

27.50

14.50

14

7

19

Model: BA8D (5301958)

14

21

Typ. Boom Extension Attachment

7

14

1

5

(BA8D Boom)

7

12

14

F

16

13

16

2

8

Page 6

DETAIL F

BA6D (5301957) & BA8D (5301958) Nozzle Assemblies

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

5.1.1

5.1.2

5.1.3

5.1.4

5.1.5

Center Harness Assembly #5277032 (BA6D & BA8D Boom Assemblies)

1.5 1.5

LH Harness Assembly #5277033 (BA6D Boom)

2.2.1

2.2.3

2.2.5

2.2.2

2.2.4

2.3

RH Harness Assembly #5277034 (BA6D Boom)

3.1.1

3.1.3

3.1.5

3.1.2

3.1.4

3.3

LH Harness Assembly #5277035 (BA8D Boom)

4.3

4.3

RH Harness Assembly #5277036 (BA8D Boom)

5.3

5.3 5.3

1.4

2.3

3.3

4.3

1.3 1.4

2.4

3.4

4.4

5.4

3.3

2.3

4.3

5.3

1.1.1

1.1.2

1.1.3

1.1.4

1.1.5

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

1.5

5.3

4.3

1.6

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

4.1.1

4.1.2

4.1.3

4.1.4

4.1.5

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

Item

No

1

1.1

1.1.1

1.1.2

1.1.3

1.1.4

1.1.5

1.2

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

1.3

1.4

1.5

1.6

2

2.1

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

2.2

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.3

2.4

3

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

FIMCO Part

Number

5277032

5277031

5056067

5116019

5016157

5018266

5046219

5277030

5056065

5116019

5016157

5018266

5046219

5086003

5020144

5020416

5051114

5277033

5277031

5056067

5116019

5016157

5018266

5046219

5277030

5056065

5116019

5016157

5018266

5046219

5020416

5051114

5277034

5277031

5056067

5116019

5016157

5018266

5046219

Description

Qty

1

1/2" QJ Center Nozzle Harness

3

1/2" TEE QJ Nozzle Assembly

1

Double Hose Shank (1/2" Hose)

1

50 Mesh Nozzle Strainer, Red

1

Seat Washer

1

Flat Spray Tip, Blue

1

Quick TeeJet Cap (Yellow)

2

1/2" ELL QJ Nozzle Assembly

1

Single Hose Shank (1/2" Hose)

1

50 Mesh Nozzle Strainer, Red

1

Seat Washer

1

Flat Spray Tip, Blue

1

Quick TeeJet Cap (Yellow)

1

Nylon Hose Tee, 1/2" HB

2

Hose, 1/2"-1 Brd. x 10"

3

Hose, 1/2"-1 Brd. x 19 3/8"

10

Hose Clamp, 3/8"

1

1/2" QJ (LH) Nozzle Harness

3

1/2" TEE QJ Nozzle Assembly

1

Double Hose Shank (1/2" Hose)

1

50 Mesh Nozzle Strainer, Red

1

Seat Washer

1

Flat Spray Tip, Blue

1

Quick TeeJet Cap (Yellow)

1

1/2" ELL QJ Nozzle Assembly

1

Single Hose Shank (1/2" Hose)

1

50 Mesh Nozzle Strainer, Red

1

Seat Washer

1

Flat Spray Tip, Blue

1

Quick TeeJet Cap (Yellow)

3

Hose, 1/2"-1 Brd. x 19 3/8"

6

Hose Clamp, 3/8"

1

1/2" QJ (RH) Nozzle Harness

3

1/2" TEE QJ Nozzle Assembly

1

Double Hose Shank (1/2" Hose)

1

50 Mesh Nozzle Strainer, Red

1

Seat Washer

1

Flat Spray Tip, Blue

1

Quick TeeJet Cap (Yellow)

List

Price

3.84

1.05

.40

.84

.61

3.84

1.05

.40

.84

.61

.88

1.77

2.17

.63

3.84

1.05

.40

.84

.61

3.84

1.05

.40

.84

.61

2.17

.63

3.84

1.05

.40

.84

.61

Item

No

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.3

3.4

4

4.1

4.1.1

4.1.2

4.1.3

4.1.4

4.1.5

4.2

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

4.3

4.4

5

5.1

5.1.1

5.1.2

5.1.3

5.1.4

5.1.5

5.2

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.3

5.4

FIMCO Part

Number

5277030

5056065

5116019

5016157

5018266

5046219

5020416

5051114

5277035

5277031

5056067

5116019

5016157

5018266

5046219

5277030

5056065

5116019

5016157

5018266

5046219

5020416

5051114

5277036

5277031

5056067

5116019

5016157

5018266

5046219

5277030

5056065

5116019

5016157

5018266

5046219

5020416

5051114

Description

Qty

1

1/2" ELL QJ Nozzle Assembly

1

Single Hose Shank (1/2" Hose)

1

50 Mesh Nozzle Strainer, Red

1

Seat Washer

1

Flat Spray Tip, Blue

1

Quick TeeJet Cap (Yellow)

3

Hose, 1/2"-1 Brd. x 19 3/8"

6

Hose Clamp, 3/8"

1

1/2" QJ (LH) Nozzle Harness (BA8D)

5

1/2" TEE QJ Nozzle Assembly

1

Double Hose Shank (1/2" Hose)

1

50 Mesh Nozzle Strainer, Red

1

Seat Washer

1

Flat Spray Tip, Blue

1

Quick TeeJet Cap (Yellow)

1

1/2" ELL QJ Nozzle Assembly

1

Single Hose Shank (1/2" Hose)

1

50 Mesh Nozzle Strainer, Red

1

Seat Washer

1

Flat Spray Tip, Blue

1

Quick TeeJet Cap (Yellow)

5

Hose, 1/2"-1 Brd. x 19 3/8"

10

Hose Clamp, 3/8"

1

1/2" QJ (RH) Nozzle Harness (BA8D)

5

1/2" TEE QJ Nozzle Assembly

1

Double Hose Shank (1/2" Hose)

1

50 Mesh Nozzle Strainer, Red

1

Seat Washer

1

Flat Spray Tip, Blue

1

Quick TeeJet Cap (Yellow)

1

1/2" ELL QJ Nozzle Assembly

1

Single Hose Shank (1/2" Hose)

1

50 Mesh Nozzle Strainer, Red

1

Seat Washer

1

Flat Spray Tip, Blue

1

Quick TeeJet Cap (Yellow)

5

Hose, 1/2"-1 Brd. x 19 3/8"

10

Hose Clamp, 3/8"

List

Price

3.84

1.05

.40

.84

.61

2.17

.63

3.84

1.05

.40

.84

.61

3.84

1.05

.40

.84

.61

2.17

.63

3.84

1.05

.40

.84

.61

3.84

1.05

.40

.84

.61

2.17

.63

Page 7

Loading...

Loading...