Page 1

Create Conguration

DirectCommand

TM

Spreader

Enter Settings

Application

Conguration Product

Application

Press to Highlight Conguration

4930rx

Start of Conguration Wizard

Fan Frame

Feed Gate

Calibration

Controller

Settings

Fan Frame

Feed Gate

Calibration

Controller

Settings

Fan Frame Feed Gate Calibration

calibrate fan frame feed gate

Channel 1

Channel 2

Channel 3 Channel 4

Channel 5

Spinner

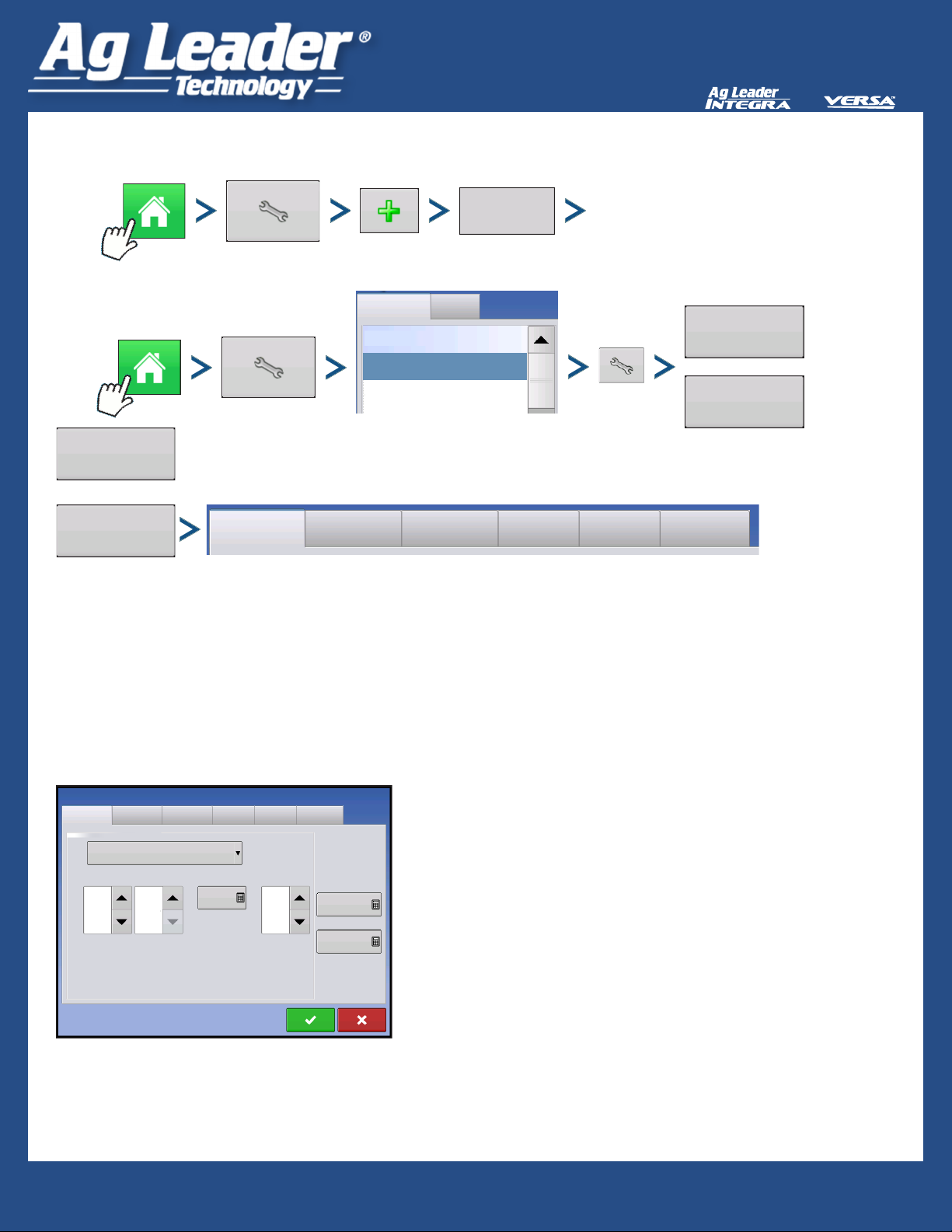

There is a tab for every channel of control with Control Valve Congurations and related settings.

Note: Five channels of control are only available with 5 channel Spreader Control Module.

Servo Valve

Spreader Control

Channel 1

Control Valve Conguration

Channel 2 Channel 3

Servo

Valve

Response 1

40 %

Valve

Response 2

8 %

Response

Threshold

Channel 4 Channel 5

Allowable

Error

15

2 %

Spinner

Shaft Speed

Calibration

180 pls/rev

Max Speed

60 rpm

Valve Response 1

fast speed of valve, decrease to slow response time,

default = 40%

Valve Response 2

slow speed of valve, decrease to slow response time,

default = 8%

Response Threshold

point where system switches between using Valve

Response 1 and Valve Response 2, increase to slow

response time, default = 15

Allowable Error

error allowed before making rate control adjustments

Shaft Speed Calibration

pulses/revolution of metering shaft

Max Speed

maximum allowable RPM of product conveyor

Quick Reference Guide

PN ?????? Rev A

AL: 2006314 - ENG Rev C

PN 2006313 Rev A

1

1

Page 2

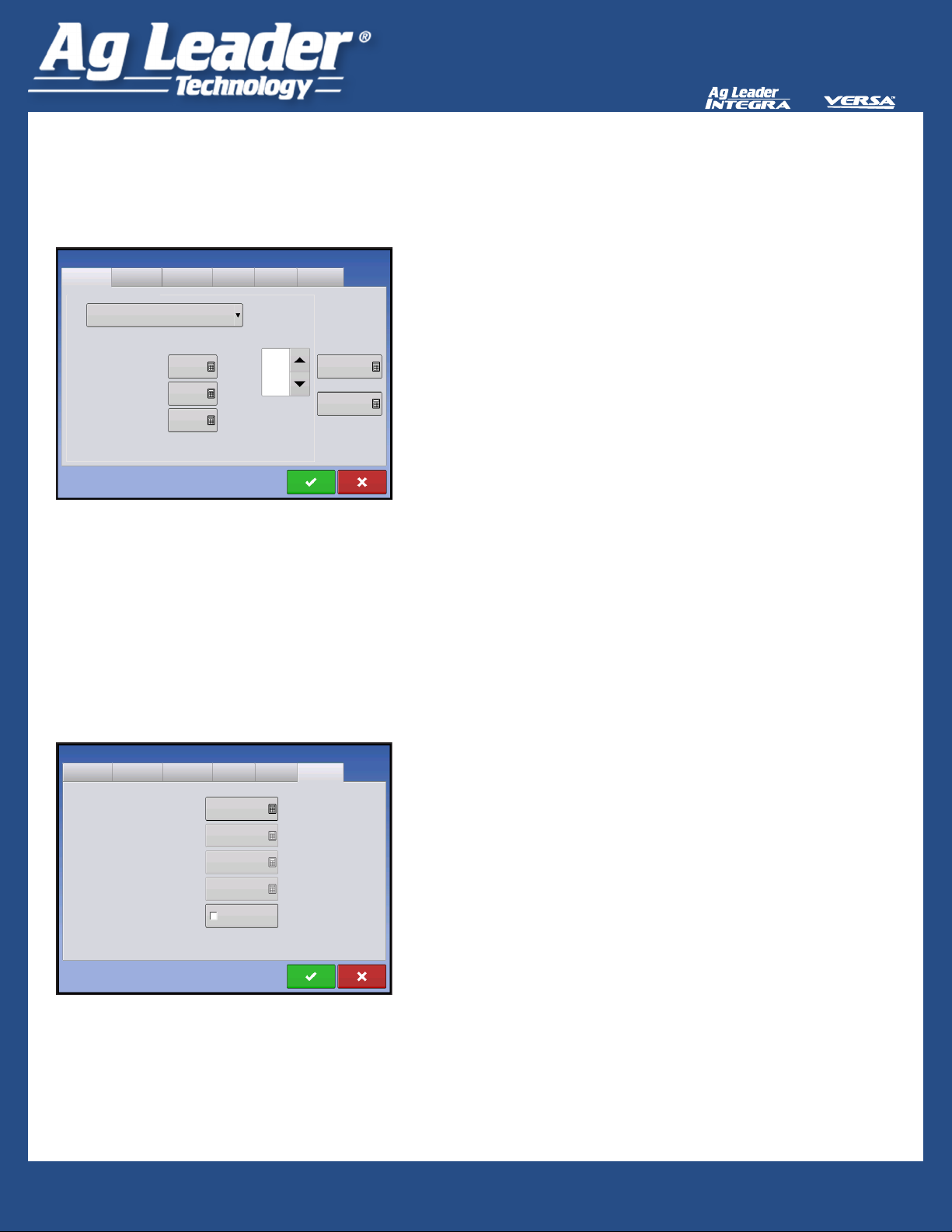

PWM Valve

DirectCommand

PWM Frequency

frequency valve is pulsed at, settings come from

manufacturer, typical range: 100-125 Hz

TM

Spreader

Spreader Control

Channel 1

Control Valve Conguration

Channel 2 Channel 3

PWM

PWM Frequency

Zero Flow Offset

PWM Gain

100

100

30

Spinner Tab

Channel 4

Channel 5

Allowable

Error

2 %

Spinner

Shaft Speed

Calibration

180 pls/rev

Max Speed

60 rpm

PWM Gain

decrease to slow response time

Zero Flow Offset

duty cycle used to start moving conveyor, if setting is

too high conveyor will not turn off, default = 30

Allowable Error

error allowed before making rate control adjustments

Shaft Speed Calibration

pulses/revolution of metering shaft

Max Speed

maximum RPM of product conveyor

Fan Speed Calibration

pulses/revolution of spinner

Channel 1

Spreader Control

Channel 2 Channel 3

Fan Speed

Calibration

PWM

Gain

PWM

Frequency

Zero RPM

Offset

Channel 4

Automatic

Control

4 pls/rev

100 Hz

Channel 5

20

30

Spinner

PWM Gain

decrease to slow response time

PWM Frequency

frequency valve is pulsed at, settings come from valve

manufacturer, typical range = 100-125 Hz

Zero RPM Offset

duty cycle used to start rotating the spinner, if setting is

too high spinner will not stop rotating, default = 30

Automatic Control

select to control the spinner speed

Quick Reference Guide

PN ?????? Rev A

AL: 2006314 - ENG Rev C

PN 2006313 Rev A

2

2

Page 3

DirectCommand

To start the Field Operation Wizard and load a conguration:

Conguration

Start Field Operation

To view run screen:

Product Control Toolbox

To change values shown on Product Tab and in Product Control

DAP

Potash

Sulfur

200

200

250

250

20

20

lb/ac

lb/ac

lb/ac

1

200

2

150

Flow:

Container:

3.6 lb/min

50 ft

Toolbox go to the next page where the Rate Control Settings

screen is explained.

Target Rate

the desired amount of product to apply

Actual Rate

3

actual rate of product being applied as determined

by the ow sensor

TM

Spreader

60 ft 0 in

1

200

2

150

Product in Bin

Target Rate #1 & #2

preset application rates that allow a quick change between rates

Manual Valve Control

allows operator manual control of valve

Prescription

allows rates to be determined by a loaded prescription

Up and Down Arrows

allow rates to be adjusted manually

Settings button

opens Rate Control Settings screen (explained on next page)

Quick Reference Guide

PN ?????? Rev A

AL: 2006314 - ENG Rev C

PN 2006313 Rev A

3

3

Page 4

DirectCommand

TM

Spreader

Rate Control

DAP

Rate 1

Potash

Rate 1 Rate 2

Sulfur

Rate 1 Rate 2

Containers

200

250

20

To access the Rate

Control Settings window:

Rate Control Settings

Rate 2

150 1

300 1

30 1

Increment

Increment

Increment

DAP

Minimum Flow

0.00 lb/min

Minimum Flow

0.00 lb/min

Minimum Flow

0.00 lb/min

200

200

lb/ac

Rx

Rx

Rx

Rate 1 and Rate 2

allows operator to set

desired target rates

Increment

values used when using

up and down arrows in the

Product Control Toolbox

Rx

press to load a map-based

prescription le

Rate Control

Containers

Bin 1 - DAP

Full:

Current: 100 ft

Bin 2 - Potash

Full:

Current: 100 ft

Bin 3 - Sulfur

Full:

Current: 15 ft

100 ft

100 ft

15 ft

Rate Control Settings

3

3

3

3

3

3

3

10 ft

10 %

3

10 ft

10 %

3

1.5 ft

10 %

Quick Reference Guide

PN ?????? Rev A

AL: 2006314 - ENG Rev C

PN 2006313 Rev A

Bin Full

press to ll

container

Bin Partially Filled

press to specify

container amount

Bin Empty

press to empty

container

3

10 ft

10 %

Tank Alarm

Setting

can set % remaining or amount

remaining for low

container alarm

4

4

Page 5

DirectCommand

TM

Spreader

5.40 ac

Fan Frame

3.500

Feed Gate

2.000

Spread Width

80 ft

Spinner Speed

700 rpm

700

Channel 1

DAP

RPM

Spreader Control

Channel 2

Product

Density

3

58 lb/ft

1

25

1

25

Feed Gate 1

Opening

2

25700

2 in

DAP

Potash

25

RPM

2

Spreader Control button

- on/off state of control channel

- shaft speed RPM

- spinner fan speed RPM

200

200

250

250

4.9 mph

lb/ac

1

200

2

150

lb/ac

Flow:

0.0 lb/min

Container:

Press button to display Spreader Control

window.

Spread Width

use numeric keypad to edit value

3

0 ft

Spinner Speed

80 ft 0 in

speed is controlled automatically based

upon this setting when system uses an

optional PWM spinner speed control valve

Chain Oiler

automatically perform oiling routine by

pressing button and following the steps

Static Calibration

performs automated routine to calibrate

Conveyor 1

Rate

.423 ft3/rev

each metering circuit while machine is

stationary

Chain

Oiler

Static

Calibration

In-Field

Calibration

Fan Frame

3.5 in

Fan Frame

Feed Gate

Fan Frame & Feed Gate Actuator Setting

optional settings used by New Leader

module

Fan Frame

enables the fan frame actuator, displays

distance between spinner bed and

spinner assembly

Feed Gate

enables the feed gate actuator

Quick Reference Guide

PN ?????? Rev A

AL: 2006314 - ENG Rev C

PN 2006313 Rev A

In-Field Calibration

performs automated routine to adjust the

calibration number for the selected metering

circuit if there is a difference between the

amount of product logged compared to

what was actually applied

Product Density

value (lb/ft3), is stored for each product. Use

the numeric keypad to edit value.

Feed Gate Opening

measure depth of product on conveyor to

ensure accurate value

Conveyor Rate

volume of product dispensed (ft3/rev) by

one revolution of the meter drive shaft

5

5

Loading...

Loading...