Page 1

VT Quick Reference Guide

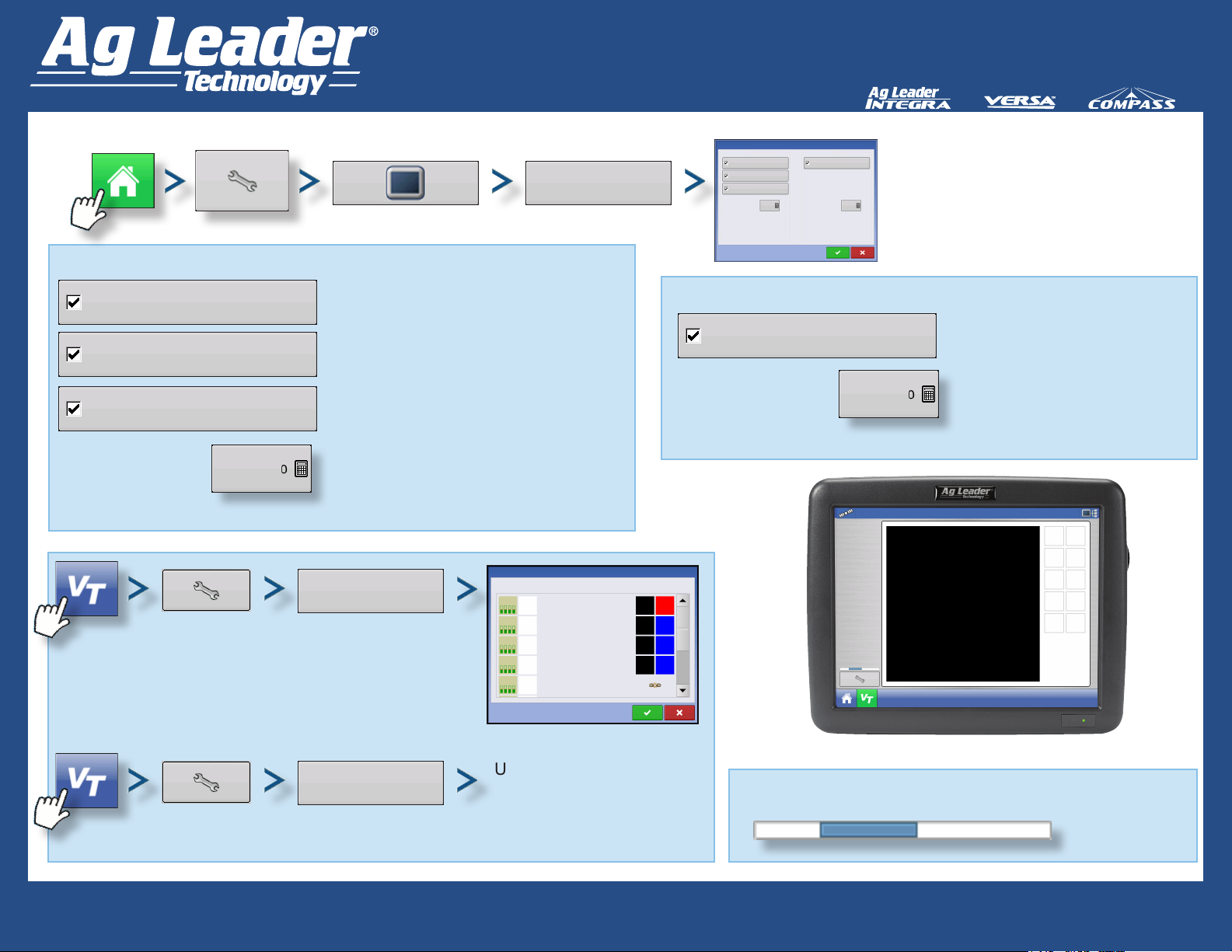

Enable Virtual Terminal

Virtual Teminal

Enable Virtual Terminal

Broadcast GPS Speed

Auxiliary Module Support

Functional Instance

Used to map implement

functions to OEM switches.

ISOBUS Settings

VT button appears in task bar once

button is checked.

Allows implement to use GPS ground

speed gathered by the display.

Assign implement functions to ISO

campatible inputs.

Always set to 0 except when there

are multiple VTs on the ISOBUS. Use

keypad to change instance. Reboot

display.

Auxiliary

Assignment

Function

VT Demo

VT Demo

VT Demo

VT Demo

VT Demo

Auxiliary Assignment

M

1

2

3

4

Virtual Terminal

Enable Virtual Terminal

Broadcast GPS Speed

Auxiliary Module Support

Function Instance

Task Controller

Enable Task Controller

Functional Instance

Input

Aux

M

Aux

F1

Aux

F2

F3

Aux

ISOBUS Settings

0

Task Controller

Enable Task Controller

Function Instance

0

Supported on compatible

equipment ECU’s.

Always set to 0 except when

there are multiple VTs on the

ISOBUS. Use keypad to change

instance. Reboot display.

Clear

Virtual Terminal

Used to clear object pools

from internal memory.

Status Bar

Quick Reference Guide

AL: 2006300 - ENG Rev C

Appears while Object Pool is in the

process of loading.

1

Page 2

Object Pool

Graphical UI elements

sent by Working Set

Master (WSM) on rst

connection with VT.

Size is dependent on

complexity of module UI.

The Object Pool is stored

locally in VT display

memory.

0 . 0 0 . 0

50 . 0

Rate

98 . 5

1

ac

Command received. Front Meter

Clutch OFF!

a c / h r

0 . 0

74 . 0

r / min

l b s / acl b s / ac

0

VT Quick Reference Guide

Virtual Terminal Screen

0 . 0

lbs / ac

Rate

98 . 5

ac

Command received. Front Meter

Clutch OFF!

50 . 0

ac / hr

0 . 8

r / min

0 . 0

lbs / ac

74 . 0

8

Softkeys

Press to

access

and adjust

implement

settings.

Up to 10

softkeys can

be populated

per screen.

ISOBUS Working Set

One or more

ISOBUS

modules that

control an

implement’s

functionality.

Arrow Button

Advance through multiple screens of

Softkeys.

This button remains hidden unless

more than 10 softkeys are present.

Quick Reference Guide

AL: 2006300 - ENG Rev C

2

Page 3

VT Quick Reference Guide

ISO Node Diagnostics

1

2

Conguration

Operator:

Virtual Terminal Alarm

Start Field Operation

0 . 0

lbs / ac

Rate

98 . 5

50 . 0

ac

Command received . Front Meter

Clutch OFF!

ac / hr

0 . 0

74 . 0

r / min

0

0 . 0

lbs / ac

11:37:10 AM

03/11/2011

3

CAN B

CAN A

233 ISO NODE

134 ISO NODE

A

4

ECU: 5000218*1547854*IMPLEMENT*VT MODULE*AG LEADER TECHNOLOGY*

Software ID: ALTECH, VT ODULE; 01.00.00.00;VT_MODULE_FW;01.00.00.00*

Active Errors:

SPN

522102

52366

FMI

12 12

3

Devices

CAN Name: 4E 9E 37OC OO

Self Congurable: Yes

Industry Group: Agriculture and Fo

B

Device Class: Sprayers

Device Class Instance: 0

Function: 128

Function Instance: 0

ECU Instance: 0

Identity Number: 1547854

Manufacturer Code: 97

C

Ag L

Firmwar

Firmwar

Diagnostics

Hardwar

Serial N

Revision:

ISO Node Diagnostics

Previously Active Errors:

522102

523666

SPN

FMI

3

OC OC

1

2 2

Caution Icon indicates

module has active trouble

A

codes (DTCs)

Equipment Type

B

ECU Manufacturer

C

SPN

FMI

1

OC

Clear Prev

Active Errors

Clear Prev

Active Errors

Suspect Parameter Number

Error Number

Fault Mode Indicator

Error State

Occurrence Count

Number of times error has occurred

Diagnostic Trouble Code (DTC)

This is SPN + FMI. Reference this

number in the implement owners

manual to diagnose error.

Clears previous active errors

from the history.

Quick Reference Guide

AL: 2006300 - ENG Rev C

3

Page 4

VT Quick Reference Guide

Virtual Terminal Alarm

Virtual Terminal Alarm

Conguration

Operator:

Start Field Operation:

11:37:10 AM

03/11/2011

When an alarm is activated on the VT, the display will

indicate the alarm by ashing “Virtual Terminal Alarm” in

the status bar.

Virtual Terminal Alarm

Low fan speed detected

Disable Main

Drive Shutoff

Alarms are acknowledged and cleared by

pressing the green check mark button.

IMPORTANT: This button is only present when

a virtual terminal alarm has been activated.

Quick Reference Guide

AL: 2006300 - ENG Rev C

4

Page 5

VT Quick Reference Guide

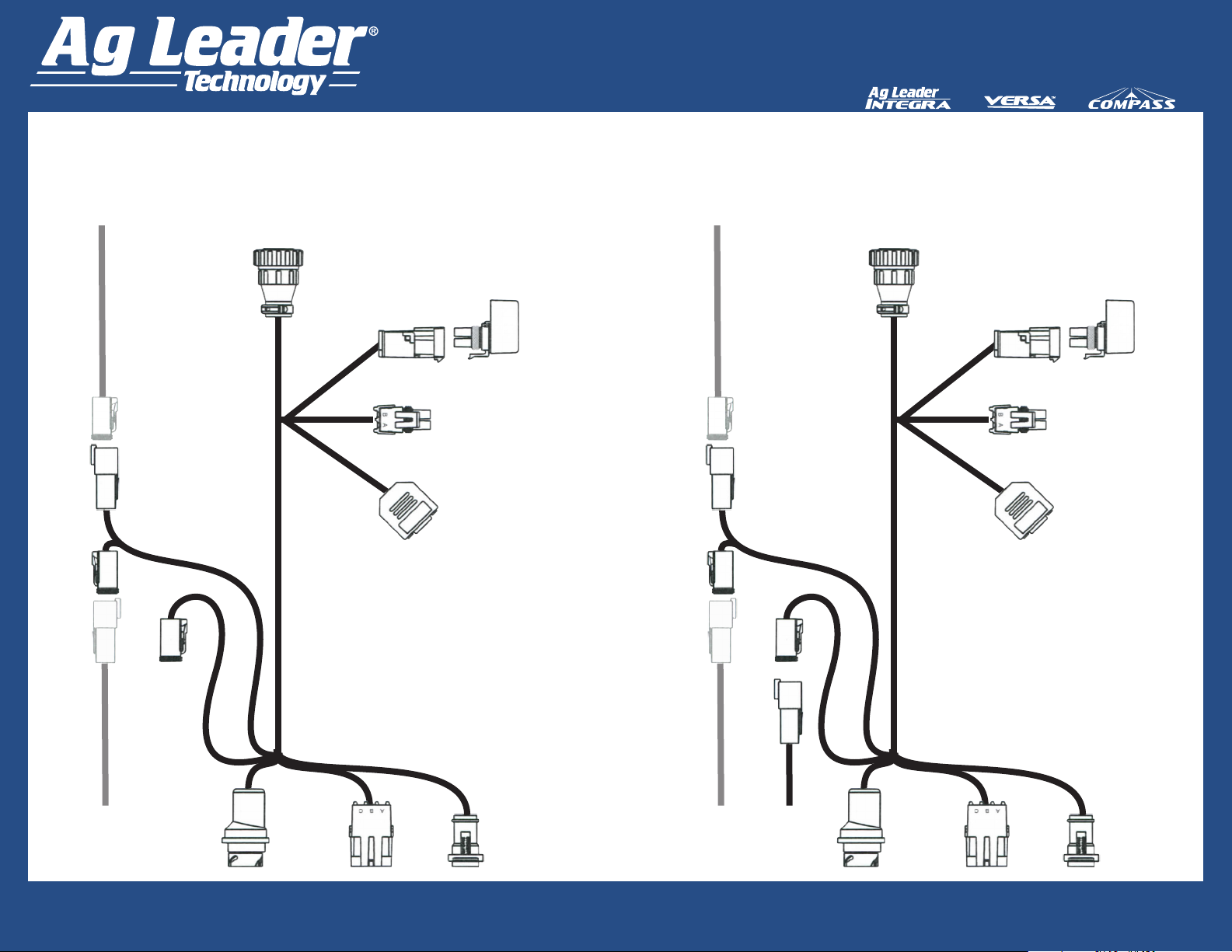

Connecting the System

Existing Tractor

ISOBUS

CAN B IN

CAN B OUT

Generic ISOBUS Installation

Display - Main

Power Control Relay

GPS

Power Out

ISOBUS/PareDyme Installation

Display - Main

Existing Tractor

ISOBUS

Power Control Relay

Power Out

CAN B IN

GPS

CAN B OUT

Guidance

Existing Tractor

ISOBUS

Power

CONNECT

NO

Ethernet

Power

In

Existing Tractor

ISOBUS

CAN

A

Quick Reference Guide

AL: 2006300 - ENG Rev C

Guidance Power

Ethernet

Power

In

CAN

A

5

Page 6

VT Quick Reference Guide

Ethernet

CAN B

Guidance

Power

Connection

CAN B IN

CAN B

OUT

Power In

Power Out

Power Control Relay

GPS

CAN A

OnTrac 2

Controller

Harness

Display - Main

Connecting the System

OnTrac 2+ ISOBUS Installation

Display - Main

Existing Tractor

ISOBUS

CAN B IN

CAN B OUT

Existing Tractor

ISOBUS

Guidance

Power

Ethernet

Power Control Relay

Power Out

GPS

OnTrac 2+

Controller

Harness

CAN A

Power In

OnTrac 2

NOT supported with

ISOBUS.

CAN A

Quick Reference Guide

AL: 2006300 - ENG Rev C

6

Page 7

VT Quick Reference Guide

Cooper Bussman Relay Module

Pin#3=AWG8 (60A) from

Rear View of

2-pin Metri-Pak

High Current

Relay Module

60

amp

fuse

30

amp

fuse

Retrot Cable Kit (Generic Tractor) Wiring Diagram

Active

Termination

Cable PN

LED

2

4002587

LED

3

CAN A

Relay

3

4

1

ISO Plug

2

Pin#2=AWG10 (30A)

to Ground

to Ground

Pin#1=AWG8 (60A)

Weather

Pack Square

Shroud 4-pin

Power Control

ISOBUS CAN Extension PN 4002586-8,16

LED

1

CAN

POWER

MODULE

CAN B

Relay

Ground

Pin#4=AWG10(30A) +12

ECU Power from Circuit Board

Aux

Power

ISO T

ISO T

Aux Power of

ISOBUS display

cable in cab

CAN B of

ISOBUS display

cable in cab

Weather Pack

Square Shroud

4-pin power

Control of

ISOBUS display

cable in cab

LED

1

Solid blue LED indicates module

is receiving +12V from the

display energizing the High

Current Relay controlling High

Current across pins 1 and 3 of

ISO plug.

LED

2

Solid green LED indicates CAN

A is receiving +12V from the

display when CAN A relay is

closed.

LED

3

Solid green LED indicates CAN

B is receiving +12V from the

module circuit board across pins

2 and 4 of ISO Plug when CAN

B relay is closed.

ISOBUS Battery Cable

PN 4002865-8,16,22

Quick Reference Guide

AL: 2006300 - ENG Rev C

100 amp

Fuse

Battery

7

Page 8

VT Quick Reference Guide

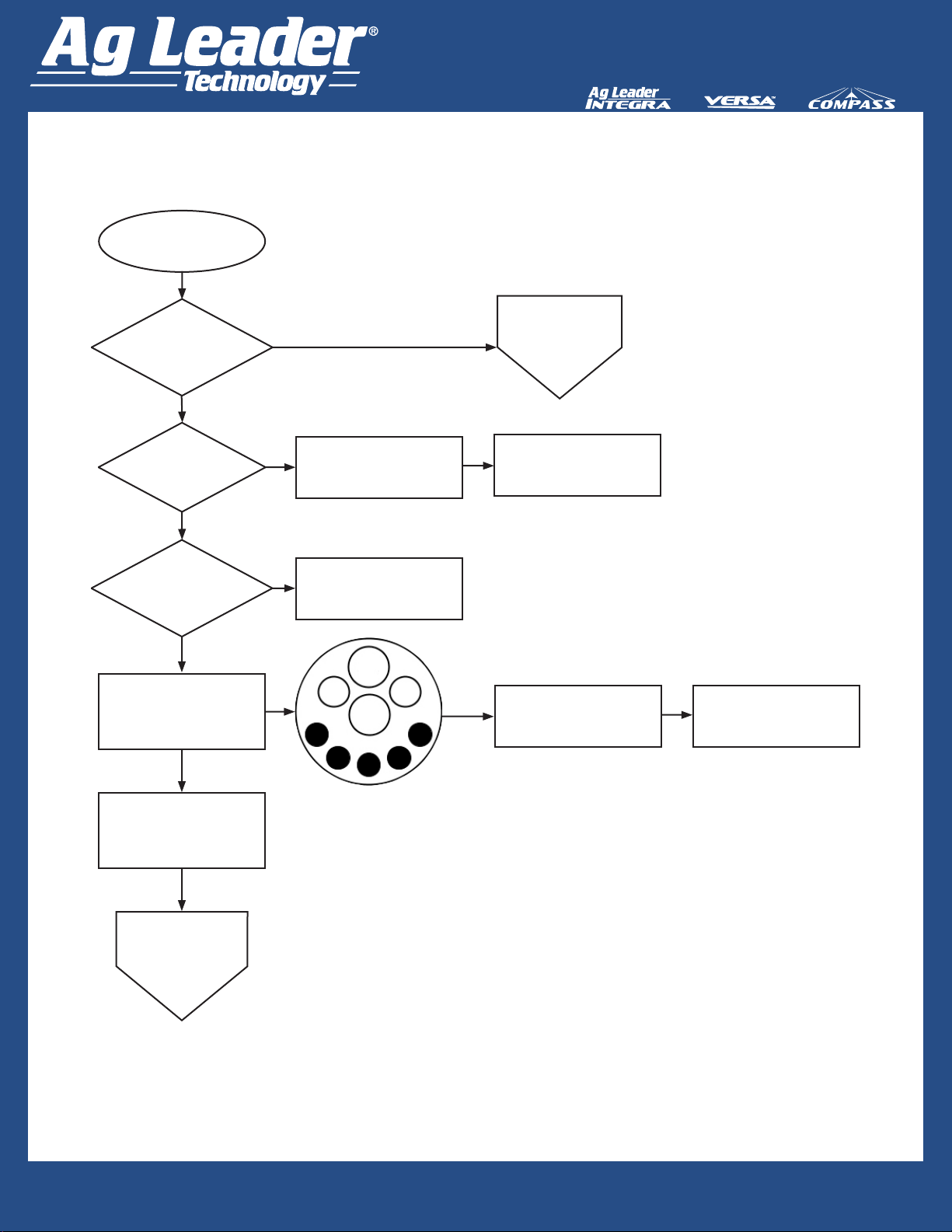

Troubleshooting Step 1: Virtual Terminal

Start

Latest display

rmware?

Yes

VT

button present

on lower left of

screen?

Yes

Press VT button located in

lower left screen.

Object

Pool(s) loaded

on screen?

Yes

No

No

No No

Upgrade rmware.

Enable Virtual Terminal

button from General tab of

Display Setup screen.

Status

Bar present

in the lower left of

display?

Yes

Has

Status Bar been

active for more than 15

minutes while object pool

loaded?

No

Wait while Object Pool(s)

nishes loading.

Go to Step 2:

Cables and

Power

Do

Object

Pool(s) look

right and function

correctly?

Yes

Troubleshooting Complete.

System should be in eld-ready

state.

Clear saved devices by

pressing Clear Saved

Device Interfaces button in

upper right corner of Virtual

No

Terminal Settings screen.

Leaving display POWERED

ON, cycle power to Tractor

ECU by turning key off to

tractor and turning back on.

Quick Reference Guide

Yes

look right and function

AL: 2006300 - ENG Rev C

Do

Object Pool(s)

correctly?

Yes

No

Go to Step 9:

ECU

8

Page 9

VT Quick Reference Guide

Troubleshooting Step 2: Cables and Power

Start

Go to Step 3:

OEM BUS

or Ag Leader ISOBUS

Retrot Cable?

OEM

Is

Ag

Leader display

cable T’d into OEM

cable?

Ag Leader ISOBUS Retrot Cable Kit

No

Connect display cable to

OEM BUS.

ISOBUS Retrot

Cable

Have Ag Leader dealer

consult ISOBUS System

Reference for support.

Yes

Is

the

implement

plugged into the ISO plug

on the rear of the

tractor?

Using voltmeter, check for

12VDC across pins 2 and 4;

and across pins 1 and 3 of

ISOBUS module plug.

Yes

Reconnect ISO Connector.

Go to Step 8:

Reload Implement

Object Pools

Plug implement into the ISO

No

plug on the rear of the tractor.

3/B

4/J

1/A

2/C

No

Check fuses and relays in

cab.

Contact your Tractor Dealer

for further diagnosis of tractor

circuitry.

Quick Reference Guide

AL: 2006300 - ENG Rev C

9

Page 10

VT Quick Reference Guide

Troubleshooting Step 3: ISOBUS Retrot Cable

Start

Is

4-pin

Power Control

Extension Cable plugged

into display cable and

fully seated?

Yes

Is

ISOBUS

CAN Extension

Cable T’d into Display

Cable and fully

seated?

Yes

Is

the

Active

Termination Cable

plugged into power on ISO

Display Cable and

fully seated?

Yes

Leaving the display power

ON, go to ISOBUS Retrot

Cable Module Mounting

Location.

Plug 4-pin Power Control

Extension Cable into the

No

display cable unit it clicks to

make sure it is fully seated.

No

Plug the ISOBUS CAN

Extension Cable into the

Display Cable until it clicks to

make sure it is fully seated.

Plug the Active Termination

No

Cable into power on the ISO

Display Cable until it clicks to

make sure it is fully seated.

Are

the 3

LEDs on the

CAN Power Module

Illuminated?

No

Yes

Is

the

implement

plugged into the ISO plug

on the rear of the

tractor?

No

Enable Virtual Terminal

button from General tab of

Yes

Go to Step 8:

Cycle Power to

ECU

Quick Reference Guide

AL: 2006300 - ENG Rev C

Step 4:

High Current

Relay Module

Setup screen.

10

Page 11

VT Quick Reference Guide

Troubleshooting Step 4: High Current Relay Module

Start

Is

battery

connected: (+)to

Pin A and (-) to ground of

High Current Relay

Module?

Connect (+Pos) battery

No

cable to Pin A and (-Neg)

battery cable to ground of

High Current Relay Module.

B

B

C

Yes

Are

battery cables

connected to battery?

Yes

Use a voltmeter and check

for 12V across Pin A and high

current relay module and

ground.

Yes

12V

across

Pin A and Ground

of Relay Module?

Yes

Check voltage across Pin B

and ground of Relay Module.

Yes

Are

12V present?

Yes

Check voltage across Pin C

and ground of Relay Module.

No

Connect battery cables to

battery.

No

No

Check 100 amp fuse on

battery cable.

Check 60 amp fuse of High

Current Relay Module.

2-pin Metri-Pak

High Current

Relay Module

60

amp

fuse

30

amp

fuse

A

Check That High Current

Relay on the High Current

Relay Module is energized.

Unplug the 2-pin Metri-Pak

from the relay. Unplugging

the connector removes

power and opens relay. Plug

connector back in and listen

for Relay to “Click” Closed.

If no “Click” is heard, the relay

has failed. Contact Ag Leader

Dealer for a replacement

High Current Relay Module.

Ground

Yes

Are

12V

present?

Yes

Check 30 Amp Fuse of High

No

Current Relay Module.

Quick Reference Guide

AL: 2006300 - ENG Rev C

Go to Step 5

CAN Power

Module

LED 1

11

Page 12

VT Quick Reference Guide

Troubleshooting Step 5: CAN Power Module LED 1

LED #1 (Blue) Indicates that the module is receiving high current power (+12 VDC) from the

display energizing the High Current Relay Controlling High Current across Pins 1 and 3 of the ISO

plug.

Start

Verify Display is Powered

On and

Tractor Key is On

Is

LED #1

Illuminated BLUE?

Yes

Go to Step 6

CAN Power

Module

LED 2

Disconnect 4 Pin Power

Control Extension Cable from

No

module.

Check voltages across

Pins A and D

Pins C and D

of Extension Cable.

Correct

Voltages?

12V across A and D

5V across C and

D

Yes

Contact Ag Leader Dealer for

Module Replacement.

4-pin Square

Weather

Pack with

Towers

Power

Control

CAN

POWER

MODULE

No

Disconnect 4 Pin Power

Control Extension Cable

From Display Cable In Cab.

Check voltages across

Pins A and D

Pins C and D

of Display Cable.

Correct

Voltages?

12V across A and D

5V across C and

Replace Power Control

Extension

Cable.

D

LED

1

Yes

LED

2

LED

3

CAN A

Relay

CAN B

Relay

Replace ISO Display Cable.

No

Quick Reference Guide

AL: 2006300 - ENG Rev C

12

Page 13

VT Quick Reference Guide

Troubleshooting Step 6: CAN Power Module LED 2

LED #2 (Green) Indicates CAN A is being provided high current power (+12V) from the CAN A

Relay of the CAN Power Module.

Start

LED#2

Illuminated

GREEN?

Yes

Leaving the Power Control

Extension Cable plugged into

the CAN Power Module, back

No

Probe Pins B (Pink Wire)

and D (Black Wire) of Power

Control Extension Pigtail on

CAN Power Module for 12V

by removing seals on the

backside of 4 Pin Weatherpack

and inserting voltmeter probes

into Pins B and D.

4-pin Square

Weather

Pack with

Towers

Power

Control

LED

1

CAN

POWER

MODULE

LED

2

LED

3

CAN A

Relay

CAN B

Relay

Go to Step 7:

CAN Power

Module

LED 3

Is voltage

correct?

No

CAN A Relay Failed

Contact Ag Leader

Dealer to Replace Module.

Yes

LED Failed.

Contact Ag Leader

Dealer to Replace Module.

Quick Reference Guide

AL: 2006300 - ENG Rev C

13

Page 14

VT Quick Reference Guide

Troubleshooting Step 7: CAN Power Module LED 3

LED #3 (Green) indicates ISOBUS/CAN B is being provided high current power (+12V) across

pins 2 and 4 of ISO Plug from CAN B relay.

4-pin Square

Start

LED#3

Illuminated

GREEN?

Weather

Pack with

Towers

Power

Control

CAN

POWER

MODULE

Using a Voltmeter Check for

No

12v Across Pins 2 and 4 of

ISO Connector

LED

1

LED

2

LED

CAN A

Relay

CAN B

Relay

4/J

3

3/B

1/A

2/C

2-pin Metri-Pak

High Current

Relay Module

60

amp

fuse

30

amp

fuse

Ground

Yes

Troubleshooting

complete. System should be

in eld-ready state.

Is voltage

correct?

Yes

Check for 12V across Pin C

of High Current Relay Module

and Ground.

Is

voltage correct?

Yes

LED Failed.

Contact Ag Leader Dealer to

replace module.

Quick Reference Guide

AL: 2006300 - ENG Rev C

No

No

CAN B Relay Failed.

Contact Ag Leader

Dealer to Replace Module.

Check 30 Amp Fuse of High

Current Relay Module.

14

Page 15

VT Quick Reference Guide

Troubleshooting Step 8:

Reload Implement Object Pools

Start

Leaving display POWERED

ON, Cycle Power to Tractor

ECU by turning OFF Key to

tractor and turning back On.

Object Pool(s)

on Screen?

Yes

Object

Pool(s) look

right

and function

correctly?

Yes

Troubleshooting

complete.

System should be in eld-

ready state.

No

lower left of display?

Been Active over 15

minutes while

Object Pool(s)

Go to Step 9:

No

Status

Bar in

Yes

Has

Status Bar

Load?

Yes

ECU

No

No

Wait while Object Pool(s)

nishes loading.

Quick Reference Guide

AL: 2006300 - ENG Rev C

15

Page 16

VT Quick Reference Guide

Troubleshooting Step 9: ECU Troubleshooting

ECU

Problem

Verify latest Firmware with

OEM, Update if

needed.

Did

Firmware

update x problem?

Yes

No

Is

Implement

UI

Ok and Malfunction

Limited to Implement High

Current Components

Not Functioning?

No

Call Ag Leader

Tech Support.

Check high current related

Yes

per steps 2-4 of

troubleshooting.

problem xed?

circuitry

Was

Yes

No

Troubleshooting

Complete. System should

be in eld-ready state.

Quick Reference Guide

AL: 2006300 - ENG Rev C

16

Loading...

Loading...