Page 1

Agilent Technologies

Z5623A Option H48

Multiport Test Set

User’s and Service Guide

Manufacturing Part Number: Z5623-90016

Printed in USA

June 2005

© Copyright 2000-2002, 2005 Agilent Technologies, Inc. All rights reserved.

Page 2

Warranty Statement

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED “AS IS,” AND IS

SUBJECT TO BEING CHANGED, WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER,

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, AGILENT DISCLAIMS

ALL WARRANTIES, EITHER EXPRESS OR IMPLIED WITH REGARD TO THIS MANUAL

AND ANY INFORMATION CONTAINED HEREIN, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. AGILENT SHALL NOT BE LIABLE FOR ERRORS OR FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH THE FURNISHING, USE, OR

PERFORMANCE OF THIS DOCUMENT OR ANY INFORMATION CONTAINED HEREIN.

SHOULD AGILENT AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT WITH

WARRANTY TERMS COVERING THE MATERIAL IN THIS DOCUMENT THAT CONFLICT

WITH THESE TERMS, THE WARRANTY TERMS IN THE SEPARATE AGREEMENT WILL

CONTROL.

DFARS/Restricted Rights Notice

If software is for use in the performance of a U.S. Government prime contract or

subcontract, Software is delivered and licensed as “Commercial computer software” as

defined in DFAR 252.227-7014 (June 1995), or as a “commercial item” as defined in

FAR 2.101(a) or as “Restricted computer software” as defined in FAR 52.227-19 (June

1987) or any equivalent agency regulation or contract clause. Use, duplication or

disclosure of Software is subject to Agilent Technologies’ standard commercial license

terms, and non-DOD Departments and Agencies of the U.S. Government will receive no

greater than Restricted Rights as defined in FAR 52.227-19(c)(1-2) (June 1987). U.S.

Government users will receive no greater than Limited Rights as defined in FAR

52.227-14 (June 1987) or DFAR 252.227-7015 (b)(2) (November 1995), as applicable in

any technical data.

ii

Page 3

Safety Notes

The following safety notes are used throughout this document. Familiarize yourself

with each of these notes and its meaning before performing any of the procedures in

this document.

WARNING Warning denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could result in

injury or loss of life. Do not proceed beyond a warning note

until the indicated conditions are fully understood and met.

CAUTION Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed beyond a caution sign

until the indicated conditions are fully understood and met.

Statement of Compliance

This instrument has been designed and tested in accordance with IEC Publication 1010, Safety

Requirements for Electronic Measuring Apparatus, and has been supplied in a safe condition. The

instruction documentation contains information and warnings which must be followed by the user to

ensure safe operation and to maintain the instrument in a safe condition.

Definitions

• Specifications describe the performance of parameters covered by the product warranty

(temperature –0 to 55 °C, unless otherwise noted.)

• Typical describes additional product performance information that is not covered by the

product warranty. It is performance beyond specification that 80% of the units exhibit

with a 95% confidence level over the temperature range 20 to 30 °C. Typical

performance does not include measurement uncertainty.

• Nominal values indicate expected performance or describe product performance that is

useful in the application of the product, but is not covered by the product warranty.

iii

Page 4

iv

Page 5

Contents

1. Instrument Description

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Guaranteed Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Typical Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Operating Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Non-Operating Storage Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

General Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Cabinet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Miscellaneous Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Available Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

UK6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Rack Ear Mounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Cleaning and Shipping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2. Installation

Checking the Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Recommended Additional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Familiarization with Safety Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Electrical Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Environmental Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Test Set Familiarization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Setting the GPIB Address of the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Connecting and Turning on the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

3. Using the Network Analyzer to Control the Test Set

Preparing the Analyzer to Control the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

How to Send a Manual Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Common Errors in Manual Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

A List of GPIB Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Restoring the Analyzer to its Normal Configuration . . . . . . . . . . . . . . . . . . . . 3-12

Disaster Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Contents-1

Page 6

Malfunctioning Command Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Malfunctioning Network Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

4. Calibrating the Network Analyzer

Performing the Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Renaming the Calibration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Recalling and Examining Calibrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

How to Recall a Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Method 1. Calibration File Is Not On “Quick Recall” List. . . . . . . . . . . . 4-14

Method 2. Calibration File Is On “Quick Recall” List . . . . . . . . . . . . . . . 4-16

How to Turn a Calibration On and Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

How to Examine the Properties of a Calibration . . . . . . . . . . . . . . . . . . . . . 4-18

5. Performance Verification

Setting Test Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Test Strategy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Insertion Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Return Loss. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Crosstalk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Setting Up Limit Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Limit Testing for Insertion Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Recalling the Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Specifying Measurement Type, Title, and Scaling . . . . . . . . . . . . . . . . . . . 5-8

Setting Up the Limit Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Turning On Limit Lines and Limit Testing. . . . . . . . . . . . . . . . . . . . . . . . 5-14

Saving the Limit Test File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Checking the Limit Test File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Limit Testing for Return Loss (Port Active) . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Recalling the Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Specifying Measurement Type, Title, and Scaling . . . . . . . . . . . . . . . . . . 5-19

Setting Up the Limit Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Turning On Limit Lines and Limit Testing. . . . . . . . . . . . . . . . . . . . . . . . 5-21

Saving the Limit Test File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Checking the Limit Test File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Limit Testing for Return Loss (Port Off) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Recalling the “Port Active” Limit Test File . . . . . . . . . . . . . . . . . . . . . . . 5-24

Specifying the Title. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Setting Up the Limit Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Saving the Limit Test File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Recalling the Limit Test File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Contents-2

Page 7

Contents

Limit Testing for Crosstalk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Specifying Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Specifying IF Bandwidth and Averaging . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Specifying Measurement Type, Title, and Scaling . . . . . . . . . . . . . . . . . . 5-32

Setting Up the Limit Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

Turning On Limit Lines and Limit Testing. . . . . . . . . . . . . . . . . . . . . . . . 5-35

Saving the Limit Test File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

Recalling the Limit Test File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

Verifying Return Loss and Insertion Loss Specifications . . . . . . . . . . . . . . . . 5-36

Measurements Using The Reflection Port . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

Measurements Using The Transmission Port . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Verifying Crosstalk Specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

6. Measuring Multiport Devices

Calibrating the Test System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

7. Advanced Topics

Using an External Computer to Control the Test Set. . . . . . . . . . . . . . . . . . . . . 7-2

GPIB Queries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Box Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Switch Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Using Rocky Mountain Basic (RMB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Using Quick Basic or Visual Basic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Using HPVEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Using National Instruments VISA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Using the Control Lines Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Control Line Commands for 9-Pin Connector:. . . . . . . . . . . . . . . . . . . . . . . . 7-6

Suggested External Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

8. Service

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

System Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

A1 Power Supply Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

A2 Controller and A3 Switch Driver Board Theory. . . . . . . . . . . . . . . . . . . . 8-4

A4 Front Panel Display Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Contents-3

Page 8

Connector Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

General Troubleshooting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Troubleshooting Power Supply Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Troubleshooting the Front Panel Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Troubleshooting the Controller and Switch Driver Boards . . . . . . . . . . . . . . 8-6

List of Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

9. Safety and Regulatory Information

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Instrument Markings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Statement of Compliance with IEC 1010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Declaration of Compliance with German Noise Requirements . . . . . . . . . . . 9-5

10. Contacting Agilent

Contacting Agilent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Contents-4

Page 9

1 Instrument Description

This chapter contains the following sections:

• Overview

• Specifications

• Electrical Requirements

• Environmental Requirements

• General Characteristics

• Available Options

• Cleaning and Shipping Instructions

Agilent Technologies Z5623A Option H48 1-1

Page 10

Instrument Description

Overview

Overview

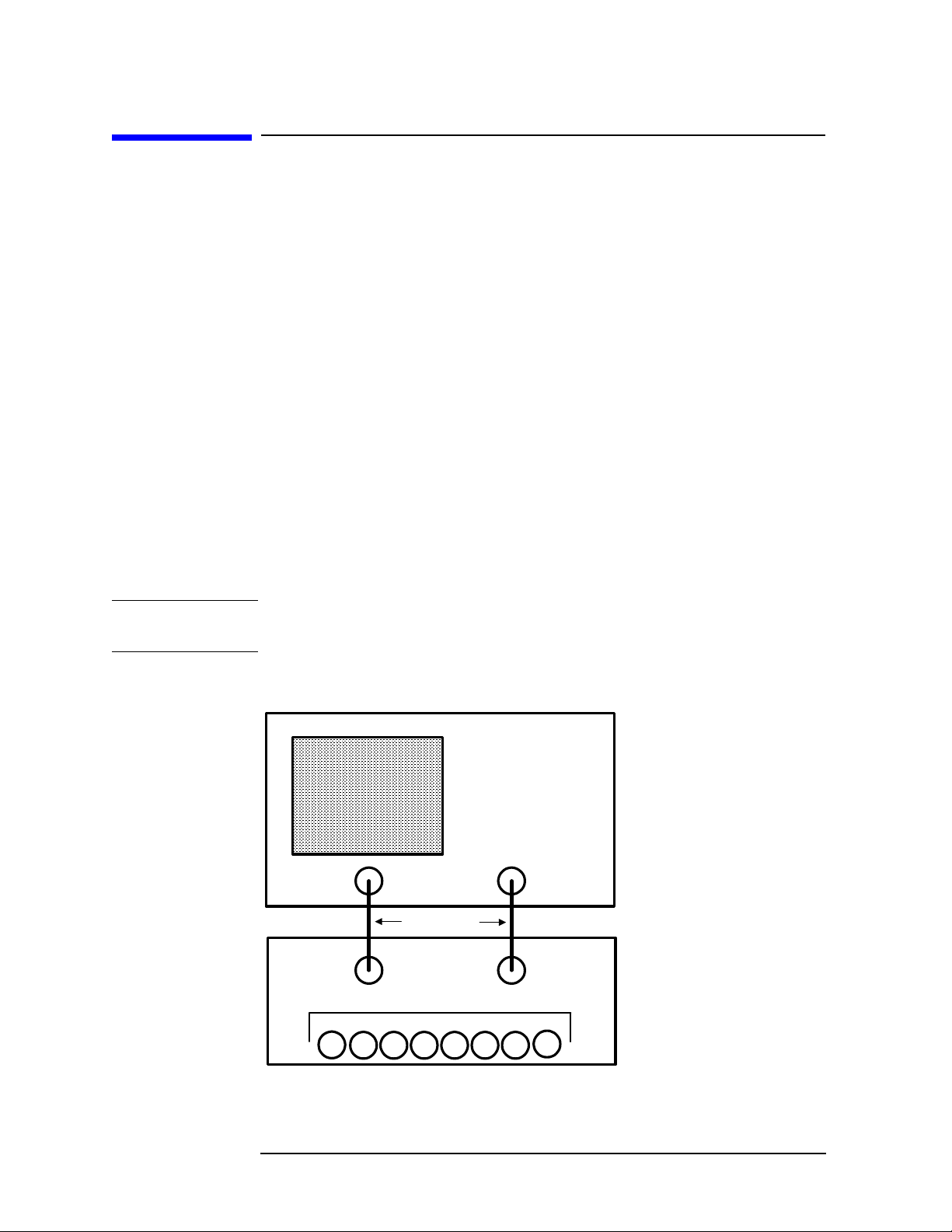

The Agilent Z5623A Option H48 Multiport Test Set is designed for use

with 50 Ω Network Analyzers such as the Agilent PNA Series (Models

E8356A, E8357A, and E8358A). Figure 1-1 shows a typical equipment

setup.

The test set reduces the time required to test multiport devices having

up to eight ports (distribution amplifiers, taps, switches, couplers, etc.).

It does this by reducing the number of device reconnects the operator

must perform. The test set can connect each of its test ports to any of

the following:

• Reflection Port

• Transmission Port

• 50 Ω termination internal to the test set.

Switching is performed with mechanical switches.

The test set is controlled by means of its GPIB interface. The control

can be performed either by a PNA Series network analyzer or by an

external computer.

NOTE

This User's and Service Guide documents the use of the test set with an

Agilent E8358A network analyzer.

Figure 1-1 Typical Equipment Setup

Network Analyzer

Port 1

RF Cables

Reflection

Port

1

Z5623A Option H48

Test Ports

2

3

4

56

Port 2

Transmission

8

7

Port

1-2 Agilent Technologies Z5623A Option H48

Page 11

Instrument Description

Specifications

Specifications

Agilent provides two different types of specifications for the test set:

• Guaranteed performance specs

• Typical performance specs

Typical performance specs have been benchmarked during product

development, but are not tested by the factory and are not guaranteed.

Agilent Technologies Z5623A Option H48 1-3

Page 12

Instrument Description

Specifications

Guaranteed Performance

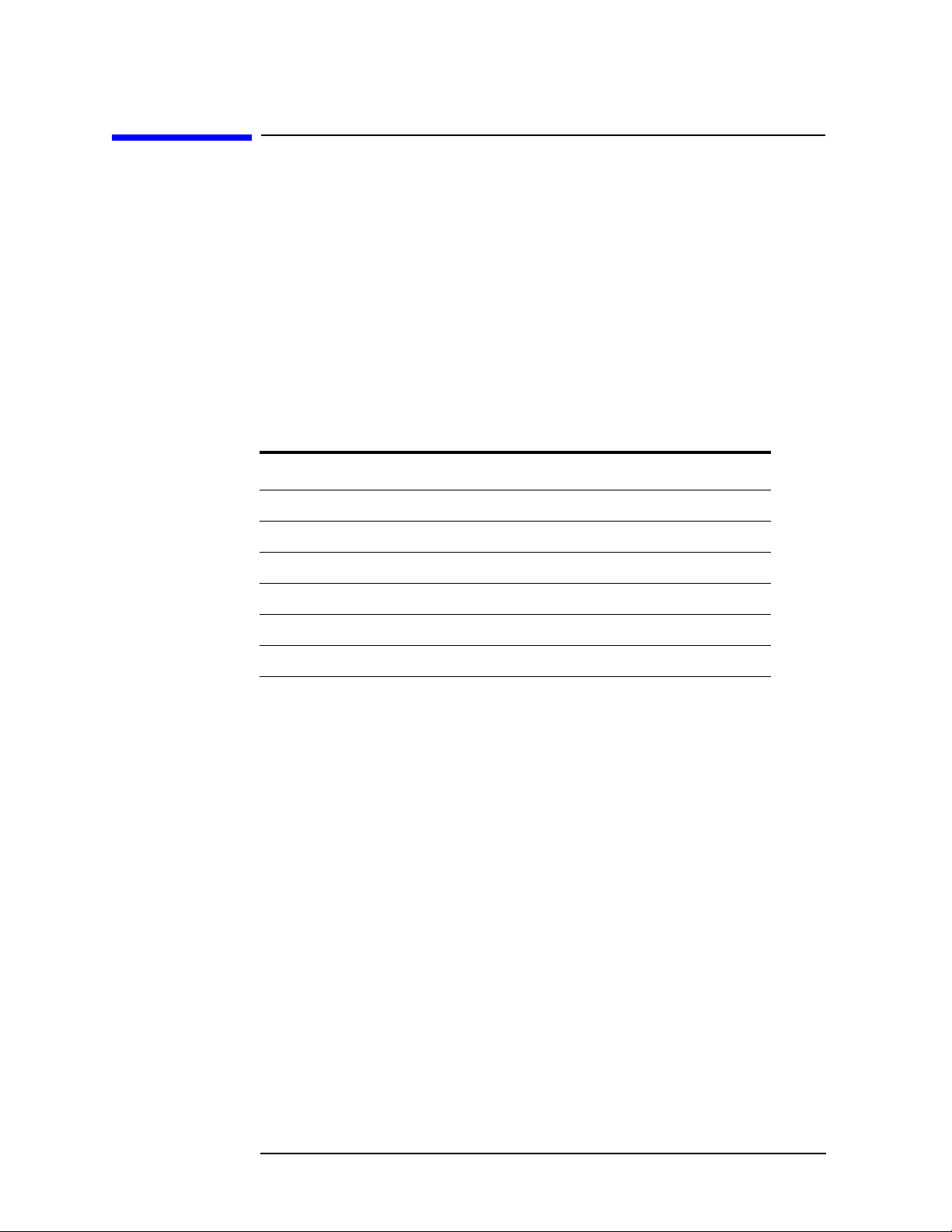

Table 1-1 Agilent Z5623A Option H48 Guaranteed Performance Specs

Parameter Specification

Frequency Range 300 kHz to 9.0 GHz

Crosstalk

a

Return Loss (port active)

Return Loss (port off)

Insertion Loss

h

g

1) –110 dB

2) –105 dB

3) –95 dB

4) –90 dB

f

1) 24 dB

2) 18 dB

3) 14 dB

4) 9 dB

1) 26 dB

2) 20 dB

3) 16 dB

4) 14 dB

1) 1.5 dB

2) 2.0 dB

3) 2.5 dB

4) 3.5 dB

b

c

d

e

b

c

d

e

b

c

d

e

b

c

d

e

Switch Lifetime 5 million cycles

Maximum Input Power

1 Watt (RF + DC)

i

a.Between any two non-connected signal paths

b. Band 1 (300 kHz to 1.3 GHz)

c. Band 2 (1.3 GHz to 3.0 GHz)

d. Band 3 (3.0 GHz to 6.0 GHz)

e. Band 4 (6.0 GHz to 9.0 GHz)

f.When using an external termination on the Reflection or

Transmission port

g.When using one of the 50 Ω internal terminations

h.From any test set port to the Reflection or Transmission port

i. Set by the power handling capability of the 50 Ω internal

terminations

1-4 Agilent Technologies Z5623A Option H48

Page 13

Typical Performance

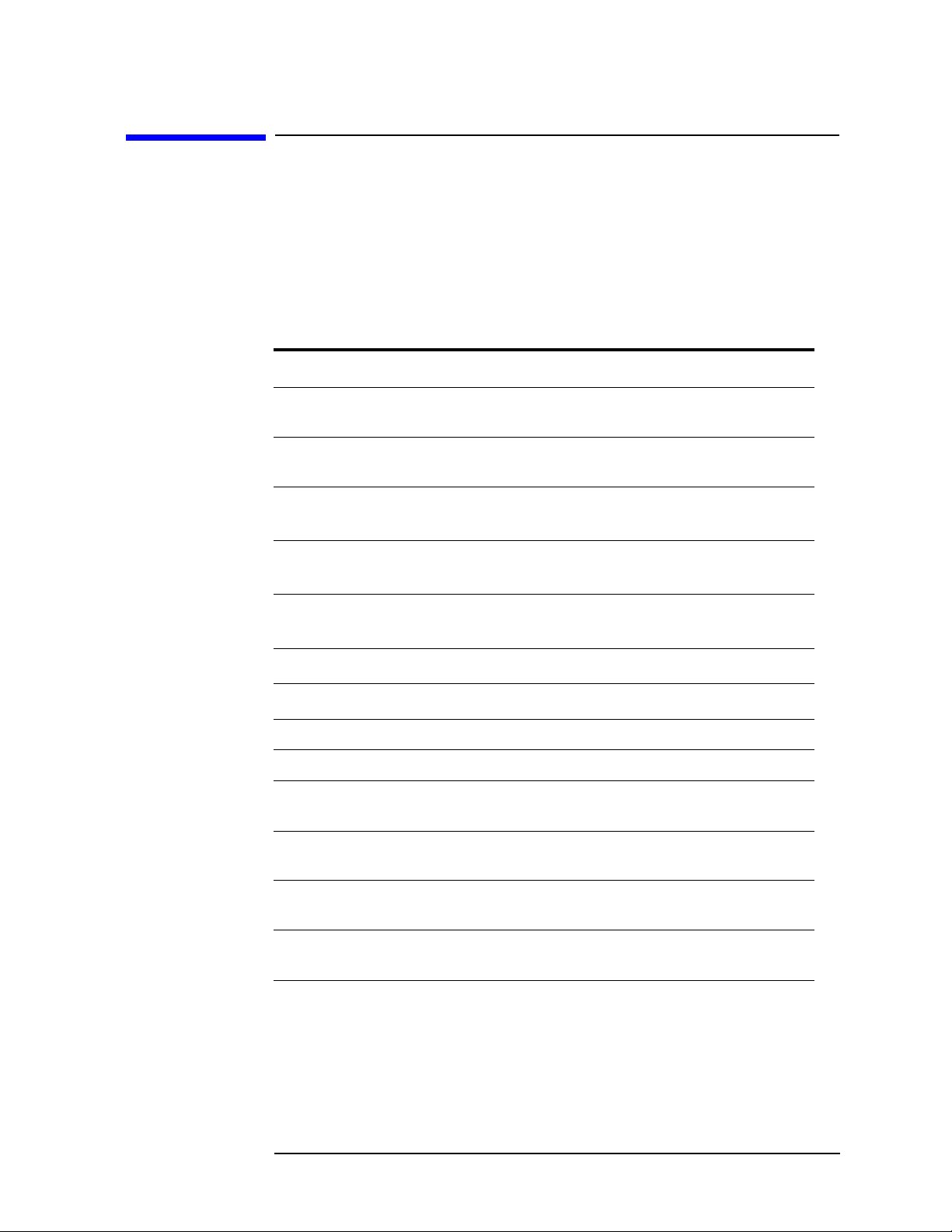

Table 1-2 Agilent Z5623A Option H48 Typical Performance Specs

Parameter Typical Performance

Instrument Description

Specifications

Source Power (max)

a

1) –8.0 dBm

2) –8.0 dBm

3) –7.0 dBm

4) –1.0 dBm

Dynamic Range (max)f1) 110 dB

2) 105 dB

3) 95 dB

4) 90 dB

Cycle Time (minimum;

IF BW = 35 kHz)

g

1) 430 mS (Dynamic Range = 86 dB)

2) 430 mS (Dynamic Range = 89 dB)

b

c

d

e

b

c

d

e

3) 430 mS (Dynamic Range = 78 dB)

4) 430 mS (Dynamic Range = 71 dB)

Cycle Time (@ 100 dB

Dynamic Range; IF

BW = 3 kHz)

g

2) 900 mS

3) 900 mS

c

d

Switching Time 11 mS

a. Power measured at test ports 1-8 on Z5623A Option

H48 when connected to the E8358A using the

8120-4782 RF Jumper cables supplied.

b. Band 1 (300 kHz to 1.3 GHz)

c. Band 2 (1.3 GHz to 3.0 GHz)

d. Band 3 (3.0 GHz to 6.0 GHz)

e. Band 4 (6.0 GHz to 9.0 GHz)

f. IF Bandwidth set to 10 Hz

g. Conditions: 2 Windows, 4 Channels, 8 Traces,

2-port cal, no band crossings, 201points.

b

c

d

e

Agilent Technologies Z5623A Option H48 1-5

Page 14

Instrument Description

Electrical Requirements

Electrical Requirements

The alternating-current (AC) power that is supplied to the test set must

meet the following requirements:

Voltage: 90 to 250 Vac

Frequency: 48 to 66 Hz

Available power: 40 watts minimum

If the available AC line voltage is outside the 90 to 250 Vac range, an

autotransformer that provides third wire continuity to earth ground

may be used.

Environmental Requirements

CAUTION

Operating Environment

Indoor use only

Operating temperature: 0 to 55 °C

Maximum relative humidity: 80 percent for temperatures up to 31 °C

decreasing linearly to 50 percent relative humidity at 40 °C

Altitude: up to 15,000 feet (4,572 meters)

Enclosure protection: IP 20, according to IEC 529

This product is designed for use in INSTALLATION CATEGORY II,

and POLLUTION DEGREE 2, per IEC 101 and 664 respectively.

Non-Operating Storage Conditions

Temperature: –40 °C to +70 °C

Humidity: 0 to 90 percent relative at +65 °C (non-condensing)

Altitude: 0 to 15,240 meters (50,000 feet)

1-6 Agilent Technologies Z5623A Option H48

Page 15

Instrument Description

General Characteristics

General Characteristics

Weight

Net: Approximately 9 kg

Shipping: Approximately 20 kg

Cabinet Dimensions

These dimensions exclude front and rear panel protrusions.

89 mm H by 425 mm W by 500 mm D (3.5 in by 16.75 in by 19.7 in)

Miscellaneous Characteristics

RF connectors: Type N female

Switch type: Mechanical

I/O Control: GPIB

Available Options

UK6

Option UK6 provides a commercial calibration certificate including

actual test data. Data includes test results including reflection,

transmission, and crosstalk for all test ports.

Rack Ear Mounts

Option 908, part number 5062-3974, provides rack mounts that make it

quick and easy to install or remove the test set from a mainframe.

For further information on these options, please contact Agilent

Technologies. Refer to Chapter 10 , “Contacting Agilent.”

Agilent Technologies Z5623A Option H48 1-7

Page 16

Instrument Description

Cleaning and Shipping Instructions

Cleaning and Shipping Instructions

Cleaning

Clean the instrument cabinet using a damp cloth only.

Shipping

Always transport or ship the instrument using the original packaging if

possible. If not, comparable packaging must be used.

1-8 Agilent Technologies Z5623A Option H48

Page 17

2 Installation

This chapter contains the following sections:

• Checking the Shipment

• Recommended Additional Equipment

• Familiarization with Safety Requirements

• Electrical Preparations

• Environmental Preparations

• Test Set Familiarization

• Setting the GPIB Address of the Test Set

• Connecting and Turning on the Test Set

Agilent Technologies Z5623A Option H48 2 -1

Page 18

Installation

Checking the Shipment

Checking the Shipment

After the test set has been unpacked, keep the original packaging

materials so they can be used if you need to transport the instrument.

Check the items received against Table 2-1 to make sure you have

received everything.

Inspect the test set and all accessories for any signs of damage that may

have occurred during shipment. If your test set or any accessories

appear to be damaged or missing, call Agilent Technologies. Refer to

Chapter 10 , “Contacting Agilent.”

Table 2-1 Accessories Supplied with Z5623A Option H48

Description Agilent Part Number Quantity

Power Cord See Figure 2-2 on page 2-6 1

Front Handle Kit 5063-9226 1

Rack Mount Kit 5063-9232 1

RF Cable 8120-4782 2

GPIB Cable .5M HP 10833D 1

User’s and Service Guide Z5623-90016 1

2 -2 Agilent Technologies Z5623A Option H48

Page 19

Recommended Additional Equipment

Recommended Additional Equipment

The equipment listed in Table 2-2 is not shipped with the test set, but is

recommended for use with it. The remainder of this User’s and Service

Guide assumes that the user has the listed equipment (or its

equivalent) available.

Table 2-2 Recommended Equipment Not Supplied With Test Set

Description Model Or Part Number Quantity

Installation

PNA Series Network

Analyzer

Electronic Calibration

Module

Keyboard with USB

cable

Mouse with USB cable Hewlett-Packard Model No.

USB Quad Hub Peracom Model No.

USB Cable

RF Cable (24”)

9/16” Wrench Agilent Part No. 8710-1770 1

3/4” Torque Wrench Agilent Part No. 8710-1766 1

Type N 50 Ohm Male

Short

Type N 50 Ohm Female

Short

Agilent Model No.

E8356A, E8357A, or E8358A

Agilent Part No. 85072-60007 1

Hewlett-Packard Model No.

SK-2502U

M-UB48

UH4000A

Peracom Model No. CA2000A

Agilent Part No. 8120-4781

Agilent Part No. 85032-60016 2

Agilent Part No. 85032-60015 2

a

a

a,b

a,b

a

1

1

1

1

3

Type N 50 Ohm Female

Termination

Type N 50 Ohm

Female-Female Adapter

Agilent Part No. 85032-60018 2

Agilent Part No. 85032-60021 1

a. Or equivalent

b. Available from Peracom Networks, Inc., Cary, North Carolina

(www.peracom.com).

Agilent Technologies Z5623A Option H48 2 -3

Page 20

Installation

Familiarization with Safety Requirements

Familiarization with Safety Requirements

This document contains two types of safety notices: Warnings and

Cautions.

A Warning denotes a hazard that may endanger the operator.

A Caution denotes a hazard that may endanger the instrument.

Before proceeding to the Electrical Preparations described in the next

section, turn to Chapter 9, “Safety and Regulatory Information,” and

review the Warnings, Cautions, and safety markings that apply to this

instrument.

Electrical Preparations

1. Ensure that the “Electrical Requirements” on page 1-6 are met.

2. Verify that the power cable is not damaged and that the power

source outlet provides a protective earth ground contact. Note that

Figure 2-1 on page 2-5 depicts only one type of power source outlet.

Refer to Figure 2-2 on page 2-6 to see the different types of power

cord plugs that can be used with your test set.

Cables are available in different lengths. For descriptions and part

numbers of cables other than those described in Figure 2-2, call

Agilent Technologies. Refer to Chapter 10 , “Contacting Agilent.”

3. If this product is to be powered by autotransformer, make sure the

common terminal is connected to the neutral (grounded) side of the

ac power supply.

2 -4 Agilent Technologies Z5623A Option H48

Page 21

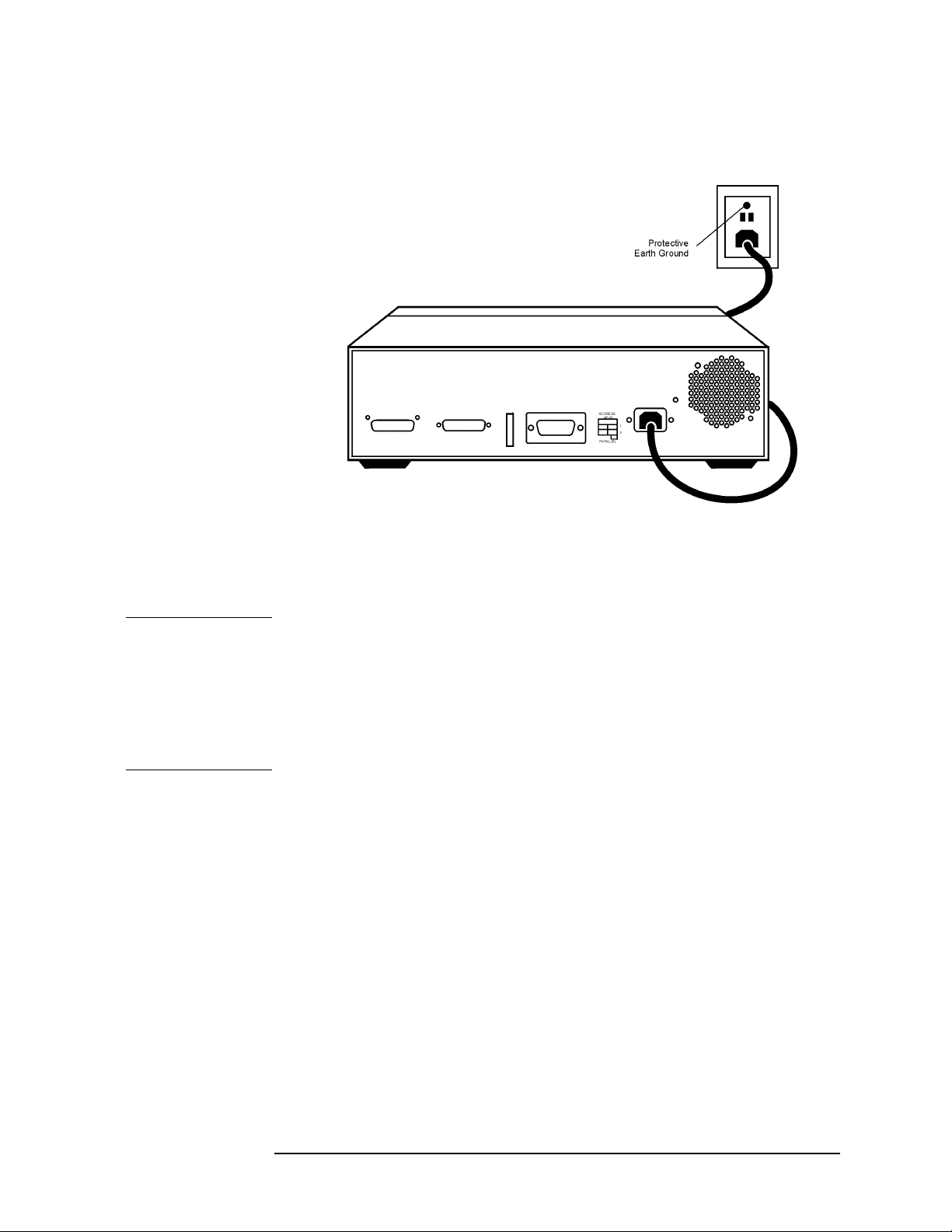

Figure 2-1 Protective Earth Ground

Installation

Electrical Preparations

WARNING

This is a Safety Class I product (provided with a protective

earthing ground incorporated in the power cord). The mains

plug shall only be inserted into a socket outlet provided with a

protective earth contact. Any interruption of the protective

conductor, inside or outside the instrument, is likely to make

the instrument dangerous. Intentional interruption of the

protective conductor is prohibited.

Agilent Technologies Z5623A Option H48 2 -5

Page 22

Installation

Electrical Preparations

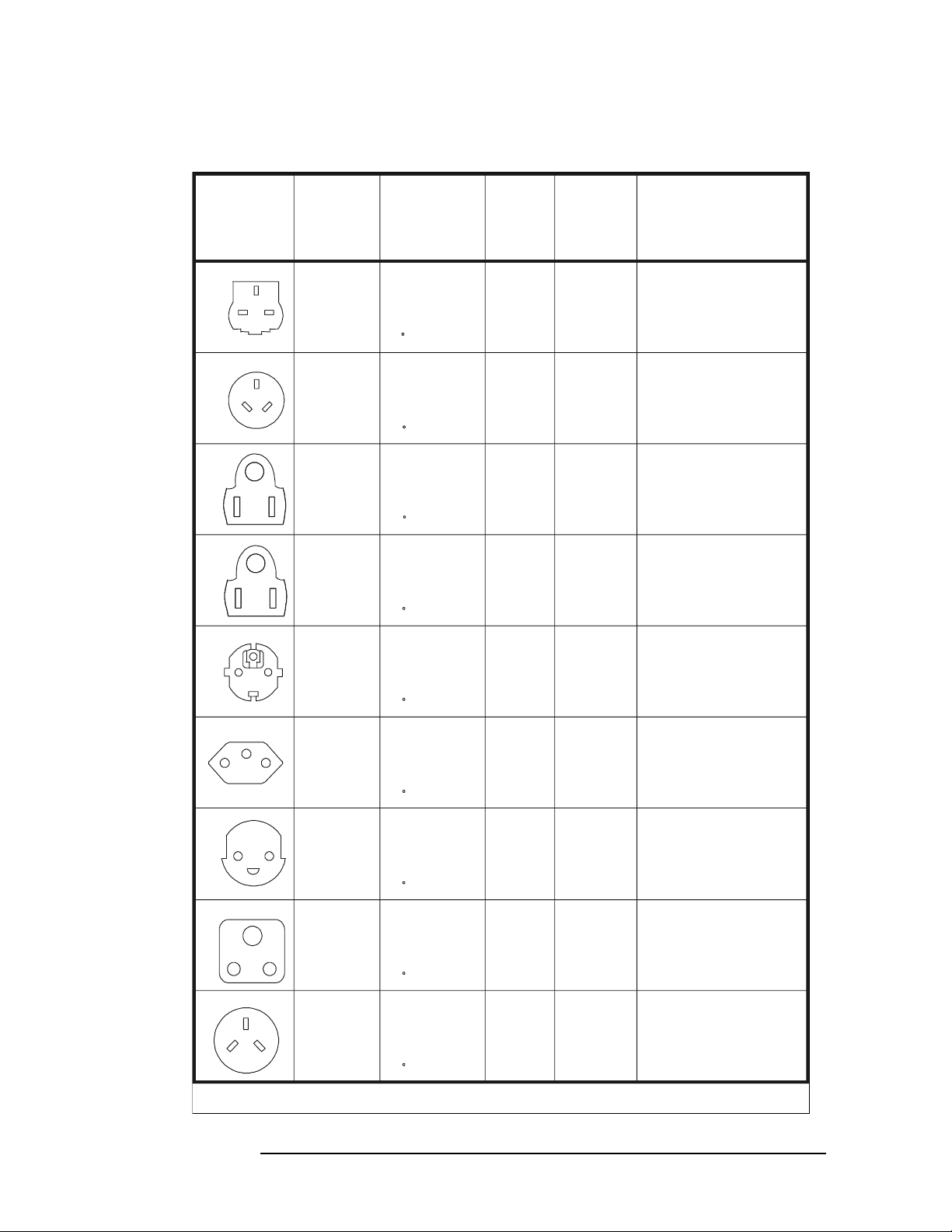

Figure 2-2 Power Cables

Plug Type

250V

250V

125V

125V

250V

230V

220V

E

LN

E

LN

EE

NNLLEENNLL

EE

NNLLEENNLL

E

E

L

N

NL

E

LN

a

Number

8120-8705

8120-8709

8120-1369

8120-0696

8120-1378

8120-1521

8120-4753

8120-4754

8120-1689

8120-1692

8120-2104

8120-2296

8120-2956

Cable

Part

b

Plug

Description

Straight

BS 1363A

90

Straight

AS 3112

90

Straight

NEMA 5-15P

90

Straight

NEMA 5-15P

90

Straight

CEE 7/VII

90

Straight

SEV Type 12

90

Straight

SR 107-2-D

Length

cm (in.)

229 (90)

229 (90)

210 (79)

200 (78)

203 (80)

203 (80)

229 (90)

229 (90)

200 (78)

200 (78)

200 (78)

200 (78)

200 (78)

Cable

Color

Mint Gray

Mint Gray

Gray

Gray

Jade Gray

Jade Gray

Gray

Gray

Mint Gra y

Mint Gray

Gray

Gray

Gray

For Use

in Country

Option 900

United Kingdom, Hong

Kong, Cyprus, Nigeria,

Singapore, Zimbabwe

Option 901

Argentina, Australia,

New Zealand, Mainland

China

Option 903

United States, Canada,

Brazil, Colombia,

Mexico,Philippines,

Saudi Arabia, Taiwan

Option 918

Japan

Option 902

Continental Europe,

Central African Republic,

United Arab Republic

Option 906

Switzerland

Option 912

Denmark

8120-2957

250V

E

L

8120-4211

N

8120-4600

250V

E

N

8120-5182

L

8120-5181

a. E =earth ground, L = line, and N = neutral.

b. Plug identifier numbers describe the plug only. The Agilent Technologies part number is for the complete cable assembly.

90

Straight

IEC 83-B1

90

Straight

SI 32

90

200 (78)

200 (78)

200 (78)

200 (78)

200 (78)

Gray

Mint Gray

Mint Gray

Jade Gray

Jade Gray

Option 917

South Africa, India

Option 919

Israel

2 -6 Agilent Technologies Z5623A Option H48

Page 23

Environmental Preparations

1. Ensure that the “Environmental Requirements” on page 1-6 are met.

2. If you are installing the test set into a cabinet, ensure there are at

least two inches of clearance around the sides and back of the test

set and the system cabinet. See Figure 2-3. The convection into and

out of the test set must not be restricted. The ambient temperature

(outside the cabinet) must be less than the maximum operating

temperature of the test set by 4 °C for every 100 watts dissipated in

the cabinet.

Figure 2-3 Ventilation Clearance Requirements

Installation

Environmental Preparations

CAUTION

If the total power dissipated in the cabinet is greater than 800 watts,

forced convection must be used.

Agilent Technologies Z5623A Option H48 2 -7

Page 24

Installation

Environmental Preparations

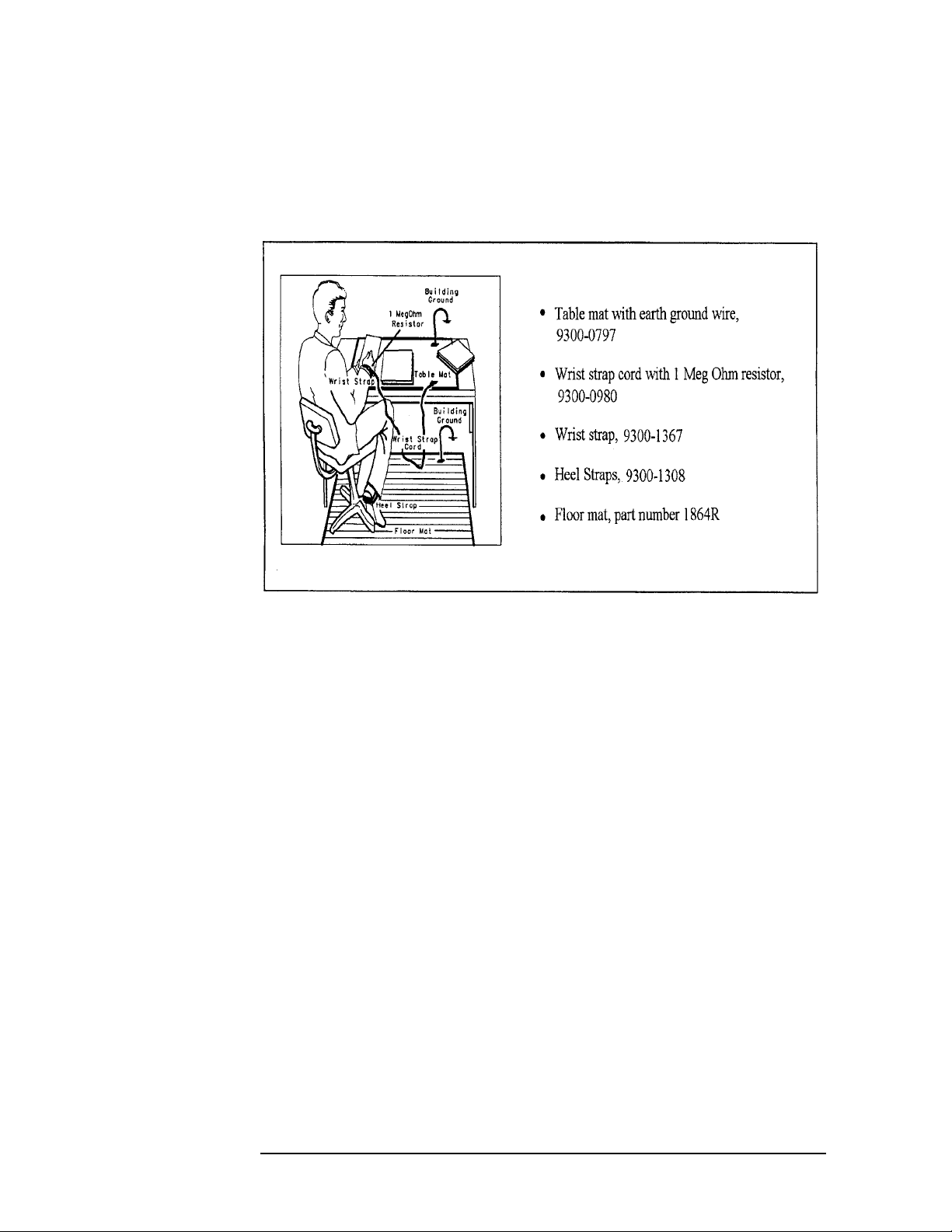

3. Set up a static safe workstation such as the one shown in Figure 2-4.

Electrostatic discharge (ESD) can damage or destroy electronic

components.

Figure 2-4 Example of an Antistatic Workstation

2 -8 Agilent Technologies Z5623A Option H48

Page 25

Test Set Familiarization

This section familiarizes the user with various front and rear panel

features of the test set.

Front Panel

Figure 2-5 Front Panel Features

Installation

Test Set Familiarization

REFLECTION

Port

POWER ON

Switch

POWER ON Switch

The POWER ON Switch turns the AC power to the test set on and off.

The switch is located at the bottom left corner of the front panel. See

Figure 2-5.

The switch disconnects the mains circuits from the mains supply after

the EMC filters and before other parts of the instrument.

PORT

CONNECTION

Status LCD

Test Ports 1 through 8

TRANSMISSION

Port

CONTROL

LINES

Connector

GROUND

Connector

CAUTION

REFLECTION Port, TRANSMISSION Port, and Test Ports 1–8

The REFLECTION Port, the TRANSMISSION Port, and Test Ports 1

through 8 are 50 Ω connectors that are used to connect to the device

under test.

Do not input more than 1 Watt maximum RF+DC to these ports or

damage to the internal RF switches or the analyzer may occur.

The GROUND Connector

The GROUND Connector provides a convenient front panel ground

connection for a standard banana plug.

Agilent Technologies Z5623A Option H48 2 -9

Page 26

Installation

Test Set Familiarization

The PORT CONNECTION Status LCD

The PORT CONNECTION Status LCD displays the following:

• Which test port is connected to the REFLECTION port

• Which test port is connected to the TRANSMISSION port

• The status (O = “Open”, L = “Low”) of each of the five control lines

(C5 through C1)

All test ports not displayed on the Status LCD are internally

terminated in 50 Ω.

The CONTROL LINES Connector

The 9-pin CONTROL LINES Connector provides the user with a way of

controlling either the Device Under Test (DUT) or other equipment. The

test set cannot source any current from this connector. Therefore, the

user must provide an external power supply and some additional

circuitry if he wishes to use the connector. Refer to“Using the Control

Lines Connector” on page 7-6 for further details.

CAUTION

CAUTION

Do not apply more than +22 Vdc to pins 1 through 5 of the CONTROL

LINES Connector.

Do not employ external circuitry that forces the test set to sink more

than 250 mA on any control line (pins 1 through 5 of the CONTROL

LINES Connector) when that line is commanded to the “Low” state

(+0.63 Vdc).

2 -10 Agilent Technologies Z5623A Option H48

Page 27

Rear Panel

Figure 2-6 Rear Panel Features

Installation

Test Set Familiarization

Not Used

GPIB

Connector

GPIB

Address

Line Module

Switches

GPIB Connector

This connector allows the test set to be controlled either by the network

analyzer or by an external controller.

GPIB Address Switches

The GPIB Address Switches set the GPIB address of the test set. See

“Setting the GPIB Address of the Test Set” on page 2-13 for

information.

Line Module

The line module contains the power cable receptacle and the line fuse.

Power Cables

The line power cable is supplied in one of several configurations,

depending on the destination of the original shipment.

Each instrument is equipped with a three-wire power cable. When

connected to an appropriate ac power receptacle, this cable grounds the

instrument chassis. The type of power cable shipped with each

instrument depends on the country of destination. See Figure 2-2,

“Power Cables,” on page 2-6 for the part numbers of these power cables.

WARNING

This is a Safety Class I product (provided with a protective

earthing ground incorporated in the power cord). The mains

plug shall only be inserted in a socket outlet provided with a

protective earth contact. Any interruption of the protective

conductor, inside or outside the instrument, is likely to make

the instrument dangerous. Intentional interruption is

prohibited.

Agilent Technologies Z5623A Option H48 2 -11

Page 28

Installation

Test Set Familiarization

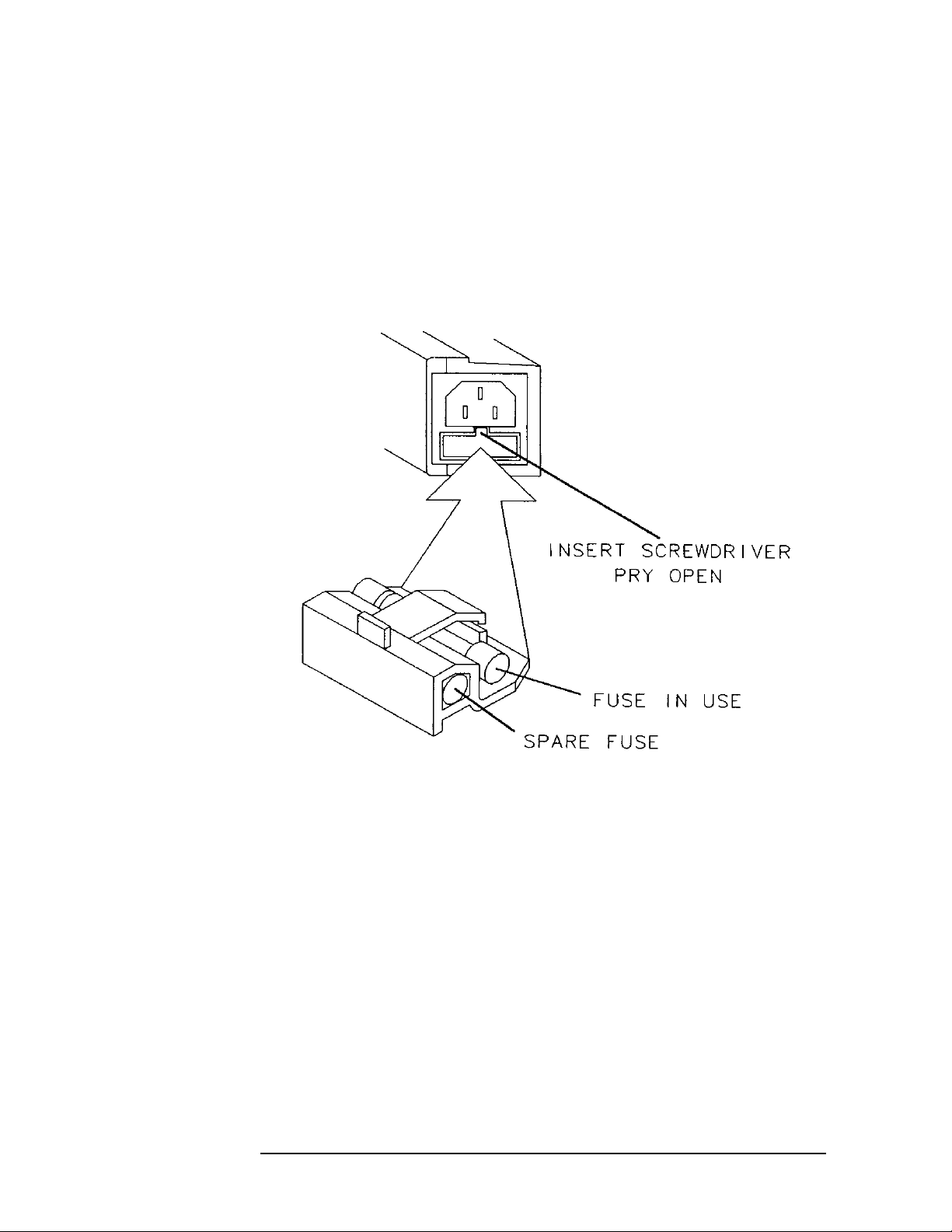

The Line Fuse

The line fuse (F 3 A/250 V, part number 2110-0780) and a spare reside

within the line module. Figure 2-7 illustrates where the fuses are and

how to access them.

Figure 2-7 Location of Line Fuses

2 -12 Agilent Technologies Z5623A Option H48

Page 29

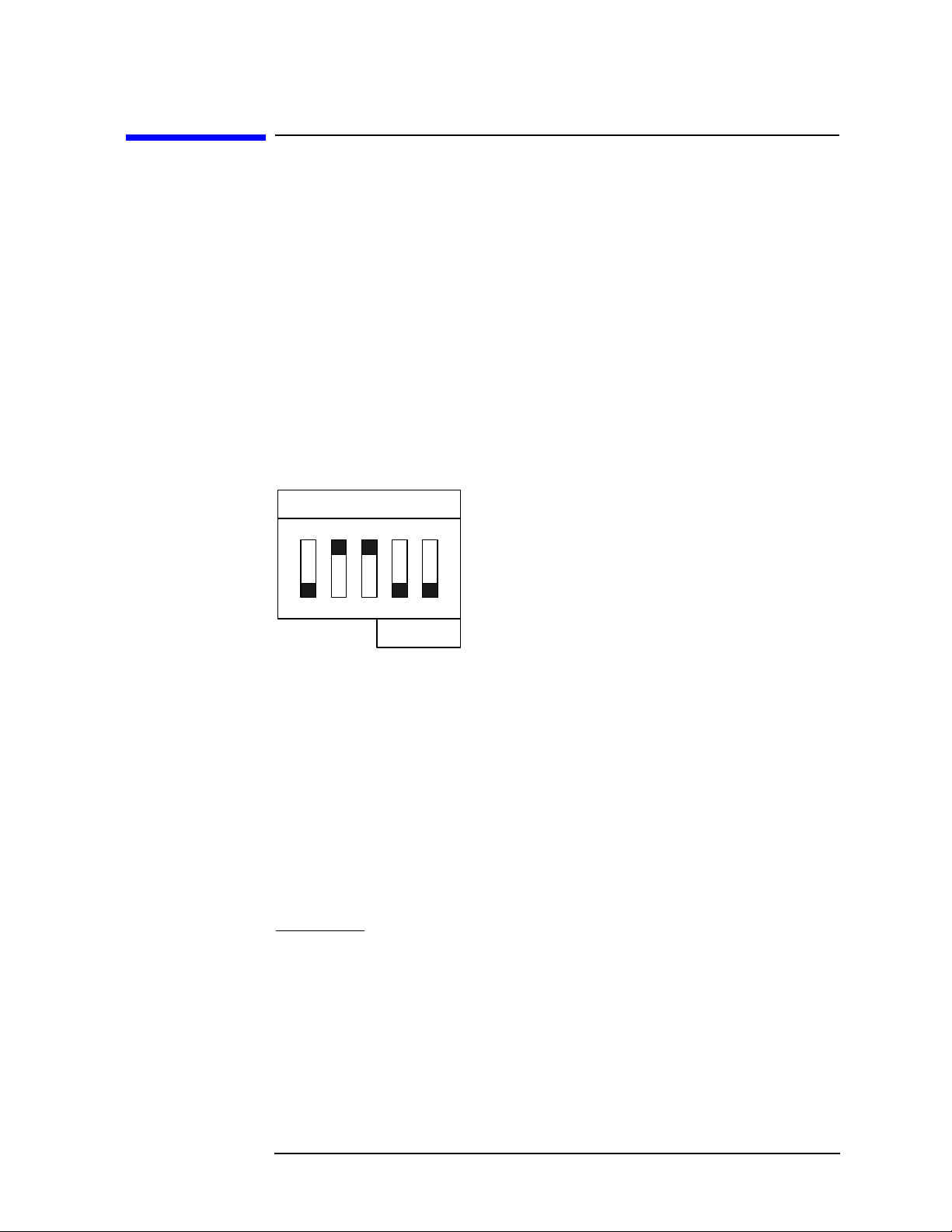

Setting the GPIB Address of the Test Set

A bank of five switches is used to set the GPIB address of the test set.

The switch bank is located on the rear panel of the test set and is shown

in Figure 2-6 on page 2-11. A diagram of the switch bank is presented

in Figure 2-8.

The switch bank sets the GPIB address in binary (base 2) format. Each

switch controls one bit of the address. To set a bit to 1, move the

corresponding switch to the up position. To set a bit to 0, move the

corresponding switch to the down position. The binary address shown

in Figure 2-8 is 01100.

Figure 2-8 GPIB Address Switches

ADDRESS:

HP-IB

168421

Installation

Setting the GPIB Address of the Test Set

Equation 2-1

1

0

12

PARALLEL

To convert the binary address to decimal (base 10) format, just multiply

each bit by the decimal value of that bit, then add the results. The

decimal value of each bit is shown above the corresponding switch.

Applying this conversion method to Figure 2-8 we obtain

016× 0=

18× 8=

14× 4=

02× 0=

02× 0=

Sum 12=

Therefore, the binary GPIB address (01100) shown in Figure 2-8 is

equal to 12 in decimal (base 10) format.

If all bits are set to 1, the GPIB address is 11111 in binary format, or 31

in decimal format. (16 + 8 + 4 + 2 + 1 = 31.) Therefore, the GPIB address

can have any value from 0 to 31 inclusive.

Agilent Technologies Z5623A Option H48 2 -13

Page 30

Installation

Connecting and Turning on the Test Set

NOTE

The test set is shipped from the factory with the GPIB address set to 12.

Connecting and Turning on the Test Set

Make the connections shown in Figure 2-9, “Detailed Equipment

Connection Diagram.” The figure shows two RF cables connecting the

network analyzer to the test set. If you intend to verify the performance

of the test set, use the long RF cables listed in Table 2-3. Otherwise, use

the short ones.

Table 2-3 RF Cables Connecting Network Analyzer to Test Set

Length Part No. Purpose

Long 8120-4781 Verification of test set performance

Short 8120-4782 Measurement of multiport devices

Plug power cords into the test set. Turn both instruments on.

NOTE

Allow the test set to warm up for at least 2 hours. For the most stable

and accurate measurements, leave the test set turned on at all times.

2 -14 Agilent Technologies Z5623A Option H48

Page 31

Connecting and Turning on the Test Set

Figure 2-9 Detailed Equipment Connection Diagram

USB Quad Hub

Port 1 Port 2 Port 3 Port 4

Up Link

Installation

USB Cable

To USB Port

on Rear Panel

To GPIB Connector

on Rear Panel

Port 1

Mouse with

USB Cable

Keyboard with USB Cable

Network Analyzer

USB Port

Port 2

GPIB Cable

To GPIB Connector

on Rear Panel

Agilent Technologies Z5623A Option H48 2 -15

Reflection

Port

1

RF Cables

Z5623A Option H48

Test Ports

2

3

4

Electronic

Calibration

Module

Transmission

Port

8

7

6

5

USB Cable

Page 32

Installation

Connecting and Turning on the Test Set

2 -16 Agilent Technologies Z5623A Option H48

Page 33

3 Using the Network Analyzer to

Control the Test Set

This chapter assumes the following:

• The instructions in Chapter 2 , “Installation,” have been

performed.

• The test set and associated equipment are connected as shown in

Figure 2-9 on page 2-15.

This chapter shows you how the network analyzer can be used to

manually control the test set. The method presented here is considered

a manual one because the user manually enters individual commands

on a keyboard connected to the network analyzer. The chapter includes

the following sections:

• Preparing the Analyzer to Control the Test Set

• How to Send a Manual Command

• Common Errors in Manual Commands

• A List of GPIB Commands

• Restoring the Analyzer to its Normal Configuration

• Disaster Recovery

Agilent Technologies Z5623A Option H48 3-1

Page 34

Using the Network Analyzer to Control the Test Set

Preparing the Analyzer to Control the Test Set

Preparing the Analyzer to Control the Test Set

Step 1. Make sure that all connections shown in Figure 2-9 on page 2-15 have

been made.

Step 2. Make sure that both the PNA Series analyzer and the test set are

turned on.

Step 3. On the network analyzer, click the System menu, scroll down to

Configure, and click SICL/GPIB. See Figure 3-1, “System Menu.”

Figure 3-1 System Menu

3-2 Agilent Technologies Z5623A Option H48

Page 35

Step 4. In the SICL/GPIB window, click System Controller and then OK. See

Figure 3-2, “SICL/GPIB Window.”

Figure 3-2 SICL/GPIB Window

Using the Network Analyzer to Control the Test Set

Preparing the Analyzer to Control the Test Set

Step 5. Locate the Minimize button (“_”) in the top right corner of the window.

See the upper right-hand corner of Figure 3-2. See also the magnified

view shown in Figure 3-3, “Minimize Window.” If the button is not

visible, click on the View menu, then scroll down to Title Bars and click

on it. When the Minimize button is visible, minimize the analyzer

window by clicking on the button.

Figure 3-3 Minimize Window

Click on

Agilent Technologies Z5623A Option H48 3-3

Page 36

Using the Network Analyzer to Control the Test Set

Preparing the Analyzer to Control the Test Set

Step 6. On the desktop, double-click the Measurement & Automation icon.

See Figure 3-4, “PNA DeskTop.”

Figure 3-4 PNA DeskTop

Step 7. From the Measurement & Automation window, click on the Devices

and Interfaces folder to expand the directory.

Step 8. Right

-click GPIBO (AT-GPIB/TNT), then click Interactive Control.

See Figure 3-5, “Interactive Control window.”

Figure 3-5 Interactive Control window

3-4 Agilent Technologies Z5623A Option H48

Page 37

Step 9. When the C:\Progam Files\National Instruments\ NI-488.2\

bin\ibic.exe

window appears, type ibdev. See Figure 3-6, “User

Controller Window.”. Then you will be prompted to:

Enter board index: “0”

Enter primary address: “12”

Enter secondary address: “0”

Enter timeout: “0”

Enter ‘EOI on last byte’ flag: “0”

Enter end-of-string byte/mode: “1”

Figure 3-6 User Controller Window

Using the Network Analyzer to Control the Test Set

Preparing the Analyzer to Control the Test Set

Step 10. If you make a mistake, close the window and repeat steps 7, 8, and 9.

Step 11. When the prompt

ud0: appears in the window, enter ibclr. This

command clears the internal bus. When the ud0: prompt is returned

after the ibclr command has been issued, you are ready to issue

commands to the test set from this window.

Agilent Technologies Z5623A Option H48 3-5

Page 38

Using the Network Analyzer to Control the Test Set

Preparing the Analyzer to Control the Test Set

Step 12. Use the mouse to size and position the PNA Series Network Analyzer

window and the command window (

Instruments \NI-488.2\bin\ibic.exe) so that both

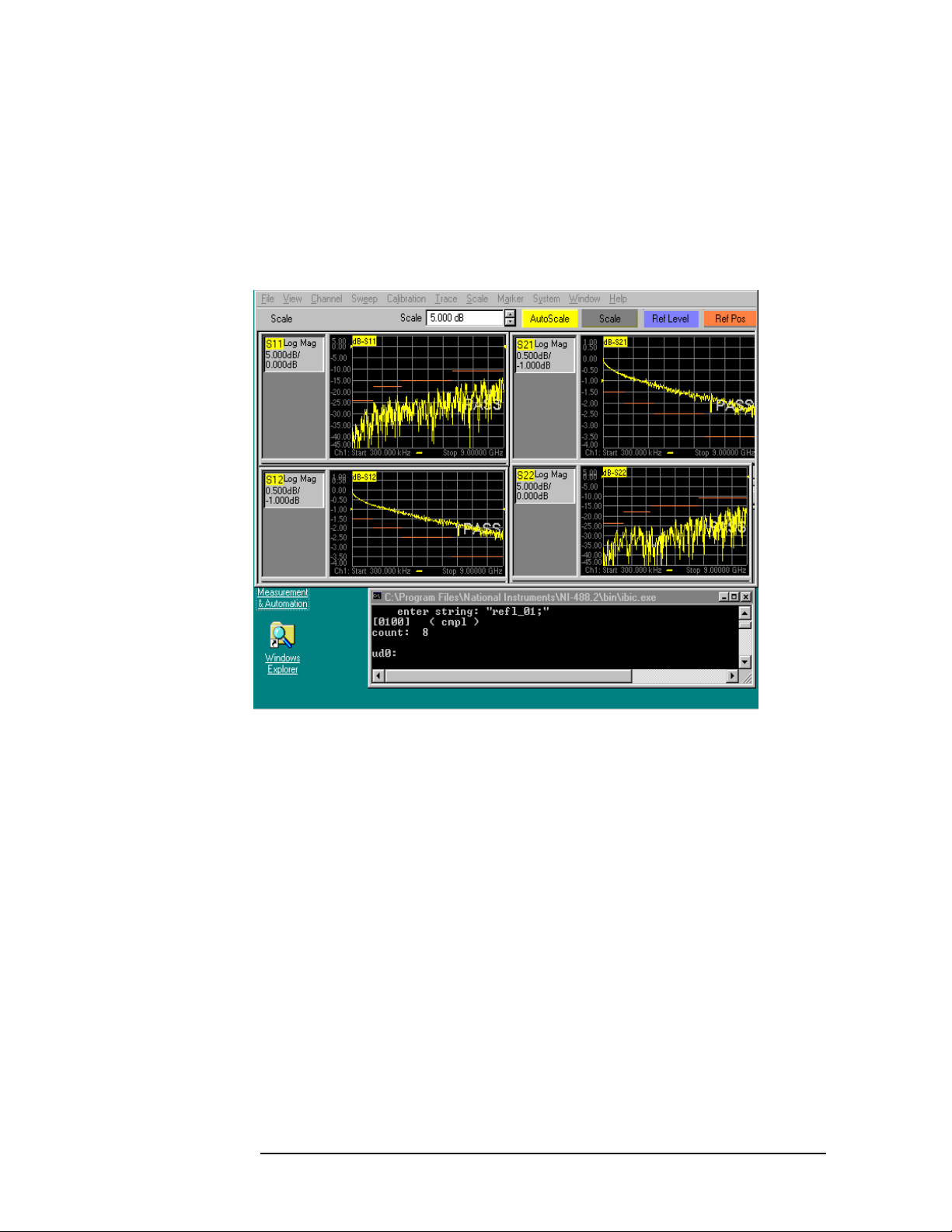

visible on the network analyzer screen. See Figure 3-7, “Manual

Control Window.”

Figure 3-7 Manual Control Window

C:\Progam Files\National

windows are

3-6 Agilent Technologies Z5623A Option H48

Page 39

Using the Network Analyzer to Control the Test Set

How to Send a Manual Command

How to Send a Manual Command

This procedure assumes the following:

• The instructions in the previous section (“Preparing the Analyzer

to Control the Test Set”) have been performed.

• The command window (C:\Program Files\

National Instruments\NI-488.2\bin\ibic.exe) shown at the

bottom of Figure 3-7 is visible on the analyzer.

Step 1. Select a command from Table 3-2 or Table 3-3.

Step 2. Click in the command window once to ensure that it is active.

Step 3. Verify that the last line of text appearing in the window is the ud0:

prompt with nothing after it.

Step 4. Type ibwrt and then press the <Enter> key.

NOTE

Step 5. When the prompt enter string: appears, type all

of the following in

exactly the order listed here:

• a double quotation mark (")

• the command selected in Step 1

•a semicolon

• another double quotation mark (")

• the <Enter> key

For example, to connect the Reflection port of the network analyzer to

Test Port #3, type “refl_03;”<Enter>. To connect the Transmission port of

the network analyzer to Test Port #7, type “tran_07;”<Enter>. See Figure

3-6, “User Controller Window.”

Step 6. Look at the PORT CONNECTION display on the test set to verify that

the command was received.

Step 7. If the message on the PORT CONNECTION display is, “ERR: Invalid

Command”, type ibclr<Enter> to clear the bus. Next, repeat Steps 3

through 5.

Use the <Up Arrow> key to recall previous commands. This will

decrease typing time and errors.

NOTE

The test set waits until it receives a semicolon before executing any

command. Once the semicolon is received, the test set combines into a

single string all of the characters it has received since the previous

semicolon. The test set then treats the string as a single command.

Agilent Technologies Z5623A Option H48 3-7

Page 40

Using the Network Analyzer to Control the Test Set

Common Errors in Manual Commands

NOTE

It is possible to issue several commands in a single line. For example,

the following string connects the Reflection port to Test Port #2,

connects the Transmission port to Test Port #5, and sets the Control

Lines to OLOOL: “refl_02;tran_05;00001001;”<Enter>.

Common Errors in Manual Commands

This section explains several common errors.

Table 3-1 Common Errors in Manual Commands

Command(s) Issued Explanation of Error Solution

“refl_01” Missing semicolon. Send a semicolon:

“;”

“refl_01”

“tran_08;”

Missing semicolon in first

command causes both

commands to be interpreted

as a single invalid

command: “refl_01tran_08;”

Resend both

commands with a

semicolon in each:

“refl_01;”

“tran_08;”

“10101;” Three leading zeroes are

missing. (This is a binary

Control Line command. It

needs three leading zeroes.)

(Decimal Control Line

commands don’t need

leading zeroes.)

Resend the command

with leading zeroes

included:

“00010101;”

3-8 Agilent Technologies Z5623A Option H48

Page 41

A List of GPIB Commands

Tab l e 3- 2 Te s t P o rt C om m and s

Connection Path GPIB

Reflection to Port 1 refl_01

Reflection to Port 2 refl_02

Reflection to Port 3 refl_03

Reflection to Port 4 refl_04

Reflection to Port 5 refl_05

Reflection to Port 6 refl_06

Reflection to Port 7 refl_07

Reflection to Port 8 refl_08

Using the Network Analyzer to Control the Test Set

A List of GPIB Commands

Command

NOTE

Transmission to Port 1 tran_01

Transmission to Port 2 tran_02

Transmission to Port 3 tran_03

Transmission to Port 4 tran_04

Transmission to Port 5 tran_05

Transmission to Port 6 tran_06

Transmission to Port 7 tran_07

Transmission to Port 8 tran_08

Reset *rst

Reflection Termination *r_term

Transmission

Termination

All Termination *all_term

*t_term

Every Test Port is connected to one and only one of the following at any

instant:

• Reflection port of the test set.

• Transmission port of the test set.

• 50 Ω termination inside the test set.

Agilent Technologies Z5623A Option H48 3-9

Page 42

Using the Network Analyzer to Control the Test Set

A List of GPIB Commands

Table 3-3 Control Line Commands

GPIB Command

Resulting

Control Line States

(C5, C4, C3, C2, C1)

Mnemonic Decimal Binary

c1_on xxxxL

c1_off xxxxO

c2_on xxxLx

c2_off xxxOx

c3_on xxLxx

c3_off xxOxx

c4_on xLxxx

c4_off xOxxx

c5_on Lxxxx

c5_off Oxxxx

0 00000000 OOOOO

1 00000001 OOOOL

a

2 00000010 OOOLO

3 00000011 OOOLL

4 00000100 OOLOO

5 00000101 OOLOL

6 00000110 OOLLO

7 00000111 OOLLL

8 00001000 OLOOO

9 00001001 OLOOL

10 00001010 OLOLO

11 00001011 OLOLL

12 00001100 OLLOO

13 00001101 OLLOL

14 00001110 OLLLO

15 00001111 OLLLL

16 00010000 LOOOO

3-10 Agilent Technologies Z5623A Option H48

Page 43

Table 3-3 Control Line Commands

Using the Network Analyzer to Control the Test Set

A List of GPIB Commands

GPIB Command

Mnemonic Decimal Binary

17 00010001 LOOOL

18 00010010 LOOLO

19 00010011 LOOLL

20 00010100 LOLOO

21 00010101 LOLOL

22 00010110 LOLLO

23 00010111 LOLLL

24 00011000 LLOOO

25 00011001 LLOOL

26 00011010 LLOLO

27 00011011 LLOLL

28 00011100 LLLOO

Resulting

Control Line States

(C5, C4, C3, C2, C1)

a

29 00011101 LLLOL

30 00011110 LLLLO

31 00011111 LLLLL

a. L = “Low”; O = “Open”; x = “Unchanged”

To connect all test ports to their internal 50 Ω loads, send the following

command:

OUTPUT 712;"*all_term"

Agilent Technologies Z5623A Option H48 3-11

Page 44

Using the Network Analyzer to Control the Test Set

Restoring the Analyzer to its Normal Configuration

Restoring the Analyzer to its Normal

Configuration

It is a good idea to restore the analyzer to its normal configuration once

you are finished using the analyzer to control the test set. To

accomplish this, use the following procedure:

Step 1. Type q in the command window, then press the <Enter> key. This

terminates the interactive control session on the analyzer.

Step 2. In the analyzer window, click System on the menu bar, then scroll

down to Configure, then click SICL/GPIB.

Step 3. In the SICL/GPIB window, click Talke r/ Listener and then OK. This

allows other devices to control the analyzer.

3-12 Agilent Technologies Z5623A Option H48

Page 45

Using the Network Analyzer to Control the Test Set

Disaster Recovery

Disaster Recovery

This section provides recovery procedures for the following problems:

• Malfunctioning Command Window

• Malfunctioning Network Analyzer

Malfunctioning Command Window

Symptoms

Any of the following symptoms indicates a malfunctioning command

window.

• No ud0: prompt is returned when the ibclr command is executed.

• An error message is returned when the ibdev command is

properly executed.

• Upon turning on the network analyzer, the following message

appears: “The device at ‘AT-GPIB/TNT’ cannot be stopped because

a program is still accessing it.”

• When the Recovery Procedure described below is performed, the

“AT-GPIB/TNT” icon observed in Step 6 has a red slash through it

(indicating that the device is presently disabled). However, when

Step 7 is performed, the pop-up menu has “Disable” as a menu

item (indicating that the device is presently enabled!).

Recovery Procedure

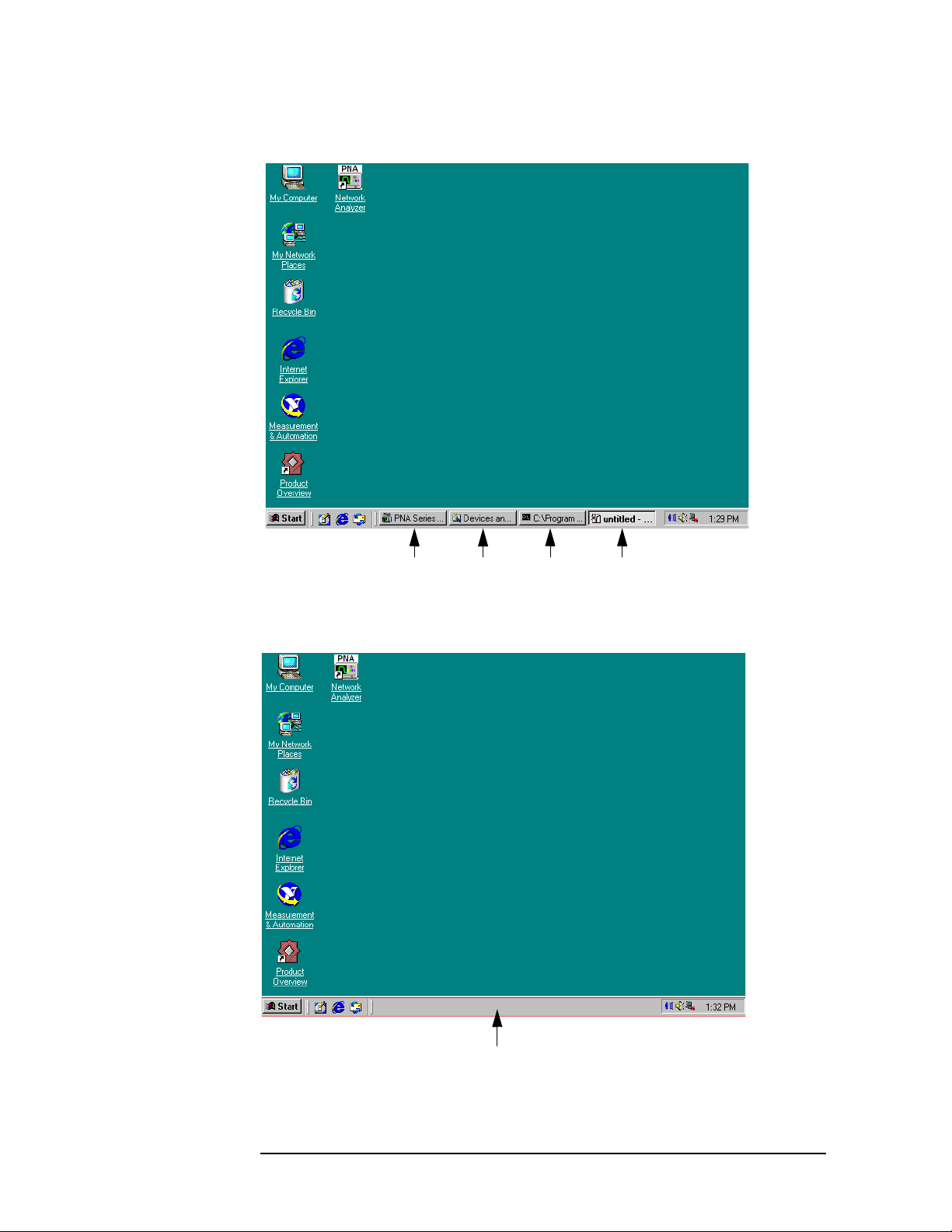

Step 1. Close every application that is running.

a. If an application’s window is open, click on the X in the upper

right-hand corner of the window.

b. If an application’s window has been minimized, locate its icon on the

task bar at the bottom of the network analyzer screen. See Figure

3-8. Click on the icon. This will open the application’s window. Next,

click on the X in the upper right-hand corner of the window to close

the application.

c. When all applications are closed, the task bar will look like the one

in Figure 3-9.

Agilent Technologies Z5623A Option H48 3-13

Page 46

Using the Network Analyzer to Control the Test Set

Disaster Recovery

Figure 3-8 Network Analyzer Screen With Four Applications Running

Four applications running

Figure 3-9 Network Analyzer Screen With No Applications Running

No applications running

3-14 Agilent Technologies Z5623A Option H48

Page 47

Using the Network Analyzer to Control the Test Set

Disaster Recovery

Step 2. Right-click on the “My Computer” icon on the network analyzer screen.

A drop-down menu will appear as shown in Figure 3-10.

Figure 3-10 Analyzer Screen After Right-Click On “My Computer” Icon

Step 3. Click Properties in the drop-down menu. A “System Properties”

window will appear as shown in Figure 3-11.

Figure 3-11 “System Properties” Window

Agilent Technologies Z5623A Option H48 3-15

Page 48

Using the Network Analyzer to Control the Test Set

Disaster Recovery

Step 4. Click the Hardware tab shown in Figure 3-11. The result is shown in

Figure 3-12.

Figure 3-12 “Hardware” Tab In “System Properties” Window

Click this button.

Step 5. Click the Device Manager button. After you do so, there will be a

10-second delay before the “Device Manager” window appears. This

window is shown in Figure 3-13 and Figure 3-14.

Step 6. Check to see if the “AT-GPIB/TNT” icon is visible as shown in Figure

3-14. If it is not, click on the “National Instruments GPIB Interfaces”

icon as in Figure 3-13.

3-16 Agilent Technologies Z5623A Option H48

Page 49

Figure 3-13 Device Manager Window

Using the Network Analyzer to Control the Test Set

Disaster Recovery

Figure 3-14 Device Manager Window With “AT-GPIB/TNT” Icon Visible

Step 7. Right

-click on the “AT-GPIB/TNT” icon. A menu will pop up.

Step 8. Click Disable on the menu.

Step 9. The following message will pop up: “Disabling this device will cause it

to stop functioning. Do you really want to disable it?” Click “Yes.” See

Figure 3-15.

Agilent Technologies Z5623A Option H48 3-17

Page 50

Using the Network Analyzer to Control the Test Set

Disaster Recovery

Figure 3-15 GPIB Device Disabling Message

Step 10. Right

-click on the “AT-GPIB/TNT” icon once again. A menu will pop up.

Step 11. Click Enable on the menu.

Step 12. Close the Device Manager window by clicking on the X in the upper

right-hand corner of the window.

Step 13. Close the System Properties window by clicking on the X in the upper

right-hand corner of the window.

The recovery procedure is now complete. To resume control of the test

set, perform the procedure described in “Preparing the Analyzer to

Control the Test Set” on page 3-2.

Malfunctioning Network Analyzer

Symptoms

Any abnormality in the network analyzer’s behavior indicates a

malfunction of the analyzer. An example would be the failure of icons to

appear on the screen of the analyzer.

Recovery Procedure

Perform a Hard Reset on the PNA Series network analyzer as follows:

First, make sure the power is on (indicated by the power switch being

green). Next, hold the power switch in for about 20 seconds, or until the

color of the switch changes from green to orange. Release the switch,

then press it again and release it immediately.

3-18 Agilent Technologies Z5623A Option H48

Page 51

4 Calibrating the Network

Analyzer

This chapter shows you how to calibrate the network analyzer so that it

can be used to verify the performance of the test set.

The calibration technique presented in this chapter uses an Electronic

Calibration (ECal) Module and is by far the easiest of all 2-port

calibration techniques. Consult the Help facility built into the PNA

Series Network Analyzer for a comprehensive tutorial on this

calibration method and on many others.

This chapter contains the following sections:

• Performing the Calibration

• Renaming the Calibration File

• Recalling and Examining Calibrations

Agilent Technologies Z5623A Option H48 4-1

Page 52

Calibrating the Network Analyzer

Performing the Calibration

Performing the Calibration

Step 1. Make the connections shown in Figure 4-1.

The figure shows two RF cables connecting the two ports of the network

analyzer to the two ports of the ECal Module. The 24” RF cables

(Agilent Part No. 8120-4781 or equivalent) listed in Table 2-2 on

page 2-3 should be used. Make sure the connectors are snugly tightened

but not overtorqued. A torque wrench set to 12 inch-pounds (Agilent

Part No. 8710-1766 or equivalent) is recommended.

Figure 4-1 Calibrating the Network Analyzer

USB Quad Hub

Port 1 Port 2 Port 3 Port 4

Up Link

USB Cable

To USB Port

on Rear Panel

Port 1

Mouse with

USB Cable

Keyboard with USB Cable

Network Analyzer

USB Port

Port 2

RF Cables

Electronic

Calibration

Module

USB Cable

4-2 Agilent Technologies Z5623A Option H48

Page 53

Step 2. Press the Preset button on the Network Analyzer.

Step 3. Verify that the Ready light on the ECal Module is green.

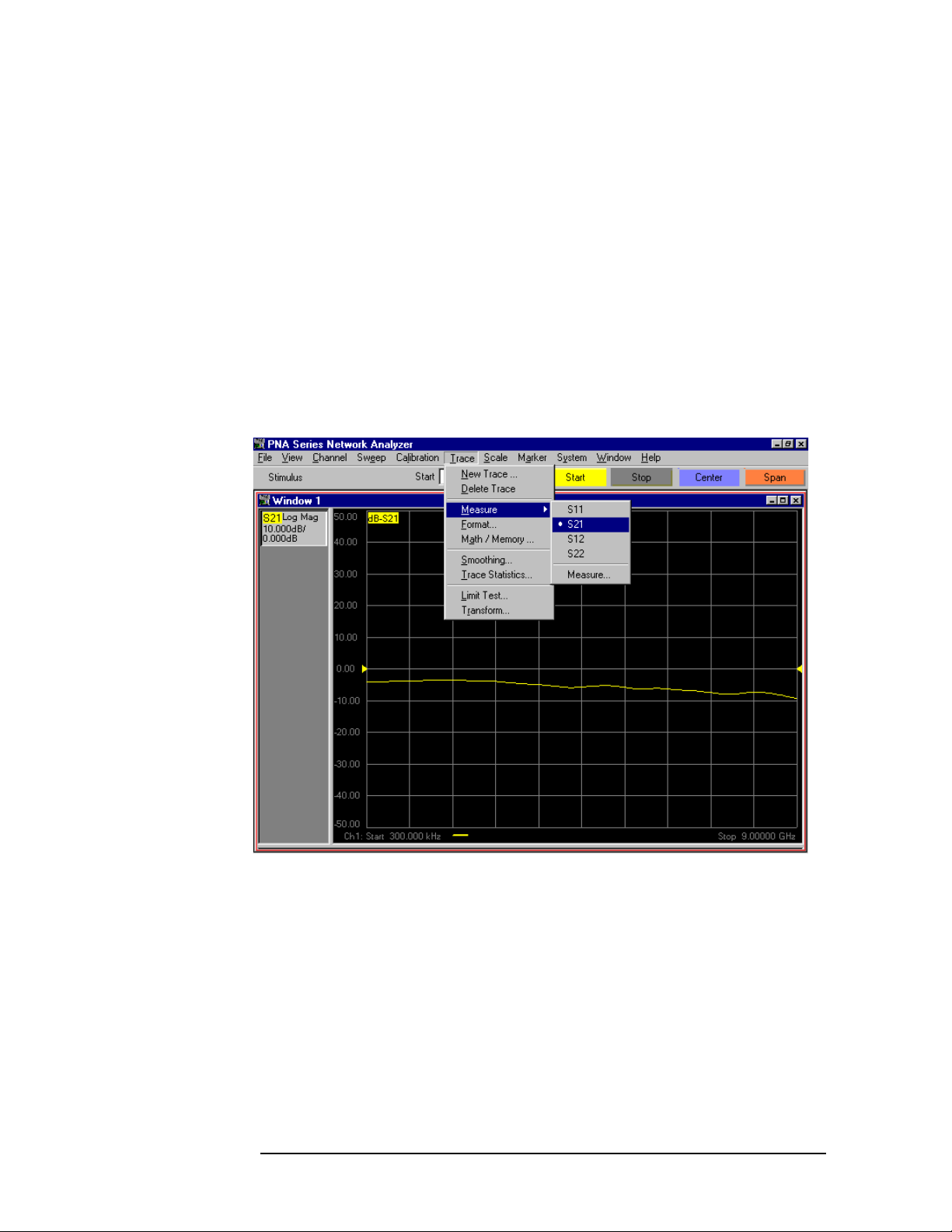

Step 4. On the network analyzer, click Calibration on the menu bar, then click

the Calibration Wizard button. See Figure 4-2.

Figure 4-2 Calibration Menu on Network Analyzer

Calibrating the Network Analyzer

Performing the Calibration

Step 5. When the window shown in Figure 4-3 comes up, click the Cal Type

button. The Cal Type window shown in Figure 4-4 will then pop up.

Figure 4-3 Cal Wizard Window

The currently selected calibration type is “None”.

Agilent Technologies Z5623A Option H48 4-3

Page 54

Calibrating the Network Analyzer

Performing the Calibration

Figure 4-4 Cal Type Window When It Is First Opened

Step 6. Click the Full SOLT 2-Port button. The result is shown in Figure 4-5.

Figure 4-5 Cal Type Window After Selecting “Full SOLT 2-Port”

Step 7. Click the OK button. The Cal Type window will then close and the Cal

Wizard window will pop back up as shown in Figure 4-6.

Figure 4-6 Cal Wizard Menu After Selection Of Cal Type Is Complete

Step 8. Verify that the currently selected calibration type shown in the Cal

Wizard window is “Full SOLT 2-Port (Omit Isolation)” as shown in

Figure 4-6.

Step 9. Click the Measure ECal Stds button in the Cal Wizard window. The

window shown in Figure 4-7 will then pop up.

4-4 Agilent Technologies Z5623A Option H48

Page 55

Figure 4-7 Electronic Calibration Window

Step 10. Click the Module button. The window shown in Figure 4-8 will then

pop up.

Figure 4-8 Module Connection Message

Calibrating the Network Analyzer

Performing the Calibration

Step 11. Click the OK button. (The connections requested in Figure 4-8 were

made in Step 1 of “Performing the Calibration” on page 4-2.) This

window will close, the window shown in Figure 4-7 will pop back up,

and the calibration will begin.

The network analyzer will complete the calibration with no further

operator actions required. The calibration will take about 5 seconds.

Step 12. Verify that the calibration has been completed. This is shown by a check

mark over the Module button as shown in Figure 4-9.

Figure 4-9 Electronic Calibration Window After Cal Is Complete

Step 13. Click the OK button shown in Figure 4-9. The window will close; the

Cal Wizard window will pop back up with the following message as

shown in Figure 4-10: “Done. Save your settings now by pressing OK”.

Agilent Technologies Z5623A Option H48 4-5

Page 56

Calibrating the Network Analyzer

Performing the Calibration

Or repeat your cal.”

Figure 4-10 Cal Wizard Window After Cal Is Complete

Step 14. Get a pen or pencil and a piece of paper. Step 16 will ask you to write

down a filename.

Step 15. Click the OK button. The calibration will now be saved to disk in the

following directory: C:\Program Files\Agilent\Network

Analyzer\Documents. The file will have a “.cst” suffix.

Step 16. Copy down the name of the file into which the calibration is saved. The

name will appear on the screen for about 10 seconds. Copy the filename,

not the path. (The path is listed in Step 15 above.) A typical filename

would be, “at006.cst”. Record also the date and time that the calibration

was performed. (The date and time can be used to locate the file in case

the filename you write down is incorrect or incomplete.)

4-6 Agilent Technologies Z5623A Option H48

Page 57

Renaming the Calibration File

In this section you will rename the calibration file to make it easier to

identify and retrieve.

Step 1. Minimize the network analyzer window. (If you are not sure how to do

this, refer to Step 5 of “Preparing the Analyzer to Control the Test Set”

on page 3-2.)

Step 2. Double-click the “My Computer” icon on the network analyzer display.

This icon can be seen in the upper left-hand corner of Figure 3-8 on

page 3-14.

Step 3. The window shown in Figure 4-11 will pop up. Click the Hard Disk (C:)

icon in that window.

Figure 4-11 “My Computer” Window

Calibrating the Network Analyzer

Renaming the Calibration File

Agilent Technologies Z5623A Option H48 4-7

Page 58

Calibrating the Network Analyzer

Renaming the Calibration File

Step 4. The window shown in Figure 4-12 will pop up. Click the “Program

Files” icon.

Figure 4-12 Root Directory of the C: Drive

Step 5. The window shown in Figure 4-13 will pop up. Click the “Agilent” icon.

Figure 4-13 “C:\Program Files” Directory

4-8 Agilent Technologies Z5623A Option H48

Page 59

Step 6. The window shown in Figure 4-14 will pop up. Click the “Network

Analyzer” icon.

Figure 4-14 “C:\Program Files\Agilent” Directory

Step 7. The window shown in Figure 4-15 will pop up. Click the “Documents”

icon.

Calibrating the Network Analyzer

Renaming the Calibration File

Figure 4-15 “C:\Program Files\Agilent\Network Analyzer” Directory

Agilent Technologies Z5623A Option H48 4-9

Page 60

Calibrating the Network Analyzer

Renaming the Calibration File

Step 8. The window shown in Figure 4-16 will pop up. It contains all of the

calibration files. Click the Type button above the files so that they will

be listed by file type. The result is shown in Figure 4-17.

Figure 4-16 Directory Containing Cal Files

Figure 4-17 Directory Containing Cal Files After Clicking “Type” Button

4-10 Agilent Technologies Z5623A Option H48

Page 61

Step 9. Move the cursor over the filename that was copied down in Step 16 of

“Performing the Calibration” on page 4-6. (If you were not able to copy

down the filename, select the “.cst” file whose date and time correspond

to when you completed the calibration.) Do not

have selected. Just keep the cursor positioned over the filename for

about two seconds (until it is highlighted as shown in Figure 4-18).

Figure 4-18 Cal File Highlighted

Calibrating the Network Analyzer

Renaming the Calibration File

click the filename you

Step 10. Move the cursor off the selected filename (either to the left or to the

right). The selected filename will remain highlighted.

Agilent Technologies Z5623A Option H48 4-11

Page 62

Calibrating the Network Analyzer

Renaming the Calibration File

Step 11. Click File on the menu bar, then scroll down and click the Rename

button as shown in Figure 4-19.

Figure 4-19 Preparing to Rename the Cal File

4-12 Agilent Technologies Z5623A Option H48

Page 63

Step 12. Give the file a new name that includes the following:

• The date the cal was performed

• The suffix “.cst”

For example, if the calibration was performed on 6/17/01, a filename of

“cal_06_17_01.cst” would be appropriate. See Figure 4-20.

Figure 4-20 The Cal File After It Has Been Renamed

Calibrating the Network Analyzer

Renaming the Calibration File

Step 13. Record the new name of the calibration file in Table 4-1. The file must

have a suffix of “.cst”.

Table 4-1 Name of Calibration File

Agilent Technologies Z5623A Option H48 4-13

.cst

Page 64

Calibrating the Network Analyzer

Recalling and Examining Calibrations

Recalling and Examining Calibrations

This section contains the following subsections:

• How to Recall a Calibration

• How to Turn a Calibration On and Off

• How to Examine the Properties of a Calibration

How to Recall a Calibration

There are two methods of recalling a calibration. The first and more

general method is used when the calibration file is not on the “quick

recall” list that appears whenever File is clicked on the menu bar. The

second method is used when the calibration file is on the “quick recall”

list. (This list displays the last eight files that were recalled.)

The examples shown here assume that the desired calibration file is

named, “cal_06_17_01.cst”.

Method 1. Calibration File Is Not On “Quick Recall” List

Step 1. In the network analyzer window, click File on the menu bar, then scroll

down and click the Recall button. See Figure 4-21.

Figure 4-21 File Recall Button

4-14 Agilent Technologies Z5623A Option H48

Page 65

Step 2. The Recall window shown in Figure 4-22 will pop up. Move the

horizontal scroll box until the desired calibration file is visible, then

click on it. The window will momentarily appear as shown in Figure

4-23. The file will then be recalled and the window will close.

Figure 4-22 File Recall Window

Calibrating the Network Analyzer

Recalling and Examining Calibrations

Figure 4-23 File Recall Window After Clicking the Desired Calibration File

Agilent Technologies Z5623A Option H48 4-15

Page 66

Calibrating the Network Analyzer

Recalling and Examining Calibrations

Method 2. Calibration File Is On “Quick Recall” List

Click File on the menu bar, then scroll down to the desired calibration

file and click it. See Figure 4-24. The file will immediately be recalled.

Figure 4-24 Recalling a Calibration File That Is On the “Quick Recall” List

How to Turn a Calibration On and Off

Click Calibration on the menu bar, then scroll down to the

Correction On/Off button.

• If the calibration is turned on, the button will have a check mark in

front of it and the text will read, “Correction ON/off ” as in Figure

4-25.

• If the calibration is turned off, the button will have no

front of it and the text will read, “Correction on/OFF” as in Figure

4-26.

To change from one state to the other, just click the button. Try it! The

trace will change instantaneously. (Compare the trace in Figure 4-25

with the trace in Figure 4-26.)

4-16 Agilent Technologies Z5623A Option H48

check mark in

Page 67

Figure 4-25 Calibration Turned On

Calibrating the Network Analyzer

Recalling and Examining Calibrations

Figure 4-26 Calibration Turned Off

Agilent Technologies Z5623A Option H48 4-17

Page 68

Calibrating the Network Analyzer

Recalling and Examining Calibrations

How to Examine the Properties of a Calibration

Step 1. Click Calibration on the menu bar, then scroll down to the Properties

button and click it. See Figure 4-27.

Figure 4-27 Calibration Properties Button

Step 2. The window shown in Figure 4-28 will pop up. Examine it carefully.

Figure 4-28 Calibration Properties Window

4-18 Agilent Technologies Z5623A Option H48

Page 69

5 Performance Verification

This chapter contains the following sections:

• Setting Test Limits

• Test Strategy

— Insertion Loss

— Return Loss

— Crosstalk

• Setting Up Limit Testing

— Limit Testing for Insertion Loss

— Limit Testing for Return Loss (Port Active)

— Limit Testing for Return Loss (Port Off)

— Limit Testing for Crosstalk

• Verifying Return Loss and Insertion Loss Specifications

• Verifying Crosstalk Specs

Agilent Technologies Z5623A Option H48 5 -1

Page 70

Performance Verification

Setting Test Limits

Setting Test Limits

A test limit is the pass/fail criterion for a measurement. A test limit can

be either a maximum limit or a minimum limit. With a maximum limit,

the measurement must not go above the limit in order for the Device

Under Test (DUT) to pass. With a minimum limit, the measurement

must not go below the limit in order for the DUT to pass.

Test limits are derived from the specifications of the DUT, but are

usually different from them because every measurement has some

uncertainty associated with it. In order to ensure that a performance

specification is met, a “guard band” must be added to account for the

uncertainty in the measurement. This can be done by applying

Equation 5-1.

Equation 5-1 How to Set Test Limits

Test Limit Specification Measurement Uncertainty±=

In Equation 5-1, the plus sign is selected if the limit is a minimum

limit, and the minus sign is selected if the limit is a maximum limit. For

example, if a specification is 20 dB minimum and the measurement

uncertainty is 2 dB, then the test limit should be set to 22 dB. In other

words, the measured value in this example must be 22 dB or greater to

insure that the actual value is 20 dB or greater. Similarly, if a

specification is 20 dB maximum and the measurement uncertainty is 2

dB, then the test limit should be set to 18 dB. In other words, the

measured value in this example must be 18 dB or less to insure that the

actual value is 20 dB or less.

The measurement uncertainties listed in Table 5-1 apply to the

performance tests described in this document. The uncertainties are

derived from the equipment used and the specific measurements

performed.

Table 5-1 Measurement Uncertainties for Performance Verification Tests

Measurement

(dB)

Crosstalk 5 557

Return Loss

(port active)

(300 kHz - 1.3 GHz)

Band 1

1.5 1.0 0.5 0.5

Band 2

(1.3 - 3 GHz)

Band 3

(3 - 6 GHz)

(6 - 9 GHz)

Band 4

Return Loss

(port off)

Insertion Loss 0.3 0.3 0.3 0.3

5 -2 Agilent Technologies Z5623A Option H48

1.5 1.5 1.0 0.5

Page 71

Performance Verification

Setting Test Limits

Applying Equation 5-1 to the uncertainties listed in Table 5-1 and to the

guaranteed specifications listed in Table 1-1 on page 1-4, we obtain the

test limits in Table 5-2:

Table 5-2 Derivation of Test Limits for Performance Verification of Test

Set

Parameter Specification Measurement

Uncertainty

Crosstalk

a,b

Return Loss

(port active)

Return Loss

(port off)

h

Insertion

i

Loss

g

1) –110 dB

2) –105 dB

3) –95 dB

4) –90 dB

1) 24 dB

2) 18 dB

3) 14 dB

4) 9 dB

1) 26 dB

2) 20 dB

3) 16 dB

4) 14 dB

1) 1.5 dB

2) 2.0 dB

3) 2.5 dB

4) 3.5 dB

c

d

e

f

c

d

e

f

c

d

e

f

c

d

e

f

1) 5 dB

2) 5 dB

3) 5 dB

4) 7 dB

1) 1.5 dB

2) 1.0 dB

3) 0.5 dB

4) 0.5 dB

1) 1.5 dB

2) 1.5 dB

3) 1.0 dB

4) 0.5 dB

0.3 dB

(all bands)

c

d

e

f

c

d

e

f

c

d

e

f

Test Limit

1) –115 dB

2) –110 dB

3) –100 dB

4) –97 dB

f

1) 25.5 dB

2) 19 dB

d

3) 14.5 dB

4) 9.5 dB

f

1) 27.5 dB

2) 21.5 dB

3) 17 dB

e

4) 14.5 dB

1) 1.8 dB

2) 2.3 dB

3) 2.8 dB

4) 3.8 dB

c

d

e

f

c

d

e

c

e

c

d

f

a. Between any two non-connected signal paths

b. Conditions: IF Bandwidth = 100 Hertz, Averaging = 10

c. Band 1 (300 kHz to 1.3 GHz)

d. Band 2 (1.3 GHz to 3.0 GHz)

e. Band 3 (3.0 GHz to 6.0 GHz)

f. Band 4 (6.0 GHz to 9.0 GHz)

g. When using an external termination on the Reflection or

Transmission port

h.When using one of the 50 Ω internal terminations

i. From any test set port to the Reflection or Transmission port

Agilent Technologies Z5623A Option H48 5 -3

Page 72

Performance Verification

Test Strategy

Test Strategy

The overall test strategy of this chapter is to verify each guaranteed

specification by means of a limit test that is stored and recalled on the

network analyzer. This strategy minimizes the number of cable

connections and the amount of time required to complete the

performance verification. It also minimizes the likelihood of operator

error.

Whenever one of the limit test files is recalled, it will do the following to

the network analyzer:

• Select the correct S-parameter measurement

• Activate the proper calibration

• Put a title on the screen

•Scale the axes

• Load a limit table

• Display limit lines

• Turn on limit testing

Limit testing tells the user immediately whether the Device Under Test

passes or fails the test. The pass / fail limits are set by the limit table.

In a manner to be described later in this section, the limit table for each

test will be derived from the test limits presented in Table 5-2.

Once the limit test file has been created for a test, the user will run the

test as follows:

• Make the necessary cable connections.

• Issue any needed commands to the test set.

• Recall the limit test file.

Test results will be immediately displayed on the screen of the network

analyzer.

The specifications that are to be verified fall into three general

categories:

• Insertion Loss

• Return Loss

•Crosstalk

The remainder of this section describes, for each category, the Sparameter measurement that will be used to verify the specifications.

The test limits of Table 5-2 will be converted to S-parameter test limits

for each category.

5 -4 Agilent Technologies Z5623A Option H48

Page 73

Performance Verification

Test Strategy

Insertion Loss