Page 1

N3970A OPTICAL POWER METER

Operating and

Maintenance Guide

Page 2

Page 3

■ N3970A OPTICAL POWER METER SOURCE QUICK REFERENCE GUIDE

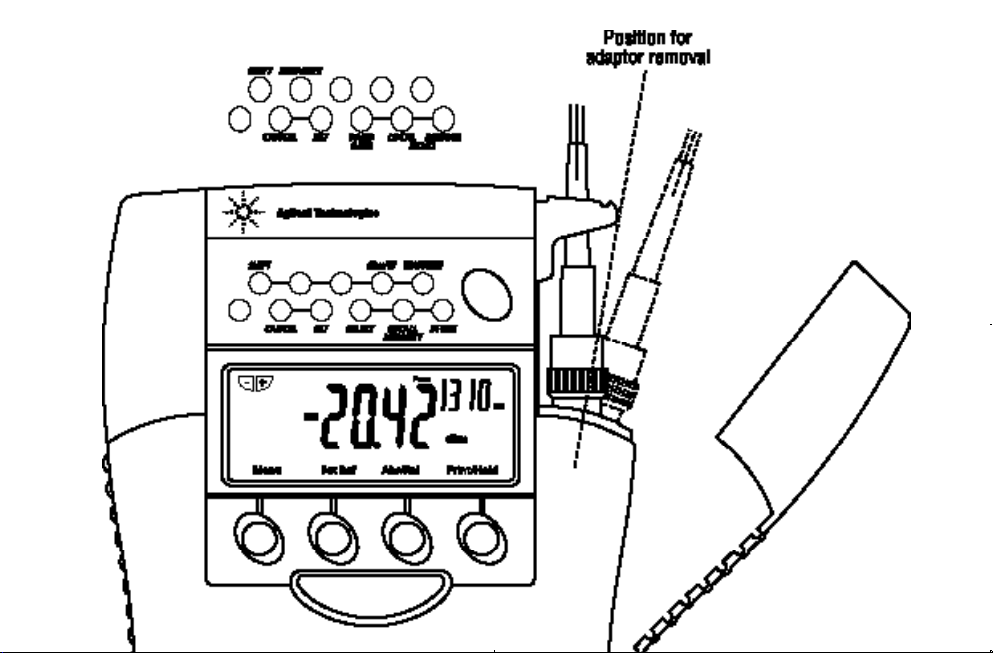

■ To remove interchangeable connector, move interface to

mid position, and pull off adaptor.

■ To defeat auto power-off, hold POWER for 3 seconds at

turn on until ON and perm are displayed.

■ To access hidden keypad, pull up display cover.

Select POWER, Source, then:

■ To set reference, push Abs/Rel and hold Set Ref for

3 seconds (3 buzzer sounds).

■ To display reference, hold Abs/Rel, so Ref flashes.

■ To stop / start display update, push Hold.

■ If a test tone is detected, meter will display Hz.

AUTOTEST OPERATION

■ No user action is required for meter to enter Autotest

mode.

■ Autotest:

seconds.

■ Can also push Autotest on meter for faster lock-on.

■ To display one wavelength only, on the power meter

push the left side of -/+ and again for the other wavelength.

Push right side of -/+ (twice) to exit.

■ Autotest remains for >8 seconds after signal loss, to allow

quick connection change.

■ To e x i tautotest, remove test lead or turn off source for >8 seconds.

Push Autotest on source and wait a few

MANUAL OPERATION

■ To turn on and select wavelength, push: POWER, Power

Meter, -/+.

■ To display linear mode, push dBm/W.

■ To display max/min values, push MAX/MIN repeatedly.

Hold MAX/MIN to reset (3 buzzer sounds). .

MEMORY

■ Enter Power Meter or Autotest modes first

■ While in Autotest mode, it is only possible to STORE.

■ To clear all memory, push both RECALL and CANCEL

together for 3 seconds. clr will display.

■ To store in next location, push STORE.

■ To change next store location, push SELECT -/+, SET.

■ To recall, push RECALL -/+ to scroll through data.

■ To exit memory display, push CANCEL.

ADDITIONAL AUTOTEST MEMORY OPERATION

■ To read or cancel memory, first exit Autotest mode, and

enter Power Meter mode.

■ Autotest memory: use -/+ to scroll wavelengths.

Page 4

■ INTRODUCTION AND A P P L I C AT I O N S

N3970A

OPTICAL POWER METER

Congratulations on your purchase of this instrument,

which has been engineered to provide the best possible

reliability, convenience and performance. To get the best

use from your equipment and ensure its safe operation,

please spend a few minutes to read this manual.

1

Page 5

■ CO N T E N T S

Service and Support 3

Introduction & applications 4-5

Safety Summary 6-7

Battery and external power 8

Optical connector 9-10

How to use:

Getting started and turning on 11-12

Autotest operation 13-14

Power meter operation 15

Storing & recalling readings 16-17

RS232 interface 18

Care of your instrument 19

Accuracy considerations 20-21

Calibration, maintenance & instrument re t u rn s 22-24

Specifications - Definition of terms 25

Specifications and ordering information 26-28

Performance test 29-38

Cleaning information 39-40

Cleaning procedures 41

Disclaimer & warranty 42

Notes 43-44

BEFORE READING FURTHER, OPEN THE CONTROL PANEL PICTURE AT THE BACK OF THE MANUAL

2

Page 6

■ S E RVICE AND SUPPORT

Any adjustment, maintenance, or repair of this product must be

p e rf o rmed by qualified personnel. Contact your customer

engineer through your local Agilent Technologies Serv i c e

Center. You can find a list of local service representatives on the

Web at: http://www.agilent.com/find/assist

If you do not have access to the Internet, one of these centers

can direct you to your nearest representative:

United States 1 800 452 4844

Canada 1 877 894 4414

(905) 206 4120 (Fax)

Europe (31 20) 547 2323

(31 20) 547 2390 (Fax)

Japan (81) 426 56 7832

(81) 426 56 7840 (Fax)

Latin America (305) 269 7500

(305) 269 7599 (Fax)

N3970A UM-1

Australia 1 800 629 485

(613) 9272 0749 (Fax)

New Zealand 0800 738 378

64 4 495 8950 (Fax)

Asia-Pacific (852) 3197 7777

(852) 2506 9284 (Fax)

3

Page 7

■ IN T R O D U C T I O N A N D AP P L I C AT I O N S

The N3970A Optical Power Meter is used for field or laboratory

testing of fiber optic systems at typically 850, 1300, 1310 and

1550 nm. It features superb measurement confidence, ease of

use and reduced cost of ownership, and is for use by installers,

technicians and engineers.

Superior measurement confidence is achieved with a unique

Total Uncertainty specification over the full temperature ,

measurement and connector range, and a NATA traceable

calibration certificate. The display hold and back light facilities

help acquire readings, and the flexible memory helps record

your results

Autotest mode enables automatic λ (wavelength) detection and

attenuation measurement (in combination with an Autotest

source). A single or dual λsource and meter in Autotest mode

automatically measure single or dual λ attenuation in one

direction.

4

High operational reliability & availability is achieved with 250

hour battery life, 3 year recommended re-calibration cycle,

negligible warm up and no range-changing delays. Dark current

offset is not required. An external power input is also provided.

The combination of features enables reduced equipment

inventory, simpler training, shorter procedures, lower skill

levels and direct labour savings in many situations, combining

to give lower cost of ownership.

The innovative optical connector port provides drop protection

during use, and is dust protected by a snap on cover. The

interchangeable optical connector system is very versatile, and

easily disassembled for cleaning.

The simple user interface guides the operator through functional

sequences, and a hidden keypad is used to access advanced

features such as log/linear display, and memory functions.

Page 8

The tone detector is very sensitive, and is useful for fiber

identification, and calibrating the modulation frequency of test

tone sources.

The instrument has shock absorbent corners, and a tough

polycarbonate housing which has passed extensive drop testing.

Typical applications

■

Singlemode testing, with versatile interc h a n g e a b l e

connectors.

■

Telecom construction, maintenance, CATV, LAN and R&D

applications.

■

Measurements where traceability and documentation are

required.

■

Quality assurance and acceptance tests.

■

Automated testing and re p o rting using optional Excel software .

■

Test tone measurement & fiber identification.

N3970A UM-1

■ IN T R O D U C T I O N A N D AP P L I C AT I O N S

5

Page 9

■ SAFETY SUMMARY

The following general safety precautions must be observed

during all phases of operation, service, and repair of this

instrument. Failure to comply with these precautions or with

specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the

instrument. Agilent Technologies Inc. assumes no liability for

the customer’s failure to comply with these requirements.

Before operation, review the instrument and manual, for safety

markings and instructions. You must follow these to ensure safe

operation and to maintain the instrument in safe condition.

WARNING

The WARNING sign denotes a hazard. It calls attention to a

procedure, practice or the like, which, if not correctly performed

or adhered to, could result in injury or loss of life. Do not

proceed beyond a WARNING sign until the indicated conditions

are fully understood and met.

6

CAUTION

The CAUTION sign denotes a hazard. It calls attention to an

operating pro c e d u re, or the like, which, if not corre c t l y

p e rf o rmed or adhered to, could result in damage to or

destruction of part or all of the product. Do not proceed beyond

a CAUTION sign until the indicated conditions are fully

understood and met.

CAUTION

m

The apparatus will be marked with this symbol when it is

necessary for the user to refer to the instruction manual in order

to protect the apparatus against damage.

Page 10

■ SAFETY SUMMARY

Initial Inspection

Inspect the shipping container for damage. If there is damage to

the container or Cushioning, keep them until you have checked

the contents of the shipment for completeness and verified the

instrument both mechanically and electrically.

The Perf o rmance Tests give pro c e d u res for checking the

operation of the instrument. If the contents are incomplete,

mechanical damage or defect is apparent, or if an instrument

does not pass the operator’s checks, notify the nearest Agilent

Technologies Sales/Service Office (see page 3).

WARNING

To avoid any hazard, do not perform electrical tests when there

are signs of shipping damage to any portion of the outer

enclosure (covers, panels, and so on).

WARNING

You MUST return instruments with malfunctions to an Agilent

Technologies Service Center for repair and calibration (see page 3).

N3970A UM-1

Line Power Requirements

The Agilent N3970A Power Meter operates at line power when

applied to the optional external power supply N3979A 9V DC

Operating Environment

The Agilent N3970A Power Meter can be operated at

temperatures between - 10°C and + 55°C and at relative

humidity of <95%.

Storage and Shipment

The Agilent N3970A Power Meter can be stored or shipped at

temperatures between - 25°C and + 70°C and at relative

humidity of less than 95%. Protect the module fro m

temperature extremes that may cause condensation within it.

REQUIREMENT COMPLIANCE

N 10149

7

Page 11

■ BATTERY AND EXTERNAL POWER

The instrument is powered by two 1.5V dry batteries (Alkaline C)for

an operating period of typically 250 hours or two 1.2V

rechargeable batteries for an operating period of approximately

125 hours.

Do not use lithium batteries or other batteries with a nominal

voltage greater than 1.8 V. The instrument will be damaged.

When the batteries are low, the low-battery indicator is shown

on the display. At this stage, there is approximately enough

energy for another 30 minutes of use.

For saving of energy the instrument automatically turns off after

10 minutes without operation.

For changing the battery, open the cover of the battery

compartment at the base of the instrument, remove the batteries,

insert new batteries (check polarity) and close the cover again.

Rechargeable batteries must be charged by an external charger.

8

For operation of the instrument by external power use Agilent

AC adaptor N3979A (9V DC, 1.33 A, ).

Use of the external power supply disconnects the batteries.

Ensure that the mains supply has the correct voltage rating and

safety compliance as relevant. Do not use non-compliant or

doubtful mains equipment.

Page 12

■ OPTICAL CONNECTOR

The optical port is mounted on a swivel, which allows the

connector to be angled outwards for accessibility, and then

pushed back and covered with the snap cover to provide dirt and

drop protection.

The other port can be used to store a spare interchangeable

optical connector.

To install the connector adaptor, align the locating slot on the

side of the adaptor with that on the instrument connector, and

push it on.

To remove the connector adaptor, move the connector port to it’s

mid-way point (see dotted line on diagram at back of manual),

and then pull off the adaptor. It is not possible to remove the

adaptor in the ‘open’ or ‘shut’ positions. With some styles of

connector, it is easier to pull off the adaptor with a test lead in

place, since this gives better grip.

Different styles of connector adaptor ( ST, SC, FC, ) can be

easily fitted by the user.

N3970A UM-1

Optical connectors are precision components, and require care

in use:

■ Always clean the mating connector tip and ferrule before

mating, using approved materials.

■ This instrument can be used with both PC and APC

connector styles (unlike sources, which are factory

configured for PC only ).

■ The soft carry case enables the instrument to be stored

without removing the test leads. This practice saves time,

and is to be recommended.

■ When not in use, keep all test ports and connectors covered

and away from dust.

■ Do not touch connector tips with your fingers,

since body oils and dirt can impair connector performance.

■ Do not use damaged or incompatible connectors.

9

Page 13

■ OPTICAL CONNECTOR

Cleaning

The glass power meter interface does not make contact with the

inserted connector: there is a slight air gap. Therefore it should

not wear out, and only needs occasional cleaning.

To clean the glass power meter interface: remove the

interchangeable adaptor to access the glass interface, then use

a sticky material such as ‘ Blu tac ‘ to dab the glass and remove

any dirt. A soft brush, alcohol, or air can are also appropriate.

Do not use anything hard that could scratch the glass.

In this manual, refer to the sections on Cleaning Information

and Procedures for further information.

Bare fiber adaptors

Bare fiber adaptors used with this power meter must achieve

fiber eccentricity of +_ 100 microns and end tolerance of

+

_ 0.3 mm, relative to the ferrule end. Be careful not to scratch

the detector interface when using adaptors, since permanent

10

meter inaccuracy may result. Preferred bare fiber adaptors

consist of a connector with fiber retention device.

If you work regularly with bare fibers, to avoid potential damage

to the meter, it is generally preferable to use an alternative

a rrangement such as a multimode pigtail with a

v-groove or mechanical splice.

Page 14

■ GETTING STA RTED AND TURNING ON

This and following sections show you how to use your

instrument:

Check that the correct accessories have been supplied, and an

optical connector adaptor has been fitted. If you have any

queries, call your supplier to resolve the situation.

Put in the batteries, or plug external power into the socket at the

top of the instrument (see Battery and External Power section).

Push the green POWER button. The display will come on.

If the battery is low, this will be indicated on the display.

Pushing POWER again will turn the instrument off.

To stop the instrument turning off 10 minutes after the last key

press, hold POWER down for 3 seconds during turn-on. PERM

on the display indicates that the unit will stay on permanently.

To back light the display temporarily, select LIGHT. To back light

continuously, hold down the button for 3 seconds. Use of the

back light will drain the batteries faster.

N3970A UM-1

This instrument uses a menu driven keypad. The function of

each button is shown on the display.

To access the optical connector, grasp a top corner of the

instrument, and pull off the cover. The connector can be

swivelled to improve access.

After instrument turn on, the instrument will perform a selfcalibration sequence, set the dark current adjustment, and then

display absolute power in dBm at the previously set λ. If HI or

LO are displayed, the input is out of range.

The hidden keypad is accessed by pulling up the hinged display

cover. The hidden keypad can operate in two modes. The

second mode is accessed by SHIFT. Access to the second mode

can be denied / permitted by typing the button sequence

: POWER (turn on instrument), SHIFT, CANCEL, SET, SELECT,

RECALL, STORE.

11

Page 15

■ GETTING STA RTED AND TURNING ON

To disable or enable the buzzer, hold down SHIFT for 3 seconds.

To add the carry strap: slip the end of the strap through the slit

on the curved section at the back of the instrument, and secure

the buckle.

This instrument requires no warm up, and no user adjustment

of dark current to achieve it’s specified performance.

To learn how to use the instrument features, go to the next

section.

Should the instrument fail to turn on, the microprocessor may

need re-booting. To do this, remove batteries and external

power for at least 40 seconds. This will not lose stored data.

12

Page 16

■ AUTOTEST OPERAT I O N

General Autotest features

For Autotest to function, all instruments involved in the test

must be Agilent Handheld instruments with an Autotest

function.

The Autotest feature performs automated measurement (and

automatic λ detection) by data exchange between instruments,

and requires minimal operator knowledge: turn the instrument

on, connect a test lead, and select AUTOTEST on the source.

Subsequent operation is automated, although some choices can

be made for convenience.

Functionality is determined by the options fitted to the

instrument(s) used. Autotest configures itself according to the

options available, and carries out the most comprehensive test

possible.

Autotest remains synchronised for about 8 seconds, which

enables the user to change optical connections without

re-starting Autotest each time.

A light source transmits Autotest signals at one or two

wavelengths to an appropriate power meter.

N3970A UM-1

Operation

Turn on the source and meter, and connect them with a test lead.

On the light source, push AUTOTEST.

This is all that is required to start Autotest operation on the

power meter.

The meter will automatically set to the correct λ and display

absolute power in dBm. The display will alternate between

wavelengths. To display only one λ at a time, push +/-.

You may also select AUTOTEST on the meter, which forces the

meter into Autotest mode, with faster synchronisation in this

mode (the source must be in Autotest mode). Push MENU to

exit.

The source power transmitted from the source is displayed on

the left hand side of the display.

Push ABS/REL to make the meter display relative power.

The stored reference value(s) are displayed on the left hand side

of the display.

To take a reference under Autotest, connect the source and

13

Page 17

■ AUTOTEST OPERAT I O N

meter with a test lead. Set the source to Autotest mode, and then

push SET REF on the meter for 3 seconds. This will store the

reference at all relevant wavelengths.

Either a ‘local’ or ‘remote’ reference can be stored.

To exit Autotest mode, either disconnect the optical test lead, or

exit Autotest mode on the light source for > 8 seconds.

Refer also to manual sections on:

■ Storing and recalling readings.

14

Page 18

After instrument turn on, the meter will be calibrated at the last

used λ. To change parameters, push POWER METER, then:

To select a calibrated λ, push +/-. λis displayed on the top right

side of the display.

To display relative power, push ABS/REL. The display will

show dB R.

To store a new reference, push SET REFfor 3 seconds.

To display the stored reference value, keep ABS/REL depressed.

To change the dBm display between linear and log, access the

hidden keypad and push dBm/W.

If the meter detects a modulated signal, the display will change

to show the actual measured modulation frequency in Hz,

and if a standard tone is detected ( eg 270 Hz, 1 KHz,

2 KHz ), a buzzer will sound. This is useful for fiber

identification and signalling. The meter can also be used to

check the actual modulation frequency of test sources.

N3970A UM-1

■ PO W E R ME T E R OP E R AT I O N

15

Page 19

■ STORING & RECALLING READINGS

There are various ways of storing and recording data, giving the

user flexible ways of working. They are summarised here for

your convenience.

Storage of reference values: A separate reference is stored for

each λ and can be recalled when the instrument is next turned

on.

Display hold: To hold the display at it’s current value, push

HOLD. This value can then be stored. Push HOLD again to

continue updating the display.

Automatic recording of maximum & minimum limits: To display

the minimum and maximum value over a period, access the

hidden keypad and push MAX/MIN. The display will show the

maximum and minimum values in sequence. Then push

MAX/MIN for 3 seconds to re-start the recording process. This

function re-sets automatically when instrument parameters are

altered.

16

Storing & recalling readings using non-volatile memory

In Autotest, stored data includes absolute & relative values at all

possible wavelengths.

Note: To recall data, the unit must be in manual ‘power meter’

mode.

In manual mode, stored data includes absolute, relative and

reference values.

You can store, display or download up to 845 readings in nonvolatile memory.

Memory No Identifier Space

1 - 199 mem 199

200 - 1990 (steps of 10) mem 179

1 - 199 ID 199

200 - 1990 (steps of 10) ID 179

1 - 199 mem / ID 89

Total memory 845

Page 20

■ STORING & RECALLING READINGS

The memory location is shown at the top right of the display.

When storing data, the memory automatically increments to

facilitate the collection of data on a job.

You can also go back and over-write particular records.

After the data has been recorded, the entire memory can be

cleared ready for the next job.

Memory operating sequence

Store data in next location: push STORE

Store data starting at a particular location: push SELECT, +/-,

SET, STORE

The memory can not be read in Autotest mode. Exit Autotest

before reading the memory.

N3970A UM-1

Read from any location: push RECALL, +/-. To display the

relative value, push ABS/REL, and to display the reference, hold

down ABS/REL.

Clear the whole memory: push CANCEL and RECALL together

for 2 seconds. CLR will display.

17

Page 21

■ RS232 INTERFA C E

The connection details of the instrument, and connecting cables are as follows :

Some (out of spec) serial ports need a 10 K resistor in the D connector across wires 1 & 2.

Wire 1 (screen) Wire 2 Wire 3

Instrument Jack Plug Body (Gnd) Ring (Tx) Tip (Rx)

9 Pin D connector for RS232 Pin 5 (Gnd) Pin 2 (Rx) Pin 3 (Tx)

The RS232 interface can be used to access and control the instrument from an external computer. All functions can be accessed

remotely. See next pages for available software.

The baud rate can be set to: 0.3, 0.6, 1.2, 2.4, 4.8, 9.6, 19.2, 38.4, 56 Kbaud. The default and printer baud rate is 9.6 Kbaud. To set the

baud rate, on the hidden keypad, select -SHIFT- BAUD RATE, then -/+ to SET the rate, followed by set. At turn on, the default is

restored.

Local / remote modes

The hidden keypad enables the user to lock out the front panel controls, by selecting LOCAL or REMOTE.

18

Page 22

■ CARE OF YOUR INSTRUMENT

■ Follow the directions in this manual on cleaning optical

connectors.

■ Limit the input optical power to no more than 5 dB over-

range.

■ During storage and transport, keep the instrument in its

carry case to protect against crushing, vibration, dust and

moisture.

■ The instrument is resistant to normal dust and moisture,

however it is not waterproof. If moisture does get into the

instrument, dry it out carefully before using it again.

■ Where possible, keep instrument away from strong sunlight.

■ During prolonged storage, remove batteries to eliminate the

possibility of acid leakage. Use only high quality sealed

alkaline batteries.

N3970A UM-1

■ Clean the instrument using alcohol or other non solvent

cleaning agents. Acetone or other active solvents may

damage the case.

■ The instrument housing is made of tough Polycarbonate

material with impact absorbing rubberised corner features,

and is therefore drop resistant.

19

Page 23

■ ACCURACY CONSIDERATIONS

All measurements

Optical connectors should be kept clean and in good condition.

Due to emitter center λ uncertainty (eg 1310 +/- 20 nm), fiber

attenuation may vary with different sources.

This λ uncertainty can also affect power meter calibration. This

is significant with InGaAs in the 850 nm band, and absolute

errors in the order of 1 dB are possible. This issue affects

absolute power measurements. It does not significantly affect

attenuation measurements where the meter was referenced to

the same source.

Source power may drift: when you have finished a test, go back

to the start position to check if source power is still within

acceptable limits. It is worth noting that most sources only

quote typical drift after warm up. Actual drift may of course be

significantly worse, and will be very variable between

instruments. The N3974A Dual Laser Source is unusual in

offering maximum drift specifications, without warm up.

20

Most available laser sources ( except the N3974A Dual Laser

Source ) are sensitive to reflections. Varying reflections can

induce source instability of around 0.3 dB. This is very difficult

to verify without a special test system, but can be a source of

errors.

Polarisation changes create disturbances in both the optical

system and measurement equipment. To reduce this, keep your

system physically stable. Keep patch leads neat, coiled and

stable.

The N3970A Optical Power Meter has an InGaAs detector.

Page 24

N3970A UM-1

■ ACCURACY CONSIDERATIONS

21

Page 25

■ CALIBRATION & MAINTENANCE

Enabling / disabling ‘shift’ keypad & re-booting the

microprocessor: See section on ‘getting started &

turning on.

Calibration

Calibration can be readily performed without opening the

instrument. Calibration is performed by setting up a singlemode

laser source at a stable but non-critical power level between -10

and -30 dBm, and adjusting the meter reading to the same value

as that shown by a reference meter.

A l t e rn a t i v e l y, known calibration constants can be

re-entered directly without using other equipment. This is useful

in case old calibration constants are to be put back, or the

instrument memory has been corrupted.

R e q u i red are laser light sources with accurate, calibrated

wavelengths and good power stability, a power meter with

appropriate calibrated wavelengths, singlemode test leads, an

anti-tamper label, and a 0.1” programming jumper. Check the

calibration certificates on your reference equipment, to ensure

current validity.

22

To enable calibration mode, open the battery compartment, hold

back the battery spring, remove the anti-tamper label, and insert

a 0.1” pitch programming shunt. Manipulation of the shunt is

easier with needle nose pliers. The meter will display ‘CAL’

Before commencing calibration:

■ Clean all connectors and the meter input ports very carefully

■ Ensure all devices have been at stable room temperature for

over an hour

■ The source is fully warmed up at the λ to be calibrated,

■ The meter battery is good.

On the meter to be calibrated, record the existing calibration

offsets as follows:

■ Select POWER METER, +/- to set the wavelength, and

MAX/MIN twice to display the offsets. Note them down.

(you can also re-enter or adjust known offsets at this point)

Page 26

■ CALIBRATION & MAINTENANCE

■ Measure and record the source power using the reference

meter

■ Transfer the same power level to the meter to be calibrated,

set MAX/MIN to display power, then +/- to adjust the

reading to match the noted reference reading. Note: The

optical power is measured only when entering this mode. It

is not continuously updated.

■ Set MAX/MIN to read and note the new stored calibration

offsets, and then SET to store and exit, or CANCEL to

abandon and exit

■ Go back and check the source power with the reference

meter, to ensure source drift is within limits.

■ When calibration is complete, remove the calibration shunt,

and place an anti-tamper label over the hole in the battery

compartment.

■ Do no forget to update your calibration re c o rds, and

schedule the next due date.

N3970A UM-1

Maintenance

CAUTION! Do not open unless the warranty has expired, you are

authorised to do so, and you have a static protected work

station. Opening the unit will invalidate any warranty claim.

There are no internal user adjustable components, fuses, or

calibration features.

The optical sensor / connector assembly is not user serviceable.

Opening the instrument:

■ Use static protected procedures

■ Remove the batteries, and leave the battery cover open.

■ Pull open the optical connector covers.

■ Place the instrument face down on a soft mat, and undo the

6 screws in the rear housing.

■ The instrument can now be gently pulled apart.

■ The instrument will come into two halves joined by a ribbon

cable. The optical section is located in the bottom half, with

the micro p ro c e s s o r, supply, calibration constants and

controls in the top half.

23

Page 27

■ CALIBRATION, MAINTENANCE & INSTRUMENT RETURNS

■ Hinged display cover removal can be done at this point.

■ The ribbon connector can be disengaged to completely

separate the instrument halves.

■ Further dis-assembly from this stage should be easily

apparent to a technician.

■ Re-assembly is the reverse of the previous procedure.

E n s u re that the ribbon cable connectors are pro p e r l y

secured so they cannot shake loose. This will be either a

moulded rubber retainer, or adhesive tape.

General electrical parameters are as follows: Vss to GND = 3V3,

-Vss = -3V3, battery power down current about 0.2 mA, active

current about 25 mA.

24

B e f o re re t u rning equipment for repair or calibration, please

check with your local Agilent Technologies Service Center

(see page 3 Service and Support) to obtain a tracking number

and shipping details. If the instrument is being returned for

calibration, please include a purchase order.

Please state clearly the problem requiring attention.

Please include your contact email, phone and fax number, and

return shipping details.

If the goods are under warranty, it would be helpful to include

the original order / contract details.

If the goods are not under warranty, work will only proceed when

a repair order has been issued. Please either include a repair

order with the equipment, or request that a quotation be

provided.

Page 28

■ SPECIFICATIONS - DEFINITION OF TERMS

Power Range The range of input powers for which the instrument can be used.

Maximum Input Power The input power is not to be exceeded to avoid destroying the instrument.

Uncertainty at

reference conditions The uncertainty for the specified set of reference conditions, including all uncertainties

in the calibration chain from the national laboratory to the test meter (connectors and

p a t c h c o rds must be absolutely clean and undamaged). Reference conditions are the

conditions during the spectral responsivity calibration.

Total Uncertainty The uncertainty for a specified set of operating conditions, including noise and drift

(connectors and patchcords must be absolutely clean and undamaged).

Autotest sensitivity The power level below which the Autotest does not work.

N3970A UM-1

25

Page 29

■ SPECIFICATIONS & ORDERING INFORMATION

Sensor Element InGaAs

Wavelength Range 850-1650 nm

Calibration Wavelengths 8501, 1300, 1310, 1550 nm

Power Range +5 to –60 dBm (850 nm)

+5 to –70 dBm (other wavelengths)

Maximum Input Power +15 dBm

Uncertainty at reference conditions 2±0.13 dB (±3%)

Total Uncertainty

Autotest sensitivity (typical)

Operating Time 250 hours

Applicable Fiber Type 9/125 µm to 62.5/125 µm

Optical Input Non-Contact, Removable Connector Adaptors

Display Type LCD, 4 digits

Display Resolution 0.01dB, 3 digits in linear mode

Display Units dB, dBm, nW, µW, mW

26

3

4

±0.3 dB (±7%) ±2pW

-40 dBm (850 nm)

-50 dBm (other wavelengths)

Page 30

■ SPECIFICATIONS & ORDERING INFORMATION

1: All specifications at 850 nm are typical.

2: 23 ± 3oK, -10 to –30 dBm, calibration wavelengths ± 2nm, fiber type standard SMF, connector type ceramic FC / PC, at day

of calibration.

3: includes uncertainty contributions due to: uncertainty at re f e rence conditions, varying optical connector types, fiber types up

to 62.5 µm core diameter and numerical apert u r e up to 0.3, operation within power range and within operating temperature range.

4: Tested at room temperature, using an optical attenuator.

Size: 190 x 130 x 70 mm, 7.9” x 5.4 x 2.9

Weight: 500 gm, 1.1 lb. Shipping 2 Kg, 4.4 lb

Operating / storage: -10 to 55°C / -25 to 70°C

Power: 2 alkaline C cells (7.6 A/hr) or external 9V DC with 2.5mm +ve pin.

Selectable auto-off, low battery indicator, back lit display.

Tone detection: 100 - 9999 Hz 1%.

Max / min: Recording feature for stability testing.

Hidden keypad: For setting advanced functions.

Damage level: > 5 dB above max reading.

Case: Polycarbonate, 1 meter drop tested.

RS232: 3.5 mm jack connector, 0.3 - 56 Kbaud, default 9.6 K.

Calibration: Performed without opening instrument.

Printing: Not supported.

N3970A UM-1

27

Page 31

■ SPECIFICATIONS & ORDERING INFORMATION

ORDERING INFORMATION

Instrument

N3970A Optical Power Meter

Standard accessories:

Included with instrument: FC, ST, SC optical connector, manual,

batteries, NATA traceable calibration certificate, carry strap,

pouch, protective holster & RS 232 cable.

Connector options: This instrument is equipped with

interchangeable optical connector adaptors, and works with

both PC and APC connectors.

The N3974A Optical Power Meter is supplied with a straight

contact output connector interface. To connect to the

instrument, you must attach your connector interface (see list

connector interfaces below) to the interface adaptor, then

connect your cable.

28

Agilent service Part No. Description

N3970-63240 ST

N3970-63246 SC

N3970-63251 FC

Optional accessories:

Agilent Part No. Description

N3979A Power Supply 9V DC

Australian and international patents

Page 32

The procedures in this section test the performance of the

instrument. The complete specifications to which the Agilent

N3970A Optical Power Meter is tested are given on pages 26-28.

All tests can be performed without access to the interior of the

instrument. The test equipment given corresponds to tests

carried out with Diamond HMS-10 connectors and FC/PC

connectors on the DUT (devise under test).

Equipment Required

Equipment required for the performance test is listed in the table

on page 30. Any equipment that satisfies the critical

specifications of the equipment given in the table may be

substituted for the recommended models.

N3970A UM-1

■ PERFORMANCE TEST

29

Page 33

■ PERFORMANCE TEST

Table 1 Required Equipment

Instrument/Accessory Recommended Required Alternative

Model Characteristics Models

Lightwave Multimeter 8163A 8164A, 8166A

Interface Module (one 81618A 81619A

channel)

Optical Head 81624A#C01

Laser Souce 1310/1550 nm 81654A 1305± 25nm 81657A or

Optical Attenuator 8156A#101 Attenuation >50 dB

Connector Interfaces 81000AI (3ea)

Connector Adaptors 81000FA

Singlemode Fiber 81101AC

81101PC 81101FC

FC Connector Adaptor for N3970-63251

N3970A

Note: Instead of 8163A, 81618A, 81624A #C01 and 81654A also the older but discontinued equipment 8153A, 81533B, 81524A

#C01 and 81554SM together with 81210LI #011 and 81310LI # 011 can be used.

30

1550±30nm 81650A & 81651A

Short Term Stability<±0.005 dB or

81655A and 81656A

Return Loss >26 dB

Repeatability <±0.01 dB

Page 34

■ PERFORMANCE TEST

Test Record

Results of the performance test may be tabulated on the Test

R e c o rd provided at the end of the test pro c e d u re. It is

recommended that you fill out the Test Record and refer to it

while doing the test. Since the test limits and setup information

are printed on the Test Record for easy reference, the record can

also be used as an abbreviated test procedure (if you are already

familiar with the test procedures). The Test Record can also be

used as a permanent record and may be reproduced without

written permission from Agilent Technologies.

Test Failure

If the Agilent N3970A fails any performance test, return the

instrument to the nearest Agilent Technologies Sales/Service

Office for repair (see page 3).

N3970A UM-1

Instrument Specification

Specifications are the perf o rmance characteristics of the

instrument that is certified. These specifications, listed on page

26, are the performance standards or limits against which the

Agilent N3970A can be tested.

Any changes in the specifications due to manufacturing

changes, design, or traceability to the National Institute of

Standards and Technology (NIST), will be covered in a manual

change supplement, or revised manual. Such specifications

supersede any that were previously published.

31

Page 35

■ PERFORMANCE TEST

Performance Test

The performance test given in this section includes the

Total Uncertainty/Accuracy Test. Perform each step in the

order given, using the corresponding test equipment.

Note Make sure that all optical connections are dry and

clean. DO NOT USE INDEX MATCHING OIL. For

cleaning, use the cleaning instructions given in "Cleaning

Procedures" on page 41.

Make sure that all patchcords are fixed to the table so that

they won't move during measurements.

Make sure that the ambient conditions are in the

following ranges:

temperature 23ºC ±3K

Relative humidity 45 to 75 %

32

Total Uncertainty / Accuracy Test

1. Make sure that you satisfy the environmental conditions.

2. Make sure all your connectors are clean.

3. Connect the equipment as shown in figure below.

Test setup for the Uncertainty Test Reference Measurement

Make sure that all Patchcords are fixed to the table and

won't move during measurements.

Page 36

■ PERFORMANCE TEST

4. Switch on the instruments.

a. Switch on the lightwave multimeter.

b. Configure the laser source.

■ Set the laser source attenuation to 0 dB

■ Set the wavelength to 1310 nm

■ Note the actual (displayed) wavelength of the laser source in

the test re p o rt

c. Switch on the attenuator.

■ Set the wavelength to the wavelength of the laser source

in the test report

d. Configure the optical head and interface module.

■ Set the unit to dBm

■ Set the averaging time, T, to 100 ms

■ Set AUTO ranging on

■ Set the wavelength to the wavelength of the laser source

■ With the laser source and attenuator disabled, zero

the power meter

e. Switch on the N3970A (DUT) for permanent operation, by

holding the POWER key down for 3 seconds during turn-on

N3970A UM-1

until PERM is shown in the display.

■ Set the DUT to "dBm"

f. Make sure that all the instruments are warmed up.

5. Make the reference measurement.

a. Enable the laser source and the attenuator output.

b. Change the attenuation of the attenuator until the optical

power meter displays -3.00 dBm.

Note In some cases the laser source will not be powerful

enough to give -3.00 dBm. In such case, set the attenuator to

0 dB and correct the appropriate values in the test report.

■ Note the setting of the attenuator for setting 1 in the test re p o rt

c. Change the attenuation of the attenuator until the optical

power meter displays -20.00 dBm.

■ Note the setting of the attenuator for setting 2 in the test re p o rt

d. Change the attenuation of the attenuator until the optical

power meter displays -30.00 dBm.

■ Note the setting of the attenuator for setting 3 in the test re p o r t

e. Change the attenuation of the attenuator until the optical

power meter displays -50.00 dBm.

■ Note the setting of the attenuator for setting 4 in the test re p o r t

33

Page 37

■ PERFORMANCE TEST

6. Measure the DUT.

a. Make sure the N3970A (DUT) has warmed up

b. Connect the attenuator output cable to the DUT as

shown in figure below.

Test Setup for the DUT Measurement

34

c. Select the correct wavelength on the DUT.

d. Set the attenuator to its value for setting 1.

■ Note the displayed power level of the DUT in the test re c o rd

e. Set the attenuator to its value for setting 2.

■ Note the displayed power level of the DUT in the test re c o rd

f. Set the attenuator to its value for setting 3.

■ Note the displayed power level of the DUT in the test re c o rd

g. Set the attenuator to its value for setting 4.

■ Note the displayed power level of the DUT in the test re c o rd

7. Repeat from list item 4 to list item 6 at 1550 nm.

Page 38

■ PERFORMANCE TEST

Model N3970A Optical Power Meter

Serial No.

Options

Firmware Rev.

Test Facility

Performed by

Special Notes

N3970A UM-1

Date

Ambient Temperature

o

Relative Humidity %

Line Frequency Hz

Customer

Report No

C

35

Page 39

■ PERFORMANCE TEST

Description Model No.

1. Lightwave Multimeter 8163A

2. Light Source 1310/1550 nm 81654A

3. Optical Head 81624A #C01

4. Optical Head Interface Module 81618A

5. Optical Attenuator 8156A #101

6.

7.

8.

9.

10.

Accessories #Product

Singlemode Fiber 1 81101AC

1 81101PC

Connector Interfaces 3 81000AI

1 N 3 9 7 0 - 6 3 2 5 1

Connector Adaptors 1 81000FA

36

Trace No Cal. Due Date

Page 40

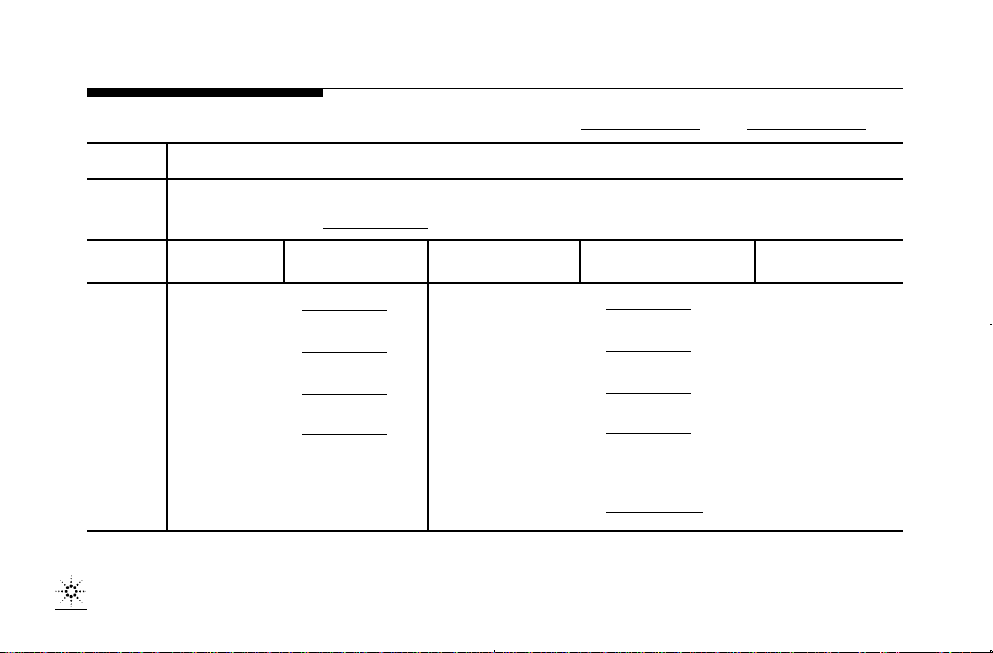

■ PERFORMANCE TEST

Model N3970A Optical Power Meter

Total Uncertainty/Accuracy Test

Test Wavelengths = 1300 nm and 1310 nm

Source Wavelength = nm

Setting

Number

1

2

3

4

Reference

(8163A Display)

-3.00 dBm

-20.00 dBm

-30.00 dBm

-50.00 dBm

Measurement Uncertainty dB

N3970A UM-1

Attenuator

Setting

dB

dB

dB

dB

Report No. Date

Minimum Spec.

(-0.3 dB of Ref.)

-3.30 dBm

-20.30 dBm

-30.30 dBm

-50.30 dBm

N3970A, DUT

Measurement results

dBm

dBm

dBm

dBm

Maximum Spec.

(+0.3 dB of Ref.)

-2.70 dBm

-19.70 dBm

-29.70 dBm

-49.70 dBm

37

Page 41

■ PERFORMANCE TEST

Model N3970A Optical Power Meter

Total Uncertainty/Accuracy Test

Test Wavelengths = 1550 nm

Source Wavelength = nm

Setting

Number

1

2

3

4

Reference

(8163A Display)

-3.00 dBm

-20.00 dBm

-30.00 dBm

-50.00 dBm

Measurement Uncertainty dB

38

Attenuator

Setting

dB

dB

dB

dB

Report No. Date

Minimum Spec.

(-0.3 dB of Ref.)

-3.30 dBm

-20.30 dBm

-30.30 dBm

-50.30 dBm

N3970A, DUT

Measurement results

dBm

dBm

dBm

dBm

Maximum Spec.

(+0.3 dB of Ref.)

-2.70 dBm

-19.70 dBm

-29.70 dBm

-49.70 dBm

Page 42

■ CLEANING INFORMAT I O N

The following Cleaning Instructions contain some general

safety precautions, which must be observed during all phases of

cleaning. Consult your specific optical device manuals or

guides for full information on safety matters.

Please try, whenever possible, to use physically contacting

connectors, and dry connections.

Clean the connectors, interfaces, and bushings carefully after use.

If you are unsure of the correct cleaning procedure for your

optical device, we recommend that you first try cleaning a

dummy or test device.

Agilent Technologies assume no liability for the customer's

failure to comply with these requirements.

For more information about Cleaning Instruments, please

consult the Pocket Guide "Cleaning Procedures for Lightwave

Test and Measurement Equipment" (Agilent P/N 5963-3538F).

If you do not have a copy of this pocket guide, Agilent will

provide you with one free of charge.

N3970A UM-1

Safety Precautions

Please follow the following safety rules.

■ Do not remove instrument covers when operating.

■ Ensure that the instrument is switched off throughout the

cleaning procedures.

■ Use of controls or adjustments or performance of procedures

other than those specified may result in hazardous radiation

exposure.

■ Make sure that you disable all sources when you are cleaning

any optical interfaces.

■ Under no circumstances look into the end of an optical

device attached to optical outputs when the device is

operational. The laser radiation is not visible to the human

eye, but it can seriously damage your eyesight.

■ To prevent electrical shock, disconnect the instrument fro m

the mains before cleaning. Use a dry cloth, or one slightly

39

Page 43

■CLEANING INFORMAT I O N

dampened with water, to clean the external case parts. Do not

attempt to clean internally.

Do not install parts or perform any unauthorised modification to

optical devices.

* Refer servicing only to qualified and authorised personnel.

Why is it important to clean optical devices ?

In transmission links optical fiber cores are about 9 µm

(0.00035") in diameter. Dust and other particles, however, can

range from tenths to hundredths of microns in diameter. Their

comparative size means that they can cover a part of the end of

a fiber core, and as a result will reduce the performance of your

system.

Furthermore, the power density may burn dust into the fiber and

cause additional damage (for example, 0 dBm optical power in

a single mode fiber causes a power density of approximately 16

million W/m2). If this happens, measurements become

40

inaccurate and non-repeatable. Cleaning is, there f o r e, an

essential yet difficult task. Unfortunately, when comparing most

published cleaning recommendations, you will discover that

they contain several inconsistencies. In this section, we want to

suggest ways to help you clean your various optical devices,

and thus significantly improve the accuracy and repeatability of

your lightwave measurements.

Page 44

■ CLEANING PROCEDURES

Keep your dust and shutter caps on when your instrument is not

in use. This should prevent it from getting too dirty. If you must

clean such instruments, please refer the instrument to the

skilled personnel of Agilent's service team.

Preferred Procedure

Use the following procedure on most occasions.

1. Blow away any dust or dirt with compressed air.

If this is not sufficient, then

a. Clean the interface by rubbing a new, dry cotton swab

o v e r the surface using a small circular movement.

b. Blow away any remaining lint with compressed air.

Procedure for Stubborn Dirt

Use this procedure when there is greasy dirt on the interface,

and using the procedure for light dirt is not sufficient. Using

isopropyl alcohol should be your last choice for recessed lens

interfaces because of the difficulty of cleaning out any dirt that

is washed to the edge of the interface.

N3970A UM-1

1. Moisten a new cotton swab with isopropyl alcohol.

2. Clean the interface by rubbing the cotton swab over the

surface using a small circular movement.

3. Take a new, dry soft tissue and remove the alcohol, dissolved

sediment and dust, by rubbing gently over the surface using

a small circular movement.

4. Blow away any remaining lint with compressed air.

41

Page 45

■ DISCLAIMER & WA R R A N T Y

Information in this manual is given in good faith for the benefit

of the user. It cannot be used as the basis for claims against

Agilent Technologies or its re p resentatives, if accidental

damage or inconvenience results from use or attempted repair

of the equipment.

Agilent Technologies products are guaranteed against defective

components and workmanship for a period of 3 years from the

date of delivery, unless specifically stated in the original

purchase contract or agreement. This warranty excludes optical

connectors or incorrect use. Opening the instrument will

invalidate the warranty. Liability is limited solely to repair of the

equipment.

42

Page 46

N3970A UM-1

■ N O T E S

43

Page 47

■ N O T E S

44

Loading...

Loading...