Page 1

N2790A

Differential Voltage

Probe

User’s Guide

For Safety, Regulatory, and publishing information, see the pages at the back of this book.

© Copyright Agilent Technologies 2010

All Rights Reserved.

Page 2

Contents

Inspecting the Probe 3

Compatibility 4

Probe Parts Supplied 5

Characteristics and Specifications 6

Cleaning the Probe 8

Using the N2790A Probe 9

Service Strategy 10

Characterization Plots 11

Performance Verification Procedures 13

2

Page 3

Inspecting the Probe

Inspecting the Probe

❏ Inspect the shipping container for damage.

Keep a damaged shipping container or cushioning material until the contents of the

shipment have been checked for completeness and the probe has been checked

mechanically and electrically.

❏ Check the accessories.

Any accessories that were supplied with the probe are listed in the “Probe Parts

Supplied” section of this manual.

• If the contents are incomplete or damaged, notify your Agilent Technologies Sales

Office.

❏ Inspect the instrument.

• If there is mechanical damage or defect, or if the probe does not operate properly

or pass calibration tests, notify your Agilent Technologies Sales Office.

• If the shipping container is damaged, or the cushioning materials show signs of

stress, notify the carrier as well as your Agilent Technologies Sales Office. Keep

the shipping materials for the carrier’s inspection. The Agilent Technologies office

will arrange for repair or replacement at Agilent Technologies’ option without

waiting for claim settlement.

3

Page 4

Inspecting the Probe

N2790A Differential Voltage Probe

The N2790A differential probe allows you to safely measure high-voltage floating

circuits with the oscilloscope grounded. It is ideal for many applications such as motor

speed controls, power supply designs, and electronic high-power converters. The

N2790A offers sufficient dynamic range and bandwidth for your application to make

the floating measurements found in high-speed power electronic circuits safely and

accurately.

With 100 MHz bandwidth, switchable attenuation of 50:1 and 500:1, and a maximum

differential voltage input of 1400V (DC + peak AC), it provides the versatility for a

broad range of applications including high-voltage circuits. Each probe comes with

sharp browser probe tips for use on small components and in tight places, alligator

clips for connecting to larger cables, and pincher clips.

The probe is powered by the autoprobe interface.

Compatibility

The N2790A differential probe is compatible with the following Agilent oscilloscopes:

• InfiniiVision Series 5000, 6000 (except 100 MHz), and 7000 with version 5.2

software or later

• Infiniium 9000 (with version 2.00 software or later), 8000 (with version 5.61

software or later), and 54830 Series (with version 5.61 software or later)

4

Page 5

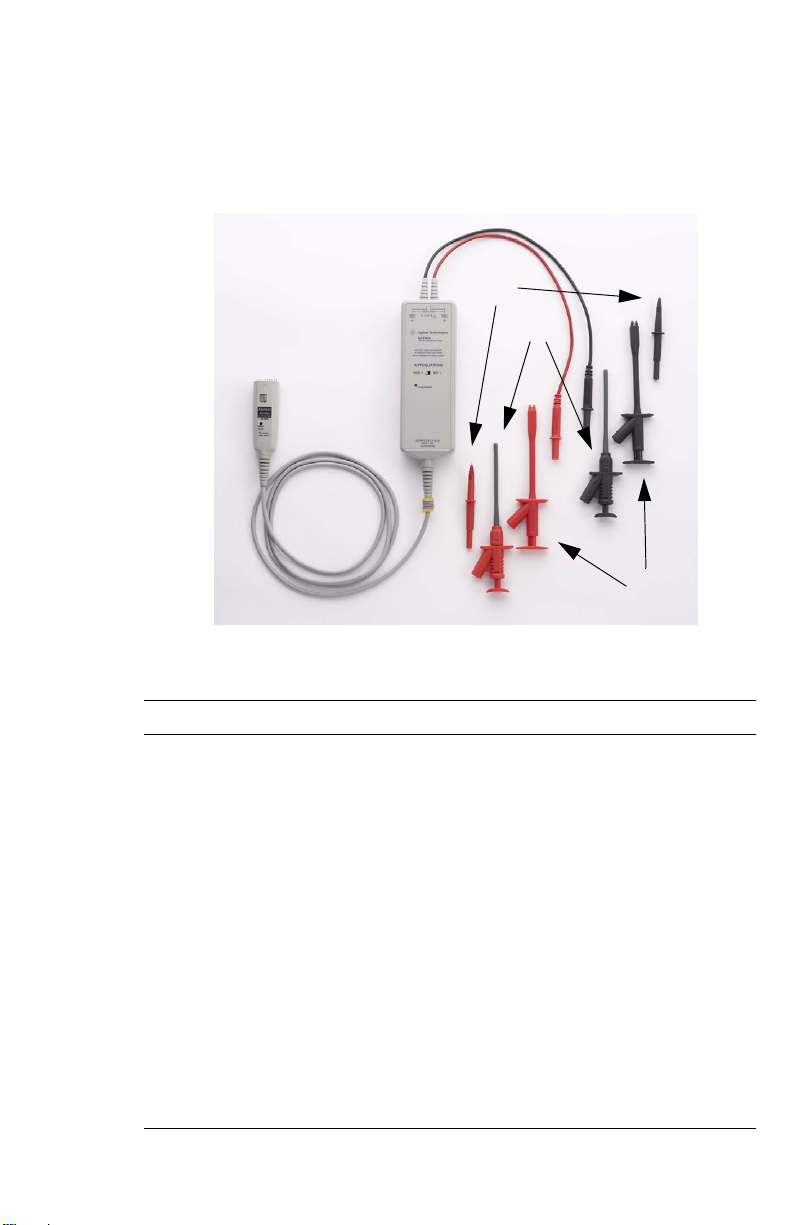

Inspecting the Probe

2

3

4

Probe Parts Supplied

The following diagram and table show the parts supplied with the N2790A Probe.

The probe tips you receive may look slightly different than the ones shown in this

picture.

Parts for N2790A Probe

Item Description Part Number

1 Differential voltage probe N2790-68701

2 Probe tips - browser tip (x2)

3 Probe tips - pincher clip (x2)

4 Probe tips - alligator plunger clip (x2)

5 Plastic pouch

6 Offset adjustment tool

To order the Probe Tip Accessory Kit (consisting of 2 browser tips, 2 pincher

clips, and 2 alligator plunger tips), order part number N2790-68700. Probe tips

are only for use with the N2790A differential voltage probe.

*Probe tips are not orderable separately.

(black and red pair)

(black and red pair)

(black and red pair)

A054*

5

Page 6

Characteristics and Specifications

Characteristics and Specifications

Characteristics and specifications for the N2790A Differential Voltage Probe are

shown below.

Electrical Characteristics

Attenuation ratios 50:1 and 500:1 (Selectable via switch on probe.)

Bandwidth (-3 dB)* 100 MHz

Gain Accuracy* \4% @ 0-20 oC, \2% @ 20-30 oC, \4% @ 30-

DC CMRR -70 dB @ 500VDC

AC CMRR -80 dB @ 50/60 Hz

Input impedance Between inputs: 8 M , 3.5 pF

Noise referenced to input < 300 mVrms @ 500:1

Propagation Delay 14.0 ns @ 50:1, 12.8 ns @ 500:1

Switch positions 500:1, 50:1

Internal power Autoprobe interface

*Denotes warranted specification after 20 minute warm-up

o

55

C

-50 dB @ 100 kHz

-50 dB @ 1 MHz

< 50 mVrms @ 50:1

Input Characteristics

Cable length 170 cm (66.9 inches)

Length of input leads 40 cm (15.7 inches)

Maximum common mode

operating voltage

(rms or DC + peak AC)

1

Maximum common mode

operating voltage derating

frequency

2

Maximum differential mode

operating voltage

(DC + peak AC)

1

Refer to the warnings on page 8 for further details on the input voltage safety rating

2

Refer to the derating plot on page 12

600V CAT III

1000V CAT II

2 MHz

1400 V @ 500:1

140 V @ 50:1

6

Page 7

Characteristics and Specifications

Output Characteristics

Output cable Safety designed BNC cable

Maximum output voltage range \2.8 V into 1 M at 500:1

Environmental Specifications

Temperature Operating: -10 °C to +50 °C

Nonoperating: -51 °C to +71 °C

Altitude Operating: 2,000 m (6,561 ft)

Nonoperating: 15,300 m (50,200 ft)

Humidity Operating: 80% room humidity @ 40 °C

Nonoperating: 90% room humidity @ 65 °C

Pollution Degree Pollution Degree 2

Safety Specifications

UL Listed: File No. E326557

Compliant with: UL 61010-031, CSA 22.2 No. 61010-031-07

7

Page 8

Cleaning the Probe

!!!!

WARNING SHOCK HAZARD!

These probes are designed for use with oscilloscopes that have a common terminal at

GROUND POTENTIAL (in accordance with OSHA requirements and the National

Electric Code). Exposed metallic surfaces of the probe and the oscilloscope MUST BE

GROUNDED. Failure to ground the common terminal during certain applications,

such as those requiring the oscilloscope to be powered from an external battery, might

expose the operator to an electrical shock hazard that could be lethal (depending on

voltage and current conditions.)

The probe inputs are safety rated to a maximum of 1000 Vrms CAT II and 600 Vrms

CAT III between either input and earth ground. These maximum ratings apply

regardless of the attenuation setting of the probe. Do not apply voltages greater than

1000 Vrms CAT II or 600 Vrms CAT III between either input and ground.

The probe tips that are provided are rated for 1000 Vrms CAT II and 600 Vrms CAT

III usage. Other probe tips may be used if they have the appropriate ratings and the

same style connectors.

Cleaning the Probe

Disconnect the probe from all power sources and clean it with a soft cloth dampened

with a mild soap and water solution. Be careful not to get water in the attenuation

switch. Make sure the probe is completely dry before reconnecting it to a power source.

8

Page 9

Using the N2790A Probe

Using the N2790A Probe

Powering the N2790A

The N2790A probe is powered by the autoprobe interface found on Agilent

InfiniiVision and Infiniium Se ries oscilloscopes.

Selecting the Correct Attenuation on the Probe and the Oscilloscope

The probe has two modes of operation, 50:1 and 500:1 attenuation. Select the desired

attenuation on the probe (via the switch on the probe) and the correct probe attenuation

setting on the oscilloscope. This will ensure that accurate voltage readings can be made

directly from the oscilloscope.

Adjusting the Probe Offset Level

The probe offset level is adjusted using the tool provided with the N2790A probe. Adjust the offset level by turning the potentiometer adjustment located on the autoprobe pod.

Measurement Tips

• Use the 50:1 range on the differential voltage probe for smaller signals, such

as ripple on a high voltage reference lead.

• Connect the red probe cable to a more positive or more negative voltage level

than the black probe cable.

• There is an overrange LED on the probe to indicate when you have exceeded

the maximum voltage of the probe.

9

Page 10

Service Strat egy

Service Strategy

For repair, calibration, and to ensure the N2790A performs to its warranted

specifications, send the probe to an Agilent Service Center for calibration testing

procedures. The probe should be tested once a year or as required by other standards.

If repair is needed and the N2790A is under warranty, normal warranty services will

apply. If the N2790A is not under warranty, repair costs will be applied.

To return the Probe to Agilent Technologies for Service

Call (877) 477-7278 for further details and the location of your nearest Agilent

Technologies Service Office.

1 Write the following information on a tag and attach it to the probe.

• Name and address of the owner

• Probe model number

• Description of service required or failure indication

2 Retain all accessories.

3 Return the probe in its case or pack the probe in foam or other

shock-absorbing material and place it in a strong shipping container. You can

use the original shipping materials or order materials from an Agilent

Technologies Sales Office. If neither are available, place 3 to 4 inches of

shock-absorbing material around the instrument and place it in a box that does

not allow movement during shipping.

4 Seal the shipment container securely.

5 Mark the shipping container as FRAGILE. In all correspondence, refer to the

instrument by model number and full serial number.

10

Page 11

Characterization Plots

10

6

10

7

10

8

-9

-6

-3

0

3

6

Vout/Vin

Vin

Vout

BW(-3dB) = 147

10

7

10

8

-80

-70

-60

-50

-40

-30

Characterization Plots

Graph of dB(Vin), dB(Vout), and dB(Vout/Vin) frequency response

Graph of dB (Vout/Vin) frequency response when inputs driven in common

(common mode rejection)

11

Page 12

Characterization Plots

Derating plot - above 2 MHz, the maximum input operating voltage decreases

as the frequency increases.

12

Page 13

Performance Verification Procedures

Performance Verification Procedures

The following procedure can be used to test and verify the DC differential gain accuracy

and bandwidth of the N2790A high voltage differential probe.

Required Test Equipment

Description Critical Specifications Recommended Model

Digitizing Oscilloscope Bandwidth: >100 MHz

Signal Generator

Precision DC voltage

source

BNC Adapter BNC (f) to Dual Banana (m)

50 BNC Feed Through

Adapter

1 M/50 selectable input

Amplitude accuracy: greater

than or equal to 0.25%

1 M/50 selectable load

Sine wave greater than or equal

to 25 MHz

Adapter

50 precision feed through Agilent 11048C Termination between

Part Number

Agilent MSO9254A Display probe output

Fluke 9500B or Fluke

5520A for DC source.

Fluke 9500B or Agilent

E8257D +1EU option for

AC source

Agilent 1251-2277 Interconnection

DC Differential Gain Accuracy

WARNING: These procedures require the application of high voltage to the

inputs of the N2790A probe. Because the adapter used in this procedure has

exposed metal surfaces, only qualified personnel should perform any testing with

voltage levels exceeding 30 V rms. All pertinent safety rules and guidelines for

elevated voltage measurements should be followed and adhered to.

WARNING: Generator produces hazardous voltages. To avoid risk of shock, do

not touch exposed metal parts after the generator output is enabled.

1 Set the volts/division on channel 1 of the oscilloscope to 20 mV/div. Set the seconds/

div to 200 s and the acquisition mode to average 32.

2 Set the volts/division on channel 2 of the oscilloscope to 50 mV/div. Trigger on channel

2, select 50 impedance.

3 Set the calibrator 9500B’s channel 2 as the trigger channel (50 load). Connect the

calibrator’s channel 2 active head to channel 2 of the oscilloscope.

4 Connect the active head channel 1 from the Fluke 9500B to channel 1 of the

oscilloscope. Set the calibrator channel 1 to 0.1V peak-to-peak amplitude and 1 KHz

(square wave, 1 M load), enable the output.

Functions

Signal source for DC

gain and bandwidth

between probe and

generator

probe and calibrator

for bandwidth

verification

13

Page 14

Performance Verification Procedures

5 Select the amplitude measurement on the oscilloscope and record the DC amplitude

(approximately 100 mV) of the square wave. This measurement is only the

oscilloscope.

6 Disable the Fluke calibrator output, disconnect the channel 1 active head from channel

1 of the oscilloscope.

7 Connect the output of the N2790A probe to channel 1 of the oscilloscope.

8 Attach the BNC adapter to the Fluke channel 1 active head.

9 Attach the differential probe input leads by clipping the alligator clamp to the BNC

adapter banana post.

10 Set the probe to 50:1. Set the Fluke calibrator to 10 V and 1 KHz standard amplitude

output (channel 1, square wave, 1 M load).

11 Enable the output of the calibrator.

12 Record the DC amplitude of the square wave and divide 50 into just the amplitude of

the oscilloscope. Verify that the probe gain accuracy is +/-2% + sc ope gain accuracy.

13 Set the calibrator to 100 V output and set the attenuation button on the probe to 500:1.

14 Record the DC amplitude of the square wave and divide 500 into just the amplitude of

the oscilloscope. Verify that the probe gain accuracy is +/-2% + scope gain accuracy.

15 Disable the calibrator output and leave the setup connected for the next procedure.

Bandwidth

1 Connect the 50 BNC feed through adapter to the calibrator’s active head channel 1.

2 Attach the BNC (f)-to-banana post adapter to the BNC feed through adapter.

3 Attach the differential probe input leads by clipping the alligator clamp to the BNC

adapter banana post.

4 Set the probe to 50:1 attenuation.

5 Set the volts/division on channel 1 of the oscilloscope to 10 mV/div and seconds/

division to 20 ns/div. Set the trace to the center of the oscilloscope. Input impedance

shoudl be set to 1 . Disable average mode.

6 Set the calibrator to sine wave, 5 V peak-to-peak amplitude. Set the frequency to 100

MHz, 50 load.

7 Write down the peak-to-peak amplitude measured by the oscilloscope. It should be

greater than or equal to 71 mV + scope error.

8 Disable the generator output and disconnect the probe input.

14

Page 15

Performance Verification Test Record

Performance Verification Test Record

Agilent Technologies

Recommended Test Interval: 1 Year

Recommended Date of Next Certification:_________

Certification Temperature:_____________________

N2790A 100 MHz Differential Probe

Serial No.:_______________________

Certification Date:_________________

Tested By:_______________________

_______________________________

_______________________________

Test Probe Settings Limits Results

Gain 50:1 196 mV to 204 mV

Gain 500:1 196 mV to 204 mV

Bandwidth 50:1 Greater than or equal to 71 mV

15

Page 16

Performance Verification Test Record

16

Page 17

Safety

!

Notices

This apparatus has been

designed and tested in

accordance with IEC Publi

cation 1010, Safety Requirements for Measuring

Apparatus, and has been

supplied in a safe condi

tion. This is a Safety Class I

instrument (provided with

terminal for protective

earthing). Before applying

power, verify that the cor

rect safety precautions are

taken (see the following

warnings). In addition, note

the external markings on

the instrument that are

described under "Safety

Symbols."

Warnings

• Before turning on the

instrument, you must con

nect the protective earth terminal of the instrument to

the protective conductor of

the (mains) power cord. The

mains plug shall only be

inserted in a socket outlet

provided with a protective

earth contact. You must not

negate the protective action

by using an extension cord

(power cable) without a pro

tective conductor (grounding). Grounding one

conductor of a two-conductor outlet is not sufficient

protection.

• Only fuses with the

required rated current, volt

age, and specified type (normal blow, time delay, etc.)

should be used. Do not use

repaired fuses or shortcircuited fuseholders. To do

so could cause a shock or

fire hazard.

• If you energize this instrument by an auto transformer (for voltage

reduction or mains isola

tion), the common terminal

must be connected to the

earth terminal of the power

source.

• Whenever it is likely that

the ground protection is

impaired, you must make

the instrument inoperative

and secure it against any

unintended operation.

• Service instructions are for

trained service personnel.

To avoid dangerous electric

-

-

-

-

shock, do not perform any

service unless qualified to do

so. Do not attempt internal

service or adjustment unless

another person, capable of

rendering first aid and

resuscitation, is present.

• Do not install substitute

-

parts or perform any unau

thorized modification to the

instrument.

• Capacitors inside the

instrument may retain a

charge even if the instru

ment is disconnected from

its source of supply.

• Do not operate the instrument in the presence of

flammable gasses or fumes.

Operation of any electrical

instrument in such an envi

ronment constitutes a definite safety hazard.

• Do not use the instrument

in a manner not specified by

the manufacturer.

To clean the instrument

If the instrument requires

cleaning: (1) Remove power

from the instrument. (2)

Clean the external surfaces

of the instrument with a soft

cloth dampened with a mix

ture of mild detergent and

water. (3) Make sure that

the instrument is com

pletely dry before recon-

necting it to a power source.

-

Safety Symbols

Instruction manual symbol: the product is marked

with this symbol when it is

necessary for you to refer to

-

the instruction manual in

order to protect against

damage to the product..

-

Hazardous voltage symbol.

Earth terminal symbol:

Used to indicate a circuit

common connected to

grounded chassis.

-

-

Agilent Technologies

P.O. Box 2197

1900 Garden of the Gods Road

Colorado Springs, CO 80901

Page 18

Notices

© Agilent Technologies, Inc.

2010

No part of this manual may

be reproduced in any form

or by any means (including

electronic storage and

retrieval or translation into

a foreign language) without

prior agreement and writ

ten consent from Agilent

Technologies, Inc. as governed by United States and

international copyright

laws.

Manual Part Number

N2790-97002, December

2010

Print History

N2790-97002, Dec 2010

N2790-97001, August 2010

N2790-97000, January 2009

Agilent Technologies, Inc.

1900 Garden of the Gods

Road

Colorado Springs, CO

80907 USA

Restricted Rights Legend

If software is for use in the

performance of a U.S. Government prime contract or

subcontract, Software is

delivered and licensed as

“Commercial computer

software” as defined in

DFAR 252.227-7014 (June

1995), or as a “commercial

item” as defined in FAR

2.101(a) or as “Restricted

computer software” as

defined in FAR 52.227-19

(June 1987) or any equiva

lent agency regulation or

contract clause. Use, dupli

cation or disclosure of Software is subject to Agilent

Technologies’ standard

commercial license terms,

and non-DOD Departments

and Agencies of the U.S.

Government will receive no

greater than Restricted

Rights as defined in FAR

52.227-19(c)(1-2) (June

1987). U.S. Government

users will receive no greater

than Limited Rights as

defined in FAR 52.227-14

(June 1987) or DFAR

252.227-7015 (b)(2) (Novem

ber 1995), as applicable in

any technical data.

-

ted by applicable law,

Agilent disclaims all

warranties, either

express or implied, with

regard to this manual

and any information

contained herein, includ

ing but not limited to the

implied warranties of

merchantability and fit

ness for a particular

purpose. Agilent shall

not be liable for errors

or for incidental or con

sequential damages in

connection with the fur

nishing, use, or performance of this document

or of any information

contained herein. Should

Agilent and the user

have a separate written

agreement with war

ranty terms covering the

material in this docu

ment that conflict with

these terms, the warranty terms in the separate agreement shall

control.

Technology Licenses

The hardware and/or soft-

ware described in this document are furnished under a

license and may be used or

copied only in accordance

with the terms of such

license.

-

-

-

WARNING

A WARNING notice

denotes a hazard. It

calls attention to an

operating procedure,

-

practice, or the like

that, if not correctly

performed or adhered

-

to, could result in

personal injury or

death. Do not proceed

-

beyond a WARNING

notice until the

-

indicated conditions

are fully understood

and met.

CAUTION

-

A CAUTION notice

-

denotes a hazard. It

calls attention to an

operating procedure,

practice, or the like

that, if not correctly

performed or adhered

to, could result in

damage to the

product or loss of

important data. Do

not proceed beyond a

CAUTION notice

until the indicated

conditions are fully

understood and met.

Document Warranty

The material contained

in this document is pro

vided “as is,” and is subject to being changed,

without notice, in future

editions. Further, to the

maximum extent permit

-

-

Page 19

Agilent Technologies

Printed in the Japan

Manual Part Number

N2790-97002

*N2790-97002*

Loading...

Loading...