Page 1

HP/Agilent 8922 GSM HSCSD Test System

Option #K09

Supplementary

User’s Guide

Systems Covered

HP/Agilent 8922 P Multi-Band Test System

Manufacturing Part Number: 08922-90218

© Copyright February 1999 Agilent Technologies

Page 2

Warranty

This Agilent Technologies instrument product is warranted against

defects in material and workmanship for a period of one year from date

of shipment.During the warranty period, Agilent Technologieswill at its

option, either repair or replace products which prove to be defective

Forwarrantyservice or repair,this product must be returned to a service

facility designated by Agilent Technologies. Buyer shall prepay shipping

charges to Agilent Technologies and Agilent Technologies shall pay

shipping charges, duties, and taxes for products returned to Agilent

Technologies from another country

Agilent Technologieswarrantsthatits software and firmware designated

by Agilent Technologies for use with an instrument will execute its

programming instructions when properly installed on that instrument.

Agilent Technologies does not warrant that the operation of the

instrument, or software, or firmware will be uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied software

or interfacing, unauthorized modification or misuse, operation outside of

the environmental specifications for the product, or improper site

preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT

TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

ii

Page 3

Limitation of Remedies and Liability

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. AGILENT TECHNOLOGIES SHALL NOT

BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON

CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Responsibilities of the Customer

The customer shall provide;

• Access to the products during the specified periods of coverage to

perform maintenance.

• Adequate working space around the products for servicing by Agilent

Technologies personnel.

• Access to and use of all information and facilities determined

necessary by Agilent Technologies to service and/or maintain the

products. (In so far as these items may contain proprietary or

classified information, the customer shall assume full responsibility

for safeguarding and protection from wrongful use.)

• Routine operator maintenance and cleaning as specified in the

Agilent Technologies Operating and Service Manuals.

• Consumables such as paper, disks, magnetic tapes, ribbons, inks,

pens, gases, solvents, lamps, filters, fuses, seals, etc.

Certification

Agilent Technologies certifies that this product met its published

specifications at the time of shipment from the factory. Agilent

Technologies further certifies that its calibration measurements are

iii

Page 4

traceable to the United States National Bureau of Standards and

Technology,to the extent allowed by the Bureau’s calibration facility,and

to the calibration facilities of other International Standards

Organization members.

Assistance

Product maintenance agreements and other customer assistance

agreements are available forAgilent Technologies products.

For any assistance, contact your local Agilent Technologies Sales and

Service Office. For a list of contact information, “Sales and Service

Offices” on page 72.

Notices

The information contained in this document is subject to change without

notice. AGILENT TECHNOLOGIES MAKES NO WARRANTYOF ANY

KIND WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT

LIMITED TO,THE IMPLIED WARRANTIESOF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. Agilent Technologies

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance

or use of this material.

Agilent Technologies assumes no responsibility for the use or reliability

of its software on equipment that is not furnished by Agilent

Technologies.

Restricted Rights Legend

If Software is for use in the performance of a U.S. Government prime

contract or subcontract, Software is delivered and licensed as

"Commercial computer software" as defined in DFAR252.227-7014(June

1995), or as a "commercial item" as defined in FAR 2.101(a) or as

iv

Page 5

"restricted computer software" as defined in FAR 52.227-19 (June 1987)

or any equivalent agency regulation or contract clause. Use, duplication

or disclosure of Software is subject to Agilent Technologies’ standard

commercial license terms and non-DOD Departments and Agencies of

the U.S. Government will receive no greater than Restricted Rights as

defined in FAR52.227-19(c)(1-2) (June 1987). U.S.Governmentusers will

receive no greater than Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR252.227-7015 (b)(2) (November 1995), as applicable

in any technical data. Copyright 2000 Agilent Technologies Inc. All

Rights Reserved.

Statement of Compliance

This product conforms to EN61010-1(1993) / IEC 1010-1(1990)

+A1(1992) +A2(1994) /CSA C22.2 No. 1010.1(1993) Safety requirements

for Electrical Equipment for Measurement, Control and Laboratory Use,

and has been supplied in a safe condition. The instruction documentation

contains information and warnings which must be followed by the user

to ensure safe operation and to maintain the instrument in a safe

condition.

Electromagnetic Compatibility (EMC)

Information

This product has been designed to meet the protection requirements of

the European Communities Electromagnetic Compatibility (EMC)

directive:

EN55011:1991 (Group 1, Class A)

EN50082-1:1992

- IEC 1000-4-2 (1995) ESD

- IEC 1000-4-3 (1995) Radiated Susceptibility

- IEC 1000-4-4 (1995) EFT

In order to preserve the EMC performance of this product, any cable

which becomes worn or damaged, must be replaced with the same type

and specification.

v

Page 6

Sound Emission

Manufacturer’s Declaration

This statement is provided to comply with the requirements of the

German Sound Emission Directive, from 18 January 1991.

This product has a sound pressure emission (at the operator position) <

70 dB(A).

• Sound Pressure Lp < 70 dB(A).

• At Operator Position.

• Normal Operation.

• According to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Schalldruckpegel Lp < 70 dB(A).

• Am Arbeitsplatz.

• Normaler Betrieb.

• Nach ISO 7779:1988/EN 27779:1991 (Typprfung).

Safety Information

The following general safety precautions must be observed during all

phases of operation, service, and repair of this instrument. Failure to

comply with these precautions or with specific warnings elsewhere in

this manual violates safety standards of design, manufacture, and

vi

Page 7

intended use of the instrument. Agilent Technologies assumes no

liability for the customer’s failure to comply with these requirements.

WARNING This is a Safety Class I instrument (provided with a protective

earthing ground, incorporated in the power cord). The mains

plug shall only be inserted in a socket outlet provided with a

protective earth contact. Any interruption of the protective

conductor inside or outside of the instrument is likely to make

the instrument dangerous. Intentional interruption is

prohibited.

DO NOT operate the product in an explosive atmosphere or in the

presence of flammable gasses or fumes.

DO NOT use repaired fuses or short-circuited fuseholders: For continued

protection against fire, replace the line fuse(s) only with fuse(s) of the

same voltage and current rating and type.

DO NOT perform procedures involving cover or shield removal unless

you are qualified to do so: Operating personnel must not remove

equipment covers or shields. Procedures involving the removal of covers

and shields are for use by service-trained personnel only.

DO NOT service or adjust alone: Under certain conditions, dangerous

voltages may exist even with the equipment switched off. To avoid

dangerous electrical shock, service personnel must not attempt internal

service or adjustment unless another person, capable of rendering first

aid and resuscitation, is present.

DO NOT operate damaged equipment: Whenever it is possible that the

safety protection features built into this product have been impaired,

either through physical damage, excessive moisture, or any other reason,

REMOVE POWER and do not use the product until safe operation can be

verified by service-trained personnel. If necessary, return the product to

an Agilent Technologies Sales and Service Office for service and repair

to ensure the safety features are maintained.

DO NOT substitute parts or modify equipment: Because of the danger of

introducing additional hazards, do not install substitute parts or perform

any unauthorized modification to the product. Return the product to an

Agilent Technologies Sales and Service Office for service and repair to

ensure the safety features are maintained.

vii

Page 8

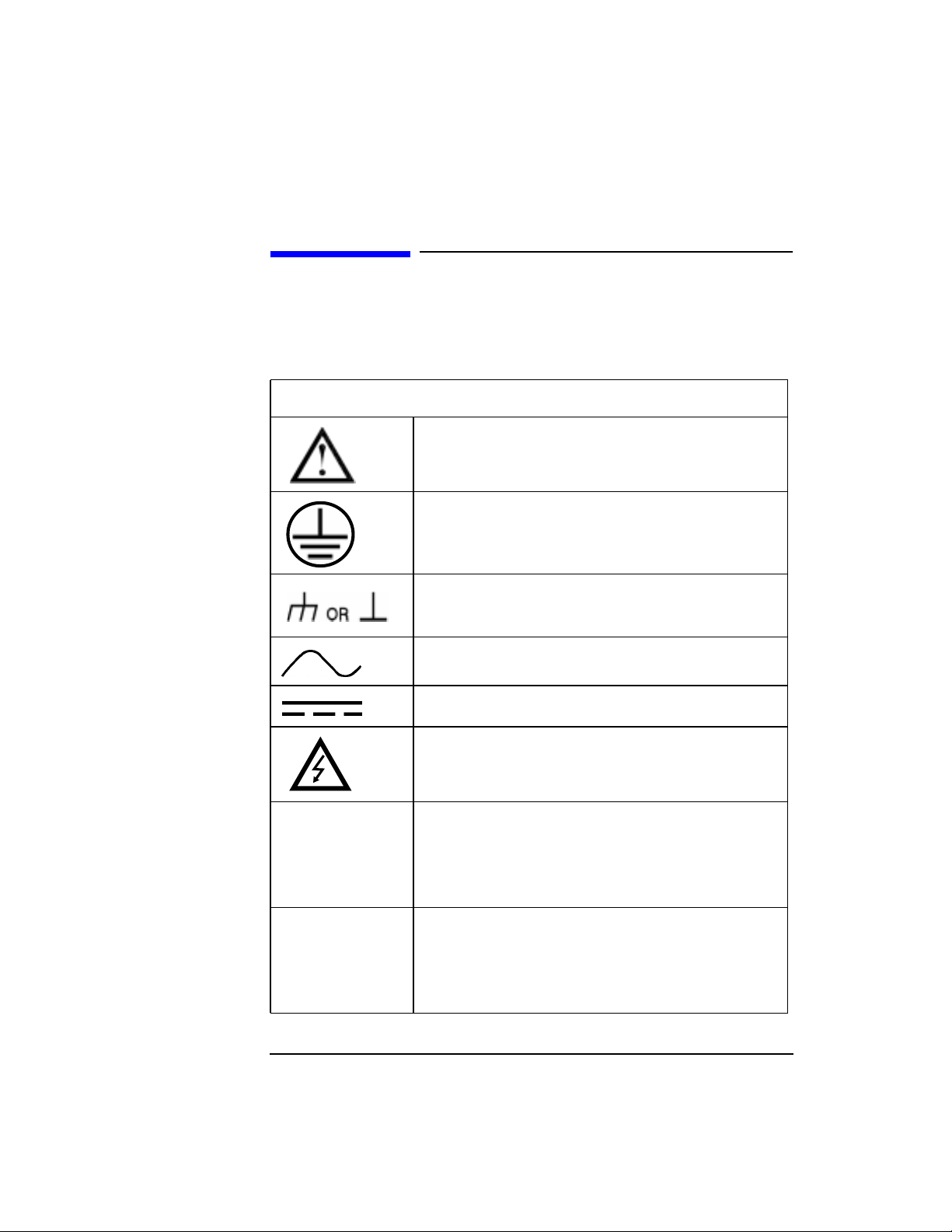

Safety Symbols

The following symbols on the instrument and in the manual indicate

precautions which must be taken to maintain safe operation of the

instrument

Safety Symbols

The Instruction Documentation Symbol. The product is

marked with this symbol when it is necessary for the user

to refer to the instructions in the supplied documentation.

Indicates the field wiring terminal that must be connected

to earth ground before operating the equipment - protects

against electrical shock in case of fault.

Frame or chassis ground terminal - typically connects to

the equipment's metal frame.

Alternating current (AC)

Direct current (DC)

Indicates hazardous voltages.

WARNING Warning denotes a hazard. It calls attention to a

procedure, which if notcorrectlyperformedoradheredto

could result in injury or loss of life. Do not proceed

beyond a warning note until the indicated conditions are

fully understood and met.

CAUTION Caution denotes a hazard. It calls attention to a

procedure, which if notcorrectlyperformedoradheredto

could result in damage to or destruction of the

instrument. Do not proceed beyond a warning note until

the indicated conditions are fully understood and met.

viii

Page 9

Safety Symbols

The CE mark shows that the product complies with all

relevant European Legal Directives.

ISM 1-A This is a symbol of an Industrial, Scientific, and Medical

Group 1 Class A product.

The CSA mark is a registered trademark of the Canadian

Standards Association, and indicates compliance to the

standards defined by them.

Indicates that a laser is fitted. The user must refer to the

manual for specific Warning or Caution information to

avoid personal injury or damage to the product.

ix

Page 10

About this Guide

Overview

This User’s Guide is a supplement to the manuals currently supplied

with the HP/Agilent 8922 GSM Test Sets. The information contained in

this User’s Guide is only relevant to the additional features of the HP/

Agilent 8922 GSM HSCSD Test System. For more information on the

HP/Agilent 8922 and HP/Agilent83220, refer the following Guides;

• Agilent 8922M⁄S User’s Guide

• Agilent 8922M⁄S Programming Reference Guide

• Agilent 83220A⁄E User’s Guide

• Agilent Multi-Band Test System Supplementary User’s Guide

User’s Guide - Abbreviations

For clarity, and unless otherwise stated, the following abbreviations will

be used:

HP/Agilent 8922P/X Option 010: this will be abbreviated to HP/

Agilent 8922

HP/Agilent 83220A/E Option 010: this will be abbreviated to HP/

Agilent 83220

x

Page 11

Contents

1. Understanding the HP/Agilent 8922 GSM HSCSD Test System

Getting an overview of the HP/Agilent 8922 GSM HSCSD Test System.2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2. Setting up the HP/Agilent 8922 GSM HSCSD Test System

Before you start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Checking the HP/Agilent 8922 Requirements for HSCSD . . . . . . . . . . . .7

Making the front panel connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Making the rear panel connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Enabling the HSCSD functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Calibrating the overall system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3. Manual operation

Configuring the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Establishing a call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Making measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Choosing which timeslot to measure. . . . . . . . . . . . . . . . . . . . . . . . . . .19

Measuring BER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Changing band and making measurements in the

E-GSM900 and DCS 1800 bands19

Changing power levels, timeslot and channels . . . . . . . . . . . . . . . . . . . .20

Ending a call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4. Screens

Config screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

1. Instrument type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2. Slave address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

xi

Page 12

Contents

HSCSD screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1. Master downlink amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2. Slave offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3. Master channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4. Master timeslot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5. Slave timeslot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6. Call Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7. Data rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8. Measure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9. Master Tx level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10. Master input level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11. Master mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

12. Slave Tx level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

13. Slave input level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14. Slave control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

15. Mobile reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

16. Peak power display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

17. To Screen menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Fast BER Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Loopback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5. Remote operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Configure Subsystem GPIB Commands . . . . . . . . . . . . . . . . . . . . . . . . . 43

CONFigure:INSTrument[:TYPE]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Display Subsystem GPIB Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DISPlay:SCReen HSCSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

HSCSD Subsystem GPIB Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . 45

HSCSd:MASTer:TCH:ARFCn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

HSCSd:MASTer:STATus:TCH:TSLot . . . . . . . . . . . . . . . . . . . . . . . . . 49

xii

Page 13

Contents

HSCSd:MASTer:DOWNlink:AMPLitude . . . . . . . . . . . . . . . . . . . . . . .50

HSCSd:MASTer:TCH:TLEVel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

HSCSd:MASTer:UPLink:AMPLitude. . . . . . . . . . . . . . . . . . . . . . . . . .52

HSCSd:MASTer:UPLink:AMPLitude:CONTrol. . . . . . . . . . . . . . . . . .53

HSCSD:MASTer:CALL:TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

HSCSD:MASTer:CALL:RATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

HSCSd:SLAVe:STATus:SYNC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

HSCSd:SLAVe:STATus:TCH:TSLot? . . . . . . . . . . . . . . . . . . . . . . . . . .57

HSCSd:SLAVe:DOWNlink:AMPLitude:OFFSet. . . . . . . . . . . . . . . . . .58

HSCSd:SLAVe:TCH:TLEVel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

HSCSd:SLAVe:UPLink:AMPLitude . . . . . . . . . . . . . . . . . . . . . . . . . . .60

HSCSd:SLAVe:UPLink:AMPLitude:CONTrol . . . . . . . . . . . . . . . . . . .61

Remote operating procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Configuring the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Establishing a call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Making measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Changing channels, timeslot and power levels. . . . . . . . . . . . . . . . . . .64

Ending a call. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Example code showing a dual-band handover from E-GSM to DCS . . .66

6. Returning equipment for repair

Return Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Sales and Service Offices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Asia Pacific:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Japan: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Australia/New Zealand: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Canada:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Europe: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Latin America: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

United States:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

xiii

Page 14

Contents

A. Upgrading the HOP Controller ROM and Firmware

Upgrading the Hop Controller ROM. . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Upgrading the firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

xiv

Page 15

1 Understanding the HP/Agilent

8922 GSM HSCSD Test System

This chapter provides an overview of the HP/Agilent 8922 GSM HSCSD

Test System.

1

Page 16

Understanding the HP/Agilent 8922 GSM HSCSD Test System

Getting an overview of the HP/Agilent 8922 GSM HSCSD Test System

Getting an overview of the HP/Agilent 8922

GSM HSCSD Test System

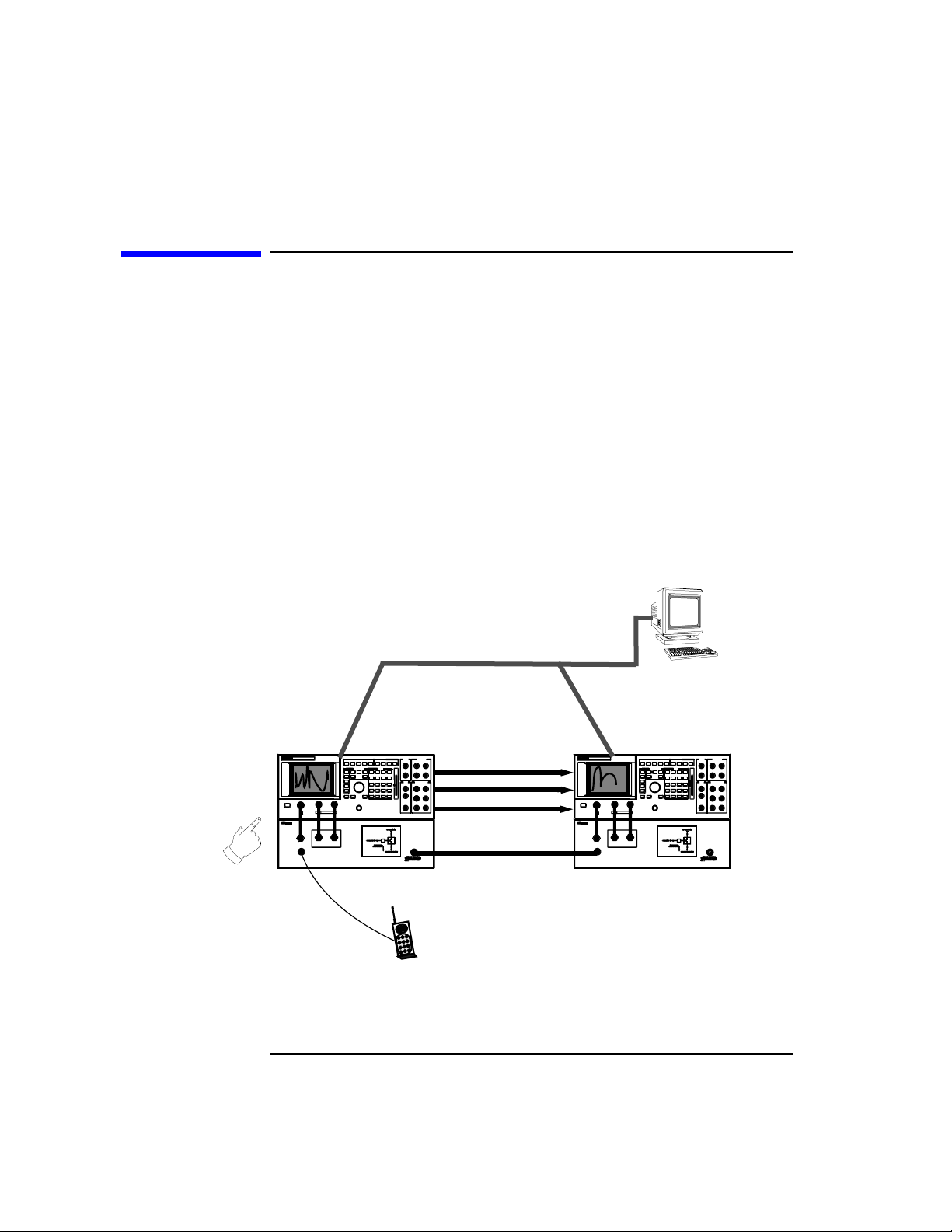

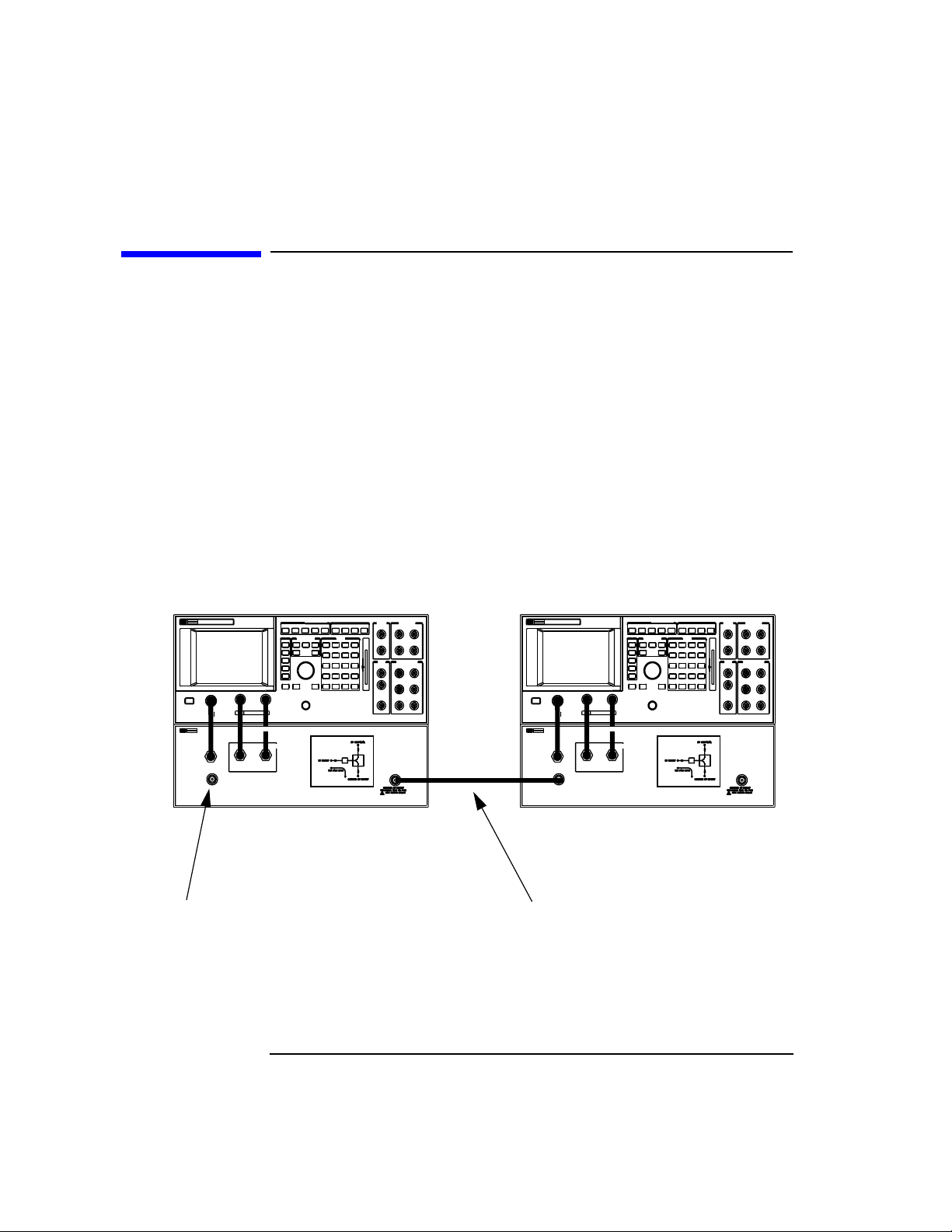

The HP/Agilent 8922 GSM HSCSD Test System option #K09, is ideal for

mobile testing in research and development, and can also be used in

manufacturing test applications. The HP/Agilent 8922 GSM HSCSD Test

System option #K09 consists of two HP/Agilent 8922 P systems

connected together in a master/slave setup as shown below.A single unit

version of the HP/Agilent 8922 GSM HSCSD TestSystem (option #K17),

ideal for manufacturing and service test, is also available.

Figure 1-1 The HP/Agilent 8922 GSM HSCSD Test System, option #K09

Master unit

Manual operation using

front panel user interface

2 Chapter1

Remote operation using

GPIB commands

Frame reset

10 MHz

GPIB control bus

Slave unit

Page 17

Understanding the HP/Agilent 8922 GSM HSCSD Test System

Getting an overview of the HP/Agilent 8922 GSM HSCSD Test System

The HP/Agilent 8922 GSM HSCSD Test System is used either as a

stand-alone instrument controlled manually via the front panel user

interface, or as part of an automated test system controlled remotely

over the GPIB bus using a PC or workstation. Note that manual and

remote operation are not possible simultaneously.

The HP/Agilent 8922 GSM HSCSD Test System provides one

configuration consisting of two uplink and two downlink timeslots (2x2)

or two downlink and one uplink timeslot (2x1). Data rates of 9.6 and 14.4

kbit/s on each timeslot are supported. The timeslots used are always

adjacent, with the master channel in the first of these slots. You are able

to independently change the uplink and downlink power levels on the

two downlink timeslots and make measurements on either timeslot as

required.

Note that the system does not perform any data channel decoding on the

uplinks and only provides pre-coded data on the downlinks. The current

system only allows transparent data links, which means that the RLP

data layer is not supported.

Operating modes The master unit operates in Active Cell Mode and is responsible for all

protocol messages. The mobile must therefore camp to the master unit,

establish the call to it and receive channel assignment commands from it

etc.

The slave unit operates in Test Mode. It generates a second downlink

TCH and can analyze a second uplink TCH (if it exists). The slave unit

remains in synchronization with the master unit at all times.

The BCH of the slave unit includes information to prevent the mobile

from camping to the slave, thus ensuring that the mobile camps to the

master unit. To discourage unsynchronised operation, the slave unit does

not generate a downlink TCH unless it has received a reset signal from

the master unit.

Chapter 1 3

Page 18

Understanding the HP/Agilent 8922 GSM HSCSD Test System

Features

Features

The HP/Agilent 8922 GSM HSCSD Test System supports the following

features. The full range of features available in speech mode is

maintained.

• Support of fully variable power level of each active timeslot on the

downlink. This provides complete freedom to control the amplitude of

the downlinks.

• Support of fully independent power control by protocol of each active

timeslot on the uplink. This allows you to independently set the Tx

level of each timeslot.

• Transmit SACCH in each active slot on the downlink (call

maintenance + power control) according to ETSI multi-frame

structure. This provides a SACCH frame in the correct position on

both the downlink TCHs.

• All existing measurement functionality and performance maintained

and performed on any slot independently. Youcan select either uplink

slot to measure, either by selecting one instrument or via a field on

the user interface.

• Support of protocol to set up a 2x2 or 2x1, 9.6 or 14.4 kbps timeslot

uplink/downlink data channel (both Mobile Originated and Mobile

Terminated). The existing HP/Agilent 8922P functionality to

originate or receive a call is still available.

• Support of burst-by-burst (fast) BER test on both 14.4 kbps timeslot

data channels simultaneously. The existing bit error test functionality

of the HP/Agilent 8922P is available in speech mode only.

• You can select any timeslot for the master channel in the range 2

through 5. The slave timeslot is always the following slot. Any

ARFCN can be used in any of the currently supported bands

(GSM900, E-GSM, DCS1800 and PCS1900).

• Dual-band assignment supported. The existing HP/Agilent 8922P

functionality to perform a dual-band assignment is maintained.

• All 2x2 HSCSD calls are in transparent mode and all 2x1 calls are in

non-transparent mode.

4 Chapter1

Page 19

2 Setting up the HP/Agilent 8922

GSM HSCSD Test System

This chapter describes how to connect and set up the HP/Agilent 8922

GSM HSCSD Test System.

5

Page 20

Setting up the HP/Agilent 8922 GSM HSCSD Test System

Before you start

Before you start

WARNING The HP/Agilent 8922 is a Safety Class 1 product (provided with a

protective earth terminal). A safety earth ground must be

provided from the mains power source to the product input

wiring terminals, power cord, or supplied power cord set.

Whenever it is likely that the protection has been impaired, the

HP/Agilent 8922 GSM HSCSD Test System must be made

inoperative and be secured against any unintended operation.

WARNING If the HP/Agilent 8922 is to be energized via an external

autotransformer for voltage reduction, make sure that the

common terminal is connected to the neu tral pole of the power

source.

6 Chapter2

Page 21

Setting up the HP/Agilent 8922 GSM HSCSD Test System

Checking the HP/Agilent 8922 Requirements for HSCSD

Checking the HP/Agilent 8922 Requirements

for HSCSD

To run the HSCSD functionality you need two HP/Agilent 8922 P

systems (one acting as a master and one acting as a slave). Each system

must be running firmware version C.01.06 or later and contain a HOP

Controller ROM with a revision number of 19980730 or greater.

To check which version of firmware is running on the HP/Agilent 8922,

go to the Config screen.

To check which version of HOP Controller ROM is installed in the HP/

Agilent 8922, go to the Service screen and select the hop_revision latch.

For details on how to upgrade the HP/Agilent 8922’s HOP Controller

ROM and firmware, see Appendix A , “Upgrading the HOP Controller

ROM and Firmware,” on page 75.

Chapter 2 7

Page 22

Setting up the HP/Agilent 8922 GSM HSCSD Test System

Making the front panel connections

Making the front panel connections

Before you connect the two HP/Agilent 8922 P systems together to form

the HP/Agilent 8922 GSM HSCSD Test System, ensure that both HP/

Agilent 8922 P systems are connected and calibrated as described in the

HP/Agilent 8922 Multi-Band Test System Supplementary User’s Guide.

For details on the HP/Agilent 8922P front panel connections, see the HP

8922 Multi-Band Test System Supplementary User’s Guide.

The RF flow must be combined and split between the two HP/Agilent

8922P systems. This is done by connecting the supplied RF link cable

(08922-61185) between the Coupled RF Port on the dual band HP/

Agilent 83220 of the master unit and the GSM/DCS/PCS RF In/Out port

on the HP/Agilent 83220 of the slave unit.

Figure 2-1 Front panel connections

Master Slave

Connect mobile here RF link cable

8 Chapter2

Page 23

Setting up the HP/Agilent 8922 GSM HSCSD Test System

Making the rear panel connections

Making the rear panel connections

Before connecting the two HP/Agilent 8922 P systems to form the HP/

Agilent 8922 GSM HSCSD Test System, ensure that both HP/Agilent

8922 P systems are connected and calibrated as described in the HP/

Agilent 8922 Multi-Band Test System Supplementary User’s Guide. See

the HP/Agilent 8922 GSM Test Set User’s Guide and the HP/Agilent

83220 User’s Guide for details on the rear panel connections.

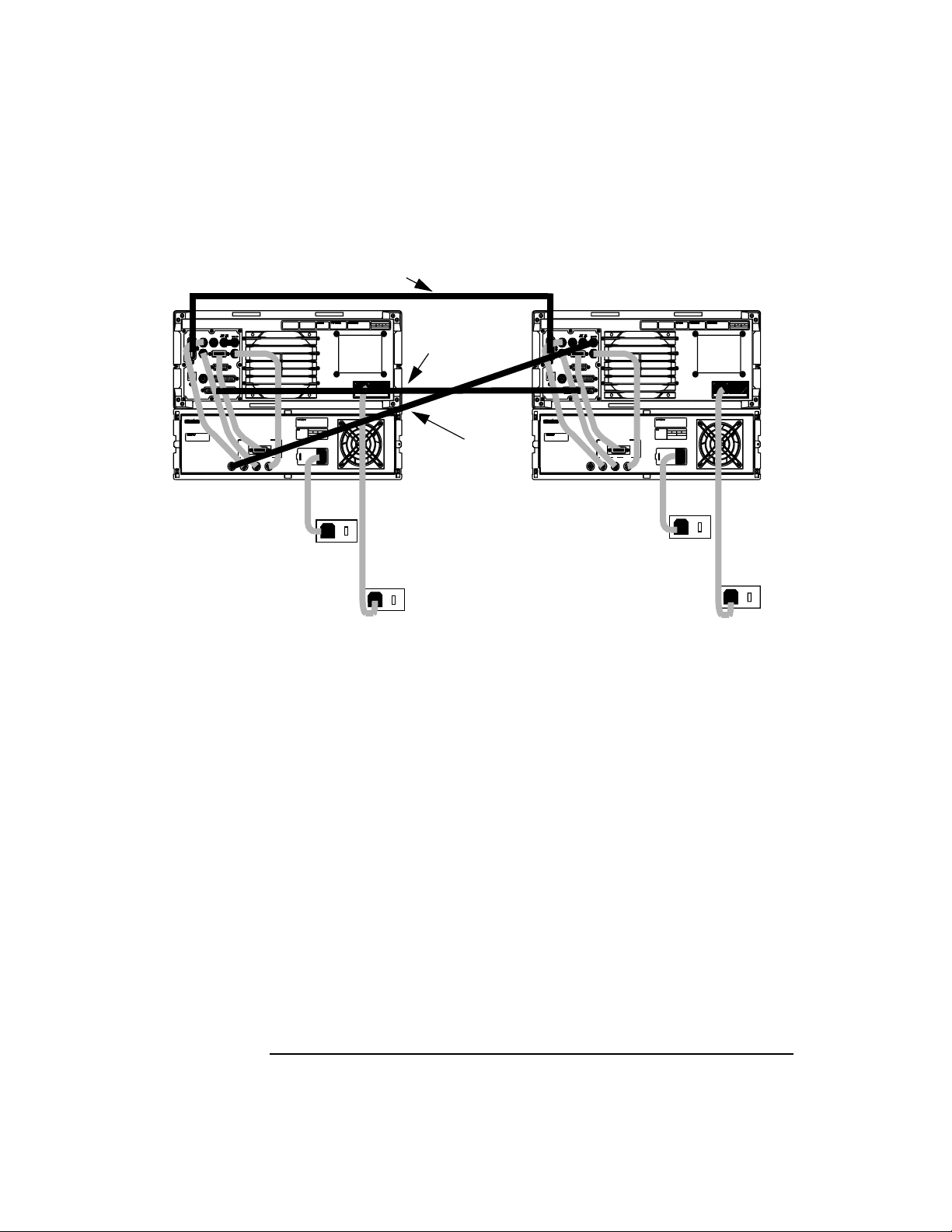

Tomake the rear panel connections of the HP/Agilent 8922 GSM HSCSD

Test System:

Step 1. Connect the system bus cable from the master unit to the slave unit (the

end with the BNC connection must be connected to the master unit).

If you are not connecting the BNC connector on the system bus cable to

for example, a spectrum analyzer, then terminate the connection using

the BNC terminator provided.

Step 2. Connect the GPIB cable from the GPIB port on the master unit to the

GPIB port on the slave unit.

NOTE If you are operating the HP/Agilent 8922 GSM HSCSD Test System

manually do not connect another GPIB controller to the GPIB bus. The

master unit operates as the controller and another device attached to the

GPIB bus results in conflicts on the GPIB bus.

Step 3. Connect the 10 MHz reference cable from the 10MHz OUT port on the

master unit to the Ref IN port on the HP/Agilent 83320 of the slave unit.

The HSCSD connections are shown below.

Chapter 2 9

Page 24

Setting up the HP/Agilent 8922 GSM HSCSD Test System

Making the rear panel connections

Figure 2-2 Rear panel connections

GPIB cable

System bus cable

10 MHz reference

cable

Master

Slave

10 Chapter2

Page 25

Setting up the HP/Agilent 8922 GSM HSCSD Test System

Enabling the HSCSD functionality

Enabling the HSCSD functionality

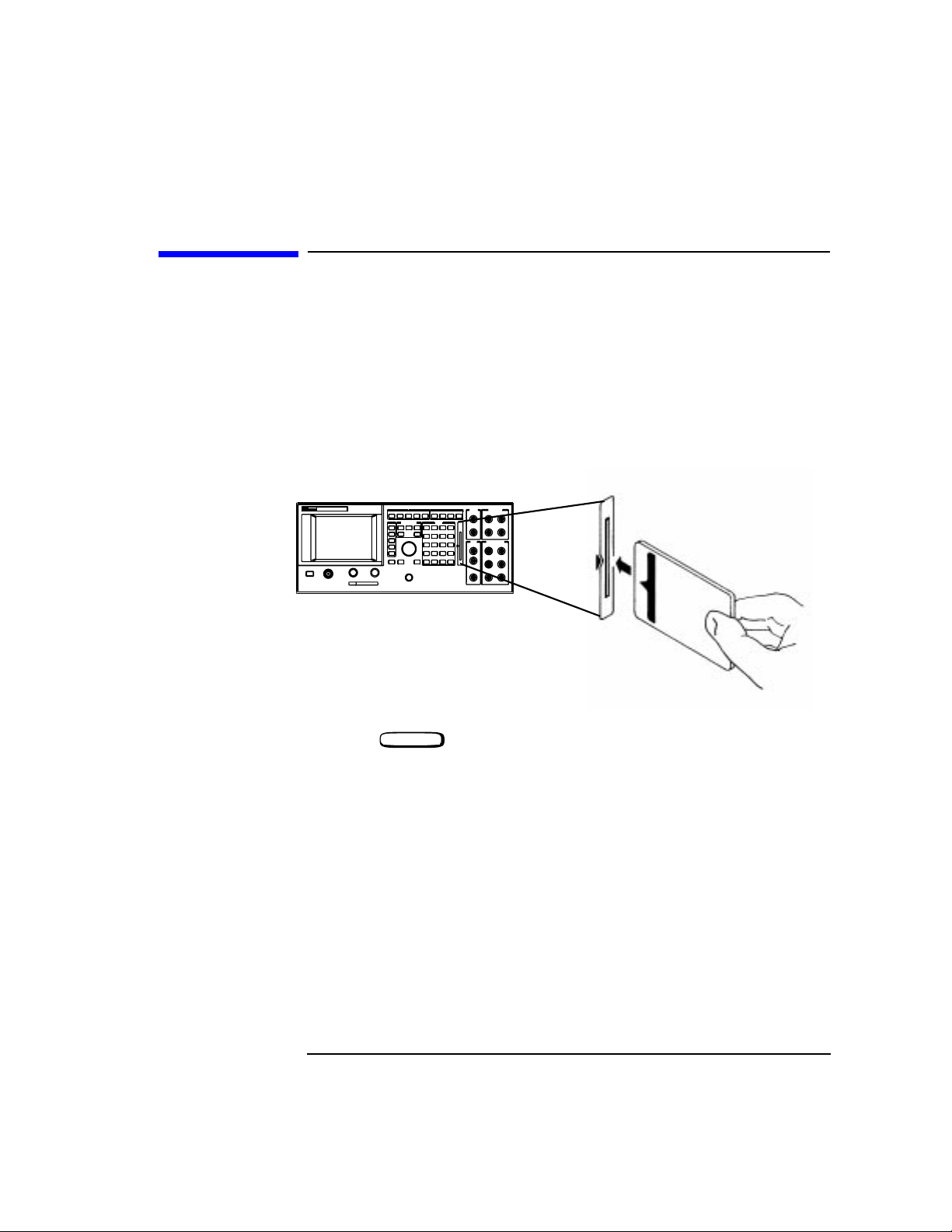

You must enable the HSCSD test functionality within the HP/Agilent

8922 using the keycard supplied as follows.

Step 1. Power on the HP/Agilent 8922.

Step 2. Insert the keycard into the HP/Agilent 8922.

Figure 2-3 Inserting the keycard into the HP/Agilent 8922

Step 3. Press the key on the front panel of the HP/Agilent 8922 to

access the TESTS screen.

Chapter 2 11

TESTS

Page 26

Setting up the HP/Agilent 8922 GSM HSCSD Test System

Enabling the HSCSD functionality

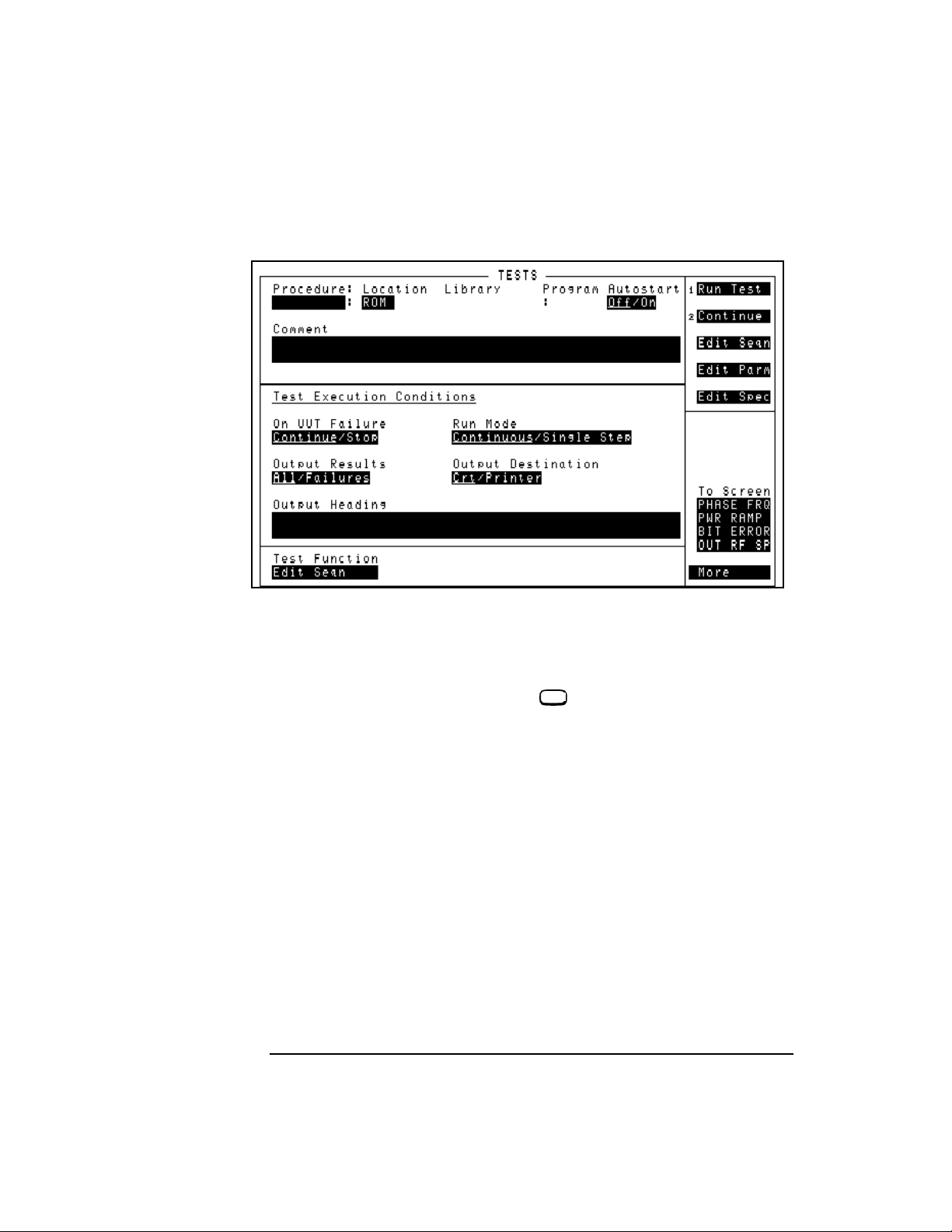

Figure 2-4 Tests screen

Step 4. Set Location to CARD.

Step 5. Select the Procedure field and select ENABLE as the procedure.

Step 6. Select the Run Test field or press the key on the front panel of the

HP/Agilent 8922 to run the program.

The option HSCSD Master is now present in the Instrument Type field

in the CONFIGURE screen indicating that the HSCSD functionality is

correctly enabled.

12 Chapter2

L1

Page 27

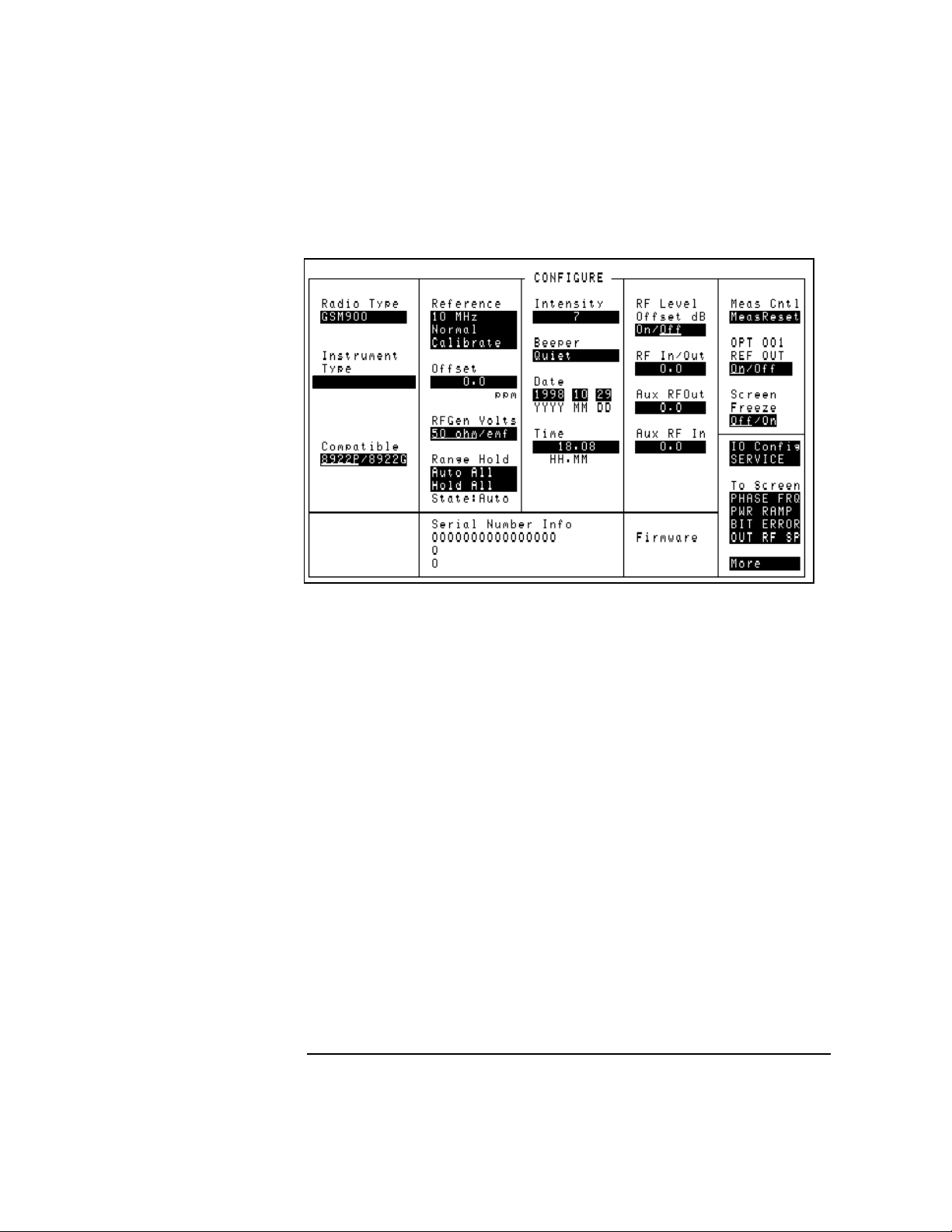

Figure 2-5 Config screen

HSCSD MASTER

Setting up the HP/Agilent 8922 GSM HSCSD Test System

Enabling the HSCSD functionality

C.01.06

To disable HSCSD

functionality

To disable the HSCSD functionality, repeat steps 1 to 4 of the procedure

for enabling the functionality, set the Procedure field to DISABLE in step

5 and complete the rest of the procedure.

Chapter 2 13

Page 28

Setting up the HP/Agilent 8922 GSM HSCSD Test System

Calibrating the overall system

Calibrating the overall system

There is an RF loss through the system from the slave unit's reported

output level to that observed by the mobile due to cable loss and a

nominal 7 dB loss through the system. Therefore once you have

connected the HP/Agilent 8922 GSM HSCSD Test System and calibrated

each unit individually (see the HP/Agilent 8922 Multi-Band Test System

Supplementary User’s Guide), you must calibrate the overall system to

account for these losses. To do this you need to adjust the RF Level

Offset field on the Config screen. To determine the necessary RF Level

Offset adjustments:

Step 1. Connect a mobile to the HP/Agilent 8922 master unit and set up a call as

described in Chapter 3 , “Manual operation,” on page 15.

Step 2. Go to HSCSD Control screen on both units and set each unit to measure

the master uplink slot.

Step 3. Go the Config screen on both units and set the RF Lev Offset so that

the transmitted power level of the master and slave units are the same.

When the transmitted power level is the same on both the master and

slave units the system is calibrated to account for its RF losses.

NOTE RF losses may be different for GSM and DCS radio modes, therefore it is

recommended that you perform calibration for both GSM and DCS.

NOTE You must calibrate the system whenever any of the following occur:

• The HP/Agilent 8922 GSM HSCSD Test System is first set up.

• Any hardware component in the system is changed (HP/

Agilent 83220 and/or HP/Agilent 8922).

• Different IF Link or Aux RF In/Out cables are used.

• After a RAM Initialize or Firmware Upgrade.

• You need to troubleshoot the system or localize faults.

14 Chapter2

Page 29

3 Manual operation

This chapter describes the basic procedures required to manually

operate the HP/Agilent 8922 GSM HSCSD Test System. For more details

on operating procedures, refer to the HP/Agilent 8922M⁄S User’s Guide.

15

Page 30

Manual operation

Configuring the system

Configuring the system

To configure the HP/Agilent 8922 GSM HSCSD Test System for manual

operation, proceed as follows.

NOTE You must configure the slave unit first as a frame reset is sent from the

master unit to the slave unit as soon as the master unit is activated. The

slave unit must be ready to receive this frame reset.

NOTE If you are operating the HP/Agilent 8922 GSM HSCSD Test System

manually do not connect another GPIB controller such as a PC to the

GPIB bus. The master unit operates as the controller and any other

device attached to the GPIB bus can result in conflicts on the GPIB bus.

Step 1. On the slave unit, navigate to the CONFIG screen and set the Instrument

Type to HSCSD Slave.

Figure 3-1 Config screen

16 Chapter3

C.01.06

Page 31

Manual operation

Configuring the system

The slave unit’s GPIB address is now automatically set to 15 (seen in the

IO Config screen) which is the default Slave Address setting on the

master unit. The slave unit’s GPIB address must be the same as the

Slave Address setting on the master unit and this helps to ensure this.

The slave unit’s Operating Mode is also automatically set to Test Mode

(seen in the Cell Status screen).

NOTE If the HP/Agilent 8922 GSM HSCSD Test System is not fitted with a new

HOP Controller ROM, selecting HSCSD Master or HSCSD Slave results

in the error Hardware portion of upgrade not present. The test set

will allow HSCSD operation, however the downlink signal could be

scrambled when the TCH ARFCN is on or near the master or slave unit’s

BCH ARFCN. For details on upgrading the HOP Controller ROM, see

Appendix A , “Upgrading the HOP Controller ROM and Firmware,” on

page 75

Step 2. On the master unit, go to the CONFIGURE screen and set the Instrument

Type to HSCSD Master.

The master unit’s Operating Mode is now automatically set to Active

Cell Mode (seen in the Cell Status screen).

The message Frame reset sent appears in the top left-hand corner of

the master unit’s screen indicating that the master unit has sent the

frame reset to the slave unit.

Note that the Slave Address field is set to 15 as default. This must

match the slave unit’s GPIB address, therefore if you change the Slave

Address setting on the master unit, you must also change the slave

unit’s GPIB address to match.

Chapter 3 17

Page 32

Manual operation

Establishing a call

Establishing a call

You establish a call in the same way as for a speech call.

Step 1. Ensure that the master timeslot is the timeslot currently being

measured on the master unit.

Todo this, navigate to the HSCSD control screen on the master unit and

set the Measure field to Master. If you do not do this the HP/Agilent 8922

does not see the signalling from the mobile, and call set up fails.

Step 2. Configure the call by navigating to the HSCSD control screen on the

master unit, and setting Call Type as a 2x2 or 2x1 and Data Rate to 9.6

or 14.4 kbits/s as required.

Step 3. Connect the mobile to the RF IN/OUT port located on the front panel of

the master unit’s HP/Agilent 83220 (see the HP/Agilent 8922 Multi-

Band Test System Supplementary User’s Guide for more information

about this port).

Step 4. Switch on the mobile.

The mobile now camps onto the broadcast channel.

Step 5. Once the mobile is connected and successfully camped on to the master

unit, initiate the call from the mobile (for example, by pressing SEND on

the mobile, or by pressing ORG CALL on the HP/Agilent 8922 master

unit). The display on the HP/Agilent 8922 now shows that the call status

is CONNECTED.

If the call cannot be established, it may be because the uplink power may

differ from the HP/Agilent 8922’s expected input level. The most likely

reason for this type of problem is that the mobile or the IF Link cable has

not been calibrated. For details on calibrating the system “Calibrating

the overall system” on page 14.

18 Chapter3

Page 33

Manual operation

Making measurements

Making measurements

Once a call is established, you can make measurements as before—see

the HP/Agilent 8922 User’s Guide for more details. Note however that

there are two new factors which you need to consider: choosing which

timeslot to perform measurements on, and performing BER on the twounit system.

Choosing which timeslot to measure

Any HSCSD instrument can measure the master or the slave timeslot.

This selection is made on the HSCSD control screen, and the

measurements on this screen include a reminder of which slot is

currently being analysed. On other screens, where this reminder is not

present, you must be aware of which slot you are measuring.

Measuring BER

To perform BER, one instrument starts a measurement, while the other

makes the measurement. Specifically, to perform BER on the slave

timeslot, you must start the BER measurement on the master unit

because it is the master unit which performs the signalling to place the

mobile in loopback mode. Once this is done, the BER measurement must

be started on the slave unit, where it will then run as normal. After the

measurement is complete, and the master unit is returned to a different

screen, the HP/Agilent 8922 signals the mobile and takes it back out of

loopback mode.

Changing band and making measurements in the

E-GSM900 and DCS 1800 bands

Changing band and making measurements in the E-GSM900 and

DCS1800 bands are performed in the same way as for the HP/Agilent

8922 Multi-Band System. See the HP/Agilent8922 Multi-Band Test

System Supplementary User’s Guide for details.

Chapter 3 19

Page 34

Manual operation

Changing power levels, timeslot and channels

Changing power levels, timeslot and channels

You can change downlink and uplink power, TCH timeslot, and TCH

ARFCN simply be typing in a new value on the HSCSD control screen. A

dual band channel assignment can be performed using the existing

procedure.

Figure 3-2 HSCSD control screen

20 Chapter3

Page 35

Manual operation

Ending a call

Ending a call

Ending a call is the same procedure as that used for a standard HP/

Agilent 8922 Test System, however the master unit must be measuring

the master timeslot. Refer to the HP/Agilent 8922M⁄S User’s Guide for

more information.

NOTE To ensure that the call ends cleanly, the master unit must be measuring

the master timeslot when the call is ended.

Chapter 3 21

Page 36

Manual operation

Ending a call

22 Chapter3

Page 37

4 Screens

This chapter describes the screens that are part of the HP/Agilent 8922

GSM HSCSD Test System. For more details on all other screens, refer to

the HP/Agilent 8922M⁄S User’s Guide. These screens are only available

for firmware revision C.01.06 and later.

23

Page 38

Screens

Config screen

Config screen

Figure 4-1 Config screen

1

2

C.01.06

1. Instrument type

Type menu

Choices Speech

HSCSD Master

HSCSD Slave

Default Speech

HSCSD Master and HSCSD Slave indicate that the HP/Agilent 8922 is

part of a multi-box solution.

Note that selecting HSCSD Master temporarily sets the GPIB control

field on the IO Config screen to Control (this happens whenever the

master unit sends a user change to the slave unit). Before the master

unit can control the slave unit, you must:

24 Chapter4

Page 39

Screens

Config screen

• set the slave GPIB address to match the address of the slave unit

• make sure that the addresses of the slave and master units are

different

• make sure that no other GPIB controller is active and attached to the

system

NOTE If you are operating the HP/Agilent 8922 GSM HSCSD Test System

manually do not connect another GPIB controller such as a PC to the

GPIB bus. The master unit operates as the controller and any other

device attached to the GPIB bus can result in conflicts on the GPIB bus.

Selecting HSCSD Slave sets the GPIB address of the instrument to 15 to

match the default slave GPIB address of the master unit.

If the HP/Agilent 8922 GSM HSCSD Test System is not fitted with a new

HOP Controller ROM, selecting HSCSD Master or HSCSD Slave results

in the error Hardware portion of upgrade not present. The test set

will allow HSCSD operation, however the downlink signal could be

scrambled when the TCH ARFCN is on or near the master or slave unit’s

BCH ARFCN. For details on upgrading the HP/Agilent 8922’s HOP

Controller ROM, see “Upgrading the HOP Controller ROM and

Firmware” on page 75.

NOTE The Instrument type field is reset to the default in the event of a reset

or power cycle. Setting this field also resets all the default values on the

HSCSD Control screen.

Chapter 4 25

Page 40

Screens

Config screen

2. Slave address

Type integer

Units none (HP-IB address)

Limits 0 thru 30

Default 15

The Slave address field appears only if you have selected HSCSD

Master as the instrument type and is the address used by the master

unit to send GPIB commands to the slave unit. This is only used when

the instrument is being operated manually.

NOTE You must ensure that the GPIB address on the slave unit matches the

value configured in the Slave address field on the master unit. The

GPIB address of the slave unit is set in the IO Config screen. However,

if you set the instrument type as HSCSD Slave, the GPIB address of the

slave is automatically set to 15 which is the default value of the Slave

address field on the master unit.

NOTE The default value is reset after a reset or power cycle. Note also that

changing the instrument type does not reset the value of this field.

26 Chapter4

Page 41

HSCSD screen

Figure 4-2 HSCSD Control screen

1

Screens

HSCSD screen

2

3

4

5

6

7

8

9, 12

10, 13

12 14

15

16

17

1. Master downlink amplitude

Type floating point

Units dBm only

Limits (GSM900) -127.0 thru +1.0

Limits (E-GSM) -127.0 thru +1.0

Limits (DCS1800) -127.0 thru -12.0

Limits (PCS1900) -127.0 thru -12.0

Default -85.0

The Master downlink amplitude field shows the downlink amplitude

of the master TCH. The amplitude of the slave TCH is calculated by

Chapter 4 27

Page 42

Screens

HSCSD screen

adding an offset (see page 28) to this value.

NOTE The default is reset when you select the instrument type (see page 24).

2. Slave offset

Type floating point

Units dBm only

Limits (GSM900) -100.0 thru +100.0

Default 0.0

The Slave offset field determines the downlink amplitude of the

master TCH by selecting the difference in amplitude between the master

and slave amplitudes. Below this field there is a read-only reminder of

the absolute level of the slave TCH.

Note that the resultant absolute amplitude must lie within the normal

RF generator limits (-127.0 thru +1.0 dBm). The error Disallowed due

to pulse mod configuration is returned if these limits are exceeded.

On a master unit, changing the Slave offset field has no effect other

than copying the value to the slave unit when being operated manually.

On a slave unit, changing the Slave offset field changes the downlink

amplitude of the unit. This field, when added to the master downlink

amplitude (see page 27) always has the same value as the RF I/O

generator amplitude.

NOTE The default is reset when the instrument type (see page 24) is selected.

3. Master channel

Type integer

Units none (ARFCN)

28 Chapter4

Page 43

Screens

HSCSD screen

Limits (GSM900) 1 thru 124

Limits (E-GSM) 0 thru 124; 995 thru 1024

Limits (DCS1800) 512 thru 885

Limits (PCS1900) 512 thru 810

Default (GSM900) 30

Default (E-GSM) 30

Default (DCS1800) 512

Default (PCS1900) 512

The Master Channel field shows the ARFCN of the TCH. There is only

one ARFCN, as HSCSD systems place all timeslots on the same ARFCN.

On a slave unit, setting this field changes the ARFCN of the downlink

TCH and analyzer appropriately.

On a master unit, this field sets the TCH ARFCN of the current call, or

the TCH ARFCN to be used for the next call. An assignment command is

sent to the mobile on the downlink FACCH.

If you try to change the ARFCN but the measurement timeslot (see page

32) is set to Slave, an error occurs and the setting is ignored. Without

this error, the acknowledgment from the mobile would be missed if the

HP/Agilent 8922 is analyzing the slave timeslot. The error reported is

Select ‘Master’ to measure before signalling mobile.

The value of this field is always the same as the TCH ARFCN on the Cell

Status screen.

NOTE The default is reset when the instrument type (see page 24) is selected.

Chapter 4 29

Page 44

Screens

HSCSD screen

4. Master timeslot

Type integer

Units none (timeslot)

Limits 2 thru 5

Default 4

The Master timeslot field indicates which timeslot is used for the

master TCH. As the slave TCH is always in the timeslot immediately

after the master, changing this field sets the slave timeslot to the value

“master timeslot plus one”.

On a master unit or a single unit, the value of this field is always the

same as the TCH timeslot field on the Cell Status screen.

NOTE The default is reset when the instrument type (see page 24) is selected.

5. Slave timeslot

Type read-only

Values 3 thru 6

Default 5

The relative position of the slave timeslot is fixed at +1. Therefore, if the

master timeslot is set to 3, the slave timeslot is set to 4. Likewise, as the

master timeslot changes, this field also changes.

On a slave unit, the value of this field is always the same as the TCH

timeslot field on the Cell Status screen.

NOTE The default is reset when the instrument type (see page 24) is selected.

30 Chapter4

Page 45

Screens

HSCSD screen

6. Call Type

Type Toggle

Units None

Default 2x2

Values 2x2 or 2x1

The Call Type field determines which type of HSCSD call the HP/

Agilent 8922 establishes the next time a call is initiated.

If you select 2x1, the HP/Agilent 8922 tries to establish a call with 2

downlinks and 1 uplink when a call is next initiated. The measure

timeslot field will no longer be visible, nor will the controls concerned

with the second uplink (Slave TX level, Slave input level, Slave

input level control mode).

If you select 2x2, the HP/Agilent 8922 sets up a call with 2 downlinks

and 2 uplinks. The Measure timeslot field appears, along with controls

associated with the second uplink. The Measure timeslot field is set to

the default for each unit (slave for slave, master for master).

NOTE Each of these changes is subject to the conditions that a call must not be

in progress when the change to this field is made and that the field will

not change if changing the slave timeslot would make it take on an

illegal value.

Chapter 4 31

Page 46

Screens

HSCSD screen

7. Data rate

Type Toggle

Units None

Choices “9.6” or “14.4”

Default “9.6”

The Data rate field determines the data rate associated with the

HSCSD 2x2 call. Selecting '9.6' sets up a call at 9.6 kbit/s per timeslot

(19.2 kbit/s) and selecting '14.4' sets up a call at 14.4 kbit/s per timeslot

(28.8 kbit/s).

NOTE The value of the Data rate field can not be changed while a call is in

progress.

8. Measure

Type Toggle

Units None

Choices “Master” or “Slave”

Default (slave unit) “Slave”

Default (other units) “Master”

The Measure field sets which of the uplink TCHs are to be measured or

demodulated. The display updates (next to the Mobile reports and

Peak Power displays) to show which timeslot is being analyzed.

The Measure field also selects which analyzer level to use, either the

Master input level (see page 34) or the Slave input level (see

page 36).

NOTE The default is reset when you select the instrument type (see page 24).

32 Chapter4

Page 47

Screens

HSCSD screen

9. Master Tx level

Type integer

Units none (Tx level)

Limits (GSM900) 1 thru 19

Limits (E-GSM) 1 thru 19

Limits (DCS1800) 0 thru 15

Limits (PCS1900) 0 thru 15; 30 thru 31

Default (GSM900) 15

Default (E-GSM) 15

Default (DCS1800) 10

Default (PCS1900) 10

On a master unit, the Master Tx level field requests a new transmit

level for the uplink master TCH. On a slave unit, this field does not make

this request.

If the instrument is operating in standard mode, setting this field

changes the master mode (see page 35) to MS TX Lev, then calculates

and sets the master’s expected input level (see page 34). If the

instrument is operating in compatibility mode, setting this field only

changes the master’s expected input level when the control type for the

master is set to MS TX Lev.

NOTE The default is reset when you select the instrument type (see page 24).

Chapter 4 33

Page 48

Screens

HSCSD screen

10. Master input level

Type float

Units dBm only

Limits (GSM900) -27 thru +41.0

Limits (E-GSM) -27 thru +41.0

Limits (DCS1800) -47 thru +33.0

Limits (PCS1900) -47 thru +33.0

Default (compatibility mode) 33.0

Default (GSM900) 13.0

Default (E-GSM) 13.0

Default (DCS1800) 10.0

Default (PCS1900) 10

The Master Input level field sets the expected power of the master

uplink TCH. You can set the level indirectly by changing the master Tx

level (see page 33) or you can change it directly. This value is used to set

the RF analyzer level when the measurement timeslot (see page 32) is

set to Master.

If the instrument is operating in standard mode, setting this field

changes the master control type (see page 35) to Manual.

If the instrument is operating in compatibility mode and the master

control type is MS TX Lev, then the instrument returns the error Can’t

change setting while MS TX Lev mode is selected and does not

make the setting.

When the measurement timeslot is set to Master, this field always has

the same value as the RF I/O analyser level.

NOTE The default is reset when you select the instrument type (see page 24).

34 Chapter4

Page 49

Screens

HSCSD screen

11. Master mode

Type menu

Choices “Manual”, “MS Tx Lev”

Default (compatibility mode) “Manual”

Default (standard mode) “MS Tx Lev”

The Master mode field either makes or breaks the link between the

Master Tx level (see page 33) and the Master input level (see page

34).

NOTE Note that in standard mode, setting either of these other values change

the Master mode field. See the description of these fields for an

explanation of the level control mode.

12. Slave Tx level

Type integer

Units none (Tx Level)

Limits (GSM900) 1 thru 19

Limits (E-GSM) 1 thru 19

Limits (DCS1800) 0 thru 15

Limits (PCS1900) 0 thru 15; 30 thru 31

Default (GSM900) 15

Default (E-GSM) 15

Default (DCS1800) 10

Default (PCS1900) 10

On the slave, the Slave Tx level field sets the transmit level (Tx Level)

of the slave TCH.

Chapter 4 35

Page 50

Screens

HSCSD screen

On both units, if the instrument is operating in standard mode, setting

this field changes the slave control field (see page 37) to MS Tx Lev, then

calculates and sets the slave expected input level (see page 36). If the

instrument is operating in compatibility mode, setting this field only

changes the slave expected input level when the slave control type is MS

Tx Lev.

NOTE The default is reset when you select the instrument type (see page 24).

13. Slave input level

Type float

Units dBm only

Limits (GSM900) -27 thru +41.0

Limits (E-GSM) -27 thru +41.0

Limits (DCS1800) -47 thru +33.0

Limits (PCS1900) -47 thru +33.0

Default (compatibility mode) 33.0

Default (GSM900) 13.0

Default (E-GSM) 13.0

Default (DCS1800) 10.0

Default (PCS1900) 10.0

The Slave input level field sets the expected power of the slave uplink

TCH. You can set the level indirectly by changing the Slave Tx level

(see page 35) or change it directly. This value is used to set the RF

analyzer level when the measurement timeslot (see page 32) is set to

Slave.

If the instrument is operating in standard mode, setting this field

changes the slave control type (see page 37) to Manual.

If the instrument is operating in compatibility mode, and the slave

36 Chapter4

Page 51

Screens

HSCSD screen

control type is MS Tx Lev, then the instrument returns an error (Can’t

change setting while MS TX Lev mode is selected.) and does not

make the setting.

NOTE The default is reset when you select the instrument type (see page 24).

14. Slave control

Type menu

Choices “Manual”, “MS Tx Lev”

Default (compatibility mode) “Manual”

Default (standard mode) “MS Tx Lev”

The Slave control field either makes or breaks the link between the

slave Tx level (see page 35) and the slave input level (see page 36).

NOTE Note that in standard mode, setting either of these other values changes

this field. See the description of these fields for an explanation of the

level control mode.

NOTE The default is reset when you select the instrument type (see page 24).

Chapter 4 37

Page 52

Screens

HSCSD screen

15. Mobile reports

The Mobile Reports are the same uplink SACCH reports as appear on

the Cell Status screen. The reports are taken from whichever uplink

timeslot is currently being analysed. You make this choice using the

Measurement timeslot field (see page 32).

16. Peak power display

The Peak Power display is the same measurement as appears on the

Cell Status screen. The measurement is made on whichever uplink

timeslot is currently being analyzed. You make this choice using the

Measurement timeslot field (see page 32). A reminder of which

timeslot is currently being analysed appears on the right if the peak

power display.

17. To Screen menu

For HSCSD, all of the To Screen and More menus are only changed in

one way; the addition of the HSCSD choice, which selects the screen as

described in page 32.

38 Chapter4

Page 53

Fast BER Screen

One extra field, labelled Loopback, appears in the Fast Bit Error screen,

when the HP/Agilent 8922 is in 2x1 mode.

Figure 4-3 Fast BER screen

Screens

Fast BER Screen

The Loopback field is a toggle field and allows the choice of either master

or slave. This instructs the mobile to either loopback the master channel

on the downlink to the master uplink or loopback the slave downlink to

the master uplink.

Note that toggling the Loopback field does not immediately instruct the

mobile to perform a loopback using the contents. Entering the screen

sends the command to the mobile to close the loop. It is therefore

necessary to enter the screen with this field set to loopback the downlink

channel of choice.

NOTE When performing Fast BER on the slave channel, it is necessary to start

the measurement on the master unit because the master unit controls all

the signalling with the mobile). As a result, this also starts a Fast BER

measurement on the master unit which should be ignored.

Chapter 4 39

Page 54

Screens

Fast BER Screen

Loopback

Type toggle

Choices “Master”, “Slave”

Default “Master”

The Loopback field selects which downlink slot is looped back on the

master uplink.

40 Chapter4

Page 55

5 Remote operation

This chapter explains how to operate the HP/Agilent 8922 GSM HSCSD

TestSystemover the GPIB. The new GPIB commands for the HP/Agilent

8922 GSM HSCSD Test System are detailed. Forthe syntax format of all

other GPIB commands, see the Agilent 8922M⁄S Programming Reference

Guide.

41

Page 56

Remote operation

Introduction

Introduction

The general principle of operation is that the settings on the slave unit

are relative to the settings on the master unit which allows the manual

and remote interfaces to operate in the same way. It is therefore

necessary to always consider the relationship between the two timeslots.

Call setup and changing channels are handled by the master unit.

However, it is vital that the slave unit remains on the same channel and

timeslot (offset by one) as the master unit. Unlike the manual user

interface, where a change made on the master unit is copied to the slave,

controlling the system remotely involves taking control of both units. As

most of the settings on the slave unit are relative to the master unit, the

slave unit must know the configuration of the master unit. The following

command sequence is a general example of how this is achieved.

MasterAddr=715

SlaveAddr=716

OUTPUT MasterAddr;”HSCSD:MASTER:COMMAND <parameters>”

OUTPUT SlaveAddr;”HSCSD:MASTER:COMMAND <parameters>”

OUTPUT SlaveAddr;”HSCSD:SLAVE:COMMAND <parameters>”

42 Chapter5

Page 57

Configure Subsystem GPIB Commands

Configure Subsystem GPIB Commands

Figure 5-1 Configure Instrument Type comand syntax

Remote operation

CONFigure

INSTrument[:TYPE]?

INSTrument[:TYPE]

Sp

string

CONFigure:INSTrument[:TYPE]

Description Sets what role the HP/Agilent 8922 plays in the multi-slot test system.

This selection differs from manually selecting the instrument type in two

ways: the GPIB status does not change to Control, and the unit’s GPIB

address does not change.

Note that you need to manually select two different GPIB addresses for

the master and slave units.

If the instrument has not been fitted with a new hop controller ROM,

selecting HSCSD Master or HSCSD Slave results in the error Hardware

portion of upgrade not present. In this case the instrument allows

HSCSD operation, but the downlink signal could be scrambled when the

TCH ARFCN is placed on or near to the master or slave's BCH ARFCN.

Syntax CONFigure:INSTrument[:TYPE]?

CONFigure:INSTrument[:TYPE] <string>

Command options ‘SPEECH’ | ‘HSCSD MASTER’ | ‘HSCSD SLAVE’

Chapter 5 43

Page 58

Remote operation

Display Subsystem GPIB Commands

Display Subsystem GPIB Commands

Figure 5-2 Display Screen command syntax

DISPlay

SCReen

Sp

string

DISPlay:SCReen HSCSD

Description This command selects the HSCSD control screen (or an error screen if

the system is not upgraded to run HSCSD).

Syntax DISPlay:SCReen <string>

Command options ‘HSCSD’

44 Chapter5

Page 59

HSCSD Subsystem GPIB Commands

HSCSD Subsystem GPIB Commands

Remote operation

Chapter 5 45

Page 60

Remote operation

HSCSD Subsystem GPIB Commands

Figure 5-3 HSCSD command syntax (master unit)

HSCSd

MASTer

TCH

STATus

DOWNlink

UPlink

ARFCn?

ARFCn

TSLot?

TSLot

TLEVel?

TLEVel

TCH

AMPLitude?

AMPLitude

AMPLitude?

AMPLitude

Sp

Sp

Sp

real

ARFCn?

TSLot?

real

integer

integer

integer

units

CONTRol?

CALL

MEASure

TYPE?

TYPE

RATE?

RATE

TSLot

CONTRol

Sp

Sp

Sp

string

string

string

Sp

string

46 Chapter5

Page 61

HSCSD Subsystem GPIB Commands

Figure 5-4 HSCSD command syntax (slave unit)

HSCSd

Remote operation

SLAVe

TCH

STATus

DOWNlink

UPlink

TLEVel?

TLEVel

SYNC?

TCH

AMPLitude?

AMPLitude

AMPLitude?

Sp

real

integer

TSLot?

OFFSet

OFFSet?

real

AMPLitude

real

CONTrol?

CONTrol

Sp

string

Chapter 5 47

Page 62

Remote operation

HSCSD Subsystem GPIB Commands

HSCSd:MASTer:TCH:ARFCn

Description Setting this during a call forces a channel assignment to the given

channel. Note that existing channel assignment commands sent to a

master or single unit have the same effect. In particular, a dual band

assignment must be performed using the existing dual band commands.

If the measurement timeslot is not set to “Master”, attempting to

perform a channel assignment on a master or single unit will produce an

error, and the setting will be ignored. The error message is Select

Master to measure before signalling mobile. When the system is

idle (that is, not on a call) this sets the channel which will be used when

the next call is established. This command must also be sent to the slave

unit.

Syntax HSCSd:MASTer:TCH:ARFCn <integer>

HSCSd:MASTer:TCH:ARFCn?

Command options

Type integer

Units: none (ARFCN)

Limits (GSM900): 1 thru 124

Limits (E-GSM): 0 thru 124; 995 thru 1024

Limits (DCS1800): 512 thru 885

Limits (PCS1900): 512 thru 810

Default (GSM900): 30

Default (E-GSM): 30

Default (DCS1800): 512

Default (PCS1900): 51

48 Chapter5

Page 63

Remote operation

HSCSD Subsystem GPIB Commands

HSCSd:MASTer:STATus:TCH:TSLot

Description Setting this during a call changes the master timeslot. Note that existing

timeslot commands sent to a master or single unit have the same effect.

When the system is idle (that is, not on a call) this sets the timeslot

which will be used when the next command is established. In a multi-box

system, this command must also be sent to the slave unit.

Note that the slave timeslot is always the slot following the master.

Consequently, in a multi-box system, the slave needs to know only the

master timeslot.

Syntax HSCSd:MASTer:STATus:TCH:TSLot <integer>

HSCSd:MASTer:STATus:TCH:TSLot?

Command options

Type integer

Units: none (timeslot)

Limits: 2 thru 5

Default: 4

Chapter 5 49

Page 64

Remote operation

HSCSD Subsystem GPIB Commands

HSCSd:MASTer:DOWNlink:AMPLitude

Description This sets the downlink amplitude of the master TCH. In all cases, this

sets the TCH level. To change the amplitude of the GSM BCH in a dual

band system, use the existing command DUALband:ATTenuation:GBCh.

See the HP/Agilent 8922 Multi-Band Test System Supplementary User’s

Guide for more details.

This command must also be sent to the slave unit.

Syntax HSCSd:MASTer:DOWNlink:AMPLitude?

HSCSd:MASTer:DOWNlink:AMPLitude <real>

Command 0ptions

Type floating point

Units: dBm only

Limits (GSM900): -127.0 thru +1.0

Limits (E-GSM): -127.0 thru +1.0

Limits (DCS1800): -127.0 thru -12.0

Limits (PCS1900): -127.0 thru -12.0

Default: -85.0

50 Chapter5

Page 65

HSCSD Subsystem GPIB Commands

HSCSd:MASTer:TCH:TLEVel

Description During a call, this sets the Tx level of the master TCH.

When the system is idle (that is, not on a call), this sets the Tx level to be

used when the next call is established. Note that this value is used

initially for both timeslots.It is only once the TCH is established, and the

mobile begins to decode the downlink SACCH, that the individual Tx

levels are used.

In standard mode, this also sets the master unit’s uplink amplitude

control to MS TX LEV, and calculates and sets the master unit’s expected

uplink amplitude. See [reference] below for details of these commands.

Syntax HSCSd:MASTer:TCH:TLEVel?

HSCSd:MASTer:TCH:TLEVel <integer>

Command options

Type integer

Units: none (Tx Level)

Remote operation

Limits (GSM900): 1 thru 19

Limits (E-GSM): 1 thru 19

Limits (DCS1800): 0 thru 15

Limits (PCS1900): 0 thru 15; 30 thru 31

Default (GSM900): 15

Default (E-GSM): 15

Default (DCS1800): 10

Default (PCS1900): 10

Chapter 5 51

Page 66

Remote operation

HSCSD Subsystem GPIB Commands

HSCSd:MASTer:UPLink:AMPLitude

Description This sets the expected input level of the master TCH. In standard mode,

this sets the master’s uplink amplitude control to MANUAL. In

compatibility mode, if the master’s uplink amplitude control is set to MS

TX LEV then an error message Can’t change setting while MS TX

Lev mode is selected. occurs and the setting is not performed.

If the measurement timeslot is set to Master, the analyser level of the

unit is set to this value.

Syntax HSCSd:MASTer:UPLink:AMPLitude?

HSCSd:MASTer:UPLink:AMPLitude <real> <units>

Command options

Type float

Units: dBm only

Limits (GSM900): -27.0 thru +41.0

Limits (E-GSM): -27.0 thru +41.0

Limits (DCS1800): -47.0 thru +33.0

Limits (PCS1900): -47.0 thru +33.0

Default (compatibility mode): 33.0

Default (GSM900) 13.0

Default (E-GSM): 13.0

Default (DCS1800): 10.0

Default (PCS1900): 10.0

52 Chapter5

Page 67

Remote operation

HSCSD Subsystem GPIB Commands

HSCSd:MASTer:UPLink:AMPLitude:CONTrol

Description This defines the relationship between the master’s Tx level, and the

master’s expected uplink amplitude. MS TX LEV indicates that setting

the master’s Tx level also sets the master’s expected uplink amplitude.

MANUAL indicates that setting the master’s expected uplink amplitude is

independent from the value of the master’s Tx level.

Note that in standard mode, setting either the master’s Tx level, or the

master’s expected uplink amplitude, forces the value of the master’s

amplitude control to MS TX LEV or MANUAL respectively.

Syntax HSCSd:MASTer:UPLink:AMPLitude:CONTrol?

HSCSd:MASTer:UPLink:AMPLitude:CONTrol <string>

Command options ‘MS TX LEV’ | ‘MANUAL’

Chapter 5 53

Page 68

Remote operation

HSCSD Subsystem GPIB Commands

HSCSD:MASTer:CALL:TYPE

Description This command selects which type of call the HP/Agilent 8922 will set up

the next time a call is initiated.

Syntax HSCSd:MASTer:CALL:TYPE

HSCSd:MASTer:CALL:TYPE?

Command options

Type toggle

Units none

Choices 2x2 or 2x1

Default 2x2

54 Chapter5

Page 69

Remote operation

HSCSD Subsystem GPIB Commands

HSCSD:MASTer:CALL:RATE

Description This command selects the data rate of the call that the HP/Agilent 8922

will set up the next time a call is initiated.

Syntax HSCSD:MASTer:CALL:RATE

HSCSD:MASTer:CALL:RATE?

Command options

Type toggle

Units none

Choices 9.6 or 14.4

Default 9.6

Chapter 5 55

Page 70

Remote operation

HSCSD Subsystem GPIB Commands

HSCSd:SLAVe:STATus:SYNC

Description This read-only field indicates whether or not the slave unit is

synchronised with the master unit. The status is set to DISABLED when

you set the instrument type to HSCSD SLAVE. This must be done before

configuring the master unit. When the master unit is configured as

HSCSD MASTER, a frame reset is sent from the master unit to the slave

unit. Upon receiving this reset, the slave unit starts to generate a TCH,

and the sync status field changes to ENABLED.

Syntax HSCSd:SLAVe:STATus:SYNC?

Command options Not applicable.

56 Chapter5

Page 71

HSCSD Subsystem GPIB Commands

HSCSd:SLAVe:STATus:TCH:TSLot?

Description This query returns the absolute timeslot.

For example, if the master’s timeslot is 3, because the slave’s timeslot

offset is fixed at +1, HSCSd:SLAVe:STATus:TCH:TSLot? would return 4.

Syntax HSCSd:SLAVe:STATus:TCH:TSLot?

Command options Not applicable.

Remote operation

Chapter 5 57

Page 72

Remote operation

HSCSD Subsystem GPIB Commands

HSCSd:SLAVe:DOWNlink:AMPLitude:OFFSet

Description This sets the amplitude offset (in dBs) of the slave timeslot, using the

master’s downlink amplitude as a reference.

The resulting amplitude must lie within the normal downlink power

range. If not, the error Disallowed due to pulse mod configuration

is produced, and the setting is ignored.

Syntax HSCSd:SLAVe:DOWNlink:AMPLitude?

HSCSd:SLAVe:DOWNlink:AMPLitude:OFFSet <real>

Command options

Type floating point

Units: dB only

Limits -100.0 thru 100.0

Default 0.0

58 Chapter5

Page 73

Remote operation

HSCSD Subsystem GPIB Commands

HSCSd:SLAVe:TCH:TLEVel

Description During a call, this sets the Tx level of the slave TCH. When the system is

idle (that is, not on a call), this sets the Tx level to be used when the next

call is connected and the slave TCH is established.

Note that this is not the Tx Level first used to establish the TCH. In

standard mode, this also sets the slave’s uplink amplitude control to MS

TX LEV, and calculates and sets the slave’s expected uplink amplitude.

Syntax HSCSd:SLAVe:TCH:TLEVel?

HSCSd:SLAVe:TCH:TLEVel <integer>

Command options

Type integer

Units: dBm only

Limits (GSM900): 1 thru 19

Limits (E-GSM): 1 thru 19

Limits (DCS1800): 0 thru 15

Limits (PCS1900): 0 thru 15; 30 thru 31

Default (GSM900): 15

Default (E-GSM): 15

Default (DCS1800): 10

Default (PCS1900): 10

Chapter 5 59

Page 74

Remote operation

HSCSD Subsystem GPIB Commands

HSCSd:SLAVe:UPLink:AMPLitude

Description This sets the expected input level of the slave timeslot.

In standard mode, this sets the slave’s uplink amplitude control to

MANUAL. In compatibility mode, if the slave’s uplink amplitude control is

set to MS TX LEV then an error occurs and the setting is not performed. If

the measurement timeslot (see page 43) is set to Slave, the analyser

level of the unit is set to this value.

Syntax HSCSd:SLAVe:UPLink:AMPLitude?

HSCSd:SLAVe:UPLink:AMPLitude <real> <units>

Command options

Type float

Units: dBm only

Limits (GSM900): -27.0 thru +41.0

Limits (E-GSM): -27.0 thru +41.0

Limits (DCS1800): -47.0 thru +33.0

Limits (PCS1900): -47.0 thru +33.0

Default (compatibility mode): 33.0

Default (GSM900) 13.0

Default (E-GSM): 13.0

Default (DCS1800): 10.0

Default (PCS1900): 10.0

60 Chapter5

Page 75

Remote operation

HSCSD Subsystem GPIB Commands

HSCSd:SLAVe:UPLink:AMPLitude:CONTrol

Description This defines the relationship between the slave Tx level, and the slave

expected uplink amplitude. MS TX LEV indicates that setting the slave’s

Tx level also sets the slave’s expected uplink amplitude. MANUAL indicates

that setting the slave’s expected uplink amplitude is independent from

the value of the slave’s Tx level.

Note that in standard mode, setting either the slave Tx level, or the slave

expected uplink amplitude, forces the value of the slave amplitude

control to MS TX LEV or MANUAL respectively.

Syntax HSCSd:SLAVe:UPLink:AMPLitude:CONTrol

HSCSd:SLAVe:UPLink:AMPLitude:CONTrol?

Command options ‘MS TX LEV’ | ‘MANUAL’

Chapter 5 61

Page 76

Remote operation

Remote operating procedures

Remote operating procedures

NOTE For remote operation to work:

• the two HP 8922P units must be put into master and slave mode by

remote control

• HSCSD settings must be made on both HP/Agilent 8922 P units

Configuring the system

The slave unit must be configured and initialized before the master unit.

Note that unlike manual configuration, the GPIB address of the slave

unit does not have to be synchronized on both units.

! Configure instruments; note we do slave first

! for a single box, we send the single command

! selecting ‘HSCSD SINGLE’

OUTPUT Slave;”CONFIGURE:INSTRUMENT:TYPE ‘HSCSD SLAVE’”

WAIT 3 !to make sure we are ready to receive reset from master

OUTPUT Master;”CONFIGURE:INSTRUMENT:TYPE ‘HSCSD MASTER’”

The slave unit must wait for the frame reset from the master unit.

! select HSCSD screen

OUTPUT Master;”DISPLAY:SCREEN HSCSD”

OUTPUT Slave;”DISPLAY:SCREEN HSCSD”

! and wait for slave to receive reset from master

REPEAT !

OUTPUT Slave;”HSCSD:SLAVE:STATUS:SYNC?”

ENTER Slave;sync$

UNTIL sync$=”””ENABLED”””

!

62 Chapter5

Page 77

Remote operation

Remote operating procedures

Establishing a call

The procedure for establishing a call is the same as for speech. Note

however, that you must be measuring the master uplink in the master

unit.

! establish a call, mobile terminated

! note we only use the master to do this

! make sure master is demodulating the master uplink

OUTPUT Master;”HSCSd:MEASure:TSLot ‘SLAVE’

!

OUTPUT Master;”DISPLAY:SCREEN CELL1”

OUTPUT Master;”CELL:CALL:ORIGINATE”

REPEAT