Page 1

Assembly Level Repair

HP/Agilent Technologies

8922 Series GSM Test Set

Agilent Part No. 08922-90213

Printed in UK

January 1998

Page 2

© Copyright 1998, Agilent Technologies. All rights reserved. Reproduction, adaptation, or translation without prior

written permission is prohibited, except as allowed under the copyright laws.

Page 3

Introduction

Introduction

The HP/Agilent 8922 product family uses an assembly level repair service strategy. The

HP/Agilent 8922 may be sent to an Agilent Technologies Sales and Service office or may

be repaired on site. This book is used for both Agilent Technologies service and owner

service.

The HP/Agilent 8922 product family currently contains the HP/Agilent 8922A, HP/

Agilent 8922B, HP/Agilent 8922E, HP/Agilent 8922F, HP/Agilent 8922G, HP/

Agilent 8922H, HP/Agilent 8922M and HP/Agilent 8922S. There are differences in both

the hardware and in the operation. In examples and task sequences this book presents

general usage, and graphical instrument representations may not exactly match the HP/

Agilent 8922 that you are servicing.

Repairing the HP/Agilent 8922

To repair the HP/Agilent 8922, follow the chapters in this book starting at the beginning

and following the “where to go next” guidelines.

Book Organization

This book contains problem identification sections, assembly replacement sections,

reference information and concept information. The chapters are sectioned in three parts;

Service Procedures, Reference Information and Theory. This sectioning helps to identify

the type of information found in a group of chapters.

i

Page 4

Introduction

ii

Page 5

Contents

1 Localizing the Problem

2 Running Diagnostics

Introduction i

Introduction 1-2

Localizing the Problem - Flow Chart (Power-Up) 1-3

Power-Up Checks 1-4

If Power-Up Checks FAILED 1-5

If Power-Up Happened Correctly 1-10

Introduction 2-2

Running Memory Card or ROM Based Diagnostics 2-3

Loading and Running the Ram Test 2-7

3 Verifying Performance

Introduction 3-2

Installing and Operating the Software 3-2

Using the Compatibility Switch for the HP/Agilent 8922F/

H or M/S 3-3

4 Using the HP/Agilent 83210A Service Kit

Introduction 4-2

Configuring the RF Extender 4-3

Extending Modules 4-5

Making Measurements 4-6

5 Troubleshooting the Controller/Display

Introduction 5-2

Parallel Bus 5-3

Serial Bus 5-4

Display 5-5

Keyboard 5-6

Contents-1

Page 6

Contents

6 Troubleshooting the Power Supply

7 Adjustments and Calibration

Introduction 6-2

Power Cord Verification 6-3

Line Voltage Selection / Line Fuse Replacement 6-5

Transformer / Power Switch 6-6

A28 Power Supply 6-7

Where To Go Next 6-8

Introduction 7-2

Timebase Adjustments 7-3

Periodic Calibrations 7-5

Sum Loop Adjustment Procedure 7-6

8 Assembly and Disassembly Procedures

Introduction 8-2

Top and Bottom Cover Removal 8-3

Inside Protective Covers 8-4

AF, Digital and RF Assemblies Removal 8-5

A1 Front Panel Removal 8-7

A10 Power Supply Regulator Removal 8-9

A11 Receiver Mixer Removal 8-10

A12 Pulse Attenuator Removal 8-12

A21 GPIB Interface Removal 8-14

A22 Display Removal 8-16

A23 Input Section Removal 8-18

A24 Attenuator Removal 8-19

A28 Power Supply Removal 8-20

Fan Removal 8-22

Transformer Removal 8-24

Contents-2

Page 7

Contents

9 Replacing a Part

10 Service Screen

11 Self-Test Error Messages

Introduction 9-2

Replaceable Parts 9-3

Firmware Upgrades 9-29

Introduction 10-2

Introduction 11-2

12 Module I/O Specifications

Introduction 12-2

A2 Audio Analyzer 2 12-3

A3 Audio Analyzer 1 12-5

A4 Modulation Distribution 12-8

A5 Premodulation Filter and NSM 12-10

A6 Signaling Source/Analyzer 12-13

A9 Global Test and Demod 12-15

A11 Receiver Mixer 12-19

A13 Output 12-22

A14 Pulse Driver 12-24

A15 Reference 12-26

A16 Receiver 12-32

A18 Spectrum Analyzer 12-36

A19 Measurement 12-38

A23 Input (HP/Agilent 8922A.B,E,F,G,H) Only 12-43

A23 Input (Agilent 8922M/S Only) 12-47

A25 Sum Loop 12-50

A17, A26 Step Loop 12-53

A27 DAC/Upconverter 12-56

Contents-3

Page 8

Contents

13 Instrument Block Diagrams

14 Block Diagram Theory of Operation

A28 Power Supply 12-58

A33 Hop Controller 12-59

Introduction 13-2

Introduction 14-2

Technical Discussion 14-3

Block Diagram 1 14-4

Block Diagram 2 14-9

Block Diagram 3

HP/Agilent 8922B Only 14-15

Block Diagram 4 14-17

Block Diagram 5 14-18

15 Diagnostics Theory

Contents-4

Introduction 15-2

AF_DIAGS 15-3

RF_DIAGS 15-5

MS_DIAGS 15-11

GSM and DCS Diagnostic Tests 15-12

Interpreting Results 15-13

Page 9

Contents

16 Measurement Theory

17 GSM Theory

Index 1

Introduction 16-2

Introduction 17-2

The GSM System 17-3

E-GSM, DCS1800 and PCS1900 Systems 17-4

Contents-5

Page 10

Contents

This Page Intentionally Left Blank

Contents-6

Page 11

1

Localizing the Problem

1-1

Page 12

Localizing the Problem

Introduction

Introduction

This chapter helps to determine if a problem actually exists and which section of the

instrument has a problem.

This chapter comprises of four sections.

❒ Localizing the Problem Flow Chart (Power-Up)

❒ Power-Up Checks

❒ If Power-Up Failed

• Power-Up Self Test Diagnostics

❒ If Power-Up Happened Correctly

• Checking the RF Analyzer using the RF Generator

• Checking the RF Analyzer using the AF Generator

1-2

Page 13

Localizing the Problem

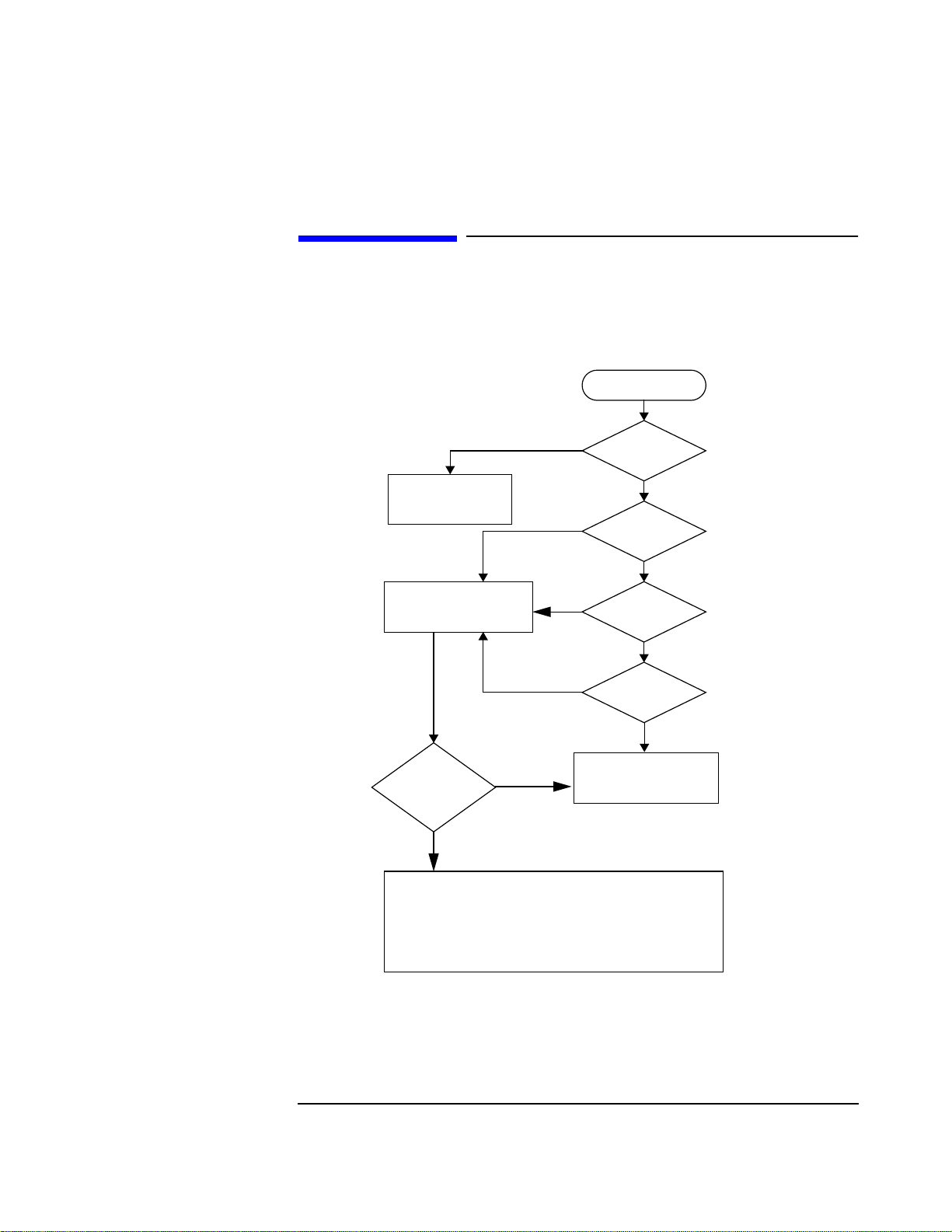

Localizing the Problem - Flow Chart (Power-Up)

Localizing the Problem - Flow Chart (Power-Up)

See "Power Up Checks", in this Chapter, for details of the steps given in the flow chart

below.

Power On

NO

Goto;

"Troubleshooting the

Power Supply"

Goto;

"Power-Up Self Test

Diagnostics"

Failure

Reported by

Diagnostics ?

YES

Goto the relevant trouble shooting section;

NO

NO

6 seconds?

NO

NO

Controls OK?

Goto;

"If Power-Up

Happened Correctly"

Fan On?

YES

Beep after

YES

Messages

OK?

YES

Keys &

YES

• "Trouble Shooting The Controller/Display" - Chapter 5.

• "Trouble Shooting The Power Supply" - Chapter 6.

• "Running Diagnostics" - Chapter 2

Figure 1-1 Localizing the Problem - Flow Chart

1-3

Page 14

Localizing the Problem

Power-Up Checks

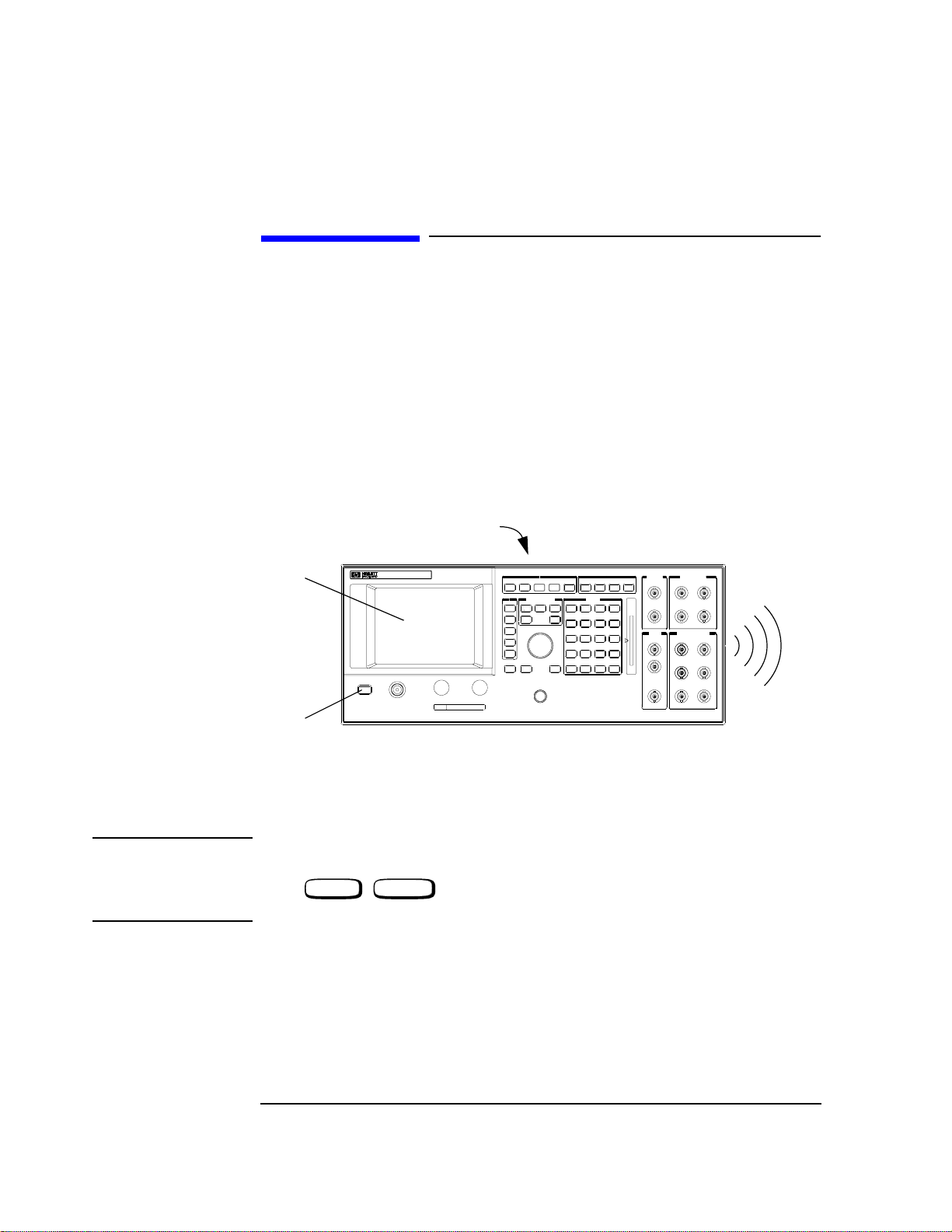

Power-Up Checks

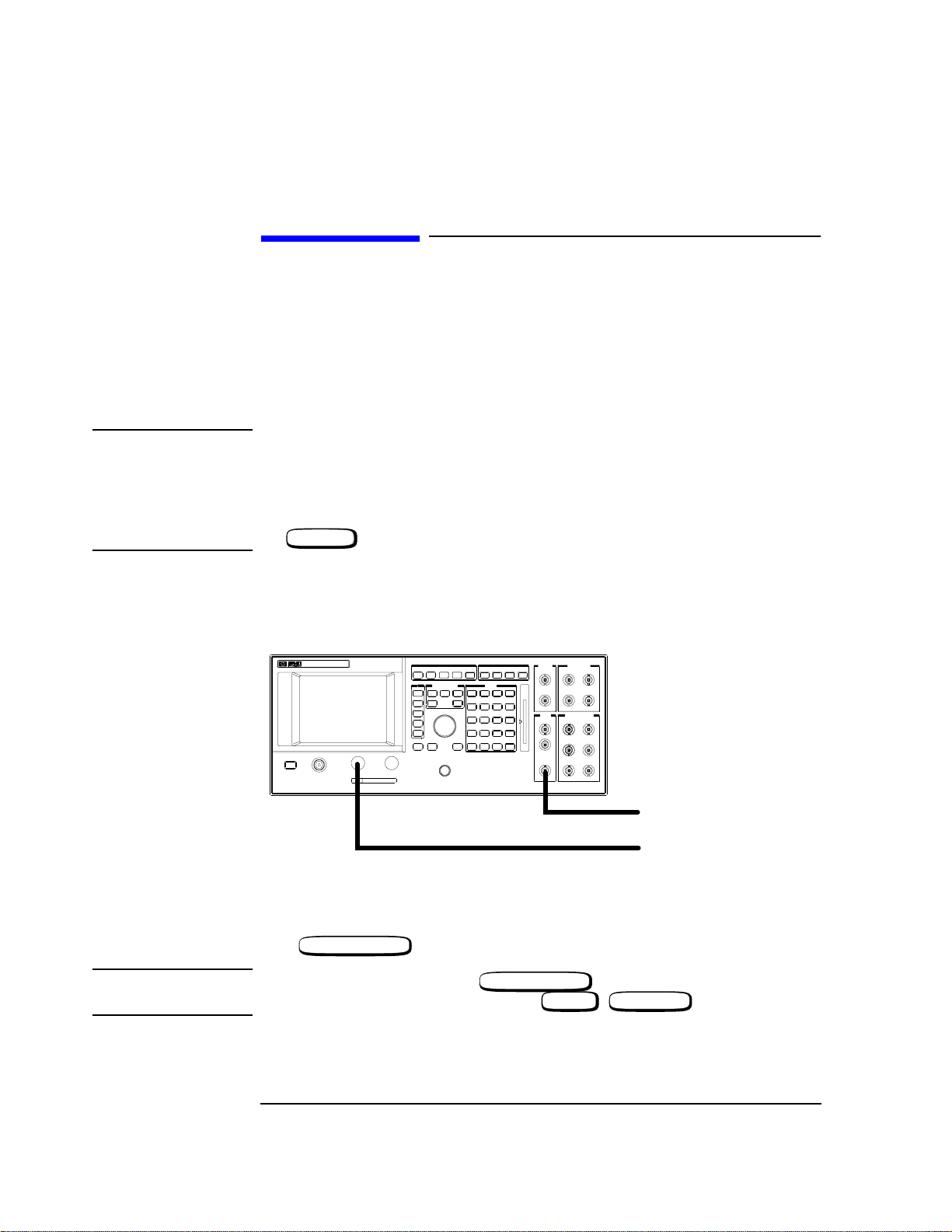

The following checks show whether the instrument is powering up correctly.

(a) Depress the power button on the front panel (see diagram).

(b) Check that the fan on the rear panel is working.

(c) Listen for a single “beep” after pressing the power switch. This can be from 6 to 20

seconds, depending on model type.

(d) Check the display on the front panel for any error messages. (The normal message

which will appear is “All host processor self-tests passed.” and/or "Frequency

Reference Cal lost. Perform Reference Calibration".)

(b)

(d)

(a)

Figure 1-2 Power-Up Checks - Agilent 8922x

NOTE If an error message appears after power up it may not be the only message

which has appeared. Only the last message will be shown on this message line.

Press , (MSG) to access the message screen for a list of all the

error messages.

SHIFT TESTS

(Rear Panel Vent)

(c)

"Beep"

1-4

Page 15

Localizing the Problem

If Power-Up Checks FAILED

If Power-Up Checks FAILED

If the power up checks failed, continue with this section.

❒ If the fan did not start, see "Troubleshooting the Power Supply", Chapter 6.

❒ If the fan started, but any of the other power-up checks failed, see "Power-Up Self Test

Diagnostics".

❒ If an error message occurs, refer to the Agilent 8922x Users Guide for additional

information.

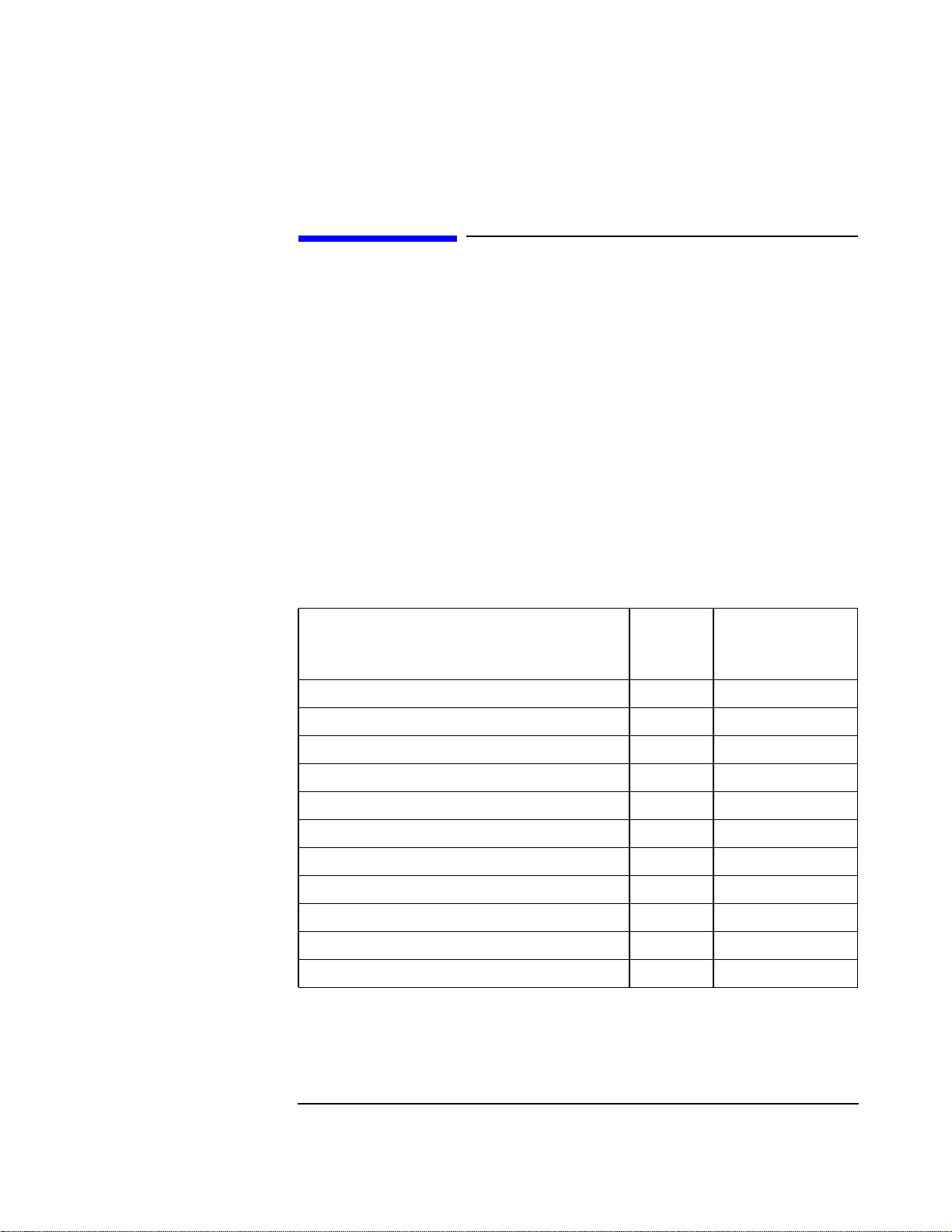

Error Message Numbers

If the error message refers to a self test error it will be of the form:

One or more self tests failed: Error Code XXXX

Where xxxx corresponds to the error message number shown in the table below.

Table 1-1 Error Message Numbers

Failure

Fatal Error - Host Processor Failure 0002 A7 Controller

Fatal Error - ROM Checksum Failure 0004 A8 Memory

Fatal Error - RAM Failure 0008 A8 Memory

Fatal Error - RAM Failure 0010 A8 Memory

Fatal Error - Timer Failure 0020 A7 Controller

Real Time Clock Failure 0040 A8 Memory

Keyboard Failure 0080 A1 Keyboard

Serial I/O Failure 0100 A21 GPIB

Internal Serial Bus Communication Failure 0200 Serial Bus

CRT Failure 0400 A19 CRT Drive

Miscellaneous Hardware Failure 0800 Miscellaneous H/W

Error

Number

Suspect Assembly

1-5

Page 16

Localizing the Problem

If Power-Up Checks FAILED

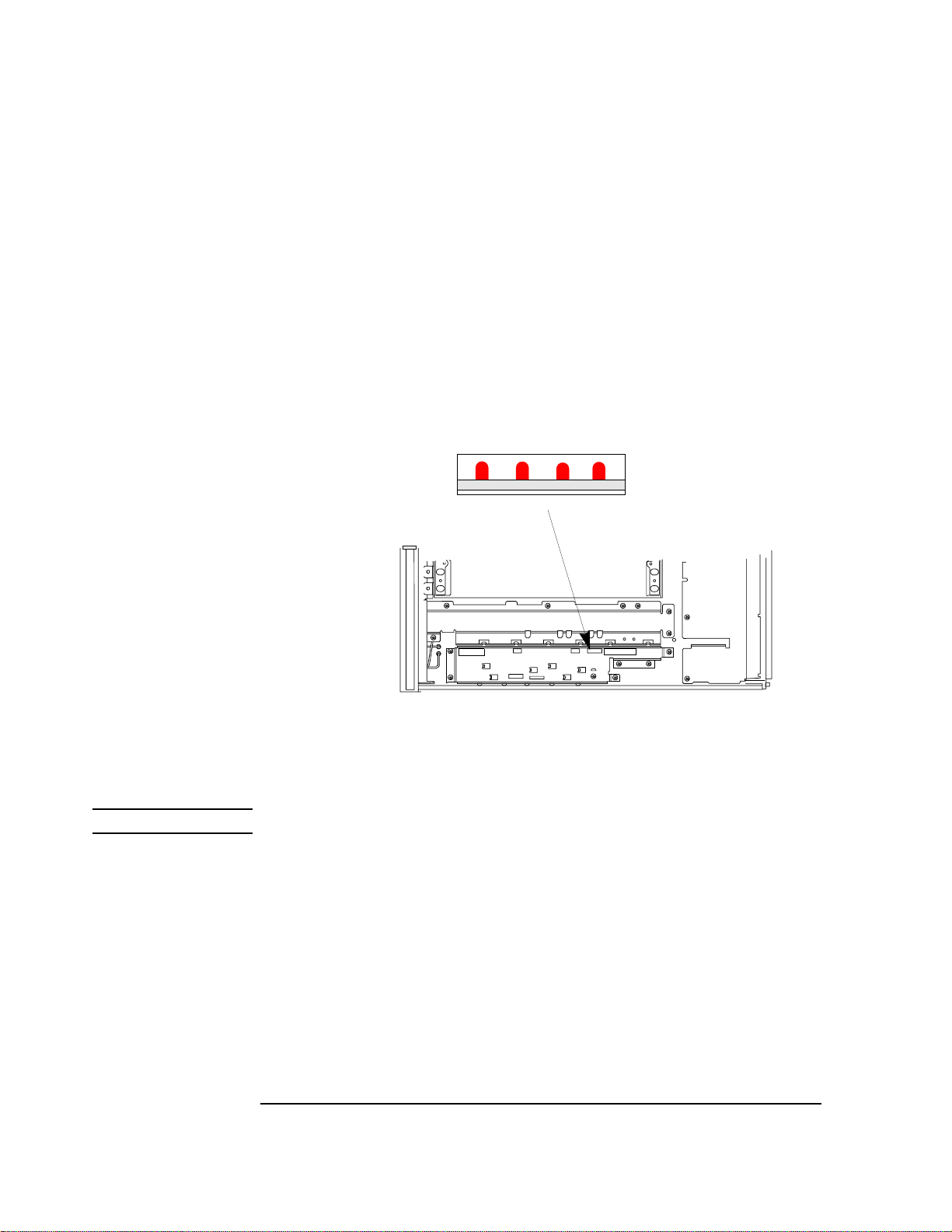

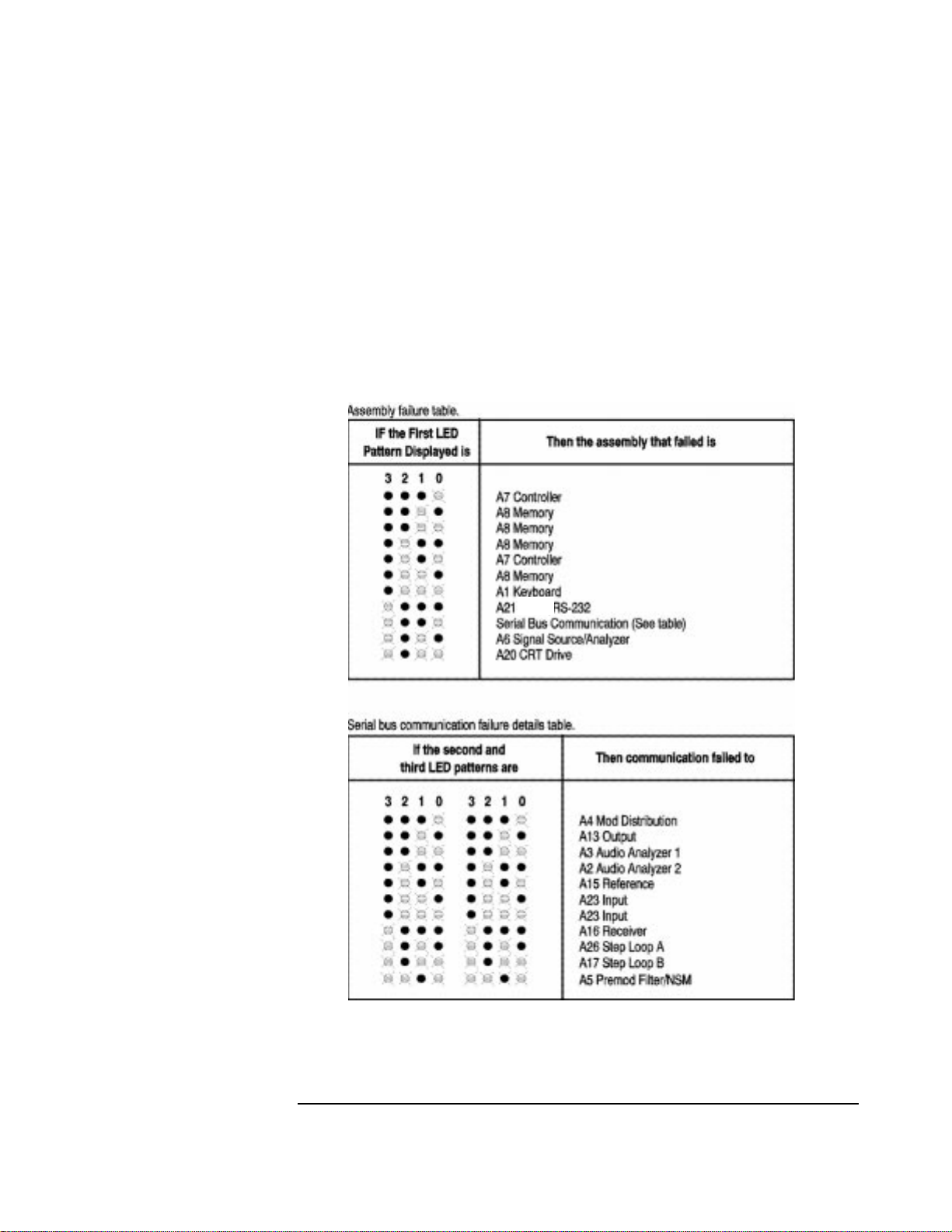

Power-Up Self Test Diagnostics

If the power-up sequence failed, the power-up self-tests can be re-run with the covers off.

The LED’s on the controller board give the results of the power-up self-test.

(a) Remove the instrument covers. Refer to the section "Top and Bottom

Covers", Chapter 8, for details.

(b) Power up the instrument.

(c) Read the LED sequence given on the controller board. These LED’s can be

read with the shields in place (refer to the diagram below)

Location of LED’s

3210

Front Panel

(View from top)

Figure 1-3 Self Test LED Location

NOTE For multiple failures, the patterns for each failure will appear in sequence.

1-6

Page 17

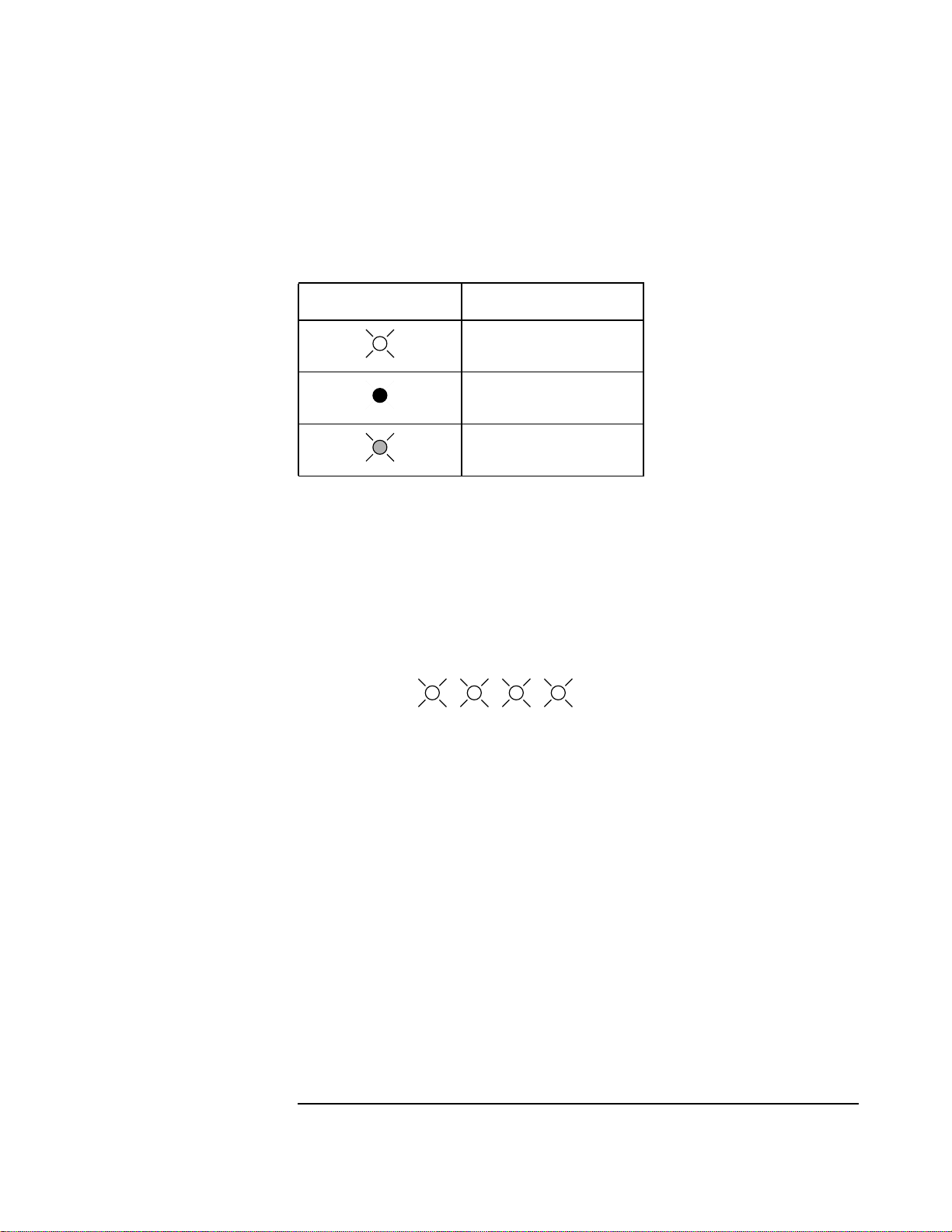

The following conventions are used to represent the LED’s throughout this chapter.

Table 1-2 LED Conventions

LED shown in tables Represnts

LED Sequences

The LED error sequence will show two states, pass or fail, which are outlined below. The

suspect assembly is given in the following tables, before moving on consult the section

"Self-Test Diagnostic Result".

Localizing the Problem

If Power-Up Checks FAILED

A ’lit’ LED

An ‘off’ LED

A flashing LED

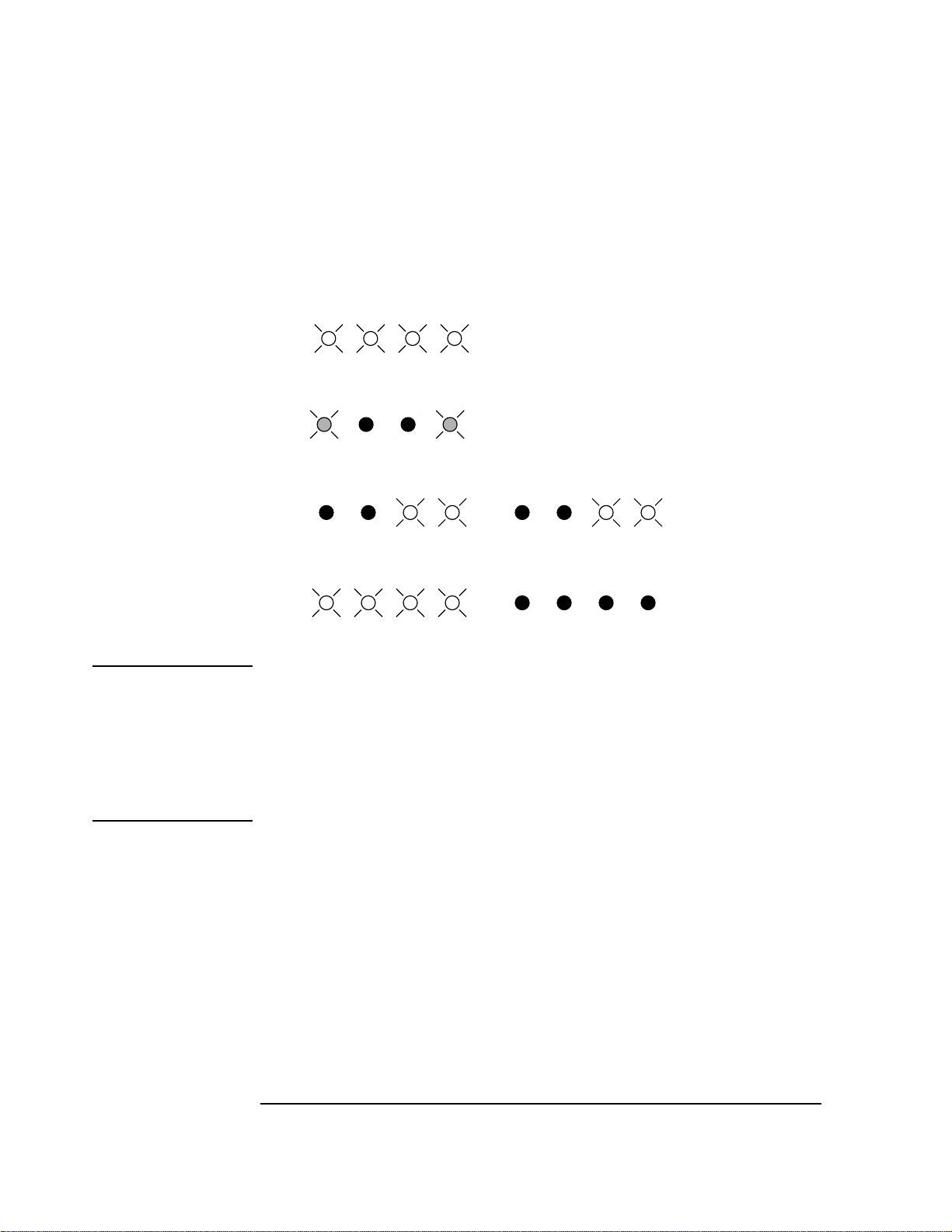

No Failures

Detected The LED’s will light for approximately 10 seconds, then all will turn

off.

3210

Lit for 10 seconds.

Failure Detected 1 The LED’s will initially all light.

2 The next pattern blinks rapidly, and shows that an assembly has

failed.

3 The third sequence flashes twice and gives further information on

the area of the board that has failed.

4 The LED’s will light then go out.

1-7

Page 18

Localizing the Problem

If Power-Up Checks FAILED

Table 1-3 Sequence of LED Patterns

3210

1

3210

2 Assembly failure.

3210 3210

3

3210 3210

4 No more errors.

NOTE 1. The third patterns are only documented for a serial bus communication failure. This is

represented by the two outside LED’s flashing.

2. The second and third patterns will be the same. It will appear as if the same pattern has

flashed twice.

For more than one error in the Agilent 8922x the LED’s will flash in the same sequence for

each assembly that is faulty.

Serial Bus

Communication

Failures

1-8

Page 19

Localizing the Problem

If Power-Up Checks FAILED

Where to Go Next

❒ If the LED’s did not light at all, go to Chapter 6, "Troubleshooting the Power Supply".

❒ If an error messgae occurs, use it in Chapter 2, "Running Diagnostics" to choose which

diagnostic test to run. See also Chapter 11 "Self Test Error Messages".

❒ If this section is used due to display problems, go to Chapter 5 "Troubleshooting the

Controller/Display" before the error messages are repaired.

GPIB/

1-9

Page 20

Localizing the Problem

If Power-Up Happened Correctly

If Power-Up Happened Correctly

If power-up happened correctly and no problem is indicated, this section is used to functionally check most of the hardware. The generators are checked first with external measurements, then the analyzers are checked with the generator. The RF Generator is

checked at 935 MHz and 10 dBm. The AF Generator is checked at 1 kHz and 1 V. These

checks are for indication only, performance tests in Chapter 3, “Verifying Performance”,

will test specifications.

NOTE If you possess an Agilent 8922S or Agilent 8922M, you should first re-configure your

instrument as an HP/Agilent 8922E or HP/8922G. To do this, select the following keys:

• CONFIG (this is accessible from the Cell Control screen in the bottom right-hand

corner).

• Compatible, select (HP 8922E or HP 8922G)

PRESET

•

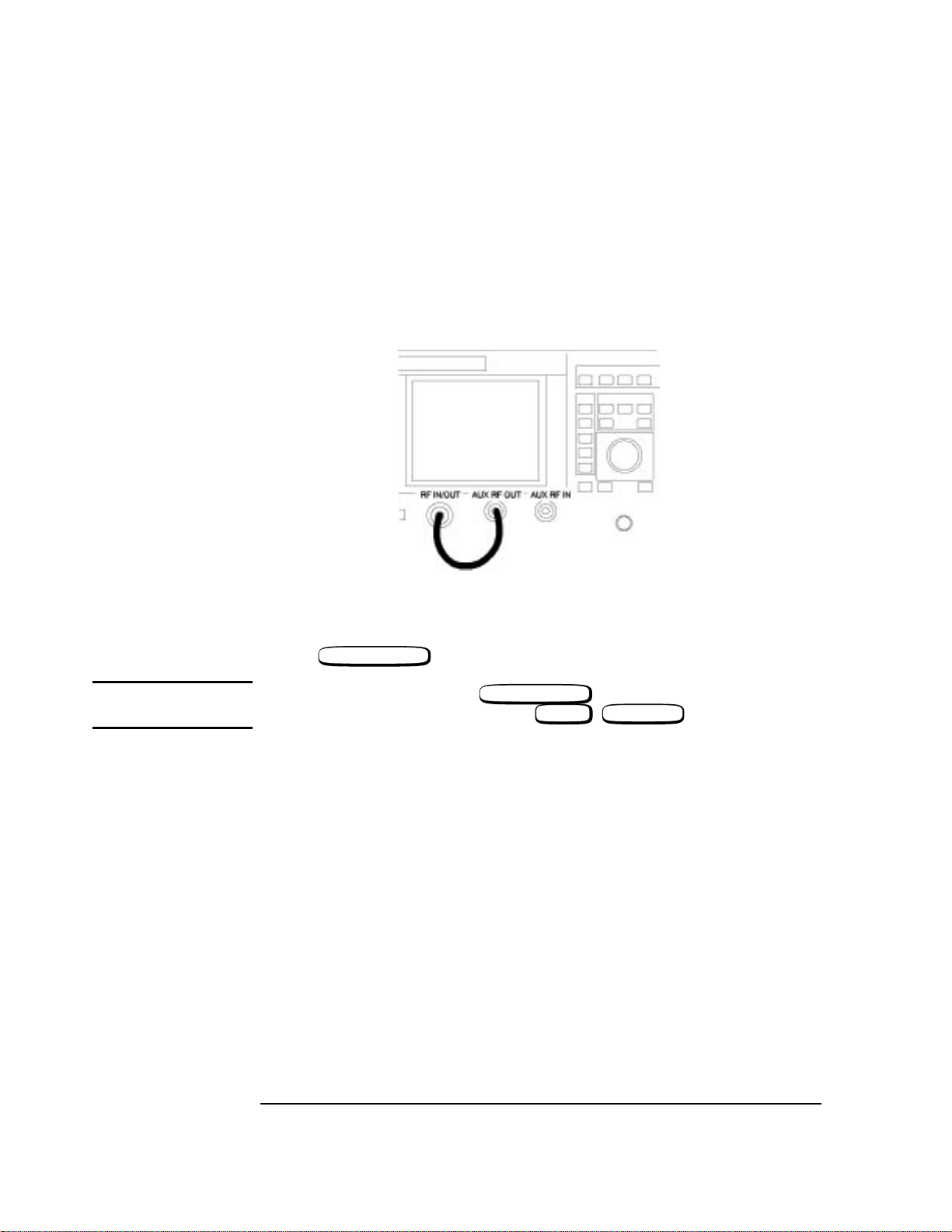

Referring to Figure 1-4, ensure the connections are made.

AUDIO RF OUT

AUDIO OUT

Figure 1-4 Front Panel Connections

RF GEN/RF ANL

Press .

NOTE On the HP/Agilent 8922A/B, press .

On the HP/Agilent 8922E/F/G/H/M/S, press , (RFG/RFA).

RF GEN/RF ANL

SHIFT CELL CNTL

AF To Oscilloscope

RF To Spectrum Analayzer

1-10

Page 21

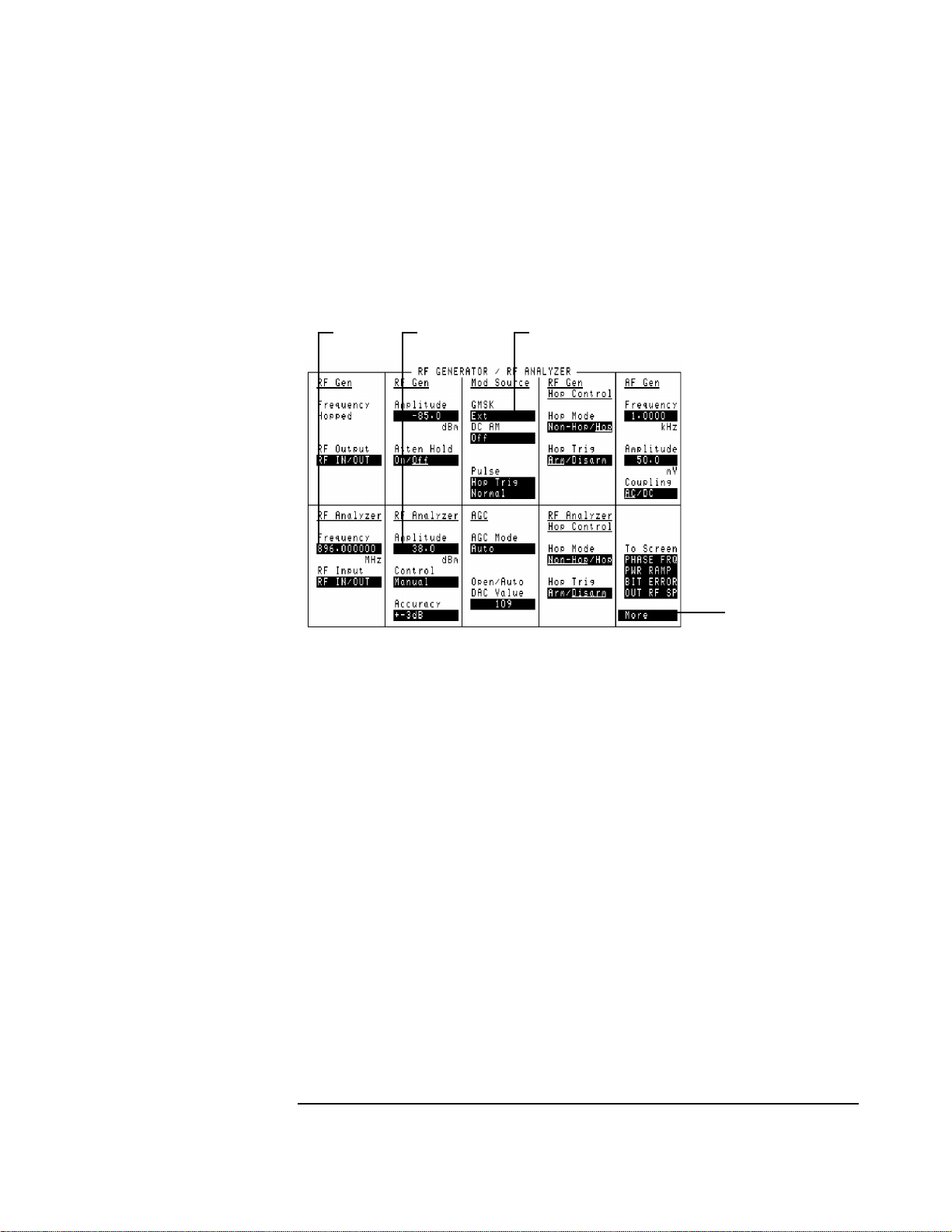

Highlight the RF Output field (1).

Select AUX RF OUT from the list of choices.

Set the RF Generator Amplitude field to 10 dBm (2).

Set the AF Generator Amplitude field to 1 V (3).

Localizing the Problem

If Power-Up Happened Correctly

1

Figure 1-5 RF Analyzer Settings

2

Where to Go Next

• If the generators are within specifications, go to the next section, “Checking the RF

Analyzer Using the RF Generator”.

• If one or both of the generators appear to be faulty, go to Chapter 2, “Running

Diagnostics” and run the appropriate tests.

3

1-11

Page 22

Localizing the Problem

If Power-Up Happened Correctly

Checking the RF Analyzer Using the RF Generator

This section tests the RF Analyzer using the RF Generator as a signal source. This task

assumes the same setting used in the previous section.

• Connect the RF In/Out to the Aux RF Out.

Figure 1-6 Front Panel Connections for the RF Analyzer

RF GEN RF ANL

Press .

NOTE On the HP/Agilent 8922A/B, press .

On the HP/Agilent 8922E/F/G/H/M/S, press , (RF GEN RF ANL).

RF GEN RF ANL

SHIFT CELL CNTL

1-12

Page 23

If Power-Up Happened Correctly

• Set the RF Analyzer Frequency field to 935 MHz (1).

• Set the RF Analyzer Amplitude field to 10 dBm (2).

• Set the Mod Source GMSK field to Off (3).

• Select More in the bottom right-hand corner of the screen (4).

12 3

Localizing the Problem

Figure 1-7 RF Generator/Analyzer Settings

4

1-13

Page 24

Localizing the Problem

If Power-Up Happened Correctly

• SelectCW/AF ANL from the list of choices, and read the CW Freq (5) and CW Power

(6) fields.

56

Figure 1-8 CW Readings

Where to Go Next

• If the analyzer measurement was within the specification, go to the next section,

“Checking the AF Analyzer using the AF Generator”.

• Ifthemeasurementwasfaulty,gotoChapter2,“RunningDiagnostics”,andrunthetest

related to the RF Analyzer.

1-14

Page 25

Localizing the Problem

If Power-Up Happened Correctly

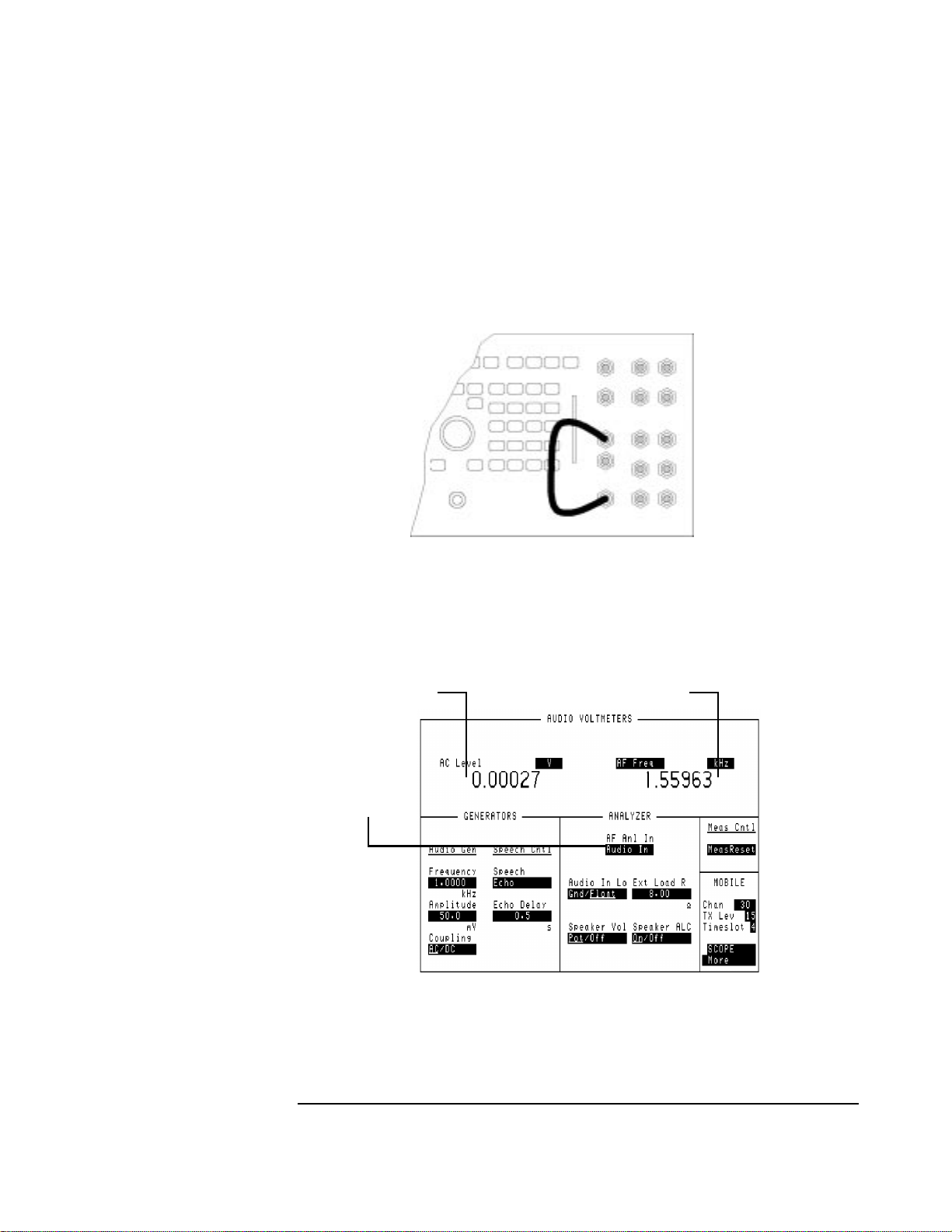

Checking the AF Analzyer Using the AF Generator

This section tests the AF Analyzer with the AF Generator as a source. The AF Generator

settings are the same as the first task, and displays the CW MEAS/AF ANL screen.

• Connect the AUDIO OUT to the AUDIO IN.

Figure 1-9 Front Panel Connections for the Audio Check

• Select More and from the list, select CW MEAS/AF ANL.

• Highlight AF Anl In and select AUDIO IN (1).

• Read the AC Level (2) and the AF Freq (3) reading.

2

1

Figure 1-10 Audio Measurements

3

1-15

Page 26

Localizing the Problem

If Power-Up Happened Correctly

Where to go next

• If the analyzer measurement was within specification, go to Chapter 2, “Running

Diagnostics” and run all the tests.

• If the analyzer measurement was faulty, go to Chapter 2, “Running Diagnostics” and

run the tests relating to the AF Analyzer.

1-16

Page 27

2

Running Diagnostics

2-1

Page 28

Running Diagnostics

Introduction

Introduction

There are two types of diagnostics for the HP/Agilent 8922: diagnostic tests and the HP/

Agilent 8922B specific “RAM Test”. The latter is appropriate for the HP/Agilent 8922B

only. The diagnostic tests are contained either on the memory card, part number 0892210003 or in ROM memory for instruments with firmware revision code A.03.00 and

above. The HP/Agilent 8922B specific “RAM Test” is contained on the “08922-10001,

8922B Driver” disk supplied with the HP/Agilent 8922B.

Most of the diagnostic tests relate to a fault in a specific instrument section. Therefore, if

chapter 1 identified a specific section of the instrument, only those tests need to be run.

The diagnostic tests whose names begin with E or G are specifically for the HP/Agilent

8922E/G. The other tests are for any HP/Agilent 8922.

This chapter comprises two sections. The first section, “Running Memory Card or RAM

Based Diagnostics”, shows how to load and run the memory card based or ROM based

diagnostics. The second section, “Loading and Running the RAM Test”, shows how to

load and run the HP/Agilent 8922B RAM test. Equipment requirements and installation

procedures are given in the HP/Agilent 8922B User’s Guide, Part Number 08922-90020.

This chapter uses the diagnostic test names from an early memory card revision. ROM

based diagnostic test names may differ from the names used in this chapter.

2-2

Page 29

Running Diagnostics

Running Memory Card or ROM Based Diagnostics

Running Memory Card or ROM Based Diagnostics

Do these steps in the order shown

1 - Press

3 Press

2 - Insert Memory Card (Optional)

TESTS

PRESET

2-3

Page 30

Move cursor here and

6

press knob.

Running Diagnostics

Running Memory Card or ROM Based Diagnostics

For Memory Cards:

4

If CARD is displayed, go to step 6, if not move the cursor to this field, press knob and continue at step 5.

Move cursor here and

8

pressknob. Followthe

instructions to start.

To select another test;

• To select another tests from thesame program use

the RESUME user key.

• To select a test from another program press

TESTS key and begin at step 6.

Select CARD

5

Select,

7

AF_DIAGS,

RF_DIAGS1,

MS_DIAGS1,

CAL_REV,

LOOP_BACK

2-4

Page 31

Running Memory Card or ROM Based Diagnostics

Reading Memory Card Diagnostic Test Results

Running Diagnostics

Test Results

Assemblies suspected to be defective

Probability Indicator

Troubleshoot the assembly with the highest

probability first and re-run test. Continue this

process withall assemblies listed until thedefect is

found. See also Chapter 15 "Diagnostic Theory'.

2-5

Page 32

Running Diagnostics

Running Memory Card or ROM Based Diagnostics

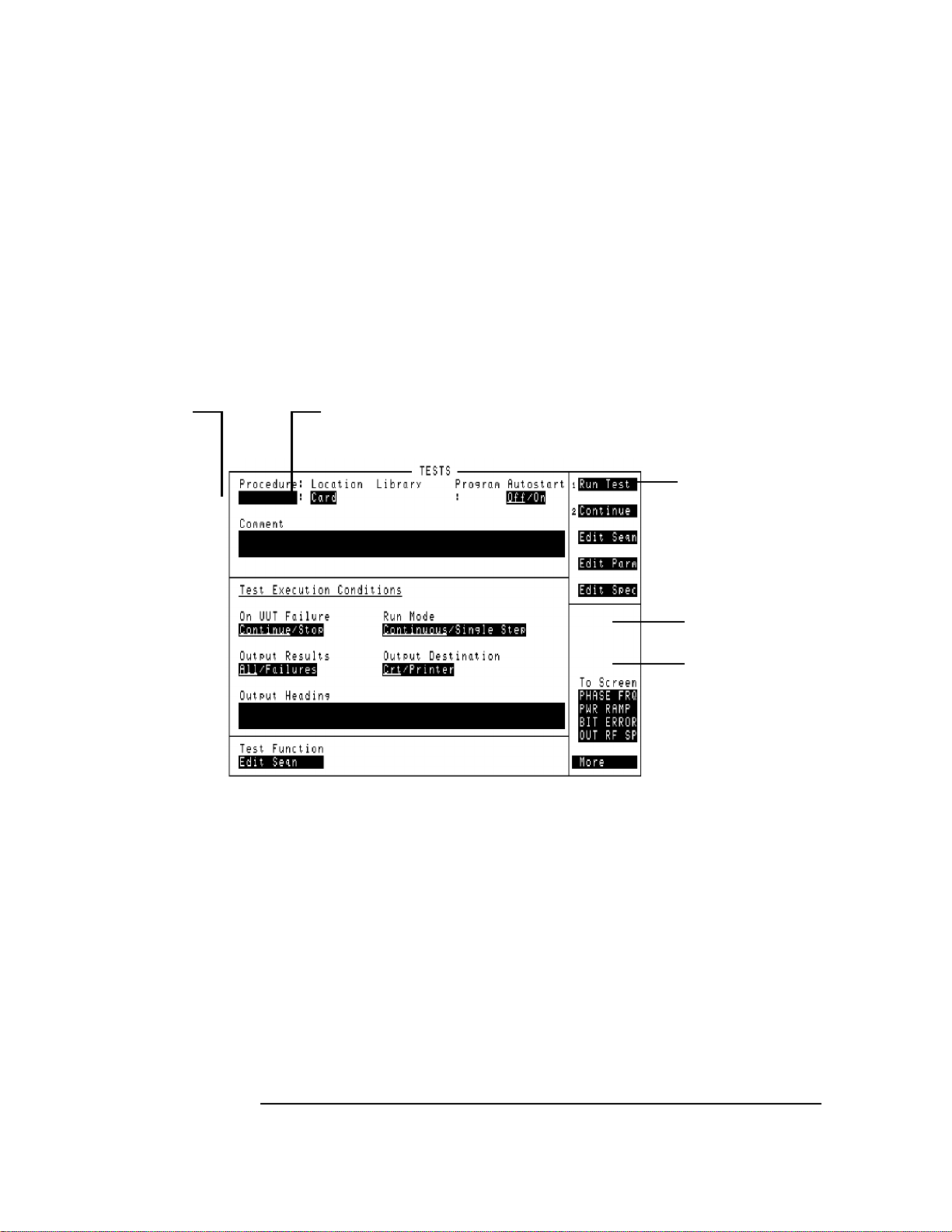

Selecting Memory Card Diagnostic Test Execution Conditions

BEFORE RUNNING A TEST

Specifies whether to run measurements continuously or

stop after completion of each measurement. This choice

can be modified when a diagnostic program is running.

Specifies whether to stop

testing or continue when a

failure occurs. This choice

can be modified when a

diagnostic program is

running.

This feature is not used by

the diagnostic program.

Specifies whether to print diagnostic test results.

WHILE RUNNING A TEST

These options are used for controlling various

parts of the tests. These options can be changed

depending on the test program. They are

selected by using the cursor and knob.

Where to Go Next:

If any high-probability failures occurred, those assemblies can be replaced and the test rerun. When the tests pass, the performance tests can be run to verify performance (refer to

Chapter 3). If low-probability failures occur, the performance tests can be run for further

indication or measurements can be made to individual assemblies using Chapters 4, 12

and 13.

2-6

Page 33

Running Diagnostics

Loading and Running the Ram Test

Loading and Running the Ram Test

Your HP/Agilent 8922B comes with software to test the Data Buffer.

Loading the RAM Test

1 Locate the floppy disk labeled “08922-10001, 8922B Driver.”

2 Insert the disk into the drive.

3 Type MSI A: (substitute your drive specifier for A: if your drive is not drive A) and

press .

4 Type LOAD “DRIVER22B”,1 and press .

The Data Buffer Driver will now be loaded and will begin to run.

5 Press

ENTER

ENTER

K3, "Test RAM

6 Use the cursor to select the output device.

7 Select the area of RAM to test and Press .

K0, "Accept

8 Repeat selection for each area of RAM.

Where to go next

• If any of the RAM areas tested bad go to chapters 8 and 9.

Selecting from a List

• Use and to scroll through the list. A beep will sound when you reach an end

⇓

⇓

of the list.

• Use or to move to the first item in the list.

• Use or to move to the last item in the list.

• Use or to select the current item and move to the next field on the

SHIFT

SHIFT

ENTER

⇓

PG UP

⇓

PG DOWN

⇓

screen.

• Use to select the current item and move to the previous field on the screen.

⇓

2-7

Page 34

Running Diagnostics

Loading and Running the Ram Test

This Page Intentionally Left Blank

2-8

Page 35

3

Verifying Performance

3-1

Page 36

Verifying Performance

Introduction

Introduction

Because of the specialized nature of the HP/Agilent 8922 and the equipment required to

support it, it is recommended that calibration and repair be performed only by specially

equipped Agilent Technologies service centers.

A list of specifications and verfication tests can be found in the HP/Agilent 8922x User’s

Guide.

Verification

Performance Test Software provided with the product is used to verify the electrical

performance of the HP/Agilent 8922 GSM Test Set. If the instrument passes this

verification, its operation and specifications are assured within the measurement

uncertainties provided in the performance test print out.

Installing and Operating the Software

Performace Test Software

This is supplied on a 3.5-inch, double-sided floppy disk and is written to run with BASIC

5.0 and later. Modifications to the program should be limited to changing the default

addresses and storing copies for back-up purposes.

Understanding the Tests

Test Descriptions contains a description of each test that is performed by the Performance

Test software. This description is intended to help locate problems if the software fails to

execute properly or to help users understand the test methodology that is used in each

performance test. The descriptions are not step by step procedures for manual

performance tests.

3-2

Page 37

Verifying Performance

Using the Compatibility Switch for the HP/Agilent 8922F/H or M/S

To Load the Program in the Agilent 8922M/S.

To verify the performance of the HP/Agilent 8922H/M you need to convert the instrument

back from an HP/Agilent 8922G, or convert the HP/Agilent 8922F/S to an HP/Agilent

8922E.

You are now ready to run the Performance Test Software.

1) Put the disk in the disk drive.

2) Type ``LOAD "PT_8922"'', press ENTER.

After you have completed the Performance Tests, return the instrument back to the

HP/Agilent 8922F/S or HP/Agilent 8922H/M using the same process in reverse.

Using the Compatibility Switch for the

HP/Agilent 8922F/H or M/S

Back Conversion

To turn the instrument from the HP/Agilent 8922H/M or HP/Agilent 8922F/S back to an

HP/Agilent 8922G or an HP/Agilent 8922E, select the following keys:

❒ CONFIG (this is accessible from the Cell Control screen in the bottom right-hand

corner).

❒ Compatible, select HP 8922G or HP 8922E

❒ HP-IB Adrs (22)

❒ PRESET

The instrument is now set up as an HP/Agilent 8922G or HP/Agilent 8922E and ready for

Performance Verification testing.

Forward Conversion

To return the instrument from an HP/Agilent 8922G back to an HP/Agilent 8922H/M or

an HP/Agilent 8922E to an HP/Agilent 8922F/S, select the following keys:

❒ More (this is accessible from the Cell Control screen in the bottom right-hand corner).

Scroll down the list and select CONFIG.

❒ Compatible, select HP 8922H/M or HP 8922F/S

❒ HP-IB Adrs (14)

❒ PRESET

The instrument is returned to an HP/Agilent 8922H/M or HP/Agilent 8922F/S.

3-3

Page 38

Verifying Performance

Using the Compatibility Switch for the HP/Agilent 8922F/H or M/S

To Configure the GPIB Addresses

1) With the program loaded, type ``EDIT DEFAULT_ADDRESS'', press ENTER.

2) Modify each line to indicate the proper instrument address (700-730).

It is now possible to re-store the program as "PT_8922" or store it under a different name.

To Run the Program

1) Type ``RUN'', press ENTER.

2) Follow the directions as they appear on the screen.

Notes on Running the Program.

The first screen which appears is the GPIB status of each piece of test equipment that is

supported. It is only necessary to have the instruments responding that will be used in each

particular test. Make certain that each instrument you will be using is responding at the

proper address. Duplicate addresses may make an instrument appear to be responding but

this is not allowed. Press "I" (for Ignore) to continue past this screen.

The second screen prompts you for the instrument model. If you have disk 08922-10006,

select HP 8922G (for HP/Agilent 8922H/M performance testing) or HP 8922E (for

HP/Agilent 8922F/S performancetesting). The third screen which will appear is the main

Performance Tests selection menu. Three options are available on this screen:

❒ Select the performance test to run, remember the test instruments and UUT must be

responding over GPIB.

❒ Turn the printer function ON or OFF. If the printer function is turned on it must be

responding over GPIB or the program will lock up.

❒ Exit from the program.

Press the key corresponding to the option that you would like to perform.

The other screens that appear are connection instructions, error messages and output

results.

3-4

Page 39

4

Using the HP/Agilent 83210A Service Kit

4-1

Page 40

Using the HP/Agilent 83210A Service Kit

Introduction

Introduction

This section is a supplement to the diagnostics program for troubleshooting the

HP/Agilent 8922 to the assembly level. The extender boards should be used when the

diagnostics cannot correctly isolate a defective assembly, or when it is necessary to verify

the module level performance of the HP/Agilent 8922.

The section provides the information necessary to extend and troubleshoot the input and

output signals for most RF, audio, and digital assemblies.

4-2

Page 41

Configuring the RF Extender

To extend RF modules, it is necessary to use the RF extender board (08922-60129) with

the correct coax jumper cables. These cables route the RF signals to and from the module

and allow the signal path to be accessed for measurements. The following table and

diagram shows the coax jumpers that are required for each RF module.

Table 4-1 Coax Jumpers for RF Extender Board

On PLUG 1 Connect Pin Number On PLUG 3 Connect Pin Numbers

Assembly

Number

ForA13 X X X

For A14 X X X X X X

3 7 9 13 17 3 9 13 15 17 20

Using the HP/Agilent 83210A Service Kit

Configuring the RF Extender

For A15 X X X X X X X X

ForA16 X X X X X X

For A17 X X

For A18 X X X

For A25 X X X

For A26 X X

ForA27 X X X X

4-3

Page 42

Using the HP/Agilent 83210A Service Kit

Configuring the RF Extender

The following example shows how to interpret table 4-2 and install the coax jumpers on

the extender board. This example shows the configuration for the A13 assembly.

Figure 4-1 RF Extender Board

4-4

Page 43

Extending Modules

The modules shown in the following table can be extended using the appropriate extender

boards from the HP/Agilent 83210A Service Kit. Assemblies that cannot be extended can

usually be accessed directly while the assembly is installed in the instrument.

Table 4-2 Extender Board Part Numbers

REF # DESCRIPTION EXTENDER

A2 Audio Analyzer 2 08920-60142

A3 Audio Analyzer 1 08920-60142

A4 Modulation Distribution 08920-60141

A5 Premod Filter and NSM 08922-60132

Using the HP/Agilent 83210A Service Kit

Extending Modules

A6 Signaling Source / Analyzer 08920-60140

A7 Controller 08920-60133

08920-90135

A8 Memory 08922-60132

A9 Global Test and Demod 08922-60133

A13 Output 08922-60129

A14 GSM Timing Gen 08922-60129

A15 Reference 08922-60129

A16 Receiver 08922-60129

A17 Step Loop B 08922-60129

A18 Spectrum Analyzer 08922-60129

A19 Measurement 08920-60138

A20 CRT Driver 08920-60135

A25 Sum Loop 08922-60129

A26 Step Loop A 08922-60129

A27 DAC / Upconverter 08922-60129

A33 Hop Controller 08920-60133

4-5

Page 44

Using the HP/Agilent 83210A Service Kit

Making Measurements

Making Measurements

Audio / Digital Assemblies

The extender boards for the audio and digital assemblies allow the boards to be extended

above the instrument. This provides better access to signals going to and from these

assemblies. Refer to the “Block Diagrams” (chapter 13) or “Module I/O Specs”

(chapter 12) for pin numbers and typical I/O characteristics for each assembly. Use the

extender board shown.

RF ASSEMBLIES

The extender boards for the RF assemblies extend the modules above the instrument. This

allows better access to control signals and allows the RF input and output signal paths to

be opened for making measurements. The following procedure outlines the steps

necessary to make measurements on the RF modules with the RF extender board.

1. Configure the RF extender card with the proper coax jumpers. Refer to table 4-2 and

figure 4-1.

2. Decide the signal path that needs to be measured. Find the correct plug number and pin

number on the “Block Diagrams” (chapter 13) or “Module I/O Specs” (chapter 12).

4-6

Page 45

Using the HP/Agilent 83210A Service Kit

Making Measurements

3. Remove the correct coax jumper and connect a measurement instrument as shown in

thefollowingdiagram.TomeasuresignalsgoingTOthemodule,measurementsshould

be made on the lower row of connectors on the extender module. Outputs coming

FROM the modules (going into the instrument) are measured on the top row of

connectors on the extender board.

4. Turn off the instrument’s power switch. Remove the module from the instrument.

Install the module onto the extender board and install the extender board into the

instrument.

5. Power on the instrument and make the measurements.

4-7

Page 46

Using the HP/Agilent 83210A Service Kit

Making Measurements

This Page Intentionally Left Blank

4-8

Page 47

5

Troubleshooting the Controller/Display

5-1

Page 48

Troubleshooting the Controller/Display

Introduction

Introduction

This chapter helps isolate problems in the control sections of the instrument, the sections

are:

• A1 Keyboard

• A7 Controller

• A8 Memory

• A20 CRT Driver

• A21 HP-IB Interface

• A33 Hop Controller

Problems in the Control sections can be broken into four types, these types are:

• Parallel Bus

• Serial Bus

• Display

• Keyboard

This chapter addresses each category in a separate section. This chapter assumes that

Chapter 13, Instrument Block Diagram will be used as a reference.

5-2

Page 49

Troubleshooting the Controller/Display

Parallel Bus

Parallel Bus

The parallel bus is at the center of the control section. The parallel bus is defined as direct

connections to the A7 Controller.These connections include the data bus, address bus and

dedicated parallel control lines.

The assemblies on the parallel bus are:

• A1 Keyboard

• A6 Signalling Source/Analyzer

• A7 Controller

• A8 Memory

• A9 Global Test/Demod

• A19 Measurement Board

• A20 CRT Driver

• A21 GPIB Interface

• A32 GSM Controller

• A33 Hop Controller

Most problems with the parallel bus are accounted for in the power-up self-tests. The self-

tests check the A7 Controller first, then the A8 Memory. If these two tests pass, the

instrument will beep once after approximately 10 seconds. If these tests do not pass, the

problem is probably on one of the two boards or something is pulling down the parallel

bus.

The assemblies that are not directly checked by the power-on self-tests are the A1

Keyboard and the A21 GPIB Interface.

5-3

Page 50

Troubleshooting the Controller/Display

Serial Bus

Serial Bus

The serial bus controls many of the assemblies through individual serial control lines. The

serial control lines are generated at the A33 Hop Controller.

The A33 Hop Controller takes parallel data from the A7 Controller and de-multiplexes the

data for the assemblies on the serial bus. In the power-up self-tests, the A33 Hop

Controller and the assemblies on the serial bus are tested. If a power-up self-test serial bus

failure occurs and no A33 failures have occurred, the problem could be between the A33

Hop Controller and the assembly identified in the failure.

5-4

Page 51

Troubleshooting the Controller/Display

Display

Display

The display section contains the A22 CRT, and the A20 CRT Drive. The A20 CRT Drive

receives parallel data from the A7 Controller and generates the drive signals for the A22

CRT. The A20 CRT Drive is tested during the power-up self-tests for the ability to receive

data and to respond back to the A7 Controller. If the A20 CRT Drive passes the power-up

self-tests and the display does not respond the signals going to the A22 CRT can be

checked at J6 on the A29 Motherboard.

Line Name Pin Number Description

INTHIGH J6(1) CRT intensity reference high. Up to 100 V with

respect to INTLOW. Floating with respect to

ground. From the A22 CRT to bias the intensity

drive circuit at the A20 CRT Drive.

INTW J6(2) CRT intensity control voltage. Up to 100 V with

respect to INTLOW. Floating with respect to ground.

From the A20 CRT Drive to the A22 CRT to vary the

intensity of the display.

INTLOW J6(3) CRT intensity reference low. Floats with respect to

ground. From the A22 CRT to the low side of the

intensity drive circuit at the A20 CRT Drive.

HSYNC J6(4) Horizontal sync pulse for the A22 CRT. A TTL

pulse at approximately 19 kHz. From the A20 CRT

Driveto the A22 CRT. The HP/Agilent 8922F/H/M/S

use a 15 kHz PAL signal.

+12CRT J6(5) Filtered +12AUX for the A22 CRT. There is a 20

kHz low pass filter on the A29 Motherboard to filter

the +12AUX for the A22 CRT.

VID J6(6) Video signal for the A22 CRT. A TTL signal to turn

the signals off and on. The rate is approximately

6.25 MHz. From the A20 CRT Drive to the A20

CRT.

VSYNC J6(7) Vertical sync pulse for the A22 CRT. A TTL signal

from the A20 CRT Drive to the A22 CRT at a rate of

approximately 60 Hz.

GND J6(8)

5-5

Page 52

Troubleshooting the Controller/Display

Keyboard

Keyboard

The A1 Keyboard assembly contains both the keys and the knob. The keyboard is

configured in a matrix with the rows being scanned with pulses from the A7 Controller

and the columns being read by the controller. The column lines are pulled up through

resistors and are pulled low when a key is pressed. The A7 Controller determines which

key is being pressed by reading which column line is pulled low and which row the

column line is being pulled low through. Since the row outputs are tri-state, the low-going

pulses are not seen on the output until a key is pressed and the current path is completed.

The keyboard can be checked with an oscilloscope by disconnecting the ribbon cable from

the keyboard and checking for the pull-up voltages on the column pins. Then with the

keyboard connected, check that the lines are being pulled low at the A7 Controller

connector J4. The pin numbers on A7-J4 are the same as those on A1-J1. The ribbon cable

connector has a mark to indicate to pin 1. Pin 2 is directly opposite pin 1.

Table 5-1 HP/Agilent 8922E/F/G/H/M/S Keyboard (HP/Agilent 8922 A/B keys shown in

parenthesis)

Column 0

Pin 9

CELL

CONFIG

(RF GEN/

RF ANL)

CELL

CNTL

(HOP

CNTRL)

MEAS

SYNC

PREV INCR×10 up arrow not used not used leftarrow

TESTS 7 4 1 0 ON/OFF

MEAS

ARM

RECALL 9 6 3 +/- % dBµV

Column 1

Pin 10

ORGCALL

(K1)

INCR÷10 down arrow not used SHIFT CANCEL

INCRSET PRESET not used not used not used

8 5 2 . ppm W

Column 2

Pin 11

RCVCALL

(K2)

Column 3

Pin 12

ENDCALL

(K3)

Column 4

Pin 13

L1(K4) L2(K5)

Column 5

Pin 14

LOCAL ENTER GHZ dBm MHz V kHzmV Hz µV

5-6

Page 53

Troubleshooting the Controller/Display

Keyboard

If the pull-up voltages are present at the end of the ribbon cable and the voltages are not

pulled down when a key is pressed, the problem is most likely on the A1 Keyboard

assembly.If the pull up voltages are present and are pulled down when a key is pressed but

the controller does not respond, the problem is most likely at the A7 Controller assembly.

The knob can be checked with an oscilloscope at the J4 connector on the A7 Controller.

When the knob is turned, pulses should be present on A7-J4 pins 19 and 21. When the

knob is pushed the level at A7-J4 pin 23 should change states. The A1 Keyboard end of

the ribbon cable should also be checked for +5 V on pins 15 and 16. If the signals are

getting to the A7 Controller the problem is most likely at the A7 Controller assembly.

Where to Go Next

If either the A1 Keyboard or A7 Controller assemblies measured in-correctly, go to

chapters 8 and 9.

5-7

Page 54

Troubleshooting the Controller/Display

Keyboard

This Page Intentionally Left Blank

5-8

Page 55

6

Troubleshooting the Power Supply

6-1

Page 56

Troubleshooting the Power Supply

Introduction

Introduction

This chapter helps verify that the power supply is at fault when no indication for power is

present upon power-up. If the power supply appears defective, the problem can be

localized to the line module, mains (line) fuse, transformer, power supply, regulator,

motherboard, or power switch. This chapter is arranged to check each section of the power

supply.The views of the instrument in this chapter are both top and bottom views with the

covers removed. Refer to chapter 8 “Assembly/Disassembly” for help in removing the

covers.

NOTE The mains (line) fuses and power supply DC fuses in the HP/Agilent 8922 are all fast-blow

fuses (not “slow-blow”).

6-2

Page 57

Power Cord Verification

Use this diagram to verify that the correct line cord is being used.

Table 6-1 Line Cords

Troubleshooting the Power Supply

Power Cord Verification

PlugType

Cable

Agilent

Part

Number

8120-1351

8120-170304

8120-1369

8120-069604

8120-1689

8120-169272

8120-1378

8120-4753

8120-1521

8120-4754

8120-1348

8120-153823

8120-2104

8120-2296

8120-3997

C

Plug Description

D

90/Straight BS1363A

90

Straight

NZSS198/ASC112

Straight/90

Straight

90

1

Straight NEMA5-15P

Straight

6

90

90

1

Straight

90

3

Straight SEV 1011

1959-24507, Type 12

4

Straight/90

4

Straight/90

a

a

a

Length,

inches

(mm)

90 (229)

90 (229)

79 (201)

87 (221)

79 (201)

79 (201)

80 (203)

90 (230)

80 (203)

90 (230)

80 (203)

80 (203)

79 (201)

79 (201)

177 (402)

Cable

Color

Mint

Gray

Mint

Gray

Gray

Gray

Mint

Gray

Mint

Gray

Jade

Gray

Jade

Gray

Jade

Gray

Dark

Gray

Dark

Gray

Gray

Gray

Gray

For Use In

Country

United Kingdom,

Cyprus, Nigeria,

Rhodesia,

Singapore

Australis,

Argentina,

New Zealand,

Mainland China

East and West

Europe, Central

African Republic,

Arabia, Egypt

United States,

Canada, Mexico,

Phillipines, Taiwan,

Japan

Switzerland

Continued Over

8120-0698 6 Straight/NEMA6-15P 90 (230) Black United States,

Canada

6-3

Page 58

Troubleshooting the Power Supply

Power Cord Verification

Table 6-1 Line Cords

Cable

PlugType

Agilent

Part

C

Plug Description

D

Number

8120-2956

8120-2957

8120-3997

8120-4211

8120-460078

8120-1860

8120-1575

8120-2191

8120-4379

a.Part number shown for plug is industry identifier for plug only. Number shown for cable is Agilent Part Number

for complete cable including plug. E = Earth Ground; L = Line; N = Neutral.

3

90/Straight

4

90/90

4

Straight/Straight

Straight IEC83-B1

Straight/90

6

Straight CEE22-V1

(Systems Cabinet Use)

0

Straight/Straight

8

Straight/90

8

90/90

Length,

a

inches

(mm)

79 (201) Gray

79 (201)

79 (201)

59 (150)

31 (79)

59 (150)

80 (203)

Cable

Color

Gray

Gray

Black

Gray

Jade

Gray

Jade

Gray

Jade

Gray

Jade

Gray

For Use In

Country

Denmark

South Africa, India

6-4

Page 59

Troubleshooting the Power Supply

Line Voltage Selection / Line Fuse Replacement

Line Voltage Selection / Line Fuse Replacement

Use this diagram to verify that the line module is set to the correct line voltage, that the

fuse is not blown, and that it is the correct value.

6-5

Page 60

Troubleshooting the Power Supply

Transformer / Power Switch

Transformer / Power Switch

Use this diagram to verify that the correct voltages are present when the instrument’s

power cord is connected. The table shows the expected values and pin numbers.

6-6

Page 61

Troubleshooting the Power Supply

A28 Power Supply

A28 Power Supply

Use this diagram to verify that the regulated voltages are present and correct at the output

of the power supply board, and at the mother board connection to the regulator. Use this

diagram also to check the fuses on the fuse board. The tables show the voltages,

connectors, pin numbers, and fuse values.

6-7

Page 62

Troubleshooting the Power Supply

Where To Go Next

Where To Go Next

If any part of the power supply is defective refer to chapter 8 “Assembly/Disassembly”

and chapter 9 “Replacing a Part” for removal and replacement. After the power supply is

repaired, go to chapter 1 “Localizing the Problem” to verify that no other problems exist.

6-8

Page 63

7

Adjustments and Calibration

7-1

Page 64

Adjustments and Calibration

Introduction

Introduction

This chapter contains information to perform the necessary calibrations and adjustments

for periodic maintenance or following repairs. Each year the timebase and periodic

calibration adjustments should be performed. Also, the overall performance of the

instrument should be verified each year with the automated performance tests in chapter 3

“Running Performance Tests”.

The calibrations and adjustments covered in this chapter are divided into three sections:

❒ Timebase Adjustments

• Standard Timebase

• Optional High Stability Timebase

❒ Periodic Calibrations (ROM based)

• Voltmeter Reference

• Audio Frequency Generator Gain

• External Modulation Path Gain

• Audio Analyzer 1 Offset

❒ Sum Loop Adjustment Procedure

7-2

Page 65

Adjustments and Calibration

Timebase Adjustments

Timebase Adjustments

Standard Timebase Adjustment Procedure (Reference Calibration)

NOTE This procedure should only be performed after the instrument has warmed up at least 30

minutes. It should be performed after replacement of the reference section A15, or if the

instrument gives an error message “Frequency reference cal lost. Perform reference

calibration.”

1. Connect a 10 MHz source to the rear panel REF IN connector.

2. On the configuration screen, select the “Calibrate” field.

3. Wait approximately 15 seconds; the reference will be calibrated.

7-3

Page 66

Adjustments and Calibration

Timebase Adjustments

Option 001 High Stability Timebase Adjustment Procedure

1. Remove the instrument top cover. Power up the instrument and let it warm up for

approximately 1 hour.

2. Remove the rear-panel cable between the Opt. 001 REF OUT and REF IN connectors

(if present).

3. Attach a high accuracy frequency counter to the rear panel OPT 001 REF OUT. The

frequency counter resolution and accuracy should be at least 1 Hz at 10 MHz.

4. Adjust the high stability timebase (see figure 7-1) until the frequency counter reads 10

MHz.

NOTE After performing this calibration, it is necessary to install a cable from the OPT 001 REF

OUT to the REF IN connector for the instrument to use the high stability timebase as the

reference.

Figure 7-1 High Stability Timebase Adjustment

Adjust to

10 Mhz

7-4

Page 67

Adjustments and Calibration

Periodic Calibrations

To Run the Periodic Self-Calibration Program

1. Press to access the TESTS screen.

2. Select the field to the right of the colon under Procedure.

3. Select ROM under the Choices: menu.

4. Select the field to the left of the colon under Procedure.

5. Select PER_CAL under the Choices: menu.

TESTS

Periodic Calibrations

6. Select .

7. Follow the instructions on the screen.

RUN TEST

7-5

Page 68

Adjustments and Calibration

Sum Loop Adjustment Procedure

Sum Loop Adjustment Procedure

This procedure should be performed whenever Step Loop A Assembly (A26) or Sum

Loop Assembly (A25) is replaced. It is not necessary to perform this adjustment for a

periodic calibration.

A spectrum analyzer is required to measure the instrument’s output during these

procedures. It is recommended to use a synthesized spectrum analyzer if possible.

Procedure:

1. Turn off the HP/Agilent 8922.

2. Remove the instrument top cover and the DAC/Upconverter Module (A27). (It is

necessary to remove the RF Cover plate that holds the module in the instrument.)

3. Power up the instrument, selecttheRFGENERATOR/RFANALYZERscreen,andset

the RF Gen Amplitude to −20 dBm at the RF IN/OUT connector.

4. Prepare the spectrum analyzer. Set the reference level to −10 dBm. Connect the HP/

Agilent 8922 RF IN/OUT to the spectrum analyzer input.

First Adjustment

5. Again from the RF GENERATOR screen, set the HP/Agilent 8922 frequency to 800

MHz.

6. Set the spectrum analyzer center frequency to 786.6 MHz. (The output from the HP/

Agilent 8922 is 13.4 MHz lower than was entered because the DAC/Upconverter is

gone).

7. Set the spectrum analyzer span to 10 MHz per division. ADJUST R32 “OFFSET” on

top of Sum Loop (A25) until the signal on the spectrum analyzer is between 776.6 and

796.6 MHz.

8. Reduce the spectrum analyzer span to 1 MHz per division and adjust R32 again until

the signal on the spectrum analyzer is centered within 2 divisions (2 MHz).

NOTE Some modules (prefix 3050A and lower) only need to be centered within 10 MHz for all

of these adjustments.

7-6

Page 69

Adjustments and Calibration

Sum Loop Adjustment Procedure

Second Adjustment

9. Now set the HP/Agilent 8922 frequency to 502 MHz.

10. Set the spectrum analyzer center frequency to 488.6 MHz with a span of 10 MHz per

division.

11. Adjust R180 “GAIN” on top of Sum Loop (A25) until the signal on the spectrum

analyzer is centered within 10 MHz.

12. Reduce the spectrum analyzer span to 1 MHz per division, and adjust R180 again until

the signal on the spectrum analyzer is centered within 2 divisions (2 MHz).

Final Adjustment

13. Set the HP/Agilent 8922 frequency to 1000 MHz.

14. Set the spectrum analyzer frequency to 986.6 MHz, then set the span to 10 MHz per

division.

15. AdjustR160“KNEEGAIN”ontopofSum Loop (A25) until the signal on the spectrum

analyzer is centered within 1 division (10 MHz).

16. Reduce the spectrum analyzer span to 1 MHz per division, then adjust R160 again until

the signal on the spectrum analyzer is centered within 2 divisions (2 MHz).

Final Check

17. Repeat the above procedures until all three adjustments pass without any further fine

tuning.

18. Turn the instrument power off and reinstall the DAC/Upconverter Module. The

adjustment is now complete.

7-7

Page 70

Adjustments and Calibration

Sum Loop Adjustment Procedure

This Page Intentionally Left Blank

7-8

Page 71

8

Assembly and Disassembly Procedures

8-1

Page 72

Assembly and Disassembly Procedures

Introduction

Introduction

Removing and replacing assemblies is straightforward. This chapter contains tool lists,

hints and drawings to help you do it effectively. Detailed step-by-step procedures are not

given for all assemblies.

After replacing certain assemblies you will need to load new calibration data into the HP/

Agilent 8922 or perform adjustments. The calibration data is supplied on a Memory Card

that is included with the replacement assembly.

Refer to chapter 9, “Replacing a Part”, for information about adjustments that are required

after replacing certain assemblies.

CAUTION Perform the following procedures only at a static safe work station. The printed circuit

assemblies in this instrument are very sensitive to STATIC ELECTRICITY DAMAGE.

Wear an anti-static wrist strap that is connected to earth ground.

Recommended Torque

1. Screws: Tighten until just snug.

2. RF connectors (SMC SMA): 62 N-cm (5.5 lb-in.)

3. Nuts holding semi-rigid coax: 51 N-cm (4.5 lb-in.)

Further Information

For further information, refer to chapter 9. This chapter contains more information about:

• Part numbers for replaceable parts.

• Ordering information.

• Adjustments required after assemblies are replaced.

8-2

Page 73

Assembly and Disassembly Procedures

Top and Bottom Cover Removal

Top and Bottom Cover Removal

1. Remove four 2-pt. Pozidriv top bumper mounting screws.

2. Remove four 2-pt. Pozidriv side mounting screws and bumpers.

3. Remove four 2-pt. Pozidriv screws and standoffs.

4. Remove fourteen TX-10 screws and top cover.

5. Remove two TX-10 screws and bottom foot.

6. Remove two TX-15 screws and bottom cover.

Tools Required

• TX-15 screw driver

• TX-10 screw driver

• 2-pt. Pozidriv screw driver

1

(Both Sides)

To remove covers, pull sides

slightly apart, slide them back a

few inches and lift off.

SIDE VIEW

3

2

4

(Both Sides)

6

(Both Sides)

8-3

Page 74

Assembly and Disassembly Procedures

Inside Protective Covers

Inside Protective Covers

All covers can be removed with a TX-15 screw driver. Screws shown circled only require

loosening.

492 Top Cover (B, E and G)

493498

506521

499501

Washer

505 Bottom Plate (B,E and G)

252

240 GPIB

Mounting

Bracket and

241-242

Screws

244

458

(Opt. 001)

502504

Nut

416421,

427456

424

114 Regular

Mounting

Bracket and

115-118

Screws

(Not Shown)

3

8-4

12 CRT Bracket

426

Page 75

Assembly and Disassembly Procedures

AF, Digital and RF Assemblies Removal

AF, Digital and RF Assemblies Removal

A27

A28

A25

A13

A15

A11

A20

A16

A18

A17

A14

A2 A3 A4 A5 A6 A9 A8 A7 A33 A34, (A,G)

A37 (B)

A19

A32

A31, (G)

A36, (B)

8-5

Page 76

Assembly and Disassembly Procedures

AF, Digital and RF Assemblies Removal

This can only be done once the top cover and inside protective covers have been

removed.

RELEASE LEVERS

PULL

RING

CAUTION Before pulling ring on the A8 Memory Board loosen the securing screw.

Use a TX-10 Torx head screwdriver to loosen.

8-6

Page 77

Assembly and Disassembly Procedures

A1 Front Panel Removal

A1 Front Panel Removal

Done with top, bottom, and inside protective covers removed.

Removing Modules

1. Remove RF cover.

2. Remove RF modules.

Disconnecting Cables

3. Disconnect RF cable on mixer assembly. (1/4-inch SMA connector)

4. Disconnect cable from connector J77 on motherboard.

5. Disconnect top cable from pulse switch.

6. Disconnect cable from connector J6 on motherboard.

7. Disconnect cable from connector J5 on motherboard.

8. Disconnect ribbon cable from front panel.

Detaching Front Panel

9. Remove TX-15 top CRT mounting screw.

10. Remove 2 TX-15 side CRT mounting screws.

11. Remove 8 TX-10 front panel mounting screws. (both sides)

NOTE Steps 12 and 13 are necessary only when complete removal of the front panel is desired.

Most repairs can be made without completing these steps.

12. Remove 15 5/8-inch hex nuts.

13. Pull front panel assembly away from chassis until speaker assembly is visible. Remove

3 TX-10 mounting screws and disconnect the speaker cable from J7 on motherboard.

Tools Required

• TX-15 screw driver

• TX-10 screw driver

• 2-pt. Pozidriv

• 5/8-inch wrench

• 1/4-inch wrench

8-7

Page 78

Assembly and Disassembly Procedures

A1 Front Panel Removal

27-30

546

(Trim)

38-43,

45, 46,

65

34

W31

Power

Switch

(A1 Mounting Screws)

7-11

47

35

A1

6

(Trim)

548

37

36

J1

70

32

33

48

31

(Nut under

volume knob)

1

(Panel

Dress)

2

(Frame)

49-52,

54-63,

66

547

(Trim)

8-8

RFI Gaskets

Top 532

Bottom 533

Right Side 528, 529

Left Side 530,531

Page 79

Assembly and Disassembly Procedures

A10 Power Supply Regulator Removal

A10 Power Supply Regulator Removal

Done with top cover removed.

1. Remove Digital cover.

2. Remove A33 Hop Controller to expose A10 screw.

3. Loosen TX-15 screw.

4. Disconnect attached cable and remove power regulator.

Tools Required

• TX-15 screw driver

• TX-10 screw driver

• 1/4-inch wrench

TOP VIEW

3

2

1

8-9

Page 80

Assembly and Disassembly Procedures

A11 Receiver Mixer Removal

A11 Receiver Mixer Removal

Done with top cover removed.

1. Remove RF cover.

2. Remove at least three RF modules.

3. Remove three TX-10 screws.

4. Disconnect all cables and remove the A11 Receiver Mixer assembly.

Tools Required

• TX-15 screw driver

• TX-10 screw driver

• 1/4-inch wrench

8-10

Page 81

Assembly and Disassembly Procedures

A11 Receiver Mixer Removal

1

2

TOP VIEW

SIDE VIEW

MIXER

3

8-11

Page 82

Assembly and Disassembly Procedures

A12 Pulse Attenuator Removal

A12 Pulse Attenuator Removal

Done with top cover removed.

1. Remove RF cover.

2. Remove at least three RF modules.

3. Remove two TX-10 screws.

4. Disconnect all cables and remove A12.

Tools Required

• TX-15 screw driver

• TX-10 screwdriver

• 1/4-inch wrench

8-12

Page 83

Assembly and Disassembly Procedures

A12 Pulse Attenuator Removal

1

2

TOP VIEW

PULSE

SWITCH

SIDE VIEW

3

8-13

Page 84

Assembly and Disassembly Procedures

A21 GPIB Interface Removal

A21 GPIB Interface Removal

Done with top cover removed.

1. Remove four TX-15 power supply cover screws.

2. Remove two 7mm bolts.

3. Remove one TX-10 screws.

4. Disconnect ribbon cable.

Tools Required

• TX-15 screw driver

• TX-10 screw driver

• 7mm wrench

8-14

Page 85

TOP VIEW

Assembly and Disassembly Procedures

A21 GPIB Interface Removal

1

2

3

4

8-15

Page 86

Assembly and Disassembly Procedures

A22 Display Removal

A22 Display Removal

Done with instrument top and bottom covers removed.

1. Do steps 1 through 11 of the A1 Front Panel removal instructions.

NOTE The front panel assembly must be separated from the main chassis. Considerable pulling

force is required to pull the front panel from the chassis.

2. Disconnect RF cable. (5/16-inch SMC connector.)

3. Remove front bezel. (Slide a flat-blade screw driver under the left bottom corner of the

bezel and pry it forward until it pops loose.)

4. Remove four TX-15 front panel mounting screws.

5. Remove two 5/18-inch hex nuts.

6. Pull theCRTassemblyandthefrontpanelapart. (Be careful not to damage RF cabling.)

7. Remove four TX-15 CRT bracket mounting screws.

8. Loosen two TX-15 input mounting screws.

9. Slide the monitor out of the CRT shield.

Tools Required

• TX-15 screw driver

• TX-10 screw driver

• 2-pt. Pozidriv

• 5/8-inch wrench

• 1/4-inch wrench

• 5/16-inch wrench

• flat blade screw driver

8-16

Page 87

Assembly and Disassembly Procedures

A22 Display Removal

3

2

CRT

4

(4 places)

5

7

CRT SIDE VIEW

6

8

8-17

Page 88

Assembly and Disassembly Procedures

A23 Input Section Removal

A23 Input Section Removal

Done with instrument top and bottom cover removed.

1. Do steps 1 through 11 of the A1 Front Panel removal instructions.

NOTE The front panel assembly must be separated from the main chassis. Considerable pulling

force is required to pull the front panel from the chassis.

2. Remove two 5/8-inch hex nuts.

3. Remove two TX-15 side mounting screws.

4. Remove one TX-15 bottom mounting screw.

5. Disconnect all cabling and remove input section assembly.

Tools Required

• TX-15 screw driver

• TX-10 screw driver

• 2-pt. Pozidriv

• 5/8-inch wrench

• 1/4-inch wrench

FRONT PANEL

AND SIDE VIEW

A22 Display

3

RIBBON

CABLE

1/4" SMC

CONNECTOR

(2 places)

2

1/4" SMC CONNECTOR

4

BOTTOM VIEW

8-18

Page 89

Assembly and Disassembly Procedures

A24 Attenuator Removal

A24 Attenuator Removal

Done with instrument top and bottom covers removed.

1. Do steps 1 through 11 of the A1 Front Panel removal instructions.

NOTE The front panel assembly must be separated from the main chassis. Considerable pulling

force is required to pull the front panel from the chassis.

2. Remove two TX-15 attenuator mounting screws.

3. Disconnect two RF cables. (5/16-inch SMA connectors.)

4. Push the top of the attenuator firmly away from the CRT until it becomes free.

Tools Required

• TX-15 screw driver

• TX-10 screw driver

• 2-pt. Pozidriv

• 5/8-inch wrench

• 1/4-inch wrench

• 5/16-inch wrench

2

(5/16" SMA)

3

4

8-19

Page 90

Assembly and Disassembly Procedures

A28 Power Supply Removal

A28 Power Supply Removal

Done with instruments top and bottom covers removed.

1. Remove power supply cover.

2. Remove standard plate. If installed remove option 001.

3. Remove five TX-10 screws that attach power supply board to the main chassis.

4. Remove the eight 2-pt. Pozidriv rear panel mounting screws (four on each side).

5. Remove the four TX-10 transformer mounting screws.

6. Remove the eight TX-10 connector plate mounting screws.

7. Disconnect cables from connectors J1 and J2.

8. Carefully slide power supply away from instrument.

Tools Required

• TX-15 screw driver

• TX-10 screw driver

• 2-pt. Pozidriv

1

2

3

8-20

TOP VIEW

BOTTOM VIEW

Page 91

Assembly and Disassembly Procedures

A28 Power Supply Removal

8-21

Page 92

Assembly and Disassembly Procedures

Fan Removal

Fan Removal

Done with top cover removed.

1. Remove four TX-15 power supply cover screws and remove cover.

2. Remove four 2-pt. fan mounting Pozidriv screws.

3. Disconnect cable and remove fan.

Tools Required

• TX-15 screw driver

• 2-pt. Pozidriv

8-22

Page 93

Assembly and Disassembly Procedures

Fan Removal

8-23

Page 94

Assembly and Disassembly Procedures

Transformer Removal

Transformer Removal

Done with top and bottom covers removed.

1. Do steps 1 through 8 of the A28 Power Supply Removal instructions.

2. Disconnect cables and remove transformer using illustration below.

Tools Required

• TX-15 screw driver

• 2-pt. Pozidriv

• Soldering equipment

• TX-10 screwdriver

8-24

Page 95

9

Replacing a Part

9-1

Page 96

Replacing a Part

Introduction

Introduction

To order parts contact your local Agilent Technologies Sales and Service office.

Assembly Replacements

For most parts, you can either order a new assembly or an exchange assembly. Exchange

assemblies are factory-repaired, inspected, and tested. If you order an exchange assembly

you must return the defective assembly for credit.

With some assemblies you will receive a Memory Card that contains factory-generated

calibration data for the assembly. There will also be an instruction sheet for loading the

calibration data into the instrument after you replace the defective assembly. With

exchange assemblies, you must return the Memory Card with the defective assembly to

receive full credit.

Adjustments after Replacing Assemblies

The following table shows which adjustments should be performed after replacing

assemblies. The adjustments and calibrations are described in chapter 8, “Assembly/

Disassembly”.

Table 9-1 Adjustments After Replacement

Assembly

Replaced

A3 Periodic Self Cal

A4 Periodic Self Cal

A15 Timebase Adjustment (standard)

A19 Periodic Self Cal

A25 Sum Loop Adjustment

A26 Step Loop Adjustment

Calibration or Adjustment

Required

9-2

Page 97

Replacing a Part

Replaceable Parts

Replaceable Parts

The following tables and figures list part numbers for replaceable parts. For more

information or details of replaceable parts, contact your local Agilent Technologies Sales

and Service Office.

9-3

Page 98

Replacing a Part

Replaceable Parts

Table 9-2 Replaceable Parts

Item Agilent Part

Number

A1 08920-60201 3 1 BD AY KEY 28480 08920-60201

J1 1250-1811 5 1 ADAPT FN F SMA (CONN, TP N) 00000 ORDER BY

W31 08922-61037 8 1 SWITCH/SPKR HARNESS ASSY (G/H/M Only) 28480 08922-61037

W31 08922-61085 1 SWITCH/SPKR HARNESS ASSY (E/F/S Only) 28480 08922-61085

1 08922-00009 6 1 PANEL DRESS (A/B Only) 28480 08922-00009

1 08922-00079 1 PANEL DRESS (E/F/S Only) 28480 08922-90079

1 08922-00053 0 1 PANEL DRESS (G/H/M Only) 28480 08922-00053

2 08922-21002 2 1 MACH FRAME (FRONT DIE) 28480 08922-21001

6 08922-40002 3 1 KEY PAD (A/B Only) 28480 08922-40002

6 08922-40003 4 1 KEY PAD (E/F/G/H/M/S Only) 28480 08922-40003

7-11 0515-2126 8 5 SMM3.0 6SEMPNTX 28480 ORDER BY

27-30 0515-0380 2 4 SMM4.0 10SEMPNTX 00000 ORDER BY

31 2950-0196 2 1 NUT HEX 1/4-36 00000 ORDER BY

32,33 2950-0054 1 2 NUT HEX 1/2-28 THD 00000 ORDER BY

34 08922-00056 3 1 CLIP WINDOW 28480 08922-00056

35 08922-40001 2 1 BEZEL - CRT 28480 08922-40001

36 0370-2110 2 1 KNOB BASE .250 JG 00000 ORDER BY

37 08920-21023 4 1 CRT WINDOW 00000 ORDER BY

38-43,

0515-1940 2 9 SMM2.5 6PCHPNTX 00000 ORDER BY

45,46,65

47 08922-00041 6 1 NAME PLATE (A Only) 28480 08922-00041

47 08922-00042 7 1 NAME PLATE (B Only) 28480 08922-00042

47 08922-00080 1 NAME PLATE (E Only) 28480 08922-00080

47 08922-00082 1 5 NAME PLATE (F Only) 28480 08922-00082

47 08922-00038 1 1 NAME PLATE (G Only) 28480 08922-00038

47 08922-00083 1 6 NAME PLATE (H Only) 28480 08922-00083

47 08922-00086 1 6 NAME PLATE (M Only) 28480 08922-00086

47 08922-00085 1 6 NAME PLATE (S Only) 28480 08922-00085

48 0370-1001 8 1 KNOB RND .125 GY 00000 ORDER BY

49-52,

2950-0035 8 15 NUT-HEX 15/32-32 THD. 00000 ORDER BY

54-63,

66

70 5041-0944 4 1 KEY CAP “POWER” 00000 ORDER BY

546-547 5001-0540 2 2 TRIM SIDE, 177H 00000 ORDER BY

548 5041-8802 9 1 TRIM, TOP FM 00000 ORDER BY

CDQty. Description Mfr. Code Mfr.Part

Number

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

9-4

Page 99

Replacing a Part

Replaceable Parts

27-30

546

(Trim)

38-43,

45, 46,

65

34

W31

Power

Switch

(A1 Mounting Screws)

7-11

47

35

A1

6

(Trim)

548

37

36

J1

70

32

33

48

31

(Nut under

volume knob)

1

(Panel

Dress)

2

(Frame)

49-52,

54-63,

66

547

(Trim)

RFI Gaskets

Top 532

Bottom 533

Right Side 528, 529

Left Side 530,531

9-5

Page 100

Replacing a Part

Replaceable Parts

Table 9-3 Replaceable Parts

Item Agilent Part

Number

A2 08920-60212 7 1 AUDIO ANALYZER 2 (Order 08920-61812)

A3 08920-60171 6 1 AUDIO ANALYZER 1

A4 08920-60209 1 1 MODULATION DISTRIBUTION (Order 08920-61809) 28480 08920-60209

A5 08922-60105 9 1 PREMOD FILTER / NSM BOARD 28480 08922-60105

A6 08920-60208 2 1 SIGNAL SOURCE/ANALY (Order 08920-61849)

A7 08920-60307 0 1 CONTROLLER (DCU) (A,B,E,F,G) (Order 08922-61811)

A7 08920-60395 5 1 CONTROLLER (DCU) (H) (Order 08922-61812)

A7 08920-60395 5 1 CONTROLLER (DCU) (S) (Order 08922-61813)

A7 08920-60395 5 1 CONTROLLER (DCU) (M) (Order 08922-61814)

A7U65 08920-87168 Order this BOOT ROM with above DCU (M only)

Note: New HOST Firmware must be downloaded to the Agilent 8922M DCU Assembly by an external controller. Contact your

local Agilent Technologies Sales and Service Office for more information

C D Qty. Description Mfr.

Code

Mfr.Part

Number

A8 08922-60156 1 8922A/B MEMORY (Order 08922-60175)

A8 08922-60163 9 1 8922E MEMORY (Order 08922-60175) 28480 08922-60163

A8 08922-60158 2 1 8922G MEMORY (Order 08922-60175) 28480 08922-60158

A8 08922-60165 2 1 8922F MEMORY (Order 08922-60175) 28480 08922-60165

A8 08922-60166 2 1 8922H MEMORY (Order 08922-60279) 28480 08922-60166

A8 08920-60279 1 8922H/S/M MEMORY Without EPROM’s 28480

A8 08922-60175 1 8922A/E/F/G MEMORY BOARD Without EPROM’s 28480 08922-60175

A9 08922-60121 9 1 GLOBAL TEST/DEMOD BOARD (A,B,E,F,G,H,M,S) 28480 08922-60121

A10 08920-60256 8 1 POWER SUPPLY REGULATOR (Order 08920-61856)

A11 08922-61007 2 1 RECEIVER MIXER (Order 08922-61807)

A12 08922-61044 7 1 PULSE ATTENUATOR (Order 08922-61844)

A13 08920-61031 0 1 OUTPUT (Order 08920-61831)

A14 08922-61023 2 1 GSM TIMING GEN / PULSE DRIVER 28480 08922-61023

9-6

Loading...

Loading...