Page 1

Installation and Quick Start Guide

8753ET/ES

Network Analyzers

Part Number: 08753-90471

Printed in USA

Print Date: February 2001

Supersedes: May 2000

Page 2

Notice

The information contained in this document is subject to change without notice.

Agilent Technologies makes no warranty of any kind with regard to this material,

including but not limited to, the implied warranties of merchantability and fitness for a

particular purpose. Agilent Technologies shall not be liable for errors contained herein or

for incidental or consequential damages in connection with the furnishing, performance,or

use of this material.

© Copyright 1999-2001 Agilent Technologies, Inc.

ii

Page 3

Certification

Agilent Technologies Company certifies that this product met its published specifications

at the time of shipment from the factory. Agilent Technologies further certifies that its

calibration measurements are traceable to the United States National Institute of

Standards and Technology, to the extent allowed by the Institute's calibration facility, and

to the calibration facilities of other International Standards Organization members.

Regulatory and Warranty Information

The regulatory and warranty information is in the User's Guide.

Assistance

Product maintenance agreements and other customer assistance agreements are available

for Agilent Technologies products. For any assistance, contact your nearest Agilent

Technologies sales or service office. See Table 2-1 on page 2-28 for the nearest office.

Safety Notes

The following safety notes are used throughout this manual. Familiarize yourself with

each of the notes and its meaning before operating this instrument.

WARNING Warning denotes a hazard. It calls attention to a procedure which, if

not correctly performed or adhered to, could result in injury or loss

of life. Do not proceed beyond a warning note until the indicated

conditions are fully understood and met.

CAUTION Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, would result in damage to or destruction of

the instrument. Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

iii

Page 4

General Safety Considerations

SOFTKEY

WARNING For continued protection against fire hazard replace line fuse only

with same type and rating (115V operation: T 5A 125V UL/ 230V

operation: T 4A H 250V IEC). The use of other fuses or material is

prohibited.

WARNING This is a Safety Class I product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only

be inserted in a socket outlet provided with a protective earth

contact. Any interruption of the protective conductor, inside or

outside the instrument, is likely to make the instrument dangerous.

Intentional interruption is prohibited.

CAUTION Ventilation Requirements: When installing the instrument in a cabinet,

the convection into and out of the instrument must not be restricted. The

ambient temperature (outside the cabinet) must be less than the maximum

operating temperature of the instrument by 4 °C for every 100 watts

dissipated in the cabinet. If the total power dissipated in the cabinet is

greater than 800 watts, then forced convection must be used.

How to Use This Guide

This guide uses the following conventions:

Front-Panel Key

Screen Text This represents text displayed on the instrument’s screen.

iv

This represents a key physically located on the

instrument.

This represents a “softkey,” a key whose label is

determined by the instrument’s firmware.

Page 5

Documentation Map

The Installation and Quick Start Guide provides procedures for

installing, configuring, and verifying the operation of the analyzer. It

also will help you familiarize yourself with the basic operation of the

analyzer.

The User’s Guide shows how to make measurements, explains

commonly-used features, and tells you how to get the most

performance from your analyzer.

The Reference Guide provides reference information, such as

specifications, menu maps, and key definitions.

The Programmer’s Guide provides general GPIB programming

information, a command reference, and example programs. The

Programmer’s Guide contains a CD-ROM with example programs.

The CD-ROM provides the Installation and Quick Start Guide, the

User’s Guide, the Reference Guide, and the Programmer’s Guide in

PDF format for viewing or printing from a PC.

The Service Guide provides information on calibrating,

troubleshooting,andservicingyouranalyzer. The Service Guide is not

part of a standard shipment and is available only as Option 0BW, or

by ordering part number 08753-90484. A CD-ROM with the Service

Guide in PDF format is included for viewing or printing from a PC.

v

Page 6

Contents

1. Installing Your Analyzer

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

STEP 1. Verify the Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

STEP 2. Familiarize Yourself with the Analyzer Front and Rear Panels . . . . . . . . . . . . . . .1-5

Analyzer Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Analyzer Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

STEP 3. Meet Electrical and Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . .1-7

STEP 4. Configure the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

To Configure the Standard Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

To Configure an Analyzer with a High Stability Frequency Reference (Option 1D5) . . .1-10

To Configure the Analyzer with Printers or Plotters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

To Configure the Analyzer for Bench Top or Rack Mount Use . . . . . . . . . . . . . . . . . . . . .1-16

STEP 5. Verify the Analyzer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

To View the Installed Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

To Initiate the Analyzer Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-22

To Run the Operator's Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

To Test the Transmission Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-24

To Test the Reflection Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-25

STEP 6. Back Up the EEPROM Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-26

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-26

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-26

EEPROM Backup Disk Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-26

2. Quick Start: Learning How to Make Measurements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Analyzer Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Measurement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Step 1. Choose measurement parameters with your test device connected . . . . . . . . . . . .2-5

Step 2. Make a measurement calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Step 3. Measure the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Step 4. Output measurement results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Learning to Make Transmission Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Step 1. Choose the measurement parameters with your test device connected . . . . . . . . .2-6

Step 2. Perform a measurement calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Step 3. Measure the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Step 4. Output measurement results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Measuring Other Transmission Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Learning to Make Reflection Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Step 1. Choose measurement parameters with your test device connected . . . . . . . . . . .2-15

Step 2. Make a measurement calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Step 3. Measure the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Step 4. Output measurement results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Measuring Other Reflection Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

If You Encounter a Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

Power-Up Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

Data Entry Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

No RF Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

Contents-vii

Page 7

1 Installing Your Analyzer

1-1

Page 8

Installing Your Analyzer

Introduction

Introduction

This chapter shows you how to install your analyzer and confirm the correct operation, by

following the steps below:

1. Verify the shipment.

2. Familiarize yourself with the analyzer front and rear panels.

3. Meet electrical and environmental requirements.

4. Configure the analyzer.

5. Verify the analyzer operation.

6. Back up the EEPROM disk.

1-2 Chapter1

Page 9

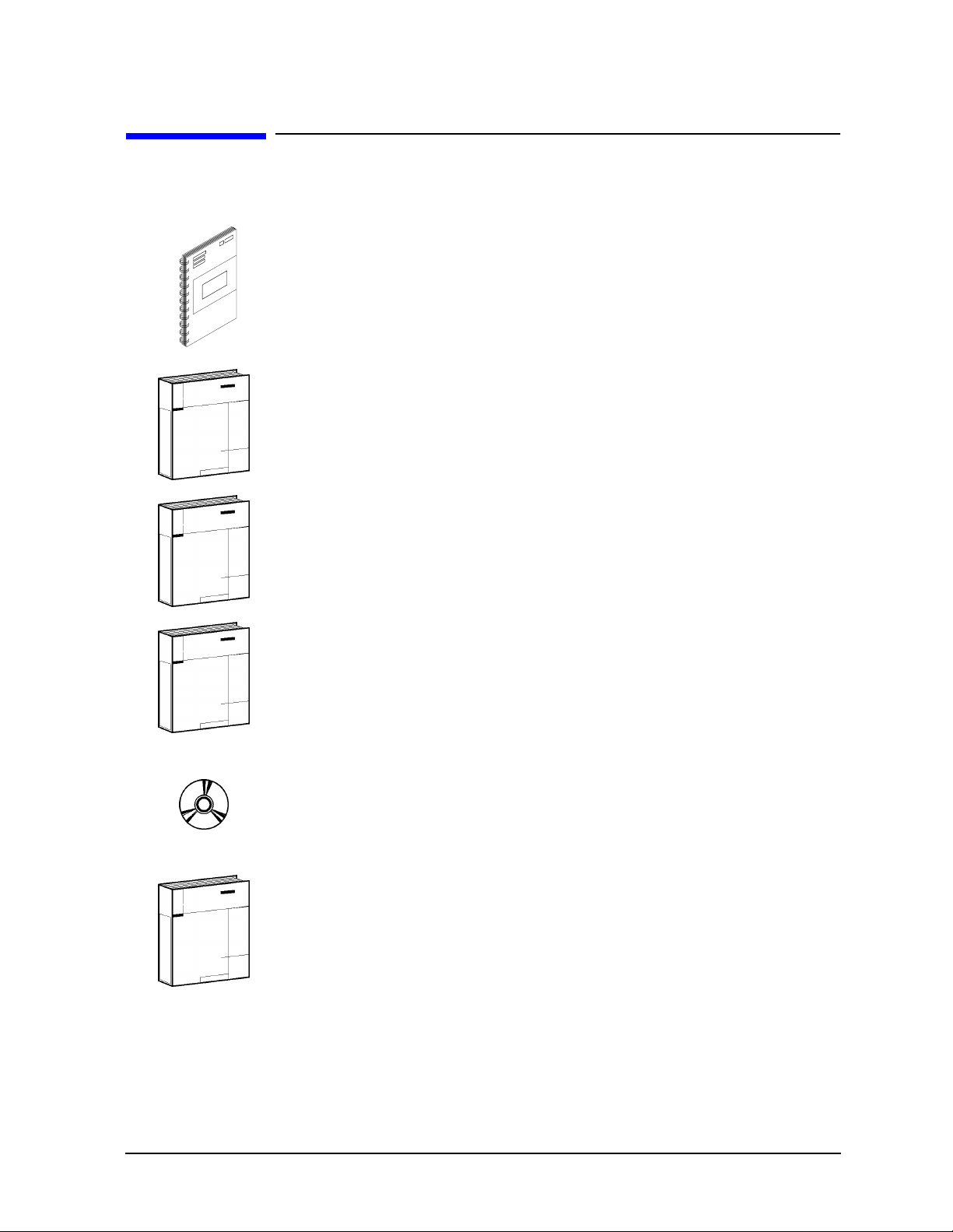

Installing Your Analyzer

STEP 1. Verify the Shipment

STEP 1. Verify the Shipment

1. Unpack the contents of all the shipping containers.

WARNING The analyzer weighs approximately 46 pounds (21 kilograms). Use correct

lifting techniques.

2. Carefully inspect the analyzer to ensure that it was not damaged during shipment.

NOTE If your analyzer was damaged during shipment, contact your nearest Agilent

Technologies office or sales representative. A list of Agilent Technologies sales and

service offices is provided in Table 2-1 on page 2-28.

ES models only: the PORT 1 and PORT 2 connectors move. This is NOT a

defect.

Chapter 1 1-3

Page 10

Installing Your Analyzer

STEP 1. Verify the Shipment

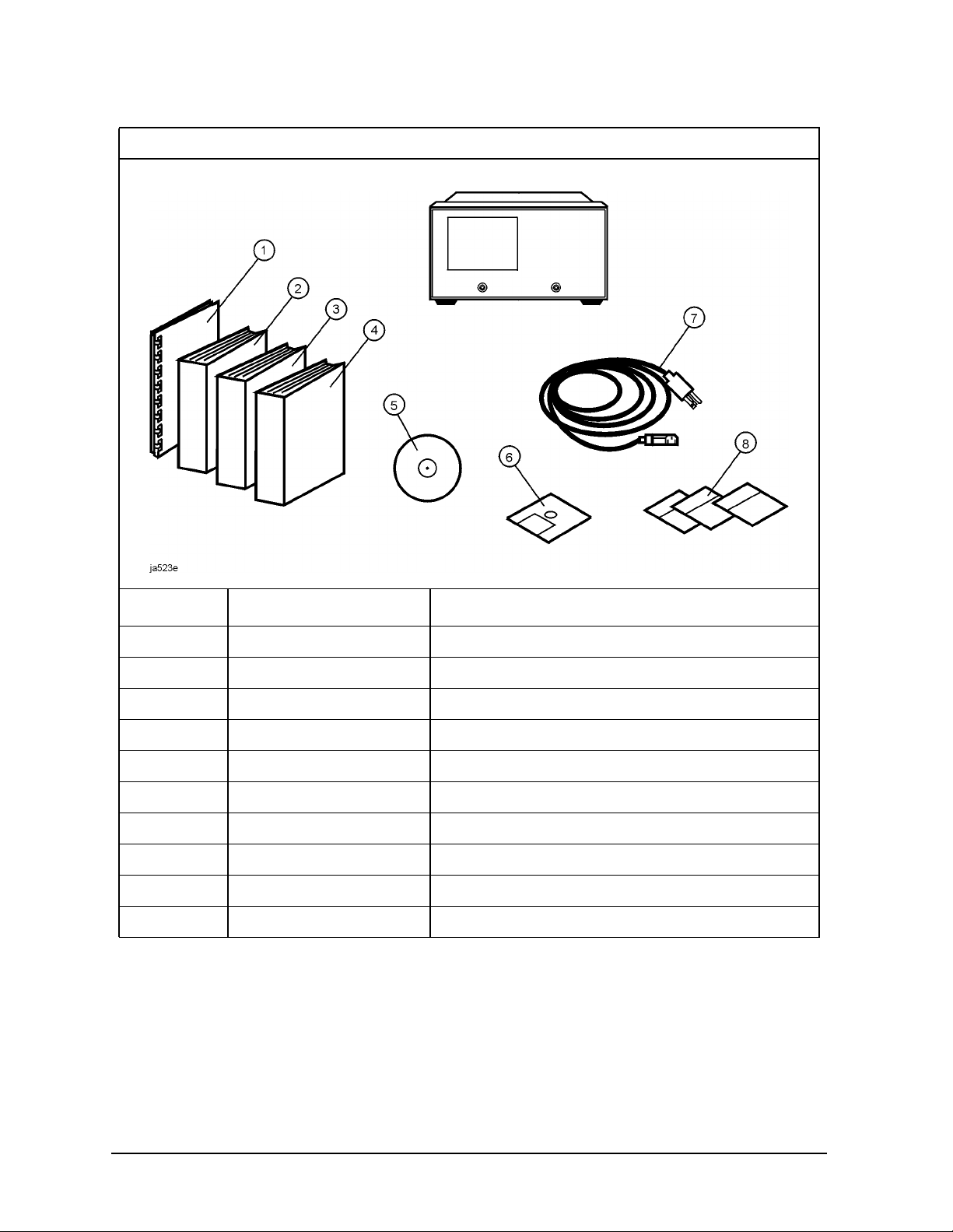

3. Verify that all the accessories have been included with the analyzer.

ItemNumber Part Number Description

1 08753-90471 Installation and Quick Start Guide

2 08753-90472 User's Guide

3 08753-90473 Reference Guide

4 08753-90475 Programmer’s Guide

5 08753-90469 CD-ROM

6 08753-10013 EEPROM Backup Disk

7 unique to country AC power cable

8 5062-9216 Rack Flange Kit (Option 1CM only)

8 5062-9236 Rack Flange Kit with Handles (Option 1CP only)

8 5062-9229 Front Handle Kit (standard)

1-4 Chapter1

Page 11

Installing Your Analyzer

STEP 2. Familiarize Yourself with the Analyzer Front and Rear Panels

STEP 2. Familiarize Yourself with the Analyzer Front and

Rear Panels

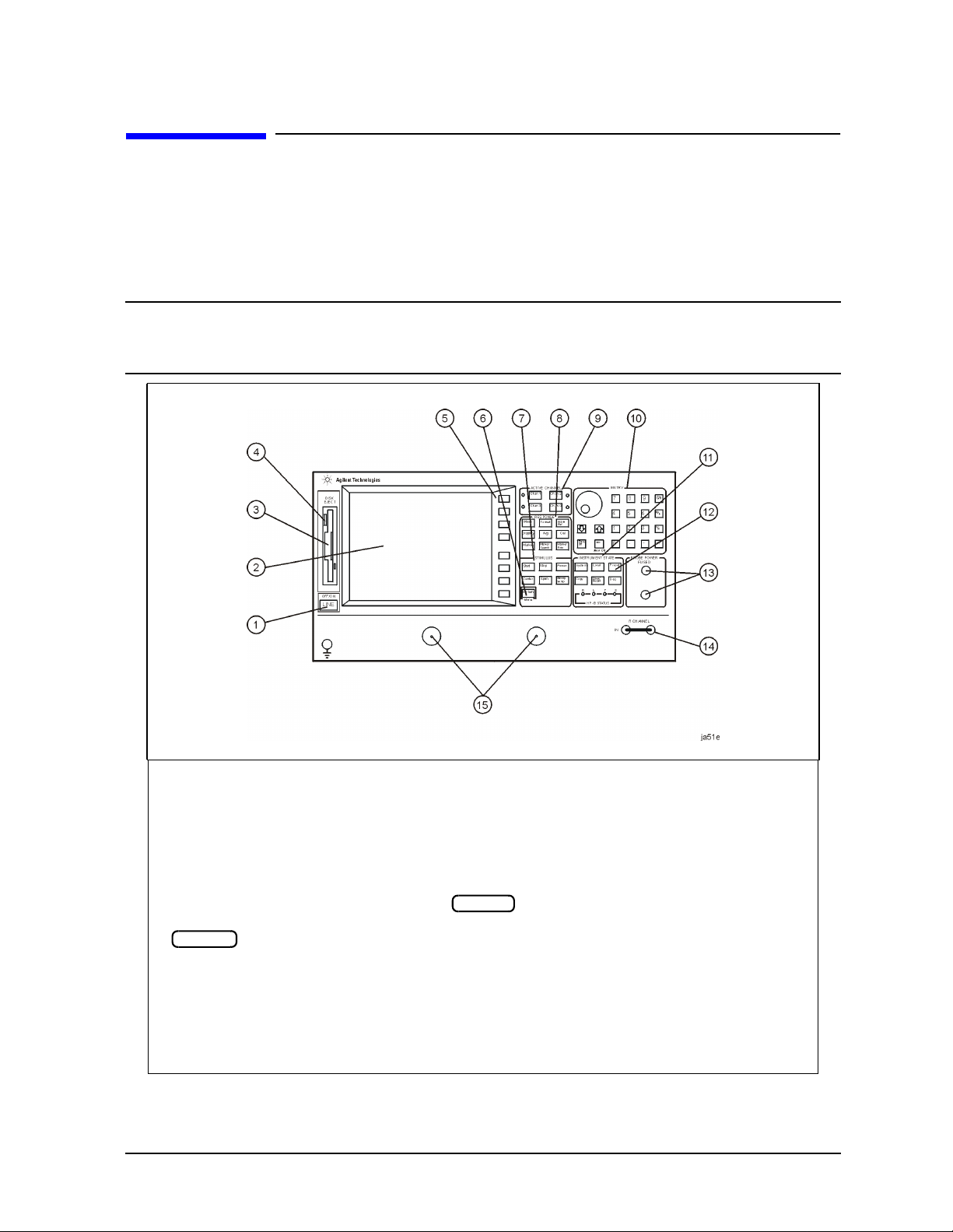

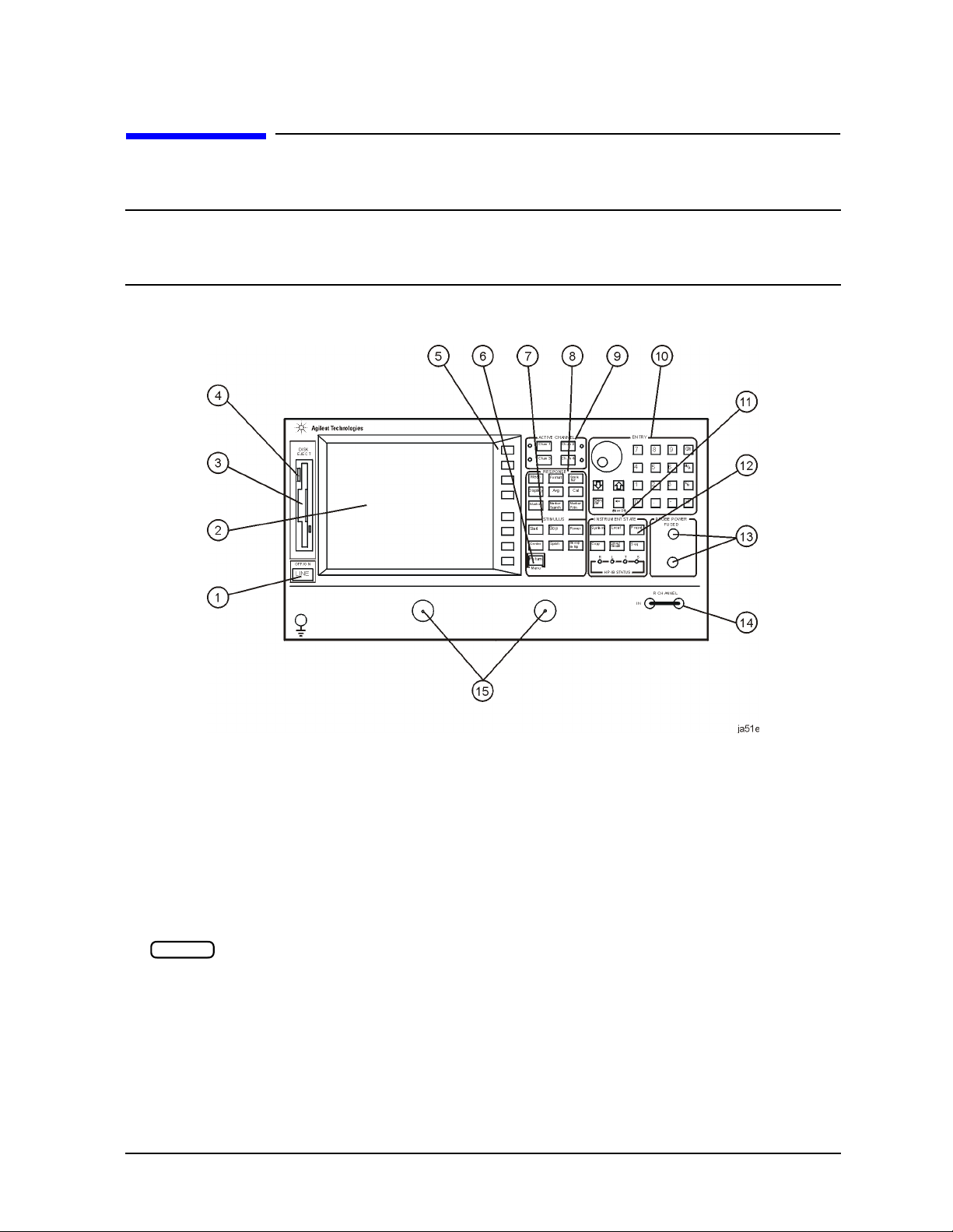

Analyzer Front Panel

CAUTION Do not mistake the line switch for the disk eject button. See the figure below. If the

line switch is mistakenly pushed, the instrument will be turned off, losing all settings

and data that have not been saved.

1 LINE (power on/off) switch 8 RESPONSE function block

2 Display 9 ACTIVE CHANNEL keys

3 Disk drive 10 ENTRY block

4 Disk eject button 11 INSTRUMENT STATE function block

5 Softkeys

6 key

Return

7 STIMULUS function block 14 R CHANNEL connectors

Chapter 1 1-5

12 key

Preset

13 PROBE POWER connectors

15 ES models only:

PORT 1

and

PORT 2

ET models only:

REFLECTION

and

TRANSMISSION

Page 12

Installing Your Analyzer

STEP 2. Familiarize Yourself with the Analyzer Front and Rear Panels

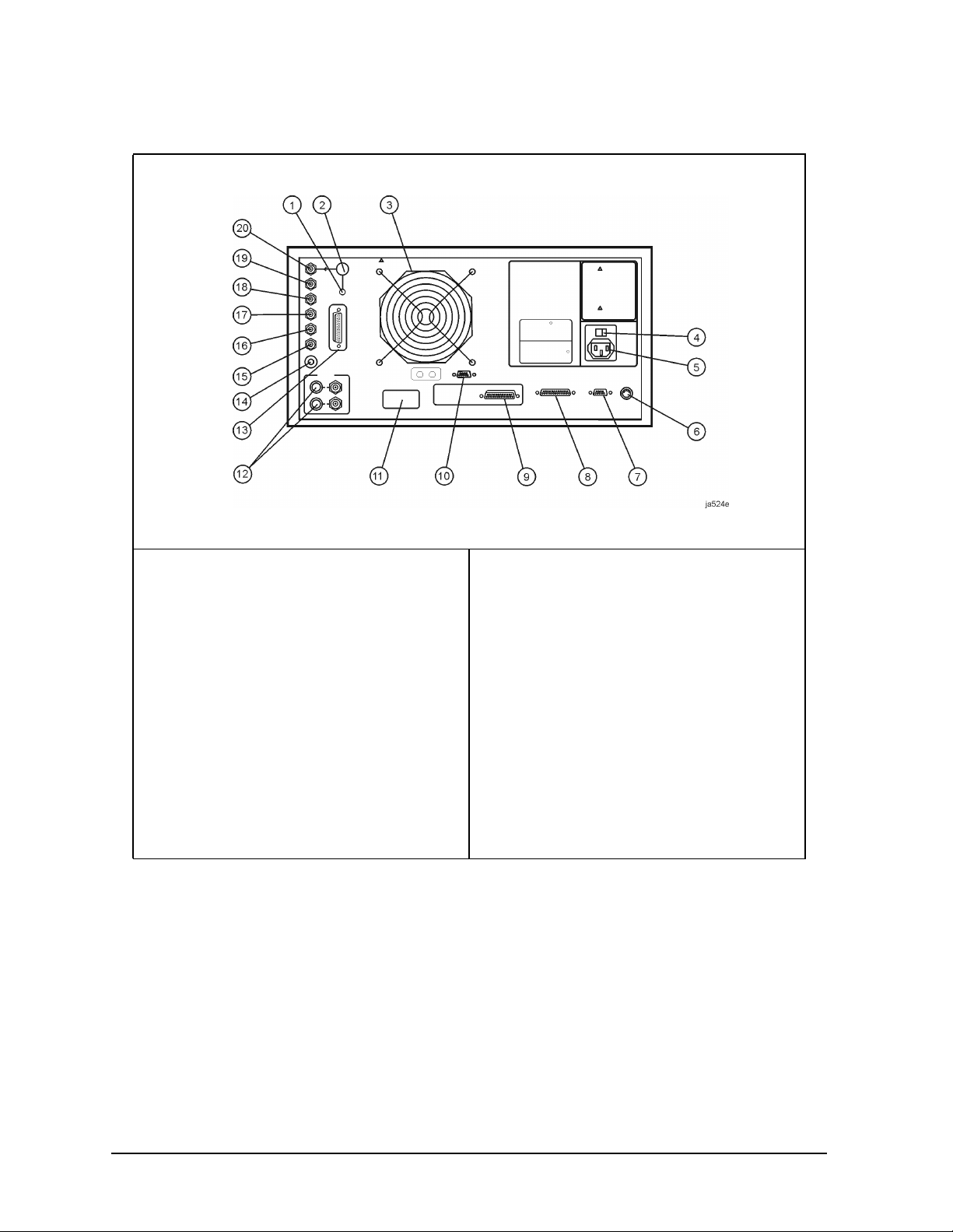

Analyzer Rear Panel

1 10 MHZ REFERENCE ADJUST

1

2 10MHZPRECISIONREFERENCE

OUTPUT

1

3 Fan

4 Line voltage selector switch

5 Power cord receptacle, with fuse

6 KEYBOARD input (mini-DIN)

7 RS-232 interface

8 PARALLEL interface

9 GPIB connector

10 EXTERNAL MONITOR: VGA

1.Option 1D5 only.

11 Serial number plate

12 BIAS INPUTS and FUSES

13 TEST SET I/O INTERCONNECT

14 MEASURE RESTART

15 LIMIT TEST

16 TEST SEQUENCE

17 EXTERNAL TRIGGER connector

18 EXTERNAL AM connector

19 AUXILIARY INPUT connector

20 EXTERNAL REFERENCE

INPUT connector

1-6 Chapter1

Page 13

Installing Your Analyzer

STEP 3. Meet Electrical and Environmental Requirements

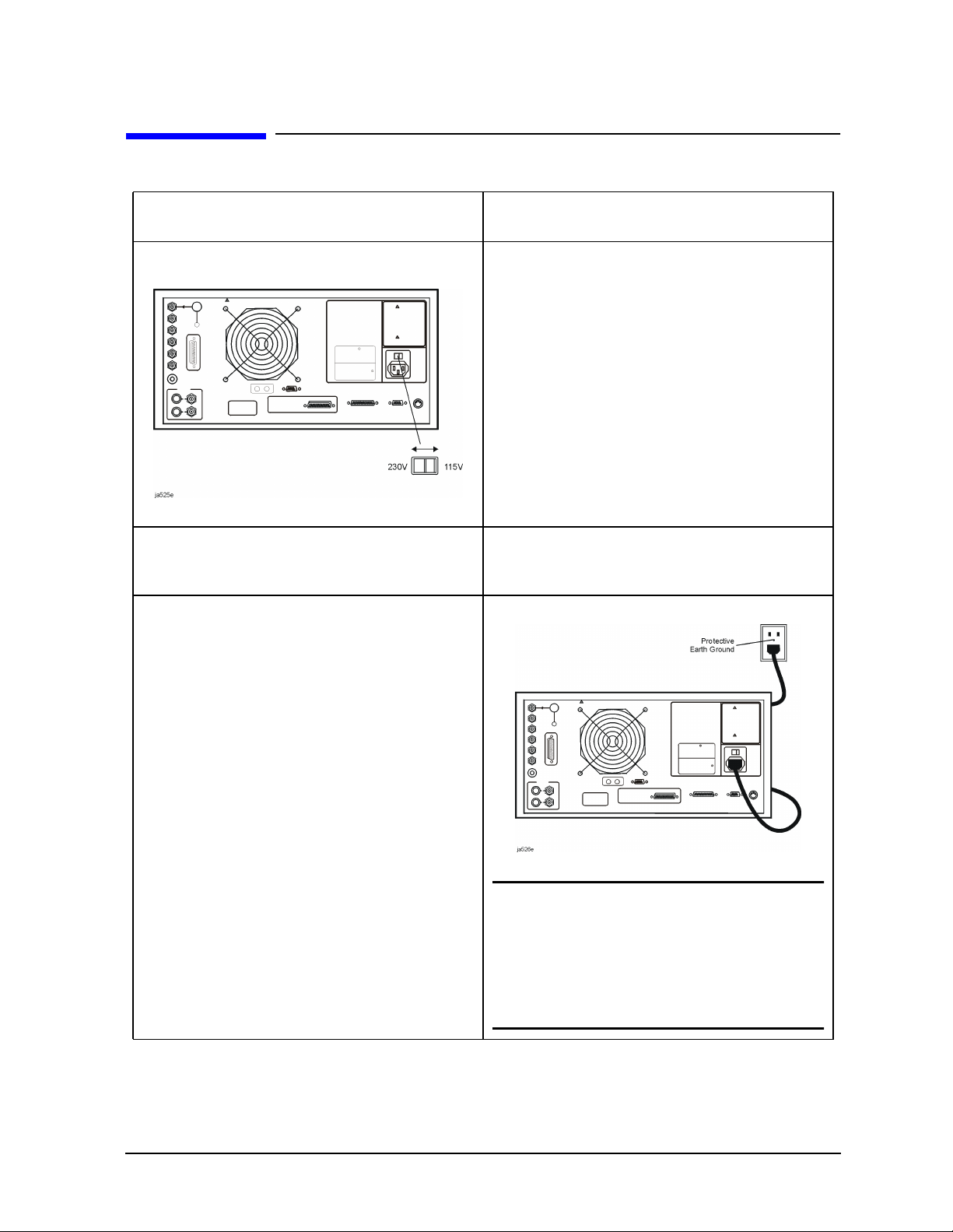

STEP 3. Meet Electrical and Environmental Requirements

1. Set the line-voltage selector to the position

that corresponds to the AC power source.

3. Ensure the operating environment meets

the following requirements:

• 0 to 55 °C

2. Ensure the available AC power source

meets the following requirements:

• 90–132 VAC

• 47–66 Hz / 400 Hz (single phase)

- or -

• 198–265 VAC

• 47–66 Hz (single phase)

The analyzer power consumption is 350 VA

maximum.

4. Verify that the power cable is not damaged,

and that the power-source outlet provides a

protective earth contact.

• < 95% relative humidity at 40 °C

(non-condensing)

• < 15,000 feet (≈ 4,500 meters) altitude

Some analyzer performance parameters are

specified for 25 °C ±5 °C. Refer to the

Reference Guide for information on the

environmental compatibility of warranted

performance.

WARNING Any interruption of the

protective (grounding)

conductor or disconnection

of the protective earth

terminal, can result in

personal injury, or may

damage the analyzer.

Chapter 1 1-7

Page 14

Installing Your Analyzer

STEP 3. Meet Electrical and Environmental Requirements

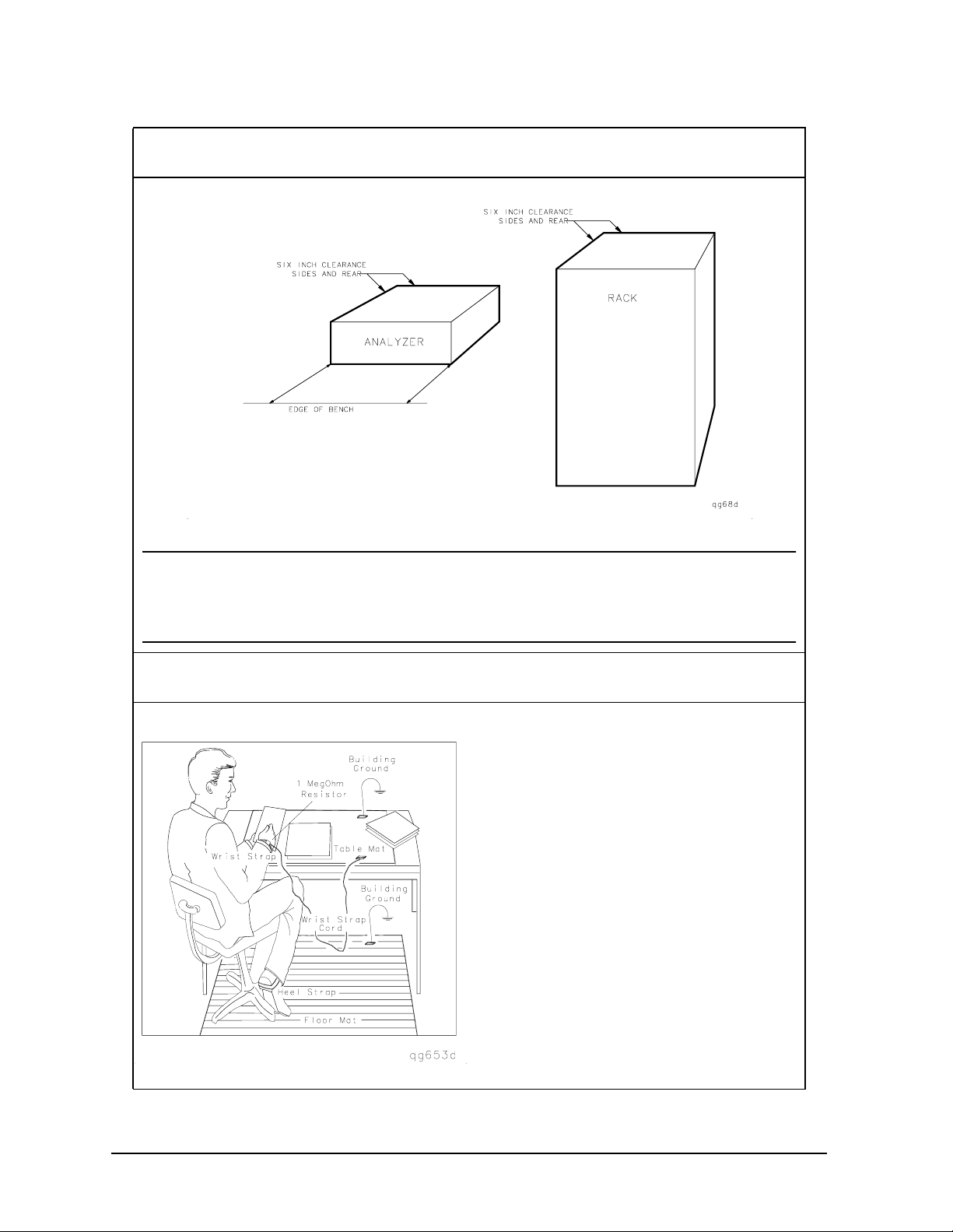

5. Ensure there are at least six inches of clearance between the sides and back of either the

stand-alone analyzer or the system cabinet.

CAUTION The environmental temperature must be 4 °C less than the maximum

operating temperature of the analyzer for every 100 watts dissipated in the

cabinet. If the total power dissipated in the cabinet is >800 watts, then you

must provide forced convection.

6. Set up a static-safe workstation. Electrostatic discharge (ESD) can damage or destroy

electronic components.

• static-control table mat and earth

ground wire: part number 9300-0797

• wrist-strap cord: part number 9300-0980

• wrist-strap: part number 9300-1367

• heel-straps: part number 9300-1308

• floor mat: not available through Agilent

Technologies

1-8 Chapter1

Page 15

STEP 4. Configure the Analyzer

STEP 4. Configure the Analyzer

This step shows you how to set up your particular analyzer configuration.

• standard configuration

• Option 1D5 configuration − high stability frequency reference

• printer or plotter configuration

• rack-mount configuration

Installing Your Analyzer

Chapter 1 1-9

Page 16

Installing Your Analyzer

STEP 4. Configure the Analyzer

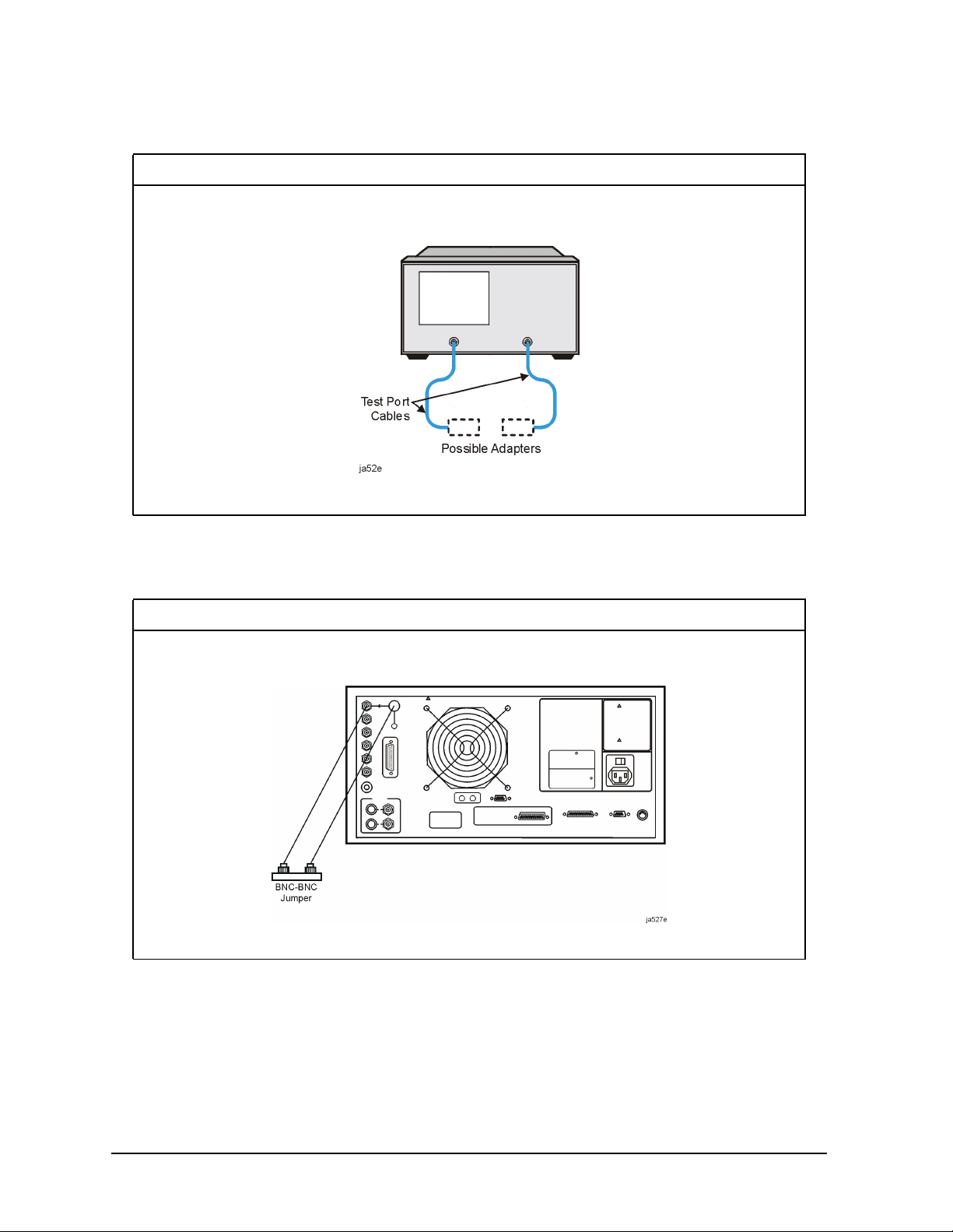

To Configure the Standard Analyzer

Connect test port cables and optional adapters if you are using other connector types.

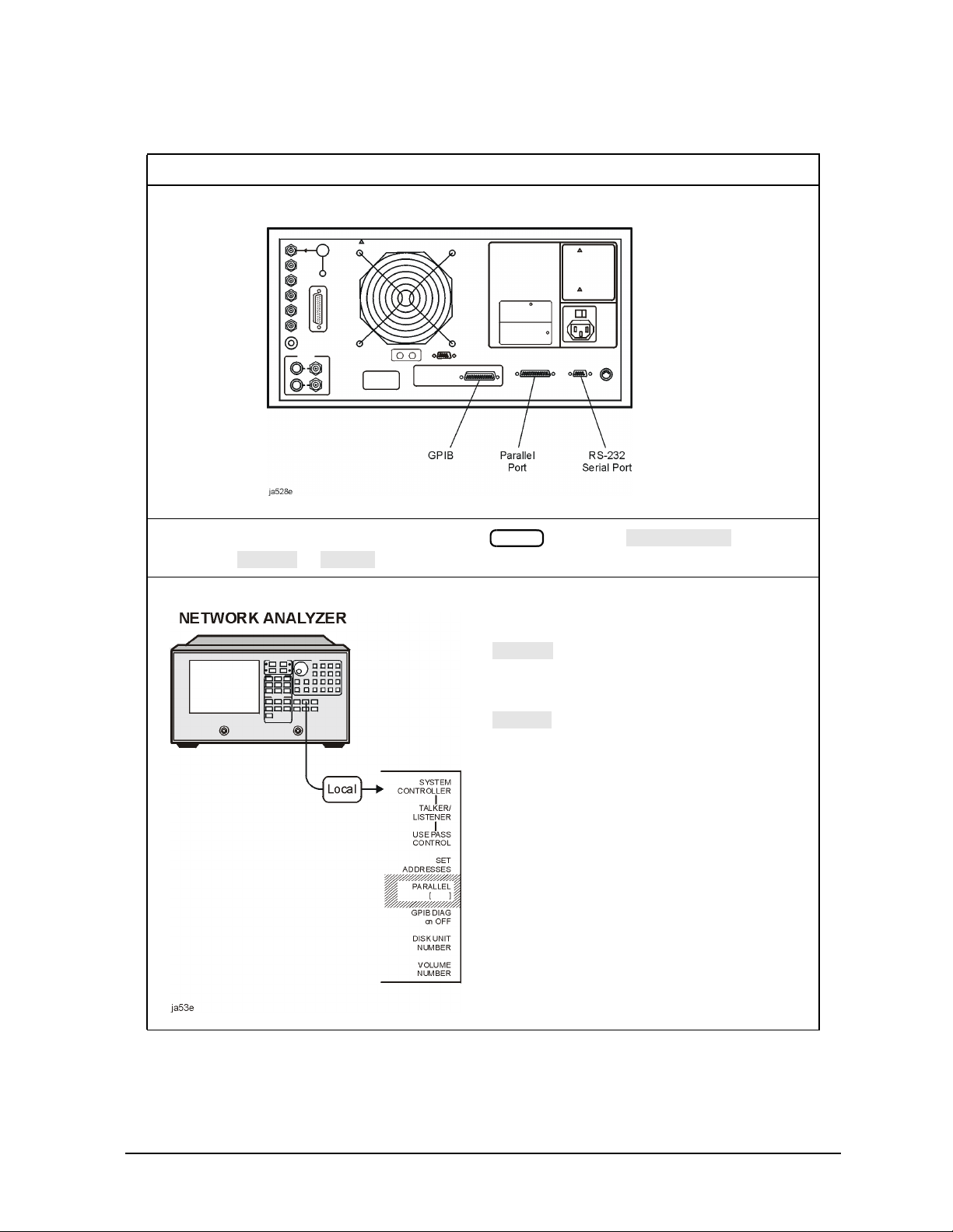

To Configure an Analyzer with a High Stability Frequency

Reference (Option 1D5)

Connect the jumper cable on the analyzer rear panel as shown.

1-10 Chapter1

Page 17

STEP 4. Configure the Analyzer

PARALLEL

COPY

GPIO

COPY

GPIO

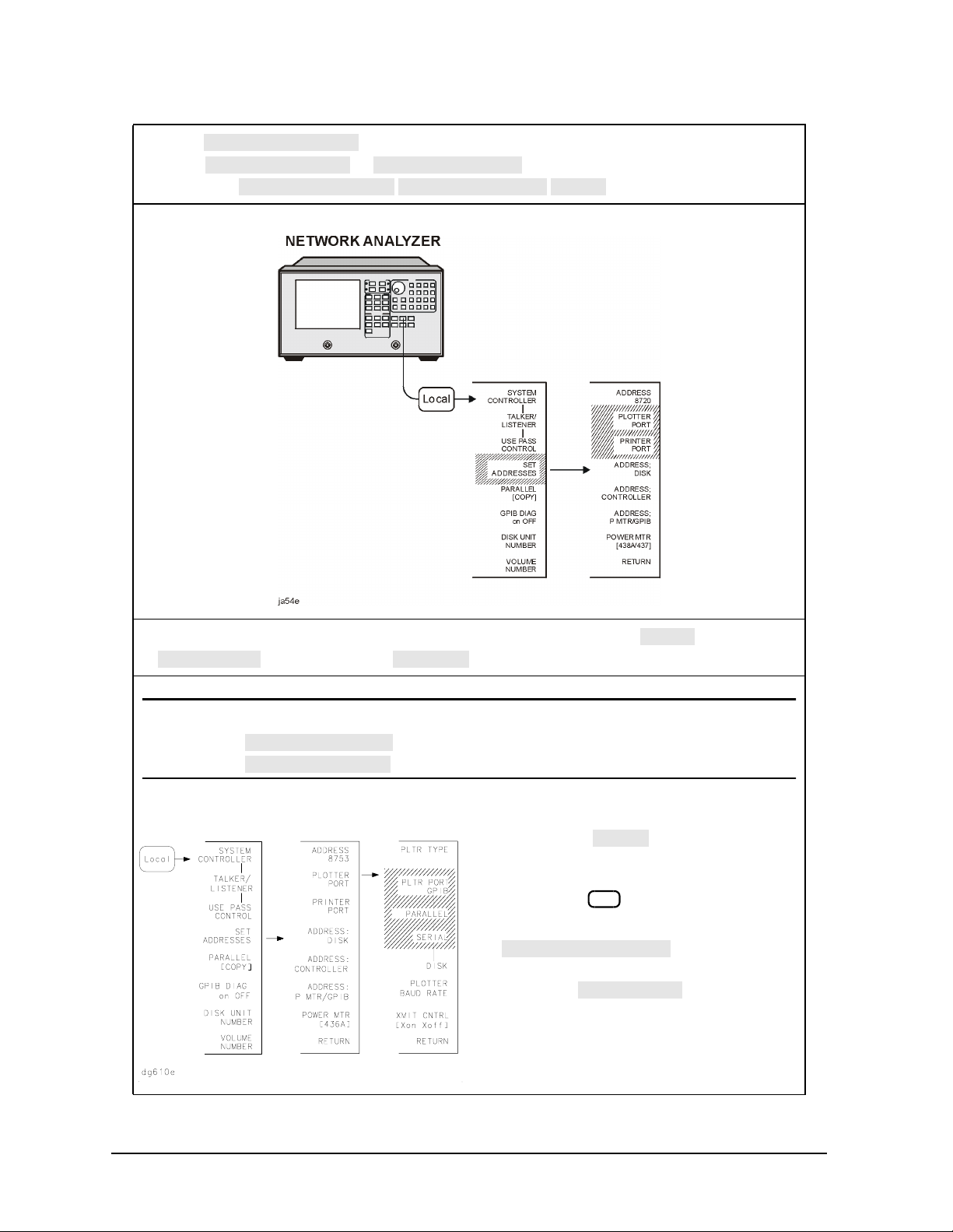

To Configure the Analyzer with Printers or Plotters

1. Connect your printer or plotter to the corresponding interface.

Installing Your Analyzer

2. If you are using the parallel interface, press and toggle until your

choice of or appears.

Local

If you choose:

the parallel port is dedicated for

normal copy device use (printers

or plotters).

the parallel port is dedicated for

general purpose I/O. The

analyzer controls the data input

oroutput through the sequencing

capability of the analyzer.

Chapter 1 1-11

Page 18

Installing Your Analyzer

SET ADDRESSES

PRINTER PORT

PLOTTER PORT

SET ADDRESSES

PLOTTER PORT

DISK

GPIB

PARALLEL

SERIAL

PLOTTER PORT

PRINTER PORT

GPIB

PARALLEL [COPY]

PARALLEL

STEP 4. Configure the Analyzer

3. Press . Then, depending on your printer/plotter device, choose

either or . Or, if you are plotting your files to

disk, press .

4. Press the key that corresponds to your printer or plotter interface: ,

(parallel port), or (serial port).

NOTE The plotter menu is shown as an example. It will only appear if you select

. Similar interface choices will appear if you select

.

• If you select , the GPIB address

selection is active. Enter the GPIB

address of your printer or plotter,

followed by .

• If you have already selected the

parallel-port configuration, you must

also select in this menu in

order to generate a printed or plotted

copy.

x1

choice for the

1-12 Chapter1

Page 19

Installing Your Analyzer

PLOTTER BAUD RATE

PRINTER BAUD RATE

PLOTTER PORT

XMIT CNTRL

Xon/Xoff

DTR/DSR

PRINTER PORT

Xon/Xoff

DTR/DSR

STEP 4. Configure the Analyzer

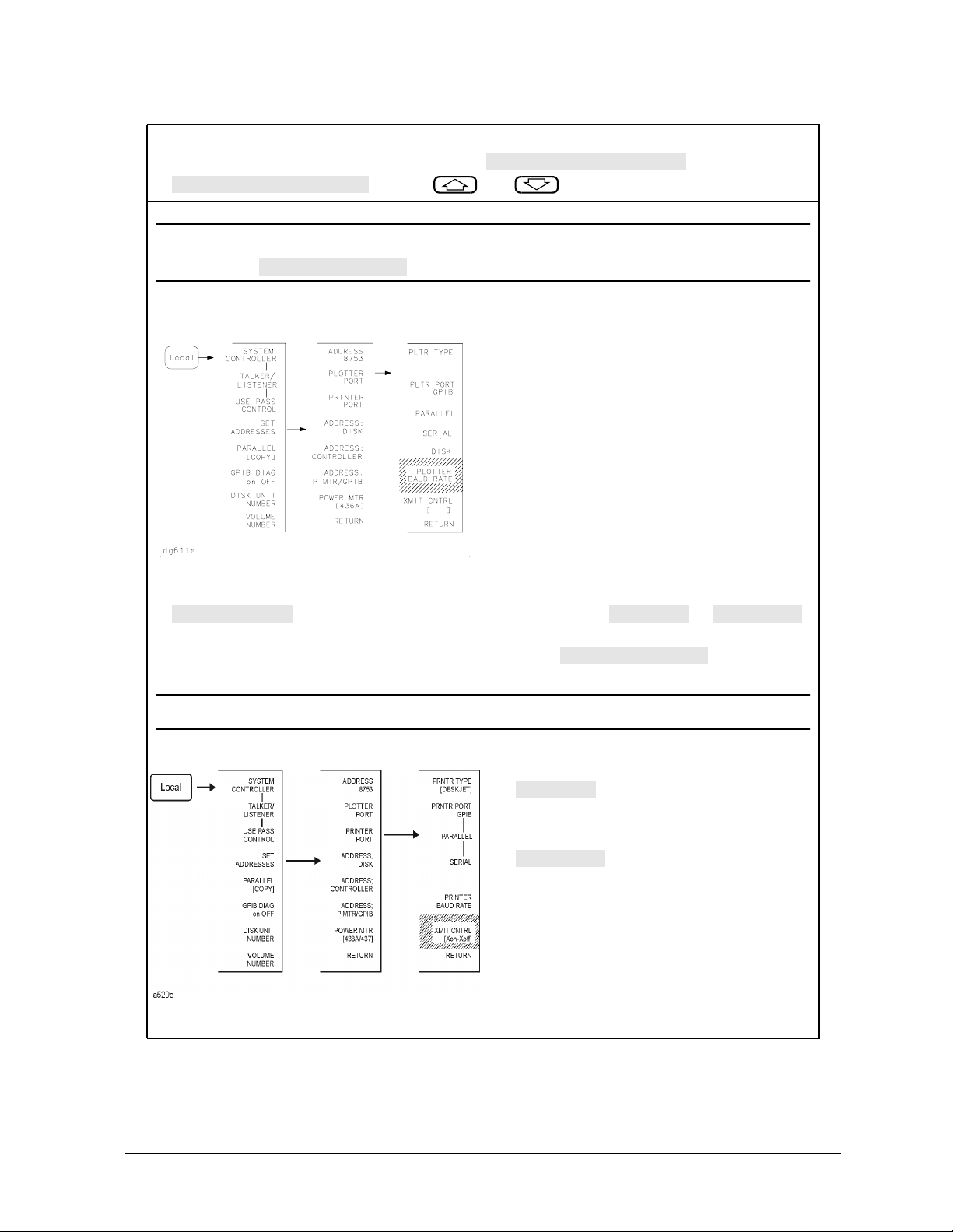

5. If you will be using the serial port, adjust the analyzer's baud rate until it is equal to the

baud rate set on the peripheral by pressing or

and the and front panel keys.

NOTE The plotter menu is shown as an example. It will only appear if you select

.

You can set the analyzer to the following

baud rates:

• 1200

• 2400

• 4800

• 9600

• 19200

6. Also, if you will be using the serial port, you must toggle the transmission control

(handshaking protocol) until your choice of or

appears (equal to the transmission control set on the peripheral). The printer menu is

shown as an example. It will only appear if you select .

NOTE Transmission control for plotters is set programmatically.

• sets transmission

on/transmission off (software

handshake).

• sets data terminal

ready/data set ready (hardware

handshake).

Chapter 1 1-13

Page 20

Installing Your Analyzer

STEP 4. Configure the Analyzer

7. If you will be creating a plot of the data, toggle until your choice of

PLOTTER

8. If you will be using a printer, toggle until your printer choice1 appears.

or appears.

HPGL PRT

PRNTR TYPE

PLTR TYPE

•Choose for a pen plotter.

•Choose for a PCL5

compatible printer.

PLOTTER

HPGL PRT

1

•Choose your printer type from these HP

printers:

THINKJET

❏

DESKJET

❏

(except for HP DeskJet 540 and

Deskjet 850C)

LASERJET

❏

PAINTJET

❏

DJ 540

❏ (for use with

HP DeskJet 540 and

Deskjet 850C—converts 100 dpi

raster information to 300 dpi raster

format)

•Choose for

EPSON-P2

Epson-compatible printers (ESC/P2

printer control language).

1.For a current printer compatibility guide, consult the web page at

http://www.agilent.com/find/pcg.

1-14 Chapter1

Page 21

Installing Your Analyzer

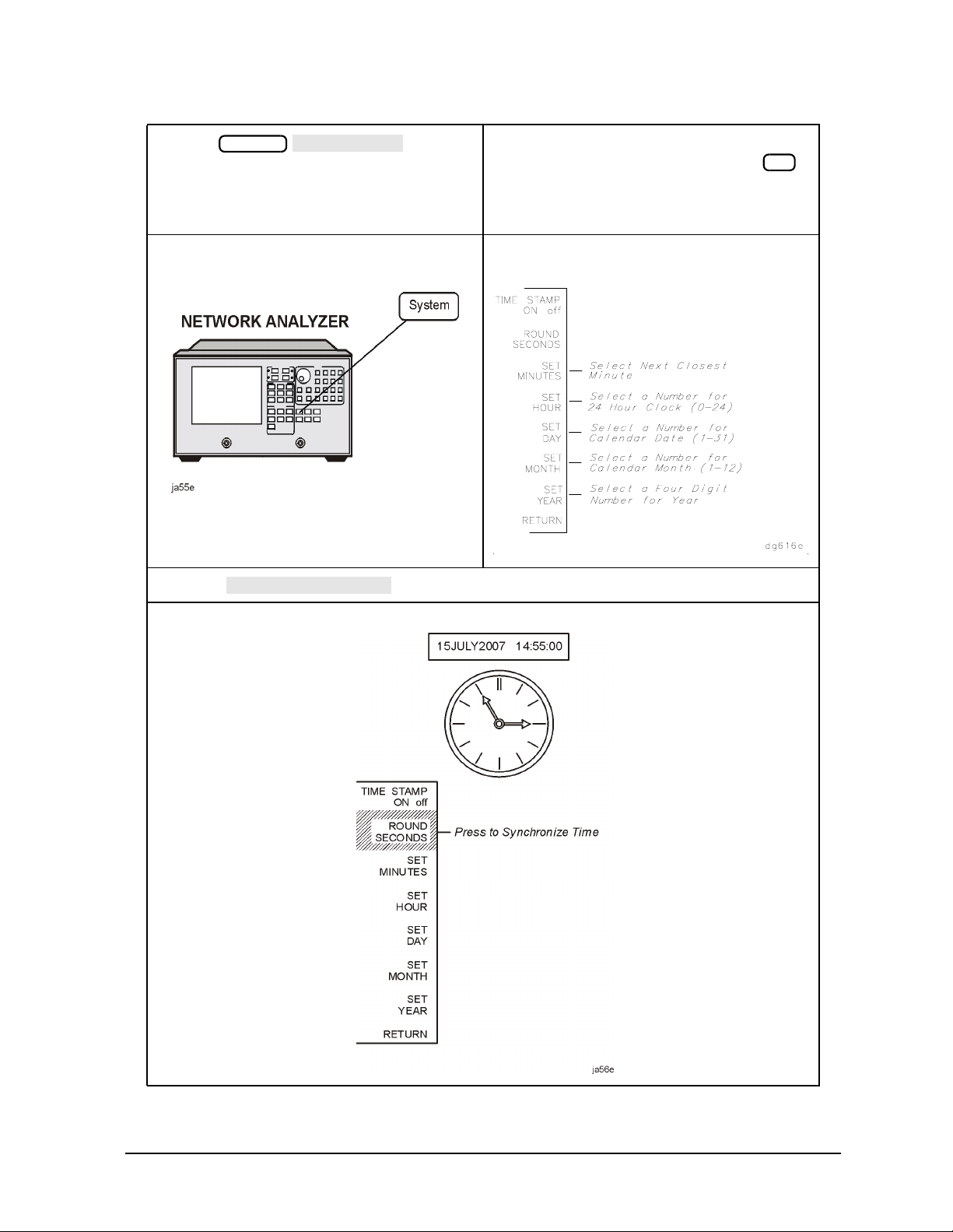

SET CLOCK

ROUND SECONDS

STEP 4. Configure the Analyzer

9. Press to begin

setting and activating the time stamp

feature so the analyzer places the time

and date on your hardcopies and disk

directories.

11. Press when the time is exactly as you have set it.

System

10. Press each of the following softkeys to

set the date and time, followed by .

x1

Chapter 1 1-15

Page 22

Installing Your Analyzer

STEP 4. Configure the Analyzer

To Configure the Analyzer for Bench Top or Rack Mount Use

There are three kits available for the analyzer:

• instrument front handles kit (standard: part number 5062-9229)

• cabinet flange kit without front handles (Option 1CM: part number 5062-9216)

• cabinet flange kit with front handles (Option 1CP: part number 5062-9236)

1-16 Chapter1

Page 23

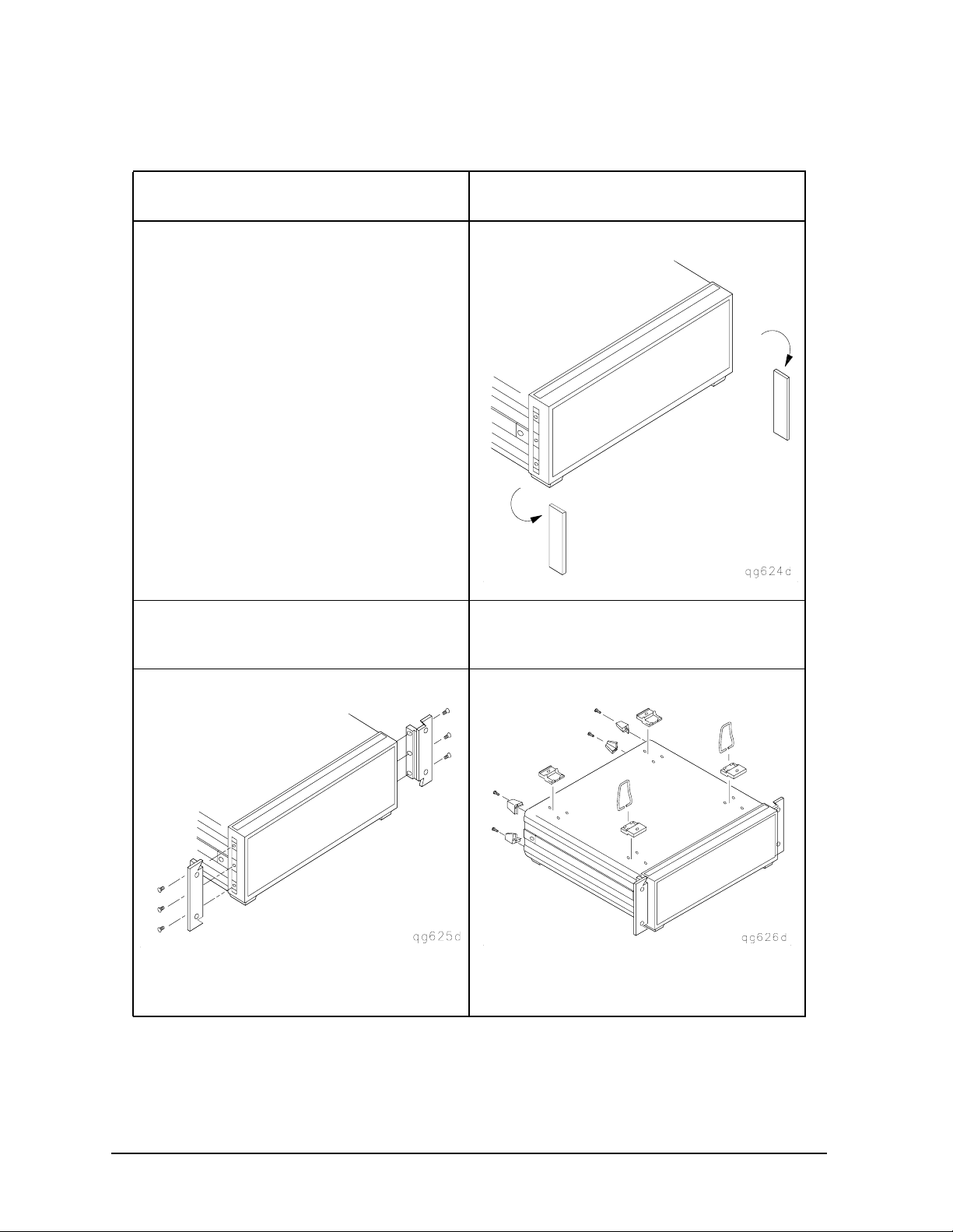

STEP 4. Configure the Analyzer

To Attach Front Handles to the Analyzer (Standard)

1. Ensure that the front handle kit is complete. 2. Remove the side trim strips.

• (2) front handles

• (6) screws

• (2) trim strips

NOTE If any items are damaged or

missing from the kit, contact the

nearest Agilent Technologies

sales or service office to order a

replacement kit.

Items within the kit (handles,

flanges, screws, etc.) are not

individually available.

Installing Your Analyzer

3. Attach the handles to the sides of the front

panel, using three screws for each handle.

4. Place the new trim strip over the screws on

the handles.

WARNING If an instrument handle is

damaged, you should replace

it immediately. Damaged

handles can break while you

are moving or lifting the

instrument and cause

personal injury or damage to

the instrument.

Chapter 1 1-17

Page 24

Installing Your Analyzer

STEP 4. Configure the Analyzer

To Attach Cabinet Flanges without Front Handles to the Analyzer

(Option 1CM)

1. Ensure that the cabinet flange kit is

complete.

• (2) cabinet mount flanges

• (6) screws

3. Attach the cabinet flanges to the sides of

the front panel using three screws for

each flange.

2. Remove side trim strips.

4. Remove the feet and the tilt stands before

cabinet mounting the instrument.

1-18 Chapter1

Page 25

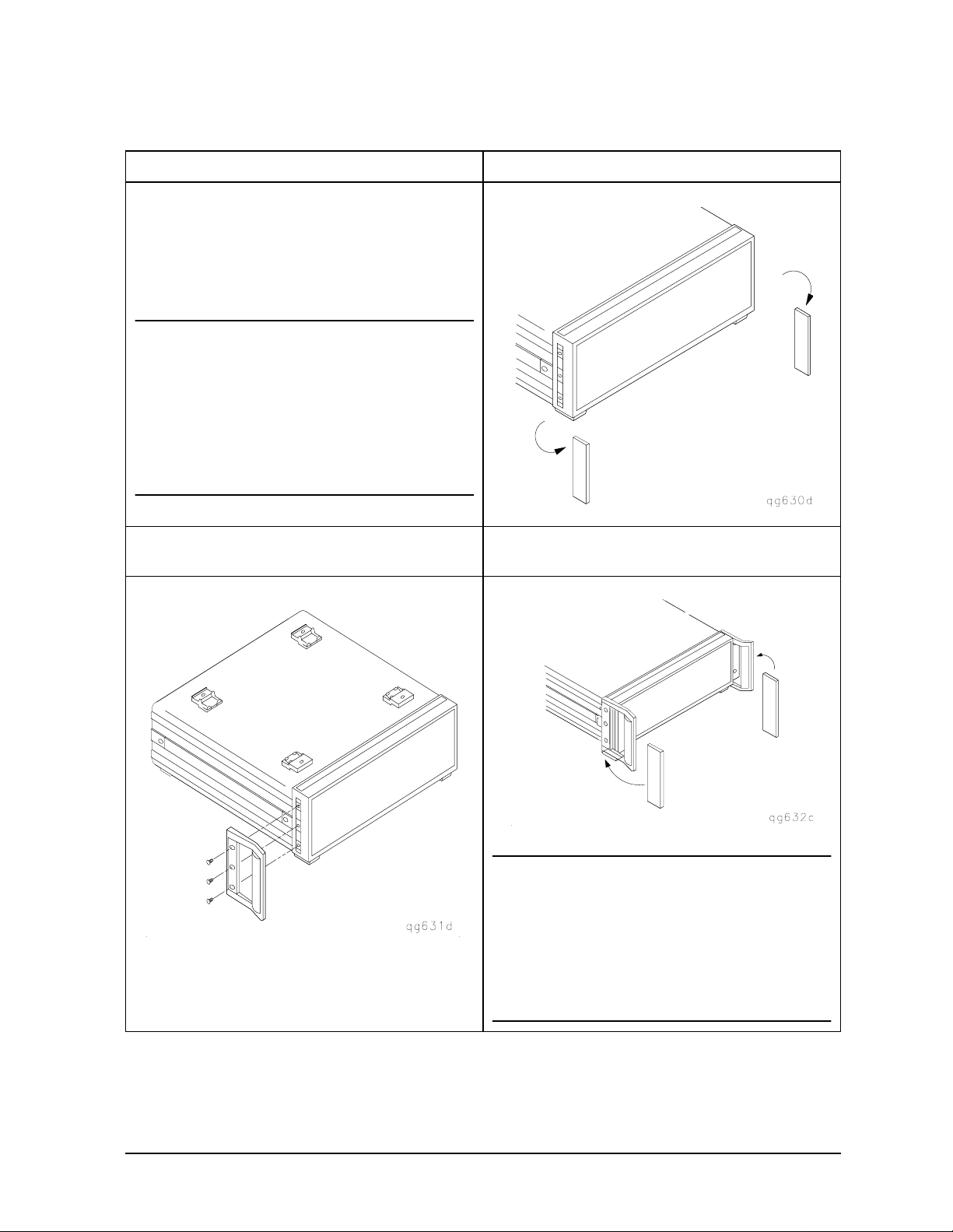

STEP 4. Configure the Analyzer

To Attach Cabinet Flanges with Front Handles to the Analyzer

(Option 1CP)

Installing Your Analyzer

1. Ensure that the cabinet flange kit with

handles is complete.

• (2) cabinet mount flanges

• (2) front handles

• (6) screws

3. Attach the cabinet mount flanges and the

handles to the sides of the front panel, using

three screws per side. (Attach the flanges to

the outside of the handles.)

2. Remove the side trim strips.

4. Remove the feet and the tilt stands before

cabinet mounting the instrument.

WARNING If an instrument handle is

damaged, you should

replace it immediately.

Damaged handles can break

while you are moving or

lifting the instrument and

cause personal injury or

damage to the instrument.

Chapter 1 1-19

Page 26

Installing Your Analyzer

STEP 5. Verify the Analyzer Operation

STEP 5. Verify the Analyzer Operation

The following procedures show you how to check your analyzer for correct operation:

• viewing installed options

• initiating self-test

• running operator's check

• testing transmission mode

• testing reflection mode

NOTE If the analyzer should fail any of the following tests, call the nearest Agilent

Technologies sales or service office to determine the type of warranty you

have. If repair is necessary, send the analyzer (and the EEPROM backup

disk) to the nearest Agilent Technologies service center with a description of

any failed test and any error message. Ship the analyzer using the original

packaging materials. Returning the analyzer in anything other than the

original packaging may result in non-warranted damage. A table listing of

Agilent Technologies sales and service offices is provided in Table 2-1 on

page 2-28.

NOTE The illustrations depicting the analyzer display were made using an ES

model. Other analyzer displays may appear different, depending on model

and options.

1-20 Chapter1

Page 27

To View the Installed Options

SERVICE MENU

FIRMWARE REVISION

Installing Your Analyzer

STEP 5. Verify the Analyzer Operation

1. Cycle the AC power using the LINE switch, or press

.

2. Locate the serial number and configuration options. Compare them to the shipment

documents.

System

Chapter 1 1-21

Page 28

Installing Your Analyzer

STEP 5. Verify the Analyzer Operation

To Initiate the Analyzer Self-Test

1. Cycle the AC power using the LINE switch.

2. Watch for the following indications that the analyzer is operating correctly:

1-22 Chapter1

Page 29

To Run the Operator's Check

SERVICE MENU

TESTS

EXTERNAL TESTS

EXECUTE TEST

CONTINUE

EXECUTE TEST

CONTINUE

EXECUTE TEST

CONTINUE

Installing Your Analyzer

STEP 5. Verify the Analyzer Operation

1. Connect the equipment as shown.

3. ET models only: Press

. Follow the prompts

shown on the analyzer display and then

press .

2. Press

Follow the prompts shown on the analyzer

display and then press .

3. ES models only: Press

shown on the analyzer display and then

press .

Preset System

. Follow the prompts

.

Chapter 1 1-23

Page 30

Installing Your Analyzer

Trans: FWD S21(B/R)

TRANSMISSN

Trans: REV S12 (A/R)

STEP 5. Verify the Analyzer Operation

To Test the Transmission Mode

1. Connect the equipment as shown and press.2. Check the forward transmission mode for

Preset Chan 2 Meas

channel 2 by pressing

or .

NOTE The test port return cable

should have low-loss

characteristics to avoid a

degradation in frequency

response at higher frequencies.

3. Look at the measurement trace displayed

on the analyzer. It should be similar to the

trace below.

4. ES models only: To check the reverse

transmission mode for channel 2, press

Meas

measurement trace should be similar to the

trace below.

. The

1-24 Chapter1

Page 31

Installing Your Analyzer

Refl: REV S22 (B/R)

STEP 5. Verify the Analyzer Operation

To Test the Reflection Mode

1. Connect the equipment as shown and press.2. Look at the measurement trace displayed

Preset

on the analyzer. It should be similar to the

trace below.

3. ES models only: Check the reverse

reflection mode for channel 1 by pressing

Meas

measurement trace should be similar to the

trace shown below.

. The

4. If you are ready to start making

measurements, continue with the next

chapter, “Quick Start: Learning How to

Make Measurements.”

Chapter 1 1-25

Page 32

Installing Your Analyzer

FILE UTILITIES

FORMAT DISK

FORMAT:LIF

FORMAT:DOS

FORMAT INT DISK

YES

SERVICE MENU

SERVICE MODES

MORE

STORE EEPR

SELECT DISK

INTERNAL DISK

RETURN

SAVE STATE

STEP 6. Back Up the EEPROM Disk

STEP 6. Back Up the EEPROM Disk

Description

Correction constants are stored in EEPROM on the A9 controller assembly. The advantage

of having an EEPROM backup disk is the ability to store all the correction-constant data to

a new or repaired A9 assembly without having to rerun the correction-constant

procedures. The analyzer is shipped from the factory with an EEPROM backup disk which

is unique to each instrument. It is prudent to make a copy of the EEPROM backup disk so

that it can be used in case of failure or damage to the original backup disk.

Equipment

3.5-inch disk.......................................................................................92192A (box of 10)

CAUTION Do not mistake the line switch for the disk eject button. If the line switch is

mistakenly pushed, the instrument will be turned off, losing all settings and

data that have not been saved.

EEPROM Backup Disk Procedure

1. Press .

2. Insert a 3.5-inch disk into the analyzer disk drive.

3. If the disk is not formatted, press .

• To format a LIF disk, select (The supplied EEPROM backup disk is

• To format a DOS disk, select .

Press and answer at the query.

4. Press . Toggle

to ON. Then press

NOTE A default file “FILE00” is created. The file name appears in the upper

Preset

Save/Recall

LIF. The analyzer does not support LIF-HFS format.)

System

Save/Recall

to store the correction-constants data onto floppy disk.

left-hand corner of the display. The file type “ISTATE(E)” describes the file as

an instrument-state with EEPROM backup.

1-26 Chapter1

Page 33

Installing Your Analyzer

FILE UTILITIES

RENAME FILE

ERASE TITLE

SELECT LETTER

DONE

STEP 6. Back Up the EEPROM Disk

5. Press . Use the front panel knob

and the softkey to rename the file “FILE00” to “N12345” where

12345 represents the last 5 digits of the instrument's serial number. (The first character

in the file name must be a letter.) When finished, press .

6. Label the disk with the serial number of the instrument, the date, and the words

“EEPROM Backup Disk.”

NOTE Whenever the analyzer is returned to Agilent Technologies for servicing

and/or calibration, the EEPROM backup disk should be returned with the

analyzer. This will significantly reduce the instrument repair time.

7. The EEPROM backup disk procedure is now complete.

Chapter 1 1-27

Page 34

2 Quick Start: Learning How to Make

Measurements

2-1

Page 35

Quick Start: Learning How to Make Measurements

Introduction

Introduction

The information and procedures in this chapter teach you how to make measurements and

what to do if you encounter a problem with your analyzer. The following sections are

included:

• Front Panel

• Measurement Procedure

• Learning to Make Transmission Measurements

• Learning to Make Reflection Measurements

• If You Encounter a Problem

NOTE The illustrations depicting the analyzer display were made using an ES

model. Other analyzer displays may appear different, depending on model

and options.

2-2 Chapter2

Page 36

Quick Start: Learning How to Make Measurements

Analyzer Front Panel

Analyzer Front Panel

CAUTION Do not mistake the line switch for the disk eject button. See the figure below.

If the line switch is mistakenly pushed, the instrument will be turned off,

losing all settings and data that have not been saved.

Figure 2-1 The Analyzer Front Panel

1. LINE switch. This switch controls AC power to the analyzer. 1 is on, 0 is off.

2. Display. This shows the measurement data traces, measurement annotation, and

softkey labels.

3. Disk drive. This 3.5-inch drive allows you to store and recall instrument states and

measurement results for later analysis.

4. Disk eject button. This button ejects the disk from the disk drive.

5. Softkeys. These keys provide access to menus that are shown on the display.

6. key. This key returns the previous softkey menu shown on the display.

Return

7. STIMULUS function block. The keys in this block allow you to control the analyzer

source's frequency, power, and other stimulus functions.

8. RESPONSE function block. The keys in this block allow you to control the

measurement and display functions of the active display channel.

Chapter 2 2-3

Page 37

Quick Start: Learning How to Make Measurements

Analyzer Front Panel

9. ACTIVE CHANNEL keys. The analyzer has four independent display channels.

These keys allow you to select the active channel. Then any function you enter applies

to this active channel. Notice that the light next to the current active channel’s key is

illuminated.

10. The ENTRY block. This block includes the knob, the step keys, and the

number pad. These allow you to enter numerical data and control the markers.

You can use the numeric keypad to select digits, decimal points, and a minus sign for

numerical entries. You must also select a units terminator to complete value inputs.

11. INSTRUMENT STATE function block. These keys allow you to control

channel-independent system functions such as the following:

• copying, save/recall, and GPIB controller mode

• limit testing

• tuned receiver mode

• frequency offset mode (Option 089)

• test sequence function

• harmonic measurements (Option 002)

• time domain transform (Option 010)

GPIB STATUS indicators are also included in this block.

12. key. This key returns the instrument to either a known factory preset state, or

Preset

a user preset state that can be defined. Refer to the “Preset State and Memory

Allocation” chapter in the Reference Guide for a complete listing of the instrument

preset condition.

13. PROBE POWER connectors. These connectors (fused inside the instrument) supply

power to an active probe for in-circuit measurements of AC circuits.

14. R CHANNEL connectors. (ES models only) These connectors allow you to apply an

input signal to the analyzer's R channel, for frequency offset mode.

15. ES models only: PORT 1 and PORT 2. These ports output a signal from the source

and receive input signals from a device under test. PORT 1 allows you to measure S

12

and S11. PORT 2 allows you to measure S21 and S22.

ET models only: REFLECTION and TRANSMISSION. The REFLECTION port

allows you to make reflection measurements, outputting a signal from the source and

receiving input signals from a device under test. The TRANSMISSION port allows you

to make transmission measurements, receiving input signals from a device under test.

2-4 Chapter2

Page 38

Quick Start: Learning How to Make Measurements

Measurement Procedure

Measurement Procedure

This is a general measurement procedure that is used throughout the guide to illustrate

the use of the analyzer.

Step 1. Choose measurement parameters with your test device

connected

• Press the key to return the analyzer to a known state.

• Connect your device under test (DUT) to the analyzer.

CAUTION Damage may result to the DUT if it is sensitive to the analyzer's default

• Choose the settings that are appropriate for the intended measurement.

❏ measurement type (S

❏ frequencies

❏ number of points

❏ power

❏ measurement trace format

• Make adjustments to the parameters while you are viewing the device response.

Preset

output power level. To avoid damaging a sensitive DUT, be sure to set the

analyzer's output power to an appropriate level before connecting the DUT to

the analyzer.

or reflection, for example)

11

Step 2. Make a measurement calibration

Press the key to begin to perform a measurement calibration using a known set of

standards (a calibration kit). Error-correction establishes a magnitude and phase

reference for the test setup and reduces systematic measurement errors.

Cal

Step 3. Measure the device

• Reconnect the device under test.

• Use the markers to identify various device response values if desired.

Step 4. Output measurement results

• Store the measurement file to a disk.

• Generate a hardcopy with a printer or plotter.

Chapter 2 2-5

Page 39

Quick Start: Learning How to Make Measurements

Trans: FWD S21 (B/R)

TRANSMISSN

AUTO SCALE

Learning to Make Transmission Measurements

Learning to Make Transmission Measurements

This example procedure shows you how to measure the transmission response of a

175 MHz bandpass filter. The measurement parameters listed are unique to this

particular test device.

For further measurement examples, refer to the “Making Measurements” chapter in the

User's Guide.

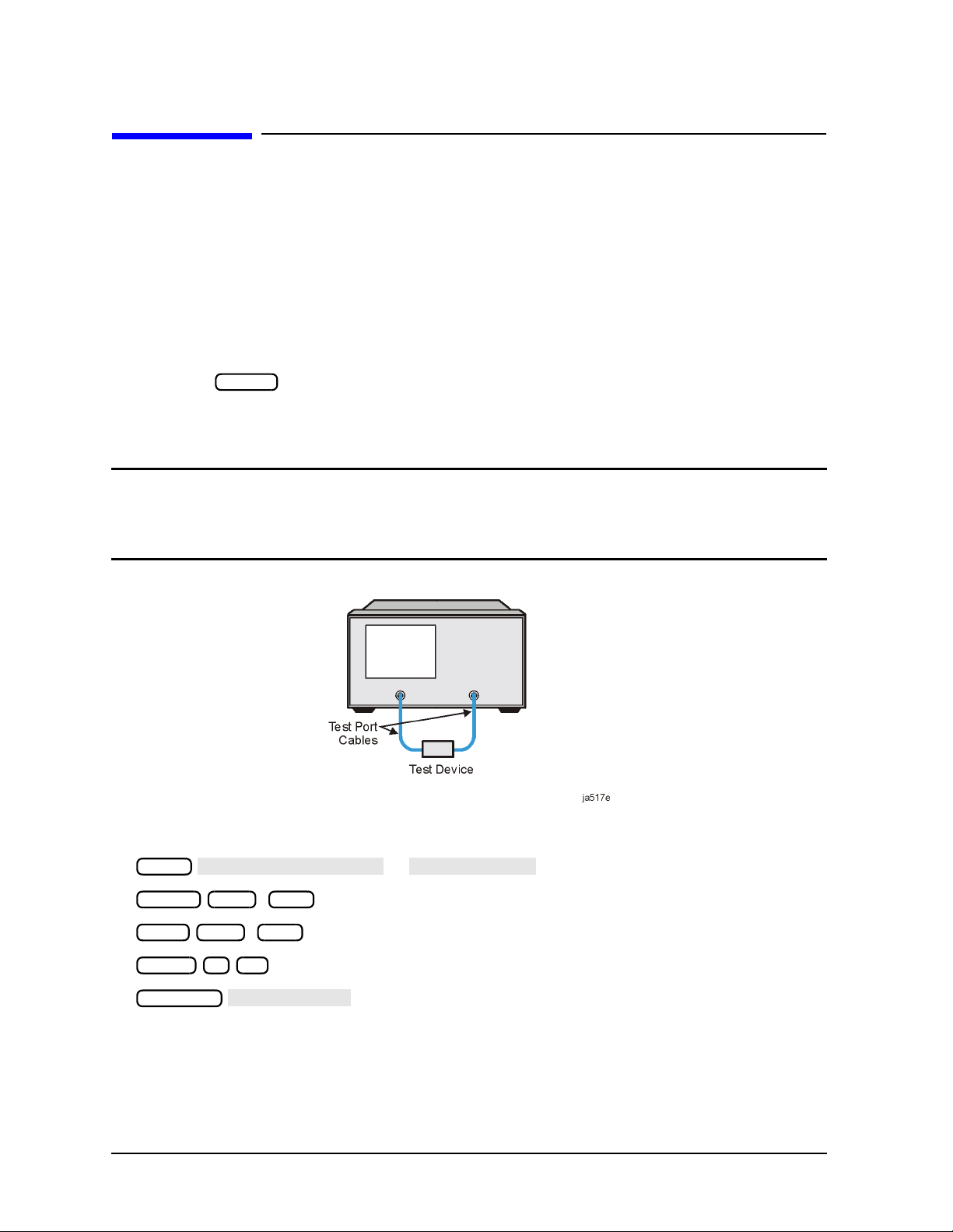

Step 1. Choose the measurement parameters with your test device connected

1. Press the key to return the analyzer to a known state.

Preset

2. Connect your test device to the analyzer as shown in Figure 2-2. Use adapters where

appropriate.

CAUTION Damage may result to the device under test if it is sensitive to the analyzer's

default output power level. Toavoid damaging a sensitive DUT, be sure to set

the analyzer's output power to an appropriate level before connecting the

DUT to the analyzer.

Figure 2-2 Device Connections for a Transmission Measurement

3. Choose the following measurement settings:

Meas

Center 200 M/µ

Span 375 M/µ

Power 5 x1

Scale Ref

4. Look at the device response to determine if these are the parameters that you want for

your device measurement. For example, if the trace is noisy you may want to increase

the test port output power (which increases the analyzer input power), reduce the IF

bandwidth, or add averaging. Or, to better see an area of interest, you may want to

change the test frequencies.

2-6 Chapter2

or

Page 40

Quick Start: Learning How to Make Measurements

CALIBRATE MENU

RESPONSE

THRU

SELECT DISK

INTERNAL MEMORY

INTERNAL DISK

EXTERNAL DISK

RETURN

SAVE STATE

Learning to Make Transmission Measurements

Step 2. Perform a measurement calibration

1. Disconnect your test device from the analyzer.

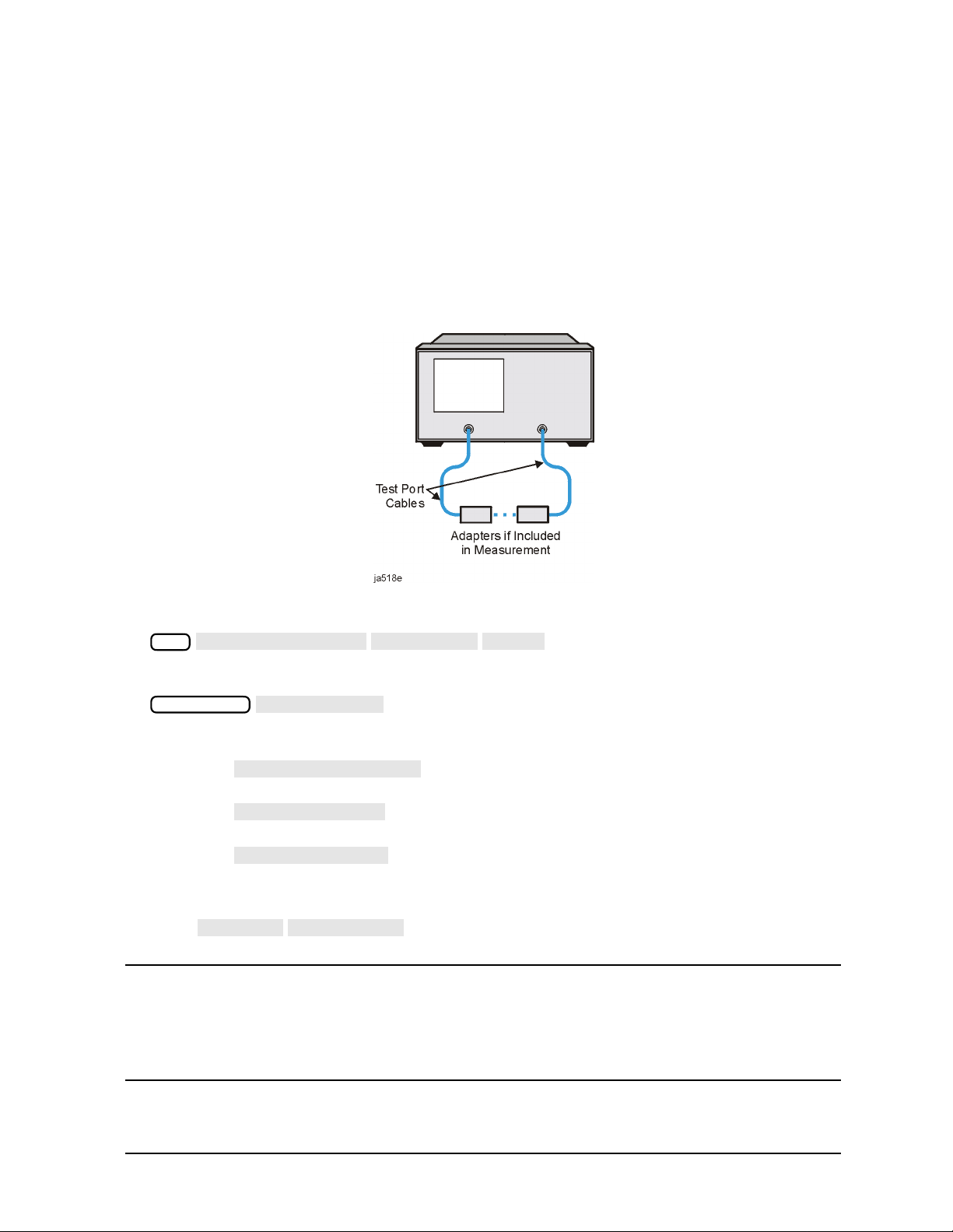

2. Connect a “thru” between the measurement cables, as shown in Figure 2-3. Include all

the adapters that you will use in your device measurement.

If noise reduction techniques are needed for the measurement, the instrument's

settings (reduced IF BW, and /or averaging) should be selected prior to any

error-correction.

Figure 2-3 Connections for a “Thru” Calibration Standard

3. Press the following keys to make a transmission response calibration:

Cal

4. To save the error-correction (measurement calibration), press:

Save/Recall

5. Next, choose from the following options:

• Choose if you want to save the calibration results and

instrument state to the analyzer's memory.

• Choose if you want to save the calibration results and

instrument state to the disk that is in the analyzer's internal disk drive.

• Choose if you want to save the calibration results and

instrument state to the disk that is in an (optional) external disk drive that is

configured to the analyzer.

6. Press to save the error-correction (measurement calibration).

NOTE Example procedures for all types of error-correction (measurement

calibrations) are located in the “Calibrating For Increased Measurement

Accuracy” chapter in the User's Guide. For information on the analyzer

operation during error-correction (measurement calibration), refer to the

“Operating Concepts” chapter in the User's Guide.

Chapter 2 2-7

Page 41

Quick Start: Learning How to Make Measurements

AUTO SCALE

Learning to Make Transmission Measurements

Step 3. Measure the device

Measuring Insertion Loss

1. Reconnect your test device as in Figure 2-2.

2. Reposition the measurement trace for the best view. This can be done by pressing

Scale Ref

position, or the scale/division.

and, if necessary, adjusting the reference level, reference

3. Press and turn the front panel knob to place the marker at a frequency of

Marker

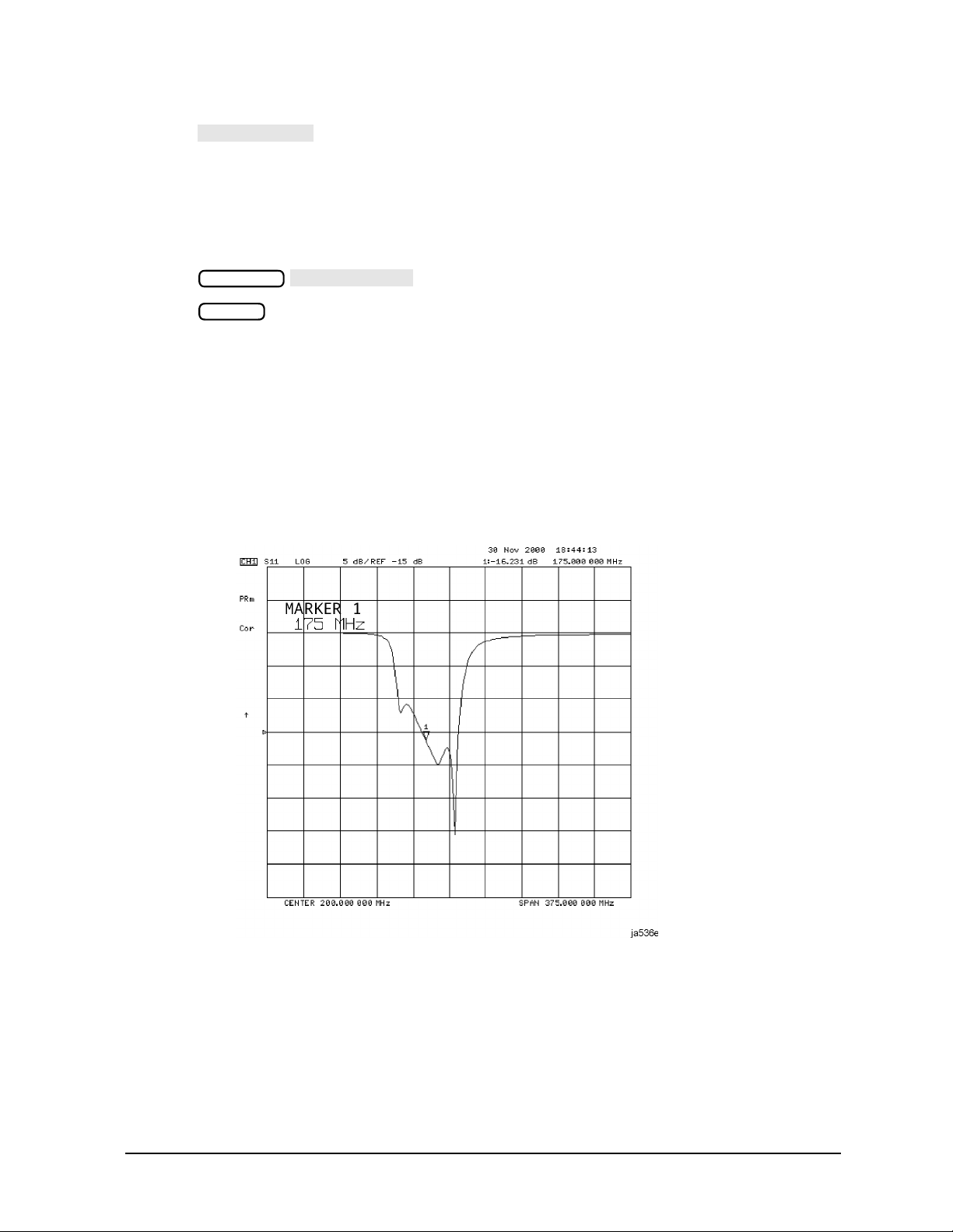

interest. Read the device's insertion loss to 0.001 dB resolution as shown in Figure 2-4.

The analyzer shows the frequency of the marker location in the active entry area

(upper-left corner of display). The analyzer also shows the amplitude and frequency of

the marker location in the upper-right corner of the display.

Figure 2-4 Example Measurement of Insertion Loss

2-8 Chapter2

Page 42

Quick Start: Learning How to Make Measurements

SELECT DISK

INTERNAL DISK

RETURN

DEFINE DISK-SAVE

DATA ARRAY on OFF

RAW ARRAY on OFF

FORMAT ARY on OFF

GRAPHICS on OFF

DATA ONLY on OFF

DATA ONLY on OFF

DATA ONLY ON off

SAVE USING BINARY

SAVE USING ASCII

RETURN

SAVE STATE

Learning to Make Transmission Measurements

Step 4. Output measurement results

This example procedure shows how to output (store) measurement results to a disk.

For more information on creating a hardcopy of the measurement results, refer to

the "Printing, Plotting, and Saving Measurement Results" chapter in the User's Guide.

CAUTION Do not mistake the line switch for the disk eject button. If the line switch is

mistakenly pushed, the instrument will be turned off, losing all settings and

data that have not been saved.

1. Insert a DOS- or LIF-formatted disk into the analyzer disk drive. The analyzer does not

support LIF-HFS (hierarchy file system).

2. Press . Choose to save the

Save/Recall

measurement results to the analyzer's internal disk drive.

3. Press .

• Toggle to ON if you want to store the error-corrected data on

disk with the instrument state.

• Toggle to ON if you want to store the raw data (ratioed and

averaged, but no error-correction) on disk with the instrument state.

• Toggle to ON if you want to store the formatted data on disk

with the instrument state.

• Toggle to ON if you want to store user graphics on disk with

the instrument state.

• Toggle to ON if you want to only store the measurement data

of the device under test. The analyzer will not store the instrument state and

error-correction (measurement calibration). Therefore, the saved data cannot be

retrieved into the analyzer.

NOTE Toggling to ON will override all of the other save

options. Because this type of data is only intended for computer

manipulation, the file contents of a save cannot be

recalled and displayed on the analyzer.

• Choose if you want to store data in a binary format.

• Choose if you want to store data in an ASCII format, to later

4. Press and the analyzer saves the file with a default title.

Chapter 2 2-9

read on a computer.

Page 43

Quick Start: Learning How to Make Measurements

SEARCH: MAX

MKR ZERO

MKR ZERO∆ REF=

WIDTHS on OFF

Learning to Make Transmission Measurements

Measuring Other Transmission Characteristics

Using the analyzer marker functions, you can derive several important filter parameters

from the measurement trace that is shown on the analyzer display.

Measuring 3 dB Bandwidth.

The analyzer can calculate your test device bandwidth between two equal power levels. In

this example procedure, the analyzer calculates the −3 dB bandwidth relative to the center

frequency of the filter.

1. Press and turn the front panel knob to move the marker to the center

Marker

frequency position of the filter passband. An alternative method is to press

Marker Search

which should put you very close to the center of the

passband.

You can also position the marker by entering a frequency location: for example, press

175 M/µ

2. Press to zero the delta marker magnitude and frequency (this

Marker

.

sets the delta marker reference). The −3 dB points will be relative to this marker.

The softkey label changes to showing you that the delta

∆

reference point is the small ∆ symbol.

3. Press to enter the marker search mode.

Marker Search

4. Toggle to ON.

The analyzer calculates the −3 dB bandwidth, the center frequency and the Q (quality

factor) of the test device and lists the results in the upper-right corner of the display.

Markers 3 and 4 indicate the location of the −3 dB points, as shown in Figure 2-5.

Figure 2-5 Example Measurement of 3 dB Bandwidth

2-10 Chapter2

Page 44

Quick Start: Learning How to Make Measurements

WIDTH VALUE

MARKER all OFF

Learning to Make Transmission Measurements

5. Press and enter .

−6 x1

The analyzer now calculates the bandwidth between −6 dB power levels.

6. Press when you are finished with this measurement.

Marker

Chapter 2 2-11

Page 45

Quick Start: Learning How to Make Measurements

MARKER 1

MKR ZERO

SEARCH: MIN

IF BW [ ]

AVERAGING on OFF

Learning to Make Transmission Measurements

Measuring Out-of-Band Rejection.

1. Press . The marker appears where you placed it during the bandwidth

measurement.

2. Press .

Marker Search

The marker automatically searches for the minimum point on the trace. The frequency

and amplitude of this point, relative to the delta symbol in the center of the filter

passband, appear in the upper-right corner of the display. This value is the difference

between the maximum power in the passband and the power in the rejection band, that

is, one of the peaks in the rejection band.

Figure 2-6 Example Measurement of Out-of-Band Rejection

NOTE You can use the marker search mode to search the trace for the maximum

3. If your measurement needs some noise reduction, you can reduce the IF bandwidth or

add averaging.

• To reduce the IF bandwidth, press .

• To add averaging, press , then toggle to ON.

2-12 Chapter2

point or for any target value. The target value can be an absolute level (for

example, −3 dBm) or a level relative to the location of the small delta symbol

(for example: −3 dB from the center of the passband).

Avg

Avg

Page 46

Quick Start: Learning How to Make Measurements

RECALL STATE

MODE MENU

REF = 1

MARKER 2

MARKER MODE MENU

MKR STATS on OFF

Learning to Make Transmission Measurements

Measuring Passband Flatness or Ripple.

Passbandflatness (or ripple) is the variation in insertion loss over a specified portion of the

passband.

Continue with the following steps to measure passband flatness or ripple.

1. Press (if necessary, scroll to the desired file using

panel keys). Press to recall the error-corrected transmission

Save/Recall

the and front

measurement that has no markers engaged.

2. Press and turn the front panel knob to move marker 1 to the left edge of the

Marker

passband.

3. Press to change the marker 1 position to the delta

∆

∆

reference point.

4. Press and turn the front panel knob to move marker 2 to the right edge of

the passband.

5. Press . Toggle to ON.

Marker Fctn

The analyzer calculates the mean, standard deviation, and peak-to-peak variation

between the ∆ reference marker and the active marker, and lists the results in the

upper-right corner of the display. The passband ripple is automatically shown as the

peak-to-peak variation between the markers.

Figure 2-7 Example Measurement of Passband Flatness or Ripple

Chapter 2 2-13

Page 47

Quick Start: Learning How to Make Measurements

Learning to Make Reflection Measurements

Learning to Make Reflection Measurements

This example procedure shows you how to measure the reflection response of a 175 MHz

bandpass filter. The measurement parameter values listed are unique to this particular

test device.

For further measurement examples, refer to the "Making Measurements" chapter in the

User's Guide.

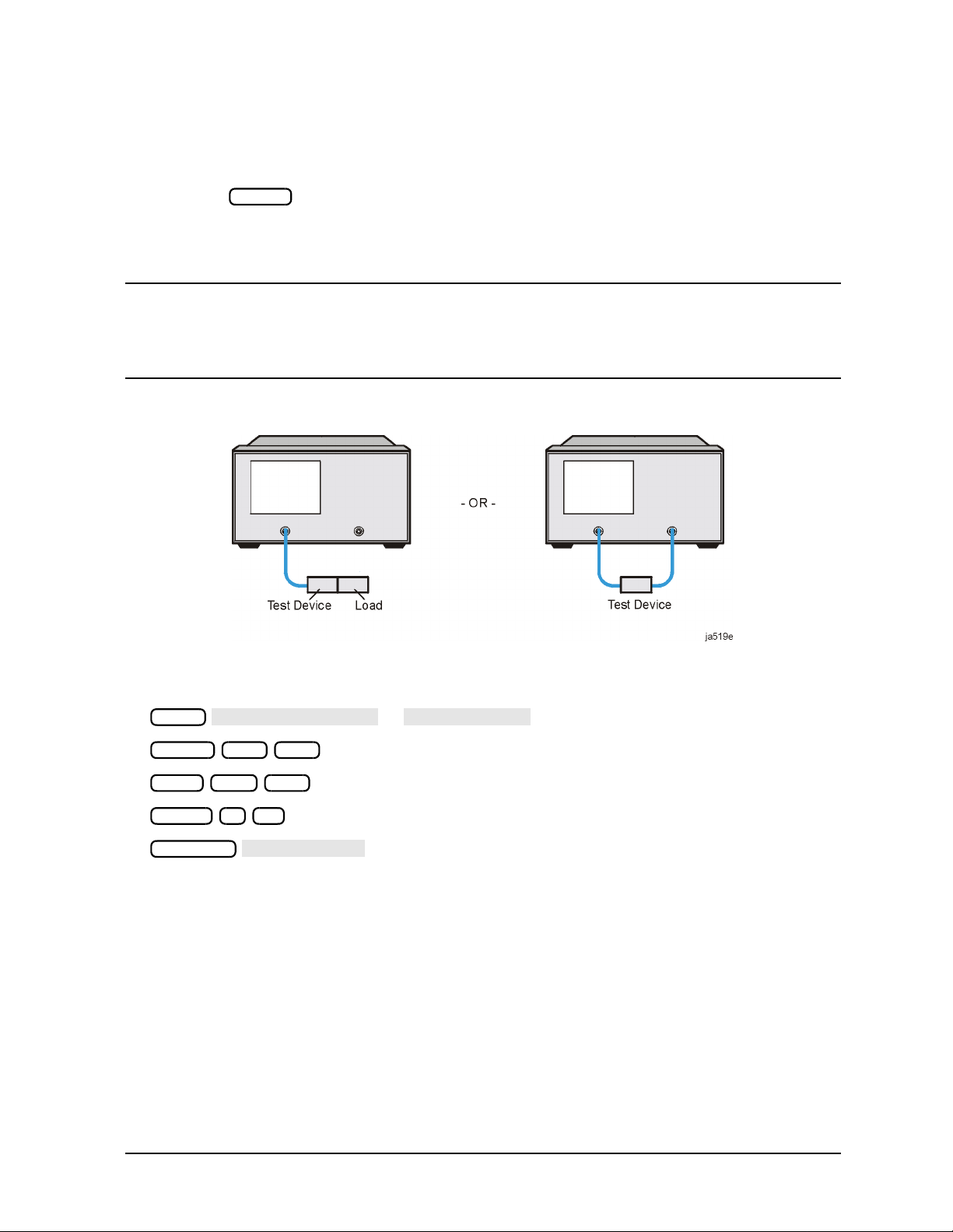

NOTE Reflection measurements monitor only one port of a test device. When a test

device has more than one port, you must ensure that the unused port(s) are

terminated in their characteristic impedance (for example, 50Ω or 75Ω). If

you do not terminate unused ports, reflections from these ports will cause

measurement errors. Figure 2-8 on page 2-15 illustrates two ways to

terminate an unused device port with the proper characteristic impedance.

The signal reflected from the device under test is measured as a ratio of the reflected

energy versus the incident energy. It can be expressed as reflection coefficient, return loss,

or standing-wave-ratio (SWR). These measurements are mathematically defined as

follows:

reflection coefficient (Γ) = reflected voltage / incident voltage

= S11 or S22 (magnitude and phase)

magnitude of reflection

coefficient (ρ)

return loss (dB) = −20 log (ρ), where ρ = |Γ|

standing-wave-ratio (SWR)

=|Γ|

= V

maximum

/ V

minimum

= (1 + ρ) / (1 −ρ)

2-14 Chapter2

Page 48

Quick Start: Learning How to Make Measurements

Refl: FWD S11 (A/R)

REFLECTION

AUTO SCALE

Learning to Make Reflection Measurements

Step 1. Choose measurement parameters with your test device

connected

1. Press the key to return the analyzer to a known state.

Preset

2. Connect your test device as shown in Figure 2-8. If using a load, make sure it has the

correct characteristic impedance.

CAUTION Damage may result to the device under test if it is sensitive to the analyzer's

default output power level. Toavoid damaging a sensitive DUT, be sure to set

the analyzer's output power to an appropriate level before connecting the

DUT to the analyzer.

Figure 2-8 Connections for Reflection Measurements

3. Choose the following measurement parameters:

Meas

Center 200 M/µ

Span 375 M/µ

Power 5 x1

Scale Ref

or

4. Look at the device response to determine if these are the measurement parameters that

you want. For example, if the trace is noisy you may want to increase the input power,

reduce the IF bandwidth, or add averaging. Tobetter see an area of interest, change the

test frequencies.

Chapter 2 2-15

Page 49

Quick Start: Learning How to Make Measurements

CAL KIT

SELECT CAL KIT

N 50

7mm

RETURN

CALIBRATE MENU

S11 1-PORT

REFLECTION 1-PORT

SHORT (M)

DONE 1-PORT CAL

DONE 1-PORT CAL

Learning to Make Reflection Measurements

Step 2. Make a measurement calibration

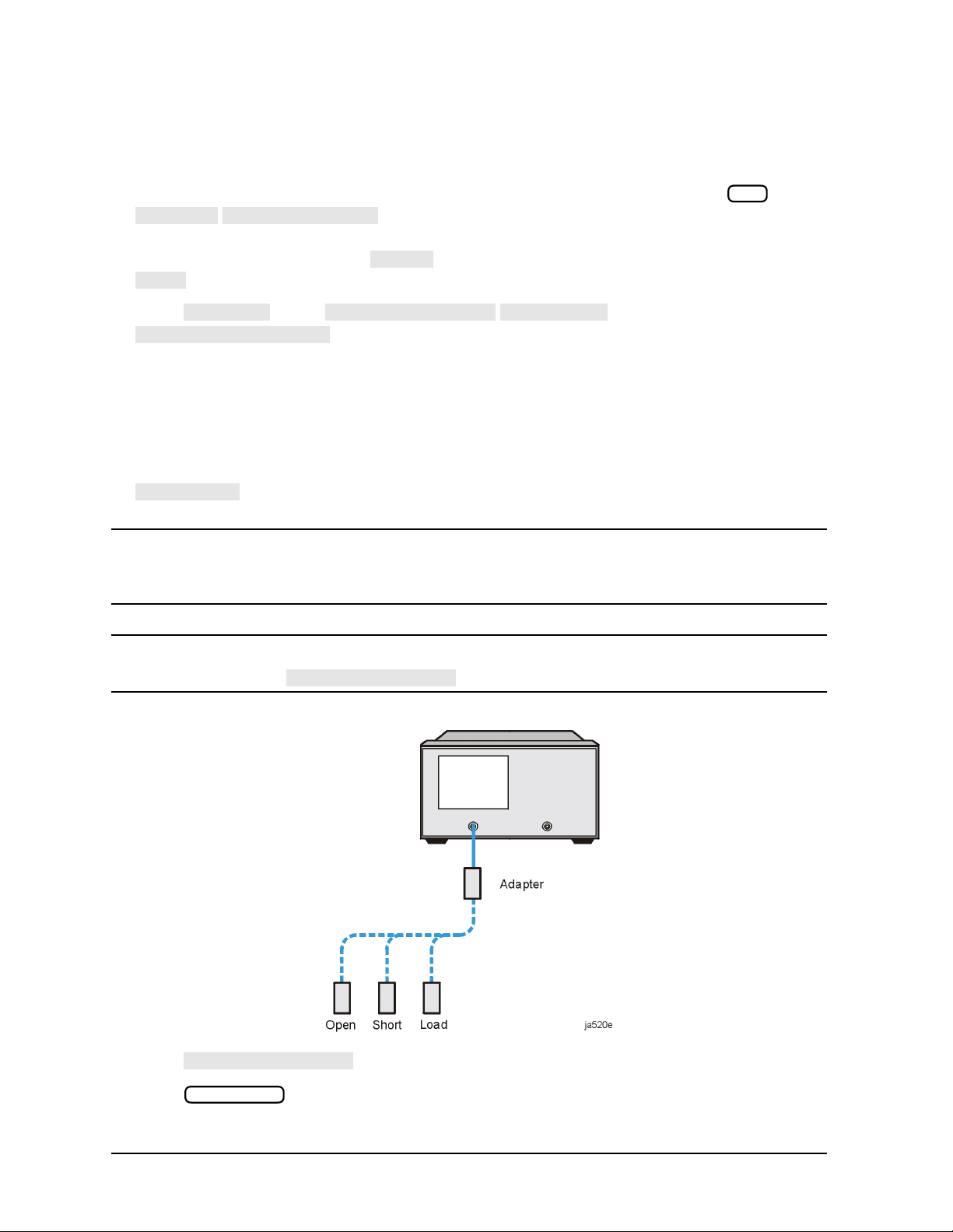

Follow these instructions to perform an S11 or reflection 1-port error correction:

1. Select a calibration kit that is appropriate to your device under test. Press

Cal

. Choose the calibration kit that is appropriate to your

test device by pressing the appropriate softkey. For example, if your test device uses

type-N 50Ω connectors, press . If your test device uses 7-mm connectors, press

Ω

, and so on.

2. Press twice, or

.

3. Follow the prompts shown on the analyzer display to connect and measure an open,

short, and load on PORT 1 or the REFLECTION port.

Any choice of male/female in the calibration process should always be made for the sex

that represents the test port. For example, if the test port had a male, type-N connector,

you would connect the female, type-N calibration device. But when you follow the

prompts on the analyzer to measure a short calibration standard, you would select

, or the sex that represents the test port.

NOTE To ensure an accurate error correction, you must connect the calibration

standards to the adapters or cables that you will include in the actual device

measurement.

NOTE If a mistake is made, standards can be measured more than once before

pressing . Only the last measurement data is used.

Figure 2-9 Connections for an S11 or Reflection 1-Port Error-Correction

4. Press after measuring the three standards.

5. Press .

Save/Recall

2-16 Chapter2

Page 50

Quick Start: Learning How to Make Measurements

SAVE STATE

AUTO SCALE

Learning to Make Reflection Measurements

6. Press to complete the process.

Step 3. Measure the device

Measuring Return Loss.

1. Connect your device to PORT 1 or the REFLECTION port.

2. Press to reposition the trace.

3. Press to read the return loss from the analyzer display as shown in

Scale Ref

Marker

Figure 2-10.

The device response indicates that the filter and the analyzer impedances are better

matched within the frequency range of the filter passband than outside the passband.

That is, the reflected signal is smaller within the filter passband than outside the

passband.

In terms of return loss, the value within the passband is larger than outside the

passband. A large value for return loss corresponds to a small reflected signal just as a

large value for insertion loss corresponds to a small transmitted signal.

Figure 2-10 Example Measurement of Return Loss

Chapter 2 2-17

Page 51

Quick Start: Learning How to Make Measurements

MORE

TITLE

ERASE TITLE

DONE

SYSTEM CONTROLLER

PRINT MONOCHROME

Learning to Make Reflection Measurements

Step 4. Output measurement results

This step in the procedure shows you how to output the measurement results to a printer.

For in-depth information on creating a hardcopy of the measurement results, refer to the

“Printing, Plotting, and Saving Measurement Results” chapter in the User's Guide.

1. Connect a printer to the analyzer as described in “To Configure the Analyzer with

Printers or Plotters” on page 1-11.

2. Press and then create a title for the

Display

measurement, as shown in Figure 2-11:

• Use an optional keyboard to type the title, or

• Use the front panel knob and the softkey menu to select each letter of the title.

3. Press when you finish creating the measurement title. The title appears on the

upper-left corner of the analyzer display.

4. Press to set up the analyzer as the controller. If you

Local

are using an GPIB printer, ensure that there is not another controller on the bus. (Note

that this step is not required when using parallel or serial printers.)

5. Press to create a black and white hardcopy.

Copy

NOTE If you encounter a problem when printing a hardcopy, refer to “To Configure

the Analyzer with Printers or Plotters” on page 1-11.

Figure 2-11 Example Measurement Title

2-18 Chapter2

Page 52

Quick Start: Learning How to Make Measurements

RECALL STATE

LIN MAG

AUTO SCALE

Learning to Make Reflection Measurements

Measuring Other Reflection Characteristics

You can derive several important filter parameters from the measurement shown on the

analyzer display. The following set of procedures is a continuation of the previous

reflection measurement procedure.

Measuring Reflection Coefficient

1. Press to recall the calibrated reflection measurement

Save/Recall

that you saved earlier in this procedure.

2. Press so the analyzer shows the same

Format

Scale Ref

data in terms of reflection coefficient, as shown in Figure 2-12.

The units “mU” displayed on the analyzer are “milli-units,” where “units” or “U” is used

to indicate that the parameter is unitless (as opposed to dB in log magnitude format).

For example, 200 mUnits = 0.2.

Figure 2-12 Example Reflection Coefficient Measurement Trace

Chapter 2 2-19

Page 53

Quick Start: Learning How to Make Measurements

SWR

AUTO SCALE

Learning to Make Reflection Measurements

Measuring Standing Wave Ratio (SWR)

Press so the analyzer shows the same data in

Format

Scale Ref

terms of standing-wave-ratio (SWR), as shown in Figure 2-13.

Now the analyzer shows the measurement data in the unitless measure of SWR where

SWR = 1 (perfect match) at the bottom of the display.

Figure 2-13 Example Standing-Wave-Ratio Measurement Trace

2-20 Chapter2

Page 54

Quick Start: Learning How to Make Measurements

POLAR

AUTO SCALE

MARKER MODE MENU

POLAR MKR MENU

LIN MKR

LOG MKR

Re/Im MKR

Learning to Make Reflection Measurements

Measuring S11 and S22 or Reflection in a Polar Format.

1. Press .

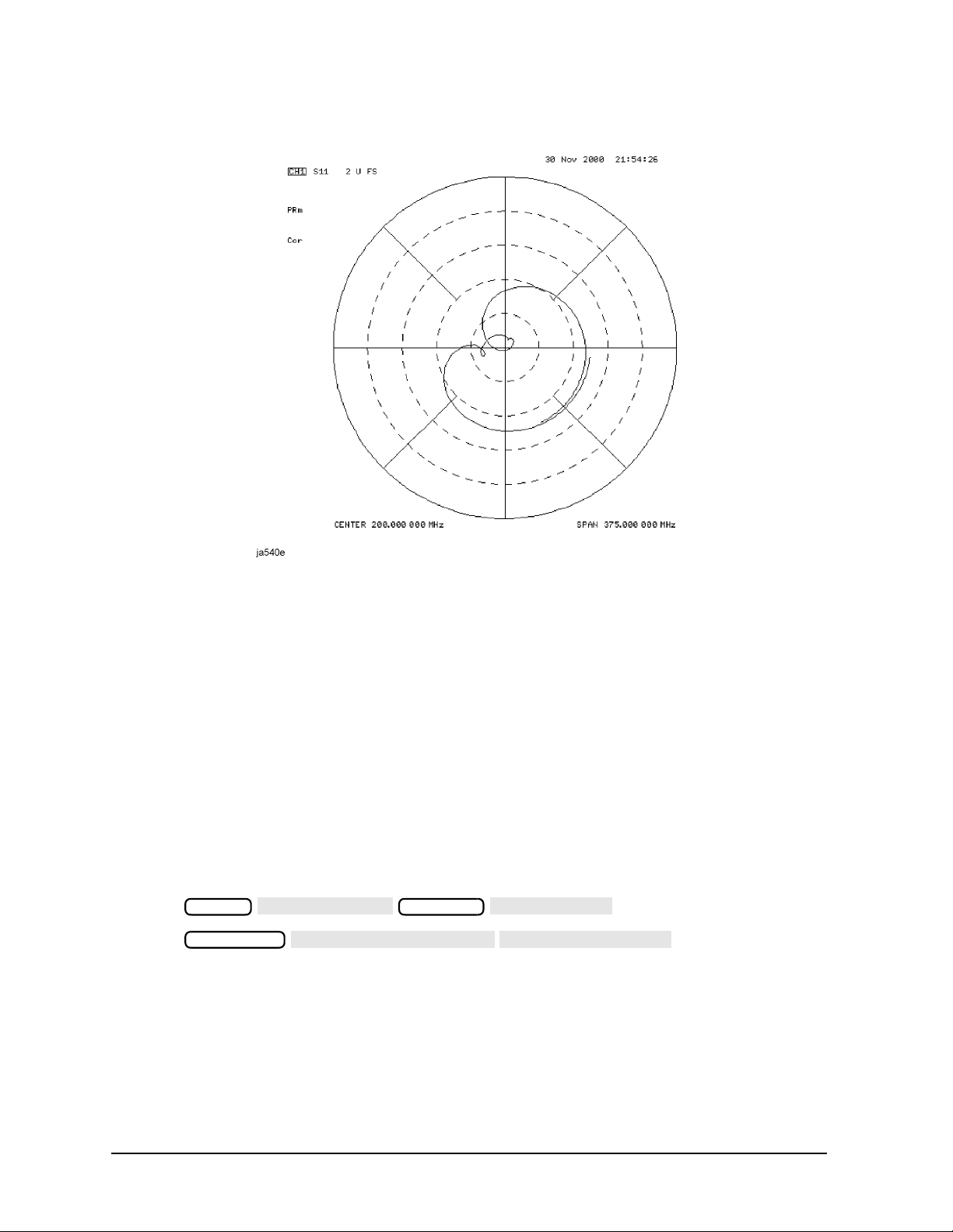

2. Press to reposition the trace, as shown in Figure 2-14.

The analyzer shows the results of an S

Format

Scale Ref

or reflection measurement with each point on

11

the polar trace corresponding to a particular value of both magnitude and phase. The

center of the circle represents a coefficient (Γ) of 0, (that is, a perfect match or no

reflected signal). The notation 2U FS or 2 units full scale indicates that the

outermost circumference of the scale shown in Figure 2-14 represents ρ = 2.00, or 200%

reflection. The phase angle is read directly from this display. The 3 o'clock position

corresponds to zero phase angle, (that is, the reflected signal is at the same phase as the

incident signal). Phase differences of 90°, 180°, and −90° correspond to the 12 o'clock, 9

o'clock, and 6 o'clock positions on the polar display, respectively.

3. Press .

Marker Fctn

4. Turn the front panel knob to position the marker at any desired point on the trace, then

read the frequency, linear magnitude and phase in the upper right-hand corner of the

display.

• Choose if you want the analyzer to show the linear magnitude and the

phase of the marker.

• Choose if you want the analyzer to show the logarithmic magnitude and

the phase of the active marker. This is useful as a fast method of obtaining a reading

of the log-magnitude value without changing to log-magnitude format.

• Choose if you want the analyzer to show the values of the marker as a

real and imaginary pair.

NOTE You can also enter the frequency of interest, from either the numeric keypad

or the optional attached keyboard, and read the magnitude and phase at that

point.

Chapter 2 2-21

Page 55

Quick Start: Learning How to Make Measurements

SMITH CHART

AUTO SCALE

MARKER MODE MENU

SMITH MKR MENU

Learning to Make Reflection Measurements

Figure 2-14 Example S11 or Reflection Measurement Trace in Polar Format

Measuring S

• Measuring Impedance

and S22 or Reflection in a Smith Chart Format.

11

The amount of power reflected from a device is directly related to the impedance of the

device and the measuring system. Each value of the reflection coefficient (Γ) uniquely

defines a device impedance; Γ = 0 only occurs when the device and analyzer impedance are

exactly the same. The reflection coefficient for a short circuit is: Γ = 1 ∠ 180°. Every other

value for Γ also corresponds uniquely to a complex device impedance, according to the

equation:

Z

= [(1 + Γ) / (1 −Γ)] × Z

L

0

where ZL is your test device impedance and Z0 is the measuring system's characteristic

impedance (usually 50Ω or 75Ω).

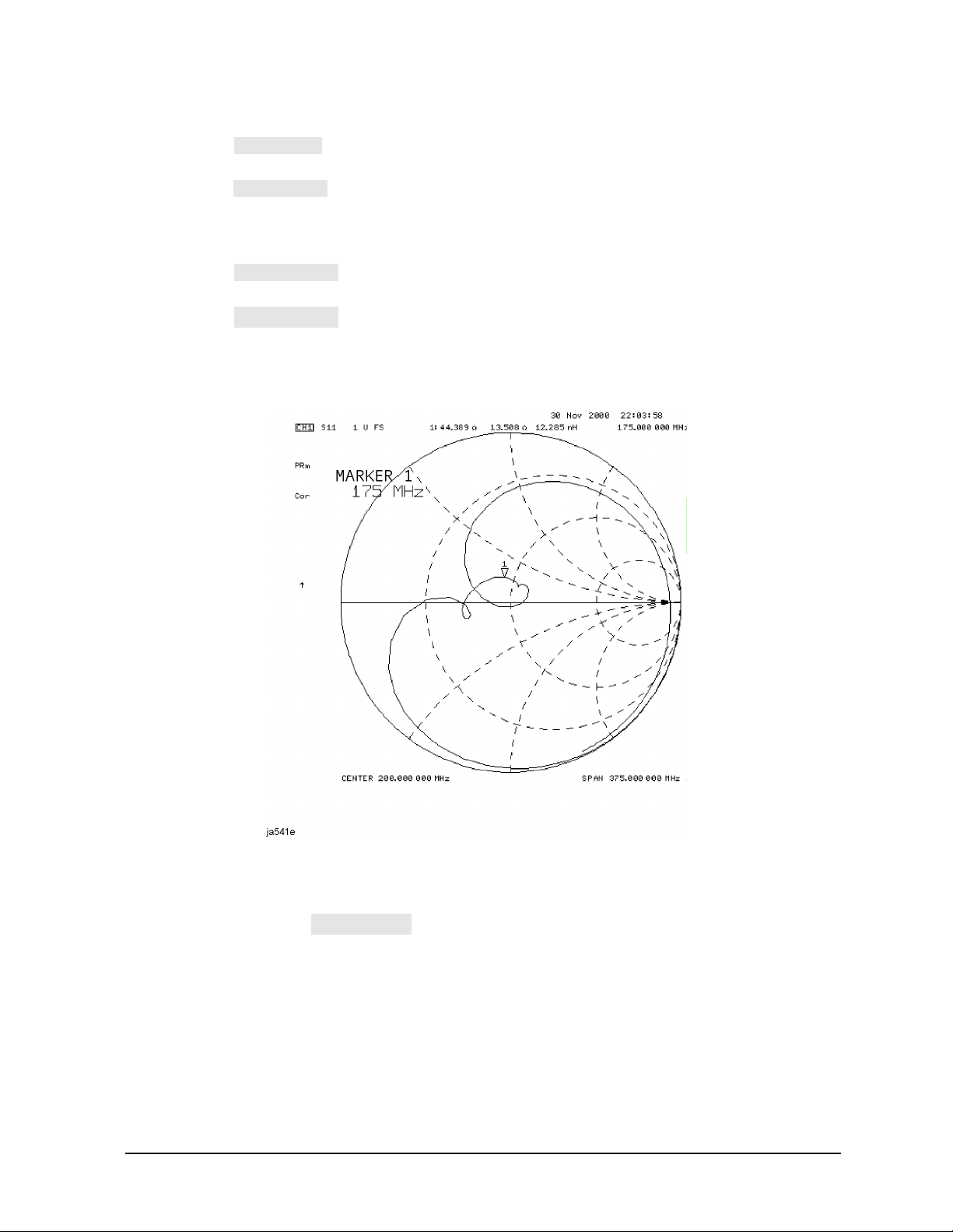

1. Press .

2. Press and turn the front

Format

Marker Fctn

Scale Ref

panel knob to read the resistive and reactive components of the complex impedance at

any point along the trace, as shown in Figure 2-15. Here the complex impedance is

6.4729 – j7.5569 Ω. This is the default Smith chart marker.

The marker annotation also gives the series inductance or capacitance (132.87 pF in

this example). The complex impedance is capacitive in the bottom half of the Smith

chart display and is inductive in the top half of the display.

2-22 Chapter2

Page 56

Quick Start: Learning How to Make Measurements

LIN MKR

LOG MKR

Re/Im MKR

R+ jX MKR

G+ jB MKR

Learning to Make Reflection Measurements

• Choose if you want the analyzer to show the linear magnitude and the

phase of the reflection coefficient at the marker.

• Choose if you want the analyzer to show the logarithmic magnitude and

the phase of the reflection coefficient at the active marker. This is useful as a fast

method of obtaining a reading of the log magnitude value without changing to log

magnitude format.

• Choose if you want the analyzer to show the values of the reflection

coefficient at the marker as a real and imaginary pair.

• Choose (the default marker format) to show the real and imaginary

parts of the device impedance at the marker. Also shown is the equivalent series

inductance or capacitance (the series resistance and reactance, in ohms).

Figure 2-15 Example Impedance Measurement Trace

• Measuring Admittance

To change the display to an inverse Smith chart graticule and the marker information to

read admittance, press .

As shown in Figure 2-16, the marker reads admittance data in the form G+jB, where G is

conductance and B is susceptance, both measured in units of Siemens (equivalent to mhos:

the inverse of ohms). Also shown is the equivalent parallel capacitance or inductance.

Chapter 2 2-23

Page 57

Quick Start: Learning How to Make Measurements

Learning to Make Reflection Measurements

Figure 2-16 Example Admittance Measurement Trace

2-24 Chapter2

Page 58

Quick Start: Learning How to Make Measurements

If You Encounter a Problem

If You Encounter a Problem

If you have difficulty when installing or using the analyzer, check the following list of

commonly encountered problems and troubleshooting procedures. If the problem that you

encounter is not in the following list, refer to additional troubleshooting sections in the

Service Guide.

Power-Up Problems

If the analyzer display does not light:

• Check that the power cord is fully seated in both the main power receptacle and the

analyzer power module.

• Check that the AC line voltage selector switch is in the appropriate position

(230 V/115 V) for your available power supply.

• Check that the analyzer AC line fuse is not open.

WARNING For continued protection against fire hazard, replace the fuse with

the same type and rating.

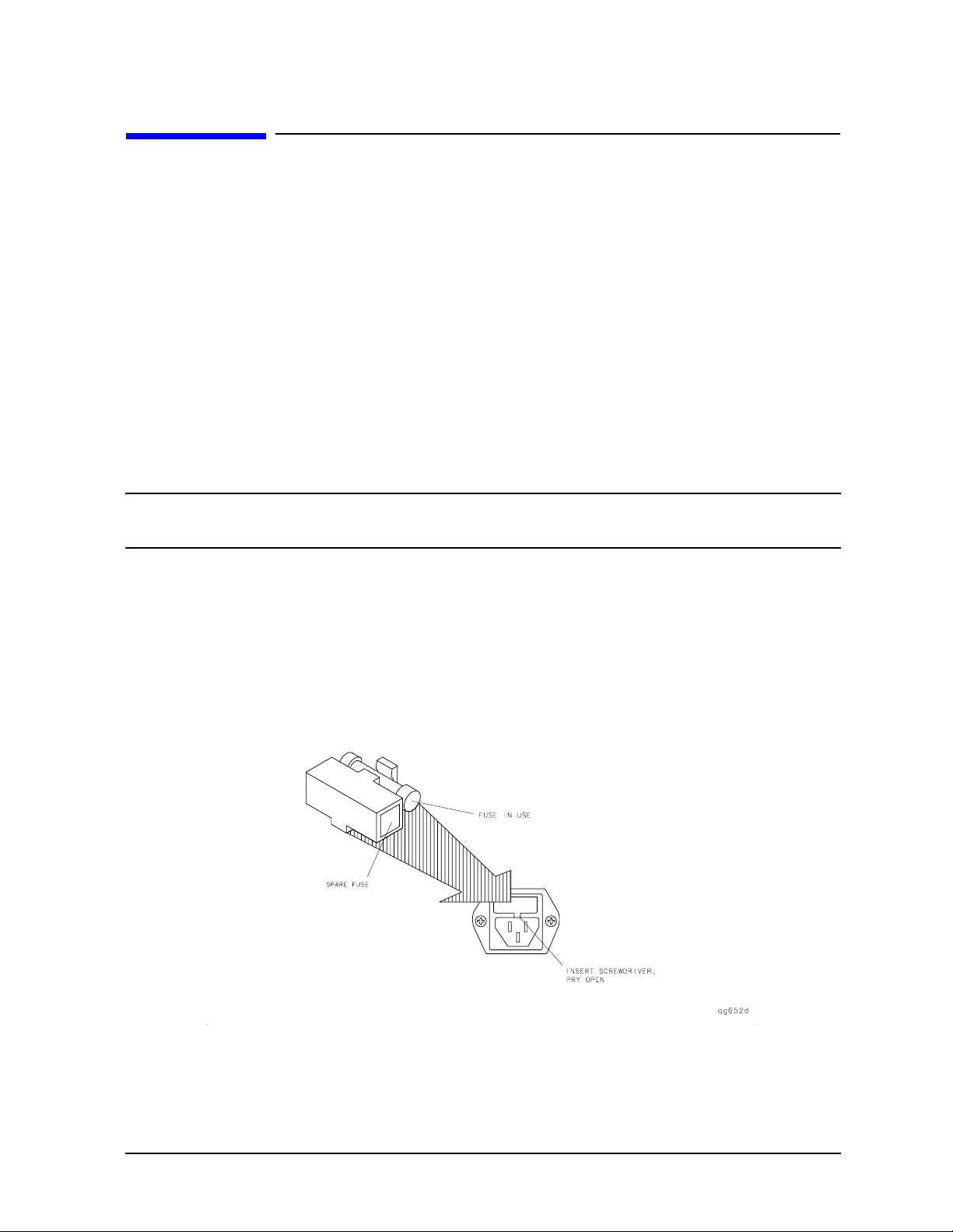

Refer to Figure 2-17 to remove the fuse from the power module. You can use a

continuity light or an ohmmeter to check the fuse. An ohmmeter should read very close

to zero ohms if the fuse is good. For 115V operation, use Fuse, T 5A 125V, UL listed/CSA

certified to 248 standard (part number 2110-1059). For 230V operation, use Fuse, T 4A

H 250V, built to IEC 127-2/5 standard (part number 2110-1036).

• Contact the nearest Agilent Technologies office for service, if necessary. A list of Agilent

Technologies sales and service offices is provided in Table 2-1 on page 2-28.

Figure 2-17 Line Fuse Removal and Replacement

Chapter 2 2-25

Page 59

Quick Start: Learning How to Make Measurements

SOURCE PWR ON off

If You Encounter a Problem

If the display lights, but the ventilation fan does not start:

❏ Check that the fan is not obstructed. To check the fan, follow these steps:

1. Switch the LINE power to the off position.

2. Check that the fan blades are not jammed.

❏ Contact the nearest Agilent Technologiesoffice for service, if necessary. A list of Agilent

Technologies sales and service offices is provided in Table 2-1 on page 2-28.

Data Entry Problems

If the data entry controls (keypad, knob, arrow keys) do not respond:

❏ Check that the ENTRY OFF function is not enabled.

The ENTRY OFF function is enabled after you press the key. To return to

Entry Off

normal entry mode, press any function key that has a numeric parameter associated

with it, for example, .

Start

❏ Check that none of the keys are stuck.

❏ Check that the selected function key accepts data.

For example, accepts data, but does not.

Scale Ref System

❏ Check that the analyzer's "R" GPIB STATUS light is not illuminated.

If the analyzer's "R" GPIB STATUS light is illuminated, a test sequence may be

running, or a connected computer controller may be sending commands or instructions

to, or receiving data from, the analyzer. Press if you want to return to LOCAL

Local

control.

If the parameter you are trying to enter is not accepted by the analyzer:

❏ Ensure that you are not attempting to set the parameter greater than or less than its

limit. Refer to the User's Guide for parameter limits.

No RF Output

If there is no RF signal at the front-panel port:

❏ Check that the signal at the test port is switched on.

1. Press and toggle to ON.

NOTE On ES models, it is possible to set the source power to come from PORT 2

❏ If you are applying external modulation (AM) to the analyzer, check the external

modulating signal or external gate/trigger signals for problems.

2-26 Chapter2

Power

instead of PORT 1, so you must check the power at the correct port. With

factory preset, the power comes from PORT 1.

Page 60

Quick Start: Learning How to Make Measurements

If You Encounter a Problem

CAUTION If the error message:

CAUTION: OVERLOAD ON INPUT X, POWER REDUCED

appears on the analyzer display, too much source power is being applied at

the input. In such a case, the input power will need to be reduced before the

source power will remain on.

❏ If phase-lock error messages appear on the analyzer display, check that the front panel

jumper is secure on the R CHANNEL connectors. If the jumper is secure and the error

messages still appear, contact your nearest Agilent Technologies office for service. A list

of Agilent Technologies sales and service offices is provided in Table 2-1 on page 2-28.

Chapter 2 2-27

Page 61

Quick Start: Learning How to Make Measurements

If You Encounter a Problem

Table 2-1 Agilent Technologies Sales and Service Offices

UNITED STATES

Instrument Support Center

Agilent Technologies

(800) 403-0801

EUROPEAN FIELD OPERATIONS

Headquarters

Agilent Technologies S.A.

150, Route du Nant-d’Avril

1217 Meyrin 2/ Geneva

Switzerland

(41 22) 780.8111

Great Britain

Agilent Technologies Ltd.

Eskdale Road, Winnersh

Triangle Wokingham,

Berkshire RG41 5DZ England

(44 118) 9696622

Headquarters

Agilent Technologies

3495 Deer Creek Rd.

Palo Alto, CA 94304-1316

USA

(415) 857-5027

Japan

Agilent Technologies Japan,

Ltd.

Measurement Assistance

Center

9-1, Takakura-Cho,

Hachioji-Shi,

Tokyo 192-8510, Japan

TEL (81) -426-56-7832

FAX (81) -426-56-7840

France

Agilent Technologies France

1 Avenue Du Canada

Zone D’Activite De Courtaboeuf

F-91947 Les Ulis Cedex

France

(33 1) 69 82 60 60

INTERCON FIELD OPERATIONS

Australia

Agilent Technologies Australia

Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

(61 3) 895-2895

Singapore

Agilent Technologies Singapore

(Pte.) Ltd.

150 Beach Road

#29-00 Gateway West

Singapore 0718

(65) 291-9088

Germany

Agilent Technologies GmbH

Agilent Technologies Strasse

61352 Bad Homburg v.d.H

Germany

(49 6172) 16-0

Canada

Agilent Technologies (Canada)

Ltd.

17500 South Service Road

Trans-Canada Highway

Kirkland, Quebec H9J 2X8

Canada

(514) 697-4232

Taiwan

Agilent Technologies Taiwan

8th Floor, H-P Building

337 Fu Hsing North Road

Taipei, Taiwan

(886 2) 712-0404

China

China Agilent Technologies

38 Bei San Huan X1 Road

Shuang Yu Shu

Hai Dian District

Beijing, China

(86 1) 256-6888

2-28 Chapter2

Page 62

Index

Numerics

3 dB bandwidth

measuring

6 dB bandwidth

measuring

A

active channel keys

location

admittance

measuring

Agilent Technologies Sales and

Service Offices

analyzer configuration

attaching cabinet flanges with

attaching cabinet flanges

attaching front handles

for bench top use

for rack mount use

option 1D5

standard

with printers or plotters

B

backing up EEPROM disk

bench top configuration

C

connectors

probe power source

R channel

D

definitions

magnitude of reflection

reflection coefficient

return loss (dB)

standing-wave-ratio (SWR)

disk drive location

disk eject button

display location

E

EEPROM backup disk

electrical and environmental

requirements

entry block location

F

front panel

, 2-10

, 2-11

, 2-3

, 2-23

, 2-28

, 1-9–1-19

front handles

without front handles

, 1-19

, 1-17

, 1-16

, 1-16

, 1-10

, 1-10

, 1-16

, 2-4

, 2-4

coefficient

, 2-14

, 2-14

, 2-14

2-14

, 2-3

, 2-3

, 2-3

, 1-26

, 1-7

, 2-4

, 1-5, 2-3

, 1-18

, 1-11

, 1-26

,

H

high stability frequency reference

configuration

I

impedance

measuring

insertion loss

measuring

installation

instrument state function block

keys

, 2-4

L

line switch

location

active channel keys

disk drive

disk eject button

display

, 2-3

entry block

instrument state function block

keys

line switch

PORT 1

PORT 2

Preset key

probe power source connectors

R channel connectors

REFLECTION port

response function block keys

Return key

softkeys

stimulus function block keys

TRANSMISSION port

M

making measurements

measurement procedure

choosing measurement

making a measurement

measuring a device

outputting measurement

measuring insertion loss with

O

operation

installed options

, 2-4

, 2-4

2-4

2-3

, 2-3

2-3

parameters

calibration

results

marker functions

, 1-20–1-25

, 1-10

, 2-22

, 2-8

, 1-2

, 2-3

, 2-3

, 2-3

, 2-3

, 2-4

, 2-4

, 2-3

, 2-4

, 2-4

, 2-4

,

, 2-3

,

, 2-4

, 2-1–2-24

, 2-5

, 2-5

, 2-5

, 2-5

, 2-5

, 2-10

, 1-21

operator’s check

self-test

testing reflection mode

testing transmission mode

operator’s check

out-of-band rejection

measuring

P

parts list

parts received

passband flatness

measuring

passband ripple

measuring

plotter configuration

polar format

measuring

PORT 1

location

PORT 2

location

Preset key

location

printer configuration

probe power connectors

location

problems, data entry

,

controls do not respond

parameters not accepted

problems, power-up

display does not light

display lights but fan does not

problems, RF output

no RF signal at front panel port

R

R channel connectors

location

rack mount configuration

rear panel

reflection measurements

admittance

choosing measurement

impedance

making a measurement

measuring in polar format

measuring in smith chart

measuringreflectioncoefficient

measuring return loss

, 1-22

, 2-4

, 2-4

, 2-4

, 2-4

start

, 2-26

2-26

, 2-4

, 1-6

2-14–2-24

parameters

calibration

format

2-19

, 1-23

, 1-25

, 1-24

, 1-23

, 2-12

, 1-4

, 2-13

, 2-13

, 1-11

, 2-21

, 1-11

, 2-26

, 2-26

, 2-26

, 2-25–2-26

, 2-25

, 2-26

,

, 1-16

,

, 2-23

, 2-15

, 2-22

, 2-16

, 2-21

, 2-22

,

, 2-17

Index 1

Page 63

Index

measuring standing wave ratio

(SWR)

results

, 2-4

1-7

, 2-3

, 2-3

, 2-20

, 2-17

, 2-18

, 2-3

, 2-17

, 2-28

, 1-3

, 2-22

, 2-22

, 2-3

, 2-20

measuring the device

outputting measurement

REFLECTION port

location

requirements

electrical and environmental

response function block keys

location

Return key, location

return loss

measuring

S

Sales and Service Offices

shipment, verifying

smith chart

smith chart format

measuring

softkeys, location

standard analyzer configuration

1-10

standing wave ratio (SWR)

measuring

stimulus function block keys

location

,

,

T

transmission measurements

2-6–2-13

3 dB bandwidth

6 dB bandwidth

choosing the measurement

parameters

insertion loss

making a measurement

calibration

measuring insertion loss with

marker functions

measuring the device

out-of-band rejection

outputting measurement

results

passband flatness

passband ripple

TRANSMISSION port

location

troubleshooting

V

verifying the shipment

, 2-4

, 2-10

, 2-11

, 2-6

, 2-8

, 2-7

, 2-10

, 2-8

, 2-12

, 2-9

, 2-13

, 2-13

, 2-25–2-27

, 1-3

,

2 Index

Loading...

Loading...