Page 1

Service Guide

Agilent Technologies

8752C

Network Analyzer

Manufacturing Part Number: 08752-90136

Printed in USA

Print Date: February 1998

Supersedes: December 1997

© Agilent Technologies, Inc. 1998

Page 2

Hewlett-Packard to Agilent Technologies Transition

This manual may contain references to HP or Hewlett-Packard. Please note that

Hewlett-Packard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. To reduce potential confusion, the only

change to product numbers and names has been in the company name prefix: where a product

number/name was HP XXXX the current name/number is now Agilent XXXX. For example,

model number HP 8752C is now model number Agilent 8752C.

Documentation Warranty

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED "AS IS," AND IS

SUBJECT TO BEING CHANGED, WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER, TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, AGILENT

DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED WITH REGARD TO

THIS MANUAL AND ANY INFORMATION CONTAINED HEREIN, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. AGILENT SHALL NOT BE LIABLE FOR

ERRORS OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN CONNECTION

WITH THE FURNISHING, USE, OR PERFORMANCE OF THIS DOCUMENT OR ANY

INFORMATION CONTAINED HEREIN. SHOULD AGILENT AND THE USER HAVE A

SEPARATE WRITTEN AGREEMENT WITH WARRANTY TERMS COVERING THE

MATERIAL IN THIS DOCUMENT THAT CONFLICT WITH THESE TERMS, THE WARRANTY TERMS IN THE SEPARATE AGREEMENT WILL CONTROL.

DFARS/Restricted Rights Notice

If software is for use in the per formance of a U.S. Government prime contract or

subcontract, Software is delivered and licensed as “Commercial computer software” as

defined in DFAR 252.227-7014 (June 1995), or as a “commercial item” as defined in FAR

2.101(a) or as “Restricted computer sof tware” as defined in FAR 52.227-19 (June 1987) or

any equivalent agency regulation or contract clause. Use, duplication or disclosure of

Software is subject to Agilent Technologies’ standard commercial l icense terms, and

non-DOD Departments and Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR 52.227-19(c)(1-2) (June 1987) . U.S. Government users

will receive no greater than Limited Rights as defined in FAR 52.227-14 (June 1987) or

DFAR 252.227-7015 (b)(2) (November 1995), as applicable in any technical data.

Page 3

Printing Copies of Documentation from the Web

To print copies of documentation from the Web, download the PDF file from the Agilent

web site:

•Go to http://www.agilent.com.

• Enter the document’s pa rt number (located on the title page) in the Quick Search box.

• Click GO.

• Click on the hyperlink for the document.

• Click the printer icon located in the tool bar.

Page 4

Contacting Agilent

This information supersedes all prior HP contact information.

Online assistance: www.agilent.com/find/assist

Americas

Brazil

(tel) (+55) 11 3351 7012

(fax) (+55) 11 3351 7024

Canada

(tel) +1 877 894 4414

(fax) +1 303 662 3369

Mexico

(tel) 1 800 254 2440

(fax) 1 800 254 4222

Asia Pacific and Japan

Australia

(tel) 1 800 225 574

(fax) 1 800 681 776

(fax) 1 800 225 539

Japan (Bench)

(tel) 0120 32 0119

(alt) (+81) 426 56 7799

(fax) 0120 01 2144

Taiwan

(tel) 0800 047 669

(fax) 0800 047 667

(fax) 886 3492 0779

China

(tel) 800 810 0508

(alt) 800 810 0510

(fax) 800 810 0507

(fax) 800 810 0362

Japan (On-Site)

(tel) 0120 802 363

(alt) (+81) 426 56 7498

(fax) (+81) 426 60 895 3

Thailand

(tel) 1 800 2758 5822

(alt) (+66) 2267 5913

(fax) 1 800 656 336

Hong Kong

(tel) 800 933 229

(fax) 800 900 701

Singapore

(tel) 1 800 275 0880

(fax) (+65) 675 5 1235

(fax) (+65) 675 5 1214

Malaysia

(tel) 1800 880 399

(fax) 1800 801 054

Europe

Austria

(tel) 0820 87 44 11*

(fax) 0820 87 44 22

France

(tel) 0825 010 700*

(alt) (+33) (0)1 6453 5623

(fax) 0825 010 701*

Italy

(tel) (+39) (0)2 9260 8484

(fax) (+39) (0)2 9544 1175

Spain

(tel) (+34) 91 631 3300

(alt) (+34) 91 631 3000

(fax) (+34) 91 631 3301

Switzerland (Italian)

(tel) 0800 80 5353 opt. 3*

(alt) (+39) (0)2 9260 8484

(fax) (+41) (0)22 567 5314

(tel) = primary telephone number; (alt) = alternate telephone number; (fax) = FAX number; * = in country number

11/16/04

Belgium

(tel) (+32) (0)2 404 9340

(alt) (+32) (0)2 404 9000

(fax) (+32) (0)2 404 9395

Germany

(tel) 01805 24 6333*

(alt) 01805 24 6330*

(fax) 01805 24 6336*

Luxemburg

(tel) (+32) (0)2 404 9340

(alt) (+32) (0)2 404 9000

(fax) (+32) (0)2 404 9395

Sweden

(tel) 0200 88 22 55*

(alt) (+46) (0)8 5064 8686

(fax) 020 120 2266*

United King dom

(tel) (+44) (0)7004 666666

(alt) (+44) (0)7004 123123

(fax) (+44) (0)7004 444555

Denmark

(tel) (+45) 7013 1515

(alt) (+45) 7013 7313

(fax) (+45) 701 3 1555

Ireland

(tel) (+353) (0)1 890 924 204

(alt) (+353) (0)1 890 924 206

(fax)(+353) (0 )1 890 924 024

Netherlands

(tel) (+31) (0)20 547 2111

(alt) (+31) (0)20 547 2000

(fax) (+31) (0)20 547 2190

Switzerland (French)

(tel) 0800 80 5353 opt. 2*

(alt) (+33) (0)1 6453 5623

(fax) (+41) (0)22 567 5313

United States

(tel) 800 829 4444

(alt) (+1) 303 662 3998

(fax) 800 829 4433

India

(tel) 1600 112 626

(fax) 1600 112 727

(fax) 1600 113 040

South Korea

(tel) 080 778 0011

(fax) 080 778 0013

Finland

(tel) (+358) 10 855 2100

(fax) (+358) (0) 10 855 2923

Israel

(tel) (+972) 3 9288 500

(fax) (+972) 3 9288 501

Russia

(tel) (+7) 095 797 3963

(alt) (+7) 095 797 3900

(fax) (+7) 095 797 3901

Switzerland (German )

(tel) 0800 80 5353 opt. 1*

(alt) (+49) (0)7031 464 63 33

(fax) (+41) (0)1 272 7373

Page 5

Service Guide

HP 8752C Network Analyzer

ABCDE

HP Part No. 08752-90136 Supersedes December 1997

Printed in USA February 1998

Page 6

Notice.

The information contained in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this material,

including but not limited to, the implied warranties of merchantability and

tness for a particular purpose. Hewlett-Packard shall not be liable for errors

contained herein or for incidental or consequential damages in connection with

the furnishing, performance, or use of this material.

c

Copyright 1995, 1997, 1998 Hewlett-Packard Company

Page 7

Contents

1. Service Equipment and Analyzer Options

Table of Service Test Equipment ................ 1-1

Principles of Microwave Connector Care ............ 1-5

Analyzer Options Available . . . . . . . . . . . . . . . . . . .

Option 003, 3 GHz Operation . . . . . . . . . . . . . . . . .

Option 004, Step Attenuator .................

Option 006, 6 GHz Operation . . . . . . . . . . . . . . . . .

Option 010, Time Domain ...... ...... ......

Option 075, 75 Impedance . . . . . . . . . . . . . . . . . .

Option 1CM, Rack Mount Flange Kit Without Handles .. ... 1-7

Option 1CP, Rack Mount Flange Kit With Handles ....... 1-8

Option AFN, add 50 Test Port Cable .............

Option AFP, add 75 Test Port Cable .... ...... ...

Option B02, External Disk Drive ...... ...... ...

Service and Support Options ..................

2. System Verication and Performance Tests

How to Test the Performance of Your Analyzer .... .....

Sections in this Chapter ....................

HP 8752C System Verication . . . . . . . . . . . . . . . . . . 2-3

Equipment ......................... 2-3

Description .... ...... ...... ...... ... 2-3

System Verication Cycle and Kit Recertication . . . . . . . . 2-4

Measurement Uncertainty ...... ...... ......

Measurement Uncertainty Window ..............

HP 8752C Type-N Test Port Characteristics (50 System) .... 2-6

Directivity ........................

Source Match (Reection) ...... ...... .....

Source Match (Transmission)* ............... 2-6

Reection Tracking ....................

Load Match ........................

Transmission Tracking . . . . . . . . . . . . . . . . . . . 2-7

1-7

1-7

1-7

1-7

1-7

1-7

1-8

1-8

1-8

1-9

2-1

2-2

2-4

2-4

2-6

2-6

2-6

2-7

Contents-1

Page 8

HP 8752C Type-N Test Port Characteristics (75 System) .... 2-7

Directivity ........................ 2-7

Source Match (Reection) ................. 2-7

Source Match (Transmission)* .. ...... ....... 2-8

Reection Tracking .... ...... ...... .... 2-8

Load Match ........................ 2-8

Transmission Tracking ...... ...... ...... . 2-8

System Verication Procedure ...... ...... ..... 2-9

In case of diculty ..................... 2-10

HP 8752C Performance Tests . . . . . . . . . . . . . . . . . . 2-11

Equipment Required to Run the Performance Tests ...... 2-12

1. Reection Test Port Output Frequency Range and Accuracy .. 2-13

Specications ........................

Equipment .. ...... ...... ...... .....

Description .........................

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .

In case of diculty .....................

2-13

2-13

2-13

2-14

2-14

2. Reection Test Port Output Power Range and Level Linearity

(For HP 8752C Analyzers without Option 004) ........ 2-15

Specications ........................

Equipment .. ...... ...... ...... .....

Description .........................

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .

2-15

2-15

2-15

2-16

Power Range and Level Linearity for an HP 8752C or an HP

8752C Option 075 ...................

2-16

Power Range and Level Linearity for an HP 8752C with Option

003 ..........................

2-17

Power Range and Level Linearity for an HP 8752C with Options

003 and 075 ...... ........ ...... .. 2-18

Power Range and Level Linearity for an HP 8752C with Option

006 .......................... 2-18

In case of diculty .. ...... ...... ...... 2-18

3. Reection Test Port Output Power Range and Level Linearity (HP

8752C with Option 004) . . . . . . . . . . . . . . . . . . .

Specications ........................

Equipment .. ...... ...... ...... .....

Description .........................

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .

2-19

2-19

2-19

2-19

2-20

Power Range for an HP 8752C with Option 004 ....... 2-20

Power Level Linearity for an HP 8752C with Option 004

or an HP 8752C withOptions 004 and 075 ........ 2-21

Contents-2

Page 9

Power Level Linearity for an HP 8752C with Options 003 and

004 .. ...... ...... ...... ...... 2-22

Power Level Linearity for an HP 8752C with Options 004 and

006 .. ...... ...... ...... ...... 2-23

Power Level Linearity for an HP 8752C with Options 003, 004,

and 075 .. ...... ...... ....... ... 2-23

In case of diculty .................... 2-23

4. Transmission Test Port Input Noise Floor Level (HP 8752C

without Option 075) .. ...... ...... ...... 2-24

Specications ........................ 2-24

Equipment ......................... 2-24

Description .... ...... ...... ...... ... 2-24

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .

Noise Floor Level at 300 kHz to 1.3 GHz (Standard Option), 300

kHz to 3 GHz (Option 003), or 300 kHz to 6 GHz (Option

006) with an IF BW of 3 kHz

...... ..... ...

Noise Floor Level at 300 kHz to 1.3 GHz (Standard Option) or

300 kHz to 3 GHz (Option 003) with an IF BW of 10 Hz . .

Noise Floor Level at 3 GHz to 6 GHz (Option 006) with an IF

BWof10Hz ...... ...... ........ ..

Noise Floor Level at 3 GHz to 6 GHz (Option 006) with IF BW of

3 kHz .........................

In case of diculty ....................

5. Transmission Test Port Input Noise Floor Level

(HP 8752C with Option 075) . . . . . . . . . . . . . . . . .

Specications ........................

Equipment .........................

Description .... ...... ...... ...... ...

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Noise Floor Level at 300 kHz to 1.3 GHz (Option 075) or 300

kHz to3 GHz (Options 075 and 003) with an IF BW of 3 kHz 2-29

Noise Floor Level at 300 kHz to 1.3 GHz (Option 075) or 300

kHz to3 GHz (Options 075 and 003) with an IF BW of 10 Hz 2-31

In case of diculty ....................

6. Test Port Crosstalk ........ ...... ...... .

Specications ........................

Equipment .........................

Description .... ...... ...... ...... ...

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Port Crosstalk for a Standard HP 8752C or an HP 8752C

with Option 003 ....................

2-24

2-24

2-26

2-27

2-28

2-28

2-29

2-29

2-29

2-29

2-31

2-32

2-32

2-32

2-32

2-33

2-33

Contents-3

Page 10

Test Port Crosstalk for an HP 8752C with Option 006 . . . . . 2-33

Test Port Crosstalk for an HP 8752C with Option 075 . . . . . 2-34

Test Port Crosstalk for an HP 8752C with Options 003 and 075 2-34

In case of diculty .. ...... ...... ...... 2-35

7. System Trace Noise . . . . . . . . . . . . . . . . . . . . . 2-36

Specications ........................ 2-36

Equipment .. ...... ...... ...... ..... 2-36

Description ......................... 2-36

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Reection Trace Noise (Magnitude) ............. 2-37

Reection Trace Noise (Phase) .. ...... ...... . 2-38

Transmission Trace Noise (Magnitude) . . . . . . . . . . . . 2-38

Transmission Trace Noise (Phase) . . . . . . . . . . . . . .

In case of diculty .. ...... ...... ......

2-39

2-39

8. Magnitude Dynamic Accuracy (HP 8752C - All Options) .... 2-40

Specications ........................

Equipment .. ...... ...... ...... .....

Description .........................

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .

In case of diculty .. ...... ...... ......

2-40

2-40

2-41

2-41

2-44

9. Phase Dynamic Accuracy (HP 8752C - All Options) ...... 2-45

Specications ........................

Equipment .. ...... ...... ...... .....

Description .........................

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .

10. Compression . . . . . . . . . . . . . . . . . . . . . . . .

Specications ........................

Equipment .. ...... ...... ...... .....

2-45

2-45

2-45

2-46

2-47

2-47

2-47

Description ......................... 2-47

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

In case of diculty .. ...... ...... ...... 2-49

Performance Test Record . . . . . . . . . . . . . . . . . . . . 2-50

3. Adjustments and Correction Constants

When to Perform the Adjustment Procedures ..........

Keep Correction Constants Current to Save Time ....... 3-1

Adjustment Procedure Error Messages ...... ...... 3-1

Perform Adjustments in This Order .... ...... ..... 3-2

Test Equipment Specications ................ 3-3

Analyzer Cover Removal . . . . . . . . . . . . . . . . . . .

1. A9 CC Jumper Position Procedure .............. 3-5

Contents-4

3-1

3-4

Page 11

A9 CC (Correction Constant) Jumper Position ........ . 3-5

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

2. Source Default Correction Constants (Test #44) ........ 3-8

Equipment ......................... 3-8

Warm-up time . . . . . . . . . . . . . . . . . . . . . . . 3-8

Description and Procedure . . . . . . . . . . . . . . . . . . 3-8

3. Source Pretune Default Correction Constants (Test #45) . . . . 3-9

Equipment ......................... 3-9

Warm-up time . . . . . . . . . . . . . . . . . . . . . . . 3-9

Description and Procedure . . . . . . . . . . . . . . . . . . 3-9

4. Analog Bus Correction Constants (Test #46) . . . . . . . . . . 3-10

Equipment ......................... 3-10

Warm-up time . . . . . . . . . . . . . . . . . . . . . . .

Description and Procedure . . . . . . . . . . . . . . . . . .

5. RF Output Power Correction Constants (Test #47) . . . . . . .

Equipment Required . . . . . . . . . . . . . . . . . . . . .

Warm-up time . . . . . . . . . . . . . . . . . . . . . . .

Description and Procedure . . . . . . . . . . . . . . . . . .

Power Sensor Calibration Factor Entry .. ...... ....

Source Correction Routine .... ...... ...... ..

6. Source Pretune Correction Constants (Test #48) . . . . . . . .

Equipment Required . . . . . . . . . . . . . . . . . . . . .

Warm-up time . . . . . . . . . . . . . . . . . . . . . . .

Description and Procedure . . . . . . . . . . . . . . . . . .

7. Display Intensity Adjustments (Test #49) ...........

Equipment Required . . . . . . . . . . . . . . . . . . . . .

Warm-up time . . . . . . . . . . . . . . . . . . . . . . .

Description and Procedure . . . . . . . . . . . . . . . . . .

3-10

3-10

3-11

3-11

3-11

3-11

3-12

3-13

3-14

3-14

3-14

3-14

3-15

3-15

3-15

3-15

Background Adjustment ................... 3-15

Maximum Intensity Adjustment . . . . . . . . . . . . . . . . 3-16

Operating Default Intensity Adjustment . . . . . . . . . . . . 3-18

8. IF Amplier Correction Constants (Test #51) ......... 3-19

Equipment Required . . . . . . . . . . . . . . . . . . . . . 3-19

Warm-up time . . . . . . . . . . . . . . . . . . . . . . .

Description and Procedure . . . . . . . . . . . . . . . . . .

3-19

3-19

9. ADC Oset Correction Constants (Test #52) . . . . . . . . . . 3-21

Equipment .........................

Warm-up time . . . . . . . . . . . . . . . . . . . . . . .

Description and Procedure . . . . . . . . . . . . . . . . . .

3-21

3-21

3-21

10. Frequency Response Correction Constants (Tests #53 and #57) 3-22

Equipment Required . . . . . . . . . . . . . . . . . . . . .

3-22

Contents-5

Page 12

Warm-up time . . . . . . . . . . . . . . . . . . . . . . . 3-22

Description and Procedure . . . . . . . . . . . . . . . . . . 3-22

11. Cavity Oscillator Frequency Correction Constants (Test #54) . 3-24

Equipment Required . . . . . . . . . . . . . . . . . . . . . 3-24

Warm-up time . . . . . . . . . . . . . . . . . . . . . . . 3-24

Description and Procedure . . . . . . . . . . . . . . . . . . 3-24

Spur Search Procedure with Filter .............. 3-26

Spur Search Procedure without Filter . . . . . . . . . . . . . 3-28

12. Serial Number Correction Constant (Test #55) ........ 3-32

Equipment .. ...... ...... ...... ..... 3-32

Warm-up time . . . . . . . . . . . . . . . . . . . . . . . 3-32

Description and Procedure . . . . . . . . . . . . . . . . . . 3-32

13. Option Numbers Correction Constant (Test #56) ...... . 3-34

Equipment .. ...... ...... ...... .....

Warm-up time . . . . . . . . . . . . . . . . . . . . . . .

Description and Procedure . . . . . . . . . . . . . . . . . .

Option 004 Installation . . . . . . . . . . . . . . . . . . .

14. Initialize EEPROMs (Test #58) . . . . . . . . . . . . . . . .

15. EEPROM Backup Disk Procedure . . . . . . . . . . . . . .

Equipment Required . . . . . . . . . . . . . . . . . . . . .

Warm-up time . . . . . . . . . . . . . . . . . . . . . . .

Description and Procedure . . . . . . . . . . . . . . . . . .

3-34

3-34

3-35

3-36

3-37

3-38

3-38

3-38

3-38

How to Make an EEPROM Backup Disk and Store CCs and Data

toIt...... ...... ...... ........ .

How to Recall CC Data from the EEPROM Disk into the Analyzer

3-39

3-40

16. Model Number Correction Constant (Option 075 Only) .... 3-42

Equipment .. ...... ...... ...... .....

Warmup time .......................

3-42

3-42

Description and Procedure . . . . . . . . . . . . . . . . . . 3-42

17. Vertical Position and Focus Adjustments . . . . . . . . . . . 3-43

Equipment .. ...... ...... ...... ..... 3-43

Warmup time ....................... 3-43

Description and Procedure . . . . . . . . . . . . . . . . . . 3-43

Vertical Position Adjustment .................

Focus Adjustment ......................

18. Display Degaussing (Demagnetizing) . . . . . . . . . . . . .

Equipment .. ...... ...... ...... .....

Warm-up time . . . . . . . . . . . . . . . . . . . . . . .

Description and Procedure . . . . . . . . . . . . . . . . . .

3-43

3-44

3-45

3-45

3-45

3-45

19. Fractional-N Frequency Range Adjustment .... ..... 3-46

Equipment Required . . . . . . . . . . . . . . . . . . . . .

3-46

Contents-6

Page 13

Warm-up time . . . . . . . . . . . . . . . . . . . . . . . 3-46

Description and Procedure . . . . . . . . . . . . . . . . . . 3-46

20. Frequency Accuracy Adjustment ...... ...... .. 3-49

Equipment Required . . . . . . . . . . . . . . . . . . . . . 3-49

Warm-up time . . . . . . . . . . . . . . . . . . . . . . . 3-49

Description and Procedure . . . . . . . . . . . . . . . . . . 3-50

21. High/Low Band Transition Adjustment ........... 3-51

Equipment Required . . . . . . . . . . . . . . . . . . . . . 3-51

Warm-up time . . . . . . . . . . . . . . . . . . . . . . . 3-51

Description and Procedure . . . . . . . . . . . . . . . . . . 3-51

22. Fractional-N Spur Avoidance and FM Sideband Adjustment . . 3-54

Equipment Required . . . . . . . . . . . . . . . . . . . . . 3-54

Warmup time .... ...... ...... ...... .

Description and Procedure . . . . . . . . . . . . . . . . .

23. Source Spur Avoidance Tracking Adjustment ........ 3-58

Equipment Required . . . . . . . . . . . . . . . . . . . . .

Warm-up time . . . . . . . . . . . . . . . . . . . . . . .

Description and Procedure . . . . . . . . . . . . . . . . . .

4. Start Troubleshooting Here

Assembly Replacement Sequence . . . . . . . . . . . . . . . .

Having Your Analyzer Serviced . . . . . . . . . . . . . . . . .

Step 1. Initial Observations . . . . . . . . . . . . . . . . . . .

Initiate the Analyzer Self-Test ................

If the Self-Test Failed .... ...... ...... ...

Step 2. Condence Test ....................

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Condence Test .... ...... ...... ....

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Step 3. HP-IB Systems Check . . . . . . . . . . . . . . . . . . 4-7

If Using a Plotter or Printer ................. 4-8

If Using an External Disk Drive . . . . . . . . . . . . . . . . 4-8

Troubleshooting Systems with Multiple Peripherals . . . . . . . 4-9

Troubleshooting Systems with Controllers . . . . . . . . . . .

Step 4. Faulty Group Isolation .................

Power Supply Check . . . . . . . . . . . . . . . . . . . . .

Check the Rear Panel LEDs . . . . . . . . . . . . . . . . .

Check the A8 Post Regulator LEDs ............. 4-11

Digital Control Check ........ ...... ......

Observe the Power Up Sequence .............. 4-12

Verify Internal Tests Passed . . . . . . . . . . . . . . . . .

3-54

3-54

3-58

3-58

3-58

4-2

4-2

4-3

4-3

4-3

4-4

4-4

4-5

4-9

4-10

4-11

4-11

4-12

4-13

Contents-7

Page 14

Source Check ........................ 4-13

Receiver Check ....................... 4-15

Accessories Check . . . . . . . . . . . . . . . . . . . . . . 4-15

5. Power Supply Troubleshooting

Assembly Replacement Sequence . . . . . . . . . . . . . . . . 5-2

Simplied Block Diagram . . . . . . . . . . . . . . . . . . . . 5-3

Start Here . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Check the Green LED and Red LED on A15 . . . . . . . . . . 5-4

Check the Green LEDs on A8 . . . . . . . . . . . . . . . . . 5-5

Measure the Post Regulator Voltages ............. 5-5

If the Green LED on A15 is not On Steadily . . . . . . . . . . . 5-7

Check the Line Voltage, Selector Switch, and Fuse . . . . . . .

If the Red LED On A15 is On . . . . . . . . . . . . . . . . . .

Check the A8 Post Regulator . . . . . . . . . . . . . . . . .

Verify the A15 Preregulator .. ...... ...... ...

Check for a Faulty Assembly . . . . . . . . . . . . . . . . .

Check the Operating Temperature ..............

Inspect the Motherboard . . . . . . . . . . . . . . . . . . .

If the Green LEDs On A8 are not All On

...... ......

Remove A8, Maintain A15W1 Cable Connection . . . . . . . .

Check the A8 Fuses and Voltages . . . . . . . . . . . . . . .

Remove the Assemblies ........ ...... .....

Briey Disable the Shutdown Circuitry .... ........

Inspect the Motherboard . . . . . . . . . . . . . . . . . . .

Error Messages ........................

Check the Fuses and Isolate A8 . . . . . . . . . . . . . . . .

Fan Troubleshooting . . . . . . . . . . . . . . . . . . . . . .

Fan Speeds ......................... 5-22

Check the Fan Voltages . . . . . . . . . . . . . . . . . . . . 5-22

Short A8TP3 to Ground ................... 5-22

Intermittent Problems ...... ...... ........ . 5-23

5-7

5-8

5-8

5-9

5-11

5-13

5-13

5-14

5-14

5-14

5-15

5-16

5-18

5-19

5-21

5-22

6. Digital Control Troubleshooting

Assembly Replacement Sequence . . . . . . . . . . . . . . . .

Digital Control Group Block Diagram .............. 6-3

Check A9 CPU Operation . . . . . . . . . . . . . . . . . . . .

A9 CC Jumper Positions ...................

Checking A9 CPU Red LED Patterns .... ...... ... 6-5

Check A19 GSP and A18 Display Operation ........... 6-7

Cycle Power and Look at the Display ............. 6-7

Contents-8

6-2

6-4

6-4

Page 15

Perform Display Intensity and Focus Adjustments ...... . 6-7

A1/A2 Front Panel Troubleshooting . . . . . . . . . . . . . . . 6-7

Check Front Panel LEDs After Preset . . . . . . . . . . . . . 6-7

Identify the Stuck Key . . . . . . . . . . . . . . . . . . . . 6-8

Inspect Cables . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Test Using a Controller . . . . . . . . . . . . . . . . . . . . 6-11

Run the Internal Diagnostic Tests . . . . . . . . . . . . . . . . 6-11

A19 GSP and A18 Display Troubleshooting ........... 6-13

Measure Display Power Supply Voltages on A19 .... .... 6-13

Measure Display Power Supply Voltages Entering A19 ..... 6-14

Run Display Test 59 ..................... 6-15

Inspect Ribbon Cable Repeat Display Test59.......... 6-15

Perform Walking One Pattern . . . . . . . . . . . . . . . . .

Run display Tests 60-65 ...... ...... ...... .

If the Fault is Intermittent ........ ...... .....

Repeat Test Function . . . . . . . . . . . . . . . . . . . . .

HP-IB Failures . . . . . . . . . . . . . . . . . . . . . . . . .

7. Source Troubleshooting

Assembly Replacement Sequence . . . . . . . . . . . . . . . .

Before You Start Troubleshooting . . . . . . . . . . . . . . . .

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Source Default Correction Constants (Test44)........

2. RF Output Power Correction Constants (Test 47) ...... 7-3

3. Sampler Magnitude and Phase Correction Constants (Test 53) 7-3

Phase Lock Error .......................

Phase Lock Loop Error Message Check ............

A4 Sampler/Mixer Check . . . . . . . . . . . . . . . . . . .

A3 Source and A11 Phase Lock Check ............ 7-8

YO Coil Drive Check with Analog Bus . . . . . . . . . . . . 7-11

YO Coil Drive Check with Oscilloscope .. ...... ... 7-12

A12 Reference Check .................... 7-13

Analog Bus Method .................... 7-13

Oscilloscope Method . . . . . . . . . . . . . . . . . . . .

100 kHz Pulses ......................

PLREF Waveforms . . . . . . . . . . . . . . . . . . . . .

REF Signal At A11TP1 PIN 9 . . . . . . . . . . . . . . .

High Band REF Signal .... ...... ..... ...

Low Band REF Signal ..................

FN LO at A12 Check . . . . . . . . . . . . . . . . . . . .

4 MHz Reference Signal .......... ...... ..

6-16

6-17

6-18

6-18

6-18

7-2

7-2

7-3

7-3

7-4

7-4

7-6

7-15

7-16

7-17

7-17

7-17

7-18

7-19

7-20

Contents-9

Page 16

2ND LO Waveforms .................... 7-21

90 Degree Phase Oset of 2nd LO Signals in High Band .. 7-21

In-Phase 2nd LO Signals in Low Band . . . . . . . . . . . 7-22

A12 Digital Control Signals Check . . . . . . . . . . . . . . 7-23

L ENREF Line . . . . . . . . . . . . . . . . . . . . . . 7-23

L HB and L LB Lines . . . . . . . . . . . . . . . . . . . 7-24

A13/A14 Fractional-N Check ................. 7-24

Fractional-N Check with Analog Bus ............ 7-24

A14 VCO Range Check with Oscilloscope ...... .... 7-26

A14 VCO Exercise . . . . . . . . . . . . . . . . . . . . . 7-28

A14 Divide-by-N Circuit Check . . . . . . . . . . . . . . . 7-29

A14-to-A13 Digital Control Signals Check. . . . . . . . . . . 7-30

H MB Line .......................

A7 Pulse Generator Check ..................

A7 Pulse Generator Check with Spectrum Analyzer .. ... 7-33

Rechecking the A13/A14 Fractional-N . . . . . . . . . . . .

A7 Pulse Generator Check with Oscilloscope . . . . . . . . .

A11 Phase Lock Check . . . . . . . . . . . . . . . . . . . .

Phase Lock Check with PLL DIAG .............

Phase Lock Check by Signal Examination . . . . . . . . . .

Source Group Troubleshooting Appendix .... ..... ...

Troubleshooting Source Problems with the Analog Bus . . . . .

Phase Lock Diagnostic Tools ...... ...... .....

Phase Lock Error Messages . . . . . . . . . . . . . . . . .

Phase Lock Diagnostic Routines . . . . . . . . . . . . . . .

Broadband Power Problems ...... ...... .....

7-32

7-33

7-35

7-35

7-37

7-37

7-37

7-39

7-39

7-39

7-39

7-40

7-40

8. Receiver Troubleshooting

Assembly Replacement Sequence . . . . . . . . . . . . . . . . 8-2

Receiver Failure Error Messages ................ 8-2

CAUTION: OVERLOAD ON REFL PORT, POWER REDUCED

CAUTION: OVERLOAD ON TRANS PORT, POWER REDUCED

...... 8-2

...... 8-3

Check the R, A, and B Inputs . . . . . . . . . . . . . . . . . . 8-4

Troubleshooting When All Inputs Look Bad ...........

Run Internal Tests 18 and 17 . . . . . . . . . . . . . . . . .

Check the 4 MHz REF Signal ..................

Check A10 by Substitution or Signal Examination ....... 8-8

Troubleshooting When One or More Inputs Look Good . . . . . . 8-11

Check the Frequency Response Correction .......... 8-11

Check the 4 kHz Signal . . . . . . . . . . . . . . . . . . . .

Check 1st LO Signal at Sampler/Mixer . . . . . . . . . . . . .

Contents-10

8-7

8-7

8-8

8-11

8-12

Page 17

Check 2nd LO Signal at Sampler/Mixer ............ 8-13

Check Input Trace . . . . . . . . . . . . . . . . . . . . . . 8-14

9. Accessories Troubleshooting

Assembly Replacement Sequence . . . . . . . . . . . . . . . . 9-2

Inspect the Accessories . . . . . . . . . . . . . . . . . . . . . 9-3

Inspect the Test Port Connectors and Calibration Devices . . . . 9-3

Inspect the Error Terms ...... ...... ...... .. 9-3

Cable Test.......................... 9-5

Verify Shorts and Opens ................... 9-6

10. Service Key Menus and Error Messages

Service Key Menus . . . . . . . . . . . . . . . . . . . . . . .

Error Messages ........................

Service Key Menus - Internal Diagnostics .. ...... ....

Tests Menu .........................

Test Options Menu . . . . . . . . . . . . . . . . . . . . . .

Self Diagnose Softkey ....................

Test Descriptions . . . . . . . . . . . . . . . . . . . . . . .

Internal Tests .. ...... ...... ........ .

External Tests . . . . . . . . . . . . . . . . . . . . . . .

System Verication Tests . . . . . . . . . . . . . . . . . .

Adjustment Tests .....................

Display Tests .. ...... ...... ..... ....

Test Patterns .. ...... ...... ...... ...

Service Key Menus - Service Features . . . . . . . . . . . . . .

Service Modes Menu . . . . . . . . . . . . . . . . . . . . .

Service Modes More Menu ..................

Analog Bus ......................... 10-25

Description of the Analog Bus ...... ...... ... 10-25

The Main ADC . . . . . . . . . . . . . . . . . . . . . . . 10-25

The Frequency Counter .................. 10-25

Analog In Menu ....................... 10-27

Analog Bus Nodes .. ...... ...... ...... ..

A3 Source . . . . . . . . . . . . . . . . . . . . . . . . .

A10 Digital IF . . . . . . . . . . . . . . . . . . . . . . .

A11 Phase Lock . . . . . . . . . . . . . . . . . . . . . .

A12 Reference . . . . . . . . . . . . . . . . . . . . . . .

A14 Fractional-N (Digital) ................. 10-47

PEEK/POKE Menu . . . . . . . . . . . . . . . . . . . . . .

Firmware Revision Softkey . . . . . . . . . . . . . . . . . . .

10-1

10-1

10-2

10-3

10-5

10-7

10-7

10-7

10-12

10-13

10-14

10-16

10-17

10-19

10-20

10-23

10-29

10-29

10-36

10-37

10-44

10-50

10-51

Contents-11

Page 18

HP-IB Service Mnemonic Denitions .............. 10-52

Invoking Tests Remotely ................... 10-52

Analog Bus Codes .... ...... ...... ..... . 10-53

Error Messages ........................ 10-54

11. Error Terms

Error Terms Can Also Serve a Diagnostic Purpose ........ 11-2

Reection 1-Port Error-Correction Procedure .......... 11-4

Response and Isolation Calibration Procedures . . . . . . . . . . 11-6

Error Term Inspection ..................... 11-8

If Error Terms Seem Worse than Typical Values ........ 11-9

Uncorrected Performance .................. 11-9

Error Term Descriptions ....................

Directivity (ED) - After a Reection 1-Port Calibration ..... 11-11

Description ........................

Signicant System Components . . . . . . . . . . . . . . .

Aected Measurements .... ...... ...... ..

Procedure . . . . . . . . . . . . . . . . . . . . . . . . .

Source Match (ES) - After a Reection 1-Port Calibration . . . . 11-13

Description ........................

Signicant System Components . . . . . . . . . . . . . . .

Aected Measurements .... ...... ...... ..

Procedure . . . . . . . . . . . . . . . . . . . . . . . . .

Reection Tracking (ER) - After a Reection 1-Port Calibration . 11-15

Description ........................

Signicant System Components . . . . . . . . . . . . . . .

Aected Measurements .... ...... ...... ..

Procedure . . . . . . . . . . . . . . . . . . . . . . . . .

Isolation (Crosstalk, EX) - After a Response and Isolation

(Transmission) Calibration . . . . . . . . . . . . . . . . . 11-17

Description ........................ 11-17

Signicant System Components . . . . . . . . . . . . . . . 11-17

Aected Measurements .... ...... ...... .. 11-17

Procedure . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Tracking (ET)....... ..... ......

Description ........................

Signicant System Components . . . . . . . . . . . . . . .

Aected Measurements .... ...... ...... ..

Procedure . . . . . . . . . . . . . . . . . . . . . . . . .

11-10

11-11

11-11

11-11

11-11

11-13

11-13

11-13

11-13

11-15

11-15

11-15

11-15

11-17

11-19

11-19

11-19

11-19

11-19

Contents-12

Page 19

12. Theory of Operation

How the HP 8752C Works ........ ...... ..... 12-2

The Built-In Synthesized Source ............... 12-3

The Source Step Attenuator (Option 004) .......... 12-3

The Built-In Transmission/Reection Test Set ......... 12-4

The Receiver Block .......... ...... ..... 12-4

The Microprocessor ........ ...... ...... 12-4

A Close Look at the Analyzer's Functional Groups . . . . . . . . 12-5

Power Supply Theory ..................... 12-6

A15 Preregulator ...................... 12-6

Line Power Module ...... ...... ...... .. 12-7

Preregulated Voltages ................... 12-7

Regulated +5V Digital Supply ...............

Shutdown Indications: the Green LED and Red LED . . . . .

A8 Post Regulator .. ...... ...... ...... ..

Voltage Indications: the Green LEDs ............

Shutdown Circuit .....................

Variable Fan Circuit and Air Flow Detector .. ...... .

Display Power . . . . . . . . . . . . . . . . . . . . . . .

Probe Power .......................

Digital Control Theory . . . . . . . . . . . . . . . . . . . . .

A1 Front Panel Keyboard ..................

A2 Front Panel Processor . . . . . . . . . . . . . . . . . . .

A9 CPU/A10 Digital IF . . . . . . . . . . . . . . . . . . . .

Main CPU . . . . . . . . . . . . . . . . . . . . . . . . .

Main RAM . . . . . . . . . . . . . . . . . . . . . . . . .

EEPROM .. ...... ....... ...... ....

Digital Signal Processor ..................

A18 Display . . . . . . . . . . . . . . . . . . . . . . . . . 12-12

A19 GSP .... ...... ...... ...... .... 12-12

A16 Rear Panel ....................... 12-13

Source Theory Overview . . . . . . . . . . . . . . . . . . . . 12-14

A14/A13 Fractional-N ........ ...... ..... . 12-14

A12 Reference . . . . . . . . . . . . . . . . . . . . . . . .

A7 Pulse Generator .....................

A11 Phase Lock . . . . . . . . . . . . . . . . . . . . . . .

A3 Source . . . . . . . . . . . . . . . . . . . . . . . . . .

Source Low Band Operation ........ ...... ....

Source High Band Operation ...... ...... ......

Signal Separation ........ ...... ...... ...

The A30 Dual Directional Coupler .............. 12-23

12-7

12-7

12-8

12-8

12-8

12-8

12-9

12-9

12-9

12-10

12-11

12-11

12-11

12-11

12-12

12-12

12-14

12-14

12-15

12-15

12-16

12-19

12-23

Contents-13

Page 20

Receiver Theory . . . . . . . . . . . . . . . . . . . . . . . . 12-23

A4/A5/A6 Sampler/Mixer . . . . . . . . . . . . . . . . . . . 12-28

The Sampler Circuit in High Band . . . . . . . . . . . . . . 12-28

The Sampler Circuit in Low Band . . . . . . . . . . . . . . 12-28

The 2nd LO Signal . . . . . . . . . . . . . . . . . . . . . 12-28

The Mixer Circuit ..................... 12-29

A10 Digital IF . . . . . . . . . . . . . . . . . . . . . . . . 12-29

13. Replaceable Parts

Assembly Replacement Sequence . . . . . . . . . . . . . . . . 13-2

Save Money with Rebuilt-Exchange Assemblies ......... 13-2

Gather This Information Before Ordering ............ 13-4

Call (800) 227-8164 to Order Parts Fast (U.S. only) .. ..... 13-4

Replaceable Part Listings . . . . . . . . . . . . . . . . . . . .

Major Assemblies ......................

Front Panel Assemblies . . . . . . . . . . . . . . . . . . . .

Rear Panel Assemblies ....................

Cables,Top View .. ...... ...... ........

Front Panel, Cables and Attaching Hardware .........

Rear Panel, Cables and Attaching Hardware . . . . . . . . . .

Source and Sampler Parts: Standard and Option 003 . . . . . .

Source and Sampler Parts: Option 004/006 .... ......

Source and Sampler Parts: Options 004 and 003/004 . . . . . .

Source and Sampler Parts: Option 006 .... ...... ..

Display Bezel Assembly ........ ...... .....

Chassis Parts ........................

Top View of Attaching Hardware and Post Regulator Fuses . . . 13-30

Bottom View of Attaching Hardware .. ...... .....

Right View of Attaching Hardware .............. 13-34

Left View of Attaching Hardware . . . . . . . . . . . . . . . 13-35

Rear Panel Attaching Hardware ............... 13-36

Replaceable Labels . . . . . . . . . . . . . . . . . . . . . . 13-37

Miscellaneous Parts and Accessories . . . . . . . . . . . . . . 13-38

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . .

13-5

13-6

13-8

13-10

13-12

13-14

13-16

13-18

13-20

13-22

13-24

13-26

13-28

13-32

13-40

Contents-14

Page 21

14. Assembly Replacement and Post-Repair Procedures

Assembly Replacement Sequence . . . . . . . . . . . . . . . . 14-2

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

Cover Removal Procedure ................... 14-3

Initial Front Panel Procedure . . . . . . . . . . . . . . . . . . 14-4

Initial Rear Panel Procedure .................. 14-6

A1, A2 Front Panel Keyboard, Interface . . . . . . . . . . . . . 14-8

How to Remove the Front Panel Keyboard or Interface .... 14-8

Reverse Removal Procedure to Reinstall . . . . . . . . . . . . 14-9

A3 Source . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-10

How to Remove the Source . . . . . . . . . . . . . . . . . . 14-10

Reverse Removal Procedure to Reinstall . . . . . . . . . . . . 14-11

A15 Preregulator .......................

How to Remove the Preregulator . . . . . . . . . . . . . . .

Reverse Removal Procedure to Reinstall . . . . . . . . . . . .

A16 Rear Panel Board Assembly .... ...... ......

How to Remove the Rear Panel . . . . . . . . . . . . . . . .

Reverse Removal Procedure to Reinstall . . . . . . . . . . . .

A18 Display . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Remove the Display .................

How to Reinstall the Display ...... ...... .....

A30 Directional Coupler ........ ........ ....

How to Remove the Directional Coupler . . . . . . . . . . . .

Reverse Removal Procedure to Reinstall . . . . . . . . . . . .

B1 Fan .... ...... ...... ...... ......

How to Remove the Fan ........ ..... ......

Reverse Removal Procedure to Reinstall . . . . . . . . . . . .

A9BT1 Battery ........................

How to Remove the Battery ................. 14-21

Replacing the Battery .................... 14-21

Post-Repair Procedures . . . . . . . . . . . . . . . . . . . . . 14-22

14-12

14-12

14-13

14-14

14-14

14-15

14-16

14-16

14-17

14-18

14-18

14-19

14-20

14-20

14-20

14-21

15. Safety and Licensing

Notice ........ ...... ...... ..... ...

Certication . . . . . . . . . . . . . . . . . . . . . . . . . .

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipment for Service . . . . . . . . . . . . . . . . . . . . .

Safety Symbols ........ ...... ...... ....

Instrument Markings . . . . . . . . . . . . . . . . . . . . . .

General Safety Considerations ........ ...... ...

Safety Earth Ground . . . . . . . . . . . . . . . . . . . . .

15-1

15-1

15-1

15-3

15-4

15-5

15-6

15-6

Contents-15

Page 22

Before Applying Power ................... 15-6

Servicing .......................... 15-6

Index

Contents-16

Page 23

Figures

2-1. Measurement Uncertainty Window .............. 2-5

2-2. Reection Test Port Output Frequency Range and Accuracy Test

Setup .......................... 2-14

2-3. Reection Test Port Output Power Range and Level Linearity Test

Setup ..........................

2-4. Reection Test Port Output Power Range Test Setup (HP 8752C

Option 004) .... ...... ...... ...... .

2-5. Reection Test Port Output Power Level Linearity Test Setup . . 2-21

2-6. Transmission Test Port Input Noise Floor Level Test Setup 1 .. 2-25

2-7. Transmission Test Port Input Noise Floor Level Test Setup 2 .. 2-25

2-8. Transmission Test Port Input Noise Floor Level Test Setup 1 .. 2-27

2-9. Transmission Test Port Input Noise Floor Level Test Setup 2 .. 2-27

2-10. Transmission Test Port Input Noise Floor Level Test Setup 1 .. 2-30

2-11. Transmission Test Port Input Noise Floor Level Test Setup 2 .. 2-30

2-12. Test Port Crosstalk Test Setup . . . . . . . . . . . . . . . . .

2-13. Reection Trace Noise Test Setup . . . . . . . . . . . . . . .

2-14. Transmission Trace Noise Test Setup ...... ...... .

2-15. Magnitude Dynamic Accuracy Test Setup .... ..... ..

2-16. Compression Test Setup ...................

3-1. Location of Major Assemblies . . . . . . . . . . . . . . . . . 3-6

3-2. NRM (Normal) and ALT (Alter) Positions of A9 CC Jumper ... 3-7

3-3. Source Adjustment Setup . . . . . . . . . . . . . . . . . . . 3-11

3-4. Maximum Intensity Adjustment Set-up .... ...... .. 3-17

3-5. IF Amplier Correction Constant Setup ........ .... 3-19

3-6. Cavity Oscillator Frequency Correction Constant Setup . . . . .

3-7. Typical Target Spur Using Filter ...... ...... ...

3-8. Cavity Oscillator Frequency Correction Alternative Setup ... 3-28

3-9. Typical Display of Four Spurs without Filter . . . . . . . . . . 3-29

3-10. Typical Display of Five Spurs without Filter . . . . . . . . . .

3-11. Variation of Display of Four Spurs without Filter . . . . . . . . 3-31

3-12. Location of Keyword Label . . . . . . . . . . . . . . . . . .

3-13. EEPROM Backup Procedure Setup .. ...... ...... 3-38

2-16

2-20

2-33

2-37

2-38

2-42

2-48

3-24

3-27

3-30

3-34

Contents-17

Page 24

3-14. Vertical Position and Focus Adjustment Controls . . . . . . . . 3-44

3-15. FN VCO TUNE Adjustment Location ...... ...... . 3-47

3-16. Fractional-N Frequency Range Adjustment Display . . . . . . . 3-48

3-17. Reection Test Port Output Frequency Accuracy Adjustment

Setup .... ...... ...... ...... .... 3-49

3-18. VCXO ADJ Adjustment Location ............... 3-50

3-19. High/Low Band Transition Adjustment Trace .... ..... 3-52

3-20. High/Low Band Adjustments Locations ............ 3-52

3-21. Fractional-N Spur Avoidance and FM Sideband Adjustment Setup 3-55

3-22. Location of API and 100 kHz Adjustments . . . . . . . . . . . 3-56

3-23. A11 Test Point and A3 CAV ADJ Locations .. ...... .. 3-58

3-24. Display of Acceptable Versus Excessive Spikes . . . . . . . . . 3-59

4-1. LED Power-up Sequence . . . . . . . . . . . . . . . . . . .

4-2. Troubleshooting Organization . . . . . . . . . . . . . . . . .

4-3. A15 Preregulator LEDs . . . . . . . . . . . . . . . . . . . .

4-4. Front Panel Power-up Sequence ...............

4-5. Equipment Setup for Source Power Check . . . . . . . . . . .

4-6. Typical Measurement Trace ...... ...... .....

4-7. HP 8752C Overall Block Diagram (1 of 4)

...........

5-1. Power Supply Group Simplied Block Diagram . . . . . . . . .

5-2. Location of A15 Diagnostic LEDs . . . . . . . . . . . . . . .

5-3. A8 Post Regulator Test Point Locations .. ...... ....

5-4. Removing the Line Fuse .... ...... ........ .

5-5. Power Supply Cable Locations ................

5-6. A15W1 Plug Detail . . . . . . . . . . . . . . . . . . . . . .

4-3

4-10

4-11

4-12

4-14

4-15

4-17

5-3

5-4

5-5

5-7

5-9

5-11

5-7. Front Panel Probe Power Connector Voltages ......... 5-20

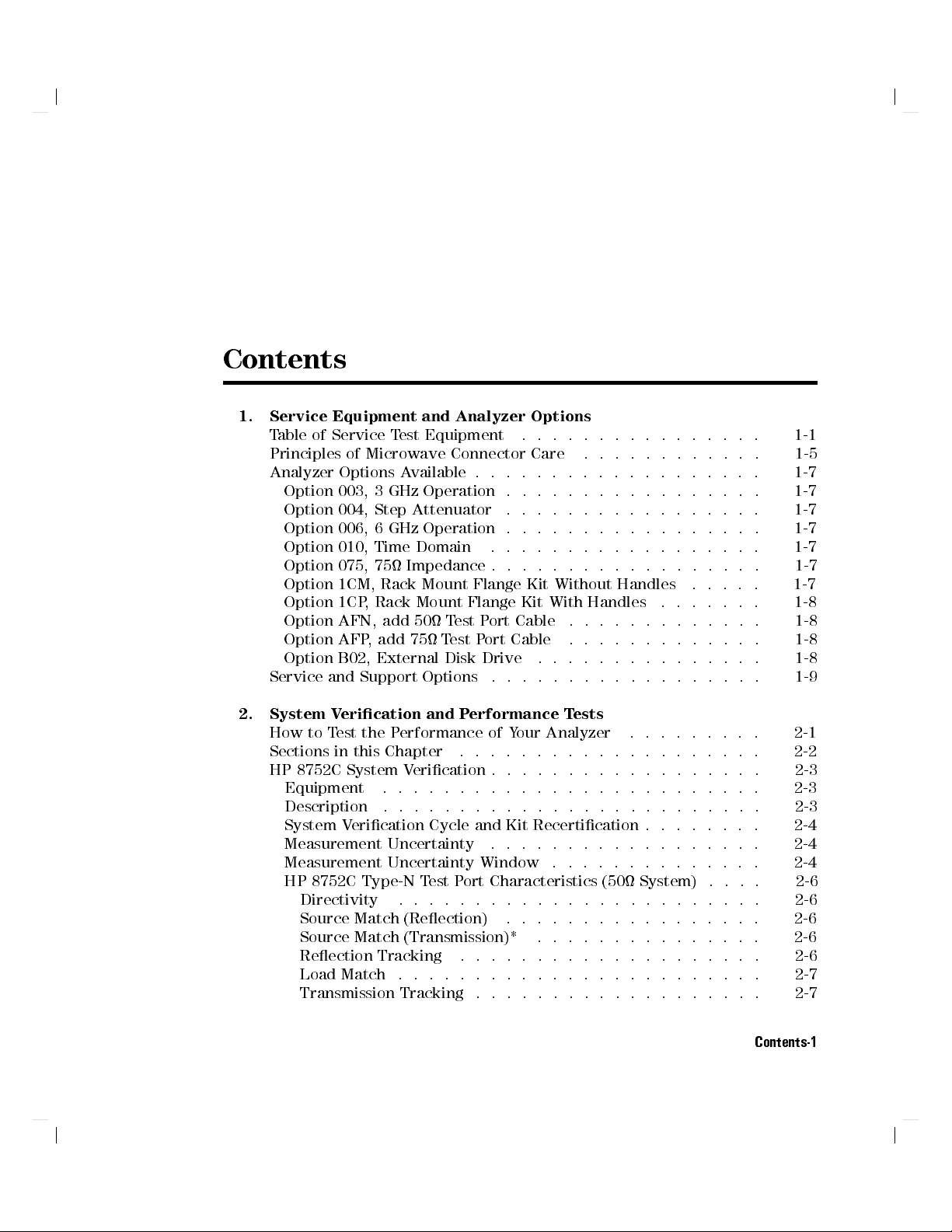

5-8. Power Supply Block Diagram . . . . . . . . . . . . . . . . .

6-1. Digital Control Group Block Diagram .. ...... .....

5-25

6-3

6-2. Jumper Positions on the A9 CPU ............... 6-4

6-3. Location of Four LEDs on A9 CPU .... ...... .... 6-5

6-4. Preset Sequence . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-5. Pin Locations on A19J5 ................... 6-13

6-6. Pin Locations on Connector of W14 . . . . . . . . . . . . . . 6-14

6-7. A9 CPU Walking One Pattern . . . . . . . . . . . . . . . . .

6-8. Pin Locations on Connector of W20 . . . . . . . . . . . . . .

6-16

6-17

7-1. Phase Lock Error Troubleshooting Equipment Setup . . . . . . 7-4

7-2. Jumper Positions on the A9 CPU ............... 7-5

7-3. Sampler/Mixer to Phase Lock Cable Connection Diagram . . . . 7-7

7-4. Waveform Integrity in SRC Tune Mode ............ 7-9

7-5. Phase Locked Output Compared to Open Loop Output in SRC

Tune Mode . . . . . . . . . . . . . . . . . . . . . . . .

7-9

Contents-18

Page 25

7-6. 1V/GHz at Analog Bus Node 16 with Source PLL O. .. ... 7-11

7-7. YO0and YO+ Coil Drive Voltage Dierences with SOURCE PLL

OFF ...... ...... ....... ...... .. 7-12

7-8. Sharp 100 kHz Pulses at A13TP5 (any frequency) ....... 7-16

7-9. High Band REF Signal (16MHzCW)............. 7-17

7-10. REF Signal at A11TP9 (5 MHz CW) .............. 7-18

7-11. Typical FN LO Waveform at A12J1 .. ...... ...... 7-19

7-12. 4 MHz Reference Signal at A12TP9 (Preset) .......... 7-20

7-13. 90 Degree Phase Oset of High Band 2nd LO Signals (16 MHz

CW) ...... ...... ....... ...... .. 7-21

7-14. In-Phase Low Band 2nd LO Signals (14 MHz CW) . . . . . . . . 7-22

7-15. L ENREF Line at A12P2-16 (Preset) . . . . . . . . . . . . . . 7-23

7-16. Complementary L HB and L LB Signals (Preset) .. ...... 7-24

7-17. 10 MHz HI OUT Waveform from A14J1 ...... ......

7-18. 25 MHz HI OUT Waveform from A14J1 ...... ......

7-19. 60 MHz HI OUT Waveform from A14J1 ...... ......

7-20. LO OUT Waveform at A14J2 .................

7-21. A14 Generated Digital Control Signals . . . . . . . . . . . . .

7-22. H MB Signal at A14P1-5 (Preset and 16 MHz to 31 MHz Sweep) .

7-23. Pulse Generator Output .. ...... ...... .....

7-24. High Quality Comb Tooth at 3 GHz ...... ...... ..

7-25. Stable HI OUT Signal in FRACN TUNE Mode . . . . . . . . . .

7-26

7-27

7-27

7-28

7-31

7-32

7-33

7-34

7-35

7-26. Typical 1st IF Waveform in FRACN TUNE/SRC TUNE Mode .. 7-36

7-27. FM Coil { Plot with 3 Point Sweep ..............

8-1. Sample R Input Trace .. ...... ...... ......

8-2. Sample A Input Trace ....................

8-3. Sample B Input Trace .... ...... ...... ....

8-4. 4 MHz REF Waveform ....................

7-38

8-4

8-5

8-6

8-8

8-5. Digital Data Lines Observed Using L INTCOP as Trigger .... 8-10

8-6. Digital Control Lines Observed Using L INTCOP as Trigger ... 8-10

8-7. 2nd IF (4 kHz) Waveform . . . . . . . . . . . . . . . . . . . 8-12

9-1. Typical Return Loss Traces of Good and Poor Cables . . . . . . 9-5

9-2. Typical Smith Chart Traces of Good Short (a) and Open (b) . . . 9-7

10-1. Internal Diagnostics Menus . . . . . . . . . . . . . . . . . .

10-2. Jumper Positions on the A9 CPU ...............

10-3. Service Feature Menus . . . . . . . . . . . . . . . . . . . .

10-4. Analog Bus Node 1 .. ...... ...... ...... .

10-5. Analog Bus Node 2 .. ...... ...... ...... .

10-6. Analog Bus Node 3 .. ...... ...... ...... .

10-7. Analog Bus Node 4 .. ...... ...... ...... .

10-8. Analog Bus Node 6 .. ...... ...... ...... .

10-2

10-9

10-19

10-30

10-31

10-32

10-33

10-34

Contents-19

Page 26

10-9. Analog Bus Node 7 ..................... 10-35

10-10. Analog Bus Node 14 . . . . . . . . . . . . . . . . . . . . . 10-38

10-11. Analog Bus Node 15 . . . . . . . . . . . . . . . . . . . . . 10-39

10-12. Analog Bus Node 16 . . . . . . . . . . . . . . . . . . . . . 10-40

10-13. Counter Readout Location .................. 10-41

10-14. Analog Bus Node 18 . . . . . . . . . . . . . . . . . . . . . 10-42

10-15. Analog Bus Node 20 . . . . . . . . . . . . . . . . . . . . . 10-43

10-16. Analog Bus Node 23 . . . . . . . . . . . . . . . . . . . . . 10-45

10-17. Analog Bus Node 29 . . . . . . . . . . . . . . . . . . . . . 10-48

10-18. Analog Bus Node 30 . . . . . . . . . . . . . . . . . . . . . 10-49

10-19. Location of Firmware Revision Information on Display . . . . . 10-51

11-1. Standard Connections for One-Port Error-Correction . . . . . . 11-4

11-2. Standard Connections for Response Calibration ........ 11-6

11-3. Standard Connections for Isolation Calibration . . . . . . . . .

11-4. Typical ED(Reection Test Port) .. ...... ...... .

11-5. Typical ES(Reection Test Port) ........ ...... .

11-6. Typical ER(Reection Test Port) .. ...... ...... .

11-7. Typical EXwith 10 Hz Bandwidth ...... ...... ..

11-8. Typical EXwith 3 kHz Bandwidth ..............

11-9. Typical ET.........................

12-1. Simplied Block Diagram of the Network Analyzer System . . .

11-7

11-12

11-14

11-16

11-18

11-18

11-20

12-2

12-2. Power Supply Functional Group, Simplied Block Diagram . . . 12-6

12-3. Digital Control Group, Block Diagram . . . . . . . . . . . . .

12-4. Low Band Operation of the Source .... ...... ....

12-5. High Band Operation of the Source . . . . . . . . . . . . . .

12-10

12-17

12-21

12-6. Receiver Functional Group (standard and Option 003) .. ... 12-24

12-7. Receiver Functional Group (Option 003 and 004) . . . . . . . .

12-8. Receiver Functional Group (Option 006) . . . . . . . . . . . .

12-25

12-26

12-9. Receiver Functional Group (Option 004 and 006) . . . . . . . . 12-27

13-1. Module Exchange Procedure ...... ...... ..... 13-3

14-1. Cover Removal Procedure .................. 14-3

14-2. Initial Front Panel Procedure . . . . . . . . . . . . . . . . . 14-4

14-3. Location of Screws on Bottom Edge of Frame . . . . . . . . . 14-5

14-4. Location of EXT REF cable and GSP Assembly

...... ..

14-5. Location of Rear Panel Fasteners ...............

14-6. Location of A1 and A2 components . . . . . . . . . . . . . .

14-7. Location of Source Parts . . . . . . . . . . . . . . . . . . .

14-6

14-7

14-8

14-10

14-8. Location of Preregulator Fasteners and Wires ......... 14-12

14-9. Location of Rear Panel Fasteners ............... 14-14

14-10. Location of Display Fasteners and Parts . . . . . . . . . . . . 14-16

14-11. Location of Coupler Screws on Bottom Front Frame . . . . . . 14-18

Contents-20

Page 27

14-12. Location of Directional Coupler Hardware . . . . . . . . . . . 14-19

14-13. Location of Fan Wire Bundle and Screws ........... 14-20

Contents-21

Page 28

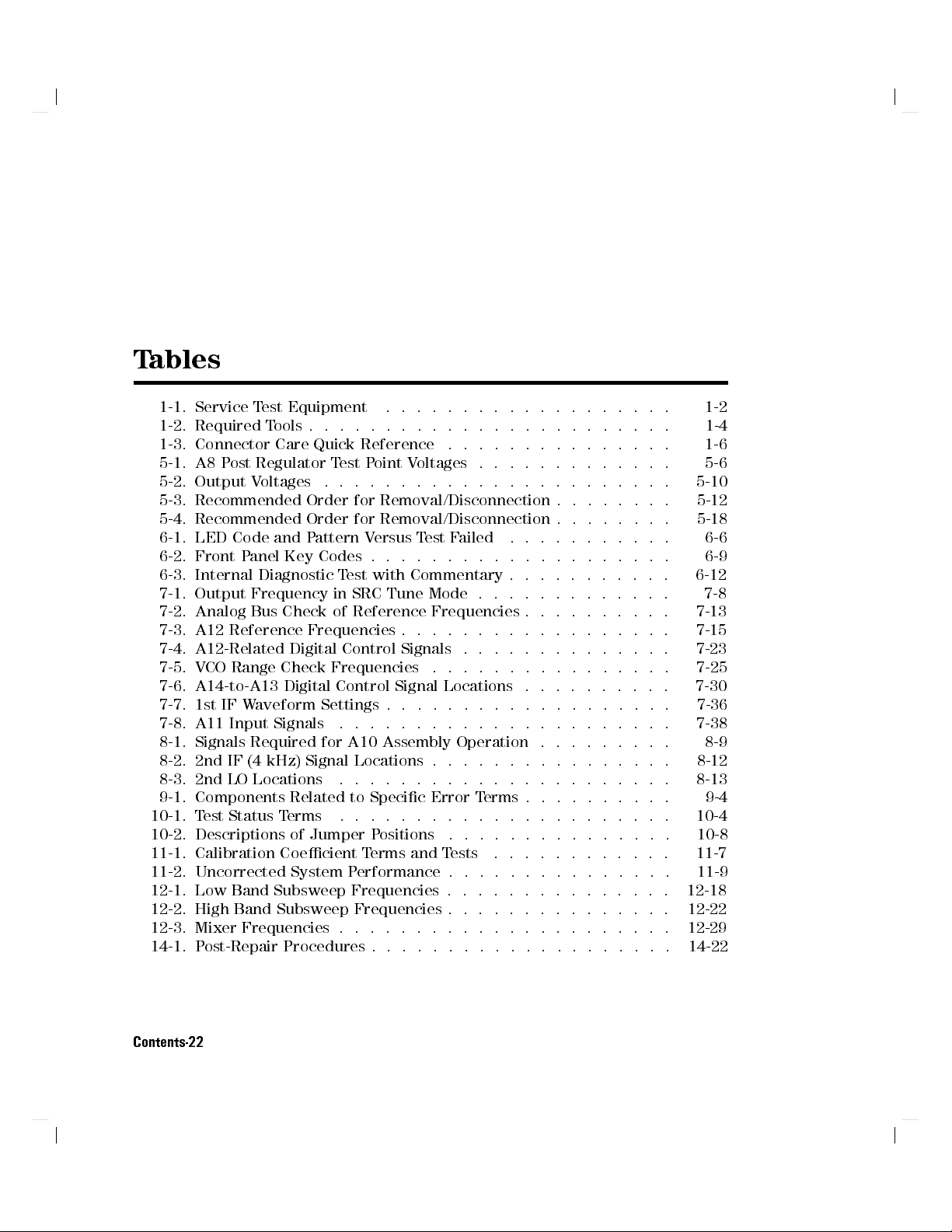

Tables

1-1. Service Test Equipment .......... ........ . 1-2

1-2. Required Tools . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3. Connector Care Quick Reference ............... 1-6

5-1. A8 Post Regulator Test Point Voltages . . . . . . . . . . . . .

5-2. Output Voltages .. ...... ...... ...... ...

5-3. Recommended Order for Removal/Disconnection . . . . . . . .

5-4. Recommended Order for Removal/Disconnection . . . . . . . .

6-1. LED Code and Pattern Versus Test Failed ...... .....

6-2. Front Panel Key Codes . . . . . . . . . . . . . . . . . . . .

6-3. Internal Diagnostic Test with Commentary . . . . . . . . . . .

7-1. Output Frequency in SRC Tune Mode . . . . . . . . . . . . .

7-2. Analog Bus Check of Reference Frequencies . . . . . . . . . .

7-3. A12 Reference Frequencies . . . . . . . . . . . . . . . . . .

7-4. A12-Related Digital Control Signals . . . . . . . . . . . . . .

7-5. VCO Range Check Frequencies ................

7-6. A14-to-A13 Digital Control Signal Locations . . . . . . . . . .

7-7. 1st IF Waveform Settings . . . . . . . . . . . . . . . . . . .

7-8. A11 Input Signals ......................

8-1. Signals Required for A10 Assembly Operation .... .....

8-2. 2nd IF (4 kHz) Signal Locations . . . . . . . . . . . . . . . . 8-12

8-3. 2nd LO Locations ...................... 8-13

9-1. Components Related to Specic Error Terms . . . . . . . . . . 9-4

10-1. Test Status Terms ........ ...... ...... .. 10-4

10-2. Descriptions of Jumper Positions .......... ..... 10-8

11-1. Calibration Coecient Terms and Tests ............

11-2. Uncorrected System Performance . . . . . . . . . . . . . . .

12-1. Low Band Subsweep Frequencies . . . . . . . . . . . . . . .

12-2. High Band Subsweep Frequencies . . . . . . . . . . . . . . .

12-3. Mixer Frequencies . . . . . . . . . . . . . . . . . . . . . .

14-1. Post-Repair Procedures . . . . . . . . . . . . . . . . . . . .

5-6

5-10

5-12

5-18

6-6

6-9

6-12

7-8

7-13

7-15

7-23

7-25

7-30

7-36

7-38

8-9

11-7

11-9

12-18

12-22

12-29

14-22

Contents-22

Page 29

Service Equipment and Analyzer Options

Table of Service Test Equipment

The following tables list the tools and test equipment required to perform the

analyzer's system verication, troubleshooting, adjustment, and performance

tests.

1

Service Equipment and Analyzer Options 1-1

Page 30

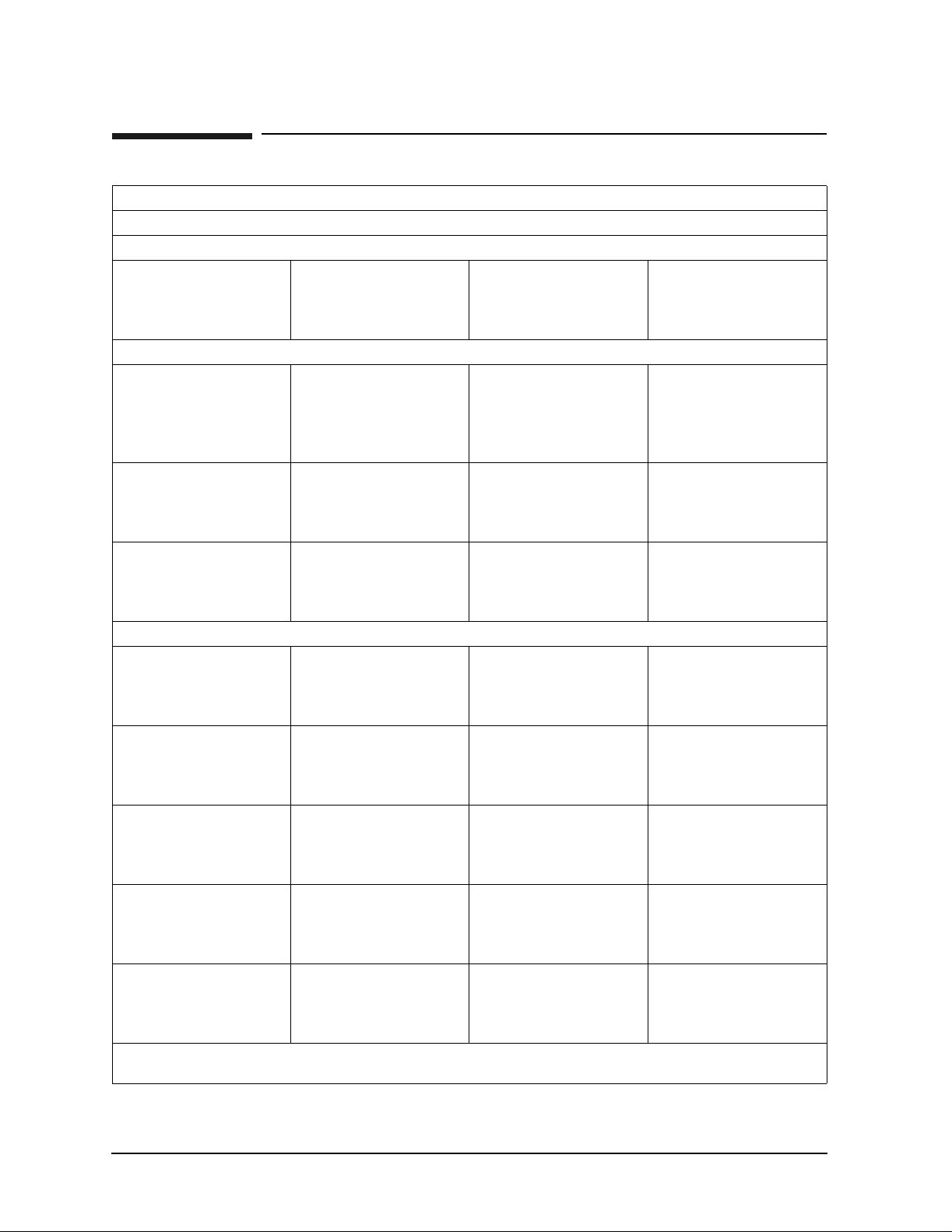

Table 1-1. Service Test Equipment

Required

Equipment

Critical

Specications

Recommended

Model

Spectrum Analyzer Freq. Accuracy67Hz HP 8563E A, T

Frequency Counter HP 5343A P

Measuring Receiver HP 8902A P

Oscilloscope Bandwidth: 100 MHz

any T

Accuracy: 10%

Digital Voltmeter Resolution: 10 mV any T

Tool Kit No substitute HP part number

T

08753-60023

Power Meter (HP-IB) No substitute HP 436A Opt. 022,

A, P,T

HP 437A or 438A

Power Sensor Frequency: 300 kHz-3 GHz, 50 HP 8482A A, P,T

Power Sensor (for Option 006) Frequency: 3 GHz-6 GHz HP 8481A Opt 006 A, P,T

Power Sensor Frequency: 300 kHz-3 GHz, 75 HP 8483A Opt. H03 P

Photometer Tektronix J16 A

Photometer Probe Tektronix J6503 A

Light Occluder Tektronix

A

016-0305-00

CRT Demagnetizer or Bulk Tape

A

Eraser

Printer HP ThinkJet,

P

DeskJet, LaserJet

Disk Drive 3.5-inch HP 9122

Floppy Disk 3.5-inch HP 92192A A

Calibration Kit Type-N, 50 No substitute HP 85032B P

Calibration Kit Type-N, 75 No substitute HP 85036B P

Verication Kit 7 mm No substitute HP 85029B P

Low Pass Filter

>

50 dB @ 2.96 Hz and passband that

HP P/N 9135-0198 A

includes 800 MHz

Step Attenuator 110 dB HP 8496A P

Attenuators (xed): Return loss:32 dB APC-7 20 dB (2) HP 8491A Opt. 020 P,T

Power Splitter 2-Way, 50 HP 11667A P,T

Minimum Loss Pad Type-N, 50 to 75 HP 11852B P,T

Use

*

1-2 Service Equipment and Analyzer Options

Page 31

Table 1-2. Service Test Equipment (2 of 2)

Required

Equipment

Adapter BNC to Alligator Clip HP P/N 8120-1292 A

Adapter APC-3.5 (m) to type-N (f) HP P/N 1250-1750 A, P

Adapter APC-3.5 (f) to type-N (f) HP P/N 1250-1745 A, P

Adapter APC-3.5 (f) to type-N (m) HP P/N 1250-1744 A

Adapter BNC (m) to type-N (f) HP P/N 1250-0077 P

Adapter type-N (m) to type-N (m) HP P/N 1250-1528 P

RF Cable 24-inch, type-N, 75 HP P/N 8120-2408 A, P

RF Cable 24-inch, type-N, 50 HP P/N 8120-4781 A, P

RF Cable Set type-N, 50 HP 11851B P

HP-IB Cable HP 10833A/B/C/D A

Coax Cable BNC HP P/N 8120-1840 A

Coax Cable BNC (m) to BNC (m), 50 HP 10503A A

Antistatic Wrist Strap HP P/N 9300-1367 A, T,P

Antistatic Wrist Strap Cord HP P/N 9300-0980 A, T,P

Static-control Table Mat and

Earth Ground Wire

*P-Performance Tests

A-Adjustment

T - Troubleshooting

Critical

Specications

Recommended

Model

HP P/N 9300-0797 A, T,P

Use

*

Service Equipment and Analyzer Options 1-3

Page 32

Table 1-2. Required Tools

T-8, T-10 and T-15 TORX screwdrivers

Flat-blade screwdrivers|small, medium, and large

5/16-inch open-end wrench (for SMA nuts)

3/16, 5/16, and 9/16-inch hex nut drivers

5/16-inch open-end torque wrench (set to 10 in-lb)

2.5-mm hex-key driver

Non-conductive and non-ferrous adjustment tool

Needle-nose pliers

Tweezers

Antistatic work mat with wrist-strap

1-4 Service Equipment and Analyzer Options

Page 33

Principles of Microwave Connector Care

Proper connector care and connection techniques are critical for accurate,

repeatable measurements.

Refer to the calibration kit documentation for connector care information.

Prior to making connections to the network analyzer, carefully review the

information about inspecting, cleaning and gaging connectors.

Having good connector care and connection techniques extends the life of these

devices. In addition, you obtain the most accurate measurements.

This type of information is typically located in Chapter 3 of the calibration kit

manuals.

For additional connector care instruction, contact your local Hewlett-P

Sales and Service Oce about course numbers HP 85050A+24A and

HP 85050A+24D.

See the following table for quick reference tips about connector care

.

ackard

Service Equipment and Analyzer Options 1-5

Page 34

Table 1-3. Connector Care Quick Reference

Handling and Storage

Do Do Not

Keep connectors clean Touch mating-plane surfaces

Extend sleeve or connector nut Set connectors contact|end down

Use plastic end-caps during storage

Visual Inspection

Do Do Not

Inspect all connectors carefully Use a damaged connector|ever

Look for metal particles, scratches, and dents

Connector Cleaning

Do Do Not

Try compressed air rst Use any abrasives

Use isopropyl alcohol Get liquid into plastic support beads

Clean connector threads

Gaging Connectors

Do Do Not

Clean and zero the gage before use Use an out-of-spec connector

Use the correct gage type

Use correct end of calibration block

Gage all connectors before rst use

Making Connections

Do Do Not

Align connectors carefully Apply bending force to connection

Make preliminary connection lightly Over tighten preliminary connection

Turn only the connector nut Twist or screw any connection

Use a torque wrench for nal connect Tighten past torque wrench \break" point

1-6 Service Equipment and Analyzer Options

Page 35

Analyzer Options Available

Option 003, 3 GHz Operation

This option extends the maximum source and receiver frequency of the analyzer

to 3 GHz.

Option 004, Step Attenuator

This option provides a source output power range from085 to +10 dBm.

Option 006, 6 GHz Operation

This option extends the maximum source and receiver frequency of the analyzer

to 6 GHz.

Option 010, Time Domain

This option displays the time domain response of a network by computing

the inverse Fourier transform of the frequency domain response. It shows

the response of a test device as a function of time or distance

reection coecient of a network versus time determines the magnitude and

location of each discontinuity. Displaying the transmission coecient of a

network versus time determines the characteristics of individual transmission

paths. Time domain operation retains all accuracy inherent with the correction

that is active in such devices as SA

antennas.

W lters,SAW delay lines, RF cables, and RF

. Displaying the

Option 075, 75 Impedance

This option oers 75 impedance bridges with type-N test port connectors.

Option 1CM, Rack Mount Flange Kit Without Handles

This option is a rack mount kit containing a pair of anges and the necessary

hardware to mount the instrument, with handles detached, in an equipment

rack with 482.6 mm (19 inches) horizontal spacing.

Service Equipment and Analyzer Options 1-7

Page 36

Option 1CP, Rack Mount Flange Kit With Handles

This option is a rack mount kit containing a pair of anges and the necessary

hardware to mount the instrument with handles attached in an equipment rack

with 482.6 mm (19 inches) spacing.

Option AFN, add 50 Test Port Cable

This option provides a second type-N male to type-N male test port cable and a

type-N female to type-N female adapter. Instructions are included for storing a

new internal calibration to account for the eects of this cable.

Option AFP, add 75 Test Port Cable

This option provides a 75 type-N male to type-N female test port cable

Instructions are included for storing a new internal calibration to account for

the eects of this cable.

Option B02, External Disk Drive

This option provides an external disk drive and an HP-IB cable

.

.

1-8 Service Equipment and Analyzer Options

Page 37

Service and Support Options

Hewlett-Packards oers many repair and calibration options for your analyzer.

Contact the nearest Hewlett-Packard sales or service oce for information on

options available for your analyzer. See the table titled \Hewlett-Packard Sales

and Service Oces" in Chapter 15.

Service Equipment and Analyzer Options 1-9

Page 38

Page 39

System Verication and Performance

Tests

How to Test the Performance of Your Analyzer

To obtain the same quality of performance testing that Hewlett-Packard has

administered at the factory, you must perform:

the system verication procedure

AND

all

of the performance test procedures.

This quality of performance testing guarantees that the analyzer is performing

within

will issue a Certicate of Calibration for your analyzer if two conditions are

met:

all

of the published specications. A Hewlett-Packard Customer Engineer

Your analyzer passes all the performed tests.

The equipment and standards that were used to perform the tests are

traceable to a national standards institute.

2

Note

If you have a particular type of measurement application that

does not use all of the analyzer's measurement capabilities,

you may ask your local Hewlett-Packard Customer Service

Center for a subset of specications that you want veried.

However, this does create the potential for making incorrect

measurements when using a dierent application.

System Verication and Performance Tests 2-1

Page 40

Sections in this Chapter

HP 8752C System Verication

HP 8752C Performance Tests

1. Reection Test Port Output Frequency Range and Accuracy

2. Reection Test Port Output Power Range and Level Linearity (HP 8752C

without Option 004)

3. Reection Test Port Output Power Range and Level Linearity (HP 8752C

with Option 004)

4. Transmission Test Port Input Noise Floor Level (HP 8752C without

Option 075 )

5. Transmission Test Port Input Noise Floor Level (HP 8752C with

Option 075 )

6. Test Port Crosstalk

7. System Trace Noise

8. Magnitude Dynamic Accuracy (HP 8752C0All Options)

9. Phase Dynamic Accuracy (HP 8752C0All Options)

10. Compression

HP 8752C Performance Test Record

2-2 System Verication and Performance Tests

Page 41

HP 8752C System Verication

Equipment

For standard HP 8752C network analyzer:

Calibration kit (50, type-N)

Cable type-N (50) 24-inch

Printer

::::: :::::: ::::::: ::::::::: ::::::::::::: ::

:::::: :::::: ::::::: ::::::::: ::::::::::::: :

:::::: :::::: ::::::: ::::::::: ::::::::

HP P/N 8120-4781

HP ThinkJet, DeskJet, LaserJet

HP 85032B

For the HP 8752C with Option 075:

Calibration kit (75, type-N)

Cable type-N (75) 24-inch

Printer

::::: :::::: ::::::: ::::::::: ::::::::::::: ::

:::::: :::::: ::::::: ::::::::: ::::::::::::: :

:::::: :::::: ::::::: ::::::::: ::::::::

HP P/N 8120-2408

HP ThinkJet, DeskJet, LaserJet

HP 85036B

Warm-up time: one hour.

Description

The HP 8752C system verication consists of performing the verication

procedure mentioned in this section. The verication procedure is

semi-automated and controlled by the analyzer's rmware.

The verication procedure involves measuring a set of calibration devices

(supplied in the HP 85032B 50 type-N calibration kit or the HP 85036B 75

type-N calibration kit) and comparing the measured data to the specication

limits drawn on the analyzer display. The measured data must fall within the

specication limits at all frequencies to pass the test.

System verication is only part of an instrument's calibration procedure.

The complete set of instrument specications can be tested by performing

the \HP 8752C System Verication" and all of the analyzer's performance

tests. An HP 85032B Option 002 or an HP 85036B Option 1BP calibration kit

(including with a Certicate of Calibration with United States National Institute

of Standards and Technology (NIST) test numbers) is required for a calibration

traceable to NIST.

Note

A Certicate of Calibration is issued if the analyzer's system

verication as well as all of the performance tests are

performed by a Hewlett-Packard Customer Engineer with all

having passed.

System Verication and Performance Tests 2-3

Page 42

System Verication Cycle and Kit Recertication

The recommended system verication cycle is every six months. Hewlett-

Packard also suggests the calibration kit be recertied annually.For more

information about the kit recertication, refer to the

HP 85032B 50 Type-N

Calibration Kit Operation and Service ManualorHP 85036B 75 Type-N

Calibration Kit Operation and Service Manual

.

Measurement Uncertainty

Associated with any analyzer are measurement errors that add uncertainty to

the measured results. This uncertainty limits how accurately a device under test

(DUT) can be measured.

The measurement uncertainty is dened to be the sum of the residual

systematic (repeatable) and random (non-repeatable) errors in the measurement

system. The systematic errors are eective directivity, eective source match,

load match, reection and transmission tracking, and isolation (crosstalk).

Random errors include errors due to noise, drift, connector repeatability, and

test cable stability.

The typical measurement uncertainties for type-N connectors using a

1-port error correction utilize an RSS (Root Sum of Squares) model for the

contributions of random errors such as noise, pin depth, pin diameter variation,

load return loss, and connector repeatability.

Measurement Uncertainty Window

The PASS/FAIL result of the limit line test generally indicates the status of the

verication test. The validity of the limit lines, drawn on the analyzer display

during the verication tests, are determined by the measurement uncertainty.

The measurement uncertainty must be taken into account when analyzing

the test results. If the analyzer detects the test data outside of the limits,a

FAIL

will be displayed on the analyzer. This

FAIL

status may not represent

a true failure if at the worst point, the test data is within the measurement

uncertainty window (not displayed on the analyzer). Refer to Figure 2-1 for

interpretations of test data.

2-4 System Verication and Performance Tests

Page 43

Figure 2-1. Measurement Uncertainty Window

System Verication and Performance Tests 2-5

Page 44

HP 8752C Type-N Test Port Characteristics (50 System)

Directivity

Frequency Range Specication Measurement Uncertainty

300 kHz to 1.3 GHz 40 dB

1.3 GHz to 3.0 GHz 35 dB

3.0 GHz to 6.0 GHz 30 dB

1

30 dB, 300 kHz to 10 MHz

1

6

3.30 dB

6

2.51 dB

6

3.30 dB

Source Match (Reection)

Frequency Range Specication Measurement Uncertainty

300 kHz to 1.3 GHz 30 dB

1.3 GHz to 3.0 GHz 25 dB

3.0 GHz to 6.0 GHz 20 dB

6

2.51 dB

6

2.88 dB

6

2.88 dB

Source Match (Transmission)*

Frequency Range Specication Measurement Uncertainty

300 kHz to 1.3 GHz 23 dB

1.3 GHz to 3.0 GHz 20 dB

3.0 GHz to 6.0 GHz 16 dB

6

2.51 dB

6

2.88 dB

6

2.88 dB

*Option 004 may degrade transmission source match as much as 2 dB, resulting in up to 0.05 dB additional

uncertainty in transmission tracking.

Reection Tracking

Frequency Range Specication Measurement Uncertainty

300 kHz to 1.3 GHz

1.3 GHz to 3.0 GHz

3.0 GHz to 6.0 GHz

2-6 System Verication and Performance Tests

6

0.2 dB

6

0.3 dB

6

0.4 dB

6

0.009 dB

6

0.019 dB

6

0.070 dB

Page 45

Load Match

Frequency Range Specication Measurement Uncertainty

300 kHz to 1.3 GHz 23 dB

1.3 GHz to 3.0 GHz 20 dB

3.0 GHz to 6.0 GHz 18 dB

1

14 dB, 300 kHz to 10 MHz for analyzers with option 006

1

6

0.40 dB

6

0.40 dB

6

0.92 dB

Transmission Tracking

Frequency Range Specication Measurement Uncertainty

300 kHz to 1.3 GHz

1.3 GHz to 3.0 GHz

3.0 GHz to 6.0 GHz

6

6

6

0.2 dB

0.3 dB

0.5 dB

6

0.043 dB

6

0.086 dB

6

0.172 dB

HP 8752C Type-N Test Port Characteristics (75 System)

Directivity

Frequency Range Specication Measurement Uncertainty

300 kHz to 10 MHz 30 dB

10 MHz to 1.3 GHz 40 dB

1.3 GHz to 3.0 GHz 35 dB

6

4.41 dB

6

4.41 dB

6

4.41 dB

Source Match (Reection)

Frequency Range Specication Measurement Uncertainty

300 kHz to 1.3 GHz 30 dB

1.3 GHz to 3.0 GHz 25 dB

6

2.88 dB

6

3.30 dB

System Verication and Performance Tests 2-7

Page 46

Source Match (Transmission)*

Frequency Range Specication Measurement Uncertainty

300 kHz to 1.3 GHz 23 dB

1.3 GHz to 3.0 GHz 20 dB

6

2.88 dB

6

3.30 dB

*Option 004 may degrade transmission source match as much as 2 dB, resulting in up to 0.05 dB additional

uncertainty in transmission tracking.

Reection Tracking

Frequency Range Specication Measurement Uncertainty