Page 1

User’s and Service Guide

Agilent Technologies

87075C

Multiport Test Set

For E506x Network Analyzers

Part No. 87075-90027

Printed in USA

Print Da te: March 200 4

© Copyright 2004 Agilent Technologies, Inc.

Page 2

WARRANTY STATEMENT

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED

“AS IS,” AND IS SUBJECT TO BEING CHANGED, WITHOUT

NOTICE, IN FUTURE EDITIONS. FURTHER, TO THE MAXIMUM

EXTENT PERMITTED BY APPLICABLE LAW, AGILENT

DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED

WITH REGARD TO THIS MANUAL AND ANY INFORMATION

CONTAINED HEREIN, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A P ARTICULAR PURPOSE. AGILENT SHALL NOT BE LIABLE

FOR ERRORS OR FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH THE

FURNISHING, USE, OR PERFORMANCE OF THIS DOCUMENT

OR ANY INFORMA TION CONTAINED HEREIN. SHOULD AGILENT

AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS COVERING THE MATERIAL IN THIS

DOCUMENT THAT CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE AGREEMENT WILL

CONTROL.

DFARS/Restricted Rights Notice

If software is for use in the performance of a U.S. Government

prime contract or subcontract, Software is delivered and licensed

as “Commercial computer software” as defined in DFAR

252.227-7014 (June 1995), or as a “commercial item” as defined in

FAR 2.101(a) or as “Restricted computer software” as defined in

FAR 52.227-19 (June 1987) or any equivalent agency regulation or

contract clause. Use, duplication or disclosure of Software is

subject to Agilent Technologies’ standard commercial license

terms, and non-DOD Departments and Agencies of the U.S.

Government will receive no greater than Restricted Rights as

defined in FAR 52.227-19(c)(1-2) (June 1987). U.S. Government

ii

Page 3

users will receive no greater than Limited Rights as defined in

FAR 52.227-14 (June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any technical data.

Certification

Agilent Technologies, Inc. certifies that this product met its

published specifications at the time of shipment from the factory.

Agilent Technologies, Inc. further certifies that its calibration

measurements are traceable to the United States National

Institute of Standards and Technology, to the extent allowed by

the Institute's calibration facility, and to the calibration facilities

of other International Standards Organization members.

Assistance

Product maintenance agreements and other customer assistance

agreements are available for Agilent Technologies, Inc. products.

For information about these agreements and for other assistance,

contact Agilent. Refer to

page 120.

Safety Notes

The following safety notes are used throughout this manual.

Familiarize yourself with each of the notes and its meaning before

operating this instrument. All pertinent safety notes for using this

product are located in

iii

Chapter 10 .

Page 4

WARNING Warning denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could

result in injury or loss of life. Do not proceed beyond a

warning note until the indicated conditions are fully

understood and met.

CAUTION Caution denotes a hazard. It calls attention to a procedure that, if

not correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed beyond a caution

sign until the indicated conditions are fully understood and met.

Printing Copies of This Document

To print copies of documentation from the Web, download the PDF

file from the Agilent web site:

• Go to http://www.agilent.com.

• Enter the document’s part number (located on the title page) in

the Quick Search box.

• Click GO.

.

iv

Page 5

Contents

1. Introduction and Installation

Introduction to the Multiport Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

A Complete Multiport Test System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Fully Characterize Your Devices with a Single Connection. . . . . . . . . .2

Improve Your Competitiveness with a Fully Specified Test System . . .3

Eliminate Redundant Connection of Calibration Standards with Test

Set Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Reduce the Effects of Test-System Drift with SelfCal . . . . . . . . . . . . . .4

Decrease Calibration Times and Increase Production Throughput . . .4

Improve Measurement Accuracy with Two-Port Calibration . . . . . . . .4

Typeface Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

If You are Using an 8712ET/ES or 8714ET/ES Analyzer . . . . . . . . . . . . .6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Step 1. Check the Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Step 2. Determine Network Analyzer Compatibility . . . . . . . . . . . . . .11

Step 3. Connect the Test Set to the Analyzer . . . . . . . . . . . . . . . . . . .12

Step 4. Satisfy Electrical and Environmental Requirements . . . . . . .14

Step 5. Activate the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Step 6. Connect Peripheral Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Cleaning the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2. Making Measurements

Measurement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Setting port connections of the multi-port test set . . . . . . . . . . . . . . . .22

Setting the measurement conditions. . . . . . . . . . . . . . . . . . . . . . . . . . .23

Calibrating the test set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Performing Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3. Test Set Cal and SelfCal

Contents-v

Page 6

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Test Set Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SelfCal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Test Set Cal: An Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting Up the Measurement Parameters. . . . . . . . . . . . . . . . . . . . . . 32

Determining the Best Position for the Calibration Reference Plane . 34

Determining the Type of Calibration Kit to Use . . . . . . . . . . . . . . . . . 36

Determine the Test Set Ports to Be Used . . . . . . . . . . . . . . . . . . . . . . 37

Performing the Test Set Cal with a Mechanical Calibration Kit . . . . 37

Performing the Test Set Cal with an ECal Module. . . . . . . . . . . . . . . 40

Saving the Test Set Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Recalling the Test Set Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Copying the Test Set Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Executing Self Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Test Set Cal and SelfCal: Theory of Operation. . . . . . . . . . . . . . . . . . . . 45

4. Front/Rear Panel

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Line Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Test Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

The REFLECTION Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

The TRANSMISSION Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

The Chassis Ground Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

The PORT CONNECTION Status LEDs . . . . . . . . . . . . . . . . . . . . . . 53

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

The PARALLEL IN Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

The PARALLEL OUT Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Line Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5. Key Reference

Contents-vi

Page 7

Contents

Cal Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

6. SCPI Command Reference

7. COM Object Reference

8. Specifications

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Test Set Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Limitation of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Exclusive Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Contacting Agilent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

9. Service

Automated Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Test Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Program Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Performance Verification Test Results . . . . . . . . . . . . . . . . . . . . . . . . 129

Manual Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

The Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

The LED Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

The Main Switch Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Contents-vii

Page 8

Contents

Post-Repair Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Rebuilt-Exchange Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Major Parts and Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Cables, Front Panel, and Main Board Assembly — Option 012

(75 Ω) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Cables, Front Panel, and Main Board Assembly— Option 006 . . . . 145

Instrument Covers and Associated Parts . . . . . . . . . . . . . . . . . . . . . 147

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

10. Safety and Regulatory Information

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Statement of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Shipping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Instrument Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Notice for Germany: Noise Declaration . . . . . . . . . . . . . . . . . . . . . . 157

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Contents-viii

Page 9

1 Introduction and Installation

1

Page 10

Introduction and Installation

Introduction to the Multiport Test Set

Introduction to the Multiport Test Set

• The 87075C is a 75-ohm multiport test set that is available with 6 or 12 test ports.

A Complete Multiport Test System

87075C multiport test sets are designed to work with E5061A (1.5 GHz) and

E5062A (3 GHz) RF network analyzers to provide complete measurement systems

for 75 ohm multiport devices. These test systems offer fast measurement speed, high

accuracy, and productivity features that will maximize your production throughput.

They feature:

• specified performance to 1.3 GHz (87075C)

• solid-state switches for fast, repeatable, and reliable switching between

measurement paths

Fully Characterize Your Devices with a Single Connection

A single connection between the multiport test set and each port of the DUT allows

complete testing of all transmission paths and port reflection characteristics. Agilent

multiport test systems eliminate time-consuming reconnections to the DUT, keeping

your production costs down and your volumes up. By reducing the number of RF

connections, you also:

• lower the risk of misconnections

• reduce operator fatigue

• minimize wear on cables, fixtures, connectors, and the DUT

2 Chapter 1

Page 11

Introduction and Installation

Introduction to the Multiport Test Set

Improve Your Competitiveness with a Fully Specified Test System

A multiport test set coupled with an E5061A/E5062A network analyzer offers fully

specified performance at the actual test po rts, wheth er y ou meas ur e in a fixture or at

the end of test cables. Specified performance means you can:

• get the same results no matter which test station you use to measure your DUT

• correlate test data from many DUTs across multiple test systems

• reduce measurement uncertainty to tighten your product specifications

• increase customer confidence in your products

Eliminate Redundant Connection of Calibration Standards with Test Set Cal

Calibrating a multiport test set using two-port error correction and a traditional

network analyzer requires a unique instrument state for each measurement path,

forcing many redundant connections of calibration standards. As the number of

ports increases, so does the number of connections required to calibrate all possible

measurement paths. Full calibration of the multiport test system is quick and simple

when performing a Test Set Cal:

• connect short, open, and load standards only once to each measurement port

• minimize the number of through standards required during calibration

Chapter 1 3

Page 12

Introduction and Installation

Introduction to the Multiport Test Set

Reduce the Effects of Test-System Drift with SelfCal

SelfCal is an internally automated calibration technique that uses solid - state

switches to measure calibration standards located inside the test set. SelfCal

executes automatically in just a few seconds (at an interval you define), so the

impact to your test process is minimal. Use SelfCal to:

• re-calibrate your multiport test system, returning it to the same measurement

accuracy achieved immediately after performing a Test Set Cal

• reduce the effects of test-system drift, improving overall measurement accuracy

between Test Set Cals

Since SelfCal does not correct for drift associated with interconnect elements

between the test set and your DUT, it is essential to use high-quality test cables,

adapters, and fixtures to ensure the best measurement accuracy.

Decrease Calibration Times and Increase Production Throughput

With SelfCal, a Test Set Cal needs to be performed about once per month, if within

the specified temperature range. This is unlike other test systems that typically

require calibration once or twice a day. Using Test Set Cal and SelfCal, you can:

• easily reduce your overall calibration times by a factor of twenty or more

• increase the amount of time a test station can be used for measuring

devices—typically, by three days per month.

Improve Measurement Accuracy with Two-Port Calibration

When using a multiport test set with an E5061A/E5062A with the option 27 5

S-parameter test set, Test Set Cal and SelfCal support full two-port calibrations.

Two-port error correction greatly improves the effective load match of the test

system, providing excellent measurement accuracy.

4 Chapter 1

Page 13

Introduction and Installation

Introduction to the Multiport Test Set

Typeface Conventions

Sample (bold) Boldface type is used when a term is

defined or emphasis.

Sample (Italic) Italic type is used for emphasis.

[ ] key Indicates a hardkey (key on the front panel

or external keyboard) labeled “Sample.”

“key” may be omitted.

Sample menu/button/box Indicates a menu/button/box on the screen

labeled “Sample” which can be

selected/executed by clicking. “menu,”

“button,” or “box” may be omitted.

Sample block/toolbar Indicates a block (group of hardkeys) or a

toolbar (s etup toolbar ) labeled “Sa mple.”

Sample 1 - Sample 2 - Sample 3 Indicates a sequential operation of Sample

1, Sample 2, and Sample 3 (menu, button,

or box). “-” may be omitted.

Chapter 1 5

Page 14

Introduction and Installation

If You are Using an 8712ET/ES or 8714ET/ES Analyzer

If You are Using an 8712ET/ES or 8714ET/ES Analyzer

This document is intended for use with E5061A and E5062A analyzers, so some of

the information (for example, key presses and calibration features) doe s not apply to

your analyzer. You can order the copy of the manual specifically written for using

the 87075C with 8712ET/ES and 8714ET/ES analyzers with the part number

87050-90026 by contacting Agilent Technologies. Refer to page 120 for contact

information. The manual can be also viewed in the Agilent web site:

http://www.agilent.com/find/manuals

6 Chapter 1

Page 15

Introduction and Installation

Installation

Installation

This section will guide you through the steps necessary to correctly and safely

install your multiport test set. The steps are:

• “Step 1. Check the Shipment”

• “Step 2. Determine Network Analyzer Compatibility”

• “Step 3. Connect the Test Set to the Analyzer”

• “Step 4. Satisfy Electrical and Environmental Requirements”

• “Step 5. Activate the Test Set”

• “Step 6. Connect Peripheral Devices”

Chapter 1 7

Page 16

Introduction and Installation

Installation

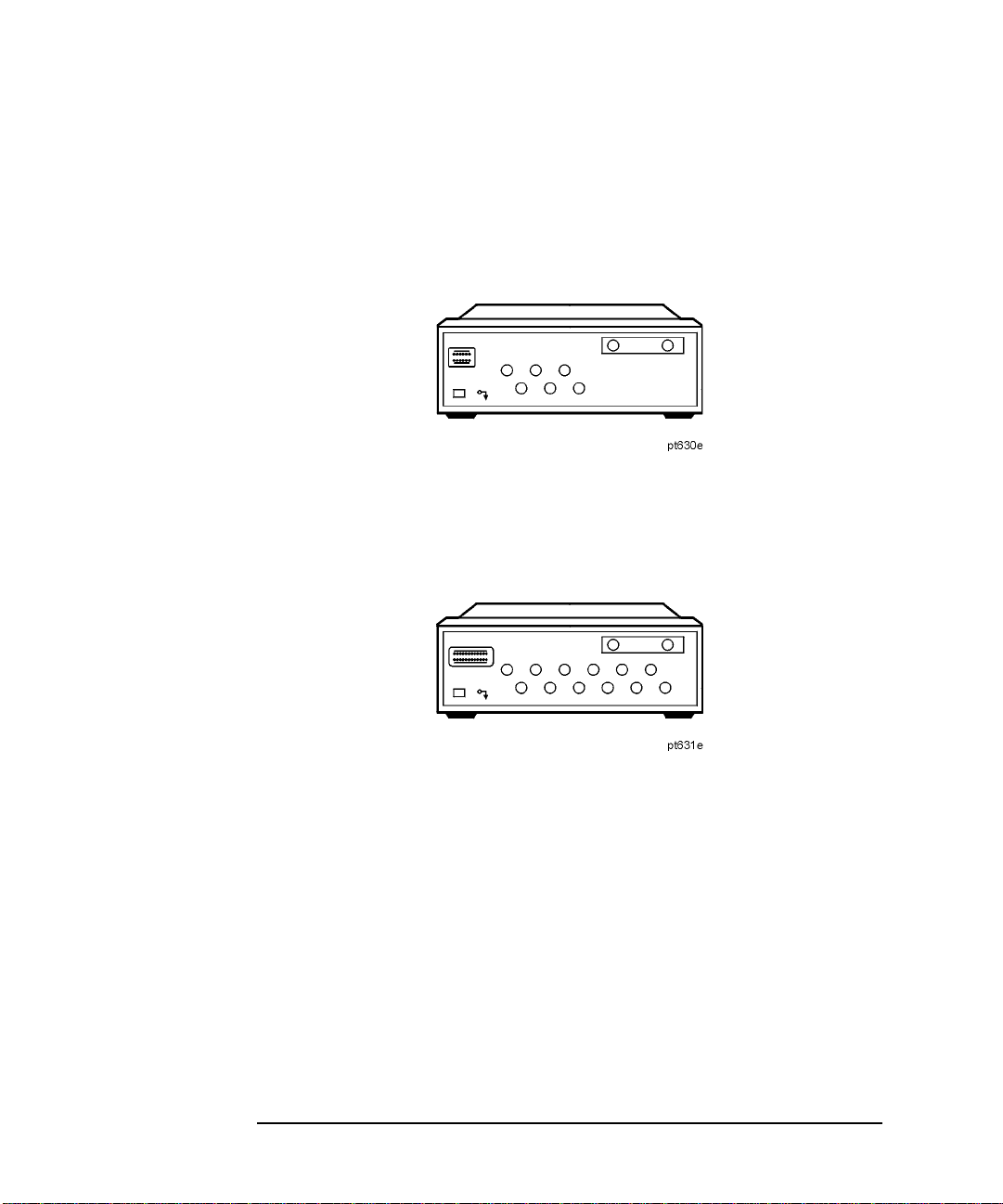

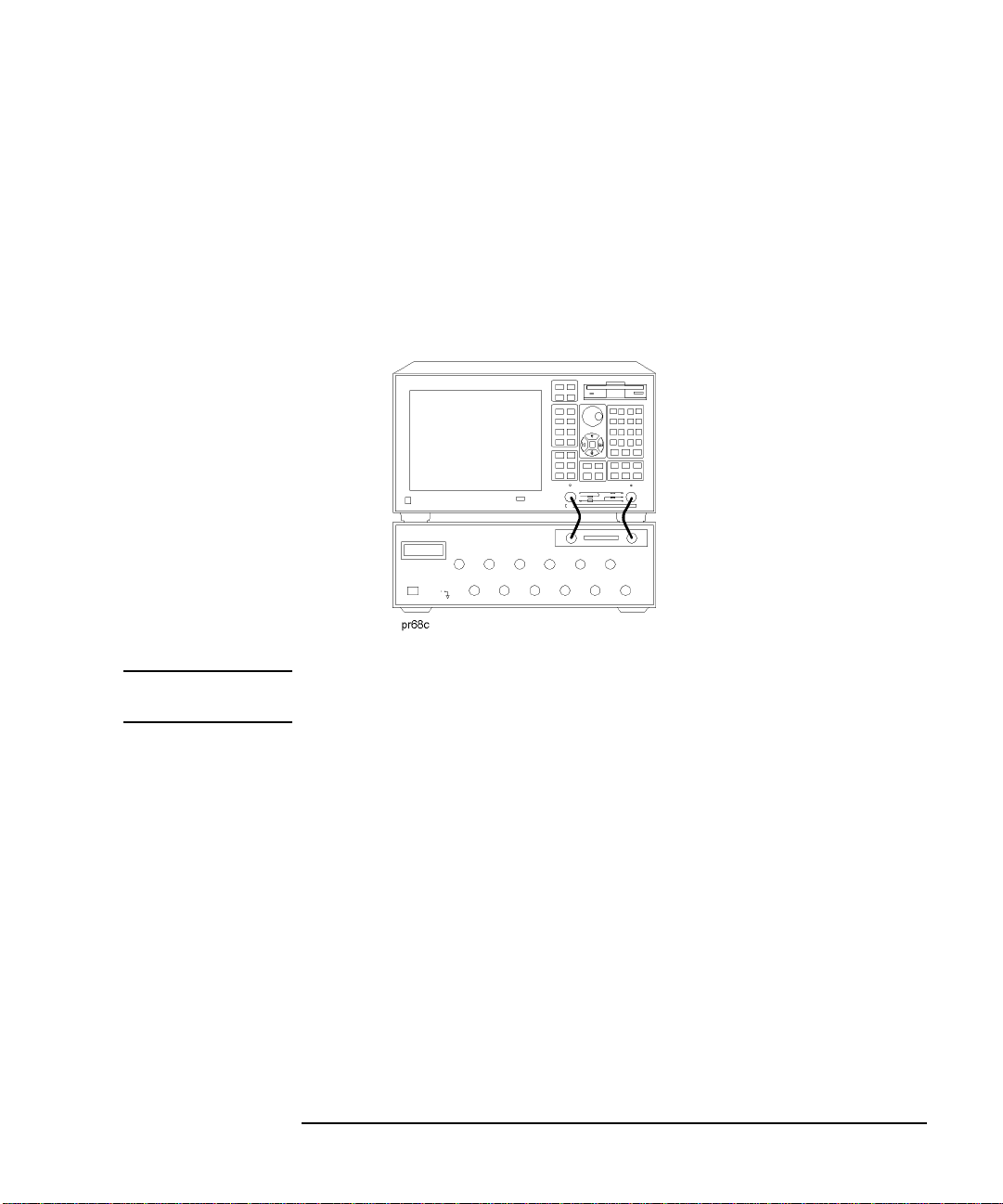

Figure 1-1 87075C Multiport Test Set — Two Versions

87075C Option 006 — Six Port Test Set

87075C Option 012 — Twelve Port Test Set

8 Chapter 1

Page 17

Introduction and Installation

Installation

Step 1. Check the Shipment

After you have unpacked your test set, keep the packaging materials to use if your

instrument should need to be returned for maintenance or repair.

NOTE The packaging material is designed to protect the test set from damage that can

happen during shipping. Returning the test set in anything other than the original

packaging may result in non-warranted damage.

Check the items received against Table 1-1 to make sure that you received everything.

Chapter 1 9

Page 18

Introduction and Installation

Installation

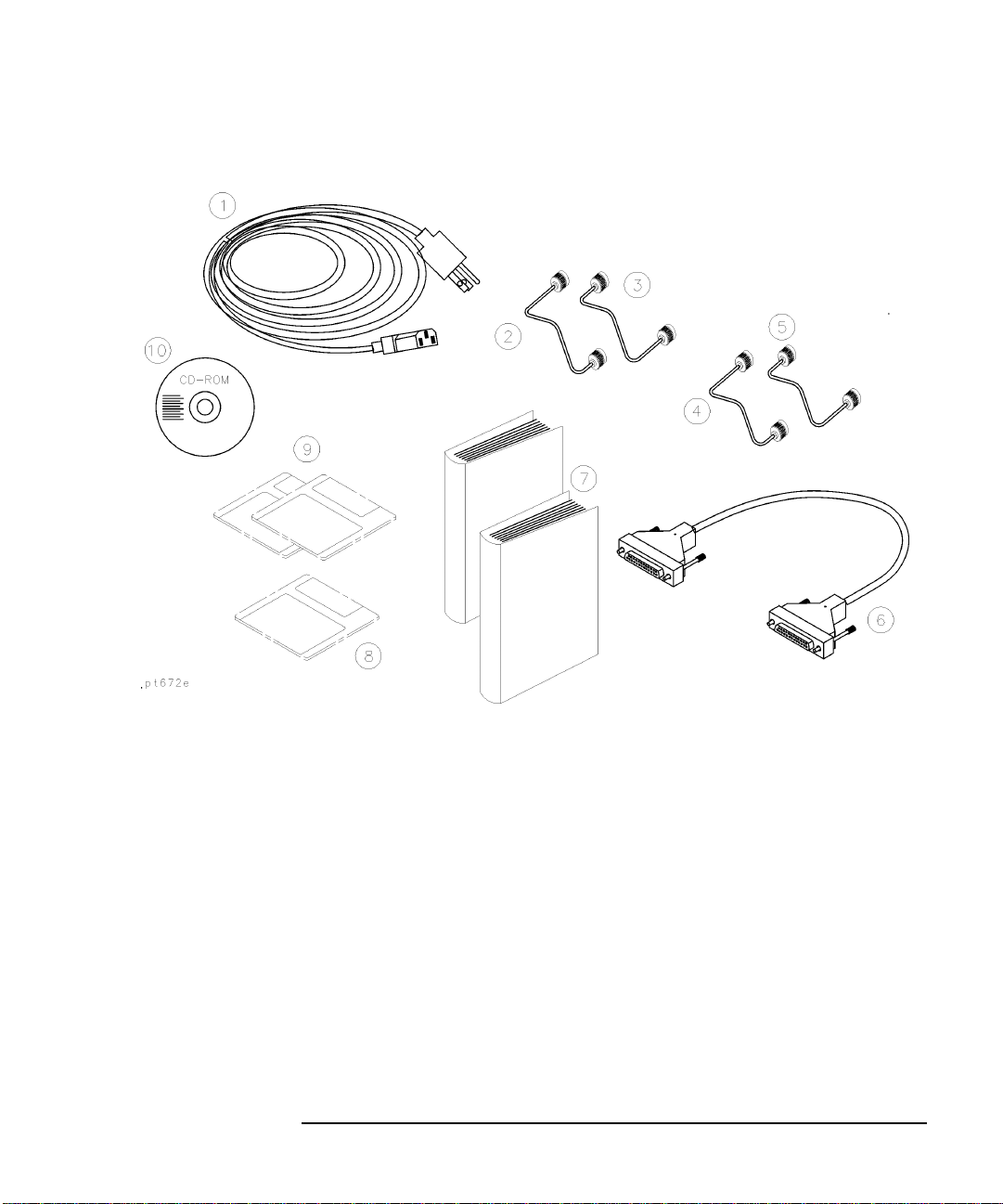

Table 1-1 Test Set Accessories Supplied

Item No. Description Quantity Part Number

1 Power Cord 1 See Figure 4-3. 2 Type-N Cable (Analyzer to test set’s

REFLECTION Port)

1

3 Type-N Cable (Analyzer to test set’s

TRANSMISSION Port)

1

4 Type-N Cable (Analyzer to test set’s

REFLECTION Port)

2

5 Type-N Cable (Analyzer to test set’s

TRANSMISSION Port)

2

1(75 Ω) 87075-60026

1(75 Ω) 87075-60028

1(75 Ω) 87075-60027

1(75 Ω) 87075-60029

6 Parallel Port Interface Cable 1 8120-6818 7 87075C User's and Service Guide (for E506x

1

87075-90027

Network Analyzers)

87050E and 87075C User’s and Service Guide

1

87050-90026

(for 871x Network Analyzers) 8 Test Set Calibration Disk 1 N/A 9 Performance T es t Progr ams Disks

1 08714-60049

(DOS and LIF formats) 10 CD-ROM 1 08714-90051

1. Not to be used with a rack-mounted system or if the analyzer has had its bottom feet removed.

See Figure 1-6 to see how these cables are to be connected.

2. You will only receive these cables if you ordered Option 1CM (rack mount kit). Use these cables

if you are rack-mounting your system, or if the bottom feet of the analyzer have been removed.

See Figure 1-6 for information on how to connect these cables.

10 Chapter 1

Page 19

Figure 1-2 Test Set Accessories Supplied

Introduction and Installation

Installation

Step 2. Determine Network Analyzer Compatibility

If you are using a 8712ET/ES or 8714ET/ES analyzer, refer t o “If You are Using an

8712ET/ES or 8714ET/ES Analyzer”.

Chapter 1 11

Page 20

Introduction and Installation

Installation

Step 3. Connect the Test Set to the Analyzer

For using your system on a bench, configure and connect the two instruments as shown in Figure 1-3: Connect the Parallel In connector of the test set to the analyzer Parallel connector. Use the parallel cable that was shipped with the multiport test set.

If you will be installing your system in a rack, read “Installing the System in a

Rack,” next in this section, before connecting the test set to the analyzer.

Figure 1-3 System Configuration

Installing the System in a Rack

The rack mount kit for the test set is Option 1CM when ordered with the test set, or

part number 5063-9214 when ordered separately.

12 Chapter 1

Page 21

Introduction and Installation

Installation

NOTE There are special semi-rigid cables that should be used to connect th e analyzer’ s test

ports to the test set’s REFLECTION and TRANSMISSION ports when used in a

rack (or a bench configuration where the analyzer’s bottom feet have been

removed). These cables were shipped with your analyzer if you ordered Option

1CM. If you order the rack mount kit separately, you will need to order these special

cables separately also. See Table 1-1 for part numbers.

To install your system in an 85043D rack, follow the instructions in the rack manual.

CAUTION When installing your system in other racks, improper installation may cause shock

hazards, overheating, dust contamination, and inferior system performance. For

support details and information about installation and warranty, call Agilent

T ech nolog ies. See page 120 for contact information.

CAUTION When installing the system in a cabinet, the convection into and out of the system

must not be restricted. The ambient temperature (outside the cabinet) must be less

than the maximum operating temperature of the system by 4 °C for every 100 watts

dissipated in the cabinet. If the total power dissipated in the cabinet is greater than

800 watts, then forced convection must be used.

Chapter 1 13

Page 22

Introduction and Installation

Installation

Step 4. Satisfy Electrical and Environmental Requirements

NOTE Refer to your network analyzer’s User’s Guide for information on electrical and

environmental requirements for your network analyzer.

1. The line power module on your multiport test set has an autoranging input. It is

designed to be used with an ac power source with a nominal voltage of either

115 V or 230 V.

2. Ensure the available ac power source meets the following requirements:

Nominal Range

Frequency: 50/60 Hz 47–63 Hz Line Voltage: 100/115 V or 230/240 V 90–264 V Power 45 W max

CAUTION This product has an autoranging line-voltage input. Be sure the supply voltage is

within the specified range.

If the ac line voltage does not fall within these ranges, an autotransformer that

provides third-wire continuity to earth ground should be used.

3. Ensure the operating environment meets the following requirements for safety:

• indoor use

• altitude up to 15,000 feet (4,572 meters)

•temperature 0 °C to 55 °C

• maximum relative humidity 80% for temperatures up to 31 °C decreasing

linearly to 50% relative humidity at 40 °C

• use only in INSTALLATION CATEGORY II, and POLLUTION DEGREE

2, per IEC 1010 and 664 respectively

4. Verify that the power cable is not damaged, and that the power source outlet

provides a protective earth ground contact. Note that the following illustration

depicts only one type of power source outlet. Refer to Figure 4-3 to see the

different types of power cord plugs that can be used with your test set.

14 Chapter 1

Page 23

Figure 1-4 Protective Earth Ground

Introduction and Installation

Installation

WARNING This is a Safety Class I product (provided with a protective earthing ground

incorporated in the power cord). The mains plug shall only be inserted in a

socket outlet provided with a protective earth contact. Any interruption of the

protective conductor, inside or outside the instrument, is likely to make the

instrument dangerous. Intentional interruption is prohibited.

Chapter 1 15

Page 24

Introduction and Installation

Installation

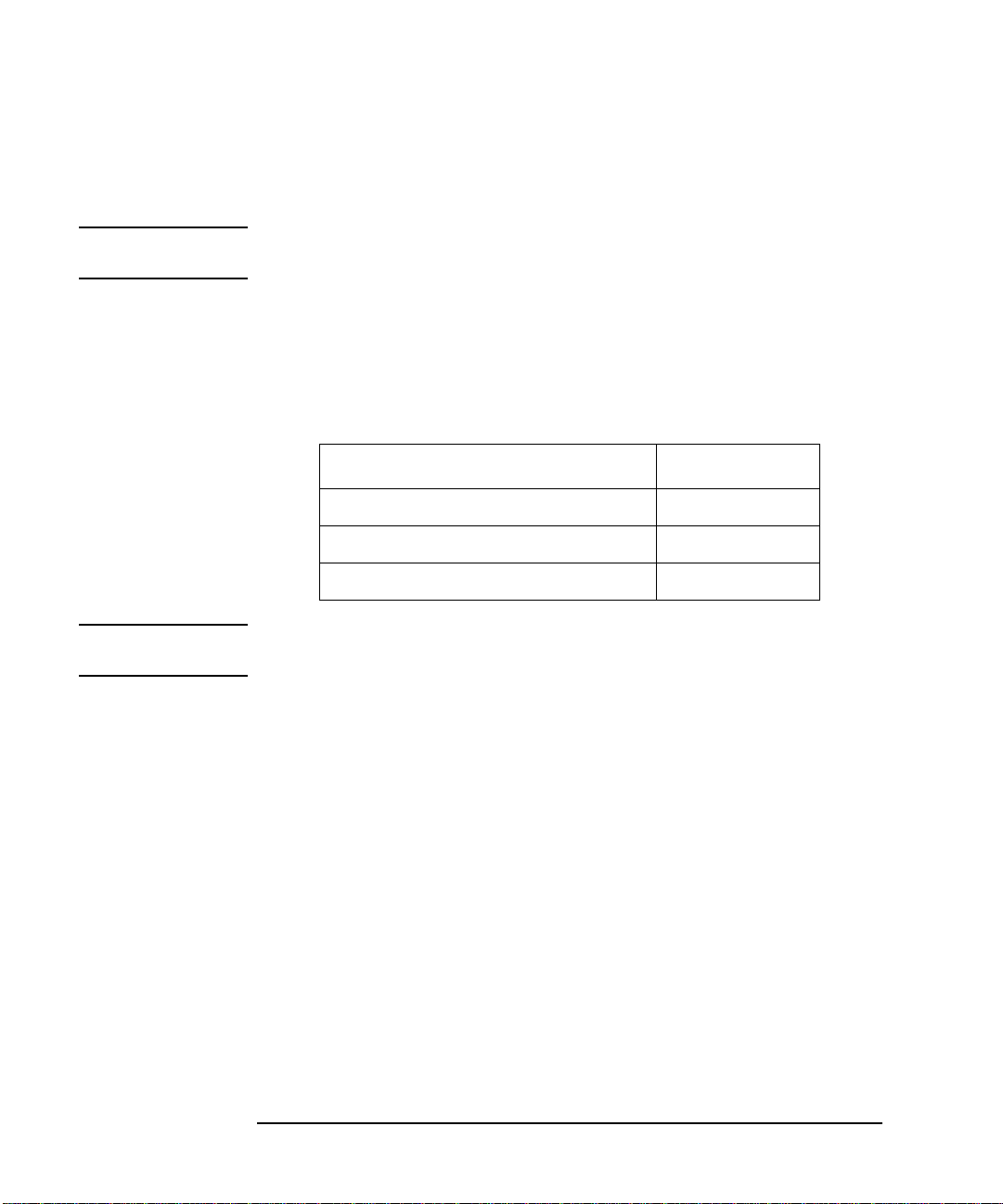

5. Ensure there are at least two inches of clearance around the sides and back of the

test set or the system cabinet.

Figure 1-5 Ventilation Clearance Requirements

6. Set up a static-safe workstation. Electrostatic discharge (ESD) can damage or destroy components.

• table mat with earth ground wire: part number 9300-0797

• wrist-strap cord with 1 Meg Ohm

resistor:

part number 9300-0980

• wrist-strap:

part number 9300-1367

• heel straps:

part number 9300-1308

• floor mat

16 Chapter 1

Page 25

Step 5. Activate the Test Set

1. Connect the semi-rigid cables that were shipped with your test set as shown in

Figure 1-6. Check Table 1-1 to be sure that you are using the correct cables with

your system configuration (the cables you use will be different depending on

whether you are using a bench system configuration—as shown in Figure

1-6—or a rack configuration).

Figure 1-6 Connect the Front Panel RF Cables

Introduction and Installation

Installation

NOTE Steps 2 and 3 must be performed before you can use your network analyzer to

control the multiport test set.

2. Turn on the test set .

3. Turn on the analyzer and Press [System] - activate the test set control.

Chapter 1 17

87075 Setup - 87075 Control to

Page 26

Introduction and Installation

Installation

Step 6. Connect Peripheral Devices

After you’ve ensured that your syst em is work ing pro perl y, connect any peripherals

that you intend to use with your system.

NOTE See your analyzer’s User’s Guide for information on peripheral connections.

18 Chapter 1

Page 27

Introduction and Installation

Preventive Maintenance

Preventive Maintenance

Preventive maintenance consists of checking the front panel connectors. This should

be done at least every six months — more often if the test set is used daily on a

production line or in a harsh environment.

Visually inspect the front panel connectors. The most important connectors are

those to which the DUT is connected. All connectors should be clean and the center

pins centered. The fingers of female connectors should be unbroken and uniform in

appearance. If you are unsure whether the connectors are good, gauge the

connectors to confirm that their dimensions are correct.

CAUTION Never connect 50 ohm cables to the front panel 75 ohm connectors of the analyzer

or test set. Otherwise, irreparable connector damage will occur.

Cleaning the Test Set

Use a dry cloth or one slightly dampened with water to clean the external case parts .

Do not attempt to clean internally.

WARNING To prevent electrical shock, disconnect the test set from power mains before

cleaning.

Chapter 1 19

Page 28

Introduction and Installation

Preventive Maintenance

20 Chapter 1

Page 29

2 Making Measurements

This chapter describes the procedure of measurement using the 87075C multi-port test set.

21

Page 30

Making Measurements

Measurement Procedures

Measurement Procedures

Measurement is performed in 4 major steps below.

• Setting the port connections of the multi-port test set

• Setting the measurement conditions

• Calibrating the test set

• Performing measurement

Multiport test system needs to be properly installed before making measurem ents.

For the installation procedure see “Installation” on page 1-7.

Figure 2-1 Mult iport Test System

Setting port connections of the multi-port test set

The procedure to set the test set port connections is described below. Note that the

port connections are set separately for each measurement channel.

Step 1. Press [Channel Next] or [Channel Prev] to select the channel for which you want

to execute multi-port measurement.

22 Chapter 2

Page 31

Step 2. Press [System].

Making Measurements

Measurement Procedures

Step 3. Press

Step 4. Press

Step 5. Press

87075 Setup.

87075 Control to make the status on.

Reflection.

Step 6. Select the port to be connected to the reflection port.

Step 7. Press

Transmission.

Step 8. Select the port to be connected to the transmission port.

Step 9. Repeat Step 1 through Step 8 for all the channels to use.

Setting the measurement conditions

The procedure to set the measurement conditions is described below. Keys or

softkeys typically used in each step are shown. For more information, see the

E5061A/E5062A User’s Guide.

Step 1. Setting measurement parameter for each trace

Set measurement parameter to be measured for each trace.

[Meas] -Corresponding softkey

Step 2. Setting the stimulus for each trace

Set the stimulus (sweep type, sweep range, power range, etc.) for each trace.

[Sweep Setup] - Corresponding softkey

[Start], [Stop], [Center], [Span] (each key for specifying the sweep range)

Step 3. Setting the data format for each trace

Set the display data format (log amplitude, polar coordinates, etc.).

[Format] - Corresponding softkey

Step 4. Setting the scale for each trace

Set the scale for each trace so that you can observe comfortably.

[Scale] -

Divisions

[Scale] - Scale/Div

Chapter 2 23

Page 32

Making Measurements

Measurement Procedures

[Scale] - Reference Position [Scale] - Reference Value

Step 5. Other settin gs

Set the graph title, trace color, and so on as necessary.

[Display] -

Edit Title Label

[System] - Misc Setup - Color Setup - Corresponding softkey

24 Chapter 2

Page 33

Making Measurements

Measurement Procedures

Calibrating the test set

The procedure to calibrate the test set is described below. Note that the calibration

procedure described here is a typical one using a mechanical calibration kit. For

more detailed information, including procedures using ECal, see Chapter 3.

Step 1. Selecting a mechanical calibration kit

Select a mechanical calibration kit you want to use for calibration. You can select a

mechanical calibration kit using one of the following 2 methods.

[Cal] - Cal Kit - Subsequent corresponding softkeys

[Cal] - Test Set Cal - Calibration - Cal Kit - Subsequent corresponding softkeys

Step 2. Selecting Cal Type

Select a calibration method from full 2-port calibration or enhanced response

calibration. If the E5061A/62A is of the T/R test set type you cannot select the full

2-port calibration.

[Cal] - Test Set Cal - Calibration - Cal Type

Step 3. Selecting an adjacent port pair and executing the measurement of the calibration

standards

Select an adjacent port pair for which you want to perform test set calibration.

Adjacent port pairs are: [1, 2], [3, 4], [5, 6], [7, 8], [9, 10], and [11, 12]. For the

87075C multi-port test set, calibration is performed for each port pair. For this

reason, when you want to use, for example, ports 1 and 5, you need to calibrate 4

ports (ports 1 and 2, and ports 5 and 6).

[Cal] - Test Set Cal - Calibration - Port x-y - Port x Open

[Cal]

- Test Set Cal - Calibration - Port x-y - Port x Short

- Test Set Cal - Calibration - Port x-y - Port x Load

[Cal]

- Test Set Cal - Calibration - Port x-y - Port y Open

[Cal]

[Cal]

- Test Set Cal - Calibration - Port x-y - Port y Short

- Test Set Cal - Calibration - Port x-y - Port y Load

[Cal]

- Test Set Cal - Calibration - Port x-y - Port x-y Thru

[Cal]

Chapter 2 25

Page 34

Making Measurements

Measurement Procedures

Step 4. Executing calibration

After the measurement of the calibration standards for necessary ports is finished,

calculate and save the calibration coefficients.

[Cal] - Test Set Cal - Calibration - Done

NOTE The calibration data of the 87075C multi-port test set has higher priority over the

analyzer’s normal calibration data. Therefore, if Test Set Cal is turned on with

normal calibration data existed, the multi-port test set calibration data is used, and

the normal calibration data is ignored.

26 Chapter 2

Page 35

Performing Measurements

The procedure to execute measurement is described below. This section describes

how to trigger actual measurement. For more information, see the E5061A/62A

User’s Guide.

Step 1. Setting the trigg e r sour ce

Select a trigger source. Because the trigger source is common to all the channels,

you need not to set it channel by channel.

Making Measurements

Measurement Procedures

[Trigger] -

Step 2. Setting the trigger mode

Select a trigger mode. You must set it separately for each channel.

[Trigger] - Corresponding softkey

Step 3. Generating a trigger

Generate a trigger from the trigger source specified in setting the trigger source.

NOTE If the internal trigger is specified, triggers are generated continuously immediately

after the setting.

Step 4. Adjusting the settings

Adjust each setting made in “Setting the measurement conditions” according to your measurement needs.

Trigger Source - Corresponding softkey

Chapter 2 27

Page 36

Making Measurements

Measurement Procedures

28 Chapter 2

Page 37

3 Test Set Cal and SelfCal

29

Page 38

Test Set Cal and SelfCal

Introduction

Introduction

This chapter presents information on the following topics:

• Test Set Cal: An Overview

• Test Set Cal and SelfCal: Theory of Operation

Measurement calibration is a process that improves measur ement accuracy by us ing

error correction arrays to remove systematic measurement errors. By implementing

the T est Set Cal and SelfCal features on your multiport system, you can increase the

accuracy of your measurements and increase the throughput of your multiport

measurements by eliminating frequent and lengthy calibration procedures.

Cal Type What is it? When to do it?

Test Set Cal

SelfCal An internally automated

A full calibration of the

multiport test system.

Requires connections of

external calibration

standards.

calibration techniq ue.

Uses solid-state switches

to measure calibration

standards located inside

the test set.

When you first set

up your test

system. Thereafter,

about once a month

if within the

specified

temperature range.

Set SelfCal to execute automatically as often as needed (typically once an hour).

Test Set Cal

A Test Set Cal is a calibration that should be performed when you first set up your

test system and thereafter on a regular, but relatively infrequent basis. The time

interval between Test Set Cals is dependent mainly on temperature. If the operating

temperature of the analyzer and test set is within the specified range, the

recommended time interval is about once a month. A Test Set Cal requires you to

connect calibration standards to all of the ports to be used.

See “Test Set Cal: An Overview” to learn how to perform a Test Set Cal.

30 Chapter 3

Page 39

Test Set Cal and SelfCal

Introduction

SelfCal

A SelfCal is an automated internal system calibration that should be performed on a

regular, frequent basis. If the operating temperature of the analyzer and test set is

within the specified range (refer to Chapter 8), the recommended time interval is

about once an hour. A SelfCal does not require removal of the DUT or external

connections of calibration standards. The SelfCal uses the results of the most recent

Test Set Cal along with measurements of internal, electronically switched open,

short, load, and through transfer standards to remove the drift of the network

analyzer and multiport test set due to environmental variations.

See “Test Set Cal and SelfCal: Theory of Operation” for detailed information on

how the Test Set Cal and SelfCal work together.

NOTE Agilent recommends that you use the Test Set Cal and SelfCal features whenever

you are using your multiport system. If you prefer, you can select from traditional

analyzer calibrations, although in doing so the Test Set Cal and SelfCal features will

not be available. Refer to your analyzer’s User’s Guide for information on these

traditional calibrations.

Chapter 3 31

Page 40

Test Set Cal and SelfCal

T est Set Cal: An Overview

Test Set Cal: An Overview

To perform a Test Set Cal the following steps are required and are explained in

detail in this section:

1. Set up measurement parameters, such as frequency range, power level, number

of measurements points, etc.

2. Determine the best position for the calibration reference plane.

3. Determine the type of calibration kit you will need to match the connectors at

your calibration reference plane.

4. Determine the number of test set ports to be used.

5. Perform the Test Set Cal.

The following optional steps are also explained in detail in this section:

6. Save the Test Set Cal.

7. Recall the Test Set Cal.

8. Copy the Test Set Cal.

9. Execute the SelfCal.

Setting Up the Measurement Parameters

You will need to determine th e measurem ent pa r a met e rs for your Test Set Cal by

determining all the measurements you will be making on a particular device and

setting your parameters accordingly. The analyzer will be able to accurately

interpolate between error-correction data po ints when most param eters are changed.

However, some special considerations are discussed below.

Frequency Range

You should set your freq uenc y range to the narrowest span possible that will cover

all of the measurements you will be making. The analyzer uses a fixed number of

frequency points during a calibration and interpolates as the frequency span is

narrowed. Setting the analyzer to the narrowest span possible for your

measurements will ensure the most accurate calibration. For example, if you will be

measuring a device that requires three different measurements, set your start

frequency to the lowest frequency used among the measurements and your stop

frequency to the highest frequency used among the measurements. See Figure 3-1.

32 Chapter 3

Page 41

The analyzer will interpolate between calibrated measurement points when the

frequency span is narrowed. However, you should be aware that best measurement

accuracy is compromised with this interpolation.

Figure 3-1 Frequency Range Example

Test Set Cal and SelfCal

T est Set Cal: An Overview

NOTE It is recommended that you set yo ur s t op f requ e ncy to 1 300 MH z. The per for mance

of the test set is not specified above 1300 MHz.

Using this method of calibration will yield accurate measurements with optimum

throughput. If your accuracy req uiremen ts are mo re imp ortant than you r th roug hp ut

requirements, you may want to perform a separate Test Set Cal for each

measurement setup, which eliminates the need for the analyzer to use interpolation.

Chapter 3 33

Page 42

Test Set Cal and SelfCal

T est Set Cal: An Overview

Other Parameters to Consider

The following parameters, if changed after calibrating, will not invalidate the

calibration, but will cause the “C?” notation to appear at the status bar of the

display:

• Sweep time

• Number of points

•Power level

• IF bandwidth

The “C?” notation indicates that a measurement parameter has changed after a

calibration was performed. For best accuracy, avoid measurements which cause the

“C?” notation to appear.

There is a trade-off be tween selecting the par ameters for best m easurement accuracy

and the resulting time required for the SelfCal routine. Generally, as your

parameters are modified for the greatest accuracy, the time required for a SelfCal

increases. For example, selecting a large number of points and a narrow system

bandwidth will improve measurement accuracy but will increase the time needed for

SelfCal. Therefore, when choosing parameters, you will have to weigh the

importance of measurement accuracy versus throughput.

Determining the Best Position for the Calibration Reference Plane

Most often you will not be connecting your DUT directly to the test set front panel.

More likely , you will be connecting you r DUT to a test fixture or t est cables t hat are

connected to the test set. See Figure 3-2 for an example. The calibration reference

plane is where you connect your calibration standards, and the measurement

reference plane is where you connect your DUT. Best measurement results occur

when these reference planes are aligned so that you calibrate out the effects of the

test fixture and its associated cables and hardware. Figure 3-2 illustrates how to

align the reference planes by connecting y our calibration stand ards at the same point

that you connect your DUT.

34 Chapter 3

Page 43

Figure 3-2 The Calibration Reference Plane

Test Set Cal and SelfCal

T est Set Cal: An Overview

Chapter 3 35

Page 44

Test Set Cal and SelfCal

T est Set Cal: An Overview

CAUTION Although the T est Set Cal can calibrate out the ef fects of you r external hardware, the

drift-removing features of the SelfCal cannot remove drift associated with any

external fixtures or cabling. See Figure 3-4.

Be sure that all external fixtures and cables are extremely stable. Agilent

recommends the use of semi-rigid cabling external to your multiport test set. Design

fixturing such that movement of all cables and connectors is minimized.

Determining the Type of Calibration Kit to Use

For the most accurate calibrations and measurements, you should select a calibration

kit to match each connector of your DUT. This will en sure that no adapters are

needed after a calibration has been performed. Procedures to select a calibration kit

is given below. For more information on calibration kits, refer to the

E5061A/E5062A User’s Guide.

Step 1. Press [Channel Next] or [Channel Prev] to select the channel for which you want

to select the calibration kit.

Step 2. Press [Cal].

Step 3. Press

Step 4. Select the calibration kit you use.

NOTE Alternatively , you can also u se [Cal] - Test Set Cal - Calibration - Cal Kit to select a

Step 1. Press [Channel Next] or [Channel Prev] to select the channel for which you want

Step 2. Press [Cal].

Step 3. Press

NOTE The calibration kit definitions for Port 1 are used for the test set ports with an odd

Cal Kit.

mechanical calibration kit. Follow these steps.

to select the calibration kit.

Test Set Cal - Calibration - Cal Kit and select a calibration kit you want to use

from the softkey menu.

number, while the definitions for Port 2 are used for the ports with an even number.

36 Chapter 3

Page 45

Test Set Cal and SelfCal

T est Set Cal: An Overview

Determine the Test Set Ports to Be Used

T o save time, calibrate the lowest number of ports necessary for your test setup. For

example, if your test setup requires the use of only 6 of the available twelve ports,

calibrate for 6 ports; there is no need to spend the time to calibrate all twelve ports.

The selection of the number of ports is necessary, in part, in order to perform the

minimum-through portion of the Test Set Cal. This portion occurs during the

calibration when measuring through standards for a transmis sion measurement (S

or S

) or measurements using 2-port calibration. Suppose that you have a 6-port

12

DUT and that you have selected the ports 1 to 6 to calibrate on your test set. A

traditional network analyzer calibration would require (in addition to connecting

opens, shorts, and loads to all connectors) that you connect a through standard

between every possible pairing of the 6 test set ports in order to measure all possible

transmission paths. This would mean 15 dif ferent connect ions of thro ugh standar ds,

each needing its own separate calibration file. The Test Set Cal simplifies this

process by only requiring a through-standard connection between 3 adjacent port

pairs of the 6 test set ports:

• Port 1 to Port 2

21

*

• Port 3 to Port 4

• Port 5 to Port 6

The analyzer calculates the remainder of the test set port combinations and saves the

data as only one calibration file. The test set calibration can be done in any

combination of the adjacent port pairs, [1, 2] and [5, 6] for example. This results in

significant calibration-time savings, which improves your measurement throughput.

Performing the Test Set Cal with a Mechanical Calibration Kit

This section describes how to perform the Test Set Cal with a mechanical calibration kit.

Step 1. Press [Channel Next] or [Channel Prev] to select the channel for which you want

to execute multi-port test set calibration.

Step 2. Press [Cal].

* Adjacent ports are those which share an internal through calibration stan-

dard. Adjacent ports are: [1, 2], [3, 4], [5, 6], [7, 8], [9, 10], [11, 12].

Chapter 3 37

Page 46

Test Set Cal and SelfCal

T est Set Cal: An Overview

Step 3. Press Test Set Cal.

Step 4. Press

Calibration.

NOTE If Calibration is disabled, the status of the multi-port test set of this channel may be

off. See "Procedure of setting ports for the multi-port test set" in the previous

chapter.

Step 5. Press

Port x-y (a port pair for which you want to execute calibration).

NOTE The multi-port test set calibration is perfo rmed for each port p air. If you want to use,

for example, ports 1 and 3 for measurement, calibration must be performed for 1-2

and 3-4.

Step 6. Connect the open standard to the Port x side and press

calibration data.

Step 7. Connect the short standard to the Port x side and press

calibration data.

Step 8. Connect the load standard to the Port x side and press

calibration data.

Step 9. Connect the open standard to the Port y side and press

calibration data.

38 Chapter 3

Port x Open to measure

Port x Short to measure

Port x Load to measure

Port y Open to measure

Page 47

Test Set Cal and SelfCal

T est Set Cal: An Overview

Step 10. Connect the short standard to the Port y side and press Port y Short to measure

calibration data.

Step 11. Connect the load standard to the Port y side and press

Port y Load to measure

calibration data.

Step 12. Connect the thru standard between ports x and y side and press

measure calibration data.

Portx- y Thru to

Step 13. Press

Return to return to the port selection menu.

Step 14. Repeat Step 5 through Step 13 for necessary port pairs.

NOTE When you calibrate the same port pair in multiple channels, you can reduce the

number of standard connections by measuring a standard while changing

measurement channels. You don’t need to complete the step 5 through 13 before

you perform calibration in other channel, thus you can measure standards for Test

Set Cal in parallel in multiple channels.

Step 15. Press

Done to finish the calibration of the multi-port test set. The calibration

coefficients are calculated and saved by this operation.

Chapter 3 39

Page 48

Test Set Cal and SelfCal

T est Set Cal: An Overview

Calibrating: Insertable Port Pairs versus Noninsertable Port Pairs

During the through portion of the calibration, if an adjacent port pair (for example,

1-to-2, 3-to-4, 5-to-6, etc.) can be connected directly without using a cable or an

adapter, the port pair is insertable. If an adjacent port pair can only be connected by

using a through cable or an adapter, the port pair is noninsertable. If the port pair is

noninsertable, the through cable or adapter is not used when the DUT is measured,

so its electrical delay must be subtracted out. This is done by modifying the

definition of the through-standard in the calibration kit for each port.

Most test fixtures have fixed-location connectors, so their port pairs can only be

connected by using a through cable. During the calibration you will be prompted to

connect a through cable between specific port pairs. If you can connect your cables

to the test set so that the cables’ adjacent port pairs are male-to-female, all of your

port pairs will be insertable. Configuring your test setup this way saves calibration

time and improves your measurement throughput.

Performing the Test Set Cal with an ECal Module

This section describes how to perform the Test Set Cal with an ECal module.

Step 1. Press [Channel Next] or [Channel Prev] to select the channel for which you want

to execute multi-port test set calibration.

Step 2. Press [Cal].

Step 3. Press

Step 4. Press

NOTE If Calibration is disabled, the status of the multi-port test set of this channel may be

Step 5. Press

NOTE The multi-port test set calibration is perfo rmed for each port p air. If you want to use,

Te st Set Cal.

Calibration.

off. See "Procedure of setting ports for the multi-port test set" in the previous

section.

Port x-y (a port pair for which you want to execute calibration).

for example, ports 1 and 3 for measurement, calibratio n must be perfo rmed for p orts

1-2 and 3-4.

40 Chapter 3

Page 49

Test Set Cal and SelfCal

T est Set Cal: An Overview

Step 6. Connect the ECal module between ports x and y and press ECal to measure

calibration data and calculate the calibration coefficients.

Step 7. Repeat Step 5 and Step 6 for necessary port pairs.

Chapter 3 41

Page 50

Test Set Cal and SelfCal

T est Set Cal: An Overview

NOTE A 2-port type ECal module is assumed in the above procedure. For a 4-port ECal

module, in case of S-parameter test set, you can connect any two of the 4 ports when

connecting the ECal module in St ep 6. In case of transmission /reflection test set, on e

of the connections listed in the table must be used.

4-Port ECal connection to T/R test set

Reflection Transmission

Port A Port B Port B Port C Port C Port D Port D Port A

Saving the Test Set Cal

It is a good idea to manually save the results of your Test Set Cal. You can save the

test set cal data as a part of the instrument state. Following is a basic procedure to

save the instrument state into the pre-defined register. See your analyzer’s User’s

Guide for more detailed information on saving, and recalling files.

Step 1. Press [Channel Next] or [Channel Prev] to select the channel for which you want

to save calibration data.

Step 2. Press [Save/Recall].

Step 3. Press

Step 4. Press

Save Type, then either State & Cal or All so that the calibration data is included in

the state data.

Save State, then the softkey corresponding to the register in which you want to

save the instrument state.

Recalling the Test Set Cal

You can recall the test set cal data as a part of the instrument state. Following is a

basic procedure to recall the instrument state from the pre-defined register. See your

analyzer’s User’s Guide for more detailed information on s avi ng, and recal l ing files.

Step 1. Press [Channel Next] or [Channel Pr ev] to select the ch annel for which y ou want

to recall calibration data.

42 Chapter 3

Page 51

Step 2. Press [Save/Recall].

Test Set Cal and SelfCal

T est Set Cal: An Overview

Step 3. Press

Recall State, then the softkey corresp onding to the r egister from which you w ant

to recall the instrument state.

Copying the Test Set Cal.

The E5061A/62A lets you temporarily save Test Set calibration data only for each

channel and copy it to another channel. When the same calibration data is used in

multiple channels, you can reduce calibration time by using this method instead of

doing the same calibration multiple times. The procedure is as follows:

Step 1. Press [Channel Next] or [Channel Prev] to select the channel for which you want

to save calibration data temporarily.

Step 2. Press [Save/Recall].

Step 3. Press

Step 4. Press one of

NOTE An area with an asterisk (*) to the right of Cal Only x contains saved data alread y. If

Step 5. Press [Channel Next] or [Channel Prev] to select a channel to which you want to

Save Channel.

Cal Only A through Cal Only D.

you press the key, the previous calibration data is deleted and new calibration data is

written over it. In this case, the previous calibration data cannot be restored.

copy calibration data.

Step 6. Press [Save/Recall].

Step 7. Press

Step 8. Press

NOTE Only keys for which saved data exists are active.

Recall Channel.

Cal Only x in which you have saved calibration data to read it out.

Executing Self Cal

The SelfCal timer feature allows you to set up your multiport system to

automatically perform a SelfCal at a user-defined interval. The default interval is 60

minutes. Your environmental conditions and accuracy requirements may dictate

either a shorter interval or allow a longer interval.

Chapter 3 43

Page 52

Test Set Cal and SelfCal

T est Set Cal: An Overview

NOTE Self Cal is set for each measurement channel and executed for a port pair selected

for the channel.

NOTE SelfCals are not automatically initiated on currently unused ports. A port is never

automatically calibrated unless it is selected— even if the time interval has been

exceeded.

NOTE SelfCals are initiated only when a trigger source is internal and a trigger mode is

continuous.

Step 1. Press [Cal].

Step 2. Press

Step 3. Press

Te st Set Cal.

Timer and enter the interval for executing Self Cal in minutes in the entry area

in the upper part of the screen.

Step 4. Press

Self Cal to make the auto Self Cal status on.

NOTE You can execute a Self Cal on the currently selected channel by press ing [Cal] - Test

Set Cal - Self CalOnce.

44 Chapter 3

Page 53

Test Set Cal and SelfCal

Test Set Cal and SelfCal: Theory of Operation

Test Set Cal and SelfCal: Theory of Operation

Adding a multiport test set to the analyzer degrades raw performance of the test

system as well as introduces drift. Test Set Cal provides the vector error correction

that allows the system to achieve good performance. A Test Set Cal is a calibration

that is performed on a regular, but infrequent basis. The results of the Test Set Cal

are used by the SelfCal feature to remove the drift associated with the hardware of

the test set and analyzer to return the multiport system to an accurately calibrated

state.

There are two steps to the Test Set Cal:

• The first step requires you to connect calibration standards (from a calibration

kit) and your own through-cables to the calibration reference plane. The

analyzer measures the known reference standards and uses those measurements

to compute error correction coefficients.

• The second step occurs once you are done measuring the calibration standards

and store the Test Set Cal data. The multiport test set contains electronically

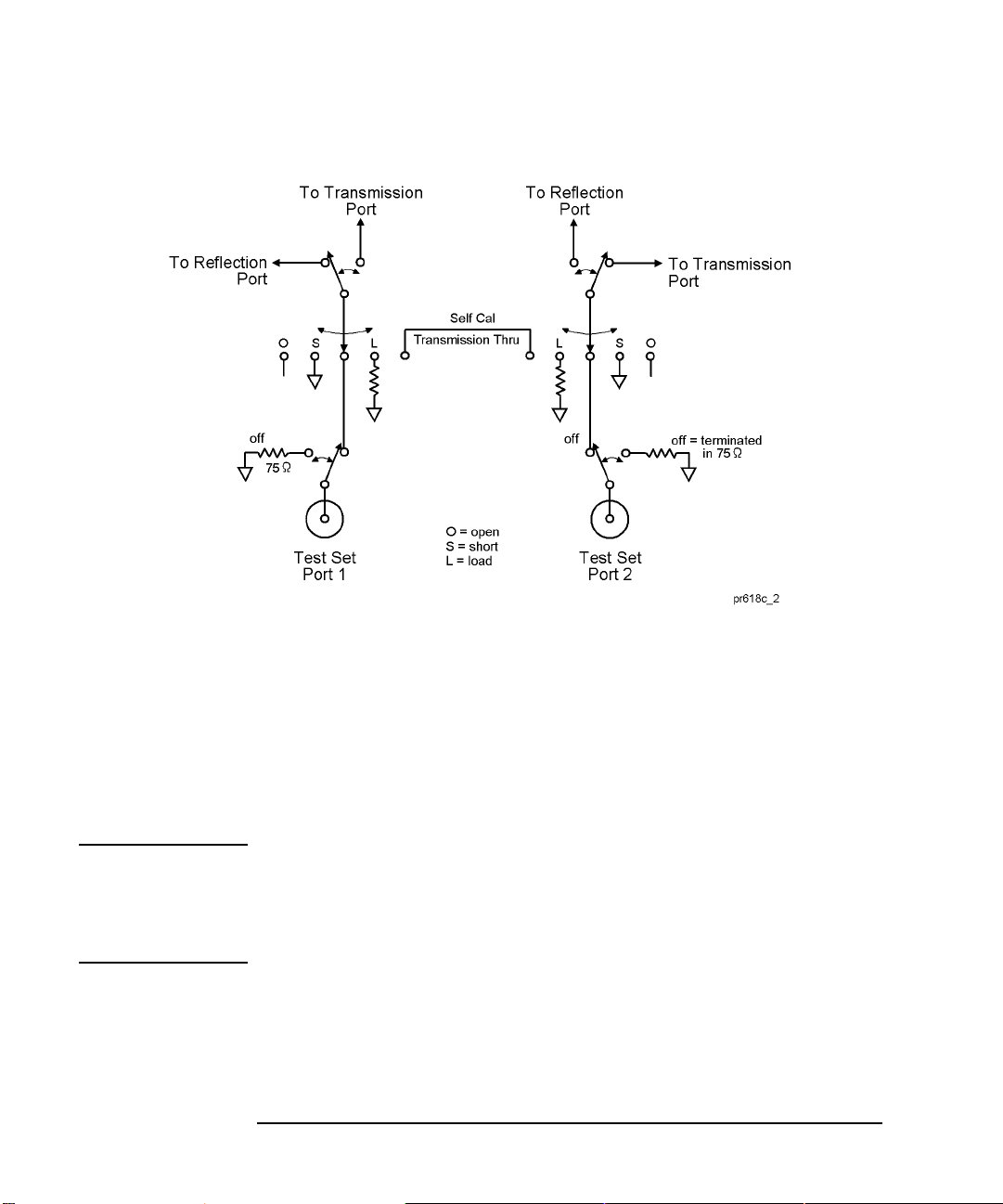

switched open, short, load, and through standards behind each port. (See Figure

3-3. This illustration depicts a two-port t e st set. The same internal sta ndards are

also included behind every port of your test set.) These standards are very stable,

yet their calibration definitions are not known like the mechanical standards.

During this second step, the analyzer makes a measurement of each internal

standard and then, using the error coefficients that were computed from the

measurements of the external standards, derives a very accurate calibration

definition for each internal standard. Once this has been done, the internal

standards act as “transfer standards” for future automatic calibrations called

SelfCals.

Chapter 3 45

Page 54

Test Set Cal and SelfCal

Test Set Cal and SelfCal: Theory of Operation

Figure 3-3 Internal Transfer Standards

A SelfCal is an automatic measurement of the test set internal standards that allows

the system to remove system drift that occurs du e to en viron mental ch anges s uch as

temperature. SelfCal allows the multiport system to recalibrate itself without having

to disconnect the DUT or connect any additional external standards or cables to the

system.

A SelfCal can be initiated manually. It is also possible to automatically perform a

SelfCal at regular, frequent time intervals. If the operating temperature of the

analyzer and test set is within the specified range (refer to Chapter 8), the

recommended time interval is about once an hour.

CAUTION Performing a Test Set Cal will effectively calibrate out the initial effects of any

external cabling and/or test fixtures. However, it must be noted that although the

SelfCal can remove drift internal to the measurement system, it cannot remove any

drift associated with cables, test fixtures and connections beyond the internal

transfer standards.

As shown in Figure 3-4, the Test Set Cal initially removes the effects of drift associated with hardware in the area designated by arrow “A.” SelfCal can only remove the effects of drift from the area designated by arrow “B.”

46 Chapter 3

Page 55

Test Set Cal and SelfCal: Theory of Operation

Drift can be minimized by controlling the environmental temperature and humidity,

and by using high quality connectors, semi-rigid cables, and fixturing that reduces

cable movement to a minimum.

Figure 3-4 Drift Removal: Test Set Cal and SelfCal

Test Set Cal and SelfCal

Chapter 3 47

Page 56

Test Set Cal and SelfCal

Test Set Cal and SelfCal: Theory of Operation

48 Chapter 3

Page 57

4 Front/Rear Panel

49

Page 58

Front/Rear Panel

This chapter contains information on the ports and switches found on the front and

rear panels of the test set.

50 Chapter 4

Page 59

Front Panel

Figure 4-1 Front Panel Features

Front/Rear Panel

Front Panel

Item Description

1 Line Power Switch 2 Port Connection Status LEDs 3 Reflection and Transmission Connectors 4Test Ports 5 Chassis Ground Connector

Line Power Switch

The test set line POWER switch is located at the bottom left corner of the front panel. See Figure 4-1. The line POWER switch turns the power to the test set to either on or off.

Chapter 4 51

Page 60

Front/Rear Panel

Front Panel

The front panel LINE switch disconnects the mains circuits from the mains supply

after the EMC filters and before others parts of the instrument.

Test Ports

The front panel test ports are 75 ohm female connectors that are used to connect to

the device under test.

CAUTION Never connect 50 ohm cables to the front panel 75 ohm connectors of the analyzer

or test set. Otherwise, irreparable connector damage will occur.

52 Chapter 4

Page 61

Front/Rear Panel

Front Panel

The REFLECTION Connector

The REFLECTION connector is a female 75 ohm type-N connector that connects

directly to the PORT 1 of the network analyzer using a semi-rigid cable that was

shipped with your test set.

CAUTION Check your analyzer's documentation for damag e limits to th e analyzer po rts. Make

sure that your test setup will not cause those limits to be exceeded.

The TRANSMISSION Connector

The TRANSMISSION connector is a female 75 ohm type-N connector that

connects directly to the PORT 2 of the network analyzer using a semi-rigid cable

that was shipped with your test set.

CAUTION Check your analyzer's documentation for damag e limits to th e analyzer po rts. Make

sure that your test setup will not cause those limits to be exceeded.

The Chassis Ground Connector

The chassis ground connector provides a convenient front panel ground connection

for a standard banana plug.

The PORT CONNECTION Status LEDs

The PORT CONNECTION status LEDs provide visual feedback of which test set

port(s) are connected to the REFLECTION and TRANSMISSION connectors of the

test set. When neither LED is lit for a particular test set port, the test set port is

terminated with the internal load.

Chapter 4 53

Page 62

Front/Rear Panel

Rear Panel

Rear Panel

Figure 4-2 Rear Panel Features

Item Description

1 Parallel In Connector

2 Parallel Out Connector

3Line Module

The PARALLEL IN Connector

This female DB-25 connector input is always connected to the network analyzer.

The analyzer provides control of the test set through this cable as well as passing

through any printer control signals to the test set’s PARALLEL OUT connector.

The PARALLEL OUT Connector

This rear panel connector cannot be used when the test set is used with the

E5061A/E5062A. Use the analyzer’s USB ports when using a printer.

54 Chapter 4

Page 63

Front/Rear Panel

Rear Panel

Line Module

The line module contains the power cable receptacle. See “S tep 4 . Satisfy Electrical

and Environmental Requirements” for power supply requirements.

Power Cables The line power cable is supplied in one of several configurations, depending on the

destination of the original shipment.

Each instrument is equipped with a three-wire power cable. When connected to an

appropriate ac power receptacle, this cable grounds the instrum ent chassis . The type

of power cable shipped with each instrument depends on the country of destination.

See Figure 4-3 for the part numbers of these power cables. Cables are available in

different lengths. Check with your nearest Agilent service center for descriptions

and part numbers of cables other than those described in Figure 4-3.

WARNING This is a Safety Class I product (provided with a protective earthing ground

incorporated in the power cord). The mains plug shall only be inserted in a

socket outlet provided with a protective earth contact. Any interruption of the

protective conductor, inside or outside the instrument, is likely to make the

instrument dangerous. Intentional interruption is prohibited.

Chapter 4 55

Page 64

Front/Rear Panel

Rear Panel

Figure 4-3 Power Cable and Line (Mains) Plug Part Numbers

56 Chapter 4

Page 65

5Key Reference

57

Page 66

Key Reference

This chapter contains an alphabetical reference of the networ k analyzer keys that are

used exclusively for the multiport test set. It also contains entries for some of the

network analyzer keys that are likely to be used while making measurements with

your multiport test set. For a complet e referen ce of net wor k anal yzer keys , see yo ur

analyzer’s User’s Guide.

58 Chapter 5

Page 67

Cal Menu

-G[UVTQMG

-G[UVTQMG (WPEVKQP

-G[UVTQMG-G[UVTQMG

[Cal] Displays the softkeys related to setting and executing calibration.

(WPEVKQP 5%2+EQOOCPF

(WPEVKQP(WPEVKQP

Key Reference

Cal Menu

5%2+EQOOCPF

5%2+EQOOCPF5%2+EQOOCPF

Correction Toggles on/off the error correction.

:SENS{1-4}:CORR:STAT

Test Set Cal Displays the softkeys to execute multi-port test set calibration.

Te st Set Cal Enables/disables the calibration data for the multi-port

:SENS{1-4}:CORR:MULT

test set.

Calibration Displays the softkeys to select ports for which you want to perform the calibration of

the multi-port test set or select a calibration method.

Port 1-2

Port1 Open Executes open calibration for port 1 of the multi-port

Port1 Short Executes short calibration for port 1 of the multi-port

Port1 Load Executes load calibration for port 1 of the multi-port test

Port2 Open Executes open calibration for port 2 of the multi-port

Port2 Short Executes short calibration for port 2 of the multi-port

Port2 Load Executes load calibration for port 2 of the multi-port test

Displays the softkeys to calibrate ports 1 and 2 of the multi-port test set.

:SENS{1-4}:CORR:MULT:C

test set.

test set.

set.

test set.

test set.

set.

OLL:OPEN 1

:SENS{1-4}:CORR:MULT:C

OLL:SHOR 1

:SENS{1-4}:CORR:MULT:C

OLL:LOAD 1

:SENS{1-4}:CORR:MULT:C

OLL:OPEN 2

:SENS{1-4}:CORR:MULT:C

OLL:SHOR 2

:SENS{1-4}:CORR:MULT:C

OLL:LOAD 2

Port1-2 Thru Executes thru calibration for ports 1 and 2 of the

multi-port test set.

Port1-2 Isol

(Optional)

Executes isolation calibration for ports 1 and 2 of the

multi-port test set.

Chapter 5 59

:SENS{1-4}:CORR:MULT:C

OLL:THRU 2,1

:SENS{1-4}:CORR:MULT:C

OLL:ISOL 2,1

Page 68

Key Reference

Cal Menu

-G[UVTQMG

-G[UVTQMG (WPEVKQP

-G[UVTQMG-G[UVTQMG

(WPEVKQP 5%2+EQOOCPF

(WPEVKQP(WPEVKQP

5%2+EQOOCPF

5%2+EQOOCPF5%2+EQOOCPF

[Cal]

(Continued)

Test Set Cal

Calibration

Port 1-2

ECal Executes 2-port ECal for ports 1 and 2 of the mu lti- po rt

test set.

:SENS{1-4}:CORR:MULT:C

OLL:ECAL 2,1

Return Returns to the softkey display in one level upper.

Port 3-4 Displays the softkeys to calibrate ports 3 and 4 of the multi-port test set. The lower

level softkeys displayed are the same as those for Port 1-2

.

:

Port 11-12 Displays the softkeys to calibrate ports 11 and 12 of the multi-port test set. The lower

level softkeys displayed are the same as those for Port 1-2.

Cal Type Selects a calibration method for calibrating each port of

the multi-port test set.

Cal Kit

Displays the softkeys to select a calibration kit to calibrate the multi-port test set. The

:SENS{1-4}:CORR:MULT:C

OLL:METH

softkey labels for the calibration kit differ depending on the registered data.

85033E Selects the 85033E calibration kit.

:SENS{1-4}:CORR:COLL:C

KIT 1

: :

User Selects a calibration kit newly registered.

Cancel Returns to the softkey display in one level upper.

Done Finishes the calibratio n and calculates the calibration

coefficients.

Return Returns to the softkey display in one level upper.

Self Cal Toggles on/off the auto calibration feature using the

internal standard of the multi-port test set.

60 Chapter 5

:

:SENS{1-4}:CORR:COLL:C

KIT 10

:SENS{1-4}:CORR:MULT:C

OLL:SAVE

:SENS{1-4}:CORR:MULT:SE

LF

Page 69

-G[UVTQMG

-G[UVTQMG (WPEVKQP

-G[UVTQMG-G[UVTQMG

(WPEVKQP 5%2+EQOOCPF

(WPEVKQP(WPEVKQP

Key Reference

Cal Menu

5%2+EQOOCPF

5%2+EQOOCPF5%2+EQOOCPF

[Cal]

(Continued)

Test Set Cal

Timer Specifies the execution interval of the auto calibration

feature using the internal standard of the multi-port test

set. You can specify 1 or more in minutes.

Self Cal Once Executes the auto calibration feature using the internal

standard for the specified port of the multi-port test set.

Return Returns to the softkey display in one level uppe r.

Return Returns to the softkey display in one level upper .

:SENS{1-4}:CORR:MULT:SE

LF:TIM

:SENS{1-4}:CORR:MULT:SE

LF:ONCE

Chapter 5 61

Page 70

Key Reference

System Menu

System Menu

-G[UVTQMG

-G[UVTQMG (WPEVKQP

-G[UVTQMG-G[UVTQMG

(WPEVKQP 5%2+EQOOCPF

(WPEVKQP(WPEVKQP

5%2+EQOOCPF

5%2+EQOOCPF5%2+EQOOCPF

[System]

87075 Setup Displays the softkeys related to setting the multi-port test set.

87075 Contr ol Enables/disables the multi-port test set.

Reflection Displays the softkeys to select the port for the reflection side of the multi-port test set.

Port 1 Select s Port 1 as the reflection-side port.

:

Port 12 Selects Port 12 as the reflection-side port.

Cancel Aborts the selection and returns to the softkey display in one level upper.

Transmission Displays the softkeys to select the port for the transmission side of the multi-port test

Port 1 Select s Port 1 as the transmission-side port.

:

Port 12 Selects Port 12 as the transmission-side port.

Cancel Aborts the selection and returns to the softkey display in one level upper.

Displays the softkeys related to co ntrol/management features of the ana lyzer.

:SENS{1-4}:MULT

:SENS{1-4}:MULT:PORT1:S

EL 1

:SENS{1-4}:MULT:PORT1:S

EL 12

set.

:SENS{1-4}:MULT:PORT2:S

EL 1

:SENS{1-4}:MULT:PORT2:S

EL 12

Property T o ggles on/of f the c onnection status (propertie s) display

of the multi-port test set.

:SENS{1-4}:MULT:PROP

..

..

..

62 Chapter 5

Page 71

-G[UVTQMG

-G[UVTQMG (WPEVKQP

-G[UVTQMG-G[UVTQMG

(WPEVKQP 5%2+EQOOCPF

(WPEVKQP(WPEVKQP

Key Reference

System Menu

5%2+EQOOCPF

5%2+EQOOCPF5%2+EQOOCPF

[System]

87075 Setup

Return Returns to the softkey display in one level uppe r.

Return Returns to the softkey display in one level upper .

(Continued)

Chapter 5 63

Page 72

Key Reference

System Menu

64 Chapter 5

Page 73

6 SCPI Command Reference

This chapter describes the SCPI command reference for the Agilent

E5061A/E5062A to con tr ol the Agilent 87075C Multi Port Test Set. It describes the

commands using their abbreviated format in alphabetical order.

65

Page 74

SCPI Command Reference

Syntax

Notational conventions in this command reference

This section describes the rules to read the description of the commands in this chapter.

Syntax

Part with heading "Syntax" describes the syntax to send a comm and from the

external controller to the E5061A/E5062A. A syntax consists of a command part

and a parameter part. The separator between the command part and the parameter

part is a space.

If there are several parameters, the separator between adjacent parameters is a

comma (,). 3 points (…) between commas indicate that parameters in that part are

omitted. For example, <value 1>,…,<value 4> indicates that 4 parameters, <value

1>,<value 2>,<value 3>,<value 4>, are required. String-type parameters, <string>,

<string 1>, and so on, must be enclosed in double quotation marks (").

You can omit the lowercase letters in syntax. For example, ":CALibration:CABLe"

can be shortened as ":CAL:CABL.

The definition of symbols used in the syntax is as follows:

<> Characters enclosed in this pair of symbols are necessary

parameter s when sending the command.

[] Part enclosed in this parenthesis pair can be omitted.

{} Part enclosed in this parenthesis pair indicates that you must

select one of the items in this part. Individual items are

separated by a vertical bar (|).

For example, ":CALC:CORR:EDEL:TIME 0.1,"

":CALCULATE1:SELECTED:CORR:EDEL:TIME 25E-3," and so on are valid for

the syntax given below.

Syntax :CALCulate{[1]|2|3|4|5|6}[:SELected]:CORRection:EDELay:TIME <value>

Description

Part with heading "Description" descri bes how to us e the command or the operat ion when executed.

66 Chapter 6

Page 75

SCPI Command Reference

Query response

Parameters

Part with heading "Parameters" describes necessary parameters when sending the

command. When a parameter is a value type or a string type enclosed with <>, its

description, allowable setup range, preset (factory-set) value, and so on are given;

when a parameter is a selection type enclosed with { }, the description of each

selection item is given.

For a value-type parameter noted with "MAX or MIN is available," you can use

MAX (or MAXIMUM) and MIN (or MINIMUM) as its parameter instead of a

value, which specifies the maximum value and minimum value within the allowable

setup range, respectively.

Query response

Part with heading "Query response" describes the data format read out when query

(reading out data) is available with the command.

Each readout parameter is enclosed with {}. If there are several items within {}

separated by the pipe (|), only one of them is read out.

When several parameters are read out, they are separated with a comma (,). Note

that, 3 points (…) between commas indicate that the data of that part is omitted. For

example, {numeric 1},…,

{numeric 4} indicates that 4 data items, {numeric 1}, {numeric 2}, {numeric 3},