Page 1

Agilent 86140BSeries

Optical Spectrum Analyzer

User’s Guide

Page 2

© Copyright

Agilent Technologies 2001

All Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibit ed ,

except as allowed under copyright laws.

Agilent Part No. 86140- 90 06 8

Printed in USA

January 2002

Agilent Technologies

Lightwave Division

3910 Brickway Boulevard,

Santa Rosa, CA 95403, USA

Notice.

The information contained in

this document is subject to

change without notice. Companies, names, and data used

in examples herein are fictitious unless otherwise noted.

Agilent Technologies makes

no warranty of any kind with

regard to this material, including but not limited to, the

implied warranties of merchantability and fitness for a

particular purpose. Agilent

Technologies shall not be liable for errors contained herein

or for incidental or consequential damages in connection with the furnishing,

performance, or use of this

material.

Restricte d Ri ghts Legend.

Use, duplication, or disclosure by the U.S. Government

is subject to res tric tio ns as se t

forth in subparagraph (c) (1)

(ii) of the Rights in Technical

Data and Computer Software

clause at DFARS 252.227-7013

for DOD agencies, and subparagraphs (c) ( 1) and (c) (2 )

of the Commercial Computer

Software Restricted Rights

clause at FAR 52.227-19 for

other agencies.

Warranty.

This Agilent Technologies

instrument product is warranted against defects in

material and workmanship for

a period of one y ear f rom date

of shipment. During the warranty period, Agilent Technologies will, at its option, either

repair or replace products

which prove to be defective.

For warranty service or repair,

this product mu st be re tur ned

to a service facility designated by Agilent Technologies. Buyer shall prepay

shipping charges to Agilent

Technologies and Agilent

Technologies shall pay shipping charges to return the

product to Buyer. However,

Buyer shall pay all shipping

charges, duties, and taxes for

products returned to Agilent

Technologies from another

country.

Agilent Technologies warrants that its software and

firmware designated by Agilent Technologies for use with

an instrument will execute its

programming instructions

when properly installed on

that instrument. Agilent Technologies does not warrant that

the operation of the instrument, or software, or firmware

will be uninterrupted or errorfree.

Limitation of Warranty.

The foregoing warranty shall

not apply to defects resulting

from improper or inadequate

maintenance by Buyer, Buyersupplied software or interfacing, unauthorized modification or misuse, ope ra tio n

outside of the environmental

specifications for the product,

or improper site preparation

or maintenance.

No other warranty is

expressed or implied. Agilent

Technologies specifically disclaims the implied warranties

of merchantability and fitness

for a particular purpose.

Exclusive Remedies.

The remedies provided herein

are buyer's sole and exclusive

remedies. Agilent Technologies shall not be liable for any

direct, indirect, speci a l, inci-

dental, or consequential damages, whether based on

contract, tort, or any other

legal theory.

Safety Symbols.

CAUTION

The caution sign denotes a

hazard. It calls attenti on to a

procedure which, if not correctly performed or adhered

to, could result in damage to

or destruction of the product.

Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

WARNING

The warning sign denotes a

hazard. It calls attenti on to a

procedure which, if not correctly performed or adhered

to, could result in injury or

loss of life. Do not proceed

beyond a warning sign until

the indicated conditions are

fully understood and met.

The instruction manual symbol. The product is marked wit h this

warning symbol when

it is necessary for the

user to refer to the

instructions in the

manual.

The laser radiation

symbol. This warning

symbol is marked on

products which have a

laser output.

The AC symbol is used

to indicate the

required nature of the

line module input

power.

| The ON symbols are

used to mark the positions of the instrument

power line switch.

The OFF symbols

are used to mark the

positions of the instrument power line

switch.

The CE mark is a registered trademark of

the European Community.

The CSA mark is a registered trademark of

the Canadian Standards Association.

The C-Tick mark is a

registered trademark

of the Australian Spectrum Management

Agency.

This text denotes the

ISM1-A

instrument is an

Industrial Scientific

and Medical Group 1

Class A product.

Typographical Conventions.

The following conventions are

used in this book:

Key type for keys or text

located on the keyboard or

instrument.

Softkey type for key names that

are displayed on the instrument’s screen.

Display type for words or

characters displayed on the

computer’s screen or instrument’s display.

User type for words or charac-

ters that you type or enter.

Emphasis type for words or

characters that emphasize

some point or that are used as

place holders for text that you

type.

ii

Page 3

General Safety Considera tions

General Safety Considerations

This product has been designed and tested in accordan c e w ith the standards

listed on the Manufacturer’s Declaration of Conformity, and has been supplied

in a safe condition. The documentation contains infor mation and warnings

that must be followed by the user to ensure safe operation and to maintain the

product in a safe condition.

Install the ins trument according to the enclosure protection provided.

This instrument does not protect ag a inst the ingress of wa te r.

This instrument protects against finger access to hazardous parts within the

enclosure.

WARNI NG If this product is not used as specified, the protection provided by the

equipment could be imp aired. This product must be used in a normal

condition (in which all means for protection are intact) only.

WARNI NG No operator serviceable parts inside. Refer servicing to qualified

service personnel. To prevent electrical shock do not remove covers.

WARNI NG This is a Safety Class 1 Product (provided with a protectiv e earthing

ground incorporated in the power cord). The mains plug shall only be

inserted in a socket outlet provided with a protective earth contact.

Any interruption of the protective c o nductor inside or outside of the

instrument is likely to make the instrument dangerous. Intentional

interruption is prohi bited.

WARNI NG To prevent electrical shock, disconnect the instrument from mains

before cleaning. Use a dr y cloth or one slightly dampened with water

to clean the external case parts. Do not attempt to clean internally.

CAUTION Fiber-optic connectors are easily damaged when connected to dirty or

damaged cables and accessories. The Agilent 86140B series’s fr ont-pa nel INPUT

connector is no exception. Whe n y o u use im proper cleaning and handling

techniques, you risk expensive instrument repairs, damaged cables, and

compromised measurements. Before you connect any fiber-optic cable to the

Agilent 86140B se ri es , re fe r to “Cleaning Connection s for Accurate

Measurements” on page 6-8.

iii

Page 4

General Safety Considera tions

CAUTION This product i s designed for use in Installation Category II and Pollution

Degree 2 per IEC 61010- 1C and 664 respectively.

CAUTION Do not use too much liquid in cleaning the optical spectrum analyzer. Water can

enter the fron t-panel keyboard, damaging sensitive electronic compon ents.

CAUTION VENTILA TION RE QUIREMENTS: When installing t he product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperatur e of the product by 4

° C for every 100 watts dissipated in the

cabinet. If the total power dissipated in the cabinet is gr eater than 800 watts,

then forced convection must be used.

CAUTION Install the instrument so that the detachable power cord is readily identifiable

and is easily reached by the operator. The detachable power cord is the

instrument disconne cti ng d evice. It disconnects the mains circui t from the

mains supply befo re other parts of the instrument. The front pane l switch is

only a standby switch and is not a LINE switch. Alternatively, an externally

installed switch or circuit breaker (which is readily identifiable and is easily

reached by the operator) may be used as a disconnecting device.

CAUTION Always use the three-prong AC power cord supplied with this instrument.

Failure to ensure adeq uate earth grounding by not us ing this cord may cause

instrument damage .

CAUTION Do not connect ac power until you have verified the line voltage is correct as

described in “Line Power Requirements” on page 1-11. Dam a ge to the

equipment could result.

CAUTION This instrument has autoranging line voltage input. Be sure the supply voltage

is within the specified range.

CAUTION The Agilent 86140B, 86141B, 86144B, 86146B and 86142B Option 004/005/006

EELED sources contain an IEC Class 1 LED, according to IEC 60825.

CAUTION Use of controls or adjustment or performance of procedures othe r than those

specified herein may result in hazardous radiation exposure.

iv

Page 5

Contents

1 Getting Started

Product Overview 1-2

Setting Up the Analyzer 1-8

Making a Measurement 1-13

The Menu Bar 1-17

The Softkey Pane ls 1 - 1 8

Laser Safety Considerations 1-29

Product Options and Accessories 1-30

2 Using the Instrument

Setting Up Measurements 2-2

Calibrating Wavelength Measurements 2-14

Saving, Recalling, and Managing Fi le s 2- 19

Analyzing Measurement Data 2-27

Analyzer Operating Mo des 2-30

3 Function Reference

4 Remote Front Pan el Operation

Remote Front Panel 4-2

5 Status Listings

Overview 5-2

Error Reporting Behavior 5-4

SCPI-Defined Errors 5-5

OSA Notices 5-1 6

OSA Warnings 5-17

Application -Specific Warnings 5-29

OSA Status Errors 5-35

OSA Errors 5-36

Firmware Errors 5-38

6 Maintenance

Changing the Printer Paper 6-2

Printer Head Cleaning Procedure 6-4

Cleaning Connections for Accurate Measurements 6-8

Returning the Instrument for Service 6-21

Contents-1

Page 6

Contents

7 Specifications and Regulatory Information

Definition of Terms 7-3

Specifications 7-5

Regulatory Information 7-21

Declaration of Conformity 7-22

Contents-2

Page 7

1

Product Overview 1-2

Setting Up the Analyzer 1-8

Making a Measurement 1-13

The Menu Bar 1-17

The Softkey Pane ls 1-18

Laser Safety Considerations 1-29

Product Options and Accessories 1-30

Getting Started

Page 8

Getting Started

Product Overview

Product Overview

The 86140B series of optical spectrum analy z er s provide fast, accurate, and

comprehensive measurement capabilities for spectral analysis.

• Full-featured SCPI c omm a nd s f or pr ogramming instruments over LAN

• Display-off feature for making faster measurements

• Remote file saving and printing for outputting measure m ent results

• Filter mode for accurate and flexible measurements

• Built-in applications for accelerating test times

Filter Mode The Agilent 861 44B and 86146B filter mode allows single dense wavelength

division mul ti plexing (DWDM) to be isolated and routed to external test

equipment. The filter mode capability is built-in to internal applications to

allow for fast and easy implementation of channel dropping. For Agilent

86146B instruments, this mode also allows the ability to measure time resolve

chirp (TRC).

Built-in

Applications

Built-in applications allow fast, repeatable measurements for WDM systems,

lasers, amplifiers, a nd pas sive components. These applications can be added

through a firmware upgrade.

WDM Application

This application allows you to measure DWDM sub-system components, (such

as transmission sub-systems, optical add/drop multiplexers, and multiplexers/

de-multiplexers) for param et er s suc h as opti cal sig nal - to-noise ratio (OSNR),

channel wavelength, channel power, and span tilt.

Passive Component Test Application

This applicati on simplifies the testing of passive c o m p onents, such as fi lte rs,

couplers, and isolators by defining a test plan that measures parameter s such

as insertion and return loss, bandwi dth, and filter shape.

1-2

Page 9

Getting Started

Product Overview

Source Test Application

This application offers automated optical source and laser characterization.

Amplifier Test Application

This applicatio n simplifies the process of characterizin g ga in and noise figure

of optical amplifiers such as EDFA’s, SOA’s and Raman amplifiers.

1-3

Page 10

Getting Started

Product Overview

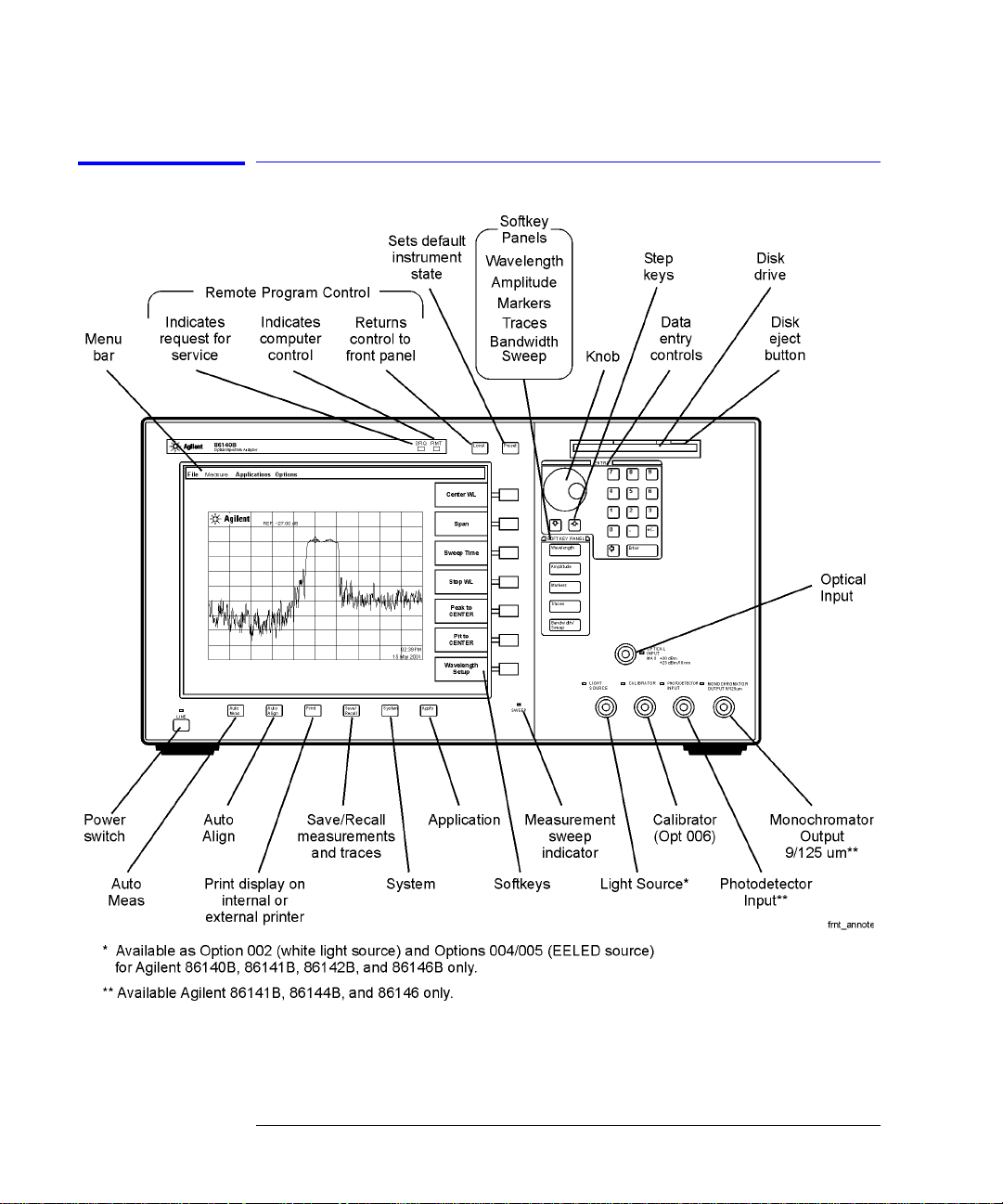

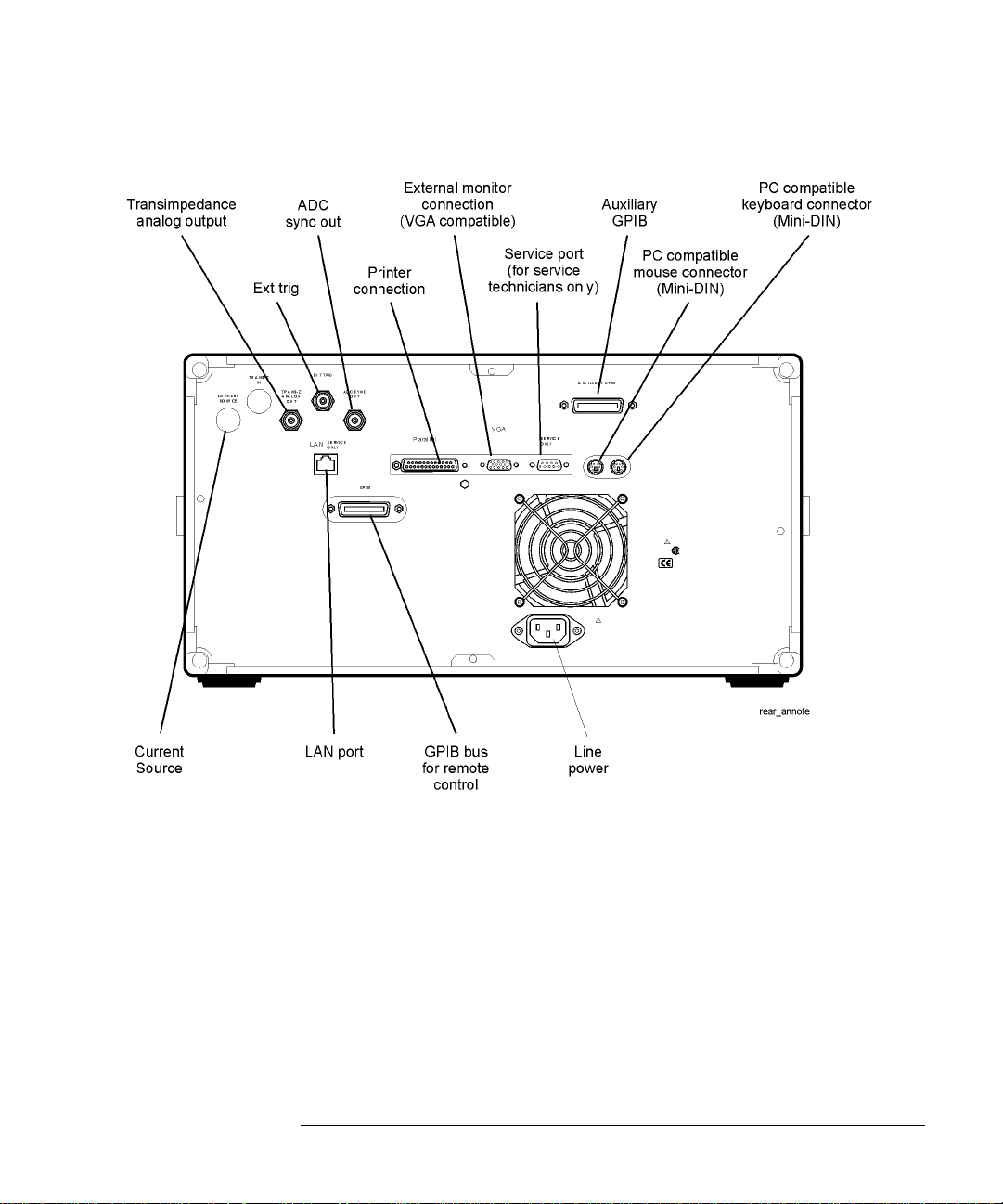

Agilent 86140B Front and Rear Panels

1-4

Page 11

Getting Started

Product Overview

1-5

Page 12

Getting Started

Product Overview

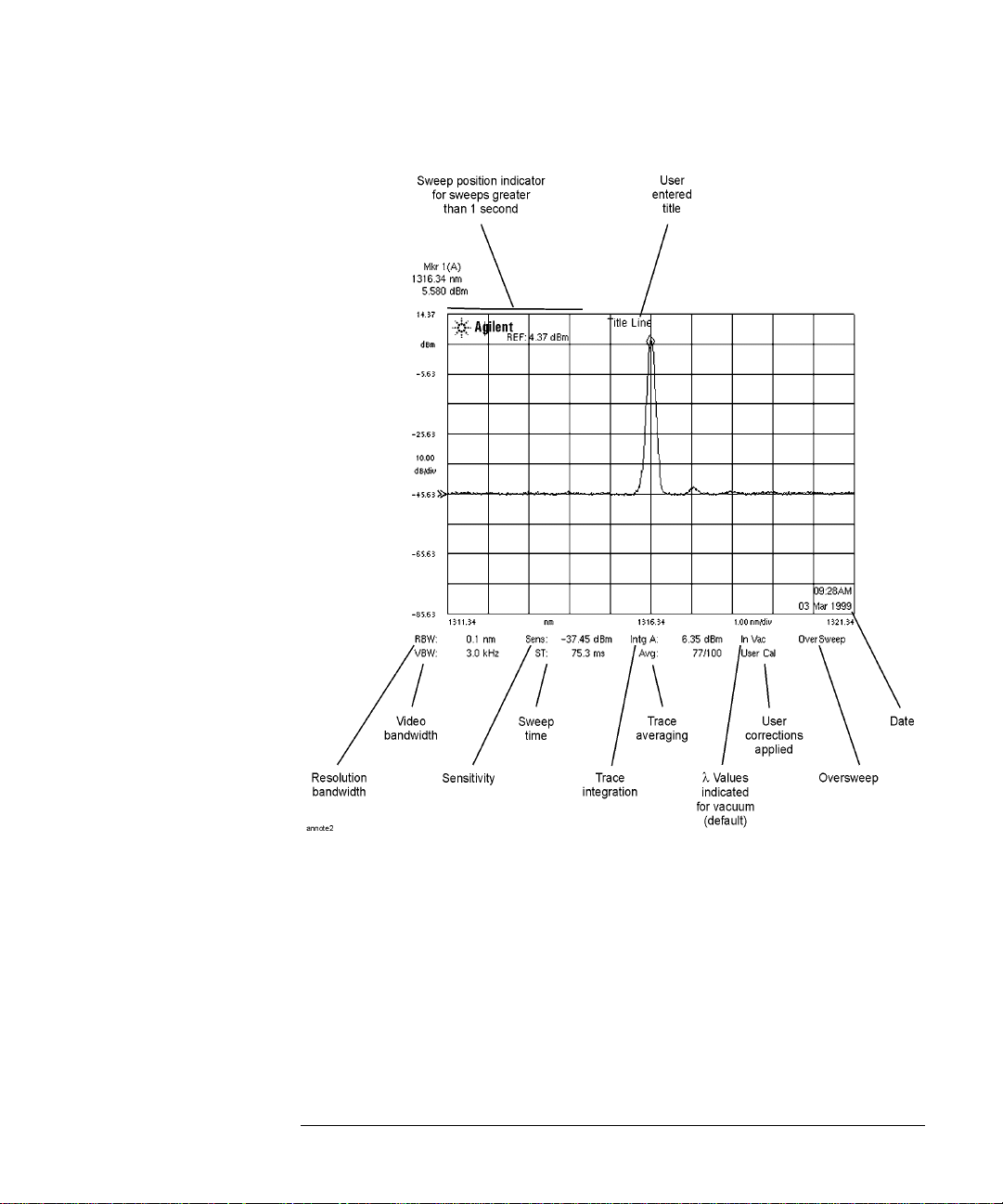

Optical Spectrum Analyzer Display

Figure 1-1. Optical Spectrum An aly zer Display

1-6

Page 13

Getting Started

Product Overview

Figure 1-2. Display Annotations

1-7

Page 14

Getting Started

Setting Up the Ana lyzer

Setting Up the Analyzer

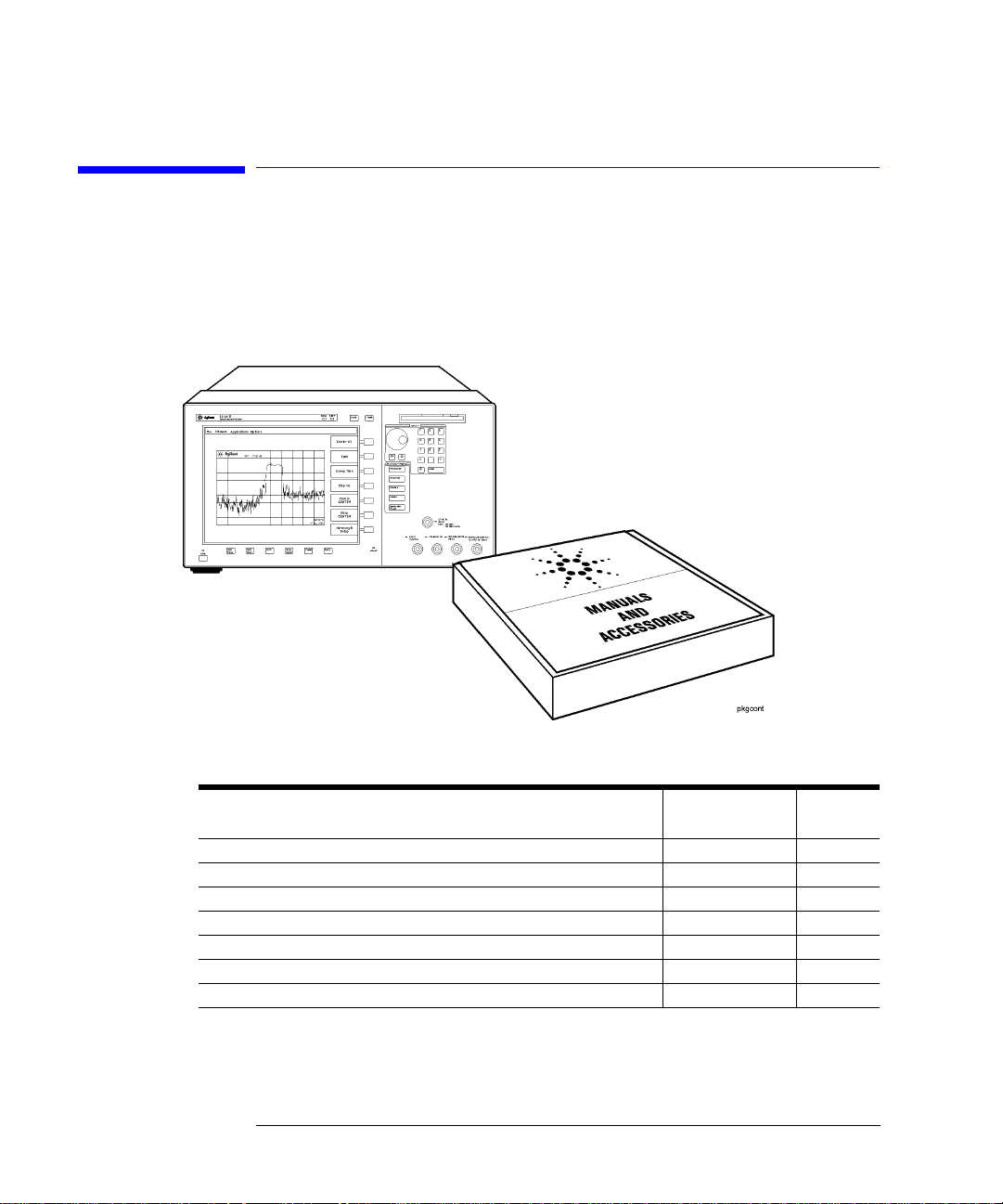

Step 1. Receive and Inspect the Shipment

Table 1-1.Items in a Standard Agilent 86140B Series Shipment

Description Product Number

BNC Cable (24 inches) 8120-1839 1

GPIB Cable 8120-3444 1

FC/PC Dust Cap 1401-0291 2

English User’s Guide Manual 86140-90068 1

Application Guide 86140-90071 1

Programming Guide 86140-90069 1

Quick Start Card 86140-90087 1

1-8

Item

Quantity

Page 15

Getting Started

Setting Up the Analyzer

Inspect the shipping container for damage.

Inspect the instrume nt.

Verify that you received the options and accessories you ordered.

Keep the shipping container and cushioning material until you have inspected

the contents of the shipment for completeness and have checked the optical

spectrum anal yz er mechanical ly and electrical ly.

If anything is missing or de fe ctive, contact your nearest Agile nt Tech nologies

Sales Office. Refer to “Returning the Instrument for Service” on page 6-21. If

the shipment was damaged, contact the carrier, then contact the nearest Agilent Technologies Sales Office. Keep the shipping materials for the carrier’s

inspection. The Agilent Technologies Sales Offi c e wi ll a rra nge for repair or

replacement at Ag ilent Technologies’ option without waiting for claim settl e-

ment.

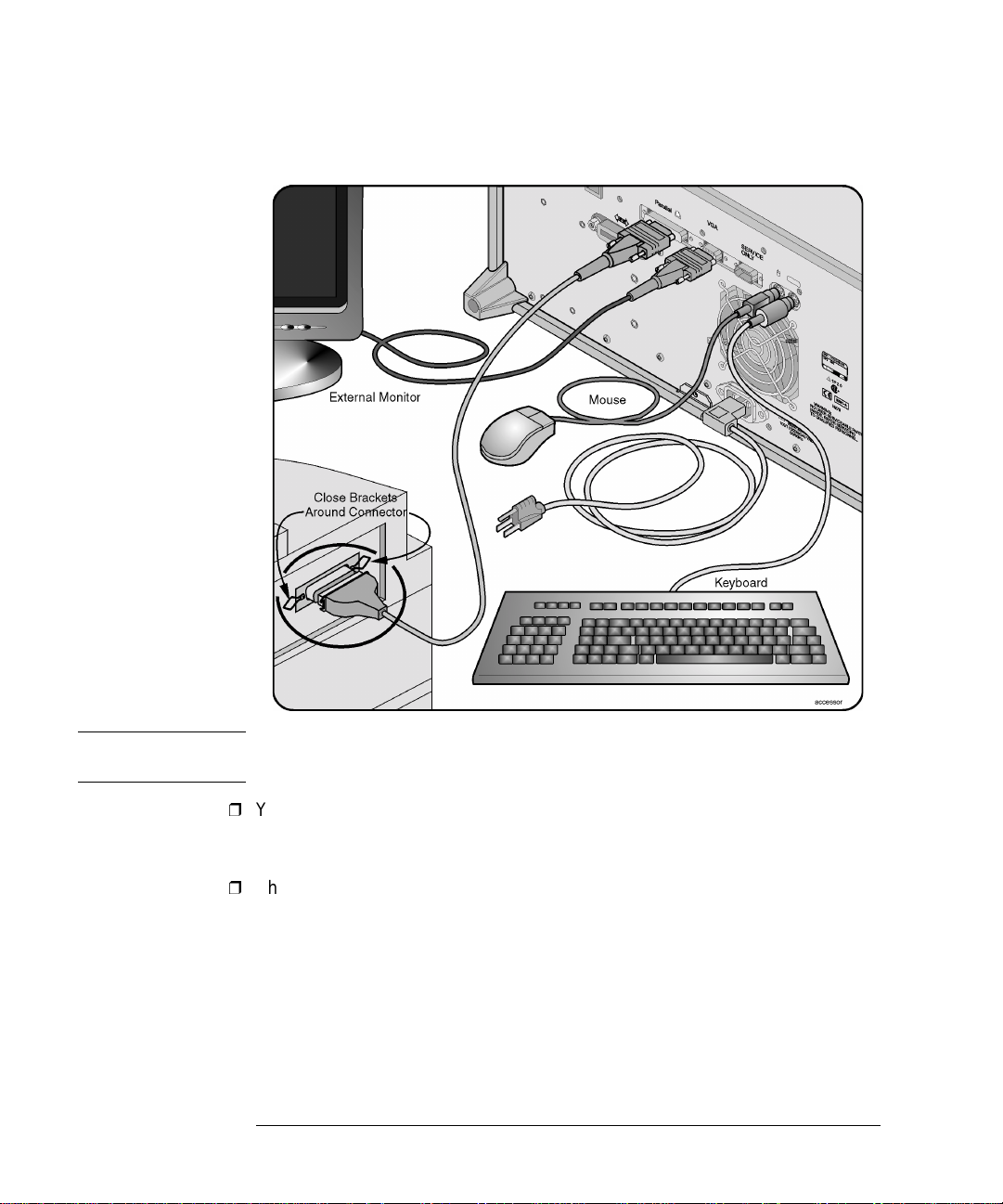

Step 2. Connect Accessories and Power Cord

Although you can operate all instrument functions using only the front-panel

keys, and trackball on portabl e m odels, these accessories make your op tical

spectrum analyzer easier to use. Connect any standard PC-compatible mouse

(or other pointing device), keyboard, or external VGA-comp a t ible display.

1-9

Page 16

Getting Started

Setting Up the Ana lyzer

CAUTION Do not stack other objects on the keyboard; this will cause self-test failures on

power-on.

You can connect a PCL-language printer (for example, an HP1 LaserJet) to the

instrument’s rear panel Parallel connector. Use a parallel Centronics printer cable, such as an HP C2950A (2 m) or HP C2951A (3 m).

The line cord provided is matched by Agilent Technologi es to the country of

origin on the order. Refer to “Accessories” on page 1-31.

1. HP and Hewlett-Packard are U.S. registered trademarks of Hewlett-Packard Company.

1-10

Page 17

Getting Started

Setting Up the Analyzer

Table 1-2. Line Power Requirements

Power 115 VAC: 110 VA MAX. / 60 WATT S MAX. / 1.1 A MAX.

230 VAC: 150 VA MAX. / 70 WATTS MAX. / 0.6 A MAX.

Voltage nominal: 115 VAC / 230 VAC

range 115 VAC: 90–132 V

range 230 VAC: 198–254 V

Frequency nominals: 50 Hz / 60 Hz

range: 47–63 Hz

Step 3. Apply Power to Instrument

Press the power switch at the lower left-hand corner of the front panel.

After a short ini tiali zation p eriod , the dis play wil l look simi lar to the pict ure on

this page.

Allow the instrument to warm up for at least 1 hour.

Step 4. Clean Connectors and Prepare for Measurements

CAUTION Fiber-optic connectors are easily damaged when connected to dirty or

damaged cables and accessories. The front-panel INP UT c o nnector of the

Agilent 86140B series is no exception. When you use improper cleaning and

handling techniques , y o u ri sk expensive instrument repairs, damaged cables,

and compromised measureme nts . Before you connect any fiber-optic cable to

the Agilent 86140B series o ptical spectrum ana lyzer, refer t o “Cleaning

Connections for Accurate Measurements” on page 6-8.

CAUTION A front-panel connector saver is provided with Agilent 86140B series

instruments. Attach the connector saver to the front-panel INPUT connector of

the instrument. You can now make your connections to the connector save r

instead of the instrument. This will help prevent damage to the front-panel

INPUT connector of the instrument. Damage to the front-panel INPUT connector

is expensive in terms of both repair costs and down-time. Use the front-panel

connector saver to prevent damage to the front-panel INPUT connector.

Note

All product specifications apply to measurements made without using the front-panel

connector saver.

After the instrument has warmed up for at least 1 hour, perform an auto align

1-11

Page 18

Getting Started

Setting Up the Ana lyzer

by pressing the fron t panel Auto Align button. This will ensure o ptimal amplitude accuracy, and can correct for any mis-alignment caused by the instrument

shipment.

T o learn more about this or any Agilent Technologies product, visit our web

site at http://www.agilent.com/ c m / in dex.shtml. Or, to learn more about fiber

optic test equipment, follow this path from the address listed:

1 Click Communications Produ cts.

2 Click Lightwave Measu rement Solutions.

3 Click Communications Solutions and then select Optical and Photonic

Solutions.

1-12

Page 19

Getting Started

Making a Measureme nt

Making a Measurement

This procedure will introduce you to the A gile nt 86140B series optical spectrum analyzer front panel controls. By following this procedure you will do the

following:

• Perform an auto alignment

• Perform a peak search

• Use a delta marker

• Print the display

Refer to “The Menu Bar” on page 1-17 and “The Softkey Panels” on page 1-18.

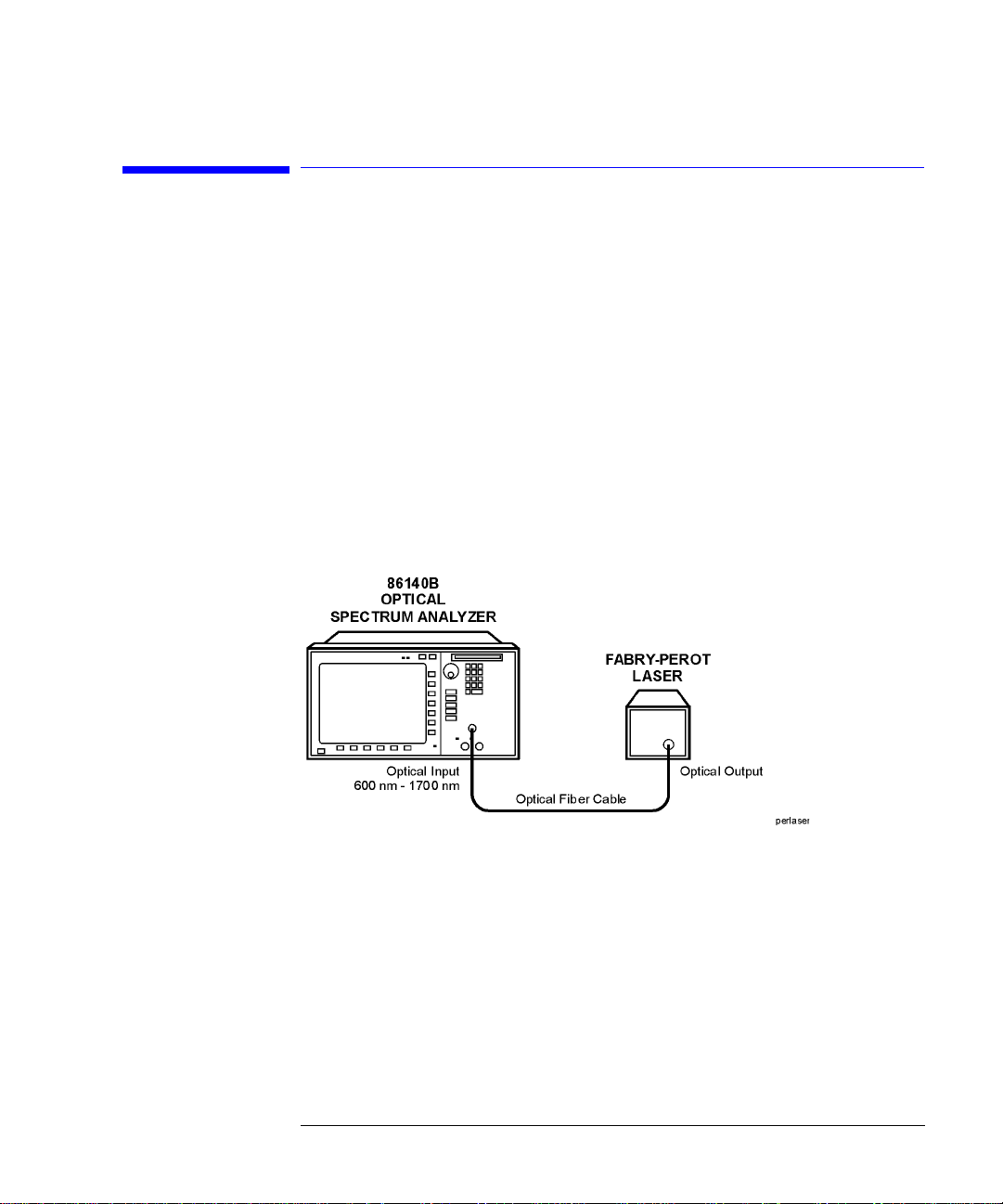

Instrument setup

A source signal must be present at the input of the optical spectrum analyzer.

In this procedure a Fabry-P erot laser is used as the source . You ca n use

another source or the optional 1310/1550 nm

used, the displa y w ill differ from tho s e sh ow n.

To set the OSA to a known state

• Press the front-panel Preset key to set the instrument to a known state. For

a complete description of preset conditions, see page 3-65.

EELED. If another source is be ing

1-13

Page 20

Getting Started

Making a Measurement

To perform an Auto Align

For maximum amplitude accuracy, perform an automatic alignment whenever

the optical spectrum analyzer has been moved, subjected to large temperature

changes, or fol lowing warm-up. See “Auto Align” on page 3-10 for more information.

1 Connect a fiber from the source to the input connector of the optical spectrum

analyzer. Be sure to follow the good connector practices described in “Cleaning

Connections for Accurate Measurements” on page 6-8.

2 Enable the source. Pre ss Markers > Peak Search to find the pe a k signal power.

3 Press the front-panel Auto Align key to optimize the detection of the incoming

signal. This takes a few mo ments to complete.

To perform a peak search

4 Press the front-panel Auto Meas key to locate and zoom-in on the si gnal. Plea se

wait until the Auto Measure routine is complete. A marker is placed on the peak

of the displayed signal.

Trace with normal marker.

1-14

Page 21

Getting Started

Making a Measureme nt

To zoom in on the signal

Press the Span softkey and then use the knob, step keys, or numeric keypad to

zoom in on the signal.

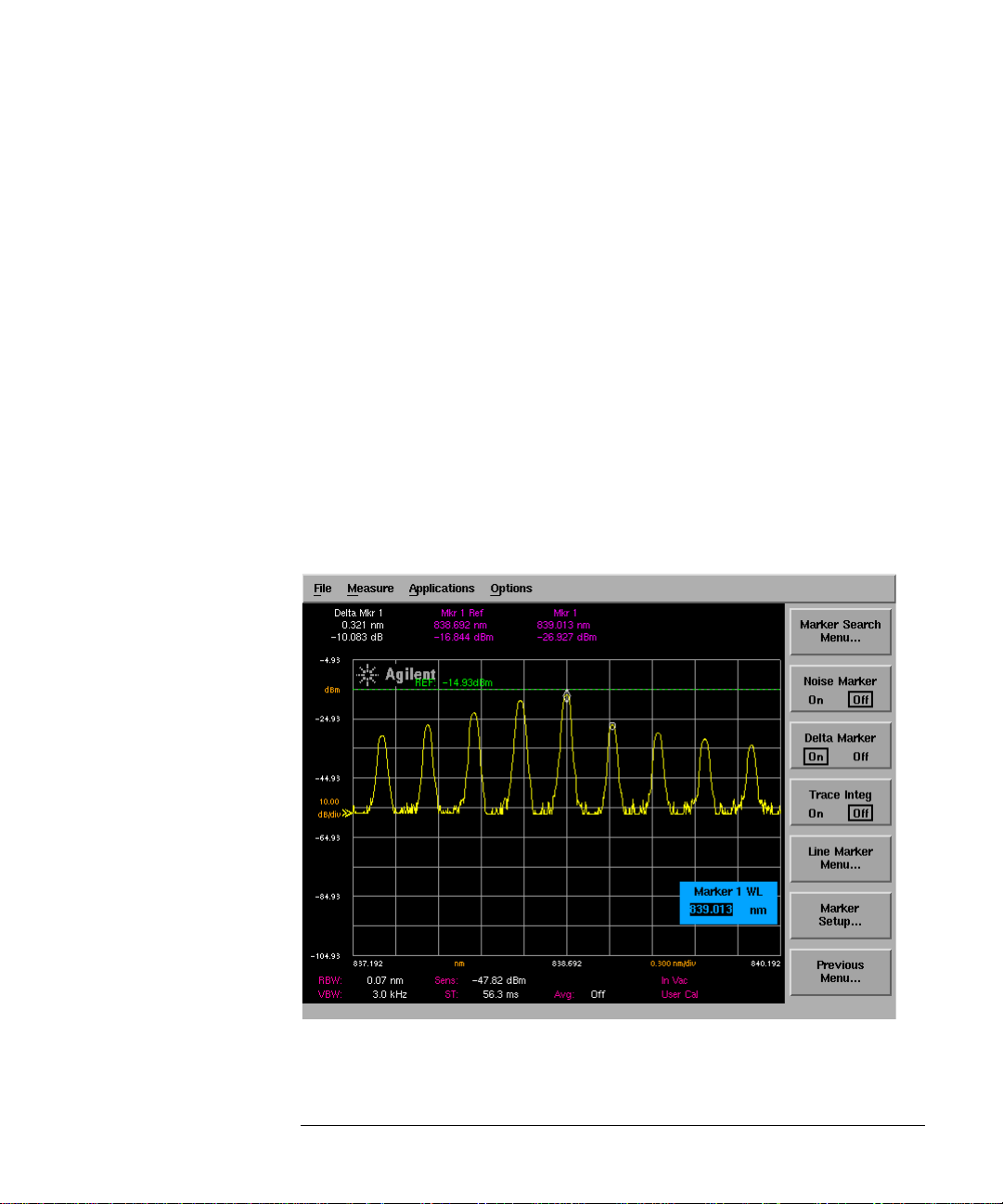

Using the delta marker

The optical spectrum analyzer has four types of markers; normal markers,

bandwidth markers, delta markers and noise markers. The marker currently

being displayed is a normal marker. In the next step we will use it as a delta

marker.

5 Press the front- panel Markers key.

6 Press the More Marker Functions.... softke y.

7 Press the Delta Marker softkey to activate the delta marker and the act iv e

function area.

8 Use the knob, step keys or nu meric entry pad to move the delta marker.

9 The reference marker remains station a ry.

Trace with delta marker.

1-15

Page 22

Getting Started

Making a Measurement

Printing the display

10 Press the Print key to print a copy of the display. The output will be sent to the

internal or external printer, depending on the printer selected.

1-16

Page 23

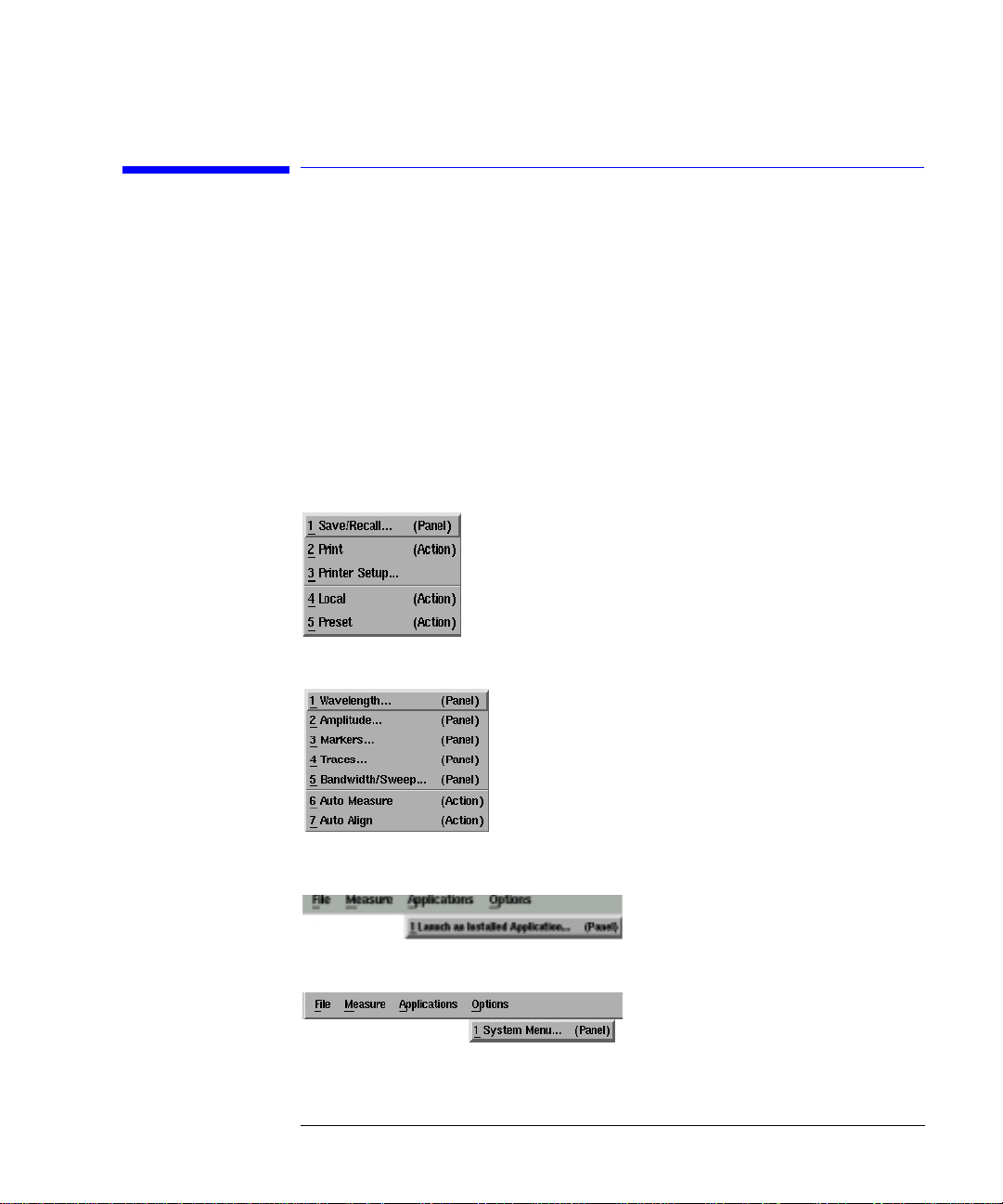

The File Menu

Getting Started

The Menu Bar

The Menu Bar

The Menu bar includes the File, Measure, Application, and Options drop-down

menus. Each menu selection includes a descriptive label.

(Action) Indicates the selection will perform an action such as

making a measurement or printing the display.

(Panel) Indicates th e selection will open a softkey panel.

The Measure

Menu

The Applications

Menu

The Options Menu

1-17

Page 24

Getting Started

The Softkey Pan els

The Softkey Panels

You can acce ss the soft key pane l s using eithe r the front-panel keys or the

menu bar. This section includes brief descriptions of the following menus. See

Chapter 3, “Function Reference” for additional information on each of the

OSA functions.

The Amplitude Menus 1-19

The Applications Menus 1-20

The Bandwidth/Sweep Menus 1-22

The Markers Menus 1-23

The Save/Recall Menus 1-24

The Systems Menus 1-25

The Traces Menus 1-27

The Wavelength Menus 1-28

1-18

Page 25

Getting Started

The Softkey Panels

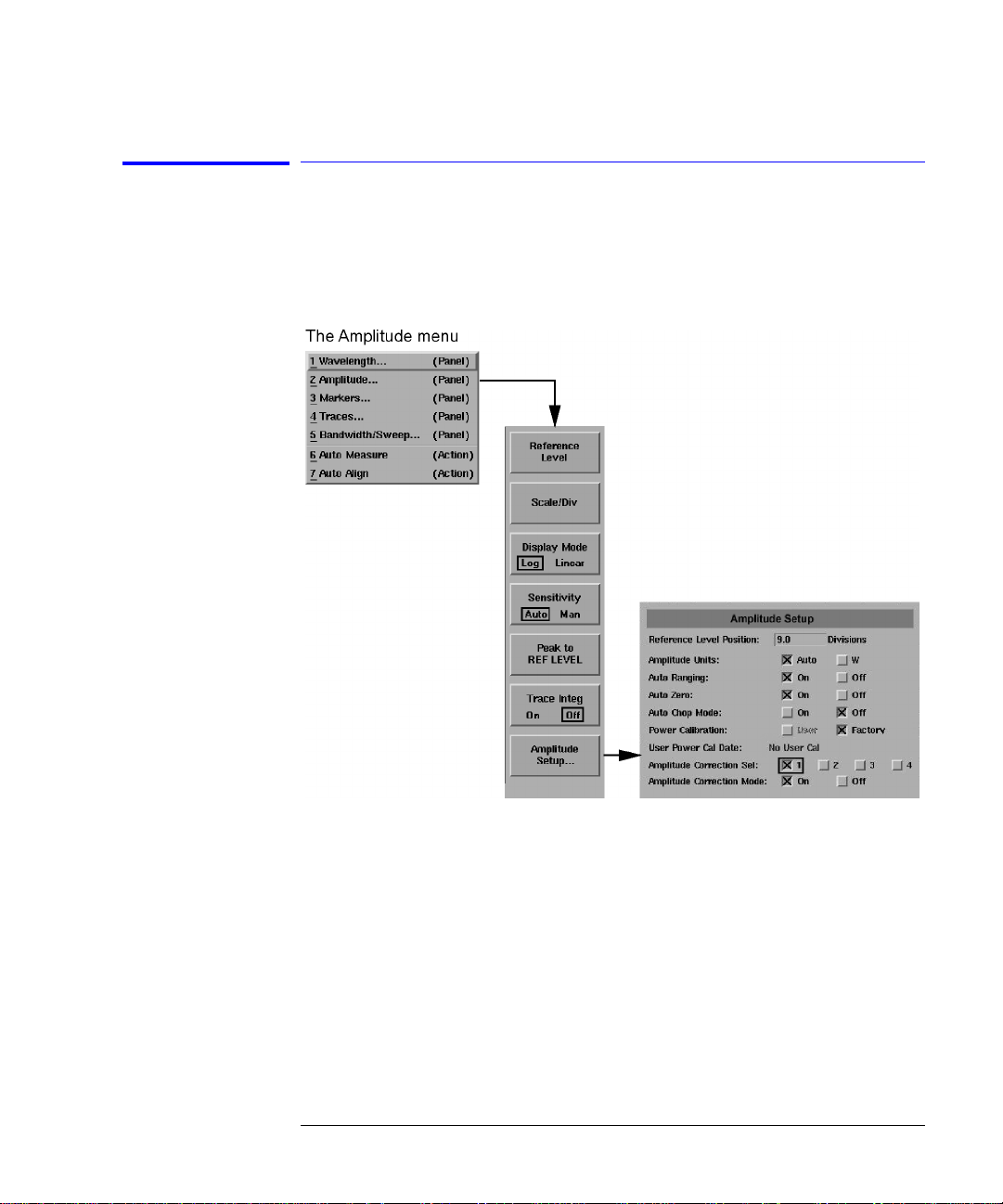

The Amplitude Menus

You can access the Amplitude softkeys using the front-panel Amplitude key or

the Measure menu Ampli tude selection on the menu bar.

1-19

Page 26

Getting Started

The Softkey Pan els

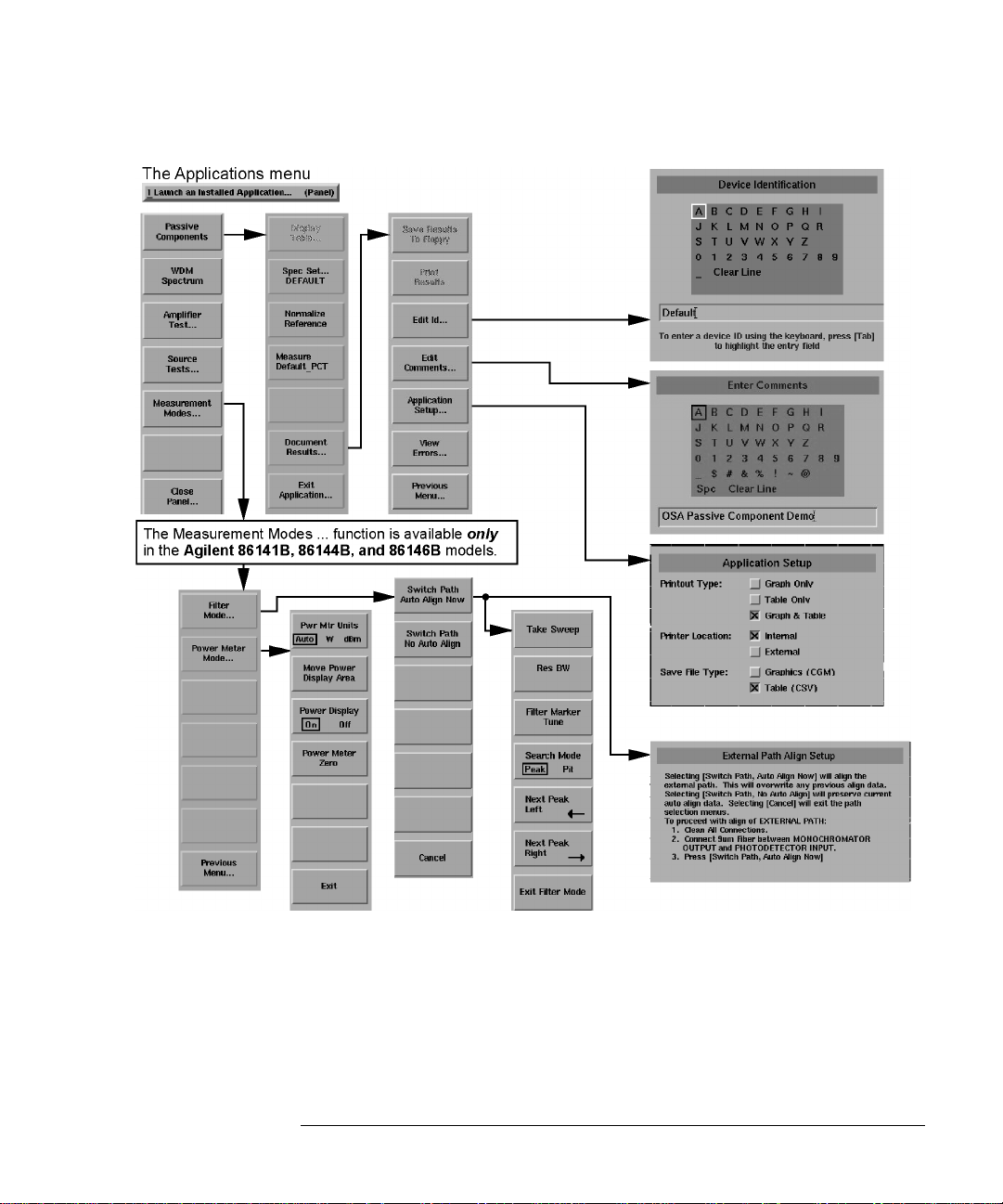

The Applications Menus

You can access the Applications (Appl’s) softkeys by using the front-panel

Appl’s key or the Applications menu Launch an Installed Application section on

the menu bar. For a complete description of the appli cations, refer to the Agilent 86140B Series Measurement Applications User’s Guide that came w it h

your instrument .

1-20

Page 27

Getting Started

The Softkey Panels

1-21

Page 28

Getting Started

The Softkey Pan els

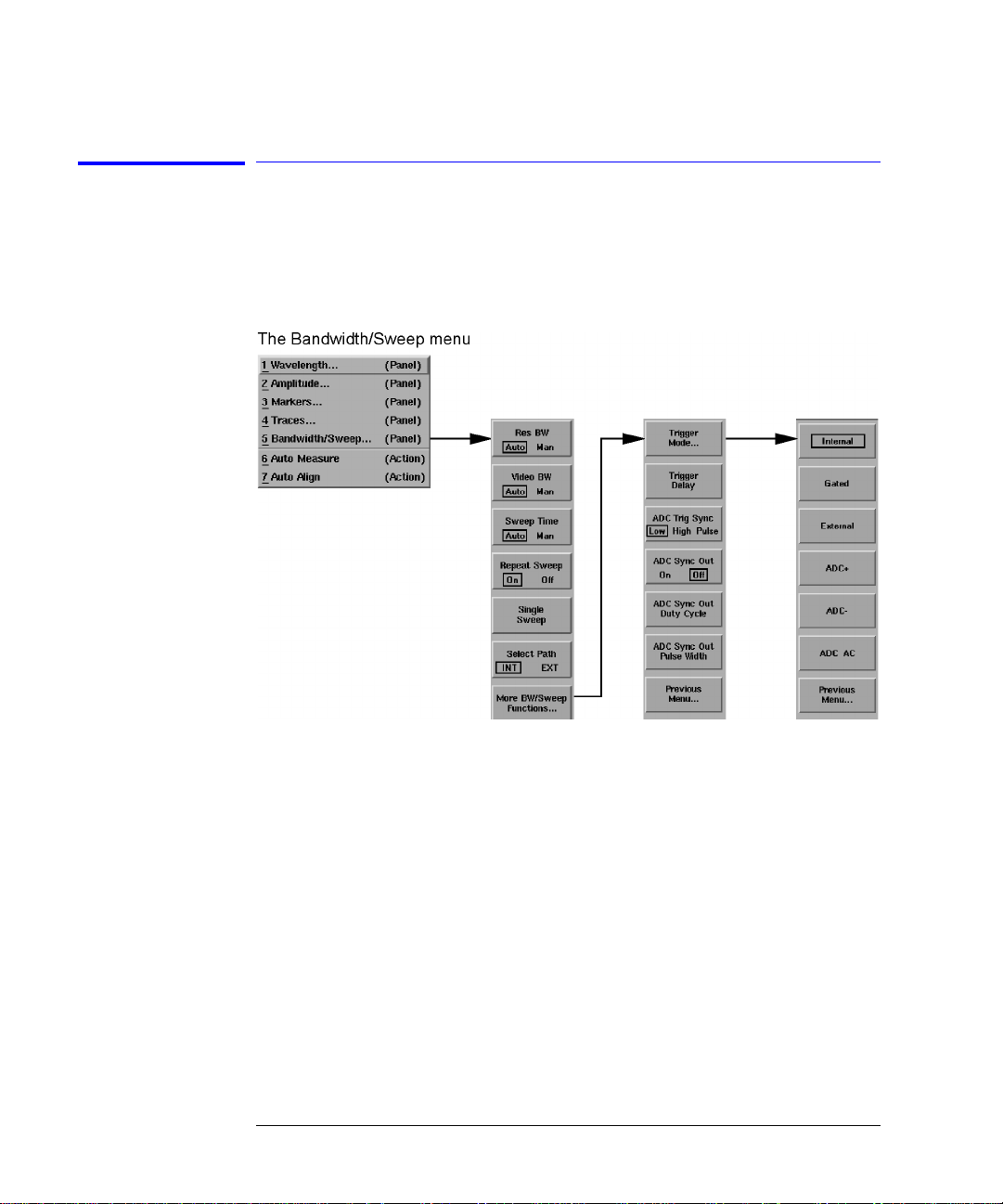

The Bandwidth/Sweep Menus

You can access the Bandwidth/Sweep softkeys by using the front-panel Bandwidth/Sweep key or the Measure menu Bandwidth/Sweep selection on the

menu bar.

1-22

Page 29

Getting Started

The Softkey Panels

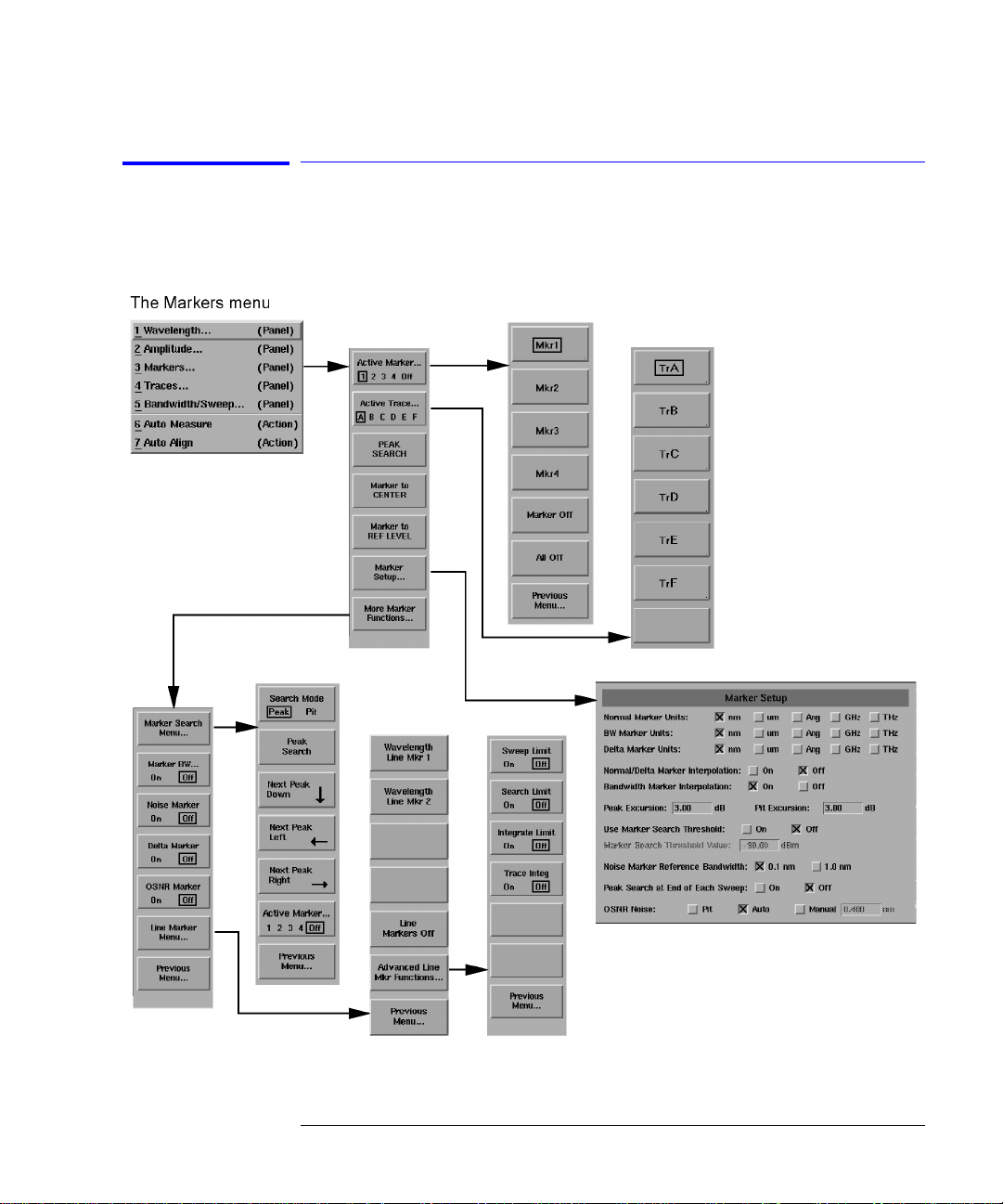

The Markers Menus

You can access the Markers softkeys by using the front-panel Markers key or

the Measure menu Marker s se lection on the menu bar.

1-23

Page 30

Getting Started

The Softkey Pan els

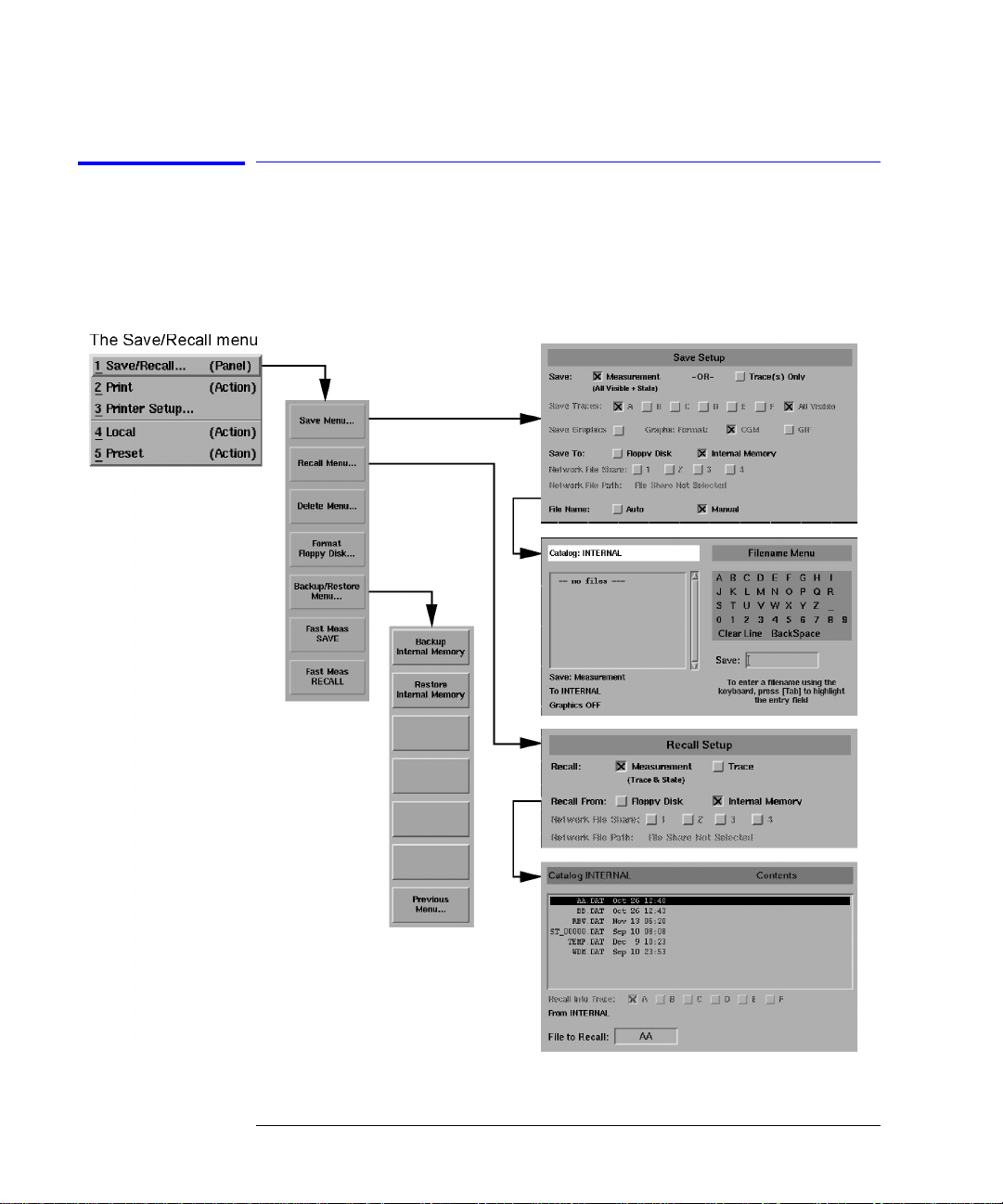

The Save/Recall Menus

You can acce ss the Save/ Recal l so ftke y s and s et up pane l s by using the drop down File menu Save/Recall selection or the front-panel Save/Recall key. Use

these functions to save, recall and print the measurement results.

1-24

Page 31

Getting Started

The Softkey Panels

The Systems Menus

Y ou can access the System softkeys by using the front-panel System key or the

Options menu System selection on the menu bar.

1-25

Page 32

Getting Started

The Softkey Pan els

The Systems Menus, continued....

1-26

Page 33

Getting Started

The Softkey Panels

The Traces Menus

You can access the Traces softkeys by using the front-panel Traces key or the

Measure menu Traces selection on the menu bar.

1-27

Page 34

Getting Started

The Softkey Pan els

The Wavelength Menus

You can access the Wavelength softkeys by using the front-panel Wavelength

key or the Measure me nu Wavelength sel ection on the menu bar.

1-28

Page 35

Getting Started

Laser Safety Consideratio ns

Laser Safety Considerations

NOTE Refer to the Tunable Laser Modules User’s Guide for complete laser safety

information.

Laser Safety Las e r radiation in the ultraviolet and far infrared parts of the spectrum can

cause damage primarily to the cornea and lens of the eye. Laser radiation in

the visible and near infrared regions of the spectrum can cause damage to the

retina of the eye.

WARNI NG Do NOT, under any c ircumsta nces, look into th e optica l output o r any

fiber/device attache d to the output while the laser is in operation.

This system should be serviced only by authorized personnel.

Do not enable the las er unless fiber or an equivalent device is attached to the

optical output connector.

CAUTION Use of controls or adjustments or performance of procedures other than those

specified herein can result in hazardous radiation exposure.

Electrical Safety The electrical safety considerations are documented in the section “General

Safety Considerations” on page -iii. Familiarize yo u rs elf with the safety mark-

ings and instru c tions before operating this system.

1-29

Page 36

Getting Started

Product Option s an d Accessories

Product Options and Accessories

Options Agilent 86140B, 86141B,

86142B, 86146B

Benchtop

Agilent 86143B, 86144B,

86145B

Portable

Instrument System Options

Current Source

White Light Source

Built-in 1310 & 1550 nm EELED Source

Built-in 1550 nm EELED Source

Wavelength Calibrator

Time Resolved Chirp Application

DWDM Spectral Analysis Application

Passive Component Test Application

Amplifier Test Application

Source Tes t Application

Opt. 001

Opt. 002

Opt. 004

Opt. 005

Opt. 006

Opt. TRC

Included

Included

Included

Included

a

Alternative Connector Inter face

FC/PC

HMS-10

DIN

ST

SC

Multimode Fiber Input

b

Standard

Opt. 011

Opt. 013

Opt. 014

Opt. 017

Opt. 025 (Agilent 86140B) Opt. 025 (Agilent 86143B)

Certificate of Cal ibr ation Included Included

a. Option available for 86146B only.

b. 50µm multimode input available on Agilent 86140B and 86143B OSA’s only.

----

----

----

---Opt. 006

Not Applicable

Included

Included

Included

Included

Standard

Opt. 011

Opt. 013

Opt. 014

Opt. 017

1-30

Page 37

Getting Started

Product Options and Accessories

Table 1-3.Accessories

Option Descriptio n Product Number

Connector Accessories

011 HP/HMS-10 Connector Adapter

HMS-10 Dust Cap

012 FC/PC Connector Adapter

FC/PC Dust Cap

Angled to Flat, FC/PC Adapter

013 DIN Optical Connector Adapter

DIN Dust Cap

014 ST Optical Connector Adapter

ST Dust Cap

017 SC Optical Connector Adapter

SC Dust Cap

08154-61701

1401-0291

08154-61702

1401-0291

1250-3175

08154-61703

1401-0291

08154-61704

1401-0291

08154-61708

1401-0291

Power Selection

900 Power Cord (United Kingdom) 8120-8705 1

901 Power Cord (Australia, New Zealand, China) 8120-0696 1

902 Power Cord (Europe) 8120-1692 1

903 Power Cord (United States) 8120-1521 1

906 Power Cord (Switzerland) 8120-2296 1

912 Power Cord (Denmark) 8120-2957 1

917 Power Cord (South Af rica, India) 8120-4600 1

918 Power Cord (Japan) 8120-4754 1

919 Power Cord (Israel) 8120-5181 1

920 Power Cord (Argentina) 8120-6868 1

921 Power Cord Chilean)( 8120-6979 1

922 Power Cord (China) 8120-8377 1

Documentation and Manuals

ABC Traditional Chinese User’s Guide

Traditional Chinese Application Guide

86140-90067

86140-90066

Certification of Calibration and Service

1BM Standard Commercial Calibration Certificate N/A 1

UK6 Commercial Calibration Certificate with Test Data N/A 1

W30 Extended Warranty to 3 Years Return for Service N/A 1

Item

Quantity

3

3

3

3

1

3

3

3

3

3

3

1

1-31

Page 38

Getting Started

Product Option s an d Accessories

Table 1-4. Available Fiber Sizes

Model

Number

86143B

Opt 025

86145B

86140B

Opt 025

86142B

b

86141B

86144B/

86146B

a. Options 002, 004, and 005 are exclusive

b. Only one option is avail ab l e on the 86141B

Optical

Input

Option 002

(White Light

Source)

µm

9

50

µm

9

µm

9 µm

50

µm

9

µm 62,5 µm 9 µm 9 µm 9 µm

N/A N/A N/A

N/A N/A N/A

62,5 µm

62,5

µm

50 µm 62,5 µm 9 µm 9 µm 9 µm 62,5 µm 62,5 µm

µm 62,5 µm 9 µm 9 µm 9 µm 50 µm 9 µm

9

Table 1-5. Additional Parts and Accessories

a

Option 004

(1310/1550

EELED)

9 µm

9

µm

a

Option 005

(1550

EELED)

9 µm

9

µm

a

Option 006

(Calibrator)

9 µm

9

µm

9 µm

9 µm

9

µm

Photo-

diode

Input

N/A N/A

N/A N/A

N/A N/A

N/A N/A

Mono

Output 1

Agilent Benchtop OSA

86140B, 86141B, 86142B,

86146B

Printer Paper (5 rolls/box) 9270-1370

Additional Connector Interfaces See Agilent 81000 series

Agilent Portable OSA

86143B, 86144B, 86145B

9270-1370

See Agilent 81000 series

External 10 dB Attenuator (FC/PC) Opt. 030 Opt. 030

Rack-Mount Flange Kit Opt. AX4 N/A

Transit Case 9211-2657

9211-5604

Soft Carrying Case N/A Opt. 042

BenchLink Lightwave Software

a. Agilent N1031A BenchLink Lightwave allows transfer of measurement results over a GPIB Interface to a PC for the purposes of

archiving, printing, and further analysis.

a

Standard Standard

1-32

Page 39

Front Panel Fiber-Optic Adapters

Getting Started

Product Options and Accessories

Front Panel

Fiber-Optic Adapter

Description Agilent Part Number

Diamond HMS-10 08154-61701

a

FC/PC

SC 08154-61708

DIN 08154-61703

ST 08154-61704

Biconic 08154-61705

a. The FC/PC is the default front-panel optical connector.

08154-61702

1-33

Page 40

Getting Started

Product Option s an d Accessories

1-34

Page 41

2

Setting Up Measurements 2-2

Calibrating Wavelength Measurements 2-14

Saving, Recalling, and Managing Fi le s 2-19

Analyzing Measurement Data 2-27

Analyzer Operating Mo des 2 -30

Using the Instrument

Page 42

Using the In s tr ument

Setting Up Measurements

Setting Up Measurements

This section con t a ins the following information that wi ll help you set up a

wavelength measurement:

• Adjusting Setup Conditions

• Operating the Internal White Light Sour c e

• Averaging Traces

• Setting Video Bandwidth

• Using Span to Zoom In

• Setting the Sensitivity

• Triggering a Measur em e nt

• Moving the Active Function Area

• Indicating an Update is Needed

2-2

Page 43

Using the softkeys

Using the Instrument

Setting Up Measurements

Adjusting Setup Conditions

Setup panels allow you to adjust setup conditions which are not frequently

changed. Refer to “Preset” on page 3-65.

Arrows allow you to navigate from field to field in the di a log box. The highlighted parameter can be changed. The front-panel number keys, step keys,

and knob allows the use r to enter a numeric value in the highlighted fi el d.

Select selects the highlighted parameter. You can enter values for a selected

parameter using the front panel knob or numeric entry pad.

Defaults resets the para m eters to their default condition.

Close Panel saves the current setup and returns you to the previous menu.

2-3

Page 44

Using the In s tr ument

Setting Up Measurements

Operating the Internal White Light Source

For Option 002 only

Option 002 provides a built-in white light source which is a stable, broadband

light source for swept-wavele ng th stimulus response testing from 900 nm to

1700 nm. The light source is ideal to perform stimulus-response measurements, and measure photod etector responsivity. Refer to “Light Source” on

page 3-33.

Note Although the light source’s lamp lasts an exceptionally long time, turn off the

light when not in use to extend the lamp’s lifetime. On the front pa n el, press

System, Optimum, Li ght Source, Select off.

1 From the front panel, pres s Sy ste m > Opti ons > Light Source > Select Off.

Performing Stimulus-Response Measurements

Stimulus-response measurements characterize optical components for loss

(or gain) versus wavelength. You can characterize devices such as couplers,

switches, filt ers, fibers, and ampl ifiers.

To perform stimulus-response measurements, you must have an amplitudestable broadband light source. Although a white-light source provides the widest wavelength input for stimulus-re spo nse meas ure m e nts , y ou can also use

an LED or the spontaneous emission from an optical amplifier.

The displayed response is a convolution of the analyzer’s resolution bandwid th

and the amplitude response of the device under test. Because of thi s convolution, the analyzer’s resolution bandwidth af f e c t s both dynamic range and the

ability to reso lv e la rge amplitude cha nges versus wavelength. Wide resolution

bandwidths increase the ability to resolve large amplitude changes.

You can display two responses at the same time. The output response versus

wavelength is displayed. The displa y ed trace shows the rati o of the output

power to the input power expressed as a logarithm (dB).

output power

response (dB) = 10 log

Making ratioed measurements is sometimes referred to as normalization. Normalized measurements are used to negate wavelength dependencies in the

source. The ratio is achieved through simple trace su bt ra c tion using logarithmic amplitude sca les. This is possible because of the following logarithmic

equality:

2-4

æö

------------------------------------

èø

input power

Page 45

Using the Instrument

Setting Up Measurements

A

æö

---

log

èø

log A log B–()=

B

1 Connect the Light Source Output to the Monochromator Input using the short

62.5/125

µm fiber. The standard connector interface is FC /P C .

2-5

Page 46

Using the In s tr ument

Setting Up Measurements

Averaging Traces

Tr a c e a ve ra ging improves your measurement repeat a bility by smoothing out

noise. For measurements involv ing slow polarization scrambling, using video

filtering to imp rov e repeatability w ill require a very narrow video bandwidt h

(less than 10 Hz). This would result in a long measurement time, where trace

averaging would be faster. Refer to “Averaging” on page 3-14.

1 From the front panel, press Traces > Averaging.

2 Toggle to select the Averaging on or off.

3 Select from the 10, 20, 50 or 100 softkeys or use the knob, step keys, or numeric

entry pad to enter the desi re d average count.

Note For measurements with fas t po lariza tion s cramb ling, vid eo filt erin g (adju sting

video bandwidth) is generally faster than trace averaging for similar

repeatability re quirement.

2-6

Page 47

Using the Instrument

Setting Up Measurements

Setting Video Bandwidth

Video bandwidth filtering occurs after the detection of the light. In the auto

coupled mode, the video bandwidth has an extremely wide rang e. This allows

the instrument to avoid unnecessary filtering that would reduce the sweep

speed more than required. Refer to “Video B W” on page 3-99.

The instrument has two de tection techniques: peak (auto mo de) and sample

(manual mode). Peak det ect ion is ben efici al f or mai nta ining the f ast est s weep

times and displaying narr ow aspect ratio signals. Sample detecti on is beneficial for obtaining best measurement accuracy and measuring low level signals.

Peak detection finds and displays th e m a ximum signal level present during

each trace poin t interval. Peak detection is used if v ideo filtering is no t

required to achieve the desired level of sensitiv ity. However, there is one

exception: if an auto-coupled sweep time is limited by either maximum motor

speed or a 50 ms auto- c oupling limit, then sample detection is used with as

narrow a digital video bandwidth as poss ib le in order to achieve maximum

sensitivity for the chosen sweep time. This exception only applies when both

sweep time and video bandwidth are auto-coupled.

Sample detectio n displays a filtered version of th e sa mp led data at the end of

each trace point interval. The filter function is varied with the video bandwidth function from 100 mHz to 3.0 kHz, or the bandwid th of the currently

selected transimpedance amplifier, whichever is less. Increased filtering provides greater sensitivity .

The detection mode is automatically determined by the instrument. You can

adjust the settings of video bandwidth, sensitivity, or sweep time to obtain the

desired detection mode. Sample detection can be forced at any time by putting video bandwidth in manual. Pe ak detection can usually be obtaine d by

placing sensitivity a nd video bandwidth in auto.

The following fun c ti o ns affect video bandwidth:

• changing the se nsitivity value

• changing the reference level

• turning auto ranging on or off

The range of video band w idths available in auto mode is much greater than

can be set manually from the front panel. A lower video bandwidth valu e

requires a longer sweep time. Because of the interdependence between the

2-7

Page 48

Using the In s tr ument

Setting Up Measurements

video bandwidth and sensitivity, it is recommended that either the sensitivity

or the video bandwidth be changed, whichever is the most important to th e

measurement task being perf ormed.

To reduce noise, you can select a narrower video bandwidth to improve

repeatability and sensitivity or select a wider video bandwidth to shorten overall measurement time. This selection allows the choice between repeatability

and measurement time based on your measurement requirements. The narrower the video bandwidth, the longer the sweep time.

1 From the front panel, press Bandwi dth/Sweep > Video BW.

2 Toggle to sele c t the video bandwidt h au tomatically or manually.

3 Use the knob, step keys, or numeric entry pad to enter the desired value.

Note For measurements with slow polarization scrambling, use trace averaging to

improve measurement repeatabilit y. T ra c e av eraging is faster than video

filtering for the sl ow polarization scram b ling application.

Using Span to Zoom In

To see a more detailed view of the device’s response, decrease the wavelength

span to expand the trace. This will enable you to precisely focus in on the

desired measurement area. Refer to “Span” on page 3-86.

Press Wavelength > Span and reduce the sp an by entering the value of 2

nm.

2-8

Page 49

Using the Instrument

Setting Up Measurements

Setting the Sensitivity

Setting sensitivity requests the lowest amplitude signal that can be measured

relative to the highe st amplitude signal d is p layed. It is defined as the signal

that is six times the RMS noi se. The mi nimum set tin g is –100 dB. An error will

be reported for values outside of this range and the sens itivity will round to

the nearest valid sensitivity. Refer to “Sensitivity” on page 3-81.

Manual allows manual input of sensitivities and enables auto gain ranging.

The “top of screen” and the sensitivity setting determines the requested

dynamic range. The system will sweep once per gain stage and may require up

to three sweeps to achieve the re q uested dynamic range.

Auto automatic ally c hoose s a sensit ivit y and a si ngle gain ran ge base d on “top

of screen”. This will re sult in approximately 40 dB of dynamic rang e.

The sweep time that is displ ayed in the lower porti on of t he displa y is the t ime

for the OSA to sweep over one gain stage. The OS A may tak e up to three

sweeps in three different gain stages to make the measurement. This depends

on the settings for sensitivity, reference level, auto range and also the particular device bein g mea sur ed. T he f inal d at a tra ce i s a b lend ed co mpos ite o f eac h

trace taken in the different gain stage s.

An increase in sensitivity may also require a narrower video bandwidth, which

will slow the sweep speed. Normally, the optical spectrum analyzer selects the

greatest sensitivity possible that does not require amplification changes during the sweep. If you manually increase the sensitivity level, the sweep pauses

to allow this change in gain.

The settings for sensitivity, video bandwidth and sweep time interact. If the

sensitivity is set to manual, the video b a nd w idth and sweep time may be

forced to Auto mo de. If the video bandw idth is set to manual, the sensitivity

and sweep time may b e forced to Auto. If the sw eep speed is set to manua l

and is set too fast, the over sweep indicator will come on in the display area.

Since these sett in gs interact, it is recommended th a t onl y on e of the settings

be changed, whic hever setting is most important to the m easurement task

being performed.

Press Amplitude, Sensitivity, toggle to manual, and enter a value.

2-9

Page 50

Using the In s tr ument

Setting Up Measurements

Triggering a Measurement

Tr igger ing a me asu rem ent sy nchr onize s the sta rt o f t he s weep to a n i nter na lly

generated trigger signal. Internal triggering ensures continuously triggered

sweeps with th e shortest delay between sweeps. Refer to “Trigger Mode,

Internal” on page 3-96.

In some measurements, the spectrum at a particular time within the modulation period is more important than the average spectrum. Gated triggering can

be used to synchronize the data acquisition portion of the OSA to a gating trigger connected to the rear-panel EXT TRIG IN connector. Gated triggering

requires a TTL-compatible signal wit h a mi n imum o f 0 Vdc and a maximum of

+5 V.

Gated triggering ignores the spectrum when the trigger input is low. It usually

is used in conjunc ti o n w i th the Max Hold function during several sweeps.

Gated triggering is used to select data samples containing valid information.

When the gating s ignal is high, the data sample is accepted. When the gati ng

signal is low, the data sample is replaced by a data point with a value of

–200 dBm. Processing con tinues according to the functions selected, suc h a s,

video bandwidth, max hold, and so forth.

If the low level exists for longer that the time needed for the grating to move

from one trace po in t to the next, then the trace will have “gaps”. There are

two ways to eliminate the gaps. You can increase the sweep time to at least:

(1.2–2 times the product trace lengt h)

2-10

× (the longest “low level” period)

Page 51

Using the Instrument

Setting Up Measurements

The display will have at least one data sample marked as valid (high level) per

trace point. Or else you can use the Max Hold function to complete a trace

over several sweeps. Multiple sw eeps fill the gaps beca use the high and low

levels of the gating signal occur independent of the grating position.

Gated triggering has no time limit for the high or low level. It can be used to

characterize pulses as narrow as a few microseconds, or to obtain a spectrum

whose timing exceeds the maximum 6.5 ms delay o f the

ADC trigger mode.

1 On the front panel press Bandwidth > Sweep > More BW Sweep > Functions >

Trigger Mode.

2 Select from int, gated, and ext.

2-11

Page 52

Using the In s tr ument

Setting Up Measurements

Moving the Active Function Area

The active function area on the display can be moved to eight different locations. This allo w s y o u to place the active area in a location that will no t interfere with the trace information. Refer to “Active Function Area Assist” on

page 3-2.

1 Press the front-panel System key.

2 Press the Move Active Area softkey. Each press of the softkey moves the

active function area to one of eight onscreen location s.

2-12

Page 53

Using the Instrument

Setting Up Measurements

Indicating an Update is Needed

This feature alerts you to take a sweep after changing any sweep related

parameters when the a nalyzer is not in sweep mode. For example, if you

change the resolution ba ndwi d th, the new resolution band width is displayed

on the bottom of the screen, but the trace data displa y ed on the screen used

the previous resolution bandwidth value.

Changing the following sweep parameters will set the Update Needed Indicator to on:

• start wavelength

• stop wavelength

• sensitivity auto/manual

• auto range enable/disable

• sensitivity

• video bandwidth auto/manual

• resolution bandwidth

• video bandwidth

• gated sweep enable/disable

• sweep continuous/single

• sweep time auto/manual

• sweep time

• sweep trace length

• reference level

• dB per division

• reference level position

• Y scale linear/log mode

• amplitude correction enable/disable

• current active ampcorr correction set

• ampcor interpolation method

• vacuum or air

• wavelength offset

• number of averages for trace avera g ing

The Update Needed Indicator, “*’”, is displayed in the upper right hand corner

of the graticule. After a sweep is taken, the Update Needed Ind ic a tor will be

set to off.

2-13

Page 54

Using the In s tr ument

Calibrating Wavelength Measurements

Calibrating Wavelength Measurements

Environmental variations such as air pressure, temperature, and humidity can

affect the index of refraction of air in the monochromator of the optical spectrum analyzer (OSA). This section discusses calibration methods that you can

use to improve the wavelength accuracy in the Agilent 8614X OSA’s. Refer to

“Calibration” on page 3-17 and to “Calibrator Multi-Pt Align” on page 3-18.

Note Many aspects of remotely programming the optical spectrum analyzers are discussed

in Product Note 86140-2R, Wavelength Calibration for the 86140X Series Optical

Spectrum Analyzers (Lit erature part number 5980-0043E).

Overview Wav elen gth cal ibra tio n ro uti nes i mpr ove w avele ng th ac cura cy b y det er minin g

errors and correcting them with offsets, using linear interpolation when necessary. For maximum wavelength accuracy, calibration points spaced a maximum of 10 nm apart are recommended.

You can perform a wavelength calibration by using one of the following methods:

• Manual Method using Internal Calibrator

• Remote Method using Internal Calibrator

• Manual Method using an Ex te rnal Single Wavelength Sou rce

• Remote Method using an External Single Wavelength Source

• External Multipoint Wavelength C a libration

These calibration routines should only be performed after the instrument’s

temperature has been stabilized by a minimum of 1 hour of continuous operation.

2-14

Page 55

Using the Instrument

Calibrating Wavelength Measure m ents

Internal Wavelength Calibration

The optional internal calibrator (1513 to 1540 nm) provides a convenient

method for increasing wavelength accuracy when used wi th an in te rnal

Enhanced Wavelength Calibration (EWC) process. The wavelength accuracy

of the OSA will be ±0.2 nm over the full wavelength range of the instrument,

with ±10 pm over 1480 to 1570 nm and ±25 pm accuracy over 1570 to 1620

nm.

The EWC range can b e se lected for either the “full” OSA range of 605 nm to

1670 nm, or the “telecom” range of 1270 to 1670 nm, a smaller span more relevant to telecommunications. EWC must be enabled for the wavelength accuracy specifications to apply in th e range selected. S etting the range to F U LL

will require a longer calibration time for an internal calibration, but will provide enhanced wavelength accuracy over the full range.

Manual method using the internal calibrator

1 Access the EWC setup panel:

System > More System Functions > Service Menu > Adv Service Functions

> More Adv Service Menu > Enhanced Wvl Cal Setup

2 Enable the functio n, if necessary, an d select the desired calibration ra n g e.

3 Clean all connec tors and connect the internal calibrator to the OSA input.

4 Access the Wavelength Calibration setup panel:

System >Calibration > Wavelength Cal Setup

5 Set the signal source to Calibrat or.

6 Press Perform Calibration.

Remote method using the internal calibrator

CALibration:WAVelength:EWC:FUNCtion ON !Enable enhanced wav e len gth

calibration.

CALibration:WAVelength:EWC:RANGe TELE !Select telecom (1270-1670) nm range

for enhanced wavelength calibration.

CALibration:WAVelength:INTernal:NORMal !Perform internal wavelength

calibration.

!The internal calibrator must be

connected before sending this

command.

2-15

Page 56

Using the In s tr ument

Calibrating Wavelength Measurements

External Single Wavelength Calibration

Using an external single-point calibration source allows the calibration to be

done at a specific wavelength. This single wavelength user calibration can be

repeated as often as necessary to correct for envir onme ntal variations and

existing multipoint wavelength offsets will be adjust ed accor di ngly. After a

single wavelength calibration, wavelength accuracy will be ±10 pm within 10

nm of the reference signal.

The Enhanced Wavelength Calibration (EWC) process can also be us ed to

increase the accuracy of the single-point calibration.

Manual method using an external source

1 Connect the external source to the O SA input.

2 Auto align the OSA to the input signal.

3 Access the Wavelengt h Ca libration setup panel:

System > Calibration > Waveleng th Cal Se tup

4 Select Air or Vacuum re fe rence for the signal source .

5 Set the signal source to Ex ternal.

6 Select the desi red Calibration Wa velength. This wavelength must be with in

±2.5 nm of the source wavelength.

7 Select Perfor m Calibration.

Remote method using an external source

• For a source with a single peak:

CALibration:WAVelength:VALue <param> !Set calibration wavelength

CALibration:WAVelength !Calibrate signal at wavelength

• For a source with multiple peaks:

CALibration:WAVelength:VALue <param> !Set calibration wavelength

CALCulate:MARKer[1|2|3|4]:X:WAVelength

<param>

CALibration:WAVelength:MARKer !Calibrate signal at marker

2-16

!Set marker wavelength

Page 57

Using the Instrument

Calibrating Wavelength Measure m ents

External Multipoint Wavelength Calibration

An external multipoint wavelength calibration can be performed over any

specified wavelength range, up to and including the full wave le ng th ran ge of

the OSA (600 nm to 1700 nm). Narrow measur ement spans can be chosen to

provide greater accuracy over a selected range. Calibrating the wavelength

every 10 nm within the desired wave length range is usua lly sufficient to

improve wavelength accuracy. After a multipoint wavelength calibration,

wavelength accuracy will be ±10 pm within 10 nm of each calibration wavelength. Refer to “Calibrator Multi-Pt Align” on page 3-18.

Note For a full explanation of external multipoint wavelength calibration, along with a

sample program to perform the calibration, refer to Product Note 86140-2,

Wavelength Calibration for the 86140X Series Optical Spectrum Analyzers

(Literature part number 5980-0043E).

The following steps outline one method for an external multipoint wavelength

calibration routine. This assumes a program executed on a external PC co ntroller. The steps outlined are those written in the pro g ra m.

1 A signal is sent from a tunable laser source into a multi-wavelength meter and

the OSA simultaneously.

2 The wavelength of the input signal is measu re d on both in struments.

3 The two measured values are co m p a red.

4 Taking the multi-wavelength meter readings as actual, the software calculates

the error offs ets at each wavelength using the equation:

WL Error = (OSA indicated WL) – (multi-wavelength meter actual WL)

5 The previous st e p s ar e repeated over the ent ir e w a velength range.

6 The data is aver aged over narrow wavelength spans to provide a suitable

correction for each span. The example below demonstrates this technique.

Once the instrument is calibrated, the new wavelength accuracy can be main-

tained for many hours without recalibration, assuming a stable temperature

environment.

Tip If the OSA is tur ne d off , the mul tip oin t da ta wi ll be ret ain ed at t he n ext p owe r-

on, but the internal thermal shift can introduce inaccuracies to the calibration

data. To help compensate for this, a single point calibra tion using the Offs et

feature in the Wavelength Calibration Setup panel can be used to adjust the

multipoint data. Access this feature by selecting Syst em > Calibration >

2-17

Page 58

Using the In s tr ument

Calibrating Wavelength Measurements

Wavelength Cal Setup and choosing the Offset option before running the single

point calibra tion. T o ins ure this offset process has pr ovided suffi cient accurac y ,

the wavelength readings of the multi-wavelength meter and the OSA should be

compared to verify the wavelength accuracy and determine if a full multipoint

wavelength recalibration is necessary.

2-18

Page 59

Using the Instrument

Saving, Recalling, and Managing Files

Saving, Recalling, and Managing Files

The functions and methods available for saving, recalling, and managing file s

that contain measurement setups and results are as follows:

• Adding a Title to the Display

• Backing Up or Restoring the Int er nal Memory

• Saving Measurement Trace Data

• Recallin g M easurement Tra c e Data

• File Sharing and Printing over a Network

Adding a Title to the Display

Refer to “Title (Display Setup Panel)” on page 3-92 and to “Date/Time (Display Setup Panel)” on page 3-20.

1 Press the front- panel System key.

2 Press the Set Title.... softkey . The Title Setup panel appears.

The Title Setup panel

3 To view the titl e o n the display, press More System Functions >Display

Setup and ch ec k the Title On box.

2-19

Page 60

Using the In s tr ument

Saving, Recall ing, and Managing Fil es

Backing Up or Restoring the Internal Memory

1 Press the front-panel Save/Recall key.

2 Press the Backup/Restore Menu.... softkey.

Note The auto span value will not be saved with the measurement. Refer to “Backup

Internal Me mory” on page 3-15.

Softkey Pan e l

Selections

Backup Internal Memory

a The analyzer Backup Utility screen appears asking you to insert a formatted

floppy disk in the external drive. The disk will not be viewable on a PC and

no trace or measurement files can be saved onto the disk until it is reformatted.

b The Backup Internal Memory function overwrites the floppy disk with a new

image. Any exist ing files or ca talogs on the flo ppy disk will be de stroyed. Any

successive backup operations will overwrite the previous backup information, so only the latest backup information can be recovered through the Restore Internal Memory operation.

Restore Internal Memory

The analyzer Restore Utility sc reen appears. Th is operation wil l re move all

files from internal memory and replace them with files from backup floppy

disks.

Saving Measurement and Trace Data

You can save measurement and trace data using the following methods:

• Fast Measurement Save Mode

• Save Setup Panel Mode

Saving Data in Fast Meas Save Mode

1 Press the front-panel Save/Recall key.

2 Press the Fast Meas SAVE softkey.

3 The instrument saves the curren t measurement state to internal memory as

FASTSAVE.dat. O nly one FASTSAVE .dat file exi sts, so perfor ming a Fast Meas

2-20

Page 61

Saving, Recalling, and Managing Files

Save will overwrite any currently existing Fast Save file.

Note The auto span value w ill not be saved with the measurement.

Saving Measurement and Trace Data

1 Press the front- panel Save/Recall key.

2 Press the Save Menu.... softkey.

3 The Save Setup panel opens. Refer to “Adjusting Setup Conditions” on page 2-3

for information on changing and se le cting items in the setup panel .

Using the Instrument

The Save Setup panel

Note The auto span value w ill not be saved with the measurement.

Save Setup Panel

Selections

Save: Measurement

Saves the measurement dat a in a binary format (.dat file). This includes the

traces and all measurement conditions. The dat file format can only be read by

the analyzer. You will not be able to v ie w this file on your PC. When the file is

recalled, the instrument state will be set to the same state as when the file was

saved.

Save: Trace(s) Only

The Trace(s) Only files are saved in comma separated variable (.csv) format

and are auto named starting with TR_00000.cs v. State files are auto named

starting with ST_00000.csv.

When the T rac e(s) Only fil e is reca lled, the tr ace dat a will be displayed under

the current instrument settings.To view the inst rum ent settings, press System > More System Functions > State Info.

2-21

Page 62

Using the In s tr ument

Saving, Recall ing, and Managing Fil es

Save Tr aces

Selects the traces to be saved.

Save Graphics

Allows you to save gra p hic data in one of two formats. These selec t ions are

valid only when sav ing to the floppy drive.

CGM (Computer Graphics Metafile format) is a vector graphics format that

describes pictures and graphical elements in geometric terms. The file is

saved with .cgm extension.

GIF (Graphics Interchange Format) is a cross-platform graphic standard.

GIF formats are commonly used on many di ffe rent platforms and readable

by many differen t kinds of sof tware. The fi le is saved with .gif extensio n. GIF

supports up to 8-bit color (256 colors).

Save to

Allows you to choose between saving data to a floppy disk or to internal memory.

File Name

Selects manual or automatic mode for choosing a file name.

4 If you have chosen Auto to select the file name, press the Auto Save softkey.

The analyzer will generate a filename and save the file.

5 If you have chosen Manual to select the file name, press the Choose File to

Save softkey. The Filename Menu setup panel opens.

The Filename Menu setup panel

2-22

Page 63

Saving, Recalling, and Managing Files

Entering a Filename Using the Arrow Keys

Using the Instrument

• Use the front-pa nel step keys (

Ý and ß) and the arrow softkeys (→ and ←)

to highlight eac h le tter of the filename.

• When the desired le tter or function is sel ected, press the Select softkey.

• Select the BackSpace function to delete individual letters.

• Select the Clear Line function to delete the entire filename.

• When you finish ent ering the filename, press the SAVE FILE softkey.

Entering a Filename using an External Keyboard

There must be a PS-2 keyboard conne c ted to the analyzer p rior to bootup.

• Press [TAB] on the keyboard to highlight the entry field.

• Enter the filename us ing the keyboard.

• When you finish ent ering the filename, press the SAVE FILE softkey.

2-23

Page 64

Using the In s tr ument

Saving, Recall ing, and Managing Fil es

Recalling Measurement and Trace Data

You can recall measurement and trace data using the following methods:

• Fast Measurement Recall Mode

• Recall Setup Panel Mode

Refer to “Recall (Recall Setup Panel)” on page 3-67.

Recalling Data in Fast Meas Recall Mode

1 Press the front-panel Save/Recall key.

2 Press the Fast Meas RECALL softk ey.

3 The instrument reca lls the measurement state previously sa v ed as

FASTSAVE.dat by the Fast Meas Save functio n.

Note The auto span value will not be saved with the measurement.

Recalling Measurement and Trace Data

Note To insu re accurate measure m e nts, a waveleng th cal ibration should be

performed each time measurement data is recalled from memory.

1 Press the front-panel Save/Recall key.

2 Press the Recall Menu.... softkey.

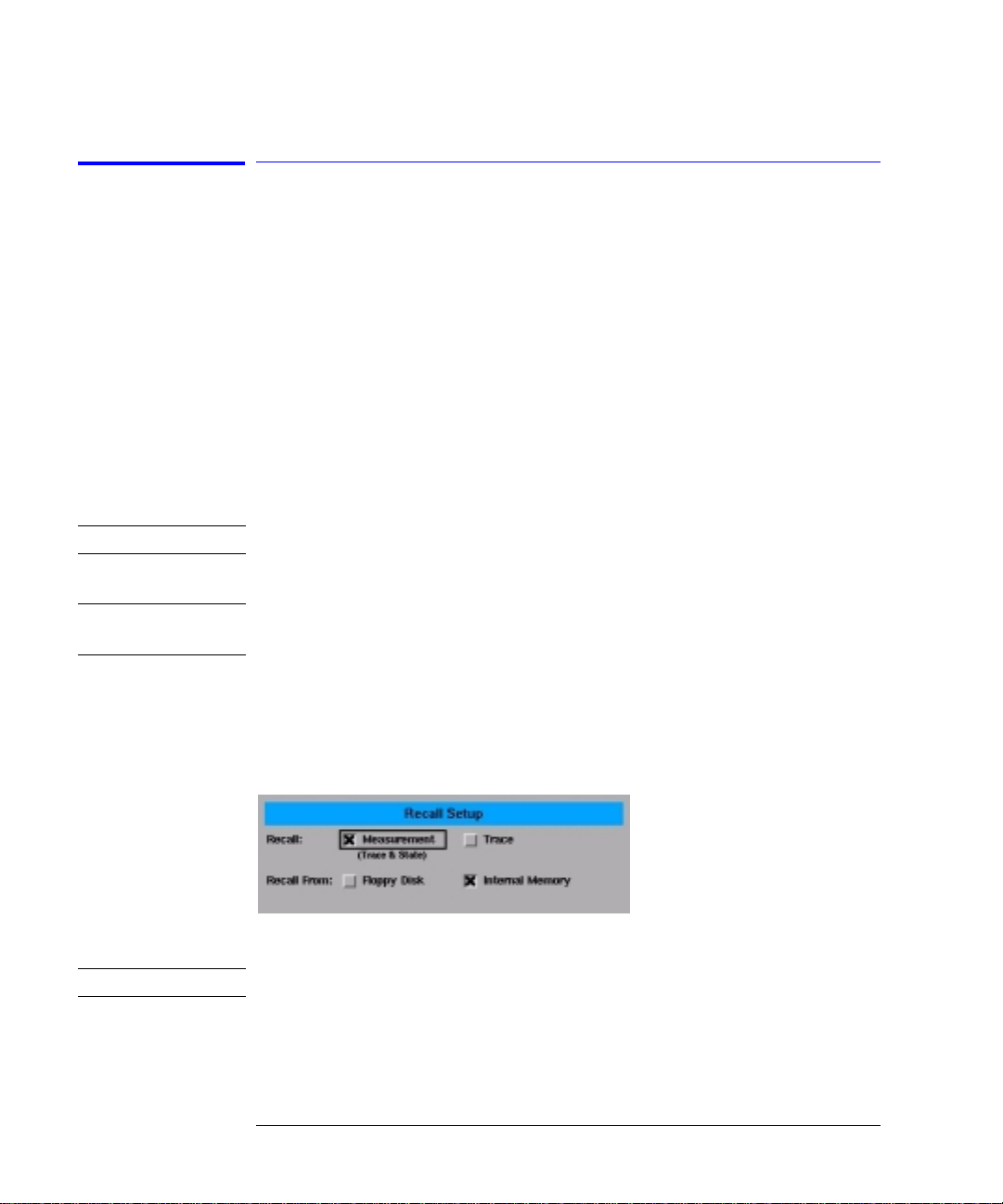

3 The Recall Setup pane l op ens.

The Recall Menu setup panel

Note The auto span value will not be saved with the measurement.

Recall Setup Panel

Selections

Recall

Selects whethe r a me a surement or trace w ill be recalled.

2-24

Page 65

Using the Instrument

Saving, Recalling, and Managing Files

Recall From

Selects whether to recall from a floppy disk or from internal memory.

4 When you are satisfied with your selections, press the Choose File to Recall

softkey. The Catalog setup panel opens.

The Catalog setup panel

5 Use the arrow keys or Prev File, Next File softkeys to highlight the desired

file. Press RECALL FILE to load the selected file.

2-25

Page 66

Using the In s tr ument

Saving, Recall ing, and Managing Fil es

File Sharing and Printing over a Network

This function uses the LAN to print to network printers and st ore, recall or

delete data on remote hard drives. The da ta can then to be acces se d a nd

shared among the users and printed on designated printers.

To access the file and printer share softkeys, you must first configure the network and enter the user share identity/user profile information for remote

shares. The softkeys for file and printer share will then become available for

selection.

Create a file or print share.

1 Configure the network. Refer to “Setting Up the OSA for Remote Operation” on

page 4-4 for instructions on how to configure the network.

2 From the front panel, pres s System > More System Functions > GPIB &

Network Setup > User Share Identity.

3 Enter the User Name, Password, and Wo rkgroup. Use the key board to enter t he

information or press Edit Field to access the User Workgroup Setup panel then

close the panel.

4 From the Network Setup, press File Share and enter the Share Path and

optional IP address. The format of the share path is \\server\”share name.”

Please note tha t yo u c a nn ot specify directories within the share. Up to four

remote file shares are available.

5 Press Printer Shares and enter the share path and optional IP address. Use the

keyboard to enter the informat io n or press Edit Field to access the User

Workgroup Setup panel. Up to four re m ote printer shares are available.

6 To activate the printer share, press System > Printer Setup and select the

configured share. To activate the file share, press Save/Recall then either

Save, Recall or Delete and select th e c o nfigured share. Note if you have no t

configured the share the Network File Share buttons will not be act iv e.

2-26

Page 67

Using the Instrument

Analyzing Measurement Data

Analyzing Measurement Data

This section provides advice and information on the following analyzer functions that allow you to analyze the meas ure d am plitude wavelength data.

• Tips for Using Traces and Markers

• Measuring the Delta between Traces

• Using Trace Math to Measure Wavelength Drif t

Tips for Using Traces and Markers

The analyzer provides the ability to display up to six traces wi t h up to fo ur

markers. Knowing a few tips makes trace and marker manipulation m uch e asier. Refer to “Traces” on page 3-95, “Marker BW” on page 3-37, “Marker Searc h

Menu” on page 3-38, “Marker Setup” on page 3-39, and “More Marker Functions” on page 3-45.

• Markers are a lw a ys placed on the currently selected active trace. Therefore,

use the Acti ve Trace fun ction to acti vate the des ired trace, th en select an a ctive

marker to be placed on that trace.

• When multiple markers are currently used on multiple traces, the Marker Status area (located at the top of the display) makes it easy to identify the state of

each marker.

Information provided for each marker in cludes:

• Wavelength

• Amplitude

• The trace associated with the marker.

For example, if marker 1 is on Trace A then the annotation will show

Mkr 1 (A).

In addition, if there are two markers on, then the delta of the wavelength and

amplitude for the two different markers is also displayed. For example, Mkr

2-27

Page 68

Using the In s tr ument

Analyzing Measurement Data

(2-1) 0.206 nm, -0.002 dB.

The color of the annotation de notes different characteri stics of the markers:

• White annotation denotes the status of the currently active mar ke r.

• Green annotation denotes the status of all currently used markers.

• Red annotation denotes that some type of an error occurred with the marker

measurement.

Moving the Active Marker from One Trace to Another

The following procedure shows you how to move the active marker (marker 1)

from Trac e A to Trace B.

1 From the front pan el, pr ess Markers > Active Trace > TrB to make Trace B

the active trace.

2 Press Active Marker > Mkr 1.

Measuring the Difference between Traces

The following procedure shows you how to find the amplitude and wavelength

difference between the maximum peaks of two different traces. Refer to “Nor-

mal/Delta Marker Interpol ati on (Marker Setup Panel)” on page 3-50.

1 From the front pa nel, press Markers > Active Trace and select the first trace

to place a marker.

2 Press Active Marker > Mkr 1 > Peak Search to place the marker on the

highest peak of the active trace.

3 Press Active Trace and select the second trace to place a marker.

4 Press Active Marker > Mkr 2 > Peak Search to pl a ce the marker on the

highest peak of the second trace.

5 View the results of th e m easur emen t fr om th e mar ker ann otat io n at t he to p of

the display.

The wavelength and amplitude of each trace marker is shown, as well as the

amplitude and wavelength difference of the peak s of the two traces.

2-28

Page 69

Using the Instrument

Analyzing Measurement Data

Using Trace Math to Measure Wavelength Drift

1 From the front panel, press Traces > Ac tive Trace > TrA.

2 Press Single Sweep, Bandwidth Swe e p , Single Sweep to update Trace A

then press Traces, Update A off.

3 Press Active Trace > TrB.

4 Press Sweep > Repeat Sweep On to continuously update the measured

response on Trace B.

5 Press Traces > Trace Math, Default Math Trace C > Log Math C = A – B.

You can now monitor the wavelength drift of your device over time.

Also Refer to “Log Math C=A–B” on page 3-35, “Log Math C=A+B” on

page 3-35, and “Log Math F=C–D” on page 3-36.

2-29

Page 70

Using the In s tr ument

Analyzer Operating Modes

Analyzer Operating Modes

This section discusses the following analyzer modes that you can use in specific measurement applications.

• Filter Mode (For Agilent 86144B/86146B only)

• Filter Mode (For Agilent 86141B only)

• Time Resolved Chirp

Filter Mode

For Agilent 86144B/86146B only

The Agilent 86144B and 86146B filter mode allows a single channel from a

dense wavelength division multiplex (DWDM) signal to be isolated and routed

to another measurement instrument. The filter mode capability is built-in to

internal applic at ions to allow for fast and easy measurements. Th e filtering is

accurate and f lexib le. It has l ow pol ariza tion d epend ent los s (PDL), adjust able

filter bandwidth, and a wide tuning range.

1 Switch to filter mode by pressing Appl > Measurement Modes > Filter Mode.

2 Select a filter bandwidth in the BW/sweep > Res BW menu .

3 Select an active tuning marker and tune it to a wavelength position.

The filter marker becomes the current marker and has the active area focus.

All other markers stay on. In the filter mode, the analyzer acts as a fixedtuned, variable wavelength, variable bandwidth, bandpass filter. It filters the

input light at a specified wavelength. The filtered light is available at the frontpanel monochrom a tor output connector. One application of the filter mod e is

the filtering (select in g) of on e particular mode of a laser source. Refer to “Fil-

ter Mode” on page 3-29, “Filter Mode Instruction Panels” on page 3-29, and

“Filter Marker Tune” on page 3-28.

2-30

Page 71

Using the Instrument

Analyzer Operating Modes

When the analyz er enters the filter mode, the sweep stops wi th the analyzer

filter tuned to the center wavelength. (If a marker is on, the analyze r filte r i s

tuned to the marker wavelength.) The last trace remain s displayed to show

the input spectrum before the filtering. A marker shows the wavelength of the

preselection. Y ou can change the filtered output (preselection) wavelength by

adjusting th e m a rk e r ’s position, then c on necting the monochromator outp ut

to another instrument. If the input spectrum changes, rec onne ct the monochromator output, then press the Take Sweep softkey to capture a new sweep.

The single mode filter can be used in conjunction with the Agilent 86130A bitalyzer error performance analyzer and/or the Agilent 86100A infinium digital

communication analyzer. Time res olve chirp (TRC) mea surements use the

Agilent 86146B Option TRC and the Agil e nt 86100A digital communication

analyzer.

2-31

Page 72

Using the In s tr ument

Analyzer Operating Modes

Table 2-6. Differences Between Agilent 86141B and 86144B/86146B

86141B Unique Operation (Internal 50 µm Fiber Switch)

Filter mode initializat ion:

• Previous settings are lost

• A single sweep is taken

Markers used:

• The marker is set to the reference level

Functions limited to:

• Taking a single sweep

• Changing resolution bandwidth

• Resolution bandwidth is Marker 1

Filter mode functions available:

• Exit recalls the last selected state parame te rs prior to entering filter mode

86144B/86146B Unique Operation (External 9

Filter mode initializat ion:

µm Fiber Connection)

• No default settings

Markers used:

• Filter marker is the normal no ise marker

• OSNR marker is the center marker

• Bandwidth marker is the center wavelength mar ker

Functions limited to:

• Fiber selection

• Applications

• Calibration

• ADC

Filter mode functions available:

• Transfer and restore state file in fi lt er mode

• Save in filter mode

2-32

Page 73

Using the Instrument

Analyzer Operating Modes

Accessing the filter mode (for 86144B/86146B only)

Note Filter mode will no t function in zero span. The filter mod e se lection will be

shaded out. The cu rrent state before entering fil ter mode will not be saved. A

sweep will not be taken . Th e reference level will not change.

1 Connect the light so urce to the optical spectrum analyz e r ’s front panel

monochromator input conne ctor.

2 Connect the monochromator output to the photodete ctor input.

3 Press Appl’s > Measurement Modes > Filter Mode. Follow the exter nal

path align setu p instruc tions an d select ei ther the Switch Pa th Auto Al ign Now

or Switch Path No Auto Align.

• Select the Switch Path Auto Align Now to perform an automatic align-

ment of the external path.

• Select Switch Path No Auto Align if you do not have the monochromator

output connected to the photodiode input, or to preserve previous align data.

Switch Path Auto Align Now switches to the 9

µm filter mode path and

performs an Auto Align. This aligns the output of the monochromator with the

photodetector input for improved amp li tude accuracy. The automatic alignment procedure sh ould be performed whenever the instrument has been:

• moved

• subjected to large temperature changes

• turned off, then on, and warmed up for an hour

The automatic alignment requires the connection of an external light source.

This can be a broadband or narrowband source. If there is insufficient signal

power, the automatic alignment will not be performe d and an error message

will be reported.

The Auto Align function saves and restores the current instrument state. This

allows the auto align to be used in the middle of a measurement routine.

If markers are turned on, auto align attempts to do the automatic alignment at

the wavelength of the active marker.

Note Auto Align Now will overwrite any previous align data.

2-33

Page 74

Using the In s tr ument

Analyzer Operating Modes