Page 1

Agilent 86100B Wide-Bandwidth Oscilloscope Getting Started

Page 2

Notices

© Agilent Technologies, Inc. 2000-2002

No part of this manual may be reproduced in any form or by any means

(including electronic storage and

retrieval or translation into a foreign language) without prior agreement and written consent from Agilent Technologies,

Inc. as governed by United States and

international copyright lays.

Manual Part Number

86100-90054

Edition

First edition, October 2002

Printed in USA

Agilent Technologies, Inc.

Lightwave Division

3910 Brickway Boulevard

Santa Rosa, CA 95403, USA

Warranty

The material contained in this document

is provided “as is,” and is subject to being

changed, without notice, in future editions. Further, to the maximum extent

permitted by applicable law, Agilent disclaims all warranties, either express or

implied, with regard to this manual and

any information contained herein, including but not limited to the implied warranties of merchantability and fitness for a

particular purpose. Agilent shall not be

liable for errors or for incidental or consequential damages in connection with the

furnishing, use, or performance of this

document or of any information contained herein. Should Agilent and the

user have a separate written agreement

with warranty terms covering the material in this document that conflict with

these terms, the warranty terms in the

separate agreement shall control.

Technology Licenses

The hardware and/or software described

in this document are furnished under a

license and may be used or copied only in

accordance with the terms of such

license.

Safety Notices

CAUTION

Caution denotes a hazard. It calls attention

to a procedure which, if not correctly performed or adhered to, could result in

damage to or destruction of the product.

Do not proceed beyond a caution sign

until the indicated conditions are fully

understood and met.

WARNING

Warning denotes a hazard. It calls attention

to a procedure which, if not correctly performed or adhered to, could result in

injury or loss of life. Do not proceed

beyond a warning sign until the indicated

conditions are fully understood and met.

Restricted Rights Legend

If software is for use in the performance

of a U.S. Government prime contract or

subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is

subject to Agilent Technologies’ standard

commercial license terms, and non-DOD

Departments and Agencies of the U.S.

Government will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater

than Limited Rights as defined in FAR

52.227-14 (June 1987) or DFAR 252.2277015 (b)(2) (November 1995), as applicable in any technical data.

ii

Page 3

Contents

1 Setting Up the Infiniium DCA

Step 1. Inspect the Shipment 1–5

Step 2. Install any Modules 1–9

Step 3. Consider Environmental Specifications 1–10

Step 4. Connect the Keyboard and Mouse (Optional) 1–11

Step 5. Connect the Line Cord 1–12

Step 6. Turn on the line power 1–15

Step 7. Set the time and date 1–17

Step 8. Connect a Printer 1–18

Step 9. Calibrate the Touch Screen 1–22

Step 10. Configure the Instrument on a LAN 1–23

Step 11. Avoid Costly Repairs 1–24

Step 12. Perform a Module Calibration 1–26

Step 13. For More Information 1–29

Cleaning Connections for Accurate Measurements 1–30

Returning the Instrument for Service 1–39

Hard Drive Recovery 1–42

Agilent Technologies Service Offices 1–43

2 Working in Comfort

3 Using the Infiniium DCA

Eye/Mask Mode 3–7

Oscilloscope Mode 3–8

TDR/TDT Mode 3–9

Using Plug-in Modules 3–10

Using the Touch Screen 3–12

Using the Quick Measure Feature 3–13

If the Display Goes Blank 3–14

Hiding and Moving Dialog Boxes 3–15

Menus 3–16

4 Using the Built-In Information System

The Infiniium DCA Help Contents 4–3

Description of the Contents Topics 4–4

Getting Help While Changing Instrument Settings 4–6

Learning About Measurements Results 4–7

Contents-1

Page 4

Contents

Hiding the Help 4–8

Printing the Contents of a Topic 4–9

Selecting the Help Language 4–10

5 Regulatory Information

Compliance with German Noise Requirements 5–2

Compliance with Canadian EMC Requirements 5–2

Declaration of Conformity - Mainframe 5–3

Declaration of Conformity - Plug-in Modules 5–4

Contents-2

Page 5

1

Step 1. Inspect the Shipment 1-5

Step 2. Install any Modules 1-9

Step 3. Consider Environmental Specifications 1-10

Step 4. Connect the Keyboard and Mouse (Optional) 1-11

Step 5. Connect the Line Cord 1-12

Step 6. Turn on the line power 1-15

Step 7. Set the time and date 1-17

Step 8. Connect a Printer 1-18

Step 9. Calibrate the Touch Screen 1-22

Step 10. Configure the Instrument on a LAN 1-23

Step 11. Avoid Costly Repairs 1-24

Step 12. Perform a Module Calibration 1-26

Step 13. For More Information 1-29

Cleaning Connections for Accurate Measurements 1-30

Returning the Instrument for Service 1-39

Hard Drive Recovery 1-42

Agilent Technologies Service Offices 1-43

Setting Up the Infiniium DCA

Page 6

Setting Up the Infiniium DCA

Setting Up the Infiniium DCA

Setting Up the Infiniium DCA

This chapter shows you how to properly set up your Infiniium DCA. Follow the

setup steps in the order presented. In addition, you will learn how to use

proper optical connection cleaning techniques to avoid costly repairs. Lastly,

this chapter explains how to return your instrument for service.

General Safety Considerations

This product has been designed and tested in accordance with the standards

listed in the Manufacturer’s Declaration of Conformity, and has been supplied

in a safe condition. The documentation contains information and warnings

which must be followed by the user to ensure safe operation and to maintain

the product in a safe condition.

Install the instrument according to the enclosure protection provided. This

instrument does not protect against the ingress of water. This instrument protects against finger access to hazardous parts within the enclosure.

1-2

Page 7

Setting Up the Infiniium DCA

General Safety Considerations

WARNING If this product is not used as specified, the protection provided by the

equipment could be impaired. This product must be used in a normal

condition (in which all means for protection are intact) only.

WARNING No operator serviceable parts inside. Refer servicing to qualified

service personnel. To prevent electrical shock do not remove covers.

WARNING To prevent electrical shock, disconnect the instrument from mains

before cleaning. Use a dry cloth or one slightly dampened with water

to clean the external case parts. Do not attempt to clean internally.

CAUTION Do not use too much liquid in cleaning the instrument. Water can enter the

front-panel keyboard, damaging sensitive electronic components.

WARNING This is a Safety Class 1 Product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only be

inserted in a socket outlet provided with a protective earth contact.

Any interruption of the protective conductor inside or outside of the

instrument is likely to make the instrument dangerous. Intentional

interruption is prohibited.

CAUTION VENTILATION REQUIREMENTS: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperature of the product by 4° C for every 100 watts dissipated in the

cabinet. If the total power dissipated in the cabinet is greater than 800 watts,

then forced convection must be used.

CAUTION This product is designed for use in Installation Category II and Pollution

Degree 2 per IEC 1010 and 664 respectively.

Installation Category: Installation Categories (overvoltage categories) are

determined by the transient overvoltage levels that may be expected. CAT I:

Mains isolated. CAT II: Line voltage in appliance and to wall outlet. CAT III:

Line voltage behind wall outlet to next level of distribution.

1-3

Page 8

Setting Up the Infiniium DCA

Instrument Markings

Instrument Markings

The instruction manual symbol. The product is marked with this warning symbol when it is necessary for the user to refer to the instructions

in the manual.

The laser radiation symbol. This warning symbol is marked on products

which have a laser output.

The AC symbol is used to indicate the required nature of the line module input power.

The Standby symbol is used to mark the position of the instrument

power line switch.

The CE mark is a registered trademark of the European Community.

The CSA mark is a registered trademark of the Canadian Standards

Association.

The C-Tick mark is a registered trademark of the Australian Spectrum

Management Agency.

This text denotes the instrument is an Industrial Scientific and Medical

ISM1-A

Group 1 Class A product.

1-4

Page 9

Step 1. Inspect the Shipment

Setting Up the Infiniium DCA

Step 1. Inspect the Shipment

❒ Inspect the shipping container for damage.

❒ Inspect the instrument.

❒ Verify that you received the options and accessories you ordered.

1-5

Page 10

Setting Up the Infiniium DCA

Options and Accessories

NOTE Keep the shipping container and cushioning material until you have inspected the

contents of the shipment for completeness and have checked the instrument

mechanically and electrically.

If anything is missing or defective, contact your nearest Agilent Technologies

Sales Office. Refer to “Agilent Technologies Service Offices” on page 1-43. If

the shipment was damaged, contact the carrier, then contact the nearest Agilent Sales Office. Keep the shipping materials for the carrier’s inspection. The

Agilent Sales Office will arrange for repair or replacement at Agilent’s option

without waiting for claim settlement.

Options and Accessories

The following table lists the accessories that may be on the Infiniium DCA

shipping list. The information on your actual shipping list is more accurate and

should supersede the information in this table.

Table 1-1. Standard Accessories

Accessory Part Number

Keyboard 1150-7809

Mouse C3751-60201

Getting Started (this book) 86100-90050

Programmer’s Guide 86100-90049

Filler panel 86101-60005

APC 3.5 (f-f) Adapter/connector saver 5061-5311

The following table lists the available product options. Make sure that you

received all of the options that you ordered.

Table 1-2. Instrument Options

Option Description

001 12 GHz Trigger Bandwidth

AX4 Rack mount flange kit

AXE Rack mount flange kit with handles

UK6 Commercial calibration certificate with test data

1-6

Page 11

Table 1-3. Optional Accessories

Accessory Description

10086A ECL terminator

11667B Power splitter, dc to 26.5 GHz, APC 3.5 mm

11667C Power splitter, dc to 50 GHz, 2.4 mm

11898A Plug-in module remote/extender

11982A High-speed lightwave receiver

54006A 6 GHz Resistive divider probe kit

54008B 24 ns delay line

54701A 2.5 GHz active probe

83430A 2.5 Gb/s Lightwave transmitter (1550 nm)

83433A 10 Gb/s Lightwave transmitter

83434A 10 Gb/s Lightwave receiver

83440B/C/D Optical-to-Electrical Converters (6/20/34 GHz)

83446A Lightwave clock and data receiver

83480A-K16 Switch matrix

83480A-K17 RIMM fixture

N1020A 6 GHz TDR probe kit (passive)

N1025A 1 GHz Active differential probe

Setting Up the Infiniium DCA

Options and Accessories

Table 1-4. Additional Adapters for Electrical Channels

Adapter Agilent Part Number

SMA (f-f) 1250-1158

APC 3.5 (f-f) 5061-5311

1-7

Page 12

Setting Up the Infiniium DCA

Options and Accessories

Table 1-5. Fiber-Optic Adapters for Optical Channels

Front Panel

Fiber-Optic

Adapter Description Agilent Part Number

Diamond HMS-10 81000AI

FC/PC 81000FI

D4 81000GI

SC 81000KI

DIN 81000SI

1-8

ST 81000VI

Biconic 81000WI

Page 13

Setting Up the Infiniium DCA

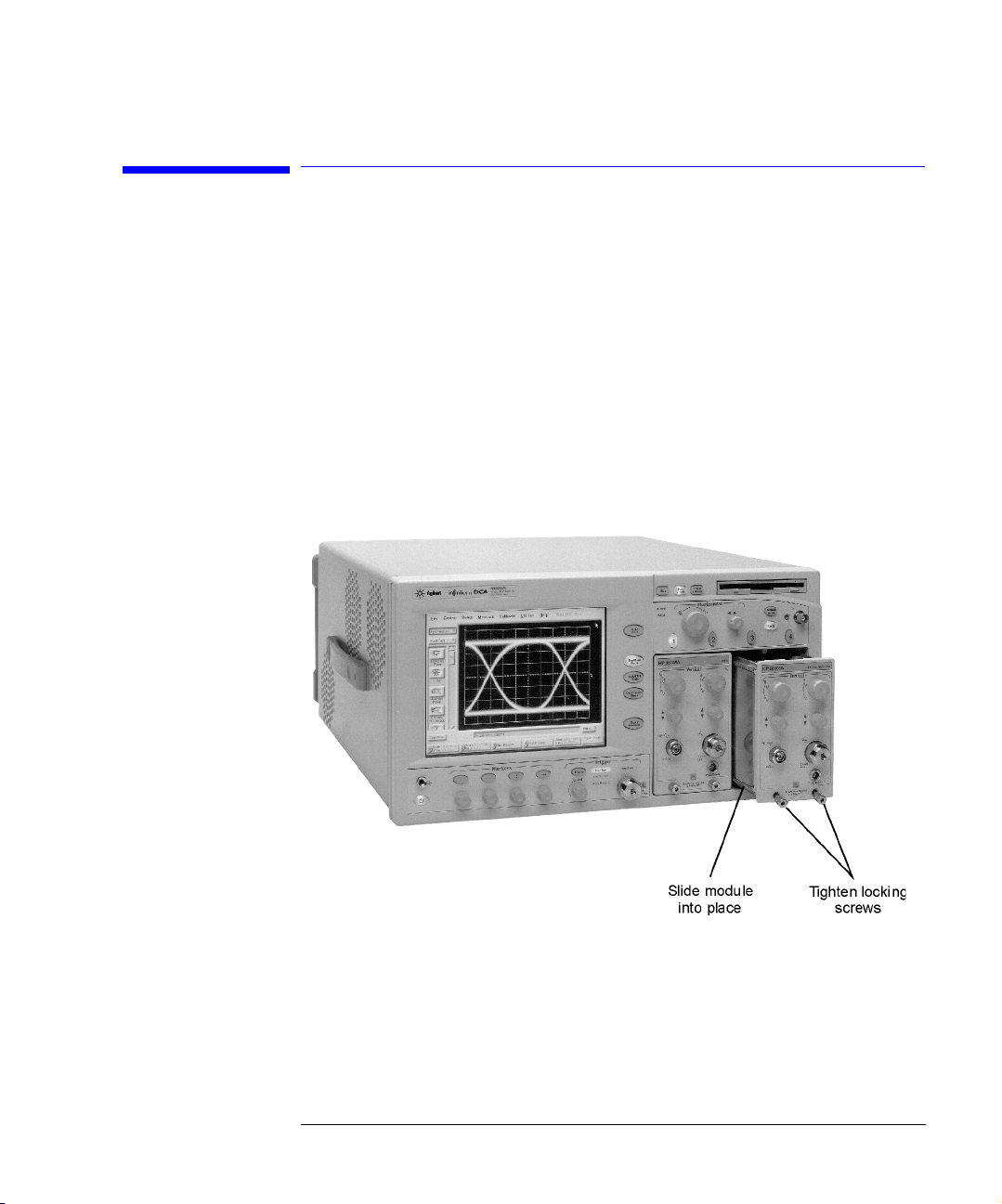

Step 2. Install any Modules

Step 2. Install any Modules

Up to two modules can be inserted into the Infiniium DCA. All documentation

(including specifications) for plug-in modules is located in the Infiniium DCA’s

Help system. To access the Help, touch or click Contents on the Help menu.

1 Slide the module into an available front-panel slot.

You can remove or install a module while the instrument is operating.

2 Finger tighten the two knurled screws on the module’s front panel.

1-9

Page 14

Setting Up the Infiniium DCA

Step 3. Consider Environmental Specifications

Step 3. Consider Environmental Specifications

Review the following specifications to ensure that your operating or storage

environment is suitable for the instrument.

Table 1-6. Environmental Specifications

Use indoor

Temperature

Operating 10 °C to +40 °C (50 °F to + 104 °F)

Non-operating -40 °C to +70 °C (-40 °F to +158 °F)

Humidity

Operating Up to 90% humidity (non-condensing) at +40 °C (+104 °F)

Non-operating Up to 95% relative humidity at + 65 °C (+149 °F)

Altitude

Operating Up to 4,600 meters (15,000 ft)

Non-operating Up to 15,300 meters (50,000 ft)

Vibration

Operating Random vibration 5-500 Hz, 10 minutes per axis, 2.41 g(rms)

Non-operating Random vibration 5-500 Hz, 10 minutes per axis, 0.3 g(rms);

Resonant search, 5-500Hz swept sine, 1 octave/minute sweep

rate, 0.75g, 5 minute resonant dwell at 4 resonances per axis.

Power requirements

Voltage 90 to 132 or 198 to 264 Vac, 48-66 Hz CAT II

Power (including modules) 545 VA; 375 W

Weight

Mainframe 15.5 kg (34 lb)

Modules 1.2 kg (2.6 lb)

Dimensions

Height 215.1 mm (8.47 in)

Width 425.5 mm (16.75 in)

Depth 566 mm (22.2 in)

Depth with front connectors

and rear feet

629 mm (24.8 in)

1-10

Page 15

Setting Up the Infiniium DCA

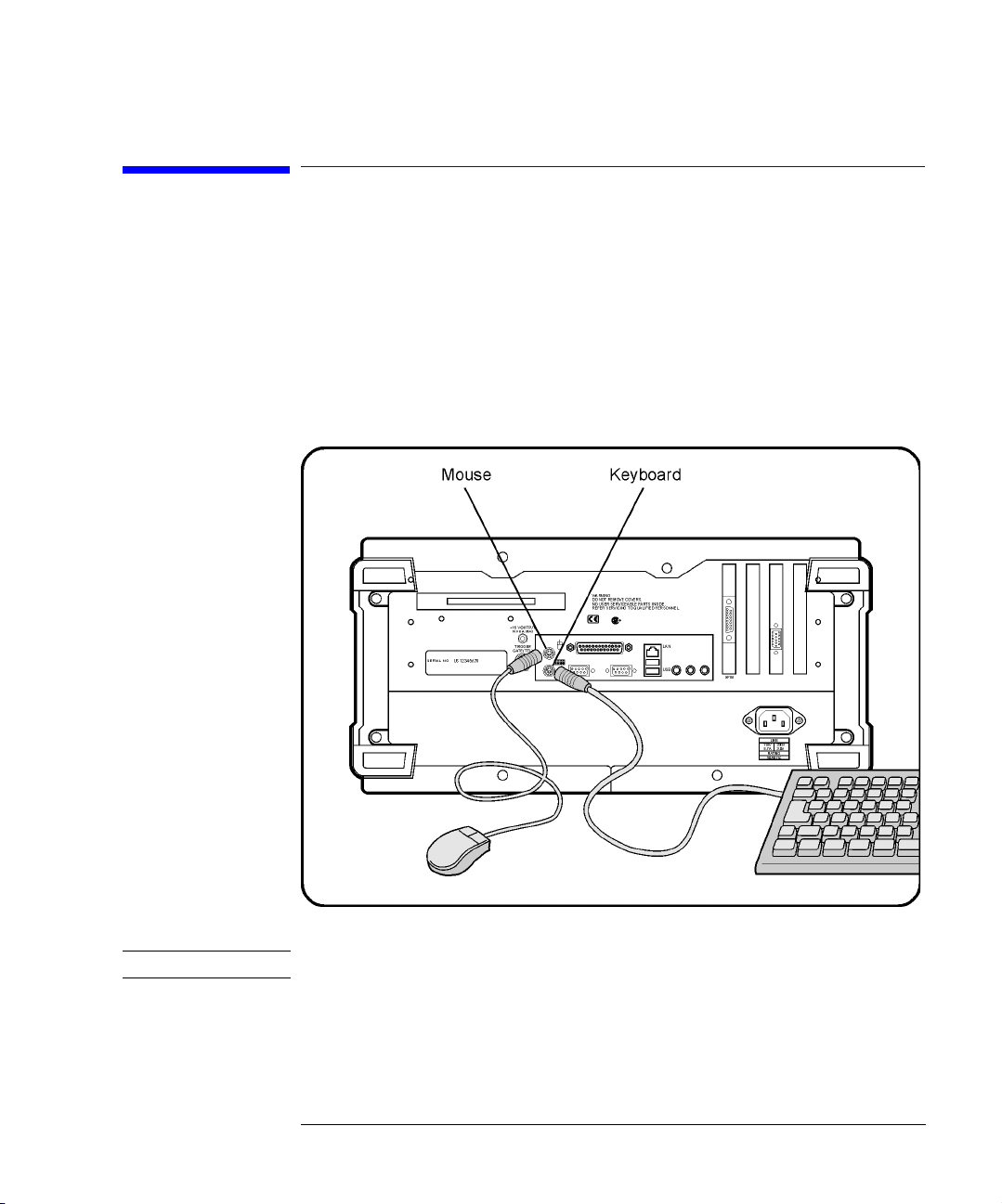

Step 4. Connect the Keyboard and Mouse (Optional)

Step 4. Connect the Keyboard and Mouse

(Optional)

Connect the standard PC-compatible mouse and keyboard that is supplied

with the instrument.

NOTE Do not stack other objects on the keyboard; this will cause self-test failures on power-on.

1-11

Page 16

Setting Up the Infiniium DCA

Step 5. Connect the Line Cord

Step 5. Connect the Line Cord

Connect the line cord as shown in the figure below.

The Infiniium DCA automatically adjusts for line input voltages in the range of

100 to 240 VAC. There is no manual selection switch. The line cord provided is

matched by Agilent to the country in which the order originates. Refer to

Table 1-8, “Available Line Cords,” on page 1-13 for a list of available line power

cords.

Install the instrument so that the detachable power cord is readily identifiable

and is easily reached by the operator. The detachable power cord is the

instrument disconnecting device. It disconnects the mains circuits from the

mains supply before other parts of the instrument. The front panel switch is

1-12

Page 17

Setting Up the Infiniium DCA

Step 5. Connect the Line Cord

only a standby switch and is not a LINE switch. Alternatively, an externally

installed switch or circuit breaker (which is readily identifiable and is easily

reached by the operator) may be used as a disconnecting device.

CAUTION Always use the three-prong AC power cord supplied with this instrument.

Failure to ensure adequate earth grounding by not using this cord may cause

instrument damage.

CAUTION Do not connect ac power until you have verified the line voltage is correct as

described in Table 1-7. Damage to the equipment could result.

CAUTION This instrument has autoranging line voltage input. Be sure the supply voltage

is within the specified range.

Table 1-7. Line Power Requirements

Power 115 VAC: 110 VA MAX. / 60 WATTS MAX. / 1.1 A MAX.

230 VAC: 150 VA MAX. / 70 WATTS MAX. / 0.6 A MAX.

Voltage nominal: 115 VAC / 230 VAC CAT II

range 115 VAC: 90–132 V

range 230 VAC: 198–254 V

Frequency nominals: 50 Hz / 60 Hz

range: 47–63 Hz

Table 1-8. Available Line Cords

Plug Type Cable Part No. Plug Description

250V 8120-1351

8120-1703

250V 8120-1369

8120-0696

Straight *BS1363A

90°

Straight *NZSS198/ASC

90°

Length

(in/cm)

90/228

90/228

79/200

87/221

Color Country

Gray

Mint Gray

Gray

Mint Gray

United Kingdom, Cyprus,

Nigeria, Zimbabwe,

Singapore

Australia, New Zealand

1-13

Page 18

Setting Up the Infiniium DCA

Step 5. Connect the Line Cord

Table 1-8. Available Line Cords

Plug Type Cable Part No. Plug Description

250V 8120-1689

8120-1692

8120-2857p

125V 8120-1378

8120-1521

8120-1992

250V 8120-2104

8120-2296

Straight *CEE7-Y11

90°

Straight (Shielded)

Straight *NEMA5-15P

90°

Straight (Medical) UL544

Straight *SEV1011

1959-24507

Type 12 90°

220V 8120-2956

8120-2957

250V 8120-4211

8120-4600

Straight *DHCK107

90°

Straight SABS164

90°

Length

(in/cm)

79/200

79/200

79/200

90/228

90/228

96/244

79/200

79/200

79/200

79/200

79/200

79/200

Color Country

Mint Gray

Mint Gray

Coco Brown

Jade Gray

Jade Gray

East and West Europe,

Saudi Arabia, So. Africa,

India (unpolarized in many

nations)

United States, Canada,

Mexico, Philippines,

Taiwan

Black

Mint Gray

Switzerland

Mint Gray

Mint Gray

Denmark

Mint Gray

Jade Gray Republic of South Africa

India

100V 8120-4753

8120-4754

* Part number shown for plug is the industry identifier for the plug only. Number shown for

cable is the Agilent Technologies part number for the complete cable including the plug.

1-14

Straight MITI

90°

90/230

90/230

Dark Gray Japan

Page 19

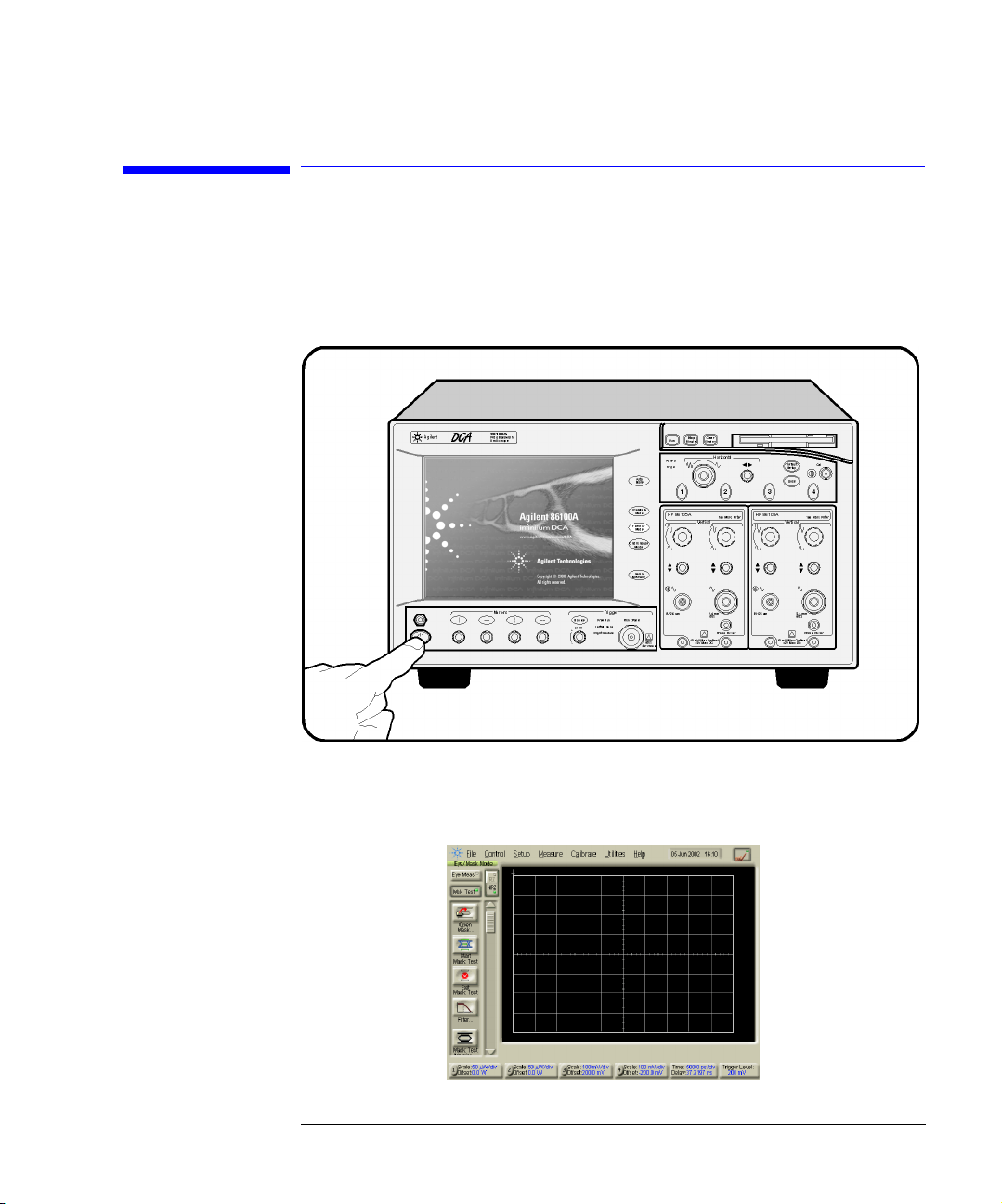

Step 6. Turn on the line power

Setting Up the Infiniium DCA

Step 6. Turn on the line power

Press the power switch at the lower left-hand corner of the front panel.

After about one minute, the Infiniium DCA will be ready to use. The display

will look similar to the following figure.

1-15

Page 20

Setting Up the Infiniium DCA

Interacting With the Display

NOTE The detachable power cord is the instrument disconnecting device. It disconnects the

mains circuits from the mains power supply before other parts of the instrument. The

front panel switch is only a standby switch and is not a LINE switch disconnecting

device.

Install the instrument so that the detachable power cord is readily identifiable and is

easily reached by the operator.

Interacting With the Display

Although you can operate all instrument functions using a keyboard and

mouse, the touch screen feature makes your Infiniium DCA even easier to use.

You can explore the instrument’s functions and settings by touching elements

on the display (such as menus, buttons, and other controls) with your finger

or the supplied stylus.

Although this book uses the term “touch” to encourage you to experience

using the touch screen, you can always click using a mouse or PC-compatible

pointing device instead.

NOTE The display will always function as a touch screen, even when a mouse and keyboard are

connected.

CAUTION Avoid touching the screen with a sharp object, as this could result in damage to

the display. Use your finger or the supplied stylus.

1-16

Page 21

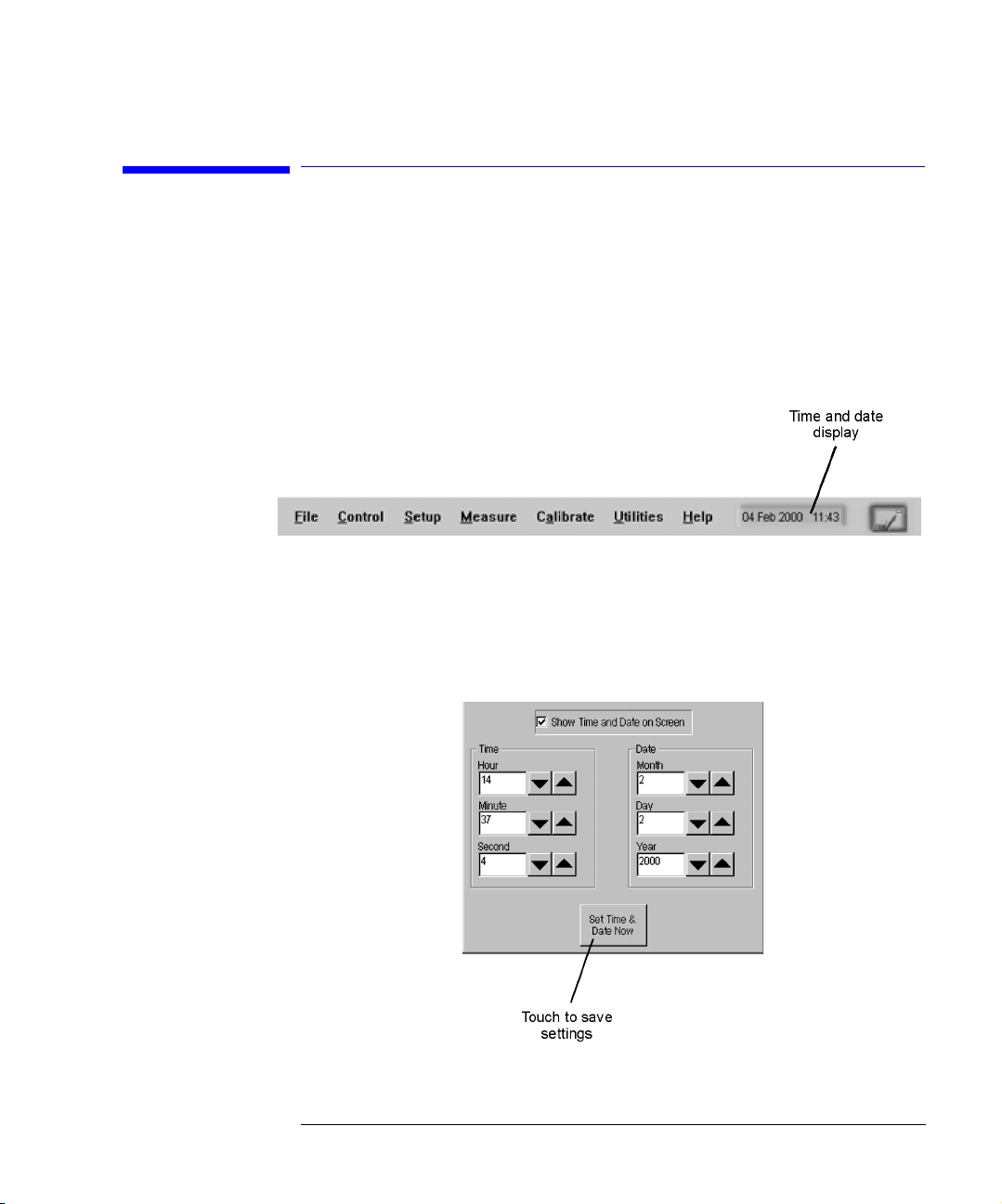

Setting Up the Infiniium DCA

Step 7. Set the time and date

Step 7. Set the time and date

1 Touch the current time and date shown near the top of the display. The Set

Tim e and Date dialog box opens.

2 Enter the current time and date in one of the following ways:

• Click the time and date text boxes, and enter the desired number.

• Click the up or down arrows next to the time and date text boxes until the

desired number is displayed.

3 Touch Set Time & Date Now to apply the changes and close the dialog box.

1-17

Page 22

Setting Up the Infiniium DCA

Step 8. Connect a Printer

Step 8. Connect a Printer

Use of a printer with the Infiniium DCA is optional. Table 1 -9 lists the PCL-language printers that are currently supported for use with the instrument. To

add a local printer, you must use the Add Printer Wizard to select the printer

driver for the printer as outlined in this procedure; the Add Printer Wizard

does not run automatically. For more information on connecting and using a

printer, refer to the built-in information system. To add a network printer, contact your network administrator.

Unsupported printers

If your printer is not in the list of supported printers, you will need the printer driver disk

that came with your printer. To install the printer driver from this disk, click Have Disk on

the Add Printer Wizard dialog box. The instrument will then prompt you to put your

printer driver disk into the front-panel disk drive (drive A) or rear-panel CD-Rom drive.

Be sure to install the Windows 98 printer driver for your printer. If a printer driver disk

was not provided or you cannot find the disk, you can contact the printer’s manufacturer

to obtain the appropriate Windows 98 printer driver.

Table 1-9. Supported Printers

HP DeskJet 850 HP DeskJet 1600C

HP DeskJet 890C HP LaserJet 4P

HP DeskJet 970 HP LaserJet 4000N

HP DeskJet 1200C

To connect a printer

1 Turn on the power to the Infiniium DCA.

2 On the File menu, select Print Setup and then Add Printer.

An online Help window opens with instructions for connecting a printer. You

do not need to read the displayed instructions at this time.

1-18

Page 23

Setting Up the Infiniium DCA

Step 8. Connect a Printer

3 Turn the power off the Infiniium DCA. Do not exit the online Help before

turning the instrument off.

4 Connect the printer to the instrument’s rear-panel Parallel port. Refer to

“Rear-panel features” on page 3-6 to locate the Parallel port. Use the cable

that came with your printer.

5 Turn the printer power on.

6 Wait five seconds and then turn the power on the Infiniium DCA again.

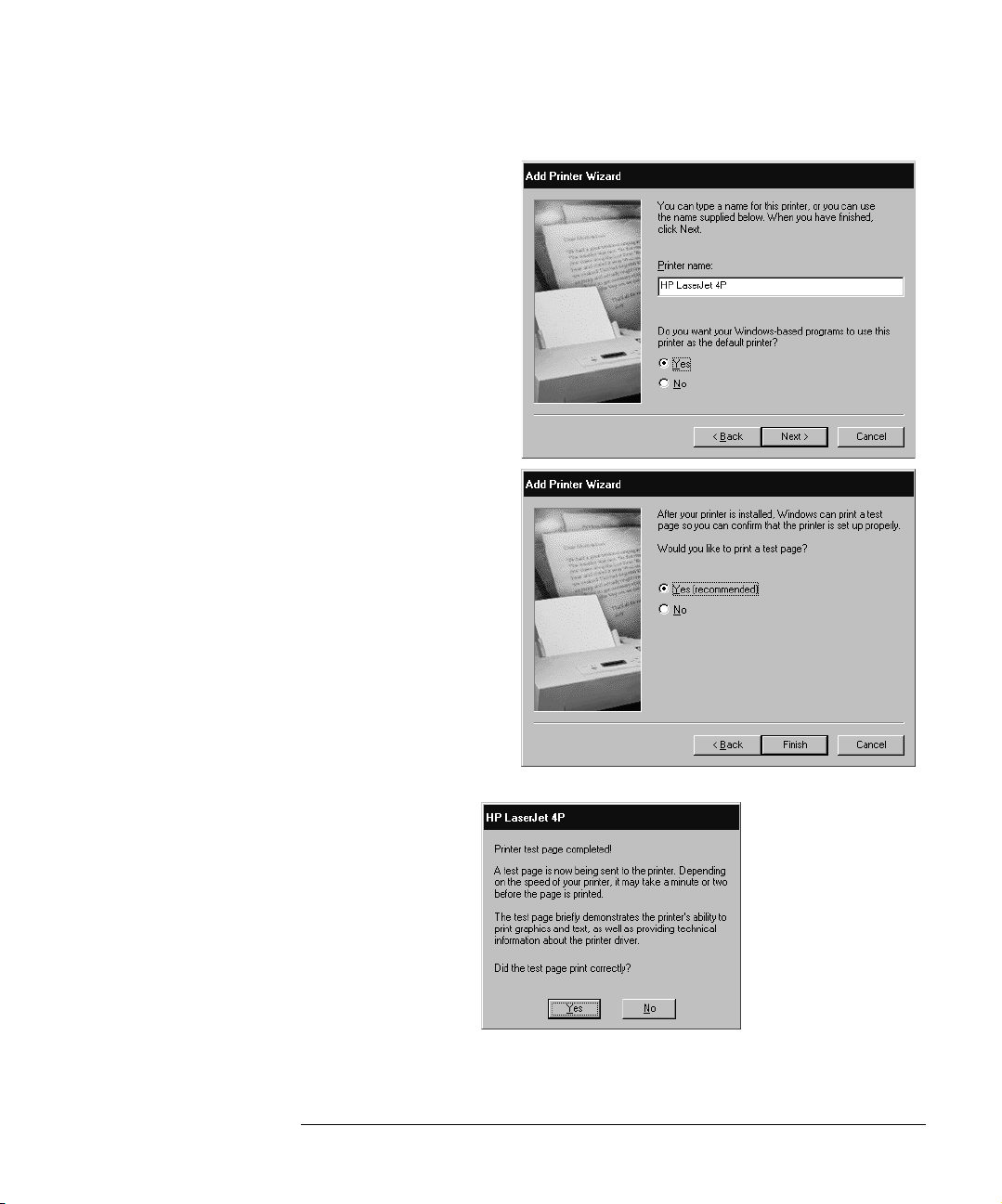

7 The following message appears. Touch No.

8 The following message appears. Touch OK.

9 The instrument

automatically recognizes

the printer connected on

the printer port and

displays the Add Printer

Wizard. Touch Next.

1-19

Page 24

Setting Up the Infiniium DCA

Step 8. Connect a Printer

10 Select Local printer and

then touch Next.

11 Select the printer

manufacturer and then

printer. Then, touch

Next. If your printer is

not listed, touch Have

Disk. The instrument

will then prompt you to

put your printer driver

disk into the front-panel

disk drive (drive A) or

CD-Rom drive. Be sure

to install the Windows 98

printer driver for your

printer.

12 Select LPT1 for the

printer port. Touch

Next.

1-20

Page 25

13 Touch Yes and then

touch Next.

14 Touch Yes to print a test

page. Then, touch Next.

15 After confirming that the

test page printed

correctly, touch Yes.

Setting Up the Infiniium DCA

Step 8. Connect a Printer

16 Turn the Infiniium DCA’s power off and then on again. The printer is now

installed and ready to use.

1-21

Page 26

Setting Up the Infiniium DCA

Step 9. Calibrate the Touch Screen

Step 9. Calibrate the Touch Screen

The touch screen configuration utility ensures that the touch screen is both

aligned and orientated with the display. Therefore, when you touch an element on the display screen, the instrument can detect the task you want to

perform.

1 On the Utilities menu, choose Touch Screen Calibration. The touch screen

configuration utility opens.

2 Touch the center of the X. The X will move to each corner of the display screen.

The final X will appear in the center of the display screen. When the display is

calibrated, the touch screen configuration utility closes.

The calibration will time out within 10 seconds if you do not touch the center

of the X. You can also press Esc on an optional keyboard to exit the touch

screen calibration.

1-22

Page 27

Setting Up the Infiniium DCA

Step 10. Configure the Instrument on a LAN

Step 10. Configure the Instrument on a LAN

You can configure this instrument on a LAN for file sharing and using network

printers. Contact your company’s network administrator to set up your instrument with the appropriate client, protocol, and configuration for your local

area network (LAN). The network setup is different for every company. If you

plan on sharing your instrument hard disk drive with other computers on your

LAN, you should have the network administrator enable file sharing as part of

the network setup. For more information on setting up a network drive, refer

to the built-in information system.

1-23

Page 28

Setting Up the Infiniium DCA

Step 11. Avoid Costly Repairs

Step 11. Avoid Costly Repairs

CAUTION Electrical channel input circuits and the trigger input circuit can be damaged

by electrostatic discharge (ESD). Therefore, avoid applying static discharges

to the front-panel input connectors. Prior to connecting any coaxial cable to

the connectors, momentarily short the center and outer conductors of the

cable together. Avoid touching the front-panel input connectors without first

touching the frame of the instrument. Be sure that the instrument is properly

earth-grounded to prevent buildup of static charge. Wear a wrist-strap or heelstrap.

CAUTION Optical channel fiber-optic connectors are easily damaged when connected to

dirty or damaged cables and accessories. When you use improper cleaning and

handling techniques, you risk expensive instrument repairs, damaged cables,

1-24

Page 29

Setting Up the Infiniium DCA

Step 11. Avoid Costly Repairs

and compromised measurements. Before you connect any fiber-optic cable to

the Infiniium DCA, refer to “Cleaning Connections for Accurate

Measurements” on page 1-30.

1-25

Page 30

Setting Up the Infiniium DCA

Step 12. Perform a Module Calibration

Step 12. Perform a Module Calibration

A module calibration establishes calibration factors for all installed modules.

The calibration factors compensate for imperfections in the measurement system (for example, variations due to ambient temperature), resulting in the

best instrument precision. It is recommended that you perform this calibration

routinely for best measurement accuracy.

The module calibration is recommended whenever the following occurs:

• Instrument power has been cycled

• A module has been removed and then reinserted

• A change in the temperature of the mainframe exceeds 5°C compared to the

temperature of the last vertical (amplitude) calibration (∆T > 5°C)

• The time since the last calibration has exceeded 10 hours

Refer to the Help for more information about instrument calibrations.

Warm-up time

Allow the instrument, with modules installed, to warm up for a period of at least one

hour before performing a vertical calibration. This ensures that the module reaches its

equilibrium temperature.

CAUTION Electrical channel input circuits and the trigger input circuit can be damaged

by electrostatic discharge (ESD). Therefore, avoid applying static discharges

to the front-panel input connectors. Prior to connecting any coaxial cable to

the connectors, momentarily short the center and outer conductors of the

cable together. Avoid touching the front-panel input connectors without first

touching the frame of the instrument. Be sure that the instrument is properly

earth-grounded to prevent buildup of static charge. Wear a wrist-strap or heelstrap.

1-26

Page 31

Setting Up the Infiniium DCA

Step 12. Perform a Module Calibration

To perform a module calibration

1 On the Calibrate menu, choose All Calibrations.

The All Calibrations dialog box opens. This dialog box allows you to view

the calibration status of modules and initiate the calibration.

2 Touch the Modules tab.

The Modules tab opens and allows you to perform a module calibration on

either the left or right module.

3 Touch the Calibrate Module button (located at the bottom of

the tab) for the module you need to calibrate. This starts the

Module calibration.

4 Remove all external devices and signals from the module.

The module calibration uses known signal levels in the instrument. Introducing an outside signal source will interfere with the calibration factors and

decrease the accuracy of the calibration.

5 Touch Continue. A progress indicator appears.

6 After the calibration completes, choose All Calibrations on the Calibration

menu.

7 The Module tab shows the status of the calibration. The tab will look similar to

the following figure. Notice that the tab indicates that the “Current user

1-27

Page 32

Setting Up the Infiniium DCA

Step 12. Perform a Module Calibration

module calibration is valid.”

1-28

Page 33

Setting Up the Infiniium DCA

Step 13. For More Information

Step 13. For More Information

There are several ways to learn more about your Infiniium DCA.

• Continue reading this book. Chapter 3, “Using the Infiniium DCA” will help you

get started using this instrument.

• Refer to the Help. The Help contains the information that would normally be in

the user’s guide.

• Visit our website at http://www.agilent.com. Use the keywords “Infiniium

DCA” or “86100B” in your search

1-29

Page 34

Setting Up the Infiniium DCA

Cleaning Connections for Accurate Measurements

Cleaning Connections for Accurate

Measurements

Today, advances in measurement capabilities make connectors and connection techniques more important than ever. Damage to the connectors on calibration and verification devices, test ports, cables, and other devices can

degrade measurement accuracy and damage instruments. Replacing a damaged connector can cost thousands of dollars, not to mention lost time! This

expense can be avoided by observing the simple precautions presented in this

book. This book also contains a brief list of tips for caring for electrical connectors.

Choosing the Right Connector

A critical but often overlooked factor in making a good lightwave measurement is the selection of the fiber-optic connector. The differences in connector types are mainly in the mechanical assembly that holds the ferrule in

position against another identical ferrule. Connectors also vary in the polish,

curve, and concentricity of the core within the cladding. Mating one style of

cable to another requires an adapter. Agilent Technologies offers adapters for

most instruments to allow testing with many different cables. Figure 1-1 on

page 1-31 shows the basic components of a typical connectors.

The system tolerance for reflection and insertion loss must be known when

selecting a connector from the wide variety of currently available connectors.

Some items to consider when selecting a connector are:

• How much insertion loss can be allowed?

• Will the connector need to make multiple connections? Some connectors are

better than others, and some are very poor for making repeated connections.

• What is the reflection tolerance? Can the system take reflection degradation?

• Is an instrument-grade connector with a precision core alignment required?

• Is repeatability tolerance for reflection and loss important? Do your specifica-

1-30

Page 35

Setting Up the Infiniium DCA

Choosing the Right Connector

tions take repeatability uncertainty into account?

• Will a connector degrade the return loss too much, or will a fusion splice be required? For example, many DFB lasers cannot operate with reflections from

connectors. Often as much as 90 dB isolation is needed.

Figure 1-1. Basic components of a connector.

Over the last few years, the FC/PC style connector has emerged as the most

popular connector for fiber-optic applications. While not the highest performing connector, it represents a good compromise between performance, reliability, and cost. If properly maintained and cleaned, this connector can

withstand many repeated connections.

However, many instrument specifications require tighter tolerances than most

connectors, including the FC/PC style, can deliver. These instruments cannot

tolerate connectors with the large non-concentricities of the fiber common

with ceramic style ferrules. When tighter alignment is required, Agilent

Technologies instruments typically use a connector such as the Diamond

HMS-10, which has concentric tolerances within a few tenths of a micron. Agilent Technologies then uses a special universal adapter, which allows other

cable types to mate with this precision connector. See Figure 1-2.

1-31

Page 36

Setting Up the Infiniium DCA

Choosing the Right Connector

Figure 1-2. Universal adapters to Diamond HMS-10.

The HMS-10 encases the fiber within a soft nickel silver (Cu/Ni/Zn) center

which is surrounded by a tough tungsten carbide casing, as shown in

Figure 1-3.

Figure 1-3. Cross-section of the Diamond HMS-10 connector.

The nickel silver allows an active centering process that permits the glass fiber

to be moved to the desired position. This process first stakes the soft nickel

silver to fix the fiber in a near-center location, then uses a post-active staking

to shift the fiber into the desired position within 0.2 µm. This process, plus the

keyed axis, allows very precise core-to-core alignments. This connector is

found on most Agilent Technologies lightwave instruments.

The soft core, while allowing precise centering, is also the chief liability of the

connector. The soft material is easily damaged. Care must be taken to minimize excessive scratching and wear. While minor wear is not a problem if the

1-32

Page 37

Setting Up the Infiniium DCA

Inspecting Connectors

glass face is not affected, scratches or grit can cause the glass fiber to move

out of alignment. Also, if unkeyed connectors are used, the nickel silver can be

pushed onto the glass surface. Scratches, fiber movement, or glass contamination will cause loss of signal and increased reflections, resulting in poor return

loss.

Inspecting Connectors

Because fiber-optic connectors are susceptible to damage that is not immediately obvious to the naked eye, bad measurements can be made without the

user even being aware of a connector problem. Although microscopic examination and return loss measurements are the best way to ensure good connections, they are not always practical. An awareness of potential problems, along

with good cleaning practices, can ensure that optimum connector performance is maintained. With glass-to-glass interfaces, it is clear that any degradation of a ferrule or the end of the fiber, any stray particles, or finger oil can

have a significant effect on connector performance.

Figure 1-4 shows the end of a clean fiber-optic cable. The dark circle in the

center of the micrograph is the fiber’s 125 µm core and cladding which carries

the light. The surrounding area is the soft nickel-silver ferrule. Figure 1-5

shows a dirty fiber end from neglect or perhaps improper cleaning. Material is

smeared and ground into the end of the fiber causing light scattering and poor

reflection. Not only is the precision polish lost, but this action can grind off the

glass face and destroy the connector.

Figure 1-6 shows physical damage to the glass fiber end caused by either

repeated connections made without removing loose particles or using

improper cleaning tools. When severe, the damage on one connector end can

be transferred to another good connector that comes in contact with it.

The cure for these problems is disciplined connector care as described in the

following list and in “Cleaning Connectors” on page 1-36.

Use the following guidelines to achieve the best possible performance when

making measurements on a fiber-optic system:

• Never use metal or sharp objects to clean a connector and never scrape the

connector.

• Avoid matching gel and oils.

1-33

Page 38

Setting Up the Infiniium DCA

Inspecting Connectors

Figure 1-4. Clean, problem-free fiber end and ferrule.

Figure 1-5. Dirty fiber end and ferrule from poor cleaning.

Figure 1-6. Damage from improper cleaning.

While these often work well on first insertion, they are great dirt magnets. The

oil or gel grabs and holds grit that is then ground into the end of the fiber.

Also, some early gels were designed for use with the FC, non-contacting con-

1-34

Page 39

Setting Up the Infiniium DCA

Inspecting Connectors

nectors, using small glass spheres. When used with contacting connectors,

these glass balls can scratch and pit the fiber. If an index matching gel or oil

must be used, apply it to a freshly cleaned connector, make the measurement,

and then immediately clean it off. Never use a gel for longer-term connections

and never use it to improve a damaged connector. The gel can mask the extent

of damage and continued use of a damaged fiber can transfer damage to the

instrument.

• When inserting a fiber-optic cable into a connector, gently insert it in as

straight a line as possible. Tipping and inserting at an angle can scrape material

off the inside of the connector or even break the inside sleeve of connectors

made with ceramic material.

• When inserting a fiber-optic connector into a connector, make sure that the fiber end does not touch the outside of the mating connector or adapter.

• Avoid over tightening connections.

Unlike common electrical connections, tighter is not better. The purpose of

the connector is to bring two fiber ends together. Once they touch, tightening

only causes a greater force to be applied to the delicate fibers. With connectors that have a convex fiber end, the end can be pushed off-axis resulting in

misalignment and excessive return loss. Many measurements are actually

improved by backing off the connector pressure. Also, if a piece of grit does

happen to get by the cleaning procedure, the tighter connection is more likely

to damage the glass. Tighten the connectors just until the two fibers touch.

• Keep connectors covered when not in use.

• Use fusion splices on the more permanent critical nodes. Choose the best con-

nector possible. Replace connecting cables regularly. Frequently measure the

return loss of the connector to check for degradation, and clean every connector, every time.

All connectors should be treated like the high-quality lens of a good camera.

The weak link in instrument and system reliability is often the inappropriate

use and care of the connector. Because current connectors are so easy to use,

there tends to be reduced vigilance in connector care and cleaning. It takes

only one missed cleaning for a piece of grit to permanently damage the glass

and ruin the connector.

Measuring insertion loss and return loss

Consistent measurements with your lightwave equipment are a good indication that you have good connections. Since return loss and insertion loss are

key factors in determining optical connector performance they can be used to

determine connector degradation. A smooth, polished fiber end should pro-

1-35

Page 40

Setting Up the Infiniium DCA

Cleaning Connectors

duce a good return-loss measurement. The quality of the polish establishes

the difference between the “PC” (physical contact) and the “Super PC” connectors. Most connectors today are physical contact which make glass-to-glass

connections, therefore it is critical that the area around the glass core be clean

and free of scratches. Although the major area of a connector, excluding the

glass, may show scratches and wear, if the glass has maintained its polished

smoothness, the connector can still provide a good low level return loss connection.

If you test your cables and accessories for insertion loss and return loss upon

receipt, and retain the measured data for comparison, you will be able to tell in

the future if any degradation has occurred. Typical values are less than 0.5 dB

of loss, and sometimes as little as 0.1 dB of loss with high performance connectors. Return loss is a measure of reflection: the less reflection the better

(the larger the return loss, the smaller the reflection). The best physically

contacting connectors have return losses better than 50 dB, although 30 to

40 dB is more common.

Visual inspection of fiber ends

Visual inspection of fiber ends can be helpful. Contamination or imperfections

on the cable end face can be detected as well as cracks or chips in the fiber

itself. Use a microscope (100X to 200X magnification) to inspect the entire

end face for contamination, raised metal, or dents in the metal as well as any

other imperfections. Inspect the fiber for cracks and chips. Visible imperfections not touching the fiber core may not affect performance (unless the

imperfections keep the fibers from contacting).

Cleaning Connectors

The procedures in this section provide the proper steps for cleaning fiberoptic cables and Agilent Technologies universal adapters. The initial cleaning,

using the alcohol as a solvent, gently removes any grit and oil. If a caked-on

layer of material is still present, (this can happen if the beryllium-copper sides

of the ferrule retainer get scraped and deposited on the end of the fiber during

insertion of the cable), a second cleaning should be performed. It is not

uncommon for a cable or connector to require more than one cleaning.

CAUTION Agilent Technologies strongly recommends that index matching compounds

not be applied to their instruments and accessories. Some compounds, such as

gels, may be difficult to remove and can contain damaging particulates. If you

think the use of such compounds is necessary, refer to the compound

manufacturer for information on application and cleaning procedures.

1-36

Page 41

Setting Up the Infiniium DCA

Table 1-10. Cleaning Accessories

Item Agilent Part Number

Isopropyl alcohol 8500-5344

Cotton swabs 8520-0023

Small foam swabs 9300-1223

Compressed dust remover (non-residue) 8500-5262

Table 1-11. Dust Caps Provided with Lightwave Instruments

Item Agilent Part Number

Laser shutter cap 08145-64521

FC/PC dust cap 08154-44102

Biconic dust cap 08154-44105

DIN dust cap 5040-9364

HMS10/dust cap 5040-9361

ST dust cap 5040-9366

Cleaning Connectors

To clean a non-lensed connector

CAUTION Do not use any type of foam swab to clean optical fiber ends. Foam swabs can

leave filmy deposits on fiber ends that can degrade performance.

1 Apply pure isopropyl alcohol to a clean lint-free cotton swab or lens paper.

Cotton swabs can be used as long as no cotton fibers remain on the fiber end

after cleaning.

2 Clean the ferrules and other parts of the connector while avoiding the end of

the fiber.

3 Apply isopropyl alcohol to a new clean lint-free cotton swab or lens paper.

4 Clean the fiber end with the swab or lens paper.

Do not scrub during this initial cleaning because grit can be caught in the

swab and become a gouging element.

5 Immediately dry the fiber end with a clean, dry, lint-free cotton swab or lens

paper.

6 Blow across the connector end face from a distance of 6 to 8 inches using

1-37

Page 42

Setting Up the Infiniium DCA

Cleaning Connectors

filtered, dry, compressed air. Aim the compressed air at a shallow angle to the

fiber end face.

Nitrogen gas or compressed dust remover can also be used.

CAUTION Do not shake, tip, or invert compressed air canisters, because this releases

particles in the can into the air. Refer to instructions provided on the

compressed air canister.

7 As soon as the connector is dry, connect or cover it for later use.

If the performance, after the initial cleaning, seems poor try cleaning the connector again. Often a second cleaning will restore proper performance. The

second cleaning should be more arduous with a scrubbing action.

To clean an adapter

The fiber-optic input and output connectors on many Agilent Technologies

instruments employ a universal adapter such as those shown in the following

picture. These adapters allow you to connect the instrument to different types

of fiber-optic cables.

Figure 1-7. Universal adapters.

1 Apply isopropyl alcohol to a clean foam swab.

Cotton swabs can be used as long as no cotton fibers remain after cleaning. The

foam swabs listed in this section’s introduction are small enough to fit into

adapters.

Although foam swabs can leave filmy deposits, these deposits are very thin, and

the risk of other contamination buildup on the inside of adapters greatly outweighs the risk of contamination by foam swabs.

2 Clean the adapter with the foam swab.

3 Dry the inside of the adapter with a clean, dry, foam swab.

4 Blow through the adapter using filtered, dry, compressed air.

Nitrogen gas or compressed dust remover can also be used. Do not shake, tip,

or invert compressed air canisters, because this releases particles in the can

into the air. Refer to instructions provided on the compressed air canister.

1-38

Page 43

Setting Up the Infiniium DCA

Returning the Instrument for Service

Returning the Instrument for Service

The instructions in this section show you how to properly package the instrument for return to a Agilent Technologies service office. For a list of offices,

refer to “Agilent Technologies Service Offices” on page 1-43.

If the instrument is still under warranty or is covered by an Agilent maintenance contract, it will be repaired under the terms of the warranty or contract

(the warranty is at the front of this manual). If the instrument is no longer

under warranty or is not covered by an Agilent maintenance plan, Agilent will

notify you of the cost of the repair after examining the unit.

When an instrument is returned to a Agilent service office for servicing, it

must be adequately packaged and have a complete description of the failure

symptoms attached.

When describing the failure, please be as specific as possible about the nature

of the problem. Include copies of additional failure information (such as the

instrument failure settings, data related to instrument failure, and error messages) along with the original cal data disks and the instrument being

returned.

Please notify the service office before returning your instrument for service.

Any special arrangements for the instrument can be discussed at this time.

This will help the Agilent service office repair and return your instrument as

quickly as possible.

Preparing the instrument for shipping

1 Write a complete description of the failure and attach it to the instrument.

Include any specific performance details related to the problem. The following

1-39

Page 44

Setting Up the Infiniium DCA

Preparing the instrument for shipping

information should be returned with the instrument.

• Type of service required.

• Date instrument was returned for repair.

• Description of the problem:

• Whether problem is constant or intermittent.

• Whether instrument is temperature-sensitive.

• Whether instrument is vibration-sensitive.

• Instrument settings required to reproduce the problem.

• Performance data.

• Company name and return address.

• Name and phone number of technical contact person.

• Model number of returned instrument.

• Full serial number of returned instrument.

• List of any accessories returned with instrument.

• The original cal data disks.

2 Cover all front or rear-panel connectors that were originally covered when you

first received the instrument.

CAUTION Cover electrical connectors to protect sensitive components from electrostatic

damage. Cover optical connectors to protect them from damage due to physical

contact or dust.

CAUTION Instrument damage can result from using packaging materials other than the

original materials. Never use styrene pellets as packaging material. They do not

adequately cushion the instrument or prevent it from shifting in the carton.

They may also cause instrument damage by generating static electricity.

3 Pack the instrument in the original shipping containers. Original materials are

available through any Agilent office. Or, use the following guidelines:

• Wrap the instrument in antistatic plastic to reduce the possibility of damage

caused by electrostatic discharge.

• For instruments weighing less than 54 kg (120 lb), use a double-walled, corrugated cardboard carton of 159 kg (350 lb) test strength.

• The carton must be large enough to allow approximately 7 cm (3 inches) on

all sides of the instrument for packing material, and strong enough to accommodate the weight of the instrument.

• Surround the equipment with approximately 7 cm (3 inches) of packing material, to protect the instrument and prevent it from moving in the carton. If

packing foam is not available, the best alternative is S.D-240 Air Cap™ from

1-40

Page 45

Setting Up the Infiniium DCA

Preparing the instrument for shipping

Sealed Air Corporation (Commerce, California 90001). Air Cap looks like a

plastic sheet filled with air bubbles. Use the pink (antistatic) Air Cap™ to

reduce static electricity. Wrapping the instrument several times in this material will protect the instrument and prevent it from moving in the carton.

4 Seal the carton with strong nylon adhesive tape.

5 Mark the carton “FRAGILE, HANDLE WITH CARE”.

6 Retain copies of all shipping papers.

1-41

Page 46

Setting Up the Infiniium DCA

Hard Drive Recovery

Hard Drive Recovery

The Infiniium DCA hard drive recovery system offers a way to recover from

situations when the instrument hard drive configuration becomes corrupt due

to inadvertent user changes to the instrument or to a virus infection.

The Infiniium DCA hard disk recovery system consists one floppy disk, one

CD-ROM, and instructions. The recovery process will re-image the internal

disk drive on the Agilent 86100B. After the recovery process is complete, the

Infiniium DCA firmware is set to the latest revision as indicated on the recovery disks.

NOTE Please be advised that all user files and the user network configuration settings will be

lost during the recovery process.

To order a free hard drive recovery package, visit

http://www.agilent.com/comms/dca

1-42

Page 47

Setting Up the Infiniium DCA

Agilent Technologies Service Offices

Agilent Technologies Service Offices

Call Center

For technical assistance, you can contact your local Agilent Call Center.

• In the Americas, call 1 (800) 452-4844

• In other regions, visit http://www.agilent.com and click Contact Us.

Service Center

Before returning an instrument for service, you must first call the Agilent

Technologies Instrument Support Center.

• In all regions, call (800) 403-0801

1-43

Page 48

Setting Up the Infiniium DCA

Service Center

1-44

Page 49

2

Working in Comfort

Page 50

Working in Comfort

Working in Comfort

Working in Comfort

To optimize your comfort and productivity, it is important that you set up your

work area correctly and use your Agilent product properly. With that in mind,

we have developed some setup and use recommendations for you to follow

based on established ergonomic principles.

Improper and prolonged use of keyboards and input devices are among those

tasks that have been associated with repetitive strain injury (RSI) to soft tissues in the hands and arms. If you experience discomfort or pain while using

your Agilent Technologies product, discontinue use immediately and consult

your physician as soon as possible.

Please study the recommendations offered here in this chapter. You may also

wish to consult your employer’s human resources department or other relevant departments for guidance specific to your company.

About Repetitive Strain Injury

Because your comfort and safety are our primary concern, we strongly recommend that you use the infiniium DCA in accordance with established ergonomic principles and recommendations. Scientific literature suggests that

there may be a relationship between injury to soft tissues - especially in the

hands and arms - and prolonged improper use of keyboards or other equipment requiring repeated motions of the hands and forearms. This literature

also suggests that there are many other risk factor that may increase the

chance of such injury, commonly called Repetitive Strain Injury.

What is RSI? Repetitive Strain Injury (RSI—also known as cumulative trauma disorder or

repetitive motion injury) is a type of injury where soft tissues in the body, such

as muscles, nerves, or tendons, become irritated or inflamed. RSI has been a

reported problem for those who perform repetitive tasks such as assembly line

work, meatpacking, sewing, playing musical instruments, and computer work.

2-2

Page 51

Working in Comfort

Mice and Other Input Devices

RSI has also been observed in those who frequently engage in activities such

as carpentry, knitting, housework, gardening, tennis, windsurfing and lifting

children.

What causes RSI? The specific causes of RSI have not been established. Nevertheless, the inci-

dence of RSI has been associated with a variety of risk factors, including:

• Too many uninterrupted repetitions of an activity or motion.

• Performing an activity in an awkward or unnatural posture.

• Maintaining a static position for prolonged periods.

• Failing to take frequent short breaks.

• Other environmental and social factors.

In addition, there have been reports associating the occurrence of RSI with

the use of keyboards, mice, and other input devices. Also, certain medical conditions, such as rheumatoid arthritis, obesity and diabetes, may predispose

people to this type of injury.

What if I

experience

discomfort?

If you are experiencing any discomfort, seek professional medical advice

immediately. Typically, the earlier a problem is diagnosed and treated, the easier it is to resolve.

Mice and Other Input Devices

Various aspects of using mice and other input devices may increase your risk

of discomfort or injury. Observing the following recommendations may reduce

that risk.

• Try to keep your hand, wrist, and forearm in a neutral position while using your

mouse or other input device.

• If you use your thumb to rotate the ball on a trackball or spaceball, keep it in a

relaxed, natural shape, and maintain a neutral posture in your hand, wrist, and

forearm.

• Hold the mouse gently by draping your fingers over it. Keep your hand relaxed

and fingers loose. Do not grip the mouse tightly.

• It takes very little pressure or force from your fingers to activate the buttons or

scroll wheel on your mouse, scrolling mouse, trackball, or other input device.

Using too much force can place unnecessary stress on the tendons and muscles

2-3

Page 52

Working in Comfort

Mice and Other Input Devices

in your hands, wrists, and forearms.

• If you are using a scrolling mouse, be sure to keep your fingers and hand in a

relaxed, neutral position when activating the scroll wheel. Also, this type of

mouse features software that can minimize the number of mouse movements

or button clicks.

• When using a mouse, trackball, or other input device, position it as close to the

keyboard as possible, and keep it at the same level as you do not have to stretch

while using it.

• Use a good quality mouse pad to enable the mouse to work most effectively and

reduce unnecessary hand and wrist movements.

• Be sure to keep your mouse and trackball clean. Regular removal of accumulated dust and dirt helps ensure proper tracking and reduces unnecessary hand

and wrist motions.

2-4

Page 53

3

Introduction 3-2

Oscilloscope Mode 3-8

Eye/Mask Mode 3-7

TDR/TDT Mode 3-9

Using Plug-in Modules 3-10

Using the Touch Screen 3-12

Using the Quick Measure Feature 3-13

If the Display Goes Blank 3-14

Hiding and Moving Dialog Boxes 3-15

Menus 3-16

Using the Infiniium DCA

Page 54

Using the Infiniium DCA

Introduction

Introduction

The Infiniium DCA is designed to measure a variety of high speed digital communication waveforms. You can operate it in any of the following three instrument modes:

• Eye/Mask Mode (100 Mb/s to 10 Gb/s) for eye diagram analysis and standards

testing (for example, SONET/SDH, Gigabit Ethernet, and Fiber Channel).

• TDR/TDT Mode for time domain reflectometry measurements

• Oscilloscope Mode (DC to 20 GHz or 50 GHz)

3-2

Page 55

Using the Infiniium DCA

Introduction

Use the touch screen

You can explore the instrument’s menus and change its settings by touching

the display. Notice that the measurement toolbar changes depending on the

selected instrument mode. Touch the channel, time and delay, and trigger

level buttons located at the bottom of the display to change the horizontal and

vertical scales. Or, you can change these settings using front-panel knobs and

buttons.

3-3

Page 56

Using the Infiniium DCA

Introduction

Refer to the Help System

To learn how to use your Infiniium DCA and to locate information on specifications (including plug-in modules), instrument features, and measurement

configuration refer to Chapter 4, “Using the Built-In Information System” in

this book.

You must provide a trigger input signal

Because high-speed oscilloscopes are not capable of triggering directly on a

test signal, you must first connect an external timing reference signal to the

front-panel trigger input connector. This input allows the Infiniium DCA to

synchonize to the input signal. You can select free-run triggering when an

external trigger is unavailable. However, you will only be able to view the

waveform for amplitude information only without any timing information. This

is an easy way to examine the amplitude of a signal.

3-4

Page 57

Using the Infiniium DCA

Introduction

Front-panel features

The following figure shows the input connectors, controls, power switch, and

other front-panel features available on the Infiniium DCA.

3-5

Page 58

Using the Infiniium DCA

Introduction

Rear-panel features

The following figure shows the rear-panel input connections available on the

Infiniium DCA.

3-6

Page 59

Using the Infiniium DCA

Eye/Mask Mode

Eye/Mask Mode

The Eye/Mask mode allows you to perform NRZ (Non-Return to Zero), or RZ

(Return to Zero) eye diagram measurements and eye mask tests. The eye diagram is typically produced by triggering

the instrument with a synchronous

clock signal.

Eye/Mask mode measurements only

work when an eye diagram, and not a

pulse, is present on the screen. Measurements made on a pulse waveform

while in Eye/Mask mode will fail.

Once you are in Eye/Mask mode, press the Autoscale button. This ensures

that an optimum eye diagram is displayed on the graticule. An optimum eye

diagram consists of a full display of the eye in addition to portions of the waveform preceding and following the eye.

When you select the Eye/Mask mode, the

measurement toolbars shown here appear.

These measurement toolbars include measurements such as rise time, fall time, jitter,

and extinction ratio, as well as the mask test

start and stop controls.

Eye measurement and mask test results

appear below the display graticule. A maximum of four eye measurement test results

are displayed and include any failures or

instrument messages that may occur.

To learn more about the Eye/Mask mode and

switching from NRZ to RZ measurement

mode, consult the Help.

3-7

Page 60

Using the Infiniium DCA

Oscilloscope Mode

Oscilloscope Mode

Use the Oscilloscope mode for pulse

type waveforms that are triggered by

an external signal. Oscilloscope mode

measurements only work when a single

valued waveform, and not an eye diagram, is present on the screen.

When you select the Oscilloscope

mode, the measurement toolbars shown

here appear. These measurement toolbars

include measurements such as rise time, fall

time, overshoot, and Vp-p. All measurements, with the exception of jitter, can be

performed on any of the following sources:

channels, waveform memories, and math

functions. One of the above sources must be

turned on in order to perform an oscilloscope measurement.

If more than one source is turned on and

you initiate a measurement, the Enter Measurement Info dialog box opens. This dialog

box allows you to select the source you want

to use for the measurement.

Measurement results appear below the display graticule. A maximum of four pulse

measurement test results are displayed and include any failures or instrument

messages that may occur.

To learn more about the Oscilloscope mode, consult the Help.

3-8

Page 61

TDR/TDT Mode

The TDR/TDT mode allows you use

time domain reflectometry (TDR) to

verify the proper functioning of the

physical components of your device

under test using a time-delayed electrical pulse. You can also use time domain

transmission (TDT) to measure both

the attenuation and propagation delay

of your device under test.

TDR/TDT mode measurements when

using a single-ended or differential

TDR/TDT 5475x series plug-in module.

When you select the TDR/TDT mode, the measurement toolbar shown here appears. This measurement

toolbar includes measurements such as Quick TDR,

normalization, rise time, and fall time. Quick TDR

allows you to view an immediate display of the characteristics of your device under test. You can also use this

toolbar to perform tasks such as setting up the stimulus and destination for your measurement.

You can use markers to to verify the impedance, voltage, and percent of reflection of a selected point on the

waveform trace. TDR/TDT markers are initiated by

turning on the X-axis marker(s) only. The Y-axis

marker(s) will then track the waveform at the position

determined by the X-axis marker. You can view the

position of the marker values in the marker values tab

located below the display graticule.

To learn more about the TDR/TDT mode, consult the

Help.

Using the Infiniium DCA

TDR/TDT Mode

3-9

Page 62

Using the Infiniium DCA

Using Plug-in Modules

Using Plug-in Modules

The Infiniium DCA holds up to two plug-in modules, which can provide up to

four measurement channels. Each input channel has its own vertical controls.

The amplitude scale knob adjusts the amplitude scale used for the input channel. Use the amplitude offset knob to position the displayed signal. You can

also set the amplitude scale and offset to specific values by touching of channel buttons shown to at the bottom of the display.

To install a module

• Slide the module into an available slot and finger tighten the two front-panel

locking screws.

3-10

Page 63

Using the Infiniium DCA

Using Plug-in Modules

You can use 8348x and 5475x series plug-in modules

In addition to a complete line of modules designed specifically for this instrument, modules designed for use with HP/Agilent 83480A and 54750A mainframes can also be installed into the Infiniium DCA. The 8348x and 5475x

series plug-in modules are equipped with a trigger input on the individual

module front panels. Repeatedly press the Infiniium DCA’s front-panel Trigger

Source button until the label for the desired trigger source is lit.

CAUTION Electrical channel input circuits and the trigger input circuit can be damaged

by electrostatic discharge (ESD). Avoid applying static discharges to the frontpanel input connectors. Prior to connecting any coaxial cable to the

connectors, momentarily short the center and outer conductors of the cable

together. Avoid touching the front-panel input connectors without first

touching the frame of the instrument. Be sure that the instrument is properly

earth-grounded to prevent buildup of static charge. Wear a wrist-strap or heelstrap.

CAUTION Optical channel fiber-optic connectors are easily damaged when connected to

dirty or damaged cables and accessories. When you use improper cleaning and

handling techniques, you risk expensive instrument repairs, damaged cables,

and compromised measurements. Before you connect any fiber-optic cable to

the digital communications analyzer, refer to “Cleaning Connections for

Accurate Measurements” on page 1-30.

3-11

Page 64

Using the Infiniium DCA

Using the Touch Screen

Using the Touch Screen

There may be times when you would like to disable the touch screen feature.

For example, when pointing out a measurement result without initiating a

change to the instrument. You can temporarily disable the touch screen for

this purpose.

A touch screen configuration utility can be used to ensure that the touch

screen is both aligned and orientated with the display. It also allows you to

adjust the touch screen speed to simulate a double-click and to turn the touch

screen sound on or off.

To temporarily disable the touch screen

• Touch the disable button which is located at the top of the display. Touch the

button a second time to reenable the touch screen.

3-12

Page 65

Using the Infiniium DCA

Using the Quick Measure Feature

Using the Quick Measure Feature

Press Quick Measure and the Infiniium DCA automatically performs four

measurements on a displayed signal. You can configure Quick Measure to

include any four measurements located on the measurement tool bar. Quick

Measure has a default set of measurements for each instrument mode. For

example, in Oscilloscope mode the default measurements are: rise time, fall

time, period, and V amplitude. In Eye/Mask mode you can also configure

Quick Measure to perform a mask test.

To configure Quick Measure

• On the Measure menu, choose Quick Measure Config.

3-13

Page 66

Using the Infiniium DCA

If the Display Goes Blank

If the Display Goes Blank

The display automatically turns off if the Infiniium DCA is powered over an

eight hour period without being used. The purpose of this feature is to extend

the life of the display. You can adjust the amount of time that must elapse

before the screen is turned off by the backlight saver utility (for example, 2, 4,

6, or 8 hours). This feature is especially useful if you are using remote measurements or leaving the instrument unattended for long periods of time.

Although not recommended, you can disable this control so that the backlight

is never turned off during inactivity.

To reactivate the display

• Touch the display screen

• Move the mouse (if applicable)

• Touch any button on the instrument front panel

• Turn any knob on the instrument front panel

To configure the backlight saver

1 On the Setup menu, choose Display.

2 Touch Enabled to enable or disable the backlight control.

3-14

Page 67

Using the Infiniium DCA

Hiding and Moving Dialog Boxes

Hiding and Moving Dialog Boxes

Sometimes, dialog boxes may cover portions of a displayed signal and graticule that you wish to see. You can either move the dialog box or make it transparent.

To move a dialog box

• Touch the top of the dialog box, and drag your finger across of display to move

the dialog box to a more convenient location.

To make a dialog box transparent

1 Select Dialog Boxes from the Setup menu.

2 Touch Opaque or Transparent.

3-15

Page 68

The File menu

Using the Infiniium DCA

Menus

Menus

The instrument menus provide access to all functions. This section shows the

layout of each menu. For detailed information on each of these menus, refer to

the Help.

3-16

Page 69

The Control menu

Using the Infiniium DCA

Menus

3-17

Page 70

The Setup menu

Using the Infiniium DCA

Menus

3-18

Page 71

The Measure

menu

Using the Infiniium DCA

Menus

The Calibrate

menu

3-19

Page 72

The Utilities menu

The Help menu

Using the Infiniium DCA

Menus

3-20

Page 73

4

The Infiniium DCA Help Contents 4-3

Description of the Contents Topics 4-4

Getting Help While Changing Instrument Settings 4-6

Learning About Measurements Results 4-7

Hiding the Help 4-8

Printing the Contents of a Topic 4-9

Selecting the Help Language 4-10

Using the Built-In Information System

Page 74

Using the Built-In Information System

Using the Built-In Information System

Using the Built-In Information System

Where is the operating manual for your infiniium DCA? It is built into your

instrument! To access the built-in information system, referred to as Help,

simply touch Contents on the Help menu. This will open the contents topic

that is shown in the figure on the following page. In this chapter, you’ll learn

features that are unique to the Infiniium DCA’s Help system as well as tips that

will make the system more useful to you.

Exploring the Help should be familiar to you because it is similar to other Windows applications. You can, of course, use the touch screen or the mouse to

explore the Help.

4-2

Page 75

Using the Built-In Information System

The Infiniium DCA Help Contents

The Infiniium DCA Help Contents

The following figure shows the 86100B Help contents. This is the starting

point for learning how to use your Infiniium DCA.

In addition to the 11 topics presented in the contents, be sure to use the index

buttons located along the bottom of the topic window. These can be very helpful in locating a topic of interest.

4-3

Page 76

Using the Built-In Information System

Description of the Contents Topics

Description of the Contents Topics

The following list describes the information you can find in each of the contents topics.

This topic contains links to useful information you may

want to read first.

Getting Started

This topic contains links to utilizing the instrument

functionality.

Using the Instrument

Setup Guide

Messages and Errors

Modules and

Specifications

4-4

This topic provides step-by-step procedures for many

configuration and measurement tasks.

This topic contains information about the status of the

instrument or an action that has been performed.

This topic contains descriptions and specifications of

plug-in modules used with the Infiniium DCA.

Page 77

Connector Care

Managing Files and

Networks

Instrument

Specifications

Using the Built-In Information System

Description of the Contents Topics

This topic provides information about optical and electrical connector care.

This topic provides information about file management,

using your network, and printing.

This topic contains descriptions of all instrument mainframe specifications.

Glossary

Technical Support

New Features

This topic provides a list of terms and their definitions.

This topic provides technical support information.

This topic contains the links to both new and enhanced

features in this version of the Infiniium DCA software.

4-5

Page 78

Using the Built-In Information System

Getting Help While Changing Instrument Settings

Getting Help While Changing Instrument

Settings

Help is available directly from dialog boxes in the graphical user interface.

• To see overview information in an open dialog box, touch the Book icon. A top-

ic window opens and describes the dialog box and its controls.

• To get information on a specific item in the dialog box, touch the What’s this?

icon. Then touch the desired control on the dialog box. A window appears with

a description of the selected control, as shown in the following figure.

Book icon

What’s this? icon

4-6

Page 79

Using the Built-In Information System

Learning About Measurements Results

Learning About Measurements Results

After a measurement is performed, the displays shows the Measure tab which

includes the measurement results. The fastest way to get help on measurement configuration or algorithms is to touch the Setup & Info button. The

following figure shows the location of this button.

4-7

Page 80

Using the Built-In Information System

Hiding the Help

Hiding the Help

When using the Help, you can temporarily hide it so that you can see the

entire display. Then, you can re-display the Help with the same topic still

showing.

• To hide the Help, touch the Minimize button located at the top of the Help

window.