Page 1

User and Service Guide

Publication number 01141-97002

July 2004

For Safety and Regulatory information, see the pages at the end

of this book.

© Copyright Agilent Technologies 2000-2004

All Rights Reserved

Agilent Technologies 1141A

Differential Probe and 1142A

Probe Control and Power

Module

Page 2

Agilent Technologies 1141A Differential Probe and

1142A Probe Control and Power Module

This manual contains information for use and service of the differential

probe system, the 1141A Differential Probe and 1142A Probe Control

and Power Module. In this document, the two models will be treated as

a system.

Each of the two instrument models that make up the differential probe

system has a serial number sticker. The sticker for the 1141A

Differential Probe is inside the probe, in the bottom cover. (See

chapter 3 for disassembly procedure.)

The 1141A/1142A probe system allows measurement of small

differential signals in the presence of much larger common-mode

signals. It has the following major features:

• 200 MHz bandwidth

• Variable offset

• dc reject

• ac coupling

• Remote operating capability

The variable offset capability can be used to measure small ac signals in

the presence of much larger dc levels. Remote operation of key

features allows the use of the probe system in automatic test situations.

The probe can be used with an oscilloscope, spectrum analyzer, or any

instrument where differential probing is required and a compatible

50 Ω input is available.

2

Page 3

Contents

1 Operating the Probe

Accessories Supplied 6

Accessories Available 8

To inspect the probe 9

Using the probe with other instruments 9

Recommended Test Equipment 9

2 Calibration Tests and Adjustment

Equipment Required 26

The Test Board 26

Calibration Tests 27

dc Gain Accuracy 28

Bandwidth 34

CMRR Test 36

Calibration Test Record 39

Adjustments 40

Probe Adjustment 40

Adjustment Procedure 42

Attenuator Adapter Adjustment 49

3Service

Introduction 54

Performance Specifications and Characteristics 55

General Characteristics 58

3

Page 4

Contents

Theory of Operation 59

Differential Probe 60

Control and Power Module 60

Attenuator Adapters 61

Test Board 62

Service Policy 63

Troubleshooting 64

Probe Troubleshooting 64

Probe Control and Power Module Troubleshooting 64

Removing and Replacing Assemblies 66

Differential Probe 66

Probe Adapters 68

Probe Control and Power Module 70

Replaceable Parts 71

Parts List 71

Ordering Information 71

Direct Mail Order System 71

Manufacturers’ Codes 72

Exploded View 73

4

Page 5

1

Operating the Probe

5

Page 6

Operating the Probe

Accessories Supplied

Introduction

This chapter shows you how to connect and operate the 1141A

Differential Probe and 1142A Probe Control and Power Module as a

differential probe system.

Accessories Supplied

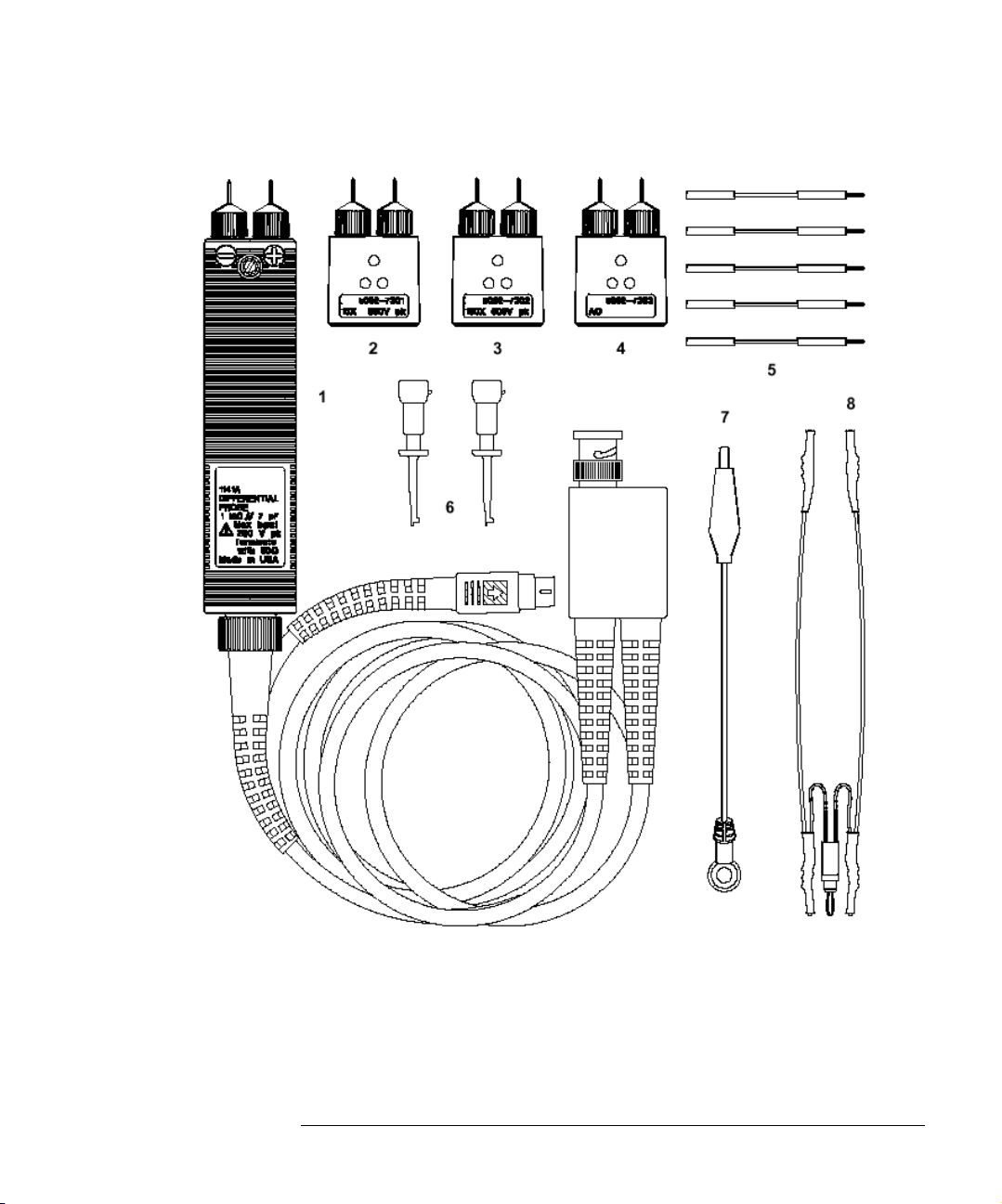

The following items are supplied as part of the 1141A/1142A probe

system. Item numbers refer to the numbers in Figure 1-1 on page -7

and Figure 1-2 on page -8. Those without item numbers are supplied

but not shown in figures. See the Replaceable Parts List for parts not

listed below.

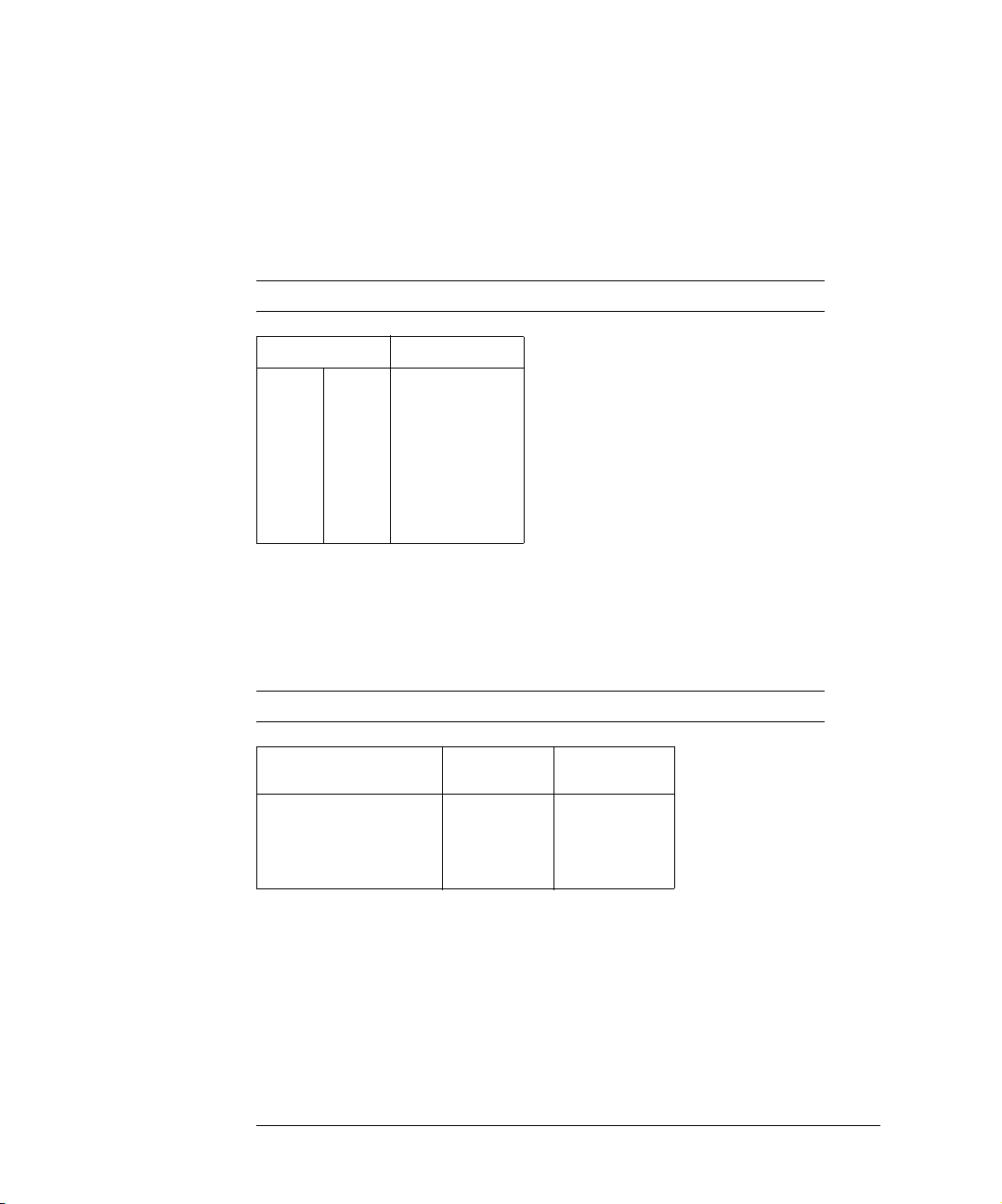

Item Description Qty Part Number

1 Differential Probe 1

2 10x Attenuator Adapter 1 5063-2144

3 100x Attenuator 1 5063-2145

4 ac Coupling Adapter 1 5063-2146

5 Two-inch Extension Leads (package 5) 1 5959-9334

6 Mini Grabbers 2 1400-1422

7 Five-inch Ground Lead 1 5061-6162

8 Shielded Signal Lead 1 01141-68702

9 Test Board 1 01141-66504

10 Flat-blade Alignment Tool 1 8710-1961

11 Circuit Connection Posts (strip of 20) 1 1251-5943

Probe Control and Power Module 1 1142A

Power Cord 1 see parts list

Carrying case

User and Service Manual 1

6

Page 7

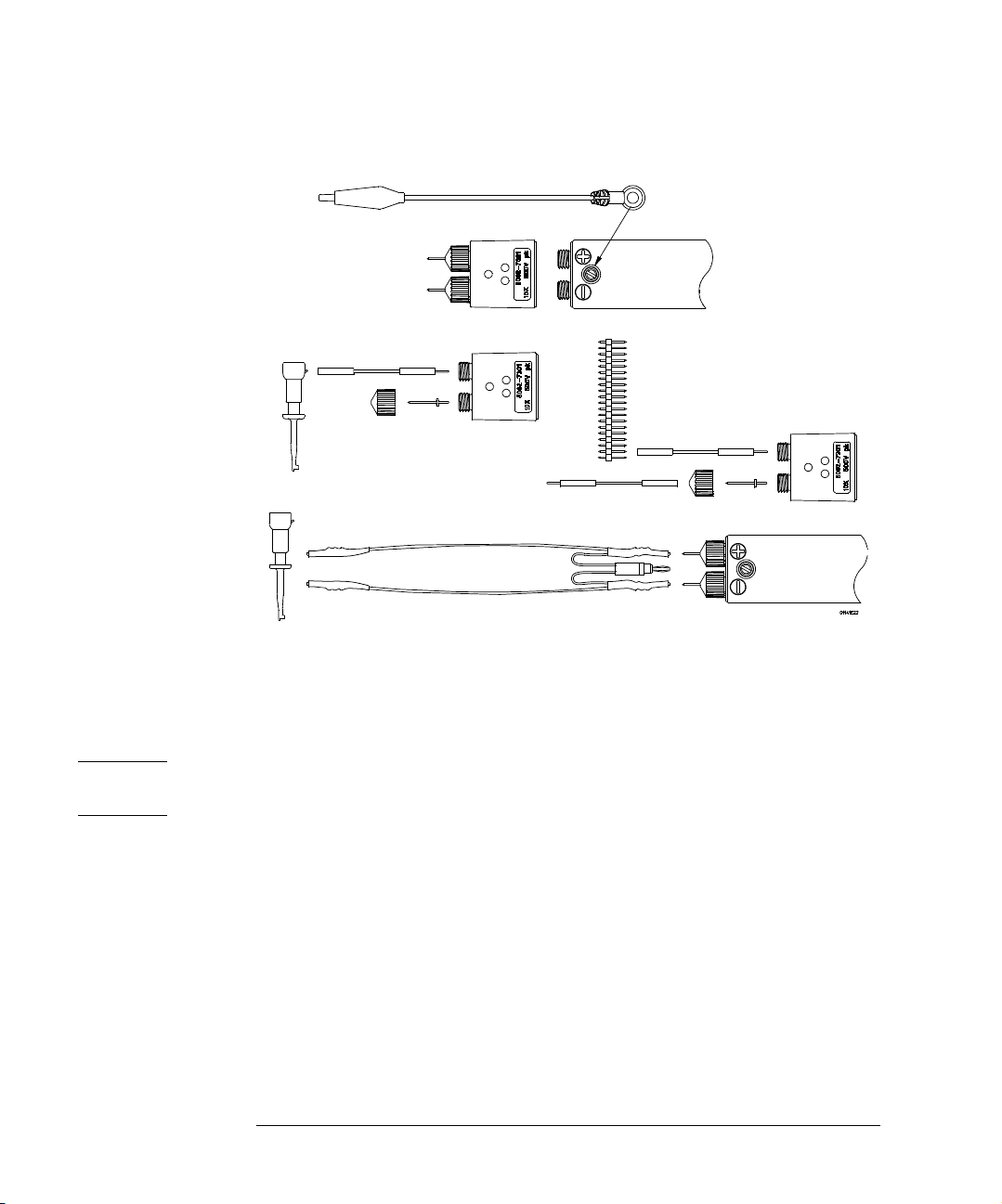

Figure 1-1

Operating the Probe

Accessories Supplied

1141A Differential Probe and Accessories

7

Page 8

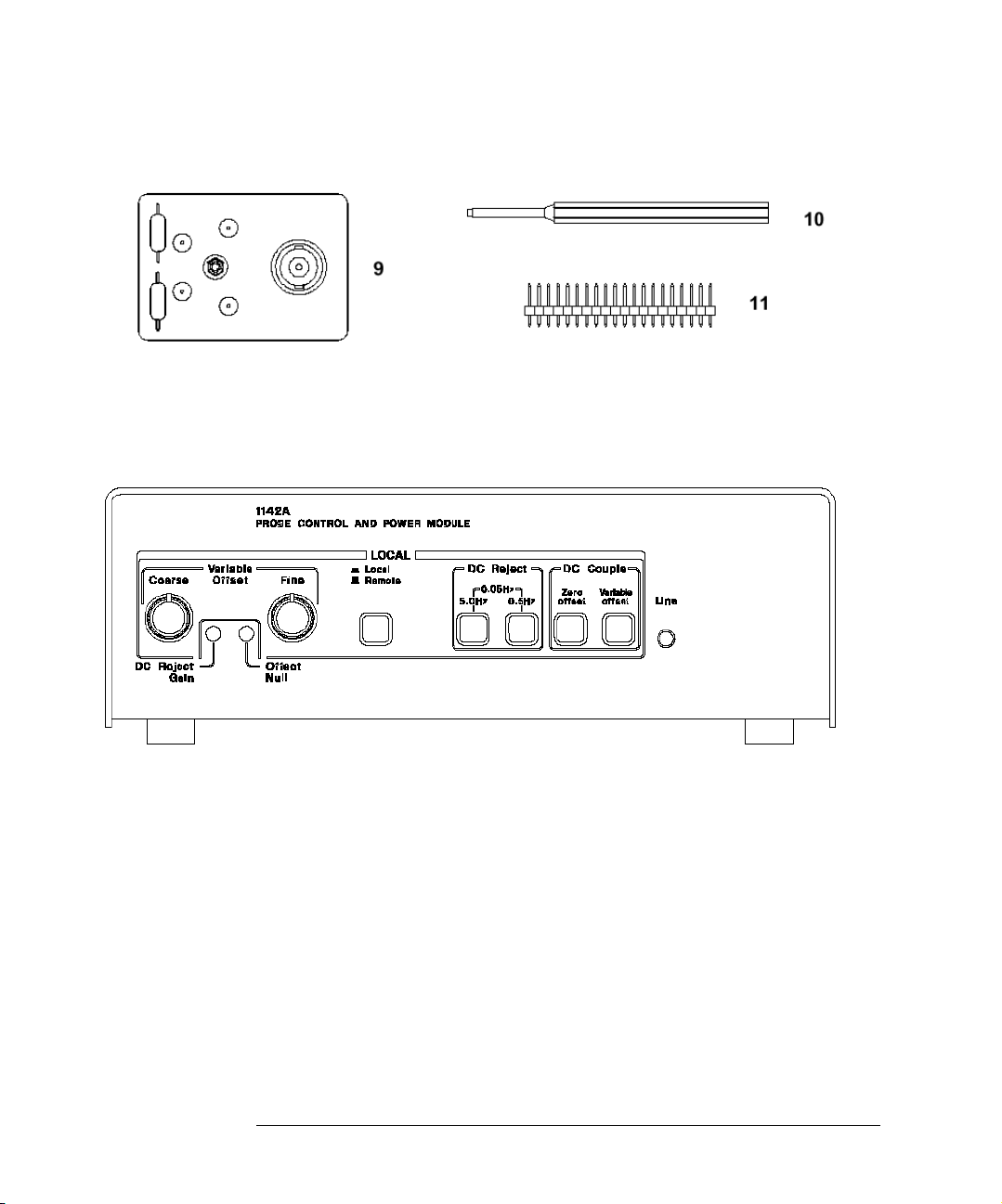

Figure 1-2

Figure 1-3

Operating the Probe

Accessories Available

1141A Miscellaneous Accessories

1142A Probe Control and Power Module

Accessories Available

The following accessories can be ordered.

• 5959-9335 Long Extension Lead (5.5 inch/14 cm), package of 5

• 5090-4833 Mini grabber for SMT, package of 20

8

Page 9

Operating the Probe

To inspect the probe

To inspect the probe

Inspect the shipping container for damage. If the shipping container or cushioning

material is damaged, it should be kept until the contents of the shipment have been

checked for completeness and the instrument had been checked mechanically and

electrically. Accessories supplied with the instrument are listed in see “Accessories

Supplied” on page 6 of this manual.

If the contents are incomplete, if there is mechanical damage or defect, or if the

instrument does not pass calibration tests, notify the nearest Agilent Technologies office.

If the shipping container is damaged, or the cushioning materials show sign of stress,

notify the carrier as well as the nearest Agilent Technologies office. Keep the shipping

materials for the carrier’s inspection. The office will arrange for repair or replacement

at Agilent Technologies’ option without waiting for a claim settlement.

Using the probe with other instruments

The 1141A/1142A probe system can be used with other instruments as well as

oscilloscopes. You can use it with a spectrum analyzer or frequency counter, or any

instrument with an input that can be terminated with 50 Ω.

If you are going to use the probe system with an instrument other than an oscilloscope,

you may need to set up the probe with an oscilloscope first. This will allow you to select

coupling and reject modes, and set offset, so the output of the probe is compatible with

signal requirements of the other instrument.

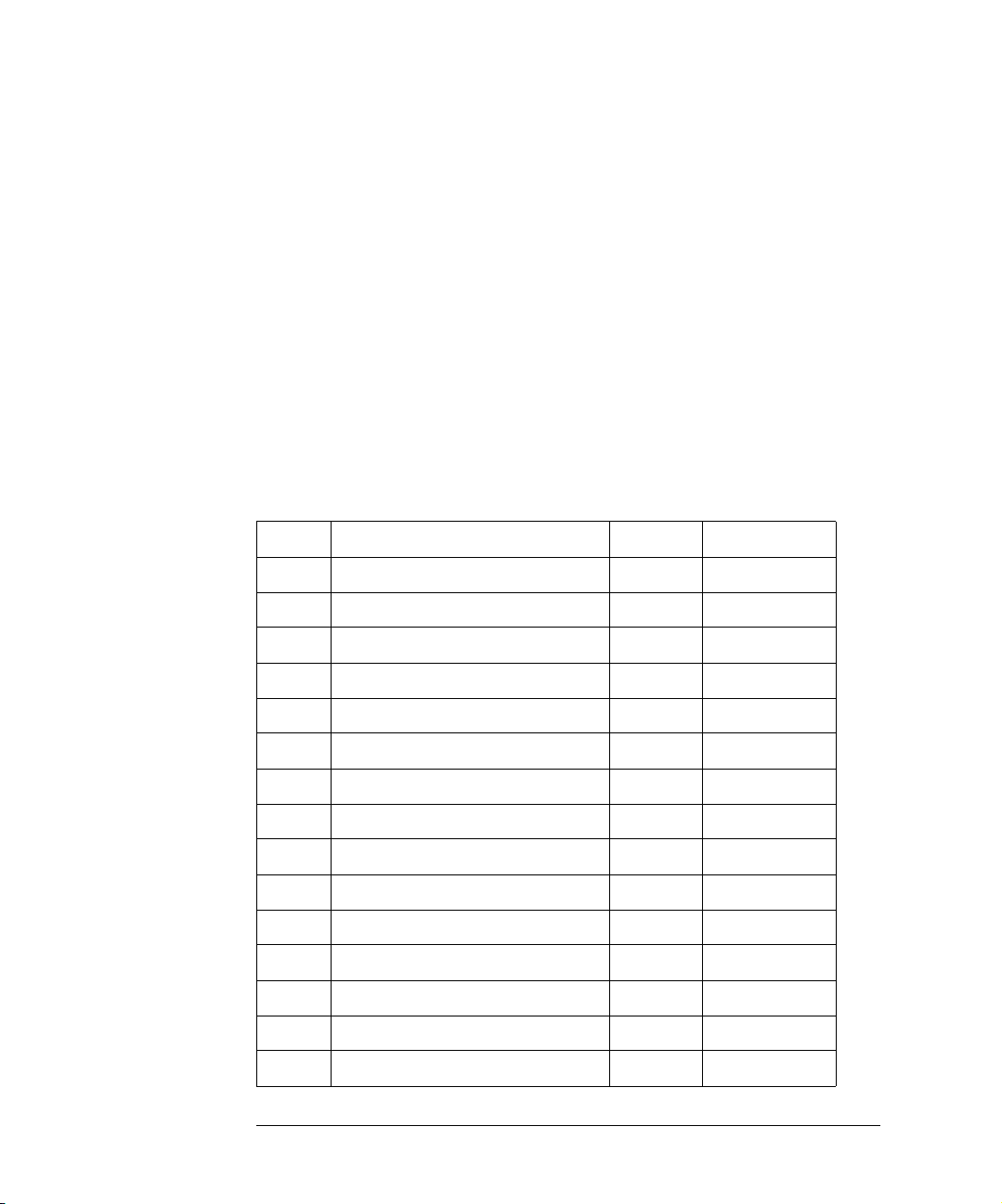

Recommended Test Equipment

The following table is a list of the test equipment required to test calibration, make

adjustments, and troubleshoot this instrument. The table indicates the critical

specifications of the test equipment and for which procedure the equipment is necessary.

Equipment other than the recommended model may be used if it satisfies the critical

specifications listed in the table.

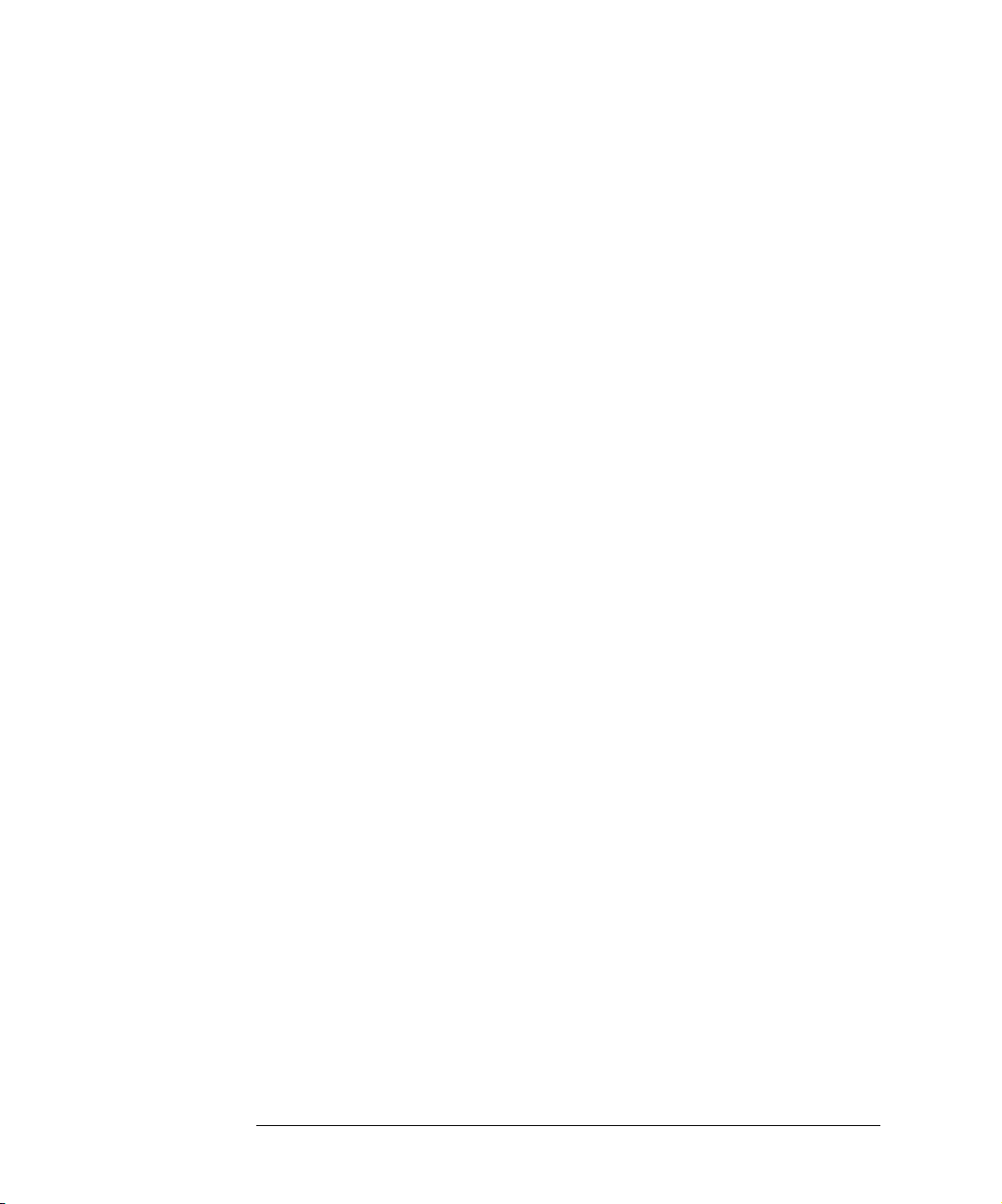

Recommended Test Equipment

Recommended

Equipment Required Critical Specifications

Signal Generator 1 to 200 MHz, 400 m V

Function Generator 2.5 to 500 kHz, 600 m V

Oscilloscope >400 MHz bandwidth, 1 mV/div sensitivity 54830B P,A

dc source ± 100 mV to 7 Vdc E3632A P

rms

p-p

to 16 V

p-p

Agilent

Model/Part Use

8648A P

33120A A

9

Page 10

Operating the Probe

Recommended Test Equipment

Recommended

Equipment Required Critical Specifications

Test Board No substitute (supplied accessory) 01141-66504 A

Load BNC Feedthrough, 50 Ω Pasternack

Cables (2) BNC, 50 Ω 36-inch 10503A P,A

Cable BNC, 50 Ω 9-inch 10502A A

Cable Type N (m) 24-inch 11500B P

Adapter Type N (m) to BNC (f) 1250-0780 A

Adapter Type N (f) to BNC (m) 1250-0077 P

Adapters (2) BNC (f) to dual banana (m) 1251-2277 P

Agilent

Model/Part Use

P

Enterprises PE600850 or Huber+Suhner

22543742

Alignment tool Small flat blade (supplied accessory) 8710-1961/

Sprague-Goodman

part number GTT-5G

P=Calibration Tests, A=Adjustments

A

Setting up the probe

The following paragraphs cover system preparation and initial adjustments.

Power Requirements

The 1141A/1142A probe system (specifically the 1142A) requires a power source of

either 90 to 132/198 to 264 Vac, 47 to 440 Hz, 25 VA maximum.

CAUTION Before connecting power to this instrument, be sure the line voltage switch on the rear

panel of the instrument is set properly.

Line Voltage Selection

Before applying power, verify the setting of the LINE SELECT switch on the rear panel

of the 1142A. The slide switch can be set to either 115 or 230 V.

10

Page 11

Operating the Probe

Recommended Test Equipment

WARNING Before connecting this instrument, the protective earth terminal of the instrument must

be connected to the protective conductor of the (Mains) power cord. The Mains plug

must be inserted in a socket outlet provided with a protective each contact. The

protective action must be negated by the use on an extension cord (power cable)

without a protective conductor (grounding). Grounding one conductor of a twoconductor outlet does not provide an instrument ground.

This instrument is provided with a three-wire power cable. When connected to an

appropriate ac power outlet, this cable grounds the instrument cabinet. The type of

power cable plug shipped with the instrument depends on the country of destination.

The 1142A Power Control and Power Module does not have a power switch. A power

switch is not required because of the low mains power requirement.

Figure 1-4

1142A Rear Panel

Procedure

Use the power cord to connect the 1142A to the ac mains.

1

2 Connect the 1141A probe cable power connector to the PROBE connector on

the rear panel of the 1142A power module.

3 Connect the output of the probe to the input of the oscilloscope.

4 Set the input impedance of the oscilloscope to 50 Ω.

If the oscilloscope does not have a selectable 50 Ω input impedance, connect a 50 Ω BNC

feedthrough termination between the probe output and the input of the oscilloscope.

5 If making an initial equipment setup, continue with the initial adjustment in

the following section.

Initial Adjustment

For a given combination of 1141A Differential Probe and 1142A Probe Control and Power

Module, you may want to adjust the Offset Null and DC Reject Gain. Typically, you need

to make these adjustments only once, before the probe is first used. You can make them

any time to optimize the system. These adjustments do not affect the specifications of

the probe system.

11

Page 12

Figure 1-5

Operating the Probe

Recommended Test Equipment

• Offset null zeroes the dc level at the output of the probe. The range of adjustment is

about ±4 mV.

• DC Reject Gain adjusts the gain of the dc reject circuit to accurately null the dc

component of an input signal. The range of adjustment is about ±0.5%.

1142A Front Panel

Equipment Needed

The following equipment is necessary for initial adjustment.

• 5 V power supply

• DVM that can measure 25 µV

•50 Ω BNC feedthrough terminator

• 01141-66504 test board

Equipment Setup

Use the following procedure to setup the differential probe system for initial adjustment.

CAUTION Do not exceed ±7 V when using the test board for this procedure. If the voltage is too

high, it will cause excessive power dissipation in the 50 Ω termination on the test board.

1 Use the probe setup procedure to set up the probe system.

2 Connect a 50 Ω BNC feedthrough terminator to the output of the probe.

3 Disconnect all accessories from the input of the probe.

4 Connect the DVM to measure the dc output of the probe at the 50 Ω load.

12

Page 13

Figure 1-6

Operating the Probe

Recommended Test Equipment

5 Set up the 1142A:

a Set the Local/Remote push button to Local.

b Under DC Couple, press Zero offset.

6 Set the power supply output to 5 V.

7 Arrange a connection between the power supply and the test board. The

negative terminal of the supply should connect to the shield of the test board

BNC.

If your power supply has standard binding posts, you can connect a banana-to-BNC

adapter to the supply and connect a BNC cable between the supply and the test board.

Adjustment

Warm up the 1141A for 30 minutes before making adjustments.

1

With the 1141A probe inputs unconnected, adjust Offset Null on the 1142A for

a minimum reading on the DVM.

The voltage swing of the adjustment is approximately ±4 mV.

On the 1142A, under DC Reject, press 5.0 Hz.

2

3 Read and record the reading on the DVM, _________ mV.

4 Connect the probe to the test board in the position shown below

(signal to + input).

Signal to + input

5 After the DVM reading stabilizes, adjust DC Reject Gain to the reading recorded

in step 3.

With a 5 V supply, the voltage swing is approximately ±12.5 mV. With a lower supply, the

voltage swings proportionally less.

Using the Accessories

The 1141A Differential Probe and accessories are designed to provide a variety of ways

to connect to circuitry and make measurements. In the descriptions, any method used

to connect to the probe signal inputs also applied to the adapters. The figure below

shows, in a general way, the use of accessories.

13

Page 14

Figure 1-7

Operating the Probe

Recommended Test Equipment

Basic Accessory Connections

Probe Tips

Probe tips fit into the receptacles in the probe and are held in place with probe tip caps.

If necessary, you can solder the probe tips into a circuit or wires can be soldered to the

tips. If you solder to the probe tips, be careful not to melt the plastic probe tip caps.

Note Because of the close tolerances between the probe tip caps and probe tips, it will be

difficult to separate the probe tips and caps once the probe tips have been soldered.

Ground Leads

The circular end of the ground lead fits over the screw on the top side of the probe.

Extension Leads

The extension leads provide a flexible connection between circuitry and the probe.

• To provide a male connection to other circuitry, connect the extension lead over the

probe tips.

• To provide a female connection, remove the probe tip caps and probe tips and connect

the extension leads to the probe.

14

Page 15

Operating the Probe

Recommended Test Equipment

Note Use extension leads and similar connection accessories carefully. Extension leads

compromise the high-frequency specifications of the probe. CMRR is particularly

sensitive to unbalanced input parameters.

To prevent pickup of stray fields when you use extension lead, either the ones supplied

with the 1141A or others, dress them carefully as follows:

• Connect the leads at right angles to the circuitry under test.

• Keep the leads as parallel as possible before they connect to the probe.

Mini-Grabbers

Mini-grabbers can be attached to the probe or adapter through the extension leads.

1

Remove the probe tip caps and tips.

2 Attach the extension leads to the probe or adapter.

3 Attach the mini-grabbers to the extension leads.

Circuit Connector Posts

These 0.025-inch square posts can be used to connect either directly to the probe or to

the extension leads.

Solder the posts directly into your circuitry or use them to make extension leads that

plug into the inputs of the probe or adapters.

Shielded Signal Leads

The shielded signal leads allow connection to points in a circuit that are up to 10 inches

apart. The leads are shielded to within approximately 1/2 inch of the end of the lead so

they minimize pick-up due to stray fields from adjacent circuitry.

1

Connect the end with the ground connector to the probe pins and ground of

the differential probe or adapter.

2 Connect the free ends of the leads to 0.025-inch square or 0.030-inch round pins

in your circuitry or to the mini-grabbers.

Note Each lead has an input capacitance of approximately 15 pF. This capacitance may limit

the bandwidth of your measurement (depending on the impedance of the circuit). Also,

CMRR may be affected because of slight differences between the input capacitance of

the two leads. CMRR is also affected by differences in impedance between the two

measurements points.

15

Page 16

Figure 1-8

Operating the Probe

Recommended Test Equipment

Adapters

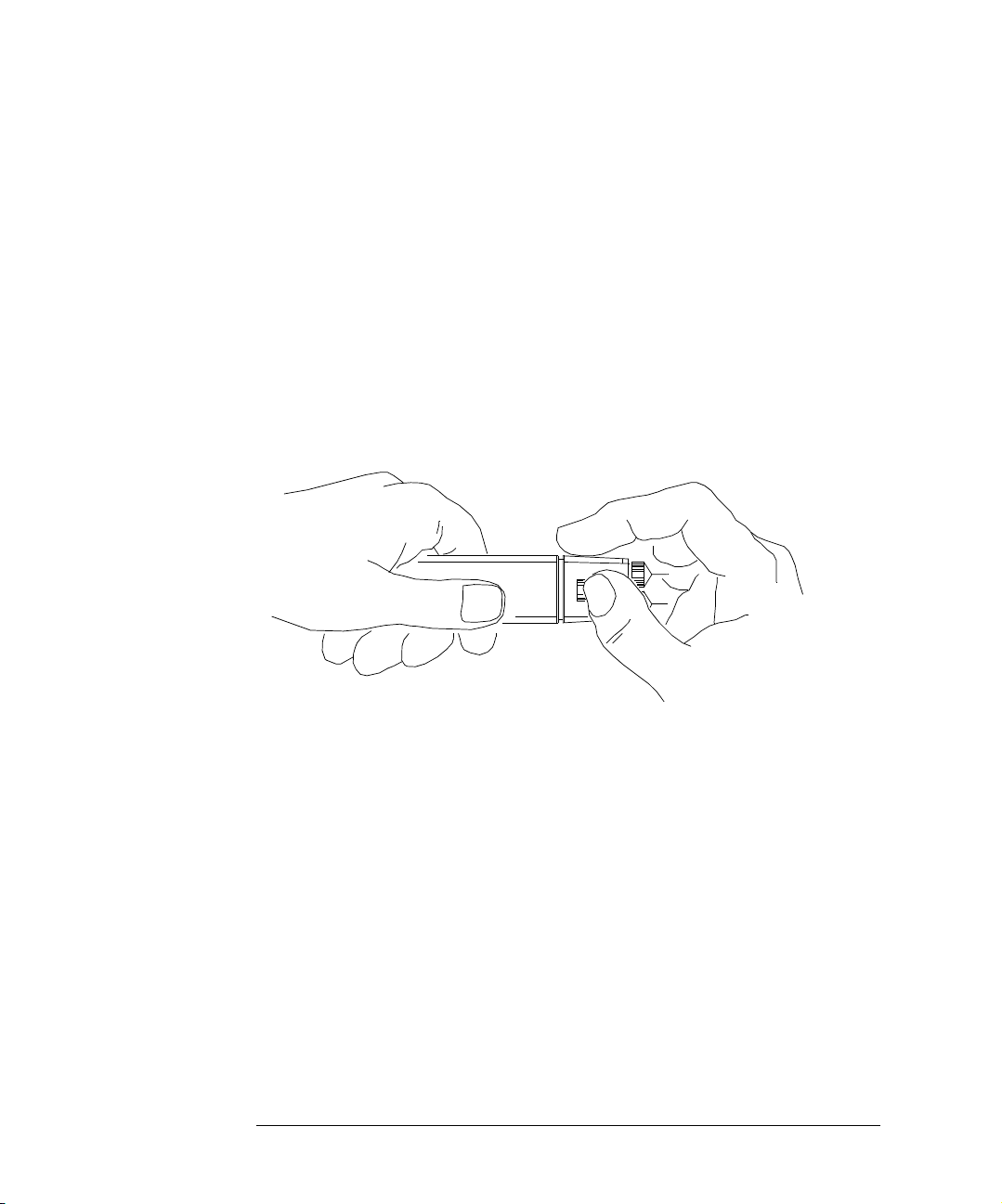

There are three adapters for use with the differential probe. Two adapters are

attenuators, a 10x and a100x. The other is an ac adapter for blocking dc from the probe

input.

The adapters are installed on the probe after the probe tip caps and probe tips have been

removed. The adapter fastens to the probe using a thumb wheel located on the underside

of the adapter. the figure below shows a good way to hold the probe while attaching the

adapter.

1

Remove the probe tip caps and probe tips, from the probe.

2 Fit the adapter over the end of the probe and rotate the thumb wheel with your

finger until the adapter fits snugly.

A snug fit is important because the ground is maintained through the thumb wheel screw.

A loosely attached adapter compromises the mechanical and electrical integrity of the

combination.

Attaching the Adapters

16

Page 17

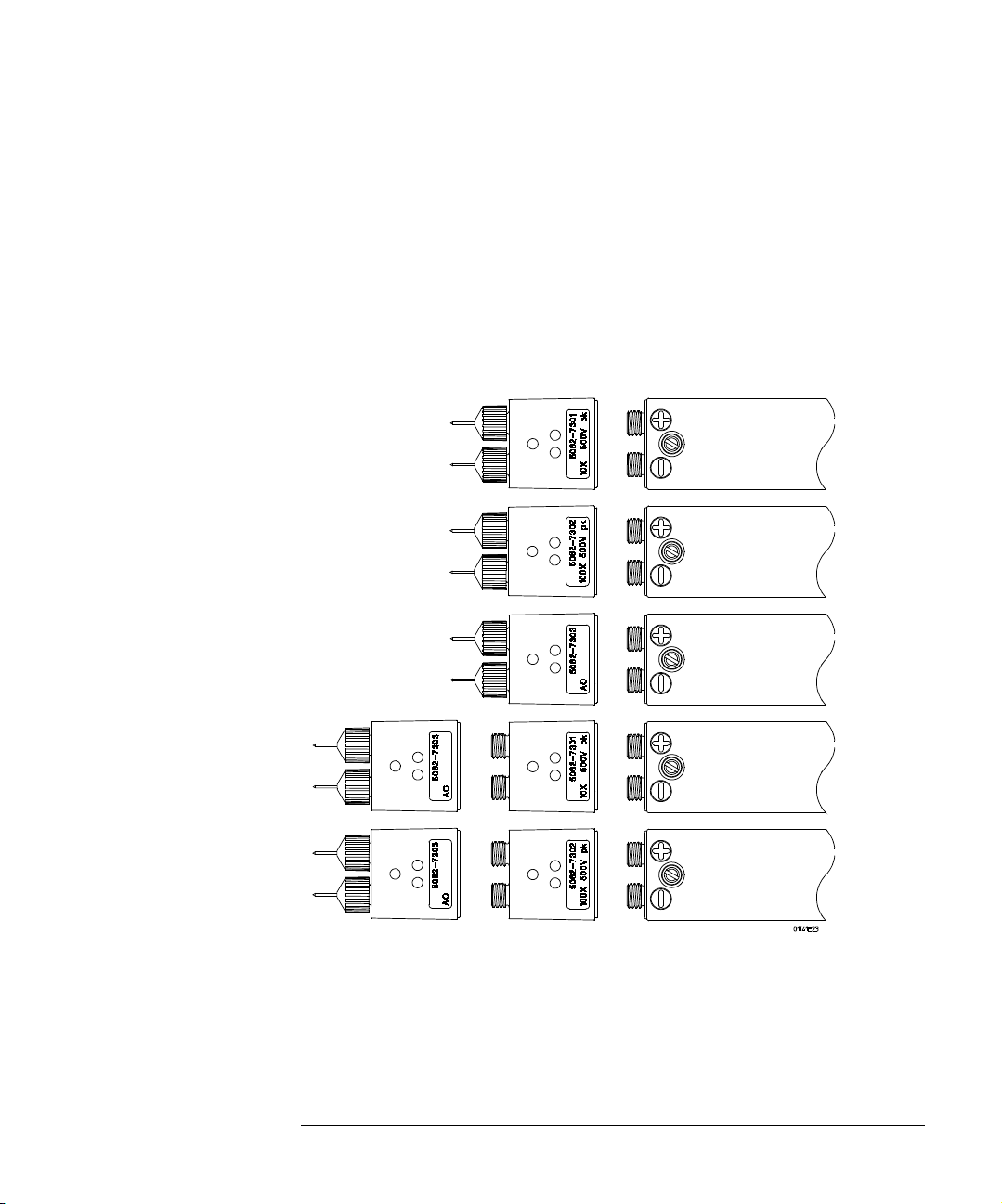

Figure 1-9

Operating the Probe

Recommended Test Equipment

Adapter Combinations

The figure below shows the allowed adapter and probe connections. There are two

specific combinations that should not be used.

• Do not attach the ac adapter between an attenuator adapter and the probe.

An attenuator adapter must be terminated by the input resistance of the probe. The

ac adapter isolates the probe input resistance.

• Do not cascade two attenuator adapters.

The attenuator adapters are designed to be terminated by the 1 MΩ resistance of the

probe. The input resistance of the attenuator adapter is 9 MΩ for the 10x adapter and

10 MΩ for the 100x adapter.

Allowed Adapter Connections

17

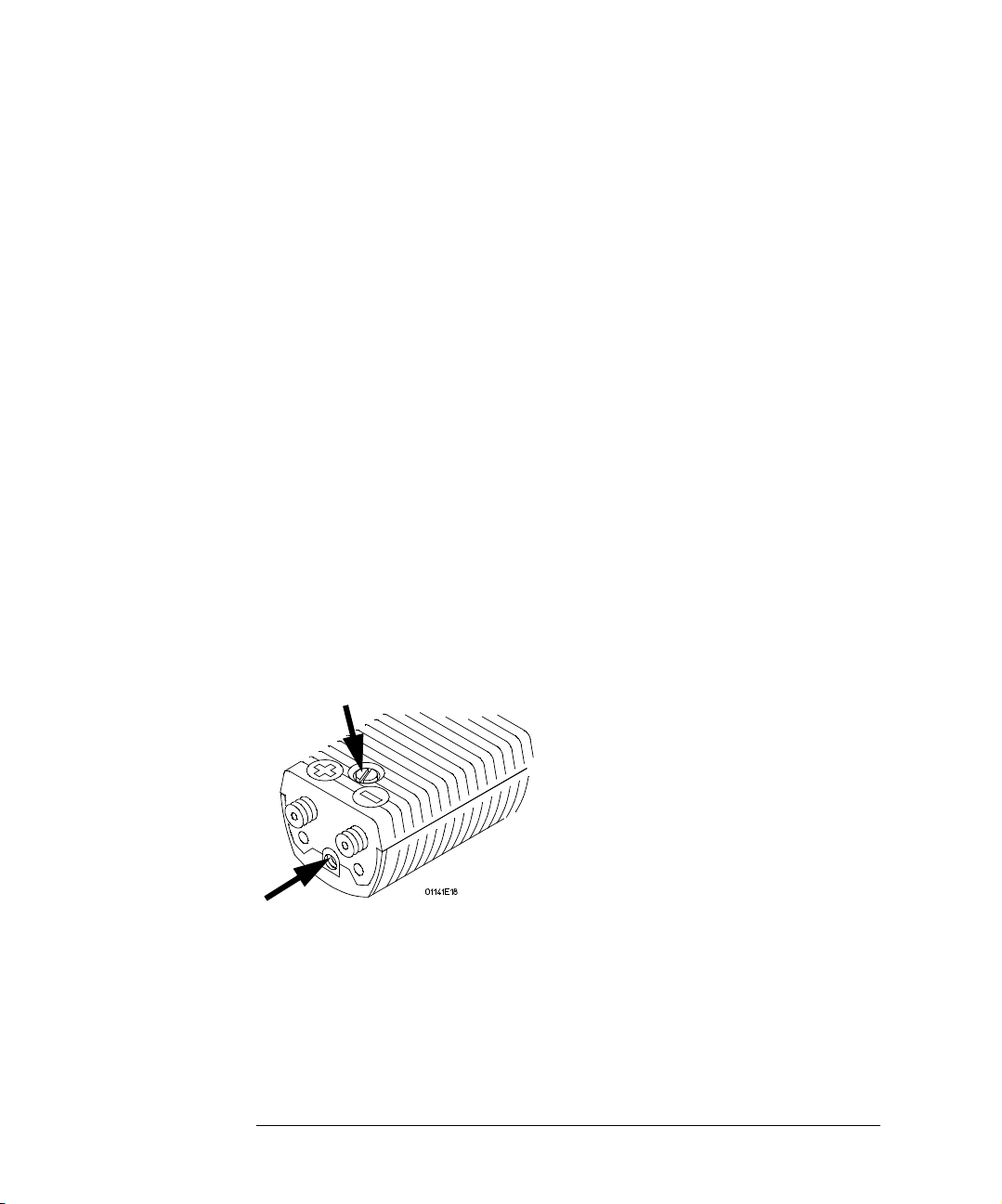

Page 18

Figure 1-10

Operating the Probe

Recommended Test Equipment

Connector Compatibility

The following are general connector characteristics for the probe, adapters, and

accessories.

• The female connectors on the probe, adapters, and other accessories are designed to

mate with 0.030-inch round or 0.0250-inch square pins.

• The probe, adapter, and extension lead pins are 0.030-inch round.

• The strip of circuit connection posts provided as an accessory has 0.025-inch square

pins.

• The mini-grabber has a 0.25-inch square pin.

• The ground connection at the end of the probe and adapters (where the adapters

fasten) accepts an M3 metric screw.

Test Board

The primary use of the test board is to apply test and calibration signals to the input of

the probe or adapters. Specific use of the test board is covered wherever it applies.

Grounding

Grounding is very important when probing circuitry. Improper grounding can increase

the common mode signal level. This reduces the effectiveness of the differential probe.

The mechanical connections at the input of the probe are ground for probe signals. The

screw where the ground lead attaches (see figure 1-7) fastens to this ground. Also, the

attenuator and ac adapter fasten to this ground through the screw connection and the

ground is carried through each adapter to its front.

Probe Grounds

Coupling Functions

There are three methods for blocking or compensating for the dc component of a signal.

Each has specific advantages.

18

Page 19

Probe System Coupling Functions

Operating the Probe

Recommended Test Equipment

dc offset dc Reject ac Coupling

Adapter

dc Blocked

Probe alone

Probe with 10x

Probe with 100x

Set-up needed

± 20 V

± 200 V

± 500 V

Adjust offset to put

signal on screen

Remote Control? Yes

CMRR

No No Yes

1

± 20 V

± 200 V

± 500 V

Select DC Reject

low-frequency

corner

1

Yes

± 20 V

± 500 V

± 500 V

Attach ac Coupling

adapter to

differential probe

No

degradation?

Low-frequency

No Yes Yes

degradation?

1

Isolated external dc reference and control signals are needed

dc Reject

dc Reject is the best method of eliminating the dc component of a signal when dc is not

a factor in the measurement.

The key characteristics are:

• The low-frequency component (from dc to the selected corner frequency) is

automatically nulled by the dc reject circuitry.

• Probe CMRR specifications are not compromised as happens when the ac coupling

adapter is uses.

• There is a selectable low frequency corner with -3dB points at 0.05 Hz, 0.5 Hz,

or 5.0 Hz.

• The voltage reject range is ±20 V with the probe alone, ±200 V with the 10x attenuator,

and ±500 V with the 100x attenuator.

19

Page 20

Operating the Probe

Recommended Test Equipment

To use dc reject:

Remove the ac adapter if it is installed.

1

2 On the front panel of the 1142A, press Local.

3 Under DC Reject on the front panel, press 5.0 Hz or 0.5 Hz individually, or

5.0 Hz and 0.5 Hz simultaneously to get 0.05 Hz.

Within the frequency and voltage characteristics noted elsewhere in this manual, low

frequencies are nulled from the input signal.

Offset

Offset is the best method to use when the low-frequency corners associated with dc

reject and the ac adapter interfere with the measurement.

The key characteristics are:

• The user manually null the dc component with the offset adjustment.

• Offset is dc coupled so there is no low frequency roll-off.

• Probe CMRR specifications are not compromised as happens when the ac coupling

adapter is used.

• The voltage offset range is ±20 V with the probe alone, ±200 V with the 10x attenuator,

and ±500 V with the 100x attenuator. (With the 100x attenuator, the offset range is

restricted by the maximum input voltage rating rather than the operating range of

the offset).

To use offset:

1

Remove the ac adapter if it is installed.

2 On the front panel of the 1142A, press Local and Variable offset.

3 Adjust the Coarse and Fine Variable Offset until the signal is displayed on the

screen of the oscilloscope.

ac Adapter

The ac adapter must be used when the dc component of the signal exceeds the operating

range of the dc reject or offset methods. The ac adapter block the dc and low frequency

component of the input by forming a high pass filter with the input impedance of the

probe or adapter.

The key characteristics are:

• The ac adapter safely blocks ±200 Vdc when attached directly to the probe or

±500 Vdc when attached to a 10x or 100x adapter.

• The probe and adapters have different input impedances, so they have different low

frequency corners with the ac adapter. When the ac adapter is directly on the probe

the -3dB corner is 15 Hz. When the ac adapter is on an attenuator the corner is 1.5 Hz.

• The low-frequency CMRR when using the ac adapter is not as good as when using the

probe alone or the probe with a 10x or 100x adapter.

CAUTION If you measure a node having a high dc potential, the blocking capacitors in the ac

adapter will charge to that potential. After making such measurements, discharge the

capacitors by grounding both inputs of the ac adapter. This will prevent damage by a

high voltage discharge into sensitive circuitry when the next measurement is made.

20

Page 21

Operating the Probe

Recommended Test Equipment

To use ac coupling:

Attach the ac coupling adapter to the input of the probe or the input of the

1

attenuator adapter.

2 On the 1142A, press Local and Zero offset.

Remote operation

For automatic test applications, the coupling and offset functions provided by the 1142A

Probe Control and Power Module can be remotely controlled through a connector on the

rear panel of the module. The connection is through a standard 9-pin female

D-subminiature connector. This style is the same as that used on some personal

computer monitor cables, which provides an economical way to connect the 1142A to

the controller interface on an automatic test system.

The following table gives the connections.

Remote Input Connections

Pin Function Pin Function Connector

1 Function Select 1 (A1R) 6 Function Select 0 (A0R)

2 Digital common 7 N.C.

3N.C. 8N.C.

4 External offset common 9 External offset

5 Shield

NOTE To minimize dc offset errors and potential noise coupling, electrically isolate all

connections between the Remote Input connector and the controlling system.

21

Page 22

Operating the Probe

Recommended Test Equipment

Function Select

The easiest way to control the function select lines is contact closures between the lines

and Digital common (pin 2) of the remote input connector. (TTL compatible control

signals can be used; but to avoid problems with ground loops, they must be electrically

isolated.) The following truth table shows the functions provided by the function select

lines. For the Remote Inputs, “0” represents a closure and “1” represents an open circuit.

Remote Functions Select Truth Table

Remote Input Function

A1R

(Pin 1)

0 0 0.05 Hz Reject

0 1 0.5 Hz Reject

105 Hz Reject

1 1 DC Couple

Variable Offset

The remote variable offset can be used when the dc couple function is remotely selected.

The offset voltage must be referenced to the External offset common (pin 4) of the

remote input connector. It must be electrically isolated from the controlling system. The

following table shows the offset range and remote offset requirements for probe and

adapter combinations.

Remote Offset Input Requirements

Probe alone ± 20 V ± 10 V

Probe with 10x adapter ± 200 V ± 10 V

Probe with 100x adapter ± 500 V ± 2.5 V

A0R

(Pin 6)

Offset Range Remote

Requirements

Cleaning Requirements

If the instrument requires cleaning: (1) Remove power from the instrument. (2) Clean

the external surfaces of the instrument with a soft cloth dampened with a mixture of

mild detergent and water. (3) Make sure that the instrument is completely dry before

reconnecting it to a power source.

22

Page 23

Operating the Probe

Recommended Test Equipment

Differential Amplifiers and CMRR

The 1141A Differential Probe is a high-impedance differential amplifier. A characteristic

of differential amplifiers is the ability to reject signals that are common to the two inputs.

The common mode rejection ratio (CMRR) is the measurement of this ability. It is

expressed as the ratio between the amplitudes of the common mode and differential

signals which product equal outputs. For example, if a common mode signal of 1 V and

differential signal of 1 mV both produce outputs of 1 mV, the CMRR is 1000:1.

The ability to reject common mode signals is dependent on the balance designed into

the differential amplifier. At higher frequencies it becomes harder to balance circuit

parasitics and parameters of devices so CMRR degrades as frequency increases. Also,

stray coupling increases with frequency and coupling may vary between the two

differential paths.

The CMRR of the 1141A Differential Probe is specified at the input of the probe and

cannot be affected expect by adjustments in the probe. However, the way the probe is

connected into the circuitry being tested can have a big influence in the overall result of

the measurement, especially at high frequencies.

The following things can affect the effective CMRR of a test setup:

• The connection to the circuit under test.

The method used to connect the probe is important because it involves the symmetry

of the differential input circuitry. For example, using different lengths of wire to

connect the circuit to the two probe inputs unbalances the inductance and

capacitance at the inputs. The effective CMRR will be reduced, especially at high

frequencies. Additionally, coupling from adjacent circuitry will be less balanced.

• The impedance of the source.

This is another instance where the symmetry of the differential circuit is important.

The impedance of the source forms a network with the input impedance of the source

forms a network with the input impedance of the connections and the probe. This

network determines the frequency response for the measurement. If each side of the

differential source has a different impedance, the frequency response of each side

will be different and the unbalance is reflected in a reduced CMRR. Of course, lower

source impedances have less effect on the frequency response of the measurement.

• The ground connection.

A poorly located ground connection allows ground loops to add to the common mode

signal.

• Frequency.

Frequency is the most important factor in CMRR only because all of the factors

mentioned above are frequency dependent. The unbalances of capacitance and

inductance are more important as frequency increases. Therefore, good highfrequency practice is important when using a high impedance differential probe.

On the other hand, if the differential probe is ac coupled to the circuit under test (the

ac adapter is being used) the CMRR will be degraded below a certain frequency; the

lower the frequency the worse the CMRR. This is because unbalance in the series

capacitances of the ac coupler becomes more significant the lower the frequency.

23

Page 24

Operating the Probe

Recommended Test Equipment

24

Page 25

2

Calibration Tests and Adjustment

25

Page 26

Calibration Tests and Adjustment

Equipment Required

Introduction

This chapter is divided into two sections. The first section gives

calibration tests and the second adjustment procedures for the 1141A

Differential Probe and 1142A Probe Control and Power Module.

Equipment Required

A complete list of equipment required for the calibration tests and adjustments is listed

in “Recommended Test Equipment” on page 9. Equipment required for individual

procedures is listed at the procedure. Any equipment satisfying the critical specifications

listed may be substituted for the recommended model.

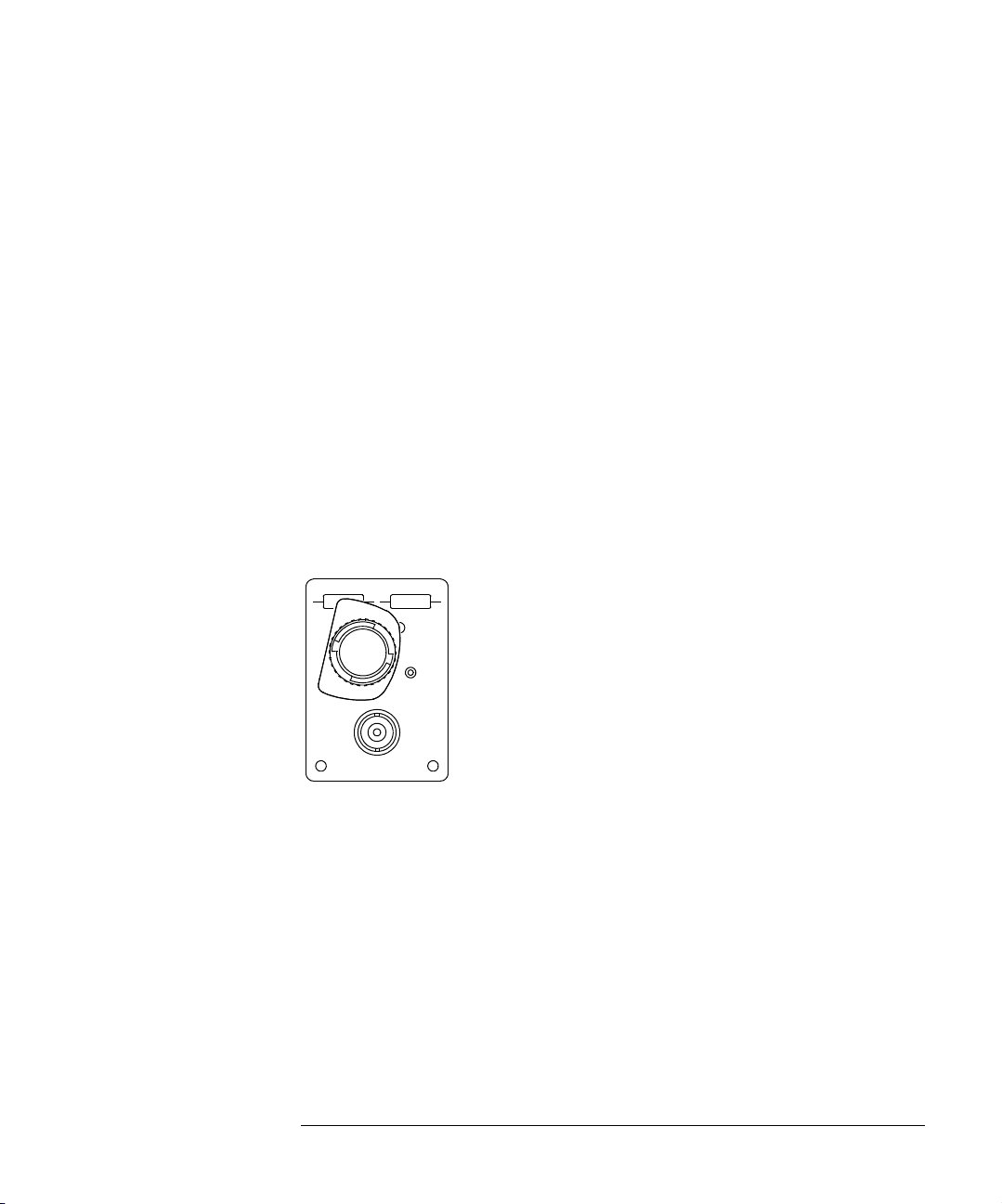

The Test Board

The test board is a supplied accessory for use during calibration tests and adjustments

to connect signals to the differential probe (with or without adapters). A BNC connector

connects the test board to a cable from the signal generator. The board includes a 50 Ω

termination (two 100 Ω resistors).

CAUTION The power rating of the 50 Ω termination is 1.0 W. Keep the signal input below 7 Vdc

or rms to avoid degrading the termination.

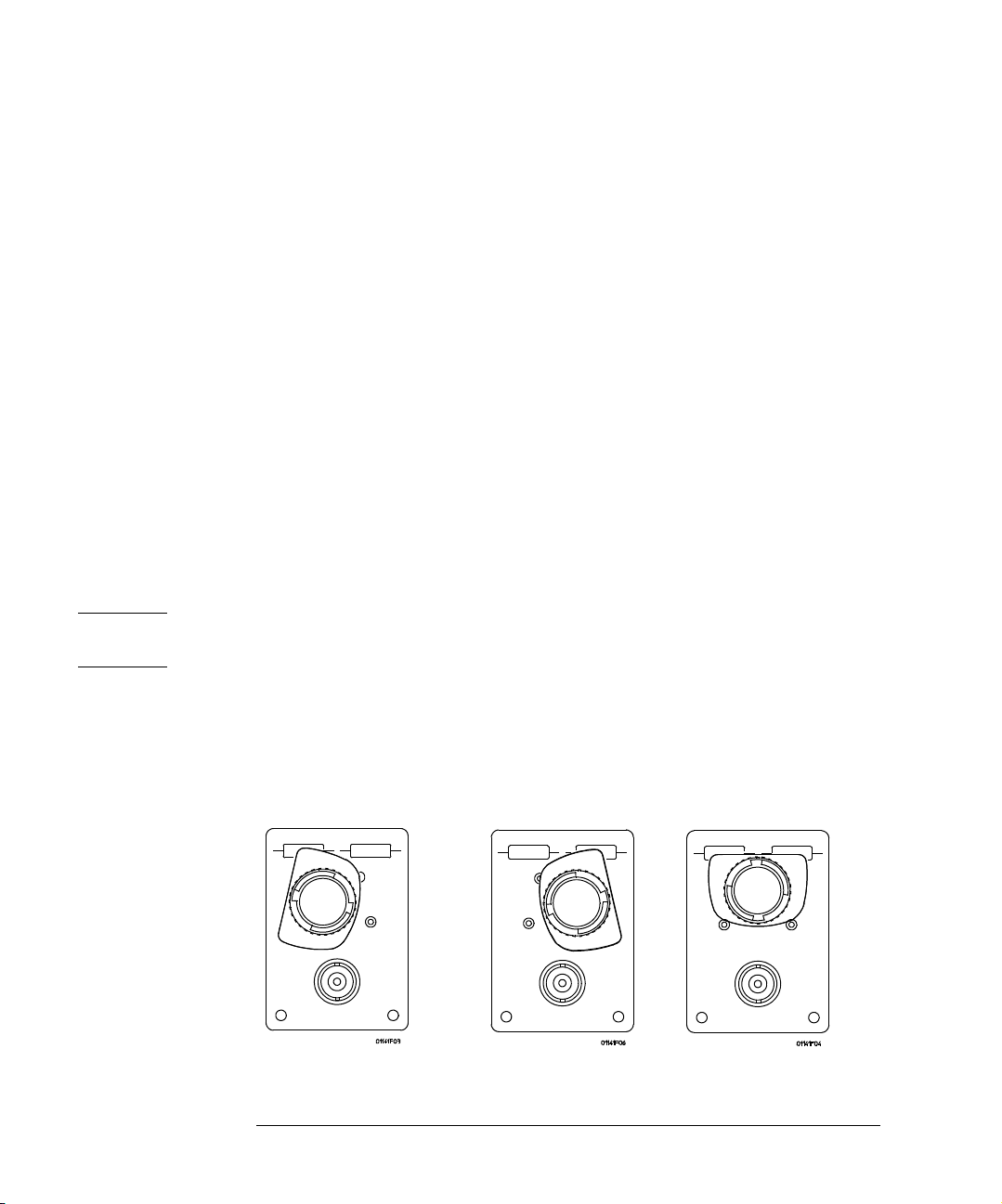

Once the probe tip caps and probe tips have been removed, the probe can be connected

to the test board in one of three ways, as shown in the figure below. At each position of

the probe, probe inputs are connected to a different combination of signal and ground.

A separate terminal on the test board connects the ground of the probe to the signal

ground.

Figure 2-1

Test Board Showing Probe Positions

26

Page 27

Calibration Tests and Adjustment

The Test Board

Calibration Tests

These procedures test the probe’s electrical performance using applicable specifications

given in “Performance Specifications and Characteristics” on page 55 as performance

standards. Specifications applicable to individual tests are noted at the test for reference.

Testing Interval

The calibration testing procedures may be performed for incoming inspection of the

instrument and should be performed periodically thereafter to ensure and maintain peak

performance. The recommended test interval is yearly or every 2,000 hours of operation.

Amount of use, environmental conditions, and the user’s experience concerning need

for testing will contribute to verification requirements.

Calibration Test Record

The results of the calibration tests may be tabulated in the Calibration Test Record

provided at the end of the calibration tests. The Calibration Test Record listed the

calibration tests and provides an area to mark test results. The results recorded in the

Calibration Test Record during initial inspection may be used for later comparisons of

the tests during periodic maintenance, troubleshooting, and after repairs or adjustments.

Calibration Test Procedures

Procedures may be done individually or in any order.

NOTE Allow the instrument to warm up for at least 30 minutes prior to beginning calibration

tests.

27

Page 28

Calibration Tests and Adjustment

dc Gain Accuracy

dc Gain Accuracy

This test checks the dc gain accuracy of the differential probe and the dc accuracy of

the differential probe with attenuator and adapters.

Specification: Probe alone, ±2%; with attenuator adapter, ±4%

Equipment Required

Equipment

Required Critical Specifications

ac/dc Calibrator

or

dc Power Supply

DVM 0.5% accuracy, 10 µV resolution 3458A or

Load BNC Feedthrough, 50 Ω Pasternack

Cables (2) BNC 50 Ω 10503A

Adapters (2) BNC (f) to dual banana (m) 1251-2277

Test Board No substitute 01141-66514

Probe Gain Test Procedure

Connect the probe and test equipment as shown in figure 2-2.

1

100 mV to 7 V

100 mV to 7 V

Recommended

Agilent

Model/Part

E3632A

E34401A

Enterprises

PE6008-50 or

Huber+Suhner

22543742

28

Page 29

Figure 2-2

Calibration Tests and Adjustment

dc Gain Accuracy

2

Set up the 1142A probe control and power module as follows:

a Set the Local/Remote push button to Local.

b Under DC Couple, press the Zero offset button.

With the 1141A Probe Amp disconnected from the test PCA, adjust the Offset

3

Null control on the 1142A until the DVM reads 0Vdc.

If the probe output voltage cannot be set to 0V, subtract this voltage from the subsequent

measurements in this test.

4 Connect the input of the Probe Amp to the test board in the position shown in

Figure 2-4 on page -31.

5 Adjust the DC Source to output 100 mV (nom.)

6 Record the V

7 Record the V

8 Connect the Probe Amp to measure a negative voltage as shown in figure 2-3.

9 Record the V

measurement from the top DVM in figure 2-2.

in1

measurement from the bottom DVM in figure 2-2.

out1

measurement from the bottom DVM in figure 2-2

out2

29

Page 30

Figure 2-3

Calibration Tests and Adjustment

dc Gain Accuracy

Signal to - input

10 Calculate probe gain as

∆V

out

--------------

∆V

Record the result of this calculation in the “Calibration Test Record” on page 39.

To pass this test, the probe gain = 0.98 to 1.02

NOTE Failure of the gain accuracy test can be caused by mis-adjustment of the probe. Perform

the Probe Adjustment procedure in the Adjustments section later in this chapter and

retest.

10x Attenuator Accuracy Test

NOTE If the gain test for the probe fails, the 10x Attenuator Accuracy Test will fail or the

results will be poor. Do not continue until the probe passes the dc gain test.

1 Disconnect the probe from the test board and connect the 10x attenuator

V

----------------------------------=

in

V

–()

out

2 V

out

1

×

in

2

1

adapter to the probe.

2 Carefully connect the input of the probe/attenuator to the test board in the

position shown in the figure below (signal to + input).

30

Page 31

Figure 2-4

Figure 2-5

Calibration Tests and Adjustment

dc Gain Accuracy

Signal to + input

3 Set the dc calibrator output 3 V dc.

4 Record the V

5 Record the V

6 Carefully connect the input of the probe/attenuator to the test board in the

measurement from the top DVM in figure 2-2.

in1

measurement from the bottom DVM in figure 2-2

out1

position shown in the figure below (signal to - input).

Signal to - input

7 Record the V

8 Calculate the 10x attenuator gain as

Record the result of this calculation in the “Calibration Test Record” on page 39.

NOTE Failure of the accuracy test for the 10x attenuator can be caused by mis-adjustment of

the low-frequency CMRR (LF CMRR) adjustment. Perform the Attenuator Adapter

Adjustment procedure in the Adjustments section later in this chapter then retest the

attenuator adapter. If if continues to fail, repair is necessary.

measurement from the bottom DVM in figure 2-2.

out2

∆V

out

--------------

∆V

in

V

----------------------------------=

V

–()

out

2 V

out

1

×

in

2

1

31

Page 32

Calibration Tests and Adjustment

dc Gain Accuracy

100x Attenuator Accuracy Test

NOTE If the gain test for the probe fails, it will be reflected in the test for the 100x attenuator

adapter. Do not continue until the probe passes the gain test.

1 Disconnect the probe/attenuator from the test board. Remove the 10x

attenuator adapter from the probe and connect the 100x attenuator adapter.

2 Carefully connect the input of the probe/attenuator to the test board in the

position shown in the figure below (signal to + input).

Figure 2-6

Signal to + input

CAUTION Avoid excessive power dissipation in the termination on the test board. Keep the voltage

input at or below ±7 Vdc.

3 Set the dc source output to 7 Vdc.

4 Record the V

5 Record the V

measurement from the top DVM in figure 2-2.

in1

measurement from the bottom DVM in figure 2-2

out1

32

Page 33

Figure 2-7

Calibration Tests and Adjustment

dc Gain Accuracy

6 Carefully connect the input of the probe/attenuator to the test board in the

position shown in the figure below (signal to - input).

Signal to - input

7 Record the V

8 Calculate the 100x attenuator gain as

Record the result of this calculation in the “Calibration Test Record” on page 39

NOTE Failure of the accuracy test for the 100x attenuator can be caused by mis-adjustment

of the low-frequency CMRR (LF CMRR) adjustment. Perform the Attenuator Adapter

Adjustment procedure in the Adjustments section later in this chapter then retest the

attenuator adapter. If if continues to fail, repair is necessary.

measurement from the bottom DVM in figure 2-2.

out2

∆V

out

--------------

∆V

in

V

----------------------------------=

V

–()

out

2 V

out

1

×

in

2

1

33

Page 34

Calibration Tests and Adjustment

Bandwidth

Bandwidth

This test checks the high-frequency response of the 1141A Differential Probe. The

bandwidth of the oscilloscope is characterized first so it is not a factor in the

measurement.

Specification (-3dB, dc coupled): dc to 200 MHz

Equipment Required

Equipment

Required

Oscilloscope 400 MHz bandwidth 54830A

Signal Generator 200 MHz at ≈ 230 mVrms 8648A

Test Board No substitute 01141-66504

Cable Type N (m) 24-inch 11500B

Adapter Type N (f) to BNC (m) 1250-0077

Procedure

This test depends on the accuracy of the termination on the test board and the

termination in the oscilloscope. Both should be with 1%.

With the N cable and N-to-BNC adapter, connect the signal generator to the

1

Critical Specifications Recommended

Model/Part

oscilloscope channel 1 input.

2 Set the signal generator for 200 MHz at 0 dBm (about 224 mVrms).

3 Set the 1142A front panel switches to Local and Zero offset.

4 On the oscilloscope press AUTOSCALE, then set the following parameters.

Menu Selection Setting

TIMEBASE (time/div) 2 ns/div

CHAN 1 (sensitivity)

(input R)

ACQUISITION Sampling Mode

Memory Depth

Sample Rate

Averaging

# of avg

100 mV/div

50 Ω DC

Real Time

Automatic

Automatic

Enabled

32

5 The signal on screen should be about six divisions amplitude.

Measure the peak-to-peak voltage of the channel 1 signal and record the

reading.

V

(1) = _____________ mV

p-p

34

Page 35

Figure 2-8

Calibration Tests and Adjustment

Bandwidth

6 Reconfigure the equipment.

a Disconnect the signal generator cable from the oscilloscope input and connect it to

the test board.

b Connect the output of the differential probe to the channel 1 input of the

oscilloscope.

c Carefully connect the input of the probe to the test board in the position shown in

the figure below (signal to + input).

Signal to + input

7 Record the V

V

(1) = _____________ mV

p-p

8 Divide the reading from step 6 by the reading from step 4.

Answer from step 6

----------------------------------------------Answer from step 4

reading on the oscilloscope.

p-p

____________ =

Record the result in the Calibration Test Record.

The result should be 0.707 or greater, indicating a probe bandwidth of 200 MHz or more.

The bandwidth can be checked at other signal levels. Change the signal generator output

level and oscilloscope V/div range proportionally.

NOTE Failure of the bandwidth test can be caused by mis-adjustment of the probe. Perform

the Probe Adjustment procedure in the Adjustments section later in this chapter.

35

Page 36

Calibration Tests and Adjustment

CMRR Test

CMRR Test

This test checks the CMRR at 1 MHz and 100 MHz.

Specification 3000:1 at 1 MHz, 10:1 at 100 MHz

Equipment Required

Figure 2-9

Equipment

Required Critical Specifications

Oscilloscope 400 MHz bandwidth at 1 mV/div 54830B

Signal Generator 1-100 MHz at = 400 mVrms 8648A

Test Board No substitute 01141-66504

Cable Type N (m) 24-inch 11500B

Adapter Type N (f) to BNC (m) 1250-0077

Procedure

Connect the probe power connector to the PROBE connection on the rear of

1

Recommended

Agilent

Model/Part

the 1142A Probe Control and Power Module.

2 Set the 1142A front panel switches to Local and Zero offset.

3 Connect the probe output to the oscilloscope channel 1 input.

4 Connect the input of the probe to the test board in the position shown in the

figure below (signal to + input).

Signal to + input

5 Connect the signal generator to the test board.

6 Set the signal generator for 1 MHz at 385 mV

rms

36

(1 V

p-p

).

Page 37

Figure 2-10

Calibration Tests and Adjustment

CMRR Test

7 On the oscilloscope, press AUTOSCALE and set the following parameters.

Menu Selection Setting

TIMEBASE (time/div) 500 ns/div

CHAN 1 (sensitivity)

(input R)

ACQUISITION Sampling Mode

Memory Depth

Sample Rate

Averaging

# of avg

200 mV/div

50 Ω DC

Real Time

Automatic

Automatic

Enabled

32

8 On the oscilloscope, measure the peak-to-peak voltage of the channel 1 signal,

then V P-P, then press 1) and record the reading.

V

(1) = _____________ mV

p-p

9 Connect the input of the probe to the test board in the position shown in the

figure below (signal to both inputs).

Signal to both input

10 Set the sensitivity to 1 mV/div.

11 After the measurement settles (averaging is complete), record the V P-P

reading.

V

(2) = _____________ mV

p-p

12 Disconnect the probe amp from the test board and measure V

channel 1.

noise pp

on

13 Calculate the CMRR result as follows

V

pp

CMRR

-------------------------------------=

V

pp

1

V

–

noisepp

2

14 The result in step 12 should be ≥ 3000, representing a CMRR of 3000:1 or more.

Record the CMRR in the Calibration Test Record.

37

Page 38

Figure 2-11

Calibration Tests and Adjustment

CMRR Test

15 Connect the input of the probe to the test board in the position shown in the

figure below (signal to + input).

Signal to + input

Figure 2-12

16 Set the signal generator for 100 MHz at 0.0 dBm (about 224 mV

, 632 mV

rms

p-p

17 Set the oscilloscope to channel 1 and change the horizontal scale to 5 ns/div.

18 After the measurement settles (averaging is complete), note the V P-P reading.

V

(1) = _____________ mV

p-p

19 Connect the input of the probe to the test board in the position shown in the

figure below (signal to both inputs).

Signal to both input

20 Set the channel 1 sensitivity to 10 mV/div.

21 After the measurement settles (averaging is complete), not the V P-P reading.

V

(2) = _____________ mV

p-p

22 Disconnect the probe amp from the test board and measure V

channel 1.

noise pp

on

23 Calculate the CMRR result as follows

V

pp

CMRR

-------------------------------------=

V

pp

1

V

–

noisepp

2

24 The result in step 21 should be ≥ 10, representing a CMRR of 10:1 or more.

Record the CMRR in the Calibration Test Record.

).

38

Page 39

Calibration Tests and Adjustment

Calibration Test Record

Calibration Test Record

1141A/1142A Differential Probe Tested by_________________________

Serial No. ______________________________ Work Order No.____________________

Recommended Test Interval - 1 Year/2000 hours Date____________________

Recommended next testing_________________ Temperature_____________

Test Limits Results

dc Gain Accuracy Probe

Only

+0.98 mV to +1.02 mV _____________

10x +0.096 mV to +0.104 mV _____________

100x +0.0096 mV to 0.0104 mV _____________

Bandwidth >0.707 at 200 MHz _____________

CMRR 1 MHz ≥3000:1 _____________

100 MHz ≥10:1

39

Page 40

Calibration Tests and Adjustment

Probe Adjustment

Adjustments

This section provides adjustment procedures for the 1141A Differential Probe and

attenuator adapters. There are no service adjustments for the 1142A Probe Control

Module.

Adjustment Interval

None of the adjustment procedures that follow should be considered for a routine

maintenance plan. The differential probe and attenuator adapters should be adjusted

under conditions specified at the beginning of the respective procedures.

NOTE Warm up the instrument for 30 minutes before starting adjustment procedures.

Probe Adjustment

This procedure adjust the high-frequency and low-frequency paths on the 1141A

Differential Probe.

NOTE Do not perform this procedure as a part of routine maintenance. Perform the procedure

only if the probe does not meet specifications or has been repaired.

CAUTION You are going to remove the covers of the probe, so the assembly inside will be exposed

while under power. The PC assembly will be electrically and mechanically vulnerable.

Do these adjustment procedures in an ESD-safe area.

Avoid inadvertent contact between the powered assembly and nearby tools and

equipment.

Avoid mechanical damage by carefully handling the exposed assembly and cables.

40

Page 41

Calibration Tests and Adjustment

Probe Adjustment

The following equipment is required for this procedure. Procedures are based on the

model or part number recommended.

Equipment Required

Equipment Required Critical Specifications Recommended

Function Generator 2.5 kHz, 1 V

Oscilloscope 300 MHz at 1 mV/div 54830B

Signal Generator 200 MHz at ≈ 300 mVrms 8648A

Test Board No substitute 01141-66504

Cables (2) BNC, 50 Ω 10503A

Adapter Type N (m) to BNC (f) 1250-0780

Probe Preparation

The probe cover must be removed before adjustment. Drift due to temperature

differences with and without covers is negligible.

1

Remove the probe tip caps and probe tips.

2 Loosen the probe clamp ring at the cable end of the probe (1/4 turn counter-

p-p

Agilent

Model/Part

33120A

clockwise) and slide it down the cable.

3 Remove the bottom cover.

a At the cable end of the probe, separate the covers about centimeter (1/2 inch).

b Slide the bottom cover toward the cable end of the probe until the locator pins at

the probe input clear the holes. Then, remove the cover.

NOTE Note the position of the ground block at the input end of the probe. The ground block

is held, through the PC assembly, by the grounding screw on the top of the probe. The

ground block must be reinstalled on the PC assembly after the top cover is removed.

Handle the PC assembly by the edges of the PC board.

4 Remove the ground connection screw on the top of the probe.

The ground block will become free.

At the cable end, the PC board fits over pins inside the top cover.

Lift the board off of the pins in the cover and slide it in the direction of the

5

cable until the input connectors clear the front of the probe.

41

Page 42

Figure 2-13

Calibration Tests and Adjustment

Adjustment Procedure

6 As shown in the figure below, use the grounding screw to reinstall the ground

block on the PC assembly.

Attaching Ground Block to Probe PC Assembly

The ground block provides a mechanical and electrical connection when the probe PC

assembly is connected to the test board.

7 Connect the probe power connector to the PROBE connection on the rear of

the 1142A Probe Control and Power Module.

8 Connect the mains power to the 1142A.

9 Set the 1142A front panel switches to Local and Zero offset.

Adjustment Procedure

Unless specified elsewhere, the procedures must be followed in the order given.

The only adjustment which may be done separately is HF COMP, the high-frequency

compensation.

HF Gain and HF CMRR

This adjustment sequence adjusts the HF Gain for unity gain at 500 kHz and the HF

CMRR for minimum with a 500 kHz common mode signal.

1

Set up the function generator.

• Sine wave

• 500 kHz

•600 mV

2 Use BNC cables to connect the function generator to the oscilloscope.

• Generator OUTPUT to oscilloscope channel 1 input

• Generator TRIG OUTPUT to oscilloscope EXT TRIG

42

p-p

Page 43

Calibration Tests and Adjustment

Adjustment Procedure

3 On the oscilloscope, then press CLEAR DISPLAY. Press AUTOSCALE, then set

up the following parameters.

Menu Selection Setting

TIMEBASE (time/div) 500 ns/div

CHAN 1 (sensitivity)

(input R)

TRIG (mode)

source

level

100 mV/div

50 Ω DC

trg’d

EXT

1.00000 V

Figure 2-14

ACQUISITION Sampling Mode

Memory Depth

Sample Rate

Averaging

# of avg

4 On the oscilloscope, measure the peak-to-peak voltage of the channel 1 signal

Real Time

Automatic

Automatic

Enabled

32

and record the reading.

V

(1) = _____________ mV

p-p

5 Disconnect the BNC cable from the channel 1 input and connect it to the BNC

connector on the test board.

6 Connect the output of the probe to the channel 1 input.

7 Carefully connect the input of the probe to the test board in the position shown

in the figure below (signal to + input).

Signal to + input

43

Page 44

Figure 2-15

Calibration Tests and Adjustment

Adjustment Procedure

8 Center adjustment R11, HF CMRR (see following figure).

R11, HF CMRR Adjustment

Figure 2-16

9 Adjust R9, HF GAIN so the V

±0.5%.

Make the adjustment slowly so the oscilloscope display has time to react to signal

averaging. Press CLEAR DISPLAY occasionally to restart averaging, which gives a

quicker indication of changes.

10

Carefully connect the probe to the test board in the position shown in the figure

(1) measurement is the same as in step 4, within

p-p

below (signal to both inputs).

Signal to both inputs

11 Set the function generator output to 1.0 V

12 On the oscilloscope, set the channel 1 sensitivity to 1.00 mV/div.

13 Adjust R11 for minimum signal amplitude as shown in V

channel 1. Adjust R11 slowly and use CLEAR DISPLAY frequently to restart

p-p

.

reading for

p-p

averaging.

Low Frequency Response and CMRR

This adjustment sequence continues from the HF Gain and HF CMRR adjustments.

Adjust R14 and C4 for pulse response, and adjust C6 for low-frequency CMRR.

1

Change the function generator settings to:

• Square wave

• 2.5 kHz

•600 mV

p-p

44

Page 45

Figure 2-17

Calibration Tests and Adjustment

Adjustment Procedure

2 Change the oscilloscope settings to:

Menu Selection Setting

TIMEBASE (time/div) 50 µs/div

CHAN 1 (sensitivity) 100 mV/div

3 Carefully connect the input of the probe to the test board in the position shown

in the figure below (signal to + input).

Figure 2-18

Signal to + input

4 Adjust R14 (LF Gain) and C4 (+ LF BANDWIDTH) for the flattest pulse top

(see figure below). Again, adjust slowly and press CLEAR DISPLAY frequently

to restart averaging.

R14 and C4 Adjustment

45

Page 46

Figure 2-19

Calibration Tests and Adjustment

Adjustment Procedure

5 Carefully connect the probe to the test board in position shown in the figure

below (signal to both inputs).

Signal to both inputs

6 Change the function generator settings to:

• Sine wave

•4 kHz

•1.0 V

7 Change the oscilloscope settings to:

p-p

Menu Selection Setting

TIMEBASE (time/div) 50 µs/div

CHAN 1 (sensitivity) 2 mV/div

8 Adjust C6 (-LF BANDWIDTH) for minimum signal amplitude on the

oscilloscope. Again, adjust C6 slowly and press CLEAR DISPLAY frequently to

restart averaging.

46

Page 47

Figure 2-20

Figure 2-21

Calibration Tests and Adjustment

Adjustment Procedure

High Frequency Compensation

This adjustment sequence continues from the Low Frequency Response and CMRR

adjustment. However, it can be done separately if the probe meets all specifications

except bandwidth. Adjust R13 for unity gain at 200 MHz.

1 Connect the signal generator to the test board and set it for 200 MHz and

300mV

2 Carefully connect the input of the probe to the test board in the position shown

(107 mV

p-p

rms

).

in the figure below (signal to + input).

Signal to + input

3 Press AUTOSCALE, then measure the peak-to-peak voltage on channel 1

(Press SHIFT (blue), press V P-P, then press 1).

4 Adjust R13 (HF COMP) to make the signal amplitude measurement on the

oscilloscope 300 mV

CLEAR DISPLAY frequently to restart averaging.

, or as close to that as possible. Adjust slowly and press

p-p

R13 Adjustment

The minimum allowable amplitude is 212 mV

325 mV

Probe Reassembly

Disconnect the probe power cable at the rear panel of the 1142A

1

2 Remove the probe PC assembly from the test board. Be sure the probe input

. the probe needs repair if the minimum cannot be reached.

p-p

. Typical values will be between 275 and

p-p

connectors remain attached to the probe.

3 Remove the grounding screw and ground block from the PC assembly.

47

Page 48

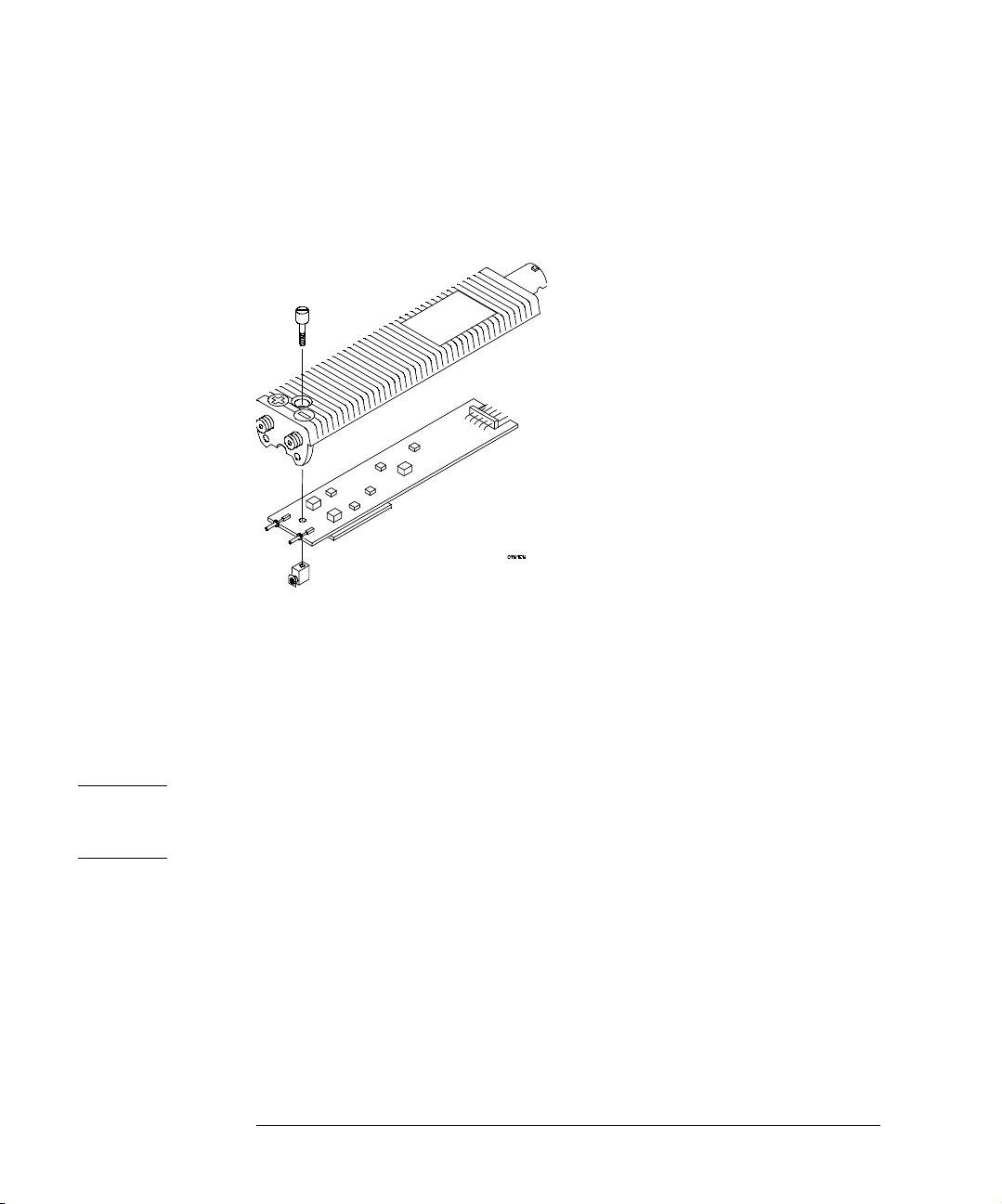

Figure 2-22

Calibration Tests and Adjustment

Adjustment Procedure

4 Assemble the PC assembly in the top cover.

The side of the PC assembly with the large hybrid is exposed when the assembly is in

the top cover. The figure below shows how the top cover, PC board, and ground block

fit together.

Reassembling the Probe

a

Insert the input connectors first, and seat the cable end of the PC assembly over the

pins at the rear of the cover.

b Position the ground block at the center-front of the PC assembly.

c Insert the grounding screw through the top cover and PC assembly and screw it into

the ground block as shown.

5 Replace the bottom cover.

a Position the cable strain relief and with one hand, hold the cable and top together.

The flange on the strain relief has a notch that fits around a protrusion in the top cover.

CAUTION Note where the two pins at the rear of the top cover enter the holes in the PC assembly.

Position the cable wires away from these two areas. Otherwise, when the bottom cover

is closed, part of it will pinch wires that are laying over these areas.

b Insert the pins at the front of the bottom cover into the holes at the front of the top

cover.

c Close the two covers together and fasten with the probe clamp ring.

48

Page 49

Calibration Tests and Adjustment

Attenuator Adapter Adjustment

Attenuator Adapter Adjustment

The following procedure should be used if it is necessary to adjust an attenuator adapter.

Attenuator adapters have only characteristics; they do not have any specifications. An

adapter will need adjustment only if one or more of the following occurs.

• If an adapter is to be used on a different 1141A probe that it was calibrated with

last.

• If an adapter needs to be optimized to requirements for a special measurement.

• If an adapter is suspected of needing adjustment.

NOTE Attenuator adapters should not be adjusted as part of routine maintenance. The design

necessary to give the high CMRR and high impedance of the attenuators makes

adjustment delicate.

Additionally, because of broadband noise, a spectrum analyzer should be used to verify

adjustment quality.

Each attenuator contains two identical voltage dividers on a ceramic substrate. There

are three adjustments. The low-frequency CMRR adjust the low-frequency balance

between the two voltage dividers. The two high-frequency adjustments are electrically

identical. Each adjusts the high-frequency compensation of one of the voltage dividers.

To meet both pulse response and CMRR characteristics they are adjusted differently.

Briefly, the adjustment procedure is:

a Adjust the positive high-frequency response (+ HF RESP) for the best pulse response

using a 3.5 kHz square wave.

b Adjust the negative high-frequency response (-HF RESP) and Low-frequency CMRR

(LF CMRR) for best CMRR using a 3.5 kHz square wave.

The following equipment is required for this procedure. Procedures are based on the

model or part number recommended.

Equipment Required

Equipment Required Critical Specifications Recommended

Function Generator 3.5 kHz, 3 V to 16 V

Oscilloscope 100 MHz at 1 mV/div 54830B

Probe/Power Module No substitute 1141A/1142A

Test Board No substitute 01141-66504

Cable BNC, 50 Ω 9-inch 10502A

Cable BNC, 50 Ω 36-inch 10503A

Alignment tool Flat blade (supplied accessory) 8710-1961/

p-p

Model/Part

33120A

Sprague-Goodman

part, GTT-5G

49

Page 50

Calibration Tests and Adjustment

Attenuator Adapter Adjustment

Adjustment Procedure

NOTE The attenuator must be adjusted when installed on the 1141A probe with which it will

be used. The specifications and characteristics will not be met if the attenuator adapter

is adjusted with one differential probe then used with another.

1 Remove the probe pins from the attenuator adapter and differential probe, then

attach the adapter to the probe.

2 Set the 1142A front panel switches to Local and Zero offset.

3 Use the 9-inch BNC cable to connect the function generator to the test board.

The short cable minimized ground-loop voltages.

4 Set up the function generator.

• Square wave

• 3.5 kHz

• 3.0 Vp-p for 10x adapter and 16 V

Use the long BNC cable to connect the Trig Out of the function generator to

5

for a 100x adapter.

p-p

the EXT TRIG of the oscilloscope.

6 Set up the oscilloscope, then set the following parameters.

Menu Selection Setting

TIMEBASE (time/div) 50 µs/div

CHAN 1 (sensitivity)

(input R)

TRIG (mode)

source

level

ACQUISITION Sampling Mode

Memory Depth

Sample Rate

Averaging

# of avg

50 mV/div

50 Ω DC

trg’d

EXT

1.00000 V

Real Time

Automatic

Automatic

Enabled

32

50

Page 51

Figure 2-23

Figure 2-24

Calibration Tests and Adjustment

Attenuator Adapter Adjustment

7 Connect the adapter/probe combination to the test board in the position shown

in the figure below.

Signal to + input

8 Adjust the + HF RESP for best overall pulse response, the flattest pulse top.

Use the figure below for adjust locations.

Adjustment Locations

9 Change the function generator to 10 V

10 On the oscilloscope, press CHAN and set the sensitivity to 1 mV/div.

(10x adapter adjustment only).

p-p

51

Page 52

Figure 2-25

Calibration Tests and Adjustment

Attenuator Adapter Adjustment

11 Connect the adapter/probe combination to the test board in the position shown

in the figure below (signal to both inputs).

Signal to both input

12 Alternately adjust the LF CMRR and then the -HF RESP for a minimum signal

on the oscilloscope. Repeat the adjustments until the signal is optimized to a

minimum. Each adjustment should be set to minimize the component of the

signal it affects most. Some high-frequency components of the signal are not

affected by either adjustment.

52

Page 53

3

Service

53

Page 54

Service

Introduction

Introduction

This section provides troubleshooting, service, and repair information for the

1141A Differential Probe and 1142A Probe Control and Power Module. The

troubleshooting information is provided to isolate a faulty assembly. When a

faulty assembly has been located, the disassembly/assembly procedures help

direct replacement of the assembly.

WARNING Maintenance should be performed by trained service personnel aware of the hazards

involved (for example, fire and electric shock). When maintenance can be performed

without power applied, the power cord must be removed from the instrument.

54

Page 55

Performance Specifications and Characteristics

Performance Specifications and Characteristics

The following table gives performance specifications used to test the 1141A and 1142A.

It also gives performance characteristics that are typical for the probe system.

Performance Specifications and Characteristics

Parameter Probe alone With 10x attenuator With 100x attenuator

SPECIFICATIONS

±20 Vdc

±0.5 V

1 MΩ

7 pF

rms

1

±200 Vdc, decreasing to

±3.0 mV at 30 Hz

±200 Vdc

linear change

±5 V

9 MΩ

3.5 pF

±500 Vdc, decreasing to

±30 mV at 30 Hz

±500 Vdc

linear change

±50 V

10 MΩ

2 pF

Bandwidth (-3 dB, dc coupled) dc to 200 MHz

Rise Time: (calculated) 1.75 ns

Gain Accuracy 2.0% 4.0%

CMRR See the graphs in figure 3-1

Maximum Input Voltage

(see figure 3-2)

Differential Input Range

DC mode with no offset ± 300 mV peak ±3.0 V peak ±30 V peak

with DC Reject or appropriate

offset

Common-mode Operating

Range

dc

dc to 30 Hz

30 Hz to 200 MHz

dc Offset Range ±20 V ±200 V ±500 V

Input Impedance Resistance

Capacitance

ac Low-freq. Response (-3dB) 15 Hz 1.5 Hz 1.5 Hz

dc Reject Response 5 Hz, 0.5 Hz, or 0.05 Hz (selectable irrespective of attenuator)

Output Impedance 50 Ω

Thermal drift ≤ 50 µVdc/°C

Displayed noises ≤ 50 µV

Overload Recovery < 1 ms from overdrive that is less than the common mode range

Note: 1. For maximum signal fidelity above 100 MHz, limit the probe input (without attenuators to ≤ 300 mV

peak-to-peak.

±200 V(dc + peak ac) ±500 V(dc + peak ac)

±20 Vdc, decreasing to

±300 mV at 30 Hz

linear change

Service

55

Page 56

Figure 3-1

Service

Performance Specifications and Characteristics

CMRR Specifications and Characteristics

Legend

A. CMRR specification for probe with no input adapters.

B. Low-frequency CMRR specification for probe with the ac adapter.

C. Typical CMRR characteristic for differential probe with no input adapters

D. Typical CMRR characteristic for differential probe with 100x attenuator adapter at input.

E. Typical CMRR characteristic for differential probe with 100x attenuator adapter at input.

56

Page 57

Figure 3-2

Maximum Input Voltage vs. Frequency

Legend

A. Input voltage limits for probe alone.

B. Input voltage limits for 10x adapter.

C. Input voltage limits for 100x adapter.

Service

Performance Specifications and Characteristics

57

Page 58

Service

General Characteristics

General Characteristics

The following characteristics apply to the 1141A Differential Probe with the 1142A Probe

Control and Power Module.

Environmental Conditions

Operating Non-operating

Temperature 0°C to +55 C° (32°F to +131°F) -40°C to +70°C (-40°F to +158°F)

Humidity up to 95% relative humidity (non-

condensing) at +40°C (+104°F)

Altitude up to 4,600 meters (15,000 ft) up to 15,300 meters (50,000 ft)

up to 90% relative humidity at +65°C

(+149°F)

Figure 3-3

Vibration Random vibration 5 to 500 Hz, 10

Power

Requirements

Weight Net: approximately 1.8 kg (4.0 lb.)

Dimensions Refer to the outline drawings below.

1142A Probe Control

and Power Module

minutes per axis, 0.3grms.

Voltage: 90 to 132/198 to 264 Vac, 47 to 440 Hz

Power: 25 VA maximum

Shipping: approximately 2.7 kg (6.0 lb.)

Random vibration 5 to 500 Hz, 10 min.

per axis, 2.41 grams. Resonant search

5 to 500 Hz swept sine, 1Octave/min.

sweep rate, (0.75g), 5 min. resonant

dwell at 4 resonances per axis.

1141A Differential

Probe

Mechanical Dimensions

58

Page 59

Figure 3-4

Service

Theory of Operation

Theory of Operation

The following discussion covers block-level theory for the 1141A/1142A differential

probe system. Refer to the block diagram below.

The differential probe system consists of two units, the 1141A Differential Probe with

its accessories and the 1142A Probe Control and Power Module. For purposes of the

following discussion, these will be called the probe and the control module respectively.

Differential Probe System Block Diagram

59

Page 60

Service

Theory of Operation

Differential Probe

The probe contains a two-path differential amplifier with unity gain. It is implemented

on a double-sided surface-mount PC board with the high-frequency path on one side and

the low-frequency path on the other. The two paths are split directly after the differential

input connections.

High-Frequency Path

The positive and negative inputs are ac-coupled at 33 Hz into identical impedance

converters. The HF CMRR adjustment balances the gain at the outputs of the impedance

converters. The impedance feed a semi-custom differential amplifier. An additional

negative input to the differential amplifier brings in the sum of the low-frequency and

feedback signals. The FREQ COMP adjustment provides variable high-frequency peaking

of the differential amp. The output amp provides two signals. A feedback signal is

summed with the low-frequency signals and the output signal is the final output of the

probe. Overall probe gain is set by the HIGH FREQ GAIN adjustment.

The entire signal portion of the high-frequency path is implemented on a hybrid IC.

Support circuitry includes bias for the impedance converters and a bias supply for

current sources on the hybrid.

Low-Frequency Path

The bandwidth of the low-frequency path is approximately 75 KHz. The positive and

negative inputs are dc coupled into identical inverting op-amps with gain of 0.5. They

provide a precision 1 M Ω input impedance for the probe. The LOW FREQ BANDWIDTH

adjustments match the gain and phase of the low-frequency path to that of the feedback

from the probe output. One of the two adjustments is set to match the properties of the

feedback and the other is to match the two low-frequency paths. These adjustments

affect the CMRR quality of the probe. The inputs of the inverting op-amps include

protection for ESD and over-voltage conditions.

The inverting op-amps feed a precision differential amplifier with unity gain and a singleended output. The output is fed to the summing amp and to the control module for use

in the dc reject circuit.

Summing Amp

The summing amp combines the feedback signal, the low-frequency signal, and the offset

signal. The LOW FREQ GAIN adjustment matches the gain of the low-frequency path to

the overall gain.

Control and Power Module

The control and power module provides offset functions, local and remote control, and

power to the probe system.

60

Page 61

Service

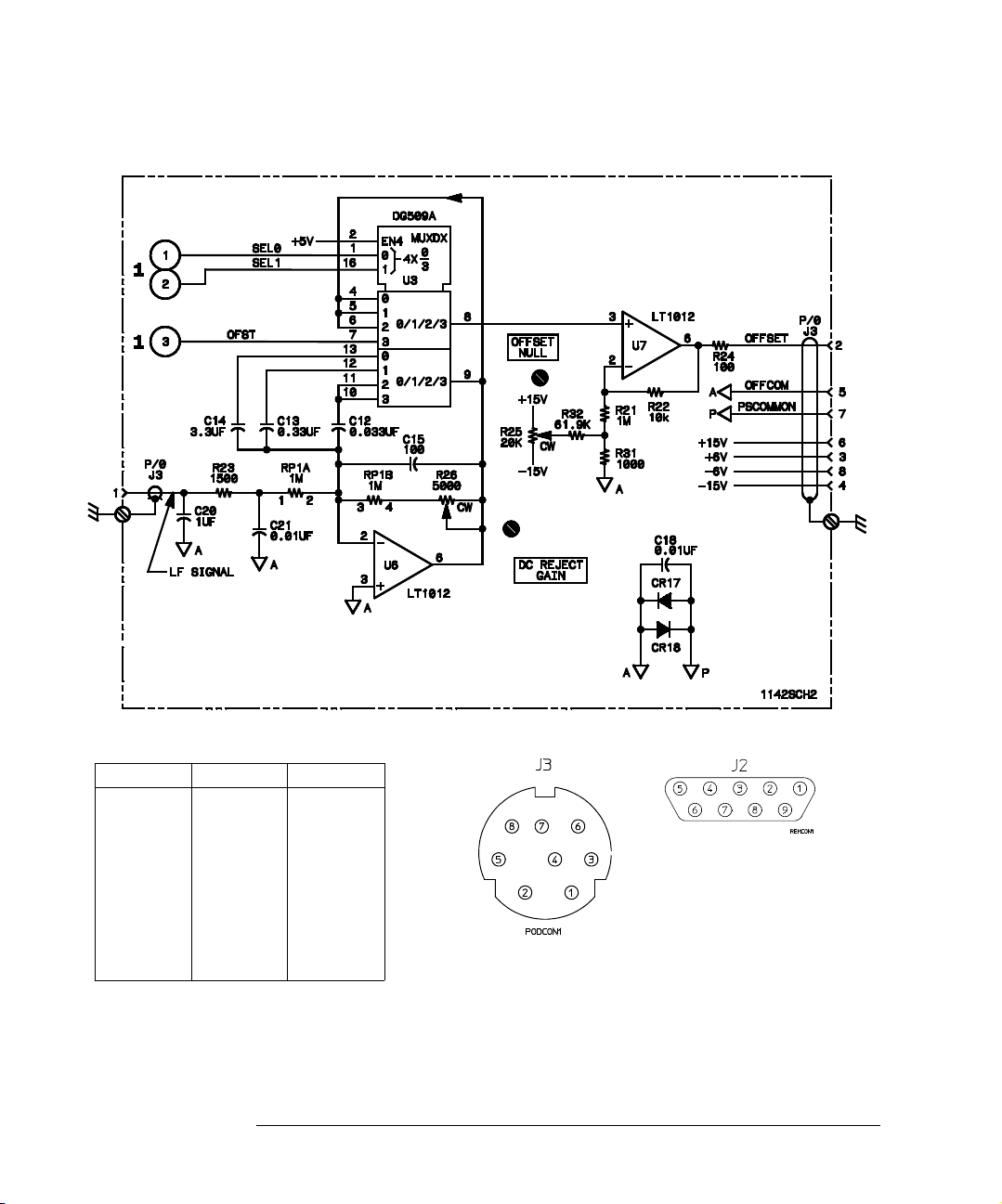

Theory of Operation

Offset Functions

There are two offset functions developed in the control module: variable offset and dc

reject. A variable offset voltage with coarse and fine adjustments can be selected by the

front panel controls. The offset level is buffered by U8 and selected by multiplexer U3

as the input to offset amp U7. The output of the offset amp is summed with the lowfrequency signal and feedback which gives dc coupling in the probe. Front panel

screwdriver adjustment Offset Null zeros the dc output from the probe when the dc input

and offset are zero.

For dc Reject, an output from the low-frequency amplifier in the probe (LFSIG) is used

to develop a voltage used to null the dc component of the input signal. LFSIG is an input

to U6, an inverting amplifier and low-pass filter. Multiplexer U3 selects one of three

capacitors to set a roll-off frequency of 0.05, 0.5, or 5 Hz. The output of U6 is selected,

again by U3, as the input to the offset amp. When the output of the offset amp is summed

into the low frequency path, the result is cancellation of the dc component of the input

signal. Front panel screwdriver adjustment DC Reject Gain adjusts the gain of the dc

reject circuit.

Local and Remote Control

The front panel switch controls the dc reject and offset functions. It also selects remote

operation, which allows control through the rear panel remote input connector.

Power Supply

The supply provides ±6 V and ±15 V for the probe and analog control circuitry as well

as +5 V for the digital control circuitry.

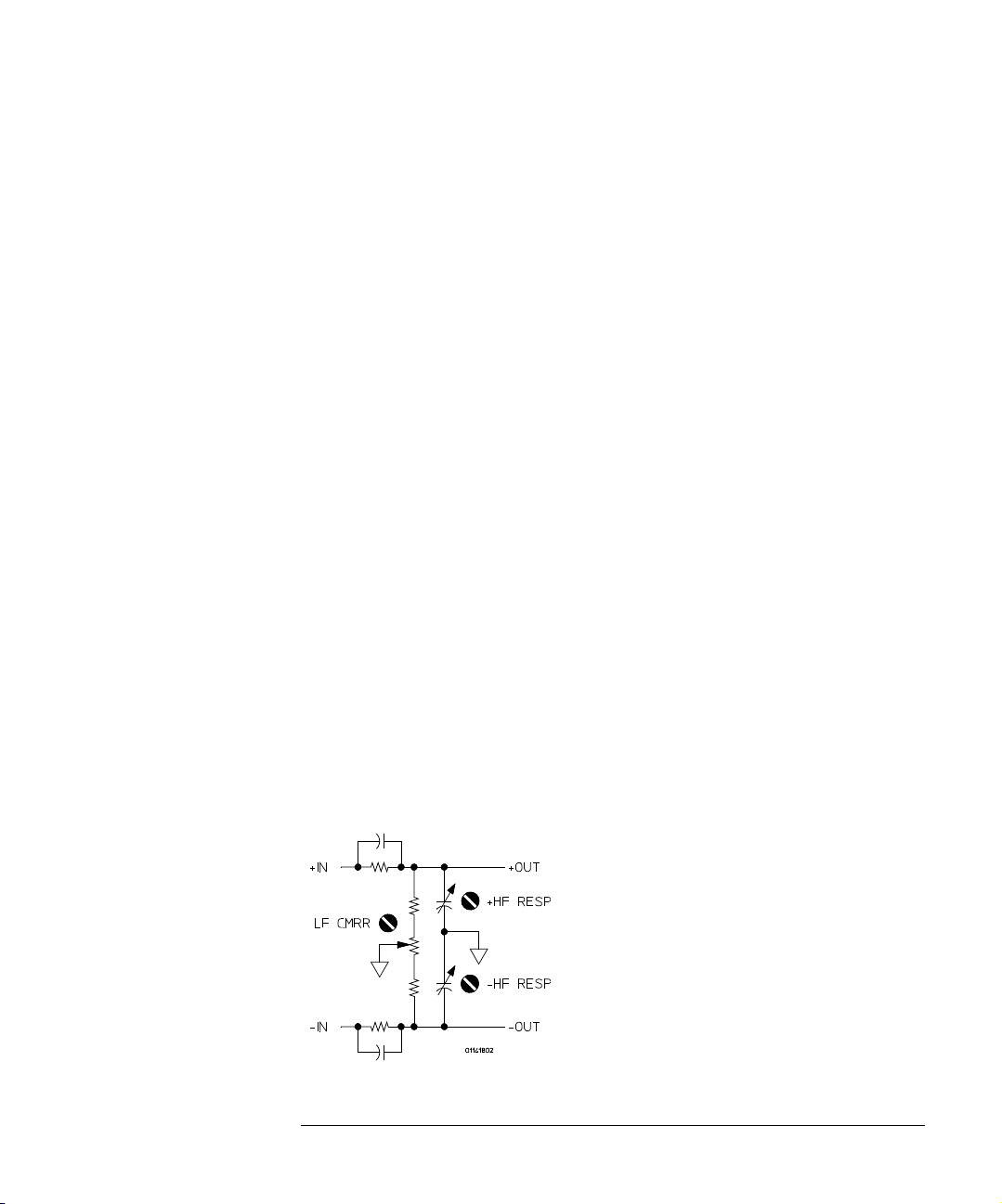

Figure 3-5

Attenuator Adapters

The 10x and 100x Attenuator Adapter are similar. A ceramic substrate carries two

attenuators, one for each input polarity. A variable resistor adjusts the low-frequency

balance (LF CMRR) between the two attenuators. The high-frequency adjustments are

the same for each attenuator. Each attenuator is adjusted differently. One attenuator is

adjusted for optimum pulse response and the other for best high-frequency CMRR.

Attenuator Adapter, Simplified Schematic

61

Page 62

Figure 3-6

Service

Theory of Operation

Test Board

The test board is a device for conveniently connecting test signals to the differential

probe. The probe can be connected to the board with the signal to the positive, negative,

or both inputs.

Test Board Schematic

62

Page 63

Service

Service Policy

Service Policy

For parts of the 1141A/1142A probe system that are complex, the service policy is for

assembly-level repair. For parts of the system with simple circuitry, the service policy is

component-level repair.

The service policy for the 1141A Differential Probe is assembly-level repair. Assemblies

include the PC assembly and cable. The PC assembly is an “exchange assembly.” A

repaired and tested assembly is shipped upon receipt of the defective assembly.

The attenuator and ac coupling adapters are shipped as complete assemblies.

The service policy for the 1142A Probe Control and Power Module is component-level

repair.

63

Page 64

Service

Troubleshooting

Troubleshooting

Use the following paragraphs to assist in troubleshooting problems with the 1141A/1142A

Differential Probe.

Probe Troubleshooting

To troubleshoot the probe:

Apply a known signal to the input of the probe.

1

2 Check for an identical output at the output coax to the cable. This connection

is the one soldered to the PC board. If the probe output cable is not terminated,

or the coax is open, the output signal will be about twice the amplitude of the

input signal.

3 If the signal is incorrect, check the power supply voltages from the 1142A Probe

Control and Power Module. Use the cable diagram on the next page.

4 Troubleshoot the cable with an ohmmeter. Use the cable diagram on the next

page.

Probe Control and Power Module Troubleshooting

The circuitry consists of simple power supplies, operational amplifiers, and TTL. Use

conventional troubleshooting techniques. A complete parts list, component locator, and

schematics are provided later in this chapter.

64

Page 65

Figure 3-7

Service

Troubleshooting

1142A Probe Control and Power Module

65

Page 66

Service

Removing and Replacing Assemblies

Removing and Replacing Assemblies

This section contains procedures for the removal and replacement of major assemblies.

CAUTION Never remove or install any assembly with the instrument power ON. Component

damage can occur.

Differential Probe

Use the following procedure to remove and replace the amplifier PC board in the

differential probe.

CAUTION ELECTROSTATIC DISCHARGE can damage electronic components. Use grounded

wrist straps and mats when servicing the probe.

CAUTION Handle the differential probe carefully once it has been disassembled. If unsupported,

the weight of the cable can put strain on the PC board.

Disassemble Probe

Remove the probe tip caps and probe tips.

1

2 Loosen the probe clamp ring at the cable end of the probe (1/4 turn counter-

clockwise) and slide it down the cable.

3 Remove the bottom cover.

a At the cable end of the probe, separate the covers about one centimeter (1/2 inch).

b Slide the bottom cover toward the cable end of the probe until the locator pins at