Page 1

7O

Agilent 10737L and Agilent 10737R

Compact Three-Axis Interferometers

Page 2

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Description

Description

NOTE In this subchapter refers to either or both of the Agilent 10737L and

Agilent 10737R interferometers.

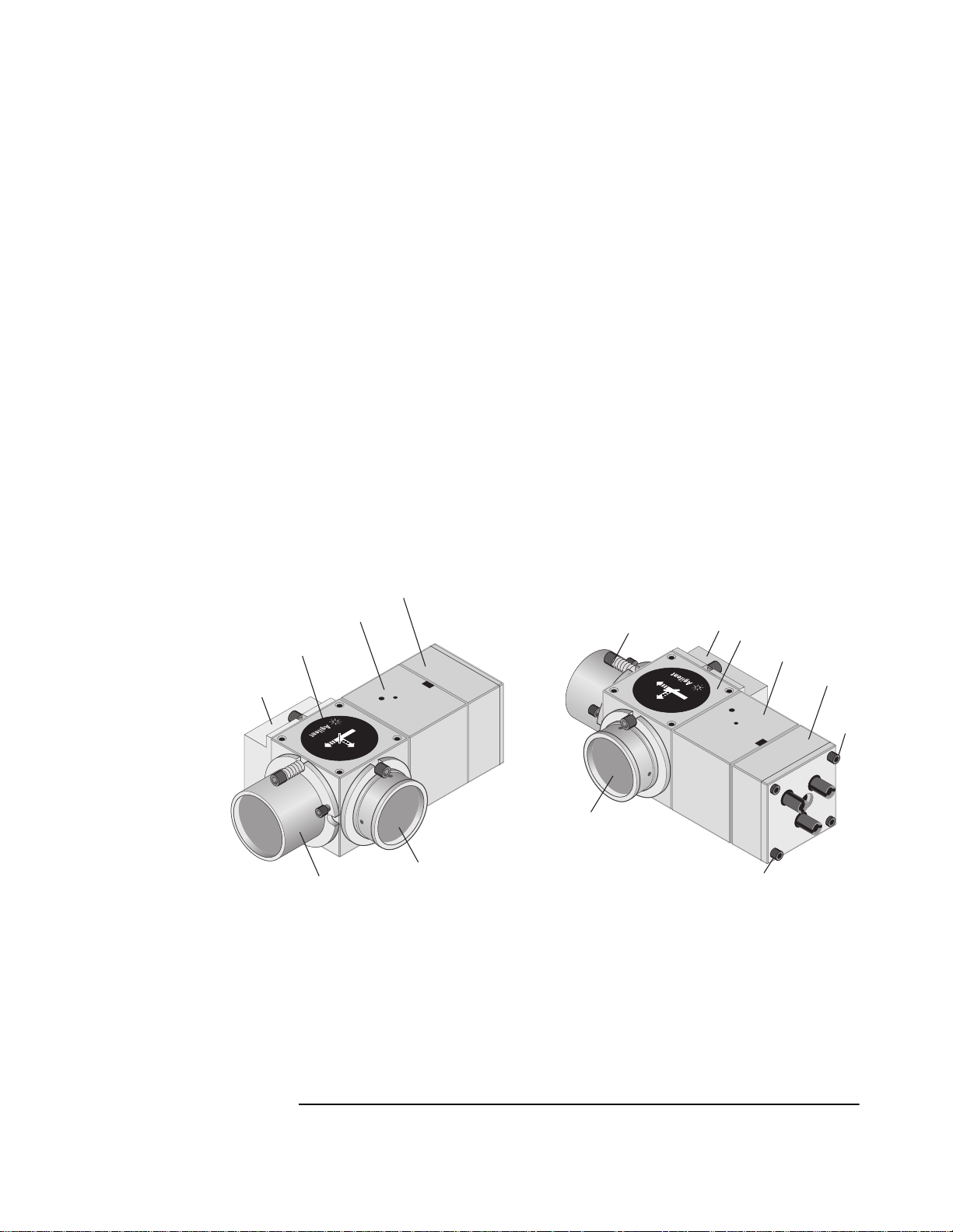

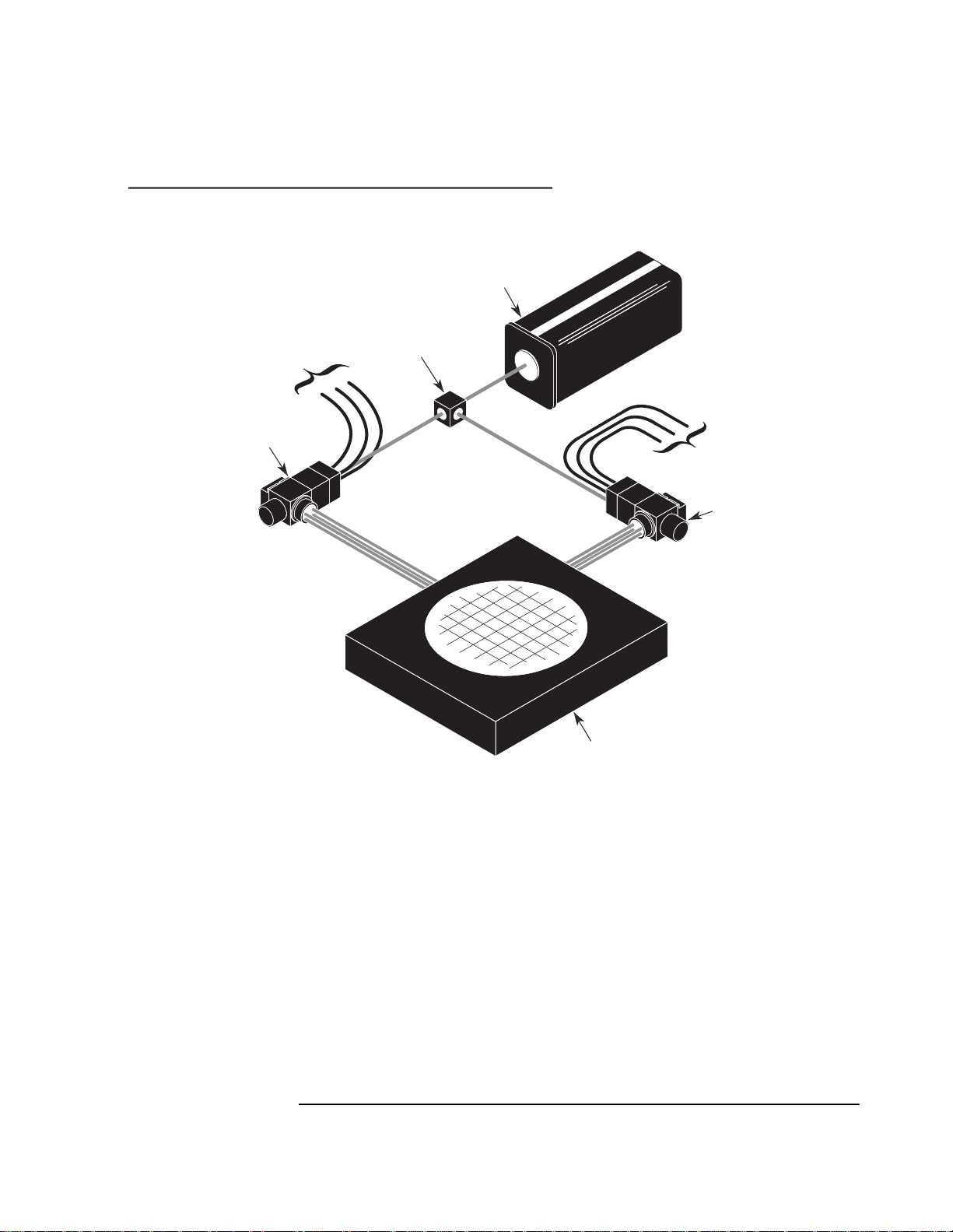

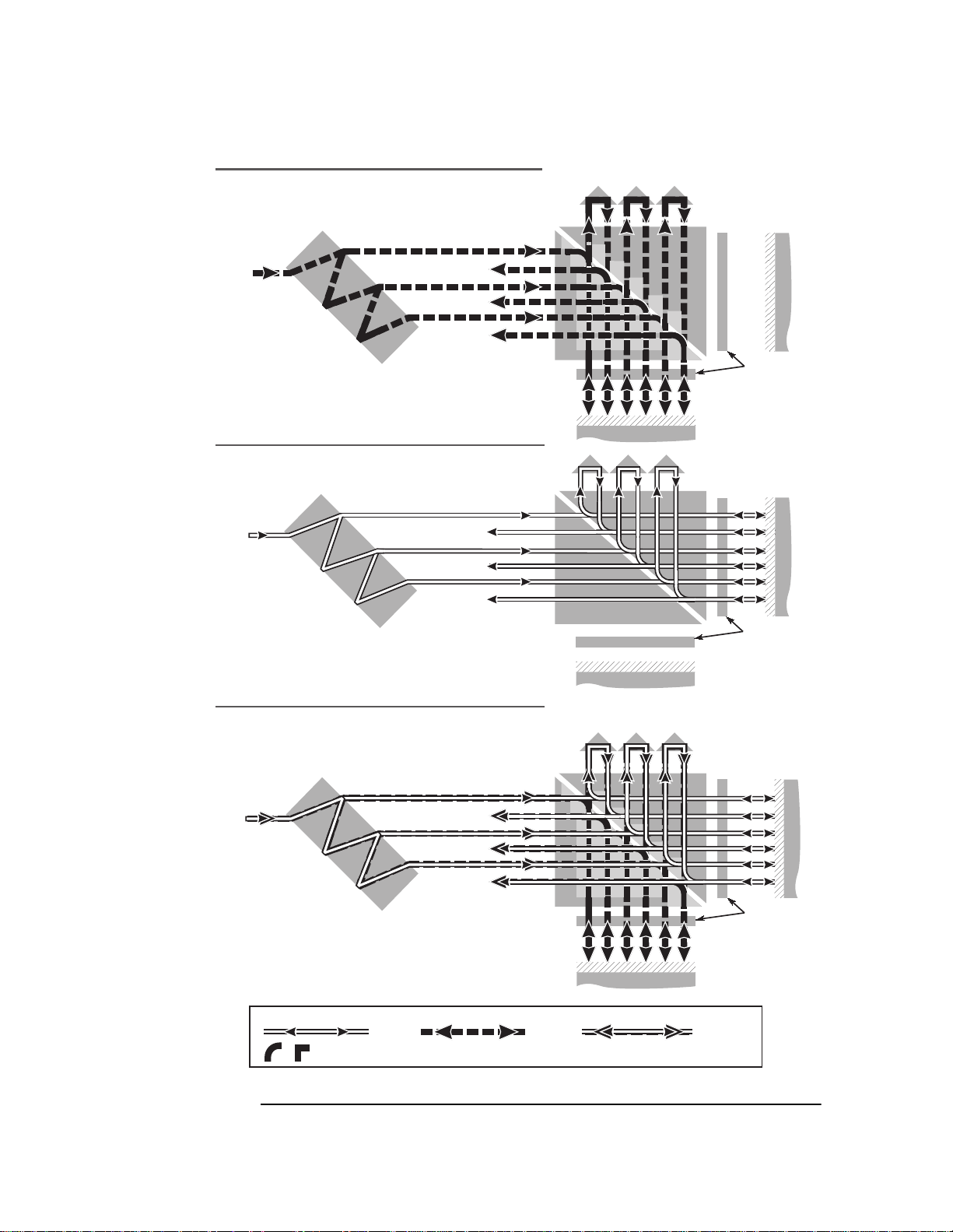

The Agilent 10737L/R Compact Three-Axis interferometers (see

figures 7O-1 through 7O-3) allow up to three measurements

(displacement, pitch, and yaw) to be made on a single axis. The

Agilent 10737L and Agilent 10737R interferometers are identical

except that the “L” bends the measurement beams to the left and the

“R” bends the beams to the right, as viewed from the incoming beam

(see figures 7O-2 and 7O-3).

These interferometers are designed to use a 3 mm diameter laser

beam, available from an Agilent 5517C-003 Laser Head.

The measurement beam parallelism inherent in the design of the

Agilent 10737L/R interferometers ensures that there is essentially no

cosine error between their three measurements and also ensures angle

accuracy for pitch and yaw measurements.

These interferometers are designed for direct attachment of

Agilent 10780F-037 Remote Receiver’s fiber-optic sensor head (one per

axis). The Agilent 10780F-037 receiver is the same as the standard

receiver, except it does not include the lens assembly that attaches to

some Agilent interferometers; in this case, the required lens assembly

is part of the Agilent 10737L/R interferometer. This simplifies user

assembly, since no optical alignment of the recei ve r is required. The

fiber-optic cables from the receivers attach directly to the axis output

apertures on the input face of t he inter feromete r. S ee fi gures 7O-2 and

7O-3.

The Agilent 10737L/R interferometers are based on the

Agilent 10706B High-Stability Plane Mirror Interferometer’s design.

Figure 7O-1 shows two views of an Agilent 10737L interferometer. In

addition to the Agilent 10706B components, the interferometer

includes the following assemblies:

• The receiver assembly. This can be removed during alignment

using the 4-40 socket-head cap screws. The 4-40 button-head

screws hold the 0.100-inch-thick cover plate and the receiver

assembly parts in place; do not try to lo osen these screws or r emove

the plate.

• The shear plate assembly. This assembly is factory-aligned and

must not be loosened or removed.

7O-2 User’s Manual

Page 3

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Description

• The corner cube assembly. This assembly is factory-aligned to

produce the required beam pattern. Do not remove the corner cube

assembly or loosen the screws holding the assembly in place.

Moving this assembly will change the output beam pattern.

1

Corner cube assembly

(Do not loosen or remove)

2

Reference mirror or high stability adapter

3

Plane mirror converter

4

Polarizing beam splitter

5

Shear plate assembly

(Do not loosen or remove)

6

Receiver assembly

7

4-40 socket-head cap screws

attaching receiver assembly

6

5

2

4

L

03

7

R

E

T

E

M

O

1

10737

1

R

0

7

3

7

L

3

-

A

X

I

S

I

N

T

E

R

R

F

E

E

T

R

E

F

M

E

O

R

R

E

F

R

E

F

R

10

1

0

E

7

T

3

7

N

I

L

S

3

I

-

X

A

3

3

2

Figure 7O-1. Agilent 10737L Compact Three-axis Interferometer

1

4

5

6

7

7

User’s Manual 7O-3

Page 4

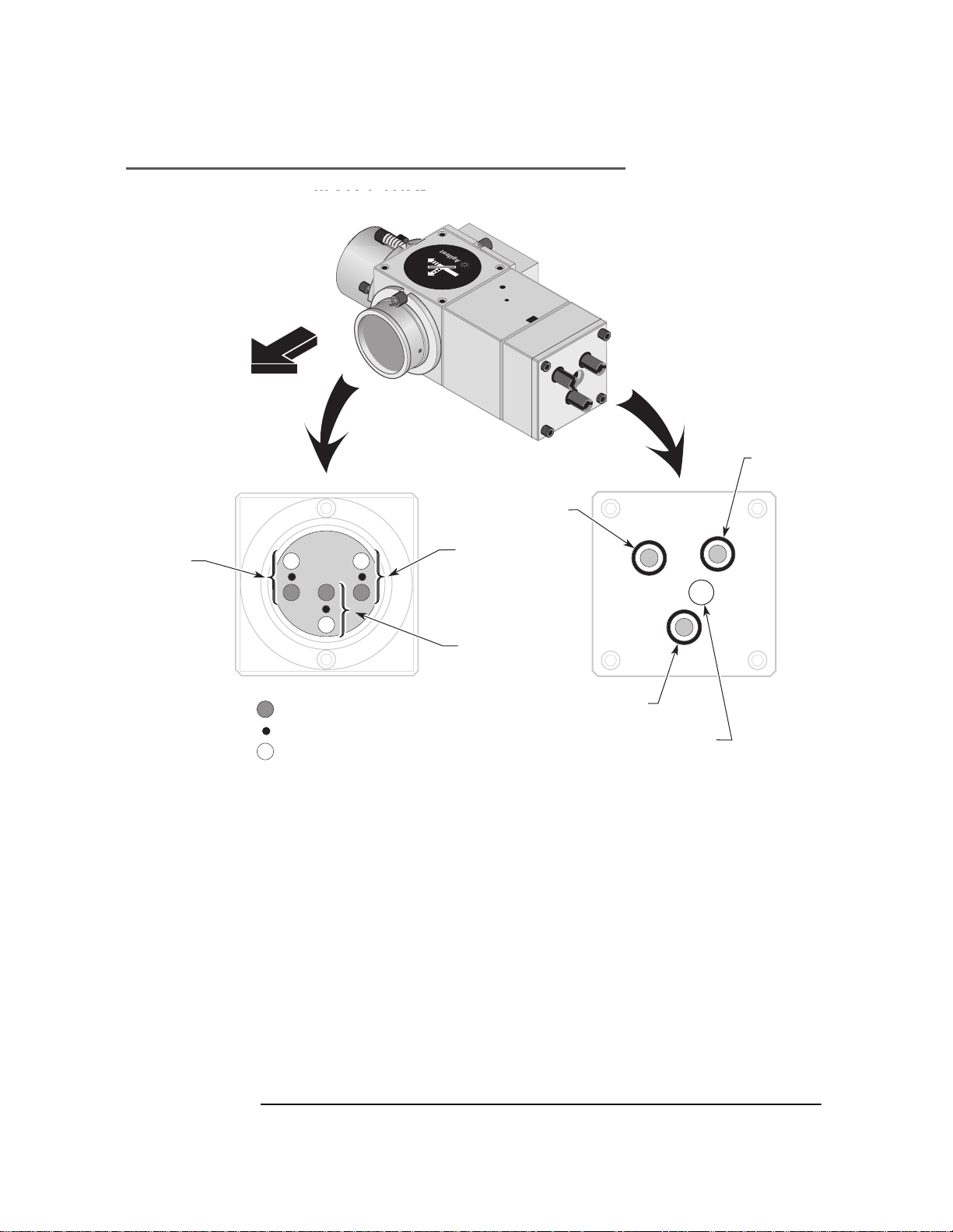

AGILENT 10737L COMPACT THREE-AXIS INTERFEROMETER

s

#2

B

To

M

easuremen

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Description

R

10737L

1

R

0

E

7

T

3

7

N

I

L

S

3

I

-

X

A

S

ee

V

iew

V

t

S

ee

iew

E

T

E

M

O

R

E

F

R

E

F

M

irro

r

A

A

O

xis

utpu

#2

t

A

xis

#1

O

utpu

t

A

x

i

A

xis

#1

= P

rimar

y m

easuremen

=

M

easuremen

= S

ec

V

iew

A

MEASUREMEN

ondar

T FACE

t Poin

t

y m

easement beam

A

xis

t beam

#3

A

O

I

npu

xis

#3

utpu

t

t for a

ll

V

INPUT FACE

A

xes

iew

B

Figure 7O-2. Agilent 10737L Compact Three-Axis Interferometer

7O-4 User’s Manual

Page 5

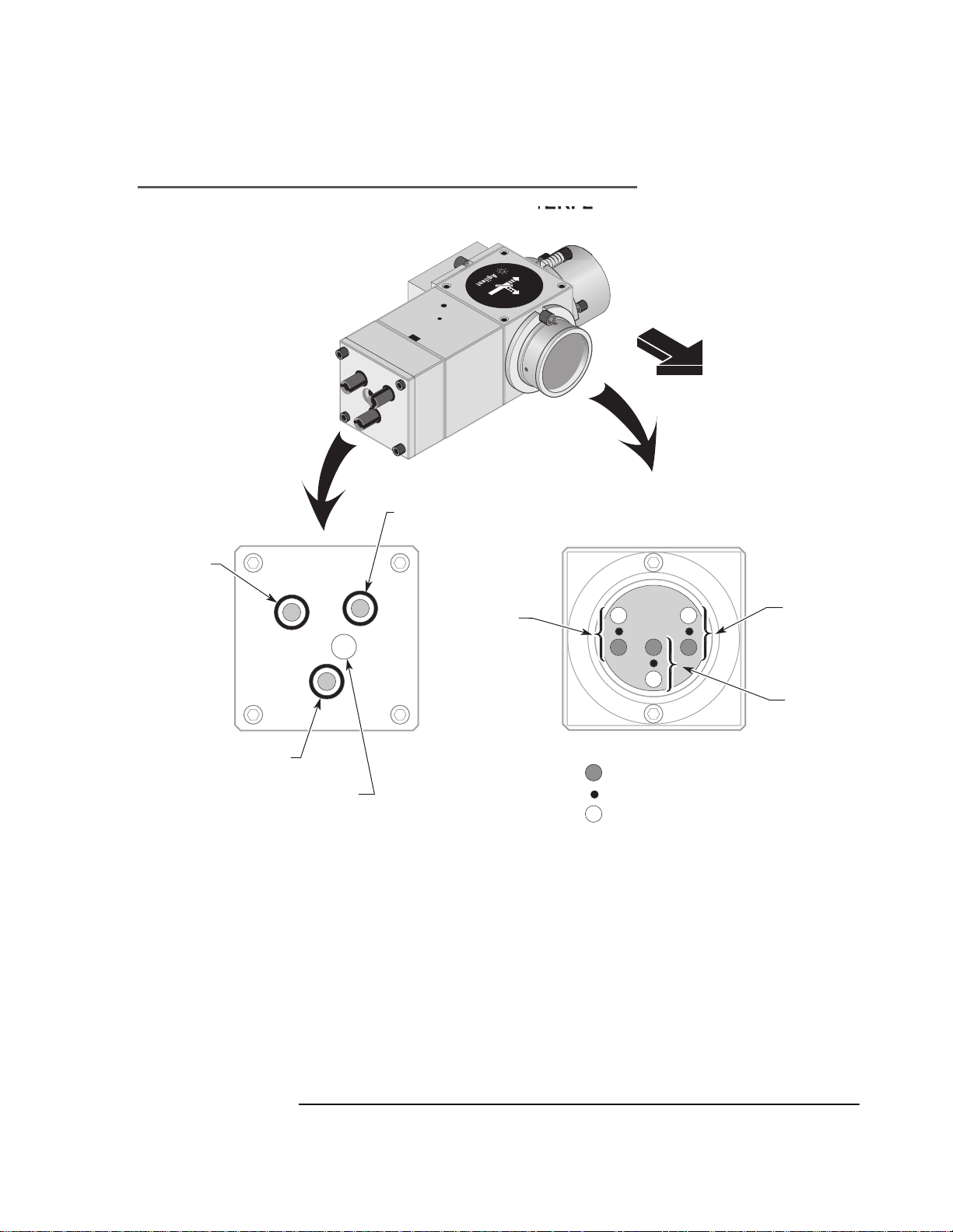

AGILENT 10737R COMPACT THREE-AXIS INTERFEROMETER

V

t

S

ee

iew

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Description

10737R

1

0

7

3

7

R

3

-

A

X

I

S

I

N

T

E

R

R

E

F

T

E

E

R

M

F

E

O

R

To

M

easuremen

S

ee

V

iew

B

A

A

xis

#2

O

u

tpu

t

M

irro

r

A

xis

O

utpu

#1

t

A

xis

A

xis

t beam

t beam

#2

#3

A

xis

#3

O

utpu

t

I

npu

t for a

V

iew

INPUT FACE

A

xis

#1

= P

rimar

y m

easuremen

=

M

= S

V

easuremen

ec

ondar

iew

ll

A

xes

A

MEASUREMEN

t Poin

y m

easuremen

B

T FACE

t

Figure 7O-3. Agilent 10737R Compact Three-Axis Interferometer

User’s Manual 7O-5

Page 6

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Description

Applications

General

The Agilent 10737L or Agilent 10737R interferometer, by making

three simultaneous distance measurements along or parallel to the

X-axis, can make these measurements:

• displacement along the X-axis

• rotation (pitch) about the Y-axis

• rotation (yaw) about the Z-axis

The angular measurements made by either of these interferometers

can be calculated by taking the arctangent of the difference between

two linear measurements involved, divided by their separation:

–()

YY’

THETA arc

-------------------tan=

D

This method for determining angle is described in more detail in the

“Electronic yaw calculation method” and “Optical yaw calculation

method” subsections under t he “Three-axis system using dis crete plane

mirror interferometers (X, Y, YAW)” section in Chapter 3, “System

Design Considerations,” of this manual.

X-Y Stage

These interferometers are well suited for X-Y stage or multiaxis

applications, such as lithography equipment. Two of these

interferometers, can measure all X, Y, pitch, roll, and yaw motions of a

stage. Since only five axes are required to make all these

measurements, the sixth axis can be used as a redundant yaw

measurement (useful for mirror mapping). In these applications, the

measurement mirrors are attached to the X-Y stage.

7O-6 User’s Manual

Page 7

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

ase

ead

g

s

ete

eam

g

s

S

S

s

eter

s

Interferometers

Description

MEASUREMENT USING AGILENT 10737R/L COMPACT

THREE-AXI

Agilent 10737L

Compact Three-axi

Interferom

INTERFEROMETER

To Fiber Optics

Receivers

B

Directin

Optic

L

r H

To Fiber Optics

Receivers

A

ilent 10737R

Compact Three-axi

Interferom

r

Multiaxi

Stage

Figure 7O-4. Measurement using two Agilent 10737R interferometers

Optical Schematics

Optical schematics for these interferometers are given in Figure 7O-5.

Each interferometer functions s i milarly to three parallel

Agilent 10706B High Stability Plane Mirror interferometers with a

three-way beam splitter in front of them.

To reduce thermal drift errors, the measurement and reference beam

paths have the same op t ica l pa th len gt h in gla ss. This mini mi zes

measurement errors due to temper atur e ch anges in t he int erfer ometer .

User’s Manual 7O-7

Page 8

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Description

MEASUREMENT PATH (fB)

Agilent 10737L and Agilent 10737R

Compact Three-Axis Interferometers

f

rom

ase

B

r

Axis #2

Axis #3

F

L

R

eference

M

irro

r

Axis #1 = fB±2 f

Axis #2 = fB±2 f

Axis #3 = fB±2 f

∆

∆

∆

1

2

3

NOTE: Because the Measurement

mirror may have a combination of

displacement, pitch, and yaw motions,

the Measurement Axes may have

different Df values, as shown

Axis #1

M

easuremen

M

irro

r

λ

/4

P

lat

e

t

REFERENCE PATH (fA)

Agilent 10737L and Agilent 10737R

Compact Three-Axis Interferometers

f

rom

ase

r

Axis #1 = f

Axis #2 = f

Axis #3 = f

A

A

A

A

F

L

Axis #2

Axis #3

Axis #1

M

M

R

λ

/4

easuremen

irro

r

eference

M

irro

r

P

lat

e

t

COMPOSITE (fA) and (fB)

Agilent 10737L and Agilent 10737R

Compact Three-Axis Interferometers

f

F

rom

L

ase

B

r

Axis #1 = fB±2 f

Axis #2 = fB±2 f

Axis #3 = fB±2 f

∆

∆

Axis #2

Axis #3

f

A

1,

f

∆

A

2,

f

A

3,

Axis #1

R

eference

M

irro

λ

/4

P

lat

r

e

M

LEGE

=

f

A

=

Rounded corners are used to help you trace paths.

ND

easuremen

M

irro

=

f

B

=

f

a

A

r

nd f

t

B

Figure 7O-5. Agilent 10737L/R Compact Three-Axis interferometers — beam paths

7O-8 User’s Manual

Page 9

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Special Considerations

Special Considerations

Laser beam power consideration

When working with an application that requires use of a separate

beam splitter, make sure that you provide enough laser beam power to

any multia x i s i nt e rferometer so all receivers connected to it receive

adequate light power. This will help ensure that each measurement

receiver in the system receives the optimum signal strength in the

intended application.

Orientation

Note that although illustrations may show an interferometer in one

orientation, you may orient the unit as required by your measurement

application—vertically, horizontally, or ups ide-down.

User’s Manual 7O-9

Page 10

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

ete

e

ottom of

ete

as sho

n

S:

s:

easurement Point

eam

cates

P

m

(

)

(

)

m

(

)

m

(

)

(

)

m

(

)

See

1

S

2

t

s No.3

t

r

m

(

)

S

m

Interferometers

Special Considerations

AGILENT 10737L THREE-AXIS INTERFEROMETER

B

interferom

wn i

specification

drawing

GENERAL NOTE

1. For Each Axi

2. Drawing not to scale.

14.38 mm

0.566

7.19 mm

MP1

0.283

See Note 1

7.19 m

0.283

r

MP3

ee Notes 1 &

econdary Measurement bea

MP = M

Darker B

Indi

rimary Measurement bea

10.11 m

0.39

68.92

(2.71)

Note

24.49 m

20.90 mm

0.83

Interferom

Input Fac

0.964

17.3 m

0.68

Measurement Mirror

r

Axis No.1

Outpu

Axis No.2

Output

Axi

Outpu

Laser Beam turns left

(viewed from top).

R

E

T

E

M

O

R

E

F

R

E

F

R

E

T

N

I

10737L

S

I

X

A

-

3

L

7

3

7

1

0

Input fo

all axes

FROM

LASER

HEAD

From

Laser Head

Figure 7O-6A. Agilent 10737L Interferometer — beam patterns

7O-10 User’s Manual

Page 11

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

R

ete

p

e

S

1

m

(

)

m

(

)

m

(

)

m

(

)

m

(

)

m

(

)

s No.2

s No.3

t

(

)

o

s:

easurement Point

eam

cates

P

m

S

m

Interferometers

Special Considerations

AGILENT 10737R THREE-AXIS INTERFEROMETE

Input for

all axes

Axis No.1

Output

FROM

LASER

HEAD

Axi

Output

Axi

Outpu

GENERAL NOTES:

1. F

r Each Axi

econdary Measurement bea

MP = M

Darker B

Indi

rimary Measurement bea

2. Drawing not to scale.

Interferom

In

ut Fac

24.49 m

17.3 mm

0.68

ee Note

0.964

r

68.92

(2.71)

MP2

20.90 m

0.83

10.11 m

0.39

14.38 m

0.566

7.19 m

0.283

MP1

See Note 1

7.19 m

0.283

MP3

See

Notes 1 & 2

Laser Beam turns right

(viewed from top).

0

1

7

3

7

R

3

-

A

X

I

S

I

N

T

10737R

E

R

F

E

R

F

E

R

O

M

E

T

E

R

Bottom of

interferometer

as shown in

specification

drawing

Measurement Mirror

From

Laser Head

Figure 7O-6B. Agilent 10737R Interferometer—beam patterns

User’s Manual 7O-11

Page 12

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Mounting

Mounting

Adjustable mounts

The Agilent 10711A Adjustable Mount provides a convenient means of

mounting, aligning, and securely locking an Agilent 10737L or

Agilent 10737R interferometer in position. Since the mount allows

some tilt and yaw adjust me n t , th e nee d for cu st o m fi xt u rin g is

minimized. The mount allows the interferometer to be rotate d about its

physical centerline, simplifying installation. Note however, that since

the input aperture is no t ce n t ered on the inpu t face, some tr a n sl a tion

of the interferometer or beam delivery opt ics may be required when the

interferometer is rotated.

Fasteners

The Agilent 10737L/R interferometers are supplied with English

mounting hardware, which is required to fasten it to its adjustable

mount.

7O-12 User’s Manual

Page 13

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Installation and Alignment

Installation and Alignment

Summary

The installation and alignment procedure has two major parts:

• Planning and setting up the laser beam path(s)

• Installing and aligning the interferometer(s).

Objectives of the installation and alignment procedure are:

1. Minimizing cosine error.

2. Maximizing signal strength at the receivers.

3. Ensuring a symmetrical range of rotation about the zero angle

point.

General

Refer to the Agilent 10706A interferometer “Installation” information

in subchapter 7C of this manual.

Tools and Equipment Required or Recommended

Table 7O-1 lists and describes the tools and equipment needed to

install and align the Agilent 10737L and 10737R interferometers.

User’s Manual 7O-13

Page 14

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Installation and Alignment

Table 7O-1. Tools and Equipment Required or Recommended

Item and Description Mfr. Part Number (Mfr =

Agilent unless otherwise

indicated)

Penta prism or similar prism that bends

light exactly 90 degrees

True square L.S. Starret, Athol, Mass. Recommended, but not required.

Washer, lock, 0.115 in id, 0.270 in od,

internal tooth; qty = 6

Screw, cap, 4-40, 0.500 in lg, hex trim

head 0.187 in (3/16 in) across flats; qty =

2

Screw, machine, 4-40, 1.75 in lg, pan

head, pozidriv; qty = 6

Screw, socket head cap, 4-40, 0.250 in

lg, hex recess 0.094 in (3/32 in) across

flats; qty = 2

Prisms of this type are available

from scientific or optical supply

shops

2190-0004 Supplied with Agilent 10737L/R

2940-0269 Supplied with Agilent 10737L/R

2200-0127 Supplied with Agilent 10737L/R

3030-0253 Supplied with Agilent 10737L/R

Comment, Note, etc.

Recommended, but not required.

For setting up right angles in the

beam paths from the laser head to the

interferometers.

An Agilent 10777A Optical Square

may be used.

For setting up beam paths parallel to

or perpendicular to machine surfaces

that are parallel to or perpendicular to

the stage mirrors.

Interferometer.

Interferometer.

Interferometer.

Interferometer.

Screw, socket head cap, 2-56, 0.187 in

lg, 0.064 in radius oval point, hex recess;

qty = 2

Hex key, 5/64 in (0.078–in) 8710-0865 Supplied with Agilent 10737L/R

Hex key, 3/32-in (0.094 in) 8710-0896 Supplied with Agilent 10737L/R

Wrench, 3/16-in open-end 8710-1740 Supplied with Agilent 10737L/R

3030-0983 Supplied with Agilent 10737L/R

Interferometer.

Interferometer.

Interferometer.

Interferometer.

Used to secure the Agilent 10711A

Adjustable Mount.

Alignment Aid 10706-60001 Supplied with the Agilent 10737L/R

Interferometer.

See Figure 7O-7 for illustration.

Alignment Aid 10706-60202 Supplied with the Agilent 10737L/R

Interferometer.

See Figure 7O-7 for illustration.

7O-14 User’s Manual

Page 15

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Installation and Alignment

Alignment aid (Agilent Part Number 10706-60001) is the same as one

used on the Agilent 10706B Plane Mirror Interferometer. Refer to the

“Alignment aids” section for the Agilent 10706B Plane Mirror

Interferometer, in subchapter 7C of this manual for a further

discussion of its use.

Alignment aid (Agilent Part Number 10706-60202), shown in

Figure 7O-7, facilitates autoreflection alignment for the high stability

adapter to achieve minimal thermal drift. It contains a quarter-wave

plate which allows the reference beam to return to the laser head

without offset. Figure 7O-10 illustrates how the aid is positioned

between the beam splitter and the high stability adapter during

alignment.

Alignment Aid

Insert between Beam Splitter

and High Stability reflector

during autoreflection.

Caution: Fragile

RGET

TA

REMOVE

ER ALIGNING

AFT

logies

Agilent Techno

Alignment Aid

P/N 10706-60001

P/N 10706-60202

Alignment Aid

P/N 10706-60202

Figure 7O-7. Agilent 10737L/R interferometers—alignment aids

User’s Manual 7O-15

Page 16

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Procedure

Procedure

Planning the measurement setup

Determine the general plan for your measurement. Examples of

measurement setups are given throughout this manual. Particularly,

your plan should address:

1. Which axes you want to measure, and what measurements you

want to make,

2. Where the interferometers will be positioned with respect to the

stage mirrors,

3. Where the laser head will be positioned and how the laser beam

will be delivered to the interferometers, and

4. Making sure you will have enough laser po wer to drive all r eceivers

in your measurement system.

Good practice defines the plan e and direc tion of all beam paths against

machined surfaces known to be parallel or perpendicular to the stage

plane.

You may need to provide special mounting arrangements for the laser

head and the optics in order to place the measurement beams where

you want them on the stage mirrors.

Initial installation and setup

1 Install the laser head, the beam-steering opti cs, and the bea m-splitting

optics in their general locations, as specified in your plan. The

interferometer(s) will be installed after the beam paths have been

established as described below.

2 Turn on power to the las er head and select the laser head’s small

output aperture.

3 Refer to Chapter 4, “System Installation and Alignment,” in this

manual, beginning with the “Alignment princip les” section, for

additional information about aligning your measurement setup.

7O-16 User’s Manual

Page 17

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Procedure

Installing and aligning an interferometer

CAUTION In performing the procedure below, perform only the removal,

disassembly or assembly steps described. Do not remove or take apart

anything you are not instructed to. Do not touch any glass surface or

allow it to be scratched, dirtied or otherwise harmed.

CAUTION Do not touch any glass surface of any optic. For cleaning instructions,

see Chapter 10, “Maintenance,” in this manual.

Perform this procedure for each interferometer in your measurement

system.

This procedure assumes that the laser head and all optics except the

interferometer(s) have been installed an d that the appropriate beam

path(s) to the stage mirror(s) have been established as described in

Chapter 4, “System Installation and Alignment,” of this manual.

The procedure has these major parts:

1. Removing the receiver assembly

2. Removing the high stability adapter (reference mirror)

3. Aligning the measurement beam path

4. Aligning the reference beam path

5. Comparing beam path alignments

Removing the receiver assembly

To remove the receiver assembly, refer to figures 7O-1 and 7O-8.

1 Use the 5/64-inch hex key to remove the two cap screws that hold the

receiver assembly to the interferometer. Set the screws in a clean, safe

place where they will not be lost.

2 Remove the receiver assembly from the i nterferometer. Set the receiver

assembly in a clean, safe place.

User’s Manual 7O-17

Page 18

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

107 37L

Interferometers

Procedure

Removing the high stability adapter (reference mirror)

To remove the high stability adapter, refer to figures 7O-1 and 7O-8,

and:

1 Use the 5/64-inch hex key to rem ov e the two cap screws with springs

that hold the high stability adapter (reference mirror) to the

interferometer. Set th e screws in a cle an, safe place wher e they will not

be lost.

2 Remove the high stability adapt er (reference mirror) from the

interferometer. Set the high stability adapt er in a clean, safe place.

Input

Beam

1

10737L

R

E

T

E

0

7

3

7

L

3

-

A

X

I

S

I

N

T

E

R

F

E

R

F

M

E

O

R

Center on One

Measurement Beam

Alignment Aid 10706-60001

Measurement

Beam

Figure 7O-8. Agilent 10737L Compact Three-Axis Interferometer with

Agilent 10706-60001 Alignment Aid

NOTE From here on, this procedure assumes that the interferometer is

installed on an Agilent adjustable mount.

7O-18 User’s Manual

Page 19

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Procedure

Aligning the measurement beam path

1 Remove the receiver assembly and high stability adapter, as describ ed

in the respective procedures, above.

2 Install the interferometer so the beam from the laser source ente rs its

input aperture and is normal to its input face.

3 Set the alignment aid (Agilent Part Number 10706-60001) on the

interferometer’s Measurement beam aperture as shown in

Figure 7O-8.

With the alignment aid installed, the beam will be reflected off the

stage mirror back to the laser head.

4 Set the laser head to the small aperture.

5 Roll and yaw the interferometer until the autoreflected beam is

centered on the small aperture of the laser.

6 Select the laser head’s large output aperture and translate the

interferometer horizontally until the input beam is centered on the

interferometer’s input aper ture.

A piece of translucent tape over the interf erometer’s input aperture

will make the input beam visible. This procedure assumes that the

vertical height of the beam was set before the interferomete r was

installed, (see the “Initial installation and setup” procedure);

alternatively, fixturing for a ver tical ad justment fo r the int erf erometer

may be used.

7 Select the laser head’s small output aperture and check that the beam

is still autoreflecting.

8 Repeat steps 3 through 7 until the beam is both autoreflecting and

centered on the interferometer's input aperture.

9 Tighten all mount adjustment screws.

10 Remove the alignment aid.

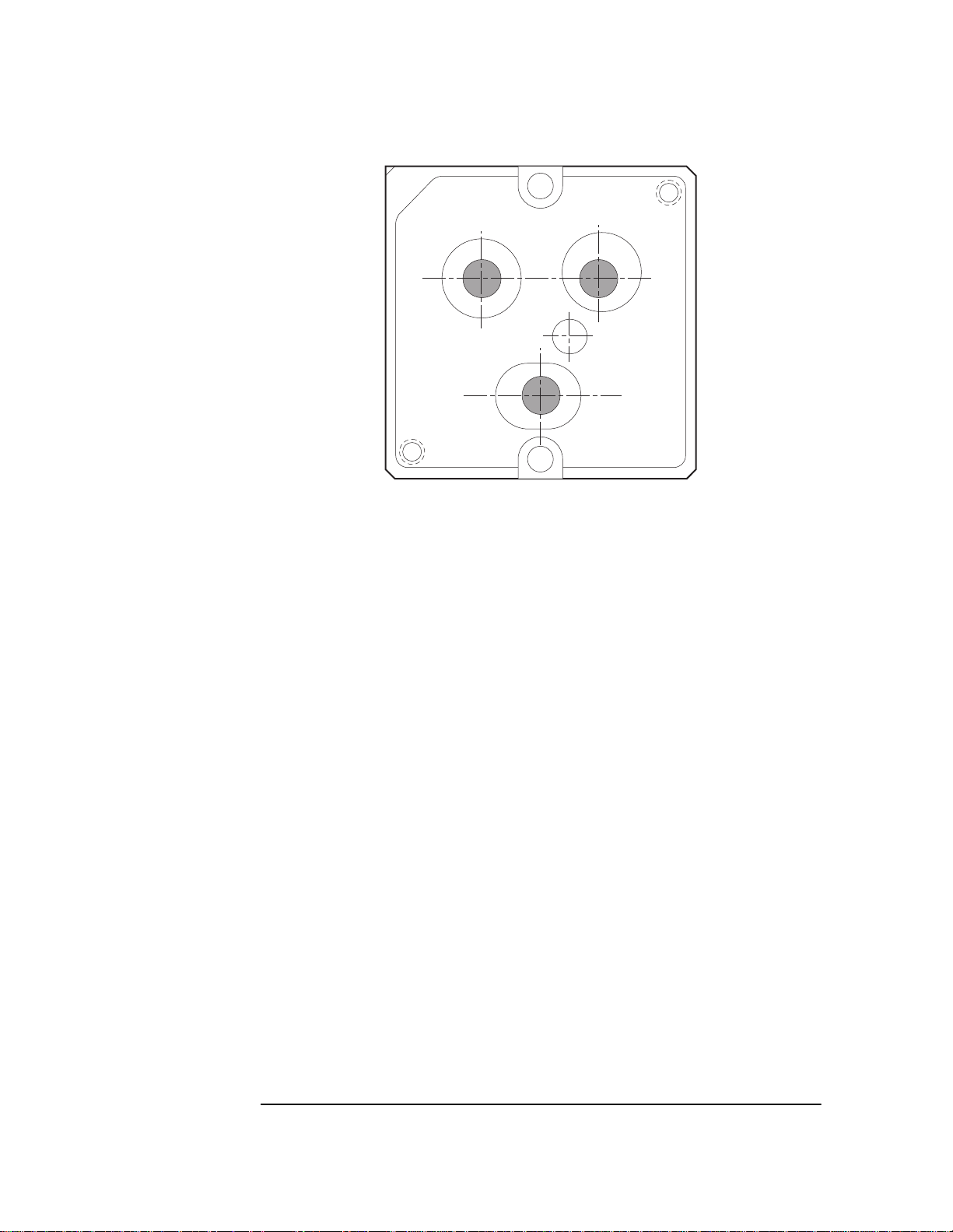

11 Check the position of the beams in the interferometer’s output

apertures (see Figure 7O-9).

Once again, translucent tape is helpful for viewing the beams in the

apertures. If any beam clipping occurs, or if the beams are far off from

the desired location, check for obstructions and recheck the alignment

(by performing steps 3 through 7 above).

User’s Manual 7O-19

Page 20

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Procedure

Figure 7O-9. Agilent 10737L Compact Three-Axis Interferometer —

return beam pattern

12 Install the receiver assembly.

To do this, reverse the “Removing the receiver ass embly” procedure,

above.

13 Plug in the fiber-optic cables.

14 Adjust each receiver’s gain by turning its gain adjustment screw to

cause the receiver’s LED to light, then reduce the gain until the LED

just turns off. For more information, see Agilent 10780F instructions in

Chapter 8, “Receivers,” of this manual.

7O-20 User’s Manual

Page 21

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Procedure

Aligning the reference beam path

NOTE The measurement path must be aligned and the laser beam centered

on the input aperture before aligning the reference mirror.

1 Remove the receiver ass embly and the plane mirror converter (see

figures 7O-1 and 7O-4), and set aside on a clean surface. Do not touch

any glass surface of any optic.

7L

R

E

T

E

M

O

R

E

F

R

E

F

R

3

107

1

E

T

N

I

0

7

3

7

L

S

3

I

-

X

A

Alignment Aid

10706-60202

Input

Beam

Figure 7O-10. Agilent 10737L Compact Three-Axis Interferometer

with 10706-60202 Alignment Aid

2 Install the refer ence mirror assembly (see figures 7O-1 and 7O-4).

The 4-40 screws on springs hold the mirror in place. The four 2-56

screws tilt the mirror for alignment. Back off the 2-56 screws so the

mirror housing is flush with the interferometer. Tighten the

4-40 screws to compress the springs completely and then back off

approximately 1-1/2 turns.

3 Place the 10706-60202 alignment aid between the beam spl itting cube

and the reference mirror (see Figure 7O-10).

4 Block the beams going to the stage mirror.

5 Set the laser to the small aperture.

User’s Manual 7O-21

Page 22

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Procedure

6 Tilt the reference mirror by adjusting the 2-56 screws until the beam

from the reference mirror autoreflects back to the center of the laser

small aperture.

7 Remove the alignment aid.

8 Check the position of the beams in the interferometer’s output

apertures (see Figure 7O-9).

Once again, translucent tape is helpful for viewing the beams in the

apertures. If any beam clipping occurs, or if the beams are far off from

the desired location, check for obstructions and recheck the alignment

(by performing steps 6 through 10 above).

9 Install the receiver assembly.

To do this, reverse the “Removing the receiver ass embly” procedure,

above.

10 Plug in the fiber-optic cables.

11 Adjust each receiver’s gain by turning its gain adjustment screw to

cause the receiver’s LED to light, then reduce the gain until the LED

just turns off. For more information, see Agilent 10780F instructions in

Chapter, 8, “Receivers,” of this manual.

12 Unblock the stage mirror beams.

Comparing beam path alignments

1 Remove the receiv er assembly.

2 Look for any lac k of overlap between the reference and measurement

return beams, translucent tape will help. If beams do not overlap,

check reference mirror alignment.

Note that if you must realign the measurement mirror, you will also

have to realign the reference mirror.

3 Install the receiver assembly and make sure all screws are tight.

7O-22 User’s Manual

Page 23

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Operation

Operation

Measurements

For an interferometer setup to measure distances along the X-axis,

measurements of displacement, pitch, and yaw are derived as

described below. These computations are done via software on the

system controller or computer .

Displacement

For the Agilent 10737L/R interferometer, displacement along the

X-axis can be measured as the average of the data returned from

measurement axis #1 and measurement axis #2.

Displacement

measurement axis #1 + measurement axis #2

------------- ------------- ------------ ----------- ------------- ------------- ------------ ------------- -----------=

2

Pitch

For the Agilent 10737L/R interferometer, pitch (rotation about the Y

axis) can be measured using data returned f rom all three measurement

axes, and the vertical offset between the common centerline of

measurement axes #1 and #2 and the centerline of measurement

axis #3 (7.19 mm, or 0.283 inch).

Displacement measurement axis #3 –

Pitch

------------- ------------ ------------- ----------- ------------- ------------ ------------- -----------

7.19 mm or 2.83inc h

radian=

Yaw

For the Agilent 10737L/R interferometer, yaw (rotation about the

Z axis) can be measured as the difference between the data returned

from measurement axis #1 and measurement axis #2, divided by the

distance between them (14.38 mm, or 0.566 inch).

measurement axis#1measurement axis #3 –

Yaw

----------- ------------- ------------- ---------- ------------- ------------- ------------- ------------ ----------- ---------

14.38 mm or 0.5666 inch

radian=

Error

The deadpath distance for an Agilent 10737L/R interferometer is the

distance between the interferometer’s measurement face and the

measurement mirror, at the measurement “zero” position. This is the

same as for the Agilent 10706B interferometer, on which it is based.

User’s Manual 7O-23

Page 24

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Specifications and Characteristics

Specifications and Characteristics

Specifications describe the device’s warranted performance.

Supplemental characteristics (indicated by TYPICAL or NOMINAL)

are intended to provide non-warranted p erformance information useful

in applying the device.

Plane mirror systems have a fundamental optical resolution of one

quarter wavelength (0.158 micron, 6.23 microinches).

Using electronic resolution extension, the sys tem resolution is

increased significantly. Depending on the system, an additio nal

resolution extension factor of 32 (for Agilent 10885A and 10895A) or

256 (for Agilent 10897B and 10898A) is usually available.

Interferometer Fundamental Optical

Resolution

Agilent 10737L or Agilent 10737R λ/4 (158.2 nm, 6.2 µin) See specifications on

System Resolution (see

NOTE)

following page.

7O-24 User’s Manual

Page 25

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

Interferometers

Specifications and Characteristics

Agilent 10737L/R Compact Three-Axis Interferometer Specifications

Linear Resolution: 5 nm (using Agilent 10885A, or Agilent 10895A electronics)

0.6 nm (using Agilent 10897A, or Agilent 10898A electronics)

Yaw Resolution: 0.35 µrad (0.07 arc-sec) (using Agilent 10885A, or Agilent 10895A electronics)

0.04 µrad (0.01 arc-sec) (using Agilent 10897A, or Agilent 10898A electronics)

Pitch and Roll Resolution: 0.7 µrad (0.14 arc-sec) (using Agilent 10885A, or Agilent 10895A electronics)

0.1 µrad (0.02 arc-sec) (using Agilent 10897A, or Agilent 10898A electronics)

*

Yaw Ra ng e

Pitch and Roll Range: ±0.44 mrad (±1.5 arc-min)

Linear Range: 10 m (33 ft) total for all three axes.

Operating Temperature: 0–40 °C (17–23 °C to ensure system non-linearity specification)

Thermal Drift Coefficient: Same as Agilent 10706B

Weight: 490 g (18 oz)

Dimensions: see Figure 7O-11 on the next page

Materials Used: Housing: stainless steel and aluminum

Installation: Uses 3-mm beam available from Agilen 5517C-003. Requires three

Measurement (Plane) Mirror

Recommendations:

Optical Surface Quality: 60-40 per Mil 0-13830

: ±0.44 mrad (±1.5 arc-min)

Optics: optical grade glass

Adhesives: vacuum grade, cyanoacrylate polarizer material

Receiver inserts: urethane foam, acetal, 15% glass fill polyester

Agilent 10780F-037 Remote Receivers. Compatible with Agilent 10711A

Adjustable Mount.

Reflectance: 98% at 633 nm at normal incidence

Flatness: Flatness deviations will appear as measurement errors when the mirror

is scanned perpendicular to the beam. Recommended range 1/4 (0.16 µm or 6 µin)

to 1/20 (0.03 µm or 1.2 µin) dependent on accuracy requirements.

* At a distance of 300 mm, maximum measurement mirror angle due to all components (i.e., yaw and pitch or yaw

and roll) between the measurement mirror and the interferometer. A six-axis system is assumed.

User’s Manual 7O-25

Page 26

Chapter 7O Agilent 10737L and Agilent 10737R Compact Three-Axis

ce

d

6-32 U

p

de.

Connectors

g

7

eceivers

t

3

m

(

)

3

m

(

)

3.0 mm

(

)

aser

or

(

)

8

m

(

)

m

(

)

(

)

38

m

(

)

(

)

m

(

)

m

(

)

6

m

(

)

m

(

)

Interferometers

Specifications and Characteristics

2 m

1.26

2 m

1.26

4x Drilled For Clearan

of 4-40 Screw and tappe

NC-2B

.250 dee

4x this side and 4x far si

7.19 mm

0.283

.2 m

1.50

7.19 m

0.283

7.19 m

0.283

10703L

R

-

To Plane Mirr

125 mm

1

0

7

3

7

L

3

4.92

66 mm

7.19 mm

0.283

2 m

3.22

(2.6)

3 x Fiber-Optic

for A

R

0.12

22.63 mm

0.891

17.3 m

0.68

ilent 10780F-03

From L

4.1 m

(2.53)

Inpu

Aperture

17.3 m

0.68

Agilent 10737L interferometer is shown; Agilent 10737R interferometer dimensions are similar.

Figure 7O-11. Agilent 10737L/R Compact Three-Axis Interferometer — dimensions

Product specifications and descriptions in this

document subject to change without notice.

Copyright (C) 2002 Agilent Technologies

Printed in U.S.A. 07/02

This is a chapter from the manual titled:

Laser and Optics User's Manual

For complete manual, order:

Paper version: p/n 05517-90045

CD version: p/n 05517-90063

This chapter is p/n 05517-90122

7O-26 User’s Manual

Loading...

Loading...