Page 1

Agilent Technologies

8494/95/96G/H Attenuators

Operating and Service

Manual

Agilent Part Number: 08495-90025

Printed in USA

Print Date: August 2004

Supersedes: July 2002

Page 2

Notice

The information contained in this document is subject to change without

notice.

Agilent Technologies makes no warranty of any kind with regard to this

material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Agilent Technologies

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or

use of this material.

Agilent Technologies assumes no responsibility for the use or reliability of

its software on equipment that is not furnished by Agilent Technologies.

This document contains propri et ary information which is protected by

copyright. All rights are reserved. No part of this document may be

photocopied, reproduced, or translated to another language without prior

written consent of Agilent Technologies.

R

ESTRICTED RIGHTS LEGEND

Use, duplication, or disclosure by the U.S. Government is subject to

restrictions as set forth in subparagraph (c)(1)(i i) of the Rights in Technical

Data and Computer Software clause at DFARS 252.227-7013 for DOD

agencies, and subpara graphs (c)(1) and (c)(2) of the Commercial Computer

Software Restricted Rights claus e at FAR 52.227-19 for other agencies.

Agilent Technologies, Inc.

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799, U.S.A.

© Copyright 2000–2002, 2004 Agilent Technologies, Inc.

ii 8494/95/96G/H Operating And Service Manual

Page 3

What You’ll Find in This Manual…

Overview, page 1

•

• Specifications, page 6

• Installation, page 10

• Operating Instructions, page 12

• Replaceable Parts, page 15

• Service, page 16

8494/95/96G/H Operating And Service Manual iii

Page 4

Warranty

Custom systems are warranted by contractual agreement between Agilent

Technologies and the customer.

Certification Agilent Technologies, Inc. , certifies th at this product met its published

specifications at the time of shipment from the factory. Agilent Technologies

further certifies that its calibration measurements are traceable to the

United States National Institute of Standards and Technology (NIST,

formerly NBS), to the extent allowed by the Institute’s calibration facility,

and to the calibration facilities of other International Standards

Organization members.

Documentation Warranty

THE MATERIAL CONTAINED IN THIS DOCUMENT IS

PROVIDED "AS IS," AND IS SUBJECT TO BEING CHANGED,

WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER, TO

THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW,

AGILENT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS

OR IMPLIED WITH REGARD TO THIS MANUAL AND ANY

INFORMATION CONTAINED HEREIN, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. AGILENT SHALL NOT BE LIABLE FOR ERRORS

OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH THE FURNISHING, USE, OR

PERFORMANCE OF THIS DOCUMENT OR ANY

INFORMATION CONTAINED HEREIN. SHOULD AGILENT

AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS COVERING THE MATERIAL IN

THIS DOCUMENT THAT CONFLICT WITH THESE TERMS,

THE WARRANTY TERMS IN THE SEPARATE AGREEMENT

WILL CONTROL.

iv 8494/95/96G/H Operating And Service Manual

Page 5

Service and Support

Product maintenance agreements and other customer assistance agreements

are available for Agilent Technologies products. Any adjustment,

maintenance, or repair of this product must be performed by qualified

personnel. Contact your customer engineer through your local Agilent

Technologies Service Center. You can find a list of local service

representatives on the Web at:

http://www.agilent.com/find/assist

Click on “Contact Us” and select your country.

Safety and Regulatory Information

Review this product and related documentation to familiarize yourself with

safety markings and instructions before you operate the instrument. This

product has been designed and tested in accordance with international

standards.

WARNING The WARNING notice denotes a hazard. It calls attention to a procedure,

practice, or the like, that, if not correctly performed or adhered to, could result

in personal injury. Do not proceed beyond a WA RNING notice until the

indicated conditions are fully understood and met.

CAUTION The CAUTION notice denotes a hazard. It calls attention to an operating

procedure, practice, or th e like, whic h, if not cor rect ly performed or adhered

to, could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

8494/95/96G/H Operating And Service Manual v

Page 6

Instrument Markings

When you see this symbol on your instrument, you should refer to the instrument’s

instruction manual for important information.

!

This symbol indicates hazardous voltages.

The laser radiation symbol is marked on products that have a laser output.

This symbol indicates that the instrument requires alternating current (ac) input.

The CE mark is a registered trademark of the European Community. If it is

accompanied by a year, it indicates the year the design was proven.

The CSA mark is a registered trademark of the Canadian Standards Association.

1SM1-A This text indicates that the instrument is an Industrial Scientific and Medical Group 1

Class A product (CISPER 11, Clause 4).

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme a la norme NMB du Canada.

This symbol indicates that the power line switch is ON.

Safety Earth Ground

Before Applying Power

This symbol indicates that the power line switch is OFF or in STANDBY position.

This is a Safety Class I product (provided with a protective earthing

terminal). An uninter ru pti ble safety earth ground must be provided from the

main power source to the product input wiring terminals, power cord, or

supplied power cord set. Whenever it is likely that the protection has been

impaired, the product must be made inoperative and secured against any

unintended operation.

Verify that the product is configured to matc h the availab le main power

source as described in the input power configuration instructi ons in this

manual. If this product is to be powered by autotransformer, make sure the

common terminal is connect ed to the neutral ( grounded) side of the ac power

supply.

vi 8494/95/96G/H Operating And Service Manual

Page 7

Overview

This manual contains operating instructions for the Agilent 8494G/H,

8495G/H, and 8496G/H attenuators. Included in the manual is information

required to install and test these attenuators.

Specification Instrument specifications are indicated in Specifications, page 6. These

specifications are the performance standards or limits against which the

instruments may be tested.

Instruments Covered by

Manual

The instruments covered by this manual have a two-part serial number. The

first four digits and letter comprise the serial numb er prefix. The last five

digits form the sequential suffix that is unique to each instrument. The

contents of this manual apply to instruments with serial prefixes 2544A and

above.

An instrument manufactured after the printing of this manual may have a

serial prefix that is not listed above. This unlisted serial prefix indicates that

the instrument is different from those documented in this manual.

Description The 8494G/H, 8495G/H, and 8496G/H are 50-ohm coaxial programmable

step-attenuators. Each attenuator is composed of three or four attenuator

sections connected in cascade. Each section consists of a precision, thin-film

attenuator card, a lossless thru-line, and a ganged pair of solenoid-actuated

slab line transmission lines. The slab lines are flexed by the solenoid

plungers to make contac t with e ither the att enuat or card or the t hru-l ine. The

slab line contacts are gold plated leaf springs which ensure long life and

extremely high repeatability.

8494/95/96G/H Operating And Service Manual 1

Page 8

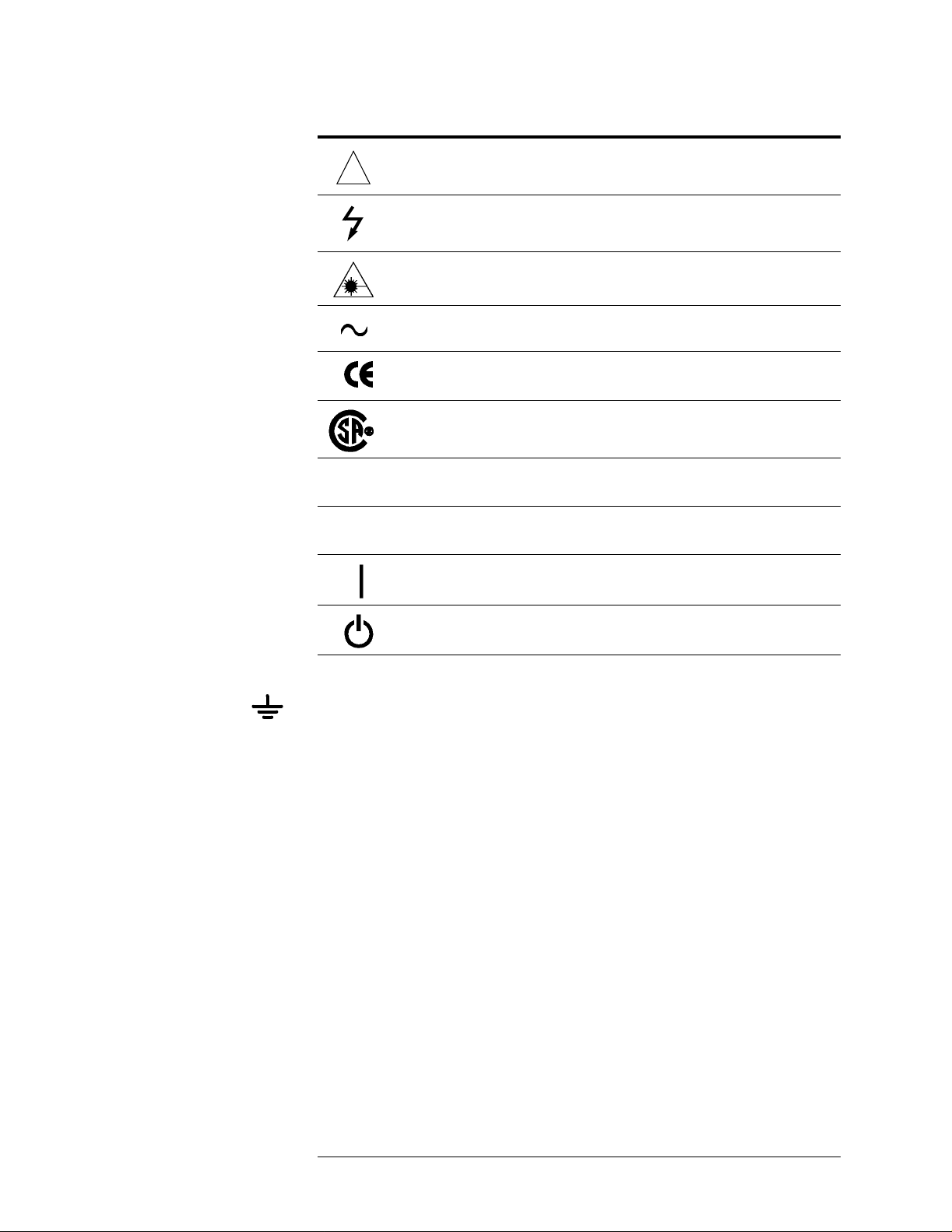

Overview

NOTE

Solenoid (K4) and

associated circuitry

are not available in

models 8495G and

8495H.

Figure 1 Typical Four Section Attenuator Schematic Diagram

Table 1 and Table 2 on page 3 and Table 3 on page 4 show the typical

switching arrangemen t to increas e the amount of atte nuation in an 8494G/H,

8495G/H, or 8496G/H in a linear manner. To ensure specified performance,

it is recomm ended that the attenuator sections that are shown in the

following tables be used. With the attenuator programmed for 0 dB

attenuation, the resultant attenuation is the insertion loss (residual

attenuation). The 8494G/ H has a minimum sele ctable step of 1 dB, while the

8495G/H and 8496G/H have a minimum selectable step of 10 dB. The

accuracy of the attenuators is within the limits given in Specifications,

page 6.

• The 8494G/H are four-section attenuators with a maximum attenuation

of 11 dB.

• The 8495G/H are three-s ec ti on at te nua tor s wi th a maximum attenuation

of 70 dB.

• The 8496G/H are four-section attenuators with a maximum attenuation

of 110 dB.

2 8494/95/96G/H Operating And Service Manual

Page 9

Table 1 8494G/H Attenuator Switching Order

8494G/H

Attenuator Sections

Atten

(dB)11 dB22 dB34 dB44 dB

0

1X

2X

3XX

4X

5X X

6XX

7XXX

8XX

Overview

9X XX

10 XXX

11XXXX

Table 2 8495G/H Attenuator Switching Order

8495G/H

Attenuator Sections

Atten

(dB)110 dB220 dB340 dB

0

10 X

20 X

30 X X

40 X

50 X X

60 X X

70XXX

8494/95/96G/H Operating And Service Manual 3

Page 10

Overview

Table 3 8496G/H Attenuator Switching Order

8496G/H

Attenuator Sections

Atten

(dB)110 dB220 dB340 dB440 dB

0

10 X

20 X

30 X X

40 X

50 X X

60 X X

70XXX

80 X X

90 X X X

100 X X X

110XXXX

Each solenoid requires a drive of 20 to 30 V with a switching current of

*

approximately 125 mA

at 24 V dc per section. The solenoid switc hing time

is less than 20 milliseconds including settling time. Once switched, the

solenoid plungers are held in place by permanent magnets and the solenoid

plungers automatically disconnect the selected coil drive and connect the

opposite coil drive (se e Figure 1 and Figur e 2). This simpl ifies the coi l driver

circuit design and reduces the amount of heat dissipated by the solenoid

coils since the solenoid coils are energized only for the 20 milliseconds

switching time.

* For serial number prefixes below 1722A, change 125 mA to 110 mA.

4 8494/95/96G/H Operating And Service Manual

Page 11

Overview

Figure 2 Typical Solenoid Coil Driver Circuits

CAUTION Do not exceed the RF power rating of 1 W average or 100 W peak with a

maximum pulse width of 10

µs. Do not connect an attenuator RF input or

output connector to greater the ±7 Vdc. If the attenuator must be connected

to a device with a potential greater than ±7 Vdc, use a blocking capacitor.

Instrument Options Each instrument is specified with an option number which denotes the

configuration of the input and output connectors.

Option Connector Description

001 Both connectors type-N female

002 Both connectors SMA female

1

003

1. Option 003 is not available on the 8495G.

Both connectors 7 mm

8494/95/96G/H Operating And Service Manual 5

Page 12

Frequency Range

and Attenuation

Specifications

Specifications

Instrument Frequency Range Attenuation

8494G dc to 4 GHz 0 dB to 11 dB in 1 dB steps

8494H dc to 18 GHz 0 dB to 11 dB in 1 dB steps

8495G dc to 4 GHz 0 dB to 70 dB in 10 dB steps

8495H dc to 18 GHz 0 dB to 70 dB in 10 dB steps

8496G dc to 4 GHz 0 dB to 110 dB in 10 dB steps

8496H dc to 18 GHz 0 dB to 110 dB in 10 dB steps

Attenuation Accuracy (±dB): (Referenced from 0 dB)

8494G/H 8495G/H

8496G/H

Attenuation Selection

(dB)

1 10 0.2 0.3 0.7 0.2 0.5 0.6 0.2 0.5 0.6

2 20 0.2 0.3 0.7 0.4 0.7 0.8 0.4 0.7 0.8

3 30 0.3 0.4 0.7 0.5 0.9 1.2 0.5 0.9 1.2

4 40 0.3 0.4 0.7 0.7 1.2 1.6 0.7 1.2 1.6

5 50 0.3 0.5 0.7 0.8 1.5 2.0 0.8 1.5 2.0

6 60 0.3 0.5 0.8 1.0 1.8 2.4 1.0 1.8 2.4

7 70 0.4 0.6 0.8 1.2 2.1 2.8 1.2 2.1 2.8

8 80 0.4 0.6 0.8 - - - 1.3 2.4 3.2

9 90 0.4 0.6 0.8 - - - 1.5 2.7 3.6

10 100 0.4 0.6 0.9 - - - 1.6 3.0 4.0

11 110 0.5 0.7 0.9 - - - 1.8 3.3 4.4

8494G 8494H 8495G 8495H 8496G 8496H

dc–4

GHz

dc–12.4

GHz

12.4–18

GHz

dc–4

GHz

dc–12.4

GHz

12.4–18

GHz

dc–4

GHz

dc–12.4

GHz

12.4–18

GHz

6 8494/95/96G/H Operating And Service Manual

Page 13

Maximum SWR

Specifications

Instrument Frequency Range (GHz) Maximum SWR

8495G dc to 4 1.35

Maximum Residual

Attenuation

8495H dc to 8

8 to 12.4

12.4 to 18

8494G,

8496G

8494H,

8496H

Instrument Maximum Residual Attenuation

8494G,

8494H

8495G,

8495H

8496G,

8496H

dc to 4 1.5

dc to 8

8 to 12.4

12.4 to 18

0.6 dB + 0.09 dB/GHz

0.4 dB + 0.07 dB/GHz

0.6 d8 + 0.09 dB/GHz

1.35

1.5

1.7

1.5

1.6

1.9

Attenuation Repeatability ±0.01 dB typical after 5 million cycles

RF Power Handling

Capability

1 W average, 100 W peak with maximum pulse width of 10 microseconds

(all models)

Solenoid Drive

Solenoids Drive Coil Voltage Switching Current

All models

(approximately)

1. For serial number prefixes below 1722S, change 125mA to 110mA.

20 to 30 Vdc 125 mA

1

at 24V

(190Ω, 65mH)

8494/95/96G/H Operating And Service Manual 7

Page 14

Specifications

Solenoid Cable Connector Refer also to Figur e 3.

Section Section 1 Section 2 Section 3 Section 4 Power

Solenoid Coil Thru-Line Atten

Card

Cable Wire Color

Connector Plug

Plug Pin Number

1. Five-foot cable and mating plug assembly provided.

2. Pin 1 Common solenoid drive (+24 Vdc).

3. Pin 6 is common for all coils. Pins 1, 7, 8, 12 and 14 are not used.

1

Code

Pin Number

8494G/H 0dB 1dB 0dB 2dB 0dB 4dB 0dB 4dB –

8495G/H 0dB 10dB 0dB 20dB 0dB 40dB – – –

8496G/H 0dB 10dB 0dB 20dB 0dB 40dB 0dB 40dB –

Option 016

Flat Pack

2

PUR YEL BLK GRN ORN BLU BRN WHT RED

567891011121

132115394106

3

Thru-Line Atten

Card

Thru-Line Atten

Card

Thru-Line Atten

Card

V+

Figure 3 Solenoid Cable Pin Configuration

8 8494/95/96G/H Operating And Service Manual

Page 15

Specifications

Minimum Life >5 million cycles per section

Switching speed Maximum 20 milliseconds including settling time.

Environment Limits The instrument should be stored in a clean, dry environment. The following

environmental limits apply to storage and shipment, and operation.

Characteristic Storage and Shipping Value Operating Value

Temperature –40 to +75 °C 0 to +55 °C

Humidity < 95% relative < 95% relative

Altitude < 7600 m (25000 ft) < 4600 m (15000 ft)

Physical Characteristics

Instrument Dimensions

(depth x width x height)

8494G/H

8496G/H

8495G/H 5.125 in x 2.875 in x 1.6875 in

1. Dimensions are for general information only. If dimensions are required for building special

enclosures, contact your Agilent field engineer.

2. Weight and width of the instrument varies with the option selected due to the type of connectors.

6.25 in x 2.875 in x 1.6875 in

159 mm x 73 mm x 43 mm

130 mm x 73 mm x 43 mm

1

Weight

16 oz

454 g

12 oz

340 g

2

8494/95/96G/H Operating And Service Manual 9

Page 16

Installation

Installation

Initial Inspection Inspect the shipping container for damage. If the shipping container or

cushioning material is damaged, it should be kept until the contents of the

shipment have been checked for completeness and the instrument has been

checked mechanically and electrically. A procedure for checking electrical

performance is given under “Operator’s Check” on page 12 (also see

“Performance Tests” on page 14). If the contents of the shipment are

incomplete, if there is mechanical damage or defect, or if the instrument

does not pass the electrical performance test, notify the nearest Agilent

Technologies off ic e. If the shipping container is damaged, or the c ushi oni ng

material shows signs of stress, notify the carrier as well as the Agilent office.

Keep the shipping materi als for the car rier's inspec tion. The office will

arrange for repair or replacement without waiting for claim settlement.

NOTE Containers and materials identical to those used in factory packaging are

available through Agilent Technologies offices. If the instrument is being

returned to Agilent for servicing, attach a tag indicating the type of service

required, return address, model number, and full serial number. Also, mark

the container FRAGILE to assure careful handling. In any correspondence,

refer to the instrument by model number and full serial number.

Mating Connectors Ma ting RF conne ctors used with the Option 0 01 must be type -N male

connectors, which comply with U.S. military standard MIL-C-39012 (See

Figure 7 on page 19). For Option 002, male SMA connectors must be used.

For Option 003, 7 mm mating connectors must be used (Figure 6 on page

18).

The solenoid drive cable connector plug is a Viking Industries, Inc., part

number TKP12-102-P-TS-100-AU (see Replaceable parts). The connector

plug and contacts witho ut the cabl e can be ord ered from a Viking distributor .

When ordering the complete cable assembly from Agilent, use the part

number listed in Table 5, “Replaceable Parts,” on page 15.

CAUTION When installing the instru ment, make sure t hat the connectors do not support

weight or bear torque. The preferred procedure is to set up all equipment in

position before connecting the instrument.

10 8494/95/96G/H Operating And Service Manual

Page 17

Installation

Installation Instructions

The attenuators may be installed with or without the base. The base is

removed by unscrewing the two fillister head screws from the bottom of the

base. The attenuat or may b e mounted withou t t he bas e by i nsert ing two 4-40

screws into the screw holes in the bottom of the attenuator. Removing the

base and mounting the attenuator does not affect the performance of the

attenuator.

The solenoid drive cable connector plug is connected to the attenuator by

aligning the plug (Pl) with the jack (Jl) on the attenuator, and then pushing

the plug over the jack. The plug is removed by grasping the ribbed sides of

the plug and squeezing them t ogether while pulli ng back until the plug clears

the jack.

8494/95/96G/H Operating And Service Manual 11

Page 18

Operating Instructions

Operating Instructions

CAUTION Do not apply RF power greater than 1 W average, or 100 W peak with a

maximum pulse width of 10 microseconds. If these limits are exceeded, the

attenuators may be damaged.

CAUTION Do not ground both solenoid drive pins at the same time. This causes rapid

cycling of the solenoid and could reduce the operating life of the attenuator.

The rapid cycling may produce a buzzing sound from the attenuator.

Either RF connector may be used as the input or output connector. Connect

the solenoid drive cabl e to the solenoi d drive connect or (J1). By applying t he

proper voltage and g rounds to t he proper p ins of J1, t he attenua tor will either

increase or decrease the amount of attenuation as selected.

Operator’s Check The Operator's Check is supplied to allow the operator to make a quick

check of the instrument prior to use or if a failure is suspected.

Description The attenuator is driven from a 50-ohm signal source at 1 kHz. The output

level from the attenuator is detected by a narrow-bandwidth voltmeter. The

attenuator and detector range switches are stepped together and the

variations in level noted. This verifies that each attenuator section is being

properly switched and checks the low-frequency accuracy of the attenuator.

NOTE The SWR meter used in this check is calibrated for a square-law detector and

therefore the range changes and errors (read in dB) are twice that indicated

by the meter.

Figure 4 Operator’s Check Setup

12 8494/95/96G/H Operating And Service Manual

Page 19

Operating Instructions

Procedure 1. Connect equipment as shown in Figur e 4 on pag e 12 with the attenuator

set to 0 dB attenuation.

2. Set the test oscillator to 0.3 Vrms at 1 kHz.

3. Set SWR meter range to 2 dB (expanded) [or for the 8494G/H to 10 dB

(expanded)] and adjust its bandwidt h to center of adjustme nt range. Fine

tune oscillator frequency to obtain maximum meter indication.

4. Set attenuator and SWR meter ra nge switch as listed in Table 4 and

verify that SWR meter indicates within limits shown.

Table 4 Attenuator and SWR Settings

SWR Meter Range

(dB)

8494G/H 8495G/H

8496G/H

10 2 0 0 0 - - Set to 0.0 Set to 0.5 - 10 6 1 10 10 0.40 1.40 - - 0.60 1.60

10 12 2 20 20 0.90 0.30 - - 1.10 0.70

10 16 3 30 30 1.35 1.25 - - 1.65 1.75

1

10

12 26 5 50 50 0.35 1.10 - - 0.65 1.90

12 32 6 60 60 0.85 0.00 - - 1.15 1.00

12 36

1

12

14 46

14 52

14 56

22 4 40 40 1.85 0.15 - - 2.15 0.85

42

8494G/H 8495G/H 8496G/H 8494G/H 8495G/H

1

1

1

1

1

Attenuation (dB) Meter Indication (dB)

Minimum Actual Maximum

8494G/H 8495G/H

8496G/H

7 70 70 1.30 0.90 - - 1.70 2.10

8 - 80 1.80 –0.15 - - 2.20 1.15

9 - 90 0.30 0.75 - - 0.70 2.25

10 - 100 0.80 –0.30 - - 1.20 1.30

11 - 110 1.75 0.60 - - 1.75 2.40

8496G/H

8494G/H 8495G/H

8496G/H

1. Adjust range by 2 dB, if needed, to obtain a on-scale indication.

8494/95/96G/H Operating And Service Manual 13

Page 20

Operating Instructions

Performance Tests The instrument can be tested to the accur acy of the “Specifications” on

page 6, with an automatic network analyzer or equivalent equipment of

suitable ac curacy. If an automatic n etwork analyzer is available, test the

instrument using the procedures in the analyzer's operating manual.

Refer to the Agilent 11713A Attenuator/Switch Driver Operating and

Service Manual for programming instructions.

Adjustments The attenuators have no internal adjustments and should not be opened. If

defective, retur n the atten uator t o the neares t Agilent Technologies offi ce for

repair.

14 8494/95/96G/H Operating And Service Manual

Page 21

Replaceable Parts

Replaceable Parts

Table 5 lists the replaceable parts which are the only parts that can be

replaced without access to the interior of the instrument. If any parts not

listed below need replacement, return the instrumen t to Agilent

Technologies.

To order a part listed in the replaceable parts table below, quote the part

number, indicate the quantity required, and address the order to the nearest

Agilent Technologies office.

CAUTION Due to special fixtures necessary for assembly, do not attempt to r eplac e an y

parts not lis ted in t he table below. If the instrument is ope ned, the warranty is

void.

Table 5 Replaceable Parts

Description Part Number

Option 003 7-mm center conductor contact 1250-0907

Option 003 7-mm connector outer shell assembly 1250-0909

Option 001 type-N female connector outer shell 1250-0914

Screws for both bases: 4-40 x 7/8 in. Fillister head 2220-0006

Cable, solenoid drive, 1.52 m (5 ft) long, connector plug on

one end and other end unterminated

Base for 8495G/H 5041-3887

Base for 8494G/H and 8496G/H 5041-3888

Connector plug and contacts only without cable TKP12-12-102P-TS-100-AU

Contact insertion/extraction tool TIE-200

1. Available from distributors of Viking Industries, Inc., Chatsworth CA 91311

8120-2178

1

1

8494/95/96G/H Operating And Service Manual 15

Page 22

Service

Service

Troubleshooting Tr oub le shooting consists of perfo rmin g the “O per at or’s Check” on page 12.

If the instrument does not perform within limits, return the instrument to

Agilent Technologies.

Repair The only recommended field r epair is re pla cing t he outer connec tor she ll fo r

the Option 001 and 003, or replacing the center contact in the 7 mm

connector. For any other repair, return the entire instrument to Agilent

Technologies.

Replacing the 7 mm

Connector Center

Conductor Contact

Figure 5 7 mm Connector

The replacement proced ure fo r the 7 mm co nnector ce nter cont act is covered

in Figure 6 on page 18. The disassembly and assembly instructions for the

7 mm connector are covered in Figure 5.

Making the Connection 1. On one connector , ret ract the c oupling slee ve by turning the coupling nut

counterclockwise until the sleeve and nut disengage.

2. On the other connector, fully extend the coupling sleeve by turning the

coupling nut clockwise. To engage coupling sleeve and coupling nut

when the sleeve is fully retracted, press back lightly on the nut while

turning it clockwise.

3. Push the connectors firmly together, and thread the coupling nut of the

connector with retracted sleeve over the extended sleeve.

16 8494/95/96G/H Operating And Service Manual

Page 23

Service

4. Close the gap between coupling nut with the nut on the extended-sleeve

connector.

To disconnect:

1. Loosen the coupling nut of the connector showing the wider gold band.

CAUTION Part the connectors carefully to prevent striking the inner conductor contact.

To care for the device:

1. Keep contacting surfaces smooth and clean. Irregularities and foreign

particles can degrade electrical performance.

2. Protect the contacting surfaces when the connector is not in use by

leaving the coupling sleeve extended.

3. Use lintless material and/or firm-bristles brush such as a tooth brush for

cleaning. If a cleaning fluid is needed, use isopropyl alcohol.

8494/95/96G/H Operating And Service Manual 17

Page 24

Service

CAUTION Do not use aromatic or chlorinated hydrocarbons, esters, ethers, terpenes,

higher alcohols, ketones, or ether-alcohols such as benzene, toluene,

turpentine, dioxane, gasoline, cellosolve acetate, or carbon tetrachloride.

Keep exposure of the connector parts to both the cleaning fluid and its

vapors as brief as possible.

Replacing Amphenol

7 mm Center Contact

Through wear or damage, the contact in the 7 mm center conductor may

need replacement. This contact is a small four-pronged contact which snaps

into a recess in the center conductor. With a magnifying glass, examine the

contact for the necessary outward spring action by carefully pushing it in.

CAUTION Do not remove this contact for inspection. It may be damaged by removal.

The prongs of the con tac t should be free fr om burrs or wear. If the contact is

removed, do not reuse it. Order contact as Amphenol part number 131-129

or Agilent part number 1250-0907.

*

Figure 6 7 mm Connector

If this cont act needs replacement, pro ceed as follows:

1. Place the instrument so the connector faces down, if possible.

2. Tap the connector lightly. The contact should now protrude slightly.

* Amphenol RF Division, Danbury, CN.

18 8494/95/96G/H Operating And Service Manual

Insert the centering pin of the Agilent collet remover with the jaws open.

(Part number of the contact extractor is 5060-0370.) If this tool is not

available, an ordinary draftsman’s mechanical pencil may be used (the

end of the jaw may have to be filed to get a good grasp at the very end).

Page 25

Service

3. Allow the jaws of the tool used to close and pull straight back from the

connector without twisting. The contact should come with the tool. If

not, repeat the process. Do not reuse the contact.

4. Snap in a new contact by pushing it in place. Test the action of the new

contact by pushing it in. It should spring out again when released.

Type N Connector

Dimensions

Figure 7 Type-N Connector

For critical dimensions for the type-N connector, see below.

Replacing the

Connector Outer Shell

NOTE The connector outer shell can be replaced only on the Option 001 (type-N

female) or the Opti on 003 ( 7 mm). The outer shell on th e Optio n 002 ( SMA)

cannot be replaced in the field. If these connectors are damaged, return the

instrument to Agilent Technologies for repair.

The connector outer shells on the 0ption 001 and 003 may be replaced as

follows:

1. With a 9/16-inch (1/2- inch for 7 mm) t hin open-end wrench, unscre w the

outer connector body.

2. Replace the connector outer shell. See Table 5 on page 15 for

replaceable parts numbers.

3. Tighten the connector with the same wrench called out in step 1.

8494/95/96G/H Operating And Service Manual 19

Loading...

Loading...