Page 1

Agilent 4291B

RF

Impedance/Material

Analyzer

Quick

SERIAL

This

JP1KE

important

Appendix

NUMBERS

manual

and

applies

above

information

A

of this

Start Guide

directly

,

or

whose

about

to

instruments

rmware is

serial

numbers

with serial

version 1.xx.

,

manual.

number prex

For

read \Serial

additional

Number" in

Agilent Part No. 04291-90031

Printed in JAPAN March 2001

Page 2

Notice

The

information

without

This

notice

document

copyright.

photocopied,

the

prior

written

contained

.

contains

All

rights

reproduced,

consent

in

proprietary

are

reserved.

or

of

this

document

No

translated

the

Agilent

is

information

part

of this

to

another

Technologies

subject to

that

is

protected by

document may

language

.

change

be

without

Agilent

Component

1-3-2,

Hyogo

MS-DOS

APC-7

R

T

echnologies

T

Murotani,

,

651-2241

R

is

a

U

is a

U.S.

Japan, Ltd.

est

PGU-Kobe

Nishi-ku,

Kobe-shi,

Japan

.S.

registered

trademark

registered trademark

of

of

Bunker

Microsoft

Ramo

Corporation.

Corporation.

c

Copyright 1997, 1998, 1999, 2001 Agilent Technologies Japan, Ltd.

Page 3

Manual

History

Printing

The

manual printing

edition.

(Minor

cause

The printing

corrections

the date

extensive

date and

date changes

and

updates that

to change

.) The

technical changes

part number

when a

indicate its

new edition

are incorporated

manual part

are incorporated.

current

is printed.

at reprint

number changes

do not

when

Safety

Summary

Note

Note

December

December

December

March

The

phases

comply

in

this

In

addition

intended

The

failure

4291B

DEGREE

LEDs

CLASS

2001

following general

of operation,

with

manual

use

A

gilent

to

comply

comply

2

in

4291B

1

LED

1997

:

1998

:

1999

:

:

::

::

these

precautions

may

it

violates

of

the

T

echnologies

with

with

in

IEC1010-1.

are

Class

PRODUCT

::

::

::

:

:

:

:

First

::

::

::

:

:

Second

::

:

:

:

:

:

:

:

:

Third

:

:

:

:

:

:

:

:

F

ourth

safety precautions

service

,

and

or

impair

safety

the

protection

standards

instrument.

assumes

these

requirements

INST

ALLA

TION

4291B

1

are

in

accordance

Edition

Edition

Edition

Edition

(part

(part

(part

(part

must

repair

of

this

with specic

provided

of

design,

no

liability

.

CA

TEGORY

INDOOR

with

number:

number:

number:

number:

be

observed

instrument.

W

ARNINGS

by

the

manufacture

for the

USE

II

and

product.

customer's

IEC825-1.

04291-90021)

04291-90031)

04291-90031)

04291-90031)

during

F

ailure

elsewhere

equipment.

,

and

POLLUTION

all

to

Ground

The

Instrument

DO

NOT

Explosive

Operate

In

Atmosphere

Keep Away From Live

Circuits

An

T

o

avoid

electric

must

be connected

cable

with earth

Do

not

operate

fumes

.

Operation

constitutes

Operating personnel must not remove

replacement and internal adjustments must be

maintenance personnel. Do not replace components with

cable connected. Under certain conditions

exist even with the power cable removed. T

a

denite

shock

to a

blade.

the

instrument

of any

safety hazard.

hazard,

safety earth

the

instrument chassis

ground

in the

presence of

electrical instrument

instrument covers

and cabinet

by

the

supplied

power

ammable gasses

in such

an environment

. Component

made by qualied

the power

, dangerous voltages

o avoid injuries

,always

disconnect power and discharge circuits before touching them.

or

may

iii

Page 4

DO NOT

A

Service Or

djust Alone

Do

not attempt

capable

internal service

of rendering

rst aid

or adjustment

and resuscitation,

unless another

is present.

person,

DO

NOT Substitute

P

arts

Dangerous

W

arning

Safety Symbols

Or Modify

Instrument

Procedure

W

arnings

Because

install

instrument.

Service

of

the

substitute

Return

Oce

for

danger

maintained.

W

arnings

procedures

warnings

Dangerous

,

such

throughout

must

be

voltages

instrument. Use

adjusting

General

are

listed

this

instrument.

denitions of

below

.

of

introducing

parts

or

perform unauthorized

the

instrument

service

as

and

the

example below

this

followed.

,

capable

extreme

safety symbols

Instruction

with

this

symbol

refer

to

the

Alternating

Direct

current.

On (Supply).

to

repair

manual.

of

causing

caution

manual

symbol:

when

instruction

current.

additional

a

Agilent T

to ensure

, precede

Instructions

death,

when

handling,

used on

equipment

the

it

is

necessary

manual.

hazards

,do

not

modications to

echnologies Sales

that safety

features are

potentially dangerous

contained

are

product

in the

present

testing,

or

is

marked

for

the

in

and

in

manuals

user

the

and

this

to

O

(Supply).

In

position

Out

position

Frame

frame

include

This

Warning

to a procedure

if not correctly performed or adhered to

of

of

(or

chassis)

(chassis)

all

exposed

push-button

push-button

terminal.

of

the

metal

sign

denotes a hazard. It calls attention

, practice

switch.

switch.

A

connection

equipment

structures

which

.

normally

, condition or the like

, could result

to

the

, which,

in injury or death to personnel.

This

Caution

to

a procedure

if not

correctly performed or adhered to

in damage to

sign denotes a hazard. It calls attention

, practice

, condition or the like

, which,

, could result

or destruction of part or all of the

product.

This

Note

sigh denotes important information. It

calls attention to a procedure, practice, condition or

the like, which is essential to highlight.

iv

Page 5

Axed

use

electrostatic

to product

anti-static handling

discharge damage

containing static

procedures to

to component.

sensitive devices

prevent

v

Page 6

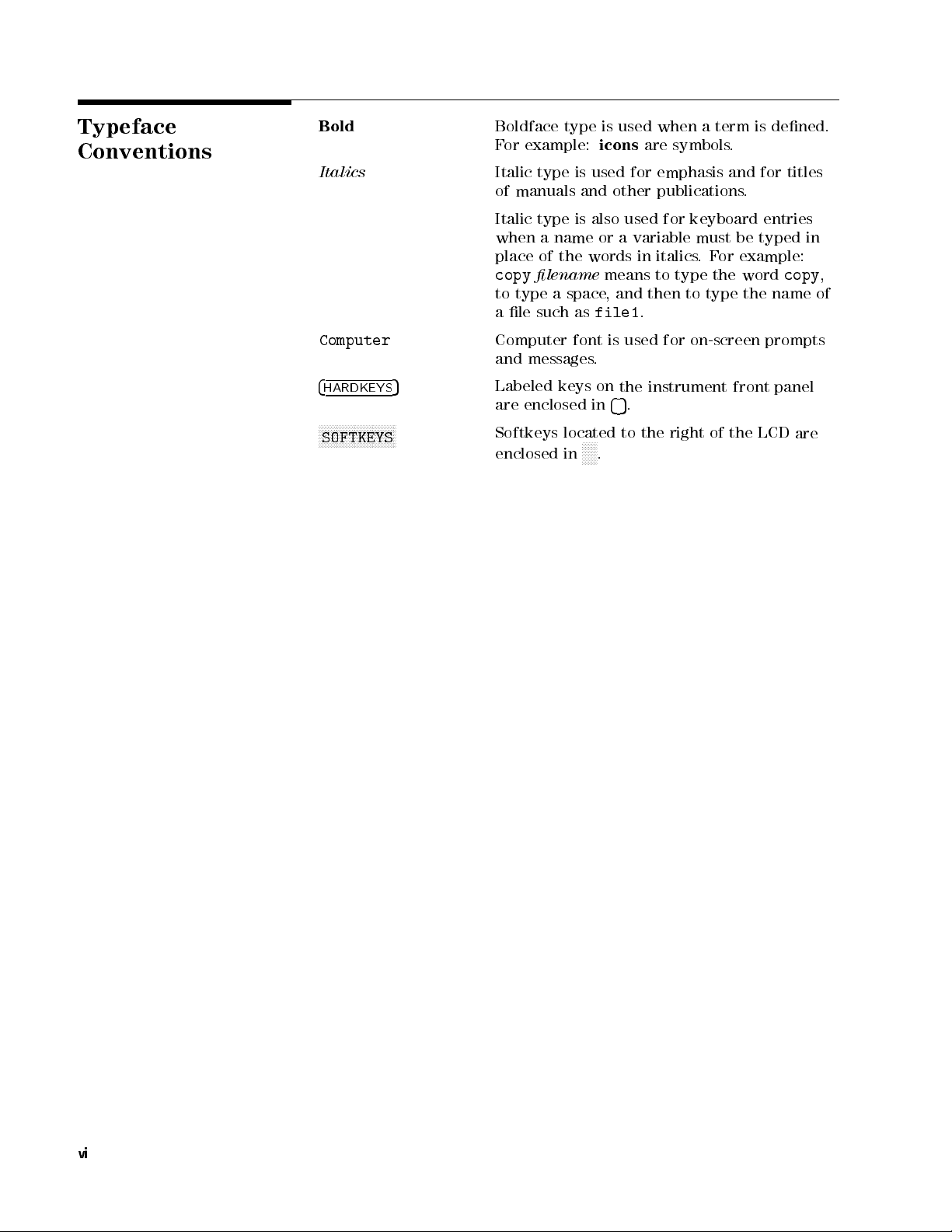

Typeface

Conventions

Bold

Italics

Boldface type

F

or example:

Italic type

of

manuals and

Italic

when

place

copy

to

type a

a

le such

is used

type is

a name

of

the

lename

space,

as

is used

icons

when a

are

symbols.

for emphasis

other publications

also used

or a

words in

means

and

file1

for keyboard

variable must

italics.

to type

then

.

to

term is

and for

For

the

type

dened.

titles

.

entries

be typed

example:

word

copy

the

name

in

,

of

Computer

4

HARDKEYS

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

SOFTKEYS

Computer font

and

messages.

5

NN

N

N

N

N

Labeled keys

are

enclosed in

Softkeys

enclosed

on

located

N

N

N

N

N

.

in

is used

the

5

.

4

to

the right

for on-screen

instrument

of

front

the

prompts

panel

LCD

are

vi

Page 7

Certication

Warranty

Agilent

specications

T

echnologies

traceable

T

echnology,

facility

Organization

This

defects

the

listed

be

T

echnologies

prove

For

Technologies

at the

further

to the

to the

,or

to the

members.

Agilent T

echnologies instrument

in material

date

of

shipment,

in

General

for

the

specied

will,

to be

defective

warranty service

service facility

shipping charges

shall pay

Buyer shall

returned

shipping charges

pay all

to

Agilent T

certies that

time of

shipment from

certies that

United States

National Institute

extent allowed

calibration facilities

and workmanship

except

that

Information

period.

at

its

During

option,

.

or

repair

,

designated by

to Agilent

shipping

Agilent T

T

echnologies

to

return

charges

echnologies

this product

its calibration

by the

of other

product

for

in

the

of

this

manual,

the

warranty

either

this

repair

product

echnologies

the

,

duties

from

another

met its

the factory

published

. Agilent

measurements are

of Standards

Institution's calibration

International

is

a

period

case

of

or

must

and

Agilent

product

,

and

warranted

of

one

certain

the

warranty

period,

replace

be

returned

.

Buyer

T

to

Buyer

taxes

country

Standards

against

year

components

shall

Agilent

products

shall

echnologies

.

However

for

products

.

and

from

that

to

a

prepay

,

Limitation

W

arranty

Of

Agilent

designated

execute

instrument.

of

error

The

improper

software

operation

improper site preparation or maintenance

No other warranty is expressed or implied. A

T

echnologies

by

Agilent

its

programming

Agilent

the

instrument,

free

.

foregoing warranty

or inadequate

or interfacing,

outside

the

warrants

T

echnologies

T

echnologies

or

software

maintenance

that

instruction

,

or

shall

not

its

for

when

does

rmware

apply

by

unauthorized modication

environmental

specications

software

use

with

property

not

warrant

will

to

defects

Buyer

.

and

rmware

an

instrument

installed

that

the

be

uninterrupted

resulting

,

Buyer-supplied

or misuse

for the

gilent T

echnologies

will

on

that

operation

from

,

product,

or

or

specically disclaims the implied warranties of merchantability and

tness for a particular purpose

.

vii

Page 8

Exclusive

Remedies

The

remedies provided

remedies

indirect,

on

.A

gilent T

special,

contract, tort,

herein are

echnologies shall

incidental,

or any

or consequential

other legal

buyer's sole

not be

liable for

theory.

and exclusive

any direct,

damages,

whether based

Assistance

Product

maintenance agreements

agreements

F

or any

and

assistance,

Service Oce

are available

contact

.A

ddresses

and other

for Agilent

your

nearest

are

provided

customer assistance

Technologies

Agilent

at

the

products

T

echnologies

back

of

.

this

Sales

manual.

viii

Page 9

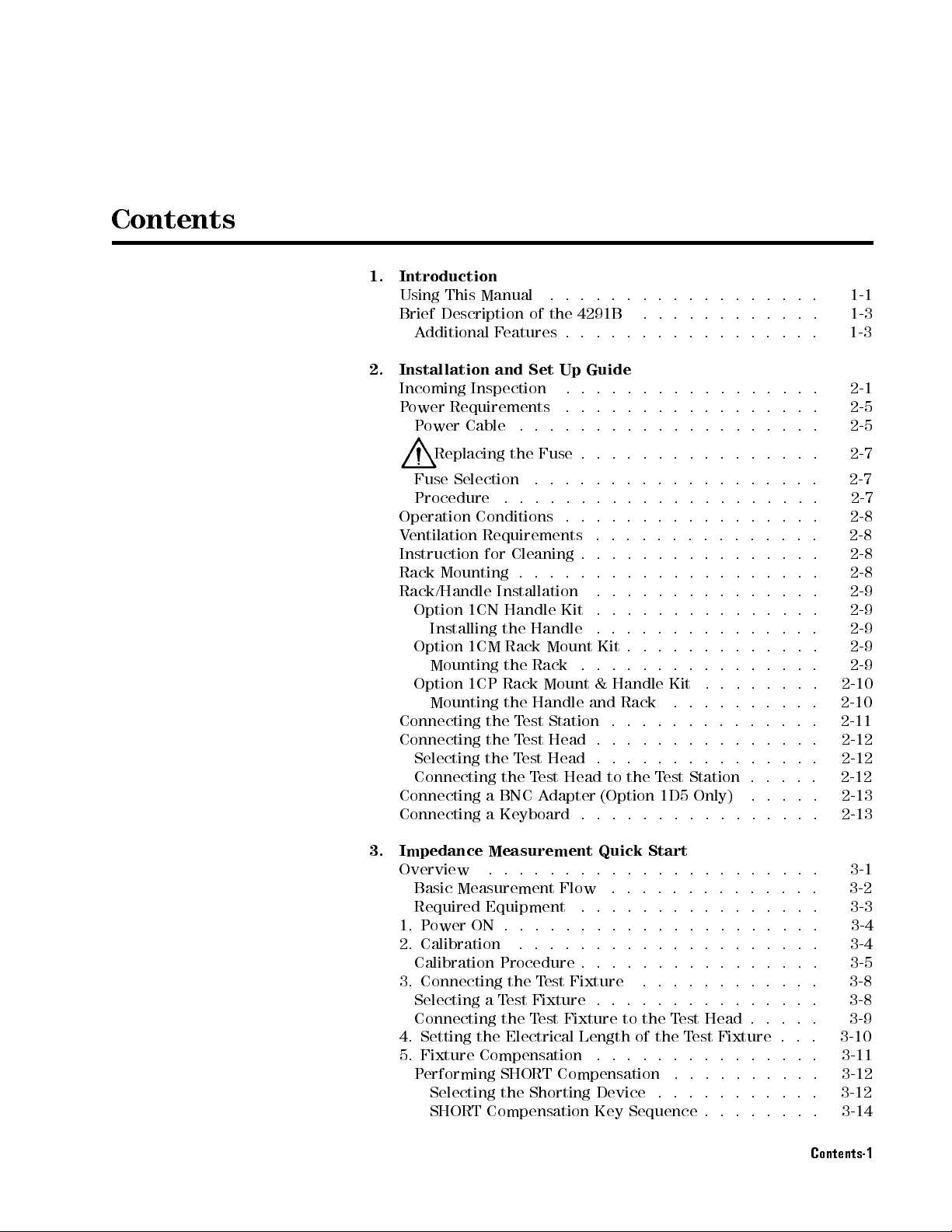

Contents

1.

Introduction

Using

This

Brief Description

Additional

2.

Installation

Incoming

P

ower

Requirements

P

ower

Manual

F

eatures

and

Inspection

Cable

.

of

Set

.

.

the

Up

.

.

.

4291B

.

.

.

.

.

.

.

.

.

.

.

.

Guide

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

..

..

.

1-1

.

1-3

1-3

2-1

. 2-5

.

2-5

Replacing

Fuse

Selection

Procedure

Operation

V

entilation

Instruction

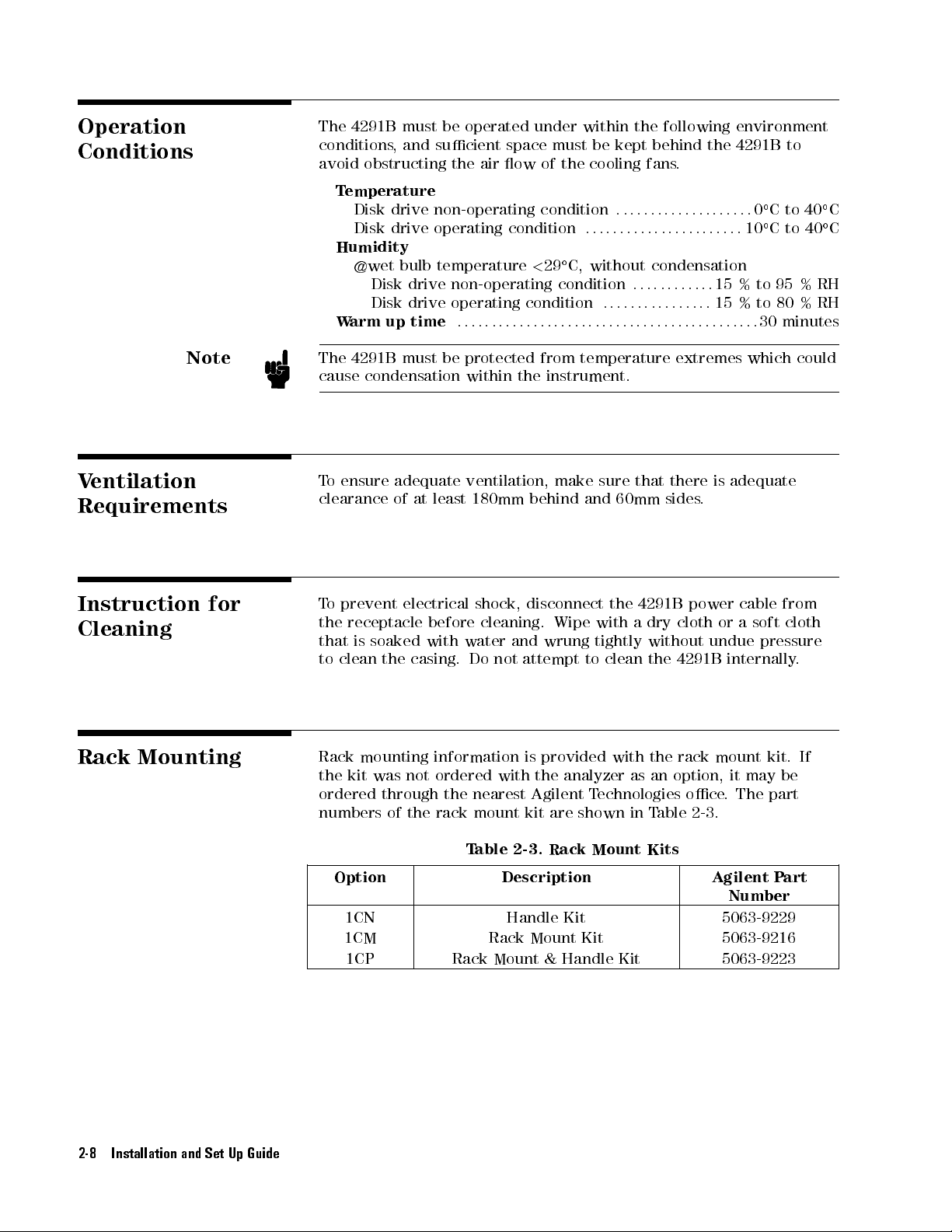

Rack

Mounting

Rack/Handle

Option

Installing the

Option

Mounting

Option

Mounting

Connecting

Connecting

Selecting

Connecting

Connecting

Connecting

3. Impedance Measurement Quick Start

Overview ...... ...... .....

Basic Measurement Flow

Required Equipment ................

1. P

ower ON

2. Calibration

Calibration Procedure . . . .

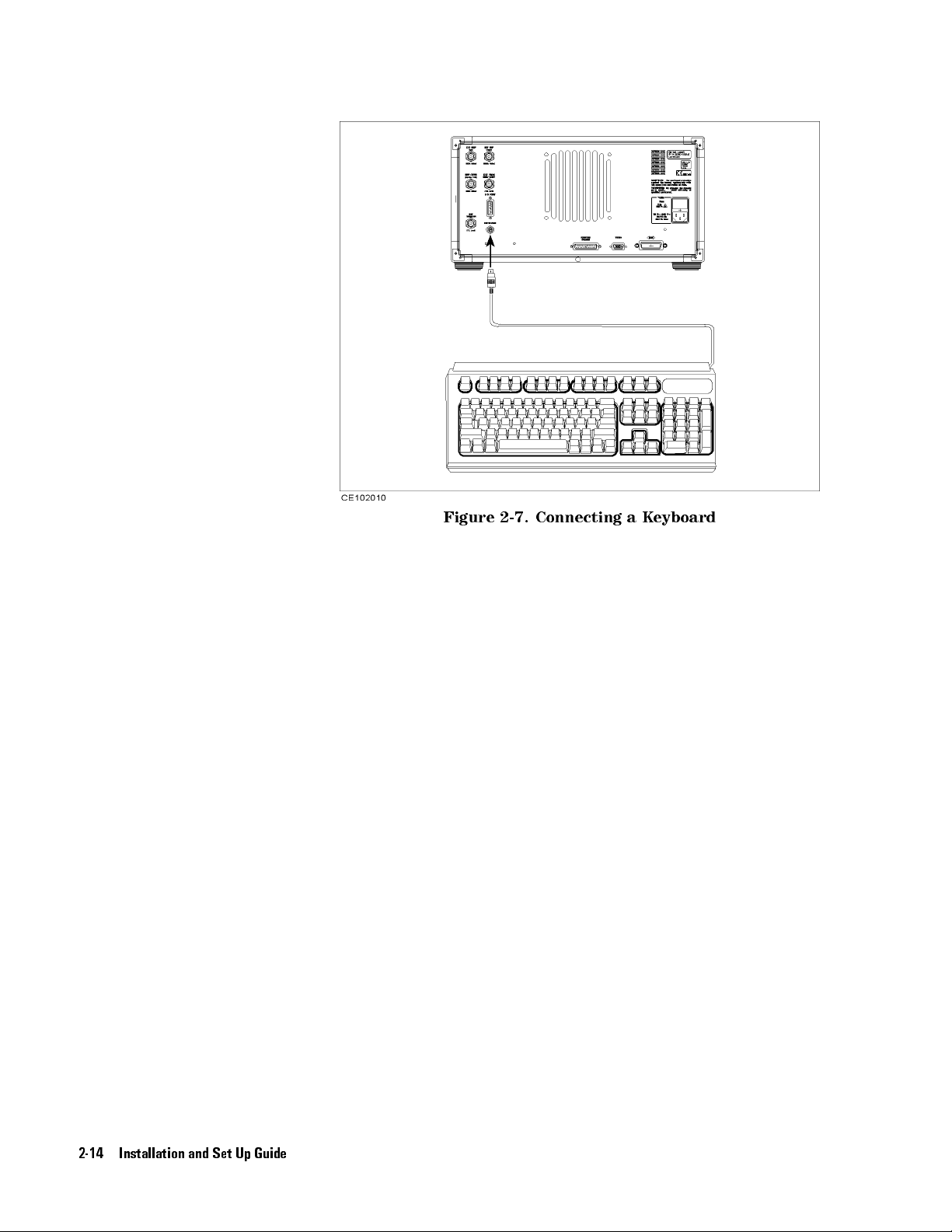

3. Connecting the T

Selecting a TestFixture...... ...... ... 3-8

Connecting the Test Fixture to the Test Head . . . . . 3-9

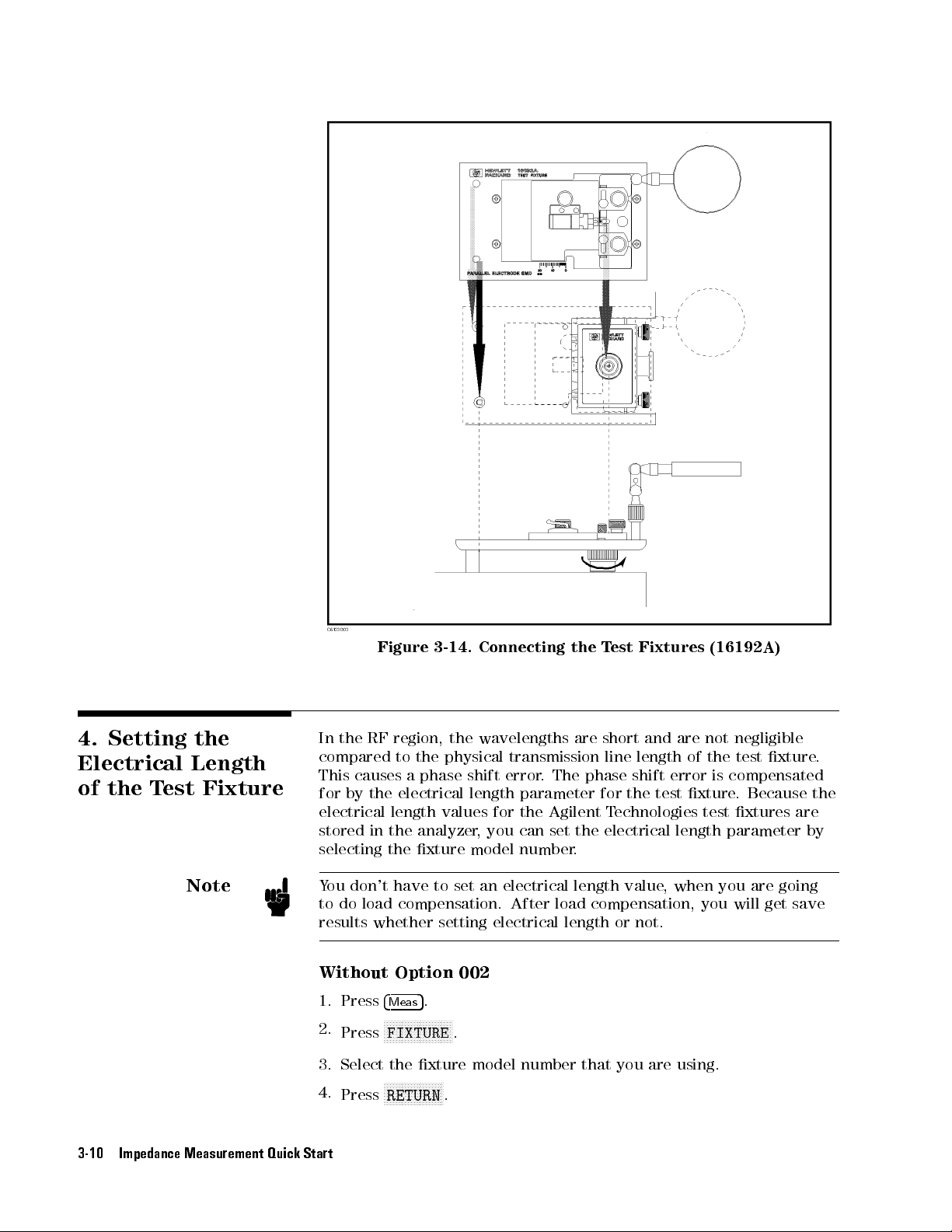

4. Setting the Electrical Length of the Test Fixture . . . 3-10

5. Fixture Compensation ............... 3-11

Performing SHORT Compensation .......... 3-12

Selecting the Shorting Device ...... ..... 3-12

SHORT Compensation Key Sequence . . . . . . . . 3-14

the

Fuse

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

Conditions

Requirements

for

Cleaning

Installation

1CN

Handle

1CM

Rack

the

1CP

Rack

the

the

T

the

T

the

T

the

a

BNC

a

Keyboard

...... ...... ...... ...

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Kit

.

.

.

.

.

.

.

.

.

Handle

Mount

Rack

Mount

Handle

est

Station

est

Head

est

Head

T

est

A

dapter

...

est Fixture

.

.

.

.

.

.

.

.

.

Kit

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

&

Handle

and

Rack

.

.

.

.

.

Head

to

(Option

.

.

.

..............

...... ...... .....

Kit

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

..

..

..

the

T

est

Station .

1D5

Only)

.

..

..

..

...... ......

.

.... ...... .

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

..

..

.

..

..

..

..

.....

.

2-7

.

2-7

.

2-7

.

2-8

.

2-8

.

2-8

.

2-8

.

2-9

.

2-9

.

2-9

. 2-9

2-9

.

2-10

.

2-10

2-11

.

2-12

.

2-12

2-12

2-13

2-13

3-1

3-2

3-3

3-4

3-4

3-5

3-8

Contents-1

Page 10

P

erforming OPEN

OPEN

6.

Connecting the

7.

Setting up

7-1.

7-2.

7-3.

7-4.

Display

8.

Measuring

P

erforming

9.

Analyzing

Using

Reading

Moving

Clearing

Equivalent

Approximation

Simulation

Clearing

Clearing

10.

Measuring

F

or

More

4.

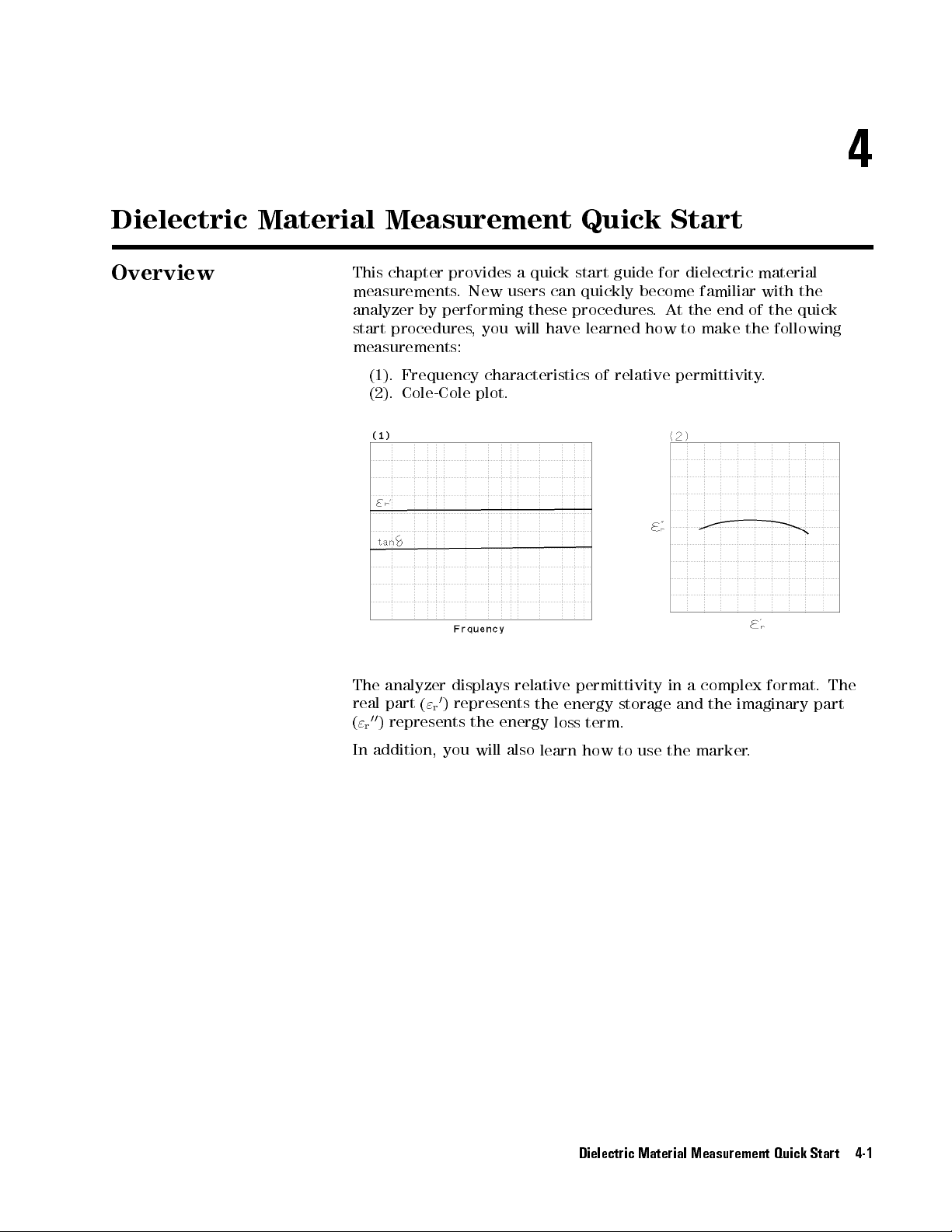

Dielectric

Overview

Brief

Basic Measurement

Required

1.

Power

2.

Calibration .

Calibration

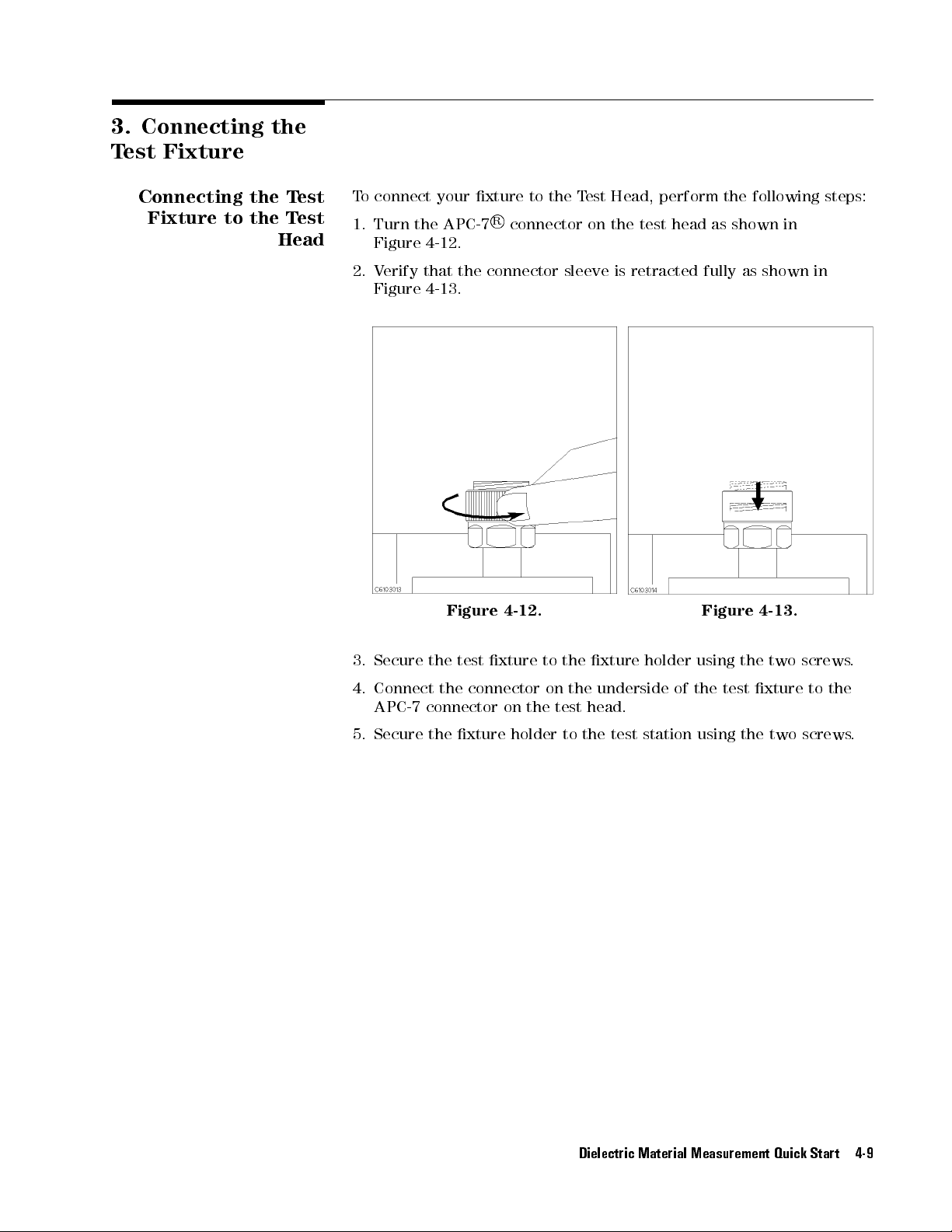

3.

Connecting

Connecting

Selecting

4.

Input

5.

Fixture

P

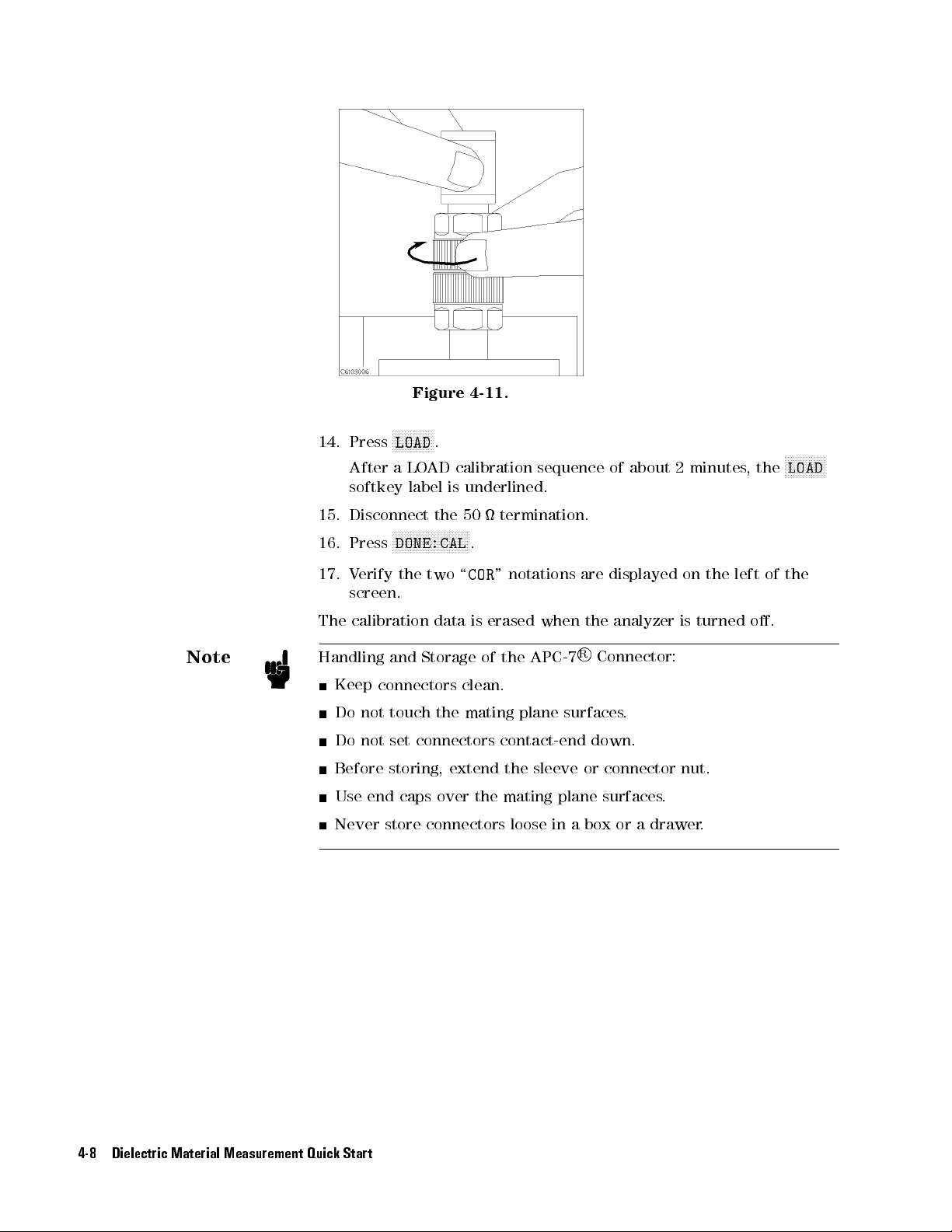

erforming

SHORT

P

erforming

OPEN Compensation Key Sequence

Performing LO

LOAD Compensation Key Sequence

6. Input the MUT Thickness . . . . . . . . . . . . . .

7. Placing the MUT in the T

8. Setting up the Analyzer

8-1. Setting up for

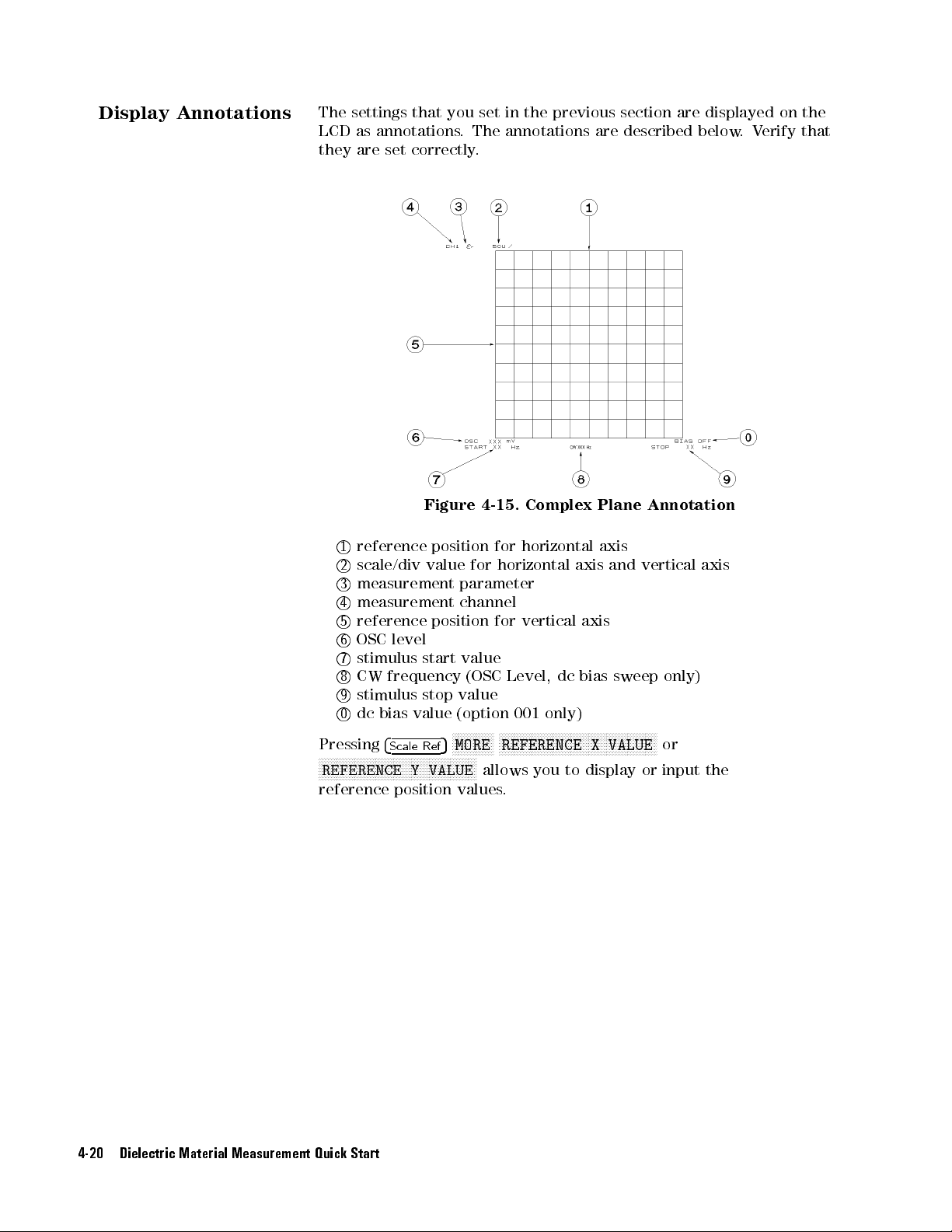

Display Annotations

8-2. Setting up for a Cole-Cole Plot ...... ... 4-19

Display Annotations ...... ...... .... 4-20

9. Measuring the MUT .. ...... ...... .. 4-21

Performing Automatic Scaling . . . . . . . . . . . . 4-21

Using the Marker . . . . . . . . . . . . . . . . . . 4-21

Marker for Frequency/OSC Level/dc bias

Compensation Key

the

Setting up

Setting up

Setting

Setting

Annotations

the

A

a

the

Marker

a

the

the

Circuit

.

the

the

Information

Material

.

.

Measurement

Equipment .

ON

Procedure .

the

the

Load

Compensation

SHORT

Compensation

OPEN

Characteristics ................ 4-21

Compensation .

Sequence

DUT

to

the

T

Analyzer

for

j

Z

for

C

up

for

C

up

for

C

DUT

utomatic

Measurement

.

Measured

Marker

Marker

Analysis

.

.

.

.

.

.

Approximated

Simulated

Other

DUT

Measurement

.

.

.

Theory

Flow

.

.

.

.

..

the

T

est

T

est

Fixture

T

est

Fixture

Thickness

Compensation

Compensation

AD Compensation . . . . . .

"

r

.

j

-

vs

.

Frequency

-

D

vs

.

-

D

vs

.

-

D

vs

.

.

.

.

.

.

.

Scaling

Result

.

.

.

.

V

alue

to

the

Minimum

.

.

.

.

.

.

.

.

.

Data

.

.

.

..

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

Fixture

to

.

.

.

.

.

Key

est Fixture . . . . . . . . .

...... ...... ..

0

-tan

..... ..... ......

..

est

Fixture

.

.

.

.

.

Frequency

OSC

Level

dc-V

(Option

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

Constant

.

.

.

.

.

.

.

.

.

.

.

.

.

Quick

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

the

T

est

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Sequence

.

.

.

vs. Frequency

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

..

001

only)

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

..

..

P

oint

.

.

.

.

.

..

..

.

.

.

.

..

..

.

.

.

.

.

.

..

.

.

Data

.

.

.

.

.......

.

.

.

.

.

..

..

..

..

..

.

.

.

.

.

.

Start

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Head

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

......

.....

.....

.

.

..

..

.

..

.

..

..

.

..

.

..

..

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

.

3-14

.

3-14

3-15

. 3-15

3-16

. 3-17

3-18

. 3-19

3-20

3-21

. 3-21

. 3-21

.

3-21

3-21

. 3-22

3-23

3-23

.

3-23

.

3-24

.

3-24

. 3-25

3-25

.

3-25

.

4-1

.

4-2

.

4-3

.

4-4

.

4-5

.

4-5

.

4-6

.

4-9

.

4-9

. 4-10

. 4-11

.

4-12

.

4-12

4-12

.

4-13

4-13

4-14

. 4-14

4-15

4-15

4-16

4-17

4-18

Contents-2

Page 11

Marker

10.

Measuring Other

F

or More

5.

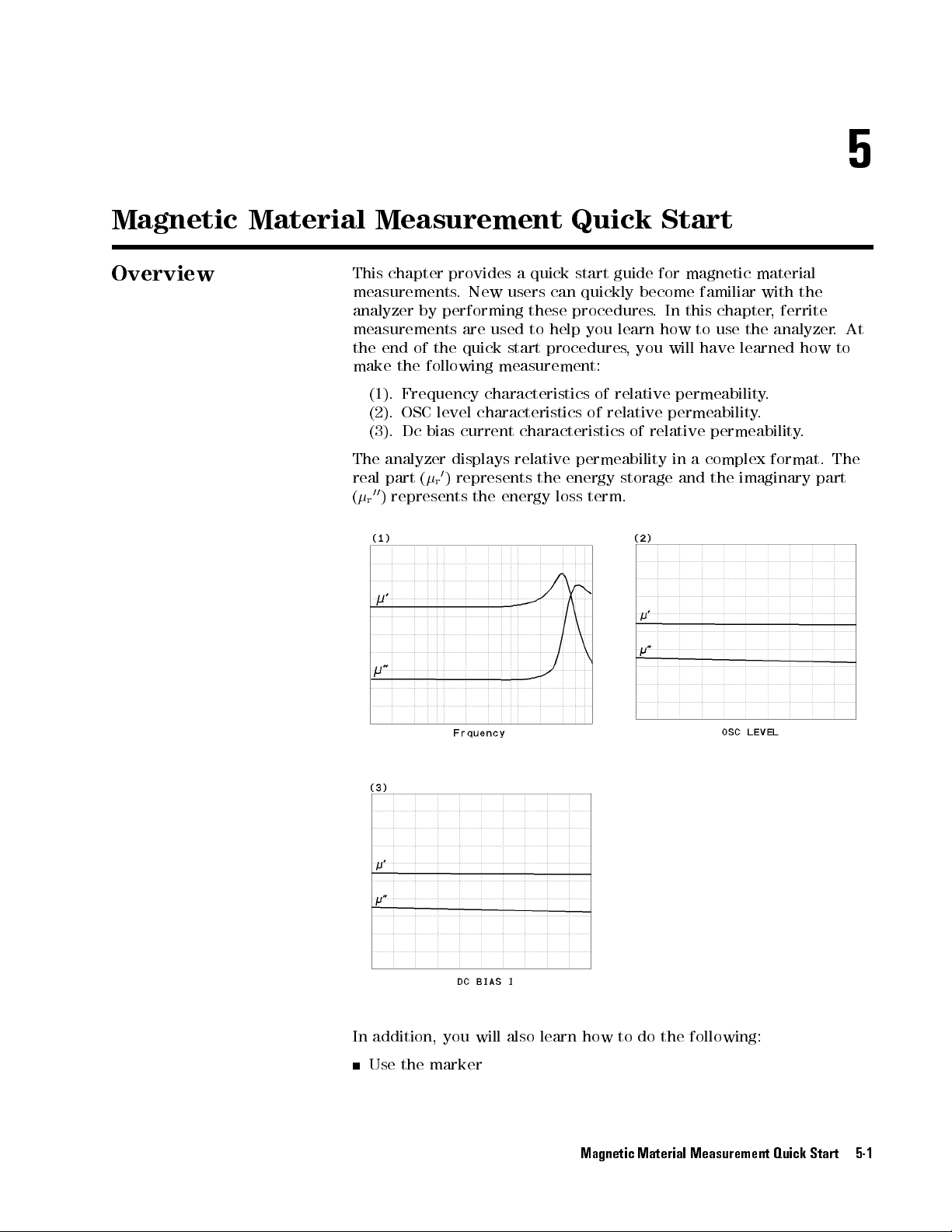

Magnetic Material

Overview

Brief

Measurement

Basic

Measurement

Required

1.

P

ower

2.

Calibration

Calibration

3.

Connecting

Selecting

Connecting

Selecting

4.

Fixture

P

erforming

SHORT

5.

Input

the

6.

Placing

7.

Setting

7-1.

Setting

7-2.

Setting

7-3.

Setting

Display

8.

Measuring

Performing

9.

Analyzing a

Using

the Marker

Reading

Moving

Clearing

10.

Measuring

F

or

More

for a

Cole-Cole Plot

Information

Measurement

..

.

.

.

Equipment

ON

.

.

.

.

.

.

.

Procedure

the

T

est

Fixture

the

Compensation

Compensation

MUT

the

up

Annotations

a Measured

the Marker

the

Information

and

the

T

est

T

est

Fixture

SHORT

Size

MUT

on

the

Analyzer

up

for

up

for

up

for

the

MUT

A

utomatic

Measurement

.

Marker

Other

..

MUT

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Theory

Flow

.

.

Fixture

Holder

Fixture

Compensation

the

0

r

0

-

r

0

r

.

to the

MUT

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Key

.

.

.

T

est

.

00

-

vs

r

00

vs

r

00

-

vs

r

.

.

.

.

.

.

Scaling

Result

.

.

.

Value

.

.

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

to

the

.

.

.

.

Sequence

.

.

Fixture

.

.

.

.

OSC

.

.

.

..

.

.

.

.

.

Maximum

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Quick

.

.

.

.

.

.

.

.

.

.

.

.

.

Frequency

Dc-I

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

T

est

.

.

..

.

.

.

.

.

.

Level

(Option

.

.

.

.

.

.

.

.

.

.

.

P

.

.

.

.

.

.

Start

.

.

.

.

.

.

.

.

Head

.

..

.

.

.

.

..

.

.

.

.

.

.

oint

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

..

.

..

.

..

.

..

.

.

..

..

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

.

.

..

.

.

..

.

.

.

..

..

.

.

..

..

..

..

..

..

.

..

..

.

.

..

..

..

..

.

.

..

..

.

.

.

.

.

.

.

.

..

..

..

..

.

..

..

..

..

001

only) 5-17

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

4-22

. 4-22

. 4-22

. 5-1

5-2

. 5-3

5-4

.

5-5

5-5

5-6

5-9

5-9

. 5-9

. 5-11

.

5-11

5-11

.

5-12

.

5-12

5-13

5-14

5-15

.

5-16

.

5-18

.

5-19

.

5-19

.

5-19

.

5-19

.

5-19

.

5-20

.

5-21

. 5-21

. 5-21

6.

F

eatures

P

erforming

User

P

erforming

User Dened Fixture Compensation Description

Performing A

Performing P

Performing Sweep A

Averaging Description

Using P

Making a P

Making a Sweep Delay Measurement . . . . . . . . .

Delay Description . . . . . . . . . . . . . . . . . . 6-5

Changing the Number of Measurement Points ..... 6-6

Number of Measurement Points Description ..... 6-6

Applying Dc Bias (Option 001 Only) .......... 6-6

Monitoring the OSC Level or the Dc Bias Level . . . . . 6-7

Performing a GO/NO-GO Test .......... ... 6-8

Editing a Limit Line Table.............. 6-8

Common

User

Dened

User

veraging . . . . . . .

oint Delay and Sweep Delay

oint Delay Measurement

to

All

Modes

Dened

Calibration

Dened

oint A

Calibration

Description

Fixture

veraging . . . . . .

veraging ............

...............

Compensation

.

.

.

.

.

..

..

.

.

.

.

..

..

.

..

...

...... ....

...... .

...... ....

.........

. 6-2

. 6-2

.

6-3

6-3

6-3

6-3

6-4

6-4

6-5

6-5

6-5

Contents-3

Page 12

Executing

P

erforming a

Editing

A

ctivating a

Constant

A

uto Level

Placing

Placing

Editing

Splitting

P

erforming

Using

the

Reading

Reading

Searching

Searching

Searching

Storing

Storing

Storing

Displaying

Displaying

Clearing

Using

the

Calculating

Turning

Saving

Saving an

Recalling

Trace

Saving

Saving

Purging

Initializing

Printing

Printing

Logging

Measurement

Smoothing

Reducing

Increasing the Sweep Speed . . . . . .

When the Measurement Result Does Not Seem Correct

a Limit

List

Sweep

a Sweep

List

Current/Voltage

Control

Characters

Letters

the

the

Marker

a

V

Y

our

the

the

Trace

O

and

aDisplay

Measured Data

a File

.

a

the

on

Label

Measurement

Independent

.

V

alue

Using

alues

by

for

a

Specic

for

Maximum/Minimum

for

P

Trace

Data

More

Traces

Memory

a

Memory

Memory

Math

Using

the

Data

Recalling

Analyzer

a Saved

..

.

.

..

a

Disk/Memory

.

.

.

.

Display

Key

Sequence

T

echniques

the

Trace

Trace

Noise

Line T

est .

Measurement

List

.

.

.

Sweep

Measurement

on

and

oints

to

Trace

the

Analyzer

Image to

Level

the

the

Screen

Changing

.

.

.

the

Using

that

the

Memory

to

to

Traces

Trace

Traces

Function

Data

Math

.

.

Setting

.

.

.

for a

.

.

.

.

.

Image

.

.

.

.

Screen

Display

Sweeps

.

.

Marker

the

P

oint

Have

the

Memory

Trace

Function

.

.

and

Setting

.

.

a

.

.

Disk

.

.

.

into

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Measurement

for

OSC

.

.

.

.

.

.

.

the

P

osition

.

.

.

for

Each

.

.

.

..

.

.

Sub-markers

.

.

.

.

P

oints

the

T

arget

Traces

Memory

.

.

Only

.

..

..

..

Measurement

.

.

TIFF

Spreadsheet

.

.

for

.

.

.

.

a

Program

.

.

.

.

.

..

Trace

Traces

.

.

.

When

..

..

and Memory

.

.

.

.

and

.

.

.

File

.

.

.

Use

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

..

.

.

Level

Sweep

.

.

.

.

.

.

.

.

.

.

or

Color

.

.

.

.

.

Channel

..

..

.

.

.

.

..

.

.

.

.

.

..

..

.

.

.

V

alue

.

.

..

.

.

.

.

.

.

.

.

.

..

It

Is

Selected.

.

.

.

.

.

.

.

.

.

.

Trace .

..

.

.

.

.

.

.

.

.

Trace

Measurement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

...... .

.

.

.

.

..

..

.

.

.

..

..

.

.

.

.

.

..

.

.

..

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

. 6-10

. 6-10

6-10

6-11

.

6-11

.

6-12

6-13

. 6-14

.

6-14

.

6-15

.

6-15

.

6-16

. 6-16

. 6-16

6-17

.

6-17

. 6-17

.

6-17

.

6-17

.

6-17

. 6-18

6-18

.

6-18

.

6-19

6-19

.

6-19

.

6-19

.

6-20

.

6-20

.

6-20

.

6-21

.

6-21

.

6-21

6-21

.

6-21

.

6-22

.

6-23

. 6-23

.

6-23

6-23

6-23

Contents-4

A. Manual Changes

Introduction .....................

Manual Changes

Serial Number

.... ...... ...... ...

....................

A-1

A-1

A-2

Page 13

B

. Maintenance

P

erformance V

Repair

Replacement

C.

Fixture

16191A

16191A

16193A

D

.

Fixture

Exchanging

Connecting

Setting

SHORT

Open compensation

Load

DUT

..

P

ossible Problems

Compensation

and

SHORT

SHORT

OPEN

Connecting

SHORT

OPEN

Connecting

Short

Open

Load

Compensation

OPEN

SHORT

Compensation

OPEN

Compensation Procedures

.

compensation

compensantion

compensation Key

compensation .

compensation Key

..

erication

.

.

.

.

.

and

of Center

16193A

.

.

.

.

.

.

Compensation

Compensation

Compensation

DUT

.

.

Compensation

Compensation

Compensation

DUT

the

the

.

.

..

.

.

device

T

est

.

..

.

.

.

.

.

.

Fixture

..

.

.

.

.

.

.

.

.

.

.

Their

Solution

Conductor

Procedures

.

.

.

.

.

.

.

.

.

Key

.

.

.

.

Key

Sequence

.

.

.

.

.

.

.

.

.

.

.

.

.

Key

.

.

.

.

Key

Sequence

.

.

.

.

holder

.

key

.

.

.

.

..

.

.

.

.

.

.

.

.

syquence

.

.

.

.

syquence

.

.

.

.

sequence .

.

.

.

.

.

.

.

.

..

Collet

for

.

.

.

.

.

.

Sequence

.

.

.

.

.

.

.

..

..

.

.

.

Sequence

.

.

.

.

.

.

.

for the

..

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

the

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

.

.

.

.

.

.

.

.

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

..

..

.

.

.

.

.

.

..

..

.

.

.

..

..

..

.

..

..

.

.

..

..

.

.

.

.

.

.

.

16194A

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

..

.

.

..

.

.

..

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. B-1

. B-1

.

B-1

.

B-2

.

C-1

C-1

.

C-2

C-3

.

C-3

C-4

.

C-5

C-5

C-6

.

C-7

.

C-7

.

C-7

.

D-1

.

D-2

.

D-3

.

D-4

.

D-4

.

D-5

.

D-5

.

D-6

.

D-6

.

D-7

E.

Calibration

Calibration

Compensation

OPEN/SHORT

OPEN/SHORT/LO

Index

Length

and

Compensation

.

.

.

.

.

.

.

.

.

.

Fixture

Compensation

AD

Fixture

.

.

.

.

.

.

.

.

.

.

.

.

Compensation

.

.

.

.

Compensation

.

.

.

.

.

and

.

.

.

.

.

.

..

.

.

.

.

Electrical

.

..

..

.

.

.

..

..

..

.

..

. E-1

. E-1

E-1

E-2

Contents-5

Page 14

Figures

1-1. Manual

2-1. Contents

2-2. Agilent

2-3. Rack

2-4. Connecting

2-5.

Connecting

2-6.

Connecting

2-7.

Connecting

3-1.

Basic

3-2. Required

3-3.

Calibration

3-4. .

3-5. .

3-6. .

3-7. .

3-8. .

3-9.

.

3-10.

3-11.

3-12.

3-13.

3-14.

3-15.

4-10. .... .

4-11. .... ..

4-12. .... ...

4-13. .... ...

4-14. Connecting the T

4-15. Complex Plane Annotation

.

.

.

.

Connecting

Fixture

4-1.

Dielectric

4-2.

Basic

4-3.

Required

4-4.

Calibration

4-5.

.

4-6.

.

4-7.

..

4-8. .

4-9. .... ...... ..... .....

5-1. Magnetic Material Measurement . . . . . . . . . . .

5-2. Basic Flow for Magnetic Material Measurements ... 5-3

5-3. Required Equipment ................ 5-4

5-4.Calibration..... ...... ..... ..... 5-5

5-5. .... ...... ..... ...... ..... 5-6

5-6. .... ...... ..... ...... ..... 5-6

5-7. .... ...... ..... ...... ..... 5-6

5-8. .... ...... ..... ...... ..... 5-7

Reference

.

P

art

Mount Kits

Flow

for

Equipment

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Compensation

Material

Flow

for

Equipment

.

..

..

.

..

..

..

..

.

.

.

.

Flow

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

. 2-4

Numbers

the T

the

T

a

BNC

a

Keyboard

Impedance

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

the

T

Dielectric

.

..

..

..

..

.

.

.....................

...... ..... ...... ...

of

P

ower

Cables

Installation

est

Station

est

Head

A

dapter

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

est

Fixtures

Measurement

.

..

..

..

.

..

.

..

..

.

.

.

.

..... ..... ...... ...

..... ..... ...... ...

est Fixtures

.

.

to

the

to

the

T

.

.

.

.

.

.

Measurements

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

(16192A)

.

.

.

.

.

.

Material

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

...

..... ..... ...

.

.

.

.

.

.

.

.

.

.

Mainframe

est

Station

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

Measurements

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...... ...

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

.

.

..

..

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

......

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

..

.

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

. 4-3

.

.

.

.

.

.

.

.

.

. 4-6

..

2-11

2-12

2-13

2-14

3-10

3-11

4-10

4-20

1-1

2-6

2-9

3-2

3-3

3-4

3-5

3-5

3-5

3-6

3-6

3-6

3-7

3-7

3-9

3-9

4-2

4-4

4-5

4-6

4-6

4-7

4-7

4-7

4-8

4-9

4-9

5-2

Contents-6

Page 15

5-9.

5-10.

5-11.

5-12.

Dimensions of

5-13.

5-14.

5-15.

Connecting

5-16.

Dimensions

6-1.

P

6-2.

P

6-3.

Number

6-4.

Level

6-5.

Limit

6-6.

List

6-7.

Label

6-8.

Split

6-9.

Uncoupled

6-10.

Marker

A

-1.

Serial

D-1.

Exchanging

D-2.

Connecting

D-3.

D-4.

D-5.

Open

D-6.

Load

D-7.

DUT

E-1.

OPEN/SHORT

..

..

..

.

.

..

.

.

..

.

.

..

.

.

oint

A

veraging

oint

Delay

of

Monitor

Line

Sweep

Function

Display

List

Number

.

.

.

.

.

.

.

.

compensation

compensation

.

.

..

.

.

.

.

.

.

.

the

.

.

.

.

.

.

the

T

of

the

and

P

oints

Function

Example

Example

.

Channels

.

Plate

the

Device

the

16194A

.

.

.

..

..

.

.

.

Fixture

.

.

.

.

.

.

.

.

.

MUT

.

.

.

.

.

.

est

Fixtures

MUT

and

Sweep

Sweep

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

Compensation

.

.

.

.

.

.

Holder

.

.

.

.

.

.

Delay

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Holder

to

the

..

.

.

.

..

..

.

.

.

.

.

.

.

..

..

.

..

..

.

.

.

.

..

.

.

.

..

(16454A

.

.

.

A

veraging

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

..

..

.

.

.

.

.

Measurement

..

..

.

.

.

.

..

.

..

.

.

.

.

.

.

..

..

..

.

.

..

..

.

.

.

.

.

.

.

.

.

..

.

.

..

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

..

..

.

.

..

..

Small)

.

.

.

.

.

.

.

..

.

..

..

..

..

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

..

..

.

..

.

.

.

.

..

..

..

..

..

..

..

.

.

.

..

.

.

T

erminal

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

..

..

.

.

..

.

.

.

..

..

..

..

..

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 5-7

. 5-7

. 5-8

.

. 5-9

. 5-10

. 5-10

.

.

..

.

. 6-4

. 6-5

.

.

.

..

.

.

.

.

. 6-15

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5-10

5-13

6-6

6-8

6-8

6-10

6-13

6-15

6-16

A

-2

D-1

D-2

D-3

D-4

D-5

D-6

D-7

E-2

Contents-7

Page 16

T

ables

2-1. Contents

2-2.

Fuse

2-3.

Rack

3-1. T

est

3-2. Dimension

3-3. MEASUREMENT

3-4. STIMULUS

3-5.

MEASUREMENT

3-6.

STIMULUS

3-7.

MEASUREMENT

3-8.

STIMULUS

3-9. MEASUREMENT

3-10.

STIMULUS

4-1.

MEASUREMENT

4-2.

STIMULUS

4-3.

MEASUREMENT

4-4.

STIMULUS

5-1.

MUT

5-2.

MEASUREMENT

5-3.

STIMULUS

5-4.

MEASUREMENT

5-5.

STIMULUS

5-6.

MEASUREMENT

5-7.

STIMULUS

A

-1.

Manual

A

-2.

Manual

..

Selection

Mount

Fixtures

of

Size

F

or

Changes

Changes

Kits

Block

Block

Block

Block

Block

Block

Block

Block

Block

.

.

.

.

.

.

.

.

.

.

.

.

Specication

Shorting

T

est

Devices

Block

P

P

arameter

Block

P

P

arameter

Block

P

P

arameter

Block P

P

arameter

Block

P

P

arameter

Block

P

P

arameter

Fixtures

Block

P

P

arameter

Block

P

P

arameter

Block

P

P

arameter

by

Serial Number

by

Firmware V

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

(1/2)

.

.

.

.

.

.

arameter

arameter

arameter

arameter Setting

arameter

arameter

arameter

arameter

arameter

Setting

Setting

Setting

Setting

Setting

Setting

.

.

.

Setting

Setting

Setting

ersion .

Setting

.

Setting

.

Setting

.

.

Setting

.

Setting

.

.

.

Setting

.

Setting

.

Setting

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 2-2

. 2-7

. 2-8

.

3-8

.

3-12

.

3-16

.

3-16

.

3-17

.

3-17

.

3-18

.

3-18

.

3-19

.

3-19

.

4-17

.

4-17

.

4-19

.

4-19

.

5-9

.

5-15

. 5-15

.

5-16

.

5-16

.

5-17

.

5-17

.

A

.

A

-1

-1

Contents-8

Page 17

Introduction

1

Using

This

Manual

This Quick

power-on,

commonly

are rst

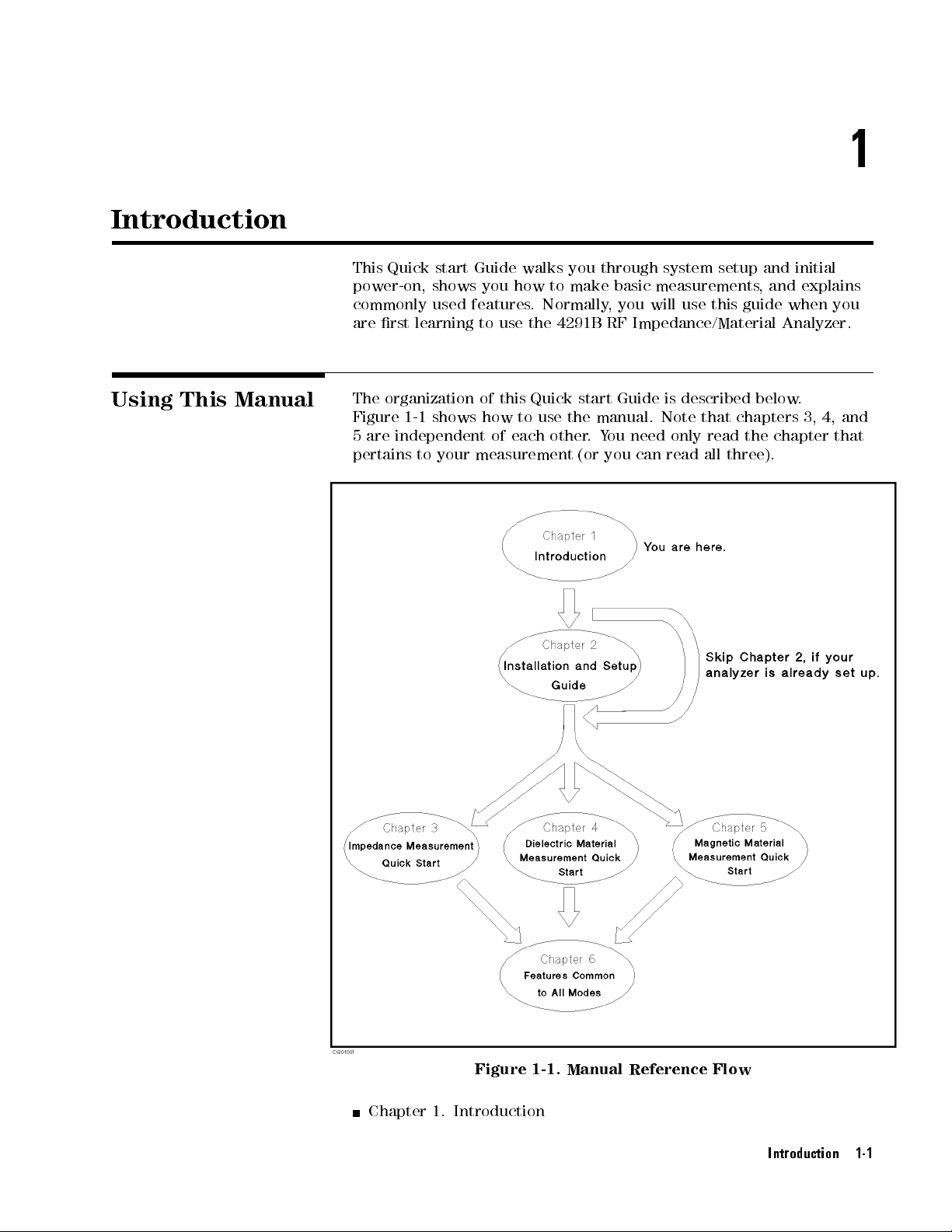

The

Figure

5

are

pertains

learning

organization

1-1

independent

to

start Guide

shows

used

you

features

to

of this

shows

how

of

your

measurement

walks

how

.

use

the

Quick start

to use

each

you

to

make

Normally

4291B

the manual.

other

.

(or

through

basic

,

RF

system

measurements

you

will

use

Impedance/Material

Guide is

described below

Note

Y

ou

need

only read

you

can

read

this

that

all

setup

guide

chapters

the

three).

and

,

and

Analyzer

chapter

initial

explains

when

.

3,

4,

you

.

and

that

Figure 1-1. Manual Reference Flow

Chapter 1. Introduction

Introduction 1-1

Page 18

This chapter

use this

manual.

provides a

brief description

of the

4291B and

how

to

Chapter 2.

This chapter

an incoming

refer to

set up

Chapter

This

for operation.

3.

chapter

measurement.

Chapter 4.

This

chapter

measurement.

Option

Chapter

This

002

5.

chapter

measurement.

Option

Chapter

This

002

6.

chapter

features

modes

of

Installation and

provides the

inspection and

this chapter

Impedance

if

Measurement

provides

Dielectric

Material

provides

Dielectric

is

installed.

Magnetic

Material

provides

Magnetic

is

installed.

F

eatures

Common

provides

and

measuremnent

operation

(impedance

Set Up

Guide

information necessary

the

setting up

analyzer

your

has

Quick

a

quick

start

guide

Measurement

a

quick

start

guide

material

measurement

Measurement

a

quick

start

guide

material

the

procedures

measurement

to

All

Modes

for

technique

,

dielectric

not

Start

that

analyzer

been

for

impedance

Quick

for

dielectric

Quick

for

magnetic

the

analyzer

can

,

and

for

performing

.

Y

ou

inspected

Start

material

is

available

Start

material

is

available

key

be

used

magnetic).

should

when

in

all

and

when

Appendix

This

repair

Appendix

This

16191A

A.

appendix

,

line

B

appendix

and

Compensation

Appendix

This

C. Calibration

appendix provides

Compensation.

Maintenance

provides

voltage

.

Compensation

setting

provides

16193A

"in

Chapter 3.

information

changes

Procedure

the

compensation

.

This

appendix

and Compensation

the explanation

on

performance

,

and fuse

for

16191A

is

referred in

of Calibration

verication,

replacement.

and 16193A

procedure for

\5. Fixture

the

and

1-2 Introduction

Page 19

Brief

of

Description

the 4291B

F

or surface-mount

4291B

designed

F

and

RF Impedance/Material

to

provide

or component

material researchers

component evaluation

Analyzer is

accurate testing

manufacturers,

,the

RF and

4291B provides

and material

an integrated

at higher

frequencies.

digital equipment

these capabilities:

testing, the

package

designers,

A

dditional

F

eatures

Broad

components

Improved

impedance

frequency coverage

and

materials

measurement accuracy

range of

Surface-mount-device

capacitors

Dielectric

permittivity

002

and

Magnetic

permeability

Direct

humidity

Impedance

Evaluate

(with Option

Chapter

Monitor

OSC

and inductors

test xture

, including

16453A

test

).

xture

of

ferrite

impedance

,

or temperature

Measurement

components

001).

6.)

test

signals

Level

or

the

and material

Dc

from 1

.

0.1

to

50

(SMD) test

.

and

built-in

Cole-Cole

and built-in

material

(with an

with

(See

\Applying

applied

Bias

Level"

MHz to

1.8 GHz

and repeatability

k

xtures for

function

plot

relaxation

function

(with

Option

dierent sizes

for

measuring

time

for

measuring

002

and

parameter measurement

external temperature

dc

bias

up

to

6

100

mA

Dc

Bias

(Option

to

your

DUT

s

.

(See

\Monitoring

in

Chapter

6.)

for

over

(with

16454A

and

001

testing

RF

an

of

chip

Option

).

versus time

chamber).

6

40

V

Only)"

in

the

,

Simulate

\Equivalent

a

component

Circuit

with

Analysis"

equivalent

in

Chapter

Others

Store

the

and

LIF

(See

\Saving

Markers

measurement

compatible

and

and

marker

data

1.4

MB

Recalling"

utilities

and

oppy

in

Chapter

(See

analyzer's

disk

\Using

Chapter 6.)

Limit lines for go/no-go testing (See \P

Test" in Chapter 6.)

Frequency linear/log/list sweep (See \P

Measurement" in Chapter 6 for list sweep

circuit

analysis

.

(See

3.)

drive

settings

and

on

the

memory

DOS

disk.

6.)

the

Marker"

in

erforming a GO/NO-GO

erforming

a List Sweep

.)

Introduction 1-3

Page 20

Page 21

2

Installation

and Set

This chapter

the following

Incoming Inspection

Power

Replacing

Operation

Ventilation

Instruction

Rack/Handle Installation

Connecting the

Connecting the

Connecting

Connecting

Up Guide

provides

information:

Requirements

the

Fuse

Conditions

Requirements

for

Cleaning

T

est

T

est

a

BNC

A

a

Keyboard

installation

Station

Head

dapter

and

setup

instructions

.

It

contains

Incoming

Inspection

W

arning

T

o

avoid

when there

outer enclosure

Inspect

hazardous

are

the

shipping

electrical

signs

(for

container

of

shipping

example

shock,

,

covers

for

damage

do

damage

,

panel,

.

not

to

If

turn

on

the

any

portion

or

display)

the

shipping container

analyzer

of

the

or cushioning material is damaged, it should be kept until the contents

of the shipment have been checked for completeness and the analyzer

has been checked mechanically and electrically

the shipment should be as listed in T

able 2-1. If the contents are

. The contents of

incomplete, if there is mechanical damage or defect, or if the analyzer

does not pass the power-on selftests

Technologies oce

. If the shipping container is damaged,

cushioning material shows signs of unusual stress

, notify the nearest Agilent

or the

, notify the carrier

as

well as the Agilent Technologies oce. Keep the shipping materials

for the carrier's inspection.

Installation and Set Up Guide 2-1

Page 22

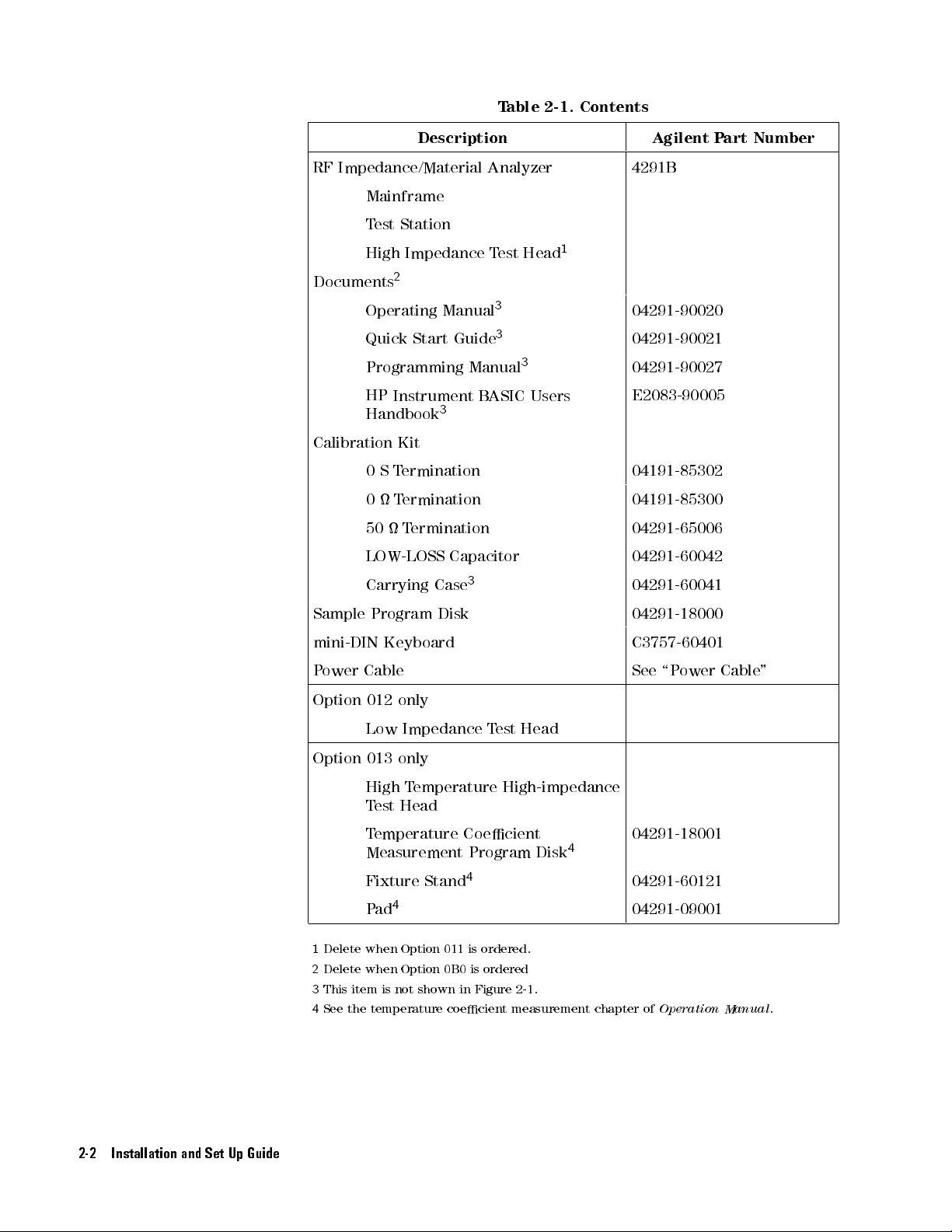

T

able 2-1.

Contents

Description Agilent P

RF

Impedance/Material Analyzer

Mainframe

T

est

Station

High

Impedance

Documents

Calibration

2

Operating

Quick

Manual

Start

Programming

HP

Instrument B

Handbook

3

Kit

0

ST

ermination

0

T

ermination

50

Termination

LOW-LOSS

Carrying

Capacitor

Case

Guide

Manual

ASIC

3

T

est

3

3

Head

3

Users

art Number

4291B

1

04291-90020

04291-90021

04291-90027

E2083-90005

04191-85302

04191-85300

04291-65006

04291-60042

04291-60041

Sample

mini-DIN

P

ower

Option

Option

1

Delete when Option 011 is

2

Delete when Option 0B0 is ordered

3

This item is not shown in Figure 2-1.

4

See the temperature coecient measurement chapter of

Program

Disk

Keyboard

Cable

012

only

Low

Impedance

013

only

High T

Test

T

emperature High-impedance

Head

emperature

T

est

Head

Coecient

Measurement Program Disk

Fixture Stand

4

Pad

4

ordered.

4

04291-18000

C3757-60401

See

\P

ower

04291-18001

04291-60121

04291-09001

Operation Manual

Cable

"

.

2-2 Installation and Set Up Guide

Page 23

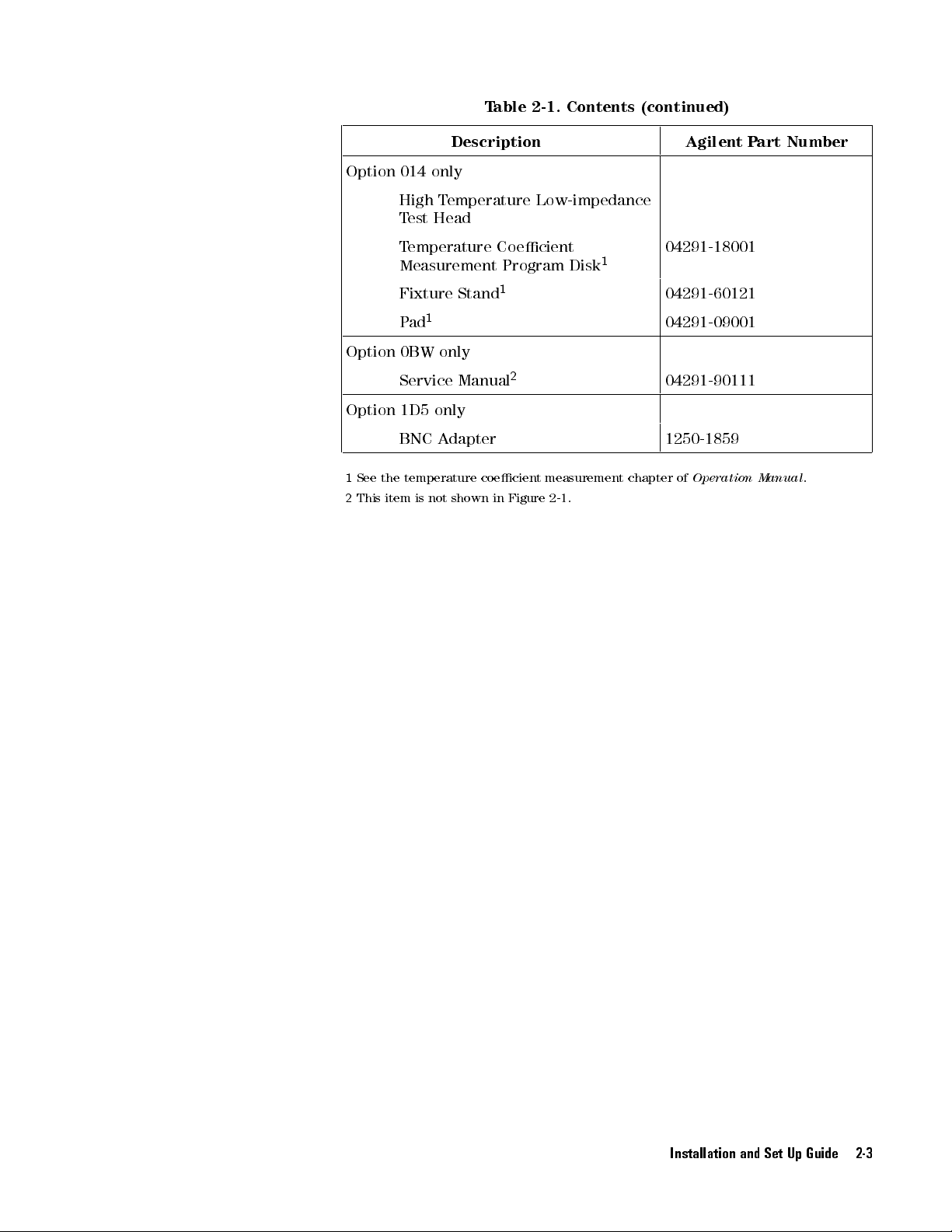

T

able 2-1.

Contents (continued)

Option

Option

Option

1

See

2

This

Description Agilent P

014

only

High

Temperature

T

est

Head

T

emperature Coecient

Measurement

Fixture

1

P

ad

0BW

only

Service

Stand

Manual

1

Program Disk

1D5 only

BNC

A

dapter

the

temperature

item

is not

coecient

shown in

Figure 2-1

Low-impedance

2

measurement

.

1

04291-18001

04291-60121

04291-09001

04291-90111

1250-1859

chapter

of

Operation

art Number

Manual

.

Installation and Set Up Guide 2-3

Page 24

2-4 Installation and Set Up Guide

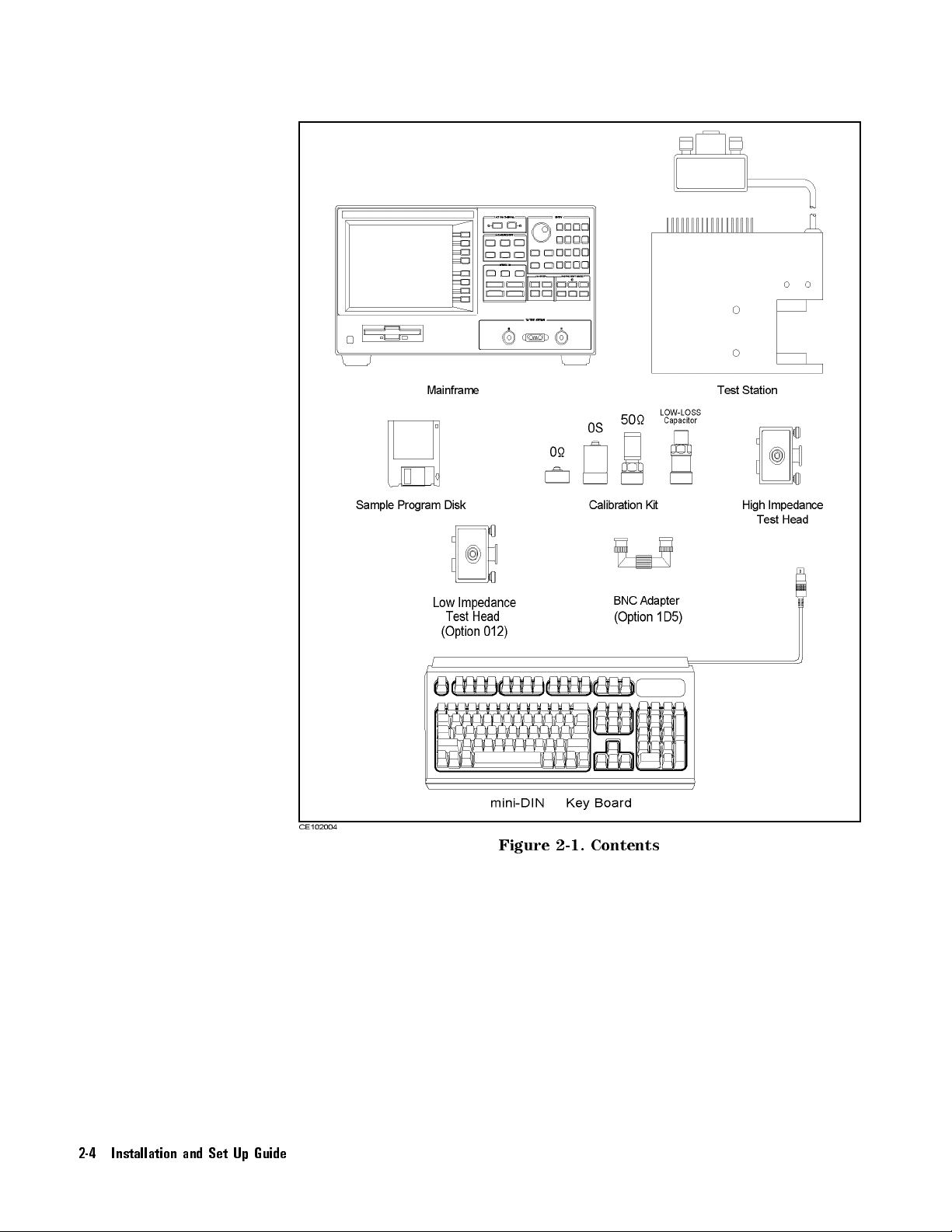

Figure 2-1.

Contents

Page 25

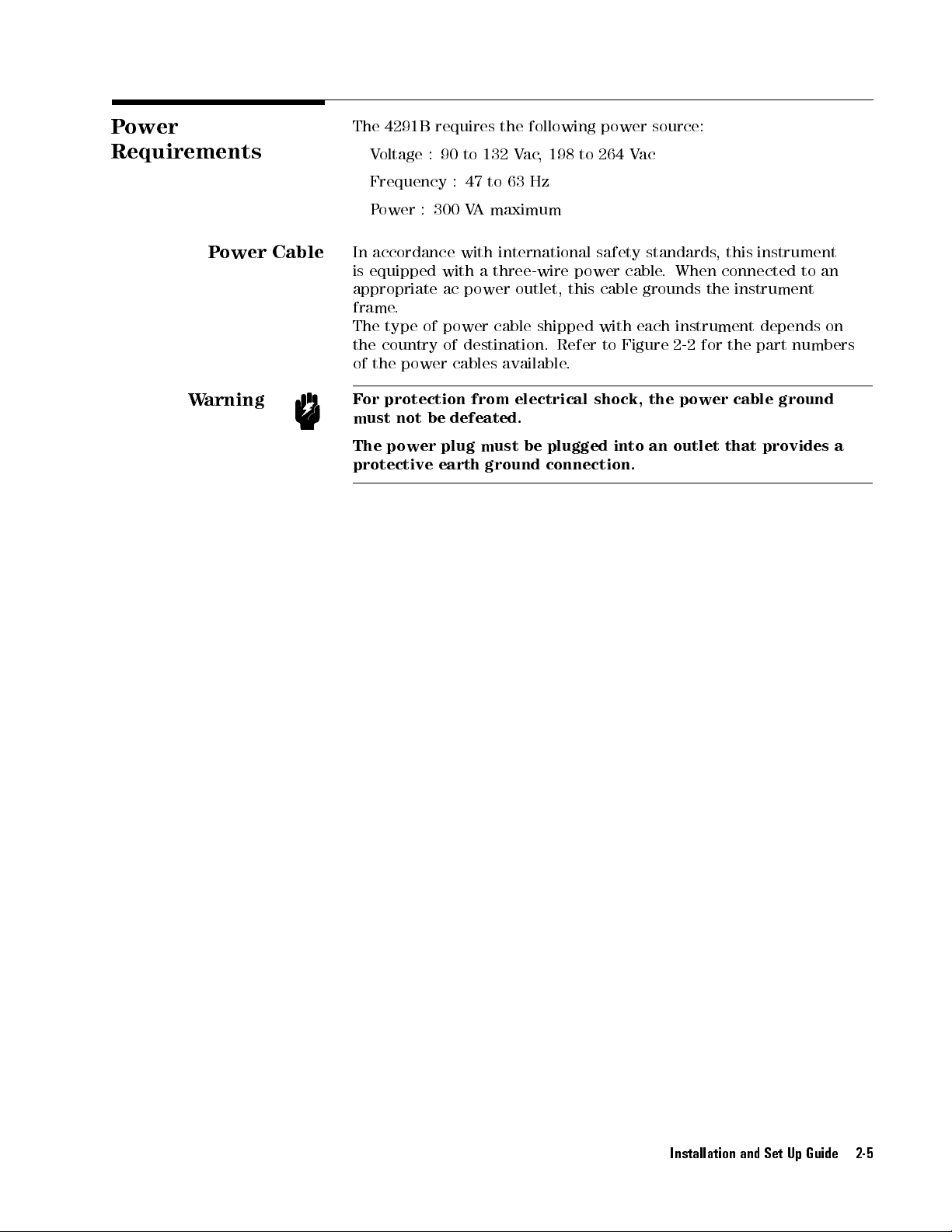

P

ower

Requirements

The

4291B requires

V

oltage :

90 to

the following

132 V

ac,

198 to

power source:

264 V

ac

P

ower

W

arning

Cable

Frequency

P

ower :

In

accordance

is

equipped

appropriate

frame

.

The

type of

the

country of

of

the power

F

or

protection

must

not

The

power

protective

:47

to 63

300 V

A maximum

with

international

with

a

three-wire

ac power

power cable

destination. Refer

cables available

from

be

defeated.

plug

must

earth

ground

Hz

power cable

outlet, this

shipped with

.

electrical

be

plugged

connection.

safety

standards,

. When

cable grounds

each instrument

to Figure

shock,

into

2-2 for

the power

an

outlet

this instrument

connected to

the

instrument

depends

the

part

cable ground

that

provides

an

on

numbers

a

Installation and Set Up Guide 2-5

Page 26

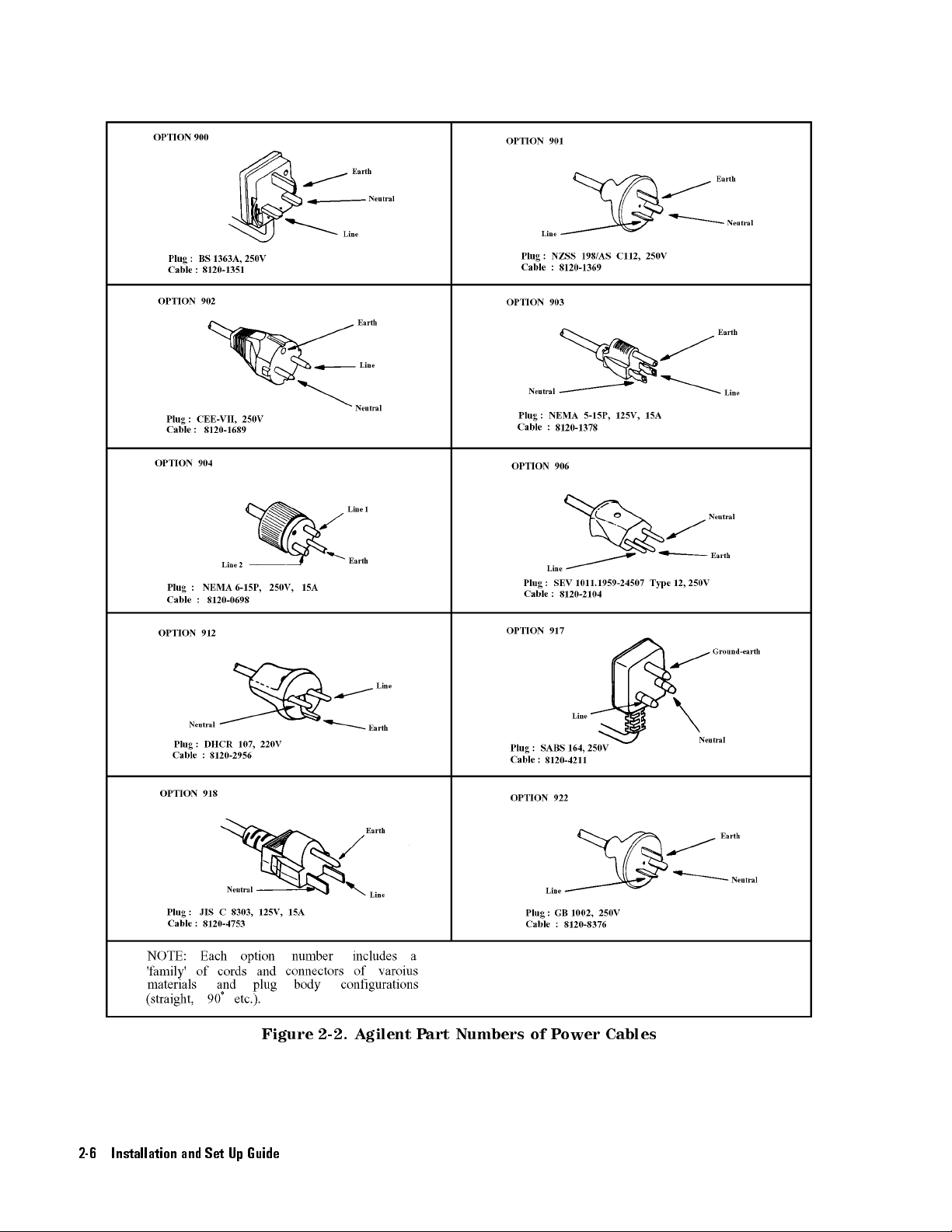

Figure 2-2. Agilent Part Numbers of Power Cables

2-6 Installation and Set Up Guide

Page 27

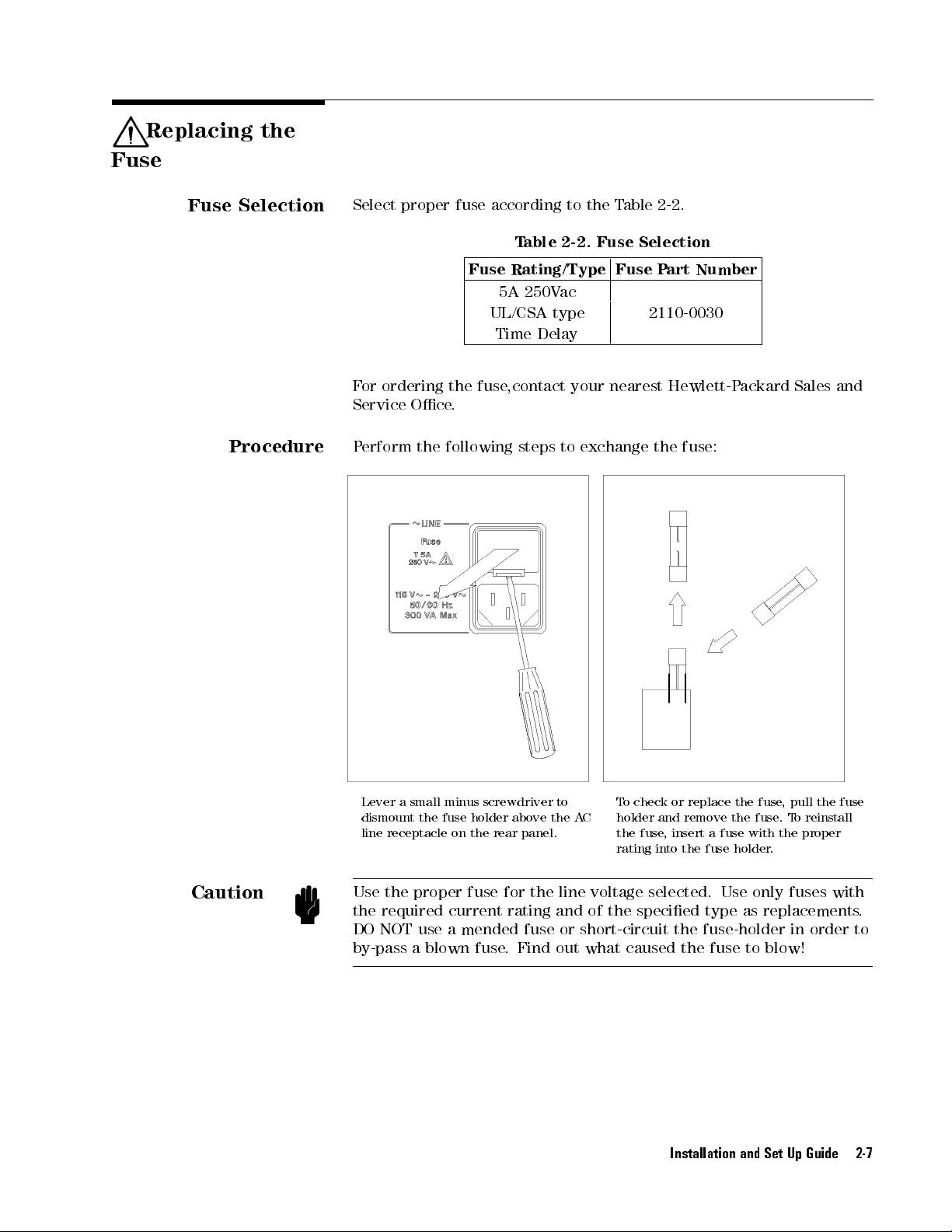

Replacing the

Fuse

Fuse

Procedure

Selection

Select

F

or

ordering