Page 1

Programming Guide

Agilent Technologies

DC Electronic Loads

Models N3300A, N3301A, N3302A,

N3303A, N3304A, N3305A, and N3306A

Part No. 5964-8198 Printed in U.S.A.

Microfiche No 5964-8199 November, 2000

Page 2

Safety Summary

The beginning of the electronic load User’s Guide has a Safety Summary page. Be sure you are familiar

with the information on this page before programming the electronic load from a controller.

Printing History

The edition and current revision of this manual are indicated below. Reprints of this manual containing

minor corrections and updates may have the same printing date. Revised editions are identified by a new

printing date. A revised edition incorporates all new or corrected material since the previous printing date.

Changes to the manual occurring between revisions are covered by change sheets shipped with the

manual.

This document contains proprietary information protected by copyright. All rights are reserved. No part of

this document may be photocopied, reproduced, or translated into another language without the prior

consent of Agilent Technologies. The information contained in this document is subject to change without

notice.

Copyright 2000 Agilent Technologies Edition 1 _________August, 2000

Update1 _________November, 2000

2

Page 3

Table of Contents

Safety Summary 2

Printing History 2

Table of Contents 3

1 - GENERAL INFORMATION 9

About this Guide 9

Documentation Summa ry 9

External References 9

SCPI References 9

GPIB References 10

VXIplug&play Power Products Instrument Drivers 10

Supported Applications 10

System Requirements 10

Downloading and Installing the Driver 10

Accessing Online Help 11

2 - INTRODUCTION TO PROGRAMMING 13

GPIB Capabilities of the Electronic Load 13

GPIB Address 13

RS-232 Capabilities of the Electronic Load 14

RS-232 Data Format 14

RS-232 Flow Control 14

Introduction to SCPI 15

Conventions Used in This Guide 15

Types of SCPI Commands 15

Multiple Commands in a Message 16

Moving Among Subsystems 16

Including Common Commands 16

Using Queries 17

Types of SCPI Messages 17

The Message Unit 17

Headers 17

Query Indicator 18

Message Unit Separator 18

Root Specifier 18

Message Terminator 18

SCPI Data Formats 18

Numerical Data Formats 18

Suffixes and Multipliers 19

Response Data Types 19

SCPI Command Completion 19

Using Device Clear 20

RS-232 Troubleshooting 20

SCPI Conformance Information 21

SCPI Conformed Commands 21

Non-SCPI Commands 21

3

Page 4

3 - PROGRAMMING EXAMPLES 23

Introduction 23

Programming the Input 23

Power-on Initialization 23

Enabling the Input 23

Input Voltage 23

Input Current 24

Setting the Triggered Volt age or Current Levels 24

Programming Transients 25

Continuous Transi ents 25

Pulse Transients 25

Toggled Transients 26

Programming Lists 26

Programming Lists for Multiple Channels 28

Triggering Transient s and Lists 29

SCPI Trigge ring Nomenclature 29

List Trigger Model 29

Initiating List Triggers 30

Specifying a Trigger Delay 30

Generating Transient and List Triggers 30

Making Measurements 31

Voltage and Current Measurements 31

Triggering Measurements 33

SCPI Trigge ring Nomenclature 33

Measurement Trigger Model 33

Initiating the Measurement Trigger System 34

Generating Me asurement Trigge rs 34

Controlling Measurement Samples 35

Varying the Sampling Rate 35

Measurement Delay 35

Multiple Measurements 35

Synchronizing Transients and Measurements 36

Measuring Triggered Transients or Lists 36

Measuring Dwell-Paced Lists 37

Programming the Status Registers 38

Power-On Conditions 41

Channel Status Group 41

Channel Summary Group 41

Questionable Status Group 41

Standard Event Status Group 41

Operation Status Group 42

Status Byte Register 42

Determining the Cause of a Service Interrupt 43

Servicing Standard Event Status and Questionable Status Events 43

Programming Examples 44

CC Mode Example 44

CV Mode Example 44

CR Mode Example 45

Continuous Transient Operation Example 45

Pulsed Transient Operation Example 46

Synchronous Toggled Transient Operation Example 46

Battery Testing Example 47

Power Supply Testing Example 49

C++ Programming Example 50

4

Page 5

4 - LANGUAGE DICTIONARY 53

Introduction 53

Subs ystem Commands 53

Common Comma nds 54

Programming Parameters 54

Calibration Commands 55

CALibrate:DATA 55

CALibrate:IMON:LEVel 55

CALibrate:IPR:LEVel 55

CALibrate:LEVel 55

CALibrate:PASSword 56

CALibrate:SAVE 56

CALibrate:STATe 56

Channel Commands 57

CHANnel INSTrument 57

Input Commands 58

[SOURce:]INPut OUTPut 58

[SOURce:]INPut:PROTection:CLEar OUTput:PROTection:CLEar 58

[SOURce:]INPut:SHORt OUTPut:SHORt 58

[SOURce:]CURRent 59

[SOURce:]CURRent:MODE 59

[SOURce:]CURRent:PROTection 59

[SOURce:]CURRent:PROTection:DELay 60

[SOURce:]CURRent:PROTection:STATe 60

[SOURce:]CURRent:RANGe 60

[SOURce:]CURRent:SLEW 61

[SOURce:]CURRent:SLEW:NEGative 61

[SOURce:]CURRent:SLEW:POSitive 61

[SOURce:]CURRent:TLEVel 62

[SOURce:]CURRent:TRIGgered 62

[SOURce:]FUNCtion [SOURce:]MODE 62

[SOURce:]FUNCtion:MODE 63

[SOURce:]RESistance 63

[SOURce:]RESistance:MODE 63

[SOURce:]RESistance:RANGe 64

[SOURce:]RESistance:SLEW 64

[SOURce:]RESistance:SLEW:NEGative 64

[SOURce:]RESistance:SLEW:POSitive 65

[SOURce:]RESistance:TLEVel 65

[SOURce:]RESistance:TRIGgered 65

[SOURce:]VOLTage 66

[SOURce:]VOLTage:MODE 66

[SOURce:]VOLTage:RANGe 66

[SOURce:]VOLTage:SLEW 67

[SOURce:]VOLTage:SLEW:NEGative 67

[SOURce:]VOLTage:SLEW:POSitive 68

[SOURce:]VOLTage:TLEVel 68

[SOURce:]VOLTage:TRIGgered 68

Measurement Commands 69

ABORt 69

MEASure:ARRay:CURRent? FETCh:ARRay:CURRent? 69

MEASure:ARRay:POWer? FETCh:ARRay:POWer ? 69

MEASure:ARRay:VOLTage? FETCh:ARRay:VOLT age? 70

5

Page 6

MEASure:CURRent? FETCh:CURRent? 70

MEASure:CURRent:ACDC? FETCh:CURRent:ACDC? 70

MEASure:CURRent:MAXimum? FETCh:CURRent:MAXimum? 70

MEASure:CURRent:MINimum? FETCh:CURRent:MI Nimum? 71

MEASure:POWe r? FETCh:POWer? 71

MEAS ure:POWer: MAXimum? FETCh:POWer:MAX imum? 71

MEAS ure:POWer: MINimum? FETCh:POWer:MINimum? 71

MEASure:VOLTage? FETCh:V OLTage? 72

MEASure:VOLTage:ACDC? FETCh:VOLTage:ACDC? 72

MEASure:VOLTage:MAXimum? FETCh:VOLTage:MAXimum? 72

MEASure:VOLTage:MINimum? FET Ch:VOLTage:MI Nimum? 72

SENSe:CURRent:RANGe 73

SENSe:SWEep:POINts 73

SENSe:SWEep:OFFSet 73

SENSe:SWEep:TINTerval 74

SENSe:WINDow 74

SENSe:VOLTage:RANGe 74

Port Commands 75

PORT0 75

PORT1 75

Lis t Commands 76

[SOURce:]LIST:COUNt 76

[SOURce:]LIST:CURRent [SOURce:]LIST:CURRent:POINts? 76

[SOURce:]LIST:CURRent:RANGe [SOURce:]LIST:CURRent:RANGe:POINts? 77

[SOURce:]LIST:CURRent:SLEW [SOURce:]LIST:CURRent:SLEW:POINts? 77

[SOURce:]LIST:CURRent:SLEW:NEGative 78

[SOURce:]LIST:CURRent:SLEW:POSitive 78

[SOURce:]LIST:CURRent:TLEVel [SOURce:]LIST:CURRent:TLEVel:POINts? 78

[SOURce:]LIST:FUNCtion [SOURce:]LIST:MODE [SOURce:]LIST:FUNCtion:POINTs? 79

[SOURce:]LIST:DWELl [SOURce:]LIST:DWELl:POINts? 79

[SOURce:]LIST:RESistance [SOURce:]LIST:RESistance:POINts? 80

[SOURce:]LIST:RESistance:RANGe [SOURce:]LIST:RESistance:RANGe:POINts? 80

[SOURce:]LIST:RESistance:SLEW [SOURce:]LIST:RESistance:SLEW:POINts? 81

[SOURce:]LIST:RESistance:SLEW:NEGative 81

[SOURce:]LIST:RESistance:SLEW:POSitive 81

[SOURce:]LIST:RESistance:TLEVel [SOURce:]LIST:RESistance:TLEVel:POINTs? 82

[SOURce:]LIST:STEP 82

[SOURce:]LIST:TRANsient [SOURce:]LIST:TRANsient:POINts? 82

[SOURce:]LIST:TRANsient:DCYCle [SOURce:]LIST:TRANsient:DCYCle:POINts? 83

[SOURce:]LIST:TRANsient:FREQuency [SOURce:]LIST:TRANsient:FREQuency:POINts? 83

[SOURce:]LIST:TRANsient:MODE [SOURce:]LIST:TRANsient:MODE:POINts? 83

[SOURce:]LIST:TRANsient:TWIDth [SOURce:]LIST:TRANsient:TWIDth:POINts? 84

[SOURce:]LIST:VOLTage [SOURce:]LIST:VOLTage:POINts? 84

[SOURce:]LIST:VOLTage:RANGe [SOURce:]LIST:VOLTage:RANGe:POINTs? 84

[SOURce:]LIST:VOLTage:SLEW [SOURce:]LIST:VOLTage:SLEW:POINts? 85

[SOURce:]LIST:VOLTage:SLEW:NEGative 85

[SOURce:]LIST:VOLTage:SLEW:POSitive 86

[SOURce:]LIST:VOLTage:TLEVel [SOURce:]LIST:VOLTage:TLEVel:POINts? 86

Transient Commands 87

[SOURce:]TRANsient 87

[SOURce:]TRANsient:DCYCle 87

[SOURce:]TRANsient:FREQuency 87

[SOURce:]TRANsient:MODE 88

[SOURce:]TRANsient:LMODE 88

[SOURce:]TRANsient:TWIDth 88

6

Page 7

Status Commands 89

Bit Configuration of Channel Status Registe rs 89

STATus:CHANnel? 89

STATus:CHANnel:CONDition? 89

STATus:CHANnel:ENABle 89

STATus:CSUM? 90

STATus:CSUMmary:ENABle 90

Bit Configuration of Operation Status Registers 90

STATus:OPERation? 90

STATus:OPERation:CONDition? 90

STATus:OPERation:ENABle 91

STATus:OPERation:NTRansition STATus:OP E Ration:PTRansition 91

Bit Configuration of Questionable Status Registers 92

STATus:QUEStionable? 92

STATus:QUEStionable:CONDition? 92

STATus:QUEStionable:ENABle 92

System Commands 93

SYSTem:ERRor? 93

SYSTem:LOCal 93

SYSTem:REMote 93

SYSTem:RWLock 93

SYSTem:VERSion? 93

Trigger Commands 94

ABORt 94

INITiate:SEQuence INITiate:NAME 94

INITiate:SEQuence2 INITiate:NAME 94

INITiate:CONTinuous:SEQuence INITiate:CONTinuous:NAME 95

TRIGger 95

TRIGger:DELay 95

TRIGger:SEQuence2:COUNt 96

TRIGger:SOURce 96

TRIGger:TIMer 96

Common Commands 97

*CLS 97

*ESE 97

Bit Configuration of Standard Event Status Enable Register 98

*ESR? 98

*IDN? 98

*OPC 98

*OPT? 99

*PSC 99

*RCL 99

*RDT? 100

*RST 100

*SAV 101

*SRE 101

*STB? 101

Bit Configuration of Status Byte Register 102

*TRG 102

*TST? 102

*WAI 102

7

Page 8

A - SCPI COMMAND TREE 103

Command Syntax 103

B - ERROR MESSAGES 107

Error Number List 107

C - COMPARING N3300A ELECTRONIC LOADS WITH EARLIER MODELS 111

Introduction 111

INDEX 115

8

Page 9

General Information

About this Guide

This manual contains programming information for the Agilent Technologies N3301A, N3302A, N3303A,

N3304A, N3305A, N3306A Electronic Load modules when installed in an Agilent Technologies N3300A

and N3301A Electronic Load mainframes. These units will be referred to as "electronic load" throughout

this manual. You will find the following information in the rest of this guide:

Chapter 1 Introduction to this guide.

Chapter 2 Introduction to SCPI messages structure, syntax, and data formats.

Chapter 3 Introduction to programming the electronic load with SCPI commands.

Chapter 4 Dictionary of SCPI commands.

Appendix A SCPI command tree.

Appendix B Error messages

Appendix C Comparison With Earlier Models

Documentation Summary

The following documents that are related to this Programming Guide have additional helpful information

for using the electronic load.

1

K Quick Start Guide - located in the front part of the User's Guide. Information on how to quickly get

started using the electronic load.

K User's Guide. Includes specifications and supplemental characteristics, how to use the front

panel, how to connect to the instrument, and calibration procedures.

External References

SCPI References

The following documents will assist you with programming in SCPI:

K Beginner's Guide to SCPI. Part No. H2325-90001. Highly recommended for anyone who has not

had previous experience programming with SCPI.

K Tutorial Description of the GPIB . Part No. 5952-0156. Highly recommended for those not familiar

with the IEEE 488.1 and 488.2 standards.

To obtain a copy of the above documents, contact your local Agilent Technologies Sales and Support

Office.

9

Page 10

1 - General Information

GPIB References

The most important GPIB documents are your controller programming manuals - GW BASIC, GPIB

Command Library for MS DOS, etc. Refer to these for all non-SCPI commands (for example: Local

Lockout).

The following are two formal documents concerning the GPIB interface:

K ANSI/IEEE Std. 488.1-1987 IEEE Standard Digital Interface for Programmable Instrumentation.

Defines the technical details of the GPIB interface. While much of the information is beyond the

need of most programmers, it can serve to clarify terms used in this guide and in related

documents.

K ANSI/IEEE Std. 488.2-1987 IEEE Standard Codes, Formats, Protocols, and Common

Commands. Recommended as a reference only if you intend to do fairly sophisticated

programming. Helpful for finding precise definitions of certain types of SCPI message formats,

data types, or common commands.

The above two documents are available from the IEEE (Institute of Electrical and Electronics Engineers),

345 East 47th Street, New York, NY 10017, USA.

VXIplug&play Power Products Instrument Drivers

VXIplug&play instrument drivers for Microsoft Windows 95 and Windows NT are now available on the

Web at http://www.agilent.com/find/drivers. These instrument drivers provide a high-level programming

interface to your Agilent Technologies electronic load. VXIplug&play instrument drivers are an alternative

to programming your instrument with SCPI command strings. Because the instrument driver's function

calls work together on top of the VISA I/O library, a single instrument driver can be used with multiple

application environments.

Supported Applications

a Agilent VEE

a Microsoft Visual BASIC

a Microsoft Visual C/C++

a Borland C/C++

a National Instruments LabVIEW

a National Instruments LabWindows/CVI

System Requirements

The VXIplug&play instrument driver complies with the following:

a Microsoft Windows 95

a Microsoft Windows NT 4.0

a HP VISA revision F.01.02

a National Instruments VISA 1.1

Downloading and Installing the Driver

NOTE: Before installing the VXIplug&play instrument driver, make sure that you have one of the

supported applications installed and running on your computer.

10

Page 11

General Information - 1

1. Access Agilent Technologies Web site at http://www.agilent.com/find/drivers.

2. Select the instrument for which you need the driver.

3. Click on the driver, either Windows 95 or Windows NT, and download the executable file to your

PC.

4. Locate the file that you downloaded from the Web. From the Start menu select Run

<path>:\agxxxx.exe - where <path> is the directory path where the file is located, and agxxxx is

the instrument driver that you downloaded .

5. Follow the directions on the screen to install the software. The default installation selections will

work in most cases. The readme.txt file contains product updates or corrections that are not

documented in the on-line help. If you decide to install this file, use any text editor to open and

read it.

6. To use the VXIplug&play instrument driver, follow the directions in the VXIplug&play online help

for your specific driver under “Introduction to Programming”.

Accessing Online Help

A comprehensive online programming reference is provided with the driver. It describes how to get

started using the instrument driver with Agilent VEE, LabVIEW, and LabWindows. It includes complete

descriptions of all function calls as well as example programs in C/C++ and Visual BASIC.

a To access the online help when you have chosen the default Vxipnp start folder, click on the Start

button and select Programs | Vxipnp | Agxxxx Help (32-bit).

- where Agxxxx i s the instrument driver.

11

Page 12

Introduction to Programming

GPIB Capabilities of the Electronic Load

All electronic load functions except for setting the GPIB address are programmable over the GPIB. The

IEEE 488.2 capabilities of the electronic load are described in Table 2-1. Refer to Appendix A of your

User's Guide for its exact capabilities.

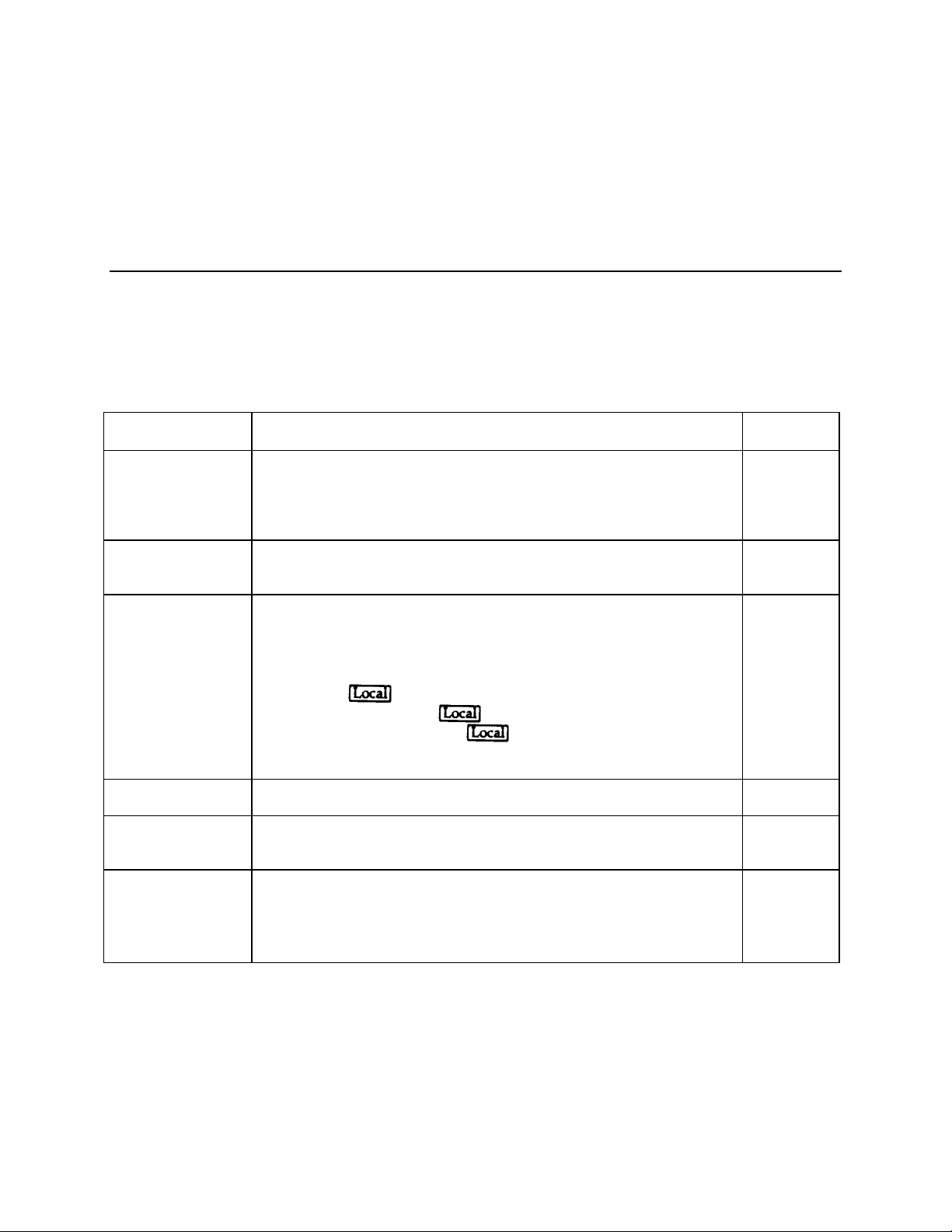

Table 2-1. IEEE 488 Capabilities of Electronic Loads

GPIB Capabilities Response Interface

Function

Talker/Listener All electronic load functions except for setting the GPIB address are

programmable over the GPIB. The electronic load can send and

receive messages over the GPIB. Status information is sent using a

serial poll. Front panel annunciators indicate the present GPIB state

of the electronic load.

Service Request The electronic load sets the SRQ line true if there is an enabled

service request condition. Refer to Chapter 3 - Status Reporting for

more information.

Remote/Local In local mode, the electronic load is controlled from the front panel

but will also execute commands sent over the GPIB. The electronic

load powers up in local mode and remains in local mode until it

receives a command over the GPIB. Once the electronic load is in

remote mode the front panel RMT annunciator is on, all front panel

keys (except

metering mode. Pressing

electronic load to local mode.

lockout so that only the controller or the power switch can return the

electronic load to local mode.

Device Trigger The electronic load will respond to the device trigger function. DT1

) are disabled, and the display is in normal

on the front panel returns the

can be disabled using local

AH1, SH1,

T6. L4

SR1

RL1

2

Group Execute

Trigger

Device Clear

The electronic load will respond to the group execute trigger function. GET

The electronic load responds to the Device Clear (DCL) and

Selected Device Clear (SDC) interface commands. They cause the

electronic load to clear any activity that would prevent it from

receiving and executing a new command (including *WAI and

*OPC?). DCL and SDC do not change any programmed settings.

DCL, SDC

GPIB Address

The electronic load operates from a GPIB address that is set from the front panel. To set the GPIB

address, press the Address key on the front panel and enter the address using the Entry keys. The

address can be set from 0 to 30. The GPIB address is stored in non-volatile memory.

13

Page 13

2 - Introduction to Programming

RS-232 Capabilities of the Electronic Load

The electronic load provides an RS-232 programming interface, which is activated by commands located

under the front panel Address key. All SCPI commands are available through RS-232 programming.

When the RS-232 interface is selected, the GPIB interface is disabled.

The EIA RS-232 Standard defines the interconnections between Data Terminal Equipment (DTE) and

Data Communications Equipment (DCE). The electronic load is designed to be a DTE. It can be

connected to another DTE such as a PC COM port through a null modem cable.

NOTE: The RS-232 settings in your program must match the settings specified in the front panel

Address menu. Press the front panel Address key if you need to change the settings.

RS-232 Data Format

The RS-232 data is a 10-bit word with one start bit and one stop bit. The number of start and stop bits is

not programmable. However, the following parity options are selectable using the front panel Address key:

EVEN

ODD

MARK

SPACE

NONE

Parity options are stored in non-volatile memory.

Baud Rate

The front panel Address key lets you select one of the following baud rates, which is stored in non-volatile

memory:

300 600 1200 2400 4800 9600

Seven data bits with even parity

Seven data bits with odd parity

Seven data bits with mark parity (parity is always true)

Seven data bits with space parity (parity is always false)

Eight data bits without parity

RS-232 Flow Control

The RS-232 interface supports the following flow control options that are selected using the front panel

Address key. For each case, the electronic load will send a maximum of five characters after holdoff is

asserted by the controller. The electronic load is capable of receiving as many as fifteen additional

characters after it asserts holdoff.

RTS-CTS

NONE

Flow control options are stored in non-volatile memory.

The electronic load asserts its Request to Send (RTS) line to signal hold-off

when its input buffer is almost full, and it interprets its Clear to Send (CTS)

line as a hold-off signal from the controller.

There is no flow control.

14

Page 14

Introduction to Programming - 2

Introduction to SCPI

SCPI (Standard Commands for Programmable Instruments) is a programming language for controlling

instrument functions over the GPIB and RS-232 interface. SCPI is layered on top of the hardware-portion

of IEEE 488.2. The same SCPI commands and parameters control the same functions in different classes

of instruments.

Conventions Used in This Guide

Angle brackets < > Items within angle brackets are parameter abbreviations. For example,

<NR1> indicates a specific form of numerical data.

Vertical bar | Vertical bars separate alternative parameters. For example, NORM | TEXT

indicates that either "TEXT" or "NORM" can be used as a parameter.

Square Brackets [ ] Items within square brackets are optional. The representation [SOURce:].

VOLTage means that SOURce: may be omitted.

Braces { } Braces indicate parameters that may be repeated zero or more times. It is

used especially for showing arrays. The notation <A>{<,B>} shows that

parameter "A" must be entered, while parameter "B" may be omitted or

may be entered one or more times.

Computer font Computer font is used to show program lines in text.

OUTPUT 723 "TRIGger:COUNt:CURRent 10" shows a program line.

Types of SCPI Commands

SCPI has two types of commands, common and subsystem.

♦ Common commands generally are not related to specific operation but to controlling overall

electronic load functions, such as reset, status, and synchronization. All common commands

consist of a three-letter mnemonic preceded by an asterisk: *RST *IDN? *SRE 8

♦ Subsystem commands perform specific electronic load functions. They are organized into an

inverted tree structure with the "root" at the top. The following figure shows a portion of a

subsystem command tree, from which you access the commands located along the various

paths. You can see the complete tree in Appendix A.

ROOT

:CURRent [:LEVel]

:MODE

:PROTection

:STATus

:OPERation [:EVENt]?

[:IMMediate]

[:LEVel]

:DELay

:CONDition?

Figure 2-1. Partial Command Tree

15

Page 15

2 - Introduction to Programming

Multiple Commands in a Message

Multiple SCPI commands can be combined and sent as a single message with one message terminator.

There are two important considerations when sending several commands within a single message:

♦ Use a semicolon to separate commands within a message.

♦ There is an implied header path that affects how commands are interpreted by the electronic load.

The header path can be thought of as a string that gets inserted before each command within a message.

For the first command in a message, the header path is a null string. For each subsequent command the

header path is defined as the characters that make up the headers of the previous command in the

message up to and including the last colon separator. An example of a message with two commands is:

CURR:LEV 3;PROT:STAT OFF

which shows the use of the semicolon separating the two commands, and also illustrates the header path

concept. Note that with the second command, the leading header "CURR" was omitted because after the

"CURR:LEV 3" command, the header path became defined as "CURR" and thus the instrument

interpreted the second command as:

CURR:PROT:STAT OFF

In fact, it would have been syntactically incorrect to include the "CURR" explicitly in the second command,

since the result after combining it with the header path would be:

CURR:CURR:PROT:STAT OFF

which is incorrect.

Moving Among Subsystems

In order to combine commands from different subsystems, you need to be able to reset the header path to

a null string within a message. You do this by beginning the command with a colon (:), which discards any

previous header path. For example, you could clear the output protection and check the status of the

Operation Condition register in one message by using a root specifier as follows:

OUTPut:PROTection:CLEAr;:STATus:OPERation:CONDition?

The following message shows how to combine commands from different subsystems as well as within the

same subsyste m:

VOLTage:LEVel 20;PROTection 28; :CURRent:LEVel 3;PROTection:STATe ON

Note the use of the optional header LEVel to maintain the correct path within the voltage and current

subsystems, and the use of the root specifier to move between subsystems.

Including Common Commands

You can combine common commands with subsystem commands in the same message. Treat the

common command as a message unit by separating it with a semicolon (the message unit separator).

Common commands do not affect the header path; you may insert them anywhere in the message.

VOLTage:TRIGgered 17.5;:INITialize;*TRG

OUTPut OFF;*RCL 2;OUTPut ON

16

Page 16

Introduction to Programming - 2

Using Queries

Observe the following precautions with queries:

♦ Set up the proper number of variables for the returned data. For example, if you are reading back

a measurement array, you must dimension the array according to the number of measurements

that you have placed in the measurement buffer.

♦ Read back all the results of a query before sending another command to the electronic load.

Otherwise a Query Interrupted error will occur and the unreturned data will be lost.

Types of SCPI Messages

There are two types of SCPI messages, program and response.

♦ A program message consists of one or more properly formatted SCPI commands sent from the

controller to the electronic load. The message, which may be sent at any time, requests the

electronic load to perform some action.

♦ A response message consists of data in a specific SCPI format sent from the electronic load to

the controller. The electronic load sends the message only when commanded by a program

message called a "query."

The following figure illustrates SCPI message structure:

Data

Headers

Header Separator

The Message Unit

The simplest SCPI command is a single message unit consisting of a command header (or keyword)

followed by a message terminator. The message unit may include a parameter after the header. The

parameter can be numeric or a string.

ABORt<NL>

VOLTage 20<NL>

Message Unit Separators

Figure 2-2. Command Message Structure

Message Unit

;

Query Indicator

; : CURR?

Message Terminator

Root Specifier

<NL>VOLT:LEV 20 TLEV 30

Headers

Headers, also referred to as keywords, are instructions recognized by the electronic load. Headers may be

either in the long form or the short form. In the long form, the header is completely spelled out, such as

VOLTAGE, STATUS, and DELAY. In the short form, the header has only the first three or four letters,

such as VOLT, STAT, and DEL.

17

Page 17

2 - Introduction to Programming

Query Indicator

Following a header with a question mark turns it into a query (VOLTage?, VOLTage:PROTection?). If a

query contains a parameter, place the query indicator at the end of the last header

(VOLTage:PROTection? MAX).

Message Unit Separator

When two or more message units are combined into a compound message, separate the units with a

semicolon (STATus:OPERation?;QUEStionable?).

Root Specifier

When it precedes the first header of a message unit, the colon becomes the root specifier. It tells the

command parser that this is the root or the top node of the command tree.

Message Terminator

A terminator informs SCPI that it has reached the end of a message. Three permitted messages

terminators are:

♦ newline (<NL>), which is ASCII decimal 10 or hex 0A.

♦ end or identify (<END>)

♦ both of the above (<NL><END>).

In the examples of this guide, there is an assumed message terminator at the end of each message.

NOTE: All RS-232 response data sent by the electronic load is terminated by the ASCII character

pair <carriage return><newline>. This differs from GPIB response data which is

terminated by the single character <newline> with EOI asserted.

SCPI Data Formats

All data programmed to or returned from the electronic load is ASCII. The data may be numerical or

character string.

Numerical Data Formats

Symbol Data Form

Talking Formats

<NR1> Digits with an implied decimal point assumed at the right of the least-significant digit.

Examples: 273

<NR2>

<NR3>

Listening Formats

<Nrf>

<Nrf+>

<Bool>

Digits with an explicit decimal point. Example: .0273

Digits with an explicit decimal point and an exponent. Example: 2.73E+2

Extended format that includes <NR1>, <NR2> and <NR3>. Examples: 273 273. 2.73E2

Expanded decimal format that includes <NRf> and MIN MAX. Examples: 273 273.

2.73E2 MAX. MIN and MAX are the minimum and maximum limit values that are

implicit in the range specification for the parameter.

Boolean Data. Example: 0 | 1 or ON | OFF

18

Page 18

Introduction to Programming - 2

Suffixes and Multipliers

Class Suffix Unit Unit with Multiplier

Amplitude V volt MV (millivolt)

Current A ampere MA (milliampere)

Power W watt MW (milliwatt)

Resistance OHM ohm MOHM (megohm)

Slew Rate A/s

R/s

V/s

Time s second MS (millisecond)

1E3 K kilo

1E-3 M milli

1E-6 U micro

Response Data Types Character strings returned by query statements may take either of the following forms, depending on the

length of the returned string:

amps/second

ohms/second

volts/second

Common Multipliers

<CRD>

<AARD>

<SRD>

SCPI Command Completion

SCPI commands sent to the electronic load are processed either sequentially or in parallel. Sequential

commands finish execution before a subsequent command begins. Parallel commands allow other

commands to begin executing while the parallel command is still executing. Commands that affect trigger

actions are among the parallel commands.

The *WAI, *OPC, and *OPC? common commands provide different ways of indicating when all

transmitted commands, including any parallel ones, have completed their operations. The syntax and

parameters for these commands are described in chapter 4. Some practical considerations for using

these commands are as follows:

*WAI

*OPC?

*OPC

Character Response Data. Permits the return of character strings.

Arbitrary ASCII Response Data. Permits the return of undelimited 7-bit ASCII. This data type

has an implied message terminator.

String Response Data. Returns string parameters enclosed in double quotes.

This prevents the electronic load from processing subsequent commands until all

pending operations are completed.

This places a 1 in the Output Queue when all pending operations have completed.

Because it requires your program to read the returned value before executing the next

program statement, *OPC? can be used to cause the controller to wait for commands

to complete before proceeding with its program.

This sets the OPC status bit when all pending operations have completed. Since your

program can read this status bit on an interrupt basis, *OPC allows subsequent

commands to be executed.

NOTE: The trigger system must be in the Idle state in order for the status OPC bit to be true.

Therefore, as far as triggers are concerned, OPC is false whenever the trigger system is

in the Initiated state.

19

Page 19

2 - Introduction to Programming

Using Device Clear

You can send a device clear at any time to abort a SCPI command that may be hanging up the GPIB

interface. The status registers, the error queue, and all configuration states are left unchanged when a

device clear message is received. Device clear performs the following actions:

♦ The input and output buffers of the electronic load are cleared.

♦ The electronic load is prepared to accept a new command string.

The following statement shows how to send a device clear over the GPIB interface using GW BASIC:

CLEAR 705 IEEE-488 Device Clear

The following statement shows how to send a device clear over the GPIB interface using the GPIB

command library for C or QuickBASIC:

IOCLEAR (705)

NOTE: For RS-232 operation, sending a Break will perform the same operation as the IEEE-488

device clear message.

RS-232 Troubleshooting

If you are having trouble communicating over the RS-232 interface, check the following:

♦ The computer and the electronic load must be configured for the same baud rate, parity, number

of data bits, and flow control options. Note that the electronic load is configured for 1 start bit and

1 stop bit (these values are fixed).

♦ The correct interface cables or adapters must be used, as described under RS-232 Connector.

Note that even if the cable has the proper connectors for your system, the internal wiring may be

incorrect.

♦ The interface cable must be connected to the correct serial port on your computer (COM1, COM2,

etc.).

20

Page 20

Introduction to Programming - 2

SCPI Conformance Information

SCPI Conformed Commands The Electronic Load conforms to SCPI Version 1995.0.

ABOR MEAS | FETC[:SCAL]:VOLT:MAX [SOUR]:RES[:LEV][:IMM][:AMP]

CAL:DATA MEAS | FETC[:SCAL]:VOLT:MIN [SOUR]:RES[:LEV]:TRIG[:AMP]

CAL:STAT SENS:CURR[:DC]:RANG[:UPP] [SOUR]:RES:MODE

INIT[:IMM]:SEQ SENS:SWE:OFFS [SOUR]:RES:RANG

INIT[:IMM]:NAME SENS:SWE:POIN [SOUR]:RES:SLEW

INIT:CONT:SEQ SENS:SWE:TINT [SOUR]:VOLT[:LEV][:IMM][:AMP]

INIT:CONT:NAME SENS:WIND[:TYPE] [SOUR]:VOLT[:LEV]:TRIG[:AMP]

INP | OUTP[:STAT] SENS:VOLT[:DC]:RANG[:UPP] [SOUR]:VOLT:MODE

INP | OUTP:PROT:CLE [SOUR]:CURR[:LEV][:IMM][:AMP] [SOUR]:VOLT:RANG

MEAS | FETC:ARR:CURR[:DC] [SOUR]:CURR[:LEV]:TRIG[:AMP] [SOUR]:VOLT:SLEW

MEAS | FETC:ARR:POW[:DC] [SOUR]:CURR:MODE STAT:OPER[:EVEN]

MEAS | FETC:ARR:V O LT [:DC] [SOUR]:CURR:PROT[:LEV] STAT:OPER:COND

MEAS | FETC[:SCAL]:CURR[:DC] [SOUR]:CURR:PROT:STAT STAT:OPER:ENAB

MEAS | FETC[:SCAL]:CURR:MAX [SOUR]:CURR:RANG STAT:OPER:NTR

MEAS | FETC[:SCAL]:CURR:MIN [SOUR]:CURR:SLEW STAT:OPER:PTR

MEAS | FETC[:SCAL]:POW[:DC] [SOUR]:LIST:COUN STAT:QUES[:EVEN]

MEAS | FETC[:SCAL]:POW:MAX [SOUR]:LIST:CURR STAT:QUES:COND

MEAS | FETC[:SCAL]:POW:MIN [SOUR]:LIST:DWEL STAT:QUES:ENAB

MEAS | FETC[:SCAL]:VOLT[:DC] [SOUR]:LIST:RES SYST:ERR

[SOUR]:LIST:VOLT SYST:VER

Non-SCPI Commands CAL:IMON:LEV [SOUR]:LIST:CURR:TLEV [SOUR]:TRAN[:STAT] CAL:IPR:LEV [SOUR]:LIST:FUNC | MODE [SOUR]:TRAN:DCYC CAL:LEV [SOUR]:LIST:RES:RANG [SOUR]:TRAN:FREQ CAL:PASS [SOUR]:LIST:RES:SLEW[:BOTH] [SOUR]:TRAN:MODE CAL:SAVE [SOUR]:LIST:RES:SLEW:NEG [SOUR]:TRAN:LMOD CHAN | INST[:LOAD] [SOUR]:LIST:RES:SLEW:POS [SOUR]:TRAN:TWID INP | OUTP:SHOR[:STAT] [SOUR]:LIST:RES:TLEV [SOUR]:VOLT:SLEW:NEG MEAS | FETC[:SCAL]:CURR:ACDC [SOUR]:LIST:STEP [SOUR]:VOLT:SLEW:POS MEAS | FETC[:SCAL]:VOLT:ACDC [SOUR]:LIST:TRAN[:STAT] [SOUR]:VOLT:TLEV PORT0[:STAT] [SOUR]:LIST:TRAN:DCYC STAT:CHAN[:EVEN] PORT1[:LEV] [SOUR]:LIST:TRAN:FREQ STAT:CHAN:COND [SOUR]:CURR:PROT:DEL [SOUR]:LIST:TRAN:MODE STAT:CHAN:ENAB [SOUR]:CURR:SLEW:NEG [SOUR]:LIST:TRAN:TWID STAT:CSUM[:EVEN] [SOUR]:CURR:SLEW:POS [SOUR]:LIST:VOLT:RANG STAT:CSUM:ENAB [SOUR]:CURR:TLEV [SOUR]:LIST:VOLT:SLEW[:BOTH] SYST:LOC [SOUR]:FUNC | MODE [SOUR]:LIST:VOLT:SLEW:NEG SYST:REM [SOUR]:FUNC | MODE:MODE [SOUR]:LIST:VOLT:SLEW:POS SYST:RWL [SOUR]:LIST:CURR:RANG [SOUR]:LIST:VOLT:TLEV TRIG[:IMM] [SOUR]:LIST:CURR:SLEW[:BOTH] [SOUR]:RES:SLEW:NEG TRIG:DEL [SOUR]:LIST:CURR:SLEW:NEG [SOUR]:RES:SLEW:POS TRIG:SOUR [SOUR]:LIST:CURR:SLEW:POS [SOUR]:RES:TLEV TRIG:TIM TRIG:SEQ2:COUN

21

Page 21

3

Programming Examples

Introduction

This chapter contains examples on how to program your electronic load. Simple examples show you how

to program:

K Input functions such as voltage, current, and resistance

K Transient functions, including lists

K Measurement functions

K The status and protection functions

NOTE: These examples in this chapter show which commands are used to perform a particular

function, but do not show the commands being used in any particular programming

environment.

Programming the Input

Power-on Initialization When the electronic load is first turned on, it wakes up with the input state set OFF. The following

commands are given implicitly at power-on:

*RST

*CLS

*SRE 0

*ESE 0

*RST is a convenient way to program all parameters to a known state. Refer to the *RST command in

chapter 4 to see how each programmable parameter is set by *RST. Refer to the *PSC command in

chapter 4 for more information on the power-on initialization of the *ESE and the *SRE registers.

Enabling the Input

To enable the input, use the command:

INPut ON

Input Voltage

The input voltage is controlled with the VOLTage command. For example, to set the input voltage to 25

volts, use:

VOLTage 25

23

Page 22

3 - Programming Examples

Maximum Voltage

The maximum input voltage that can be programmed can be queried with:

VOLTage? MAXimum

Input Current

All models have a programmable current function. The command to program the current is:

CURRent <n>

where <n> is the input current in amperes.

Maximum Current

The maximum input current that can be programmed can be queried with:

CURRent? MAXimum

Overcurrent Protection

The electronic load can also be programmed to turn off its input if the current protection level is reached.

As explained in chapter 4, this protection feature is implemented the following command:

CURRent:PROTection:STATe ON | OFF

NOTE: Use CURRent:PROTection:DELay to prevent momentary current limit conditions caused

by programmed input changes from tripping the overcurrent protection.

Setting the Triggered Voltage or Current Levels To program voltage or current triggered levels, you must specify the voltage or current level that the input

will go to once a trigger signal is received. Use the following commands to set a triggered level:

VOLTage:TRIGgered <n> or

CURRent:TRIGgered <n>

NOTE: Until they are explicitly programmed, triggered levels will assume their corresponding

immediate levels. For example, if a electronic load is powered up and VOLTage:LEVel is

programmed to 6, then VOLTage:LEVel:TRIGger will also be 6 until you program it to

another value. Once you program VOLTage:LEVel:TRIGger to a value, it will remain at

that regardless of how you subsequently reprogram VOLTage:LEVel. Then, when the

trigger occurs, the VOLTage:LEVel is set to the VOLTage:LEVel:TRIGger value.

Generating Triggers

You can generate a single trigger by sending the following command over the GPIB:

TRIGger:IMMediate

Note that this command will always generate a trigger. Use the TRIGger:SOURce command to select

other trigger sources such as the mainframe's external trigger input.

24

Page 23

Programming Examples - 3

Programming Transients

Transient operation is used to synchronize input changes with internal or external trigger signals, and

simulate loading conditions with precise control of timing, duration, and slew. The following transient

modes can be generated:

Continuous

Pulse

Toggled

NOTE: Before turning on transient operation, set the desired mode of operation as well as all of

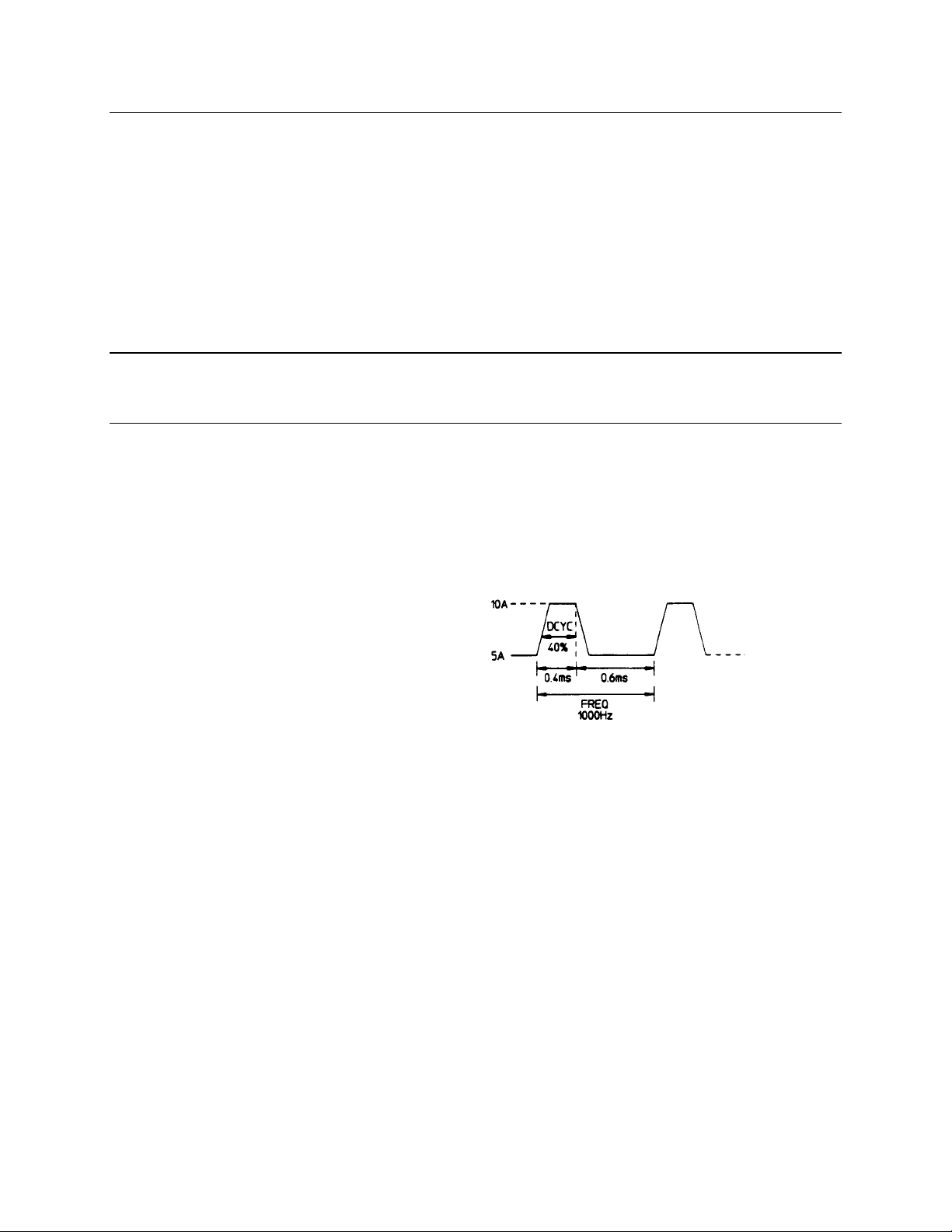

Continuous Transients In continuous operation, a repetitive pulse train switches between two load levels, a main level (which can

be either the immediate or triggered level) and a transient level. The rate at which the level changes is

determined by the slew rate (see slew rate descriptions for CV, CR, or CV mode as applicable). In

addition, the frequency and duty cycle of the continuous pulse train are programmable. Use the following

commands to program continuous transients:

TRANsient:MODE CONTinuous

CURRent 5

CURRent:TLEVel 10

TRANsient:FREQuency 1000

TRANsient:DCYCle 40

TRANsient ON

Generates a repetitive pulse stream that toggles between two load levels.

Generates an load change that returns to its original state after some time period.

Generates a repetitive pulse stream that toggles between two load levels. Similar to

Continuous mode except that the transient points are controlled by explicit triggers

instead of an internal transient generator.

the parameters associated with transient operation. At *RST all transient functions are set

to OFF.

This example assumes that the CC mode is active and the slew rate is at the default setting (maximum

rate). The load module starts conduction at the main level (in this case 5 amps). When transient

operation is turned on (no trigger is required in continuous mode), the module input current will slew to

and remain at 10 amps for 40% of the period (400 µs). The input current will then slew to and remain at 5

amps for the remaining 60% (600 µs) of that cycle.

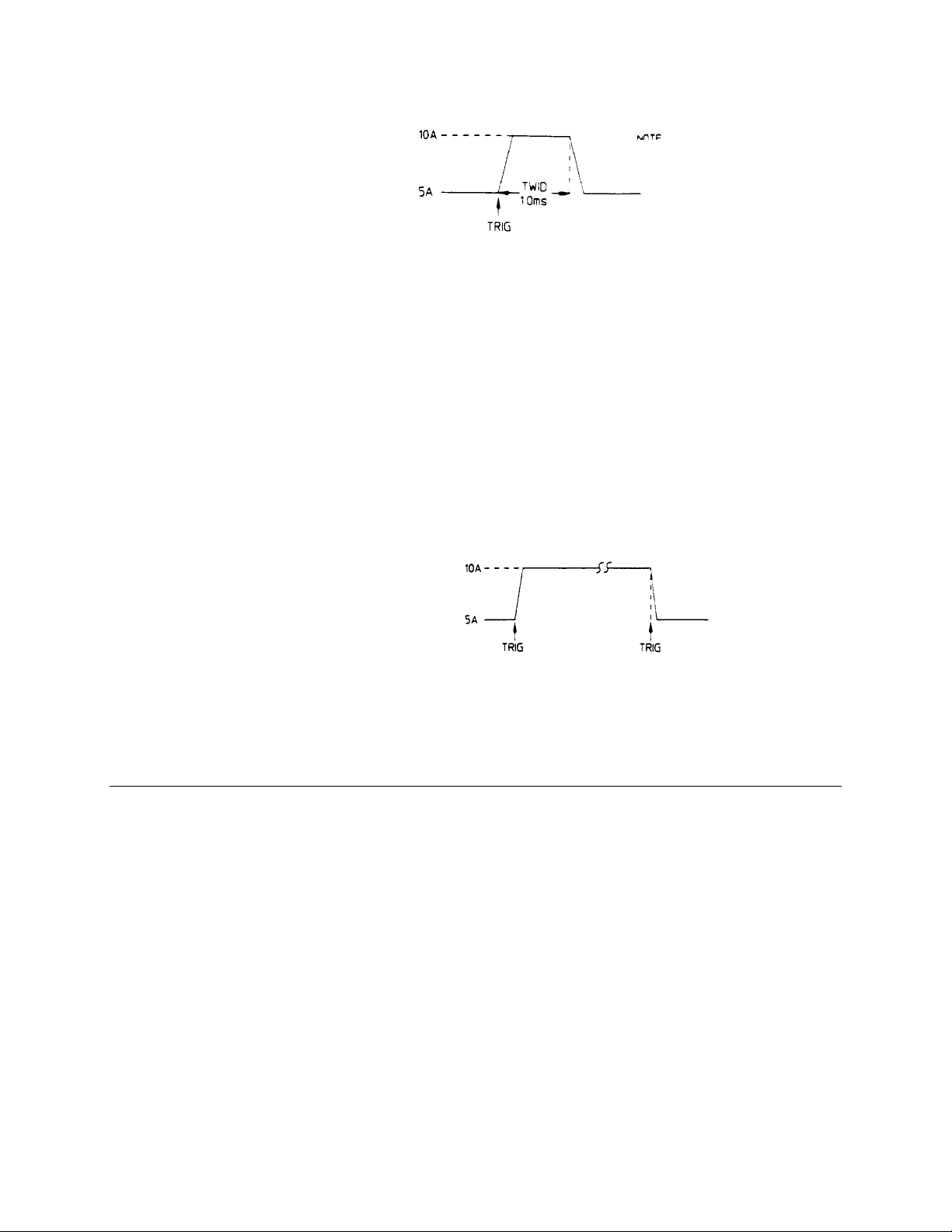

Pulse Transients

Pulsed transient operation generates a load change that returns to its original state after some time

period. It is similar to continuous operation with the following exceptions:

a. To get a pulse, an explicit trigger is required. To specify the trigger source, use

TRIGger:SOURce. See "Triggering Transients".

b. One pulse results from each trigger. Therefore, frequency cannot be programmed.

Use the following commands to program pulsed transients:

25

Page 24

3 - Programming Examples

TRIGger:SOURce EXTernal

TRANsient:MODE PULSe

CURRent 5

CURRent:TLEVel 10

TRANsient:TWIDth .01

TRANsient ON

This example assumes that the CC mode is active, the slew rate is at the factory default setting

(maximum rate), and a trigger signal is connected to the mainframe's external trigger input. The load

module starts conduction at the main current level setting (5 amps). When the transient mode is turned

on and an external trigger signal is received, the input level starts increasing at a rate determined by the

slew rate. When the value specified by the transient level setting (10 amps) is reached, it stays there for

the remainder of the time determined by the pulse width setting (10 milliseconds). After this time has

elapsed, the input level decreases to the main level again at the rate specified by the slew setting and

remains there until another trigger is received. Any triggers that occur during the time the transient level is

in effect will re-trigger the pulse, extending the pulse by another pulse-width value.

Toggled Transients

Toggled transient operation causes the module input to alternate between two pre-defined levels as in

continuous operation except that the transient transitions are controlled by explicit triggers instead of the

internal transient generator. See "Triggering Transients". Use the following commands to program toggled

transients:

TRIGger:SOURce EXTernal

TRANsient:MODE TOGGle

CURRent 5

CURRent:TLEVel 10

TRANsient ON

This example assumes that the CC mode is active, the slew rate is at the factory default setting

(maximum rate), and a trigger signal is connected to the mainframe's external trigger input. Toggled

transient operation is similar to that described for continuous and pulse operation, except that each time a

trigger is received the input alternates between the main and transient input current levels.

Programming Lists

List mode lets you generate complex sequences of input changes with rapid, precise timing, which may be

synchronized with internal or external signals. This is useful when running test sequences with a minimum

amount of programming overhead.

You can program up to 50 settings (or steps) in the list, the time interval (dwell) that each setting is

maintained, the number of times that the list will be executed, and how the settings change in response to

triggers. All list data is can be stored in nonvolatile memory when saved in locations 0, 7, 8, or 9 using the

*SAV command. This means that the programmed data for any list will be retained when the electronic

load is turned off. Use the *RCL command to recall the saved state. *RST clears the presently active list

but will not clear the lists saved in locations 0, 7, 8, or 9.

List steps can be either individually triggered, or paced by a separate list of dwell times that define the

duration of each step. Therefore, each of the up to 50 steps has an associated dwell time, which specifies

the time (in seconds) that the input remains at that step before moving on to the next step. The following

procedure shows how to generate a simple 9-step list of current and voltage changes.

26

Page 25

Programming Examples - 3

Step 1

Step 2

Set the mode of each function that will participate in the sequence to LIST. For example:

CURRent:MODE LIST

Program the list of input values for each function. The list commands take a comma-separated

list of arguments. The order in which the arguments are given determines the sequence in

which the values will be input. For example, to vary the input current of the electronic load to

simulate a 25%, 50%, and 100% load, a list may include the following values:

LIST:CURRent[:LEVel] 15, 30, 60, 15, 30, 60, 15, 30, 60

You must specify a list for all current functions, whether or not the functions will be used. For

example, to synchronize the previous current list with another list that varies the slew rate from

0.01A/µs, to 0.1A/µs, to 1A/µs (programmed in A/s), the lists may include the following values:

LIST:CURRent[:LEVel] 15, 30, 60, 15, 30, 60, 15, 30, 60

LIST:CURRent:SLEW 1E+5, 1E+5, 1E+5, 1E+6, 1E+6, 1E+6, 1E+7, 1E+7, 1E+7

LIST:CURRent:RANGe 60

LIST:CURRent:TLEVel 0

All lists must have the same number of data values or points, or an error will occur when the list

system that starts the sequence is initiated. The exception is when a list has only one item or

point. In this case the single-item list is treated as if it had the same number of points as the

other lists, with all values being equal to the one item. For example:

LIST:CURRent 15, 30, 45, 60;SLEW 1E+6

is the same as:

LIST:CURRent 15, 30, 45, 60

LIST:CURRent:SLEW 1E+6, 1E+6, 1E+6, 1E+6

Step 3

Step 4

Step 5

Determine the time interval that the input remains at each level or point in the list before it

advances to the next point. The time is specified in seconds. For example, to specify five dwell

intervals, use:

LIST:DWELl 1, 1.5, 2, 2.5, 3

The number of dwell points must equal the number of input points. If a dwell list has only one

value, that value will be applied to all points in the input list.

Determine the number of times the list is repeated before it completes. For example, to repeat a

list 10 times use:

LIST:COUNt 10

Entering INFinity makes the list repeat indefinitely. At *RST, the count is set to 1.

Determines how the list sequencing responds to triggers. For a closely controlled sequence of

input levels, you can use a dwell-paced list. To cause the list to be paced by dwell time use:

LIST:STEP AUTO

As each dwell time elapses, the next point is immediately input. This is the *RST setting.

If you need the input to closely follow asynchronous events, then a trigger-paced list is more

appropriate. In a trigger-paced list, the list advances one point for each trigger received. To

enable trigger-paced lists use:

LIST:STEP ONCE

The dwell time of each point determines the minimum time that the input remains at that point.

If a trigger is received before the previous dwell time completes, the trigger is ignored.

Therefore, to ensure that no triggers are lost, program the dwell time to "MIN".

Step 6

Use the list trigger system to trigger the list. See "Triggering Transients and Lists".

27

Page 26

3 - Programming Examples

Programming Lists for Multiple Channels

You can program separate lists for individual channels on a load mainframe. Once lists have been

programmed for each channel, they can all be triggered at the same time using the list trigger system.

NOTE: All lists must have the same number of data values or points, or an error will occur when

the list system that starts the sequence is initiated.

Step 1

Step 2

Step 3

Step 4

Select the channel for which you want to program the list. All subsequent list commands will be

sent to this channel until another channel is selected.

CHANnel 1

Program the list of values for each function for that channel. The list commands take a comma-

separated list of arguments. For example:

LIST:CURRent 15, 30, 60, 15, 30, 60, 15, 30, 60

LIST:CURRent:SLEW 1E+5, 1E+5, 1E+5, 1E+6, 1E+6, 1E+6, 1E+7, 1E+7, 1E+7

.

.

.

Add other list functions.

Select the next channel for which you want to program a list. All subsequent list commands will

now be sent to this channel.

CHANnel 2

Program the list of values for each function for that channel. You can program different

functions for each channel, however all functions must have the same number of steps

LIST:VOLTage 30, 60, 30, 30, 60, 30, 30, 60, 30

LIST:VOLTage:SLEW 1E+5, 1E+5, 1E+5, 1E+6, 1E+6, 1E+6, 1E+7, 1E+7, 1E+7

.

.

.

Add other list functions. You do not have to program the same number of functions for each

channel.

Step 5

Step 6

28

Repeat steps 3 and 4 for any other channel that you wish to program.

Use the list trigger system to trigger the list. This is described under "Triggering Transients and

Lists".

Page 27

Programming Examples - 3

Triggering Transients and Lists

Continuous, pulse, and toggled transient modes respond to triggers as soon as the trigger is received.

This is not the case for lists. Lists have an independent trigger system that is similar to the measurement

trigger system. This section describes the list trigger system. The measurement trigger system is

described under "Triggering Measurements".

SCPI Triggering Nomenclature

In SCPI terms, trigger systems are called sequences. When more than one trigger system exists, they are

differentiated by naming them SEQuence1 and SEQuence2. SEQuence1 is the list trigger system and

SEQuence2 is the measurement trigger system. The electronic load uses aliases with more descriptive

names for these sequences. These aliases can be used instead of the sequence forms.

Sequence Form Alias

SEQuence1 LIST

SEQuence2 ACQuire

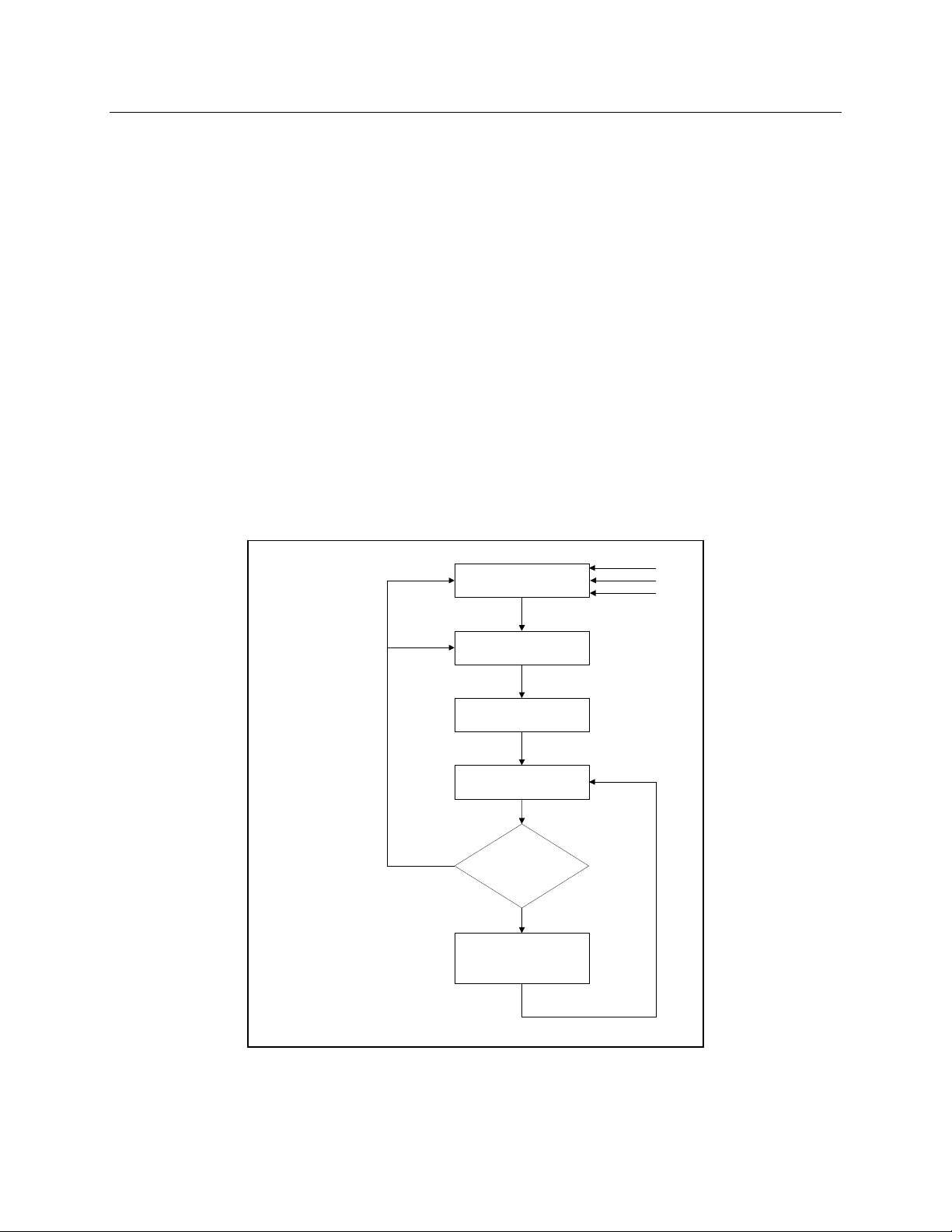

List Trigger Model

Figure 3-3 is a model of the list trigger system. The rectangles represent states. The arrows show the

transitions between states. These are labeled with the input or event that causes the transition to occur.

INITiate:CONTinuous OFF

INITiate:CONTinuous ON

or

List not complete and

LIST:STEP ONCE

INITIATED STATE

DELAYING STATE

LIST STEP CHANGE

NO

WAIT FOR DWELL

TO COMPLETE

IDLE STATE

LIST:STEP

AUTO?

YES

ABORt

*RST

*RCL

INITiate[:IMMediate]

TRIGGER RECEIVED

DELAY COMPLETED

Figure 3-3. Model of List Triggers

29

Page 28

3 - Programming Examples

Initiating List Triggers

When the electronic load is turned on, the list trigger system is in the idle state. In this state, the list

system ignores all triggers. Sending the following commands at any time returns the list system to the Idle

state:

ABORt

*RST

*RCL

The INITiate commands move the list system from the Idle state to the Initiated state. This enables the

list system to receive triggers. INITiate commands are not channel-specific, they affect all installed load

modules. To initiate the list system for a single triggered action, use:

INITiate:SEQuence1 or

INITiate:NAME LIST

NOTE: Whenever a list is initiated or triggered, the φ1 annunciator is lit on the front panel.

After a trigger is received and the action completes, the list system will return to the Idle state. Thus it will

be necessary to initiate the list system each time a triggered action is desired.

To keep the list system initiated for multiple actions without having to send an Initiate command for each

trigger, use:

INITiate:CONTinuous:SEQuence1 ON or

INITiate:CONTinuous:NAME LIST, ON

Specifying a Trigger Delay

A time delay can be programmed betweent he receipt of the trigger system and the start of the triggered

action. This delay applies to both list and measurement triggers. At *RST the trigger delay is set to 0,

which mens there is no trigger delay. To program a trigger delay use:

TRIGger:DELay <n>

Generating Transient and List Triggers

Use one of the following triggering methods to generate transients and lists:

TRIGger:SOURce BUS | EXTernal | HOLD | LINE | TIMer

After you have specified the appropriate trigger source, you can generate triggers as follows:

Single triggers over

the bus

Continuous triggers

synchronized with the

ac line frequency

Continuous triggers

synchronized with the

internal timer

Send one of the following commands over the GPIB:

TRIGger:IMMediate

*TRG

a group execute trigger

Send the following command over the GPIB:

TRIGger:SOURce LINE

Send the following commands over the GPIB:

TRIGger:TIMer <time>

TRIGger:SOURce TIMer

External trigger

30

Apply a low to high signal to the external trigger input at the back of the

mainframe.

Page 29

Programming Examples - 3

Making Measurements

The electronic load has the ability to make several types of voltage or current measurements. The

measurement capabilities of the electronic load are particularly useful with applications that draw current

in pulses.

All measurements are performed by digitizing the instantaneous input voltage or current for a defined

number of samples and sample interval, storing the results in a buffer, and then calculating the measured

result. Many parameters of the measurement are programmable. These include the number of samples,

the time interval between samples, and the method of triggering. Note that there is a tradeoff between

these parameters and the speed, accuracy, and stability of the measurement in the presence of noise.

There are two ways to make measurements:

♦ Use the MEASure commands to immediately start acquiring new voltage or current data, and

return measurement calculations from this data as soon as the buffer is full. This is the easiest

way to make measurements, since it requires no explicit trigger programming.

♦ Use an acquisition trigger to acquire the data. Then use the FETCh commands to return

calculations from the data that was retrieved by the acquisition trigger. This method gives you the

flexibility to synchronize the data acquisition with a trigger. FETCh commands do not trigger the

acquisition of new measurement data, but they can be used to return many different calculations

from the data that was retrieved by the acquisition trigger.

Making triggered measurements with the acquisition trigger system is discussed under "Triggering

Measurements".

NOTE: For each MEASure form of the query, there is a corresponding query that begins with the

header FETCh. FETCh queries perform the same calculation as their MEASure

counterparts, but do not cause new data to be acquired. Data acquired by an explicit

trigger or a previously programmed MEASure command are used.

Voltage and Current Measurements

The SCPI language provides a number of MEASure and FETCh queries, which return various

measurement parameters of voltage and current waveforms.

DC Measurements

To measure the dc input voltage or current, use:

MEASure:VOLTage? or

MEASure:CURRent?

DC voltage and current is measured by acquiring a number of readings at the selected time interval,

optionally applying a Hanning window function to the readings, and averaging the readings. Windowing is

a signal conditioning process that reduces the error in dc measurements made in the presence of periodic

signals such as line ripple. At power-on and after a *RST command, the following parameters are set:

SENSe:SWEep:TINTerval 10E-6

SENSe:SWEep:POINts 1000

This results in a data acquisition time of 10 milliseconds. Adding a command processing overhead of

about 20 milliseconds results in a total measurement time of about 30 milliseconds per measurement

sample.

31

Page 30

3 - Programming Examples

Ripple rejection is a function of the number of cycles of the ripple frequency contained in the acquisition

window. More cycles in the acquisition window results in better ripple rejection. If you increase the time

interval for each measurement to 45 microseconds for example, this results in 5.53 cycles in the

acquisition window at 60 Hz, for a ripple rejection of about 70 dB.

Note that the processing overhead time will vary, depending on the number of measurement samples. If

you reduce the number of sample points, you will also reduce the command processing overhead. If you

increase the number of sample point (up to a maximum of 4096) you increase the command processing

overhead.

RMS Measurements

To read the rms content of a voltage or current waveform, use:

MEASure:VOLTage:ACDC? or

MEASure:CURRent:ACDC?

This returns the total rms measurement, including the dc portion.

Minimum and Maximum Measurements

To measure the maximum or minimum voltage or current of a pulse or ac waveform, use:

MEASure:VOLTage:MAXimum?

MEASure:VOLTage:MINimum?

MEASure:CURRent:MAXimum?

MEASure:CURRent:MINimum?

Measurement Ranges

The electronic load has two current and two voltage measurement ranges. The commands that control the

measurement ranges are:

SENSe:CURRent:RANGe MIN | MAX

SENSe:VOLTage:RANGe MIN | MAX

When the range is set to MAX, the maximum current or voltage that can be measured is a function of the

current and voltage rating of the load module that is being programmed (see Table 4-1).

Returning Measurement Data From the Data Buffer

The MEASure and FETCh queries can also return all data values of the instantaneous voltage or current

buffer. The commands are:

FETCh:ARRay:CURRent?

FETCh:ARRay:VOLTage?

This is a useful feature if, for example, you have entered multiple measurements into the buffer as a result

of measuring the response to a triggered list. Data is returned from the buffer in the same order in which it

was entered into the buffer. Refer to "Synchronizing Transients and Measurements" for more information.

32

Page 31

Programming Examples - 3

Triggering Measurements

You can use the data acquisition trigger system to synchronize the timing of the voltage and current data

acquisition with a trigger source. Then use the FETCh commands to return different calculations from the

data acquired by the measurement trigger.

SCPI Triggering Nomenclature

In SCPI terms, trigger systems are called sequences. When more than one trigger system exists, they are

differentiated by naming them SEQuence1 and SEQuence2. SEQuence1 is the list trigger system and

SEQuence2 is the measurement trigger system. The electronic load uses aliases with more descriptive

names for these sequences. These aliases can be used instead of the sequence forms.

Sequence Form Alias

SEQuence2 ACQuire

Measurement Trigger Model

Figure 3-1 is a model of the measurement trigger system. The rectangular boxes represent states. The

arrows show the transitions between states. These are labeled with the input or event that causes the

transition to occur.

IDLE STATE

INITIATED STATE

DELAYING STATE

SENSe:SWEep:POINts

ACQUIRED

NO

TRIGger:COUNt

COMPLETE?

YES

ABORt

*RST

*RCL

INITiate[:IMMediate]

TRIGGER RECEIVED

DELAY COMPLETED

Figure 3-1. Model of Measurement Triggers

33

Page 32

3 - Programming Examples

Initiating the Measurement Trigger System

When the electronic load is turned on, the trigger system is in the idle state. In this state, the trigger

system ignores all triggers. Sending the following commands at any time returns the trigger system to the

Idle state:

ABORt

*RST

*RCL

The INITiate commands move the trigger system from the Idle state to the Initiated state. This enables the

electronic load to receive triggers. INITiate commands are not channel-specific, they affect all installed

load modules. To initiate a measurement trigger, use:

INITiate:SEQuence2 or

INITiate:NAME ACQuire

After a trigger is received and the data acquisition completes, the trigger system will return to the Idle state

unless multiple measurements are programmed using the TRIGger:SEQuence2:COUNt command. Thus

it will be necessary to initiate the system each time a triggered acquisition is desired.

NOTE: You cannot initiate measurement triggers continuously. Otherwise, the measurement data

in the data buffer would continuously be overwritten.

Generating Measurement Triggers

Use one of the following triggering methods to generate measurements:

TRIGger:SOURce BUS | EXTernal | HOLD | LINE | TIMer

After you have specified the appropriate source, you can generate measurement triggers as follows:

Single triggers over

the bus

Continuous triggers

synchronized with the

ac line frequency

Continuous triggers

synchronized with the

internal timer

External trigger

When the acquisition finishes, any of the FETCh queries can be used to return the results. Once the

measurement trigger is initiated, if a FETCh query is sent before the data acquisition is triggered or before

it is finished, the response data will be delayed until the trigger occurs and the acquisition completes. This

may tie up the controller if the trigger condition does not occur immediately.

Send one of the following commands over the GPIB:

TRIGger:IMMediate (this overrides TRIG:SOUR HOLD)

*TRG

a group execute trigger

Send the following command over the GPIB:

TRIGger:SOURce LINE

Send the following commands over the GPIB:

TRIGger:TIMer <time>

TRIGger:SOURce TIMer

Apply a low to high signal to the external trigger input at the back of the

mainframe.

One way to wait for results without tying up the controller is to use the SCPI command completion

commands. For example, you can send the *OPC command after INITialize, then occasionally poll the

OPC status bit in the standard event status register for status completion while doing other tasks. You can

also set up an SRQ condition on the OPC status bit going true, and do other tasks until an SRQ interrupt

occurs.

34

Page 33

Programming Examples - 3

Controlling Measurement Samples

Varying the Sampling Rate

You can vary both the number of data points in a measurement sample, as well as the time between

samples. You can also specify a delay from the trigger to the start of the measurement. This is illustrated

in the following figure.

SENS:SWE:POIN <value>

SENS:SWE:TINT <value>

SENS:SWE:OFFS <value>

Trigger1 Trigger2 Trigger4Trigger3

TRIG:SEQ2:COUN <value>

Figure 3-2. Sense Commands Used to Vary the Sampling Rate

At power-on, the input voltage and current sampling rate is 10 microseconds. This means that, not

accounting for the command processing overhead, it takes about 41 milliseconds to fill up 4096 data

points in the data buffer. You can vary this data sampling rate with:

SENSe:SWEep:TINTerval <sample_period>

SENSe:SWEep:POINts <points>

For example, to set the time interval to 50 microseconds per sample with 500 samples, use:

SENSe:SWEep:TINTerval 50E-6;POINts 500.

Measurement Delay

You can delay the start of a measurement in relation to the trigger. This is useful if you do not want to start

taking measurements at the beginning of an input transient or list step during the time that the input

voltage or current is still slewing or settling into its programmed value. To offset the measurement from

the beginning of the input transient or list step, use:

SENSe:SWEep:OFFSet 10E-3

In this example, the measurement occurs 10 milliseconds after the start of the trigger. The offset can be

set to a negative value, but this number cannot exceed the TRIGger:DELay value.

Multiple Measurements

The electronic load also has the ability to set up several acquisition triggers in succession and

concatenate the results from each acquisition in the measurement buffer. This is useful for making

measurements from lists. To set up the trigger system for a number of sequential acquisitions use:

TRIGger:SEQuence2:COUNt <number>

35

Page 34

3 - Programming Examples

With this setup, the instrument performs each acquisition sequentially, storing the digitized readings in the

internal measurement buffer. A trigger signal is required to make each measurement. It is only necessary

to initialize the measurement once at the start; after each completed acquisition the instrument will wait for

the next valid trigger condition to start another. The results returned by MEASure or FETCh will be the

average of the total data acquired.

If you do not want the instrument to average the acquisition data, use the FETCh:ARRay commands to

return the raw data from the voltage or current measurement buffer.

NOTE: The total number of data points cannot exceed 4096. This means that the trigger count

multiplied by the number of points cannot exceed 4096; otherwise an error will occur.

Synchronizing Transients and Measurements

The transient and measurement systems are independent of each other. However, it possible to

synchronize the two systems through the use of triggers. This is because when both transient and

measurement systems have been initialized, the same trigger signal will affect both systems. For

example, you may have an application where you need to measure the effects of a list step.

Measuring Triggered Transients or Lists

Measuring triggered transients or lists is generally a straightforward process because you are using the

same trigger to generate the output transient and simultaneously take the measurement. The following

example illustrates how to make measurements from a simple 3-step trigger paced list. Each list step has

a duration of two seconds. Each step-measurement consists of three data points with an offset of 100

milliseconds.

Step 1

Step 2

Step 3

Step 4

Set the mode of each function that will participate in the sequence to LIST. For example:

CURRent:MODE LIST

Program the list of input values for each function.

LIST:CURRent 15, 30, 60

LIST:CURRent:SLEW 1E+6, 1E+6, 1E+6

LIST:CURRent:RANGe 60

LIST:CURRent:TLEVel 0

Specify the number of triggered measurements that will be taken.

TRIGger:SEQuence2:COUNt 3

The number of measurements should match the number of steps in the list.

Specify the time interval and the number of points in each triggered measurement.

SENSe:SWEep:TINTerval 100E-3

SENSe:SWEep:POINts 3

In this example, three measurements or data points are taken at each list step, separated by

100ms intervals. Make sure that all of the measurement samples complete within the step time

interval. If another trigger occurs while a measurement is in progress, the measurement

system will ignore the trigger. Also note that the number of data points specified in this step

multiplied by the measurement count specified in step 3 cannot exceed 4096.

Step 5

36

Specify a delay time from the start of the trigger until the measurement is taken.

SENSe:SWEep:OFFset 100E-6

This specifies the offset in seconds, in this case, 100 microseconds

Page 35

Programming Examples - 3

Step 6

Step 7

Step 8

NOTE: Each load module retains its measurement data. If multiple lists have been executed, you

Initiate both the transient (list) and the measurement trigger systems.

INITiate:SEQuence1

INITiate:SEQuence2

Specify the trigger source and the timing that will control the list steps and the measurements.

TRIGger:TIMer 2

TRIGger:SOURce TIMer

In this example the trigger source is the internal trigger. Because the internal timer starts

running as soon as the TRIGger:SOURce:TIMer command is executed, the trigger that starts

the list and measurement will not occur until the end of the two-second timer window within

which the trigger is received. After the initial trigger occurs, the list will remain at each step for

two seconds before the next trigger occurs.

Return the current measurements from the data array. In this case, a total of nine

measurements were taken, three at each list step. To return the measurement data you must

first dimension an array, then fetch the data.

Dimension an array here

FETch:CURRent:ARRay ARRAY1

must select each channel in turn, and fetch the measurement data from that channel.

Measuring Dwell-Paced Lists

The main difference between a trigger-paced list and a dwell-paced list is that no triggers occur between

steps in a dwell-paced list. Only one measurement will be taken during the time the list is executed.

Therefore, to capture measurement data for the entire time the list is executed, the total measurement

time of a dwell paced list (time interval X number of points) must equal the total dwell time of the list.

Step 1

Step 2

Step 3

Step 4

Step 5

Program the list as previously described under "Measuring Triggered Transients or Lists."

Specify a dwell time for each list step. For example:

LIST:DWELl 1, 1.5, 2, 2.5, 3

Add up the total number of dwell times to determine the time of the entire list. For the previous

example, the total dwell time adds up to 10 seconds. This is the time it takes to execute the

list.

Specify the time interval and the number of points for the measurement.

SENSe:SWEep:TINTerval 100E-3

SENSe:SWEep:POINts 100

In this example, the measurement interval is set to take 100 measurement points at 100ms

intervals. The total time of the measurement therefore equals the total dwell time of the list.

Return the measurements from the data array.

Dimension an array here

FETch:CURRent:ARRay ARRAY1

When you read back the measurement from the array, you must determine at what point

during the list that the measurement occurred. One way to do this is to multiply the

measurement number by the measurement interval. For example, multiply measurement #5 by

100ms, and you get 500ms, which is the time that the measurement was made.

37

Page 36

3 - Programming Examples

Programming the Status Registers

You can use status register programming to determine the operating condition of the electronic load at any

time. For example, you may program the electronic load to generate an interrupt (assert SRQ) when an

event such as a current protection occurs. When the interrupt occurs, your program can then act on the

event in the appropriate fashion.

Table 3-1 defines the status bits. Figure 3-4 shows the status register structure of the electronic load. The

Standard Event, Status Byte, and Service Request Enable registers and the Output Queue perform

standard GPIB functions as defined in the IEEE 488.2 Standard Digital Interface for Programmable

Instrumentation. The Operation Status and Questionable Status registers implement functions that are

specific to the electronic load.

Table 3-1. Bit Configurations of Status Registers

Bit Signal Meaning

Operation Status Group

0

5

0

1

3

4

8

9

10

11

12

13

CAL

WTG

VF

OC

OP

OT

EPU

RRV

UNR

LRV

OV

PS

Calibrating. The electronic load is computing new calibration constants

Waiting. The electronic load is waiting for a trigger

Channel Status Group

Voltage Fault. Either an overvoltage or a reverse voltage has occurred. This bit reflects

the active state of the FLT pin on the back of the unit. The bit remains set until the

condition is removed and INP:PROT:CLE is programmed.

Overcurrent. An overcurrent condition has occurred. This occurs if the current exceeds

102% of the rated current or if it exceeds the user-programmed current protection level.

Removing the overcurrent condition clears the bit. If the condition persists beyond the

user programmable delay time, bit 13 is also set and the input is turned off. Both bits

remain set until the condition is removed and INP:PROT:CLE is programmed.

Overpower. An overpower condition has occurred. This occurs if the unit exceeds the

rated power of the input. Removing the overpower condition clears the bit. If the condition

persists for more than 3 seconds, bit 13 is also set and the input is turned off. Both bits

remain set until the condition is removed and INP:PROT:CLE is programmed.

Overtemperature. An overtemperature condition has occurred. Both this bit and bit 13 are

set and the input is turned off. Both bits remain set until the unit is cooled down and

INP:PROT:CLE is programmed.

Extended Power Unavailable. When EPU status is true, an overpower condition that

persists for more than 3 seconds will cause the input to be shut off and bit 13 to be set.

When EPU satus is false, an overpower condition will be reported in bit 3, but this will not

cause the input to be turned off. The state of the EPU bit is dependent on the internal

temperature of the load.

Remote Reverse Voltage. A reverse voltage condition has occurred on the sense

terminals. Both this bit and bit 0 are set. Removing the reverse voltage clears this bit but

does not clear bit 0. Bit 0 remains set until INP:PROT:CLE is programmed.

Unregulated. The input is unregulated. When the input is regulated the bit is cleared.

Local Reverse Voltage. A reverse voltage condition has occurred on the input terminals.