Agilent Technologies 8960 Series 10 E5515A,B Wireless Communications Test Set

Agilent Technologies E1960A GSM Mobile Test Application

Programming Guide

Test Application Revision A.04

© Copyright Agilent Technologies 1998, 1999

Printed in U.S.A. March 2000

Agilent Part Number: E1960-90002

Revision G

http://www.agilent.com/find/8960support/

Notice

Information contained in this document is subject to change with out notice.

All Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibited, except as allowed under the copyright laws.

This material may be reproduced by or for the U .S. Government pursuant to the Copyright

License under the clause at DFARS 52.227-7013 (APR 1988).

Agilent Technologies, Inc.

Learning Products Department

24001 E. Mission

Liberty Lake, WA 99019-9599

U.S.A.

Safety, Warranty, and Regional Sales and

Service Offices Information

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\programming_guide_front.fm

3

Safety, Warranty, and Regional Sales and Service Offices Information

Manufacturer’s Declaration

This statement is provided to comply with the requirements of the German Sound Emission Directive,

from 18 January 1991.

This product has a sound pressure emission (at the operator position) < 70 dB(A).

• Sound Pressure Lp < 70 dB(A).

• At Operator Position.

• Normal Operation.

• According to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigung

• Schalldruckpegel Lp < 70 dB(A).

• Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Am Arbeitsplatz.

• Normaler Betrieb.

• Nach ISO 7779:1988/EN 27779:1991 (Typprüfung).

4

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\programming_guide_front.fm

Safety, Warranty, and Regional Sales and Service Offices Information

Safety Considerations

GENERAL

This product and related documentation must be reviewed for familiarization with safety markings and

instructions before operation.

This product has been designed and tested in accordance with IEC Publication 1010, "Safety

Requirements for Electronic Measuring Apparatus," and has been supplied in a safe condition. This

instruction documentation contains information and warnings which must be followed by the user to

ensure safe operation and to maintain the prod uct in a safe condition.

SAFETY EARTH GROUND

A uninterruptible safety earth ground mu st be provided from the main power source to the product

input wiring terminals, power cord, or supplied power cord set.

SAFETY SYMBOLS

Indicates instrument damage can occur if indicated operating limits are exceede d.

!

Indicates hazardous voltages.

Indicates earth (ground) terminal

WARNING A W ARNING note denotes a hazard. It calls attention to a procedure, practice, or

the like, which, if not correctly performed or adhered to, could result in

personal injury. Do not proceed beyond a WARNING sign until the indicated

conditions are fully under s tood and met.

CAUTION A CAUTION note denotes a hazard. It calls attention to an operation procedure, practice,

or the like, which, if not correctly performed or adhered to, could result in damage to or

destruction of part or all of the prod uct. Do not proceed beyond an CAUTION note until

the indicated conditions are fully understood and met.

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\programming_guide_front.fm

5

Safety, Warranty, and Regional Sales and Service Offices Information

WARNING This product is a Safety Class I instrument (provided with a protective earthing

ground incorporated in the power co r d). The mains plug shall only be inserted

in a socket outlet provided with a protective ear th contact. Any interruption of

the protective conductor inside or outside of the product is likely to make the

product dangerous. Intentional interruption is prohibited.

Whenever it is likely that the protection has been impaired, the instrument

must be made inoperative and be secur ed agai nst any unintended operation.

If this instrument is to be energized via an autotransformer (for voltage

reduction), make sure the common terminal is connected to the earth termin al

of the power source.

If this product is not used as specified, the protection provided by the

equipment could be impaired. This prod uc t must be used in a normal cond ition

(in which all means for protection are intact) only.

No operator serviceable parts in this product. Refer servicing to qualified

personnel. To prevent electrical shock, do not remove covers.

Servicing instructions are fo r us e by qu alified personnel only. To avoid

electrical shock, do not perform any servicing unless you are qualified to do so.

The opening of covers or removal of parts is likely to expose dangerous

voltages. Disconnect the product from all voltage sources while it is being

opened.

The power cord is connected to internal capacitors that my remain live for

5 seconds after disconnecting the plug from its power supply.

For Continued protection against fire hazard, replace the line fuse(s) only with

250 V fuse(s) or the same current rating and type (for example, normal blow or

time delay). Do not use repaired fuses or short circui ted fuseholders.

Always use the three-prong ac power cord supplied with this product. Failure to

ensure adequate earth grounding by not using this cord may cause product

damage.

This product is designed for use in Installation Category II and Pollution

Degree 2 per IE C 1010 and IEC 664 respectively. FOR INDOOR USE ONLY.

This product has autoranging line voltage input, be sure the supply voltage is

within the specified range.

To prevent electrical shock, disconnect instrument from mains (line) before

cleaning. Use a dry cloth or one slightly dampened with water to clean the

external case parts. Do not attempt to clean internally.

Ventilation Requirements: W hen installing the product in a ca bin et, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operati ng

temperature of the product by 4° C for every 100 watts dissipated in the cabinet.

If the total power dissipated in the cabinet is greater than 800 watts, then forced

convection must be used.

6

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\programming_guide_front.fm

Safety, Warranty, and Regional Sales and Service Offices Information

Product Markings

CE - the CE mark is a registered trademark of the European Community. A CE mark accompanied by a

year indicated the year the design was proven.

CSA - the CSA mark is a registered trademark o f the Canadian Standards Association.

CERTIFICATION

Agilent Technologies, Inc. certifies that this product met its published specifications at the time of

shipment from the factory. Agilent Technologies further certifies that its calibration measurements are

traceable to the United States National Institute of Standards and Technology, to the extent allowed by

the Institute’s calibration facility, and to the calibration facilities of other International Standards

Organization members

WARRANTY

This Agilent Technologies instrument product is warranted against defects in material and

workmanship for a period of one year from date of shipment. During the warranty period, Agilent

Technologies, Inc. will at its option, either repair or replace products which prove to be defective.

For w arranty service or repair, this product must be returned to a service facility designated by Agilent.

Buyer shall prepay shipping charges to Agilen t and Agilent shall pay shipping charges, duties, and

taxes for products returned to Agilent from another country.

Agilent warrants that its software and firmware designated by Agilent for use with an instrument will

execute its programming instruct io ns when properly installed on that instrument. Agilent does not

warrant that the operation of the instrument, or software, or firmware will be uninterrupted or error

free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance

by Buyer, Buyer-supplied software or interfacing, unauthorized modification or misuse, operation

outside of the environmental specific ations for the product, or improper site preparation or

maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT SPECIFICALLY DISCLAIMS

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EX CLUSIVE REMEDIES.

AGILENT SHALL NOT BE L IABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASE ON CONTRACT, TORT, OR ANY OTHER LEGAL

THEORY.

ASSISTANCE

Product maintenance agreements and other customer assistance agreements are available for Agilent

Technologies products. For any assistance, contact your nearest Agilent Technologies Sales and Service

Office.

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\programming_guide_front.fm

7

Safety, Warranty, and Regional Sales and Service Offices Information

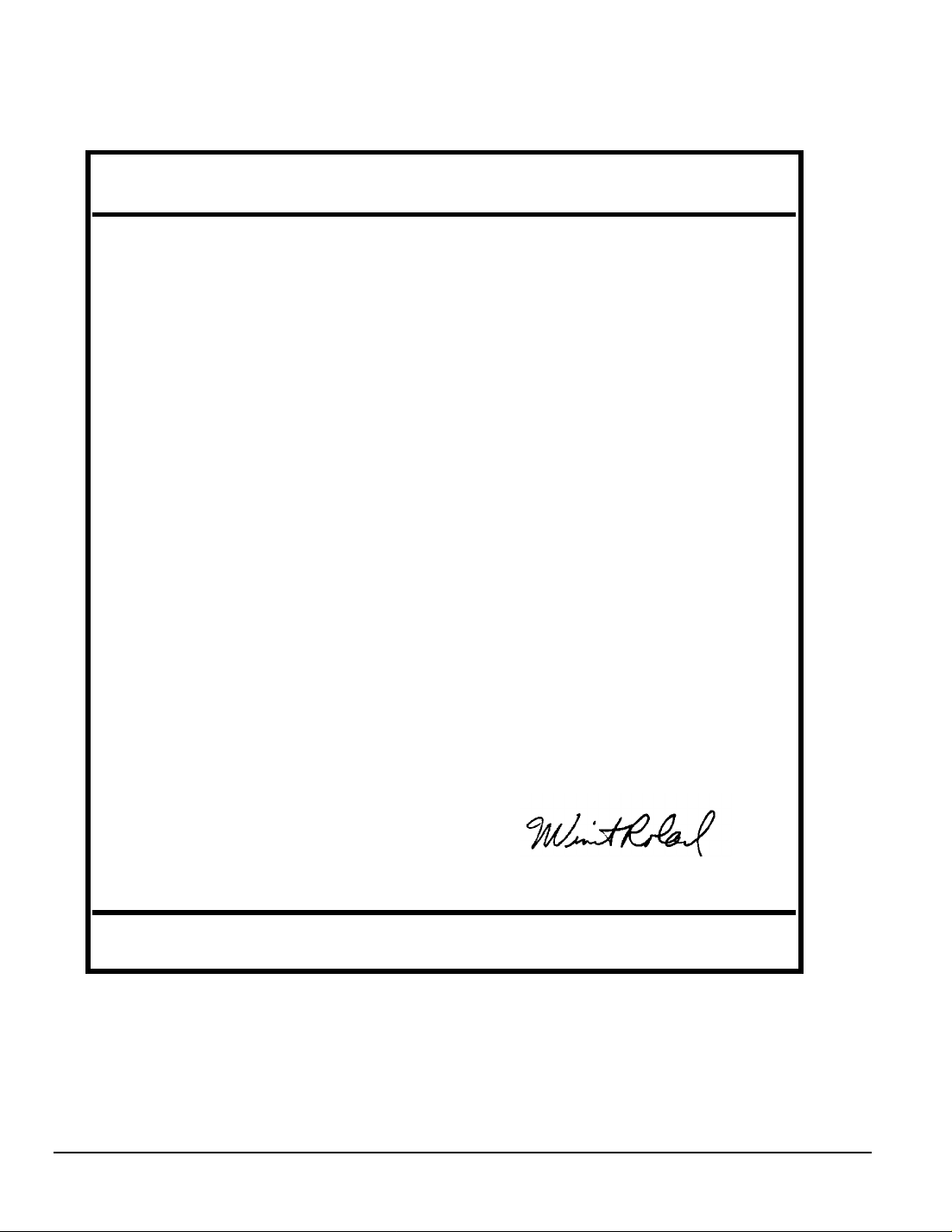

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: Agilent Technologies Inc.

Manufacturer’s Address: 24001 E. Mission Avenue

Liberty Lake, Washington 99019-9599

USA

declares that the product

Product Name: Agilent Technologies 8960 Series 10

Wireless Communications Test Set

Model Number: Agilent Technologies E5515A,B

Product Options: This declaration covers all options of

the above product.

conforms to the following Product specifications:

Safety: IEC 1010-1:1990+A1+A2 / EN 61010-1:1993

EMC: CISPR 11:1990/EN 55011:1991- Group 1, Class A

EN 50082-1 : 1992

IEC 801-2:1991 - 4kV CD,8kV AD

IEC 801-3:1984 3V/m

IEC 801-4:1988 0.5 kV Sig. Lines, 1 kV Power Lines

Supplementary Information:

This product herewith complies with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC

and carries the CE-marking accordingly.

Spokane, Washington USA November 20,1998

European Contact: Your local Agilent Technologies Sales and Service Office or Ag ilent Technologi es GmbH

Department ZQ/Standards Europe, Herrenberger Strass e 130, D-71034 Böblinger, Germany (FAX+49- 7031-14-3143)

Vince Rola nd

Reliability & Regulatory

Engineering Manager

8

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\programming_guide_front.fm

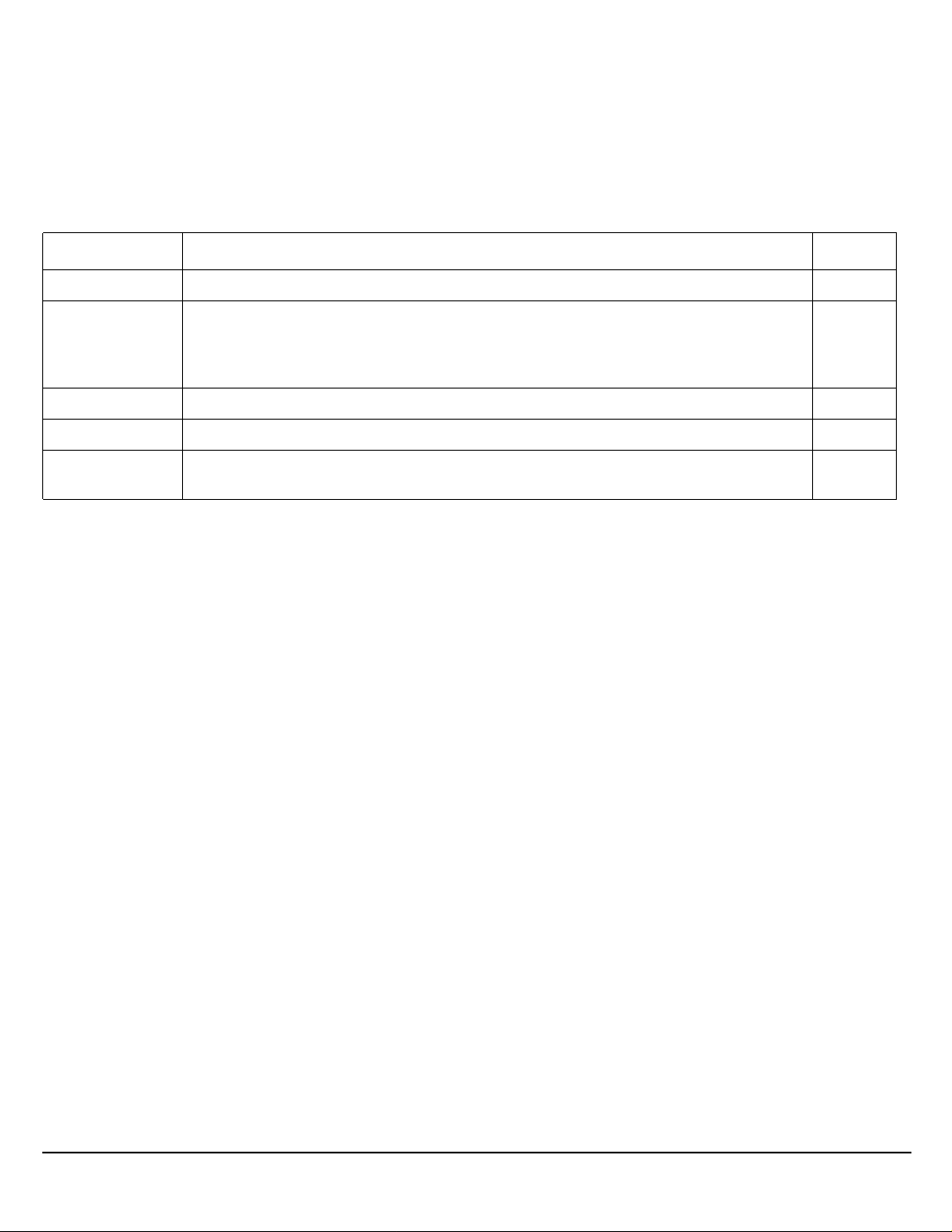

Table 1. Regional Sales and Service Offices

Safety, Warranty, and Regional Sales and Service Offices Information

United States of America:

Agilent Technologies

Test and Measurement Call Center

P.O. Box 4026

Englewood, CO 8015 5-4 026

(tel) 1 800 452 4844

Japan:

Agilent Technologies Japan Ltd.

Measurement Ass ista nce Cente r

9-1 Takakura-Cho, Hachioji-Shi,

Tokyo 192-8510, Japan

(tel) (81) 456-56-7832

(fax) (81) 426-56-7840

Asia Pacific:

Agilent Technologies

19/F, Cityplaza One,

111 Kings Road,

Taikoo shing, Hong Kong, SAR

Canada:

Agilent Technologies Canada Inc.

5159 Spectrum Way

Mississaua, Ontario

L4W 5G1

(tel) 1 877 894 4414

Latin America:

Agilent Technologie s

Latin America Region

Headquarters

5200 Blue Lagoon Drive,

Suite #950

Miami, Florida 33126

U.S. A.

(tel) (305) 267 4245

(fax) (305) 267 4286

Europe:

Agilent T e chn ologie s

European Marketing

Organization

P.O. Box 999

1180 AZ Amstelveen

The Netherlands

(tel) (3120) 547 9999

Australia/New Zealand:

Agilent Technologies

Australia Pty Ltd

347 Burwood Highway

Forest Hill, Wictoria 3131

(tel) 1 800 629 485

(Austrailia)

(fax) (61 3) 9272 0749

(tel) 0 800 738 378

(New Zealand)

(fax) (64 4) 802 6881

(tel) (852) 2599 7899

(fax) (852) 2506 9233

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\programming_guide_front.fm

9

Safety, Warranty, and Regional Sales and Service Offices Information

10

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\programming_guide_front.fm

Contents

Introduction

Conventions Used in This Programming Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Purpose of This Programming Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

How This Programming Guide Is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

How to Use This Programming Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

About the Programming Examples Presented in This Programming Guide . . . . . . . . .16

Step 1: Set the Test Set’s Operating Mode to Active Cell

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Overview of Active Cell Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Setting the Test Set’s Operating Mode to Active Cell . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Step 2: Configure the Base Station Emulator (BSE)

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Configuring the Broadcast Channel Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Configuring the Traffic Channel Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Things That Can Go Wrong . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Step 3: Configure the Measurement Execution Parameters

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Configuring Measurement Averaging Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Configuring Measurement Triggering Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Configuring the Burst Synchronization Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Configuring Measurement Timeout Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Configuring Measurement Specific Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Step 4: Establish an Active Link with Mobile Station

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Process for Making a Base Station Originated Call . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Process for Making a Mobile Station Originated Call . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Step 5: Set the Mobile Station’s Operating Conditions

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Step 6: Make Measurements

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Things That Can Go Wrong . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Step 6a: Start Set Of Concurrent Measurements

Starting Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

11

Contents

Step 6b: Determine if a Measurement Is Done

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Step 6c: Obtain a Set of Measurement Results

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Step 7: Perform an Intra-Cell Handover

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Performing an Intra-Cell Handover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Performing a Dual-Band Handover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Step 8: Disconnect the Mobile Station from the BSE

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Terminating an Active Call from the Base Station Emulator . . . . . . . . . . . . . . . . . . . . 58

Terminating an Active Call from the Mobile Station . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Comprehensive Program Example

Example Program With Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Example Program Without Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

12

Programming the Agilent Technologies 8960 Series 10 for GSM Mobile Testing in Active Cell Operating Mode

Programming the Agilent Technologies 8960

Series 10 for GSM Mobile Testing in Active Cell

Operating Mode

13

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_intro.fm

Programming the Agilent Technologies 8960 Series 10 for GSM Mobile Testing in Active Cell Operating Mode

Introduction

Introduction

Conventions Used in This Programming Guide

Throughout this Programming Guide the term “test set” refers to an Agilent Technologies 8960 Series 10

wireless communications test set with the E1960A GSM mobile test application installed.

Purpose of This Programming Guide

The test set represents state-of-the-art technology in one-box-testers and contains many powerful test

capabilities which are accessible through easy-to-use GPIB programming commands. The purpose of this

Programming Guide is to teach you how to write a basic control program, using the test set’s GPIB command

set. This program will perform fundamental manufacturing tests on a GSM mobile station with the test set

operating in active cell mode.

How This Programming Guide Is Organized

The Programming Guide is organized around a typical set of tasks a control program would normally perform

when testing a GSM mobile station in a manufacturing environment. The set of tasks is shown in “Figure 1.

Typical Flow of Tasks Performed by Control Program” on page 15.

Typically in a manufacturing environment, steps 1, 2, and 3 are done once each time a production run is

started, steps 4 and 8 are done once for each mobile station tested during the production run, and steps 5, 6,

and 7 are done iteratively for each mobile station tested durin g the production run. The number of iterations

for steps 5, 6, and 7 is dependent upon how many mobile station operating conditions are being tested (that is,

number of channels, number of power levels, and so fourth).

14

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_intro.fm

Programming the Agilent Technologies 8960 Series 10 for GSM Mobile Testing in Active Cell Operating Mode

Figure 1. Typical Flow of Tasks Performed by Control Program

Start

Step 1:

Set test set’s operating

mode to active cell.

Step 2:

Configure base station

emulator (BSE).

Step 3:

Configure measurement

execution parameters.

Step 4:

Establish active link

with mobile station.

Step 5:

Set mobile station

operating conditions.

Introduction

Step 7:

Perform

intra-cell handover.

Step 6a:

Start set of concurrent

measurements.

Step 6b:

No

Determine if a

measurement

is done.

Yes

Assign

mobile station

to new TCH?

No

Step 8:

Disconnect mobile

station from BSE.

Stop

Step 6: Make measurements.

Yes

Step 6c:

Obtain set of

measurement results.

All measurements done.

15

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_intro.fm

Programming the Agilent Technologies 8960 Series 10 for GSM Mobile Testing in Active Cell Operating Mode

Introduction

How to Use This Programming Guide

This Programming Guide is divided into 9 sections. Sections 1 through 8 (step 1 through 8) should be read in

sequence. Each section, in order, discusses one of the tasks to be performed by the control program, showing

how to accomplish that task using the test set’s GPIB command set. As you progress through each section your

understanding of how the test set’s GPIB interface operates will increase as you see the control program

evolve.

The last section of the Programming Guide presents a “Comprehensive Program Example” on page 63 which

uses all of the topics discussed in sections 1 through 8 together in one program to give the programmer a sense

of how to tie everything together.

About the Programming Examples Presented in This Programming Guide

Programming Lang uage:

Programming examples presented in this Prog ramming Guide are written in the Rocky Mountain BASIC

programming language, also known as RMB.

Syntax Used in Programming Examples:

1. Programming examples use the shortened form of the command syntax to minimize GPIB bus transactions.

The shortened form of a command is defined by use of capital letters in the command syntax.

Example 1. Command Syntax:

CALL:STATus:TCHannel:TSLot?

Example 2. Shortened Form:

CALL:STAT:TCH:TSL?

2. Programming examples do not include default nodes. Default nodes in the command syntax are defined by

enclosing the node inside the [ ] brackets.

Example 3. Command Syntax:

CALL[:CELL[1]]:ACTivated[:STATe]<ON|1|OFF|0>

Example 4. Command Syntax without Default Nodes:

CALL:ACT <ON|1|OFF|0>

3. Programming examples make extensive use of compound commands using the ; and the ;: separators. Refer

to the test set’s reference information for information on the definition and use of these command

separators.

16

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_intro.fm

Step 1: Set the Test Set’s Operating Mode to Active Cell

Step 1: Set the Test Set’s Operating Mode to Active Cell

Background

The test set contains a GSM base station emulator (BSE). The BSE’s primary purpose is to provide the GSM

call processing necessary for parametric measurements on the RF and audio signals of a GSM mobile station

(MS).

An important characteristic of the test set’s BSE is its operating mode. The operating mode sets the way in

which the BSE interacts with the mobile station. The BSE has two operating modes; active cell mode and test

mode.

Active cell mode is used when emulating a no rmal GSM cell. Test mode is used when it is not possible, or not

desired, to communicate with the MS via over-the-air signaling, but downlink stimulus and uplink

measurements are still needed.

This Programming Guide focuses on programming the test set’s BSE in active cell operating mode.

Overview of Active Cell Operating Mode

Active cell is the default operating mode of the test set’s BSE and is used when emulating a normal GSM cell

(that is, active signaling between the MS and the BSE).

Active Cell Features

The basic features provided by the BSE when the operating mode is set to active cell are:

• Generation of a BCH (broadcast channel) without TCH (traffic channel).

• Support for location updating.

• Call setup, both MS and BSE originated.

• Changing TCH parameters during a call using ov er-the-air signaling.

• BSE initiated and MS initiated call disconnection.

• All measurements supported in the test application are available.

• The BSE automatically controls the test set’s demodulation receiver.

17

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step1.fm

Step 1: Set the Test Set’s Operating Mode to Active Cell

Setting the Test Set’s Operating Mode to Active Cell

The test set’s operating mode is set using the CALL:OPERating:MODE command.

Example 1. Command Syntax:

CALL:OPERating:MODE <CELL|TEST>

Example 2. Programming Example:

!**********************************************************************

! Step 1: Set Test Set Operating Mode To Active Cell

!**********************************************************************

!

OUTPUT Test_set;”CALL:OPER:MODE CELL

18

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step1.fm

Step 2: Configure the Base Station Emulator (BSE)

Step 2: Configure the Base Station Emulator (BSE)

Background

The test set contains a GSM base station emulator (BSE). In active cell operating mode the BSE, using the

test set’s GMSK modulated source, generates a downlink (BSE to MS direction) broadcast channel (BCH)

which represents a cell. The MS can camp to this signal, just as it would camp to a cell on a real network. The

BSE can then page the MS on the B CH and listen to the response of the MS on the uplink (MS to BSE

direction), using the test set’s demodulating receiver. Calls can then be set up with the establishment of a

traffic channel (TCH) in both the downlink and uplink directions. Measurements can be made, using the

BSE’s measuring receiver, under essentially identical conditions to that which the MS would experience on a

real network.

The BS Emulator can emulate a cell in any one of the following GSM frequency bands:

• PGSM - Primary (band) GSM, also known as GSM900

• EGSM - Extension (band) GSM (includes PGSM)

• DCS - Also known as DCS1800

• PCS - Also known as PCS1900

NOTE The term GSM is used to refer to any combination of, or all of, the supported bands. It is not used

as a shortened term for PGSM.

The task of configuring the BSE consists of configuring the BCH and the TCH. There are numerous

parameters that can be configured for both the BCH and the TCH. It may not be necessary to configure all the

parameters all the time. The test set’s default settings should allow a properly fun ctioning MS to successfully

camp on the cell under most circumstances.

In a manufacturing environment it may be desirable to explicitly configure the BCH and TCH parameters to

ensure that the settings have not been corrupted by someone setting a parameter’s value through the test set’s

front panel.

19

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step2.fm

Step 2: Configure the Base Station Emulator (BSE)

Configuring the Broadcast Channel Parameters

The broadcast channel parameters are configured using the CALL processing subsystem commands shown in

the following table.

T able 1. Broadcast Channel Settable Parameters

Parameter Command Syntax Footnote

Broadcast Band CALL[:CELL[1]]:BAND <PGSM|EGSM|DCS|PCS> 1

Cell Power CALL[:CELL[1]]:POWer[:AMPlitude]<numeric value>[<suffix>]

Cell Power State CALL[:CELL[1]]:POWer:STATe <ON|1|OFF|0>

Cell Power and State CALL[:CELL[1]]:POWer[:SAMPlitude]<numeric value>[<suffix>] 2

Cell BCH Number CALL[:CELL[1]]:BCHannel[:ARFCn][:SELected]<numeric value>

OR

CALL[:CELL[1]]:BCHannel[:ARFCn]:<PGSM|EGSM|DCS|PCS>

<numeric value>

Mobile Country Code CALL[:CELL[1]]:MCCode <numeric value> 4

PCS Mobile Country Code CALL[:CELL[1]]:PMNCode:V ALue <numeric value> 4

Use PCS MNC CALL[:CELL[1]]:PMNCode:STATe <ON|1|OFF|0> 4

PCS Mobile Country Code

and Use PCS NMC State

Mobile Network Code CALL[:CELL[1]]:MNCode <numeric value> 4

Location Area Code CALL[:CELL[1]]:LACode <numeric value> 4

Network Color Code CALL[:CELL[1]]:NCCode <numeric value> 4

Base Station Color Code CALL[:CELL[1]]:BCCode <numeric value> 4

Paging IMSI CALL:PAGing:IMSI <string>

Repeat Paging State CALL:PAGing:REPeat[:STATe] <ON|1|OFF|0>

Paging Mode CALL:PAGing:MODE <NORMal | REORg> 7

Paging Multiframes CALL:PAGing:MFRames <numeric value>

Auto IMEI Request CALL:IMEI:AUTO <ON|1|OFF|0>

CALL[:CELL[1]]:PMNCode[:SVALue] <numeric value> 4, 5

3

BA Table Entries CALL[:CELL[1]]:BA:TABle[:SELected][<numeric value>{,<numeric

value>}]

OR

CALL[:CELL[1]]:BA:TABle:<PGSM|EGSM|DCS|PCS> [<numeric

value>{,<numeric value>}]

XXXXXXXXX XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

20

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step2.fm

6

Step 2: Configure the Base Station Emulator (BSE)

Table Footnotes

1 The broadcast band setting becomes the selected (:SELected) band (see note 3).

2 Sets amplitude to <numeric value> and state to ON in one command.

3 Sets the BCH channel for the broadcast band selected with the broadcast band command (see note 1).

4 Can only be set when Cell Activated State = OFF.

See "Things That Can Go Wrong" on page 23.

5 Sets PCS mobile country code to <numeric value> and state to ON in one command.

6 Sets the BA table entries for the broadcast band selected with the broadcast band comman d (see note 1).

7 Setting Paging Mode to Normal causes the MS to use discontinuous reception (that is, DRX = ON).

Example 1. Programming Example:

The following program example illustrates proper use of the BSE BCH conf iguration commands. Not all

parameters are accessed. Note the use of the c ell activated state command to set the network configuration

parameters.

!**********************************************************************

! Step 2: Configure Base Station Emulator (BSE)

!**********************************************************************

!

OUTPUT Test_set;”CALL:CELL:BAND PGSM”

OUTPUT Test_set;”CALL:PAG:MODE REOR” ! Sets discontinuous reception to OFF

OUTPUT Test_set;”CALL:ACT OFF”

OUTPUT Test_set;”CALL:CELL:MCC 1;LAC 1;MNC 1;NCC 1;BCC 5”

OUTPUT Test_set;”CALL:ACT ON”

OUTPUT Test_set;”CALL:BCH 20”

OUTPUT Test_set;”CALL:POW:SAMP -85”

21

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step2.fm

Step 2: Configure the Base Station Emulator (BSE)

Configuring the Traffic Channel Parameters

The traffic channel parameters are configured using the CALL processing subsystem commands shown in the

following table.

Table 2. Traffic Channel Settable Parameters

Parameter Com ma nd Syn t ax Footnote

TCH Band CALL:TCHannel:BAND <PGSM|EGSM|DCS|PCS> 1

Channel

Number

Loopback Mode CALL:TCHannel:LOOPback <OFF|A|B|C>

Timeslot CALL:TCHannel:TSLot <numeric value>

Downlink

Speech Source

XXXXXXXXX XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

CALL:TCHannel[:ARFCn][:SELected] <numeric value>

OR

CALL:TCHannel[:ARFCn]:<PGSM|EGSM|DCS|PCS> <numeric value>

CALL:TCHannel:DOWNlink:SPEec h

<NONE|ECHO|PRBS15|S IN300|SIN1000|SIN3000>

2

Table Footnotes

1 The TCH band setting becomes the selected band (see Note 2).

2 Sets the TCH channel for the TCH band selected with the TCH Band command (see Note 1).

Example 2. Programming Example:

The following program example illustrates proper use of the BSE TCH configuration commands. Not all

parameters are accessed.

OUTPUT Test_set;”CALL:TCH 45”

OUTPUT Test_set;”CALL:TCH:TSL 4”

22

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step2.fm

Step 2: Configure the Base Station Emulator (BSE)

Things That Can Go Wrong

Trying to Set the MCC, MNC, LAC, NCC, or BCC While the

Cell Activated State = ON

Trying to set any of the network configuration parameters while the cell is in the active state will generate the

following error:

GSM operation rejected; Attempting to set <MCC|MNC|LAC|NCC|BCC> while generating a BCH

Background The network configuration parameters are encoded into the messaging broadcast on the BCH.

Changing the network parameter values while the BCH is active would require the BCH to be stopped, and

have the new values encoded, and then the BCH would have to be re-started. This would cause calls to be

dropped or disrupt a MS camped to the cell. Consequently the network configuration parameters cannot be

changed while the cell is active.

Control of the Cell Activated State The active/inactive state of the cell is controlled using the cell

activated state command. This command is only used when the operating mode is set to active cell mode.

Example 3. Command Syntax:

CALL[:CELL[1]]:ACTivated[:STATe]<ON|1|OFF|0>

Example 4. Programming Example:

OUTPUT Test_set;"CALL:ACT ON"

Effects of Activating and Deactivating the Cell

Effects of Deactivating the Cell Among others (refer to the test set’s reference information for a complete listing of

actions), setting the cell activated state to OFF causes the following actions to take place:

• The control program is no longer prevented from setting the following parameters: MCC, MNC, PCS MNC, Use PCS

MNC, BCC, NCC and LAC.

• All signaling operations, uplink demodulation and downlink (BCH & TCH) generation are stopped.

• Any measurements that rely on uplink demodulation are aborted. No special error messages are generated.

Effects of Activating the Cell Among others (refer to the test set’s reference information for a complete listing of

actions), setting the cell activated state to ON causes the following actions to take place:

• The control program is prevented from setting the following parameters: MCC, MNC, PCS MNC, Use PCS MNC, BCC,

NCC and LAC.

• If the cell activated state was previously OFF, the TDMA frame number of the BS emulator starts from zero, and a

BCH is generated.

• If a TCH was pres ent prior to setting cell activated state to OFF, the TCH is not reinstated.

23

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step2.fm

Step 3: Configure the Measurement Execution Parameters

Step 3: Configure the Measurement Execution Parameters

Background

Measurement execution parameters control the conditions under which a measurement operates. The general

set of measurement execution parameters and their generic categories are as follows:

• Measurement Averaging (used by most measurements)

Multi-Measurement Count State

Multi-Measurement Count State

• Measurement Triggering (used by m ost measurements)

Trigger Arm

Trigger Source

Trigger Delay

Trigger Qualifier

• Measurement Synchronization (used by some measurements)

Burst Synchronization

• Measurement Timeouts (used by all measurem ents)

Measurement Timeout

Measurement Timeout State

• Measurement Specific (execution parameters specific to an individual measurement)

NOTE Not all measurements use all the execution parameters shown above. Additionally, some

measurements have parameters that are specific to the measurement such as offset frequency

lists or filter settings. Each measurement has its own set of parameters which are unique to it

and have no affect on the execution of other measurements. Refer to the GPIB syntax listing for a

detailed list of execution parameters for individual measurements.

24

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step3.fm

Step 3: Configure the Measurement Execution Parameters

Overview

The SETup subsystem is used to configure measurement parameters. Each individual measurement

parameter can be set and queried using the associated SETup subsystem command. The general hierarchy of

the SETup subsystem command structure is as follows:

SETup:<meas-mnemonic>:<measurement parameter><parameter setting/value>

The following table shows the measurements available in the Agilent E1960A GSM mobile test application

and their associated <meas-mnemonic> used in the SETup command syntax.

Table 1. Measu r ement Mnemonics Used In The SETup Subsystem

Measurement <meas-mnemonic>

Transmit Powe r TXPower

Power vs Time PVTime

Phase & Frequency Error PFERror

Output RF Spectrum ORFSpectrum

Bit Error BERRor

Fast Bit Error FBERror

Decoded Audio DAUDio

Analog Audio AAUDio

I/Q Tuning IQTuning

Dynamic Power DPOWer

25

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step3.fm

Step 3: Configure the Measurement Execution Parameters

Configuring Measurement Averaging Parameters

Multi-Measurement Count State Parameter

The Multi-Measurement Count St ate parameter is used to turn measureme nt averaging on and off.

Example 1. Command Syntax:

SETup:<meas-mnemonic>:COUNt:STATe <ON|1|OFF|0>

Example 2. Programming Example:

OUTPUT Test_set;"SET:PVT:COUN:STATe ON"

would turn measurement averaging ON for the power versus time measurement.

Multi-Measuremen t Cou nt Number Parameter

The Multi-Measurement Count Number param eter sets the number of measurement samples taken during

each measurement cycle when the COUNt:STATe parameter is set to ON.

Example 3. Command Syntax:

SETup:<meas-mnemonic>:COUNt:NUMBer <numeric value>

Example 4. Programming Example:

OUTPUT Test_set;"SET:TXP:COUN:NUMB 10"

would set the number of averages to 10 for the transmit power measurement.

Configuring Multi-Measu r ement Count State and Count Number Simultan eou sly

The multi-measurement count state can be set to ON and the multi-measurement count number can be set to

some value using a single complex command.

Example 5. Command Syntax:

SETup:<meas-mnemonic>:COUNt[:SNUMber] <numeric value>

Example 6. Programming Example:

OUTPUT Test_set;"SET:TXP:COUN:SNUM 10"

would set the multi-measurement count state to ON an d set the number of averages to 10 for the transmit

power measurement. Note that in this example the optional command mnemonic :SNUMber has been

included for purposes of clarity.

26

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step3.fm

Step 3: Configure the Measurement Execution Parameters

Configuring Measurement Triggering Parameters

Trigger Source Parameter

The Trigger Source parameter selects the sour ce of the measurement trigger signal.

Example 7. Command Syntax:

SETup:<meas-mnemonic>:TRIGger:SOURce <AUTO|IMMediate|PROTocol|RISE>

Example 8. Programming Example:

OUTPUT Test_set;"SET:TXP:TRIG:SOUR AUTO"

would set the trigger source to AUTO for th e transmit power measurement.

Trigger Delay Parameter

The Trigger Delay parameter controls the delay between the trigger event (the point in time at which the

trigger signal is received) and the start of sampling. Negative values indicate that the sampling should occur

prior to the trigger event.

Example 9. Command Syntax:

SETup:<meas-mnemonic>:TRIGger:DELay <numeric value>[<suffix>]

Example 10. Programming Example:

OUTPUT Test_set;"SET:TXP:TRIG:DEL 10 US"

would set the trigger delay to 10 µs for the transmit power measurement.

Trigger Qualifier Parameter

The Trigger Qualifier parameter enables or disables automatic tr igger re-arming following a trigger event

which occurred when no valid sign al (burst) was present.

Example 11. Comma nd Syntax:

SETup:<meas-mnemonic>:TRIGger:QUALifier <ON|1|OFF|0>

Example 12. Programming Example:

OUTPUT Test_set;"SET:TXP:TRIG:QUAL ON"

would turn the trigger qualifier on for the transmit power measurement.

27

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step3.fm

Step 3: Configure the Measurement Execution Parameters

Trigger Arm Parameter

The Trigger Arm parameter determines whether a measurement will make one measurement then stop

(single), or automatically re-arm upon completion of one measurement and repeat the process (continuous).

Example 13. Comma nd Syntax:

SETup:<meas-mnemonic>:CONTinuous <ON|1|OFF|0>

NOTE The recommend trigger arm setting for all measurements when using the remote user interface

is single (CONTinuous OFF).

Example 14. Programming Example:

OUTPUT Test_set;"SET:TXP:CONT OFF"

would set the trigger arming to single for the transmit power measurement.

Configuring the Burst Synchronization Parameter

Burst Synchroniz a tion Parameter

The burst synchronization parameter specifies where in the sampled data stream the measurement algorithm

starts making its analysis of the captured data. Burst synchronization occur s after the measurement data is

captured. The burst synchronization parameter’s setting determines how the measurement’s time reference is

developed from the sampled data.

Not all measurements will have synchronization choices and not all synchronization choices will be available

in measurements that use synchronization. Measurement synchronization and measurement triggering are

independent settings and may be used in any combination.

Example 15. Comma nd Syntax:

SETup:<meas-mnemonic>:BSYNc <MIDamble|AMPLitude|NONE>

Example 16. Programming Example:

OUTPUT Test_set;"SET:PVT:BSYN MID"

would set the burst synchronization to midamble for the power versus time measurement.

28

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step3.fm

Step 3: Configure the Measurement Execution Parameters

Configuring Measurement Timeout Parameters

Measurement Timeout State Parameter

The Measurement Timeout State parameter is used to enable or disable measurement timeout functionality.

Example 17. Comma nd Syntax:

SETup:<meas-mnemonic>:TIMeout:STATe <ON|1|OFF|0>

Example 18. Programming Example:

OUTPUT Test_set;"SET:PVT:TIM:STAT ON"

would enable measurement timeouts for the power versus time measurement.

Measurement Timeout Time Parameter

The Measurement Timeout Time parameter sets the maximum time that a measurement will ex ecu te befo re

failing with a timeout error (when the TIMEout:STATe parameter is set to ON).

Example 19. Comma nd Syntax:

SETup:<meas-mnemonic>:TIMeout:TIME <numeric value>[<suffix>]

Example 20. Programming Example:

OUTPUT Test_set;"SET:TXP:TIM:TIME 10 S"

would set the measurement timeout time to 10 seconds for the transmit power measurement.

Configuring Measuremen t Timeout Stat e and Timeout Time Simu ltan eously

The measurement timeout state can be set to ON and the measurement timeout time can be set to some value

using a single complex command.

Example 21. Comma nd Syntax:

SETup:<meas-mnemonic>:TIMeout[:STIMe] <numeric value>[<suffix>]

Example 22. Programming Example:

OUTPUT Test_set;"SET:TXP:TIM:STIM 10"

would set the measurement timeout state to ON and set the measurement timeout time to 10 seconds for the

transmit power measurement. Note that in this example th e optional command mnemonic :STIMe has been

included for purposes of clarity.

29

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step3.fm

Step 3: Configure the Measurement Execution Parameters

Configuring Measurement Specific Parameters

Background

Some measurements have parameters that are specific to the measurement. Refer to the GPIB syntax listings

for a detailed list of execution parameters for individual measurements. This section gives you some insight

into the possible programming techniques that can be used to configure these measurement specific execution

parameters.

Sending Comma-Separated Parameter Configuration Lists to the Test Set

High-level measurements in the test applic ation may require numerous parameters to configure the

measurement. For example: the output RF spectrum measurement can require up to 22 frequency offsets for

the modulation part of the measurement and up to 8 frequency offsets for the switching part of the

measurement. The offsets are sent as comma separated lists. There are a variety of techniques that can be

used to send these lists. Some of these techniques are shown below.

1. Include each individual parameter in the command itself. For example:

OUTPUT Test_set;"SET:ORFS:SWIT:FREQ .4MHZ,.6MHZ,-.4MHZ,-.6MHZ"

2. Store the parameter values in a data structure and send the command with the data structure appended to

it. For example:

• Using a string variable:

DIM Swit_offs$[255]

Swit_offs$=”.4MHZ,.6MHZ,-.4MHZ,-.6MHZ,1.2MHZ,-1.2MHZ”

OUTPUT Test_set;”SET:ORFS:SWIT:FREQ “&Swit_offs

• Using numeric arrays:

OPTION BASE 1

REAL Swit_offs(8),Mod_offs(22)

!

DATA 400,-400,600,-600,1200,-1200,1800,-1800

DATA .1,-.1,.2,-.2,.25,-.25,.4,-.4,.6,-.6,.8,-.8

DATA 1,-1,1.2,-1.2,1.4,-1.4,1.6,-1.6,1.8,-1.8

!

READ Swit_offs(*)

READ Mod_offs(*)

!

Swit_img:IMAGE K,7(K,”KHZ,”),K,”KHZ”

Mod_img:IMAGE K,21(K,”MHZ,”),K,”MHZ”

OUTPUT Test_set USING Swit_img;”SET:ORFS:SWIT:FREQ”,Swit_offs(*)

OUTPUT Test_set USING Mod_img;”SET:ORFS:MOD:FREQ”,Mod_offs(*)

30

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step3.fm

Step 3: Configure the Measurement Execution Parameters

Example 23. Programming Example:

The following example illustrates configuring the measurement execution parameters for the output RF

spectrum, transmit power, and phase and frequency error measurements.

!***************************************************************************

! Step 3: Configure Measurement Execution Parameters

!***************************************************************************

!

! Configure ORFS Measurement:

!

OUTPUT Test_set;”SET:ORFS:SWIT:COUN 5” ! Examples of using complex

OUTPUT Test_set;”SET:ORFS:MOD:COUN 10” ! commands to set multi-meas

! state and count at same time.

OUTPUT Test_set;”SET:ORFS:TRIG:SOUR AUTO” ! Set trig source to AUTO.

OUTPUT Test_set;”SET:ORFS:CONT OFF” ! Set trig mode to single.

OUTPUT Test_set;”SET:ORFS:TIM 60” ! Set timeout time to 60 sec.

! Put switching and modulation offsets to be tested into string variables.

Swit_offs$=”400KHZ,-400KHZ,600KHZ,-600KHZ,1200KHZ,-1200KHZ,1800KHZ,-1800KHZ”

Mod_offs$=”.2MHZ,-.2MHZ,.4MHZ,-.4MHZ,.6MHZ,-.6MHZ,.8MHZ,-.8MHZ,1MHZ,-1MHZ”

OUTPUT Test_set;”SET:ORFS:SWIT:FREQ “&Swit_offs$

OUTPUT Test_set;”SET:ORFS:MOD:FREQ “&Mod_offs$

!

! Configure TX Power Measurement:

!

OUTPUT Test_set;”SET:TXP:COUN 3”

OUTPUT Test_set;”SET:TXP:TRIG:SOUR RISE;QUAL ON”

OUTPUT Test_set;”SET:TXP:CONT OFF”

OUTPUT Test_set;”SET:TXP:TIM 20”

!

! Configure Phase & Frequency Error Measurement:

!

OUTPUT Test_set;”SET:PFER:COUN 8”

OUTPUT Test_set;”SET:PFER:TRIG:SOUR PROT;QUAL ON”

OUTPUT Test_set;”SET:PFER:CONT OFF”

OUTPUT Test_set;”SET:PFER:TIM 30”

OUTPUT Test_set;”SET:PFER:BSYN MID

31

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step3.fm

Step 4: Establish an Active Link with Mobile Station

Step 4: Establish an Active Link with Mobile Station

Background

Call Connect/Disconnect Synchronization

When the control program requires that an active link be established/terminated between the mobile station

and the test set, the commands necessary to initiate the call connect/disconnect process are sent to the test set

(for a BS originated/terminated call) or to the mobile station (for a MS originated/terminated call). In either

case, synchronization is defined as the control program being able to empirically determine when the call has

been successfully connected/disconnected so that the control program can proceed, or being able to empirically

determine that the call has not been successfully connected/disconnected so that the control program can take

appropriate action.

The determination is made by monitoring the call state as the call connect/disconne ct process progresses.

Call States

At any instant in time a call can be in one of the following states:

•Idle

• Setup Request

• Proceeding

• Alerting

• Disconnecting

• Connected

Setup Request, Proceeding, Alerting and Disconne cting are referred to as transitory states because the

amount of time which the call can spend in any of these states is limited by G S M protocol (that is, the call

transitions through these states, it is not allowed to stay in a transitory state forever).

NOTE If repeat paging is on it is possible for the call process to stay in one of the transitory states

beyond the time specified by the GSM protoc ol timers.

The control program can directly query the state of a call with the CALL:STATus:STATe? query command,

which immediately returns the current call state (that is, Idle, Setup Request, Proceeding, Alerting,

Disconnecting, or Connected)

32

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step4.fm

Step 4: Establish an Active Link with Mobile Station

Determining if a Call Connect/Disconnect Process is Com pleted

The most common technique used by control progr ams to determine if a call connect/disconnect process has

completed (either successfully or unsuccessfully), is to repeatedly query the call state using the

CALL:STATus:STATe? query command inside a program loop. The return value from each query is checked to

determine if the connect/disconnect process is proceeding or has reached the desired state.

There are, however, some inherent problems associated with this technique:

• The rapid polling of the instrument increases bus traffic and places increased demand on the instrument’s

processors to respond to the constant stream of queries.

• The control program must handle failure conditions. F or example: if a call origination process is started but

the call never leaves the Idle state, the control program must incorporate some technique to prevent the

program from staying in the loop forever waiting for a transition ou t of the Idle state.

The test set implements a set of commands designed specifically for call connect/disconnect synchronization.

(see “Step 8: Disconnect the Mobile Station from the BSE” on page 57 for call disconnect synchronization).

These commands directly address many of the inh erent problems discussed above. When properly used these

commands eliminate the need for rapid polling of the instrument, and relieve the programmer of many of the

tasks associated with error handling.

Call Connect/Disconnect Synchronization Commands

Call Connected State Query Command The call-c onnected-state query com mand is used to query the

connected state of a call. This command allows the control program to determine if a call is connected (that is,

in the Connected state) or disconnected (that is, in the Idle state), with a built-in provision to automatically

wait if the call is in one of the transitory states.

The basic operation of this query is:

• If the call is in the Connected state when the query is received by the test set, the query immediately

returns a 1.

• If the call is in the Idle state (that is, disconnected) when the query is received by the test set, the query

immediately returns a 0.

• If the call is in one of the transitory states (that is, Setup Request, Proceeding, Alerting, or Disconnecting)

when the query is received by the test set, the query ha ngs (that is, does not return an answer) until the

call state changes to either Idle or Conn ected and then behaves as above.

The call-connected-state query command can be used at any time to determine the connected state of a call.

The built-in provision to automatically wait if the call is in one of the transitory states eliminates the need for

rapid polling when the call-connected-state query command is used to synchronize to a call connect/disconnect

process.

NOTE If repeat paging is on, a call origination process ca n stay in one of the transitory states until the

mobile either answers the page or until the user stops the paging process. This means that if a

call-connected-state query command is sent to the test set with repeat paging set to on, the query

could hang “forever”.

33

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step4.fm

Step 4: Establish an Active Link with Mobile Station

Example 1. Command Syntax:

CALL:CONNected[:STATe]?

Using the Call Connected State Query for Call Connect Synchronization The call-connected-state query only

hangs if the call is in a transitory state, otherwise it immediately returns a 1 (Connected state) or a 0 (Idle state). At the

start of a call connect process the call state is Idle. Sending call-connected-state query at the start of a call connect

process could immediate ly r eturn a zer o if the que ry i s sat i sfied be fore the co nne c tion pro ce ss ha s star te d (tha t is, moved

from the Idle state into one of the transitory states). For correct call connect synchronization it is necessary that the

query be temporarily held off until after the call connect process has started. A call-state-change-detector is provided

which can be used to temporarily hold off the query from returning an answer until the appropriate state change has

occurred.

Call Connected Arm Command The call-connec ted-arm command is used to ‘arm’ the

call-state-change-detector.

Example 2. Command Syntax:

CALL:CONNected:ARM[:IMMediate]

If the call-state-change-detector is armed when a call-connected-state query is received, the reply is held off

until the call-state-change-detector is disarmed. The call-state-change-detector is disarmed upon a state

change from any of the transitory states to the Idle or Connected state.

The call-state-change-detector is not disarmed by a state change from Idle to any of the transitory states, from

Connected to any of the transitory states, nor is it disarmed by any transitions from Idle to Idle, or Connected

to Connected. These restrictions ensure that when the call-connected-state query returns an answer:

• the connect process has started since the call state must have moved from Idle to one of the transitory

states

AND

• the connect process has fin i shed since the call state has moved from a transitor y state to either the Idle or

Connected state .

The arm state of the change detector can be queried with the call-connected-arm-state query command. This

query never hangs and immediately returns a 1 if the change detector is armed and a 0 if it is not armed. The

command is:

Example 3. Command Syntax:

CALL:CONNected:ARM:STATe?

34

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step4.fm

Step 4: Establish an Active Link with Mobile Station

Using the Call Connected Arm Command for Call Connect Synchronization The call-state-change-detector arm

command is used by the control program to tell the test set that it is expecting a change to the state of a call prior to

initiating the state change. By first arming the call-state-change-detector, then querying the call connected state, and

then attempting a BS or MS originated call, the call-connected-state query will hang until the connection operation

begins and then reaches a final (Idle or Connected) state.

However, if the change detector is armed and a call connection is attempted but the call sta t e never progresses from the

Idle state, the call-connected-state query would hang forever. This could easily happen if the mobile is badly broken, the

mobile is not connected to the test set, no one pushes the “send” button on the mobile, etc.

A call-state-change-detector time-out timer is provided which is used to prevent the call-connected-state query from

hanging forever.

Call Connected Time-out Command The call-connected-time-out command is used to set the time-out

value for the call-state-change-detector time-out timer.

Example 4. Command Syntax:

CALL:CONNected:TIMeout <numeric value>[<suffix>]

Using the Call State Change Detecto r Time-out for Cal l Connect Synchronization The

call-state-change-detector time-out mechanism allows the test set to disarm the call-state-change-detector which releases

the call connected s tate query if it is currently hanging.

The time-out timer is start ed wheneve r the call-s tate-c hange-det ector is ar med or gets re armed whe n already ar med. The

duration of the time-out is set using the call-connected-time-out command and should be set to the maximum amount of

time the control program should wait between arming and the connect process to begin. Once the process starts and the

call state has moved into one of the transitory sta tes the GSM define d protocol time rs take ove r and prevent the ca ll state

from staying in a transitory state foreve r.

If the timer expires while the call is in the Idle or Connected state, the call-state-change-detector is disarmed, which

releases the call connected state query if it is currently hanging.

If the timer expires while the call is in one of the transitory states it is ignored as, once in any transitory state, the

GSM-defined protocol timers limit the amount of time that can be spent in any transitory state.

Call-state-change-detector Auto Arming As a programming convenience the test set automatically arms

the call-state-change-detector, using a fixed time-out value of 60 seconds, whenever a BS originate or BS

disconnect is requested.

Because of this, there is never a need for the control program to explicitly arm the call-state-change-detector

or set a call-state-change-detector time-out value before BS initiated events. If for sake of coding efficiency, the

programmer wishes to use the same code segment for both BS and MS call processing events, the commands to

arm the call-state-change-detector and to set the call-state-change-detector time-out time will be accepted but

ignored should the control program actually send the commands to the test set for BS call processing events.

35

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step4.fm

Step 4: Establish an Active Link with Mobile Station

Overview

Establishing an active link with the mobile station when the test set is in active cell operating mode can be

accomplished in one of two ways:

• Base station originated call

• Mobile station originated call

Process for Making a Base Station Originated Call

The recommended process for making a base station originated call is shown in

“Step 4: Figure 1. Process for Making a Base Station Originated Call” on page 37.

The CALL:ORIGinate command is used to initiate a base station originated call.

If the call origination process fails it is necessary to send the CALL:END command to the test set to force

immediate termination of all processes as sociated with the current call origination. This ensures that if

another CALL:ORIGinate command is sent to the test set before all pro cesses associated with the failed call

origination have been terminated, it will not be ignored. Note that if the test set is currently executing a call

origination and it receives another call origination command it will be ignored (that is, you are telling the test

set to do something it is already doing and hence it will accept the command but it will be ignored).

36

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step4.fm

Step 4: Figure 1. Process for Making a Base Station Originated Call

Start

Set paging IMSI.

Set paging repeat state.

Originate a call.

Send call connected

state query command.

Enter response from

call connected state

query.

Step 4: Establish an Active Link with Mobile Station

Call connected?

Yes

Proceed with control

program.

No

Send CALL:END

command.

Invoke error

handler.

37

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step4.fm

Step 4: Establish an Active Link with Mobile Station

Example 5. Pr ogr amming Example:

!**********************************************************************

! Step 4: Establish Active Link with Mobile Station

!**********************************************************************

!

OUTPUT Test_set;”CALL:PAG:IMSI ‘001012345678901’” ! Set paging IMSI

OUTPUT Test_set;”CALL:PAG:REP OFF” ! Set paging repeat state to off

OUTPUT Test_set;”CALL:ORIG” ! Start a base station originated call

OUTPUT Test_set;”CALL:CONN:STAT?” ! Hanging GPIB query

ENTER Test_set;Call_connected ! Program will hang here until

! origination passes or fails

IF NOT Call_connected THEN ! Check if connection successful

OUTPUT Test_set;”CALL:END”

! <put error handler here>

END IF

! Call is connected so proceed with control program

Call Origination Process Commands

Paging the Mobile Station Paging the mobile station is accomplished using the CALL:ORIGinate

command.

Example 6. Command Syntax:

CALL:ORIGinate

Example 7. Programming Example:

OUTPUT Test_set;"CALL:ORIG"

would start the process of making a base station originated call.

Setting the Paging IMSI The paging IMSI is set using the PAGing:IMSI command.

Example 8. Command Syntax:

CALL:PAGing:IMSI <string>

38

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step4.fm

Step 4: Establish an Active Link with Mobile Station

Example 9. Programming Example:

OUTPUT Test_set;"CALL:PAG:IMSI ‘001012345678901’"

would set the paging IMSI to 001012345678901.

Setting the Paging Repeat State The paging repeat state is set using the PAGing:REPeat:STATe

command.

Example 10. Comma nd Syntax:

CALL:PAGing:REPeat[:STATe] <ON|1|OFF|0>

Example 11. Programming Example:

OUTPUT Test_set;"CALL:PAG:REP OFF"

would turn on paging repeat.

Process for Making a Mobile Station Originated Call

The recommended process for making a mobile station originated call is shown in

“Step 4: Figure 2. Process For Making A Mobile Station Originated Call” on page 40.

There is no facility in the test set to initiate a call connect from the mobile station. This must be accomplished

manually or through a test bus built into the mobile station.

If the call origination process fails it is necessary to send the CALL:END command to the test set to force

immediate termination of all processes as sociated with the current call origination. This ensures that if the

mobile station attempts another originate before all processes associated with the failed call origination have

been terminated, it will not be ignored. Note that if the test set is currently executing a call origination and it

receives another call origination command it will be ignored (th at is, you are telling the test set to do

something it is already doing and hence it will accept the command but it will be ignored).

For mobile station originated calls where the call is originated by physically dialing a number (as opposed to

using a test bus) ensure that the call-state-change-detector time-out time is long enough to allow a human to

dial the number.

39

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step4.fm

Step 4: Establish an Active Link with Mobile Station

Step 4: Figure 2. Process For Making A Mobile Station Originated Call

Start

Set call state change

detector time-out time.

Arm call state change

detector.

Send call connected

state query command.

Originate a call from

mobile station.

Enter response from

call connected sta te

query.

Call connected?

No

Yes

Proceed with control

program.

Send CALL:END

command.

Invoke error

handler.

40

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step4.fm

Step 4: Establish an Active Link with Mobile Station

Example 12. Programming Ex ample:

OUTPUT Test_set;”CALL:CONN:TIM 5” ! Set timeout time to 5 seconds

OUTPUT Test_set;”CALL:CONN:ARM” ! Arm the change detector

OUTPUT Test_set;”CALL:CONN:STAT?” ! Initiate call connect state query

DISP “Originate call from mobile station.”

ENTER Test_set;Call_connected ! Program will hang here until

! origination passes or fails

IF NOT Call_connected THEN ! Check if connection successful

OUTPUT Test_set;”CALL:END”

! <put error handler here>

END IF

! Call is connected so proceed with control program

41

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step4.fm

Step 5: Set the Mobile Station’s Operating Conditions

Step 5: Set the Mobile Station’s Operating Conditions

Overview

The mobile station’s operating conditions are set using the CALL processing subsystem commands shown in

the following table.

Table 1. Settable Mobile Station Operating Conditions

Parameter Command Syntax Table Footnotes

Timing Advance CALL:MS:TADVance <numeric value>

Transmit Level CALL:MS:TXLevel[:SELected] <numeric value>

OR

CALL:MS:TXLevel:<PGSM|EGSM|DCS|PCS> <numeric value>

Discontinuous

Transmission

CALL:MS:DTX[:STATe] <ON|1|OFF|0>

Table Footnotes

1 The TCH band setting becomes the selected band.

Example 1. Programming Example:

!**********************************************************************

! Step 5: Set Mobile Station Operating Conditions

!**********************************************************************

!

OUTPUT Test_set;”CALL:MS:DTX OFF”

OUTPUT Test_set;”CALL:MS:TXL 14

1

42

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step5.fm

Step 6: Make Measurements

Step 6: Make Measurements

Background

The multiple signal path, DSP based, multiple processor architecture of the test set allows the test set to make

concurrent measurements. This means that:

• multiple measurements can execute and finish at the same time (concurrently)

• individual measurement completion is not influenced by other measurement processes

• availability of measurement results is not dependent upon the sequence that the measurements were

requested in

• results from measurements that take few processor cycles are available without having to wait for

measurements that take many processor cycles

There are no special programming commands or techniques required to implement measurement concurrency.

“Step 6: Figure 1. Process for Making Measurements” on page 44 shows the recommended process for making

concurrent measurements using the test set’s command set.

43

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step6.fm

Step 6: Make Measurements

Step 6: Figure 1. Process for Making Measurements

Start set of concurrent

measurements using

INITiate command.

Start

INITiate:DONE? query

returns WAIT (no

measurements are done).

Determine

which measurement

is done using

INITiate:DONE?

query .

INITiate:DONE? query

returns NONE (all

measurements are done).

Stop

INITiate:DONE? query

returns name of

measurement that is done.

Use FETCh? query to

obtain measurement

results.

44

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step6.fm

Step 6: Make Measurements

Example 1. Pr ogr amming Example:

The following program segment illustrates making a transmit power measurement and a phase and frequency

error measurement concu rr ently using the recommended pro cess shown in “Step 6: Figure 1. Process for

Making Measurements” on page 44.

!**********************************************************************

! Step 6: Make Measurements

!**********************************************************************

!

! Step 6a: Start Set of Concurrent Measurements:

!

OUTPUT Test_set;”INIT:TXP;PFER”

!

! Step 6b: Determine If A Measurement Is Done:

!

LOOP

OUTPUT Test_set;”INIT:DONE?”

ENTER Test_set;Meas_done$

!

! Step 6c: Obtain Measurement Results

!

SELECT Meas_done$

CASE “TXP”

OUTPUT Test_set;”FETC:TXP:POW?”

ENTER Test_set;Avg_tx_power

CASE “PFER”

OUTPUT Test_set;”FETC:PFER:RMS?”

ENTER Test_set;Max_rms_phas_er

END SELECT

EXIT IF Meas_done$ = “NONE”

END LOOP

45

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step6.fm

Step 6: Make Measurements

Things That Can Go Wrong

Measurement Integrity Always Returns a Value of 6

Background A measurement integrity value of 6 indicates that some characteristic of the input signal is

under range. Typically this will be the amplitude (power) of the DUT signal. This low amplitude will cause the

level of the DSP sampler to be below a threshold required by the measurement algorithm to produce results of

specified accuracy.

Possible Cause One of the most likely causes of a measurement underrange condition is DUT signal loss

caused by fixture loss or cable loss.

Suggested Workaround Fixture loss or cable loss can be compensated for by using the RF IN/OUT port’s

amplitude offset parameter.

Example 2. Command Syntax:

SYSTem:CORRection:GAIN <numeric value>[<suffix>]

SYSTem:CORRection:STATe <1|ON|0|OFF>

Complex form of command (sets gain to <numeric value> and state to ON using single command):

SYSTem:CORRection:SGAin <numeric value>[<suffix>]

Example 3. Programming Example:

OUTPUT Test_set;"SYST:CORR:SGA -6"

would set the RF IN/OUT port’s amplitude offset to −6 dB and set the corr ection state to ON.

46

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step6.fm

Step 6a: Start Set Of Concurrent Measurements

Step 6a: Start Set Of Concurrent Measurements

Starting Measurements

The INITiate command is used to start measurements. Each individual measurement in a test application can

be started using the INITiate command. For starting measurements, the syntax of the INITiate command is

as follows:

Example 1. Command Syntax:

INITiate:<meas-mnemonic>[:ON]

The following table shows the measurements available in the Agilent Technologies E1960A GSM mobile test

application and their associated <meas-mnemonic> used in the INITiate command syntax.

Table 1. Measurement Mnemonics U sed In The INITiate Subsystem

Measurement <meas-mnemonic>

Transmit Power TXPower

Power vs Time PVTime

Phase & Frequency Error PFERror

Output RF Spectrum ORFSpectrum

Bit Error BERRor

Fast Bit Error FBERror

Decoded Audio DAUDio

Analog Audio AAUDio

I/Q Tuning IQTuning

Dynamic Power DPOWer

47

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step6a.fm

Step 6a: Start Set Of Concurrent Measurements

Example 2. Programming Example:

OUTPUT Test_set;"INIT:TXP"

would start the transmitter power measurement.

Using Compound Commands to Start Mu ltiple Measurements

More than one measurement can be started using a single INITiate command. For example:

OUTPUT Test_set;"INIT:TXP;PFER"

would start the transmit power measurement and the phase and frequency error measurement. These

measurements would then run concurrently.

48

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step6a.fm

Step 6b: Determine if a Measurement Is Done

Step 6b: Determine if a Measurement Is Done

Background

After a set of concurrent measurements have been star ted, it is desirable that the control program be able to

determine when individual measurement results are available so that the control program can request that

measurement’s results without having to wait on other measurements which have not yet completed.

Overview

The INITiate:DONE? query command is used to determine wh ich measurement is finished.

As the name implies, the query returns the name of whichever active measurement is done so that the control

program can request that measurement’s results.

This command is query only and retu rns only one response per query. The responses returned and their

meaning are shown in the following table.

Once a measurement is reported as being done via the INITiate:DONE? query it is removed from the done list

(measurements are only reported as being done once). The design of the INITiate:DONE? query is predicated

on the control program immediately fetching a measurement’s results once it is reported as being do ne.

Table 1. Responses Returned from INITiate:DONE? Query

Response Meaning

TXP The transmit power measurement is done.

PVT The power versus time measurement is done.

PFER The phase and frequency error measurement is done.

ORFS The output RF spectrum measurement is done.

AAUD The analog audio measurement is done.

DAUD The decoded audio measurement is done.

BERR The bit error measurement is done.

FBER The fast bit error measurement is done.

DPOW The dynamic power measurement is done.

IQT The I/Q Tuning measurement is done.

WAIT There are one or more measurements that are in

progress, but none of those measurements are done yet.

NONE No measurements are in progress.

49

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step6b.fm

Step 6b: Determine if a Measurement Is Done

Example 1. Command Syntax:

INITiate:DONE?

Example 2. Programming Example:

See “Programming Example:” on page 45.

50

S:\Hp8960\E1960A GSM Mobile Test Application\A.04 Release\Proguide\Chapters\prog_prog_guide_step6b.fm

Step 6c: Obtain a Set of Measurement Results

Step 6c: Obtain a Set of Measurement Results

Background