HP 8924E CDMA Mobile Station Test Set

User’s Guide

Firmware Version A.02.00 and above

!

POWER

DO NOT APPLY

RF WHEN OFF

RF IN/OUT

MAX PWR

CDMA CALL CONTRO L

CDMA SCRNS

CELL

CALL

CTRL

SPECTRUM

GEN

CTRL

ANALOG SCRNS

ENCODER

RF

ANL

AF

ANL

SPEC ANL

RF

GEN

END

CALL

RANGE

RX

TEST

MSRPT

TX

TEST

DECODER

RX

TEST

ACP

TX

TEST

SCOPE

DUPLEX

CALL ANS

USER DATA

k1’

k1

k2’

k2

k3’

k3

ASSIGN

k4

RELEASE

k5

!

6 W

MAX PWR

200 mW

!

FUNCTIONS

MSG

PRINTER

HELP

PRINT

DATA FUNCTIONS

REF SET

METER

INCR

INCR

: 10

SET

LO LIMIT HI LIMIT

CURSOR

CONTROL

CANCELSHIFT

I/O CONFIG CONFIG

PREV TESTS

AVG

INCR X10

PUSH TO

SELECT

ANTENNA INDUPLEX OUT

INSTRUMENT STATE

ADRS

SAVE

LOCAL

RECALL

789

456

123

+

0

YES

ON/OFF

Ω

NO

%

ppm

dBµV

W

AUDIO OUTSQUELCHVOLUMEMIC/ACC

MAX

!

12 v Pk

_

HOLD

MEAS

RESET

ENTER

dB

GHz

dBm

%

MHz

V

s

kHz

mV

ms

Hz

µV

AUDIO IN

MAX

!

42 v Pk

PRESET

MEMOR

Y CARD

LOHI

HP Part No. 08924-90057

Printed in U. S. A.

October 1998

Rev. C

1

Copyright © Hewlett-Packard Company 1998

Notice Information contained in this document is subject to change without notice.

All Rights Reserved. Reproduct ion, adaptation, or translati on without prior written

permission is prohibited, except as allowed under the copyright laws.

This material may be reproduced by or for the U.S. Government pursuant to the

Copyright License under the clause at DFARS 52.227-7013 (APR 1988).

Hewlett-Packard Company

Learning Products Department

24001 E. Mission

Liberty Lake, WA 99019-9599

U.S.A.

2

Manufacturer’s Declaration

This statement is provided to c omply with the req uiremen ts of t he German So und

Emission Directive, from 18 January 1991.

This product has a sound pressure emission (at the operator position) < 70 dB(A).

• Sound Pressure Lp < 70 dB(A).

• At Operator Position.

• Normal Operation.

• According to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Schalldruckpegel Lp < 70 dB(A).

• Am Arbeitsplatz.

• Normaler Betrieb.

• Nach ISO 7779:1988/EN 27779:1991 (Typprüfung).

3

Safety

Considerations

GENERAL

This product and related document ation must be revi ewed for familiariz ation with

safety markings and instructions before operation.

This product has been designed and tested in accordance with IEC Publication

1010, "Safety Requirements for Electronic Measuring Apparatus," and has been

supplied in a s af e condition. This ins tr uction documentati on contains information

and warnings which must be followed by the user to ensure safe operation and to

maintain the product in a safe condition.

SAFETY EARTH GROUND

A uninterruptible safety earth ground must be provided from the main power

source to the product input wiring terminals, power cord, or supplied power cord

set.

CHASSIS GROUND TERMINAL

To prevent a potential shoc k hazard, always co nnect the rear-pa nel chassis gr ound

terminal to earth ground when operating this instrument from a dc power source.

SAFETY SYMBOLS

Indicates instrument damage can occur if indicated operating limits are exceeded.

!

Indicates hazardous voltages.

Indicates earth (ground) terminal

WARNING

A WARNING note denotes a hazard. It calls attention to a procedure,

practice, or the like, which, if not correctly performed or adhered to, could

result in personal injury. Do not proceed beyond a WARNING sign until the

indicated conditions are fully understood and met.

CAUTION

A CAUTION note denotes a hazard. It calls attention to an operation procedure,

practice, or the like, which, if not correctly performed or adhered to, cou ld resu lt

in damage to or destruction of part or all of the product. Do not proceed beyond

an CAUTION note until the indicated conditions are fully unde rstood and met.

4

Safety Considerations for this Instrument

WARNING This product is a Safety Class I instrument (provided with a protective

earthing ground incorporated in the power cord). The mains plug shall only

be inserted in a socket outlet provided with a protective earth contact. Any

interruption of the protective conductor inside or outside of the p roduct is

likely to make the product dangerous. Intentional interruption is

prohibited..

Whenever it is likely that the protection has been impaired, the instrument

must be made inoperative and be secured against any unintended operation.

If this instrument is to be energized via an autotransformer (for voltage

reduction), make sure the common terminal is connected to the earth

terminal of the power source.

If this product is not used as specified, the protection provided by the

equipment could be impaired. This product must be used in a normal

condition (in which all means for protection are intact) only.

No operator serviceable parts in this product. Refer servicing to qualified

personnel. To prevent electrical shock, do not remove covers.

Servicing instructions are for use by qualified personnel only. To avoid

electrical shock, do not perform any servicing unless you are qualified to do

so.

The opening of covers or removal of parts is likely to expose dangerous

voltages. Disconnect the product from all voltage sources while it is being

opened.

Adjustmen ts describe d i n t h e ma nu al are perfor me d w i t h po w e r su p pl i e d t o

the instrument while protective covers are removed. Energy available at

many points may, if contacted, result in personal injury.

The power cord is connected to internal capacitors that my remain live for

5 seconds after disconnecting the plug from its power supply.

For Continued protection against fire hazard, replace the line fuse(s) only

with 250 V fuse(s) or the same current rating and type (for example, normal

blow or time delay). Do not use repaired fuses or short circuited

fuseholders.

5

CAUTION: Always use the three-prong ac power cord supplied with this product. Failure to ensure

adequate earth grounding by not using this cord may cause product damage.

This product is designed for use in Installation Category II and Pollution Degree

2 per IEC 1010 and IEC 664 respectively.

This product has autorangi ng line voltage input, be sure the supply voltage is

within the specified range.

Ventilation Requirements: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperature of the product by 4° C for every 100 watts dissipated in the cabinet.

If the total power dissipated in the cabin et is greater than 80 0 watts, then forced

convection must be used.

Product Markings CE - the CE mark is a registered trademark of the European Community. A CE

mark accompanied by a year indicated the year the design was proven.

CSA - the CSA mark is a registered trademark of the Canadian Standards

Association.

6

HP 8924E

Hewett-Packard Warranty Statement for Commercial Products

Duration of

Warranty: 1 year

1. HP warrants HP hardware, accessories and supplies against defects in materials and

workmanship for the period specified above. If HP receives notice of such defects

during the warranty period, HP will, at its option, either repair or replace products

which prove to be defective. Replacement products may be either new or like-new.

2. HP warrants that HP software will not fail to execute its programming instructions, for

the period specified above, due to defects in material and workmanship when p roperly

installed and used. If HP receives notice of such defects during the warranty period, HP

will replace software media which does not execute its programming instructions due

to such defects.

3. HP does not warrant that the operation of HP products will be uninterrupted or error

free. If HP is unable, within a reasonable time, to repair or replace any product to a

condition as warranted, customer will be entitled to a refund of the purchase price upon

prompt return of the product.

4. HP products may contain remanufactured parts equivalent to new in performance or

may have been subject to incidental use.

5. The warranty p eriod begins on the date of delivery or on the date of installation if

installed by HP. If customer schedules or delays HP installation more than 30 days after

delivery, warranty begins on the 31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or inadequate mainte-

nance or calibration, (b) software, interfacing, parts or supplies not supplied by HP, (c)

unauthorized modification or misuse, (d) operation outside of the published environmental specifications for the product, or (e) improper site preparation or maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE WARRANTIES

ARE EXCLUSIVE AND NO OTHER WARRANTYOR CONDITION, WHETHER

WRITTEN OR ORAL IS EXPRESSED OR IMPLIED AND HP SPECIFICALLY

DISCLAIMS ANY IMPLIED WARRANTIES OR CONDITIONS OR MERCHANTABILITY, SATISFACTORY QUALITY, AND FITNESS FOR A PARTICULAR

PURPOSE.

8. HP will be liable for damage to tangible property per incident u p to the greater of

$300,000 or the actual am ount paid f or th e product t hat is the subject of th e claim, an d

for damages for bodily injury or death, to the extent that all such damages are determined by a court of competent jurisdiction to have b een directly caused b y a defective

HP product.

7

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS

WARRANTY STATEMENT ARE CUSTOMER’S SOLE AND EXCLUSIVE

REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO EVENT WILL HP OR ITS

SUPPLIERS BE LIABLE FOR LOSS OF DATA OR FOR DIRECT, SPECIAL,

INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST PROFIT OR DATA), OR

OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR

OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND:

THE WARRANTY TERMS CONTAINED IN THIS STATEMENT, EXCEPT TO

THE EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE RESTRICT OR

MODIFY AND ARE IN ADDITION TO THE MANDATORY STATUTORY

RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

8

HP 8924E Support

Contacts

Repair assistance is available for the HP 8924E CDMA Mobile Test Set from the factory

by phone and e-mail. Internal Hewlett-Packard users can contact the factory through

HPDesk or cc:Mail© (Lotus Corporation). Parts information is also available from

Hewlett-Packard.

When calling or writing for repair assistance, please have the fo llowing information

ready:

• Instrument model number (HP 8924E)

• Instrument Serial Number (tag located on the rear panel).

• Installed options - if any (tag located on the rear panel).

• Instrument firmware revision (displayed at the top of the screen when the Test Set is

powered up, and is also displayed on the CONFIGURE screen).

Support Telephone

1 800 827 3848 (Spokane Division Service Assistance, U.S. only)

1 509 921 3848 (Spokane Division Service Assistance, International)

1 800 227 8164 (HP Direct Parts Ordering, U.S. only)

1 916 783 0804 (HP Service Parts Identification, U.S. & Intl.)

Electronic mail (Internet): Spokane_Service@spk.hp.com

HP Desk: Spokane Service / HP1000/21

cc:Mail: SERVICE, SPOKANE /HP-Spokane,desk1

Numbers:

9

Table 1 Regional Sales and Service Offices

United States of America

U.S. Instrument Support Center

For Test & Measurement Equipment

Repair & Calibration.

Hewlett-Packard Company

Englewood, Colorado 80112

Telephone: (800) 403-0801

Fax: (888) 857-8161

South Eastern E urope

Sales and Service

Hewlett-Packard Ges. m.b.h.

Liebigasse 1

P.O. Box 72

A-1222 Vienna, Austria

Telephone: 43 222 2500 0

Telex: 13 4425

Asia

Sales and Service

Hewlett-Packard Asia Ltd.

22-30/F Pere gri n e T ow e r

Lippo Center

89 Queensway, Central

Hong Kong

G.P.O. Box 863 Hong Kong

United States of America

Customer Information Center

For Assistance On All HP

Products.

Hewlett-Packard Company

Tel: (800) 752-0900

6:00 am to 5:00 pm Pacific Time

Parts Direct: 1-800-227-8164

European Multicountry Region

Sales and Service

Hewlett-Packard S.A.

P.O. Box 95

150, Route dv Nant_dl_AVRIL

CH-1217 Meyrin 2

Geneva, Switzerland

Telephone: (41/22) 780-81 11

Fax: (41/22) 780-8542

Japan

Sales and Service

Hewlett-Packard Japan, Ltd.

3-29-21, Takaido-Higashi

Suginami-Ku, Tokyo 168-8585

Telephone: 81 3 3331-6111

Fax: 81 3 3331-6631

United Kingdom

Sales and Service

Hewlett-Packard Ltd.

Cain Road

Amen Corner

Bracknell, Berkshire

RG12 1HN

United Kingdom

Telephone: 44 344 360000

Fax: 44 344 363344

Northern Europe

Sales and Service

Hewlett-Packard Nederland B.V.

Startbaan 16

1187 XR

Amstelveen, The Netherlands

P.O. Box 667

Telephone: 31/20 5476911 X 6631

Fax: 31-20-6471825NL

International Sales Branch

Headquarters

Sales and Service

Hewlett-Packard S.A.

39 Rue Veyrot

P.O. Box 365

1217 Meyrin 1

Geneva, Switzerland

Telephone: 852-848-7777

Fax: 852-868-4997

Australia, New Zealand

Sales and Service

Hewlett-Packard Ltd.

P.O. Box 221

31-41 Joseph Street

Blackburn, Victoria 3130

Telephone: (61/3) 895-2895

Fax: (61/3) 898-9257

10

Canada

Sales and Service

Hewlett-Packard (Canada) Ltd.

5150 Spectrum Way

Mississauga, Ontario L4W 5G1

Canada

Telephone: (416) 206-4725

Fax: (416) 206-4739

Telephone: 41-22-780-4111

Fax: 41-22-780-4770

Canada

Service Center

Hewlett-Packard Company

17500 Transcanada Highway

S. Serv Road

Kirkland, Quebec H9J 2X8

Canada

Telephone: (416) 206-3295

Table 1 Regional Sales and Service Offices (Continued)

Canada

Service Center

Hewlett-Packard Ltd.

11120 178 Street

Edmonton, A lberta T5S 1P2

Canada

Telephone: (403) 486-6666

Fax: (403) 489-8764

Latin America

Hewlett-Packard Company

LAHQ Mexico City

Col. Lomas de Virreyes

11000 Mexico D.F.

Mexico

Telephone: (52/5) 326-4000

Fax: (52/5) 202 7718

11

In this Book Throughout this manual the term "Test Set" is used to denote the HP 8924E.

Test Set screens sh own in thi s ma nual may not match those display ed on the Test

Set in every detail.

Chapter 1, Getting Started

This chapter provides basic remote and front-panel operating procedures, a quick check

for verifying operation, HP-IB programming procedures, and simple programming

examples.

Chapter 2, Configuring Your Test Set

This chapter provides information about setting screen inten sity , setting RF voltage

interpretation, setting time and date, and setting the beeper’s volume.

Chapter 3, Operating Overview

This chapter explains how to specify units of measure, how to use the analog meter,

how to use measurement averaging, how to set a measurement reference, how to set

measurement limits, how to enter and change values, how to save and recall instrument

setups, how to use the USER keys, and how to set a frequency offset. It also descri bes

some important interactions that occur between screen settings.

Chapter 4, Keys

This chapter provides front-panel key descriptions.

Chapter 5, Connectors

This chapter describes the front and rear panel connectors.

Chapter 6, Screens

This chapter provides a picture of each screen available on the Test Set with an overview of the functions provided.

Chapter 6, Fields

This chapter provides a description of the functions performed by each field.

Chapter 7, Memory Cards, Mass Storage

This chapter describes memory cards and mass storage devices used with the

Test Set.

12

Error Messages

This section discusses error and operating messages.

13

14

Contents

1 Getting Started

Before Connecting a Radio 26

Accessing the Test Set’s Screens 27

Changing A Field’s Setting 30

Obtaining Measurement Results 34

Control Annunciators 35

Verifying th at the Test Set is Operating P roperly 36

15

Contents

2 Configuring Your Test Set

Recommended Calibration Procedures 40

Instrument Display Setup 42

16

Contents

Operating Overview

3

To Change the Measurement Display 45

To Enter and Change Values 51

Saving and Recalling Instrument Setups 54

Using USER Keys 59

Setting an RF Generator/Analyzer Frequency Offset 62

Setting an RF Generator/Analyzer Level Offset 63

Printing A Screen 64

Triggering Analog Measurements In Local Mode (Front Panel

Operation) 65

Triggering CDMA Measurements In Local Mode (Front Panel

Operation) 66

17

Contents

4 Description of Keys

Keys That Begin with the Letter A 69

Keys That Begin with the Letter C 70

Keys That Begin with the Letter E 71

Keys That Begin with the Letter H 72

Keys That Begin with the Letter I 73

Keys That Begin with the Letter K 74

Keys That Begin with the Letter L 75

Keys That Begin with the Letter M 76

Keys That Begin with the Letter O 77

Keys That Begin with the Letter P 78

Keys That Begin with the Letter R 79

Keys That Begin with the Letter S 80

Keys That Begin with the Letter Y 81

Keys That Begin with a Number 82

Symbol Keys 83

Miscellaneous Hardware 84

DATA FUNCTIONS Keys 85

USER Keys 86

18

Contents

5 Description of Connectors

Connectors That Begin with the Letter A 89

Connectors That Begin with the Letter C 92

Connectors That Begin with the Letter D 96

Connectors That Begin with the Letter E 97

Connectors That Begin with the Letter H 98

Connectors That Begin with the Letter M 99

Connectors That Begin with the Letter P 101

Connectors That Begin with the Letter R 103

Connectors That Begin with the Letter S 105

Connectors That Begin with a Number 107

19

Contents

6 Description of Screens

Analog Meas Screen 110

Authentication (Call Control) 112

Call Configure (Call Control) 113

Call Control Screen 114

Call Data (Call Control) 115

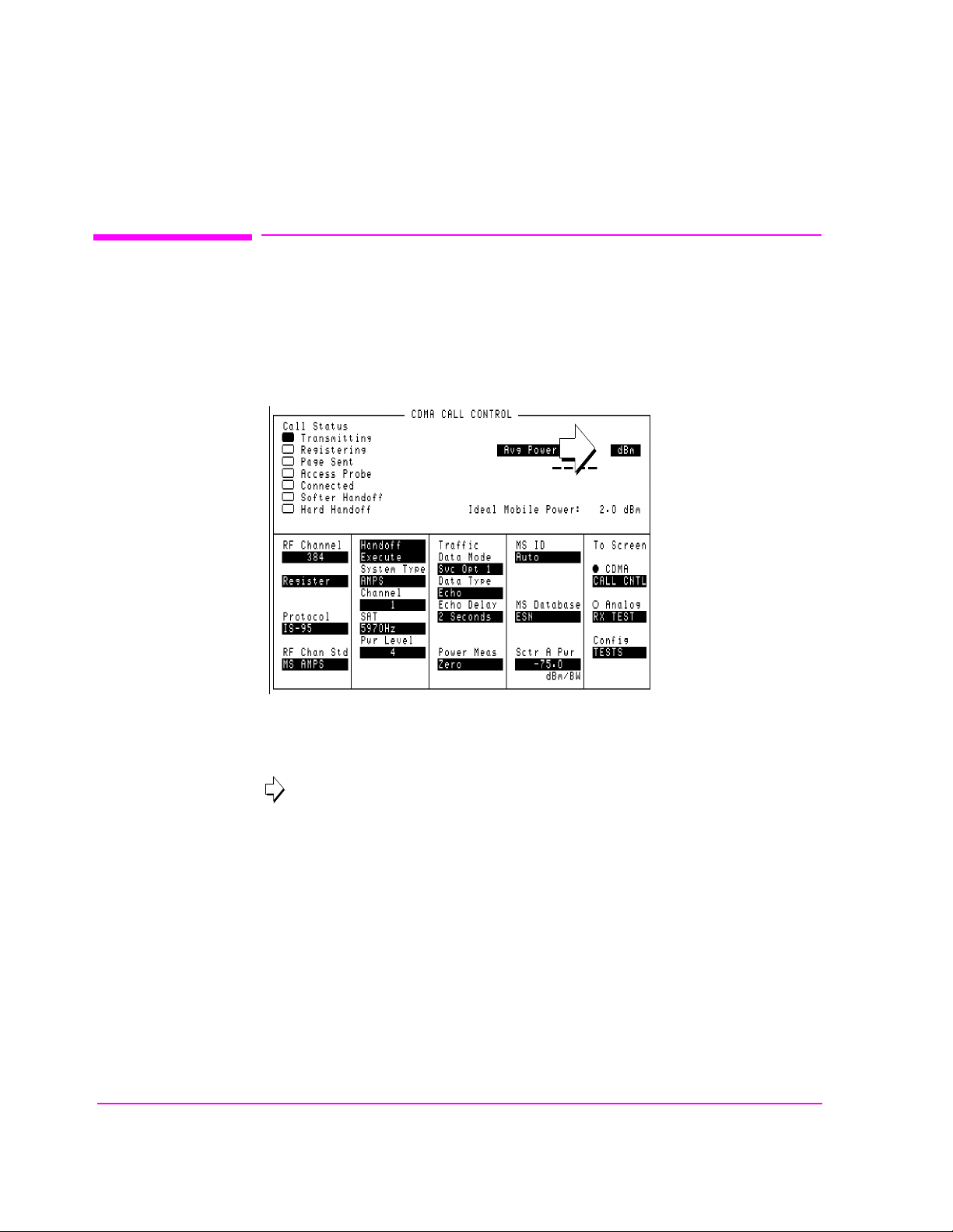

CDMA Call Control Screen 118

CDMA Cell Site Configuration Screen 119

CDMA Cellular Mobile Receiver Test Screen 120

CDMA Cellular Mobile Transmitter Test Screen 122

CDMA Generator Control Screen 123

CDMA Mobile Reporting Screen 125

CDMA Transmitter Power Range Test Screen 126

CDMA Reverse Channel Spectrum Screen 127

Configure Screen 128

I/O Configure Screen 129

Oscilloscope Screens 130

Print Configure Screen 131

Spectrum Analyzer Screens (Opt 012 only) 132

20

Contents

7 Description of Fields

Fields That Begin with the Letter A 136

Fields That Begin with the Letter B 156

Fields That Begin with the Letter C 159

Fields That Begin with the Letter D 172

Fields That Begin with the Letter E 187

Fields That Begin with the Letter F 194

Fields That Begin with the Letter G 199

Fields That Begin with the Letter H 200

Fields That Begin with the Letter I 202

Fields That Begin with the Letter L 207

Fields That Begin with the Letter M 208

Fields That Begin with the Letter N 220

Fields That Begin with the Letter O 227

Fields That Begin with the Letter P 231

Fields That Begin with the Letter R 241

Fields That Begin with the Letter S 258

Fields That Begin with the Letter T 268

Fields That Begin with the Letter U 279

Fields That Begin with the Letter V 281

21

Contents

Fields That Begin with the Letter W 283

Fields That Begin with a Number 284

22

Contents

8 Memory Card s/Mass Storage

Using Memory Cards 286

Backing Up Procedure and Library Files 292

Copying Files Using IBASIC Commands 293

Default File System 295

Mass Storage Device Overview 297

Mass Storage Access 306

DOS and LIF File System Considerations 307

Using the ROM Disk 311

Using RAM Disk 312

Using External Disk Drives 314

23

Contents

Index 347

24

1

Getting Started

This chapter will help familiarize you with fundamental Test Set operation,

including:

• Accessing screens and fields

• Making a simple measurement

• Preparation for remote operation via HP-IB

25

Chapter 1, Getting Started

Before Connecting a Radio

Before Connecting a Radio

NOTE: The RF IN/OUT port should be used for all transmitter tests when the radio is co nnected

directly to the Test Set. (All MSUT (Mobile Station Under Test) transmitter power

measurements are made through this port). Off-the-air measurements can be made using the

highly-sensitive ANT IN port.

CAUTION: Overpower Damage — Refer to the Test Set’s front panel for maximum input power level.

Exceeding this level can cause permanent instrument damage.

Other Damage — Blocking the fans’s rotation or operating the Test Set in an

environment that causes excessive heat may cause damage.

Important: If excessive temperatures are sensed on the power supply regulator

assembly, the Test Set’s power supply will shut off. After temperature has

lowered to within normal operating range, use the POWER switch to cycle power

on. Remove RF power from the RF IN/OUT connector whenever the Test Set is

off.

26

Accessing the Test Set’s Screens

CDMA and Analog Modes

The Test Set has two operating modes, analog and CDMA. In CDMA mode, the

Test Set configures its elf as a cali brate d CDMA ba se st ation. In Anal og mode, the

Test Set has AMPS, NAMPS and TACS analog cellular phone test capability.

CDMA is the default power-up mode. To enter analog mode from CDMA mode:

• press one of th e ANLG SCRNS key s, or

• select a screen from the Analog To Screen menu, or

• programmatically select an analog screen using the display (DISP) HP-IB subsystem,

or

• execute a CDMA to Analog handoff.

Chapter 1, Getting Started

Accessing the Test Set’s Screens

To enter CDMA mode from analog mode:

• press one of the CDMA SCRNS keys, or

• select a screen from the CDMA To Screen menu, or

• programmatically select a CDMA screen using the display (DISP) HP-IB subsystem.

27

Chapter 1, Getting Started

Accessing the Test Set’s Screens

Functions Screens

Screens that control various instrument functions such as configuration, access to

the Tests subsystem, and the PREV (previous screen) key are found under the

front-panel “Functions” bracket.

CDMA Digital Transceiver Measurements

Analog Transceiver Tests

!

POWER

DO NOT APPLY

RF WHEN OFF

RF IN/OUT

MAX PWR

!

6 W

DUPLEX OUT

MAX PWR

200 mW

!

ANTENNA IN

Figure 1 Accessing Test Set Screens

Instrument Functions

CDMA CALL CONTRO L

CDMA SCRNS

CELL

CALL

CTRL

SPECTRUM

GEN

CTRL

ANALOG SCRNS

ENCODER

RF

ANL

AF

ANL

SPEC ANL

RF

GEN

END

CALL

RANGE

RX

TEST

MSRPT

TX

TEST

DECODER

RX

TEST

ACP

TX

TEST

SCOPE

DUPLEX

CALL ANS

USER DATA

k1’

k1

k2’

k2

k3’

k3

ASSIGN

k4

RELEASE

k5

FUNCTIONS

MSG

PRINTER

HELP

PRINT

DATA FUNCTIONS

REF SET

METER

INCR

INCR

: 10

SET

LO LIMIT HI LIMIT

CURSOR

CONTROL

CANCELSH IFT

I/O CONFIG CONFIG

PREV TESTS

AVG

INCR X10

PUSH TO

SELECT

INSTRUMENT STATE

ADRS

LOCAL

789

456

123

0

NO

YES

ppm

ON/OFF

W

AUDIO OUTSQUELCHVOLUMEMIC/ACC

MAX

!

12 v Pk

SAVE

RECALL

+

Ω

%

dBµV

_

HOLD

MEAS

RESET

ENTER

dB

GHz

dBm

%

MHz

V

s

kHz

mV

ms

Hz

µ

V

AUDIO IN

MAX

!

42 v Pk

PRESET

MEMOR

Y CARD

LOHI

28

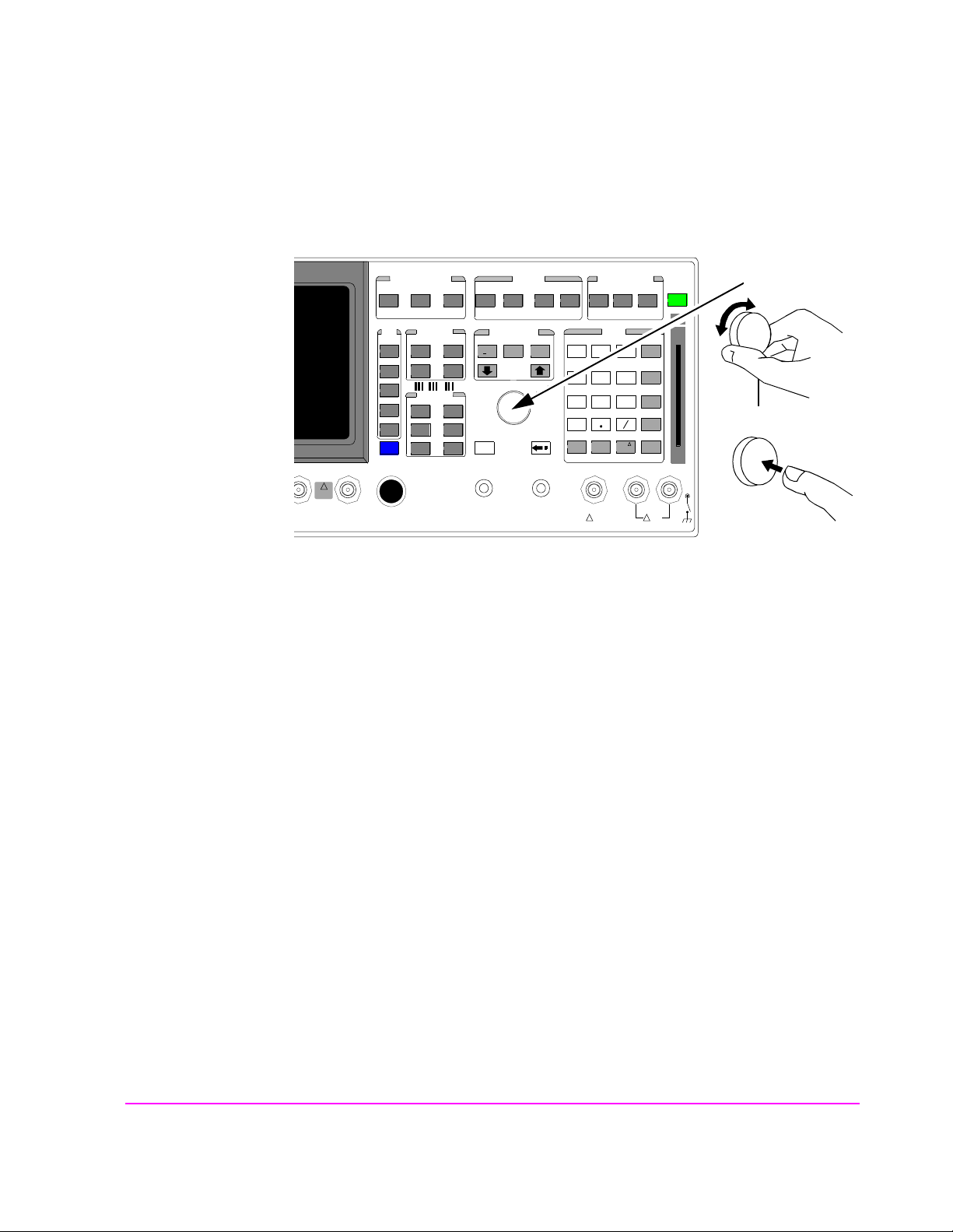

Cursor Control

Chapter 1, Getting Started

Accessing the Test Set’s Screens

INSTRUMENT STATE

ADRS

SAVE

LOCAL

RECALL

789

456

123

+

0

YES

ON/OFF

Ω

NO

%

ppm

dBµV

W

AUDIO OUTSQUELCHVOLUMEMIC/ACC

MAX

!

12 v Pk

_

HOLD

MEAS

RESET

ENTER

dB

GHz

dBm

%

MHz

V

s

kHz

mV

ms

Hz

µ

V

AUDIO IN

MAX

!

42 v Pk

PRESET

1

MEMOR

Y CARD

2

LOHI

MAX PWR

200 mW

!

ANTENNA IN

CDMA CALL CON TROL

CDMA SCRNS

CELL

CALL

CTRL

SPECTRUM

GEN

CTRL

CDMA SCRNS

ENCODER

RF

ANL

AF

ANL

SPEC ANL

RF

GEN

END

CALL

RANGE

RX

TEST

MSRPT

TX

TEST

DECODER

RX

TEST

ACP

TX

TEST

SCOPE

DUPLEX

CALL ANS

USER DATA

k1’

k1

k2’

k2

k3’

k3

ASSIGN

k4

RELEASE

k5

FUNCTIONS

MSG

PRINTER

HELP

PRINT

DATA FUNCTIONS

REF SET

METER

INCR

INCR

: 10

SET

LO LIMIT HI LIMIT

CURSOR

CONTROL

CANCELSHIFT

I/O CONFIG CONFIG

PREV TESTS

AVG

INCR X10

PUSH TO

SELECT

1. Position

To position the cursor, rotate the Cursor Control knob, which moves the cursor from

field to field or from menu item to menu item. Normally the cursor appears as a small

highlighted rectangular box.

2. Select

To select an item, push the Cursor Co ntrol knob . After selection, the background of the

item selected becomes highlighted or the item selected appears in an associated field.

29

Chapter 1, Getting Started

Changing A Field’s Setting

Changing A Field’s Setting

There are several types of CRT display fields in the Test Set. This section

describes some of the different types of fields, and how they are used.

Units-of-Measure Field

Figure 2 Units-of-Measure Field

Units-of-measure fields allow selection of valid units for given measurement. See

figure 2 to see an example of a units-of-measure field.

in

To change a unit-of-measure

1. Position the cursor at the unit field on the display.

2. Press a key labeled with a different unit-of-measure (such as W).

3. If the new units are valid, the measurement valu e will be displayed in the new unit-of-

measure.

30

Underlined Immediate-Action Field

Chapter 1, Getting Started

Changing A Field’s Setting

Figure 3 Underlined Immediate-Action Field

Underlined immediate action fields provide a choice of two settings. See in

figure 3 to see an example of an underlined immediate-action field.

To change an underlined entry

1. Position the cursor at the field.

2. Push the CURSOR CONTROL knob or the ENTER key to underline the desired

choice.

31

Chapter 1, Getting Started

Changing A Field’s Setting

One-of-Many Field

Figure 4 One-of-Many Field

One-of-many fields displ ay a list of ch oic es when sel ected. See in figure 4 to

see an example of a one-of many field.

To make a one-of-many choice

1. Position the cursor at the field.

2. Push the C

3. Move the cursor through the choices by turning the knob.

4. Push the C

URSOR CONTROL knob or the ENTER key to display the choices.

URSOR CONTROL knob or the ENTER key to make the choice.

32

Numeric-Entry Field

Chapter 1, Getting Started

Changing A Field’s Setting

Figure 5 Numeric-Entry Field

Numeric-entry fields contain numeric values. See in figure 5 to see an

example of a numeric-entry field.

To change a value

1. Position the cursor at the field.

2. Key in the desired number using the DATA keys.

3. Press ENTER to select the choice.

OR

1. Position the cursor at the field.

2. Push the C

3. Turn the knob to increment or decrement the value.

4. Push the C

URSOR CONTROL knob to highlight the desired choice.

URSOR CONTROL knob or the ENTER key to select the choice.

33

Chapter 1, Getting Started

Obtaining Measurement Results

Obtaining Measurement Results

Setting Up a Call

To obtain CDMA measurements, the Test Set must have the MSUT (Mobile

Station Under Test) on a call (the Connected annunciator on the CDMA CALL

CONTROL screen is lit when the MSUT is on a call).

The procedure for setting up a call is provided in “Setting Up a Call”, found in the HP

8924E Introduction to Operation

performing CDMA tests.

Triggering and Displaying Measurements

. In this guide, there are also procedures for

When operate d over the front panel (loca l control), Tes t Set measurement results

are obtained by selecting a screen that displays the desired measurement, arming

the measurement if necessary, and observing the displayed value.

When operated remotely, measurement results are obtained via HP-IB by

triggering a measurement if necessary and querying the desired measurement

field.

NOTE: In CDMA mode, transmitter (TX) measu rements and rec eiver (RX) measur ements c an

run concurrently. For example, an Average Power or Channel Power measurement

can be queried while the RX TEST screen is selected and an FER measurement is

running.

For a detailed description of triggering measurements, see

Displaying Measurements" on page 34

.

"Triggering and

34

Control Annunciators

The letters and symbols at the top right corner of the display indicate these conditions:

R indicates the Test Set is in remote mode. The Test Set can be put into the remote mode

by an external controller or by an IBASIC program running on the built-in IBASIC co ntroller.

• L indicates the Test Set has been addressed to listen.

• T indicates the Test Set has been addressed to talk.

• S indicates the Test Set has sent the require service message by setting the service re-

quest (SRQ) bus line true. (See "Status Reporting" on page 117).

• C indicates the Test Set is currently the active controller on the bus.

Chapter 1, Getting Started

Control Annunciators

• * indicates an IBASIC program is running.

• ? indicates an IBASIC program is waiting for a user response.

• - indicates an IBASIC program is paused.

35

Chapter 1, Getting Started

Verifying that the Test Set is Operating Properly

Verifying that the Test Set is Operating Properly

If your Test Set powers-up and displays the CDMA CALL CONTROL screen,

but you suspect an instrument pro blem, the CDMA Mode Quick Check will verify

operation of the instrument’s basic functions.

CDMA Mode Quick Check

NOTE: This procedure assumes that the Test Set is configured for cellular mobile station testing, not

PCS. If necessary, access the CONFIGURE screen and turn PCS Intrfc Control Off

then be necessary to cycle power.

1. Remove any cabling from the front-panel connectors.

2. Turn instrument power on (if it is not already on).

. It will

3. Press the PRESET key.

4. Press and release the SHIFT key then the TESTS key to access the CONFIGURE

screen.

5. Position the cursor in the RF Display field, and press the knob to select Freq. The

RF Offset and (Gen)-(Anl)fields will appear below RF Display.

6. Change the (Gen)-(Anl) value to 0 MHz.

7. Position the cursor in the Output Port field and Select Dupl

8. Press GEN CTRL, +/-, 5, 0 ENTER to adjust Sector A Power to -50 dBm/BW.

9. Press and release the SHIFT key then the GEN CTRL key to access the CDMA

REVERSE CHANNEL SPECTRUM analyzer screen.

10. Position the cursor in the Ref Level field, and press +/-, 1, 0, ENTER to enter a

reference level of -10 dBm.

11. The display should show a CDMA signal, approximately 1.23 MHz wide.

.

If no failure is indicated by this test, but you still suspect a problem, refer to the

performance tests information in the HP 8924E Assembly Level Repair Manual.

36

Analog Mode Quick Check

1. Remove any connected cables (except for line power).

2. Turn instrument power on (if it is not already on).

3. Press the PRESET key.

4. Press and release the SHIFT key, then the TESTS key to access the CONFIGURE

screen.

5. Position the cursor in the RF Display field, and press the knob to select Freq.

6. The RF Offset and RF Offset and (Gen)-(Anl) fields will appear below the

RF Display.

7. Change the(Gen)-(Anl) value to 0 MHz.

8. Press and release the SHIFT key, then k4 to select the ASSIGN function, then press the

ENTER key. This will assign pre-defined settings to th e USER keys.

Chapter 1, Getting Started

Verifying that the Test Set is Operating Properly

9. Press DUPLEX, k3, +/-, 2, 4, ENTER to set the RF Generator’s Amplitude.

10. Press k5, and position the curs or in fr ont of FM Demod at top of t he Choices menu.

11. Press ENTER to select the FM Demodulator for the AF Analyzer’s input.

12. Turn the VOLUME knob clockwise to hear a 1 kHz tone (default for AFGen1 Freq ).

13. The TX Frequency measurement should be about 870 MHz (the same as the RF

Gen Freq setting).

14. FM deviation should be about 2.1 kHz (rms).

15. SINAD should be about 40 dB.

16. Press and release the SHIFT key, then the DUPLEX key to access the

OSCILLOSCOPE screen.

17. Two complete sinewave cycles should be displayed.

18. Deviation should be 3 kHz peak (1.5 units above the center line).

19. Press and release the SHIFT key then the RF GEN key to access the SPECTRUM

ANALYZER.

20. A 100 MHz FM carrier should be displayed.

21. The signal level should be approximately 0 dBm when reading the Lvl display. The

level will vary with the marker’s position.

If no failure is indicated by this test, but you still suspect a problem, refer to the

Performance Tests information in the HP 8924E Assembly Level Repair Manual.

37

Chapter 1, Getting Started

Verifying that the Test Set is Operating Properly

38

2

Configuring Your Test Se t

This chapter will help you prepare the Test Set for making measurements. This

includes:

• Calibration Guidelines

• Setting screen intensity

• Setting time and date

• Setting beeper volume

39

Chapter 2, Configuring Your Test Set

Recommended Calibration Procedures

Recommended Calibration Procedures

Step-by-step calibrat i on proce dur es are located in the HP 8924E Introduction to

Operation, “Calibrate the Test Set”.

Use the table below to determine which calibration procedures need to be

performed.

40

Chapter 2, Configuring Your Test Set

Recommended Calibration Procedures

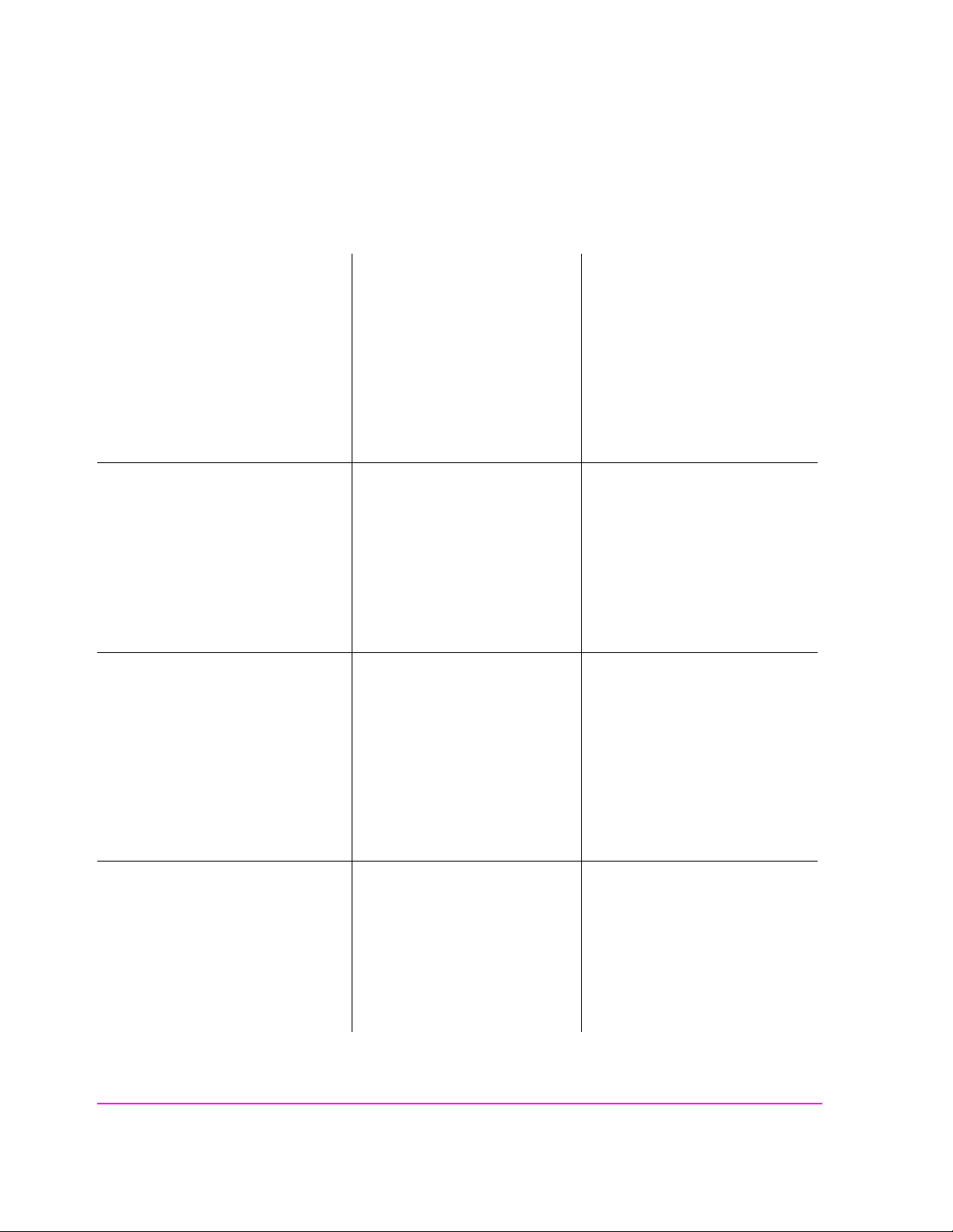

Table 2 Recommended Calibration Procedures

After 30 minute

warm-up period

After fi rmware is

upgraded

When the "Uncal"

light is flashing

Before making an

Average Power

measurement

If the RF connections to the PCS

interface are

adjusted

If the ambient

temperature

changes more 5

degrees C after 30

minute warm-up

period

CDMA Channel

Levels

Channel Power

Measurements

RF Generator

Levels

Average Power

Measurement

Zeroing

After calibrating

CDMA Channel

levels (also known

as “PCB CAL”.

41

Chapter 2, Configuring Your Test Set

Instrument Display Setup

Instrument Display Setup

The following procedures are related to features available on the CONFIGURE

screen. The Test Set wi ll retain these settings du ring power cycles or instrument

PRESET.

To Set Screen Intensity

1. Access the CONFIGURE screen.

2. Select the Intensity field.

3. Rotate the knob to change the sett ing (1=dim, 8=bright).

To Set the Date and Time

1. Access the CONFIGURE screen.

2. Select the Date field and use the DATA keys to enter the date in the format shown

below the field.

3. Select the Time field and use the DATA keys to enter the time in the format shown

below the field.

The Test Set has a built-in clock that keeps track of the date and time. It is

powered by an internal battery to keep it operating when the instrument is off.

To Change the Beeper’s Volume

1. Access the CONFIGURE screen.

2. Select the Beeper field to display the volume choices.

3. Select the desired choice.

The beeper alerts you to important operating and measurement conditions. It

beeps any time a message is displayed at the top of the screen. These messages

warn you of conditions su ch as ex ceeding th e RF input le vel or try ing to set a f ield

to an unacceptab le value. Therefore, it is recommended t hat you d o not disable the

beeper.

42

3

Operating Overview

43

Chapter 3, Operating Overview

The information in this chapter describes how to use many of the operating

features of the Test Set, including:

• "To Change the Measurement Display" on page 45

• "To Enter and Change Values" on page 51

• "Saving and Recalling Instrument Setups" on page 54

• "Using USER Keys" on page 59

• "Setting an RF Generator/Analyzer Frequency Offset" on page 62

• "Setting an RF Generator/Analyzer Level Offset" on page 63

• "Printing A Screen" on page 64

44

To Change the Measurement Display

To Use the On/Off Function

The on/off function is used for the following operations.

• Measurements that are displayed as numbers, or as meters using the METER f unction,

can be turned on and off.

• The data functions REFerence, METer, HLIMit and LLIMit can be turned on and off.

• Any instrument funct ion that g enerates a s ignal can be tu rned on and off. This includes

the CDMA Sector A Power, Sector B Power, and AWGN.

• Trace displays, such as the CDMA Reverse Channel Spectrum Analyzer, cannot be

turned off.

Chapter 3, Operating Overview

To Change the Measurement Display

The front-panel ON/OFF key is used to turn measurements, instrument functions

and data functions on or off.

Front-Panel Example

The following front-panel operation turns Avg Power off.

1. Move the cursor in front of the unit-of-measure for the Avg Power measurement.

2. Press the ON/OFF key. The Avg Power measurement field displays the word OFF

in place of units

45

Chapter 3, Operating Overview

To Change the Measurement Display

To Use the METER Format

The METER function displays measurements graphically. The METER format is

available for most me asu re ments. To determine if the METER format is provide d

for a measurement, position the cursor in front of the measurement’s units field

and press the knob. If the message “Press ON/OFF, LIMITs, REF, AVG,

METER, or units” is displayed, the METER format is provided.

As a measurement is displayed on the meter, the value is also displayed in small

digits below the meter. You can specify the high and low end points and number

of intervals, or you can use the default meter settings.

1. Position the cursor in front of the measurement’s unit-of-measure.

2. Press and release the SHIFT key, then the INCR SET key to select the METER func-

tion. The default number of average samples is displayed below the measurement.

3. Select On/Off

4. Repeat steps 1 and 2 then select LoEnd, Hi End, or Intervals to enter each meter

end point and the meter intervals.

5. Repeat steps 1, 2, and 3 to cancel the meter function.

from the Meters: field on the CRT display

Front-Panel Example

The following front panel operation turns on the A vg Power measurement meter.

1. Move the cursor in front of the unit-of-measure for the Avg Power measurement).

2. Press and release the SHIFT key, then the INCR SET key to select the METER func-

tion, then press the ENTER key. The meter will appear below the m easurement units

field with default low/high ends and n umbe r of in tervals. To tur n off the measurement

meter, repeat this process.

46

To Set a Measurement Reference

The REF SET function establishes a measurement reference point. This allows

you to make a direct comparison between two measurement results, or between a

measurement standard and the actual measurement results.

Referenced measurements are displayed as either a ratio (dB) or difference

between the measured value and the reference.

1. Position the cursor in front of the unit-of-measure for the measurement you want to set

the reference for.

2. Press and release the SHIFT key, then the INCR ÷10 key to select the REF SET func-

tion.

3. Enter the reference value.

4. Ref appears below the measurement value to indicate that a reference has been set. The

measurement field may display a different unit-of-measur e, and limit choices fo r units.

Front-Panel Example

Chapter 3, Operating Overview

To Change the Measurement Display

The following front-panel operation sets a 10 dBm reference for Avg Power

measurements.

1. Move the cursor in front of the unit-of-measure for the Avg Power measurement).

2. Press and release the SHIFT key, then the INCR ÷10 key.

3. Enter 10 dBm using the DATA keys.

The abbreviation Ref will appear below the Avg Power measurement field and

Avg Power measurements will be expressed in dB. Absolute p ower (mW, W) will

not be selectable.

47

Chapter 3, Operating Overview

To Change the Measurement Display

To Use Measurement Averaging

The AVG (average) function allows you to reduce the effects of a rapidly

changing measurement by displaying the average value of a number of

measurements.

1. Position the cursor in front of the measurement’s unit-of-measure.

2. Press and release the SHIFT key, then the INCR × 10 key to select the AVG function.

The default number of average samples is displayed below the measurement.

• Enter the desired number of measurement samples to be used for calculating the

average, or

• Press the ON/OFF key to use the currently-displayed number of samples.

3. To turn averaging off, position the cursor in front of the unit-of-measure and press re-

lease the SHIFT key, then the INCR × 10 key, then the ON/OFF key to turn averaging

off.

Front-Panel Example

The following front-panel operation averages Avg Power measurements over

10 samples.

1. Move the cursor in front of the unit-of-measure for the Avg Power measurement.

2. Press and release the SHIFT key, then the INCR × 10 key to select the AVG function.

3. Enter 10 using the DATA keys and press the ENTER key. The abbreviation Avg will

appear below the Avg Power measurement field.

48

To Set Measurement Limits

The LO LIMIT and HI LIMIT functions are used to define a measurement

“window” to alert you to measurements that are outside these limits. When limits

are assigned,

A measurement that goes above or below the defined li mi t s cau ses thr ee things to

happen:

1. A message appears at the top of the screen indicating a limit was exceeded.

2. The Lo or Hi indicator by the measurement flashes.

3. The Beeper beeps if it is has not been turned off in the CONFIGURATION screen.

Limits are helpful when you can’t watch the Test Set display while you are

making an adjustment on the equip ment you are test ing or r epairing . They are a lso

a convenient way of alerting you to long-term measurement drift without having

to observe the screen.

Chapter 3, Operating Overview

To Change the Measurement Display

Lo and/or Hi appear by the measurement.

1. Position the cursor in front of the unit-of-measure for the measurement you are setting

limits for.

2. Press and release the SHIFT key, then the down-arrow key to select the LO LIMIT

function.

3. Enter the measurement’s low limit value and unit-of-measure.

4. Press and release the SHIFT key, then the up-arrow key to select the LO LIMIT func-

tion.

5. Enter the measurement’s high limit value and unit-of-measure.

1

1

To reset a limit that has been exceeded:

1. Position the cursor in front of the unit-of-measure for the measurement you assigned

the limit to.

2. Press and release the SHIFT key, then the down-arrow (LO LIMIT) or up-arrow (HI

LIMIT key, or press the MEAS RESET key.

To remove a limit you have set:

1. Position the cursor in front of the unit-of-measure for the measurement you assigned

the limit to.

2. Press and release the SHIFT key, then the down-arrow (LO LIMIT) or up-arrow (HI

LIMIT key, then press the ON/OFF key.

1. The fundamental unit for the LIMITs does not have to be the same as the measurement’s units. For instance, when measuring AC Level in Volts, you can set HI and LO

LIMITs in units of dBm if desired.

49

Chapter 3, Operating Overview

To Change the Measurement Display

Front-Panel Example

This example sets limits for the Avg Power measurement. These limits will

indicate if the power level is between

1. Position the cursor in front of the unit-of-measure for the Avg Power measurement

(the default is dBm).

2. Press and release the SHIFT key, then the down-arrow key to select the LO LIMIT

function.

3. Enter −5 using the DATA keys and press the ENTER key.

4. Press and release the SHIFT key, then the up-arrow key to select the HI LIMIT func-

tion.

5. Enter 5 using the DATA keys and press the ENTER key.

The Hi limit and Lo limit annunciators will appear below the Avg Power

measurement field.

−5 dBm and +5 dBm.

To Specify Units-of-Measure for CRT Display

Most measurements, data functi ons, and instrument functions all ow you to specify

which unit-of-measurement should appear on the CRT display.

1. Position the cursor in front of the present unit-of-measurement.

2. Press the key labeled with the desired unit.

Front-Panel Example

The following front-panel operation causes the Test Set t o dis pla y Avg Power in

units of Watts instead of dBm.

1. Press the PRESET key.

2. Press the CALL CTRL key to access the CDMA CALL CONTROL screen.

3. Move the cursor in front of the unit-of-measure for the Avg Power measurement

(dBm).

4. Press the RATIO W key. The measurement value is changed immediately to display in

Watts.

50

To Enter and Change Val ues

To Enter Decimal Values

Values can be entered and changed using various methods, depending on your

testing needs.

1. Position the cursor in front of the numeric entry field to be changed.

2. Either:

• Enter the number and unit-of-measure directly using the keypad, or

• Press the CURSOR CONTROL knob or the ENTER key to highlight the field, and

use the knob, or

• Use the down-arrow and up-arrow keys to increment or decrement the present

value.

Chapter 3, Operating Overview

To Enter and Change Values

Front-Panel Example

The following front panel operation changes Sector A Power to -73 dBm/BW.

1. Move the cursor in front of the Sector A Power field.

Enter −73 dBm using the DATA keys.

2.

51

Chapter 3, Operating Overview

To Enter and Change Values

To Enter Hexadecimal Values

Hexadecimal (Hex) values are used for entering some signaling parameters, such

as MIN (Mobile Identificat ion Number). No unit-of-measure is associated with

these values.

Hexadecimal values are either entered from the keypad (using the A-F shifted

functions), or by using the

Front-Panel Example

The following front-panel operation enters the Hexadecimal number

#H0D2565F15 into the MIN field.

1. Move the cursor to the field below MS ID.

2. If the field currently says Phone Num press the ENTER key, use the CUR SOR CON-

TROL knob to select MIN, and press the ENTER key again. (If MIN is already selected,

proceed to step 3.)

3. Use the CURSOR CONTROL knob to select the numeric entry field below MIN.

4. Enter 0, then press and release the SHIFT key, then the 3 key (to select D), enter 256 5,

press and release the SHIFT key, then the 5 key (to select F), enter 15, and then press

the ENTER key. This is the hexadecimal code derived from the phone number

321-456-7890.

Choices menu.

To Enter Values With Exponents

Front-Panel Example

The following front-panel operation changes Confidence (limit) to 95.

1. Press the CALL CTRL key.

2. Move the cursor in front of the Confidence field.

3. Enter 9 EEX 1.

The EEX key can be used to enter values in exponential notation. Exponential

notation is only allowed on floating-point entry fields.

52

To Increment/Decrement Values

Incrementing and decr ement ing values on the Test Se t c an b e performed from the

front panel with the CURSOR CONTROL knob or the up/down arrow keys., or

the INCR

÷10 and INCR ×10 keys.

Chapter 3, Operating Overview

To Enter and Change Values

The INCR

÷10, INCR ×10, and INCR SET keys are used to assign a specific

increment value. To change an increment/decrement setting:

1. Move the cursor to the numeric entry field to be changed.

2. To change the current increment/decrement setting by a factor of 10, use the INCR ÷10

or INCR ×10 keys.

3. To set a specific increment/decrement value, press INCR SET, and enter the desired

value.

Front-Panel Example

The following front panel operation sets the increment value on the Sector A

Power

field to 3 dB.

1. Press the CDMA SCRNS, CALL CTRL key.

2. Move the cursor in front of the Sector A Power field.

3. Press INCR SET, 3, ENTER.

4. Turn the knob or press the up/down arrow keys.

53

Chapter 3, Operating Overview

Saving and Recalling Instrument Setups

Saving and Recalling Instrument Setups

The save and recall functions allow you to store different instrument setups and

retrieve them later, eliminating the task of re-configuring the Test Set.

The number of available sa ve regi ster s depends on how many cha nges were made

to the BASE instrument setup for each save. (See

page 58

registers that can be used (typically over 200).

SAVE/RECALL register settings can be saved to several types of mass storage.

This allows you to “back up” the settings in case you need to clear them from

memory (see

when a firmware upgrade is performed.

.) The smaller the number of changes, the greater the number of SAVE

"Memory Considerations" on page 58) for running large programs, or

"To Specify a BASE Setting" on

54

To Save an Instrument Setup

1. Press and release the SHIFT key, then the PREV key to access the I/O CONFIGURE

screen. Select the storage media using the Save/Recall field. (The default storage

media is internal memory.)

2. Make any changes to the instrument that you want to save in a register.

3. Press and release the SHIFT key, then the RECALL key to select the SAVE function.

4. Use the DATA keys or the Save: menu at the bottom right of the screen to enter the

save register name.

Front-Panel Example

This example saves the current instrument settings.

1. Press and release the SHIFT key, then the RECALL key to select the SAVE function.

A prompt appears at the top of the screen asking you to enter a name.

2. Using the DATA keys, enter 123, then press the ENTER key to assign a name.

Chapter 3, Operating Overview

Saving and Recalling Instrument Setups

To Recall an Instrument Setup

1. Press and release the SHIFT key, then the PREV key to access the I/O CONFIGURE

screen and select the media to recall settings from using the Save/Recall field. (The

default is internal memory.)

2. Press the RECALL key.

3. Use the knob to select the desired se tup to be recalled from the Recall menu at the

bottom right of the screen.

Front-Panel Example

This example recalls the current instrument se ttings.

Press RECALL, 1, 2, 3, ENTER. The saved instrument settings are recalled.

55

Chapter 3, Operating Overview

Saving and Recalling Instrument Setups

To Clear All SAVE Registers

1. Press the RECALL key.

2. Use the knob to position the cursor in front of the entry in the Recall menu at the

bottom right of the screen.

3. Press the knob or the ENTER key. A prompt appears at the top of the screen to verify

that you want to clear all registers.

4. Press the ON/OFF key to select YES.

To Remove (Clear) an Individual SAVE Register

1. Specify where the register is stored using the Save/Recall field on the I/O

CONFIGURE screen.

2. Press the RECALL key.

3. Use the knob to position the cursor in front of the register to be removed from the Re-

call menu at the bottom right of the screen. The register name and percentage of

SAVE memory occupied by that register are indicated at the very top of the screen.

4. Press the ON/OFF key. A prompt appears, asking if you want to del ete the save register.

5. Press the ON/OFF key to select YES. (Press the RATIO W key to select NO.)

To Choose a Register Name

You can use any number, letter, or combination of numbers and letters as a name

for storing instrument settings. For instance; if you want to save a setup for testing

a “Vulcan7” radio, you can save the setting as “VULCAN7”.

Two register names are reserved for special purposes: POWERON and BASE.

56

Chapter 3, Operating Overview

Saving and Recalling Instrument Setups

To Specify a POWERON Setting

You can specify the instrument setting at power-on by following the procedure

described in

name POWERON. If a SAVE Register named P OWERON is detected b y the Test

Set during its power-on r outine, the Test Set wil l confi gure itse lf usi ng the s ettings

stored in the POWERON register.

NOTE: If the Test Set does not successfully complete its power-on routine because of the

POWERON settings (e.g., the Test Set displays a message that requires you to cycle power

to recover) you must:

1. Turn off the Test Set.

2. Hold down the PRESET and the Hz/uV keys simultaneously.

3. Turn on power while holding the PRESET and the Hz/uV keys down until the CALL

CONTROL screen appears.

"To Save an Instrument Setup" on page 55, and choosi ng the regi st er

This procedure will clear all SAVE registers, including POWERON.

57

Chapter 3, Operating Overview

Saving and Recalling Instrument Setups

To Specify a BASE Setting

The BASE register con tains any field settings the user has SAVE d that are

different from the in strument PRESET s tate. It e stablishes a referen ce point for all

future SAVEs. (The PRESET state is st ored i n the BASE r egist er unti l you SAVE

another instrument setup.)

When you SAVE an instrument setup, the new setup is compared to the BASE

settings, and any differences are stored under the register name you supply.

Because only differences are stored, a much larger number of instrument setups

can be saved than if the contents of every field was saved.

When you RECALL an instrument setting, every field is reset to the BASE

settings. The S AVED settings are then used to re-establish the desired instrument

setup.

You can define your own BASE setting . If your desire d setti ngs are very dif fere nt

from the PRESET values, you may want to change the BASE register. This will

decrease the amount of memory used to SAVE each setup, and allow you to

SAVE many more setups.

CAUTION: Since each SAVE/RECALL register only contains the differences between the setup being

saved and the present BASE register settings, changing the BASE results in all other saved

setups being ERASED from memory (including the POWERON setting if one has been

saved).

Unless you consistently change the same fields to the same value each time you

use the instrument, you should probably not create your own BASE settings .

Memory Considerations

When the Save/Recall field of the I/O CONFIGURE screen is set to

Internal, instrument setups are saved to the same non-volatile RAM used to

create RAM Disk(s) and run IBASIC programs. By saving a large number of

instrument setups, you reduce the amount of RAM available to run programs. If

you get a “memory overflow” message while trying to load a program, you must

clear one or more SAVE/RECALL registers to free RAM space).

58

Using USER Keys

User keys instantly access instrument settings without using the knob. You can

use USER keys to move quickly between fields on the same scre en, an d to a ccess

field settings that are not normally available on the screen you are using.

Local USER keys are used to move between settings on the screen that is

displayed. When the USER key is pressed, the cursor instantly moves to, and

selects, the assigned field; eliminating the need to turn and push the knob. Five

local USER keys are available for each screen: K1, K2, K3, K4, and K5.

Global USER keys are used to access sett ings th at are no t avail able on t he curre nt

screen. Three global USER keys are available: K1’, K2’, and K3’. (These are

shifted functions of the local USER keys.)

Chapter 3, Operating Overview

Using USER Keys

When defining USER keys, the ASSIGN f unctio n is used to c reate key defini tions;

the RELEASE function removes the definitions. Re-assigning a USER key to a

different field setting automatically Releases it from the setting it was previousl y

associated with.

59

Chapter 3, Operating Overview

Using USER Keys

To Assign Local USER Keys

1. Move the cursor to the field you want to assign a local USER key to.

2. Press and release the SHIFT key, then the K4 key to select the ASSIGN function. Press

a local USER key (K1-K5). The USER key number appears in front of the field you

assigned it to.

Example of Assigning a Local USER Key

Use this example to assign local USER key K1 to the Filter 1 field in the RX

TEST screen.

1. Access the RX TEST screen and position the cursor in front of the Filter 1 field.

2. Press and release the SHIFT key, then the K4 key to select the ASSIGN function.

3. Press K1. A small 1 appears next to the field indicating that USER key K1 has been

assigned to it.

4. Move the cursor to any other field on the screen and press K1. The cursor immediately

returns to the Filter 1 field. The field is also highlighted to change the entry using

the CURSOR CONTROL knob or arrow keys.

To Release Local USER Keys

1. Display the screen containing the USER key assignment to be removed.

2. Press and release the SHIFT key, then the K5 key to select the RELEASE function.

3. Press the USER key (K1-K5) that you want to release.

60

To Assign Global USER Keys

1. Move the cursor to the field you want to assign a global USER key to.

2. Press and release the SHIFT key, then the k4 key to select the ASSIGN function.

3. Press a global USER key (K1’ -K3’). Unlike a l ocal USER key, the USE R key number

does not appear in front of the field you assigned a global USER key to. A prompt appears at the top of the screen confirming the key assignment.

Example of Assigning a Globa l USE R Key

Use this example to assign global USER key K1’ to the AF Anl In field, and

then access this field in the OSCILLOSCOPE screen.

1. Access the AF ANALYZER screen and position the cursor in front of the AF Anl In

field.

2. Press and release the SHIFT key, then the K4 key to select the ASSIGN function.

Chapter 3, Operating Overview

Using USER Keys

3. Press and release the SHIFT key, then the K1’ key. Notice the prompt Global User

key 1 assigned. at the top of the screen.

4. Access the OSCILLOSCOPE screen.

5. Press SHIFT, K1’.

AF Anl Input

present input is set to FM Demod). To change the input, use the arrow keys, or

press the ENTER key to access the

A field that is ac cessed us ing a glob al USER key i s only dis played at the top of the

screen while it is being accessed. Moving the cursor to any other field in the

screen causes the USER key field to disappear until it is accessed again.

To Release Global USER Keys

1. Move the cursor to the field with the global USER key assigned to it.

2. Press SHIFT, K5, SHIFT, and the USER key to be released (K1’-K3’).

, FM Demod is displayed at the top of the screen (assuming the

Choices menu.

61

Chapter 3, Operating Overview

Setting an RF Generator/Analyzer Frequency Offset

Setting an RF G enerator/Ana l yzer Frequency Offset

You can set a fixed frequency offset between the RF Generator and the RF

Analyzer. At power-up and instrument preset this feature is ON with a

transmit/receive frequency offset of 45 MHz.

NOTE: A 45 MHz offset is required for making a call or making measurements in CDMA mode.

To Turn Off RF Frequency Offset

1. Access the CONFIGURE screen.

2. Position the cursor be low the RF Display field and select Freq.

3. Set the RF Offset to Off

To Change the RF Frequency Offset

1. Access the CONFIGURE screen.

2. Position the cursor be low the RF Display field and select Freq.

3. Set the RF Offset to On

4. Enter an offset frequency ((Gen)-(Anl)).

.

.

62

Setting an RF Generator/Analyzer Level Offset

Setting an RF Generator/Analyzer Level Offset

You can correct for path loss by setting up an RF Level Offset on the front-panel

RF connector(s) used in your application. At power-up and instrument preset this

feature is OFF with 0.0 dB loss in all connector fields.

An RF Level Offset is required t o ensure proper powe r levels to the anal yzer when

testing CDMA mobile stations.

Refer to “Calibrate the Test Set” in the HP 8924E Introduction to Operation.

Chapter 3, Operating Overview

63

Chapter 3, Operating Overview

Printing A Screen

Printing A Screen

To Print A Screen’s Contents

1. Connect a printer to the appropriate rear-panel connector.

2. Press and release the SHIFT key, then the PRINT key to access the PRINT CONFIG-

URE screen and set the Printer Port field to the appropriate type of printer connection.

• If HP-IB is selected, enter the HP-IB Printer Address of the printer.

3. Select the type of printer you are us ing i n the Model field. If yo ur pri nter is n ot lis ted,

configure your printer to emulate one that is listed.

4. Enter a Print Title using the knob (optional). The title will appear at the to p of

your printout.

5. Display the screen you want to print and press the PRINT key.

To interrupt printi ng, s el ect the Abort Print field on the PRINT CONFIGURE

screen.

64

Chapter 3, Operating Overview

Triggering Analog Measurements In Local Mode (Front Panel Operation)

Triggering Ana log Measurements In Local Mode (Front Panel Operation)

• Repetitive retriggering is the only trigger mode available from the front panel for

analog measurements. Single trigger mode can be simulated using the Test Set’s

measurement HOLD feature. Selecting the HOLD key causes all currently displayed

measurement results to be held on the screen and stops the current measurem ent cycle.

To resume making measurements press the HOLD key again.

Manual Operation:

1. Press then release the SHIFT key, then press the

MEAS RESET key to HOLD measurement results.

2. Select HOLD again to return to Repetitive mode.

CDMA CALL CONTROL

CDMA SCRNS

CELL

CALL

CTRL

SPECTRUM

GEN

CTRL

ANALOG SCRNS

ENCODER

RF

ANL

AF

ANL

SPEC ANL

RF

GEN

END

CALL

RANGE

RX

TEST

MSRPT

TX

TEST

DECODER

RX

TEST

ACP

TX

TEST

SCOPE

DUPLEX

CALL ANS

USER DATA

k1’

k1

k2’

k2

k3’

k3

ASSIGN

k4

RELEASE

k5

FUNCTIONS

MSG

PRINTER

HELP

PRINT

DATA FUNCTIONS

REF SET

METER

INCR

INCR

: 10

SET

LO LIMIT HI LIMIT

CURSOR

CONTROL

CANCELSHIFT

I/O CONFIG CONFIG

PREV TESTS

AVG

INCR X10

PUSH TO

SELECT

Meas Reset begins a measurement cycle, interrupting any measurement in progress.

INSTRUMENT STATE

ADRS

SAVE

LOCAL

RECALL

789

456

123

+

0

YES

ON/OFF

Ω

NO

%

ppm

dBµV

W

AUDIO OUTSQUELCHVOLUMEMIC/ACC

MAX

!

12 v Pk

_

HOLD

MEAS

RESET

ENTER

dB

GHz

dBm

%

MHz

V

s

kHz

mV

ms

Hz

µ

V

AUDIO IN

MAX

!

42 v Pk

PRESET

MEMOR

Y CARD

LOHI

65

Chapter 3, Operating Overview

Triggering CDMA Measurements In Local Mode (Front Panel Operation)

Triggering CDMA Me asurements In Local Mod e (Front Panel Operat ion)

For FER and Rho Suite of Measurements

• Continuous - Once a measurement has completed, the Test Set is internally re-

triggered and another measurement cycle begins.

• Single - Requires selection of the Arm field to be begin a measurement cycle.

Manual Operation:

1. Position the cursor at the Single/Cont field.

2. Press the knob to underline the desired mode.

3. If you selected Single, select the Arm field to

trigger a measurement.

Test Status

Meas Cntl

Single/Cont

Arm

Disarm

CDMA CELLULAR MOBILE RECEIVER TEST

Connected

Svc Opt 2

Testing

Passed

Failed

Max Frames

Max Frames

On/Off

Confidence

FER Specs

Display

Interim

Results

Yes/No

95.00

3.00

%

%

Traffic

Data Mode

Svc Opt 1

Data Rate

Full

Eb/Nt

FER

Errors Counted

Frames Counted

----

Sector A

Power

-75.0

dBm/BW

Traffic

15.6

AWGN

-75.0

dbm/BW

dB

%

To Screen

CDMA

CALL CNTL

Analog

RX TEST

Cnfig

PRNT CNFG

When Single is selected, the Arm and Disarm fields are displayed. When Continuous is selected the

Arm and Disarm fields will not appear.

66

4

Description of Keys

The keys are listed in alphabetical order.

67

Chapter 4, Description of Keys

!

POWER

DO NOT APPLY

RF WHEN OFF

RF IN/OUT

MAX PWR

!

6 W

MAX PWR

200 mW

!

ANTENNA INDUPLEX OUT

Figure 6 HP 8924E Front Panel

CDMA CALL CONTRO L

CDMA SCRNS

CELL

CALL

CTRL

SPECTRUM

GEN

CTRL

ANALOG SCRNS

CALL

CTRL

CALL CNFG

AUTHEN

RANGE

MS RPT

ANLG

MEAS

CALL

DATA

SCOPESPEC ANL

END

CALL

RX

TEST

TX

TEST

CALL ANS

USER DATA

k1’

k1

k2’

k2

k3’

k3

ASSIGN

k4

RELEASE

k5

FUNCTIONS

MSG

PRINTER

HELP

PRINT

DATA FUNCTIONS

REF SET

METER

INCR

INCR

: 10

SET

LO LIMIT HI LIMIT

CURSOR

CONTROL

CANCELSHIFT

I/O CONFIG CONFIG

PREV TESTS

AVG

INCR

X10

PUSH TO

SELECT

INSTRUMENT STATE

ADRS

LOCAL

789

456

123

0

YES

NO

ppm

ON/OFF

W

AUDIO OUTSQUELCHVOLUMEMIC/ACC

MAX

!

12 v Pk

SAVE

RECALL

+

Ω

%

dBµV

_

HOLD

MEAS

RESET

ENTER

dB

GHz

dBm

%

MHz

V

s

kHz

mV

ms

Hz

µ

AUDIO IN

!

PRESET

MEMOR

Y CARD

V

LOHI

MAX

42 v Pk

68

Keys That Begin with the Letter A

ADRS

Press and release the SHIFT key, then the LOCAL key to display the HP-IB

address of the Test Set. There is no equivalent HP-IB command for the ADRS

key.

See Also

"I/O Configure Screen" on page 129

ANS

Chapter 4, Description of Keys

Keys That Begin with the Letter A

AVG

ASSIGN

This key functions only when Answer Mode is set to Manual.

Pressing this key answers CDMA-mode mobile-station-originated calls by

removing the ring back tone from the mobile station’s audio path and allowing

user conversation or other traffic to be exchanged.

The Test Set will autom atically answer calls if

Answer Mode is set to Auto.

Press and release the SHIFT key, then the INCR x10 key to access the average

function. This enables or disables measurement averaging.

See Also

"To Use Measurement Averaging" on page 48

This key is used to assign the User Keys, K1 through K5, and K1’ through K3’.

Press and release the SHIFT key, then the K4 key to select the ASSIGN function.

See Also

"Using USER Keys" on page 59

69

Chapter 4, Description of Keys

Keys That Begin with the Letter C

Keys That Begin with the Letter C

CALL

When this key is pressed, the Test Set attempts a CDMA-mode page to a mobile

station. The Call Status annunciators on the CDMA CALL CONTROL screen

indicate call flow.

Refer to “Set Up a Call” chapter in the HP 8924E Introduction to Operation.

CANCEL

CANCEL is used to cancel an entry in progress, or to stop a running IBASIC

program. For example, if you press RECALL to recall an instrument setup, and

then decide not to recall a setting, pressing CANCEL exits the recall procedure.

70

Keys That Begin with the Letter E

END CALL

When this key is pressed, the Test Set disconnects any CDMA-mode call that is

currently connected.

ENTER

ENTER is used to select a field or screen, and to enter numbers when the unit-ofmeasure is not specified. This function is identical to pressing the cursor-control

knob.

Chapter 4, Description of Keys

Keys That Begin with the Letter E

EEX

Press and release the SHIFT key, then the +/ - key to access the exponent funct ion.

This function is used for entering numbers using scientific notation.

See Also

"To Enter Values With Exponents" on page 52

71

Chapter 4, Description of Keys

Keys That Begin with the Letter H

Keys That Begin with the Letter H

HOLD

Press and release the SHIFT key, then the MEAS RESET key. This stops all

measurements. Selecting HOLD again resumes measurements.

The HOLD key is used to hold/resume all active measurements. There is no

equivalent HP-IB command for th e HOLD key . Howeve r, t he f unc ti ona li ty o f t he

HOLD key can be implemented remotely by using Single Triggering of

measurements.

See Also

“Measurement Triggering Process” in the Operating Overview chapter of the

HP 8924E User’s Guide.

72

Keys That Begin with the Letter I

INCR ÷ 10, INCR SET, INCR x10

These keys are used to change the increment/decrement value when changing

field values.

The increment divide-by-10 function reduces the increment setting by a factor of

10 (new increment setting = current setting

The increment setting function sets the increment value for real-number numeric

entry field s.

The increment multipl y-by-1 0 funct ion i ncreas es the in crement s etti ng by a f actor

of 10 (new increment setting = current setting

Chapter 4, Description of Keys

Keys That Begin with the Letter I

÷ 10).

× 10).

73

Chapter 4, Description of Keys

Keys That Begin with the Letter K

Keys That Begin with the Letter K

K1 - K5, & K1’- K3’

These keys are used to dis play f ields fr om anoth er scree n, or ac cess f ields wit hout

using the CURSOR CONTROL knob or changing screens.

See Also

"Using USER Keys" on page 59

74

Keys That Begin with the Letter L

LOCAL

LOCAL returns the instrument to manual control after HP-IB control is used,

except when the Test Set is in local-lockout mode. The Test Set returns to Local

operation (full front-panel control) when either the Go To Local (GTL) bus

command is received, the fron t-panel LOCAL key is pr essed or t he REN line goes

false. When th e Test Set returns to local mode the output signals and inte rnal

settings remain unchanged, except that triggering is reset to “repetitive” and

settling is reset to “f ull”. The LOCAL key wi ll not func tion if the Tes t Set is in t he

local lockout mode.

Chapter 4, Description of Keys

Keys That Begin with the Letter L

LO LIMIT, HI LIMIT

Press and release the SHIFT key, t hen t he down-arrow key to a cce ss the low limit

function.Press and release the SHIFT key, then the up-arrow key to access the

high limit function. These functions are used to set measurement endpoints.

Exceeding the end points causes screen prompts to blink until they are reset.

75

Chapter 4, Description of Keys

Keys That Begin with the Letter M

Keys That Begin with the Letter M

MEAS RESET