Page 1

Agilent Technologies 8922M/S GSM Test Set

Programming Reference Guide

Agilent Part No. 08922-90212

Printed in UK

January, 1998

Page 2

© Copyright 1998, Agilent Technologies. All rights reserved. Reproduction, adaptation, or translation without prior

written permission is prohibited, except as allowed under the copyright laws.

Station Road, South Queensferry, Scotland, EH30 9TG, UK

Page 3

1 Command Guidelines

Command Names............................................................................................................................................................................ 1-2

Programming Format Conventions................................................................................................................................................. 1-2

If you have Agilent Technologies 8922M/S Option 010................................................................................................................1-3

Units of Measure............................................................................................................................................................................. 1-4

Measurement Subsystems............................................................................................................................................................... 1-5

Syntax Diagrams............................................................................................................................................................................. 1-5

Optional Commands ....................................................................................................................................................................... 1-6

Command Descriptions................................................................................................................................................................... 1-7

Output RF Spectrum Modulation Reference Measurement Averaging..........................................................................................1-8

2 GPIB Tutorial and Examples

GPIB Programming Exercises........................................................................................................................................................ 2-2

Exercise A - Establishing a Link ....................................................................................................................................................2-3

Example B - Controlling the Mobile ..............................................................................................................................................2-4

Example C - Making Measurements .............................................................................................................................................. 2-6

Example D - Adding Robustness.................................................................................................................................................. 2-11

Example E - Faster Testing........................................................................................................................................................... 2-12

GPIB Commands Used in Exercises.............................................................................................................................................2-14

Example Programs........................................................................................................................................................................2-16

Sample Output ..............................................................................................................................................................................2-18

Program 1...................................................................................................................................................................................... 2-19

Program 2...................................................................................................................................................................................... 2-29

Program 3...................................................................................................................................................................................... 2-40

Transient Settling Times ..............................................................................................................................................................2-50

Contents

3 AF Analyzer Subsystem

AIN .................................................................................................................................................................................................3-4

DEMPhasis .....................................................................................................................................................................................3-4

DEMPhasis:GAIN .......................................................................................................................................................................... 3-4

DETector......................................................................................................................................................................................... 3-4

DETector:PKLocation.....................................................................................................................................................................3-5

DETector:SETTling........................................................................................................................................................................ 3-5

ELResistor ...................................................................................................................................................................................... 3-5

FILTer1............................................................................................................................................................................................3-6

FILTer2............................................................................................................................................................................................3-6

GTIMe ............................................................................................................................................................................................ 3-6

INPut...............................................................................................................................................................................................3-7

INPut:GAIN.................................................................................................................................................................................... 3-7

SMPoint .......................................................................................................................................................................................... 3-7

NOTCh:GAIN.................................................................................................................................................................................3-7

RANGing........................................................................................................................................................................................3-8

SPEaker:MODE.............................................................................................................................................................................. 3-8

SPEaker:VOLume...........................................................................................................................................................................3-8

Contents-1

Page 4

Contents

4 AF Generator Subsystem

AMPLitude .....................................................................................................................................................................................4-3

COUPling........................................................................................................................................................................................ 4-3

FREQuency..................................................................................................................................................................................... 4-3

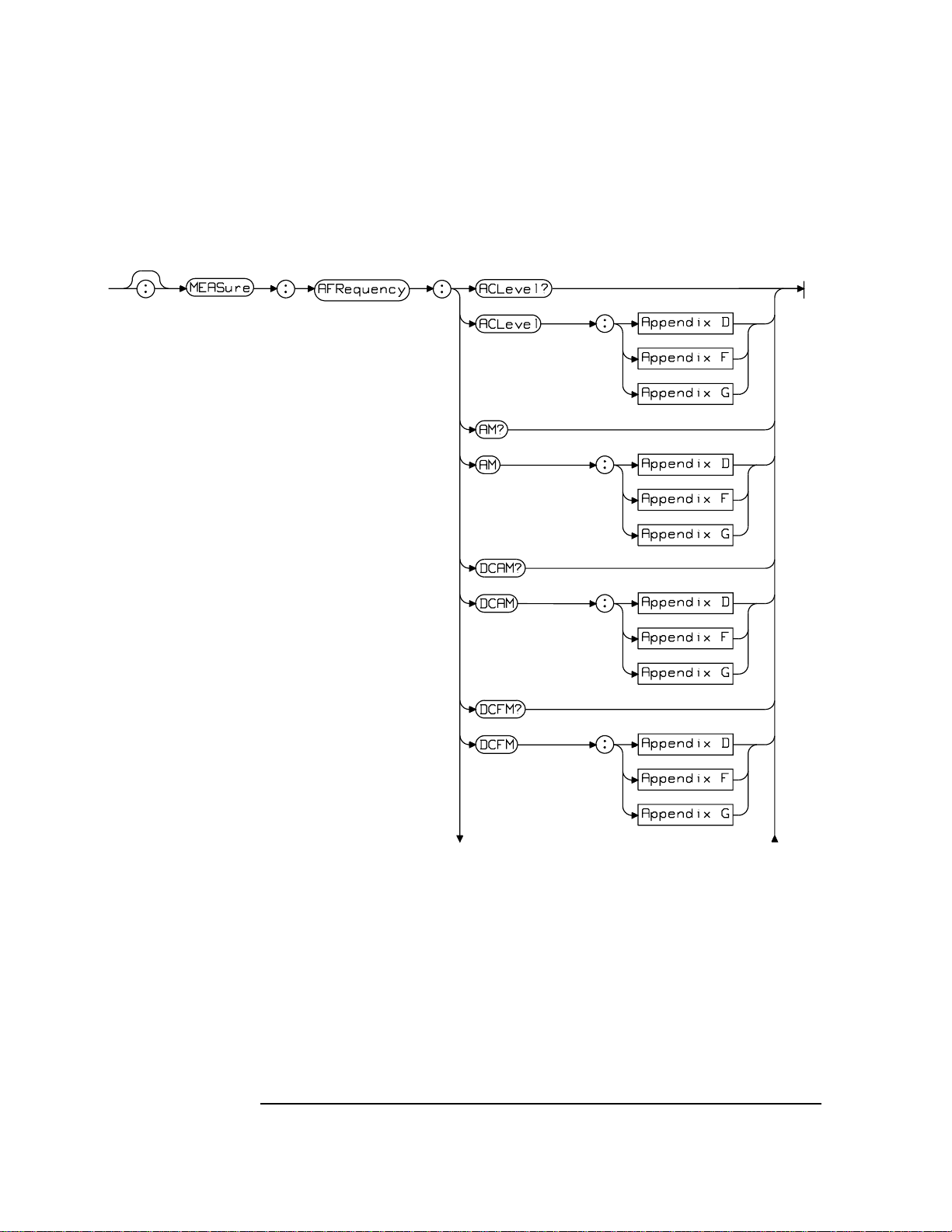

5 Audio Frequency Commands (Measure Subsystem)

ACLevel..........................................................................................................................................................................................5-4

AM..................................................................................................................................................................................................5-4

DCAM.............................................................................................................................................................................................5-4

DCFM............................................................................................................................................................................................. 5-5

DCVolts........................................................................................................................................................................................... 5-5

DISTortion......................................................................................................................................................................................5-5

FM................................................................................................................................................................................................... 5-6

FREQuency..................................................................................................................................................................................... 5-6

SELect............................................................................................................................................................................................. 5-6

SINad .............................................................................................................................................................................................. 5-7

6 Bit Error Test Subsystem

BITS................................................................................................................................................................................................6-3

LOOPback:LDELay .......................................................................................................................................................................6-3

LOOPback:LDELay:MODE...........................................................................................................................................................6-3

TYPE...............................................................................................................................................................................................6-4

7 Bit Error Test Commands (Measure Subsystem)

BESelect.......................................................................................................................................................................................... 7-4

BERRor:COUNt............................................................................................................................................................................. 7-4

BERRor:ICOunt.............................................................................................................................................................................. 7-4

BERRor:IRATio.............................................................................................................................................................................. 7-5

BERRor:RATio...............................................................................................................................................................................7-5

BTESted..........................................................................................................................................................................................7-5

CRC:COUNt...................................................................................................................................................................................7-6

CRC:ICOunt ...................................................................................................................................................................................7-6

CRC:IRATio....................................................................................................................................................................................7-6

CRC:RATio..................................................................................................................................................................................... 7-7

FERasure:COUNt........................................................................................................................................................................... 7-7

FERasure:ICOunt............................................................................................................................................................................ 7-7

FERasure:IRATio............................................................................................................................................................................ 7-8

FERasure:RATio.............................................................................................................................................................................7-8

FLSelect..........................................................................................................................................................................................7-8

FLTYpe........................................................................................................................................................................................... 7-9

IBTested..........................................................................................................................................................................................7-9

SSTatus........................................................................................................................................................................................... 7-9

Contents-2

Page 5

8 Cell Configuration Subsystem

ABCCh............................................................................................................................................................................................ 8-7

ABCCh:BCC .................................................................................................................................................................................. 8-7

CCHannel........................................................................................................................................................................................ 8-7

CCHannel:SDCCH8:ARFCn.......................................................................................................................................................... 8-8

CCHannel:SDCCH8:TSLot............................................................................................................................................................ 8-8

BA...................................................................................................................................................................................................8-8

CA...................................................................................................................................................................................................8-9

MA1................................................................................................................................................................................................8-9

MA1:IOFFset.................................................................................................................................................................................. 8-9

MA2..............................................................................................................................................................................................8-10

MA2:IOFFset................................................................................................................................................................................ 8-10

[:GSM900]:BA..............................................................................................................................................................................8-10

[:GSM900]:CA .............................................................................................................................................................................8-11

[:GSM900]:MA1 .......................................................................................................................................................................... 8-11

[:GSM900]:MA1:IOFFset ............................................................................................................................................................ 8-11

[:GSM900]:MA2 .......................................................................................................................................................................... 8-12

[:GSM900]:MA2:IOFFset ............................................................................................................................................................ 8-12

LAI:MCCode................................................................................................................................................................................8-12

LAI:MNCode................................................................................................................................................................................ 8-13

LAI:LACode.................................................................................................................................................................................8-13

SCELl:ARFCn..............................................................................................................................................................................8-13

SCELl:BCC .................................................................................................................................................................................. 8-13

SCELl:NCC .................................................................................................................................................................................. 8-14

STATe............................................................................................................................................................................................8-14

Contents

9 Cell Control Subsystem

AUDio:DAI:ATESt......................................................................................................................................................................... 9-8

AUDio:DAI:NORMal.....................................................................................................................................................................9-8

AUDio:LOOPback.......................................................................................................................................................................... 9-8

AUDio:LOOPback:FAST............................................................................................................................................................... 9-8

AUDio:LOOPback:FE.................................................................................................................................................................... 9-8

AUDio:LOOPback:OFF................................................................................................................................................................. 9-9

AUDio:LOOPback:NOFE.............................................................................................................................................................. 9-9

AUDio:SPEech:CONFigure........................................................................................................................................................... 9-9

AUDio:SPEech:EDELay.............................................................................................................................................................. 9-10

AUDio:SPEech:GAIN.................................................................................................................................................................. 9-10

AUDio:SPEech:PRBS:PATTern ...................................................................................................................................................9-10

CALL:CONNect...........................................................................................................................................................................9-11

CALL:COUNt:BSYNc.................................................................................................................................................................9-11

CALL:COUNt:DERRor | FERRor ............................................................................................................................................... 9-11

CALL:COUNt:PAGE ................................................................................................................................................................... 9-11

CALL:COUNt:RACH .................................................................................................................................................................. 9-12

CALL:COUNt:RESet................................................................................................................................................................... 9-12

CALL:END................................................................................................................................................................................... 9-12

CALL:LIMit .................................................................................................................................................................................9-12

CALL:ORIGinate .........................................................................................................................................................................9-13

CALL:PAGing.............................................................................................................................................................................. 9-13

CALL:RECeive.............................................................................................................................................................................9-13

CALL:SIGNaling.......................................................................................................................................................................... 9-14

Contents-3

Page 6

Contents

CALL:TCH:ARFCn .....................................................................................................................................................................9-14

CALL:TCH:TSLot........................................................................................................................................................................ 9-14

CALL:STATus:CALLer................................................................................................................................................................9-14

CALL:STATus:CIPHering[:STATe] ............................................................................................................................................. 9-15

CALL:STATus:MM[:STATe]........................................................................................................................................................ 9-15

CALL:STATus:RR[:STATe] ......................................................................................................................................................... 9-16

CALL:STATus:STATe................................................................................................................................................................... 9-16

CALL:STATus:TCH:ARFCn........................................................................................................................................................9-16

CALL:STATus:TCH:MALLocation.............................................................................................................................................9-17

CALL:STATus:TCH:MODE........................................................................................................................................................ 9-17

CALL:STATus:TCH:TSLot.......................................................................................................................................................... 9-17

CALL:STATus:TCH:TYPE..........................................................................................................................................................9-17

CALL:TCHControl....................................................................................................................................................................... 9-18

CALL:TCHControl:EXECute ...................................................................................................................................................... 9-18

MODE........................................................................................................................................................................................... 9-18

MS:DRX[:STATe].........................................................................................................................................................................9-19

MS:DTX[:STATe]......................................................................................................................................................................... 9-19

MS:TADVance..............................................................................................................................................................................9-19

MS:TADVance:MODE................................................................................................................................................................. 9-19

MS:TLEVel...................................................................................................................................................................................9-20

TCH1 or TCH2:ARFCn................................................................................................................................................................ 9-20

TCH1 or TCH2:MALLocation.....................................................................................................................................................9-20

TCH1 or TCH2:MODE ................................................................................................................................................................ 9-20

TCH1 or TCH2:TSLot..................................................................................................................................................................9-21

TCH1 or TCH2:TYPE..................................................................................................................................................................9-21

10 Configure Subsystem

BADDress.....................................................................................................................................................................................10-7

BEEPer.......................................................................................................................................................................................... 10-7

BMODe......................................................................................................................................................................................... 10-7

COMPatible .................................................................................................................................................................................. 10-8

DATE ............................................................................................................................................................................................10-8

INTensity.......................................................................................................................................................................................10-8

OFLevel:MODE............................................................................................................................................................................10-8

OFLevel:AUXin............................................................................................................................................................................ 10-9

OFLevel:AUXout.......................................................................................................................................................................... 10-9

OFLevel:RFINout.........................................................................................................................................................................10-9

OPERation:AUTO......................................................................................................................................................................10-10

OPERation:HOLD......................................................................................................................................................................10-10

PRINt:ADDRess.........................................................................................................................................................................10-10

PRINt:DESTination....................................................................................................................................................................10-11

PRINt:FFENd .............................................................................................................................................................................10-11

PRINt:FFSTart............................................................................................................................................................................10-11

PRINt:LINes............................................................................................................................................................................... 10-11

PRINt:PRINter............................................................................................................................................................................10-12

PRINt:TITle................................................................................................................................................................................10-12

RADio.........................................................................................................................................................................................10-12

RFIMpedance.............................................................................................................................................................................. 10-12

ROSCillator:CALibrate .............................................................................................................................................................. 10-13

ROSCillator[:FREQuency].........................................................................................................................................................10-13

Contents-4

Page 7

ROSCillator:OFFset.................................................................................................................................................................... 10-13

ROSCillator:TUNing..................................................................................................................................................................10-13

ROUT.......................................................................................................................................................................................... 10-14

SPORt:BAUD ............................................................................................................................................................................. 10-14

SPORt:DATA.............................................................................................................................................................................. 10-14

SPORt:IBECho........................................................................................................................................................................... 10-14

SPORt:PARity............................................................................................................................................................................. 10-15

SPORt:RPACe.............................................................................................................................................................................10-15

SPORt:SIN.................................................................................................................................................................................. 10-15

SPORt:STOP...............................................................................................................................................................................10-16

SPORt:XPACe............................................................................................................................................................................ 10-16

TIME........................................................................................................................................................................................... 10-16

11 CW Subsystem

PMZero......................................................................................................................................................................................... 11-2

12 CW Commands (Measure Subsystem)

FREQuency[:ABSolute]............................................................................................................................................................... 12-3

FREQuency:ERRor.......................................................................................................................................................................12-3

FREQuency:SELect...................................................................................................................................................................... 12-3

POWer...........................................................................................................................................................................................12-4

Contents

13 DISPlay Subsystem

[:SCReen]...................................................................................................................................................................................... 13-3

BETest:MNUMber:LEFT............................................................................................................................................................. 13-3

BETest:MNUMber:RIGHt............................................................................................................................................................13-3

CELL:SACCh:ACEL1..................................................................................................................................................................13-3

CELL:TCH[:SELect].................................................................................................................................................................... 13-4

DSPanalyzer:AMPLitude:MASK................................................................................................................................................. 13-4

DSPanalyzer:AMPLitude:MASK:PCS.........................................................................................................................................13-4

DSPanalyzer:VIEW...................................................................................................................................................................... 13-4

FREeze.......................................................................................................................................................................................... 13-5

MSYNc:BURSt:NUMBer ............................................................................................................................................................ 13-5

ORFSpectrum:VIEW.................................................................................................................................................................... 13-5

PULSe:VIEW ...............................................................................................................................................................................13-6

SANalyzer:CONTrol .................................................................................................................................................................... 13-6

14 DSP Analyzer Subsystem

AMPLitude:MARKer:POSition:FALL......................................................................................................................................... 14-3

AMPLitude:MARKer:POSition:MID...........................................................................................................................................14-3

AMPLitude:MARKer:POSition:RISE.......................................................................................................................................... 14-3

AMPLitude:PMZero.....................................................................................................................................................................14-3

AMPLitude:TIME ........................................................................................................................................................................ 14-4

DBITs:TPOLarity......................................................................................................................................................................... 14-4

PHASe:MARKer:POSition...........................................................................................................................................................14-4

PHASe:MIDamble........................................................................................................................................................................ 14-4

Contents-5

Page 8

Contents

15 DSP Analyzer Commands (Measure Subsystem)

[:AMPLitude]:AMPLitude ...........................................................................................................................................................15-4

[:AMPLitude]:MARKer:LEVEL:FALL.......................................................................................................................................15-4

[:AMPLitude]:MARKer:LEVEL:MID......................................................................................................................................... 15-5

[:AMPLitude]:MARKer:LEVEL:RISE........................................................................................................................................15-5

[:AMPLitude]:MARKer:TIME:FALL.......................................................................................................................................... 15-6

[:AMPLitude]:MARKer:TIME:MID............................................................................................................................................ 15-6

[:AMPLitude]:MARKer:TIME:RISE........................................................................................................................................... 15-7

[:AMPLitude]:MSUMmary..........................................................................................................................................................15-7

[:AMPLitude]:NPFLatness...........................................................................................................................................................15-8

[:AMPLitude]:PPFLatness............................................................................................................................................................ 15-8

[:AMPLitude]:PTCPower.............................................................................................................................................................15-8

[:AMPLitude]:TRACe..................................................................................................................................................................15-9

DBITs............................................................................................................................................................................................ 15-9

DBITs:TAGS.................................................................................................................................................................................15-9

FBIT............................................................................................................................................................................................15-10

FMERrors ...................................................................................................................................................................................15-10

PHASe[:ERRor]:FREQuency..................................................................................................................................................... 15-10

PHASe[:ERRor]:PEAK..............................................................................................................................................................15-11

PHASe[:ERRor]:RMS................................................................................................................................................................15-11

PHASe:MARKer:ERRor............................................................................................................................................................15-12

PHASe:MARKer:TIME..............................................................................................................................................................15-12

PHASe:MBURst.........................................................................................................................................................................15-12

PHASe:MBURst:COUNt ...........................................................................................................................................................15-13

PHASe:MBURst:DONE............................................................................................................................................................. 15-13

PHASe:MBURst:ERRors........................................................................................................................................................... 15-13

PHASe:TRACe...........................................................................................................................................................................15-13

SSTatus....................................................................................................................................................................................... 15-14

16 EMMI Subsystem (Agilent 8922M Only)

BRATe...........................................................................................................................................................................................16-3

DATA?...........................................................................................................................................................................................16-3

DATA <data entry>.......................................................................................................................................................................16-4

RESet ............................................................................................................................................................................................ 16-4

TIMEout:MS:XON.......................................................................................................................................................................16-4

TIMEout:MS:RESPonse............................................................................................................................................................... 16-5

17 Fast Bit Error Test

BITS..............................................................................................................................................................................................17-3

LOOPback:LDELay .....................................................................................................................................................................17-3

LOOPback:LDELay:MODE.........................................................................................................................................................17-3

FORMat ........................................................................................................................................................................................ 17-3

RFGenerator:ATSLot.................................................................................................................................................................... 17-4

Contents-6

Page 9

18 Fast Bit Error Test (Measure Subsystem)

BTESted........................................................................................................................................................................................ 18-3

IBTested........................................................................................................................................................................................ 18-3

BERRor:COUNt........................................................................................................................................................................... 18-3

BERRor:ICOUnt........................................................................................................................................................................... 18-3

BERRor:IRATio............................................................................................................................................................................ 18-4

BERRor:RATio.............................................................................................................................................................................18-4

BESelect........................................................................................................................................................................................ 18-4

SSTatus......................................................................................................................................................................................... 18-4

19 Fast TX Carrier Power (Measure Subsystem)

FTCPower[:POWer]...................................................................................................................................................................... 19-2

20 Hop Control Subsystem

ADDRess ...................................................................................................................................................................................... 20-4

ADDRess:NEXT .......................................................................................................................................................................... 20-4

ADDRess:RESet...........................................................................................................................................................................20-4

ADDRess:SOURce.......................................................................................................................................................................20-4

CTENd..........................................................................................................................................................................................20-5

DELete..........................................................................................................................................................................................20-5

INSert............................................................................................................................................................................................ 20-5

RFANalyzer or RFGenerator:CTENd...........................................................................................................................................20-6

RFANalyzer or RFGenerator:DELete...........................................................................................................................................20-6

RFANalyzer or RFGenerator:FREQuency ...................................................................................................................................20-6

RFANalyzer or RFGenerator:INSert............................................................................................................................................ 20-7

RFANalyzer or RFGenerator:MODE...........................................................................................................................................20-7

RFANalyzer or RFGenerator:SETTling.......................................................................................................................................20-7

RFANalyzer or RFGenerator[:TRIGger]:ASTate......................................................................................................................... 20-8

Contents

21 IEEE 488.2 Common Commands

*CLS (Clear Status)......................................................................................................................................................................21-2

*ESE (Event Status Enable) ......................................................................................................................................................... 21-3

*ESR? (Event Status Register) ....................................................................................................................................................21-4

*IDN? (Identification Number) .................................................................................................................................................... 21-5

*OPC (Operation Complete) ....................................................................................................................................................... 21-6

*OPT? .......................................................................................................................................................................................... 21-7

*RCL (Recall) ..............................................................................................................................................................................21-8

*RST (Reset)................................................................................................................................................................................. 21-9

*SAV (Save) ............................................................................................................................................................................... 21-10

*SRE (Service Request Enable) ................................................................................................................................................ 21-11

*STB? (Status Byte) .................................................................................................................................................................. 21-12

*TST? (Test) .............................................................................................................................................................................. 21-13

*WAI (Wait) ...............................................................................................................................................................................21-14

Contents-7

Page 10

Contents

22 LOGGing Subsystem

DATA:FLUSh ...............................................................................................................................................................................22-3

DATA:CLEar.................................................................................................................................................................................22-3

PFILter..........................................................................................................................................................................................22-3

STATe............................................................................................................................................................................................22-4

23 Measurement Sync Subsystem

BURSt:LENGth............................................................................................................................................................................23-3

BURSt:SPSPosition......................................................................................................................................................................23-3

BURSt:TQUalifier ........................................................................................................................................................................ 23-3

BURSt:TYPE................................................................................................................................................................................23-4

BURSt:UDSPattern.......................................................................................................................................................................23-4

SYNC:BSELect ............................................................................................................................................................................ 23-4

SYNC:MODE...............................................................................................................................................................................23-5

24 Mobile Station Commands (Measure Subsystem)

MS:TERRor..................................................................................................................................................................................24-3

MS:TADVance..............................................................................................................................................................................24-3

SACCh:ACEL1:ARFCn...............................................................................................................................................................24-3

SACCh:ACEL1:BCC....................................................................................................................................................................24-3

SACCh:ACEL1:NCC................................................................................................................................................................... 24-3

SACCh:ACEL1:RLEVel...............................................................................................................................................................24-4

SACCh:FULL:RLEVel .................................................................................................................................................................24-4

SACCh:FULL:RQUality .............................................................................................................................................................. 24-4

SACCh:PARTial:RLEVel..............................................................................................................................................................24-4

SACCh:PARTial:RQUality...........................................................................................................................................................24-4

SACCh:RESet............................................................................................................................................................................... 24-5

SACCh:TADVance........................................................................................................................................................................24-5

SACCh:TLEVel ............................................................................................................................................................................24-5

Contents-8

Page 11

25 MS Information Subsystem

CIPHering:AMODe...................................................................................................................................................................... 25-3

CIPHering:KC .............................................................................................................................................................................. 25-3

CIPHering:KI................................................................................................................................................................................ 25-4

CIPHering:RAND......................................................................................................................................................................... 25-4

CIPHering:SRES .......................................................................................................................................................................... 25-4

CIPHering[:STATe].......................................................................................................................................................................25-4

MS:ATTach................................................................................................................................................................................... 25-5

MS:CMARk:PCLass?................................................................................................................................................................... 25-5

MS:CMARk:REVision?............................................................................................................................................................... 25-5

MS:CMARk:BAND?.................................................................................................................................................................... 25-5

MS:IMEI:REQuest .......................................................................................................................................................................25-6

MS:IMEI?..................................................................................................................................................................................... 25-6

MS:IMSI:SPAGing....................................................................................................................................................................... 25-6

MS:IMSI? .....................................................................................................................................................................................25-6

MS:LAI:LACode? ........................................................................................................................................................................ 25-6

MS:LAI:MCCode? .......................................................................................................................................................................25-7

MS:LAI:MNCode?....................................................................................................................................................................... 25-7

MS:ONUMber? ............................................................................................................................................................................ 25-7

MS:PAGPer................................................................................................................................................................................... 25-7

MS:SRES? .................................................................................................................................................................................... 25-7

[:PAGing]:IMSIdentity ................................................................................................................................................................. 25-8

[:PAGing]:TMSI:REALlocation...................................................................................................................................................25-8

[:PAGing]:TMSI:STATe................................................................................................................................................................ 25-8

Contents

26 OSCilloscope Subsystem

CONTrol....................................................................................................................................................................................... 26-3

MARKer:NPEak...........................................................................................................................................................................26-3

MARKer:PPEak............................................................................................................................................................................ 26-3

MARKer:POSition........................................................................................................................................................................ 26-3

SCALe:TIME................................................................................................................................................................................ 26-4

SCALe:VERTical:AM..................................................................................................................................................................26-4

SCALe:VERTical:FM................................................................................................................................................................... 26-4

SCALe:VERTical:OFFSet............................................................................................................................................................26-5

SCALe:VERTical:VOLTs............................................................................................................................................................. 26-5

TRIGger:LEVel............................................................................................................................................................................. 26-5

TRIGger:MODE........................................................................................................................................................................... 26-6

TRIGger:PRETrigger.................................................................................................................................................................... 26-6

TRIGger:RESet............................................................................................................................................................................. 26-6

TRIGger:SENSe ...........................................................................................................................................................................26-7

TRIGger:SOURce......................................................................................................................................................................... 26-7

TRIGger:TYPE.............................................................................................................................................................................26-7

Contents-9

Page 12

Contents

27 Oscilloscope Commands (Measure Subsystem)

MARKer:LEVel:AM.....................................................................................................................................................................27-3

MARKer:LEVel:FM..................................................................................................................................................................... 27-3

MARKer:LEVel:VOLTs ............................................................................................................................................................... 27-3

MARKer:TIME.............................................................................................................................................................................27-4

TRACe..........................................................................................................................................................................................27-4

28 Output RF Spectrum Subsystem

FREQuency:OFFSet..................................................................................................................................................................... 28-3

MARKer:POSition........................................................................................................................................................................ 28-3

MODE........................................................................................................................................................................................... 28-4

SACalibrate................................................................................................................................................................................... 28-4

29 Output RF Spectrum Commands (Measure Subsystem)

FBIT..............................................................................................................................................................................................29-3

FMERrors .....................................................................................................................................................................................29-3

MARKer:LEVel............................................................................................................................................................................29-3

MARKer:TIME.............................................................................................................................................................................29-4

[:POWer]....................................................................................................................................................................................... 29-4

SSTatus......................................................................................................................................................................................... 29-5

TRACe..........................................................................................................................................................................................29-6

30 PULSe On/Off Ratio Subsystem

MARKer[:POSition]:FALL .......................................................................................................................................................... 30-3

MARKer[:POSition]:RISE........................................................................................................................................................... 30-3

MARKer:OPOSition:FALL..........................................................................................................................................................30-3

MARKer:OPOSition:RISE...........................................................................................................................................................30-4

SACalibrate................................................................................................................................................................................... 30-4

31 Pulse On/Off Ratio Commands (Measure Subsystem)

FBIT..............................................................................................................................................................................................31-3

FMERrors .....................................................................................................................................................................................31-3

MARKer:LEVel:FALL ................................................................................................................................................................. 31-3

MARKer:LEVel:RISE .................................................................................................................................................................. 31-4

MARKer:TIME:FALL.................................................................................................................................................................. 31-4

MARKer:TIME:RISE................................................................................................................................................................... 31-5

OORatio:FALL.............................................................................................................................................................................31-5

OORatio:RISE .............................................................................................................................................................................. 31-5

SSTatus......................................................................................................................................................................................... 31-6

TRACe:FALL ...............................................................................................................................................................................31-7

TRACe:RISE ................................................................................................................................................................................ 31-7

Contents-10

Page 13

32 RF Analyzer Subsystem

AGC:CALibrate............................................................................................................................................................................ 32-4

AGC:DVALue...............................................................................................................................................................................32-4

AGC:MODE................................................................................................................................................................................. 32-4

AMPLitude1 .................................................................................................................................................................................32-4

AMPLitude2 .................................................................................................................................................................................32-5

[:AMPLitude]:ACCuracy..............................................................................................................................................................32-5

[:AMPLitude]:CONTrol............................................................................................................................................................... 32-5

FREQuency................................................................................................................................................................................... 32-6

FREQuency:GTIMe...................................................................................................................................................................... 32-6

FREQuency:HMEas .....................................................................................................................................................................32-6

FREQuency:OFFSet..................................................................................................................................................................... 32-7

GTIMe .......................................................................................................................................................................................... 32-7

INPut.............................................................................................................................................................................................32-7

ARFCn..........................................................................................................................................................................................32-7

33 RF Generator Subsystem

AMPLitude1 .................................................................................................................................................................................33-3

AMPLitude1:ATTenuation[:AUTO]............................................................................................................................................. 33-3

AMPLitude2 .................................................................................................................................................................................33-3

AMPLitude2:ATTenuation[:AUTO]............................................................................................................................................. 33-3

FREQuency................................................................................................................................................................................... 33-4

MODulation:DCAM.....................................................................................................................................................................33-4

MODulation:DCAM:DVALue......................................................................................................................................................33-5

MODulation:GMSK .....................................................................................................................................................................33-5

MODulation:PULSe .....................................................................................................................................................................33-5