Agilent Technologies 8920B

RF Communications Test Set

User’s Guide

Firmware Version B.06.00 and above

POWE

OF O

ANT INDUPLEX OUTRF IN/OUT

!

MAX POWER

!

MAX POWER 200

Agilent Part No. 08920-90221

Printed in U. S. A.

April 2000

Rev. E

USER

ASSIG

RELEA

SHIFT

k1’

k1

k2’

k2

k3’

k3

k4

k5

SCREEN CONTROL

CANCE

MIC/

REF

INCR

CONFIHELPMSSG HOLD PRINT

DUPLETXRX PREV TESTS

DATA FUNCTIONS

METER

AVG

INCR

INCR

LO HI

CURSOR CON-

PUSH TO

YES

ON/OFF

INSTRUMENT STATE

ADRS

SAVE

LOCAL

RECAL

DATA

789

456

123

_

+

0

NO

AUDIO SQUELCVOL-

MAX

!

MEAS

ENTER

dB

GHz

%

MHz

s

kHz

Hzms% Ωppm

AUDIO IN

!

PRESE

MEMO

LOHI

MAX

1

© Copyright Agilent Technologies 1996-2000. All Rights Reserved

Notice No part of this manual may be reproduc ed in any form or by any means (i ncluding

electronic sto rage and retrie val or translatio n into a for eign language) wit hout prior

agreement and written consent from Agilent Technologies Inc. as governed by

United States and international copyright laws.

The material contained in this document is subject to change without notice.

Agilent Technologies makes no warranty of any kin d wit h r eg ard to this material ,

including, but not limited t o, the impl ied warra nties of merchantabi lity an d fitnes s

for a partic ular purpose . Agilent Technologies Inc. shall not be liable for er rors

contained herein or for inciden tal or consequenti al damages in connection with the

furnishin g, performance, or use of this material.

U.S. Government users will receive no greater than Limited Rights as defined in

FAR 52.227-14 (June 1987) or DFAR 252.227-7015 (b)(2) (November 1995), as

applicable in any technical data.

Agilent Technologies

Learning Products Department

24001 E. Mission

Liberty Lake, WA 99019-9599

U.S.A.

Edition/Print Date All Editions and Updates of this manual and their creation dates are listed below.

Rev. A . . . . . October 1996

Rev. B . . . . . September 1997

Rev. C . . . . . December 1997

Rev. D . . . . . October 1999

Rev. E . . . . . April 2000

2

Safety Summary The following general safety precautions must be observed during all phases of

operation of this instrument. Failure to comply with these precautions or with

specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Agilent Technologies Inc.

assumes no liability for the customer’s failure to comply with these requirements.

GENERAL

This product is a Safety Class 1 instrument (provided with a protective earth

terminal). The protectiv e features of this product may be impaired if it is used in a

manner not specified in the operation instructions.

All Light Emitting Diodes (L EDs) used in this product are Class 1 LEDs as per IEC

60825-1.

This product has been designed and tested in accordance with IEC Publication

1010, "Safety Requirements for Electronic Measuring Apparatus," and has been

supplied in a s afe c ondi tion. This instruction documentation cont ai ns information

and warnings which must be followed by the user to ensure safe operation and to

maintain the product in a safe condition.

ENVIRONMENTAL CONDITIONS

This instrument is intended for indoor use in an installation category II, pollution

degree 2 environment. It i s designed to opera te at a maximum relati ve humidity of

95% and at altitudes of up to 2000 meters. Re fer to the s pecificati ons tables f or the

ac mains voltage requirements and ambient operating temperature range.

V entilation Requirements: When installing the product in a cabinet, the convection

into and out of the product must not be restricted. The ambient temperature

(outside the cabin et) must be les s than t he maximum oper atin g temper atu re of th e

product by 4° C for every 100 watts dissipated in the cabinet. If the total power

dissipated in th e cabi net is great er th an 8 00 watts , then force d con vecti on must b e

used.

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage, the correct fuse is

installed, and all safety precaution s are taken. No te the instrument's external

markings described under Safety Symbols.

3

GROUND THE INSTRUMENT

T o mi nimize s hock hazard , the inst rument chas sis and cove r must be connec ted to

an electrical protective earth ground. The instrument must be connected to the ac

power mains through a grounded power cable, with the ground wire firmly

connected to an electrical ground (safety ground) at the power outlet. Any

interruption of the protective (grounding) conductor or disconnection of the

protective earth terminal will cause a potential shock hazard that could result in

personal injury.

FUSES

Only fuses with the requ ired rated current, volt age, and specified type (normal

blow , time de lay, etc.) should be used. Do not use repai red fuses or short- circuited

fuse holders. To do so could cause a shock or fire hazard.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

DO NOT REMOVE THE INSTRUMENT COVER

Operating personnel mus t not remove in strument cover s. Component repl acement

and internal adjustments must be made only by qualified service personnel.

Instruments that appear damaged or defective should be made inoperative and

secured against unintended operation until they can be repaired by qualified

service personnel.

WARNING: The WARNING sign denotes a hazard. I t calls at tention to a procedure, practice, o r

the like, which, if not correctly performed or adhered to, could result in personal

injury. Do not proceed beyond a WARNING sign until the in dicated conditions are

fully understood and met.

CAUTION: The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the

like, which, if not correctly performed or adhered to, could result in damage to or

destruction of part or all of the product. Do not proceed beyond a CAUTION sign until the

indicated conditions are fully understood and met.

4

Safety Symbols

Caution, refer to accompanying documents

Warning, risk of electric shock

Earth (ground) terminal

Alternating current

Frame or chassis terminal

Standby (supply). Uni ts with this s ymbol are not c ompletely di sconnected from a c

mains when this switch is off.

T o completely disconnect the unit from ac mains, either disconnec t the power cord,

or have a qualified electrician install an external switch.

Product Markings CE - the CE m ark is a registered trademark of the European Com munity. A CE

mark accompanied by a year indicated the year the design was proven.

CSA - the CSA mark is a registered trademark of the Canadian Standards

Association.

CERTIFICATION Agilent Technologies certifies th at this produc t met its published specific ati ons at

the time of shipment fr om the fac tory . Agilent Technologies furthe r certifies tha t its

calibration measurements are traceable to the United States National Institute of

Standards and Technology, to the extent allowed by the Institute’s calibration

facility, and to the calibration facilities of other International Standards

Organization members

5

Agilent Technologies Warranty Statement for Commercial Products

Agilent Technologies 8920B RF Communications Test Set

Duration of

Warranty: 1 year

1. Agilent Technologies warrants Agilent Technologies hardware, accessories and

supplies against defects in materials and workmanship for the period specified above.

If Agilent Technologies receives notice of such defects during the warranty period,

Agilent Technologies will, at its option, either repair or replace products which prove

to be defective. Replacement products may be either new or like-new.

2. Agilent Technologies warrants that Agilent Technologies software will not fail to exe-

cute its programming instructions, for the period specified above, due to defects in material and workmanship when properly installed and used. If Agilent Technologies

receives notice of such defects during the warranty period, Agilent Technologies will

replace software media which does not execute its programming instructions due to

such defects.

3. Agilent Technologies does not warrant that the operation of Agilent Technologies

products will be uninterrupted or error free. If Agilent Technologies is unable, within

a reasonable time, to repair or replace any product to a condition as warranted,

customer will be entitled to a refund of the purchase price upon prompt return of the

product.

4. Agilent Technologies products may contain remanufactured parts equivalent to new in

performance or may have been subject to incidental use.

5. The warranty period begins on the date of delivery or on the date of installation if

installed by Agilent Technologies. If customer schedules or delays Agilent

Technologies installation more than 30 days after delivery, warranty begins on the 31st

day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or inadequate mainte-

nance or calibration, (b) software, interfacing, parts or supplies not supplied by Agilent

Technologies, (c) unauthorized modification or misuse, (d) operation outside of the

published environmental specifications for the product, o r (e) improper site preparation

or maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE WARRANTIES

ARE EXCLUSIVE AND NO OTHER WARRANTYOR CONDITION, WHETHER

WRITTEN OR ORAL IS EXPRESSED OR IMPLIED AND AGILENT TECHNOLOGIES SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTIES OR CONDITIONS OR MERCHANTABILITY, SATISFACTORY QUALITY, AND FITNESS

FOR A PARTICULAR PURPOSE.

6

8. Agilent Technologies will be liable for damage to tangible property per incident up to

the greater of $300,000 or the actual amount paid for the product that is the subject of

the claim, and for damages for bodily injury or death, to the extent that all such damages are determined by a court of competent jurisdiction to have been directly caused

by a defective Agilent Technologies product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS

WARRANTY STATEMENT ARE CUSTOMER’S SOLE AND EXCLUSIVE

REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO EVENT WILL AGILENT

TECHNOLOGIES OR ITS SUPPLIERS BE LIABLE FOR LOSS OF DATA OR FOR

DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST

PROFIT OR DATA), OR OTHER DAMAGE, WHETHER BASED IN CONTRACT,

TORT, OR OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND:

THE WARRANTY TERMS CONTAINED IN THIS STATEMENT, EXCEPT TO

THE EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE RESTRICT OR

MODIFY AND ARE IN ADDITION TO THE MANDATORY STATUTORY

RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

ASSISTANCE Product maintenance agreements and other customer assistance agreements are

available for Agilent Technologies products. For any assistance, contact your

nearest Agilent Technologies Sales and Service Office.

7

DECLARATION OF CONFORMITY

Manufacturer’s Name:

according to ISO/IEC Guide 22 and EN 45014

Agilent Technologies

Manufacturer’s Address:

24001 E. Mission Avenue

Liberty Lake, Washington 99019-9599

USA

declares that the product

Product Name:

Model Number:

Product Options:

RF Communications T est Set / Cell Site Test Set

A g i l e n t Te c hn o lo g ies 89 2 0A , 89 2 0B , an d 8 9 21A

This declaration covers all options o f the above

product.

conforms to the following Product specifications:

Safety: IEC 1010-1:1990+A1+A2/EN 61010-1:1993

EMC: CISPR 11:1990 / EN 55011:1991 Group 1, Class A

EN 50082-1 : 19 92

IEC 801-2:1991 - 4 kV CD, 8 kV AD

IEC 801-3:1984 - 3V/m

IEC 801-4:1988 - 0.5 kV Sig. Lines, 1 kV Power Lines

Supplementary Information:

This is a class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

This product herewith complies with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC and carries the CD-marking accordingly

Spokane, Washington USA Date October 17, 1996 Vince Roland/Quality Manager

8

.

Table 1 Regional Sales Offices

United States of America:

Agilent Technologies

Test and Measurement Call Center

P.O. Box 4026

Englewood, CO 80155-4026

(tel) 1 800 452 4844

Japan:

Agilent Technologies Japan Ltd.

Measurement Assistance Center

9-1 Takakura-Cho, Hachioji-Shi,

Tokyo 192-8510, Japan

(tel) (81) 456-56-7832

(fax) (81) 426-56-7840

Asia Pacific:

Agilent Technologies

24/F, Cityplaza One,

111 Kings Road,

Taikoo Shing, Hong Kong

Canada:

Agilent Technologies Canada Inc.

5150 Spectrum Way

Mississauga, Ontario

L4W 5G1

(tel) 1 877 894 4414

Latin America:

Agilent Technologies

Latin America Region

Headquarters

5200 Blue Lagoon Drive,

Suite #950

Miami, Florida 33126

U.S. A.

(tel) (305) 267 4245

(fax) (305) 267 4286

Europe:

Agilent Technologies

European Marketing Organization

P.O. Box 999

1180 AZ Amstelveen

The Netherlands

(tel) (3120) 547 9999

Australia/New Zealand:

Agilent Technologies

Australia Pty Ltd.

347 Burwood Highway

Forest Hill, Victoria 3131

Australia

(tel) 1 800 629 485

(fax) (61 3) 9272 0749

New Zealand

(tel) 0 800 738 378

(fax) (64 4) 802 6881

(tel) (852) 3197 7777

(fax) (852) 2506 9233

9

Service and

Support

Table 2

Any adjustment, maintenance, or repair of this product must be performed by

qualified personnel. Contact your customer engineer through your local Agilent

T echnologies Ser vice Center . You can find a list of lo cal service repres entatives on

the Web at:

http://www.agilent-tech.com/services/English/index.html

If you do not have access to the Internet, one of these cent ers can direct y ou to your

nearest representative:

United States Test and Measurement Call Center

(Toll free in US)

Europe

Canada

Japan Measurement Assistance Center

Latin America

Australia/New Zealand

Asia-Pacific

(800) 452-4844

(31 20) 547 9 900

(905) 206-4725

(81) 426 56 7832

|(81) 426 56 7840 (FAX)

(305) 267 4288 (FAX)

1 800 629 485 (Australia)

0800 738 378 (New Zealand)

(852) 2599 7777

(852) 2506 9285 (FAX)

10

Manufacturer’s

Declaration

This statement is provi ded to co mply wi th the requir ements of the Ger man Sou nd

Emission Directive, from 18 January 1991.

This product has a sound pressure emission (at the operator position) < 70 dB(A).

• Sound Pressure Lp < 70 dB(A).

• At Operator Position.

• Normal Operation.

• According to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Schalldruckpegel Lp < 70 dB(A).

• Am Arbeitsplatz.

• Normaler Betrieb.

• Nach ISO 7779:1988/EN 27779:1991 (Typprüfung).

11

In this Book The Agilent Technologies 8920B is referred to i n this docu ment as the " Test Set."

Chapter 1, Get Started

This chapter describes the basic operation of the Test Set. It also provides a quick

check that verifies that the Test Set is operating properly.

Chapter 2, Configuring Your Test Set

This chapter describes various instrument configuration settings that affect the general

operation of the instrument.

Chapter 3, Operating Overview

This chapter contains detailed operating instructions and examples for using several

instrument features.

Chapters 4 through 23, Screen and Field Descriptions

These chapters contains reference information fo r each scr een an d its fields . Man y o f

the descriptions contain signal flow diagrams that relate the screen’ s fields to the functions they perform. The screens are arranged in alphabetical order by title at the top of

the screen; Signaling Encoder and Signaling Decoder are alphabetized by the names

Encoder and Decoder.

Chapter 24, Connector, Key, and Knob Descriptions

This chapter describes the purpose and use of each connector and control.

Chapter 25, Modifications, Accessories, Manuals, Support

This chapter describes retrofit kits, accessories, manuals, and customer support available for your Test Set.

Error Messages

This section discusses error and operating messages.

12

Contents

1 Get Started

Before Connecting a Radio 40

Accessing the Test Set’s Screens 41

Changing A Field’s Setting 43

How do I Verify that the Test Set is Operating Properly? 46

Instrument Functional Diagr am 48

13

Contents

2 Configurin g Your Test Set

General Operating Information 52

14

Contents

3 Operating Overview

Interaction Between Screens 56

Displaying Measurements 60

Entering and Changing Numbers 66

Printing A Screen 69

Using Meas urement Limit Indicators 70

Averaging Measurements 72

Setting A Measurement Reference 73

Using Memory Cards 74

Saving and Recalling Instrument Setups 79

Using USER Keys 83

Setting an RF Generator/Analyzer Offset 87

Using Remote Control 88

15

Contents

4 Adjacent Channel Power Screen

How the Test Set Measures Adjacent Channel Power (ACP) 94

Field Descriptions 95

16

Contents

5 AF Analyzer Screen

Block Diagram 104

17

Contents

6 Call Processing Subsystem

Description of the Call Processing Subsystem 118

Using the Call Processing Subsystem 122

The CALL CONTROL Screen 126

Using the CALL CONTROL Screen to Test Call Processing

Functions 142

Using the CALL CONTROL Screen to test AMPS

Authentication 152

AUTHENTICATION Screen 163

CALL DATA Screen 166

CALL DATA Screen Messa ge Fiel d Descript i ons 171

Using the CALL DATA Screen 188

CALL BIT Screen 197

CALL BIT Screen Message Field Descriptions 204

Using the CALL BIT Screen 248

ANALOG MEAS Screen 253

Using the ANALOG MEAS Screen 256

CALL CONFIGURE Screen 259

18

Contents

7 Configure Screen

Field Descriptions 262

19

Contents

8 Signaling Decoder Screen

Field Descriptions for Decoder Modes 276

AMPS-TACS, NAMPS-NTACS Decoder 277

Using the AMPS/TACS, NAMPS/NTACS Decoder 282

Continuous Digital Controlled Squelch System Decoder 286

Using the CDCSS Decoder 290

Digital Paging Decoder 291

Dual-Tone Multi-Frequency (DTMF) Decoder 295

Using the DTMF Decoder 300

EDACS Decoder 301

Using the EDACS Decoder 304

Function Generator Decoder 307

Using the Function Generator Decoder 310

LTR Decoder 311

Using the LTR Decoder 315

MPT 1327 Decod er 317

NMT Decoder 322

Using the NMT Decoder/Encoder 327

Creating NMT Tests 332

Tone Sequence Decoder 341

20

Contents

9 Duplex Test Screen

Block Diagram 346

Field Descriptions 347

21

Contents

10 Signaling Encoder (AF Generator 2)

Field Descriptions for Encoder Modes 360

AMPS-TACS NAMPS-NTACS Encoder 361

Using the AMPS-TACS, NAMPS-NTACS Encoder 374

CDCSS Encoder 375

Using the CDCSS Encoder 379

Digital Paging Encoder 380

DTMF Sequence Encoder 385

EDACS Encoder 389

Using the EDACS Encoder 395

Function Ge nerator Encoder 400

LTR Encoder 403

Using the LTR Encoder 407

MPT 1327 Encod er 411

Using the MPT 1327 Encoder 424

Nordic Mobile Telephone (NMT) Encoder 427

Tone Sequence Encoder 439

22

Contents

11 Help Screen

Field Descriptions 444

23

Contents

12 I/O Configure Screen

Field Descriptions 446

24

Contents

13 Message Screen

Field Descriptions 452

25

Contents

14 Oscilloscope Screen

Field Descriptions 454

Using the Oscilloscope 461

26

Contents

15 Print Configure Screen

Field Descriptions 464

27

Contents

16 Radio Interface Screen

Radio Interface Functional Description 468

Field Descriptions 470

Using the Radio Interface (Manual Operation) 473

Using The Radio Interface (Remote Operation) 479

28

Contents

17 RF Analyzer Screen

Block Diagram 482

Field Descriptions 483

29

Contents

18 RF Generator Screen

Block Diagram 494

Field Descriptions 495

30

Contents

19 RX Test Screen

Block Diagram 504

Field Descriptions 505

31

Contents

20 Service Screen

Field Descriptions 512

32

Contents

21 Spectrum Analyzer Screen

Field Descriptions 516

Using the Spectrum Analyzer 528

33

Contents

22 Tests Screen

Description of the Tests Subsystem 530

TESTS (Main Menu) 532

TESTS (Channel Information) 535

TESTS (Test Parameters) 537

TESTS (Order of Tests) 538

TESTS (Pass/Fail Limits) 540

TESTS (Save/Delete Procedure) 542

TESTS (Execution Conditions) 545

TESTS (External Devices) 548

TESTS (Printer Setup) 551

TESTS (IBASIC Controller) 554

ROM Programs 556

34

Contents

23 TX Test Screen

Block Diagram 560

Field Descriptions 561

35

Contents

24 Connector, Key, and Knob Descriptions

Connector Descriptions 572

Key Descriptions 590

Knob Des c riptions 59 4

36

Contents

25 Modifications, Accessories, Manuals Support

Modifications 596

Accessories 599

Agilent Technologies Support for Your Instrument 609

37

Contents

Index 625

38

1

Get Started

39

Chapter 1, Get Started

Before Connecting a Radio

Before Connecting a Radio

The RF IN/OUT port should be used for all transmitter tests when the radio is connected

directly to the Test Set. (All UUT transmitter power measurements are made through this

port). Off-the-air measurements can be made using the ANT IN port.

CAUTION: Overpower Damage — Refer to the Test Set’s front panel for maximum input power level.

Exceeding this level can cause permanent instrument damage.

POWER

0

OFF0ON

SINAD dB

RF Gen Freq

AFGen1 Freq

100.000000

AFGEN1 To

Amplitude

FM

-80.0

dBm

Atten Hold

On/Off

Output Port

RF Out/Dupl

RF IN/OUT

MAX PWR 60W

!

CONTINUOUS

RX TEST

AF Gen2 Freq

1.0000

1.0000

kHzMHz

AFGEN2 To

FM

Off

Off

kHz

DUPLEX OUT ANT IN

AC Level

Filter 1

50Hz HPF

kHz

Filter 2

15kHz LPF

Ext Load R

8.00

!

MAX POWER 200mW

V

To Screen

RF GEN

RF ANL

AF ANL

SCOPE

SPEC ANL

ENCODER

DECODER

RADIO INT

More

MSSG

RX

USER

k1

ENTER

k2’

k2

k3’

k3

ASSIGN

k4

RELEASE

k5

SHIFT CANCEL

SCREEN CONTROL

HELPTXCONFIG

REF SET METER AVGk1’

HOLD

DUPLEX

PREV

DATA FUNCTIONS

INCR

INCR

INCR

X10

SET

-10

HI LIMITLO LIMIT

CURSOR CONTROL

PUSH TO SELECT

VOLUME SQUELCHMIC/ACC AUDIO OUT AUDIO IN

ADRS

PRINT

LOCAL

TESTS

7 8 9

E4F

5 6

B

1C2D3

A

0 .

NO

ppm

ON/OFF

W

MAX

!

12 V PK

INSTRUMENT STATE

SAVE

RECALL

RESET

DATA

ENTER

EEX

_

+

/

%

dBuV

HI LO

20nobug.ds4

Speaker or Audio OutMic Audio InMic KeyAntenna

MEAS

PRESET

dB

GHv

dBm

%

MHv

V

s

kHv

mV

ms

Hz

MEMORY

uV

CARD

MAX

!

42 V PK

Radio Under Test

Figure 1 Connecting a Radio to the Test Set

40

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\getstart.fb

Accessing the Test Set’s Screens

List of Screens

The following table lists all the screens that could be provided by the Test Set.

Table 3

Chapter 1, Get Started

Accessing the Test Set’s Screens

Analog Measurement Screens

Adjacent Channel Power Configure

AF Analyzer I/O Configure

Decoder Print Configure

Duplex

Encoder Help

Oscilloscope Message

Radio Interface

RF Analyzer Service

RF Generator

RX Test Call Control

Spectrum Analyzer Call Data

TX Test Call Bit

Software Control Screens

Instrument Configuration

User Assistance Screens

Service Assistance Screen

Call Processing Screens

Call Configure

Screens

Tests Analog Measure

Tests (IBASIC Controller) Authentication

41

Chapter 1, Get Started

Accessing the Test Set’s Screens

Accessing Screens

Test Set’s screens can be accessed through

• Front-panel keys

• The front-panel Cursor Contro l kno b (us i ng t he To Screen menu, see item 5 in Fig-

ure 3 on page 43)

• GPIB, using the DISPlay subsystem.

Knob

Access to

Additional

Screens

POWER

0

OFF0ON

SINAD dB

RF Gen Freq

AFGen1 Freq

100.000000

AFGEN1 To

Amplitude

FM

-80.0

dBm

Atten Hold

On/Off

Output Port

RF Out/Dupl

RF IN/OUT

MAX PWR 60W

!

CONTINUOUS

Knob Access to

Screens

RX TEST

AC Level

AF Gen2 Freq

Filter 1

1.0000

1.0000

Off

50Hz HPF

kHz

kHzMHz

Filter 2

AFGEN2 To

15kHz LPF

FM

Off

kHz

Ext Load R

8.00

DUPLEX OUT ANT IN

!

MAX POWER 200mW

V

To Screen

RF GEN

RF ANL

AF ANL

SCOPE

SPEC ANL

ENCODER

DECODER

RADIO INT

More

Front-Panel Key

Access to Screens

SCREEN CONTROL

MSSG

HELPTXCONFIG

HOLD

RX

USER

k1

ENTER

k2’

k2

k3’

k3

ASSIGN

k4

RELEASE

k5

SHIFT CANCEL

DATA FUNCTIONS

REF SET METER AVGk1’

INCR

-10

CURSOR CONTROL

PUSH TO SELECT

PRINT

DUPLEX

PREV

TESTS

INCR

INCR

X10

SET

HI LIMITLO LIMIT

VOLUME SQUELCHMIC/ACC AUDIO OUT AUDIO IN

ADRS

LOCAL

7 8 9

E4F

5 6

B

1C2D3

A

0 .

NO

ppm

ON/OFF

W

MAX

!

12 V PK

INSTRUMENT STATE

SAVE

RECALL

DATA

EEX

_

+

/

%

dBuV

HI LO

20nobug.ds4

MEAS

PRESET

RESET

ENTER

dB

GHv

dBm

%

MHv

V

s

kHv

mV

ms

Hz

MEMORY

uV

CARD

MAX

!

42 V PK

Figure 2 Accessing the Screens

42

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\getstart.fb

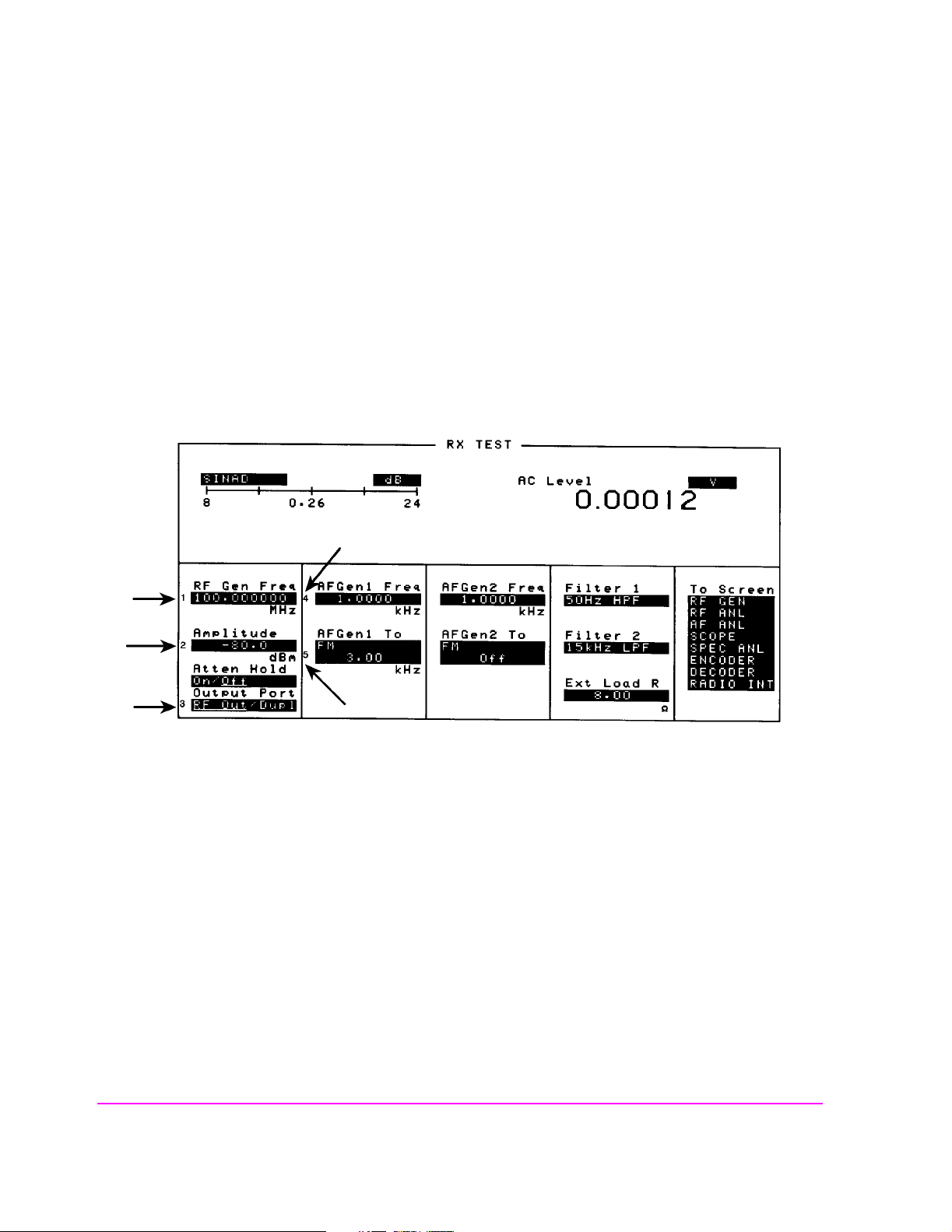

Changing A Field’s Setting

There are several types of CRT display fields in the Test Set. This section

describes some of the different types of fields.

Chapter 1, Get Started

Changing A Field’s Setting

3

Figure 3 Different Types of Fields

1

rxscrn.wmf

intro4.wmf

542

43

Chapter 1, Get Started

Changing A Field’s Setting

Unit-of-Measure Field

Unit-of-measure can be changed to display measurements in different values or

magnitudes. See item 1 in

To change a unit-of-measure

1. Position the cursor at the unit field on the display.

2. Press a key labeled with a different unit-of-measure (such as W).

If the new units are valid, the measurement value is displayed in the unit.

Underlined Immediate-Action Field

Underlined immediat e act ion f ield s pro vid e a c hoice of t wo sett ings. See ite m 2 in

Figure 3 to see an example of an underlined immediate-action field.

To change an underlined entry

1. Position the cursor at the field.

2. Push the CURSOR CONTROL knob or the ENTER key to move the underline under

the desired choice.

Figure 3 to see an example of a units-of-measure field.

The underlined setting is immediately activated when selected.

44

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\getstart.fb

One-of-Many Field

Numeric-Entry Field

Chapter 1, Get Started

Changing A Field’s Setting

One-of-many fields disp lay a list of choices when sel ect ed. See item 3 in Figure 3

to see an example of a one-of many field.

To make a one-of-many choice

1. Position the cursor at the field.

2. Push the Cursor Control knob or the ENTER key to display the choices.

3. Move the cursor through the choices by turning the k n ob.

4. Push the Cursor Control knob or the ENTER key to make the choice.

The choice is immediately activated when selected.

The To Screen menu (see item 5 in Figure 3) is a variation of the one-of-many

field.

Numeric-entry fields contain valu es for setting s like Exter nal Load Resist ance and

RF Generator Frequency.See item 4 in

Figure 3 to see an example of a numeric-

entry field.

To change a value

1. Position the cursor at the field.

2. Key in the desired number using the DATA keys.

3. Press ENTER to select the choice.

OR

1. Position the cursor at the field.

2. Push the Cursor Control knob to highlight the desired choice.

3. Turn the knob to increment or decrement the value.

4. Push the Cursor Control knob or the ENTER key to select the choice.

45

Chapter 1, Get Started

How do I Verify that the Test Set is Operating Properly?

How do I Verify that the Test Set is Operating Properly?

If your Test Set powers-up and displays the RX TEST screen, but you suspect an

instrument problem, use the Instrument Quick Check to verify operation of the

basic instrument functions.

If no failure is indicated by this test, but you still suspect a problem, refer to the

“Performance Tests” information in the Assembly Level Repair Manual.

46

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\getstart.fb

Instrument Quick Check

1. Set up the quick check:

Chapter 1, Get Started

How do I Verify that the Test Set is Operating Properly?

a. Connect a cable between the DUPLEX OUT and ANT IN ports.

b. Turn instrument power on (if it is not already on).

c. Press PRESET.

d. Press DUPLEX to access the DUPLEX TEST screen.

e. Set the Tune Mode field to Manual

f. Set the Tune Freq field to 825 MHz.

g. Set the Input Port field to Ant.

h. Set the RF Gen Freq field to 825 MHz.

i. Set the Amplitude field to -10 dBm.

j. Set the Output Port field to Dupl

k. Verify that AFGen1 Freq is set to 1.0000 kHz, and that AFGen1 To is set to

FM and 3.00 kHz.

l. Set the AF Anl In field to FM Demod.

m. Set the Filter 1 field to 300Hz HPF.

n. Set the Filter 2 field to 3kHz LPF.

o. Verify that De-Emphasis is Off

p. Set the Detector field to Pk+-/2.

q. Turn the VOLUME knob clockwise until you hear a tone (1 kHz default for

AFGen1 Freq).

.

.

.

2. Check the following readings:

❒ SINAD should be >35 dB.

❒ FM Deviation should be about 3.0 kHz.

3 Access the OSCILLOSC OPE screen using the To Screen menu. With the default

Vert/div setting of 2 kHz and a default Time/div setting of 200 µs

see two complete sinewaves across the screen.

1

4 Access the SPECTRUM ANALYZER

an 825 MHz FM carrier.

1. Optional on some Test Set models.

using the To Screen menu. You should see

, you should

47

Chapter 1, Get Started

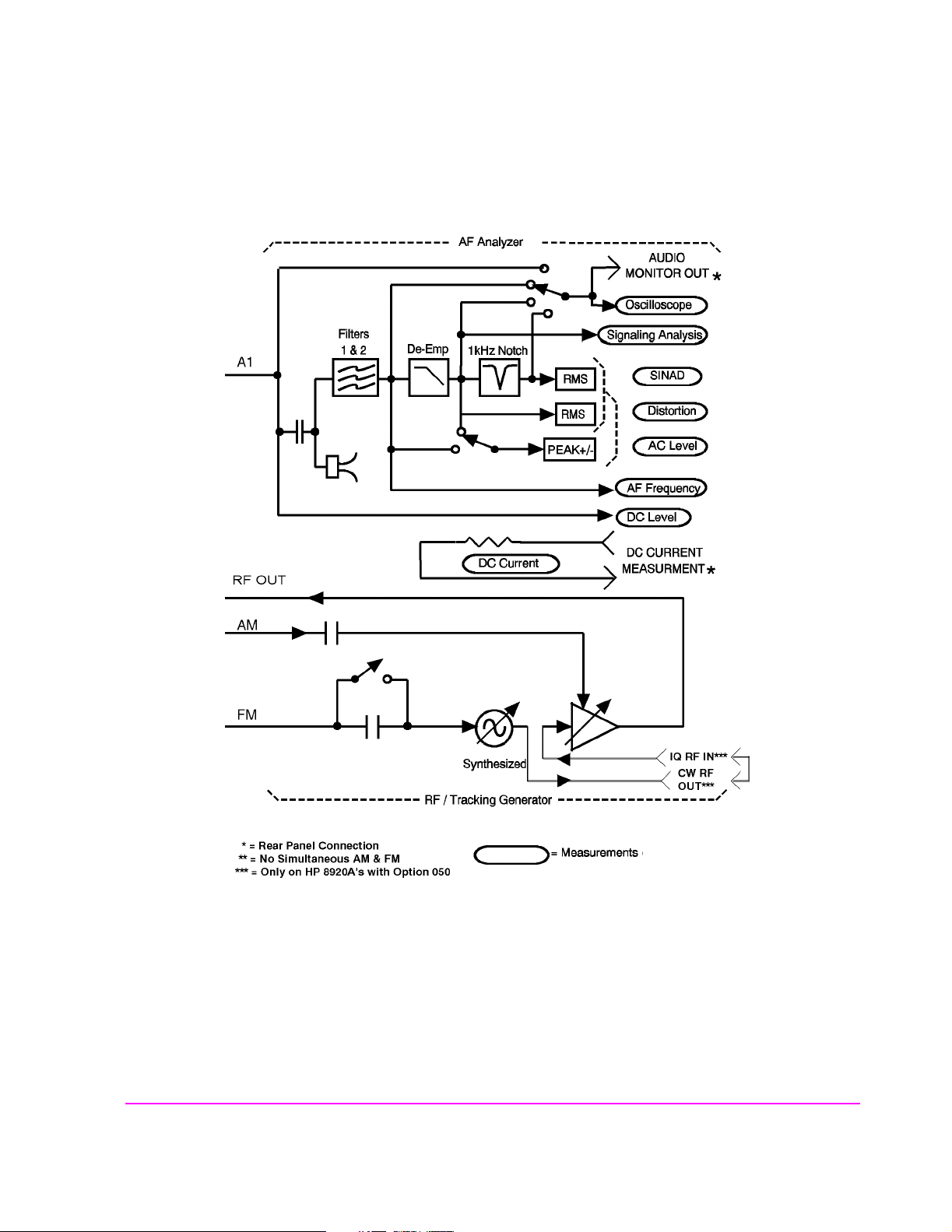

Instrument Functional Diagram

Instrument Functional Diagram

Figure 4 Instrument Functional Diagram (1 of 2)

48

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\getstart.fb

Chapter 1, Get Started

Instrument Functional Diagram

Figure 5 Instrument Functional Diagram (2 of 2)

intr-bd2.wmf

49

Chapter 1, Get Started

Instrument Functional Diagram

50

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\getstart.fb

2

Configuring Your Test Set

The CONFIGURE and I/O CONFIGURE screens contain a number of settings used to

alter instrument operation and hardware communication settings. The GPIB address,

screen intensity, serial communication parameters, and sev eral o ther settings , are ch ange d

in these screens.

Most CONFIGURE and I/O CONFIGURE screen entries are saved when the instrument

is turned off.

51

Chapter 2, Configuring Your Test Set

General Operating Information

General Operating Information

The following configuration information discusses general operating information

for some of the fields in these screens.

To Set Screen Intensity

1. Access the CONFIGURE screen.

2. Select the Intensity field.

3. Rotate the knob to change the setting (1=dim, 8=bright).

To Set RF Voltage Interpretation (50 /emf)

1. Access the CONFIGURE screen.

2. Position the cursor in front of the RFGen Volts field.

3. Press the Cursor Control knob or press ENTER to select 50 ohm or emf.

Ω

Voltage settings can control either:

• the voltage across a 50-ohm load, or

• the open circuit voltage (emf).

This setting affects the RF Generator’s and the Tracking Generator’s amplitudes.

To Set the Date and Time

1. Access the CONFIGURE screen.

2. Select the Date field and use the DATA keys to enter the d ate in the fo rmat shown b e-

low the field.

3. Select the Time field and use the DATA keys to enter the time in the format shown

below the field.

The Test Set has a built-in clock that keeps track of the date and time. It is

powered by an internal battery to keep it operating when the instrument is off.

52

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\configts.fb

To Change the Beeper Volume

1. Access the CONFIGURE screen.

2. Select the Beeper field to display the volume choices.

3. Select the desired choice.

The beeper alerts you to important operating and measurement conditions. It

beeps any time a message is displayed at the top of the screen. These messages

warn you of condition s such as exc eeding the RF input lev el or t rying to s et a field

to an unacceptab le value. Therefor e, it is r ecommende d that yo u do not disable the

beeper .

To Verify or Change the Low-Battery Setting

1. Access the CONFIGURE screen.

Chapter 2, Configuring Your Test Set

General Operating Information

2. The current time setting is shown under the Low Battery field.

3. Select that field to display a list of setting choices.

• Select the desired time, or

• Select Disable to eliminate the low-battery warning.

The low-battery warning system is used to alert you when you have not used any

front-panel controls within a specified amount of time. This setting is only used

with DC power. It does not actually monitor the DC supply voltage. Since

batteries are most often used for a DC supply, this function helps you conserve

power by reminding you that the Test Set is still turned on.

When the specified time has elapsed be tween front-panel entrie s, the Beeper

sounds and a message appears at the top of the screen alerting you to the

condition.

This setting is saved when the instrument is turned off.

53

Chapter 2, Configuring Your Test Set

General Operating Information

54

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\configts.fb

3

Operating Overview

The information in this section discusses some frequently used operating features

of the Test Set.

From reading

• What “fields” and “screens” are.

• How to use the Cursor Control knob to select different fields and screens.

Chapter 1, “Get Started,” you should understand:

55

Chapter 3, Operating Overview

Interaction Between Screens

Interaction Between Screens

Most fields operate globally; changing the setting in any screen automatically

changes that setting in all screens where it is available.

example of this field type.

AFGen1 Freq is an

Figure 6 Example of How Global Fields Work

Priority fields give the RX TEST and TX TEST screens priority control of their

settings. No matter wh at these fields were set to in other screens, if the RX T EST

or TX TEST screen is accessed, the field changes to whatever it was last set to in

these screens. The RF Generator’s

Amplitude field is an example of this field

type. These fields and their preset values are listed in

56

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Table 4.

Chapter 3, Operating Overview

Interaction Between Screens

Table 4 Priority RX TEST and TX TES T Field s

Priority Field RX TEST TX TEST

RF Gen Amplitude Presets to −80 dBm (changeable) Always Off

AFGen1 To Presets to FM (changeable) Always Audio Out

AF Anl In Always Audio In Presets to FM Demod (changeable)

Detector Always RMS Presets to Pk +− Max (changeable)

De-emphasis Always Off

AF Anl Measurement Presets to SINAD (changeable) Presets to Audio Freq (changeable)

Presets to 750 (changeable)

µs

Using your Test Set, duplicate the steps in Figure 7 to demonstrate how the

Priority fields operate.

57

Chapter 3, Operating Overview

Interaction Between Screens

fig2-2.wmf

Figure 7 Example of How Priority Fields Work

58

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Priority CALL CONFIGURE Field

The Input Att field located on the CALL CONFIGURE screen is another

priority field. Similar fields labeled

ADJACENT CHANNEL POWER screen, RF ANALYZER screen, and the

SPECTRUM ANALYZER screen.

Chapter 3, Operating Overview

Interaction Between Screens

Input Atten are located on the

Setting the

Input Atten fields found on the other screens. Setting the Input Atten field

updates all other

Input Att field. Acc essing the CA LL CONFIG URE screen changes the input

attenuator to the current value of the

Atten

Input Att field from the CALL CONFIGURE screen updates all

Input Atten fields but does not change the setting of the

Input Att field and updates all Input

fields.

59

Chapter 3, Operating Overview

Displaying Measurements

Displaying Measurements

Figure 8 Where To Access Measurements

60

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

scntxrx.wmf

Displaying RF Measurements

Transmitter Frequency

Chapter 3, Operating Overview

Displaying Measurements

TX Frequency

Figure 8 on page 60.)

in

Transmitter Frequency Error

TX Freq Error

Figure 8 on page 60.)

(1) in

Transmitter Power

TX Power

RF In (Refer to item (2) in Figure 8 on page 60). If Ant (antenna) is selected, the

is displayed when Tune Mode is set to Auto. (Refer to item (1)

is displayed when Tune Mode is set to Manual. (Refer to item

is only measured and displayed here when the Input Port is set to

measurement is replaced by four dashes (- - - -).

You can measure low power levels on the ANT IN port using the Spectrum

Analyzer.

1

Refer to “TX Power” on page 569 and “TX Pwr Zero” on page 570 for more

information on measuring transmitter power.

CAUTION: Connecting a signal of >200 mW to the ANT IN (antenna) port can cause instrument damage

(although internal protection circuits can typically withstand a short-duration sig nal of 1 or 2

Watts). If the overpower circuit is triggered, remove the signal from the ANT IN port and turn

the Test Set off and on to reset it.

1. Optional on some Test Set models.

61

Chapter 3, Operating Overview

Displaying Measurements

Displaying AF Measurements

FM Deviation, AM Depth, AC Level

The AF Anl In set ting deter mines the AF Analy zer’ s input and the measure ment

displayed in the top-right corner of the measurement area (see

measurements are available in the TX TEST, DUPLEX TEST , RF GENERATOR,

RF ANALYZER, and AF ANALYZER screens. (Refer to item (3) in

page 60

Table 5 AF Measurements Selected by AF Analyzer Input Setting

.)

Measurement AF Anl In Setting

FM Deviation FM Demod, FM Mod

Table 5). These

Figure 8 on

AM Depth AM Demod, AM Mod

AM Depth

a. AC Level is also measured in the RX TEST screen, but

a

always uses the AUDIO IN connector as the input. (Refer

to item (5) in Figure 8 on page 60.)

SSB Demod, AudioIn, Radio Int,

Ext Mod, Mic Mod, Audio Out

62

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Chapter 3, Operating Overview

Displaying Measurements

SINAD, Distortion, SNR, AF Frequency, DC Level, DC Current

Selecting the curren tly-displaye d measurement ca uses the To Screen menu t o be

replaced by a list of measurement choices. Select the ne w choice to replace th e old

measurement. These measurements are available in the RX TEST, TX TEST,

DUPLEX TEST, RF GENERATOR, RF ANALYZER, and AF ANALYZER

screens. ( Refer to item (4) in

Figure 8 on page 60)

The Distortion measurement is only for a 1 kHz tone.

The SINAD measurement is normally shown using an analog-type meter and

small digits, but can be changed to display in large digits only. (See

Analog METER Format” on page 65

.)

“To Use the

DC Current can only be measured using the rear- pan el DC CURRENT

MEASUREMENT connections.

Selecting SNR (Signal/Noise Ratio) turns off the other audio measurement. For

more information on making this measurement, see

“RF Gen Freq” on page 509.

AF Power

AF Power is measured in the RX TEST screen by specifying the external load

resistance,

Ext Load R, and changing the unit of measure for the AC Level

measurement to W (Watts), mW, or dBm. (The milliwatt (mW) unit is selected by

pressing SHIFT, E NTER) Refer to item (5)

Figure 8 on page 60.

63

Chapter 3, Operating Overview

Displaying Measurements

To Change the Measurement’s Unit-of-Measure

1. Position the cursor in front of the present unit-o f -measu r ement.

2. Press the key labeled with the desired unit.

All measurements allow you to change the associated unit-of- measure. For

instance; the

changed to display in mW, dBm, V, mV, or dB

Select mW by pressing SHIFT, ENTER.

For example; to display transmitter power in units of dBm instead of Watts:

1. Move the cursor in front of the unit-of-measure for the TX Power measurement (W).

2. Press the dBm key . The measurement value is ch anged immediately to display in dBm.

TX Power measurement is usually displayed in Watts, but can be

µV.

64

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

To Use the Analog METER Format

To display measurement results using the analog meter format, use the following

procedure.

1. Position the cursor in front of the unit-of-measure for the measurement you want to dis-

play.

2. Press and release the SHIFT key, then the INCR SET key to display the Meters menu

in the lower-right corner of the screen.

3. Select On/Off to display the meter.

4. Repeat steps 1 and 2 to enter each meter end point and the meter intervals.

5. Repeat steps 1, 2, and 3 to cancel the METER function.

The METER function displays an equivalent analog display. (This is the SINAD

measurement’s default state when the instrument is turned on or preset). As the

measurement is displayed graphically on the meter, the value is also displayed in

small digits below the meter.

Chapter 3, Operating Overview

Displaying Measurements

You can specify the high and low end points and display interval, or you can use

the default meter settings.

This function is only available for measurements displayed using the large digits,

such as the measurements displayed in the RX TEST and TX TEST screens.

To Make Beat Frequency Measurements

1. Select the DUPLEX TEST screen to set up for beat frequency oscillator measurements.

2. Set the AF Anl In field to SSB Demod.

3. Manually adjust the Tune Freq field to the desired carrier frequency.

65

Chapter 3, Operating Overview

Entering and Changing Numbers

Entering and Changing Numbers

Values for numeric entry fields can be entered and changed using various

methods, depending o n y our testing needs. The unit-of-measure fo r some of these

fields can also be changed (such as changing the RF Generator’s

units from dBm to

To Enter Numbers

1. Position the cursor in front of the numeric entry field to be changed.

2. Use one of the following methods:

a. enter the number and unit-of-measure directly using the keypad,

or

b. press the Cursor Control knob or ENTER to highlight the field, and use the

knob,

µV).

Amplitude

or

c. use the down-arrow or the up-arrow keys to increment or decrement the pres ent

value.

Decimal Values

Decimal values are used for most numeri c entry fields, such as the RF Gen Freq

setting. The acceptabl e entries for decimal va lue s ar e 0 t h r ough 9, ., +/ -, a nd EEX.

The +/- key is used for entering negative numbers. For example; when entering

the RF Generator

−47 dBm: +/- 4 7 dBm.

Amplitude you can enter this sequence to set the value to

The EEX key can be used when entering exponential notation. For example; to

3

× 10

enter 1.25

kHz you could use the sequence: 1 . 2 5 EEX 3 kHz.

66

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Hexadecimal Values

Hexadecimal (Hex) values are used for entering some signaling parameters in the

ENCODER, such as AMPS

communications parameters, such as the RADIO INTERFACE

field. The acceptable entries for decimal values are 0 through 9 and A through F.

No unit-of-measure is associated with these values.

Hexadecimal values are either entered from the keypad (A through F are shifted

functions), or by using the

selected (such as the AMPS

To Enter and Change the Unit-of-Measure

Entering the Unit-of-Measure for Settings

When a number is entered, the unit-of-measure is either specified or implied.

Chapter 3, Operating Overview

Entering and Changing Numbers

Filler data field, and for specifying remote

Output Data

Choices menu displ ayed when ce rtain fields are

Filler field).

When the unit is implied, the current unit is used. For example; if the present RF

frequency is 250 MHz, and you want to change it to 225 MHz, you would enter

this sequence: 2 2 5 ENTER.

When the unit is specifie d, the uni ts ch ange to wh atever yo u specif y. For example;

if the present

RF Gen Freq setting is 250 MHz, a nd you want to cha nge it to 455

kHz, you would enter this sequence: 4 5 5 kHz.

Changing the Unit-of-Measure for Settings

T o c hang e the prese nt uni t-of -measur e, posi tion the c ur sor in f ront of the f ield and

press the key labeled with the desired unit. For example, position the cursor in

front of the

RF Gen Freq field and push GHz or kHz to display the setting in

either of these units.

67

Chapter 3, Operating Overview

Entering and Changing Numbers

To Change the Increment or Decrement Setting

Using the Pre-Defined Increment/Decrement Keys

The INCR ×10] and INCR ÷10] keys change the increment/decrement value by a

factor of 10.

For example; if the

the knob or push of the down-arrow or up-arrow keys, pushing INCR

Tune Freq presently changes by 10 MHz for every click of

×10] once

changes th e increment value to 100 MHz.

Specifying An Increment Value

The INCR SET key is used to assign a specific increment value. The increment

value may use different units than the field you are incrementing/decrementing.

For instance; if the RF Generator

Amplitude setting is displayed in dBµV, you

could increment in units of dB or mV.

To change the increment value;

1. Move the cursor to the numeric entry field to be changed.

2. Press INCR SET, and enter the desired value and u nit-of-measure using the DAT A keys.

3. Use the down-arrow and up-arrow keys or CURSOR CONTROL knob to change the

field’s value by the increment value you set.

Example of Setting an Increment Value

This example changes the Tune Freq in increments of 15 MHz.

1. Access the TX TEST screen and position the cursor in front of the Tune Freq field.

2. Press 1 0 0 MHz to set the frequency at 100 MHz.

3. Press INCR SET 1 5 MHz.

4. Turn the Cursor Control knob. The field’s value changes by 15 MHz for each knob

click.

68

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Printing A Screen

To Print A Screen’s Contents

1. Connect a printer to the appropriate rear-panel connector.

2. Access the PRINT CONFIGURE screen from the More menu and set the Printer

Port field to the appropriate type of printer connection.

• If HP-IB is selected, enter the GPIB Printer Address of the printer.

3. Select the type of printer you are using in the Model field. If your printer is not listed,

configure your printer to emulate one that is listed.

4. Enter a Print Title using the knob, if desired. This text will appear at the top of

your printout.

Chapter 3, Operating Overview

Printing A Screen

5. Display the screen you want to print and press and release the SHIFT key, then the

TESTS key to access the PRINT function.

To interrupt printing, select the Abort Print field on the PRINT CONFIGURE

screen.

69

Chapter 3, Operating Overview

Using Measurement Limit Indicators

Using Measurement Limit Indicators

The LO LIMIT and HI LIMIT functions are used to define a measurement

“window” to alert you to measurements that are outs ide these limits. When limits

are assigned, Lo and/or Hi appear by the measurement.

A measurement that goes above or be low t he defined limits causes thr ee thi ngs to

happen:

1. A message appears at the top of the screen indicating a limit was exceeded.

2. The Lo or Hi indicator by the measurement flashes.

3. The Beeper beeps if it is has been enabled in the CONFIGURE screen.

Limits are helpful when you can’t watch the Test Set’s display while you are

making an adjustment on the eq uipment you are test ing or r epairing. They are a lso

a convenient way of alerting you to long-term measurement drift without having

to observe the screen.

To Set A HI and/or LO LIMIT

1. Position the cursor in front of the unit-of-measur e for the measuremen t that you are set-

ting limits for.

2. Press and release the SHIFT key, then the down-arrow key to access the LO LIMIT

function, and enter the measurement’s low-limit value and its unit-of-measure.

3. Press and release the SHIFT key, then the up-arrow key to access the HI LIMIT func-

tion, and enter the measurement’s high-limit value and its unit-of-measure.

1. The fundamental unit for the LIMITs does not have to be the same as the measure-

ment’s units. For instance; when measuring AC Level in Volts, you can set HI and LO

LIMITs in units of dBm.

1

1

70

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

To Reset or Remove Limits

To reset a limit that has been exceeded

1. Position the cursor in front of the measurement’s unit-of-measure.

2. Press and release the SHIF T key, then the down-arrow (or up-arrow key) to access the

LO LIMIT (or HI LIMIT) function, then press ENTER or MEAS RESET.

To remove a limit

1. Position the cursor in front of the unit-of-m easure for the assigned limit.

2. Press and release the SHIF T key, then the down-arrow (or up-arrow key) to access the

LO LIMIT (or HI LIMIT) function, then press ON/OFF.

Example of Setting HI and LO LIMITs

This example sets limits for the TX Freq Error measurement. Limits are being

set to indicate if a 100 MHz carrier varies more than

Chapter 3, Operating Overview

Using Measurement Limit Indicators

± 10 kHz.

1. Position the cursor in front of the unit-of-measure for the TX FREQ ERROR measure-

ment (the default is kHz).

2. Press and release the SHIFT key, then the down-arrow to access the LO LIMIT func-

tion, then enter 1 0 kHz.

3. Press and release the SHIFT key, then the up-arrow to access the HI LIMIT function,

then enter 1 0 kHz.

71

Chapter 3, Operating Overview

Averaging Measurements

Averaging Measurements

The AVG (average) function allows you to display the average value of a number

of measurements. You enter the number of measu rement sampl es used to calcul ate

and display the measurement average. This dampens the effects of rapidly

changing measurements, providing a more usable measurement display.

To Use Measurement Averaging

1. Position the cursor in front of the measurement’s unit-of-measure.

2. Press and release the SHIFT key, then the INCR ×10 key to access the AVG function.

The default number of average samples is displayed below the measurement.

• Enter the desired number of measurement samples to b e used for calculating the average, or

• Press ON/OFF to use the currently-displayed number of samples.

3. To turn averaging of f, position the curs or in front of the unit- of-measure and pr ess and

release the SHIFT key, then the INCR ×10 key to access the AVG function, then press

the ON/OFF key.

When the averaging function is first enabled, a numeric average is calculated and

displayed each time a measurement is made. This continues until the specified

number of samples is reached. From that point on, the averaging function

performs an exponential filtering operation that mimics an RC filter.

Because of the exponential response, any large measurement changes result in a

displayed value that ramps up or down to the actual measured value.

Pressing MEAS RESET clears the mea suremen t hist ory for all measu rements and

starts the averaging process over.

Example of Using Measurement Averaging

This example enables the SINAD measurement to be averaged using 25 samples.

1. Press PRESET and wait for the instrument to display the RX TEST screen.

2. Position the cursor in front of the unit-of-measure for the SINAD measurement (default

is dB).

3. Press and release the SHIFT key, then the INCR ×10 key to access the AVG function,

enter 2 5, then press the ENTER key. Avg appears below the displayed measurement

value to indicate that averaging is being used.

72

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Setting A Measurement Reference

The REF SET function establishes a measurement reference point. This allows

you to make a direct comparison between two measurement results, or between a

measurement standard and the actual measurement results.

Referenced measurements are displayed in one of two ways, depending on the

type of measurement:

Displayed value = Measurement − Reference. The difference between the measured

value and the reference value is displayed in the same unit-of-measure.

or

Displayed value = Measurement ÷ Reference. A ratio of the measured value to the

reference value is displayed in dB.

Chapter 3, Operating Overview

Setting A Measurement Reference

To Use the Present Value as a Reference

Position the cursor in front of the unit-of-measure for the measurement you want to set the

reference for .

1. Press and release the SHIFT key, then the INCR ÷10 key to access the REF SET func-

tion; then press enter ENTER.

2. Ref appears below the measurement.

The measurement displayed is now referenced to the measurement value present

when the reference was set.

To Set a Specific Reference

1. Position the cursor in front of the unit-of-measure for the measurement you want to set

the reference for.

2. Press and release the SHIFT key, then the INCR ÷10 key to access the REF SET func-

tion.

3. Enter a reference value.

4. Ref appears below the measurement value to indicate a reference has been set.

The measurement displayed is now referenced to the value you entered.

73

Chapter 3, Operating Overview

Using Memory Cards

Using Memory Cards

OTP (One Time Programmable) cards provide removable read-only storage. File

editing and erasure are not possible. These cards cannot be programmed by the

Test Set; they require a special memory card programmer to save files.

SRAM cards provide removable read/write memory for your files, similar to a

flexible disk. Data can be stored, re-stored, read, or erase d as needed.

SRAM memory cards require a battery to maintain stored information.

Table 6 Memory Card Part Numbers

Inserting and Remov ing Memory Cards

Memory Type

64 kilobytes SRAM 83230A

1 Mbyte SRAM 83231A

Figure 9 illustrates how to in sert a memory card into th e Test Set’s front panel. To

remove a memory card, simply pull it out.

The Test Set’s memory-card label is marked with an arrow that must be inserted

on the left side (when you are facing the Test Set) of the front-panel slot.

Agilent

Techn ol ogies

Part Number

74

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Chapter 3, Operating Overview

Using Memory Cards

NOTE: Memory cards may be inserted and removed with the Test Set powered on or off.

Figure 9 Inserting a Memory Card

75

Chapter 3, Operating Overview

Using Memory Cards

Setting the Write-Protect Switch

The SRAM memory card’s write-protect switch lets the user secure its contents

from being overwritten or erased. The switch has two positions (see

• Read-write – The memory-card contents can be changed or erased, and new files may

written on the card.

• Read-only – The memory-card contents can be read by the Test Set, but cannot be

changed or erased.

Figure 10):

Figure 10 Setting the SRAM Write-Protect Switch

76

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Chapter 3, Operating Overview

Using Memory Cards

The Memory Card Battery

SRAM memory cards use a lithium battery to power the card. Listed below are the

batteries for the Test Set’s SRAM cards. SRAM cards typically retain data for

over 1 year at 25

SRAM Card Battery Part Numbers - CR2025 or Agilent Technologies1420-0509

Replacing the Battery

1. Turn the Test Set on and insert the memory card. An inserted memory card takes power

from the Test Set, preventing the card’s contents from being lost.

2. Hold the memory card in the slot with one hand and pull the battery holder out with your

other hand . (See Figure 11 on page 78.)

NOTE: The Test Set’s SRAM cards have a Battery Holder Lock switch immediately above the Write-

Protect switch. If the switch is in the locked posi tion the battery cannot be removed . Ensure

that the Battery Holder Lock s witch is in the un locked position before trying to remove the

battery.

° C. To retain data, the battery should be replaced annually.

3. Install the battery with the side marked “+” on the same side mark ed “+” on the battery

holder. Avoid touching the flat sides of the battery , finger oils may contaminate battery

contacts in the memory-card.

4. Re-insert the battery holder into the memory card.

NOTE: The Test Set’s SRAM cards have a Battery Holder Lock switch immediately above the Write-

Protect switch. Ensure that the Battery Holder Lock switch is in the locked position after

installing the new battery.

5. Remove the memory card from the Test Set.

77

Chapter 3, Operating Overview

Using Memory Cards

Figure 11 Replacing the Memory Card’s Battery

WARNING: Do not mutilate, puncture, or dispose of batteries in fire. The batteries can burst or explode,

releasing hazardous chemicals. Discard unused batteries according to the manufacturer’s

instructions.

Memory Card Initialization

All new SRAM cards must be initialized before they can be used to store

information. The RAM_MANAGER procedure stored on the internal ROM Disk

can be used to quickly initialize any SRAM memory card.

SRAM Memory Cards can also be initiali zed from th e TESTS screen by i nsert ing

the memory card into the fr ont-pa nel slot and sel ecti ng the Save/Del ete f ield, then

selecting

on screen instructions to complete the process.

If the error messag e

the memory card has not been properly initialized. Check the SRAM battery to

ensure that it’s charged and inserted correctly in the battery holder.

Init Card or pressing the k3 USER k ey to in itia lize a card. Fo llow th e

ERROR 85 Medium uninitialized appears on the scr een

78

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Saving and Recalling Instrument Setups

The SAVE and RECALL functions allow you to store different instrument setups

and retrieve them later, eliminating the task of re-configuring the Test Set.

The number of available sa ve regi sters depends on how many chan ges we re made

to the base instrument setup for each save. (Se e

smaller the number of changes, th e greater the number of save registers that can

be used (typically over 200).

Save/Recall register settings can be saved to several types of mass storage. This

allows you to “back up the settings in case you need to clear them from memory

“Memory Considerations” on page 82) for running large programs, or when a

(see

firmware upgrade is performed (see

Chapter 3, Operating Overview

Saving and Recalling Instrument Setups

“BASE Settings” on page 82.) The

“Save/Recall” on page 449).

To Save an Instrument Setup

Use the More menu to access the I/O CONFIGURE screen. )

1. Select the storage media using the Save/Recall field. (The default is internal mem-

ory.

2. Make any changes to the instrument that you want to save in a register.

3. Press and release the SHIFT key then the RECALL key to access the SAVE function.

4. Use the DATA keys or the Save menu at the bottom right of the screen to enter the reg-

ister’s name.

To Recall an Instrument Setup

Use the More menu to access the I/O CONFIGURE screen.

1. Select the media to recall settings from using the Save/Recall field. The default is

internal memory.

2. Press RECALL.

3. Use the knob to select the desired setup to be recalled from the Recall menu at the

bottom-right of the screen.

79

Chapter 3, Operating Overview

Saving and Recalling Instrument Setups

Example of Saving and Recalling an Instrument Setup

This example SAVES changes made to the RX TEST scr een, an d then RECALLS

them. The register is saved to wherever the

memory - unless you have changed it).

1. Access the RX TEST screen and set the RF Gen Freq to 500 MHz.

2. Set Amplitude to -35 dBm.

3. Press and release the SHIFT key then the RECALL key to access the SAVE function.

A prompt appears at the top of the screen asking you to enter a name.

4. Using the DATA keys, press 1 2 3 ENTER to assign a name to these changes.

5. Press PRESET and wait for the instrument to return to normal o peratio n.

6. If not already displayed, access the RX TEST screen. Notice that the RF Gen Freq

and Amplitude settings are reset to their preset values.

7. Press RECALL 1 2 3 ENTER. The RF Gen Freq and Amplitude are changed to

the settings you saved in register 123 (500 MHz and -35 dBm).

Save/Recall field is set (internal

To Remove (Clear) an Individual Save Register

Specify where the register is stored using the Save/Recall field on the I/O CONFIGURE screen.

1. Press RECALL.

2. Use the knob to position the cursor in front of the register to be removed from the Re-

call menu at the bottom-right of the screen. The register name and percentage of

memory occupied by that register are indicated at the top of the screen.

3. Press ON/OFF. A prompt appears, asking if you want to delete the save register.

4. Press YES.

80

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

To Clear All Save Registers

1. Press RECALL.

2. Use the knob to position the cursor in front of the *Clr All* entry in the Recall

menu at the bottom-right of the screen.

3. Press the knob or press ENTER. A prompt appears at the top of the screen to verify that

you want to clear all registers.

4. Press YES.

Register Names

You can use any number, letter, or combination of numbers and letters as a name

for storing instrumen t settin gs. For in stance; i f you want to s ave a setup for testing

a “Vulcan7” radio, you can save the setting as “VULCAN7”.

Two register names are reserved for special purposes: POWERON and BASE.

Chapter 3, Operating Overview

Saving and Recalling Instrument Setups

POWERON Settings

When the Test Set is turned on, it uses a set of instrument setup parameters

specified at the time of manufacture. You can have the instrument power up in a

different state by making the desired changes to the original settings, and then

saving them using the name POWERON.

The next time the instrument is turned on, the instrument returns to the state

present when you saved the POWERON setting. For instance; if the

OSCILLOSCOPE screen was displayed when POWERON was saved, it is the

screen that is displayed when you turn the instrument on.

81

Chapter 3, Operating Overview

Saving and Recalling Instrument Setups

BASE Settings

The BASE register contains any field settings the user has saved that are different

from the instrument preset state. It establishes a reference point for all future

saves. If a base is not saved, the preset state is used as the reference.

When you save an instrument setup, the new setup is compared to the base

settings, and any differences are stor ed under the register name you supply.

Because only differences are stored, a much larger number of instrument setups

can be saved than if the contents of every field was saved.

When you recall an ins trument se tting, eve ry field is reset to the base sett ings. The

saved settings are then used to re-establish the desired instrument setup.

CAUTION: Since each save/recall register only contains the differences between the s etup be ing s aved an d

the present base register settings, changing the base settings causes all other saved set u ps t o be

erased from memory (including the POWERON setting if one has been saved).

Unless you consistently change the same fields to the same value each time you use the

instrument, you should avoid creating your own BASE settings.

Memory Considerations

When the Save/Recall field of the I/O CONFIGURE screen is set to

Internal, programs are saved to the same non-volatile RAM used to create

RAM Disk(s) and run IBASIC pro gra ms. By saving a large nu mber of instrument

setups, you reduce the amount of RAM available to run programs. If you get a

“memory overflow” message while trying to load a program, you must clear one

or more save/recall registers to free RAM space.

Instrument Hardware Changes

Recalling a saved register that uses a hardware option that has been removed

(such as an audio filter) results in unspecified operation. Re-install the needed

option bef ore attempting to recall the associated register(s).

82

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Using USER Keys

Chapter 3, Operating Overview

Using USER Keys

User keys instantly access instrument settings without using the knob. You can

use user keys to move quickly between fields on the same screen, and to access

field settings that are not normally available on the screen you are using.

Local user keys are used to move between settings on the screen that is d is played.

When the user key is pressed, the cursor instantly moves to, and selects, the

assigned field; eliminating the need to turn and push the knob. Five local user

keys are available for each screen: k1, k2, k3, k4, and k5.

Five factory-as si gned local user keys are av ail able in each screen; h oweve r, using

these keys removes any other local user keys you may have already set up.

Global user keys are used to access settings that are not available on the current

screen. Three global user keys are available: k1’, k2’, and k3’. (These are shifted

functions of the local user keys.)

When defining user keys, the ASSIGN function is used to create key definitions;

the RELEASE function removes the definitions. Re-assigning a user key to a

different field setting automatically releases it from the setting it was previously

associated with.

83

Chapter 3, Operating Overview

Using USER Keys

To Use the Pre-Assigned Local USER Keys

1. Press and release the SHIFT key, then the k4 key to access the ASSIGN function; the n

press the ENTER key. The numbers 1 thr oug h 5 appear in front of various fields. (See

Figure 12.)

2. Press the different local user keys (k1 to k5) and notice how the cursor immediately

moves to the corresponding field.

3. To stop using the default local user keys, press and release the SHIFT key, then the k5

key to access the RELEASE function; then press the ENTER key.

Figure 12 An Example of Pre-Assigned Local User Keys

84

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

scnusr.wmf

To Assign Local USER Keys

1. Move the cursor to the field you want to assign a local user key to.

2. Press and release the SHIF T key, then the k4 key to access the ASSIGN function. Then

press a local USER key (k1-k5). The user key number appears in front of the field you

assigned it to.

Example of Assigning a Local USER Key

Use this example to assign local USER key k1 to the Filter 1 field in the R X

TEST screen.

1. Access the RX TEST screen and position the cursor in front of the Filter 1 field.

2. Press and release the SHIFT key, then the k4 key to access the ASSIGN f unction; then

press k1. A sm all 1 appears next to the field indicating that USER key k1 has been assigned to it.

Chapter 3, Operating Overview

Using USER Keys

3. Move the cursor to any other field on th e sc reen and pres s k1 . Th e cur so r immedi ately

returns to the Filter 1 field. The field is also highlighted to change the entry using

the CURSOR CONTROL knob or arrow keys.

To Release Local USER Keys

1. Display the screen containing the user key assignment to be removed.

2. Press and release the SHIF T key , th en the k5 key to access the RELEASE f unction; then

press the USER key (k1-k5) .

85

Chapter 3, Operating Overview

Using USER Keys

To Assign Global USER Keys

1. Move the cursor to the field you want to assign a global user key to.

2. Press and release the SHIF T key, then the k4 key to access the ASSIGN function. Then

press SHIFT and a global USER key (k1’ - k3’). Unlike a local user key, the user key

number does not appear at this field; instead, a prompt appears at the top of the screen

confirming the key assignment.

Example of Assigning a Global USER Key

Use this example to assig n g lobal USER key k 1’ to the AF Anl In field, and then

access this field from the OSCILLOSCOPE screen.

1. Access the AF ANALYZER screen and position the cursor in front of the AF Anl In

field.

2. Press and release the SHIFT key, then the k4 key to access the ASSIGN function.

3. Press SHIF T, k1’. Notice the prompt Global User key 1 assigned. at the top

of the screen.

4. Access the OSCILLOSCOPE screen.

5. Press SHIFT, k1’.

AF Anl Input

present input is set to FM Demod). To change the input, use the arrow keys

(down-arrow or up-arrow), or press ENTER to access the

A field that is accessed using a global user key is only displayed at the top of the

screen while it is being accessed. Moving the cursor to any other field in the

screen causes the user key field to disappear until it is accessed again.

To Release Global USER Keys

1. Move the cursor to the field with the global user key assigned to it.

2. Press and release the SHIFT key, then the k5 key to access the RELEASE function.

Then press SHIFT and the USER key to be released (k1’-k3’).

, FM Demod is displayed at the top of the screen (assuming the

Choices menu.

86

S:\agilent\8920\8920b\USRGUIDE\BOOK\CHAPTERS\opoverv.fb

Setting an RF Generator/Analyzer Offset

You can set a fixed frequency offset between the RF Generator and the

RF Analyzer. This feature is convenient for testing radios with a fixed

transmit/receive frequency offset.

To Set an RF Offset

1. Access the CONFIGURE screen.

2. Position the cursor in front of the RF Offset field, and press the Cursor Control knob,

or press ENTER to turn the offset On or Off.

3. Select the (Gen)-(Anl) field and enter the frequency offset value.

Chapter 3, Operating Overview

Setting an RF Generator/Analyzer Offset

Example of Setting an RF Offset

1. Access the CONFIGURE screen.

2. Set the RF Offset to On.

3. Enter an offset frequency ((Gen)-(Anl)) of 10 MHz.

4. Access the DUPLEX screen.

5. Set the Tune Mode to Manual.

6. Select the RF Gen Freq field, and rotate the Cursor Control knob to vary the RF Gen-

erator’s frequency.

7. Notice that the Tune Freq value changes to maintain the 10 MHz difference between

the generator and the analyzer.

1

1. Manual tuning is used in this example to prevent possible unexpected Tune

Frequency changes during the procedure.

87

Chapter 3, Operating Overview

Using Remote Control

Using Remote Control

The Test Set can be remotely controlled several ways:

• Using GPIB control from a computer/con troller.

• Using IBASIC programs on memory cards.

• Using an ASCII terminal connected to the serial port.

Using GPIB Control