HP 8920B RF Communications Test Set

HP-IB Programmer’s Guide

SCREEN CONT ROL

POWE

OF O

!

MAX POWER

!

ANT INDUPLEX OUTRF IN/O U T

MAX POWER 200

USER

ASSIG

RELEA

SHIFT

k1’

REF

INCR

k1

k2’

k2

k3’

k3

k4

k5

CANC E

MIC/

CONFIHELPMSSG HOLD PRINT

DUPLETXRX PREV TESTS

DATA FUNCTIONS

METER

INCR

LO HI

CURSOR CON-

PUSH TO

AVG

INCR

ON/OFF

ADRS

LOCAL

789

456

123

0

YES

NO

AUDIO SQUELCVOL-

MAX

!

Firmware Versions: HP 8920B B.05.00 and above

INSTRUMENT STATE

SAVE

MEAS

RECAL

DATA

ENTER

dB

GHz

%

MHz

s

kHz

_

+

Hzms% Ωppm

AUDIO IN

!

PRESE

MEMO

LOHI

MAX

HP Part No. 08920-90222

Printed in U. S. A.

September 1997

Rev. B

1

Copyright © Hewlett-Packard Company 1995

Notice Information containe d in this document is subject to change without notic e .

All Rights Reserved. Reproduction, adaptation, or translation without prior

written permission is pr ohibited, except as allowed under the copyright laws.

This material may be reproduced by or for the U.S. Gover nment pursuant to

the Copyright License under the cla use at DFARS 52.227-7013 (APR 1988).

Hewlet t-Packard Company

Learning Products Department

24001 E. Mission

Liberty Lake, WA 99019-9599

U.S.A.

2

Manufacturer’s

Declaration

This statement is provide d to comply with the requirements of

the German Sound Emission Directive, from 18 January 1991.

This product has a sound pressure emission (at the operator

position) < 70 dB(A).

• Sound Pressure Lp < 70 dB(A).

• At Operator Position.

• Normal Operation.

• According to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigu

ng

Diese Information ste ht im Zusammenh ang mit den Anforderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Schalldruckpegel Lp < 70 dB(A).

• Am Arbeitsplatz.

• Normaler Betrieb.

• Nach ISO 7779:1988/EN 27779: 1991 (Typprüfung).

3

Safety Considerations GENERAL

This product and related document at ion must be reviewed for familiarizat ion

with safety markings and instr uctions before operation.

This product is a Safety Class I instrument (provided with a protective earth

terminal).

SAFETY EARTH GROUND

A uninterruptible safety earth ground must be provided from the main power

source to the product input wiring terminals, power cord, or supplied power

cord set.

CHASSIS GROUND TERMINAL

To prevent a potential shock hazard, always connect the rear-panel chassis

ground terminal to earth ground when operating this instrument from a dc

power source.

SAFETY SYMBOLS

WARNING

CAUTION

!

Indicates inst rument damage can occur if indicated operating limits are

exceeded.

Indicates hazar dous voltages.

Indicates earth (g rou nd) terminal

A WARNING note denotes a hazard. It calls atte ntion to a proc edure, practice, or

the like, which, if not correctly performed or adhered to, could result in personal

injury. Do not proceed beyond a WARNING sign until the indicated conditions

are fully understood and met.

A CAUTION note denotes a hazard. It calls attention to an operation

procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in damage to or destruction of part or all of the

product. Do not proceed beyond an CAUTION note until the indicated

conditions are fully unde rstood and met.

4

Safety Considerations for this Instrument

WARNING: This product is a Safety Class 1 instrument (provided with a protective earthing ground

incorporate d in the power cord) The mains plug shall only be inserted in a socket outlet

provided with a protective earth contact. Any interruption of the protective conductor

inside or outside of the product is likely to make the product dangerous. Intentional

interruption is prohibited.

Whenever it is li kely that the protection has been impaired, the instrument must

be made inoperati ve and be secured against an y unintended operation.

If this instru ment is to be energized via an au totransformer (for voltage

reduction), make sure the common terminal is connected to the earth term inal of

the power source.

If this product is not used as specified, the protection provided by the equipm ent

could be impaired. This product must be used in a norm al condition (in which al l

means for proctection are intact) only.

No operator service able parts in this product. Refer servicing to qua lified

personnel. To pre vent electrical shock, do not remove covers.

Servicing instructions are for use by quali fied personnel only. To a void electrical

shock, do not perform any servicing unless you are qualified to do so.

The opening of covers or removal of parts is likely to expose dangerous

voltages. Dis connect the product from all voltage sources while it is being

opened.

Adjustments described in the manual are performed with power supplied to the

instrument whil e protec tive c overs ar e removed. Energy avai la ble at many points

may, if contacted, result in personal injury.

The power cord is connecte d to internal capac itors that my remain live for

5 seconds after disconnecting the plug from its power supply.

For continued protection against fire hazard, replace th e line fuse(s) only with

250 V fuse(s) or the same current rating and type (for example, normal blow or

time delay). Do not use repa ired fuses or short circuited fuseholders .

CAUTION: Always use the three-prong ac power cord supplied with this product. Failure to

ensure adequat e earth grounding by not using this cord may cause product

damage.

This product has autoranging line vol tage input, be sure th e s upply voltage is

within th e s p ec if ied rang e .

5

CERTIFICATION Hewlett-Packard Company certifies that this product met its published

specifications at the time of shipment from the factory. Hewlett-Packard

further certif ies that i ts c alibration measu rements are traceable to the Unite d

States National Institute of Standards and Technology, to the extent allowed

by the Institute’s ca libration facility, and to the calibration facilities of other

International Standards Organization members

WARRANTY This Hewlett-Packar d instr ument product in warranted against defects in

material and workmanship for a period of one year from date of shipment.

During the warranty peri od, Hewlett-Packard Company will at its option,

either repair or replace products which prove to be defective.

For warranty service or repair , this product must be returned to a service

facility desi gnated by HP. Buyer shal l prepay shippi ng charges to HP and HP

shall pay s hipping c harges, dut ies, and taxe s for pr oducts returne d t o HP fro m

another country.

HP warrants that it s software and firmware designa te d by HP for use with an

instrument will exec ute its progr amming instr uctio ns when properly inst all ed

on that instrument. HP does not warrant tha t the operation of the instrument,

or software, or fir mw ar e w ill be un int er ru pte d or erro r fre e.

LIMITATION OF

WARRANTY

EXCLUSIVE

REMEDIES

The foregoing warranty shall not apply to defects resulting from improper or

inadequate maintena nce by Buyer, Buyer-supplied software or inte rfacing,

unauthorized modification or misuse, operation outside of the environmental

specifications for the product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTIDCULAR

PURPOSE.

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. HP SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER BASE ON CONTRACT, TORT, OR ANY

OTHER LEGAL THEORY.

ASSISTANCE Product maintenance agreements and other customer assistanc e agreements

are available for Hewle tt-Packard products. For any assistanc e, contact your

nearest Hewlett-Packard Sales and Service Office.

6

DECLARATION OF CO NF ORMITY

Manuf ac tu r er ’ s N a m e : Hewl ett-Pack ar d Co mpany

Manufacturer’s Address: Spokane Division

24001 E. Mission Ave.

Liberty Lake, WA 99019-9599

Declares that the product(s):

Product Name: RF Communications Test Set

Model Number(s): HP 8920A, 8920B

Product Options: All

Conforms to the following product specifications.

Safety: HD 401/IEC 348

EMC: EN 55011 (1991) /CISPR 11 (1990): ‘Group 1, Class A

EMC: EN 50082-1 (1992) /IEC 801-2 (1991): 4 kV CD, 8 kv AD

/IEC 801-3 (1991): 3 V/m

/IEC 801-4 (1991): 1k V Power Lines

0.5 kV Signal Lines

Supplementary Information:

The product herewith complies with the re quirements of the Low Voltage Directive

73/23/EEC an d EMC Directive 89/336/EEC.

Spokane,

Washington

Date Vince Roland, SKD Quality Manager

Europe an Co n t ac t: Yo u r local Hewlet t- P a ck a r d S al e s and S er v i ce Of fice or HewlettPackard GmbH. Dept. ZQ/S tandards Europe, Herrenberger StarBe 130, D- 7030

Boblingen (Fax: +49-7031-14-3143).

7

In this Book Chapter 1, Using HP-IB, describes the general guidelines for using HP-IB and how

to prepare the Test Set for HP-IB usage. This chapter includes example programs for

controlling the basic functions of the Test Set.

Chapter 2, HP-IB Command Guidelines, conta ins information about se quential

and overlapped commands, command syntax, units of measure, and measurement

stat es. A shor t exampl e program is also presented to familiarize the user with remo te

operation of the Test Set.

Chapter 3, HP-IB Commands, contains command syntax diagrams, equivalent

front-pane l key commands, IEEE 488.2 Common Commands and triggering

commands.

Chapter 4, Advanced Operations, includes information abou t increasing

measurement throughput, status report ing, error reporting, servi ce requests,

instrument initializati on, and passing control .

Chapter 5, Memory Cards/Mass Storage, describes the types of mass storage

(RAM disk, ROM disk, ext ernal disk drives, SRAM cards, and ROM ca rds) and the

file system formats (DOS, LIF) available in the Test Set.

Chapter 6, IBASIC Controller, describes how to develop Instrument BASIC

(IBASIC) progr am s for use on the Test Set’s built -in IBAS IC Controller. Topics

discus sed are: interfacing to the IBASIC Con troller u sing the serial p o rts, over view

of the three program development methods, entering and editing IBASIC programs,

program control usi ng the PROGram Subsystem, and an introduction to writ ing

programs for the TESTS subsystem.

Chapter 7, Programming the Call Proce ssing Subsystem, describes how to

control the Te st Set’s Call Proces sing Subsystem usi ng the Call Processi ng

Subsys tem’s remo t e us er in te r f ac e . Top i cs d iscussed ar e : ac ce s si ng th e C all

Processing Subs yst em screens, handling error messa ges, controlling program flow

using the Call Pr oce ssing Status Register Group, and how to query data messages

received from the mobile station. Example programs are provide d sho wing how to

control the Cal l P rocessing Subsystem using service request s and register polling.

Error Messages describes the Text Only HP-IB Errors and the Numbered HP-IB

Errors. This section als o descr ibe s other type s of error messag es tha t the Test Set

displays and where to find more information about those types of error messages.

8

Trademark

Acknowledgements

Microsoft ®, Microsoft® Windows, and MS-DOS® are registered

trademarks of Microsoft Co rpo ration.

ProComm® is a registered tra demark of DATASTORM TECHNOLOGIES,

INC.

Conventions Used In

This Manual

The generic abbreviation "PC" is used to represent computers compatible with the

IBM personal computer (PC) running the MS-DOS operating system.

The term "workstation" is used to represent HP 9000 Series 200/300 System

Controllers.

The acronym IBASI C is u sed throug hout thi s manual t o re fer to Ins trument B ASIC, a

subset of the Hewlett-Pack ard Rocky Mounta in BASIC programming language. The

term IBASIC Controller refers to the Test Set’s built-in IBASIC Controlle r.

A field on the Test Set’s display is repre se nted in the following manner:

AF Anl In.

A front-panel keycap is represented in the following manner: [TESTS].

When keys are pressed one-at-a-time, they are separated by commas. For

example, [SHIFT], [TESTS] means to press and rele ase the [SHIFT] key, then

press and release the [TESTS] key.

When keys are pressed simultaneously, they are connected by a plus sign, +.

For example, [Alt]+[ P ] means to hold down the [Alt] key and press [ P ].

Definition of Test Set The generic term "Test Set" is used inte rcha ngeably in the manual for the

HP 8920B.

9

10

Contents

1 Using HP-IB

Overview of the Test Set 18

Getting Started 26

Remote Operation 39

Addressing 41

IEEE 488.1 Remote Interface Messag e Capabilities 42

Remote/Local Modes 45

2 Methods For Reading Measurement Results

Background 50

HP BASIC ‘ON TIMEOUT’ Example Program 52

HP BASIC ‘MAV’ Example Program 56

3 HP-IB Command Guidelines

Sequential and Overlapped Commands 62

Guidelines for Operation 63

4 HP-IB Commands

HP-IB Syntax Diagrams 86

Adjacent Channel Power (ACP) 89

AF Analyzer 91

11

Contents

AF Generator 1 94

AF Generator 2 Pre-Modulation Filt ers 95

AF Generator 2/Encoder 96

Configure, I/O Configure 111

Call Processing 117

Decoder 157

Display 161

Measure 163

Oscilloscope 170

Program 175

Save/Rec al l Reg ist ers 176

RF Analyzer 177

RF Generator 179

Radio Interface 180

Spectrum Analyzer 181

HP-IB Only Co m ma n ds 183

Status 184

System 185

Tests 186

Trigger 189

12

Contents

Integer Number Setting Synt ax 190

Real Number Setting Syntax 191

Multiple Real Number Setting Syntax 192

Number Measurement Syntax 193

Multiple Number Measurement Synta x 195

Equivalent Front-Panel Key Commands 196

IEEE 488.2 Common Commands 224

Common Command Descriptions 225

Triggering Measuremen ts 243

5 Advanced Operation s

Increasing Measurement Throughput 252

Status Reporting 260

HP-IB Service Requests 311

Instrument Initialization 321

Passing Control 334

6 Memory Cards/Mass Storage

Default File System 346

Mass Storage Device Overview 348

13

Contents

Default Mass Storage Locations 355

Mass Storage Access 357

DOS and LIF File System Considerations 358

Using the ROM Disk 364

Using Memo ry Cards 365

Backing Up Procedure and Library Files 371

Copying Files Using IBASIC Commands 372

Using RAM Disk 374

Using External Disk Drives 376

7 IBASIC Controller

Introduction 378

The IBASIC Controller Screen 379

Important Notes for Program Development 381

Program Development 382

Interfacing to the IBASIC Controller using Serial Ports 384

Choosing Your Development Method 398

Method #1. Progr am Devel opment on a n External BASIC Language

Computer 400

Method #2. Developing Progr ams on th e Test Set Using the IBASIC

EDIT Mode 408

14

Contents

Method #3. Developing Programs Using Word Processor on a PC

(Least Preferred) 4 1 3

Uploading Programs from the Test Set to a PC 420

Serial I/O from IBASIC Programs 421

PROGram Subsystem 424

The TESTS Subsystem 452

8 Programming The Call Processing Subsystem

Description of the Call Proc ess ing Subsystem’s Remote User

Interface 460

Using the Call Processing Subsystem’s Remote User Interface 464

Programming The CALL CONTROL Screen 474

Programming The AUTHENTICATION Screen 510

Programming The CALL DATA Screen 519

CALL DATA Screen Message Field Descriptions 525

Programming The CALL BIT Screen 546

CALL BIT Screen Message Field Descriptions 561

Programming The ANALOG MEAS Screen 612

Programming The CALL CONFIGURE Screen 620

Example Programs 624

15

Contents

9 Error Messages

Index 673

16

1

Using HP-IB

17

Chapter 1, Using HP-IB

Overview of the Test Set

Overview of the Test Set

The Test Set combines up to 22 separate test instruments and an Instrument

BASIC (IBASIC) Controller into one pac kag e. All of the Test Set’s functions can

be automatically contr olled through application programs running on the built-in

IBASIC Controller or on an external controller connected through HP-IB.

Developing programs for the Test Set is simplified if the programmer has a basic

understanding of how the Test Set operates. An overview of the Test Set’s

operation is best presented in terms of how information flows through the unit.

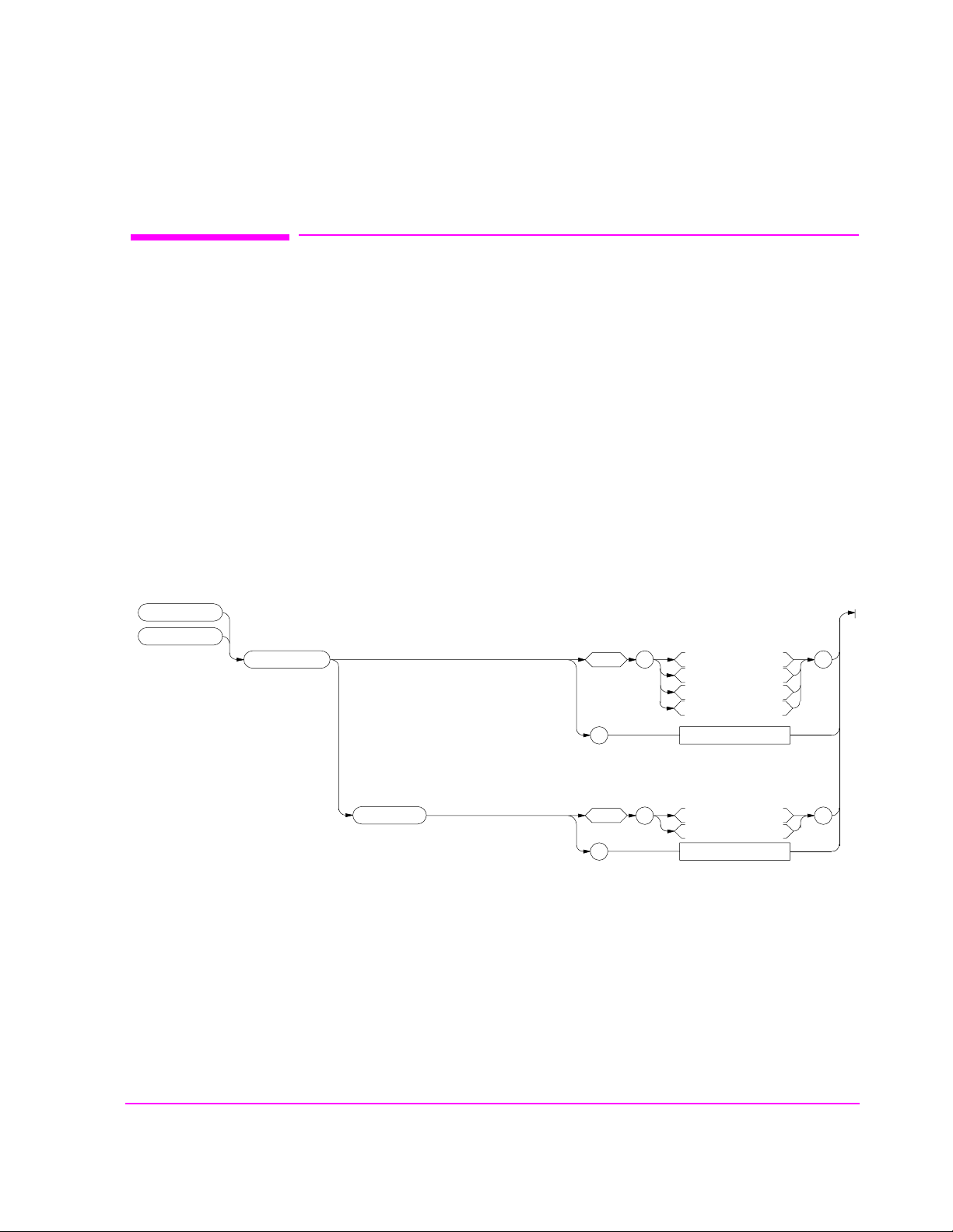

The simplified block di agrams shown in

depict how instrument cont rol information and measurement result inf ormat ion

are routed among the Test Se t’s ins truments, ins trument contr ol hardware, built- in

IBASIC controller, and other components.

figure 1 on page 2 4 and figure 2 on page 25

The Test Set has two operating modes: Manual Control mode and Automatic

Control mode. In Manual Control mode the Test Set’ s operation is controlled

through the front panel keypa d/r otary knob. There are two Automatic Control

modes: Internal and External. In Internal Automatic Control mode the Test Set’s

operation is cont rolled by an application pro gram running on the built-in IBASIC

Controller. In External Automatic Control mode the Test Set’s operation is

controlled by an external controller connected to the Test Set through the HP-IB

interface.

18

Manual Control Mode

The Test Set’s primary instr uments a re shown on the left side of figure 1 . There

are two classes of instruments in the Test Set: signal analyzers (RF Analyzer , AF

Analyzer, Oscilloscope, Spectrum Analyzer, Signaling Decoder) and signal

sources (RF Generator, AF Generator #1, AF Genera tor #2/Signaling Encoder).

The Test Set’s measurement capability can be extended by adding application

specific “top boxes” such as the HP 83201A Dual Mode Cellular Adapter.

Since so many instruments are integrated into the Test Set, it is not feasible to

have an actual “front panel” for each instrument. Therefore, each instrument’s

front panel is maintained in firmware and is displayed on the CRT whenever the

instrument is select ed. Only one instrument front panel can be displaye d on the

CRT at any given time (up to four measurement results can be displa yed

simultaneously if desired). Just as with stand alone instruments, instrument front

panels in the Test Set can contain instrument setting information, measurement

result(s), or data input from the DUT.

Chapter 1, Using HP-IB

Overview of the Test Set

Using the Test Set in Manual Control mode is very analogous to using a set of

bench or rack-mounted test equipme nt. To obta in a measurement result with a

bench or racked system, the des ired measurement must be “active. ” For exa mple,

if an RF power meter is in the bench or racked system and the user wishes to

measure the power of an R F carrie r they m ust turn the po wer met er on, a nd l ook at

the front panel to see the measurement result. Other instruments in the system

may be turned off but this would not prevent the operator from measuring the RF

power.

Conceptually, the same is tr ue for the Test Set. In orde r to make a measur ement or

input data from a DUT, the desired measurement field or data field must be

“active.” This is done by using the front panel keypad/rotary knob to select the

instrument whose front panel contains the desired measurement or data field and

making sure that the desired measurement or data field is turned ON.

Figure 1 shows that instrument selection is handled by the To Screen control

hardware which routes the selected instrument’s front panel to the CRT for

display. Once an instrument’s front panel is displayed on the CRT, the user can

manipulate the in strument set tings, s uch as turning a specif ic measur ement or da ta

field on or off, using the keypad/rotary knob.

Figure 1 also shows that instrument

setup is handled by the Instrument Control hardware which routes setup

information from the front panel to the individual instruments .

An HP-IB/RS-232/Par allel Printer interface capability is available in the Test Set.

In Manual Control mode this provides the capability of connecting an external

HP-IB, serial, or parallel printer to the Test Set so that display screens can be

printed.

19

Chapter 1, Using HP-IB

Overview of the Test Set

Internal Automatic Control Mode

In Internal Automatic Control mode the Test Set’s operation is controlled by an

application program running on the built-in Instrument BASIC (IBASIC)

Controller. The built-in controller runs programs written in IBASIC, a subset of

the Hewlett-Packard BASI C programming la nguage used on the HP 9000 Series

200/300 System Controlle rs. IBASIC is the only programming language

supported on the built-in IBASIC Controller.

Similarities Between the Test Set’s IBASIC Controller and Other Single-Tasking

Controllers

The architect ure of the I BASIC Contr oller is s imila r to tha t of oth er sin gle-tas king

instrumentati on controllers. Only one program can be run on the IBASIC

Controller at any given time. The program is loaded into RAM memory from

some type of ma ss storage device. Fiv e types of mass sto rage d ev ices are

available to the Test Set: SRAM memory cards, ROM memory cards, exter nal

disk drives con nect e d to th e HP -IB int erfa ce, internal RAM disc, and internal

ROM disc. Three types of interfaces are available for connecting to external

instruments and equipment: HP-IB, RS-232, and 16-bit parallel (available as Opt

020 Radio Int erfa ce Card).

Figure 2 shows how infor mati on is routed in side the Test S et when i t is in Int ernal

Automatic Control mode. In Manual Control mode certain Test Set resources are

dedicated to manual operation. These resources are switched to the IBASIC

Controller when an IBASIC program i s running. These incl ude the serial i nterface

at select code 9, the HP-IB interfac e at select cod e 7, the p aral lel pr inter i n terface

at select code 15, and the CRT. In Manual Control mode, fron t panel inf ormation

(instrument settings, measurement results, data input from the DUT) is routed to

the CRT through the To Screen control hardware. In Internal Automatic Control

mode the measurement results and data input from the DUT are routed to the

IBASIC Co ntr oll er thr o ugh a de d icat ed HP-IB interface. Also, in Internal

Automatic Control mode, the CRT is dedicat ed to the IBASIC Controller for

program and graphics displ ay. This mean s instrument front panels cannot be

displayed on the CRT when an IBASIC program is running.

20

Chapter 1, Using HP-IB

Overview of the Test Set

Differences Between the Test Set’s IBASIC Controller and Other Single-Tasking

Controllers

The IBASIC Controller is unlike othe r single tasking instrumentation co ntrollers

in several ways. First, it does not have a keyboard. This imposes some limitati ons

on creating and editing IBASIC programs directly on the Test Set. In Internal

Automatic Control mode a “virtual” key board is available in firmware which

allows the operator to ente r alpha numeric data into a dedicated input fiel d using

the rotary knob. This is not the recommended pr ogramming mode for the IBASIC

Controller. This feature is provided to allow user access to IBASIC programs for

short edits or troubleshooting. Several programming modes for developing

IBASIC programs to run on the internal IBASIC Controller are discussed in this

manual.

Secondly, the I BASIC Contr oller ha s a dedic ate d HP-IB interface, select code 8 in

figure 2 , for communicating with the internal instrumen ts of the Tes t Set. This

HP-IB interface is only available to the IBASIC Controller. There is no external

connector for this HP-IB int erface. No external instruments may be added to this

HP-IB interface. The HP-IB interface, select code 7 in

figure 2 , is used to

interface the Test Set to external instruments or to an external controller. The

dedicated HP-IB interface at select code 8 conforms to the IEEE 488.2 Standard

in all respects bu t one. T he difference being that each instrumen t on the bus does

not have a unique address. The Instrument Co ntrol Hardware determines which

instrument is being addressed through the command syntax. Refer to

"HP-IB Commands"

for a listing of the HP-IB command syntax for the Test Set.

chapte r 4 ,

21

Chapter 1, Using HP-IB

Overview of the Test Set

External Automatic Control Mode

In External Automatic Control mode the Test Set’s oper ation is controlled by an

external contr oller c onnec ted t o the Te st Set thr ough the HP-IB interface. When in

External Automati c Control mode t he Tes t Set’s int ernal conf iguratio n is the sa me

as in Manual Control Mode with two exceptions:

1. Configura ti on and setup comm ands are rec eived th rough the ext ernal HP-IB int erfac e,

select code 7, rather than from the front-panel keypad/ro tary knob.

2. The MEASure command is used to obtain measurement results and DUT data t hrough

the external HP-IB interface.

Figure 1 on page 24

shows how information i s routed insi de t he Test Set in Manua l

Control mode. F igure 1 also shows t hat certain Te st Set re sources are dedicated to

the IBASIC Controller (Memory Card, ROM disk, Serial Interface #10) and are

not directly accessible to the user in Manual Control Mode. In addition, figure 1

shows that Serial Interface #9 and Parallel Printer Interfa ce #15 are accessible as

write-only inte rfaces for print ing in Manual Control mode. These sa me condit ions

are true when in External Automatic Control mode. If the user wished to access

these resources from an exter nal control ler, an IBASIC progra m would have to be

run on the Test Set from the external controller.

22

Writing programs for the Test Set

One of the design goals for automatic control of the Test Set was that it operate

the same way programmatically as it does manually. This is a key point to

remember when developing progr ams for the Test Set. The benefit of this

approach is that to automate a part ic ular task, one need only figure out how to do

the task manually and then duplic at e the same process in software. This has

several implications when designing and writing programs for the Test Set:

1. In Manu al Co ntrol mod e a me asurement must be “a cti ve ” in or d er to ob t ain a meas ur e-

ment result or input data from the DUT. From a programming perspective this means

that before attemptin g to read a m easurement res ult or to input data from the DUT, the

desired screen for the measurement result or data field mu st be s elected using the DISPlay command and the field must be in the ON state.

2. In Manual Con trol mode instrument configu ration informat ion is not routed throu gh the

To Screen control hardware block. From a programming perspective this mea ns that

configuration in form ation c an be sent to a ny desired i nstrum ent with out having to firs t

select th e in st r u ment’s fron t p an el wi t h th e DI SP l ay co m m an d .

Chapter 1, Using HP-IB

Overview of the Test Set

Keeping these points in mind durin g program development will minimize

program development time and reduc e proble ms encountered when running the

program.

23

Chapter 1, Using HP-IB

Overview of the Test Set

#9

CRT

FRONT PANEL

CONTROL

TO SCREEN

HARDWARE

KEYPAD/

ROTARY KNOB

FRONT

PANEL

INFORMATION

MEMORY CARD

IBASIC

INST RUMENT CON-

HP - IB

ROM DISK

CONTROLLER

#8

TROL HARDWARE

INSTRUMENT

#10

SERIAL I/F

SERIAL I/F

PARALLEL

SETUP

INFORMATION

#7

#15

HP - IB

PRINTER

RF GEN

AF GEN #1

MEASUREMENT RESULTS AND DUT DATA

GEN

AF GEN #2

FUNCTION

ENCODER

SIGNALING

AF ANALYZER

SPECTRUM

ANALYZER

OSCILLOSCOPE

RF ANALYZER

Figure 1 Manual Control Mode

24

TOP

BOXES

DECODER

SIGNALING

Chapter 1, Using HP-IB

Overview of the Test Set

#9

CRT

KEYPAD/

FRONT PANEL

CONTROL

TO SCREEN

HARDWARE

ROTARY KNOB

FRONT

PANEL

INFORMATION

MEMORY CARD

IBASIC

INSTRU M ENT CON-

CONTROLLER

HP - IB

TROL HARDWARE

ROM DISK

#8

INSTRUMENT

#10

SERIAL I/F

SETUP

INFORMATION

PARALLEL

SERIAL I/F

#7

#15

HP - IB

PRINTER

RF GEN

AF GEN #1

MEASUREMENT RESULTS AND DUT DATA

GEN

AF GEN #2

FUNCTION

ENCODER

SIGNALING

AF ANALYZER

Figure 2 Internal Automatic Cont rol Mode

TOP

BOXES

SPEC TRUM

ANALYZER

OSCILLOSCOPE

DECODER

SIGNALING

RF ANALYZER

25

Chapter 1, Using HP-IB

Getting Started

Getting Started

What is HP-IB?

The Hewlett-Packa rd Inte rface B us (HP-IB) i s Hewlet t-Pac kard’s i mplement ation

of the IEEE 488.1-1987 Standard Digital Interface for Programmable

Instrumentation. Incorporation of the HP-IB into the Test Set pr ovides several

valuable capabil ities:

• Programs running in the Test Set’s IBASIC Controller can control all the Test Set’s

functions using its internal HP-IB. This capability provides a single-instrument automated test system. (Th e HP 11807 Radio Test Software utilizes this capability.)

• Programs running in the Test Set’s IBASIC Controller can control other instruments

connected to the external HP- I B.

• An external controller, connected to the external HP-IB, can re motely cont r ol the Test

Set.

• An HP-IB prin te r, conn ec ted to the e xte rnal HP -IB , can be used to print t est resul ts and

full screen images.

26

HP-IB Information Provided in This Man ual

What Is Explained

How to configure the Test Set for HP-IB ope ration

• How to make an instrument sett ing over HP-IB

• How to read-back instrument settings over HP-IB

• How to make measurements over HP-IB

• How to co n nect exte r na l P C s , te r m i n als or contr o llers to the Test Set

• HP-IB command syntax for the Test Set

• IBASIC program development

• IBASIC program transfer over HP-IB

Chapter 1, Using HP-IB

Getting Started

• Various advance d f unction s s uch as, i ncreasi ng me asure ment throughpu t, sta tus reporting, error reporting, pass control, and so forth

What Is Not Explained

• HP-IB (IEEE 488.1, 488.2) theory of operation

• HP-IB electrical specifications

• HP-IB connector pin functions

1

1

1

• IBASIC programming (oth er than general guidel ines related to HP-IB)2

1. Refer to the Tutor i a l D e scripti on of the Hewlett- P ackard I n terfac e Bu s

(HP P/N 5952-0156) for detaile d information on HP-IB theory and operat ion.

2. Refer to the HP Instrument BASIC Users Handbook Version 2.0 (HP P/N E2083-

90005) for more information on the IBASIC Version 2.0 language.

27

Chapter 1, Using HP-IB

Getting Started

General HP-IB Programming Guidelines

The following guidelines should be consider ed when de veloping programs which

control the Test Set through HP-I B:

• Guideline #1. Avoid using the TX TEST and RX TEST screens.

The RX TEST and TX TEST screens are specifi cally designed for manual testing of

land mobile FM radios and , when displayed, automat ica lly configure six “priority”

fields in th e Test Set for this purpose. The pr iority fields and their preset values ar e

listed in table 1 on page 29. When the TX TEST screen or the RX TEST screen is dis-

played, certain priorit y fields are hidden and are not settable. The priority field s which

are hidden are listed in table 1 on page 29.

When the TX TEST screen or the RX TEST screen is displayed, any HP-IB commands

sent to the Test Set to change the value of a hidden pri ority field are ignored. Hidden priority fields on the TX TEST or RX TEST screens are not settable manually or programmatically.

Displaying eith er of the se scree ns aut omati call y re-conf igur es the 6 “prio rit y” fiel ds as

follows:

1. When ente rin g th e R X TEST screen,

a. the RF Generator’s Amplitude field, the AFGen1 To field and the AF An-

alyzer’s measurement fi eld (measurement displayed in upper, right portion of

CRT display) are

• set to their preset values upon entering the screen for the first time since

power-up, OR

• set to their preset values if the PRESET key is selected, OR

• set to th e la s t set t in g m ad e w h il e in the screen

b. the RF Generator Amplitude field and the AFGen1 To field are

• set to their preset values whenever entering the screen, OR

• set to th ei r pr ese t v al u es if th e PR ES ET key is sel ected

28

Chapter 1, Using HP-IB

Getting Started

2. When ente rin g th e TX TEST screen ,

a. The AF Anl In field, the De-Emphasis field, the Detector field a nd the

AF Analyzer Measuremen t field (measurement di splayed in upper, right portion

of CRT display) are,

• set to their preset values upon entering the screen for the first time since

power-up, OR

• set to their preset values if the PRESET key is selected, OR

• set to th e la s t set t in g m ad e w h il e in the screen

b. The AF Analyzer AF Anl In, De-Emphasis and Detector fields are,

• set to their preset values whenever entering the screen, OR

• set to th ei r pr ese t v al u es if th e PR ES ET key is sel ected

Table 1 RX TEST Screen and TX TEST Screen Priority Field Preset Values

Priority

Field

RF Gen

RX TEST

Screen Preset

Value

−80 dBm No Off Yes

Field Hidden

On RX TEST

Screen

TX TEST

Screen Preset

Value

Amplitude

AFGen1 To FM No Audio Out Yes

AF Anl In Audio In Yes FM Demod No

Detector RMS Yes Pk ± Max No

De-emphasis Off Yes 750 µsNo

AF Analyzer

SINAD No Audio Freq No

Measurement

Field

Hidden On

TX TEST

Screen

29

Chapter 1, Using HP-IB

Getting Started

• Guideline #2. When developing programs to make measurements always follow this

recommended sequence:

1. Bring t he Test Set to it s prese t stat e usi ng the front -pan el PRESET key. Th is ini tial

step allows you to s t art dev eloping the m easurem ent se quen ce wit h most fi elds in a

known state.

2. Make the measurement manually using the front-panel con trols of the Test Set.

Record, in sequential order, the screens select ed and the se ttings made wi thin each

scree n. The rec ord of the scr eens sele cted an d setting s made in eac h screen bec omes

the measurement procedure.

3. Record the measurement result(s).

In addition to the DISPlay com mand, the signa li ng ENCode r and DECod er requi re

further commands to display the correc t fields for ea ch signaling mode. For example, DISP ENC;:ENC:MODE 'DTMF'.

4. Develop the program using the measurement proced ure ge nerated in step 2. Be sure

to start the prog rammatic measurem ent sequenc e by bringing the Test Set to its pre set

state using the *RST Common Command. As the measurement procedure requires

changing screens, us e the DISPlay command to s elect t he des ired scr een fol lowed by

the cor re c t co mmands to set the de s ired field(s) .

When IBASIC programs are running the CRT is dedicated to the IBASIC Controller for

program and gr aphics di spla y. This means ins trume nt front p anels ar e not di spla yed on th e

CRT when an IBASIC program is running. However, the DISPlay <scre en> command

causes all setting and measurement fie lds in the <screen> to be access ible programmatically. Attempting to read from a screen that has not been made accessible by the DISPlay

comman d wil l cause

HP-IB Error:-420 Query UNTERMINATED, or

HP-IB Error: -113 Undefined header

Make sure the desired measurement is in the ON state. This is the preset state for most

measurements. However, if a previous program has set the state to OFF, the measurement

will not be available. Attempting to read from a measurement field that is not in the ON

state wil l ca us e HP-IB Error:-420 Query UNTERMINATED.

5. If the trigger mode has been changed, trigger a reading.

Triggering is se t to F ULL SETTling and REPetitive RETRiggering after receipt of the

*RST Common Command. These settings cause the Test Set to trigger itself and a sepa rate trigger command is not necessary.

30

Chapter 1, Using HP-IB

Getting Started

6. Send the MEASure query com m and to initiate a reading. This will place the mea-

sured value into the Test Set’ s Output Queue.

When making AF Analyzer SINAD, Dis tortio n, Sig nal to Noi se Ratio, AF Fr equenc y, DC

Level, or Current me as urements, the me as urement type must firs t be selected using the

SELect co mmand.

For example, MEAS:AFR:SEL'SINAD' followed by MEAS:AFR:SINAD?

7. Use the ENTER statement to transfer the measured value to a variable within the

context of the program.

The following example program illustr ates how to make settings and then take a

reading from the Test Set. This setup takes a reading from the spectrum analyzer

marker after tuning it to the RF generator’s output frequency.

Example

10 Addr=714

20 OUTPUT Addr;"*RST" !Preset to known state

30 OUTPUT Addr;"TRIG:MODE:RETR SING" !Sets single trigger

40 OUTPUT Addr;"DISP RFG" !Selects the RF Gen screen

50 OUTPUT Addr;"AFG1:FM:STAT OFF" !Turns FM OFF

60 OUTPUT Addr;"RFG:AMPL -66 DBM" !Sets RF Gen ampl to -66 dBm

70 OUTPUT Addr;"RFG:FREQ 500 MHZ" !Sets RF Gen freq to 500 MHz

80 OUTPUT Addr;"RFG:AMPL:STAT ON" !Turns RF Gen output ON

90 OUTPUT Addr;"DISP SAN"!Selects Spectrum Analyzer’s screen

100 OUTPUT Addr;"SAN:CRF 500 MHZ" !Center Frequency 500 MHz

110 ! -------------------MEASUREMENT SEQUENCE------------------120 OUTPUT Addr;"TRIG" !Triggers reading

130 OUTPUT Addr;"MEAS:SAN:MARK:LEV?" !Query of Spectrum

140 !Analyzer’s marker level

150 ENTER Addr;Lvl !Places measured value in variable Lvl

160 DISP Lvl!Displays value of Lvl

170 END

The RF Generator’s output por t and the Spectrum Analyz er’s input port are pres et

to the RF IN/OUT port. This allows the Spectrum Analyzer to measure the RF

Generator with no e xternal conne ction s. The Spectr um Analy zer marker is a lways

tuned to the center frequency of the Spectrum Analyzer after preset. With the RF

Generator’s o utput port and Spectrum Analyzer input port both directed to the RF

IN/OUT port, the two will internally couple with 46 dB of gain, giving a measured

value of approximate ly -20 dBm. While not a nor mal mode of ope ration th is setup

is convenient for demonstr ation since no external cables are required. This also

illustrates the value of starting from the preset state sinc e fewer programming

commands are required.

31

Chapter 1, Using HP-IB

Getting Started

• Guideline #3. Avoid program hangs.

If the program stops or “ hangs up” whe n trying t o ENTER a mea sured value , it i s most

likely that the desired measurement field is not available. There are several reasons

that can happen:

1. The screen where the measurement field is located has not been DISPlayed before

querying the measurement field.

2. The measurement is no t turned ON.

3. The squelc h control is set too high. If a measure ment is turned ON but is n ot avail-

able due to the Squelch setting, the m easurement field contains four dashes

(- - - -). Thi s is a val id state. The Test Set is waiting for a sign al of suff icient str ength

to unsqu e lch the recei v er be f o re m ak i n g a measurem en t . If a m ea s u rement fiel d

which is squelched is queried the Test Set will wait indefinitely for the receiver to

unsquelch and return a measured value.

4. The RF Anal yzer’s In put Port i s set t o ANT (an tenna) whil e tryin g to read T X pow-

er. TX powe r i s not measu rable with the Input Port set t o ANT. The T X power m easurement field will display four dashes (- - - -) indicating the measurement is

unavailable.

5. The inpu t signal to the Tes t Set i s very unsta ble causin g the Tes t Set to c ontinuou sly

autorange. This condition will be apparent if an attempt is made to make the measurement manually.

6. Trigger mode has been set to single trigger (TRIG:MODE:RETRig SINGle) and a

new measurement cycle has not been triggered before attempting to read the measured value.

7. The program is att em pting to make an FM deviation or AM depth meas urem ent

while in the RX TEST screen. FM or AM measurements are not available in the RX

TEST screen. FM or AM measurements are made from the AF Analyzer screen by

setting the AF Anl In field to FM or AM Demod.

32

Chapter 1, Using HP-IB

Getting Started

• Guideline #4. Use single quotes and spaces properly.

The syntax diagr a ms in chapter 4, "HP-IB Commands," show where single quotes

are need e d an d whe r e sp aces are need ed .

Example

OUTPU T 714 ;" DI SP<space >A FAN"

OUTPU T 714 ;" AF AN:DEMP< sp ace>’Off’ "

Improper use of single quotes and spaces will cause,

HP-IB Error:-103 Invalid Separator

• Guideline #5. Ensure th at sett ab le fie lds ar e ac tiv e b y us ing the STAT e ON com man d.

When making settings to fields that can be turned OF F with the STATe ON/OF F com-

mand (refer to the Chapter 4, "HP-IB Commands"), make sure the STATe is ON if

the program uses that field. Note that if the STATe is OFF, just setting a numeric value

in the field will not change the STATe to ON. This is different than front-panel operation whereby the pr ocess of selecting the field and entering a value automatica lly sets

the STATe to ON. Programmatically, fields must be explicitly set to the ON state if

they are in the OFF state.

For example, the fol lowing comm and line would set a new AMPS ENCoder SAT t one

deviation and then turn on the SAT tone (note the use of the ; to back up one level in

the command hier archy so that more than one command can b e ex ecuted in a sing l e

line):

Example

OUTPUT 714;"ENC:AMPS:SAT:FM 2.1 KHZ;FM:STAT ON"

To just turn on the SAT tone witho ut changing the current setting the following commands would be used:

OUTPU T 714 ;" EN C:AMPS:S AT :FM:STAT ON "

33

Chapter 1, Using HP-IB

Getting Started

• Guideline #6. Numeric values are returned in HP-IB Units or Attribute Units only.

When querying measurements or se ttings through HP-IB, the Test Set always returns

numeric values in HP-IB Units or Attribute Units, regardless of the current Display

Units setting. HP-IB Units, Attribute Units and Display Units determine the units-ofmeasure u sed for a measurement or sett in g , for exa mple, Hz, Volts, Wat ts, Amper es,

Ohms. Refer to "Specifying Units-of-Measure for Settings and Measurement

Results" on page 67 for further information.

For example, if the Test Set’ s front panel is displaying T X Frequency as 835.02 MHz,

and the field is que ried through HP-IB, the value returned will be 835020000 since the

HP-IB Units for frequency are Hz. Note that changing Displ ay Units will not change

HP-IB Units or Attribute Units. Note also that setting the value of a numeric field

through HP-IB can be done using a variety of units-of-measure. The HP-IB Units or

Attribute Units for a queried value can always be determined using the :UNITs? command or :AUNits? c ommand respectively (refer to "Number Measurement Syntax"

on page 193 or "Multiple Number Measurement Syntax" on page 195, for com-

mand syntax).

Control Annunciators

The letters and symbols at the top right c orn er of the display indicate these

conditions:

• R indicates the Test Set is in remote mode. The Test Set can be put into the remote mode

by an external con troller or by an IBAS IC program runni ng on the buil t-in IBASIC c ontroller.

• L indicates th at the Test Set has been addressed to Listen.

• T indicates th at the Test Set has been addressed to Talk.

• S indicat es that the Tes t Set has sent the Require Servic e messa ge by sett ing the Servic e

Request (SRQ) bus line true. (See "Status Reporting" on page 260.)

• C indicates that the Test Set is currently the Active Controller on the bus.

• * indicates that a n IBASIC program is running.

• ? indicates that an IBASIC program is waiting for a user response.

• - indicates that an IBASIC program is paused.

34

Preparing the Test Set For HP-IB Use

1. If other HP-IB devices are in the system, attach an HP-IB c able from the Test Set’s rear-

panel HP-IB connector to any one of the other devices in the test system.

2. Access the I/O CONFIGURE screen and perform the following steps:

a. Set the Test Set’s HP-IB address using the HP-IB Adrs field.

b. S et the Test Set’ s HP-IB Contro ller capab ility using the Mode field.

• Talk&Listen configures the Tes t S et to not be the System Controller. The Test Set

has Active Controller capability (take control/pass con trol) in this mode. Use thi s setting if the Test Set will be controlled through HP-IB from an external controller.

• Control configures the Test Set to be the System Controller. Use this setting if the

Test Set will be the only controll er on the HP-IB. Selecting the Control mode automatically make s the Test Set th e Active Contro ller.

Chapter 1, Using HP-IB

Getting Started

NOTE: Only one System Controller can be configured in an HP-IB system. Refer to "Passing

Control" on page 334 for furthe r information.

3. If an HP-IB prin ter is or wil l be c onnect ed to the Test S et’s re ar panel HP-IB c onne ctor

then,

a. access the P R I N T CO N FIGURE scr een.

b. select one of the supported HP-IB printer models using the Model field.

c. set the Printer Port field to HP-IB.

d. s et the printer address using the Printer Address field.

35

Chapter 1, Using HP-IB

Getting Started

Using the HP-IB with the Test Set’s built-in IBASIC Controller

The Test Set has two HP-IB interfaces, an internal-only HP-IB at select code 8

and an external HP-IB at select code 7. The HP-IB at select code 8 is only

available to the built- in IBASIC Controller and is used exclusively f or

communication between the IBASIC Controller and the Test Set. The HP-IB at

select code 7 serves three pur pose s:

1. It al lows the Test Set to be controlled by an external controller

2. It al lows the Test Set to print to an external HP-IB printer

3. It al lows the built-in IBASIC Controller to control external HP-IB devices

IBASIC programs running on the Test Set’s IBASIC Controller must use the

internal-only HP-IB at select code 8 to control the Test Set. IBASIC programs

would use the external HP-IB at select c ode 7 to control HP-IB devices connected

to the rear panel HP-IB connector.

NOTE: Refer to "Overview of the Test Set" on page 18 for a deta il ed ex p l an at io n o f th e Te s t S et ’ s

architecture.

When using a BASIC language Workstation with an HP-IB int erf ace at select

code 7 to control the Test Set, HP-IB commands would look like this:

Example

! This command is sent to the Test Set at address 14.

OUTPU T 714 ;" *R ST"

! This command is sent to another instrument whose address is 19.

OUTPU T 719 ;" *R ST"

When executing the same commands on the Test Set’s IBASIC Controller, the

commands would look like this:

Example

OUTPU T 814 ;" *R ST"

! Command sent to internal-only HP-IB at select code 8,

! Test Set’s address does not change

OUTPU T 719 ;" *R ST"

! Command sent to external HP-IB at select code 7,

! other instrument’s address does not change.

36

Basic Programming Examples

The following simple examples illustrate the basic approach to controlling the

Test Set through the HP-IB. The punctuation and command syntax used for these

examples is given in Chapter 4, "HP-IB Commands".

The bus address 714 used in the following BASIC language examples assumes an

HP-IB interface at select code 7, and a Test Set HP-IB address of 14. All examples

assume an external controller is being used.

To Change a Field’s Setting over HP-IB

1. Use the DI SPlay comman d to acce ss th e screen c ontain ing th e field whos e sett ing is to

be changed.

2. Make the desired setting using the proper command syntax (refer to Chapter 4, "HP-

IB Commands" for proper syntax).

The following example makes several instrument setting changes:

Chapter 1, Using HP-IB

Getting Started

Example

OUTPUT 714;"DISP RFG" !Display the RF Generator screen.

OUTPUT 714;"RFG:FREQ 850 MHZ" !Set the RF Gen Freq to 850 MHz.

OUTPUT 714;"RFG:OUTP ’DUPL’"!Set the Output Port to Duplex.

OUTPUT 714;"DISP AFAN"!Display the AF Analyzer screen.

OUTPUT 714;"AFAN:INP ’FM DEMOD’"!Set the AF Anl In to FM Demod.

To Read a Field’s Setting over HP-IB37

1. Use the DI SPlay c ommand to acce ss th e screen c ontain ing th e field whos e sett ing is to

be read.

2. Use th e Query form o f the syntax f o r that field to place the setting value into the Test

Set’s output buffer.

3. Enter the val ue into the corr ect varia ble ty pe within the progr am context ( refer to Chap-

ter 4, "HP-IB Commands", for proper variable type).

37

Chapter 1, Using HP-IB

Getting Started

The following example reads sev era l fields.

Example

OUTPUT 714;"DISP AFAN"!Display the AF Analyzer screen.

OUTPUT 714;"AFAN:INP?"!Query the AF Anl In field

ENTER 714;Af_input$ !Enter returned value into a string ariable.

OUTPUT 714;"DISP RFG"!Display the RF Generator screen

OUTPUT 714;"RFG:FREQ?"!Query the RF Gen Frequency field.

ENTER 714;Freq !Enter the returned value into a numeric variable

NOTE: When querying measure ments or se ttings throug h HP-IB, the Test Set al ways returns

numeric values in HP-IB Units or Attribute Units, re gardless of the current Display

Units setting. Refer to "HP-IB Units (UNIT s)" on page 70 and "Attribute Units

(AUNits)" on page 73 for further information.

To Make a Simple Measurement

The basic m ethod for makin g a measurement is very similar to t he method used to

read a field setting.

1. Use the DISP l ay co m ma n d to ac cess the scre en co n ta in i n g th e desired me asu r e m en t .

2. Use the MEASure form of the syntax for that measurement to place the measured value

into the Test Set’s output buffer.

3. Enter the va lue in to t he corr ec t va ria ble t ype with in t he progra m con tex t (re fe r to chap -

ter 4, "HP-IB Commands" for proper variable type).

The following example measures the power of an RF signal .

Example

!Display the RF Analyzer screen.

OUTPUT 714;"DISP RFAN"

!Measure the RF power and place result in output buffer.

OUTPU T 714 ;" ME AS:RFR:P OW? "

!Enter the measured value into a numeric variable.

ENTER 714;Tx_power

The above example i s ver y simple and i s designe d to de monstr ate the fundamenta l

procedure for obtain ing a measurement result. Many other factors must be

considered when designing a measuremen t proced ure, suc h as inst rument sett ings,

signal routing, settling time, filtering, triggering and measurement speed.

38

Remote Operation

Chapter 1, Using HP-IB

Remote Operation

The Test Set can be operated remotely through the Hewlet t-Packard I nterface Bus

(HP-IB). Except as otherwis e noted, the Test Set complies with the IEEE

488.1-1987 and IEEE 488.2-1987 Standa rds. Bus compatibility, prog ramming

and data formats are describe d in the following sections.

All front-panel f unctio ns, excep t those li sted in

table 2, are programmable thr ough

HP-IB.

Table 2 Non-Programmable Front Pa n el F unc tions

Function Comment

ON/OFF Power Switch

Volume Control Knob

Squelch Control Knob The position of the Squelch Control knob cannot be programm ed. How-

ever squelch can be programmed to either the Open or Fixed position.

Refer to the Test Set’s User’s Guide for more information.

Cursor Control Knob

SHIFT Key

CANCEL Key

YES Key

NO Key

ENTER Key

Backspace (lef t-arrow) K ey

PREV Key

HOLD ( SHIFT, PREV Keys)

PRINT ( SHIFT, TESTS Keys)

ADRS ( SHIFT, LOCAL Keys)

ASSIGN ( SHIFT, k4 Keys)

RELEASE ( SHIFT, k5 Keys)

39

Chapter 1, Using HP-IB

Remote Operation

Remote Capabilities

Conformance to the IEEE 488.1- 1987 Standard

For all IEEE 488.1 functions implemented, the Test Set adheres to the rules and

procedures as outlin ed in that Standard.

Conformance to the IEEE 488.2- 1987 Standard

For all IEEE 488.2 functions implemented, the Test Set adheres to the rules and

procedures as outlin ed in that Standard with the exception of the *OPC Common

Command. Refer to the *OPC Common Command description.

IEEE 488.1 Interface Functions

The interface functions that the Test Set implements are listed in table 3.

Table 3 Test Set IEEE 488.1 Interface Function Capabilities

Function Capability

Talker T6: No Talk Only Mode

Extended Talker T0: No Extended T alker Capability

Listener L4: No Lis te n On ly M od e

Extended Listener LE0: No Extended Listener Capability

Source Handshake SH1: Complete Capability

Acceptor Handshake AH1: Complete Capability

Remote/Local RL1: Complete Capability

Service Request SR1: Complete Capability

Parallel Poll PP0: No Parallel Poll Capability

Device Clear DC1: Complete Capability

Device Trigge r DT1: Complete Capability

Controlle r C1: System Controller

C3: Send REN

C4: Respo nd to S RQ

C11:No Pass Control to Self, No Parallel Poll

Drivers E2: Tri-S tate Drivers

40

Addressing

Factory Set Address

Extended Addressing

Chapter 1, Using HP-IB

Addressing

The Test Set’s HP-IB address is set to decimal 14 at the factory. The address can be

changed by following the instru ctions in "Setting the Test Set’ s Bus Address" on page

41

.

Extended addressi ng (se condary command) capabili ty i s not imple mented i n the Test

Set.

Multiple Addressing

Multiple addressing c apability is not implemented in the Test Set.

Setting the Test Set’s Bus Address

The Test Set’s HP-IB bus address is set using the HP-IB Adrs field which is located

on the I/O CONFIGURE screen. To set the HP-IB bus address; select the I/ O

CONFIGURE screen and position the cursor ne xt to the

address can be set from decimal 0 to 30 using the numeric DATA keys, or by

pushing and then rotating the Cursor Cont rol knob. There are no DIP switches for

setting the HP-IB bus address in the Test Set. The new setting is retained when the

Test Set is turned off.

Displayi ng t he Bus Add ress

The Test Set’s HP-IB bus address can be displayed by pressing and releasing the

SHIFT key, then the LOCAL key. The address is displayed in the upper left-hand

corner of the display screen.

HP-IB Adrs field. The

41

Chapter 1, Using HP-IB

IEEE 488.1 Remote Interface Message Capabilities

IEEE 488.1 Remote Interface Message Capabilities

The remote interface message capabili tie s of the Test Set and the associated IEEE

488.1 messages and control lines are listed in table 4.

Table 4 Test Set IEEE 488.1 Interface Message Capability

Message Type Implemented Response

IEEE

488.1

Message

Data Yes All front- panel functio ns , except thos e listed in table 2 on

page 39, are programmable. The Test Set can send status

byte, mes sa g e and setting i nf o r mation. All measuremen t

results (except dashed “- - - -” displays) and error messages are availa ble through the bus.

Remote Yes R emote programming mode is entered when the Remote

Enable (REN) bus control line is true and the Test Set is

addressed to listen. The R annuncia tor will appear in the

upper-right corner of the displ ay s creen when the Test Set

is in remote mode. All front-panel keys are disabled

(except for the LOCAL key, POWER switch, Volume

control and Squelch control knobs). When the Test Set

enters re mote m ode the o utpu t si gnal s a nd i nter nal sett ing s

remain unchanged, except that triggering is reset to the

state it was last set to in remote mode (Refer to "Trigger-

ing Measurements" on page 243).

Local Yes The Test Set returns to local mode (full front-panel con-

trol) when either the Go To Local (GTL) b u s command is

received, the fr ont-pa n el LOCAL key is pressed or the

REN line goes false. When the Test Set returns to local

mode the output signals and internal settings remain

unchanged, exce pt that triggering is reset to

TRIG:MODE:SETT FULL;RETR REP. The LOCAL key

will not funct ion if the Test Set is in the local lockout

mode.

DAB

END

MTA

MLA

OTA

REN

MLA

GTL

MLA

Local Lockout Yes Local Lockout disables all front-panel keys including the

LOCAL key. Only the System Controller or the POWER

switch can return the Test Set to local mode (front-pa nel

control).

42

LLO

IEEE 488.1 Remote Interface Message Capabilities

Table 4 Test Set IEEE 488.1 Interface Message Capability (Continued)

Message Type Implemented Response

Chapter 1, Using HP-IB

IEEE

488.1

Message

Clear Lockout/

Set Local

Yes The Test Set returns to local mode (front-pane l co ntrol)

and local lockout is clea red when the REN bus control line

goes false. When the Test S et returns to local mode the

output signals and internal settings remain unchanged,

except that triggering is set to TRIG:MODE:SETT

FULL;RETR REP.

Service Request Yes The Test Set sets t he Service Request (SRQ) bus line true

if any of the enable d conditions in the St atus Byte Register, as define d by the Se rvice Re ques t Enabl e Regist er, are

true.

Status Byte Yes The Test Set responds to a Seria l Po ll Enable (SPE) bus

command by sending an 8-bi t status byte when address ed

to talk. Bit 6 will be true, logic 1, if the Te st Set has sent

the SRQ message

Status Bit No The Test Set does not ha ve the capability to respond to a

Parallel Poll.

Clear Yes This message clears the Input Buffer and Output Queue,

clears any commands in process , puts the Test Set into the

Opera tio n Compl et e idl e stat e an d prepar es the Te s t Set to

receive new commands. The Device Clear (DC L) or

Selected Device Cle ar (SDC) bus commands

REN

SRQ

SPE

SPD

STB

MTA

PPE

PPD

PPU

PPC

IDY

DCL

SDC

MLA

• do not change any settings or stored data (except as

noted previously)

• do not interrupt front panel I/O or any Test Set

operation in progre ss (except as noted previously)

• do not change the c ontents of the Status Byte Register

(other than clea r i n g the MAV bit as a consequence of

clearin g the Output Queue).

The Test Set responds equally to DCL or SDC bus commands.

43

Chapter 1, Using HP-IB

IEEE 488.1 Remote Interface Message Capabilities

Table 4 Test Set IEEE 488.1 Interface Message Capability (Continued)

Message Type Implemented Response

IEEE

488.1

Message

Trigger Yes If in remote programming mode and addressed to listen,

the Test Set makes a triggered meas urement fol lowi ng the

GET

MLA

trigger conditions currently in effect in the instrument.

The Test Set responds equally to the Group Execute Trigger (GET) bus command or the *TRG Common Command.

Take Control Yes The Test Set begins to act as the Active Controller on the

bus.

TCT

MTA

Abort Yes The Test Set stops talking and listening IFC

44

Remote/Local Modes

Remote Mode

In Remote mode all front-panel key s are disabled (except for the LOCAL key,

POWER switch, Volume control and Squelch control). The LOCAL key is only

disabled by the Local Lockout bus command. When in Remote mode and

addressed to Listen the Test Set r espo nds to the Data, Remote, Local, Clear

(SDC), and Trigger messages. When the Test Set is in Remote mode, the

annunciator will be displayed in the upper right corner of the display screen and

triggering is set to the state it was last set to in Remote mode (if no previous

setting, the default is FULL SETTling and REPetitive RETRiggering). When the

Test Set is being addressed to List en or Talk the L or T annunciators will be

displayed in the upper-right corner of the display screen.

Chapter 1, Using HP-IB

Remote/Local Modes

R

Local Mode

In Local mode the Test Set’s front-panel controls are fully operational. The Test

Set uses FULL SETTling and REPetitive RETRiggering in Local mode. When the

Test Set is being addressed to List en or Talk the L or T annunciators will be

displayed in the upper-right corner of the display screen.

Remote or Local Mode

When addressed to Talk i n Remote or Local mode, the Test Set can issue the Data

and Status Byte messages and respond to the Take Control message. In addition

the Test Set can issue the Service Request Messa ge (SRQ). Regardless of whether

it is addressed t o talk or liste n, the Test Set will respond to the Clear (DCL), Local

Lockout, Clear Lockout/Set Local, and Abort messages.

45

Chapter 1, Using HP-IB

Remote/Local Modes

Local To Remote Tran si t i on s

The Test Set switches from Local to Remote mode upon receipt of the Remote

message (REN bus line true and Test Set is addressed to li sten). No instrument

settings are changed by the tra nsition from Local to Remote mode, but triggering

is set to the state it was last set to in Remote mode (if no previous setting, the

default is FULL SETTling and REPetitive RETRigge ring). The

the upper-right corner of the display is turned on.

When the Test Set makes a transition from loca l to remot e mode, all currently

active measurements are fla gged as invalid causing any currently availa ble

measurement results to becom e unava ilable. If the HP-IB trigger mode is

:RETR REP then a new measurement cycle is started and measurement results

will be available for all active measurements when valid results have been

obtained. If the HP-IB trigge r mode is :RETR SING then a measurement cy cl e

must be start ed by issuing a tr igger event. Ref er to

page 243

R annunciator in

"Triggering M easurements" on

for more information.

Remote To Local Tran sitions

The Test Set switches from Remote to Local mode upon receipt of the Local

message (Go To Local bus message is sent and Test Set is addressed to listen) or

receipt of the Clear Lockout/S e t Local message (REN bus line false). No

instrument se ttings are changed by the trans ition from Remote to Local mode, but

triggering is reset to FULL SETTling and REPetitive RETRiggering. The

annunciator in the upper ri ght corne r of the display is turned off.

If it is not in Local Lockout mode the Test Set switches from Remote to Local

mode whenever the front-pane l LOCAL key is presse d.

If the Tes t Set was in Loca l Lockout mode when the Local message was received,

front-panel c ontrol is returned, but Local Lockout mode is not cleared. Unless the

Test Set receives the Clear Lockout/Set Local message, the Test Set will sti ll be in

Local Lockout mode the next time it goes to the Remote mode.

R

46

Chapter 1, Using HP-IB

Remote/Local Modes

Local Lockout

The Local Lockout mode disables the front- panel LOCAL key and allows return

to Local mode only by commands from the System Contr oller (Clear Lockout/Set

Local message).

When a data transmission to the Test Set is interrupted, which can happen if the

LOCAL key is pressed, the data being transmitted may be lost. This can leave the

Test Set in an unknown state. The Local Lockout mode prevents loss of data or

system control due to someone unint ent ionally pressing front-panel keys.

NOTE: Return to Local mode can also be accomplished by setting the POWER switch to OFF and

back to ON. However, return ing to Local mode in this way has the following disadvantages:

1. It defeats the purpose of the Local Lockout mode in that the Active Controller will lose

control of the test set.

2. Instrument configuration is reset to the power up condition thereby losing the

instrument configuration set by the Active Controller.

Clear Lockout/Set Local

The Test Set returns to Local mode when it receives the Clear Lockout/Set Local

message. No instrument settings are changed by the transit ion from Remote mode

with Local Lockout to Local mode but trigger ing is r eset to FULL SETTling and

REPetitive RETRiggering.

47

Chapter 1, Using HP-IB

Remote/Local Modes

48

2

Methods For Reading Measurement Results

49

Chapter 2, Methods For Reading Measurement Results

Background

Background

One of the most com mo n rem o te user i nte rface operations pe rfo rm ed o n an

Test Set is to query and read a measurement result. Generally, this operati on is

accomplished by sending the que ry command to the Test Set, f ollowed

immediately by a request to read the requested measurement result. Using

Hewlett-Packar d Rocky Mountain BASIC (RMB) language, this operation would

be written using the OUTPUT and ENTER command as follows:

OUTPUT 714;"MEAS:RFR:POW?"

ENTER 714 ;P ow er

Using this programming structure, the control program will stay on the ENTER

statement unt il it is sat isfied - that is - until the Test Set has returned the requested

measurement result. This structure works correctl y as long as the Test Set r eturns

a valid measurement result. If, for some reason, the Test Set does not return a

measurement result, the control program becomes “hung” on the ENTER

statement and program execution effectively stops.

In order to prevent the contro l progra m from becoming “hung” programmers

usually enclose the oper ation wi th some form of tim eout f unction. The for m of the

timeout will of course depend upon the programming language being used. The

purpose of the timeout is to specify a fixed amount of time that the control

program will wait for the Test Set to return the requested result. After this time

has expired the control program will abandon the ENTER statement and try to

take some corrective action to regain control of the Test Set.

If the cont rol program does not send the proper commands in the proper sequence

when trying to regain control of the Test Set, unexpected operation will result.

When this condition is encount ered, power must be cycled on the Test Set to

regain control.

50

Chapter 2, Methods For Reading Measurement Results

Background

This situation can be avoided entirely by:

1. sending a Selected Device Clear (SDC) int erface message to put the Test Set ’ s HP-IB

subsystem into a known state.

2. sending a command to terminate the requested measurement cycle.

These commands issued in this order will all ow the control program to regain

control of the Test Set. Any other sequence of commands will result in

unexpected operation.

The following programs demonst rate a recommended technique for querying and

entering data from the Test Set. This technique will prevent the Test Set from

getting into a ‘hung’ st ate su ch tha t power must be cy cled on the Test S et to re gain

manual or programmatic control.

There are a variety of programming constructs which can be used to implement

this technique. In the programming examples presented, a function call is

implemented which returns a numeric meas urement result. The function call has

two pass parameters; the query command (passed as a quoted string) and a timeout value (passed as a integer number).

The time-out value represents how long you want to wait, in seconds, f or the Test

Set to return a valid measurement result. If a valid measurement result is not

returned by the Test Set within the time-out value, the function returns a very

large number. The calling progr am can check the value and take appropriate

action.

The program examples are writte n so as to be self-explanatory. In practice, the

length of: variable names, line labels, function names, etc., will be

implementation dependent.

51

Chapter 2, Methods For Reading Measurement Results

HP BASIC ‘ON TIMEOUT’ Example Pr ogram

HP BASIC ‘ON TIMEOUT’ Example Program

The following example program demonstrates a recommended technique which

can be utilized in situat ions where a measurement result timeout value of 32.76 7

seconds or less is adequate . In the HP RMB language, the timeout parameter for

the ON TIMEOUT command has a maximum value of 32.767 seconds. If a

timeout value of greater than 32.767 seconds is required refer to the HP BASIC

‘MAV’ Bit Example Program.

The measurement result time out val ue is defined to mean the amount of time the

control program is willi ng to wait for the Test Set to return a valid measurement

result to the control pro gram.

Lines 10 thru 230 in this example set up a measurement situation to demonstrate

the use of the recommended technique. The recommended technique is exampled

in the Measure Function.

NOTE: Lines 50 and 60 should be included in the beginning of all control program. These lines are

required to ensure that the Test Set is properly reset. This covers the case where the program

was previously run and was stopped with the Test Set in an error condition.

52

Chapter 2, Methods For Reading Measurement Results

HP BASIC ‘ON TIMEOUT’ Example Program

10 COM /Io_names/ INTEGER Inst_addr,Bus_addr

20 CLEAR SCREEN

30 Inst_addr=714

40 Bus_addr=7

50 CLEAR Inst_addr

60 OUTPUT Inst_addr;"TRIG:ABORT"

70 OUTPUT Inst_addr;"*RST"

80 OUTPUT Inst_addr;"DISP RFAN"

90 !

100 ! Execute a call to the Measure function with a request to measure RF

110 ! power. The time out value is specified as 10 seconds. The value

120 ! returned by the function is assigned to the variable Measure_result.

130 !

140 Measu re _r es ult=FNMe asu re("MEAS :R FR :POW?",10 )

150 !

160 ! Check the result of the function call.

170 !

180 IF Measure_result=9.E+99 THEN

190 PRINT "Measurement failed."

200 ELSE

210 PRINT "Power = ";Measure_result

220 END IF

230 END

240 !**** ** ** ** ******** *** ******** ** ** ********* ** ** ********* ** **

250 ! Recommended Technique:

260 !**** ** ** ** ******** *** ******** ** ** ********* ** ** ********* ** **

270 DEF FNMeasure(Query_command$,Time_out_value)

280 COM /Io_names/ INTEGER Inst_addr,Bus_addr

290 DISABLE

300 ON TIMEOUT Bu s_ ad dr,Time_o ut _v alue RECOVE R Ti med_out

310 OUTPUT Inst_addr;"TRIG:MODE:RETR SING;:TRIG:IMM"

320 OUTPUT Inst _a dd r;Query_c om ma nd$

330 ENTER Inst_addr;Result

340 OUTPUT Inst_addr;"TRIG:MODE:RETR REP"

350 ENABLE

360 RETURN Result

370 Timed _o ut :!

380 ON TIMEOUT Bus_addr,Time_out_value GOTO Cannot_recover

390 CLEAR Inst_addr

400 OUTPUT Inst _a dd r;"TRIG:A BO RT ;MODE:RET R RE P"

410 ENABLE

420 RETURN 9.E+99

430 Canno t_ re co ver:!

440 DISP "Cannot regain control of Test Set."

450 STOP

460 FNEND

53

Chapter 2, Methods For Reading Measurement Results

HP BASIC ‘ON TIMEOUT’ Example Pr ogram

Comments for Recommended Routine

Table 5 Comments for Measure Function from ON TIMEOUT

Example Program

Program Line

Number

50

60

290

300

310

Comments

Send a Selected Device Clear (SDC) to the Test Set to put the HP-IB subsystem

into a known state. This allows the control program to regain programmatic

control of the Test Set if it is in an error state when the program begins to run.

Command the Test Set to abort the currently executing meas urement cycle. This

will force th e Test Set to stop waiting for any measurement results to be available

from measurements which may be in a n invalid state when the program begins to

run.

Turn event initiated branches off (except ON END, ON ERROR and ON

TIMEOUT) to ensure that the Measure function will not be exited until it is

finished.

Set up a timeout for any I/O activ ity on t he HP-IB. This wil l al low the func tion t o

recover if the bus hangs for any reason.

Set the triggering mode to singl e followed by a trigger immediate command. This

ensures that a new measurement cycle will be start ed when the TRIG:IMM

command is sent. This sequence, that is: se t to single trigger and then send a

trigger command, guarantees that the measurement result returned to the ENTER

statement will accurate ly reflect the state of the DUT when the TRIG:IMM

command was sent. The ’IMM’ keyword is optional.

320

330

340

Send the query command passed to the Measure function to the Test Set.

Read the measurement result.

Set the trigger mode to repetitive retr iggering. Setting the trigge r mode to

repetitive will be implementa tion dependent.

350

Re-enable event initiate d branching. If any event initiated branches were logged

while the Measure function was executing the y will be executed when system

priority permits.

54

Chapter 2, Methods For Reading Measurement Results

HP BASIC ‘ON TIMEOUT’ Example Program

Table 5 Comments for Measure Function from ON TIMEOUT

Example Program (Continued)

Program Line

Number

360

370

380

390

400

410

Comments

Exit the Measure function and return the result value.