Page 1

Quick Reference Guide

HP

8753E Network Analyzer

HEWLETT

FB

HP Part No. 08753-90368 Supersedes January 1998

Printed in USA October 1998

PACKARD

Page 2

Notice.

The information contained in this document is subject to change without

notice.

Hewlett-Packard makes no warranty of any kind with regard to

this material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Hewlett-Packard

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance,

or use of this material.

@Copyright 1998 Hewlett-Packard Company

Page 3

Regulatory Information

The regulatory information is in the User’s Guide supplied with the

analyzer.

Safety, Warranty, and Assistance

Refer to the User’s Guide for information on safety, warranty, and

assistance.

iii

Page 4

HP 87533 Network Analyzer

Documentation Map

The Installation and Quick Start Guide

familiarizes you with the

HP 8763E/Option 011 network analyzer’s

front and rear panels, electrical and

environmental operating requirements, as

well

as procedures for installing, configuring,

and verifying the operation of the analyzer.

The User’s Guide shows how to make

measurements, explains commonly-used

features, and tells you how to get the most

performance from your analyzer.

The Quick Reference Guide provides a

summary of selected user features.

a

@

The

HP-II3

Programming and Command

BP-B3

0

I!3

Reference Guide provides programming

information for operation of the network

analyzer under

control.

iv

The HP BASIC Programming Examples

Guide provides a tutorial introduction using

BASIC programming examples to

demonstrate the remote operation of the

network analyzer.

The System Verification and Test Guide

provides the system verification and

performance tests and the Performance Test

Record for your HP 8763E/Option 011

network analyzer.

Page 5

Contents

1.

HP 87533 Front and Rear Panel

Front Panel Features

Analyzer Display

Rear Panel Features and Connectors

2. Making Measurements

Basic Measurement Sequence and Example

Basic Measurement Sequence

Basic Measurement Example

Step 1. Connect the device under test and any required

test equipment.

Step 2. Choose the measurement parameters.

Step 3. Perform and apply the appropriate

error-correction.

Step 4. Measure the device under test.

Step 5. Output the measurement results.

Using the Display Functions

‘lb View Four Channels Simultaneously

Description of the Auxiliary Channels

Quick Four-Parameter Display

‘lb Make an Auxiliary Channel Active:

lb Save a DataTrace to the Display Memory

lb View the Measurement Data and Memory Trace

lb Divide Measurement Data by the Memory Trace

‘lb Subtract the Memory Trace from the Measurement

Data Trace

‘RI

Ratio Measurements in Channel 1 and 2

lb Title the Active Channel Display

Using Markers

‘lb Activate Display Markers

Delta Markers and Statistics

Search for a Specific Amplitude

Searching for the Maximum Amplitude

Searching for the Minimum Amplitude

Markers and the Backspace Key

..................

...................

.............

.............

................

................

..............

...................

.....................

.............

.............

..........

.......

....

.......

......

........

........

............

........

.....

. .

. .

......

..........

............

.......

.......

...........

l-l

l-4

l-9

2-2

2-2

2-2

2-2

2-2

2-3

2-3

2-3

2-4

2-4

2-5

2-6

2-6

2-7

2-7

2-8

2-8

2-8

2-8

2-9

2-9

2-9

2-10

2-10

2-10

2-11

Contents-l

Page 6

‘lb Move Marker Information off of the Graticules

‘Ib

Move Marker Information back onto the Graticules

Testing A Device with Limit Lines

Creating Flat Limit Lines

...............

Creating a Sloping Limit Line

Creating Single Point Limits

Editing Limit Segments

................

Deleting Limit Segments

RunningaLimitTest

.................

Reviewing the Limit Line Segments

Activating the Limit

Test

Measuring Gain Compression

Measurements using the Swept List Mode

Connect the Device Under Test

Observe the Characteristics of the Filter

Choose the Measurement Parameters

Set Up the Lower Stop Band Parameters

SetUptheBassBandParameters

Set Up the Upper Stop Band Parameters

Calibrate and Measure

................

...........

.............

.............

..............

.........

..............

..............

........

............

.......

.........

......

..........

......

. .

2-11

2-12

2-13

2-13

2-16

2-18

2-20

2-20

2-21

2-21

2-21

2-22

2-27

2-28

2-29

2-30

2-30

2-30

2-31

2-31

3. Making

Mixer

Measurements

Measurement Considerations . . . . . . . . . . . . . .

Minimizing Source and Load Mismatches . . . . . . .

Reducing the Effect of Spurious Responses . . . . . .

Eliminating Unwanted Mixing and Leakage Signals . . .

HowRFandIFAreDefined . . . . . . . . . . . . .

Frequency Offset Mode Operation . . . . . . . . . . .

Differences Between Internal and External R Channel

Inputs . . . . . . . . . . . . . . . . . . . . . .

Power Meter Calibration . . . . . . . . . . . . . . .

Conversion Loss using the Frequency Offset Mode . . . .

High Dynamic Range Swept RF/IF Conversion Loss

Conversion Compression using the Frequency Offset Mode

Isolation Example Measurements . . . . . . . . . . . .

LO to IF Isolation . . . . . . . . . . . . . . . . . .

RF Feedthrough . . . . . . . . . . . . . . . . . . .

Contents-Z

. . .

3-l

3-l

3-2

3-2

3-2

3-4

3-4

3-5

3-6

3-12

3-16

3-2 1

3-22

3-23

Page 7

4. Printing, Plotting, and Saving Measurement Results

ConIlguring

Defining a Print Function

If You Are Using a Color Printer

lb Reset the Printing Parameters to Default Values

ConIlguring

If You Are Plotting to an

If You Are Plotting to a Pen Plotter

If You Are Plotting to a Disk Drive

Defining a Plot Function

Choosing Display Elements

Selecting Auto-Feed

Selecting Pen Numbers and Colors

Selecting Line Types

Choosing Scale

Choosing Plot Speed

‘lb Reset the Plotting Parameters to Default Values

If You Are Plotting to an HPGL Compatible Printer

‘Ib

Save Measurement Results

Recalling an Instrument State

a Print Function

..............

...............

...........

a Plot Function

..............

HPGL/2

Compatible Printer .

..........

..........

................

..............

.................

..........

.................

....................

.................

..............

.............

...

...

. .

5. Optimizing Measurement Results

Increasing Measurement Accuracy

Connector Repeatability

Interconnecting Cables

Temperature Drift

Frequency Drift

...................

Performance Verification

...............

................

..................

...............

Reference Plane and Port Extensions

Measurement Error-Correction

Clarifying Type-N Connector Sex

...........

.........

.............

...........

Response Error-Correction for Reflection Measurements

Response Error-Correction for Transmission

Measurements

..................

Response and Isolation Error-Correction for Transmission

Measurements

One-Port Reflection Error-Correction

Full Two-Port Error-Correction

Power Meter Measurement Calibration

Entering the Power Sensor Calibration Data

Compensating for Directional Coupler Response

Using Sample-and-Sweep Correction Mode

Using Continuous Correction Mode

Increasing Sweep Speed

lb Use Swept List Mode

..................

..........

.............

.........

......

....

.......

..........

................

...............

4-l

4-2

4-2

4-2

4-3

.

4-3

4-4

4-5

4-6

4-6

4-6

4-7

4-8

4-9

4-9

4-9

4-9

4-10

4-12

5-l

5-l

5-l

5-l

5-2

5-2

5-2

5-3

5-3

5-3

5-4

5-4

5-6

5-7

5-9

5-9

5-9

5-10

5-l

1

5-12

5-12

Contents-3

Page 8

‘Ib Decrease the Frequency Span

lb Set the Auto Sweep Time Mode

‘lb

Widen the System Bandwidth

‘Ib Reduce the Averaging Factor

...........

..........

...........

...........

lb Reduce the Number of Measurement Points

'IbSettheSweepType

lb Activate Chop Sweep Mode

lb Use Fast

2-Port

Increasing Dynamic Range

Increase the

Test Port

Reduce the Receiver Noise Floor

Change System Bandwidth

Change Measurement Averaging

Reducing Trace Noise

Activate Averaging

Change System Bandwidth

Reducing Receiver Crosstalk

................

............

Calibration

............

...............

Input Rower

..........

...........

.............

..........

.................

..................

..............

..............

6. Softkey Locations

7. Error Messages

Error Messages in Alphabetical Order . . . . . . . . . .

Index

.....

5-13

5-13

5-14

5-14

5-15

5-15

5-16

5-16

5-17

5-17

5-17

5-17

5-17

5-18

5-18

5-18

5-18

7-l

Contents-4

Page 9

Figures

l-l. BP 87533 Front Panel

l-2.

Analyzer Display (Single Channel, Cartesian Format) . .

l-3. BP 87533 Rear Panel

2-l.

Basic Measurement Setup

2-2. Four Parameter Display

2-3. Marker 1 as the Reference Marker

2-4. Example Statistics of Measurement Data

2-5. Markers before Pressing the Backspace Key

2-6. Markers after Pressing the Backspace Key

2-7. Example Flat Limit Line

2.8. Example Flat Limit Lines

2-9. Sloping Limit Lines

2-10. Example Single Point Limit Lines

2-11. Diagram of Gain Compression

2-12. Gain Compression using Linear Sweep and

DZ:,Dl

2-13. Gain Compression using Power Sweep

2-14. Swept List Measurement Setup

2-15. Characteristics of a Filter

2-16. Calibrated Swept List Thru Measurement

2-17. Filter Measurement using Linear Sweep

(Power: 0

2-18. Filter Measurement using Swept List Mode

3-l.

Down Converter

3-2. Up Converter

3-3. An Example Spectrum of RF, LO, and IF Signals Present

in a Conversion Loss Measurement

3-4. Connections for R Channel and Source Calibration

3-5. Connections for a One-Sweep Power Meter Calibration for

Mixer Measurements

3-6. Measurement Setup from Display

3-7. Conversion Loss Example Measurement

3-S.

Connections for Broad Band

3-9. Connections for Receiver Calibration

t.0 DZ OH

dBm/lF

Port

................

................

..............

...............

..........

.......

......

.......

...............

...............

.................

...........

............

..............

.........

............

..............

.......

BW: 3700

Port

Connections

Connections

Hz)

.........

......

..........

............

........

...............

...........

........

Power

Meter Calibration

.........

...

2-10

2-l

2-12

2-14

2-15

2-17

2-19

2-22

2-24

2-26

2-28

2-29

2-32

2-33

2-34

3-10

3-11

3-13

.

3-13

l-l

l-4

l-9

2-2

2-5

2-9

1

3-3

3-3

3-6

3-7

3-9

Contents-5

Page 10

3-10. Connections for a High Dynamic Range Swept IF

Conversion Loss Measurement . . . . . . . . . .

3-11. Example of Swept IF Conversion Loss Measurement . .

3-14

3-15

3-12. Conversion Loss and Output Power as a Function of Input

Power Level Example . . . . . . . . . . . . . .

3-16

3-13. Connections for the First Portion of Conversion

Compression Measurement . . . . . . . . . . . .

3-17

3-14. Connections for the Second Portion of Conversion

Compression Measurement . . . . . . . . . . . .

3-15. Measurement Setup Diagram Shown on Analyzer Display

3-18

3-19

3-16. Example Swept Power Conversion Compression

Measurement . . . . . . . . . . . . . . . . . .

3-17. Signal Flow in a Mixer Example

. . . . . . . . . . .

3-18. Connections for a Mixer Isolation Measurement . . . .

3-19. Example Mixer LO to RF Isolation Measurement . . . .

3-20. Connections for a Mixer RF Feedthrough Measurement .

3-21. Example Mixer RF Feedthrough Measurement . . . . .

4-l. Plot Components Available through Definition . . . . .

4-2. Line Types Available . . . . . . . . . . . . . . . . .

4-3. Locations of Pl and P2 in :XHLE

PLOT C GHHTI

Mode . . . . . . . . . . . . . . . . . . . . . .

4-4. Data Processing Flow Diagram . . . . . . . . . . . .

5-l.

Standard Connections for a Response Error-Correction for

Reflection Measurement . . . . . . . . . . . . .

3-20

3-21

3-22

3-22

3-23

3-23

4-6

4-8

4-9

4-11

5-3

5-2. Standard Connections for Response Error-Correction for

Transmission Measurements . . . . . . . . . . .

5-4

5-3. Standard Connections for a Response and Isolation

Error-Correction for Transmission Measurements . .

5-5

5-4. Standard Connections for a One-Port Reflection

Error-Correction . . . . . . . . . . . . . . . . .

5-5. Standard Connections for

Full

Two-Port Error-Correction

5-6. Sample-and-Sweep Mode for Power Meter Calibration

5-7. Continuous Correction Mode for Power Meter Calibration

5-6

5-7

.

5-10

5-11

Contents-f3

Page 11

‘Ihbles

2-l.

Connector Care Quick Reference

4-l.

Default Pen Numbers and Corresponding Colors

4-2. Default Pen Numbers for Plot Elements

4-3. Default Line Types for Plot Elements

5-l.

Band Switch Points

6-1.

Softkey

Locations

.................

..................

...........

....

........

.........

2-l

4-7

4-7

4-a

5-13

6-2

Contents-7

Page 12

1

HP 87533 Front and Rear Panel

Front Panel Features

Caution

Figure l-l shows the location of the following front panel features and

key function blocks. These features are described in more detail later in

this chapter.

Do not mistake the line switch for the disk eject

button. See the figure below. If the line switch is

mistakenly pushed, the instrument will be turned off,

losing all settings and data that have not been saved.

Figure l-l. HP 87533 Front Panel

LINE switch.

1.

on, 0 is off.

This switch controls ac power to the analyzer. 1 is

HP 87533 Front and Rear Panel

l-l

Page 13

2.

Display.

This shows the measurement data traces, measurement

annotation, and softkey labels. The display is divided into specific

information areas, illustrated in Figure

l-2.

3.

Disk drive.

This 3.5 inch drive allows you to store and

recall

instrument states and measurement results for later analysis.

Disk eject button.

4.

5.

Softkeys.

These keys provide access to menus that are shown on

the display.

6.

STlMULUS

function block. The keys in this block allow you to

control the analyzer source’s frequency, power, and other stimulus

functions.

RJZSPONSE

7.

function block. The keys in this block allow you

to control the measurement and display functions of the active

display channel.

ACTIVE CHANNEL keys.

8.

These keys activate one of the four

measurement channels. Once activated, a channel can then be

configured for making measurements.

The analyzer has four display channels.

1 or 3, and

(Chanj

activates channel 2 or 4. Refer to “Using

(-1)

activates channel

Display Functions” in Chapter 2 for information on enabling

channels 3 and 4 and making them active.

The ENTRY block.

9.

This block includes the knob, the step @)

keys, and the number pad. These allow you to enter numerical

data and control the markers.

You can use the numeric keypad to select digits, decimal points,

and a minus sign for numerical entries. You must also select a units

terminator to complete value inputs.

The backspace key @ has two independent functions:

@

H

Modifies entries and test sequences.

n

Turns off the

softkey

menu and, if more than one marker is

active, the marker information is displayed in the softkey area.

Refer to “Markers and the Backspace Key” in Chapter 2.

1-2

HP 87533 Front and Rear Panel

Page 14

10. INSTRUMENT STATE function block. These keys allow you

to control channel-independent system functions such as the

following:

w

copying, save/recall, and

w

limit testing

n

external source mode

n

tuned receiver mode

n

frequency offset mode

n

test sequence function

n

harmonic measurements (Option 002)

n

time domain transform (Option 010)

HP-R3

STATUS indicators are also included in this block.

11.

IPreseT) key.

This key returns the instrument to either a known

factory preset state, or a user preset state that can be

HP-R3

controller mode

deEned.

Refer to the “Preset State and Memory Allocation” chapter for a

complete listing of the instrument preset condition.

12.

PROBE POWER connector.

This connector (fused inside the

instrument) supplies power to an active probe for in-circuit

measurements of ac circuits.

13.R CX4NNEL connectors.

These connectors allow you to apply an

input signal to the analyzer’s R channel, for frequency offset mode.

14.

PORT 1 and PORT

2. These ports output a signal from the source

and receive input signals from a device under test. PORT 1 allows

you to measure

and

S22.

SIZ

and ‘&I. PORT 2 allows you to measure

HP 87533 Front and Rear Panel

Sal

l-3

Page 15

Analyzer Display

14

P

/@

2

b

PWd

Format)

Figure

1

d

l-2.

Analyzer Display (Single Channel, Cartesian

The analyzer display shows various measurement information:

w

The grid where the analyzer plots the measurement data.

n

The currently selected measurement parameters.

w

The measurement data traces.

Figure

l-2

illustrates the locations of the different information labels

described below. In addition to the single-channel display shown in

Figure

l-2,

multiple graticule and channel displays are available, as

described in “Using Display Functions” in Chapter 2.

When multiple channels are superimposed or displayed in separate

graticules, information is arranged as follows:

n

Channel(s) displayed and measurement parameter(s) are at the top of

each graticule.

n

Stimulus frequency information is at the bottom of each graticule.

n

Marker information (when selected) is on the right side of each

graticule.

l-4

HP 87633 Front and Rear Panel

Page 16

Stimulus Start

1.

Value.

This value could be any one of the

following:

l

The start frequency of the source in frequency domain

measurements.

m

The start time in CW mode (0 seconds) or time domain

measurements.

n

The lower power value in power sweep.

When the stimulus is in center/span mode, the center stimulus

value is shown in this space.

Stimulus Stop

2.

Value.

This value could be any one of the

following:

m

The stop frequency of the source in frequency domain

measurements.

m

The stop time in time domain measurements or CW sweeps.

l

The upper limit of a power sweep.

When the stimulus is in center/span mode, the span is shown in

this space. The stimulus values can be blanked.

(For CW time and power sweep measurements, the CW frequency

is displayed centered between the start and stop times or power

values.)

Status Notations. This area shows the current status of various

3.

functions for the active channel.

The following notations are used:

Avg =

Sweep-to-sweep averaging is on. The averaging count is

shown immediately below.

Cor =

Error correction is on. (For error-correction procedures,

refer to Chapter 5, “Optimizing Measurement Results.“)

HP 87533 Front and Rear Panel

l-6

Page 17

C?

=

Stimulus parameters have changed from the

error-corrected state, or interpolated error correction is

on. (For error-correction procedures, refer to Chapter 5,

“Optimizing Measurement Results.

“)

c2 =

Del =

ext =

of.5

=

Of?=

Gat =

H=2

Full two-port error-correction is active and either the

power range for each port is different (uncoupled), or the

TESTS E T

S GJH 0 L D

is activated. The annotation

occurs because the analyzer does not switch between

the test ports every sweep under these conditions.

The measurement stays on the active port after an

initial cycling between the ports. (The active port is

determined by the selected measurement

You can update

PlEAStJRE

all

the parameters by pressing

RESTHRT,

or(Meas)

key.

narameter.)

m

Electrical delay has been added or subtracted, or port

extensions are active.

Waiting for an external trigger.

Frequency offset mode is on.

Frequency offset mode error, the IF frequency is not

within 10 MHz of expected frequency. LO inaccuracy is

the most likely cause.

Gating is on (tune domain Option 010 only). (For time

domain measurement procedures, refer to Chapter 2,

“Making Measurements.“)

=

Harmonic mode is on, and the second harmonic is being

measured (harmonics Option 002 only). (See “Analyzer

Options Available” later in this chapter.)

1-6

HP 87533 Front and Rear Panel

Page 18

H-3

=

Harmonic mode is on, and the third harmonic is being

measured (harmonics Option 002 only). (See “Analyzer

Options Available” later in this chapter.)

Hld =

man=

PC =

PC? =

P? =

P1

=

PRm

=

Smo =

tsH

=

t=

‘=

Hold sweep.

Waiting for manual trigger.

Power meter calibration is on. (For power meter

calibration procedures, refer to Chapter 5, “Optimizing

Measurement Results.“)

The analyzer’s source could not be set to the desired

level, following a power meter calibration. (For power

meter calibration procedures, refer to Chapter 5,

“Optimizing Measurement Results.

Source power is unleveled at start or stop of sweep.

(Refer to the

for troubleshooting.)

Source power has been automatically set to minimum,

due to receiver overload.

Power range is in manual mode.

Trace smoothing is on.

Indicates that the test set hold mode is engaged.

That is, a mode of operation is selected which would

cause repeated switching of the step attenuator. This

hold mode may be overridden.

Fast sweep indicator. This symbol is displayed in the

status notation block when sweep tune is less than 1 .O

second. When sweep time is greater than 1.0 second, this

symbol moves along the displayed trace.

Source parameters changed: measured data in doubt

until a complete fresh sweep has been taken.

tip

8753E

Network

“)

Andgzer

Service Guide

Active Entry Area.

4.

current value.

Message Area.

5.

Title.

6.

This is a descriptive alpha-numeric string title that you

define and enter through an attached keyboard or as described in

Chapter 4, “Printing, Plotting, and Saving Measurement Results.”

This displays the active function and its

This displays prompts or error messages.

HP 87633 Front and Rear Panel

l-7

Page 19

7.

Channel. This is the channel selected with the

IChanl)

and

IChan2)

keys. For multiple, superimposed channel displays, more than one

channel will be shown.

8.

Measured Input(s). This shows the S-parameter, input, or ratio of

inputs currently measured, as selected using the

(Meas)

key. Also

indicated in this area is the current display memory status.

9.

Format. This is the display format that you selected using the

[=I

10.

Scale/Div. This is the scale that you selected using the

key.

(jScaleRef_)

key, in units appropriate to the current measurement.

11.

Reference Level. This

value

is the reference line in Cartesian

formats or the outer circle in polar formats, whichever you

selected using the

C-1

key. The reference level is also

indicated by a small triangle adjacent to the graticule, at the left

for channel 1 and at the right for channel 2 in Cartesian formats.

12.

Marker Values. These are the values of the active marker, in

units appropriate to the current measurement.

@efer

to “Using

Analyzer Display Markers” in Chapter 2, “Making Measurements.“)

13.

Marker Stats, Bandwidth. These are statistical marker values

that the analyzer calculates when you access the menus with the

[Marker]

key. (Refer to “Using Analyzer Display Markers” in

Chapter 2, “Making Measurements.“)

14.

Softkey

Labels. These menu labels redefine the function of the

softkeys that are located to the right of the analyzer display.

Pass Fail. During limit testing, the result will be annunciated

15.

as

PHSS

if the limits are not exceeded, and

FH

I L

if any points

exceed the limits.

1-8

HP 87533 Front and Rear Panel

Page 20

Rear Panel Features and Connectors

Figure

Figure

described below. Requirements for input signals to the rear panel

connectors are provided in Chapter 7 of the User’s

2.

3.

4.

5.

l-3

illustrates the features and connectors of the rear panel,

1.

HP-IJS connector. This allows you to connect the analyzer to an

external controller, compatible peripherals, and other instruments

for an automated system.

PARALLEL

output to a peripheral with a parallel input. Also included, is a

general purpose input/output (GPIO) bus that can control eight

output bits and read five input bits through test sequencing.

W-232

a peripheral with an

KEYBOARD

connect an external keyboard. This provides a more convenient

means

analyzer’s front panel keyboard.

Power cord receptacle, with fuse. For information on replacing

the fuse, refer to the

interface. This connector allows the analyzer to

interface. This connector allows the analyzer to output to

input

to enter a title for storage files, as well as substitute for the

Quick Start Guide

l-3.

HP 87533 Rear Panel

RS-232

(serial) input.

(mini-DIN).

HP 8753E

or the HP

This connector allows you to

Network

8753E

Ana&er

Network

Guide.

Installation and

Ana&.zer Service

Guide.

HP 87633 Front and Rear Panel

l-9

Page 21

Line voltage selector switch. For more information, refer to the

6.

HP

87533 Network Analyzer Installation and Quick Start

7.

Fan. This fan provides forced-air cooling for the analyzer.

10

MHZ

8.

9.

10 MHZ

PRECISION

REPEaENCE

REFERENCE

OUTPUT. (Option

ADJUST. (Option

lD5)

lD5)

GuiaTe.

EXTERNAL REFERENCE INPUT connector.

10.

This allows for a

frequency reference signal input that can phase lock the analyzer

to an external frequency standard for increased frequency

accuracy.

The analyzer automatically enables the external frequency

reference feature when a signal is

COMeCted

to this input. When

the signal is removed, the analyzer automatically switches back to

its

internal

AUXILIARY INPUT connector.

11.

frequency reference.

This allows for a dc or ac voltage

input from an external signal source, such as a detector or function

generator, which you can then measure using the S-parameter

menu. (You can also use this connector as an analog output in

service routines, as described in the service manual.)

EXTERNAL AM connector.

12.

This allows for an external analog

signal input that is applied to the ALC circuitry of the analyzer’s

source. This input analog signal amplitude modulates the RF

output signal.

EXTERNAL TRIGGER connector.

13.

This allows connection of an

external negative-going ‘ITL-compatible signal that will trigger a

measurement sweep. The trigger can be set to external through

softkey

TEST SEQUENCE.

14.

functions.

This outputs a TTL signal that can be

programmed in a test sequence to be high or low, or pulse

(10

pseconds)

high or low at the end of a sweep for robotic part

handler interface.

15.

LIMIT

TEST.

This outputs a TTL signal of the limit test results as

follows:

n

Pass:

TTL high

n

Fail: TTL low

MEASURE RESTART.

16.

This allows the connection of an optional

foot switch. Using the foot switch will duplicate the key sequence

(Meas) MEHSIURE RESTHRT.

l-10 HP 87633 Front and Rear Panel

Page 22

17.

TEST SET INTERCONNECT. This allows you to connect an

HP 87533 Option 011 analyzer to an HP 85046AB or

85047A

S-parameter test set using the interconnect cable supplied with the

test set. The S-parameter test set is then fully controlled by the

analyzer.

18. BIAS

INPUTS

AND

BUSES. These connectors bias devices

connected to port 1 and port 2. The fuses (1 A, 125 V) protect the

port 1 and port 2 bias lines.

19.

Serial number plate. The serial number of the instrument is

located on this plate.

20.

EXTERNAL MONITOR: VGA. VGA output connector provides

analog red, green, and blue video signals which can drive a VGA

monitor.

HP

8763E

Front and Rear Panel

l-11

Page 23

Making Measurements

2

lhble 2-l.

Do

Keep connectors clean

Extend sleeve or connector nut

Use plastic end-caps during storage

Do

Inspect all connectors carefully

Look for particles, scratches, and dents

Do

Try compressed air first Use any abrasives

Use isopropyl alcohol

Clean connector threads

Do

Clean and zero the gage before use Use an out-of-spec connector

Use the correct gage type

Use correct end of calibration block

Gage all connectors before first use

Align connectors carefully

Make preliminary connection lightly

Turn only the connector nut

Use a torque wrench for

Connector Care Quick Reference

Handling and Storage

Do Not

Touch

mating-plane surfaces

Set connectors contact-end down

Visual Inspection

Do Not

Use a damaged connector - ever

Connector Cleaning

Do Not

Get liquid into plastic support beads

Gaging Connectors

Do Not

Makim

Connections

Do Not

Apply bending force to connection

Over tighten preliminary connection

Twist or screw any connection

final

connect

Tighten wrench past “break” point

Making Measurements 2-1

Page 24

Basic Measurement Sequence and Example

Basic Measurement Sequence

There are Eve basic steps when you are making a measurement.

1. Connect the device under test and any required test equipment.

2. Choose the measurement parameters.

3. Perform and apply the appropriate error-correction.

4. Measure the device under test.

5. Output the measurement results.

Basic Measurement Example

In the following example, a magnitude and insertion phase response

measurement is made.

Step 1. Connect the device under test and any required test

equipment.

1. Make the connections as shown in Figure

2-l.

DEVICE UNDER TEST

Figure

Step 2. Choose the measurement parameters.

2. Press

Setting the Frequency Range

3. ‘lb set the center frequency to 134 MHz, press:

Icenter)(isiJm

2-2 Making Measurements

w

2-l.

Basic Measurement Setup

PRESET:

FHC:TUR’f.

Page 25

4. ‘lb set the span to 30

Setting the Source Power

MHz,

press:

5. lb change the power level to -5

dBm,

press:

Setting the Measurement

6. lb change the number of measurement data points to 101, press:

CMenu) tAlJMBER

OF PO1

HTS @

7. ‘lb select the transmission measurement, press:

(Meas)fr*3n~:Ft~JD !221 (B/R>

8. ‘lb view the data trace, press:

@--

HUTOSCHLE

Step 3. Perform and apply the appropriate error-correction.

9. Refer to the “Optimizing Your Measurement Results” chapter.

10. lb save the instrument state and error-correction in the analyzer

internal memory, press:

Step 4. Measure the device under test.

11. Replace any standard used for error-correction with the device

under test.

12. lb measure the insertion loss of the

bandpass

filter, press:

Step 5. Output the measurement results.

13. lb create a hardcopy of the measurement results, press:

&)

PRI

HT

(or

F’LOT)

Making Measurements 2-3

Page 26

Using the Display Functions

To

View Four Channels Simultaneously

Note

A full two-port calibration must be active before

enabling auxiliary channels 3 or 4. Refer to Chapter 5,

“Optimizing Measurement Results” in the User’s Guide

for a description of a full two-port error correction.

1. Press

cG]LDisplay)

SETUP.

DUAL:

L!UHD

2. Put channel 1 in the upper graticule and channel 2 in the lower

graticule:

Set

DUHL CHHt4 on

3. Enable auxiliary

Set

HCIX

CHHH on

OFF to

chaMel3:

OFF to

OH.

OH.

4. Enable auxiliary channel 4:

Press

Ichan

and set

HUX CHHH

on

OFF

to

rJt.1.

5. Create a four-graticule display:

Set

SPLITD

I!%-

1

X-2X-4X

to

4X.

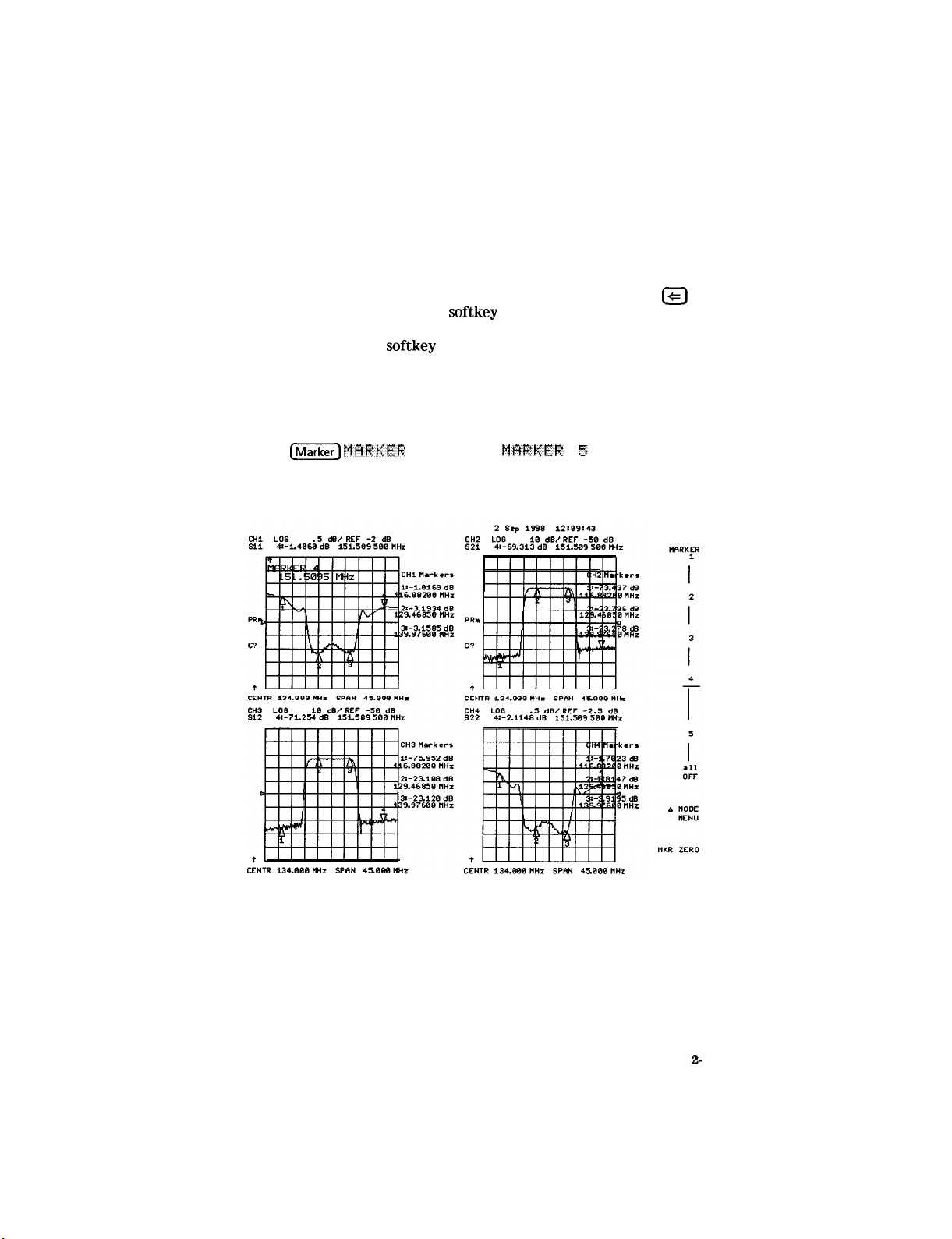

See Figure 2-2 for the resulting display. This is the default channel

orientation, where channel 1 is the upper left graticule,

ChaMd 2

is the

upper right graticule, channel 3 is the lower left graticule, and channel 4

is the lower right graticule.

2-4 Making Measurements

Page 27

Description of the Auxiliary Channels

n

Channels 1 and 2 are the primary channels.

n

Channel 3 is the auxiliary channel for channel 1.

n

Channel 4 is the auxiliary channel for channel 2.

n

The auxiliary channels can be independently

conEgored

from each

other and the primary channels in all variables except stimulus; an

auxiliary channel always has the same stimulus values as its primary

channel.

The default measurement parameter for each channel is:

n

Channel 1;

w

Channel 2;

n

Channel 3;

n

Channel 4;

Sll

S21

S12

S22

*

CENTR 134.888 mr

SPAN 45.888 ““7.

t

CENTR 134.888 tlH7.

SPAN 4%3GG

Figure 2-2. Four Parameter Display

Making Measurements 2-5

lwz

Page 28

Quick Four-Parameter Display

A quick way to set up a four-parameter display once a full two-port

calibration is active is to use one of the options in the

After a full two-port calibration has been performed or recalled from a

previously saved instrument state:

($$i&)

menu.

1. Press

2. Press DUHL I

3. Press

4.

Press

(e).

4

FHRHM

SETUP

ISrClflD

DISPLHYS.

13.

SETlAP.

To Make an Auxiliary Channel Active:

Ichan

activates channels 1 and 3, and

(than)

activates channels 2

and 4.

The following steps illustrate how the measurement channel

LED indicators work. From step 5 in “lb View Four Channels

Simultaneously”:

1. Press

The LED adjacent to

(than).

Cm)

is flashing. This indicates that

ChaMel4

is

active and may be configured.

2. Press

(than).

The LED adjacent to

(G)

is constantly lit. This

indicates that channel 1 is active.

3. Press

(G)

again. The LED is flashing, indicating that channel 3 is

active and may be configured.

Once active, a channel’s markers, limit lines, format, and other variables

can be applied and changed. Also, the active entry and stimulus values

will change

to the color of the active channel.

2-6 Making Measurements

Page 29

‘Ib

Save a Data Trace to the Display Memory

Press

fj-1

To

View the Measurement Data and Memory Trace

1. lb view a data trace that you have already stored to the active

channel memory, press:

(DiSP’ad

2. lb view both the memory trace and the current measurement data

trace, press:

DATA-MEtlOR’T’.

ME M C! R

Y

Making Measurements 2-7

Page 30

To

Divide Measurement Data by the Memory Trace

1. You must have already stored a data trace to the active channel

memory.

2.

Press

Cj~DHTH.~MEM.

To

Subtract the Memory Trace from the

Measurement Data Trace

1. You must have already stored a data trace to the active channel

memory.

2. Press

‘lb

1.

2. Press

To

1. Press

2. Press

(Display)DHfH-MEN.

Ratio Measurements in Channel 1 and 2

Press

CChanl] [j]

PO

I

CxJ [Menu] t.4 cl rl B

P

0 I H T S and enter the same

value that you observed for the channel 1 setting.

NIJllBER

ER

OF

0

t4TS.

F

Title the Active Channel Display

&%j-J NC7 I?

El? WE

measurement display. Use an external keyboard or the analyzer front

panel.

E f I

TL

I“ I TLE

E

to access the title menu.

and enter the title you want for your

2-8

Making Measurements

Page 31

Using Markers

To

Activate Display Markers

1.

Press

c-1

Delta Markers and Statistics

M tW K

ER

1.

Press

PlEtW

C-1

A

A MODE

REF=

1 to make marker 1 a

reference marker.

Move marker 1 to any point that you want to reference.

2.

3.

Press

NHRKER

2 and move marker 2 to any position that you want

to measure in reference to marker 1.

35 ma EBB

CENTER 134

BBB 888 Wlr

SPelli

Figure 2-3. Marker 1 as the Reference Marker

MHZ

aw000032

Making Measurements 2-9

Page 32

4. Press (Marker)

MKR

tZODE MENLI STMTS OH

to calculate and

display the statistics of the measurement data between the active

marker and the delta reference marker.

CHl

PRm

SZl

c

CENTER

I

og

125. 000

MFlG

20 dB/ REF 0

BOO

MHz

dB

SPAN

Figure 2-4. Example Statistics of Measurement Data

Search for a Specific Amplitude

Searching for the Maximum Amplitude

2: -3.7131

120. 000 000 MHz

dB

1. Press

2. Press

(Marker3 rtlRRKER

SEHRCH.

SEHRCH: IIHX.

Searching for the Minimum Amplitude

1. Press (Marker)

2. Press

SEARCH.

SEHRCH: PlIN.

2-10 Making Measurements

PlH!?:KER

Page 33

Markers and the Backspace Key

Besides modifying entries and test sequences, the backspace key @ has

a second function; it toggles the

than one marker is active, moves the marker information off of the

graticules and into the softkey area. This function makes data traces

and marker information easier to view.

To Move Marker Information off of the Graticules

1. Activate markers 1 through 5:

1 through

Press

(j-1

MHRKER

The display will appear similar to Figure 2-5.

softkey

display on and off and, if more

MHRtCER 5

Figure 2-5. Markers before Pressing the Backspace Key

Making Measurements

2-

11

Page 34

2.

Press

@

The display will appear similar to Figure 2-6. Notice that the marker

information has moved off of channels’ 2 and 4 graticules and into the

softkey display area.

CH4 “arkerr

ir-1.7885 dG

116.882QQ

MHZ

Z-38129 dG

123.46898

tlHZ

3:-3.9114 dG

i39.97688 tlk

CEHTR 134.888 MZ

SPAN

45.888

NHz

*

CEHTR i34.@38lWz

SPAN 45.8BBMHz

Figure 2-6. Markers after Pressing the Backspace Key

To Move Marker Information back onto the Graticules

3.

Press

@.

Notice that the marker information moves back onto the graticules

and that the

softkey

hardkey

2- 12

Making Measurements

softkey

menu is also restored when a

menu is restored as shown in Figure 2-6. The

softkey

or

hardkey

must be one which opens a menu, such as

is pressed. The

CE]

or

Lsystem).

Page 35

l&sting

A Device with Limit Lines

Creating Flat Limit Lines

In this example procedure, the following flat limit line values are set:

Frequency Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power Range

127

MHz to 140 MHz.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -27 dB to -21

100 MHz to 123 MHz.. . . . . . . . . . . . . . . . . . . . . . . . . . . . -200 dB to -65

146 MHz to 160 MHz.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -200 dB to -65

dB

dB

dB

Note

1. ‘lb access the limits menu and activate the limit lines, press:

2

lb create a new limit line, press:

The analyzer generates a new segment that appears on the center of

the display.

3.

‘lb

specify the limit’s stimulus value, test limits (upper and lower),

and the limit type, press:

Note

The minimum value for measured data is -200

You could also set the upper and lower limits by using

the p1

IDDLE

use these keys for the entry, press:

M

I D D

L E

DELTH LIMITS@@

This would correspond to a test specification of -24

f3 dB.

‘4FlLlJE

6’ H

L U E

and

1-24) @

DELTH

LIMITS keys. lb

dB.

4. lb define the limit as a flat line, press:

L

I

M

I TT ‘i’ P

E FL H T

L

I

t.1

E R E TURN

Making Measurements 2-13

Page 36

5. lb terminate the flat line segment by establishing a single point limit,

press:

Figure 2-7 shows the flat limit lines that you have just created with

the following parameters:

w

stimulus from 127 MHz to 140 MHz

n

upper limit of -21

n lower limit of -27

dB

dB

aw000010

Figure 2-7. Example Flat Limit Line

6. ‘lb create a limit line that tests the low side of the filter, press:

FID[)

!s T I PI l-1 L 1-l !;

tJPPER

LClWEl?

D III 14 E

L I td I TT 7’ P

il D D

!;T IMIJLIJ!~

D 0 t4

E

L I tl I T

2-14 Making Measurements

VHLIJE mm

LIMITa

LIMIT

(-2oo_)@

E FL H T

‘6’ 17

L U E

TYPE SINGLE

L I NE I? E T U R

1123_) m

F’O

I MT

bl

RETURN

Page 37

7.

To

create a limit line that tests the high side of the

press:

bandpass

filter,

LIMIT TYPE FLAT LI

H Cl Cl

!;TIMiJLlJS

DfJHE

LIMIT TYPE

‘v’ 13

L U E

1160_) m

SIHGLE POIt.iT F3ETURt.I

Figure 2-8. Example Flat Limit Lines

t.+E RETURt.1

Making Measurements

2-15

Page 38

Creating a Sloping Limit Line

This example procedure shows you how to make limits that test the

shape factor of a SAW Elter. The following limits are set:

Frequency Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power Range

123 MHz to 125 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -65 dB to -26 dB

144

MHz

to 146 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -26 dB to -65

1. lb access the limits menu and activate the limit lines, press:

dB

@jG)LIMIT

PlEMJ

LIMIT LINE

OH

EDIT LIMIT

LIHE

CLEMR LISTYES

2. ‘lb establish the start frequency and limits for a sloping limit line that

tests the low side of the filter, press:

HDD

LIMIT TYPE

SLOPI HG

L I HE RETURN

3. ‘lb terminate the lines and create a sloping limit line, press:

HDD

ST1

MULUS VHLUE @m

UPPER

LrJWER LIMIT

D B F4

LIMIT TYPE

LIMIT I-26J@

E

SIt4lI;LE

1-2oo_)a

PO1 HT

RETUFrH

2- 16

Making Measurements

Page 39

4. ‘lb establish the start frequency and limits for a sloping limit line that

tests the high side of the Elter, press:

5.

lb terminate the lines and create a sloping limit line, press:

H[>D

LIMIT

You could use this type of limit to test the shape factor of a

TYPE SIHGLE

POIHT

F.:ETURH

filter.

Figure 2-9. Sloping Limit Lines

Making Measurements 2-17

Page 40

Creating Single Point Limits

In this example procedure, the following limits are set:

from -23 dB to -28.5 dB at 141 MHz

from -23 dB to -28.5 dB at 126.5 MHz

1. lb access the limits menu and activate the limit lines, press:

~~]LIMIT

CLEHR LIST ‘r’E:s

2.

‘lb

designate a single point limit line, as shown in Figure 2-10, you

must

deEne

l

downward pointing, indicating the upper test limit

n

upward pointing, indicating the lower test limit

Press:

t4EHU LIMfT

two pointers:

LINE OH

EDIT

LIMIT

LINE

2-18

Making

Measurements

Page 41

aw000013

Figure 2-10. Example Single Point Limit Lines

Making Measurements 2-19

Page 42

Editing Limit Segments

This example shows you how to edit the upper limit of a limit line.

1. ‘lb access the limits menu and activate the limit lines, press:

=LItlIT

2. ‘lb move the pointer symbol

MENU

LfHIT LIHE

(>)

on the analyzer display to the

KU4

EDIT

LIHIT LINE

segment you wish to modify, press:

SE G ME H T @)

or @j repeatedly

OR

$

E C; tl

E t4

T and enter the segment number followed by

3.

‘Ib

change the upper limit (for example, -20) of a limit line, press:

EDIT IJPPER

LIMIf~~f)Ot~IE

@).

Deleting Limit Segments

1. lb access the limits menu and activate the limit lines, press:

~LIMIT

2. lb move the pointer symbol

MEElCl

LIMIT

(>)

on the analyzer display to the

LINE OH

EDIT LIMIT

LIHE

segment you wish to delete, press:

SEC;

tl

E H

T @)

or Q repeatedly

OR

S

EG tl

E

H

T and enter the segment number followed by (xl.

3. ‘lb delete the segment that you have selected with the pointer

symbol, press:

DELETE

2-20 Making Measurements

Page 43

Running a Limit Test

1. lb access the limits menu and activate the limit lines, press:

[~~LIPIIT

Reviewing the Limit Line Segments

The limit table data that you have previously entered is shown on the

analyzer display.

2. lb verify that each segment in your limits table is correct, review the

entries by pressing:

SEGMENT

3. lb modify an incorrect entry, refer to the “Editing Limit Segments”

procedure, located earlier in this section.

@-j

MENIJ

and

LIMIT LINE

@

Qt4

EDIT

LIMIT

LIHE

Activating the Limit

Test

4. lb activate the limit test and the beep fail indicator, press:

0 1.4

[j)

0

Note

L I M

I T

ME

1.4 CI

L I tl

I T

T E 5 T

Selecting the beep fail indicator BEEP

BEEPF H

I L

F R I L

1.4

0 14

is

optional and will add approximately 50 ms of sweep

cycle time. Because the limit test will still work if the

limits lines are off, selecting L I

tl

I T

If4EOH

is

L

also optional.

The limit test results appear on the right side on the analyzer display.

The analyzer indicates whether the filter passes or fails the defined

limit test:

q

The message

FH

I L

will appear on the right side of the display if

the limit test fails.

q

The analyzer beeps if the limit test fails and if BEEP

F H I L

0 t4

has been selected.

q

The analyzer alternates a red trace where the measurement trace is

out of limits.

q

A TTL signal on the rear panel BNC connector “LIMIT TEST”

provides a pass/fail (5

V/O

V) indication of the limit test results.

Making Measurements 2-21

Page 44

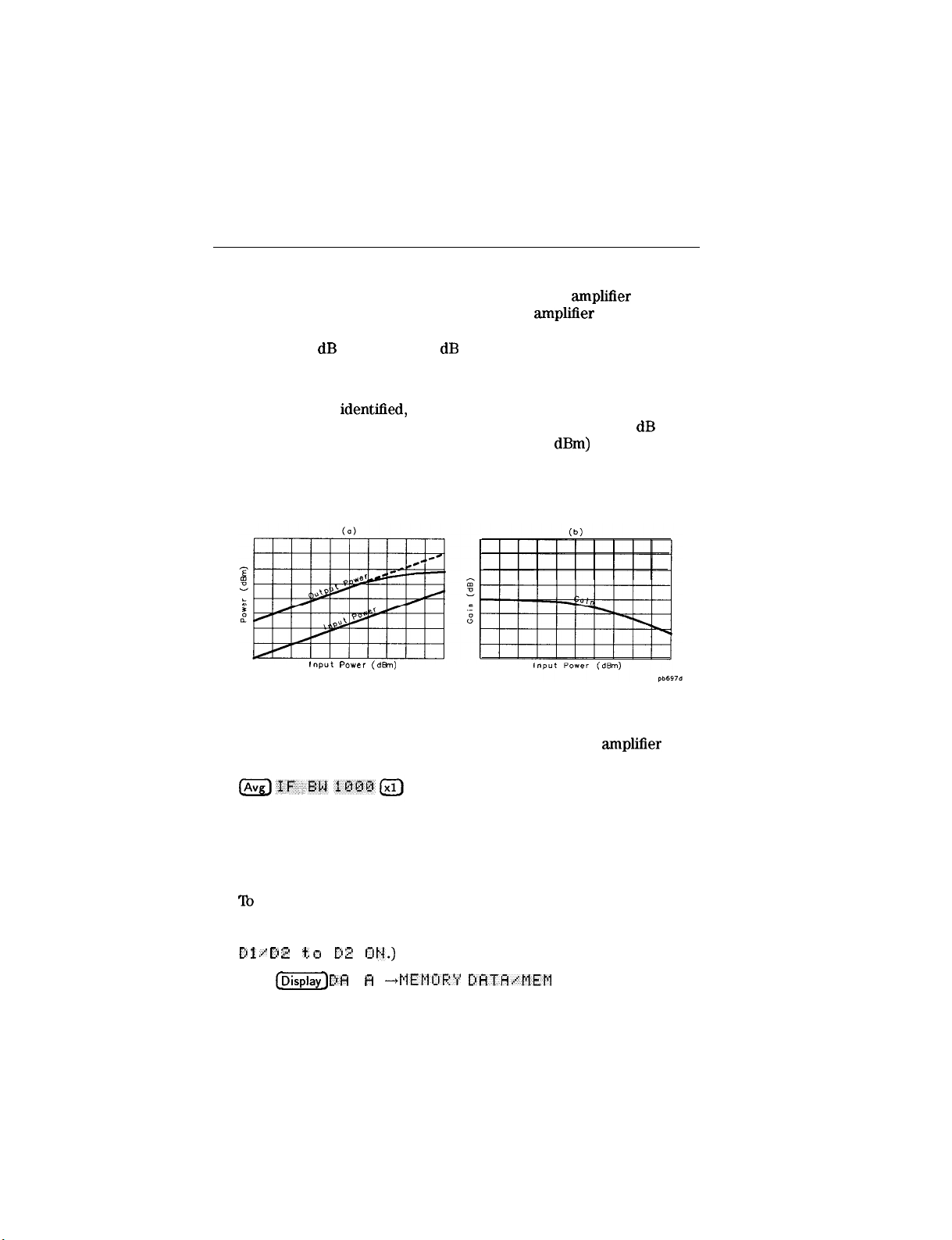

Measuring Gain Compression

Gain compression occurs when the input power of an

increased to a level that reduces the gain of the

amplifier

ampliEer

is

and causes

a nonlinear increase in output power. The point at which the gain

is reduced by 1 dB is called the 1 dB

compression point. The gain

compression will vary with frequency, so it is necessary to End the

worst case point of gain compression in the frequency band.

Once that point is

that CW frequency to measure the input power at which the 1

compression occurs and the absolute power out (in

identiEed,

you can perform a power sweep of

dB

dBm)

at compression.

The following steps provide detailed instruction on how to apply various

features of the analyzer to accomplish these measurements.

Input Power (dh)

Figure 2-11. Diagram of Gain Compression

1. Set up the stimulus and response parameters for your

amplifier

under test. lb reduce the effect of noise on the trace, press:

2. Perform the desired error correction procedure. Refer to Chapter 5,

“Optimizing Measurement Results,” for instructions on how to make

a measurement correction.

3. Hook up the amplifier under test.

4.

‘Ib

produce a normalized trace that represents gain compression,

perform either step 5 or step 6. (Step 5 uses trace math and

step 6 uses uncoupled channels and the display function

Et 2

D 1 .* D 2t.

5.

Press

13

(jw) DH

III 1.1.)

--+ME~~I~IRY DHTH..~‘MEM

T H

to produce a

normalized trace.

2-22 Making Measurements

Page 45

6.

‘lb

produce a normalized trace, perform the following steps:

a. Press

~~~D!JHL:

SETIJP and set

CslJHL C:HHt4

on OFF to

QIJHD

OH

to view channels 1 and 2

simultaneously.

b. ‘lb uncouple the channel stimulus so that the channel power will

be uncoupled, press:

IMenu) COlfPLET) CH CtFF

This will allow you to separately increase the power for

channel 2 and channel 1, so that you can observe the gain

compression on channel 2 while channel 1 remains unchanged.

c. ‘lb display the ratio of channel 2 data to channel 1 data on the

channel 2 display, press:

(Chan2)(-)

0 N

7. Press

. This produces a trace that represents gain compression only.

(W)

MBRE

and set DF:,Dl t,o

D2

on

OFF

MARKER1 and position the marker at approximately

mid-span.

8.

Press(j)SCHLE~DIV(iJ@iJtochangethescaletoldB

per division.

9. Press

IMenu)

F’rJWER.

10. Increase the power until you observe approximately 1 dB of

compression on channel 2, using the step keys or the front panel

knob.

to

11. ‘lb locate the worst case point on the trace, press:

(Marker) MKR

SE

HRCH SEHRCH: Pl

I

N

Making Measurements 2-23

Page 46

CHI S21II og

PRmPRm

C?C?

tt

CHl

START

CHl START

DZ/

DZ/

PRmPRm

C?C?

I

CHZ

START

MAGogMAG

1.000

1.000 000

I I I

1.000 000

000

10 dB/10

MHz

MHz

MHz

dB/

REFREF 0

I

I

Figure 2-12.

Gain Compression using Linear Sweep

dB0dB 1

STOP100E. 000 000

STOP100E. 000 000

19.723

19.723

dB1

I I I I I

STOP 1 000.000 000

and 1321

D 1 t, 0 D

MHz

dB

MHz

MHz

2 ij

t.4

12. If C 0 IJ P

L E

D

I:

H0

F F

was selected, recouple the channel

stimulus by pressing:

[Menu)

13. lb place the marker

tMarkerFctn_) MHRKEE

14.

‘lb

COIJF3LED

IX ON

exuctl~

MODE

on a measurement point, press:

MENlJ MHRKERS: DIS’C:RETE

set the CW frequency before going into the power sweep mode,

press:

Iseq) $iPEC: I AL FiJNl:T 1ljt.j:; MHRI(ER + CL4

15. Press

16.

m

SWEEP TYPE

MEPIIJ POWEFF: SWEEF’.

Enter the start and stop power levels for the sweep.

Now channel 1 is displaying a gain compression curve. (Do not pay

attention to channel 2 at this time.)

2-24

Making Measurements

Page 47

17. ‘lb maintain the calibration for the CW frequency, press:

Icar] ItdfERPrJL I3t.I C~;~RREt;‘fTOb~ Ok+

18.

Press

[jj[j]

SETIJP and set

I)LiftL CXHk4 art

19.

IfD2YDl to D2 rJt.4

DZ,Cfl f,o

I32

DUAL: QUAI>

OFF to ON.

was selected, press MORE

OFF.

20. Press

Now channel 2 displays absolute output power (in

Ihneas) IHPIJT

PORTS

B.

dBm)

as a

function of power input.

2 1.

Press

[Scale]

SlZHLE1D IV

Ilo]@

to change the scale of

channel 2 to 10 dB per division.

22. Press

m

@ Ixl) to change the scale of channel 1 to 1 dB per

division.

Note

A receiver calibration will improve the accuracy of

this measurement. Refer to Chapter 5, “Optimizing

Measurement Results.”

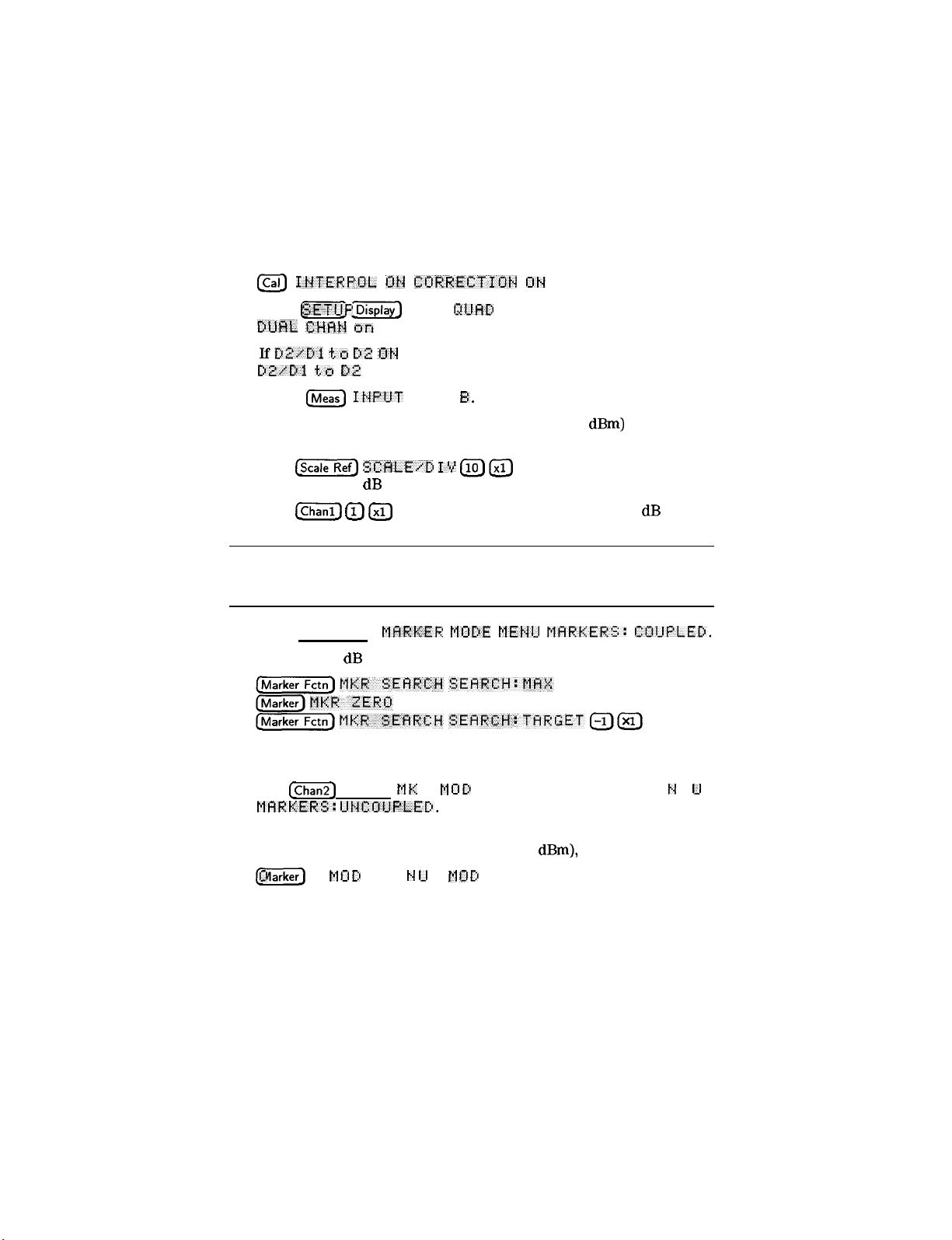

23. Press (Marker)

IIARKER MClDE MEt,+U MHRKERS: C:OIJPLED.

24. ‘lb find the 1 dB compression point on channel 1, press:

Notice that the marker on channel 2 tracked the marker on

channel 1.

25. Press

[Chan2]

[Marker) M K

ME t4

MFIRKERS:

IJHCrSUPLED.

R

E

UM 0 I>

26. lb take the channel 2 marker out of the A mode so that it reads the

absolute output power of the amplifier (in

@iii)

A

I:1

F F

td 0 I> Etl E td U AM 0 I)

E

dBm),

press:

Making Measurements 2-25

Page 48

CHl Szl

PRm

C?

t

CHZ

PRm

t

log MFlG

I I

B

log MFlG

2 dB/ REF 19.01

I

5 dB/ REF 0

dB

dB1 -.

I

1: 7.6474

9956

x

dB

I

dB

START -25. 0 dBm CW

Figure 2-13. Gain Compression using Power Sweep

2-26 Making Measurements

1.000 000

MHz

STOP

0.0 dBm

Page 49

Measurements using the Swept List Mode

Stepped

Swept List Mode

The ability to completely customize the frequency sweep while using

swept list mode is useful when setting up a measurement for a device

with high dynamic range, like a Elter. The following measurement of a

filter illustrates the advantages of using the swept list mode.

Note

List

Mode

Primary channels 1 and 2 can be set up independently

from each other with different frequency

lists (stepped or swept). Press m and set

CrJClPLED

primary channels from each other. You can then

create an independent frequency list for each primary

ChaMel.

Due to the permanent stimulus coupling between

primary and auxiliary channels, channel 3 and 4 will

have the same frequency lists as channels 1 and 2

respectively.

In this mode, the source steps to

each defined frequency point,

stopping while data is taken. This

mode eliminates IF’ delay and allows

frequency segments to overlap.

However, the sweep time can be

substantially slower than for a

continuous sweep with the same

number of points.

This mode takes data while sweeping

through the defined frequency

segments, increasing throughput by

up to 6 times over a stepped sweep.

In addition, this mode allows the test

port power and IF bandwidth to be

set independently for each segment

that is defined. The frequency

segments in this mode cannot

overlap.

CW ljt.4 af f

to OFF to uncouple the

Making Measurements 2-27

Page 50

Connect the Device Under

1. Connect the equipment as shown in the following illustration:

Figure 2-14. Swept List Measurement Setup

2. Set the following measurement parameters:

!521 (B/R>

Test

2-28 Making Measurements

Page 51

Observe the Characteristics of the Filter

CENTER

900.000

500.000

000

MHZ

SPAN

000

MHZ

Figure 2-15. Characteristics of a Filter

w

Generally, the pass band of a Elter exhibits low loss. A relatively low

incident power may be needed to avoid overdriving the next stage of

the DUT (if that stage contains an

ampliEer)

or the network analyzer

receiver.

n

Conversely, the stop band of a filter generally exhibits high isolation.

‘lb measure this characteristic, the dynamic range of the system will

have to be maximized. This can be done by increasing the incident

power and narrowing the IF bandwidth.

Making Measurements 2-29

Page 52

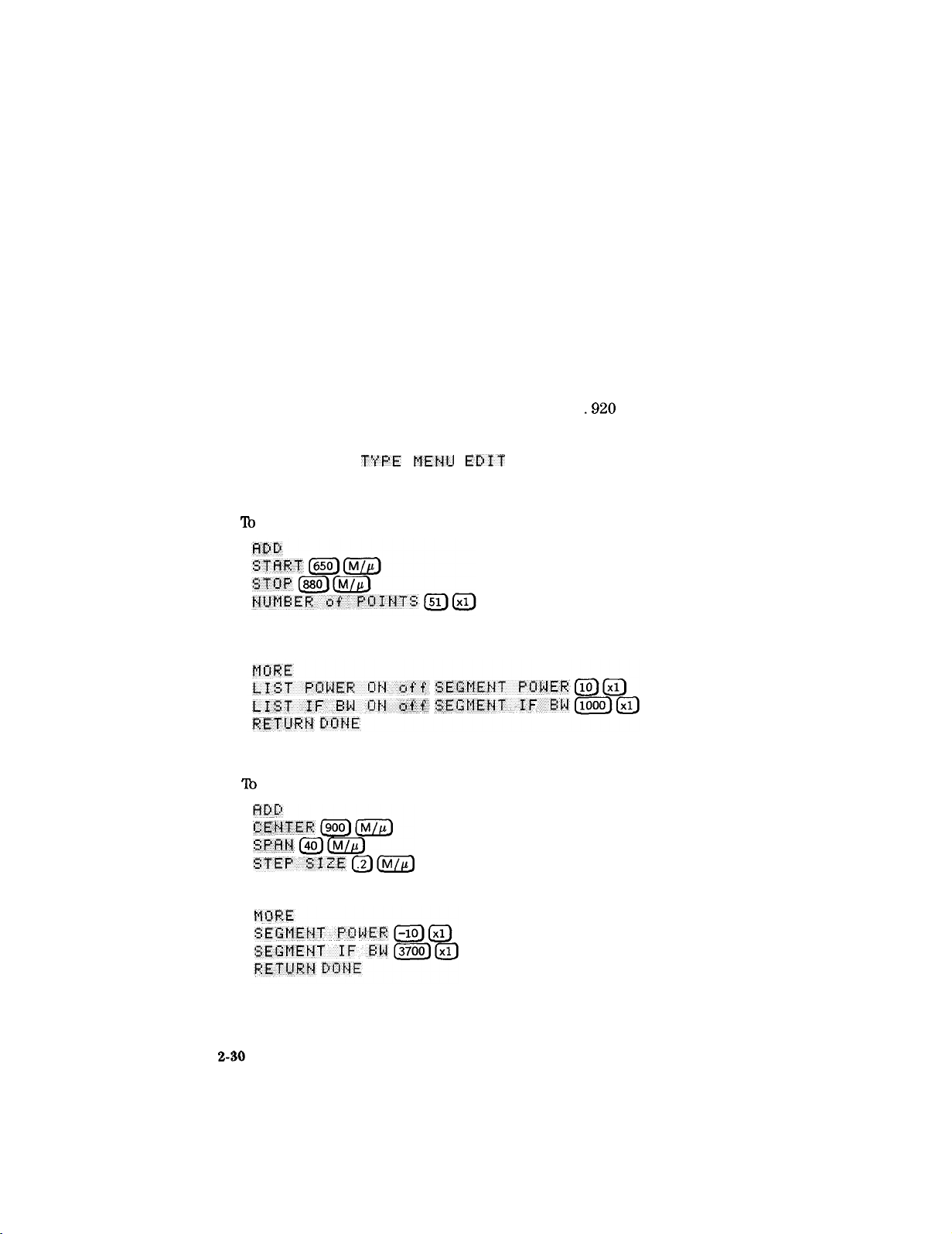

Choose the Measurement Parameters

1. Decide the frequency ranges of the segments that will cover the stop

bands and pass band of the filter. For this example, the following

ranges will be used:

Lower stop band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650 to 880 MHz

880

Pass band

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper stop band.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. ‘lb set up the swept list measurement, press

(Menu) SWEEP T-

‘I’F’E MEHIJ EDIT

LIST

Set Up the Lower Stop Band Parameters

3.

‘lb

set up the segment for the lower stop band, press

4. lb maximize the dynamic range in the stop band (increasing the

incident power and narrowing the IF bandwidth), press

to 920 MHz

.920

to 1150 MHz

Set Up the Pass Band Parameters

5.

‘lb

set up the segment for the pass band, press

6.

‘lb specify a lower power level for the pass band, press

Z-30

Making Measurements

Page 53

Set Up the Upper Stop Band Parameters

7. ‘lb set up the segment for the upper stop band, press

H D D

8. ‘lb maximize the dynamic range in the stop band (increasing the

incident power and narrowing the lF bandwidth), press

9. Press

[SONE

LIST

FF?EL!

[SWEPTI.

Calibrate and Measure

1. Remove the DUT and connect a thru between the test ports.

2. Perform a full two-port calibration. Refer to Chapter 5, “Optimizing

Measurement Results.”

3. With the thru connected, set the scale to autoscale to observe the

benefits of using swept list mode.

n

The segments used to measure the stop bands have less noise, thus

maximizing dynamic range within the stop band frequencies.

H

The segment used to measure the pass band has been set up for

faster sweep speed with more measurement points.

Making Measurements 2-3 1

Page 54

CENTER

000.000 000 MHZ SPAN

500.000 000

MtiZ

Figure 2-16. Calibrated Swept List Thru Measurement

4. Reconnect the filter and adjust the scale to compare results with the

first filter measurement that used a linear sweep.

n

In Figure 2-18, notice that the noise level has decreased over

10

dB, confirming

that the noise reduction techniques in the stop

bands were successful.

w

In Figure 2-18, notice that the stop band noise in the third segment

is slightly lower than in the first segment. This is due to the

narrower IF bandwidth of the third segment (300 Hz).

2-32 Making Measurements

Page 55

CENTER 900.000 000 MHZ

SPAN

500.000 000 MHZ

Figure 2-17.

Filter Measurement using Linear Sweep

(Power: 0

dBm/IP BW:

3700 Hz)

Making Measurements 2-33

Page 56

,

loa

CHI

s2:

PRrn

CO!-

CENTER 900.000 000

MAG

m

-

SEGMENT I

Power: +I 0 dBm

IF BW: 1000 Hz

II

MHz

d0,

REF

I

I I

SEGZNT

0

I

dB

SPAN

2

500.000 000 MHZ

SEGMENT 3

Power:

+I0

IF BW: 300 Hz

dBm

Power: -10 dBm

IF BW: 3700 Hz

Figure 2-18. Filter Measurement using Swept List Mode

pge51 e

2-34 Making Measurements

Page 57

3

Making Mixer Measurements

Measurement Considerations

To

ensure successful mixer measurements, the following measurement

challenges must be taken into consideration:

w

Mixer Considerations

q

Minimizing Source and Load Mismatches

q

Reducing the Effect of Spurious Responses

q

Eliminating Unwanted Mixing and Leakage Signals

n

Analyzer Operation

q

How RF and IF Are Defined

q

Frequency Offset Mode Operation

q

Differences Between Internal and External R Channel Inputs

q

Power Meter Calibration

Minimizing Source and Load Mismatches

When characterizing linear devices, you can use vector accuracy

enhancement to mathematically remove all systematic errors, including

source and load mismatches, from your measurement. This is not

possible when the device you are characterizing is a mixer operating

over multiple frequency ranges. Therefore, source and load mismatches

are not corrected for and will add to overall measurement uncertainty.

You should place attenuators at all of the test ports to reduce the

measurement errors associated with the interaction between mixer port

matches and system port matches. ‘lb avoid overdriving the receiver,

you should give extra care to selecting the attenuator located at the

mixer’s IF port. For best results, you should choose the attenuator value

so that the power incident on the analyzer R channel input is less than

-10

dBm

and greater than -35

dBm.

Making Mixer Measurements 3-l

Page 58

Reducing the Effect of Spurious Responses

By choosing test frequencies (frequency list mode), you can reduce the

effect of spurious responses on measurements by avoiding frequencies

that produce IF signal path distortion.

Eliminating Unwanted Mixing and Leakage Signals

By placing filters between the mixer’s IF port and the receiver’s input

port, you can eliminate unwanted mixing and leakage signals from

entering the analyzer’s receiver. Filtering is required in both fixed and

broadband measurements. Therefore, when conIiguring broad-band

(swept) measurements, you may need to trade some measurement

bandwidth for the ability to more selectively filter signals entering the

analyzer receiver.

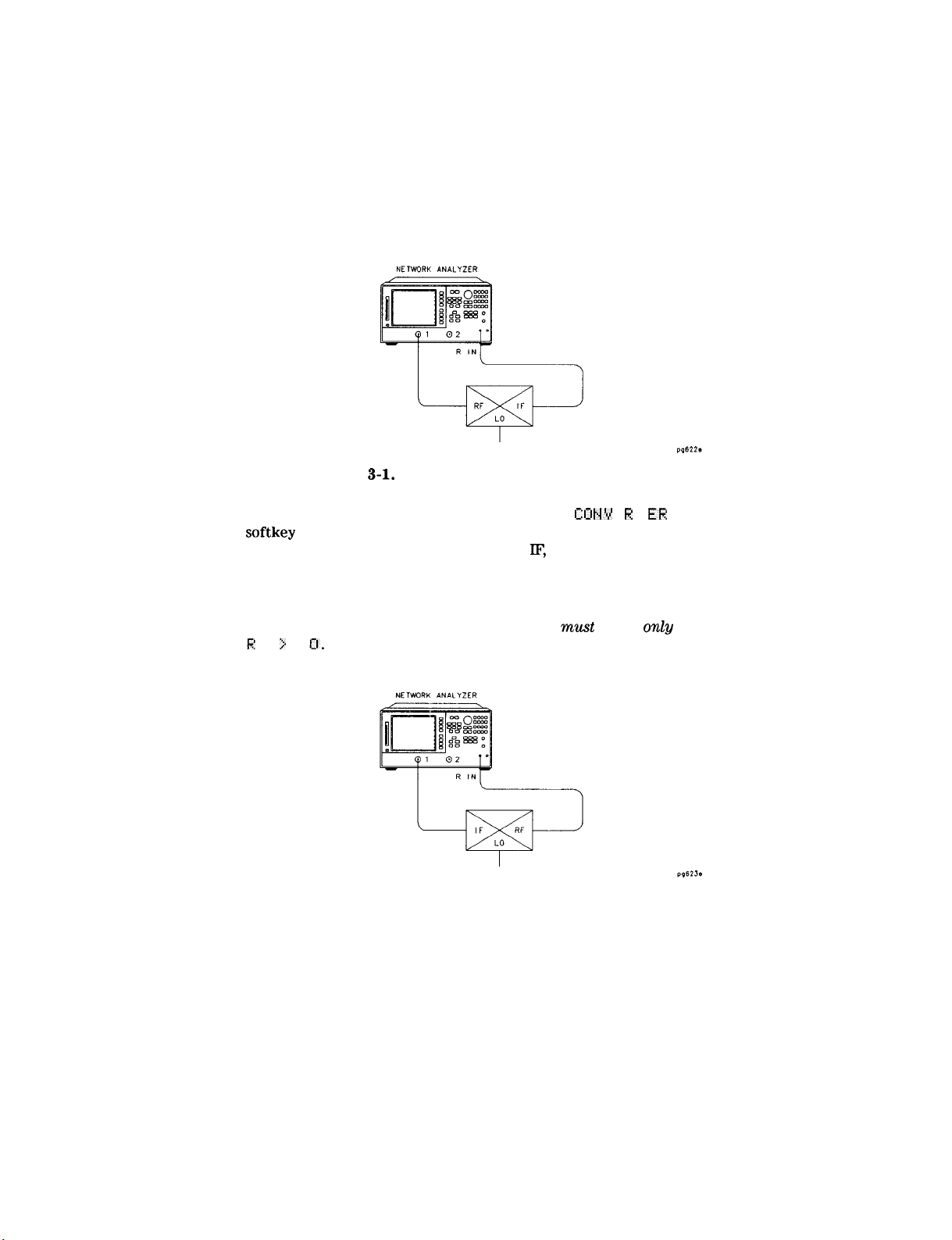

How RF and IF Are Defined

In standard mixer measurements, the input of the mixer is always

connected to the analyzer’s RF source, and the output of the mixer

always produces the lF frequencies that are received by the analyzer’s

receiver.

However, the ports labeled RF and IF on most mixers are not

consistently connected to the analyzer’s source and receiver ports,

respectively. These mixer ports are switched, depending on whether a

down converter or an up converter measurement is being performed.

It is important to keep in mind that in the setup diagrams of the

frequency offset mode, the analyzer’s source and receiver ports are

labeled according to the mixer port that they are connected to.

n

In a down converter measurement where the D 12 W

El

C rJ N 5’

E RT E

softkey is selected, the notation on the analyzer’s setup diagram

indicates that the analyzer’s source frequency is labeled RF,

connecting to the mixer RF port, and the analyzer’s receiver

frequency is labeled IF, connecting to the mixer IF port.

Because the RF frequency can be greater or less than the set LO

frequency in this type of measurement, you can select either

F:F >

Lo or RF .<

3-2 Making Mixer Measurements

t-111.

R

Page 59

Figure

n

In an up converter measurement where the UP

3-l.

Down Converter Port Connections

C: 0 t.1’4

E R T

El?

softkey is selected, the notation on the setup diagram indicates that

the analyzer’s source frequency is labeled

IF,

connecting to the

mixer IF port, and the analyzer’s receiver frequency is labeled RF,

connecting to the mixer RF port.

Because the RF frequency will always be greater than the set

LO frequency in this type of measurement, you

I?

F > L

0.

must

select

on&

Figure 3-2. Up Converter Port Connections

Making Mixer Measurements 3-3

Page 60

Frequency Offset Mode Operation

Frequency offset measurements do not begin until all of the frequency

offset mode parameters are set. These include the following:

n

Start and Stop IF Frequencies

n

LO frequency

w

Up Converter / Down Converter

H RF>LO/RF<LO

The LO frequency for frequency offset mode must be set to the same

value as the external LO source. The offset frequency between the

analyzer source and receiver will be set to this value.

When frequency offset mode operation begins, the receiver locks onto

the entered IF signal frequencies and then offsets the source frequency

required to produce the IF. Therefore, since it is the analyzer receiver

that controls the source, it is only necessary to set the start and stop

frequencies from the receiver.

Differences Between Internal and External R Channel Inputs

Due to internal losses in the analyzer’s test set, the power measured

internally at the R channel is 16 dB lower than that of the source.

compensate for these losses, the traces associated with the R channel

have been offset 16 dB higher. As a result, power measured

at the R channel via the R CHANNEL IN port will appear to be 16

higher than its actual value. If power meter calibration is not used, this

offset in power must be accounted for with a receiver calibration before

performing measurements.

‘Ib

directly

dB

3-4 Making Mixer Measurements

Page 61

Power Meter Calibration

Mixer transmission measurements are generally conligured as follows:

measured output power

(Watts)

/set input power (Watts)

OR

measured output power

For this reason, the set input power must be accurately controlled in

order to ensure measurement accuracy.

Higher measurement accuracy may be obtained through the use of

power meter calibration. You can use power meter calibration to correct

for power offsets, losses, and

analyzer source and the input to the mixer under test.

(dBm) -

tlatness

set input power

variations occurring between the

(dBm)

Making Mixer Measurements

3-6

Page 62

Conversion Loss using the Frequency Offset Mode

Conversion loss is the measure of efficiency of a mixer. It is the ratio

of side-band IF power to RF signal power, and is usually expressed in

dB.

(Express ratio values in dB amounts to a subtraction of the

power in the denominator from the dB power in the numerator.) The

mixer translates the incoming signal, (RF), to a replica, (IF), displaced

in frequency by the local oscillator, (LO). Frequency translation is

characterized by a loss in signal amplitude and the generation of

additional sidebands. For a given translation, two equal output signals

are expected, a lower sideband and an upper sideband.

Figure 3-3.

An Example Spectrum of RF, LO, and IF Signals Present in a

Conversion Loss Measurement

dB

The analyzer allows you to make a swept RF/IF conversion loss

measurement holding the LO frequency fixed. You can make this

measurement by using the analyzer’s frequency offset measurement

mode. This mode of operation allows you to offset the analyzer’s source

by a fixed value, above or below the analyzer’s receiver. That is, this

allows you to use a device input frequency range that is different from

the receiver input frequency range.

The following procedure describes the swept IF frequency conversion

loss measurement of a broadband component mixer:

1. Set the LO source to the desired CW frequency and power level.

CW frequency = 1000

Power = 13

3-6 Making Mixer Measurements

dBm

MHz

Page 63

2. Set the desired source power to the value which will provide

-10

dBm

or less to the R channel input. Press:

(Menu)

POWER

3. Calibrate and zero the power meter.

4. Connect the measurement equipment as shown in Figure 3-4.

PWW RHNGE Mi3t.I @a

Caution

‘lb prevent connector damage, use an adapter (BP

part

number 1250-1462) as a connector saver for R

CHANNEL IN,

PCWER

SENSOR

Figure 3-4. Connections for R Channel and Source Calibration

5. From the front panel of the BP 87533, set the desired receiver

frequency and source output power by pressing:

B

Istart)(iEJ@Jij

IStop_l@zJm

FREtS! OFFS ON

(MenuJ POWER @a

I NSTRUIlEt4T

MCIDE Ft?EIS!

OFFS

IlENIJ

6. ‘lb view the measurement trace, press:

m

I 11 F’ UT

P 0 F?

T S

I%

7. Select the BP 87533 as the system controller:

Making Mixer Measurements 3-7

Page 64

8. Set the power meter’s address:

BET HDDRESSE!;

H[>DRESS:

P

MTR....‘HP

IE

c##_l(xl_l

9. Select the appropriate power meter by pressing

PrJWER

(HP

436A

MTR C

or HP

1 until the correct model

438At437).

mrmber

is displayed

10. Press

C

listed on the power sensor.

CAL

Ical) PWRNTR

t3L

F FIG

FACfQR

TO RSE

Ixx] @

C:HL LOSSJSE~~:~R

tA5

Cl RFi and enter the correction factors as

Press HD D

DUNE

for each correction factor. When

LISTS

FR E Q U E t4 C ‘f Ixx]

m

finished, press Er U HE .

11. lb perform a one sweep power meter calibration over the IF

frequency range at 0

dBm,

press:

12. ‘lb calibrate the R channel over the IF range, press:

Once completed, the display should read 0

dBm.

3-8 Making Mixer Measurements

Page 65

13. Make the connections as shown in Figure 3-5 for the one-sweep

power meter calibration over the RF range.

NElWRR ARALYYfER

Figure 3-5.

Connections for a One-Sweep Power Meter Calibration for Mixer

Measurements

14. lb set the frequency offset mode LO frequency from the analyzer,

press:

I

HSTRUMEHT

FF;EB I:IFF!~

L 0M

E N U F I? E Q U E

15.

‘lb

select the converter type and a high-side LO measurement

configuration, press:

PlODE

tfEk+lJ

t.4 c;Y

:

CbJ m

m

Making Mixer Measurements 3-9

Page 66

Figure 3-6. Measurement Setup from Display

16. lb view the measurement trace, press:

‘$1 EM PK3iSlJRE