Page 1

HP BASIC Programming

Examples Guide

HP 8753E Network Analyzer

Including Option 011

HP Part No. 08753-90413

Printed in USA

January 1998

© Copyright 1998 Hewlett-Packard Company

Page 2

The information contained in this document is subject to change

without notice.

Hewlett-Packard makes no warranty of any kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance,

or use of this material.

2

Page 3

How to Use This Guide

This guide uses the following conventions:

Front-Panel Key This represents a key physically located on the

instrument.

Softkey This represents a “softkey”, a key whose label is

determined by the instrument firmware.

Screen Text This represents text displayed on the instrument’s

screen.

3

Page 4

HP 8753E/Option 011 Network Analyzer

Documentation Map

The Installation and Quick Start Guide

familiarizes you with the HP 8753E/Option 011

network analyzer’s front and rear panels,

electrical and environmental operating

requirements, as well as procedures for installing,

configuring, and verifying the operation of the

analyzer.

The User’s Guide show how to make

measurements, explains commonly-used features,

and tells you how to get the most performance

from your analyzer.

The Quick Reference Guide provides a

summary of selected user features.

The HP-IB Programming Examples Guide

provides a tutorial introduction using BASIC

programming examples to demonstrate the remote

operation of the network analyzer.

The HP BASIC Programming Examples

Guide provides a tutorial introduction using

BASIC programming examples to demonstrate the

remote operation of the network analyzer.

The System Verification and Test Guide

provides the system verification and performance

test and the Performance Test Record for your HP

8753E/Option 011 network analyzer.

4

Page 5

Contents

1. HP BASIC Programming Examples Guide

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

System Setup and HP-IB Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

HP 8753E Network Analyzer Instrument Control Using BASIC . . . . . . . . . . . . . . . . . . . . . . .14

Command Structure in BASIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Command Query. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Operation Complete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Preparing for Remote (HP-IB) Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

I/O Paths. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Measurement Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Step 1. Setting Up the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Step 2. Calibrating the Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Step 3. Connecting the Device under Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Step 4. Taking the Measurement Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Step 5. Post-Processing the Measurement Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Step 6. Transferring the Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

BASIC Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Program Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Analyzer Features Helpful in Developing Programming Routines. . . . . . . . . . . . . . . . . . . .23

Analyzer-Debug Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

User-Controllable Sweep. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Example 1: Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Example 1A: Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Example 1B: Verifying Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5

Page 6

Contents

Example 2: Measurement Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Calibration Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Example 2A: S11 1-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Example 2B: Full 2-Port Measurement Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Example 2C: Adapter Removal Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Example 2D: Using Raw Data to Create a Calibration (Simmcal). . . . . . . . . . . . . . . . . . . . 35

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Example 2E: Take4 — Error Correction Processed on an External PC. . . . . . . . . . . . . . . . 40

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Example 3: Measurement Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Trace-Data Formats and Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Example 3A: Data Transfer Using Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Example 3B: Data Transfer Using FORM 4 (ASCII Transfer). . . . . . . . . . . . . . . . . . . . . . . 50

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Example 3C: Data Transfer Using Floating-Point Numbers . . . . . . . . . . . . . . . . . . . . . . . . 53

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Example 3D: Data Transfer Using Frequency-Array Information . . . . . . . . . . . . . . . . . . . 55

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Example 3E: Data Transfer Using FORM 1 (Internal-Binary Format). . . . . . . . . . . . . . . . 58

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

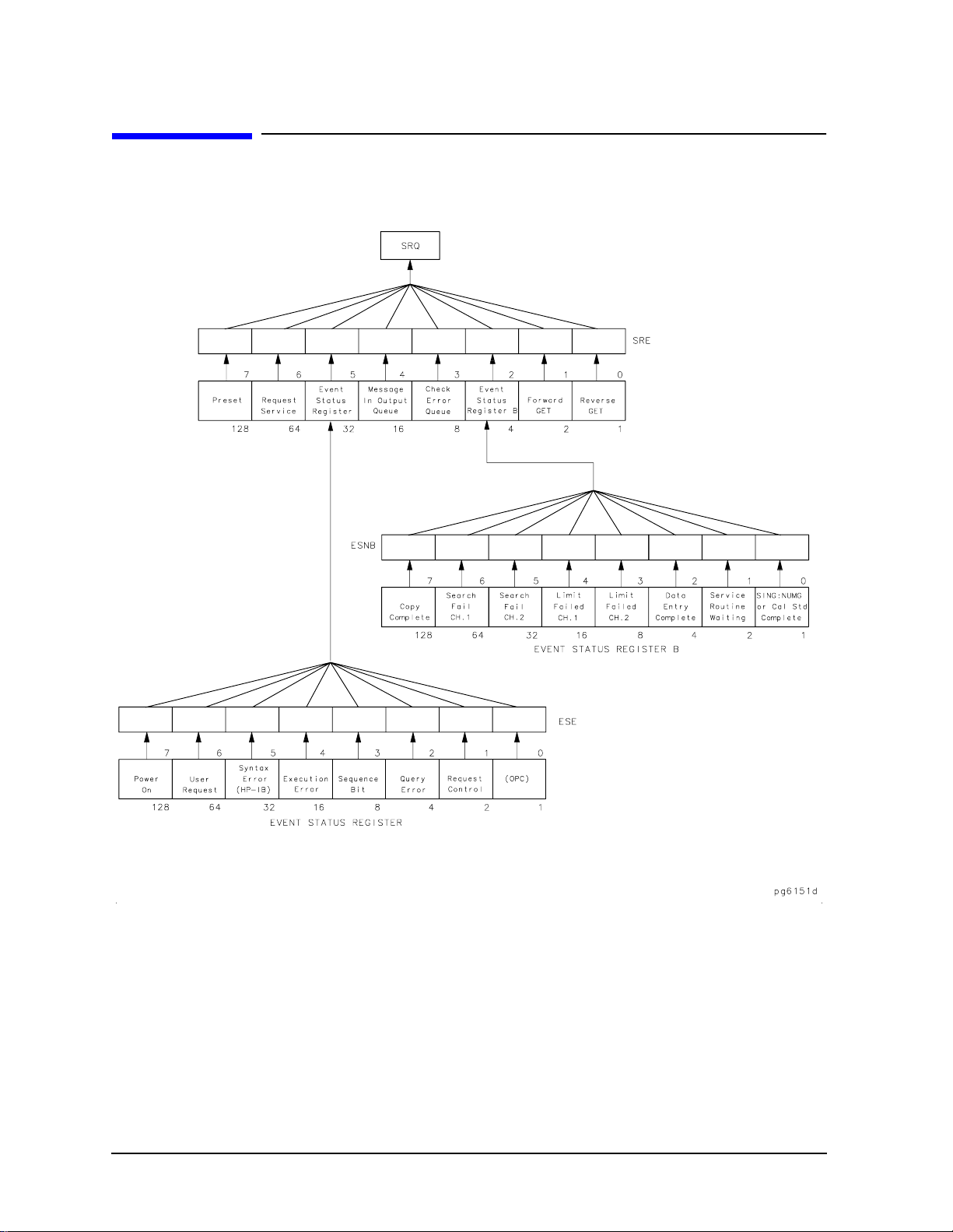

Example 4: Measurement Process Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Example 4A: Using the Error Queue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Example 4B: Generating Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Example 4C: Power Meter Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6

Page 7

Contents

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Example 5: Network Analyzer System Setups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Saving and Recalling Instrument States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Example 5A: Using the Learn String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Example 5B: Reading Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Example 5C: Saving and Restoring the Analyzer Instrument State. . . . . . . . . . . . . . . . . . .75

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Example 6: List-Frequency Tables and Limit-Test Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Using List Frequency Sweep Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Example 6A1: Setting Up a List Frequency Table In Stepped List Mode. . . . . . . . . . . . . . .79

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Example 6A2: Setting Up a List Frequency Table In Swept List Mode . . . . . . . . . . . . . . . .80

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Example 6B: Selecting a Single Segment from a Table of Segments . . . . . . . . . . . . . . . . . .84

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Using Limit Lines to Perform PASS/FAIL Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Example 6C: Setting Up a Limit-Test Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Example 6D: Performing PASS/FAIL Tests While Tuning . . . . . . . . . . . . . . . . . . . . . . . . . .90

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Example 7: Report Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Example 7A1: Operation Using Talker/Listener Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Example 7A2: Controlling Peripherals Using Pass-Control Mode . . . . . . . . . . . . . . . . . . . .95

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Example 7A3: Printing with the Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Example 7B1: Plotting to a File and Transferring the File Data to a Plotter. . . . . . . . . . .100

7

Page 8

Contents

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Utilizing PC-Graphics Applications Using the Plot File. . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Example 7B2: Reading Plot Files From a Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Example 7C: Reading ASCII Disk Files to the Instrument Controller's Disk File. . . . . . 109

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Example 8: Mixer Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Example 8A: Comparison of Two Mixers — Group Delay, Amplitude or Phase . . . . . . . . 113

Running the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Limit Line and Data Point Special Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Example Display of Limit Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Limit Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Output Results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Constants Used Throughout This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Output Limit Test Pass/Fail Status Per Limit Segment. . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Output Pass/Fail Status for All Segments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Example Program of OUTPSEGAF Using BASIC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Output Minimum and Maximum Point Per Limit Segment. . . . . . . . . . . . . . . . . . . . . . . . 126

Output Minimum and Maximum Point For All Segments . . . . . . . . . . . . . . . . . . . . . . . . . 127

Example Program of OUTPSEGAM Using BASIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Output Data Per Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Output Data Per Range of Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Output Limit Pass/Fail by Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

8

Page 9

1 HP BASIC Programming Examples

Guide

9

Page 10

HP BASIC Programming Examples Guide

Introduction

Introduction

This is an introduction to the remote operation of the HP 8753E Network Analyzer using

an external controller. This is a tutorial introduction using BASIC programming examples

to demonstrate the remote operation of the network analyzer. The examples used in this

document are on the “HP 8753E HP BASIC Programming Examples” disk.

The user should be familiar with the operation of the analyzer before attempting to

remotely control the analyzer via the Hewlett-Packard Interface Bus (HP-IB). See the HP

8753E Network Analyzer User's Guide for analyzer operating information.

The following computers operating with BASIC 6.2 can be used in these examples:

• HP 9000 Series 200/300

• HP 9000 Series 700 with HP BASIC-UX

This document is not intended to teach BASIC programming or to discuss HP-IB theory

except at an introductory level.

For more information concerning B ASIC , seeT able 1-1 for a list of manuals supporting the

BASIC revision being used. For more information concerning the Hewlett-Packard

Interface Bus, see Table 1-2.

Table 1-1 Additional BASIC 6.2 Programming Information

Description HP Part Number

HP BASIC 6.2 Programming Guide

HP BASIC 6.2 Language Reference (2 Volumes)

Using HP BASIC for Instrument Control, Volume I

Using HP BASIC for Instrument Control, Volume II

Table 1-2 Additional HP-IB Information

Description HP Part Number

HP BASIC 6.2 Interface Reference

Tutorial Description of the Hewlett-Packard Interface Bus

98616-90010

98616-90004

82303-90001

82303-90002

98616-90013

5021-1927

An IBM-compatible personal computer with an HP-IB/GPIB interface card may also be

used as an instrument controller. Hewlett-Packard provides a software package, HP

BASIC for Windows, that will execute the HP BASIC examples as described in this

document. Contact your local Hewlett-Packard sales office for further information on this

package.

10 Chapter 1

Page 11

HP BASIC Programming Examples Guide

Introduction

Required Equipment

Computer........................................................................................................HP9000Series

BASIC operating system......................................................................................BASIC 6.2

Programming Examples disk: HP BASIC, Visual BASIC, and Visual C++...08753-10035

HP-IB interconnect cables........................................................................HP 10833A/B/C/D

Test device ......................................................................suc h as a 125 MHz bandpass filter

NOTE The test device shipped with the instrument is a 10.24 GHz bandpass filter. If

you wish to use this device, the frequency ranges of the example programs

must be modified accordingly.

The computer must have enough memory to store:

• BASIC 6.2 (4 MBytes of memory is required)

• the required binaries

Upon receipt, make copies of the “Programming Examples” disks. Label them

“Programming Examples BACKUP”. These disks will act as reserves in the

event of loss or damage to the original disks.

Optional Equipment

See the “Compatible Peripherals” chapter in theHP 8753E Network Analyzer User's Guide

for complete information on the following optional equipment:

Calibration kits

Test port return cables

Plotter

Printer

Disk drive

System Setup and HP-IB Verification

This section describes how to:

• Connect the test system.

• Set the test system addresses.

• Set the network analyzer's control mode.

• Verify the operation of the system's interface bus (HP-IB).

Chapter 1 11

Page 12

HP BASIC Programming Examples Guide

Introduction

Figure 1-1 The HP 8753E Network Analyzer System with Controller

1. Connect the analyzer to the computer with an HP-IB cable as shown in Figure 1-1.

2. Switch on the computer.

3. Load the BASIC 6.2 operating system.

4. Switch on the analyzer.

a. To verify the analyzer's address, press:

Local, SET ADDRESSES, ADDRESS: 8753

The analyzer has only one HP-IB interface, though it occupies two addresses: one for

the instrument and one for the display. The display address is equal to the

instrument address with the least-significant bit incremented. The display address

is automatically set each time the instrument address is set.

The default analyzer addresses are:

• 16 for the instrument

• 17 for the display

CAUTION Other devices connected to the bus cannot occupy the same address as

the analyzer.

The analyzer displays the instrument's address in the upper right section of the

display. If the address is not 16, return the address to its default setting (16) by

pressing:

16, x1, Preset

12 Chapter 1

Page 13

HP BASIC Programming Examples Guide

Introduction

b. Set the system control mode to either “pass-control” or “talker/listener” mode. These

are the only control modes in which the analyzer will accept commands over HP-IB.

For more information on control modes, see the HP-IB Programming and Command

Reference Guide. To set the system-control mode, press:

Local, TALKER/LISTENER

or

Local, USE PASS CONTROL

5. Chec k the interface bus by performing a simple command from the computer controller.

Type the following command on the controller:

OUTPUT 716;”PRES;” Execute or Return

NOTE HP 9000 Series 300 computers use the Return key as both execute and

enter. Some other computers may have an

performs the same function. For reasons of simplicity, the notation

Enter, Execute, or Exec key that

Return

is used throughout this document.

This command should preset the analyzer. If an instrument preset does not occur , there

is a problem. Check all HP-IB addresses and connections. Most HP-IB problems are

caused by an incorrect address and faulty/loose HP-IB cables.

Chapter 1 13

Page 14

HP BASIC Programming Examples Guide

HP 8753E Network Analyzer Instrument Control Using BASIC

HP 8753E Network Analyzer Instrument Control Using

BASIC

A remote controller can manipulate the functions of the analyzer by sending commands to

the analyzer via the Hewlett-Packard Interface Bus (HP-IB). The commands used are

specific to the analyzer. Remote commands executed over the bus take precedence over

manual commands executed from the instrument's front panel. Remote commands are

executed as soon as they are received by the analyzer. A command only applies to the

active channel (except in cases where functions are coupled between channels). Most

commands are equivalent to front-panel hardkeys and softkeys.

Command Structure in BASIC

Consider the BASIC command for setting the analyzer's start frequency to 50 MHz:

OUTPUT 716;”STAR 50 MHZ;”

The command structure in BASIC has several different elements:

the BASIC command statement OUTPUT - The BASIC data-output statement.

the appendage 716 - The data is directed to interface 7 (HP-IB), and

on to the device at address 16 (the analyzer). This

appendage is terminated with a semicolon. The next

appendage is STAR, the instrument mnemonic for

setting the analyzer's start frequency.

data 50 - a single operand used by the root mnemonic STAR

to set the value.

unit MHZ - the units that the operand is expressed in.

terminator ; - indicates the end of a command, enters the data,

and deactivates the active-entry area.

The “STAR 50 MHZ;” command performs the same function as pressing the following

keys on the analyzer's front panel:

Start, 50, M/u

STAR is the root mnemonic for the start key, 50 is the data, and MHZ are the units. Where

possible, the analyzer's root mnemonics are derived from the equivalent key label.

Otherwise they are derived from the common name for the function. HP-IB Programming

and Command Reference Guide. lists all the root mnemonics and all the different units

accepted.

The semicolon (;) following MHZ terminates the command within the analyzer. It removes

start frequency from the active-entry area, and prepares the analyzer for the next

command. If there is a syntax error in a command, the analyzer will ignore the command

and look for the next terminator. When it finds the next terminator, it starts processing

14 Chapter 1

Page 15

HP BASIC Programming Examples Guide

HP 8753E Network Analyzer Instrument Control Using BASIC

incoming commands normally. Characters between the syntax error and the next

terminator are lost. A line feed also acts as a terminator. The BASIC OUTPUT statement

transmits a carriage return/line feed following the data. This can be suppressed by putting

a semicolon at the end of the statement.

The OUTPUT 716; statement will transmit all items listed (as long as they are separated

by commas or semicolons) including:

literal information enclosed in quotes,

numeric variables,

string variables,

and arrays.

A carriage return/line feed is transmitted after each item. Again, this can be suppressed by

terminating the commands with a semicolon. The analyzer automatically goes into remote

mode when it receives an OUTPUT command from the controller. When this happens, the

front-panel remote (R) and listen (L) HP-IB status indicators illuminate. In remote mode,

the analyzer ignores any data that is input with the front-panel keys, with the exception of

Local. Pressing Local returns the analyzer to manual operation, unless the universal HP-IB

command LOCAL LOCKOUT 7 has been issued. There are two ways to exit from a local

lockout. Either issue the LOCAL 7 command from the controller or cycle the line power on

the analyzer.

Setting a parameter such as start frequency is just one form of command the analyzer will

accept. It will also accept simple commands that require no operand at all. For example,

execute:

OUTPUT 716;"AUTO;"

In response, the analyzer autoscales the active channel. Autoscale only applies to the

active channel, unlike start frequency, which applies to both channels as long as the

channels are stimulus-coupled.

The analyzer will also accept commands that switch various functions ON and OFF. For

example, to switch on dual-channel display, execute:

OUTPUT 716;"DUACON;"

DUACON is the analyzer root mnemonic for “dual-channel display on.” This causes the

analyzer to display both channels. To go back to single-channel display mode, for example,

switching off dual-channel display, execute:

OUTPUT 716;"DUACOFF;"

The construction of the command starts with the root mnemonic DUAC (dual-channel

display) and ON or OFF is appended to the root to form the entire command.

The analyzer does not distinguish between upper- and lower-case letters. For example,

execute:

OUTPUT 716;"auto;"

Chapter 1 15

Page 16

HP BASIC Programming Examples Guide

HP 8753E Network Analyzer Instrument Control Using BASIC

NOTE The analyzer also has a debug mode to aid in troubleshooting systems. When

the debug mode is ON, the analyzer scrolls incoming HP-IB commands across

the display. To manually activate the debug mode, press

HP-IB DIAG ON

OUTPUT 716;"DEBUOFF;"

. To deactivate the debug mode from the controller, execute:

Local,

Command Query

Suppose the operator has changed the power level from the front panel. The computer can

find the new power level using the analyzer's command-query function. If a question mark

is appended to the root of a command, the analyzer will output the value of that function.

For instance, POWE 7 DB; sets the analyzer's output power to 7 dB, and POWE?; outputs

the current RF output power at the test port to the system controller. For example:

Type SCRATCH and press

Type EDIT and press

10 OUTPUT 716;"POWE?;"

20 ENTER 716;Reply

30 DISP Reply

40 END

Return to clear old programs.

Return to access the edit mode. Then type in:

Running the Program

The computer will display the preset source-power level in dBm. Change the power level

by pressing

When the analyzer receives POWE?, it prepares to transmit the current RF source-power

level. The BASIC statement ENTER 716 allows the analyzer to transmit information to the

computer by addressing the analyzer to talk. This illuminates the analyzer front-panel

talk (T) light. The computer places the data transmitted by the analyzer into the variables

listed in the ENTER statement. In this case, the analyzer transmits the output power,

which gets placed in the variable Reply.

The ENTER statement takes the stream of binary-data output from the analyzer and

reformats it back into numbers and ASCII strings. With the formatting set to its default

state, the ENTER statement will format the data into real variables, integers, or ASCII

strings, depending on the variable being filled. The variable list must match the data the

analyzer has to transmit. If there are not enough variables, data is lost. If there are too

many variables for the data available, a BASIC error is generated.

Local, Menu, POWER, XX, x1. Now run the program again.

The formatting done by the ENTER statement can be changed. For more information on

data formatting, see the HP-IB Programming and Command Reference Guide section

titled “ Array Data F ormats . ” The formatting can be deactivated to allow binary transfers of

data. Also, the ENTER USING statement can be used to selectively control the formatting.

ON/OFF commands can be also be queried. The reply is a one (1) if the function is active, a

zero (0) if it is not active. Similarly, if a command controls a function that is underlined on

the analyzer softkey menu when active, querying that command yields a one (1) if the

16 Chapter 1

Page 17

HP BASIC Programming Examples Guide

HP 8753E Network Analyzer Instrument Control Using BASIC

command is underlined, a zero (0) if it is not. For example, press Meas. Though there are

seven options on the measurement menu, only one is underlined at a time. The underlined

option will return a one (1) when queried.

For instance, rewrite line 10 as:

10 OUTPUT 716;"DUAC?;"

Run the program once and note the result. Then press Local, Display, DUAL CHAN to toggle the

display mode, and run the program again.

Another example is to rewrite line 10 as:

10 OUTPUT 716;"PHAS?;"

In this case, the program will display a one (1) if phase is currently being displayed. Since

the command only applies to the active channel, the response to the PHAS? inquiry

depends on which channel is active.

Operation Complete

Occasionally, there is a need to query the analyzer as to when certain analyzer operations

have completed. For instance, a program should not have the operator connect the next

calibration standard while the analyzer is still measuring the current one. T o provide such

information, the analyzer has an “operation complete” reporting mechanism, or OPC

command, that will indicate when certain key commands have completed operation. The

mechanism is activated by sending either OPC or OPC? immediately before an

OPC-compatible command. When the command completes execution, bit 0 of the

event-status register will be set. If OPC was queried with OPC?, the analyzer will also

output a one (1) when the command completes execution.

As an example, type SCRATCH and press

Type EDIT and press

Return.

Return.

Type in the following program:

10 OUTPUT 716;"SWET 3 S;OPC?;SING;" Set the sweep time to 3 seconds, and OPC a single sweep.

20 DISP "SWEEPING"

30 ENTER 716;Reply The program will halt at this point until the analyzer completes the

sweep and issues a one (1).

40 DISP "DONE"

50 END

Running the Program

Running this program causes the computer to display the sweeping message as the

instrument executes the sweep. The computer will display DONE just as the instrument

goes into hold. When DONE appears, the program could then continue on, being assured

that there is a valid data trace in the instrument.

Chapter 1 17

Page 18

HP BASIC Programming Examples Guide

HP 8753E Network Analyzer Instrument Control Using BASIC

Preparing for Remote (HP-IB) Control

At the beginning of a program, the analyzer is taken from an unknown state and brought

under remote control. This is done with an abort/clear sequence. ABORT 7 is used to halt

bus activity and return control to the computer. CLEAR 716 will then prepare the analyzer

to receive commands by:

• clearing syntax errors

• clearing the input-command buffer

• clearing any messages waiting to be output

The abort/clear sequence readies the analyzer to receive HP-IB commands. The next step

involves programming a known state into the analyzer. The most convenient way to do this

is to preset the analyzer by sending the PRES (preset) command. If preset cannot be used,

the status-reporting mechanism may be employed. When using the status-reporting

register, CLES (Clear Status) can be transmitted to the analyzer to clear all of the

status-reporting registers and their enables.

Type SCRATCH and press

Type EDIT and press

10 ABORT 7 This halts all bus action and gives active control to

20 CLEAR 716 This clears all HP-IB errors, resets the HP-IB interface, and clears

30 OUTPUT 716;"PRES;" Presets the instrument. This clears the status-reporting system, as

40 END Running this program brings the analyzer to a known state, ready to

Return.

Return. Type in the following program:

the computer.

the syntax errors. It does not affect the status-reporting system.

well as resets all of the front-panel settings, except for the HP-IB

mode and the HP-IB addresses.

respond to HP-IB control.

The analyzer will not respond to HP-IB commands unless the remote line is asserted.

When the remote line is asserted, the analyzer is addressed to listen for commands from

the controller. In remote mode, all the front-panel keys are disabled (with the exception of

Local and the line-power switch). ABORT 7 asserts the remote line, which remains asserted

until a LOCAL 7 statement is executed.

Another way to assert the remote line is to execute:

REMOTE 716

This statement asserts the analyzer's remote-operation mode and addresses the analyzer

to listen for commands from the controller. Press any front-panel key except

that none of the front-panel keys will respond until

Local can also be disabled with the sequence:

REMOTE 716

LOCAL LOCKOUT 7

18 Chapter 1

Local has been pressed.

Local. Note

Page 19

HP BASIC Programming Examples Guide

HP 8753E Network Analyzer Instrument Control Using BASIC

After executing the code above, none of front-panel keys will respond. The analyzer can be

returned to local mode temporarily with:

LOCAL 716

As soon as the analyzer is addressed to listen, it goes back into local-lockout mode. The

only way to clear the local-lockout mode, aside from cycling line power, is to execute:

LOCAL 7

This command un-asserts the remote line on the interface. This puts the instrument into

local mode and clears the local-lockout command. Return the instrument to remote mode

by pressing:

Local, TALKER/LISTENER

or

Local, USE PASS CONTROL

I/O Paths

One of the features of HP BASIC is the use of input/output paths. The instrument may be

addressed directly by the instrument's device number as shown in the previous examples.

However, a more sophisticated approach is to declare I/O paths such as: ASSIGN @Nwa TO

716. Assigning an I/O path builds a look-up table in the computer's memory that contains

the device-address codes and several other parameters. It is easy to quickly change

addresses throughout the entire program at one location. I/O operation is more efficient

because it uses a table, in place of calculating or searching for values related to I/O. In the

more elaborate examples where file I/O is discussed, the look-up table contains all the

information about the file. Execution time is decreased, because the computer no longer

has to calculate a device's address each time that device is addressed.

For example:

Type SCRATCH and press

Type EDIT and press

Return.

Return.

Type in the following program:

10 ASSIGN @Nwa TO 716 Assigns the analyzer to ADDRESS 716.

20 OUTPUT @Nwa;"STAR 50 MHZ;" Sets the analyzer's start frequency to 50 MHz.

NOTE The use of I/O paths in binary-format transfers allows the user to

quickly distinguish the type of transfer taking place. I/O paths are used

throughout the examples and are highly recommended for use in device

input/output.

Chapter 1 19

Page 20

HP BASIC Programming Examples Guide

Measurement Process

Measurement Process

This section explains how to organize instrument commands into a measurement

sequence. A typical measurement sequence consists of the following steps:

1. setting up the instrument

2. calibrating the test setup

3. connecting the device under test

4. taking the measurement data

5. post-processing the measurement data

6. transferring the measurement data

Step 1. Setting Up the Instrument

Define the measurement by setting all of the basic measurement parameters. These

include:

• the sweep type

• the frequency span

• the sweep time

• the number of points (in the data trace)

• the RF power level

• the type of measurement

• the IF averaging

• the IF bandwidth

You can quickly set up an entire instrument state, using the save/recall registers and the

learn string. The learn string is a summary of the instrument state compacted into a

string that the computer reads and retransmits to the analyzer. See “Example 5A: Using

the Learn String.”

Step 2. Calibrating the Test Setup

After you have defined an instrument state, you should perform a measurement

calibration. Although it is not required, a measurement calibration improves the accuracy

of your measurement data.

The following list describes several methods to calibrate the analyzer:

• Stop the program and perform a calibration from the analyzer's front panel.

• Use the computer to guide you through the calibration, as discussed in:

❏ “Example 2A: S

20 Chapter 1

1-Port Measurement Calibration.”

11

Page 21

HP BASIC Programming Examples Guide

Measurement Process

❏ “Example 2B: Full 2-Port Measurement Calibration.”

❏ “Example 2C: Adapter Removal Calibration.”

❏ “Example 2D: Using Raw Data to Create a Calibration (Simmcal).”

❏ “Example 2E: Take4 — Error Correction Processed on an External PC.”

• Transfer the calibration data from a previous calibration back into the analyzer, as

discussed in “Example 5C: Saving and Restoring the Analyzer Instrument State.”

Step 3. Connecting the Device under Test

After you connect your test device, you can use the computer to speed up any necessary

device adjustments such as limit testing, bandwidth searches, and trace statistics.

Step 4. Taking the Measurement Data

Measure the device response and set the analyzer to hold the data. This captures the data

on the analyzer display.

By using the single-sweep command (SING), you can insure a valid sweep. When you use

this command, the analyzer completes all stimulus changes before starting the sweep, and

does not release the HP-IB hold state until it has displayed the formatted trace. Then

when the analyzer completes the sweep, the instrument is put into hold mode, freezing the

data. Because single sweep is OPC-compatible, it is easy to determine when the sweep has

been completed.

The number-of-groups command (NUMGn) triggers multiple sweeps. It is designed to

work the same as single-sweep command. NUMGn is useful for making a measurement

with an averaging factor n (n can be 1 to 999). Both the single-sweep and

number-of-groups commands restart averaging.

Step 5. Post-Processing the Measurement Data

The HP 8753E Network Analyzer HPIB Programming and Command Reference Guide

figure titled “The Data Processing Chain For Measurement Outputs” shows the process

functions used to affect the data after you have made an error-corrected measurement.

These process functions have parameters that can be adjusted to manipulate the

error-corrected data prior to formatting. They do not affect the analyzer's data gathering.

The most useful functions are trace statistics, marker searches, electrical-dela y offset, time

domain, and gating.

After Performing and activating a full 2-port measurement calibration, any of the four

S-parameters may be viewed without taking a new sweep.

Step 6. Transferring the Measurement Data

Read your measurement results. All the data-output commands are designed to insure

that the data transmitted reflects the current state of the instrument.

Chapter 1 21

Page 22

HP BASIC Programming Examples Guide

BASIC Programming Examples

BASIC Programming Examples

The following sample programs provide the user with factory-tested solutions for several

remotely-controlled analyzer processes. The programs can be used in their present state or

modified to suit specific needs. The programs discussed in this section can be found on the

“HP 8753E HP BASIC Programming Examples” disk received with the analyzer.

• Example 1: Measurement Setup

❏ Example 1A: Setting Parameters

❏ Example 1B: Verifying Parameters

• Example 2: Measurement Calibration

❏ Example 2A: S

1-Port Measurement Calibration

11

❏ Example 2B: Full 2-Port Measurement Calibration

❏ Example 2C: Adapter Removal Calibration

❏ Example 2D: Using Raw Data to Create a Calibration (Simmcal)

❏ Example 2E: Take4 — Error Correction Processed on an External PC

• Example 3: Measurement Data Transfer

❏ Example 3A: Data Transfer Using Markers

❏ Example 3B: Data Transfer Using FORM 4 (ASCII Transfer)

❏ Example 3C: Data Transfer Using Floating-Point Numbers

❏ Example 3D: Data Transfer Using Frequency−Array Information

❏ Example 3E: Data Transfer Using FORM 1 (Internal Binary Format)

• Example 4: Measurement Process Synchronization

❏ Example 4A: Using the Error Queue

❏ Example 4B: Generating Interrupts

❏ Example 4C: Power Meter Calibration

• Example 5: Network Analyzer System Setups

❏ Example 5A: Using the Learn String

❏ Example 5B: Reading Calibration Data

❏ Example 5C: Saving and Restoring the Analyzer Instrument State

• Example 6: Limit-Line Testing

❏ Example 6A1: Setting Up a List-Frequency Table In Stepped List Mode

❏ Example 6A2: Setting Up a List-Frequency Table In Swept List Mode

22 Chapter 1

Page 23

HP BASIC Programming Examples Guide

BASIC Programming Examples

❏ Example 6B: Selecting a Single Segment from a Table of Segments

❏ Example 6C: Setting Up a Limit Test Table

❏ Example 6D: Performing PASS/FAIL Tests While Tuning

• Example 7: Report Generation

❏ Example 7A1: Operation Using Talker/Listener Mode

❏ Example 7A2: Controlling Peripherals Using Pass-Control Mode

❏ Example 7A3: Printing with the Serial Port

❏ Example 7B1: Plotting to a File and Transferring the File Data to a Plotter

• Utilizing PC-Graphics Applications Using the Plot File

❏ Example 7B2: Reading Plot Files From a Disk

❏ Example 7C: Reading ASCII Disk Files to the Instrument Controller's Disk File

• Example 8: Mixer Measurements

❏ Example 8A: Comparison of Two Mixers — Group Delay, Amplitude or Phase

Program Information

The following information is provided for every example program included on the

“Programming Examples” disk:

• A program description

• An outline of the program's processing sequence

• A step-by-step instrument-command-level tutorial explanation of the program

including:

❏ The command mnemonic and command name for the HP-IB instrument command

used in the program.

❏ An explanation of the operations and affects of the HP-IB instrument commands

used in the program.

Analyzer Features Helpful in Developing Programming

Routines

Analyzer-Debug Mode

The analyzer-debug mode aids you in developing programming routines. The analyzer

displays the commands being received. If a syntax error occurs, the analyzer displays the

last buffer and points to the first character in the command line that it could not

understand.

Chapter 1 23

Page 24

HP BASIC Programming Examples Guide

BASIC Programming Examples

You can enable this mode from the front panel by pressing Local, HP-IB DIAG ON. The debug

mode remains activated until you preset the analyzer or deactivate the mode. You can also

enable this mode over the HP-IB using the DEBUON; command and disable the debug mode

using the DEBUOFF; command.

User-Controllable Sweep

There are three important advantages to using the single-sweep mode:

1. The user can initiate the sweep.

2. The user can determine when the sweep has completed.

3. The user can be confident that the trace data has be derived from a valid sweep.

Execute the command string OPC?;SING; to place the analyzer in single-sweep mode and

trigger a sweep. Once the sweep is complete, the analyzer returns an ASCII character one

(1) to indicate the completion of the sweep.

NOTE The measurement cycle and the data acquisition cycle must always be

synchronized. The analyzer must complete a measurement sweep for

the data to be valid.

24 Chapter 1

Page 25

HP BASIC Programming Examples Guide

Example 1: Measurement Setup

Example 1: Measurement Setup

The programs included in Example 1 provide the user the option to perform

instrument-setup functions for the analyzer from a remote controller. Example 1A is a

program designed to setup the analyzer's measurement parameters. Example 1B is a

program designed to verify the measurement parameters.

Example 1A: Setting Parameters

NOTE This program is stored as EXAMP1A on the “Programming Examples” disk

received with the network analyzer.

In general, the procedure for setting up measurements on the network analyzer via HP-IB

follows the same sequence as if the setup was performed manually. There is no required

order, as long as the desired frequency range, number of points, and power level are set

prior to performing the calibration first, and the measurement second.

This example sets the following parameters:

• reflection log magnitude on channel 1

• reflection phase on channel 2

• dual channel display mode

• frequency range from 100 MHz to 500 MHz

The following is an outline of the program's processing sequence:

• An I/O path is assigned for the analyzer.

• The system is initialized.

• The analyzer is adjusted to measure return loss (S

) on channel 1 and display it in log

11

magnitude.

• The analyzer is adjusted to measure return loss (S11) on channel 2 and display the

phase.

• The dual-channel display mode is activated.

• The system operator is prompted to enter the frequency range of the measurement.

• The displays are autoscaled.

• The analyzer is released from remote control and the program ends.

The program is written as follows:

10 ! This program performs some example queries of network analyzer

20 ! settings. The number of points in a trace, the start frequency

30 ! and if averaging is turned on, are determined and displayed.

40 !

50 ! EXAMP1B

60 !

70 ASSIGN @Nwa TO 716 ! Assign an I/O path for the analyzer

80 !

Chapter 1 25

Page 26

HP BASIC Programming Examples Guide

Example 1: Measurement Setup

90 CLEAR SCREEN

100 ! Initialize the system

110 ABORT 7 ! Generate an IFC (Interface Clear)

120 CLEAR @Nwa ! SDC (Selected Device Clear)

130 OUTPUT @Nwa;"OPC?;PRES;" ! Preset the analyzer and wait

140 ENTER @Nwa;Reply ! Read in the 1 returned

150 !

160 ! Query network analyzer parameters

170 OUTPUT @Nwa;"POIN?;" ! Read in the default trace length

180 ENTER @Nwa;Num_points

190 PRINT "Number of points ";Num_points

200 PRINT

210 !

220 OUTPUT @Nwa;"STAR?;" ! Read in the start frequency

230 ENTER @Nwa;Start_f

240 PRINT "Start Frequency ";Start_f

250 PRINT

260 !

270 OUTPUT @Nwa;"AVERO?;" ! Averaging on?

280 ENTER @Nwa;Flag

290 PRINT "Flag =";Flag;" ";

300 IF Flag=1 THEN ! Test flag and print analyzer state

310 PRINT "Averaging ON"

320 ELSE

330 PRINT "Averaging OFF"

340 END IF

350 !

360 OUTPUT @Nwa;"OPC?;WAIT;" ! Wait for the analyzer to finish

370 ENTER @Nwa;Reply ! Read the 1 when complete

380 LOCAL @Nwa ! Release HP-IB control

390 END

Running the Program

The analyzer is initialized and the operator is queried for the measurement's start and

stop frequencies. The analyzer is setup to display the S

reflection measurement as a

11

function of log magnitude and phase over the selected frequency range. The displays are

autoscaled and the program ends.

Example 1B: Verifying Parameters

NOTE This program is stored as EXAMP1B on the “Programming Examples” disk

received with the network analyzer.

This example shows how to read analyzer settings into your controller. HP-IB

Programming and Command Reference Guide contains additional information on the

command formats and operations. Appending a “?” to a command that sets an analyzer

parameter will return the value of that setting. Parameters that are set as ON or OFF

when queried will return a zero (0) if OFF or a one (1) if active. Parameters are returned in

ASCII format, FORM 4. This format is varying in length from 1 to 24 characters-per-value.

In the case of marker or other multiple responses, the values are separated by commas.

The following is an outline of the program's processing sequence:

• An I/O path is assigned for the analyzer.

• The system is initialized.

• The number of points in the trace is queried and dumped to a printer.

• The start frequency is queried and output to a printer.

• The averaging is queried and output to a printer.

26 Chapter 1

Page 27

HP BASIC Programming Examples Guide

Example 1: Measurement Setup

• The analyzer is released from remote control and the program ends.

The program is written as follows:

10 ! This program performs some example queries of network analyzer

20 ! settings. The number of points in a trace, the start frequency

30 ! and if averaging is turned on, are determined and displayed.

40 !

50 ! EXAMP1B

60 !

70 ASSIGN @Nwa TO 716 ! Assign an I/O path for the analyzer

80 !

90 CLEAR SCREEN

100 ! Initialize the system

110 ABORT 7 ! Generate an IFC (Interface Clear)

120 CLEAR @Nwa ! SDC (Selected Device Clear)

130 OUTPUT @Nwa;"OPC?;PRES;" ! Preset the analyzer and wait

140 ENTER @Nwa;Reply ! Read in the 1 returned

150 !

160 ! Query network analyzer parameters

170 OUTPUT @Nwa;"POIN?;" ! Read in the default trace length

180 ENTER @Nwa;Num_points

190 PRINT "Number of points ";Num_points

200 PRINT

210 !

220 OUTPUT @Nwa;"STAR?;" ! Read in the start frequency

230 ENTER @Nwa;Start_f

240 PRINT "Start Frequency ";Start_f

250 PRINT

260 !

270 OUTPUT @Nwa;"AVERO?;" ! Averaging on?

280 ENTER @Nwa;Flag

290 PRINT "Flag =";Flag;" ";

300 IF Flag=1 THEN ! Test flag and print analyzer state

310 PRINT "Averaging ON"

320 ELSE

330 PRINT "Averaging OFF"

340 END IF

350 !

360 OUTPUT @Nwa;"OPC?;WAIT;" ! Wait for the analyzer to finish

370 ENTER @Nwa;Reply ! Read the 1 when complete

380 LOCAL @Nwa ! Release HP-IB control

390 END

Running the Program

The analyzer is preset. The preset values are returned and printed out for: the number of

points, the start frequency, and the state of the averaging function. The analyzer is

released from remote control and the program ends.

Chapter 1 27

Page 28

HP BASIC Programming Examples Guide

Example 2: Measurement Calibration

Example 2: Measurement Calibration

This section shows you how to coordinate a measurement calibration over HP-IB. You can

use the following sequence for performing either a manual measurement calibration, or a

remote measurement calibration via HP-IB:

1. Select the calibration type.

2. Measure the calibration standards.

3. Declare the calibration done.

The actual sequence depends on the calibration kit and changes slightly for 2-port

calibrations, which are divided into three calibration sub-sequences. The following

examples are included:

• Example 2A is a program designed to perform an S11 1-port measurement calibration.

• Example 2B is a program designed to perform a full 2-port measurement calibration.

• Example 2C is a program designed to accurately measure a “non-insertable” 2-port

device, using adapter removal.

• Example 2D is a program designed to use raw data to create a calibration, sometimes

called Simmcal.

• Example 2E is a program designed to offload the calculation of the 2-port error

corrected data to an external computer.

Calibration Kits

The calibration kit tells the analyzer what standards to expect at each step of the

calibration. The set of standards associated with a given calibration is termed a “class. ” F or

example, measuring the short during an S

calibration step. All of the shorts that can be used for this calibration step make up the

class, which is called class S11B. For the 7-mm and the 3.5-mm cal kits, class S11B uses

only one standard. For type-N cal kits, class S11B contains two standards: male and

female shorts.

When doing an S

selecting

SHORT automatically measures the short because the class contains only one

1-port measurement calibration using a 7- or 3.5-mm calibration kit,

11

standard. When doing the same calibration in type-N, selecting

menu, allowing the operator to select which standard in the class is to be measured. The

sex listed refers to the test port: if the test port is female, then the operator selects the

female short option. Once the standard has been selected and measured, the

must be pressed to exit the class.

1-port measurement calibration is one

11

SHORT brings up a second

DONE key

Doing an S11 1-port measurement calibration over HP-IB is very similar. When using a 7or 3.5-mm calibration kit, sending CLASS11B will automatically measure the short. In

type-N, sending CLASS11B brings up the menu with the male and female short options . T o

28 Chapter 1

Page 29

HP BASIC Programming Examples Guide

Example 2: Measurement Calibration

select a standard, use STANA or STANB. The STAN command is appended with the

letters A through G, corresponding to the standards listed under softkeys 1 through 7,

softkey 1 being the topmost softkey.

The STAN command is OPC-compatible. A command that calls a class is only

OPC-compatible if that class has only one standard in it. If there is more than one

standard in a class, the command that calls the class brings up another menu, and there is

no need to query it. DONE; must be sent to exit the class.

Example 2A: S11 1-Port Calibration

NOTE This program is stored as EXAMP2A on the “Programming Examples”

disk received with the network analyzer.

The following program performs an S

1-port calibration, using either the HP 85031B

11

7-mm calibration kit or the HP 85033D 3.5-mm calibration kit. If you wish to use a

different calibration kit, modify the example program accordingly. This program simplifies

the calibration by providing explicit directions on the analyzer display while allowing the

user to run the program from the controller keyboard. More information on selecting

calibration standards can be found in the Optimizing Measurement Results chapter of the

HP 8753E/Option 011 Network Analyzer User's Guide.

The following is an outline of the program's processing sequence:

• An I/O path is assigned for the analyzer.

• The system is initialized.

• The appropriate calibration kit is selected.

• The softkey menu is deactivated.

• The S

• The S

-calibration sequence is run.

11

-calibration data is saved.

11

• The softkey menu is activated.

• The analyzer is released from remote control and the program ends.

The program is written as follows:

1 ! This program guides the operator through a 1-port calibration.

2 ! The operator must choose either the HP 85031B 7 mm calibration kit

3 ! or the HP 85033D 3.5 mm calibration kit.

4 ! The routine Waitforkey displays a message on the instrument’s

5 ! display and the console, to prompt the operator to connect the

6 ! calibration standard. Once the standard is connected, the

7 ! ENTER key on the computer keyboard is pressed to continue.

8 !

9 ! EXAMP2A

10 !

11 ASSIGN @Nwa TO 716 ! Assign an I/O path for the analyzer

12 !

13 CLEAR SCREEN

14 ! Initialize the system

15 ABORT 7 ! Generate an IFC (Interface Clear)

16 CLEAR @Nwa ! SDC (Selected Device Clear)

17 ! Select CAL kit type

18 INPUT “Enter a 1 to use the HP 85031B kit, 2 to use the HP 85033D kit”,Kit

19 IF Kit=1 THEN

Chapter 1 29

Page 30

HP BASIC Programming Examples Guide

Example 2: Measurement Calibration

20 OUTPUT @Nwa;”CALK7MM;”

21 ELSE

22 OUTPUT @Nwa;”CALK35MD;”

23 END IF

24 !

25 OUTPUT @Nwa;”MENUOFF;” ! Turn softkey menu off.

26 !

27 OUTPUT @Nwa;”CALIS111;” ! S11 1 port CAL initiated

28 !

29 CALL Waitforkey(“CONNECT OPEN AT PORT 1”)

30 OUTPUT @Nwa;”OPC?;CLASS11A;” ! Open reflection CAL

31 ENTER @Nwa;Reply ! Read in the 1 returned

32 OUTPUT @Nwa;”DONE;” ! Finished with class standards

33 !

34 CALL Waitforkey(“CONNECT SHORT AT PORT 1”)

35 OUTPUT @Nwa;”OPC?;CLASS11B;” ! Short reflection CAL

36 ENTER @Nwa;Reply ! Read in the 1 returned

37 OUTPUT @Nwa;”DONE;” ! Finished with class standards

38 !

39 CALL Waitforkey(“CONNECT LOAD AT PORT 1”)

40 IF Kit=1 THEN ! Reflection load CAL

41 OUTPUT @Nwa;”OPC?;CLASS11C;”

42 ELSE

43 OUTPUT @Nwa;”CLASS11C;”

44 OUTPUT @Nwa;”OPC?;STANA;”

45 END IF

46 !

47 ENTER @Nwa;Reply ! Read in the 1 returned

48 !

49 OUTPUT 717;”PG;” ! Clear the analyzer display

50 !

51 DISP “COMPUTING CALIBRATION COEFFICIENTS”

52 !

53 OUTPUT @Nwa;”OPC?;SAV1;” ! Save the ONE PORT CAL

54 ENTER @Nwa;Reply ! Read in the 1 returned

55 !

56 DISP “S11 1-PORT CAL COMPLETED. CONNECT TEST DEVICE.”

57 OUTPUT @Nwa;”MENUON;” ! Turn on the softkey menu

58 !

59 OUTPUT @Nwa;”OPC?;WAIT;” ! Wait for the analyzer to finish

60 ENTER @Nwa;Reply ! Read the 1 when complete

61 LOCAL @Nwa ! Release HP-IB control

62 !

63 END

64 !

65 ! **************************** Subroutines ******************************

66 !

67 Waitforkey: ! Prompt routine to read a keypress on the controller

68 SUB Waitforkey(Lab$)

69 ! Position and display text on the analyzer display

70 OUTPUT 717;”PG;PU;PA390,3700;PD;LB”;Lab$;”, PRESS ENTER WHEN READY;”&CHR$(3)

71 !

72 DISP Lab$&” Press ENTER when ready”; ! Display prompt on console

73 INPUT A$ ! Read ENTER key press

74 !

75 OUTPUT 717;”PG;” ! Clear analyzer display

76 SUBEND

Running the Program

NOTE This program does not modify the instrument state in any way. Before

running the program, set up the desired instrument state.

The program assumes that the test ports have either a 7-mm or 3.5-mm interface or an

adapter set using either a 7-mm or 3.5-mm interface. The prompts appear just above the

message line on the analyzer display. Pressing

the program and measures the standard. The program will display a message when the

measurement calibration is complete.

30 Chapter 1

Enter on the controller keyboard continues

Page 31

HP BASIC Programming Examples Guide

Example 2: Measurement Calibration

Example 2B: Full 2-Port Measurement Calibration

NOTE This program is stored as EXAMP2B on the “Programming Examples”

disk received with the network analyzer.

The following example program performs a full 2-port measurement calibration using

either the HP 85031B 7-mm calibration kit or the HP 85033D 3.5-mm calibration kit. If

you wish to use a different calibration kit, modify the example program accordingly. A full

2-port calibration removes both the forward- and reverse-error terms so all four

S-parameters of the device under test can be measured. PORT 1 is a female test port and

PORT 2 is a male test port.

The following is an outline of the program's processing sequence:

• An I/O path is assigned for the analyzer.

• The system is initialized.

• The appropriate calibration kit is selected.

• The softkey menu is deactivated.

• The 2-port calibration sequence is run.

• The operator is prompted to choose or skip the isolation calibration.

• The softkey menu is activated.

• The analyzer is released from remote control and the program ends.

The program is written as follows:

1 ! This program guides the operator through a full 2-port calibration.

2 ! The operator must choose either the HP 85031B 7 mm calibration kit

3 ! or the HP 85033D 3.5 mm calibration kit.

4 ! The routine Waitforkey displays a message on the instrument’s

5 ! display and the console to prompt the operator to connect the

6 ! calibration standard. Once the standard is connected, the

7 ! ENTER key on the computer keyboard is pressed to continue.

8 !

9 ! EXAMP2B

10 !

11 ASSIGN @Nwa TO 716 ! Assign an I/O path to the analyzer

12 !

13 CLEAR SCREEN

14 ! Initialize the analyzer

15 ABORT 7 ! Generate an IFC (Interface Clear)

16 CLEAR @Nwa ! SDC (Selected Device Clear)

17 ! Select CAL kit type

18 INPUT “Enter a 1 to use the HP 85031B kit, 2 to use the HP 85033D kit”,Kit

19 IF Kit=1 THEN

20 OUTPUT @Nwa;”CALK7MM;”

21 ELSE

22 OUTPUT @Nwa;”CALK35MD;”

23 END IF

24 !

25 OUTPUT @Nwa;”MENUOFF;” ! Turn softkey menu off.

26 !

27 OUTPUT @Nwa;”CALIFUL2;” ! Full 2 port CAL

28 !

29 OUTPUT @Nwa;”REFL;” ! Reflection CAL

30 !

31 CALL Waitforkey(“CONNECT OPEN AT PORT 1”)

32 OUTPUT @Nwa;”OPC?;CLASS11A;” ! S11 open CAL

33 ENTER @Nwa;Reply ! Read in the 1 returned

34 OUTPUT @Nwa;”DONE;” ! Finished with class standards

Chapter 1 31

Page 32

HP BASIC Programming Examples Guide

Example 2: Measurement Calibration

35 !

36 CALL Waitforkey(“CONNECT SHORT AT PORT 1”)

37 OUTPUT @Nwa;”OPC?;CLASS11B;” ! S11 short CAL

38 ENTER @Nwa;Reply ! Read in the 1 returned

39 OUTPUT @Nwa;”DONE;” ! Finished with class standards

40 !

41 CALL Waitforkey(“CONNECT LOAD AT PORT 1”)

42 IF Kit=1 THEN ! S11 load CAL

43 OUTPUT @Nwa;”OPC?;CLASS11C;”

44 ELSE

45 OUTPUT @Nwa;”CLASS11C;”

46 OUTPUT @Nwa;”OPC?;STANA;”

47 END IF

48 !

49 ENTER @Nwa;Reply ! Read in the 1 returned

50 !

51 CALL Waitforkey(“CONNECT OPEN AT PORT 2”)

52 OUTPUT @Nwa;”OPC?;CLASS22A;” ! S22 open CAL

53 ENTER @Nwa;Reply ! Read in the 1 returned

54 OUTPUT @Nwa;”DONE;” ! Finished with class standards

55 !

56 CALL Waitforkey(“CONNECT SHORT AT PORT 2”)

57 OUTPUT @Nwa;”OPC?;CLASS22B;” ! S22 short CAL

58 ENTER @Nwa;Reply ! Read in the 1 returned

59 OUTPUT @Nwa;”DONE;” ! Finished with class standards

60 !

61 CALL Waitforkey(“CONNECT LOAD AT PORT 2”)

62 IF Kit=1 THEN ! S22 load CAL

63 OUTPUT @Nwa;”OPC?;CLASS22C;”

64 ELSE

65 OUTPUT @Nwa;”CLASS22C;”

66 OUTPUT @Nwa;”OPC?;STANA;”

67 END IF

68 !

69 ENTER @Nwa;Reply

70 !

71 DISP “COMPUTING REFLECTION CALIBRATION COEFFICIENTS”

72 !

73 OUTPUT @Nwa;”REFD;” ! Reflection portion complete

74 !

75 OUTPUT @Nwa;”TRAN;” ! Transmission portion begins

76 !

77 CALL Waitforkey(“CONNECT THRU [PORT1 TO PORT 2]”)

78 DISP “MEASURING FORWARD TRANSMISSION”

79 OUTPUT @Nwa;”OPC?;FWDT;” ! Measure forward transmission

80 ENTER @Nwa;Reply ! Read in the 1 returned

81 !

82 OUTPUT @Nwa;”OPC?;FWDM;” ! Measure forward load match

83 ENTER @Nwa;Reply ! Read in the 1 returned

84 !

85 DISP “MEASURING REVERSE TRANSMISSION”

86 OUTPUT @Nwa;”OPC?;REVT;” ! Measure reverse transmission

87 ENTER @Nwa;Reply ! Read in the 1 returned

88 !

89 OUTPUT @Nwa;”OPC?;REVM;” ! Measure reverse load match

90 ENTER @Nwa;Reply ! Read in the 1 returned

91 !

92 OUTPUT @Nwa;”TRAD;” ! Transmission CAL complete

93 !

94 INPUT “SKIP ISOLATION CAL? Y OR N.”,An$

95 IF An$=”Y” THEN

96 OUTPUT @Nwa;”OMII;” ! Skip isolation cal

97 GOTO 114

98 END IF

99 !

100 CALL Waitforkey(“ISOLATE TEST PORTS”)

101 !

102 OUTPUT @Nwa;”ISOL;” ! Isolation CAL

103 OUTPUT @Nwa;”AVERFACT10;” ! Average for 10 sweeps

104 OUTPUT @Nwa;”AVEROON;” ! Turn on averaging

105 DISP “MEASURING REVERSE ISOLATION”

106 OUTPUT @Nwa;”OPC?;REVI;” ! Measure reverse isolation

107 ENTER @Nwa;Reply ! Read in the 1 returned

108 !

109 DISP “MEASURING FORWARD ISOLATION”

32 Chapter 1

Page 33

HP BASIC Programming Examples Guide

Example 2: Measurement Calibration

110 OUTPUT @Nwa;”OPC?;FWDI;” ! Measure forward isolation

111 ENTER @Nwa;Reply ! Read in the 1 returned

112 !

113 OUTPUT @Nwa;”ISOD;AVEROOFF;” ! Isolation complete averaging off

114 OUTPUT 717;”PG;” ! Clear analyzer display prompt

115 !

116 DISP “COMPUTING CALIBRATION COEFFICIENTS”

117 OUTPUT @Nwa;”OPC?;SAV2;” ! Save THE TWO PORT CAL

118 ENTER @Nwa;Reply ! Read in the 1 returned

119 !

120 DISP “DONE WITH FULL 2-PORT CAL. CONNECT TEST DEVICE.”

121 OUTPUT @Nwa;”MENUON;” ! Turn softkey menu on

122 !

123 OUTPUT @Nwa;”OPC?;WAIT;” ! Wait for the analyzer to finish

124 ENTER @Nwa;Reply ! Read the 1 when complete

125 LOCAL @Nwa ! Release HP-IB control

126 !

127 END

128 !

129 ! ************************* Subroutines *******************************

130 !

131 SUB Waitforkey(Lab$)

132 ! Position and display prompt on the analyzer display

133 OUTPUT 717;”PG;PU;PA390,3700;PD;LB”;Lab$;”, PRESS ENTER WHEN READY;”&CHR$(3)

134 !

135 DISP Lab$&” Press ENTER when ready”; ! Display prompt on console

136 INPUT A$ ! Read ENTER keypress on controller

137 OUTPUT 717;”PG;” ! Clear analyzer display

138 SUBEND

Running the Program

NOTE Before running the program, set the desired instrument state. This

program does not modify the instrument state in any way.

Run the program and connect the standards as prompted. After the standard is connected,

press

Enter on the controller keyboard to continue the program.

The program assumes that the test ports have either a 7-mm or 3.5-mm interface or an

adapter set using either a 7-mm or 3.5-mm interface. The prompts appear just above the

message line on the analyzer display. After the prompt is displayed, pressing

Enter on the

computer console continues the program and measures the standard. The operator has the

option of omitting the isolation calibration. If the isolation calibration is performed,

averaging is automatically employed to insure a good calibration. The program will display

a message when the measurement calibration is complete.

Example 2C: Adapter Removal Calibration

NOTE This program is stored as EXAMP2C on the “Programming Examples”

disk received with the network analyzer.

This program shows how to accurately measure a “non-insertable” 2-port device. A device

is termed “non-insertable” if its connectors do not match those of the analyzer front panel.

More information on the adapter removal technique can be found in the “Optimizing

Measurement Results” chapter of the HP 8753E Network Analyzer User's Guide.

The following is an outline of the program's processing sequence:

• An I/O path is assigned for the analyzer.

• The system is initialized.

Chapter 1 33

Page 34

HP BASIC Programming Examples Guide

Example 2: Measurement Calibration

• The internal disk is selected as the active storage device.

• The system operator is prompted for the name of the instrument state file which has a

2-port calibration performed for Port 1's connector.

• The calibration arrays for Port 1 are recalled from the corresponding disk file.

• The system operator is prompted for the known electrical delay value of the adapter.

• The new calibration coefficients, with the effects of the adapter removed, are computed

by the analyzer using the adapter delay in conjunction with the calibration arrays for

both ports.

• The analyzer is released from remote control and the program ends.

CAUTION Do not mistake the line switch for the disk eject button. If the line

switch is mistakenly pushed, the instrument will be turned off, losing

all settings and data that have not been saved.

The program is written as follows:

1 ! This program demonstrates how to do adapter removal over HP-IB.

2 !

3 ! EXAMP2C

4 !

5 REAL Delay ! Adapter electrical delay in picoseconds

6 !

7 ASSIGN @Nwa TO 716 ! Assign an I/O path for the analyzer

8 CLEAR SCREEN

9 ! Initialize the system

10 ABORT 7 ! Generate an IFC (Interface Clear)

11 CLEAR @Nwa ! SDC (Selected Device Clear) analyzer

12 OUTPUT @Nwa;”OPC?;PRES;” ! Preset the analyzer and wait

13 ENTER @Nwa;Reply ! Read in the 1 returned

14 !

15 ! Select internal disk.

16 !

17 OUTPUT @Nwa;”INTD;”

18 !

19 ! Assign file #1 to the filename that has a 2-port

20 ! cal previously performed for Port 1’s connector.

21 !

22 PRINT “Enter the name of the instrument state file which”

23 PRINT “has a 2-port cal performed for Port 1’s connector”

24 INPUT ““,F1$

25 OUTPUT @Nwa;”TITF1”””;F1$;”””;”

26 !

27 ! Recall the cal set for Port 1.

28 !

29 DISP “Loading cal arrays, please wait”

30 OUTPUT @Nwa;”CALSPORT1;”

31 OUTPUT @Nwa;”OPC?;NOOP;”

32 ENTER @Nwa;Reply

33 !

34 ! Assign file #2 to the filename that has a 2-port

35 ! cal previously performed for Port 2’s connector.

36 !

37 CLEAR SCREEN

38 PRINT “Enter the name of the instrument state file which”

39 PRINT “has a 2-port cal performed for Port 2’s connector”

40 INPUT ““,F2$

41 OUTPUT @Nwa;”INTD;TITF2”””;F2$;”””;”

42 !

43 ! Recall the cal set for Port 2.

44 !

45 DISP “Loading cal arrays, please wait”

46 OUTPUT @Nwa;”CALSPORT2;”

47 OUTPUT @Nwa;”OPC?;NOOP;”

34 Chapter 1

Page 35

HP BASIC Programming Examples Guide

Example 2: Measurement Calibration

48 ENTER @Nwa;Reply

49 !

50 ! Set the adapter electrical delay.

51 !

52 INPUT “Enter the electrical delay for the adapter in picoseconds”, Delay

53 OUTPUT @Nwa;”ADAP1”&VAL$(Delay)&”PS;”

54 !

55 ! Perform the “remove adapter” computation.

56 !

57 DISP “Computing cal coefficients...”

58 OUTPUT @Nwa;”MODS;”

59 OUTPUT @Nwa;”OPC?;WAIT;”

60 ENTER @Nwa;Reply

61 LOCAL 7 ! Release HP-IB control

62 DISP “Program completed”

63 END

Running the Program

The analyzer is initialized and the internal disk drive is selected. The operator is queried

for the name of the instrument state file having a 2-port calibration performed for Port 1's

connector. The calibration arrays for Port 1 are recalled from the corresponding disk file.

The system operator is prompted for the name of the instrument state file having a 2-port

calibration performed for Port 2's connector. The calibration arrays for Port 2 are recalled

from the corresponding disk file. The system operator is prompted for the known electrical

delay of the adapter and this value is written to the analyzer. The calibration coefficients

with adapter effects removed are computed and the program ends.

Example 2D: Using Raw Data to Create a Calibration (Simmcal)

NOTE This program is stored as EXAMP2D on the “Programming Examples”

disk received with the network analyzer.

This program simulates a full 2-port cal by measuring the raw data for each “standard”

and then loading it later into the appropriate arrays. The program can be adapted to

create additional calibrations using the same arrays. It uses the HP85031B 7-mm cal kit.

CAUTION This feature is not currently supported with TRL calibrations.

The following is an outline of the programs' processing sequence:

• An I/O path is assigned for the analyzer.

• The system is initiated.

• The number of points is set to correspond to the size of the dimensioned memory arrays

and ASCII data format is selected.

• The 7-mm calibration kit is selected, sweep time is set to 1 second, and the analyzer is

placed into hold mode.

• S11 measurement is selected for gathering the forward reflection standards.

• The system operator is prompted to connect each of the three standards, one at a time.

• Following each prompt, a single sweep is taken and the raw measured data for that

standard is read from the analyzer into a corresponding memory array in the controller.

• S22 measurement is selected for gathering the reverse reflection standards.

Chapter 1 35

Page 36

HP BASIC Programming Examples Guide

Example 2: Measurement Calibration

• The system operator is prompted in the same manner as before and the raw data for the

three standards is measured and stored away as before.

• The system operator is prompted to make the thru connection between Port 1 and Port

2.

• S21 measurement is selected, a single sweep is taken and the raw data is read into an

array corresponding to forward transmission.

• S11 measurement is selected, a single sweep is taken and the raw data is read into an

array corresponding to forward thru match.

• S12 measurement is selected, a single sweep is taken and the raw data is read into an

array corresponding to reverse transmission.

• S22 measurement is selected, a single sweep is taken and the raw data is read into an

array corresponding to reverse thru match.

• The analyzer begins the normal 2-port calibration procedure, but with the default beep

turned off.

• A single sweep is taken for the measurement of each standard to provide “dummy”

data, which is immediately replaced with the previously measured raw data from the