Installation Guide

Rack Mount Kits

For rack mounting HP 86120A/B/C instuments.

HP Part No. 5962-5907

Printed in USA

February 1996

First Edition

© Copyright Hewlett-Packard Company 1996

All Rights Reserved. Reproduction, adaptation, or translation without prior

written permission is prohibited, except as allowed under copyright laws.

Hewlett-Packard Company

Lightwave Operations

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799, USA

(707) 577-1400

Notice.

The information contained in this document is subject to

change without notice. Companies, names, and data used in examples

herein are fictitious unless otherwise noted. Hewlett-Packard makes no

warranty of any kind with regard to this material, including but not limited to, the implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for errors

contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material.

Restricted Rights Legend.

Use, duplication, or disclosure by the U.S.

Government is subject to restrictions as set forth in subparagraph (c)

(1) (ii) of the Rights in Technical Data and Computer Software clause

at DFARS 252.227-7013 for DOD agencies, and subparagraphs (c) (1)

and (c) (2) of the Commercial Computer Software Restricted Rights

clause at FAR 52.227-19 for other agencies.

2

Safety Symbols

The following safety symbols are used throughout this manual. Familiarize yourself with each of the symbols and its meaning before operating this instrument.

CAUTION The caution sign denotes a hazard to the instrument. It calls attention to a

procedure which, if not correctly performed or adhered to, could result in

damage to or destruction of the instrument. Do not proceed beyond a caution

sign until the indicated conditions are fully understood and met.

WARNING The warning sign denotes a life-threatening hazard. It calls attention

to a procedure which, if not correctly performed or adhered to, could

result in injury or loss of life. Do not proceed beyond a warning sign

until the indicated conditions are fully understood and met.

3

Introduction

Introduction

The installation instructions in this book apply to the following kits:

• Rack-mount kit, 86120-60030

• Rack-mount kit with handles, 86120-60031

• Rack-slide kit, 1494-0059

These kits mount 4.5-inch instruments into a rack with 482.6 mm (19 inch)

spacing. For a list of parts contained in the kits, refer to “Replacement Parts”

on page 17.

CAUTION When installing the rack-mount kits, the instrument’s cover must be

temporarily removed. Because this exposes the internal circuits to

electrostatic disharge, perform the procedure at a static-safe workstation.

Refer to “Electrostatic Discharge Information” on page 19.

5HTXLUHG#7RROV The following tools are needed to assemble the rack- mount kits. If a 7 mm nut

driver is unavailable, the needlenose pliers may be substituted.

#1 pozidrive screwdriver

#2 pozidrive screwdriver

4 mm hex key (included with kit)

7 mm nut driver (preferred) or needlenose pliers

5.5 mm nut driver (preferred) or needlenose pliers

T-6 TORX driver

T-10 TORX driver, right angle (included with kit)

T-15 TORX driver

For any assistance, contact your nearest Hewlett-Packard Sales and Service

Office. Refer to “Hewlett-Packard Sales and Service Offices” on page 21.

4

,QWURGXFWLRQ

&RQWHQWV

To rack mount the instrument 6

To install the rack-slide kit 15

Replacement Parts 17

Electrostatic Discharge Information 19

Hewlett-Packard Sales and Service Offices 21

5

To rack mount the instrument

To rack mount the instrument

Please observe the following. Circled numbers in this procedure refer

to items shown in figures. HP part numbers are listed in parenthesis.

You will find these part numbers listed on the bags that contain the

parts.

WARNING The opening of covers or removal of parts is likely to expose

dangerous voltages. Disconnect the instrument from all voltage

sources while it is being opened.

1. Disconnect the power cord from the instrument.

2. Place the instrument face down as illustrated in

Figure 1

.

3. Remove the eight screws (four per side) securing the front bumpers

➁

to the instrument.

4. Remove the two screws securing the handle, and remove the handle.

5. Use a 4 mm hex key (8710-1755) to loosen the four screws ➂ in the

rear feet to disengage the cover assembly ➀ from the instrument.

CAUTION Beneath the cover, located in the vicinity of the handle attachment screws, are

two finger springs that reduce electro-magnetic interference (EMI). These

springs can be damaged. To avoid damage, perform the following steps

carefully to remove the cover.

6. Located the side of the instrument opposite to where the handles

were attached. While applying pressure to this side, simultaneously

pull on the instrument foot that is located on the side where the

handle was attached.

This action relieves strain on the springs while removing the

cover.

6

7R#UDFN#PRXQW#WKH#LQVWUXPHQW

.

Figure 1. Preparing the cover assembly

7. Slide the instrument cover assembly toward the rear of the

instrument, and remove the cover from the instrument.

8. Remove the two screws ➃ that attach the rear feet to the cover

assembly, and remove the feet. These screws are located inside the

cover.

9. Remove the six screws that secure the two bottom tilt-stand feet,

and remove the feet. The screws are located inside the cover. Use

the T-10 right-angle TORX key included with the kit.

CAUTION Be careful to protect the instrument’s cable assemblies and components from

damage when you replace the cover assembly. Use key caution to avoid

damaging the EMI springs. If you damage an EMI spring, you can order a new

one using HP part number 8160-0656.

10.Slide the cover assembly back onto the instrument chassis while

applying pressure to the side of the cover that is opposite the handle

7

To rack mount the instrument

attachment points.

Gentle pressure ensures that the cover will not bind against the

EMI springs. Make sure that the seam in the cover is located on

the bottom of the instrument.

CAUTION Make sure that the instrument’s cover properly engages the gasket in the

instrument’s front frame.

11.Onto each of the four socket-head cap screws (0515-0049), place a

split-lock washer (2190-0587) and a flat washer (3050-0894).

12.Use these screws to temporarily attach the instrument’s cover.

13.Locate the rack-mount kit’s rear support ➁ (5002-0634) and rear

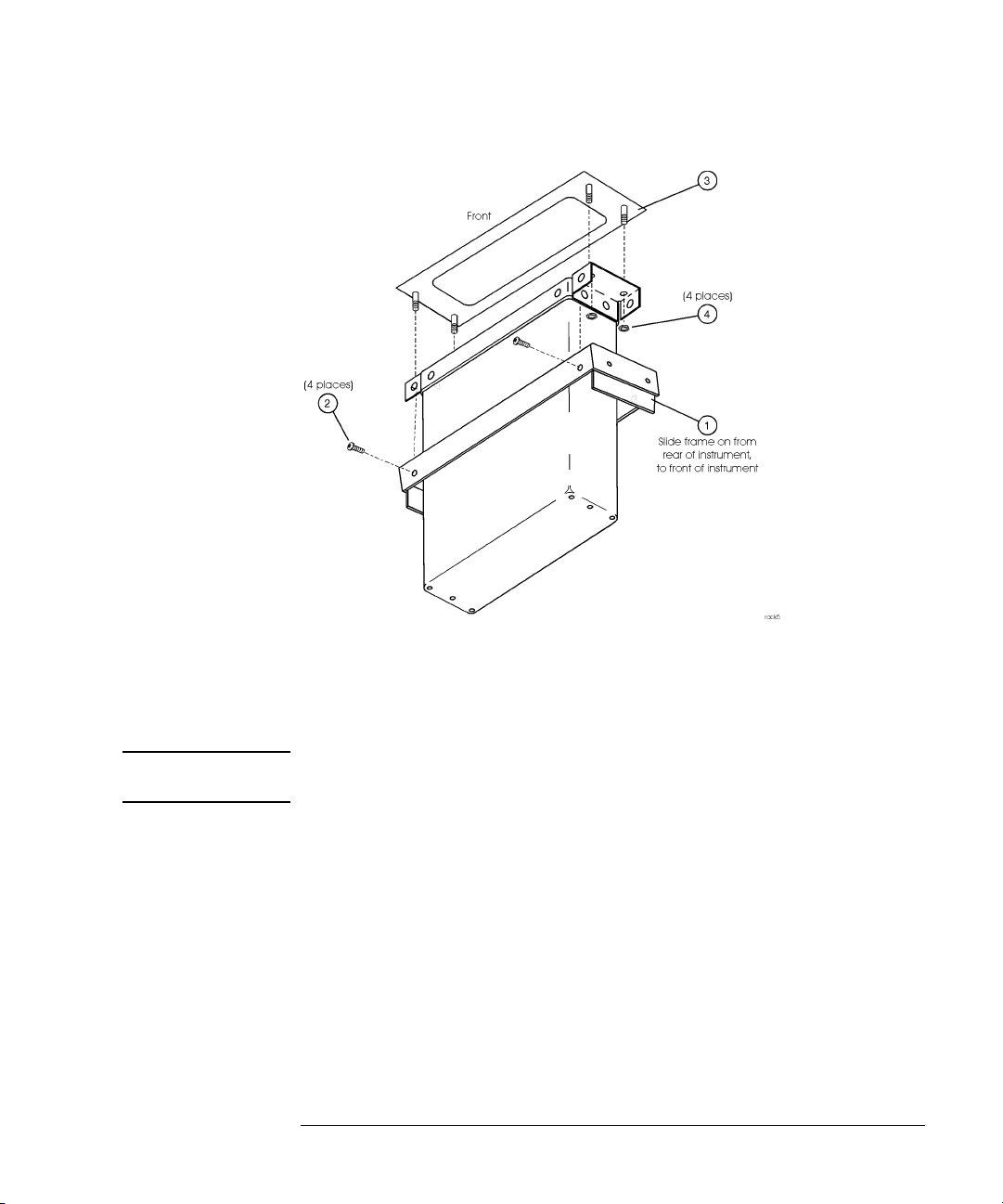

frame ➀ (5021-5804) as illustrated in Figure 2.

The text “METRIC” on the frame and the two adjacent holes

illustrated in the figure identify the top sides. This orientation

ensures that the top of the frame and the top of the rear support

are joined correctly.

Figure 2. Assembling the rack’s rear frame

14.Position the rear support’s studs into the corresponding top row of

holes in the rear frame.

15.Slightly squeeze the rear support until the bottom row of studs clears

8

7R#UDFN#PRXQW#WKH#LQVWUXPHQW

the rear frame and insert into the bottom row of holes. Fasten with

eight nuts ➂ (0535-0031). Alternately tighten each nut to the

recommended torque of 6 inch-pounds.

16.Attach the four side struts (5021-5837) to the rack’s rear frame using

eight screws ➀ (0515-1331). See Figure 3.

Figure 3. Attaching the side struts

17.Connect the two front mounting brackets ➀ (5002-0633) to the

instrument’s front frame using four pan-head screws ➂ (0515-1079).

See Figure 4. Tighten each screw to a torque of 6 inch-pounds.

18.Locate the kit’s front frame (5021-8403). Look into the frame as if

you were looking into the front of an instrument. Find the two vent

holes which are about half an inch long and a quarter of an inch high.

When the frame is installed, these holes must be oriented along the

bottom of the instrument.

9

To rack mount the instrument

Figure 4. Attaching the mounting brackets

19.Slide the kit’s front frame ➀ over the rear of the instrument until it is

over the instrument’s front frame. See Figure 5.

20.Attach the frame to the front brackets using four flat-head screws ➁

(0515-1234).

21.Place the dress panel ➂ (5002-0640) over the instrument’s front

panel. Secure with four nuts ➃ (0535-0082) tightened to a torque of

6 inch-pounds.

do not

If you

have a 7 mm nut driver, use the spring clips rather

than the six nuts. Apply the spring clips to the dress panel studs

using needlenose pliers.

CAUTION Do not overtorque the nuts.

10

7R#UDFN#PRXQW#WKH#LQVWUXPHQW

Figure 5. Attaching the front

22.Place the instrument on its front frame.

CAUTION Avoid damaging the instrument’s front panel and input connector by placing it

onto a surface protected by cloth.

23.Remove the four socket-head cap screws that secure the

instrument’s cover. Do not remove the cover. You attached these

screws in step 12.

24.Place the rack-mount kit frame onto the instrument as shown in

Figure 6.

11

To rack mount the instrument

Figure 6. Attaching the rack frame

25.Secure the four side struts to the front frame using eight screws ➀

(0515-1331). Torque the screws to 12 inch-pounds.

26.Use the four socket-head cap screws ➀ removed in step 23 to secure

the instrument’s cover as shown in Figure 7.

12

7R#UDFN#PRXQW#WKH#LQVWUXPHQW

Figure 7. Securing the frame

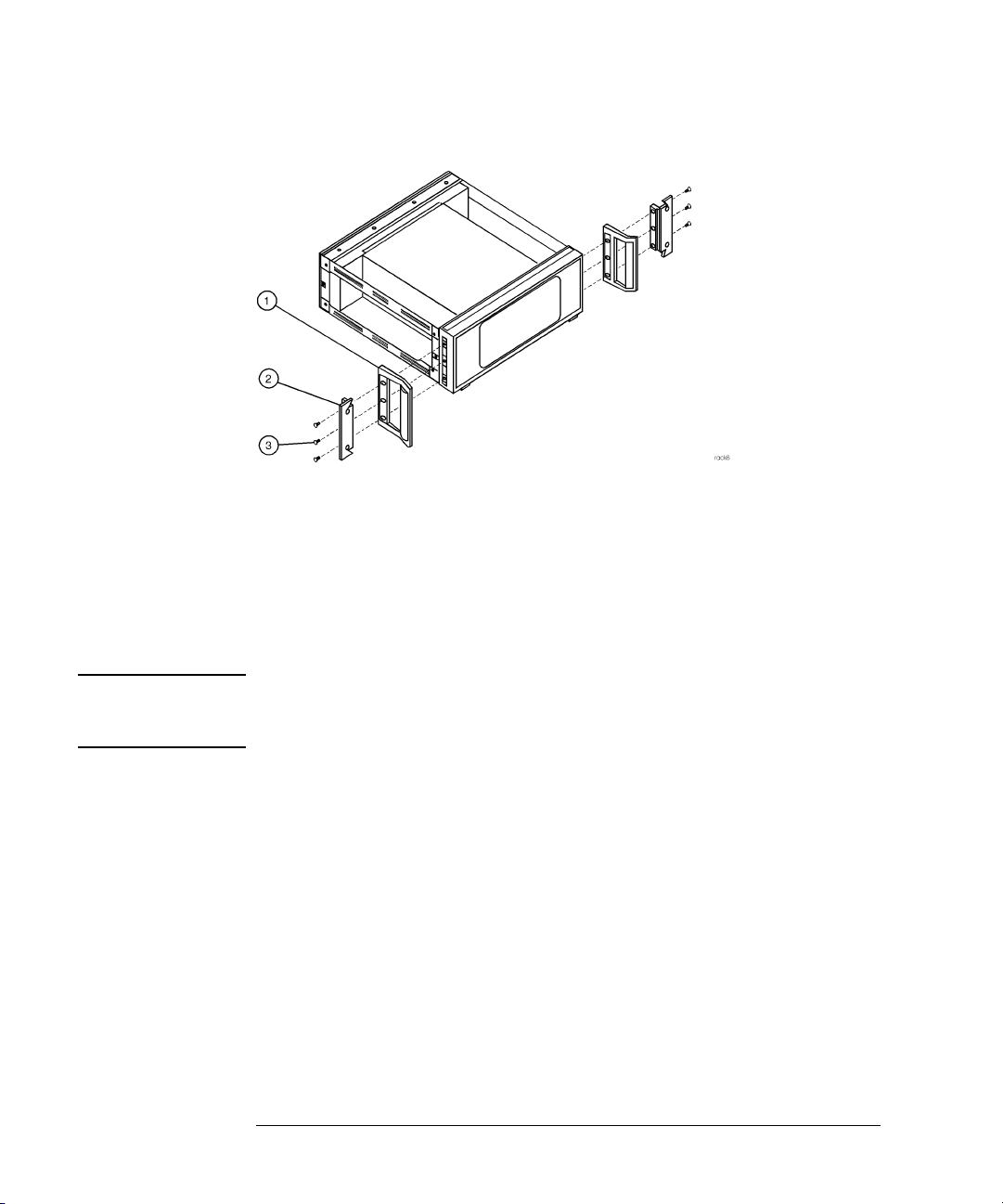

27.Place the instrument in its operating position. See Figure 8.

28.If you are installing the rack-mount kit with handles (5062-3983),

mount the handles ➀ and rack flanges ➁ to the rack frame using six

pan-head screws ➂. Tighten each screw to a torque of 12 inchpounds.

13

To rack mount the instrument

Figure 8. Attaching the flanges and handles

29.If your installing the rack-mount kit without handles (5062-3977),

mount rack flanges ➁ directly to the rack frame using six pan-head

screws ➂. Tighten each screw to a torque of 12 inch-pounds.

30.The instrument is now ready to mount into the system rack.

WARNING If an instrument handle is damaged, it should be replaced immediately.

Damaged handles can break while the instrument is being moved or

lifted. This may cause damage to the instrument or personal injury.

14

7R #LQVWDOO#WKH#UDFN0VOLGH#NLW

To install the rack-slide kit

1. Install the rack-mount kit as described in “To rack mount the

instrument” on page 6.

2. Expand each rack slide to its full length.

Note that Figure 9 does not show the rack slide extended to its

full length.

Figure 9. Installing rack slides

3. Separate the inner slide member ➀ from the outer slide member ➁

by pressing the release button located on the inner slide member.

15

To install the rack-slide kit

4. Pull the inner slide member out of the assembly.

5. Attach an inner slide member to each side of the rack-mount frame

using four (two per side) M5 X 0.8 X 14 mm pan-head screws ➂.

6. Insert two unistrut nuts ➃ in each of the four vertical columns of the

systems rack.

7. Compress each outer-slide member to its shortest length, revealing

the holes ➄ for screws ➅. If necessary, press the release button ➆.

8. Attach an outer slide member to each side of the systems rack, using

two M4 X 0.7 X 12 mm flat-head screws ➅ in the front and two M4 X

0.7 X 12 mm pan-head screws ➇ in the rear.

9. Place the instrument into the rack by sliding the inner slide members

into the outer slide members. Use the release buttons, located on the

slides, to enable complete compression of the slides.

10.To prevent the rack slides from accidentally opening, use screws to

secure the rack frame to the system cabinet.

16

Replacement Parts

Table 1. Rack-Mount Kits (86120-60030 and 86120-60031)

5HSODFHPHQW#3DUWV

HP Part

Number

5062-3983 1 Front-handle kit (with handles). Supplied with 86120-60031

5062-3977 1 Front-handle kit (without handles). Supplied with 86120-

8710-1755 1 Hex Key, 4mm

8710-1657 1 T10 right-angle TORX key

5002-0640 1 Dress Panel

5021-8403 1 Front Frame

5002-0633 2 Front Bracket

5002-0634 1 Rear Support

5021-5804 1 Rear Frame

5021-5837 4 Side Strut

0535-0031 8 Nut M3 X 0.5mm

0535-0082 4 Nut M4 X 0.7mm

2190-0587 4 Lock Washer M5.0 ID

Qty Description

kit.

60030 kit.

3050-0894 4 Flat Washer M5.0 ID

0510-1148 6 Push-On Retainer Clips

0515-0049 4 Screw, Socket-Head M5 X 0.8 X 12 mm-LG

0515-1079 4 Screw, Mach M3 X 0.5 8 mm-LG PAN-HD

0515-1234 4 Screw, Mach M3.5 X 8 mm-LG FLAT-HD

0515-1331 16 Screw, Mach M4 X 0.7 6 mm-LG FLT-HD

17

Replacement Parts

Table 2. Rack Slide Kit (HP part number 1494-0059)

HP Part

Number

— 2 Slides (not sold separately)

0515-0949 4 Screw, Mach M5 X 0.8 14 mm-LG PAN-HD

0515-1013 4 Screw, Mach M5 X 0.7 12 mm-LG FLAT-HD

0515-0909 4 Screw, Mach M4 X 0.7 12 mm-LG PAN-HD

0535-0080 8 Unistrut Nut M4 X 0.7

Qty Description

18

(OHFWURVWDWLF#'LVFKDUJH#,QIRUPDWLRQ

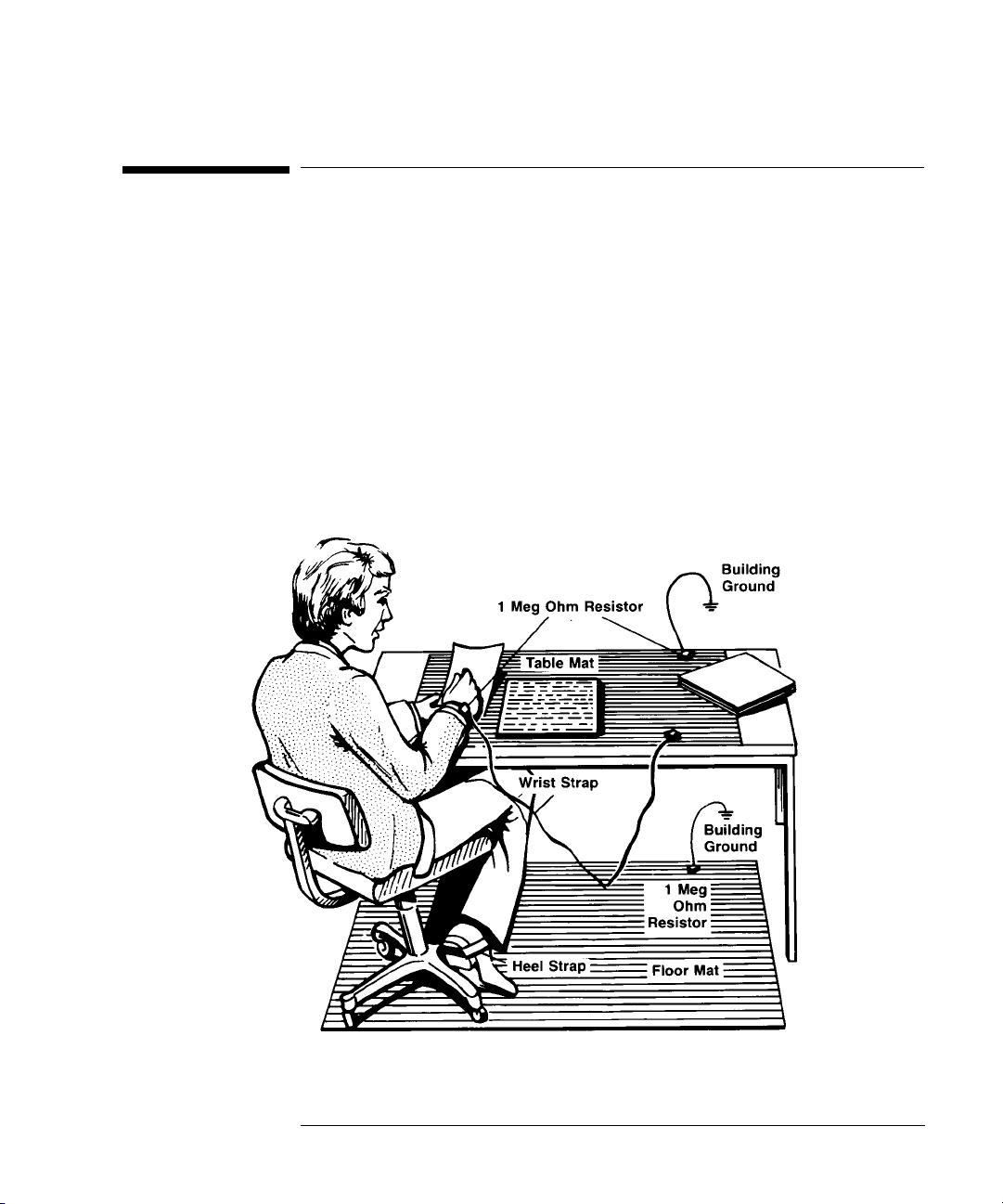

Electrostatic Discharge Information

Electrostatic di schar ge (ESD) can dama ge or des troy electro nic compone nts.

All work on electroni c ass embl ie s shou ld be performed at a static-safe work

station. The following figure sh ows an example of a static-safe wo rk station

using two types of ESD protection:

• Conductive table-mat and wrist-strap combination.

• Conductive floor-mat and heel-strap combination.

19

Electrostatic Discharge Information

Both types, when used together, provide a significant level of ESD

protection . Of the two, onl y the table-mat and wrist- strap combi nation

provides adequate ESD protection when used alone.

To ensure user safety, the static-safe accessories must provide at least 1 MΩ

of isolation from ground. Refer to Table 3 on page 20 for information on

ordering static-safe accessories.

WARNING These techniques for a static-safe work station should not be used

when working on circuitry with a voltage potential greater than 500

volts.

The following suggestions may help reduce ES D damage t hat occ urs duri ng

testing and servicing operations.

• Personnel should be grounded with a resistor-isolated wrist strap before removing any assembly from the unit.

• Be sure all instruments are properly earth-grounded to prevent a

buildup of static charge.

Table 3 on page 20 lists static-safe accessories that can be obtained from

Hewlett-Packard using the HP part numbers shown.

Table 3. Static-Safe Accessories

HP Part

Number

9300-0797

9300-0980 Wrist-strap cord 1.5 m (5 ft)

9300-1383 Wrist-strap, color black, stainless steel, withoutcord, has four adjustable

9300-1169 ESD heel-strap (reusable 6 to 12 months).

20

Set includes: 3M static control mat 0.6 m

ft) ground wire. (The wrist-strap andwrist-strap cord are not included. They

must be ordered separately.)

links and a 7 mm post-type connection.

Description

×

1.2 m (2 ft× 4 ft) and 4.6 cm (15

U.S. FIELD OPERATIONS

+HZOHWW03DFNDUG#6DOHV#DQG#6HUYLFH#2IILFHV

Hewlett-Packard Sales and Service Offices

Hewlett-Packard Sales and Service Offices (1 of 2)

Headquarters

Hewlett-Packard Company

19320 Pruneridge Avenue

Cupertino, CA 95014 U.S.A.

(800) 752-0900

Colorado

Hewlett-Packard Company

24 Inverness Place, East

Englewood, CO 80112

(303) 649-5000

New Jersey

Hewlett-Packard Company

120 West Century Road

Paramus, NJ 07653

(201) 586-5400

EUROPEAN FIELD OPERATIONS

Headquarters

Hewlett-Packard S.A.

150, Route du Nant-d’Avril

1217 Meyrin 2/Geneva Switzerland

(41 22) 780.8111

Great Britain

Hewlett-Packard Ltd.

Eskdale Road, Winnersh Triangle

Wokingham, Berkshire RG11 5DZ

California, Northern

Hewlett-Packard Company

301 East Evelyn

Mountain View, CA 94041

(415) 694-2000

Georgia

Hewlett-Packard Company

2000 South Park Place

Atlanta, GA 30339

(404) 955-1500

Texas

Hewlett-Packard Company

930 East Campbell Road

Richardson, TX 75081

(214) 231-6101

France

Hewlett-Packard France

1 Avenue Du Canada

Zone D’Activite De Courtaboeuf

F-91947 Les Ulis Cedex France

(33 1) 69 82 60 60

California, Southern

Hewlett-Packard Company

1421 South Manhatten Ave.

Fullerton, CA 92631

(714) 999-6700

Illinois

Hewlett-Packard Company

5201 Tollview Drive

Rolling Meadows, IL 60008

(708) 342-2000

Germany

Hewlett-Packard GmbH

Hewlett-Packard Strasse

61352 Bad Homburg Germany

(+49 6172) 16-0

21

Hewlett-Packard Sales and Service Offices

Hewlett-Packard Sales and Service Offices (2 of 2)

INTERCON FIELD OPERATIONS

Headquarters

Hewlett-Packard Company

3495 Deer Creek Rd.

Palo Alto, California 94304-1316

(415) 857-5027

China

China Hewlett-Packard Company

38 Bei San Huan X1 Road

Shuang Yu Shu

Hai Dian District

Beijing, China

(86 1) 256-6888

Taiwan

Hewlett-Packard Taiwan

8th Floor, H-P Building

337 Fu Hsing North Road

Taipei, Taiwan

(886 2) 712-0404

Australia

Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

(61 3) 895-2895

Japan

Yokogawa-Hewlett-Packard Ltd.

1-27-15 Yabe, Sagamihara

Kanagawa 229, Japan

(81 427) 59-1311

Canada

Hewlett-Packard Ltd.

17500 South Service Road

Trans-Canada Highway

Kirkland, Quebec H9J 2X8

Canada

(514) 697-4232

Singapore

Hewlett-Packard Singapore Ltd.

Pte. Ltd.

Alexandra P.O. Box 87

Singapore 9115

(65) 271-9444

22

Loading...

Loading...