User’s Guide

Agilent 86030A Lightwave Component

Analyzer System

© Copyright Agilent

Technologies, Inc. 2000, 2002

All Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibit ed ,

except as allowed under copyright laws.

Agilent Technologies Part No.

86030-90023

Printed in USA

March 2002

Agilent Technologies, Inc.

Lightwave Division

3910 Brickway Boulevard

Santa Rosa, CA 95403, USA

Notice.

The information contained in

this document is subject to

change without notice. Companies, names, and data used

in examples herein are fictitious unless otherwise noted.

Agilent Technologies makes

no warranty of any kind with

regard to this material, including but not limited to, the

implied warranties of merchantability and fitness for a

particular purpose. Agilent

Technologies shall not be liable for errors contained herein

or for incidental or consequential damages in connection with the furnishing,

performance, or use of this

material.

Restricte d Ri ghts Legend.

Use, duplication, or disclosure by the U.S. Government

is subject to res tric tion s as se t

forth in subparagraph (c) (1)

(ii) of the Rights in Technical

Data and Computer Software

clause at DFARS 2 52.227-7013

for DOD agencies, and subparagraphs (c) (1) and (c) (2)

of the Commercial Computer

Software Restricted Rights

clause at FAR 52.227-19 for

other agencies.

Warranty.

This Agilent Technologies

instrument product is warranted against defects in

material and workmanship for

a period of one year from date

of shipment. During the warranty period, Agilent Technologies Company will, at its

option, either repair or

replace products which prove

to be defective. For warranty

service or repair, this product

must be returned to a service

facility designated by Agilent

Technologies. Buyer shall prepay shipping charges to Agilent Technologies and Agilent

Technologies shall pay shipping charges to return the

product to Buyer. However,

Buyer shall pay all shipping

charges, duties, and taxes for

products returned to Agilent

Technologies from another

country.

Agilent Technologies warrants that its software and

firmware designated by Agilent Technologies for use with

an instrument will execute its

programming instructions

when properly installed on

that instrument. Agilent Technologies does not warrant that

the operation of the instrument, or software, or firmware

will be uninterrupted or errorfree.

Limitation of Warranty.

The foregoing warranty shall

not apply to defects resulting

from improper or inadequate

maintenance by Buyer, Buyersupplied software or interfacing, unauthorized modification or misuse, ope ra tio n

outside of the environmental

specifications for the product,

or improper site preparation

or maintenance.

No other warranty is

expressed or implied. Agilent

Technologies specifically disclaims the implied warranties

of merchantability and fitness

for a particular purpose.

Exclusive Remedies.

The remedies provided herein

are buyer's sole and exclusive

remedies. Agilent Technologies shall not be liable for any

direct, indirect, special, incidental, or consequential damages, whether based on

contract, tort, or any other

legal theory.

Safety Symbols.

CAUTION

The caution sign denotes a

hazard. It calls attenti on to a

procedure which, if not correctly performed or adhered

to, could result in damage to

or destruction of the product.

Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

WARNING

The warning sign denotes a

hazard. It calls attenti on to a

procedure which, if not correctly performed or adhered

to, could result in injury or

loss of life. Do not proceed

beyond a warning sign until

the indicated conditions are

fully understood and met.

The instruction manual symbol. The product is marked wit h this

warning symbol when

it is necessary for the

user to refer to the

instructions in the

manual.

The laser radiation

symbol. This warning

symbol is marked on

products which have a

laser output.

The AC symbol is used

to indicate the

required nature of the

line module input

power.

| The ON symbols are

used to mark the positions of the instrum ent

power line switch.

❍ The OFF symbols

are used to mark the

positions of the instrument power line

switch.

The CE mark is a registered trademark of

the European Community.

The CSA mark is a registered trademark of

the Canadian Standards Association.

The C-Tick mark is a

registered trademark

of the Australian Spectrum Management

Agency.

This text denotes the

ISM1-A

instrument is an

Industrial Scientific

and Medical Group 1

Class A product.

ii

Software License

The following License Terms

govern your use of the accompanying Software unless you

have a separate signed agreement with Agilent.

License Grant. Agilent grants

you a license to Use one copy

of the Software. “Use” means

storing, loading, installing,

executing or displaying the

Software. You may not modify

the Software or disable any

licensing or control features of

the Software. If the Software

is licensed for “concurrent

use,” you may not allow more

than the maximum numb e r of

authorized users to Use the

Software concurrently.

Ownership. The Software is

owned and copyrighted by

Agilent or its third party suppliers. Your license confers no

title to, or ownership in, the

Software and is not a sale of

any rights in the Software.

Agilent’s third party suppliers

may protect their rights in the

event of any violation of these

License Terms.

Copies and Adaptations. You

may only make copies or

adaptations of the Software

for archival purposes or when

copying or adaptation is an

essential step in the authorized Use of the Software. You

must reproduce all copyright

notices in the original Software on all copies or adaptations. You may not copy the

Software onto any public network.

No Disassembly or Decryption. Y ou may not disassemble

or decompile the Software

unless Agilent’s prior written

consent is obtained. In some

jurisdictions, Agilent’s consent

may not be required for limited disassembly or decompi-

lation. Upon request, you will

provide Agilent with reasonably detailed information

regarding any disassembly or

decompilation. You may not

decrypt the Software unless

decryption is a necessary part

of the operation of the Software.

Transfer. Your license will

automatically terminate upon

any transfer of the Software.

Upon transfer, you must

deliver the Software, including

any copies and related documentation, to the transferee.

The transferee must accept

these License Terms as a condition of the transfer.

Termination. Agilent may terminate your license upon

notice for failure to comply

with any of these License

Terms. Upon termination, you

must immediately destroy the

Software, together with all

copies, adaptations and

merged portions in any form.

Export Requirements. You

may not export or re-expor t

the Software or any copies or

adaptation in violation of any

applicable laws or regu lat io ns.

U.S. Government Restricted

Rights. The Software and Documentation have been developed entirely at private

expense. They are delivered

and licensed as “commercial

computer software” as defined

in DFARS 252.227-7013 (Oct

1988), DFARS 252.211-7015

(May 1991) or DFARS

252.227-7014 (J u n 19 95) , as a

“commercial item” as defined

in FAR 2.101(a), or as

“Restricted computer software” as defined in FAR

52.227-19 (Jun 1987) (or any

equivalent agency regulation

or contract clause), whichever

is applicable. You have those

rights provided for such Software and Documentation by

the applicable FAR or DFARS

clause or the Agilent standard

software agreement for the

product involved.

Limited Software Warranty

Software. Agilent Technologies warrants for a period of

one year from the date of purchase that the software product will execute its

programming instructions

when properly installed on the

instrument indicated on this

package. Agilent Technologies does not warrant that the

operation of the software will

be uninterrupted or error free.

In the event that this software

product fails to execute its

programming instructions

during the warranty period,

Customer’s remedy shall be to

return the media to Agilent

Technologies for replacement. Should Agilent Technologies be unable to replace the

media within a reasonable

amount of time, Customer’s

alternate remedy shall be a

refund of the purchase price

upon return of the product

and all copies.

Media. Agilent Technologies

warrants the media upon

which this product is recorded

to be free from defects in

materials and workmanship

under normal use for a period

of one year from the date of

purchase. In the event any

media prove to be defective

during the warranty period,

Customer’s remedy shall be to

return the media to Agilent

Technologies for replacement. Should Agilent Technologies be unable to replace the

media within a reasonable

amount of time, Customer’s

alternate remedy shall be a

refund of the purchase price

upon return of the product

and all copies.

Notice of Warranty Claims.

Customer must notify Agilent

Technologies in writing of any

warranty claim not later than

thirty (30) days after the expiration of the warranty period.

Limitation of Warranty. Agilent Technologies makes no

other express warranty,

whether written or oral, with

respect to this product. Any

implied warranty of merchantability or fitness is limited to

the one year duration of this

written warranty.

This warranty gives specific

legal rights, and Customer

may also have other rights

which vary from state to state,

or province to province.

Exclusive Remedies. The remedies provided above are Customer’s sole and exclusive

remedies. In no event shall

Agilent Technologies be liable

for any direct, indirect, special, incidental, or consequential damages (including lost

profit) whether based on warranty, contract, tort, or any

other legal theory.

Warranty Service. Warranty

service may be obtained from

the neares t Agilent Technologies sales office or other location indicated in the owner’s

manual or service booklet.

iii

General Safety Considerations

This product has been designed and tested in accordance with IEC Publi cation 1010, Safety Requirements for El ectronic Measuring Apparatus, and ha s

been supplied in a safe condition. The instruction docum entation contains

information and warnings which must be followed by the user to ensure safe

operation and to ma intain the product in a safe condition.

WARNI NG If this product is not used as specified, the protection provided by the

equipment could be impaired. This product must be used in a normal

condition (in which all means for protection are intact) only.

WARNI NG No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock, do not remove covers.

iv

Contents

General Safety Considerations iv

1 Installation

Installation 1-2

Step 1. Prepare the Site 1-4

Step 2. Install the Monitor Mount Assembly 1-6

Step 3. Install the Keyboard/Mouse Transmitter and the Work Surface 1-8

Step 4. Confirm Front and Rear Panel Connections 1-9

Step 5. Turn the System On 1-11

Step 6. Configure for Remote Operation 1-12

2 Getting Started

Configuration Options 2-6

Front Panel Featu r es 2- 8

Rear Panel Features 2-11

Software Overview 2-12

File Menu 2-13

Options Me nu 2-20

Tools Menu 2-27

Laser Safety Considera tions 2-30

Accurate Measurements 2 -3 3

Electrostatic Discharge Information 2-44

Quick Start 2-47

3 Measurement Techniques

The Calibrati o ns 3-2

Saving and Reusing 86030A Calibration Sets 3-5

O/O Response and Isola tion Bandwid th Calibration 3-8

O/E Response and Isolation Bandwidth Calibration 3-11

O/E Response a nd Match Bandwid th Calibrati on 3-14

E/O Response and Isolation Bandwidth Calibration 3-23

Agilent 86030A System Example Measurements 3-28

Electrical Mismatch Ripple and its Effects on Measure m e nts 3-29

Magnitude Response and Deviation From Linear Phase of a Lightwave

Receiver 3-41

O/E RF Overload Detection Measurement 3-51

Contents-1

Contents

4 Remote Operation

86030A Remote Operation Overview 4-3

COM Fundamentals 4-5

Getting a Handle to the Server Object 4-9

Configuring for DCOM Pro gr amming 4-12

COM Data Types 4-15

Tutorial Using 86030A Remote Operation 4- 18

List of Available Commands 4-25

System Properties 4-29

System Methods 4-32

Data Methods 4-34

Network Analyzer Metho ds 4-39

Calibration Methods 4-41

86032A Testset Methods 4-77

Enumerated Values 4-80

System Messages 4-82

Optical Test Set Error and Action Messages

with Descriptions 4-84

System Error and Action Messages

with Descriptions 4-86

Network Analyzer Error and Action Messages with Descriptions 4-91

Error Codes and Error Handling 4-94

5 Theory of Operation

System Opera tion 5-2

Lightwave Test Set Operation 5-3

Measurement Calibration 5-6

O/O Measurement Cal ibration 5-7

O/E Measurement Calibration 5-9

E/O Measurement Calibration 5-11

Electrical Measurement Calibration 5-14

O/E Display Sca ling Calculatio ns 5-16

E/O Display Sca ling Calculatio ns 5-17

O/O Display Sc a l ing Calculations 5- 1 8

6System Verification

Lightwave Verification 6-3

Contents-2

If the Lightwave Verification Test Fails 6-7

7 Maintenance

86032A Test Set T roubleshooting Diagnostics 7-7

Modulator Troubleshooting Tips 7-16

Agilent Technologies Support and Maintenance 7-17

Electrostatic Discharge Information 7-19

Returning the System for Service 7-22

Agilent Technologies Servic e Offices 7-25

After Repair 7-26

8 Specifications and Regulatory Information

General Specifications 8-3

Electrical Specifications 8-4

Optical to Optical (O/O) Specifications 8-6

Optical to Electrical (O/E) Specifications 8-7

Electrical to Optical (E/O) Specifications 8-12

Characteristics 8-16

Optical to Electrical (O/E) Characteristics 8-18

Electrical to Optical (E/O) Characteristics 8-21

Regulatory Information 8-24

Declaration of Conformity 8-25

Contents

Contents-3

1

Step 1. Prepare the Site 1-4

Step 2. Install the Monitor Mount Assembly 1-6

Step 3. Install the Keyboard/Mouse Transmitter and the Work Surface 1-8

Step 4. Confirm Front and Rear Panel Connections 1-9

Step 5. Turn the System On 1-11

Step 6. Configure for Remote Operation 1-12

Installation

Installation

Installation

Installation

The instructions in this chapter show you how to i nst all the 86030A 50 GHz

LCA. For overseas sales, the product is shipped without an ac power connector. You should have a local electrician provide and install an ac connector that

meets the stand ards for the region. Al so, be sure to set all i nstruments to use

the local line vo ltage.

WARNI NG This system is a Safety Class I Product (provided with a protective

earthing ground incorporated in the power cord). The mains plug shall

only be inserted in a socket outlet provided with a protective earth

contact. Any int erruption of the protective conduc tor inside or

outside of the produc t is likely to make the product dangerous.

Intentional interruption is prohibited.

WARNI NG To prevent electric shoc k, disconnect the system fro m mains before

cleaning. Use a dry cloth or one slightly dampened with water to clean

the external case parts. Do not attempt to clean internally.

WARNI NG HP/Agilent 86032A: No operator serviceable parts inside. Refer

servicing to qualified personnel. To prevent electrical shock, do not

remove covers.

WARNI NG HP/Agilent 86032A: For continued protection against fire hazard,

replace line fuse only with same type and ratings. Use a 6.3A 250V fuse.

The use of other fuses or materials is prohibited.

WARNI NG HP/Agilent 86032A and HP/Agile nt 86030A: If the syst em and t est set

products are not use d as specified, the protection provided by the

equipment could be impaired. These products must be use d i n a

normal condition (in w hich all means for protectio n are intact) only.

CAUTION Do not load any software on the 86030A system computer.

1-2

Installation

Installation

CAUTION HP/Agilent 86032A and HP/Ag i lent 86030A: This system and test set are

designed for use in INSTALLA TION CATEGORY II and POLLUTION DEGREE

2, per IEC 1010 and 664 respectively.

CAUTION HP/Agilent 86030A: Ventilation Requirements. When instal li ng the produ c t in

a cabinet, the con v ection into and out of t he product must not be restricted.

The ambient temperature (outside the cabinet) must be less than the

maximum operating temperature of the product by 4°C for every 100 watts

dissipated in the cabinet. If the total power dissipated in the cabinet is greater

than 800 watts, then forced convection must be used.

CAUTION The warranty and ca l ibration will be voided on systems wh ere the individual

instruments, including fiber-optic cables, RF cables, or GPIB cables are

removed by the customer. The system should only be disassembled by an

Agilent Customer Engineer. Instruments should not be swapped or removed by

non-Agilent personnel.

1-3

Installation

Step 1. Prepare the Site

Step 1. Prepare the Site

Your site should accommodate the dimensions, weight s, and powe r cons umption limits shown in the following fig ure.

WARNI NG This system weighs approximately 600 lbs (270 kg). To avoid inj uries,

use proper moving equipment and use extreme car e when installing.

WARNI NG Install the system so the power cords are readily identifiable and are

easily reached by the operator. The power cords are the disconnecting

device. They disconnect the mains circuits from the mains supply

1-4

Installation

Step 1. Prepare the Site

before other parts of the system. Alternately, an externally installed

switch or circuit breaker (which is readily identifiable and is easily

reached by the operator) may be used as a disconnecting device.

CAUTION HP/Agilent 86030A and HP/Agi le nt 86032A: Install the system and tes t se t

according to the enclosure protection provided. This system and test set do not

protect against the ingre s s of water. The system and test set protects against

finger access to hazardous parts within the enclosure.

CAUTION Before switching on this system, make sure the line voltage selector switch on

the HP/Agilent 86032A lightwave test set’s rear panel is se t to the voltage o f the

mains supply, that the correc t fuse is instal led, and t hat the s upply v oltage is in

the specified range.

1-5

Installation

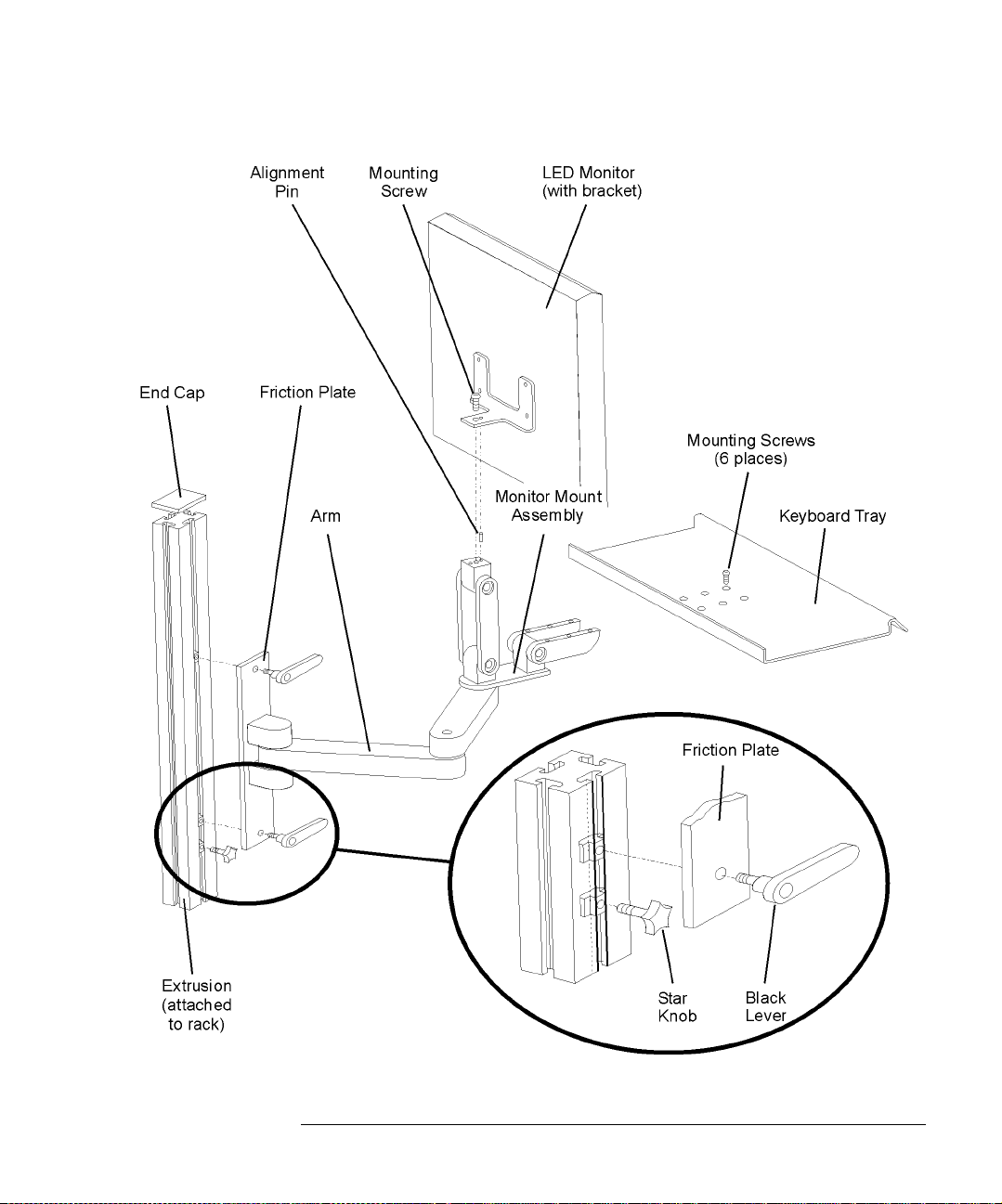

Step 2. Install the Monitor Mount Assembly

Step 2. Install the Monitor Mount Assembly

1 Remove the black end cap from the top of the extrusion.

2 Slide the star knob o nto the lower part of the ex trusion and tighten.

3 Loosen the two black levers on the friction plate and slide it onto the extrusion.

4 Move the friction plate to the desired height and tighten the two black levers.

5 Loosen the star k nob and raise it unti l it stops below the fric tion plate, then

tighten the knob securely to prevent the friction plate, arm, and monitor mount

assembly from falling.

WARNI NG If the star knob is not installed properly, the friction plate, arm, and

monitor mount assembly may fall, causing injur y to the user or damage

to the monitor and mounting components.

6 Attach the keyboard tray to the monitor mount assembly using the six provided

mounting screws. Tighten with a 1/8” Allen wrench.

7 Attach the LCD monitor to the monitor mount assembly with the pro v id ed

mounting screw. Tighten with a 7/32” Allen wrench. Make sure the moni to r is

properly oriented with the alignment pin, then tighte n with a 7/32” Allen

wrench.

CAUTION Tighten all hardware on the arm and monitor mount assembly as necessary to

prevent the monitor and keyboard from ti pping unexpectedly.

CAUTION Be careful when swinging the arm around in front of the system to avoid

striking the 8510C and other sys te m components.

8 Replace the black end cap on the extrusion.

9 Connect the monito r cabl e s to the LCD monitor and secure the cabl es to the

bottom of the arm using tie wraps.

1-6

Installation

Step 2. Install the Monitor Mount Assembly

1-7

Installation

Step 3. Install the Keybo a r d/M ouse Transmitter and the Work Surface

Step 3. Install the Keyboard/Mouse Transmitter

and the Work Surface

1 Slide the keyboard/mouse transmitter into the plastic holder on the bottom

side of the work surface. Use the cable clamps on the bottom of the work

surface to secure the cables.

2 Attach the wor k su rface rails to the rack using a T-25 torx dr iver.

3 Slide the work surface over the rails and secure it using the hardware provided.

4 Route the transmitter cables through the rack and attach to the appropriate

computer connectors using extension cables, if necessary .

The Connect button on the transmitter should be towards the plastic holder.

1-8

Installation

Step 4. Confirm Front and Rear Panel Connections

Step 4. Confirm Front and Rear Panel

Connections

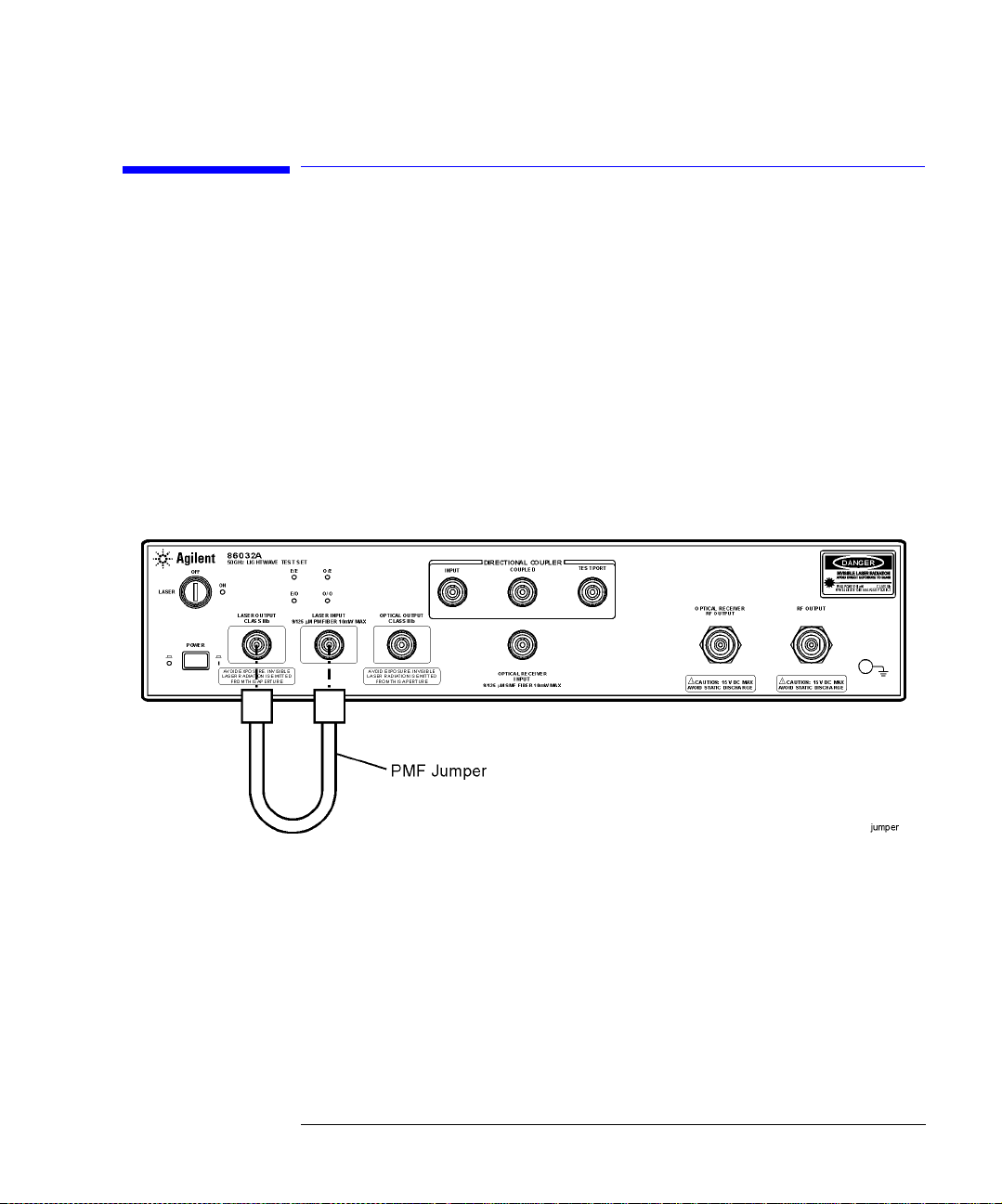

1 Connect the jumper betw een t he L ASER OUTPUT and LASER INPUT on the 86032A

front panel. Refer to Figure 1-1.

You must clean the connectors every time the jumper is connected. Refer to

“Cleaning Connectors” on page 2-40.

2 Confirm the cabling of the Agilent/HP 86030A system. Refer to Figure 1-2.

Figure 1-1. Location of the PMF Jumper

1-9

Installation

Step 4. Confirm Front and Rear Panel Connections

Figure 1-2. Agilent 86030A Cabling Configuration

1-10

Installation

Step 5. Turn the System On

Step 5. Turn the System On

1 Plug in the Power Distribution Units (PDU).

2 Turn on the system , and allow it to warm up fo r two hours.

3 When prompted for the password, enter Agilent.

4 Make certain that the laser key is in th e ON position.

5 From the Windows Start menu on the 86030A computer, select Programs,

Agilent, 86030A Main to open the software.

A splash screen will appear displaying the software title followed by the appli-

cation screen shown in the following figure.

NOTE Do NOT attempt to close the analyzer appl i cation until the 86030A system

status window says “System Ready .”

6 Perform a system verification. Refer to “Lightwave Verification” on page 6-3.

1-11

Step 6. Configure for Remote Operation

This step provides instructions for configuring and installing the 86030A controller software on a client PC, which is external to the analyzer system. This

step is only necessary if you will be opera tin g the 86030A remotely. For information on available commands and remote operation, refer to Chapter 4,

“Remote Operation”.

Client PC

Minimum

Requirements

Configure the Client PC for a Private LAN Interface

• Windows NT 4.0 Service Pack 6

• LAN Card

These instructions assume that your computer already has a second ne twork

adapter (LAN card) and a TCP/IP protocol installed. The first LAN card must

have a static IP to work on your public LAN in the presence of the second

card.

1 On the client PC, click Start, Settings, Control Panel.

2 Double-clic k Ne tw ork.

3 Select the Protocols tag and click Properties.

4 In the list displayed, select the type of LAN adapter card that you have installed

in the client PC.

5 Click Adpater and select the second LAN card.

6 Click Specify, IP Ad dress and enter the fol lowing settings.

• For IP Address, enter 192.168.000. 001

• For Subnet Mask, enter 255.255.255.0

• For Default Gateway: enter 192.168.000.001

7 Click Apply.

Installation

Step 6. Config ure for Remote Operat ion

NOTE If you get an error at least twice, indicating the adap te r card has an empty

primary window address, click Yes.

8 For the TCP/IP Properties window, click OK.

9 On the Network window, click Close.

10 Restart the PC.

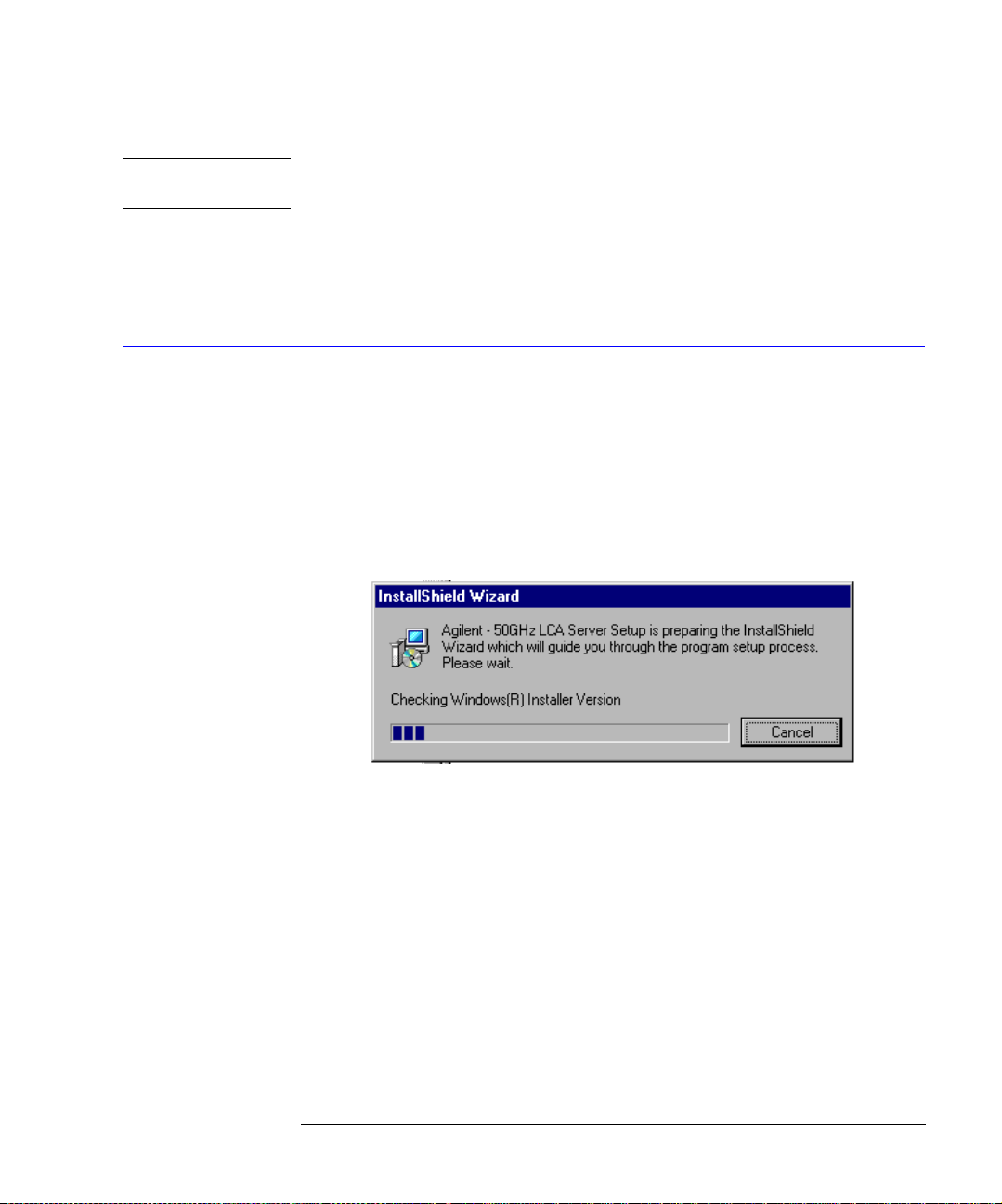

Install the Controller Software

1 Insert the disk labled “Agilent 86030A Controller Software” into the client

conputer CDROM drive.

2 Locate the file “86030A_Inst.exe” on the disk.

3 Double-click the file to start the installation process.

4 The window below will appear, indicating the setup process has begun.

• If a window appears stating that the Windows installer is an old er versio n,

click OK to allow the setup to upgrade the installer. It may take a few moments for the Welc o m e sc reen to appear.

• Restart the computer after the installer is upgraded so the setup may continue.

5 When the InstallShield window appears, the installation process has begun.

Click Next.

6 Enter the User Nam e and Organization, then click Next.

7 Select Complete setup, and cli c k Ne x t.

8 Click Install. The installation may take a few minutes.

9 Click Finish to complete the installation.

1-13

Installation

Step 6. Configure for Re m ote Ope ration

1-14

2

System Overview 2-2

Configuration Options 2-6

Front Panel Featu r es 2-8

Rear Panel Features 2-11

Software Overview 2-12

File Menu 2-13

Options Menu 2-20

Tools Menu 2-27

Laser Safety Considera tions 2-30

Accurate Measurements 2-33

Electrostatic Discharge Infor m ati on 2-44

Quick Start 2-47

Getting Started

Getting Started

System Overview

System Overview

The Agilent 86030A 50 GHz lightwave component analyzer provides accurate

and repeatable characterization of electro-optical , opt ical, and electri cal components.

You can characterize components such as O/E photodiode receivers, E/O photodiodes, lightwave modulators, and other opti cal and electrical components

used in 40 Gb/s lightwave systems.

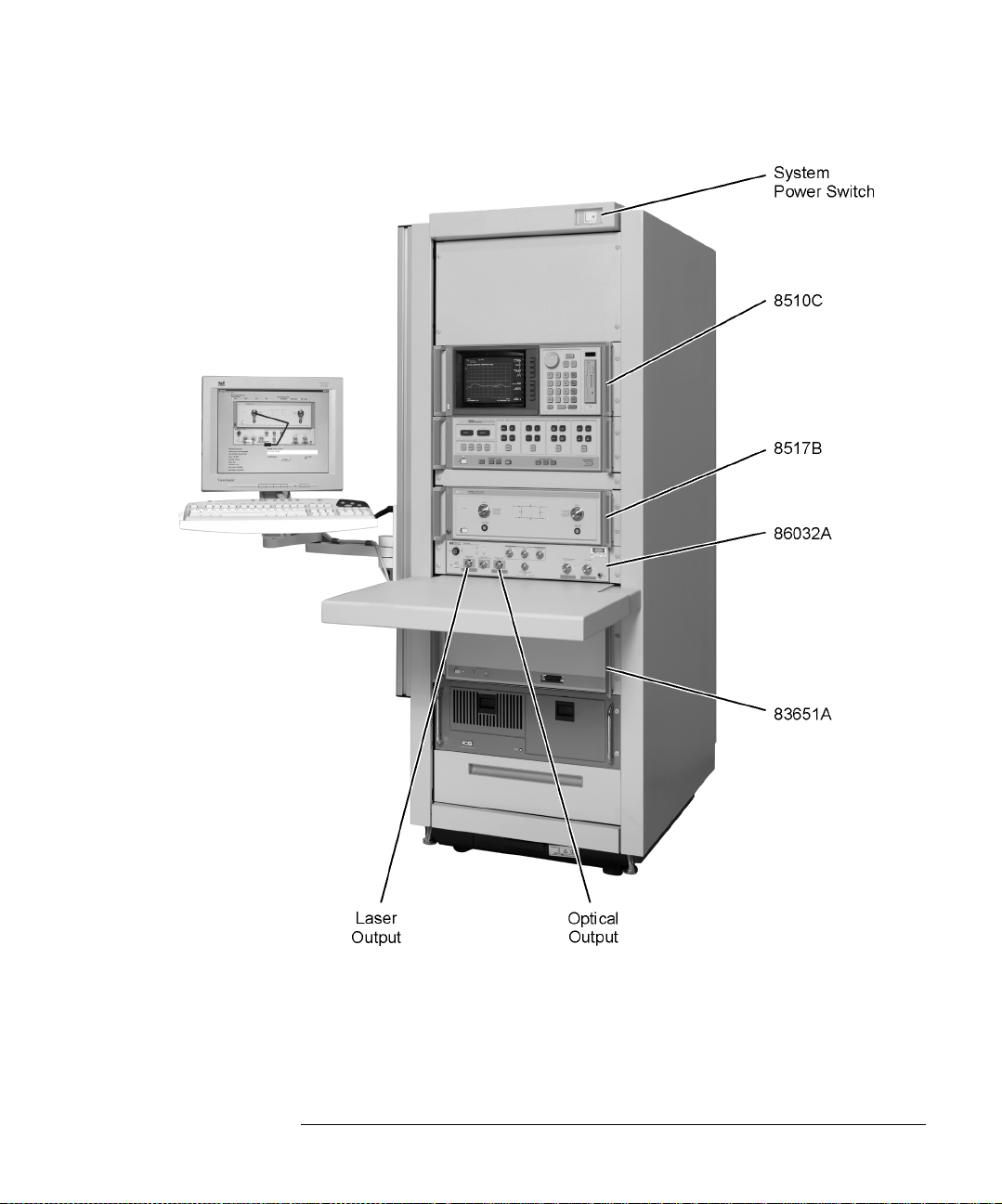

The Agilent 860 30 A system consists o f the following item s:

• 85107B vector network analyzer system

• 86032A 50 GHz lightwave test set

• system softwar e

• personal comput er, serving as the system c on t roller

• controller software for a client computer

NOTE You can control the 86030A directl y us in g the sy stem computer, or remotely

using the controller software on a client computer.

2-2

Getting Started

System Overview

2-3

Getting Started

System Overview

Calibrated Measurements

One of the key benefits of the 50 GHz lightwave component analyzer is its ability to perform calibrated measurements of optical component s. The system

contains an O/E receiver that has been factory calibrated in magnit ude , and

characterized in phase. The ability to make calibrated measure men ts assures

accuracy , reliability, and confidence in the components being measured. Additionally, the laser source, optical modulator, and calibrated O/E receiver are

temperature stabilized which also improves the accuracy and repeatability of

measurements.

Verification Device

A verification device is included with the N1012A Lightwave Verification Kit.

The device is an O/E photodetector and includes associated amplitude and

phase data. You can use this verification device at any time to verify the measurement integrity of your system. The 86030A system provides a guided verification routine that measures the verific ati on de vice , and displ ays a graph of

its response versus acceptable tolerances. The verif icat ion device allows yo u

to periodically monitor system calibration, and detect when the optical test set

needs to be recalibrated. You can also use the device to resolve uncertainty if

unexpected results are obtained from a test device. This verification capability

provides confi dence in the measurem ent integrity of the sy stem.

Measurement Software

Guided measurement software provides an easy-to-use operator interface. It

provides pictorial diagrams of interconnections for configuration, calibration,

and measurements. On-screen prompts also guide you through the entire

measurement pr oc ess, from the calibra tion to the measure m ent.

Data Management

Display, analysis, and archiving of data is easy and straightforward with the

system. The measured data is displayed on the Agilent 8510C network analyzer. Full use of the analyzer’s func tions such as markers , data formats, and

data scaling features are available. Data can be archived to disk in either ASCII

text or Microsoft

1

Excel formats. The included Excel software allows data to

be displayed and analyzed using standard Excel features and formats. Data

connectivity to a local area network (LAN) is provided via a LAN card in the

system’s PC.

1. Microsoft and Excel are registered U.S. trademarks of Microsoft Corporation.

2-4

System Overview

System Accessories

The accessories described below may be shipped with your system.

Table 2-1.System Accessories

Description Agilent Model/Part Number

Verification Kit N1012A

86030A User’s Guide 86030-90023

2.4 mm 8510C Calibration Kit 85056A

2.4 mm Flexible Cables 85133F

Controller (Client) Software CDROM 86030-10004

86030A Operating System Software CDROM 86030-10002

86032A Calibration Coeff icients Floppy Disk Unique to 86032A Test Set

Bias Network 0.045 - 50 GHz (2.4 mm)

a

11612B

Getting Started

a. The bias network is not part of the 86030A shipment, yet it may be helpful when

measuring modul ators.

2-5

Getting Started

Configuration Option s

Configuration Options

The standard Agilent/HP 86030 A sy stem is supplied with FC/PC optical connectors. If other optical connectors are desired, ordering one of the following

connector options will replace the FC/PC connectors with the desired opti cal

connectors.

Table 2-2. Available Options for the 86030A System

Option Number Description Part Number

011 Diamond HMS-10 connector interface 08154-61701

013 DIN 47256 connector interface 08154-61703

014 ST optical connector int erface 08154-61704

017 SC optical connector interface 08154-61708

230 220-240 VAC operation

WARNI NG During measurements, laser light emits from the front-panel OPTICAL

OUTPUT connector and the LASER OUTPUT connector. This light

originates from the system ’s laser source. Always keep these

connectors covered when not in use.

NOTE If you would like to change the optical connectors to a different type, you can

order a quantity of seven of the replac em ent part number, shown above.

2-6

Getting Started

Configuration Options

CAUTION The warranty and ca l ibration will be voided on systems wh ere the individual

instruments are removed by the customer. The system should only be

disassembled by a Agilent Technologies Cust o mer Engineer. Instruments

should not be replaced by non-Agi lent Technologies personnel.

Measuremen t ac curacy—it’s up to you!

Fiber-optic connectors are easily damaged when connected to dirty or damaged cables

and accessories. The 86030A’s front-panel SOURCE OUTPUT and RECEIVER INPUT con-

nectors, 86032A Laser Output and External Laser Input are no exception. When you use

improper cleaning and handling techniques, you risk expensive instrument repairs, damaged cables, and compromised measurements. Before you connect any electrical cable

to the 86030A, refer to “Electrostatic Discharge Information” on page 7-19.

2-7

Getting Started

Front Panel Features

Front Panel Features

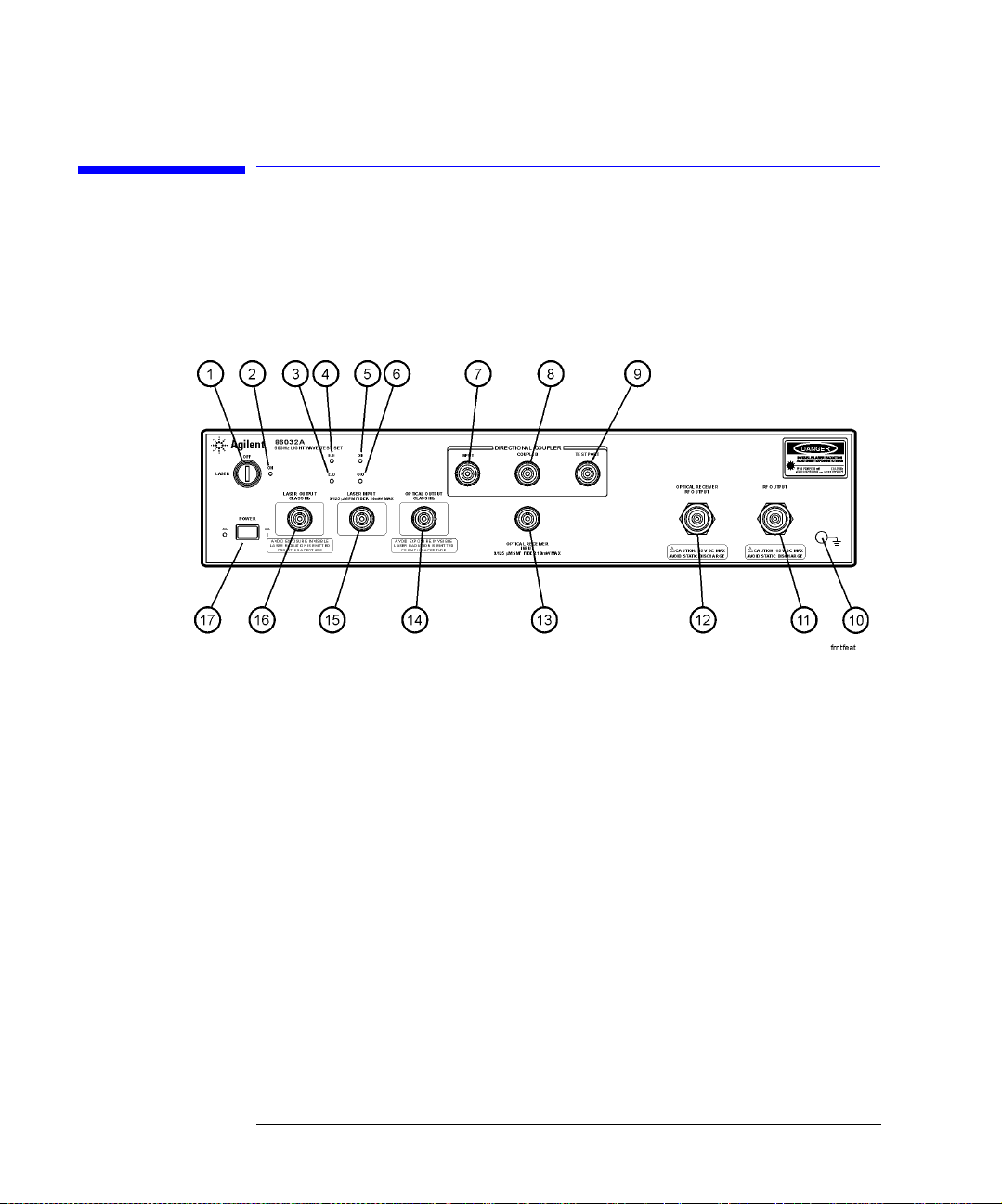

Figure 2-3. 86032A Front Panel

2-8

Getting Started

Front Panel Features

1. LASER Key Turns the laser on and off. Note that the laser is not operational

until it is activated by the 86030A software program. You can turn

on the laser manually from the Diagnostic software. From the

Windows Start menu, select Programs, Agilent Technologies 50

GHz LCA, 50 GHz Diagnostics. From the Laser menu, click Laser

ON. Make sure the laser key on the 86032A is i n th e on position.

WARNI NG Do NOT, under any c ircums tances, look in to the op tical ou tput or a ny

fiber/device attached to the output while the laser is in operation.

Refer to “Laser Safety Considerations” on page 2-30.

2. Laser LED Indicates the state of the laser. When the LED is lit, the laser is

on. Note that the laser is not operational until it is activated by

the 86030A software program. You can turn on the laser manually

from the Diagnostic software. From the Windows Start menu,

select Programs, Agilent Technol ogies 50 GHz LCA, 50 GHz

Diagnostics. From the Laser menu, click Laser ON.

3. E/O LED When on, indicates the internal measurement path is selected for

an E/O (electrical-to-optical) device.

4. E/E LED When on, the internal measurement path is selected for an E/E

(electrical-to-el ect rical) device. The test set is in a bypass mode

for E/E device selection and the laser is shut down. The test set

will need to be in the ON position for use in E/E mode.

5. O/E LED When on, the internal measurement pat h is selected for an

(optical-to-electrical) O/E device.

6. O/O LED When on, the internal measurement path is selected for an

(optical- t o -optical) O/O dev i c e .

7. DIRECTIONAL COU PLER

INPUT

8. DIRECTIONAL COU PLER

COUPLED

9. DIRECTIONAL COU PLER

TEST PORT

10. Grounding Receptacle Ground path that is provided to connect a static strap.

11. RF OUTPUT RF output that provides RF drive power for E/O devices.

12. OPTICAL RECEIVER RF

OUTPUT

Input for the optical direction coupler. This port is usually

connected to the OPTICAL OUTPUT.

Port for the coupler output. This port is usually connected to the

OPTICAL RECEIVER INPUT.

Coupler output port (transmission) or test port (reflection).

Test set optical receiver output.

2-9

Getting Started

Front Panel Features

13.OPTICAL RECEIVER

INPUT

14. OPTICAL OUTPUT Modulato r output.

15. LASER INPUT External laser input.

16. LASER OUTPUT Output of internal laser.

17. POWER Switch Turns the instrument power on.

Test set optical receiver input.

CAUTION Use care in handling optical connectors. Damage to an optical te st port

connector can require a costly repair and lost productivity for the system. Keep

optical cables connected to the te st ports to protect the connectors from

damage. Also, make sure to clean the connectors before each use. Refer to

“Accurate Measurements” on page 2-33.

2-10

Rear Panel Features

Getting Started

Rear Panel Features

Figure 2-4. 86032A Rear Panel

1. Remote Programming

Connector

2. Laser Remote Shutdown Turns the laser on or off. When the BN C short is connected, the

3. Line Module This assembly houses the line cord connector.

4. RF REF OUTPUT RF output of the test set that is used to route the 8517B electrical

5. EXT ALC DC output from the leveling detector on the internal ALC circuit.

6. RF INPUT RF input port from the source output of the network analyzer.

Allows for remote control of the instrument’s front panel via the

86030A software installed on the system PC.

laser is enabled. When removed, the laser is disabled.

test set for phase locking.

This output is routed to the EXT ALC port of the network analyzer

source.

2-11

Getting Started

Software Overview

Software Overview

The 86030A software sets up instrument states on the network analyze r and

lightwave test set, and guides you through the measurement calibration and

measurement pro c e dures. The program combines the measur ement calibration traces with the calibration data response of the lightwave receiver, and

loads the result back into the network analyzer to provide calibrated lightwave

measurements. You can save and view trace data using Microsoft Excel, and

manually control the 86032A test se t operation.

2-12

Getting Started

File Menu

File Menu

The File menu is used to save data as either an ASCII text file or an Excel

worksheet. Using Graph Excel Data allows you to automatically view saved

data in an Excel worksheet as tabular data, or as graphical data in log magnitude, phase or delay formats. The File menu is also used to exit the application.

Save Data

Text File Text File allows you to save data as an ASCII text file in four different formats:

• Raw Data

• Log Magnitude

• Phase

• Delay

2-13

Getting Started

File Menu

Raw Data saves trace data in a ASCII text format (.txt) known as a CITIFile

(common instrumentation trans fer and interchange file). The CITIFile format

is useful when data will be exchanged with another network analyzer. The

data file saves both real and imaginary pairs independent of the format of the

active screen. However, any trace smoothing that was applied to the measurement will not be saved (that is, Smoothing On is activated from the 8510C

Response menu).

Formatted Data, Log Mag, Phase, Delay saves trace data with any trace

smoothing tha t w as a pp lied t o t he m easu remen t (t ha t is , Smoo th ing On i s acti vated from the 8510C Response menu), but only retains the values of the format that was selected for saving (that is, Log Magnitude, Phase, or Delay).

Excel File Excel File allows you to save the trace display as a Microsoft Excel workbook

(.xls extension). The Ex cel f orma t is usef ul when you want t o vi ew or ed it th e

data in an Excel spreadsheet.

Raw Data saves both re al and imaginary pairs independent of the format of

the active screen. This data can later b e v iewed in either Log Ma gnitude or

Phase format from the File, Graph Excel Data menu. Any trace smoothing that

was applied to the measurement will not be saved (that is, if Smoothing On is

activated from the 8510C Response menu).

Formatted Data saves trace data and any trace smoothing that was applied

to the measurement, bu t only viewed using the format that the data was originally saved (that is, Log Magnitude, Phase, or Delay).

2-14

Getting Started

File Menu

Log Mag saves the log magnitude format. This is the standard Cartesian format used to display magnitude-onl y m ea surements of insertion loss, return

loss, or absolute power in dB versus frequency.

Phase saves the phase of data versus frequen c y in a Cartesian forma t.

Delay saves the group delay format, with marker values given in seconds.

Group delay is the measurement of signal transmission time through a test

device. It is defined as the derivative of the phase char acte ri st ic wi th re sp ect

to frequency. Since the derivative is basically the instantaneous slope (or rate

of change of phase with frequency), a perfectly l inear phase shift results in a

constant slope, and therefore a constant gro up delay.

Graph Excel Data

Raw Data Data allows you to view trace data in either Log Magnitude o r P ha se format.

However, any trace smoothing that was applied to the measurement will not

be captured. (that is, if Smoothing On was activated from the 8510C Response

menu).

Log Magnitude displays the trace data in Cartesian format as logarithmic

(dB) magnitude versus frequency.

Phase displays the trace data in Cartesian format as phase versus frequency.

Formatted Data, Formatted Data allows you to view trace data in the format that it was saved

(that is, Log Magnitu de, Phase, or Delay) includ in g an y t ra c e smo o thing that

was applied to the measurement

Log Mag displays the log magnitude format. This is the standard Cartesian

format used to display magnitude-only measurements of insertion loss, return

loss, or absolute power in dB versus frequency.

2-15

Getting Started

File Menu

Phase displays the phase shift of data versus frequency in a Cartesian for m a t.

Delay displays the group del a y for mat, with marker values given in seconds.

Group delay is the measurement of signal transmission time through a test

device. It is defined as the derivative of the phase char acte ri st ic wi th re sp ect

to frequency. Since the derivative is basically the instantaneous slope (or rate

of change of phas e w i th frequency), a perfe c tly linear phase shif t re sults in a

constant slope, and therefore a constant group delay. See Figure 2-5.

Figure 2-5.

Note, however, that the phase characteristic typically consists of both linear

and higher order (deviations from linear) components. The linear component

can be attributed to the electrical length of the test device, and represents the

average signal tra nsit time. The higher order componen ts are interpreted as

variations in transit time for diff erent frequencies, and represent a source of

signal distort ion. See Figure 2-6.

2-16

Figure 2-6.

Getting Started

File Menu

Group Delay τ

dφ–

-------- -==

g

dω

in Radians

in Radians

1–

dφ

----------- -

------

360°

⋅=

df

φ in Degrees

f in Hz (ω 2πf)=

The analyzer compu tes group delay from th e phase slope. Phase data is used

to find the phase change, ∆φ, over a specified frequency aperture, ∆ƒ, to

obtain an approximation for the rate of change of phase with frequency

(Figure 2-7). This value, τ

, represents the group delay in seconds a ss uming

g

linear phase change over ∆ƒ. It is important that ∆φ be ≤180°, or errors will

result in the group de lay data. These errors c a n be significant for l ong delay

devices.

Figure 2-7.

2-17

Getting Started

File Menu

When deviations fr om linear phase are pres ent, changing the frequency step

can result in different values for group delay. Note that in this case the computed slope var ies as the aperture ∆ƒ is increased (Figure 2-8). A wider aper-

ture results in loss of the fine grain variations in group delay. This loss of detail

is the reason tha t in a n y comparison of group delay data it is important to

know the aperture use d t o mak e th e mea su rement.

Figure 2-8.

In determining the group delay aperture, there is a trade-off between resolution of fine detai l a nd ra pid variations in g ro u p delay, which can look like a

noisy trace. Th es e rapid va ria tio ns can be red uc ed by incre asi ng the a per tur e,

but this will tend to smooth out the fine detail. More detail will become visible

as the aperture is decreased, but the varia ti ons will als o incr e ase , possi b ly to

the point of obscuring the detail. A good practice is to use a smaller aperture

to assure that small variations are not missed, then incre a s e the ape rture to

smooth the trace.

2-18

Exit

Exit closes the 86030A software application.

Getting Started

File Menu

2-19

Getting Started

Options Menu

Options Menu

The Options menu allows you to set and monitor system functions.

Auto Bias

Auto Bias allows you to bias the modulator to operate at quadrature or at maximum optical power. Under typical circumstances the lightwave modulator is

biased to operate at qu adrature. Quadrature is the point where the slope of

the optical power versus voltage is maximally positive. Refer to Figure 2-9.

2-20

Getting Started

Options Menu

Power at

Quadrature (1)

Voltage at

Quadrature (2)

Figure 2-9. Effect of Bias V oltage on Modulat ed Optical Power

The point midway between the max im um and mini m um optical power points,

on the positive slope of the bias curve. The quadrature point allows maximum

optical power variations versus modulation vol tag e.

The voltage where the optical power is at the quadrature point. The auto-biasing routine sele c t s this voltage to bias the internal optic al modulator.

2-21

Getting Started

Options Menu

Voltage at

Maximum Optical

Power (3)

Voltage at

Minimum Op tical

Power (4)

Maximum Optical

Power (5)

Minimum Op tical

Power (6)

The voltage at which the maximum output power occurs (V

The voltage at which the minimum output power occurs (V

min

max

).

).

The maximum optical output power.

The minimum optical output power.

How to Determine if Auto Bias Values are Reasonable

The following formulas will help you to determine if the modula tor auto bias

settings are val id. R efe r to Figure 2-9 on page 2-21

Voltage at Maximum Optical Power – Voltage at Minimum Optical Power

should between 3 and 6 volts.

Vmax Vmin+

Voltage at Quadrature should be approximately

Maximum Optical Power should be > 3 dBm

Power at Quadrature should be > 0 dBm

Tip: You can set this value manually. From the Tools menu, click on Mo nitor

T es t Set. I n th e Mo dif y Bia s Voltage text box, ent er t he de si re d v alu e an d th en

click Set Modulator Bias Voltage to.

Refer to “Modulator Troubleshooting Tips” on page 7-16 for more informatio n.

----------------------------------

2

2-22

Getting Started

Options Menu

Auto Bias At Cal

Auto Bias At Cal when selected, an auto bias is performed before each calibration. The auto bias is performed after you click either Resp Cal or Resp-Isol

Cal.

Customize

Customize allows you to set and monitor certain parameters that affect the

operation of the system.

Standard The Standard Settings dialog box allows you to set and monitor certain param-

eters controll ed by the network anal yz e r.

2-23

Getting Started

Options Menu

GPIB Address displays the current address setting for the ana l yzer. This

value must correspond to the actual address on the 8510 GPIB address bus.

Failure of these two numbers to match will prevent operation.

Average Factor is used to improve the sensitivity of the measurement. For

the Step Mode of operation for e ach m odulation frequency point, mu lt iple

data point samples (equ a l to the number of averages) are mea s ured by the

system, and averaged together to provide a single averag e value . Averaging

multiple data poi nts together reduces the effects of noise on the measurement. The improvement in sensitivity is equ a l to:

dB 10log10number of averages()=

Note the 8510C network analyzer only averages with powers of 2 (that is, 1, 2,

4, 8, 16, 32, 64, 128, 256, 512, 1024, and so on). Therefore, if an averaging factor of 500 is set on the analyzer, the analyzer will default to 256 averages.

Bias Interval, mins corresponds to the number of minutes before prompting

you to perform another modulator auto bias.

Refl Standard % corresponds to the percent of refl ection of the Reflection

Standard used in the system. This is useful for O/O reflection modes.

Averaging when selected, the network analyzer will perform averaging at

each data point.

Split Screen E/O when selected, th e ne tw ork analyzer displays both the

bandwidth and reflection measurement on the display. This function is only

valid with an E/O Bandwidth and Reflection measurement. Bandwidth is

2-24

Getting Started

Options Menu

displayed on c ha n nel 1 and Reflection is displayed on chan nel 2. When this

function is cleare d, use the network anal y z er front panel channel buttons to

select between the two measurements.

Time Date Stamp when selected, the time and date st a m p is applied to the

trace on the network analyzer.

Scale Excel Chart when selected, the trace data save d fr om the netw ork

analyzer will be auto-scaled to fit into an Excel chart.

Step Sweep/Ramp Sweep toggles between st ep sw eep and ramp sweep

modes.

Step Sweep is a digital sweep beginning at the start frequency and ending at

the stop frequency with the so urce phase locked and the data measured at a

frequency interval determined by the number of points selected on the network analyzer (STIMULUS MENU, STEP). An up arrow on the trace identifies

the data point just measured. The step mode is recommended when you need

the best modulation frequency acc uracy and re pe atab ility.

Dwell time prior to measurement a t ea c h frequency point is controlled by th e

sweep time setting. Measurement time at each point is determined by the

averaging factor.

NOTE System specifications are only warranted when using the Step Sweep mode of

operation.

Ramp Sweep selects continuous linear analog sweeps beginning at the start

frequency and ending at th e stop frequency. The rate is determined by the

sweep time, measuring data at frequency intervals set by the number of

points. (8510 access, STIMULUS MENU, RAMP)

Advanced The Advanced Settings dialog box allows changing of default power values.

2-25

Getting Started

Options Menu

External Leveling when checked, the system uses external leveling. Whe n

cleared, the system uses internal leveling. Normal system operation uses

external leveling.

Src Pwr, E to X, dBV for E/O mode and E/ E mode, dis plays the 83651A

external leveling source power.

Src Pwr, O to X, dBV for O/E mode and O/O mode, displays the 83651A

external leveling source power.

Default Settings when selected, resets the source power to its factory

default values.

Setting the Power

at the RF Output

Port

CAUTION Do not exceed -3 to +5 dBm at the 8510 RF output port. Due to variations in

The power at the 860 30 A RF output port is set at the fa cto ry for a nominal 0

dBm. You can change the RF output power level by followin g these steps:

1 Connect a power meter to the R F ou tput po rt.

2 On the 8510, press Span, 0, Hz, Center Frequency, 25, GHz.

3 In the 86030A Options menu, click Customize, Advanced.

4 In the Src Pwr, EtoO, dBV box, enter the power value and click OK. Make the

changes to the power level in small deviations from the default state.

amplifier gain, error messages may appear on the analyzer screen. Reduce or

increase the power setting to remove the error mes sages.

System Verification

A System Verification performs a measurement on the verification device over

the entire frequenc y range. The verifica tion device is the 83440D Option 050

lightwave detector supplied in the N1012A verification kit. Once the verification is completed, the results are displayed in an Excel wor ksh eet alo ng with

the error bars that were computed from the factory measurement of the verification device. For the system to pass the verification test, the verification

device trace must fit within the error bars. A pass or fail indicator is displayed

at the bottom of the worksh eet. Refer to “Lightwave Verification” on page 6-3

for more informatio n .

2-26

Getting Started

Tools Menu

Tools Menu

The Tools menu is used to monitor and modify 86032A test set param ete rs.

Modify Test Set

Curent Laser Output Power (dBm) displays the valu e of the laser power

coming from the LASER OUTPUT port of the test set.

Set Laser Output Power to:(dBm), when Modify Power is selected, the

value will be updated to the value specified in this text box.

2-27

Getting Started

Tools Menu

Modify Power sets the internal laser of the 86030A test set to the power

specified in the Modify Power text box. This value will be used until you

restart the 86030 A so ftware. Valid settings are from 0 dBm to 10 dB m .

Set Optical O utput Pwr to Nominal Setting sets the laser to its factory

default setting. When the software is start ed , the power always defaults back

to the factory setting.

Current Modulator Bias Voltage (V) displays the value last applied to the

internal modulator bias tee attached to the optical modula tor.

Set Modulator Bias Voltage to: (V), when Mo di fy Bias Voltage is selected,

the bias voltage will be updated to the value specified in this te xt box . The

range is –10 to +10 volts.

Modify Bias Volt age sets the bias voltage to the va lue entered in the Set

Modulator Bias Voltage text box.

Turn Laser On turns on the laser inside the 86032A test set. This command

does not change the power of the laser. This function is useful in E/O mode

when you may want to use the internal high power laser as a stimulus for testing optical mo dul a tors. The optical po w e r is normally off in the E / O m o de .

Turn Laser Off turns off the laser inside the 86032A test set. This command

does not change power of the laser. If the laser is turned off and then turned

back on again, the original power of the laser will be used.

Set Mod. Bias to Quadrature when clicked, performs an auto bias on the

modulator and sets the mod ul a tor bias voltage to the midpoint of the mo dulated optical power curve. Biasing at quadrature maximizes the modulation

response and minimize s dis tortion of the modulated sig nal .

The power of the laser is assumed to have been previously set. If the laser

power is too low or if the laser is turned of f, the auto bias routi ne will fail and

display a message indicating that a bias point could not be found. For this

command to func tio n p rop erly, the laser po wer sho uld be lef t a t it s defa ult set ting or set to a reasonable power value (between 3 and 12 dBm) prior to performing this function.

Set Mod Bias to Maximum when selected, performs an auto bias on the

modulator and sets the modulator at maximum optical output power.

The power of the laser is assumed to have been previously set. If the laser

power is too low or if the laser is turned of f, the auto bias routi ne will fail and

display a message indicating that a bias point could not be found. For this

command to function properly , the laser power should be left to its default setting or set to a reasonable power value (between 3 and 12 dBm) prior to performing this function.

2-28

Getting Started

Tools Menu

E/X when selected, puts the 86032A test set into electrical excitation mode .

The RF signal coming in to the optical test set will be routed out of the front

panel connector marked “RF OUTPUT.” Therefore, the RF signal will not be

routed to the optical modulator in the test set.

O/X when selected, puts the 86032A test set into optical excitation mode. The

RF signal comin g into the test set will be routed to the optical modulator,

rather than out the front pane l connector marked “RF OUTPUT.”

Monitor Test Set

The Monitor Test Set dialog box is used to monitor and update the power and

voltage levels of the 86032A test set.

Optical Output Power (dBm) displays the current optical power coming

from the 86032A OPTICAL OUTPUT port.

Optical Receiver Input (dBm) displays the current optical power coming

into the 86032A OPTICAL RECEIVER INPUT por t.

Current Modulator Bias Setting (V) displays the current value of the

86032A bias voltage on the modulator.

2-29

Getting Started

Laser Safety Co nsiderations

Laser Safety Considerations

Laser Safety Laser ra diation in the ultraviolet and fa r infrared parts of the spectrum c an

cause damage primarily to the cornea and lens of the eye. Laser radiation in

the visible and near infrared regions of the spectrum can cause damage to the

retina of the eye.

The CW laser sources use a laser from which the greatest dangers to exposure

are:

1 To the eyes, where aqueous flare, cataract formation, and/or corneal burn are

possible.

2 To the skin, where burning is possible.

WARNI NG Do NOT, under any c ircums tances, look in to the op tical ou tput or a ny

fiber/device attached to the output while t he laser is in operation.

This system should be serviced onl y b y au thorized personne l.

Do not enable the laser unless fiber or an equivalent device is attached to the

optical output connector.

CAUTION Use of controls or adjustments or performance of procedures other than those

specified herein can re s ult in hazardous radiation exposu re.

Laser

Classifications

United States-FDA Laser Class IIIb. The system is rated USFDA (United

States Food and Drug Administration) Laser Class IIIb according to Part 1040,

Performance Standards fo r L igh t Em i tting Products, from the Cente r for

Devices and Radiological Health.

Internationa l -IEC Lase r Class 3B. Th e syst em is rat ed IEC (Int ern ati ona l El ectrotechnical Commission) Laser Class 3B laser products according to Publication 825.

International-IEC 825. The sy st em helps satisfy the I nt ernational (IEC8 2 5)

safety requirements with the use of a REMOTE SHUTDOWN and a KEY

SWITCH.

2-30

Getting Started

Laser Safety Consideratio ns

Laser Warning

Labels

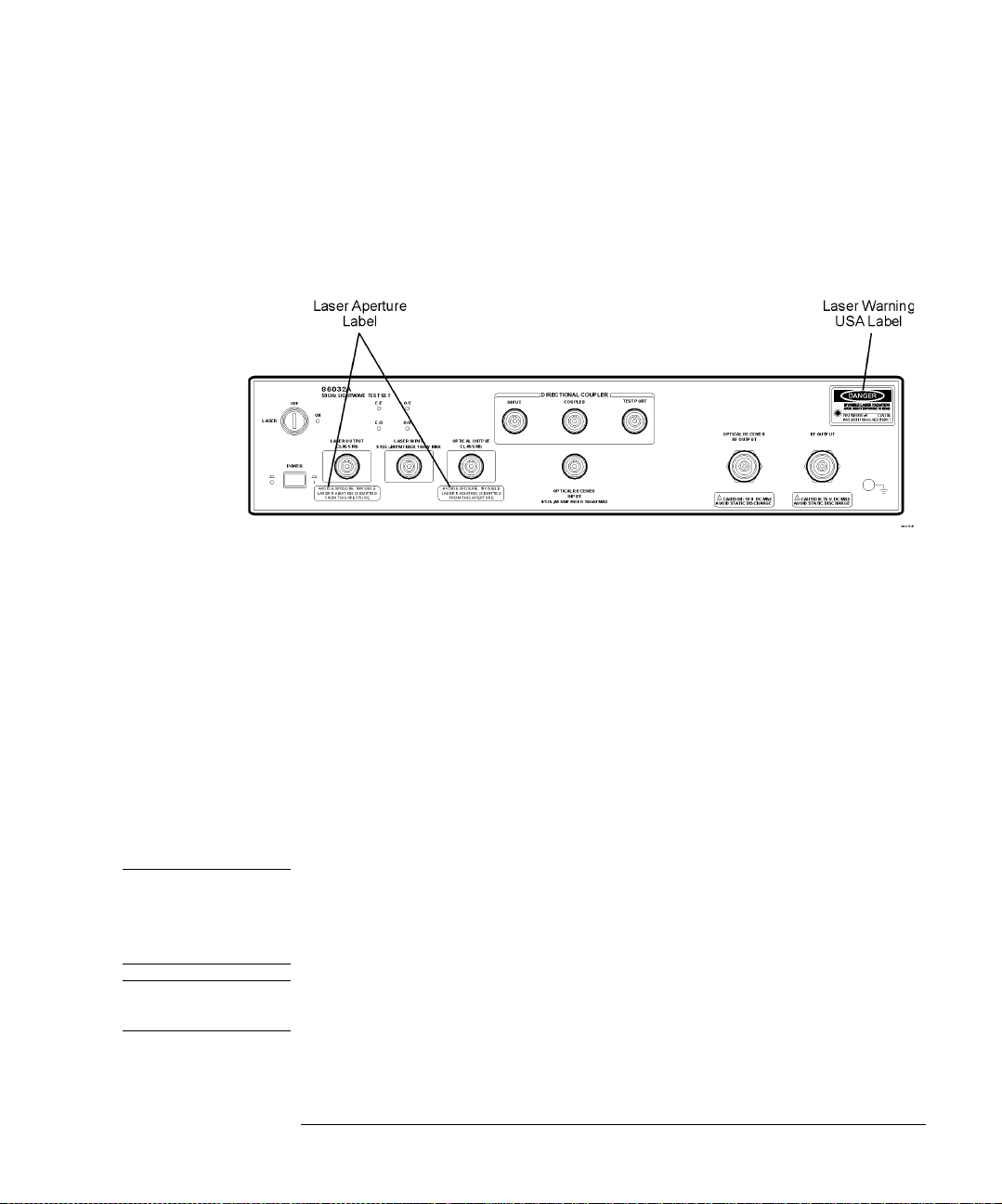

The 86030A is shipped with the followi ng war ni ng l abel s. For syste m s us ed

outside of the USA, both laser aperture and laser warning label s wi ll be

included with the shipment ( The labels are lo c a ted in the same bo x a s this

manual). Place th ese labels direc tly over the USA laser w a rning and aperture

labels.

Figure 2-10. Laser safety label locations

Electrical Safety The electrical safety considerations are documented in the section “General

Safety Considerations ” on page iv. Familiarize yourself with the saf ety mark-

ings and instru c tions before operating this system.

Service Limited service may be performed on this system in accordance with informa-

tion provided in Chapter 7, “Maintenance”. For all othe r repairs the system

must be returned to Agilent Technologies.

Maintenance On a daily basis, practice the techniques for proper connector use and care.

Refer to the Lightwave Connection Techniques for Better Measurements

booklet. If you should ever need to clean the cabinet, use a damp cloth only.

CAUTION Exposure to tempera tu res above 55°C may cause the front panel fiber to

retract. In this case a matching compound can be used to temporarily

improve return loss. However, the system sho uld be returned to Agilent

Technologies for repair.

CAUTION This product i s designed for use in INSTA L LATION CATEGORY II and

POLLUTION DEGREE 2, per IEC 1010 and 664 respectively.

2-31

Getting Started

Laser Safety Co nsiderations

Learn proper connector care

When you use improper cleaning and handling techniques, you risk expensive system

repairs, damaged cables, and compromised measurements. Repair of damaged connectors due to improper use is not covered under warranty.

Clean all cables before applying to any connector. Refer to the Lightwave Connections

Techniques for Better Measurements booklet.

2-32

Getting Started

Accurate Measu rem e nts

Accurate Measurements

Today, advances in measurement capabilities make connectors and connection techniques more important than ever. Damage to the connectors on calibration and verification devices, test ports, cables , and ot her device s can

degrade measurement accuracy and damage instruments. Replacing a damaged connector can cost thousands of dollars, not to mention lost time! This

expense can be avoided by observing the simple precautions presented in this

book. This book also contains a brief list of tips for caring for electrical connectors.

Choosing the Right Connector

A critical but often overlooked factor in making a good lightwave measure ment is the selection of the fiber-optic connector. The differences in connector types are mainly in the mechanic a l assembly that holds the ferrule in

position against another identical ferrule. Connectors also vary in the polish,

curve, and conce ntricity of the core w ithin the cladding . Mating one style o f

cable to another requires an adapter. Agilent Technologies offers adapters for

most instruments to allow testing with many different cables. The Figure 2-11

on page 2-34 shows the basic components of a typical connector.

The system tole ranc e for reflection and in se rtion loss must be kno wn w hen

selecting a connector from the wide variety of currently available connectors.

Some items to consider when selecting a connector are:

• How much insertion loss can be allowed?

• Will the connector need to make multiple connecti ons ? Some con ne ctors are

better than others, and some are very poor for making repeate d connections.

• What is the reflection tolerance? Can the system take reflection degradation?

• Is an instrument-grade connector with a pre ci si on core alig nmen t re qu ir ed ?

• Is repeatability tolerance for reflection and loss important? Do your specifica-

2-33

Getting Started

Accurate Measurements

tions take repeatability uncertain ty into account?

• Will a connector degrade the return loss too much, or will a fusion splice be required? For example, many DFB lasers cannot operate with reflections from

connectors. Often as much as 90 dB isolation is needed.

Figure 2-11. Basic components of a connector.

Over the last few ye a rs, the FC/PC style co nnector has emerged a s the most

popular connector for fiber-optic applications. While not the highest performing connector, it represents a good compromise between performance, reliability, and cost. If properly maintained and cleaned, this connector can

withstand many repeated connections.

However, many instrument specifications require tighter tolerances than most

connectors, including the FC/PC style, can deliver. These instruments cannot

tolerate connectors with the l arge non-concentricities of the f ibe r com m o n

with ceramic style ferrules. When tighter alignme n t is required,

Agilent instrument s ty pically use a connector such as the Di am ond H MS- 10,

which has concentric tolerances within a few tenths of a micron. Agilent then

uses a special universal adapter, which allows other cable types to mate with

this precisio n connector. See Figure 2-12 on page 2-35.

2-34

Getting Started

Accurate Measu rem e nts

Figure 2-12. Universal adapters

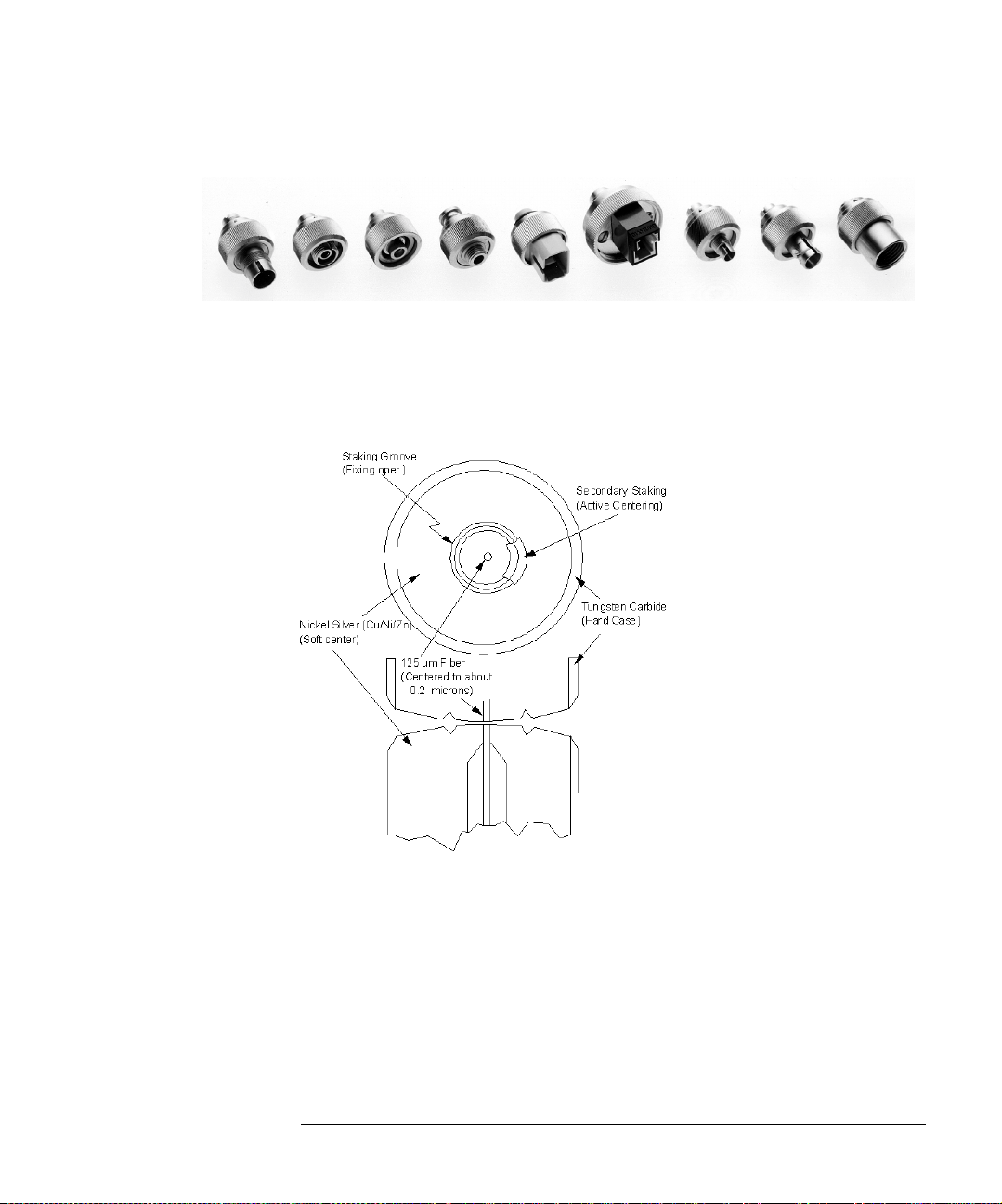

The HMS-10 enca se s the fiber within a soft nickel silver (Cu/ Ni/Zn) center

which is surrounded by a tough tungsten carbide casing, as shown in

Figure 2-13.

Figure 2-13. Cross-section of the Diamond HMS-10 connector.

The nickel silver allows an active centering process that permits the glass fiber

to be moved to the desired positi on. This process first stakes the soft nicke l

silver to fix the fiber in a near-center location, then uses a post-active staking

to shift the fiber into the desired position within 0.2 µm. This process, plus the

keyed axis, allo ws very precise core-to-core alignm ents. This connecto r is

found on most Agilent lightwave instruments.

2-35

Getting Started

Accurate Measurements

The soft core, wh ile allowing precis e ce n tering, is also the c h ief liability of the

connector. The soft material is easily damaged. Care must be taken to minimize excessive scratching and wear. While minor wear is not a problem if the

glass face is not affected, scratches or grit can cause the glass fiber to move

out of alig nment. Also, if unkeye d co nnecto rs ar e used , the nicke l sil ver ca n be

pushed onto the glass surface. Scratches, fiber movement, or glass contamination will cause lo s s of sign al and increa sed re flect ion s, resu ltin g in p oor retu rn

loss.

Inspecting Connectors

Because fiber-optic connectors are susceptible to damage that is not immediately obvious to the naked eye, bad measurements can be made without the

user even being aware of a connector problem. Although microscopic examination and return loss measurements are the best way to ensure good connections, they are not always practical. An awareness of potential problems, along

with good cleaning practices, can ensure that optimum conne ctor performance is maintained. With glass-to-glass interfac es, it is clear that any degradation of a ferrule or the end of the fiber, any stray particles, or finger oil can

have a significant effect on connector performance.

Figure 2-14 shows the end of a clean fiber-optic cable. The dark circle in the

center of the micrograph is the fiber’s 125 µm core and cladding which carries

the light. The surrounding area is the soft nickel-silver ferrule. Figure 2-15

shows a dirty fiber end from neglect or perhaps improper cleaning. Material is

smeared and gr ou nd i nto t he end o f t he f ib er cau si ng l igh t sc att erin g an d po or

reflection. Not only is the precision polish lost, but this action can grind off the

glass face and destroy the connector.

Figure 2-16 shows physical damage to the glas s fib er end caused by either

repeated connections made without removing loose particles or using

improper cleaning tools. When severe, the damage on one connector end can

be transferred to another good connecto r that comes in contact with it.

The cure for these p roblems is discipline d c onnector care as desc ribed in the

following list and in “Cleaning Connectors” on page 2-40.

Use the following guidelines to achieve the best possible performance when

making measurements on a fiber-optic system:

• Never use metal or sharp objects to clean a connector and never scr a pe the

connector.

• Avoid matching gel and oils.

2-36

Figure 2-14. Clean, problem-free fiber end and ferrule.

Getting Started

Accurate Measu rem e nts

Figure 2-15. Dirty fiber end and ferrule from poo r cl eaning.

Figure 2-16. Damage from improper cleaning .

2-37

Getting Started

Accurate Measurements

While these often work well on first insertion, they are great dirt magnets. The

oil or gel grabs and holds grit that is then ground into the end of the fiber.

Also, some early ge ls were designed for use with the FC, non-contacting connectors, using small glass spheres. When used with contacting connectors,

these glass balls can scratch and pit the fiber. If an index matching gel or oil

must be used, apply it to a freshly cleaned connector, make the measurement,

and then immed ia tely clean it o ff. Never use a gel for lo n ger-term connections

and never use it to improve a damaged connector. The gel can mask the extent

of damage and continued use of a damaged fiber can trans fer damage to the

instrument.

• When inserting a fiber-optic c able into a connector, gently insert it in as

straight a line as possible. Tipping and inserting at an angle can scrape material

off the inside of the connector or even break the inside sleeve of connectors

made with ceramic material.

• When inserting a fiber-optic connector into a connector, make sure that the fiber end does not touch the outside of the mating connec tor or adapter.

• Avoid over tightening connections.

Unlike common electrical connections, tighte r is not better. The purpose of

the connector is to bring two fiber ends together. Once they touch, tightening

only causes a greater force to be applied to the delicate fibers. With connectors that have a convex fiber end, the end can be pushed off-axis resulting in

misalignmen t a nd e xc essive return lo ss. Many measurements are actuall y

improved by backing off the connector pressure. Also, if a piece o f grit does

happen to get by the cleaning procedure, the tighter connection is more likely

to damage the glass. Tighten the connectors just until the two fibers to uch.

• Keep connectors covered when not in use.

• Use fusion splices on the more permanent critical nodes. Choose the best con-

nector possible. Replace connecting cables regularly. Frequently measure the

return loss of the connector to check for degradation, and clean every connector, every time.

All connectors should be treated like the high-quality lens of a good camera.

The weak link in instrument and syste m reliability is often the inappropriate

use and care of the connector. Because current connectors are so easy to use,

there tends to be reduced vigilance in connector care and cleaning. It takes

only one missed cle a ning for a piece of grit to perm a nently damage the glass

and ruin the conne c to r.

2-38

Getting Started

Accurate Measu rem e nts

Measuring insertion loss and return loss

Consistent measurements with your lightwave equipme nt are a good indication that you have good connections. Since return loss and insertion loss are

key factors in determining optical connector performance they can be used to

determine connector degradation. A smooth, polished fiber end should produce a good return- l o ss measurement. The qual ity of the polish estab lishes

the difference bet w een the “PC” (physical contact) and the “Super PC” connectors. Most connectors today are physical contact which make glass-to-glass

connections, therefore it is critical that the area around the glass core be clean

and free of scratches. Altho ug h the major area of a connector, excluding the

glass, may show scra tc hes and wear, if the glass has maintai n e d its polished

smoothness, the connector can st ill provide a good low level return loss co nnection.

If you test your cables and acces so ries for insertion loss and re tur n loss upon

receipt, and retain the measured data for comparison, you will be able to tell in

the future if any degradation has occurred. Typical values are less than 0.5 dB

of loss, and somet im es as little as 0.1 dB of loss with high performa nc e co nnectors. Return loss is a measure of reflection: the le ss reflection the better

(the larger the return loss, the smaller the reflection). The best physically

contacting connectors have return losses better than 50 dB, although 30 to 40

dB is more common.

To Test Insertion Loss

Use an appropriate lightwave source and a compatible lightwave receiver to

test insertion loss. Examples of test equipment configurations include the following equipment:

• 71450A or 71451A Optical Spectrum Analyzers with Option 002 built-in white

light source.

• 8702 or 8703 Lightwave Component Analyzer system.

• 83420 Chromatic Dispersion Test Set with an 8510 Network Analyzer.

• 8153 Lightwave Multimeter with a source and power se ns or module.

To Test Return Loss

Use an appropriate lightwave source, lightwave receiver, and lightwave coupler to test return loss. Examples of test equipment configurations include the

following equipm ent:

• Agilent 8703 Lightwave Component Analyzer.

• Agilent 8702 Lightwave Component Analyzer with the appropriate source,

receiver, and lightwave coupler.

• Agilent 8504 Precision Reflectometer.

• Agilent 8153 Lightwave Multimeter with a source and power sensor module in

2-39

Getting Started

Accurate Measurements

conjunction with a lightwave coupler.

• Agilent 81554SM Dual Source and Agilent 81534A Return Loss Module.

Visual inspection of fiber ends

Visual inspection of fiber ends can be helpful. Contamination or imperfections

on the cable end face can be detected as well as cracks or chips in the fiber

itself. Use a microscope (100X to 200X magni fi cati on) to in spect the entire

end face for contam ina tion, raised meta l , or dents in the metal as we ll as any

other imperfections. Inspect the fiber for cracks and chips. Visible imperfections not touching the fibe r cor e m ay no t affe ct pe rformance (unless the

imperfections keep the fibers from contacting).

WARNI NG Always remove both ends of fiber-optic cables from any instrument,

system, or device before visually inspecting the fiber ends. Disable all

optical sources before disconnecting fiber-optic cables. Failure to do

so may result in permanent injury to your eyes.

Cleaning Connectors

The procedures in this section provide the proper steps for cleaning fiberoptic cables and Agilent univers a l a da p ters. The initial cl ea ning, using the

alcohol as a solvent, gently removes any grit and oil. If a caked-on layer of

material is still present, (this can happen if the beryllium-copper sides of the

ferrule retainer get scraped and deposited on the end of the fiber during insertion of the cable), a second cleaning should be performed. It is not uncommon

for a cable or connector to require more than one cleaning.

CAUTION Agilent strongly recommends that index matching compounds not be applied

to their instruments and accessories. Some compounds, such as gels, may be

difficult to remove and can contain damaging particulates. If you think the use

of such compounds is necessary, refer to the compound manufacturer for

information on applica tion and cleaning procedure s.

2-40

Accurate Measu rem e nts

Table 2-3. Cleaning Accessories

Item Agilent Part Number

Pure isopropyl alcohol —

Cotton swabs 8520-0023

Small foam swabs 9300-1223

Compressed dust remover (non-residue) 8500-5262

Table 2-4. Dust Caps Provided with Lightwave Inst rume nts

Item Agilent Part Number

Laser shutter cap 08145-64521

FC/PC dust cap 08154-44102

Getting Started

Biconic dust cap 08154-44105

DIN dust cap 5040-9364

HMS10/Agilent dust cap 5040-9361

ST dust cap 5040-9366

To clean a non-lensed connector

CAUTION Do not use any type of foam swab to clean optical fiber ends. Foam swabs can

leave filmy deposits on fiber e nds that can degrade performance.

1 Apply pure isoprop yl alcoh ol to a clean lint-free cotton swab or len s pape r.

Cotton swabs can be used as long as no cotton fibers remain on the fiber end

after cleaning.

2 Clean the ferrules and o the r parts of the connector while avoidi ng the end of

the fiber.

3 Apply isopropyl alcohol to a new clean lint-free cotton swab or lens paper.

4 Clean the fiber end with the swab or lens paper.

2-41

Getting Started

Accurate Measurements

Do not scrub during this initial cleaning because grit ca n be caught in the

swab and become a gouging element.