Performance Tests and

Adjustments Manual

HP

8568B Spectrum Analyzer

HEWLETT

PACKARD

HP Part No. 08568-90118

Printed in USA

September 1993

@Copyright Hewlett-Packard Company 1993

All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the

copyright laws.

1212 Valley House Drive, Rohnert Park, CA 94928-4999, USA

Certification

Hewlett-Packard Company certifies that this product met its

published specifications at the time of shipment from the factory.

Hewlett-Packard further certifies that its calibration measurements

are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute’s calibration facility,

and to the calibration facilities of other International Standards

Organization members.

Warranty

This Hewlett-Packard instrument product is warranted against defects

in material and workmanship for a period of one year from date of

shipment. During the warranty period, Hewlett-Packard Company

will, at its option, either repair or replace products which prove to be

defective.

For warranty service or repair, this product must be returned to a

service facility designated by Hewlett-Packard. Buyer shall prepay

shipping charges to Hewlett-Packard and Hewlett-Packard shall pay

shipping charges to return the product to Buyer. However, Buyer shall

pay all shipping charges, duties, and taxes for products returned to

Hewlett-Packard from another country.

Hewlett-Packard warrants that its software and firmware designated

by Hewlett-Packard for use with an instrument will execute

its programming instructions when properly installed on that

instrument. Hewlett-Packard does not warrant that the operation

of the instrument, or software, or firmware will be uninterrupted or

error-free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse,

operation outside of the environmental specifications for the

product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED.

HEWLETT-PACKARD SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. HEWLETT-PACKARD SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT,

TORT, OR ANY OTHER LEGAL THEORY.

. . .

III

Assistance

Product maintenance agreements and other customer assistance

agreements are available for Hewlett-Rwkard products.

Fbr

any assistance, contact your nearest

Service

OJke.

Hewlett-Packard

Sales and

Safety Symbols

The following safety symbols are used throughout this manual.

Familiarize yourself with each of the symbols and its meaning before

operating this instrument.

Caution

Warning

General Safety Considerations

Warning

The caution sign denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could result in

damage to or destruction of the instrument. Do not proceed beyond a

caution sign until the indicated conditions are fully understood and

met.

The warning

procedure which, if not correctly performed or adhered to, could

result in injury or loss of life. Do not proceed beyond a

sign until the indicated conditions are fully understood and met.

Before this instrument is switched on,

properly grounded through the protective conductor of the ac

power cable to a socket outlet provided with protective earth

contact.

Any interruption of the protective (grounding) conductor, inside

or outside the instrument, or disconnection of the protective

earth terminal can result in personal injury.

sign denotes a hazard. It calls attention to a

warning

make sure it has been

Warning

Caution

There are many points in the instrument which can, if contacted,

cause personal injury. Be extremely careful.

Any adjustments or service procedures that require operation

of the instrument with protective covers removed should be

performed only by trained service personnel.

Before this instrument is switched on, make sure its primary power

circuitry has been adapted to the voltage of the ac power source.

Failure to set the ac power input to the correct voltage could cause

damage to the instrument when the ac power cable is plugged in.

V

HP

8568B

Spectrum Analyzer

Documentation

Outline

Included with the HP Model

manuals: the Installation and Verification Manual, the Operating and

Programming Manual, and the Performance Tests and Adjustments

Manual.

8568B

Spectrum Analyzer are three

HP

8568B

HP

and Programming

Performance

Adjustments Manual

HP

85680B

Troubleshooting and

HP

85662A

Troubleshooting and

Installation

and Verification

Manual

8568B

Operating

Manual

HP

8568B

Tests

RF Section

Repair Manual

IF-Display

Section

Repair Manual

General information, installation, specifications, characteristics, and

operation verification.

Manual and remote operation, including complete syntax and

command description. Accompanying this manual is the separate,

pocket-sized Quick Reference Guide.

Electrical performance tests and adjustment procedures.

and

RF Section service information.

IF-Display Section service information.

vi

Contents

1. General Information

Introduction

Instruments Covered by this Manual

Operation Verification

Option 462 Instruments

Option 857 Instruments

2. Performance Tests

Introduction

Verification of Specifications

Calibration Cycle

Equipment Required

Test Record

1. Center Frequency Readout Accuracy Test ....

2. Frequency Span Accuracy Test

3. Sweep Time Accuracy Test

4. Resolution Bandwidth Accuracy Test

5. Resolution Bandwidth Selectivity Test

6. Resolution Bandwidth Switching Uncertainty Test

7. Input Attenuator Switching Uncertainty Test . .

8. Frequency Response Test

9. RF Gain Uncertainty Test

10. IF Gain Uncertainty Test

11. Log Scale Switching Uncertainty Test .....

12. Amplitude Fidelity Test

13. Average Noise Level Test

14. Residual Responses Test

15. Spurious Responses Test

16. Residual FM Test

17. Line-Related Sidebands Tests

18. Calibrator Amplitude Accuracy Test

19. Fast Sweep Time Accuracy Test

20.

21. Frequency Reference Error Test

‘Ihble

2-19. Performance Test Record

Test 1. Center Frequency Readout Accuracy Test ...

Test 2. Frequency Span Accuracy Test

Test 3. Sweep Time Accuracy

Test 4. Resolution Bandwidth Accuracy

Test 5. Resolution Bandwidth Selectivity

Test 6. Resolution Bandwidth Switching Uncertainty

Test

Test 7. Input Attenuator Switching Uncertainty Test

Test 8. Frequency Response Test

Test 9. RF Gain Uncertainty Test

Test 10. IF Gain Uncertainty Test

.....................

.........

................

...............

...............

.....................

.............

..................

................

....................

.........

(220

ms)

............

............

...........

............

...........

............

............

...............

.........

(~20

1st

LO Output Amplitude Test

......................

.........

........

..........

........

............

.......

.......

..........

..........

..........

......

......

......

......

ms) ....

.

l-l

l-l

l-2

1-2

l-2

2-l

2-l

2-l

2-2

2-2

2-3

2-6

2-9

2-13

2-15

2-18

2-20

2-22

2-31

2-33

2-39

2-41

2-45

2-47

2-49

2-56

2-60

2-62

2-63

2-66

2-67

2-69

2-70

2-71

2-72

2-73

2-74

2-75

2-76

2-77

2-78

2-79

Contents-l

Test 11. Log Scale Switching Uncertainty Test

Test 12. Amplitude Fidelity Test

Test 13. Average Noise Level Test

Test 14. Residual Responses Test

Test 15. Spurious Responses Test

Test 16. Residual FM Test

Test 17. Line-Related Sidebands Test

...........

..........

...........

..........

..............

.........

Test 18. Calibrator Amplitude Accuracy Test

Test 19. Fast Sweep Time Accuracy Test

Test 20.

1st

LO Output Amplitude Test

Test 21. Frequency Reference Error Test

Adjustments

3.

(~20

ms)

........

.......

Introduction .....................

Safety Considerations .................

Equipment Required .................

Adjustment Tools ...................

Factory-Selected Components

.............

Related Adjustments .................

Location of Test Points and Adjustments

........

1. Low-Voltage Power Supply Adjustments ......

2. High-Voltage Adjustment (SN

2. High-Voltage Adjustment (SN

3. Preliminary Display Adjustments (SN

3001A

and Below) . .

3004A

and Above) . .

3001A

Below) .....................

3. Preliminary Display Adjustments (SN

3004A

Above) .....................

4. Final Display Adjustments (SN

4. Final Display Adjustments (SN

3001A

3004A

and Below)

and Above)

5. Log Amplifier Adjustments ............

6. Video Processor Adjustments ...........

7. 3 MHz Bandwidth Filter Adjustments .......

8. 21.4 MHz Bandwidth Filter Adjustments .....

9. 3 dB Bandwidth Adjustments ..........

10. Step Gain and 18.4 MHz Local Oscillator

Adjustments ..................

11. Down/Up Converter Adjustments ........

12. Time Base Adjustment (SN

32

17AO5568

and Above)

12. Time Base Adjustment (SN

2840A

and Below, also

.............

2848A

to

3217A05567)

13. 20 MHz Reference Adjustments .........

14. 249 MHz Phase Lock Oscillator Adjustments

15. 275 MHz Phase Lock Oscillator Adjustment ....

16. Second IF Amplifier and Third Converter

Adjustment ...................

17. Pilot Second IF Amplifier Adjustments ......

18. Frequency Control Adjustments .........

19. Second Converter Adjustments .........

20. 50 MHz Voltage-Tuned Oscillator Adjustments

2 1. Slope Compensation Adjustments ........

22. Comb Generator Adjustments ..........

23. Analog-To-Digital Converter Adjustments .....

24. Track and Hold Adjustments ...........

25. Digital Storage Display Adjustments .......

Low-Noise DC Supply

................

....

.....

. .

and

and

.

.

...

. .

2-82

2-83

2-84

2-85

2-86

2-87

2-88

2-89

2-90

2-91

2-92

3-l

3-2

3-2

3-2

3-3

3-4

3-4

3-25

3-29

3-39

3-45

3-52

3-59

3-61

3-65

3-69

3-72

3-77

3-84

3-87

3-92

3-95

3-99

3-103

3-107

3-110

3-112

3-116

3-119

3-123

3-130

3-133

3-136

3-139

3-142

3-145

3-150

Contents-2

Crystal Filter Bypass Network Configuration . . . . . 3-151

4. Option 462

Introduction . . . . . . . . . . . . . . . . . . . . .

4. 6 dB Resolution Bandwidth Accuracy Test . . . . .

4. Impulse and Resolution Bandwidth Accuracy Test

5. 6 dB Resolution Bandwidth Selectivity Test . . . .

5. Impulse and Resolution Bandwidth Selectivity Test .

6. Impulse and Resolution Bandwidth Switching

Uncertainty Test . . . . . . . . . . . . . . . .

Test 4. 6 dB Resolution Bandwidth Accuracy Test (p/o

Table

2-19, Performance Test Record) . . . . . . .

Test 4. Impulse and Resolution Bandwidth Accuracy

Test (p/o

Table

2-19, Performance Test Record) . .

Test 5. 6 dB Resolution Bandwidth Selectivity (p/o

‘Ihble

2-19, Performance Test Record) . . . . . . .

Test 5. Impulse and Resolution Bandwidth Selectivity

(p/o Table 2-19, Performance Test Record) . . . . .

Test 6. Impulse and Resolution Bandwidth Switching

Uncertainty (p/o

‘Iable

2-19, Performace Test

Record) . . . . . . . . . . . . . . . . . . . . .

9. 6 dB Resolution Bandwidth Adjustments . . . . .

9. Impulse Bandwidth Adjustments . . . . . . . . .

4-l

4-2

4-4

.

4-10

4-13

4-16

4-18

4-19

4-21

4-22

4-23

4-24

4-27

5. Option 857

Introduction . . . . . . . . . . . . . . . . . . . . .

12. Option 857 Amplitude Fidelity Test . . . . . . .

Performance Test Record . . . . . . . . . . . . . . .

Test 12. Option 857 Amplitude Fidelity Test . . . . .

6.

Major Assembly and Component Locations

IF-Display Section Figure Index . . . . . . . . . . . .

RF Section Figure Index . . . . . . . . . . . . . . .

5-l

5-2

5-7

5-8

6-l

6-2

Contents-3

Figures

l-l. Service Accessories, HP Part Number 08568-60001

2-l.

Center Frequency Accuracy Test Setup

2-2. Center Frequency Readout Error Measurement

2-3. Frequency Span Accuracy Test Setup

2-4. Sweep Time Accuracy Test Setup

2-5.

Penlift

Output Signal

2-6. Resolution Bandwidth Measurement

2-7. 60 dB Bandwidth Measurement

2-8. Bandwidth Switching Uncertainty Measurement

2-9. Attenuator Switching Uncertainty Test Setup

2-10. Attenuator Switching Uncertainty Measurement

2-l

1. Frequency Response Test Setup (20 MHz to 1.5

2-12. Frequency Response Measurement (20 MHz to 1.5

2-13. Frequency Response Test Setup (100 kHz to 20 MHz)

2-14. Frequency Response Measurement (100 kHz to 20 MHz)

2-15. Frequency Response Test Setup (100 Hz to 100

2-16. RF Gain Uncertainty Measurement

2-17. IF Gain Uncertainty Test Setup

2-18. IF Gain Uncertainty Measurement

2-19. IF Gain Uncertainty Measurement (2

2-20. Log Scale Switching Uncertainty Measurement

2-21. Amplitude Fidelity Test Setup

2-22. Amplitude Fidelity Measurement

2-23. Average Noise Level Measurement

2-24. Residual Responses Measurement

2-25. Harmonic Distortion Test Setup

2-26. Intermodulation Distortion Test Setup

2-27. Intermodulation Distortion Products

2-28. Bandwidth Filter Slope Measurement

2-29. Slope Detected Residual FM

2-30. Peak-to-Peak Amplitude Measurement

2-31. Line Related Sidebands Measurement

2-32. Calibrator Amplitude Accuracy Test Setup

2-33. Fast Sweep Time Accuracy

2-34. Fast Sweep Time Measurement

2-35.

1st

LO Output Amplitude Test Setup

2-36.

Frequency Reference Test Setup

3-l.

Low-Voltage Power Supply Adjustments Setup

3-2. IF-Display Section Low-Voltage Adjustments (SN

and Below) ...................

3-3. IF-Display Section Low-Voltage Adjustments (SN

and Above) ...................

3-4. Location of RF Section Low-Voltage Adjustments

3-5. High Voltage Adjustment Setup

3-6. Location of High Voltage Adjustments

3-7. Location of Label and Test Point . . . . . . . . . . .

................

...........

............

.............

(~20

ms Test Setup)

(~20

........

........

..........

.........

.....

.........

...........

..........

.......

dB)

..........

..........

..........

...........

........

.........

........

........

........

......

.......

ms)

.........

...........

...........

........

. .

....

...

...

GHz)

GHz)

kHz)

....

....

....

3001A

3004A

...

l-8

2-3

2-4

2-6

2-9

2-11

2-14

2-16

2-19

2-20

2-21

2-22

.

2-24

2-25

.

2-26

2-27

.

2-32

2-33

2-35

2-36

2-40

2-41

2-43

2-46

2-48

2-50

2-52

2-53

2-57

2-58

2-58

2-61

2-62

2-63

2-64

2-66

2-68

3-25

3-26

3-26

3-27

3-30

3-31

3-32

Contents-4

3-8. Location of

AlA

Components ...........

3-9. CRT Cut-Off Voltage

3-10. Waveform at AlA3TP5’ : : : : : : : : : : : : : :

3-11. Discharging the CRT Post-Accelerator Cable

3-12. High Voltage Adjustment Setup

...........

3-13. Location of High Voltage Adjustments

3-14. Location of

AlA

Label and Test Point

........

3-15. Discharging the CRT Post-Accelerator Cable

3-16. Preliminary Display Adjustments Setup

3-17. Location of

3-18.

AlA2, AlA4,

3-19. X+ and X- Waveforms

3-20. Composite X Deflection Waveform

AlA2, AlA4, AlA5,

and

AlA

Adjustment Locations

...............

and

A3A2

..........

.....

........

.....

.......

.....

....

3-21. Rise and Fall Times and Overshoot Adjustment

Waveform

3-22.

5OV,-,

Signal ....................

3-23. Preliminary Display Adjustments Setup

3-24. Location of

3-25.

AlA

Adjustment Locations

3-26. X+ and X- Waveforms

3-27. Composite X Deflection Waveform

...................

.......

AlA

and

A3A2

............

.............

...............

..........

3-28. Rise and Fall Times and Overshoot Adjustment

Waveform

3-29.

5OV,-,

Signal ....................

3-30. Location of Final Display Adjustments on

and

AlA5.

3-31. Final Display Adjustments Setup

3-32. Location of Final Display Adjustments on

3-33. Log Amplifier Adjustments Setup

3-34. Location of Log Amplifier Adjustments

3-35. Video Processor Adjustments Setup

3-36. Location of Video Processor Adjustments

3-37. 3 MHz Bandwidth Filter Adjustments Setup

...................

AlA2, AlA4,

...................

...........

AlA

...

..........

........

.........

.......

.....

3-38. Location of Center, Symmetry, and 10 Hz Amplitude

Adjustments

3-39. Location of 3 MHz Peak Adjustments

3-40. 21.4 MHz Bandwidth Filter Adjustments Setup

3-41. Location of

3-42. Location of

3-43. Location of

A4A4

A4A4

A4AS

Adjustments

3-44. Location of

A4A8

3-45. Location of 3 dB Bandwidth Adjustments

..................

.........

....

21.4 MHz LC Filter Adjustments . .

21.4 MHz Crystal Filter Adjustments

21.4 MHz LC Filter and Attenuation

..................

21.4 MHz Crystal Filter Adjustments

......

3-46. Step Gain and 18.4 MHz Local Oscillator Adjustments

Setup

......................

3-47. Location of IF Gain Adjustment ...........

3-48. Location of 10 dB Gain Step Adjustments

3-49. Location of .l dB Gain Step, 18.4 MHz LO, and +

Adjustments

..................

......

1OV

3-50. Down/Up Converter Adjustments Setup .......

3-51. Location of Down/Up Converter Adjustments

.....

3-52. Time Base Adjustment Setup ............

3-53. Location of

A27Al

Adjustment ...........

3-54. Time Base Adjustment Setup ............

3-55. Location of

A27A2

Adjustment ...........

:

3-34

3-35

3-36

3-38

3-40

3-41

3-42

3-44

3-46

3-47

3-47

3-48

3-49

3-49

3-51

3-53

3-54

3-54

3-55

3-56

3-56

3-58

3-60

3-61

3-62

3-65

3-66

3-69

3-70

3-72

3-73

3-75

3-77

3-78

3-79

3-80

3-81

3-85

3-87

3-88

3-89

3-91

3-92

3-93

3-95

3-98

3-99

3-102

Contents-5

3-56. 20 MHz Reference Adjustments Setup ........

3-57. Location of 20 MHz Reference Adjustments .....

3-58. Typical Signal at

A16TP3

..............

3-59. 249 MHz Phase Lock Oscillator Adjustments Setup . .

3-60. Location of 249 MHz Phase Lock Oscillator Adjustments

3-61. 275 MHz Phase Lock Oscillator Adjustment Setup ...

3-62. Location of 275 MHz PLO Adjustment ........

3-63. Second IF Amplifier Adjustments Setup .......

3-64. Location of 301.4 MHz BPF and 280 MHz AMPTD

Adjustments ..................

3-65. 301.4 MHz Bandpass Filter Adjustment Waveform . .

3-66. Minimum Image Response at 258.4 MHz .......

3-67. Pilot Second IF Amplifier Adjustments Setup .....

3-68. Location of 269 MHz Bandpass Filter Adjustments . .

3-69. 269 MHz

Bandpass

Filter Adjustments Waveforms . .

3-70. Frequency Control Adjustments Setup ........

3-71. Location of Frequency Control Adjustments .....

3-72. Second Converter Adjustments Setup ........

3-73. Location of Second Converter Adjustments ......

3-74. Typical PILOT

3-75. Typical PILOT

3-76. Typical

3-77. Typical

Bandpass

Bandpass

3-78. 50 MHz Voltage-Tuned Oscillator Adjustments Setup

2ND

IF Bandpass (SHIFT t)......

2ND

IF Bandpass (SHIFT 1)......

(SHIFT t).............

(SHIFT 1).............

.

3-79. Location of 50 MHz VT0 Adjustments ........

3-80. Slope Compensation Adjustment Setup ........

3-81. Location of

A22R66

TILT Adjustment ........

3-82. Slope Compensation Adjustment Waveforms .....

3-83. Location of Comb Generator Adjustments ......

3-84. Comb Teeth Display .................

3-85. Analog-To-Digital Converter Adjustments Setup ....

3-86. Location of Analog-To-Digital Converter Adjustments .

3-87. Track and Hold Adjustments Setup .........

3-88. Location of Track and Hold Adjustments .......

3-89. Digital Storage Display Adjustments Setup ......

3-90. Location of Digital Storage Display Adjustments ...

3-91. Sample and Hold Balance Adjustment Waveforms ...

3-92. Waveform Before Adjustment ............

3-93. Low-Noise DC Supply ................

3-94. Crystal Filter Bypass Network Configurations .....

4-l.

Resolution Bandwidth Measurement .........

4-2. Impulse Bandwidth Test Setup ............

4-3. 6 dB Resolution Bandwidth Measurement ......

4-4. 60 dB Bandwidth Measurement ...........

4-5. 60 dB Bandwidth Measurement ...........

4-6. Bandwidth Switching Uncertainty Measurement ...

4-7. Location of Bandwidth Adjustments .........

4-8. Location of Bandwidth Adjustments .........

5.1. Option 857 Amplitude Fidelity Test Setup ......

6-l.

RF Section, Top View ................

6-2. RF Section, Front View ...............

6-3. RF Section, Bottom View ..............

6-4. IF Section, Top View (SN

6-5. IF Section, Top View (SN

3001A

and Below) .....

3004A

and Above) .....

6-6. IF Section, Front View ...............

3-103

3-104

3-106

3-107

3-108

3-110

3-111

3-112

3-114

3-l

14

3-115

3-116

3-118

3-118

3-119

3-120

3-123

3-124

3-127

3-127

3-128

3-128

3-130

3-131

3-133

3-135

3-135

3-136

3-137

3-139

3-140

3-142

3-143

3-145

3-146

3-147

3-147

3-150

3-151

4-3

4-4

4-8

4-11

4-14

4-17

4-25

4-28

5-2

6-4

6-5

6-6

6-7

6-8

6-9

Contents-6

6-7. IF Section, Bottom View . . . . . . . . . . . . . .

6-10

Contents-7

lhbles

2-l.

Performance Test Cross-Reference ..........

2-2. Center Frequency Readout Error Test Record .....

2-3. Wide Span Error ..................

2-4. Span Error .....................

2-5. Sweep Time Accuracy, Sweep Times

2-6. Sweep Time Accuracy, Sweep Times

2-7. Sweep Time Accuracy, Sweep Times

220

ms .....

~20 s

220

......

ms (Alternate

Procedure) ...................

2-8. Bandwidth Accuracy ................

2-9. Resolution Bandwidth Selectivity ..........

2-10. Bandwidth Switching Uncertainty ..........

2-11. Input Attenuator Switching Uncertainty .......

2-12. IF Gain Uncertainty, 10 dB Steps ..........

2-13. IF Gain Uncertainty, 2 dB Steps ...........

2-14. IF Gain Uncertainty, 0.1 dB Steps ..........

2-15. Log Scale Switching Uncertainty ...........

2-16. Log Amplitude Fidelity ...............

2-

17. Linear Amplitude Fidelity ..............

2-18. Fast Sweep Time Accuracy

(~20

ms) .........

3-1. Adjustment Cross Reference .............

3-2. Adjustable Components ...............

3-3. Factory-Selected Components ............

3-4. Standard Value Replacement Capacitors .......

3-5. Standard Value Replacement 0.125 Resistors .....

3-6. Standard Value Replacement 0.5 Resistors ......

3.5. Initial Adjustment Positions .............

3-6. Initial Adjustment Positions .............

3-7. Parts for Low-Noise DC Supply ...........

3-8. Crystal Filter Bypass Network Configuration for

and

A4A8

(21.4 MHz) ..............

3-9. Crystal Filter Bypass Network Configuration for

(3 MHz)

4-l.

6 dB Resolution Bandwidth Accuracy ........

.....................

A4A4

A4A7

4-2. Impulse Bandwidth Accuracy ............

4-3. 6 dB Resolution Bandwidth Accuracy ........

4-4. 6 dB Resolution Bandwidth Selectivity ........

4-5. Impulse and Resolution Bandwidth Selectivity ....

4-6. Bandwidth Switching Uncertainty ..........

5-l.

Log Amplitude Fidelity (10 Hz RBW; Option 857) ...

5-2. Log Amplitude Fidelity (10 kHz RBW; Option 857) . .

5-3. Linear Amplitude Fidelity . . . . . . _ . . . . . . .

2-2

2-5

2-7

2-8

2-11

2-12

2-12

2-14

2-17

2-19

2-21

2-35

2-36

2-38

2-40

2-42

2-44

2-65

3-3

3-5

3-13

3-20

3-21

3-23

3-59

3-62

3-150

3-151

3-151

4-3

4-8

4-9

4-12

4-15

4-17

5-4

5-5

5-6

Contents-E

General Information

1

Introduction

Warning

This HP

Performance Tests and Adjustments Procedures. The Performance

Tests provided should be performed for the following reasons:

w

If the test equipment for the Operation Verification Program is not

available.

n If the instrument does not pass all of the Operation Verification

tests.

w

For complete verification of specifications not covered by the

Operation Verification program.

The adjustment procedures should be performed for the following

reasons:

w

If the results of a performance test are not within the specifications.

w

After the replacement of a part or component that affects electrical

performance.

The adjustment procedures require access to the interior of the

instrument and therefore should only be performed by qualified

service personnel. There are voltages at many points in the

instrument which can, if contacted, cause personal injury. Be

extremely careful. Adjustments should be performed only by

trained service personnel.

8568B

Tests and Adjustments Manual contains two sections:

Instruments Covered

by this Manual

Power is still applied to this instrument with the LINE switch in

STANDBY. There is no OFF position on the LINE switch. Before

removing or installing any assembly or printed circuit board,

remove the power cord from the rear of both instruments and

wait for the MAINS indicators (red

Capacitors inside the instrument may still be charged even if the

instrument has been disconnected from its source of power.

Use a non-metallic tuning tool whenever possible.

This manual contains procedures for testing and adjusting HP

Spectrum Analyzers, including those with Option 001 (75 Ohm RF

INPUT), Option 400 (400 Hz operation), Option 462, and Option 857

installed. The procedures in this manual can also be used to adjust HP

8568A

Spectrum Analyzers that have been converted into HP

Spectrum Analyzers through the installation of an HP

Kit (formerly HP 8568A+

OlK

Retrofit Kit).

LEDs)

to go completely out.

8568AB

General Information

8568B

8568B

Retrofit

l-1

Operation Verification

A high confidence level in the instrument’s operation can be achieved

by running only the Operation Verification Program, since it tests

most of the instrument’s specifications. It is recommended that the

Operation Verification Program be used for incoming inspection and

after repairs, since it requires much less time and test equipment.

A description of the program can be found in the Installation and

Verification manual.

Option 462

Instruments

Option 857

Instruments

Option 462 instruments require that the performance tests and

adjustment procedures listed below be performed instead of their

standard versions included in chapters two and three. Information on

Option 462 versions are located in Chapter 4, Option 462.

6 dB Bandwidths:

Test 4, 6 dB Resolution Bandwidth Accuracy Test

Test 5, 6 dB Resolution Selectivity Test

Adjustment 9, 6 dB Bandwidth Adjustments

Impulse Bandwidths:

Test 4, Impulse and Resolution Bandwidth Accuracy Test

Test 5, Impulse and Resolution Selectivity Test

Test 6, Impulse and Resolution Bandwidth Switching Uncertainty

Test

Adjustment 9, Impulse Bandwidth Adjustments

Option 857 instruments require that the performance test procedure

listed below be performed instead of the standard version included in

Chapter 2. Information on Option 857 is located in Chapter 5, Option

857.

Test 12, Option 857 Amplitude Fidelity Test

l-2

General Information

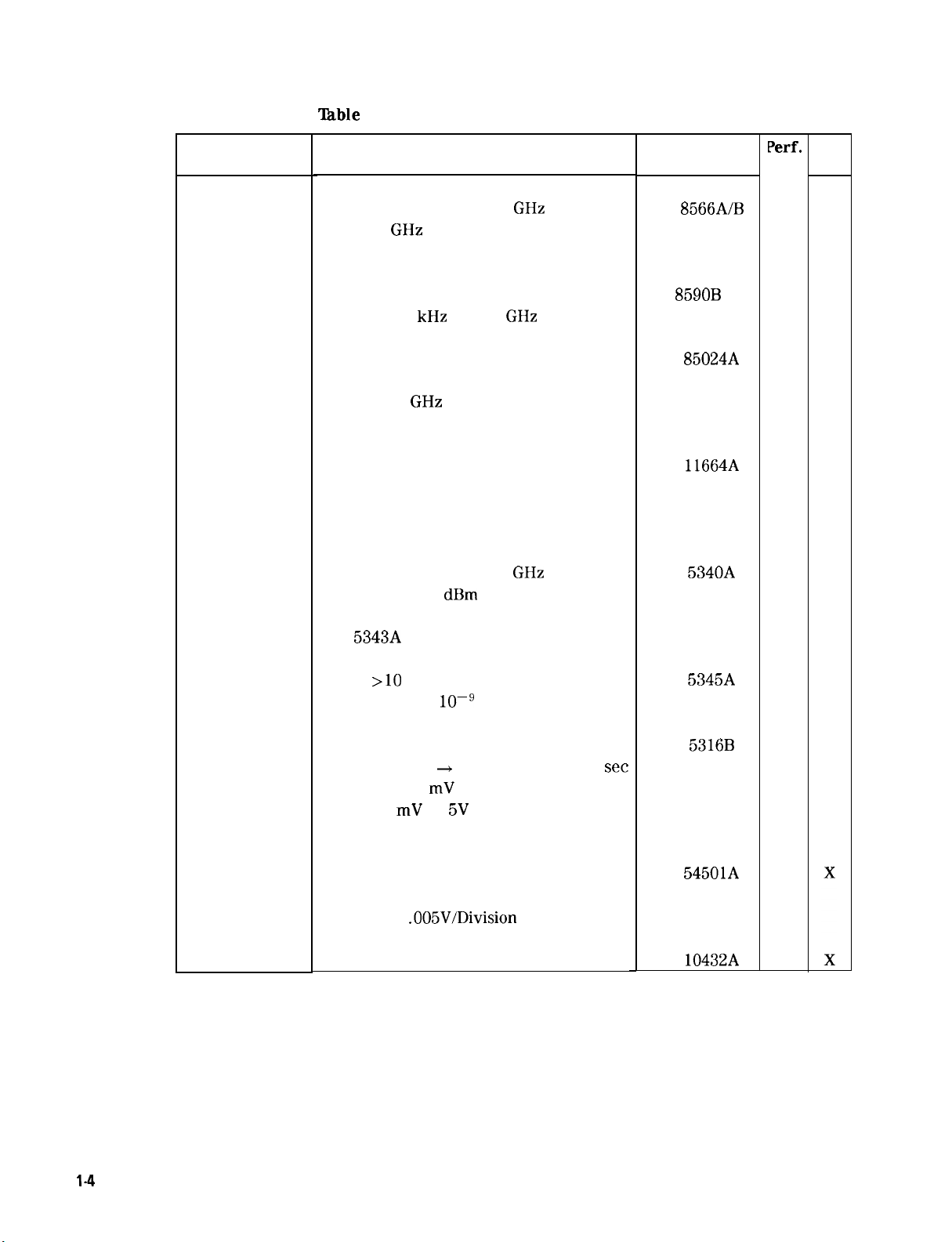

‘Ihble

l-l. Recommended Test Equipment (1 of 5)

Instrument

SIGNAL

SOURCES

Synthesized

Sweeper

Signal

Generator

Frequency

Synthesizer

Critical Specifications for

Equipment Substitution

Frequency: 10 MHz to 1500 MHz

Output Power: + 10 dBm maximum (leveled)

Aging Rate: ~1 x 10mg/day

Spurious Signals:

135

dBc

125

(~7 GHz)

dBc

(<20 GHz)

Amplitude Modulation: dc to 100 kHz

Leveling: Internal, External Power Meter

Frequency: 20 MHz to 450 MHz

SSB Phase Noise: >130 dB below carrier at

20 kHz away

Stability:

(HP

~10

ppm/lO min.

8340A

may be substituted)

Frequency: 200 Hz to 80 MHz

Stability: f 1 x

lo-‘/day

Amplitude Range: + 13 to -86 dBm with 0.01

resolution

Attenuator Accuracy: <

f0.07 dB

(+ 13 to -47 dBm)

dB

Zecommended

Model

HP

8340A

HP

8640B

HP

3335A

Perf.

Test

X

X

4dj.

X

X

Pulse

Generator

Function

Generator

Frequency

Standard

Pulse Width: 10 nsec to 250 nsec

Rise and Fall Times: ~6 nsec

Output Level: +

Output: Sine Wave and Triangle Wave,

2.5V

2Vp-p

Range: 100 Hz to 500 kHz (Sweep Function Available)

Output: 1, 2, 5, or 10 MHz

Accuracy:

Aging Rate: ~1 x

<fl

x

lo-lo/day

10-l’

HP

HP

HP

8116A

3312A

5061B

X

X

X

X

X

General Information 1-3

‘Ihble

l-l. Recommended Test Equipment (2 of 5)

Instrument

ANALYZERS

Spectrum

Analyzer

Spectrum

Analyzer

AC Probe

Scalar

Network

Analyzer

Detector

(2 required)

COUNTERS

Frequency

Counter

Critical Specifications for

Equipment Substitution

Frequency: 100 Hz to 2.5

2 to 22

GHz

Preselected

RF Spectrum Analyzer

Frequency: 9 kHz to 1.8

GHz

High Frequency Probe

10 MHz-l10

GHz

Compatible with HP 8757E

Frequency: 10 MHz to 18

Sensitivity: -30 dBm

HP-IB Compatible

5343A

(HP

may be substituted)

GHz

GHz

Recommended

Model

HP

8566A/B

8590B

HP

85024A

HP 8757E

11664A

HP

HP

5340A

Perf.

Test

Adj.

X

X

X

X

X

X

Electronic

Counter

j = Universal

Counter

OSCILLOSCOPE

Oscilloscope

Probe

Range:

Resolution: 2 x

>lO

MHz

lo-’

gate time

Ext. Time Base: 1, 2, 5, or 10 MHz

Frequency: dc to 100 MHz

Time Interval A

+

B: 100 nsec to 200

set

Sensitivity: 50 mV rms

Range: 30 mV to 5V p-p

Digitizing OSCOPE, 4 Channel

Frequency: 100 MHz

Sensitivity:

.005V/Division

10: 1 Divider, compatible with oscilloscope

HP

HP

HP

HP

5345A

5316B

54501A

10432A

X

X

l-4

General Information

‘Ihble

l-l. Recommended Test Equipment (4 of 5)

Instrument

ATTENUATORS

(Cont’d)

20

dB

Attenuator

TERMINATIONS

Termination

FIWERS

Low-Pass

Filter

Low-Pass

Filter

Low-Pass

Filter

Critical Specifications for

Equipment Substitution

?requency:

rype

Impedance: 500; BNC

?latness:

Cut-off Frequency:

Xejection: >40 dB at 1750 MHz

ht.-off

Cut-off Frequency: 50 MHz

200 Hz to 18

N Connectors

ho.25 dB

2400

Frequency: 300 MHz

GHz

MHz and ~500 MHz

Recommended

Model

HP

8491B,

Option 020

11593A

HP

Telonic

TLS450-7EE

HP 0955-0455

HP 0955-0306

Perf.

Test

X

X

X

1dj.

MISCELLANEOUS

DEVICES

Power

Splitter

Directional

Bridge

SPECIAL

DEVICES

Display

Adjustment

PC Board

Low-Noise

DC Supply

Crystal Filter

Bypass Network

(4 required)

Frequency:

backing:

Required for preliminary display adjustments

Zefer to Figure 70

(Optional)

Xefer

1 MHz to 1500 MHz

~0.2 dB

to Figure 71

HP

11667A

HP

8721A

HP85662-60088

X

X

X

X

X

X

l-6

General Information

‘Ihble

l-l. Recommended

Test

Equipment (5 of 5)

Instrument

Critical Specifications for

Recommended Perf. Adj

Equipment Substitution

Model

Test

CABLES

Cable Assembly Frequency Range: 200 Hz to 22

GHz

HP 8120-4921

X

APC 3.5 Male Connectors

Length: 91 cm (36 inches)

SWR:

cl.4

at 22

Cable BNC, 122 cm (48 in.) (3 required)

Test Cable *

BNC (m) to SMB Snap-On (f)

Test Cable SMA (m) to SMA (m)

Test Cable SMA (m) to SMA (m)

GHz

10503A

x x

HP 85680-60093

HP 85680-20094

HP5061-5458 X X

ADAPTERS

Adapter Type N (f) to BNC (m) HP1250-0077 X

Adapter Type N (m) to BNC (m) HP1250-0082 X

Adapter Tee, SMB Male Connectors HP 1250-0670

Adapter Type N (m) to N (m)

(f)(2

Adapter

Type N (m) to BNC

required) HP1250-0780 X

Adapter BNC Tee (m) (f) (f)

Adapter Type N (m) to SMA (f)

Adapter Type N (f) to BNC

Adapter

Adapter

APC-3.5

APC-3.5

(f) to

(f) TO N

(f)(2

APC-3.5

(f)(2

required) HP1250-1474 X

(f) HP1250-1749 X

required) HP 1250-1745

HP1250-0778 X

HP1250-0781 X

HP1250-1250 X

a

X

X

X

X

BOARD

EXTENDERS

Extender *

12

required)

Extender *

13

required)

Extender *

PC Board: 36 contacts;

2 rows of 18

PC Board: 30 contacts;

2 rows of 15

PC Board: 20 contacts;

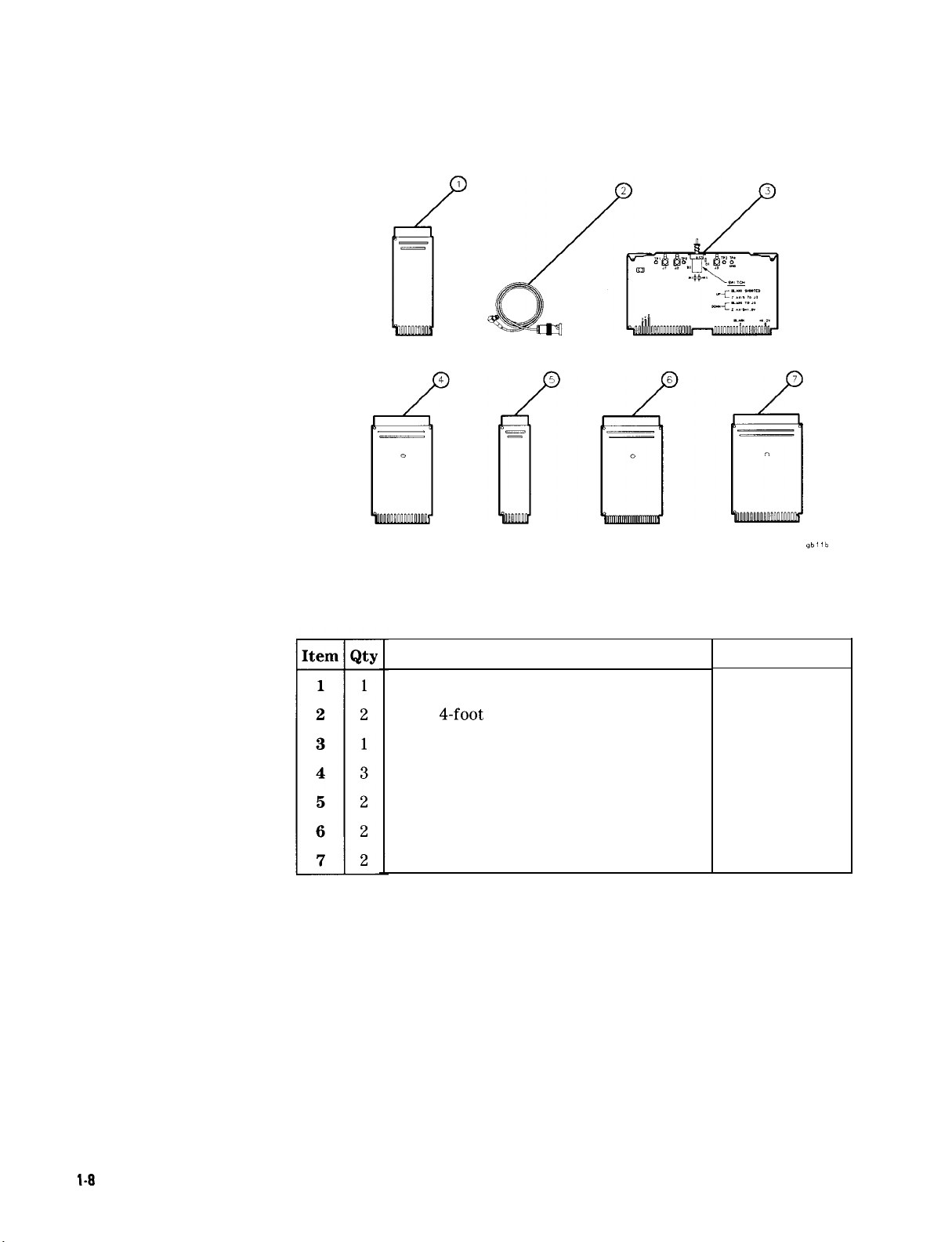

2 rows of 10

Extender * PC Board: 12 contacts;

12

required) 2 rows of 6

PC Board

PC Board extracting tool

Extractor

* Part of Service Accessories

HP 08505-60042

HP 08505-60041

HP 85680-60028

HP08505-60109

HP 03950-4001

X

X

X

X

,X

General Information

l-7

Description

HP Part Number

ExtenderBoard:20contacts;2rowsof

Cable: 4-foot long; BNC to SMB snap-on

PC Board: Display Adjustment Test

ExtenderBoard:

30

contacts;2rowsof

ExtenderBoard:12contacts;2rowsof

ExtenderBoard:50contacts;2rowsof

ExtenderBoard:36contacts;2rowsof

10

15

6

25

18

85680-60028

85680-60093

85662-60088

08505-60041

08505-60109

85680-60034

08505-60042

Figure l-l. Service Accessories, HP Part Number 08568-60001

l-8

General Information

Performance Tksts

2

Introduction

Verification of

Specifications

The procedures in this section test the instrument’s electrical

performance using the Specifications in the Installation and

Verification Manual as the performance standards. None of the

tests require access to the interior of the instrument. The manual

Performance Tests

if semi-automatic test equipment (for Operation Verification) is not

available or the Performance Test is not in the Operation Verification

Program. (Refer to the Installation and Verification Manual for

information on Operation Verification.)

When a complete verification of specifications is required, proceed as

follows:

1. Run the Operation Verification Program.

2. The Operation Verification Program verifies compliance with

specifications of all tests it performs. The tests not performed by

the Operation Verification Program must be done manually and are

as follows:

n Center Frequency Readout Accuracy

n Spurious Responses

H

Fast Sweep Time Accuracy

n

1st

LO Output Amplitude Responses

provided

in this section should be performed only

Calibration Cycle

n Frequency Reference Error

If the results of a performance test are marginally within

specification, go to the Adjustments section of this manual and

perform the related adjustment procedures. When an adjustment is

directly related to a performance test, the adjustment procedure is

referenced under RELATED ADJUSTMENT in the performance test.

This instrument requires periodic verification of performance. The

instrument should have a complete verification of specifications at

least every six months.

Performance Tests

2-l

Equipment Required

Equipment required for the manual performance tests and

adjustments is listed in

at the beginning of this manual. Any equipment that satisfies the

critical specifications given in the list may be substituted for the

recommended model.

‘Ihble

2-1, Recommended Test Equipment,

Test Record

Note

Function or Characteristic Tested Test Performance Test

Center Frequency Readout

Frequency Spans

Sweep Time Accuracy

3-dB

Bandwidths

Bandwidth Shape

Bandwidth Amplitudes

The Operation Verification Program provides a detailed test record

when a printer is used with the controller. If manual performance

tests are done, results of the performance tests may be tabulated in

the HP

HP

and the acceptable ranges for the measurement values obtained

during the tests.

Allow

Performance Tests.

able

(220

8568B

Performance Test Record at the end of this section. The

8568B

Performance Test Record lists all of the tested specifications

l/2-hour

2-1. Performance Test Cross-Reference

ms)

warm-up time for the HP

No.

1

Center Frequency Readout Accuracy Test

2

Frequency Span Accuracy Test

3

Sweep Time Accuracy Test

4

Resolution Bandwidth Accuracy Test

5

Resolution Bandwidth Selectivity Test

6

Resolution Bandwidth Switching Uncertainty Test

8568B

before beginning the

Input Attenuator

Frequency Response

RF Gains

IF Gains

Log Scales Accuracy

Log and Linear Amplifier Fidelity 12 Amplitude Fidelity Test

Noise Floor

Residual Responses

Spurious Responses

Residual FM

Line-Related Sidebands

CAL OUTPUT Level

Fast Sweep Times

1ST

LO OUTPUT Amplitude

Frequency Reference

Accuracay

7

Input Attenuator Switching Uncertainty

8 Frequency Response Test

9

RF Gain Uncertainty Test

10

IF Gain Uncertainty Test

11

Log Scale Switching Uncertainty Test

13

Average Noise Level Test

14 Residual Responses Test

15 Spurious Responses Test

16 Residual FM Test

17 Line-Related Sidebands Test

18

Calibrator Amplitude Accuracy Test

19

Fast Sweep Time Accuracy Test

20

1ST

LO OUTPUT Amplitude Test

21

Frequency Reference Error Test

2-2 Performance Tests

1. Center

Frequency Readout

Accuracy ‘I&t

1. Center Frequency Readout Accuracy

Test

Related Adjustments

Specification

Description

Frequency Control Adjustments

Time Base Adjustment

Step Gain and 18.4 MHz Local Oscillator Adjustments

50 MHz Voltage-Tuned Oscillator Adjustments

(uncorrected)

f2%

of frequency span + frequency reference error x tune frequency

+30% of resolution bandwidth setting + 10 Hz) in AUTO resolution

bandwidth after adjusting FREQ ZERO at stabilized temperature.

A synthesized signal source that is phase-locked to a known frequency

standard is used to input a signal to the analyzer. The frequency

readout of the analyzer is compared to the actual input frequency

for several different frequency settings over the analyzer’s range.

The signal source is phase-locked to a standard known to be as

accurate as the analyzer’s internal frequency reference to minimize

the “frequency reference error x center frequency” term of the

specification.

SPECTRUH

FAEQUENCY

ANALYZER

SIONAL

INPUT

2

ADAPTER

STANDARD

CABLE ASSENBLY

Figure 2-1. Center Frequency Accuracy

SYNTHESIZED

Test

Setup

SHEEPER

Performance Tests

2-3

1. Center Frequency Readout Accuracy Test

Equipment

Procedure 1.

Synthesized Sweeper . . . . . . . . . HP

Frequency Standard . 10 MHz standard,

e.g. HP

5061A

accy

within + 1 part in

8340A

Adapter, Type N (m) to SMA (f) . . . HP1250-1250

61 cm (24 in.) Cable Assembly, SMA Male Connectors HP 5061-1086

Connect CAL OUTPUT to SIGNAL INPUT 2.

2.

3.

4.

5.

6.

7.

Press

[INSTR

PRESET),

@

on the analyzer.

Adjust FREQ ZERO for a maximum amplitude trace.

Press

(1tds-r~

PRESET).

Set the synthesized sweeper for a 100.000 MHz signal at a level of

approximately 0

Connect equipment as shown in Figure

Set analyzer

dBm.

~CENTER

2-l.

FREQUENCY) and [FREQUENCY SPAN) and

synthesized sweeper frequency according to Table 2-2. At each

setting, press

CREFERENCE

[PEAK

SEARCH).~~)

LEVEL) as necessary to place signal peak at a convenient

to center the signal. Adjust

level.

8.

Record the CENTER readout frequency in the table for each

setting. The limits for this frequency are given in the table. See

Figure 2-2.

lOlo,

2-4 Performance Tests

Figure 2-2. Center Frequency Readout Error Measurement

1. Center Frequency Readout Accuracy

Test

Note

Spectrum analyzer center frequency readout can fall outside of

specified limits if 10 MHz frequency reference has not been calibrated

within the past year. To eliminate “frequency reference error x

tune frequency” term, substitute spectrum analyzer 10 MHz FREQ

REFERENCE rear panel output for frequency standard and repeat

test.

‘Ihble

2-2. Center Frequency Readout Error

[FREQUENCYSPAN)I(CENTER FREQumcy~

100 MHz

100 MHz

100 MHz

10 MHz

10 MHz

10 MHz

10 MHz

1 MHz

100

kHz

10

kHz

I

Spectrum Analyzer

(MHz)

\

I

100

500

1000

100

500

1000

1500

1000

1000

1000

Test

Center Readout

(MHZ)

\

Min Measured

98

498

998

99.8

499.8

999.8

1499.8

999.98

999.998

999.9998

Record

I

Max

102

502

1002

100.2

500.2

1000.2

1500.2

1000.02

1000.002

1000.0002

Performance Tests 2-5

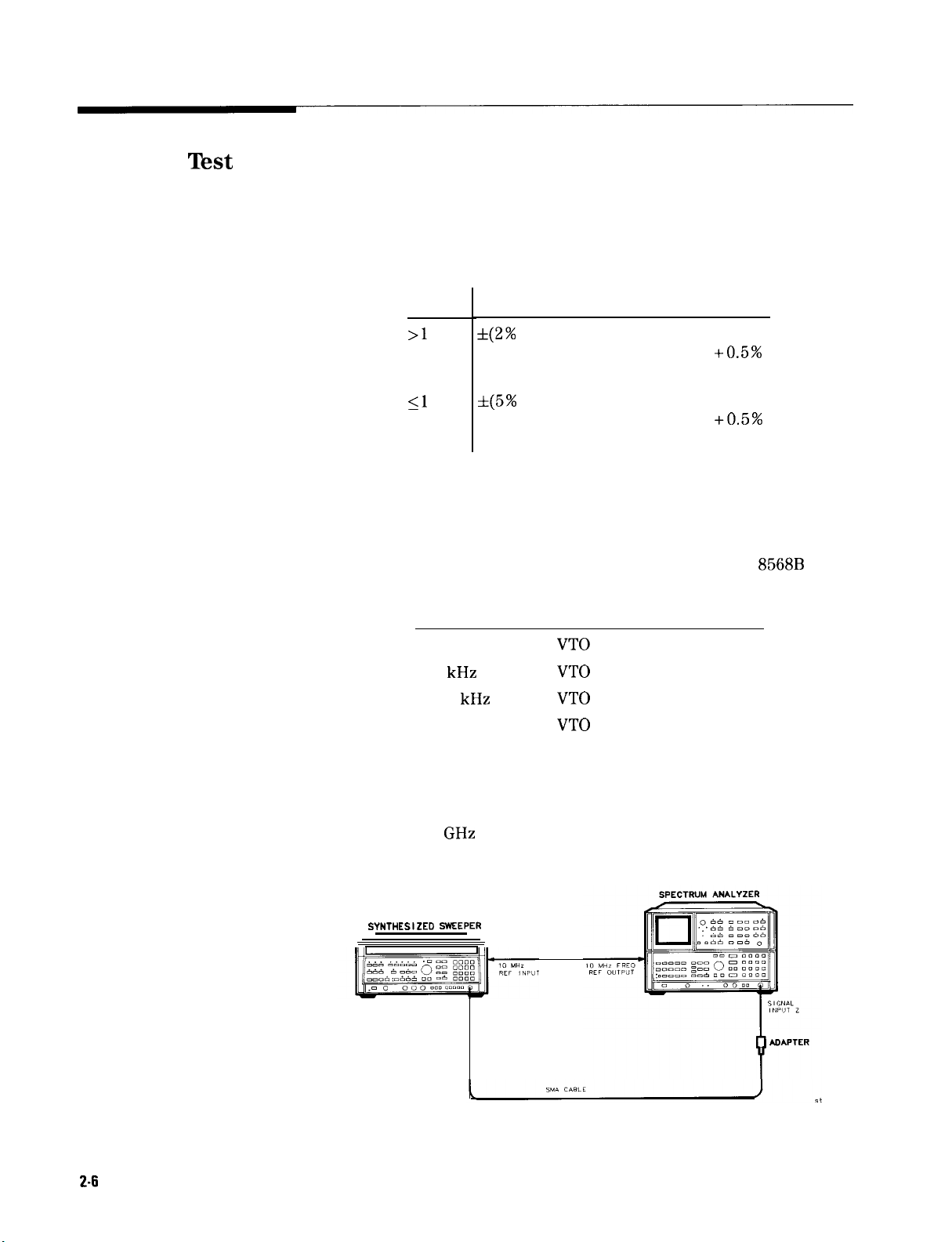

2. Frequency Span

Accuracy

lkst

Related Adjustments

Specification

Description

Frequency Control Adjustments

50 MHz Voltage-Tuned Oscillator Adjustments

Span

>l

MHz

51 MHz

Frequency Span accuracy is determined by measuring a frequency at

5% of sweep and then at 95% of sweep. These frequencies correspond

to half a division from

The spans chosen are based on the architecture of the HP

hardware:

200 Hz

100

100.1 kHz

1 MHz

1.01 MHz

20 MHz

20.1 MHz

1.5

f(2%

of the actual frequency

separation between two points +0.5%

of span setting)

445%

of the actual frequency

separation between two points +0.5%

of span setting)

each edge of the CRT.

Span

kHz

GHz

Uncertainty

Assembly Being Swept

VT0 Oscillator (low divide)

VT0 Oscillator (low divide)

VT0 Oscillator (high divide)

VT0 Oscillator (high divide)

FM Coil of Yig Oscillator

FM Coil of Yig Oscillator

Main Coil of Yig Oscillator

Main Coil of Yig Oscillator

8568B

RF

2-6

Performance Tests

SYNTHESIZED WEEPER

Figure 2-3. Frequency Span Accuracy Test Setup

2. Frequency Span Accuracy Test

Equipment

Procedure

Synthesized Sweeper.....................................................................

83640A

AdapterTypeN(m) to SMA(f).................................................1250-1250

Cable;SMAconnectors....................................................................

Cable; BNC122cm(48in)............................................................HP

.5061-5458

10503A

1. Connect equipment as shown in Figure 2-3.

2. Press

3. Press [CENTER FREQUENCY] 100 MHz, [FREQUENCY

QNsTR

PRESET]

on analyzer.

SPAN_) 200

Hz.

4. Connect synthesized sweeper tot spectrum analyzer RF input 2.

5. On synthesized sweeper, select external REFERENCE and key in

(jj’

6. Press

0 dBm.

Icw]

and key in 99.999 910 MHz.

7. Press MARKER [PEAK SEARCH) on spectrum analyzer and record

marker reading under FREQ C of

Table

2-3.

8. Set synthesized sweeper frequency to 100.000 090 MHz.

9. Press MARKER

[PEAK SEARCH] and record marker reading under

FREQ D of Table 2-3.

10. Repeat the span measurement procedure of steps 6 through 9 for

each frequency span listed in

Table

2-3.

Spectrun

Frequent y

&an

200Hz

IOOkHz

100.1

kHz

1MHz

1.01 MHz

20MHz

20.1 MHz

1.5

GHz

Analyzer

Center

Frequent y

100

MHz

100MHz

100

MHz

100

MHz

100

MHz

100

MHz

100

MHz

900

MHz

11. Determine the frequency difference between the two measured

points. Enter this value under the A DUT column in

‘fable

2-3.

12. The frequency span error is the difference between A DUT and A

SYNTH. (See table 2-3 for values). Calculate the span error and

record it in

13. Compare the table 2-4

Table

2-4.

spec

to the span error value calculated in

step 12.

lhble

2-3. Wide Span Error

Synthesized

Freq. A

Cf-.45

99.999 910 MHz

99.955 000 MHz

99.954955 MHz

99.550 000 MHz

99.550550MHz

91.000 000 MHz

90.955 000 MHz

225 MHz

span

c

100.000090 MHz

100.045 000 MHz

100.045 045 MHz

100.450000 MHz

100.450500 MHz

109.000000 MHz

109.045.000 MHz

Freq. B

cf +

SweeDer

.45 span

1575 MHz

A Synth

(B-4

180 Hz

90.000 Hz

90.090kHz

900.000kHz

909.000kHz

18.000 MHz

18.090 MHz

1350 MHz

1

I

I

I

I

I I

I

I

I

I

I

I

Performance Tests 2-7

2. Frequency Span Accuracy

Test

Freq Span

r-

1

1.5

GHz

-I-

SDan

ADUT-ASyn

from

‘Ihble

Error

‘Ihble

2-4. Span Error

Min

2-3

-5000

-5,005

-50,000

-23,230

-460,000

-462,300

-34,500.OOO

Spec.

-10

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz ]

34,500O.OOO

Max

10

5000

5,005

50,000

23,230

460,000

462,300

-I

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Note

The specification in Table 2-4 was derived using the following formula:

For spans

For spans 2 1 MHz, the

> 1 MHz, the

spec

is: >*[(.02)(A synth freq) + (.005)(span)]

spec

is:

>&[(.05)(A

synth freq) + (.005)(span)]

2-8 Performance Tests

3. Sweep Time

Accuracy Test

(220

ms)

3. Sweep Time Accuracy Test (220 ms)

Related Adjustment

Specification

Description

Frequency Control Adjustments

*lo%

for sweep times

&20%

for sweep times

Preferred Procedure

This test is for sweep times

Fast Sweep Time Accuracy Test (Test 19).

A universal counter is connected to the PENLIFT RECORDER

OUTPUT (on the rear panel) of the spectrum analyzer. The counter is

used in time interval mode to determine the “pen down” (sweep time)

interval of the PENLIFT RECORDER OUTPUT. The

voltage level corresponds directly to the sweeping of the analyzer

(pen down = OV) and not-sweeping of the analyzer (pen up =

DVM is used to set the appropriate trigger level for the counter.

Alternate Procedure

Perform this procedure if the equipment for the preferred procedure

is unavailable.

Sweep time accuracy for sweep times

using the HP

measurement.

8568B’s

5100

seconds

>lOO

seconds

220

ms. For faster sweep times, refer to

penlift

220

ms can also be measured

internal frequency counter for a time interval

output

15V).

A

SPECTRUM ANALYZER

DIGITAL

Figure 2-4. Sweep Time Accuracy Test Setup

VOLTMETER

UNIVERSAL

COUNTER

\

Performance Tests 2-9

3. Sweep Time Accuracy

Test

(220 ms)

Equipment

Procedure

Sweep Times 220 ms

Universal Counter ..........................................

Digital Voltmeter

...........................................

1. Connect equipment as shown in Figure 2-4.

2. Press [INSTR PRESET) on the spectrum analyzer.

3. Key in the following settings:

(CENTER FREQUENCY)

[FREQUENCY SPAN]

.....................................

...........................................

4. Set up the universal counter as follows:

a. Set all front panel keys in “out” position.

b. Set POWER switch to ON.

c. Set GATE TIME vernier control to 9 o’clock.

d. Set SEPXOM A switch to COM A position.

e. Depress T.I. A + B switch (making sure the blue shift key is

out).

f. Set Channel A trigger level to trigger on negative slope.

HP

HP

500

5316A

3456A

MHZ

0 kHz

g. Set Channel B trigger level to trigger on positive slope.

h. Set both Channel A and Channel B

ac/dc

switches to

de.

i. Connect the digital voltmeter to Channel A TRIGGER LEVEL

OUT. (Be sure to ground the DVM properly.)

j. Adjust Channel A trigger level to set a DVM voltage reading of

0.3 v.

k. Repeat steps i and j for Channel B.

5. Set analyzer @WEEP TIME) to 20 ms. Allow the universal counter

enough time to settle at this sweep time.

2-10

Performance Tests

3. Sweep Time Accuracy Test (220 ms)

+15v

-r-l

ov- ---

START+TI”E

MEASUREMENT

Figure 2-5.

NOTE:PULSE

JI

INTERVAL

WIDTH APPROXIMATE

t-SWEEP RETRACE

t-ACTIVE SNEEP +

MEASUREMENT

Penlift

Output Signal

rl

1 L

STOPhE

INTERVAL

---

6. Note the measured sweep time on the universal counter and

record this value in

Table

2-5. The measured sweep time should

be a value between the minimum and maximum values given in

Table

2-5.

7. Repeat steps 5 and 6 for each sweep time setting in

‘Ihble

2-5.

Sweep Time Accuracy, Sweep Times

220

Table

ms

2-5.

[SWEEP

20

50

100 ms

500

8. Press MARKER

TIME)

ms

ms

ms

1s

450

900

(NORMAL].

Min

18

45

90

Marker A Time

Measured

ms

ms

ms

ms

ms

9. Use @J to place the marker at the second vertical graticule.

10. Press

@FiHIFT),[Xi!FF~.

11. Set analyzer [SWEEP TIME) to 20 s. Allow the universal counter

enough time to settle at this sweep time.

12. Note the measured sweep time on the universal counter and

record this value in Table 2-6. The measured sweep time should

be a value between the minimum and maximum values given in

Table

2-6.

13. Repeat steps 11 and 12 for 200 s sweep time.

Performance Tests

2-11

3. Sweep Time Accuracy Test (220 ms)

‘Ihble

2-6.

Sweep Time Accuracy, Sweep Times

220

s

Sweep Times 220 ms

(Alternate Procedure)

Start-Up Time

Measurement

[SWEEP TIME)

Marker A Time

Min Measured Max

4.4 s

14. Sweep times

20 s 3.6 s

200 s

220

ms are tested without external test equipment

32 s 48 s

by the following procedure.

15. Press

16. Set @WEEP TIME] according to

~NSTR PRESET).

Table

2-7. Press MARKER

Rotate the DATA knob to place the marker on the left edge of the

CRT display. Key in

17. Press

[SHIFT) [REsy

CSHIFT) [my.

three times. The Active Function Block

reads SWEEP GEN followed by a measured sweep time. This is

the start-up time. Record it in

‘Ihble

2-7. The start-up time must

be subtracted from the SWEEP GEN time measured in step 19.

(Adding the start-up time to the

[SWEEP TIME] setting effectively

subtracts it from the SWEEP GEN time.)

18. Press MARKER (OFF).

(j-1.

Sweep Time

Measurement

19. Press

@?i] (REST

three times and note the SWEEP GEN

reading. The limits for the SWEEP GEN reading are listed in

Table

2-7. (For example, assume the start-up time measured in

step 17 was 700

,US

for a [SWEEP TIME) of 20 ms. The limits for the

SWEEP GEN readings would be 19.3 to 22.7 ms.)

20. Repeat steps 16 to 19 for each sweep time shown in Table 2-7.

lhble

2-7.

Sweep Time Accuracy, Sweep Times

220

ms

(Alternate Procedure)

SWEEP

20 ms

50 ms

100 ms

500 ms

1s

10 s

50 s

100 s

150 s

-rIME_)

Min Measured

18.0 ms 22.0 ms

45.0 ms 55.0 ms

90.0 ms

450ms

900

ms

45.0

90.0 ms 10.0 ms

20.0 s 80.0 ms

Sweep Gen Readout

Max

110

ms

550

ms

1.10 ms

9.00 ms 11.0 ms

ms 55.0 ms

2-12 Performance Tests

4. Resolution Bandwidth Accuracy

Test

4. Resolution Bandwidth Accuracy Test

Related Adjustment

Specification

Description

Equipment

Procedure

(For instruments with Option 462, refer to Chapter 4.)

3-dB

Bandwidth Adjustments

&20%,

3 MHz

+lO%, 3 kHz to 1 MHz

&20%

10 Hz to 1 kHz

30 kHz and 100 kHz bandwidth accuracy figures apply only with

190% Relative Humidity, <

40°C.

The 3 dB bandwidth for each resolution bandwidth setting is

measured with the MARKER function to determine bandwidth

accuracy. The CAL OUTPUT is used for a stable signal source.

None Required

1.

Press [INSTR PRESET).

2.

Connect CAL OUTPUT to SIGNAL INPUT 2.

3.

Key in spectrum analyzer setting as follows:

(CENTER FREQUENCY)

FREQUENCY SPAN)

[m)

[REFERENCE LEVEL)

4.

Press SCALE LIN pushbutton. Press

.....................................................

........................................

...........................................

........................................

csHIFT],[my

(resolution

-10 dBm

bandwidth).

5.

Adjust [REFERENCE LEVEL] to position peak of signal trace at

reference level (top) graticule line. Press SWEEP

6.

Press MARKER

[ml

and place marker at peak of signal trace

[SINGLE).

with DATA knob. Press MARKER In] and position movable marker

3 dB down from the stationary marker on the positive-going edge

of the signal trace (the MARKER A amplitude readout should be

-3.00 dB

ho.05 dB).

It may be necessary to press SWEEP

ICONT)

and adjust [CENTER FREQUENCY) to center trace on screen.

7.

Press MARKER

(ZJ

and position movable marker 3 dB down

from the signal peak on the negative going edge of the trace (the

MARKER A amplitude readout should be .OO dB

dB

bandwidth is given by the MARKER A frequency readout (see

Figure 2-6). Record this value in

Table

2-8.

f0.05 dB).

20

MHZ

.5

MHz

3 MHz

The 3

Performance Tests

2-13

4. Resolution Bandwidth Accuracy Test

Figure 2-6. Resolution Bandwidth Measurement

8. Vary spectrum analyzer settings according to

the 3 dB bandwidth for each resolution bandwidth setting by the

procedure of steps 6 and 7 and record the value in

measured bandwidth should fall between the limits shown in the

table.

‘Ihble

2-8. Bandwidth Accuracy

[REW)

3

1 MHz

300

100 kHz

30

10

3

1

300

100 Hz

30

10 Hz

‘FREQUENCY SPAN] MARKER A Readout of 3

1

MHz

kHz

kHz

kHz

kHz

kHz

Hz

Hz

T

5

2

500

200

50

20

5

2

500

200

100 Hz

100 Hz

MHz

MHz

kHz

kHz

kHz

kHz

kHz

kHz

Hz

Hz

Min

2.400

270.0

27.00

2.700

MHz

900 kHz

kHz

90.0 kHz

kHz

9.00 kHz

kHz

800

240

80

24

8

Hz

Hz

Hz

Hz

Hz

‘fable

Measured

2-8. Measure

‘Ihble

3

dl

2-8. The

Bandwidth

Max

3.600

1.100 MHz

330.0

33.00

3.300

MHz

kHz

110.0 kHz

kHz

11.00 kHz

kHz

1.200 kHz

360

Hz

120 Hz

36

Hz

12 Hz

2-14 Performance Tests

5. Resolution Bandwidth Selectivity Test

6. Read the 60 dB bandwidth for the 3 MHz resolution bandwidth

setting from the MARKER A frequency readout (see Figure 2-7)

and record the value in

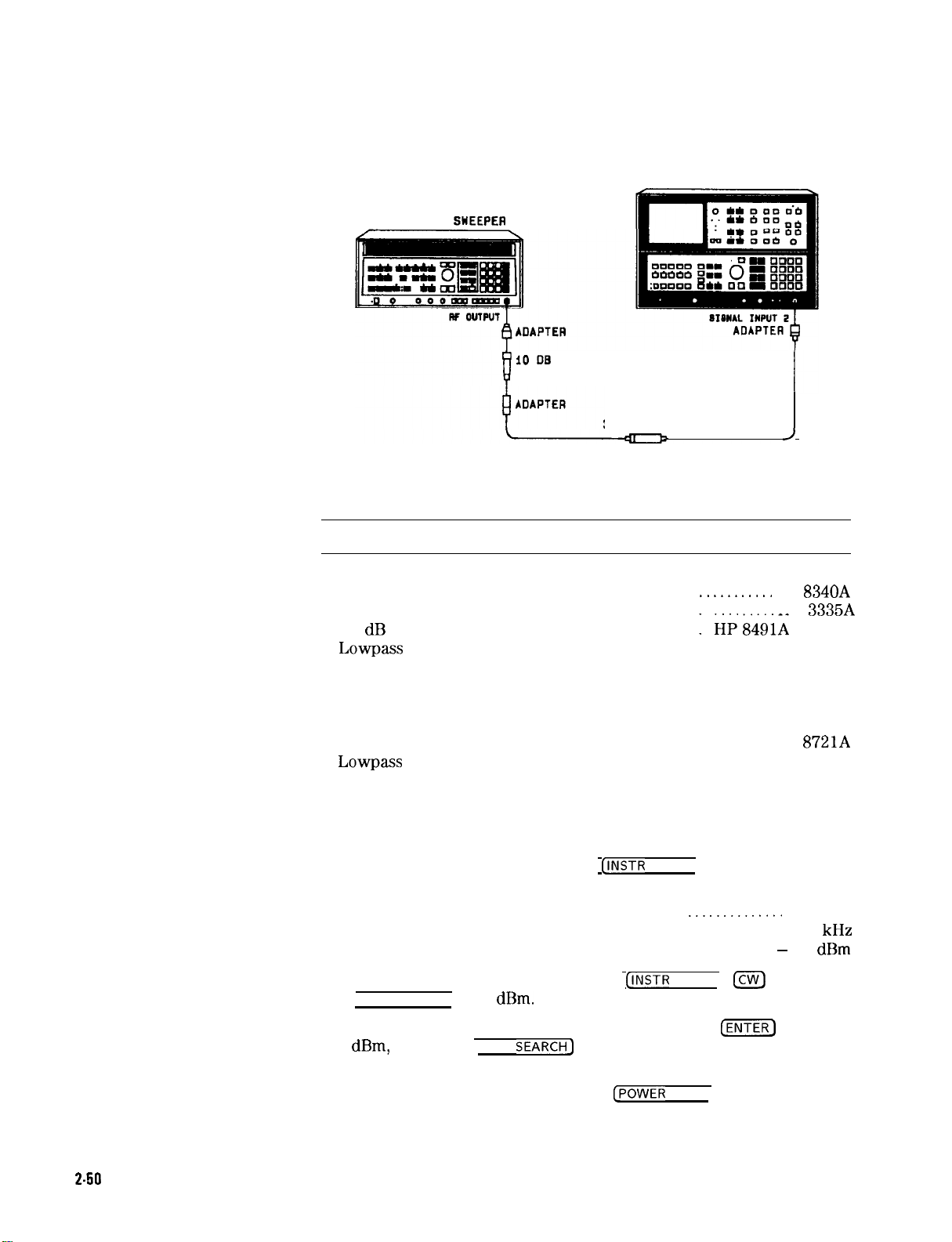

7. Vary spectrum analyzer settings according to Table 2-9. Measure

the 60 dB bandwidth for each resolution bandwidth setting by the

procedure of steps 4 through 6 and record the value in

Table

2-9.

‘fable

2-9.

8. Record the 3 dB bandwidths from

Table

2-8 in

Table

2-9.

9. Calculate the bandwidth selectivity for each setting by dividing

the 60 dB bandwidth by the 3 dB bandwidth. The bandwidth

ratios should be less than the maximum values shown in

‘fable

2-9.

10. The 60 dB bandwidth for the 10 Hz resolution bandwidth setting

should be less than 100 Hz.

2-16 Performance Tests

Figure 2-7. 60 dB Bandwidth Measurement

5. Resolution Bandwidth Selectivity Test

‘lhble

2-9. Resolution Bandwidth Selectivity

Spectrum Analyzer

RES]

(FREQUENCY SPAN)

@iiFSE]

3 MHz 20 MHz 100 Hz

1 MHz

300

kHz

100

kHz

30 kHz500 kHz

10

3 kHz 50 kHz

1

300 Hz 5 kHz

100 Hz

30 Hz 500 Hz

10 Hz 100 HZ

15 MHz

5 MHz

2 MHz

kHz200 kHz

kHz 10 kHz

2 kHz

300 Hz

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

Measured Measured

3

6OdB

dB

Bandwidth

Selectivity Selectivity Ratio

Bandwidth Bandwidth (60 dB BW

3dBBW)

60 dB points separated by

+

cl00

Maximum

15:l

15:l

15:l

15:l

13:l

13:l

13:l

11:l

11:l

11:l

11:l

Hz

Performance Tests 2-17

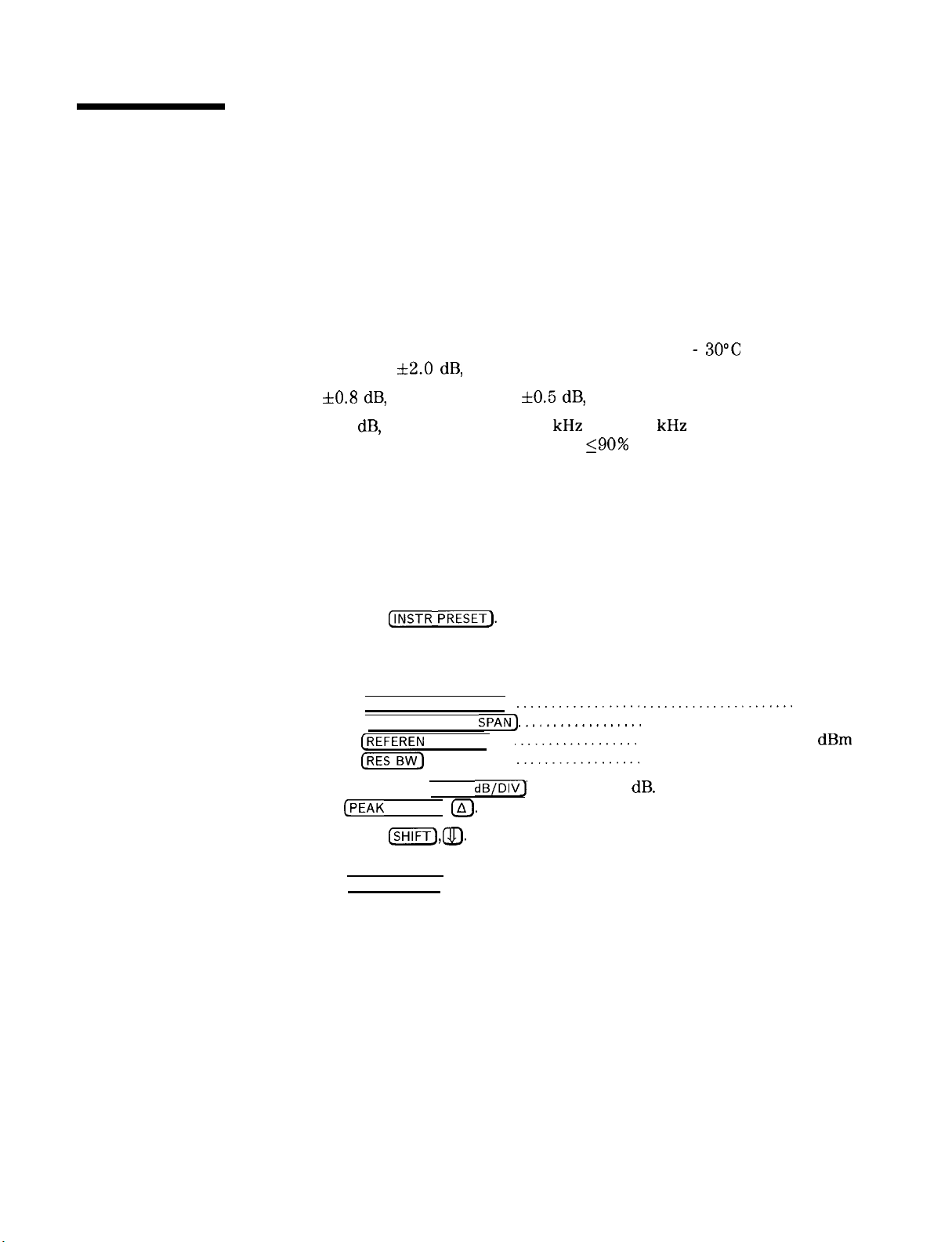

6. Resolution Bandwidth Switching Uncertainty Test

(For instruments with Option 462, refer to Chapter 4.)

Related Adjustments

Specification

Description

Equipment

Procedure

3 MHz Bandwidth Filter Adjustments

21.4 MHz Bandwidth Filter Adjustments Down/Up Converter

Adjustments

(uncorrected; referenced to 1 MHz bandwidth; 20 warm-up)

f0.8 dB,

fl.O

k2.0 dB,

30 Hz bandwidth

dB,

3 MHz bandwidth 30 kHz and 100 kHz bandwidth switching

10 Hz bandwidth

*0.5 dB,

100 Hz to 1 MHz bandwidth

30°C

after 1 hour

uncertainty figures only applicable 190% Relative Humidity

The CAL OUTPUT signal is applied to the input of the spectrum

analyzer. The deviation in peak amplitude of the signal trace is then

measured as each resolution bandwidth filter is switched in.

None Required

1.

Press (INSTR PRESET).

Connect CAL OUTPUT to SIGNAL INPUT 2.

2.

Key in the following control settings:

3.

(CENTER FREQUENCY)

[FREQUENCY SPAN]

REFERENCE LEVEL]

&sTE,

..................

..................

..................

..................

......................

.......................

......................

.......................

20

5

-8

1

MHz

MHz

dBm

MHz

2-18 Performance Tests

Press LOG (ENTER

4.

[PEAK SEARCH)

Press

5.

6.

m,@J

Key in settings according to Table 2-10. Press MARKER

[PEAK SEARCH] at each setting, then read the amplitude deviation

a.

dB/bIvj

and key in 1

dB.

Press MARKER

from the MARKER A readout at the upper right of the display (see

Figure 2-8). The allowable deviation for each resolution bandwidth

setting is shown in the table.

6. Resolution Bandwidth Switching Uncertainty Test

Figure 2-8. Bandwidth Switching Uncertainty Measurement

‘Ihble

2-10. Bandwidth Switching Uncertainty

1 MHz

5 MHz

3 MHz 5 MHz

300 kHz

100

kHz 500 kHz

5 MHz

30 kHz 500 kHz

10 kHz 50 kHz

3 kHz 50

1

kHz 10

300 Hz 1

100 Hz

1

30 Hz 200 Hz

10 Hz 100 Hz

kHz

kHz

kHz

kHz

Deviation

(MKR A

Readout,

0 (ref)

dB)

Allowable

Deviation

(dB)

0 (ref)

IlIl.00

Zto.50

Ito.

Ito.

f0.50

f0.50

Ito.

dZo.50

Ito.

f0.80

f2.00

Performance Tests

2-l

9

7. Input Attenuator Switching Uncertainty

Test

6. Press MARKER

7. Set

[~~J’JREFERENCE

amplitude according to

(PEAK SEARCH) and record the deviation from the 10

CPEAK SEARCH),(KJ

LEVEL], and frequency synthesizer

Table 2-l

1. At each setting, press MARKER

dB

setting from

the MARKER A amplitude readout (see Figure 2-10). The deviation

should not exceed

~Sl”‘i

r’

*l.O dB

-40. i

dBm l

IB

at any setting.

ATTi” 20 ,dB ,

, , ,

HKR A

0

Hz

i

Figure

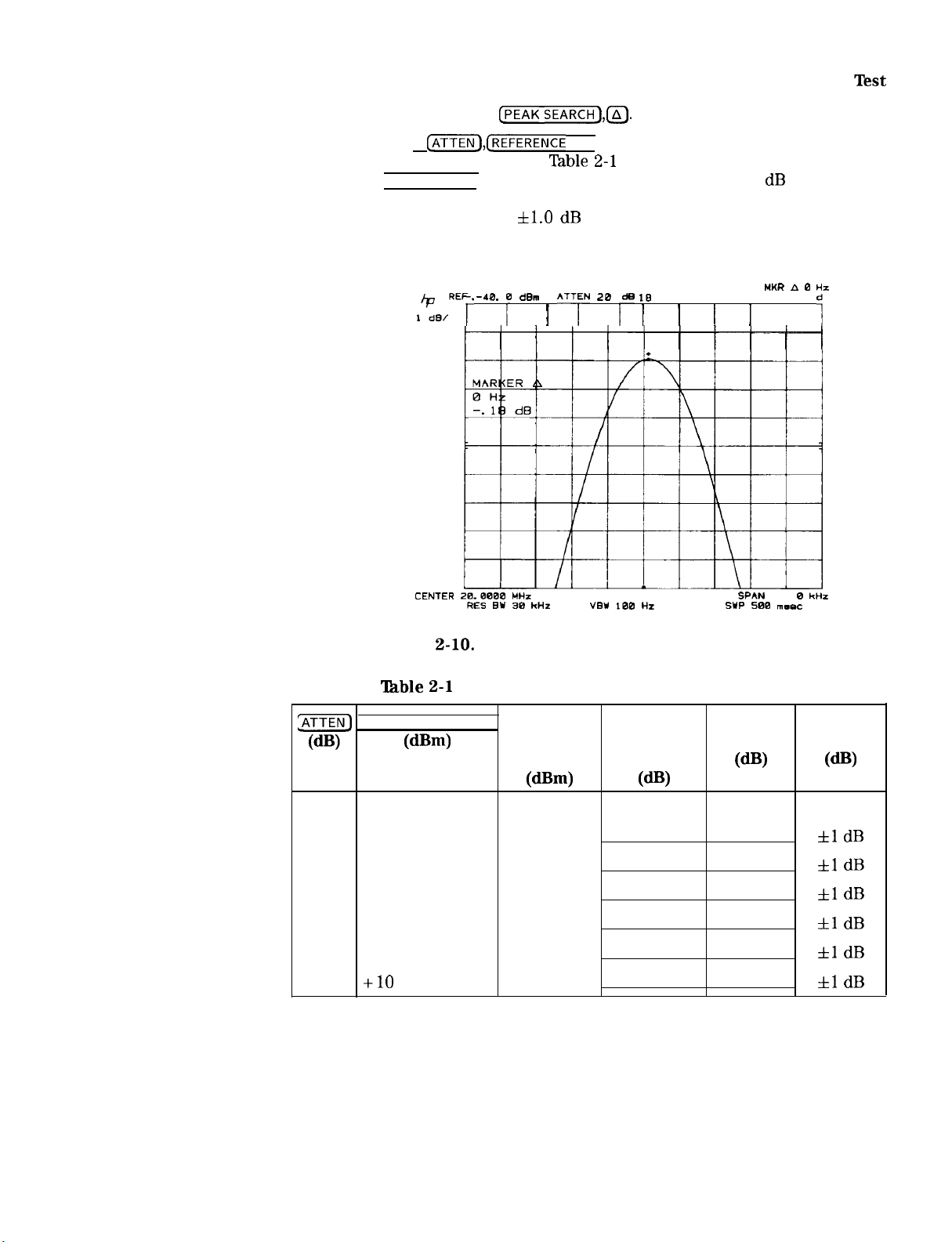

‘Ihble 2-l

Lz)

10

20

30

40

50

[REFERENCE LEVEL) Frequency

-50

-40

-30 -32

-20

-10 -12

60 0

70

+lO

CENTER

Wm)

28.0000

2-10.

RES

MHz

BY30

kHz

VBW

100 Hz SVP 500

SPAN

Attenuator Switching Uncertainty Measure]

1. Input Attenuator Switching Uncertainty

Deviation Corrected Allowable

Synthesizer (MARKER A Deviation Deviation

Amplitude Amplitude

Wm)

-52

0

(W

(ref)

WV

0

(ref)

-42

-22

-2

8

100.

n3mP.z

0

ktiz

nent

(9

fl

dB

fl

dB

fl

dB

fl

dB

fl

dB

fl

dB

Performance Tests 2-21

8. Frequency

Response Test

Related Adjustment

Specification

Description

SYNTHESIZED SWEEPER

Slope Compensation Adjustment

SIGNAL INPUT 1

~tl.5 dB,

*I dB,

100 Hz to 1.5

GHz

100 Hz to 500 MHz

SIGNAL INPUT 2

fl dB,

100 kHz to 1.5

GHz

Frequency response at both analyzer inputs is tested by slowly

sweeping a flat signal source over the frequency range and observing

the peak-to-peak variation in trace amplitude. The test is divided into

three parts. First, the response is tested from 20 MHz to 1.5

GHz

with a power-meter-leveled synthesized sweeper. Next, a frequency

synthesizer is used to check the response from 100 kHz to 20 MHz.

Finally, SIGNAL INPUT 1 is tested from 100 Hz to 100 kHz with a

function generator.

SPECTRUM ANALYZER

POWER METER

I

OPTION 001. ADD 50

Figure 2-11. Frequency Response Test Setup (20 MHz to 1.5

I

OHMS/75

RECORDER

OUTPUT

I I

OHM PAD AND ADAPTER

POWER SENSOR

GHz)

.\

I

ADA,PT,ERS

\I

I

GNAL

NPUT

gb12b

2-22 Performance Tests

8. Frequency Response Test

Note

Equipment

Procedure

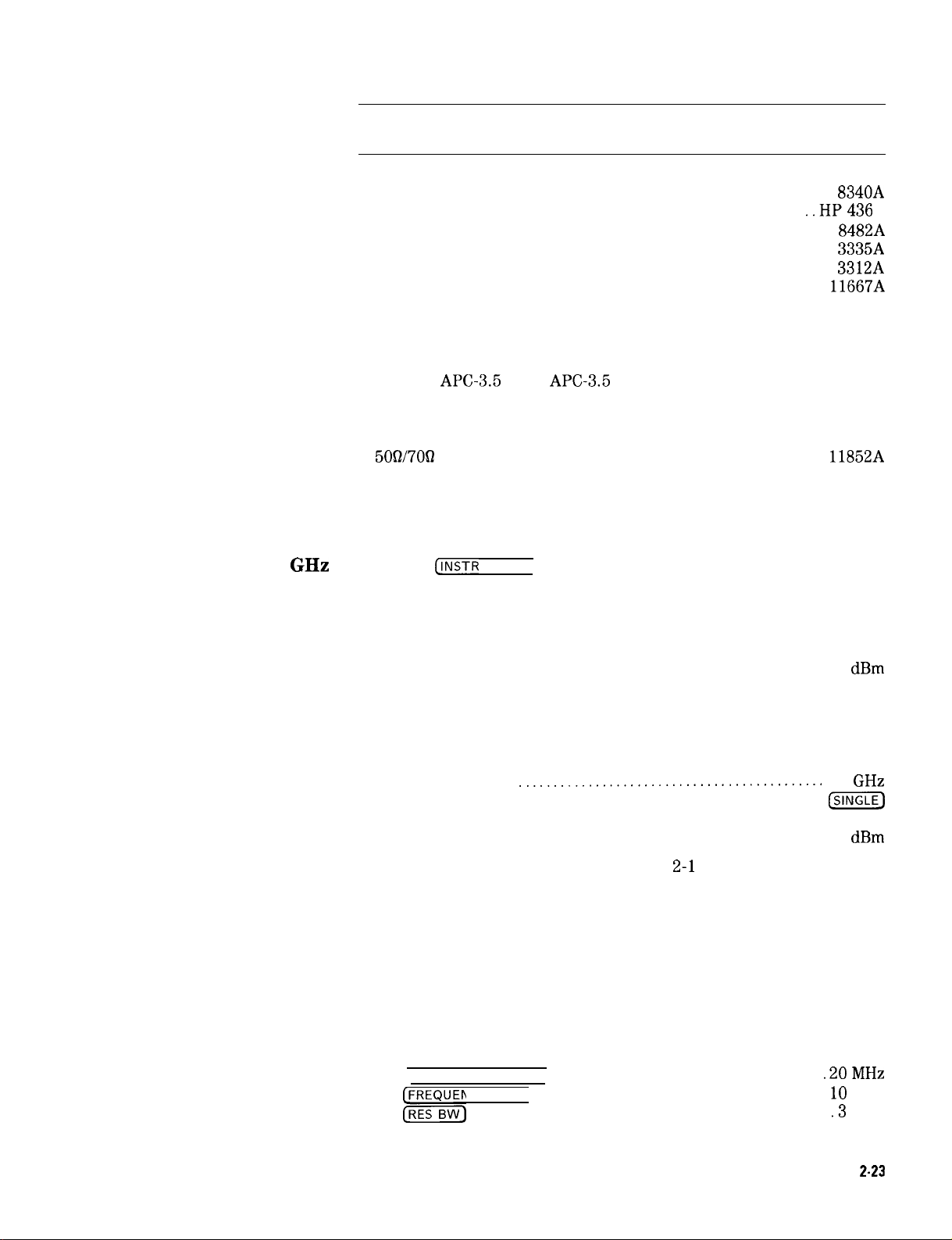

20 MHz to 1.5

GHz

Equipment listed is for three test setups, Figure 2-11, Figure 2-13, and

Figure 2-15.

Synthesized Sweeper .......................................

Power Meter

Power Sensor

...............................................

...............................................

Frequency Synthesizer .....................................

Function Generator ........................................

Power Splitter

.............................................

Adapter, Type N (m) to BNC (f) ........................

Adapter, Type N (m) to BNC (m) .......................

Adapter, Type N (m) to Type N (m)

Adapter, Type N (m) to SMA (f)

Adapter, APC-3.5 (f) to APC-3.5 (f)

....................

........................

....................

Cable, SMA Connectors ................................

HP

8340A

..HP436

HP

8482A

HP

3335A

HP

3312A

HP

11667A

HP 1250-0780

HP 1250-0082

HP 1250-0778

HP 1250-1250

HP 1250-1749

HP 5061-5458

Additional Equipment for Option 001:

5OfY700

Adapter, Type N (f) to BNC (m) (7561)

1.

Minimum Loss Pad ...............................

..................

HP

HP 1250-1534

Press ~NSTR PRESET) on spectrum analyzer and synthesized

11852A

sweeper.

A

2.

Set controls as follows:

Power Meter

MODE

RANGE HOLD

CAL FACTOR %

. . . . . dBm

. . . OFF

. . . 100

Synthesized Sweeper

START FREQ

STOP FREQ

SWEEP

SWEEP TIME

POWER LEVEL

3.

Connect equipment as shown in Figure

...........................................

............................................

.................................................

.............................................

......................................

2-l

1. The RECORDER

0.00 dBm

OUTPUT on rear panel of power meter is connected to LEVELING

EXT INPUT of the synthesized sweeper. One output arm of the

power splitter is connected directly to SIGNAL INPUT 2 of the

spectrum analyzer via the N-to-N adapter. The power sensor

connects directly to the other splitter output.

4.

Depress RANGE HOLD button on power meter.

5.

Select METER leveling on synthesized sweeper.

6.

Key in the following spectrum analyzer settings:

20 MHz

1.5

GHz

[-)

120 s

[CENTER FREQUENCY)

FREQUENCY SPAN]

km)

............................................................................................

......................................

Performance Tests

.20

10

.3

MHZ

MHz

MHz

2.23

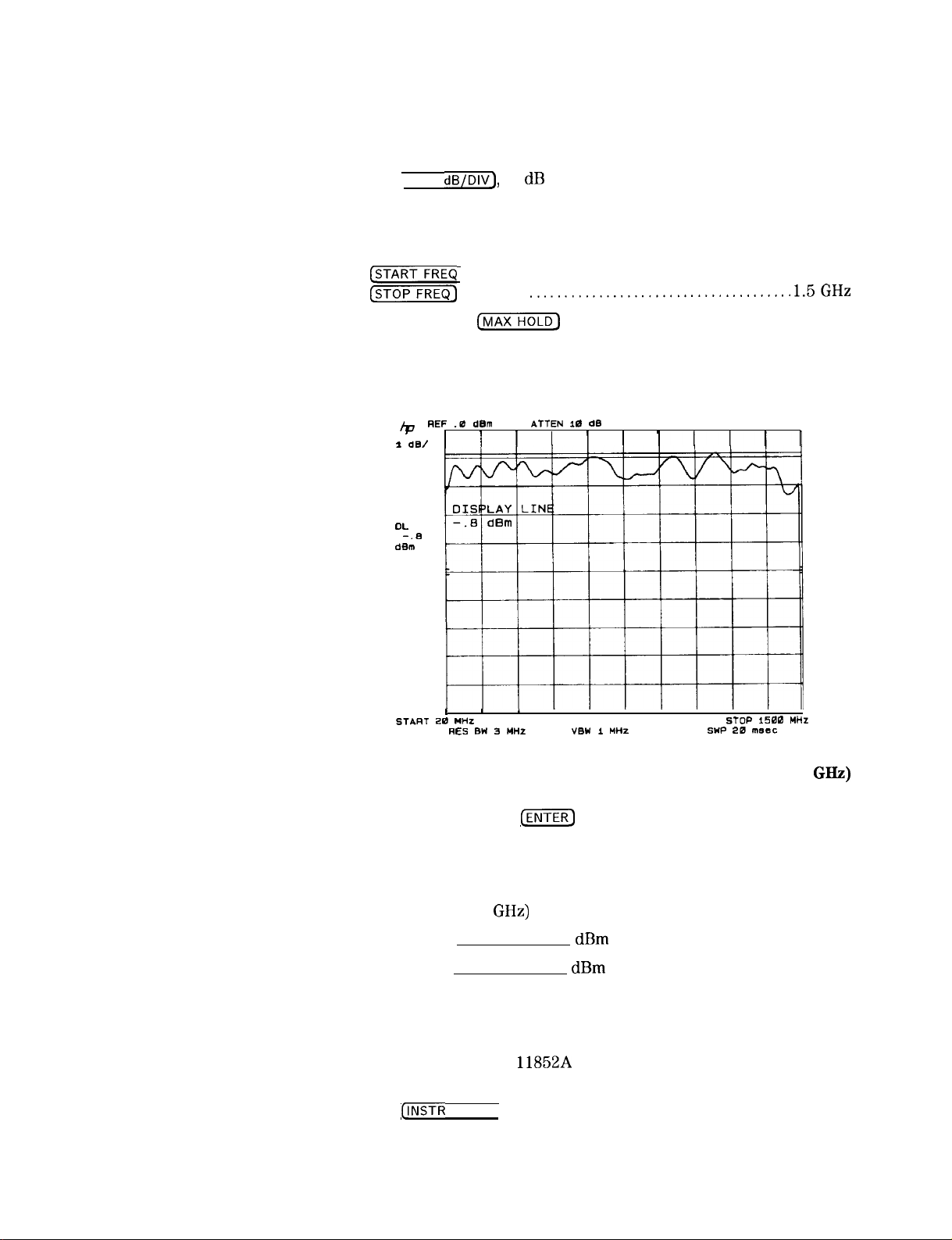

8. Frequency Response Test

Adjust POWER LEVEL on synthesized sweeper (using data knob)

7.

to place peak of 20 MHz signal near reference level (top) graticule

line.

Press

[ENTER

8.

dB/mv],

1

dB

on spectrum analyzer. Adjust POWER

LEVEL on synthesized sweeper to position peak of signal 2

divisions below the reference level line.

Key in the following spectrum analyzer settings:

9.

START FREQ)

km)

Press TRACE A

10.

Press SWEEP SINGLE on the synthesized sweeper.

11.

rp

I dB/

DL

-.B

dBm

START 20 nnz

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

REF .0

darn

,

RES BW

[MAX)

I

..__..................................

on the analyzer.

ATTEN

10

dB

I

3

Mnt

VBW 1 MHZ

I

STOP 1500 MHZ

SWP 20

mssc

20.MHz

1.5GHz

2-24 Performance Tests

Figure 2-12. Frequency Response Measurement (20 MHz to 1.5

12. Press DISPLAY LINE

[ENTER)

on the spectrum analyzer. Use the

GHz)

Display Line to measure the maximum and minimum points on the

trace. Record measurements below.

SIGNAL INPUT 2

(20 MHz to 1.5

Maximum

Minimum

GHz)

dBm

dBm

13. To check SIGNAL INPUT 1, use the type N male to BNC male

adapter to connect the power splitter directly to SIGNAL INPUT

1.

Option 001: Use HP

11852A

Minimum Loss Pad and adapters

between splitter and spectrum analyzer input.

14. Press

[INSTR PRESET) on spectrum analyzer, then activate SIGNAL

INPUT 1 with the pushbutton.

8. Frequency Response Test

Option 001: Set [REFERENCE LEVEL] TO -6.0 dBm.

100

kHz

to 20 MHz

15. Repeat steps 6 through 11. Press DISPLAY LINE

[ENTER)

spectrum analyzer. Use the Display Line to measure the maximum

and minimum points on the trace. Record measurements below.

SIGNAL INPUT 1

(20 MHz to 1.5

Maximum

Minimum

16. Press MARKER

MHz. Press DISPLAY LINE

(-1

GHz)

dBm

dBm

on spectrum analyzer. Set marker to 500

(ENTER]

on the spectrum analyzer. Use

the Display Line to measure the maximum and minimum points

between 20 MHz and 500 MHz. Record measurements below.

SIGNAL INPUT 1

(20 MHz to 500

Maximum

Minimum

GHz)

dBm

dBm

17. Set the frequency synthesizer controls as follows:

FREQUENCY

SWEEP WIDTH

AMPLITUDE

.............................................

.........................................

.............................................

(Option 001: + 4 dBm)

on the

20 MHz

19.9 MHz

-2 dBm

OPTIOW 001: MO

Figure 2-13. Frequency Response Test Setup (100

18. Connect equipment as shown in Figure 2-13. The output of the

frequency synthesizer should be connected to SIGNAL INPUT 1.

Option

SPECTRUM ANALYZER

8IHIAL

INPUT

i

I

l-f