Page 1

Calibration Guide

Agilent Technologies 8560 E-Series and EC-Series

Spectrum Analyzers

Manufacturing Part Number: 08560-90160

Supersedes December 1999

Printed in USA

November 2000

© Copyright 1991-2000 Agilent Technologies, Inc.

Page 2

Notice

The information contained in this document is subject to change without notice.

Agilent Technologies makes no warranty of any kind with regard to this material,

including but not limited to, the implied warranties of merchantability and fitness for a

particular purpose. Agilent Technologies shall not be liable for errors contained herein or

for incidental or consequential damages in connection with the furnishing, performance, or

use of this material.

Certification

Agilent Technologies certifies that this product met its published specifications at the time

of shipment from the factory. Agilent Technologies further certifies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute's calibration facility, and to the

calibration facilities of other International Standards Organization members.

Regulatory Information

The specifications and characteristics chapters and General Regulatory and Safety

Information chapter in this manual contain regulatory information.

Warranty

This Agilent Technologies instrument product is warranted against defects in material

and workmanship for a period of one year from date of shipment. During the warranty

period, Agilent Technologies will, at its option, either repair or replace products which

prove to be defective.

For warranty service or repair, this product must be returned to a service facility

designated by Agilent Technologies. Buyer shall prepay shipping charges to Agilent

Technologies and Agilent Technologies shall pay shipping charges to return the product to

Buyer. However, Buyer shall pay all shipping charges, duties, and taxes for products

returned to Agilent Technologies from another country.

2

Page 3

Agilent Technologies warrants that its software and firmware designated by Agilent

Technologies for use with an instrument will execute its programming instructions when

properly installed on that instrument. Agilent Technologies does not warrant that the

operation of the instrument, or software, or firmware will be uninterrupted or error-free.

L

IMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or

inadequate maintenance by Buyer, Buyer-supplied software or interfacing,

unauthorized modification or misuse, operation outside of the environmental

specifications for the product, or improper site preparation or maintenance.

NO OTHER WARRANTYISEXPRESSEDORIMPLIED. AGILENT TECHNOLOGIES

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

E

XCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE

REMEDIES. AGILENT TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Assistance

Product maintenance agreements and other customer assistance agreements are available

for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales and Service Office.

Cleaning

The instrument front and rear panels should be cleaned using a soft cloth with water or a

mild soap and water mixture.

3

Page 4

General Safety Considerations

WARNING Before this instrument is switched on, make sure it has been properly

grounded through the protective conductor of the ac power cable to

a socket outlet provided with protective earth contact.

Any interruption of the protective (grounding) conductor, inside or

outside the instrument, or disconnection of the protective earth

terminal can result in personal injury.

WARNING There are many points in the instrument which can, if contacted,

cause personal injury. Be extremely careful.

Any adjustments or service procedures that require operation of the

instrument with protective covers removed should be performed

only by trained service personnel.

CAUTION Before this instrument is switched on, make sure its primary power circuitry

has been adapted to the voltage of the ac power source.

Failure to set the ac power input to the correct voltage could cause damage to

the instrument when the ac power cable is plugged in.

Differences between Agilent Technologies 8560

E-Series and EC-Series Spectrum Analyzers

1. EC-series analyzers use a color LCD display which is not adjustable. E-series

instruments use a monochrome CRT display which can be adjusted for focus and

intensity. E-series analyzers use a high-voltage module (HVM), located in the power

supply, to supply power to the CRT. EC-series analyzers do not use an HVM.

2. EC-series analyzers offer fast analog-to-digital-conversion (FADC) digitized sweep

times as a standard feature. EC-series FADC circuitry is integrated into the A2

controller board. E-series instruments offer FADC feature as an option (Option 007)

which is implemented through the use of the A16 FADC board. FADC enables you to

view displays with fast sweep times, between 30 ms and 50 µs.

3. EC-series instruments offer a rear-panel VGA connection as a standard feature.

E-series instruments do not have a rear-panel VGA connector. The VGA connection is

always active and does not require user activation.

In all other operational respects the 8560 EC-series and E-series are identical.

4

Page 5

Contents

1. Using Operation Verification Software − Volume I

What You'll Find in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using Operation Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Operation Verification Menu Softkeys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10 MHz Reference Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1ST LO OUTPUT Amplitude Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Calibrator Amplitude Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Displayed Average Noise Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Fast Sweep Time Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Frequency Readout/Frequency Counter Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Frequency Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Frequency Span Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

IF Gain Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Image and Multiple Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Input Attenuator Switching Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Noise Sidebands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

RES BW Accuracy and Selectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

RES BW Switching and IF Alignment Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Residual FM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Scale Fidelity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Second Harmonic Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Operation Verification Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2. 8560E/EC Specifications and Characteristics

Specifications and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Calibration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Frequency Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Amplitude Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Tracking Generator Specifications (Option 002) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Inputs and Outputs Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Frequency Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Amplitude Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Option 002 Tracking Generator Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Inputs and Outputs Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

3. 8561E/EC Specifications and Characteristics

Specifications and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Calibration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Frequency Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Amplitude Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Inputs and Outputs Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Frequency Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Amplitude Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

5

Page 6

Contents

Inputs and Outputs Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

4. 8562E/EC Specifications and Characteristics

Specifications and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Calibration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Frequency Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Amplitude Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

Inputs and Outputs Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Frequency Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Amplitude Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

Inputs and Outputs Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

5. 8563E/EC Specifications and Characteristics

Specifications and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

Calibration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

Frequency Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

Amplitude Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Inputs and Outputs Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

Frequency Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Amplitude Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

Inputs and Outputs Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

6. 8564E/EC Specifications and Characteristics

Specifications and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .218

Calibration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

Frequency Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

Amplitude Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Inputs and Outputs Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .237

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .238

Frequency Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

Amplitude Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .246

Inputs and Outputs Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

7. 8565E/EC Specifications and Characteristics

Specifications and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .258

Calibration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

Frequency Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

Amplitude Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .269

Inputs and Outputs Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .277

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .278

Frequency Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .282

Amplitude Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .286

6

Page 7

Contents

Inputs and Outputs Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

8. Using Performance Tests:

3335A Source not Available

What You'll Find in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

11a. Resolution Bandwidth Switching and IF Alignment Uncertainty . . . . . . . . . . . . . . . . 308

12a. Resolution Bandwidth Accuracy and Selectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

13a.Input AttenuatorSwitchingUncertainty:8560E/EC,8561E/EC,8562E/EC,and8563E/EC

321

14a. Input Attenuator Switching Uncertainty: 8564E/EC and 8565E/EC . . . . . . . . . . . . . . 329

15a. IF Gain Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

16a. Scale Fidelity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

33a. Second Harmonic Distortion: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

34a. Second Harmonic Distortion: Agilent 8561E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

36a. Frequency Response: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

37a. Frequency Response: 8561E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

38a. Frequency Response: 8562E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

39a. Frequency Response: Agilent 8563E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 417

40a. Frequency Response: Agilent 8564E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 436

41a. Frequency Response: Agilent 8565E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 458

43a. Third Order Intermodulation Distortion: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

44a. Third Order Intermodulation Distortion: Agilent 8561E/EC . . . . . . . . . . . . . . . . . . . . 484

45a. Third Order Intermodulation Distortion: Agilent 8562E/EC, Agilent 8563E/EC . . . . 491

46a. Third Order Intermodulation Distortion: Agilent 8564E/EC, Agilent 8565E/EC . . . . 500

9. General Regulatory and Safety Information

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 510

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 511

10. Using Performance Tests − Volume II

What You'll Find in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 514

Performance Tests versus Operation Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 515

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 516

85629B Functional Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 521

Running the Functional Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 523

1. 10 MHz Reference Output Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

2. 10 MHz Reference Output Accuracy (Option 103) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 538

3. Fast Sweep Time Accuracy (EC-Series and E-Series with Option 007) . . . . . . . . . . . . . . 540

4. Calibrator Amplitude Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 542

5. Displayed Average Noise Level: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 544

6. Displayed Average Noise Level: 8561E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550

7. Displayed Average Noise Level: 8562E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 556

8. Displayed Average Noise Level: 8563E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 563

9. Displayed Average Noise Level: 8564E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 571

10. Displayed Average Noise Level: 8565E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 580

7

Page 8

Contents

11. Resolution Bandwidth Switching and IF Alignment Uncertainty . . . . . . . . . . . . . . . . .590

12. Resolution Bandwidth Accuracy and Selectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .593

13. Input Attenuator Switching Uncertainty: 8560E/EC, 8561E/EC, 8562E/EC/, 8563E/EC. . .

601

14. Input Attenuator Switching Uncertainty: 8564E/EC, 8565E/EC. . . . . . . . . . . . . . . . . . .608

15. IF Gain Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .615

16. Scale Fidelity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .620

17. Residual FM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .630

18. Noise Sidebands: 8560E, 8561E, and 8563E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .633

19. Noise Sidebands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .636

20. Image, Multiple, and Out-of-Range Responses: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . .640

21. Image, Multiple, Out-of-Band, and Out-of-Range Responses: 8561E/EC . . . . . . . . . . . .643

22. Image, Multiple, and Out-of-Band Responses: 8562E/EC . . . . . . . . . . . . . . . . . . . . . . . .647

23. Image, Multiple, and Out-of-Band Responses: 8563E/EC . . . . . . . . . . . . . . . . . . . . . . . .651

24. Image, Multiple, and Out-of-Band Responses: 8564E/EC . . . . . . . . . . . . . . . . . . . . . . . .657

25. Image, Multiple, and Out-of-Band Responses: 8565E/EC . . . . . . . . . . . . . . . . . . . . . . . .664

26. Frequency Readout/Frequency Count Marker Accuracy: 8560E/EC . . . . . . . . . . . . . . . .672

27. Frequency Readout/Frequency Count Marker Accuracy: 8561E/EC . . . . . . . . . . . . . . . .675

28. Frequency Readout Accuracy/Frequency Count Marker Accuracy: 8562E/EC . . . . . . . .678

29. Frequency Readout Accuracy/Frequency Count Marker Accuracy: 8563E/EC . . . . . . . .681

30. Frequency Readout Accuracy/Frequency Count Marker Accuracy: 8564E/EC . . . . . . . .685

31. Frequency Readout Accuracy/Frequency Count& Marker Accuracy: 8565E/EC. . . . . . .689

32. Pulse Digitization Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .694

33. Second Harmonic Distortion: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .698

34. Second Harmonic Distortion: 8561E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .700

35. Second Harmonic Distortion: 8562E/EC, 8563E/EC, 8564E/EC, 8565E/EC . . . . . . . . . .705

36. Frequency Response: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .712

37. Frequency Response: 8561E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .723

38. Frequency Response: 8562E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .738

39. Frequency Response: 8563E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .758

40. Frequency Response: 8564E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .774

41. Frequency Response: 8565E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .793

42. Frequency Span Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .813

43. Third Order Intermodulation Distortion: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . .816

44. Third Order Intermodulation Distortion: 8561E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . .820

45. Third Order Intermodulation Distortion: 8562E/EC, 8563E/EC . . . . . . . . . . . . . . . . . . .826

46. Third Order Intermodulation Distortion: 8564E/EC, 8565E/EC . . . . . . . . . . . . . . . . . . .834

47. Gain Compression: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .842

48. Gain Compression: 8561E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .845

49. Gain Compression: 8562E/EC, 8563E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .849

50. Gain Compression: 8564E/EC, 8565E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .854

51. 1ST LO OUTPUT Amplitude: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .859

52. 1ST LO OUTPUT Amplitude: 8561E/EC, 8562E/EC, 8563E/EC, 8564E/EC,8565E/EC 863

53. Sweep Time Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .866

54. Residual Responses: 8560E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .872

55. Residual Responses: 8561E/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .875

56. Residual Responses: 8562E/EC, 8563E/EC, 8564E/EC, 8565E/EC . . . . . . . . . . . . . . . . .878

57. IF INPUT Amplitude Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .881

58. Gate Delay Accuracy and Gate Length Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .884

8

Page 9

Contents

59. Delayed Sweep Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 890

60. Tracking Generator Level Flatness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 893

61. Absolute Amplitude and Vernier Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 897

62. Maximum Leveled Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 900

63. Power Sweep Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 903

64. RF-Power-Off Residuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 906

65. Harmonic Spurious Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 909

66. Non-Harmonic Spurious Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 913

67. LO Feedthrough Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 919

68. Tracking Generator Feedthrough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 922

69. Frequency Tracking Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 926

70. Tracking Generator Frequency Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 929

11. 8560E/EC Performance Test Record

Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 934

12. 8561E/EC Performance Test Record

Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 958

13. 8562E/EC Performance Test Record

Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 980

14. 8563E/EC Performance Test Record

Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1002

15. 8564E/EC Performance Test Record

Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1028

16. 8565E/EC Performance Test Record

Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1058

9

Page 10

Contents

10

Page 11

1 Using Operation Verification

Software − Volume I

11

Page 12

Using Operation Verification Software − Volume I

What You'll Find in This Chapter

What You'll Find in This Chapter

This automated test software is designed to give a high confidence level

of spectrum analyzer operation in a reasonable amount of time.

Instructions for using the software, brief descriptions of the tests, and a

list of the software error messages are included in this chapter. Refer to

Table 1-3, on page 20, for the names of manual performance tests that

are not included in the automated operation verification software.

What Is Operation Verification?

Operation Verification automates many of the performance tests. It is

recommended as a check of instrument operation for incoming

inspection or after a repair. It performs 80 to 85 percent of the manual

performance tests in less than 60 minutes (75 minutes for the Agilent

8564E/EC and Agilent 8565E/EC). It is designed to test an instrument

operating within a 20 °Cto30°C temperature range using a minimum

set of test equipment. Refer to Table 1-1, on page 16 for a list of tests

performed.

If a test does not pass, the related manual performance test needs to be

run. Related manual performance tests are listed at the top of each

operation verification test description and the test procedures are in

“Using Performance Tests” Chapter 10, of Volume II of the calibration

guide.

Operation Verification versus Performance Tests

The performance tests verify that the analyzer performance meets all

specifications. Performance verification consists of executing all of the

manual performance tests. It is time-consuming and requires extensive

test equipment.

12 Chapter1

Page 13

Using Operation Verification Software − Volume I

Getting Started

Getting Started

First, make sure you have a compatible controller (computer), the

proper test equipment, and a printer for recording test results. The

following paragraphs describe requirements for controllers, test

equipment, and printers. Once the proper equipment is identified,

proceed to “Equipment Connections.”

Spectrum Analyzers

The 8560 E-Series and EC-Series Operation and Verification software

tests the following spectrum analyzers:

Spectrum Analyzer Software Revision

8560E/EC all

Agilent 8561E/EC

Agilent 8562E/EC

Agilent 8563E/EC

Agilent 8564E/EC

Agilent 8565E/EC

all

D.00.00 and later

all

C.00.00 and later

C.00.00 and later

Errors will occur if this software is used to test spectrum analyzers

other than those listed above. Other versions of the operation

verification software are available for testing other 8560 Series

spectrum analyzers.

Controller (Computer)

Operation Verification software requires using any combination of one

of the following controllers and the HP BASIC operating system:

Controller

9000 model 216

9000 model 236

9000 model 310

Chapter 1 13

Page 14

Using Operation Verification Software − Volume I

Getting Started

Operating System

HP BASIC 2.0 with extensions 2.1

HP BASIC 3.0 and required BIN files

HP BASIC 4.0 and required BIN files

Other 9000 Series 300 controllers are compatible with the Operation

Verification software; however, the graph printouts might not be full

width. This is especially true with medium- and high-resolution

displays.

The Operation Verification program requires at least 500K of free

memory. The computer can have either single or dual GPIB ports. Refer

to “Dual-Bus Operation,” on page 28, under “Using Operation

Verification,” on page 22, for information on using the program with

dual GPIB ports.

Test Equipment

Table 1-1, on page 16, lists the operation verification tests and the test

equipment required for each test. You do not need all the test

equipment connected to perform operation verification. You need only

connect the equipment specified in each test to run that test.

NOTE The Agilent 3335A Synthesizer Level Generator, which is used in

several operation verification tests, has been obsoleted. If an Agilent

3335A is not available, alternate test equipment can be used to perform

comparable tests manually. Chapter 8 in this volume contains the

information on alternate test equipment and manuals test procedures

you will need to perform these tests.

Table 1-2, on page 19, summarizes the equipment required to run the

Operation Verification tests. Some tests, like 10 MHz Reference

Accuracy, can use various model numbers of a particular equipment

type. Information about selecting the equipment model number you

want to use is provided in “Setting GPIB Addresses,” on page 25, in this

chapter under “Using Operation Verification,” on page 22.

NOTE The validity of Operation Verification program measurements depends

in part on required test equipment measurement accuracy. Verify

proper calibration of test equipment before testing the analyzer with

the software.

14 Chapter1

Page 15

Using Operation Verification Software − Volume I

Getting Started

Printers

All test results are sent to a GPIB printer. The program does not run

without being connected to a GPIB printer. Virtually any GPIB

graphics workstation printer can work. These tests have been run using

the HP ThinkJet, 2671G, 82906A, and 9876G printers.

Warmup Time

Test Equipment Warmup Allow sufficient warmup time for test

equipment. Refer to their individual operating and service manuals for

warmup specifications.

Spectrum Analyzer Warmup Warm the spectrumanalyzer up for at

least five minutes before performing the first test.

NOTE Since the preselector in the Agilent 8561E/EC, Agilent 8562E/EC,

Agilent 8563E/EC, Agilent 8564E/EC and Agilent 8565E/EC spectrum

analyzers is not peaked during the Frequency Response test, allow a 30

minute warmup at 20 °Cto30°C before beginning this test. If you start

running All Testsafter five-minute warmup, the spectrum analyzer will

have warmed up for 30 minutes by the time the Frequency Response

test begins.

Chapter 1 15

Page 16

Using Operation Verification Software − Volume I

Getting Started

Table 1-1 Equipment Required for Each Operation Verification Test

Test Name Equipment Required

10 MHz

Reference

Accuracy

1ST LO

OUTPUT

Amplitude

Accuracy

Calibrator

Amplitude

Accuracy

Displayed

Average

Noise Level

Fast Sweep

Time

Accuracy

Agilent

8560E/EC

5342A,

5343A, or

5350B*

8902A or

436A or

438A

8485A or

8481A

8902A,

436A or

438A

8481A, or

8482A

909D 909D 909D 909D 85138B 85138B

5342A,

5343A, or

5350B**

Agilent

8561E/EC

5342A,

5343A, or

5350B*

8902A or

436A or

438A

8485A or

8481A

8902A,

436A or

438A

8481A, or

8482A

5342A,

5343A, or

5350B**

Agilent

8562E/EC

5342A,

5343A, or

5350B*

8902A or

436A or

438A

8485A or

8481A

8902A,

436A or

438A

8481A, or

8482A

5342A,

5343A, or

5350B**

Agilent

8563E/EC

5342A,

5343A, or

5350B*

8902A or

436A or

438A

8485A or

8481A

8902A,

436A or

438A

8481A, or

8482A

5342A,

5343A, or

5350B**

Agilent

8564E/EC

5342A,

5343A, or

5350B*

8902A or

436A or

438A

8485A or

8481A

8902A,

436A or

438A

8481A, or

8482A

5342A,

5343A, or

5350B**

Agilent

8565E/EC

5342A,

5343A, or

5350B*

8902A or

436A or

438A

8485A or

8481A

8902A,

436A or

438A

8481A, or

8482A

5342A,

5343A, or

5350B**

Frequency

Readout/

Counter

Accuracy

Frequency

Span

Accuracy

8340A/B or

83640A or

83650A

8120-4921

8340A/B or

83640A or

83650A

11667A/B

8120-4921

8340A/B or

83640A or

83650A

8120-4921

8340A/B or

83640A or

83650A

11667A/B

8120-4921

8340A/B or

83640A or

83650A

8120-4921

8340A/B or

83640A or

83650A

11667A/B

8120-4921

8340A/B or

83640A or

83650A

8120-4921

8340A/B or

83640A or

83650A

11667B

8120-4921

83640A or

83650A

8120-6164

83640A or

83650A

11667C

8120-6164

83650A

8120-6164

83650A

11667C

8120-6164

16 Chapter1

Page 17

Using Operation Verification Software − Volume I

Table 1-1 Equipment Required for Each Operation Verification Test

Test Name Equipment Required

Getting Started

Frequency*

Response

IF Gain*

Uncertainty

Image and

Multiple

Responses

Agilent

8560E/EC

8340A/B or

83640A or

83650A

3335A

8902A or

436A or

438A

8482A

11667A/B

8120-4921

3335A 3335A 3335A 3335A 3335A 3335A

8340A/B or

83640A or

83650A

8902A or

436A or

438A

8481A

11667A/B

8120-4921

Agilent

8561E/EC

8340A/B or

83640A or

83650A

3335A

8902A or

436A or

438A

8481A

11667A/B

8120-4921

8340A/B or

83640A or

83650A

8902A or

436A or

438A

8481A

11667A/B

8120-4921

Agilent

8562E/EC

8340A/B or

83640A or

83650A

3335A

8902A or

436A or

438A

8481A

11667A/B

8120-4921

8340A/B or

83640A or

83650A

8902A or

436A or

438A

8481A

11667A/B

8120-4921

Agilent

8563E/EC

8340A/B or

83640A or

83650A

3335A

8902A or

436A or

438A

8485A

11667B

8120-4921

8340A/B or

83640A or

83650A

8902A or

436A or

438A

8485A

11667B

8120-4921

Agilent

8564E/EC

83640A or

83650A

3335A

8902A or

436A or

438A

8487A

11667C

8120-6164

83640A or

83650A

8902A or

436A or

438A

8487A

11667C

8120-6164

Agilent

8565E/EC

83650A

3335A

8902A or

436A or

438A

8487A

11667C

8120-6164

83650A

8902A or

436A or

438A

8487A

11667C

8120-6164

Input*

Attenuator

Switching

Uncertainty

Noise

Sidebands

RES BW*

Accuracy/

Selectivity

3335A 3335A 3335A 3335A 3335A 3335A

8662A or

8663A or

CAL

OUTPUT

signal

3335A 3335A 3335A 3335A 3335A 3335A

8662A or

8663A or

CAL

OUTPUT

signal

Chapter 1 17

8662A or

8663A or

CAL

OUTPUT

signal

8662A or

8663A or

CAL

OUTPUT

signal

8662A or

8663A or

CAL

OUTPUT

signal

8662A or

8663A or

CAL

OUTPUT

signal

Page 18

Using Operation Verification Software − Volume I

Getting Started

Table 1-1 Equipment Required for Each Operation Verification Test

Test Name Equipment Required

RES BW*

Switching

Uncertainty

Residual

FM

Scale*

Fidelity

Second

Harmonic

Distortion

Agilent

8560E/EC

Agilent

8561E/EC

Agilent

8562E/EC

Agilent

8563E/EC

Agilent

8564E/EC

Agilent

8565E/EC

3335A 3335A 3335A 3335A 3335A 3335A

8662A or

8663A

8662A or

8663A

8662A or

8663A

8662A or

8663A

8662A or

8663A

8662A or

8663A

3335A 3335A 3335A 3335A 3335A 3335A

8340A/B or

83640A or

83650A

8902A or

436A or

438A

8485A or

8481A

11667A/B

0955-0306

8120-4921

8340A/B or

83640A or

83650A

8902A or

436A or

438A

8485A or

8481A

11667A/B

11689A (2

required)

0955-0306

8120-4921

8340A/B or

83640A or

83650A

8902A or

436A or

438A

8485A or

8481A

11667A/B

11689A (2

required)

0955-0306

8120-4921

8340A/B or

83640A or

83650A

8902A or

436A or

438A

8485A or

8481A

11667B

11689A (2

required)

0955-0306

8120-4921

83640A or

83650A

8902A or

436A or

438A

8485A or

8481A

11667C

11689A (2

required)

0955-0306

8120-6164

83650A

8902A or

436A or

438A

8485A or

8481A

11667C

11689A (2

required)

0955-0306

8120-6164

* The 3335A Synthesizer Level Generator, which is used in several operation verification tests, has been

obsoleted. If an 3335A is not available, alternate test equipment can be used to perform comparable tests

manually. Chapter 8 in this volume contains the information on alternate test equipment and manuals test

procedures you will need to perform these tests.

* *The Agilent 5350B is supported only in software revision D.00.00 and later.

18 Chapter1

Page 19

Using Operation Verification Software − Volume I

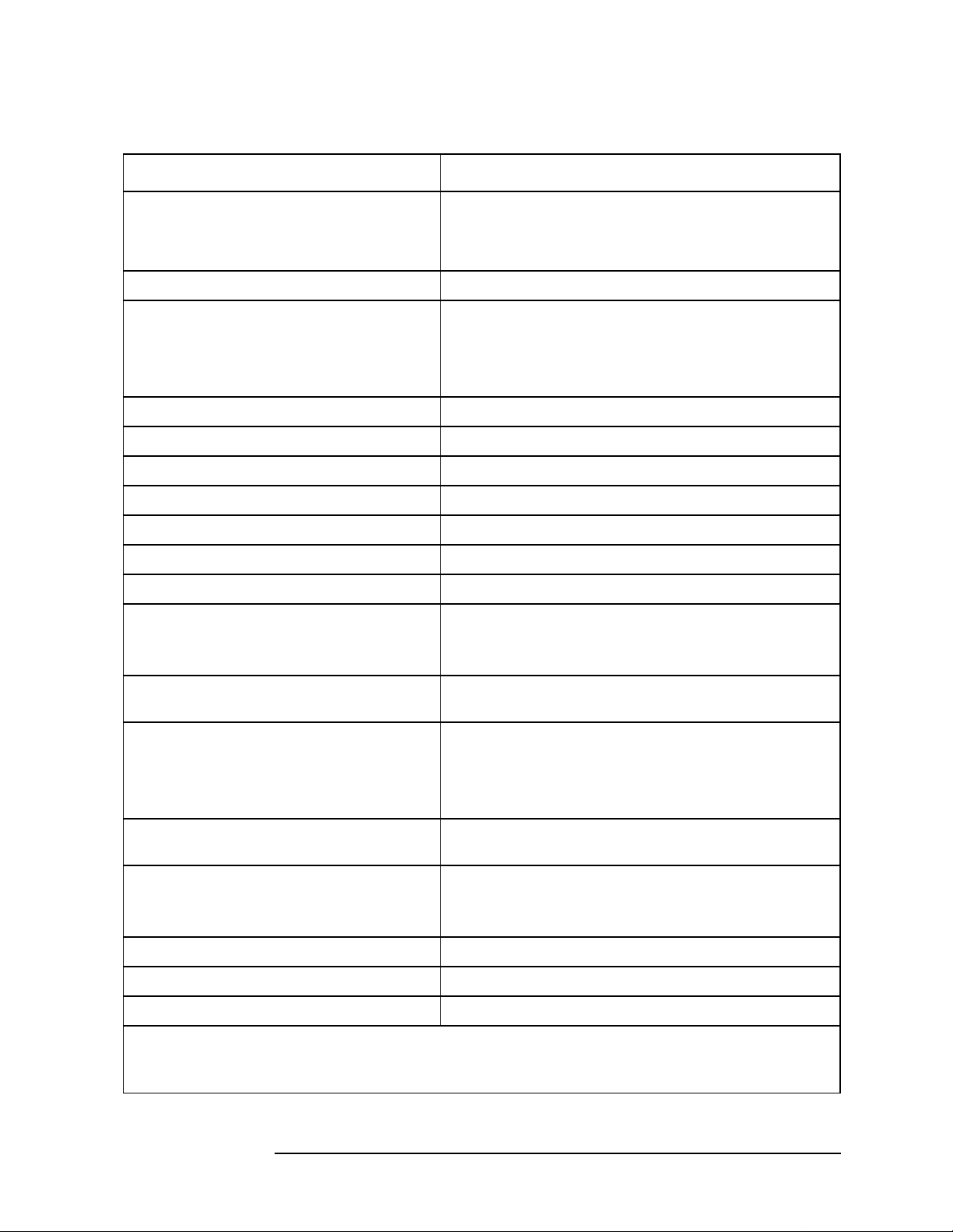

Table 1-2 Required Test Equipment Summary

Type of Equipment Model Number

Controller* Series 200 9000 model 216 ( 9816)

9000 model 236 ( 9836)

or 9000 model 310

Synthesizer/level generator 3335A

Getting Started

Synthesized sweeper (10 MHz to 26.5 GHz)

(10 MHz to 40 GHz)

(10 MHz to 50 GHz)

Synthesized signal generator 8662A/8663A

Measuring receiver 8902A

Power meter 436A or 438A (alternate)

Microwave frequency counter 5343A

Microwave frequency counter 5342A (alternate)

Microwave frequency counter 5350B (alternate) †

Power sensor (100 kHz to 4.2 GHz) 8482A

Power sensor (50 MHz to 26.5 GHz)

(50 MHz to 50 GHz)

Power sensor (10 MHz to 18 GHz) 8481A (alternate for 8560E/EC, 8561E/EC, and

Power splitter (dc to 18 GHz)

(dc to 26.5 GHz)

(dc to 50 GHz)

8340A/B ( 8560E/EC, 8561E/EC, 8562E/EC, and

8563E/EC)

85640A ( 8564E/EC)

85650A ( 8565E/EC)

8485A ( 8560E/EC, 8561E/EC, 8562E/EC, and

8563E/EC)

8487A ( 8564E/EC and 8565E/EC)

8562E/EC)

11667A ( 8560E/EC, 8561E/EC, and 8562E/EC)

11667B ( 8560E/EC, 8561E/EC, 8562E/EC, and

8563E/EC)

11667C ( 8564E/EC and 8565E/EC)

4.4 GHz low-pass filter (two required) 11689A ( 8561E/EC, 8562E/EC, 8563E/EC, 8564E/EC,

and 8565E/EC)

50 Ω termination (dc to 26.5 GHz)

(dc to 50 GHz)

50 MHz low-pass filter 0955-0306

Miscellaneous cables and adapters As per test setup

GPIB printer See “Printers”

*

500 kilobytes of free memory is required for the test program.

†

Th 5350B is supported only in software revision D.00.00 and later.

909D ( 8560E/EC, 8561E/EC, 8562E/EC, and 8563E/EC)

85138B ( 8564E/EC and 8565E/EC)

Chapter 1 19

Page 20

Using Operation Verification Software − Volume I

Getting Started

Table 1-3 Manual Performance Tests That Are Not Automated

Pulse Digitization Uncertainty

Third Order Intermodulation Distortion

Gain Compression

Sweep Time Accuracy

Residual Responses

IF Input Amplitude Accuracy

Gate Delay Accuracy and Gate Length Accuracy

Delayed Sweep Accuracy

These tests apply only to 8560E/EC Option 002:

Tracking Generator Level Flatness

Absolute Amplitude and Vernier Accuracy

Maximum Leveled Output Power

Power Sweep Range

RF-Power-Off Residuals

Harmonic Outputs

Non-Harmonic Outputs

Tracking Generator Feedthrough

LO Feedthrough Amplitude

Frequency Tracking Range

Tracking Generator Frequency Accuracy

Equipment Connections

Computer (Controller) Setup

For 9000 model 216 or model 236 computers, setup instructions are

provided in Chapter 1, “Computer Installation,” of the BASIC

Operating Manual. For 9000 model 310 computers, setup information

is provided in Configuration Reference Manual for Series 300

computers.

20 Chapter1

Page 21

Using Operation Verification Software − Volume I

Getting Started

GPIB Cables

All test equipment controlled by GPIB should be connected to the

internal GPIB of the controller (select code 7). If the controller has only

one GPIB connector, connect the spectrum analyzer to it as well. If the

controller has dual GPIB connectors, connect the spectrum analyzer

under test to the second GPIB (typically, select code 8).

10 MHz Reference

The 10 MHz REF IN/OUT on the spectrum analyzer under test should

be connected to the synthesized sweeper external frequency reference.

That is, it should be connected to the FREQUENCY STANDARD EXT

of the 8340A/B or the 10MHz REF INPUT of the 83640A or 83650A.

Connect the synthesized sweeper 10 MHz REF OUTPUT to the

40/N MHz REF INPUT of the 3335A. Do not connect the spectrum

analyzer 10 MHz REF IN/OUT to the external frequency reference

input of the 8663A; doing so invalidates the Noise Sidebands test

results.

NOTE Terminate the 3335A 10 MHz REF OVEN OUTPUT in 50 Ω. Do not

connect the 10 MHz output to the external frequency reference input of

any other test equipment.

Test Setups

Test setups for each test are included with the test. These are in the

“Test Descriptions” section of this chapter. The program prompts the

operator to make appropriate equipment connections if the correct

equipment setup is not detected.

Chapter 1 21

Page 22

Using Operation Verification Software − Volume I

Using Operation Verification

Using Operation Verification

Loading the Program

Load BASIC into the computer. BASIC choices are:

• BASIC 2.0 and extensions 2.1

• BASIC 3.0 or 4.0, which must include the following binaries:

MAT

IO

GRAPH

GRAPHX

PDEV

IB

MS

CLOCK

CS80

DISC

KBD

For configuration instructions, refer to the BASIC Operating Manual.

Next, insert the Operation Verification software disk into the disk

drive, then type:

LOAD “VERIFY_6XE”,1

NOTE A double-sided disk drive must be used. The Operation Verification

software will not fit on a single-sided formatted disk.

Press

Series 300 computers, to load the software and start the program

running.

EXECUTE on 9000 Series 200 computers, or RETURN on 9000

22 Chapter1

Page 23

Using Operation Verification Software − Volume I

Using Operation Verification

Program Operation

Operation Verification consists of three menus. They are the Conditions

Menu, the Test Menu, and the Sensor Utilities Menu, which are

accessed from the Conditions Menu. Program operation is controlled

through a combination of softkeys and user prompts. Some prompts,

primarily in the Conditions and Sensor Utilities Menus, require

computer keyboard entries. Terminate keyboard entries with the

RETURN or ENTER key. Most prompts, however, tell the user what to do

next or provide informational messages.

If the message (any key) follows a prompt, pressing any key on the

keyboard continues the program. If the message (any key

or `Q' to quit) follows a prompt, pressing any key except Q

continues the program. Pressing Q terminates the current procedure at

the next, most logical point in the program.

Conditions Menu

The first menu screen displayed is the Conditions Menu. The pointer

displayed along the left edge of the screen may be moved with the knob

(if one is present) or the up (⇑) and down (⇓) arrow keys. Notice that the

menu has two pages. Moving the pointer below the last entry on the

page brings up the next page. Similarly, moving the pointer above the

first entry on a subsequent page brings up the preceding page. The two

pages of the Conditions Menu have a four-line overlap. The last four

lines of page 1 appear as the first four lines on page 2.

Chapter 1 23

Page 24

Using Operation Verification Software − Volume I

Using Operation Verification

Test Record Header Information

The information in the first six entries of this menu is printed out as

part of the operation verification test record. The spectrum analyzer

model number and serial number are stored in the analyzer memory.

Software revisions before C.00.00 will not display the complete list of

options if there are more than two. The program queries these numbers

via GPIB and displays them. If the spectrum analyzer under test does

not respond at the address listed under GPIB Addresses, or no address

is listed, a message appears where the model and serial numbers are

normally displayed.

The program also queries the time and date in the computer. If an 9000

Series 200 computer is used, it might be necessary to reset the time and

date; 9000 Series 300 computers have built-in real-time clocks.

Entries for Operator, Test Conditions, and Other Comments are

optional. Blank spaces are provided on the test record if no entry is

made. To make or to change an entry, move the pointer to the line

where the entry is to be made or changed. Press

Change Entry and type

in your new entry. Entries for Operator, Test Conditions, and Other

Comments can be up to 37 characters long, but only the first 25

characters of the Operator entry are printed on the test record.

System Mass Storage File Location

Calibration factor data for different power sensors and a customized set

of conditions may be stored on disk. The mass storage unit specifier

(msus) for the disk containing this information should be entered as the

system mass storage file location. Refer to the BASIC Operating

Techniques Manual for information on the syntax of the msus. Software

revision C.00.00 and later allows a system mass storage file location

with more than 37 characters though only the first and last 17

characters will be displayed.

The Operation Verification program disk comes write-protected from

the factory. If you want to use this disk for storing your power sensor

and conditions data files, it is necessary to disable the write-protect

mechanism.

NOTE A double-sided disk drive must be used. The Operation Verification

software will not fit on a single-sided formatted disk.

24 Chapter1

Page 25

Using Operation Verification Software − Volume I

Using Operation Verification

Power Sensors

The Operation Verification program supports four models of power

sensors, but only two models are necessary to run all the tests. The

Agilent 8481A may be substituted for the Agilent 8482A. The

Agilent 8485A is required for the Agilent 8562E/EC and

Agilent 8563E/EC, and the Agilent 8487A is required for the

Agilent 8564E/EC and Agilent 8565E/EC. Refer to “Sensor Utilities

Menu,” on page 28, for more information regarding storing, viewing,

editing, and purging cal factor data for power sensors.

To select a particular sensor of a certain model number, move the

pointer to the desired model number and press

Change Entry. Enter the

last five digits of the power sensor serial number (that is, the serial

number suffix). The program checks to see that a data file containing

the cal factor data for that particular sensor exists.

To create, edit, view, or purge power sensor cal factor data files, press

Sensor Utils to bring up the Sensor Utilities Menu. Refer to “Sensor

Utilities Menu,” on page 28, in this chapter for more information.

A WARNING message appears if the program does not find a data file for

the sensor. If this occurs, check that the system mass storage file

location specifies the disk where the power sensor data resides. If the

system mass storage file location is correct, the cal factor data for that

particular sensor has not been stored.

NOTE Power sensor data files created using the VERIFY_62 Operation

Verification software (for 8560A/61A/61B/62A/62B/63A spectrum

analyzers) are not compatible with the VERIFY_6XE Operation

Verification software.

Refer to “Sensor Utilities Menu,” on page 28, in this chapter for

additional information.

Setting GPIB Addresses

The last 11 lines (last 12 lines, for revision D.00.00 and later) of the

Conditions Menu are for selecting the GPIB addresses of test

equipment used for the Operation Verification program. It is not

necessary to use all the test equipment listed. Some model numbers

listed are “alternates.” Table 1-1, on page 16, lists the test equipment

required for each test and Table 1-2, on page 19, lists model numbers

allowed for a particular type of test equipment.

NOTE For software revisions B.01.00 and earlier, the Conditions Menu has

two entries for Agilent 8340A/B synthesized sweepers. Only

Agilent 8340A/B #1 is used.

Software revisions D.00.00 and later have an entry for an Agilent 5350

Series microwave frequency counter.

Chapter 1 25

Page 26

Using Operation Verification Software − Volume I

Using Operation Verification

Entering zero as the test equipment address results in that model

number being unavailable in the program (NA is displayed in the

address field). To minimize possible confusion later, enter a zero for the

address of each piece of test equipment that is not available.

Enter the address for each piece of test equipment that is available,

including the spectrum analyzer under test. Addresses must contain

the select code of the bus to which the equipment is connected followed

by the equipment address on that bus. For example, if the 8902A is at

address 14 on a bus with a select code of 7, enter an address of 714. If

the 8902A were on a bus with a select code of 12, you should enter an

address of 1214.

A question mark (?) next to a GPIB address indicates the address has

not been checked to verify a response. An asterisk (*) next to a GPIB

address indicates the address was checked and that an instrument

responds at that address. If there is neither an asterisk nor a question

mark next to an address, the address has been checked and no response

was detected.

Storing and Loading the Conditions File

The information in the Conditions Menu may be stored for future use

by pressing

Store Conds. A file named CONDITIONS is created on the

disk specified by the system mass storage file location.

NOTE CONDITIONS files for software versions B.01.00 and earlier are not

compatible with software versions C.00.00 and C.01.00. Versions

C.00.00 and later CONDITIONS files include entries for the 83640A

and 83650A sweepers and the 8487A power sensor.

CONDITIONS files for software versions C.01.00 and earlier are not

compatible with software versions D.00.00 and later. Versions D.00.00

and later CONDITIONS files include entries for 5350 Series

microwave frequency counters.

When running the Operation Verification program in the future, set the

system mass storage file location to read the disk where the

CONDITIONS file is located and press

Load Conds. If the

CONDITIONS file resides on the default system mass storage file

location, the CONDITIONS file is loaded automatically the next time

the program is run.

The default system mass storage file location is :,700,1. For the 9000

Model 236 ( 9836), it is necessary to use an external disk drive. The disk

drive must support double-sided format.

26 Chapter1

Page 27

Using Operation Verification Software − Volume I

Using Operation Verification

Getting to the Test Menu

Once all necessary items in the Conditions Menu are selected, you can

run a test by pressing Test Menu. Before the Test Menu is displayed,

these things occur:

• Appropriate power sensor data files are loaded.

• GPIB is checked for a response at each address.

• Serial and model number of the spectrum analyzer under test are

queried.

• Reference level calibration is performed.

NOTE Power sensor data files created using the VERIFY_62 Operation

Verification software (for 8560A/61A/61B/62A/62B/63A spectrum

analyzers) are not compatible with the VERIFY_6XE Operation

Verification software.

Refer to “Test Menu,” on page 30, “Test Menu” in this chapter for more

details on running the tests. If a printer is unavailable, the Conditions

Menu is displayed again rather than the Test Menu. All test results

must be sent to the printer.

NOTE Without a printer, Operation Verification tests do not run.

Verifying the GPIB

To see which test equipment responds on GPIB, press

Verify Bus. This

check only verifies that there is a response at the address listed; it

cannot tell that a particular piece of equipment is at a particular

address. This is useful for verifying GPIB connections without entering

the Test Menu.

Querying the Spectrum Analyzer Serial Number

The Operation Verification program automatically queries the

spectrum analyzer serial and model number on three occasions: at

program initiation, when loading the CONDITIONS file, and when

entering the Test Menu. To query the analyzer serial and model

numbers at any other time, press

Query DUT S/N. This is helpful for

testing multiple spectrum analyzers; you do not have to reload the

CONDITIONS file or restart the program.

Exiting Operation Verification

Press

Exit Program to exit the Operation Verification program.

Chapter 1 27

Page 28

Using Operation Verification Software − Volume I

Using Operation Verification

Dual-Bus Operation

The Operation Verification program may be used on dual GPIB

systems, such as the microwave test set. In these systems, all the test

equipment is connected to GPIB at select code 7, and the device under

test (for example, the spectrum analyzer) is connected to GPIB at select

code 8.

To run this program in a dual-bus configuration, enter equipment

addresses as described in “Setting GPIB Addresses,” on page 25,

making sure that each address properly identifies the bus select code to

which it is connected. Program operation is the same for dual-bus and

single-bus configuration.

Sensor Utilities Menu

Operation Verification needs to know the cal factors of each power

sensor being used. Create, edit, view, and delete data files containing

cal factors for each power sensor in the Sensor Utilities Menu. Power

sensor data filenames include the last five digits of the power sensor

serial number. For example,

for 8481A power sensors the filename is SEN81NNNNN

for 8482A power sensors the filename is SEN82NNNNN

for 8485A power sensors the filename is SEN85NNNNN

for 8487A power sensors the filename is SEN87NNNNN

where NNNNN represents the last five digits of the power sensor serial

number (the serial number suffix). Note that the first two digits in the

filename correspond to the last two digits of the power sensor model

number.

All power sensor data files available on the system mass storage

location file are listed upon entering the Sensor Utilities Menu.

NOTE Power sensor data files created using the VERIFY_62 Operation

Verification software (for 8560A/61A/61B/62A/62B/63A Spectrum

Analyzers) are not compatible with the VERIFY_6XE Operation

Verification software.

28 Chapter1

Page 29

Adding a Power Sensor Data File

Using Operation Verification Software − Volume I

Using Operation Verification

Toadd a new power sensor data file, press

Add File, and enter the power

sensor model number as requested. An error message is displayed if a

disk is not found at the current system mass storage file location.

When prompted for the power sensor serial number, enter only the last

five digits (the serial number suffix). You are then prompted for a cal

factor frequency and for the cal factor. These frequency/cal-factor pairs

need not be entered in order of increasing frequency; the program

inserts the pairs in their proper place. All frequencies should be entered

in MHz.

A 50 MHz Cal-Factor must be entered in order to calibrate the power

sensor. Some power sensors do not include a 50 MHz Cal-Factor on

their chart or calibration record; it is listed as part of the Calibration

Procedure on the case of the power sensor.

If a mistake is made entering a cal factor, enter the frequency of the

erroneous cal factor at the next frequency prompt. Enter the correct cal

factor at the next prompt. If an error was made entering the frequency

value, enter the erroneous frequency at the next frequency prompt and

a zero for the cal factor to delete that frequency point.

Once all cal factor data for a power sensor is entered, enter an S at the

next frequency prompt. The power sensor data is then stored on disk.

Viewing and Editing a Power Sensor Data File

Press

View/Edit to view or edit a power sensor data file. Only data files

listed on the screen can be viewed or edited. If a file is created but data

is not stored, the filename is listed, but no data is viewed and it cannot

be edited.

To change the cal factor at a particular frequency, enter that frequency

at the frequency prompt, then enter the new cal factor.

To delete a frequency/cal factor pair, enter the frequency of the pair to

be deleted and a cal factor of zero. Add a frequency/cal factor pair by

entering the new frequency at the frequency prompt and the new cal

factor.

Deleting a File

Press

Delete File to remove a listed file. At the prompt, enter the

filename exactly as it appears on-screen. You are asked for confirmation

to delete the file.

Chapter 1 29

Page 30

Using Operation Verification Software − Volume I

Using Operation Verification

Changing the System Mass Storage File Location

To add, edit, or view power sensor data on a disk other than the one

currently specified by the system mass storage file location, press

System File. Enter the msus of the new system mass storage file

location. All power sensor files residing on that disk are listed. Upon

returning to the Conditions Menu, the system mass storage file location

is the one determined in the Sensor Utilities Menu.

Listing Available Power Sensor Data Files

Press

List Files to list all power sensor data files on the currently

specified system mass storage location file.

Returning to the Conditions Menu

Press

Cond Menu to return to the Conditions Menu.

Test Menu

The Test Menu displays all tests that can be performed by the

Operation Verification program. Notice that the menu has two pages.

Tests may be run in any of five modes. These are listed below.

• All Tests runs all 17 tests in the sequence shown on screen.

• Single Sequence runs a user-defined sequence of tests once.

• Single Test runs one test once.

• Repeat Sequence runs a user-defined sequence of tests until testing

is aborted.

• Repeat Test runs a single test until the testing is aborted.

If GPIB controlled equipment for a given test does not respond over

GPIB, that test is flagged MISSING ETE (missing electronic test

equipment). These tests cannot be run and, if they are included as part

of a sequence (All Tests,Single Sequence, or Repeat Sequence), they are

ignored. See “List Equipment,” below.

If a test does not apply to the spectrum analyzer,the test will be flagged

TEST NOT APPLICABLE. For example, if the spectrum analyzer is an

E-Series instrument which does not have Option 007, the Fast Sweep

Time Accuracy test will have the message TEST NOT APPLICABLE next

to it.

Equipment connection prompts are displayed on the computer screen.

Most tests check equipment connections and only prompt the operator

if a misconnection is detected.

30 Chapter1

Page 31

Using Operation Verification Software − Volume I

Using Operation Verification

If more than one power meter (or the measuring receiver and one of the

power meters) is present, the program asks which model to use as the

power meter. Enter the model number without the alphabetic character

(for example, enter 8902 for an 8902A). Similarly, if more than one

frequency counter is present, the program asks which counter to use.

Again, enter the model number without the alphabetic character.

The test currently being run and its test number are indicated in the

screen title block of the spectrum analyzer under test.

All Tests

To run all 17 tests in the sequence shown, press

All Tests. The pointer

moves to each test as it is being run. All Tests can be run in

approximately 60 minutes (75 minutes for an Agilent 8564E/EC or

Agilent 8565E/EC).

Three softkeys are displayed when running All Tests. Press

ABORT TEST to abort the current test and continue to the next test.

Press

ABORT SEQUENCE to abort the All Test mode. Pressing Restart

aborts and restarts the current test. If the spectrum analyzer is in the

middle of a sweep, no action is taken until the sweep is completed.

Single Sequence

Use this mode to perform a subset of the tests, to run a particular test a

specified number of times, or to run all 16 tests in a sequence different

from the All Tests sequence. After pressing

Single Sequence, you are

prompted for a test number. The sequence is displayed after each

prompt. Up to 25 test numbers may be entered (test number

duplication is permitted). Enter a zero to terminate building the

sequence and begin testing.

If an error is made in entering the sequence, enter a zero at the next

prompt, then press

ABORT SEQUENCE. Now press Single Sequence to

reenter the correct sequence.

The ABORT TEST, ABORT SEQUENCE, and Restart softkeys have the

same function as in the All Test mode.

Single Test

Press

is running, press

Chapter 1 31

Single Test to run the test indicated by the pointer. Once the test

Restart to abort and restart the test.

Page 32

Using Operation Verification Software − Volume I

Using Operation Verification

Repeat Sequence

The Repeat Sequence mode performs a user-defined set of tests

repeatedly until the sequence is aborted. For example, if the desired

sequence is test numbers 6,7,8,6,7,8,6,7,8,…, press

Repeat Sequence

and enter the sequence of 6,7,8. When the last test of this sequence is

completed, the sequence is repeated.

The ABORT TEST, ABORT SEQUENCE, and Restart softkeys have the

same function as in the All Test mode.

Repeat Test

Use the Repeat Test mode to run a single test indefinitely. Move the

pointer to the test to be repeated. Testing can be stopped by pressing

ABORT REPEAT. Press ABORT TEST to abort and restart the test.

Calibrate Power Sensor

The Operation Verification program keeps track of which power sensor

is being used and the elapsed time since it was last calibrated.

The program prompts the user to recalibrate the power sensor if more

than 2 hours elapses since the last calibration. Also, if the power sensor

is changed, the new power sensor must be calibrated.

If there is a significant change in ambient temperature, or improved

power meter accuracy is desired, it is advisable to recalibrate the sensor

more often than the program requires. Press

Cal Sensor and follow the

instructions on the computer screen to recalibrate the power sensor.

List Equipment

To obtain a list of required test equipment for running a test, move the

pointer to the test, press

List Equip. All GPIB controlled equipment and

passive devices, other than required cables and adapters, are listed. If a

test is flagged MISSING ETE but all test equipment appears present,

press

Menu and verify that the equipment is present. Press

List Equip to see what is needed, then return to the Conditions

Cond Menu to

return to the Conditions Menu from the Test Menu.

32 Chapter1

Page 33

Using Operation Verification Software − Volume I

Using Operation Verification

Test Results

At the end of each test, a PASS, SHORT PASS, or MEASUREMENT IS OUT

OF TOLERANCE message is printed on the test record and displayed next

to the test on the computer screen.

PASS indicates that the test is fully completed and all measurements

are within specification limits.

SHORT PASS indicates that the test was abbreviated, usually due to

equipment limitations, but the measurements made were within

specification limits. Not all tests can be abbreviated. The meaning of

Short Pass varies between each test; refer to “Test Descriptions” in this

section for more information.

NOTE A Short Pass is sufficient for passing Operation Verification alone. If

Operation Verification is used as part of performance verification, all

tests must yield a PASS result.

MEASUREMENT IS OUT OF TOLERANCE indicates that one or more of the

measurements made during the test did not meet specification limits. If

the data is shown in tabular form, the symbol <<<< is placed next to the

out-of-tolerance data. In the event of a measurement-out-of-tolerance

condition, it is recommended that any related manual performance test

be performed to verify out-of-tolerance conditions. The related

performance test for each operation verification test is listed at the

beginning of each test description in this chapter.

NOTE Because test results are expected to change over a period of time,

Agilent Technologies warrants only the specification range and not the

repeatability of data for any given specification.

Chapter 1 33

Page 34

Using Operation Verification Software − Volume I

Operation Verification Menu Softkeys

Operation Verification Menu Softkeys

This section provides a brief description of each menu of softkeys. More

detailed information is provided in “Program Operation” in this

chapter. The softkey order shown below may vary with what appears on

the computer display; the order differs depending on whether an 9000

Series 200 or Series 300 computer is used.

Conditions Menu

Test Menu displays the Test Menu, which allows you to run tests

once, repeatedly, or in a user-defined sequence. Refer to

“Test Menu.”

Load Conds loads the CONDITIONS file from the disk specified by

the system mass storage file location.

Sensor Utils displays the Sensor Utilities Menu, which allows

viewing, editing, and adding power sensor data files.

Refer to “Sensor Utilities Menu.”

Change Entry permits changing a Conditions Menu entry, indicated

by the pointer along the left edge of the computer

display. Press the

RETURN or ENTER keys to terminate

an entry.

Verify Bus checks each listed GPIB address for response.

Verify Bus does not verify that a particular piece of

equipment is at a specified address.

Query DUT S/N queries the GPIB for the serial number and model

number of the spectrum analyzer under test.

Store Conds stores the current conditions in the CONDITIONS file

on the specified system mass storage file location.

Exit Program exits the Operation Verification program.

34 Chapter1

Page 35

Using Operation Verification Software − Volume I

Operation Verification Menu Softkeys

Sensor Utilities Menu

View/Edit allows user to view and edit power sensor data files.

Add File creates a new power sensor data file.

Delete File deletes a power sensor data file. User is asked for

confirmation before deletion takes place.

List Files lists all power sensor data files on the disk currently

specified by the system mass storage file location.

System File allows user to change the currently specified system

mass storage file location.

Cond Menu returns you to the Conditions Menu.

Test Menu

All Tests runs all 16 tests in the order listed by the program.

Single Sequence allows entry of a test sequence that is run once.

Single Test runs the test indicated by the pointer, once.

Repeat Sequence allows entry of a test sequence that runs repeatedly

until you abort testing.

Repeat Test runs the test indicated by the pointer repeatedly until

you abort the testing.