Agilent Technologies 8510XF

Network Analyzer System

Service Quick

Reference Guide

Agilent Part Number: E7340-90013

Printed in USA

Print Date: May 2002

Supersedes: June 2001

Notice

Restricted Rights Legend

If software is for use in the performance of a U.S. Government prime

contract or subcontract, Software is delivered and licensed as "Commercial

computer sofware" as defined in DFAR 252.227-7014 (June 1995), or as a

"commercial item" as defined in FAR 2.101(a) or as "Restricted computer

software" as defined in FAR52.227-19(June1987) or any equivalentagency

regulation or contract clause. Use, duplication or disclosure of Software is

subject Agilent Technologies’ standard commercial license terms, and nonDOD Departments and Agencies of the U.S. Government will receive no

greater than Restricted Rights as defined FAR 52.227-19(c)(1-2) (June

1987). U.S. Government users will receiveno greater than Limited Rights as

defined in FAR 52.227-14 (June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any technical data.

Hewlett-Packard to Agilent Technologies Transition

This documentation supports a product that previously shipped

under the Hewlett-Packard company brand name. The brand

name has now been changed to Agilent Technologies. The two

products are functionally identical, only our name has changed.

The document still includes references to Hewlett-Packard

products, some of which have been transitioned to Agilent

Technologies.

Windows ® is a registered copyright of Microsoft corportation.

© Copyright 1998, 2001–2002 Agilent Technologies, Inc

ii

8510XF Service Quick Reference Guide

What You’ll Find in This Manual…

Chapter 1 Installation “Preflight” Checkout

Chapter 2 Upgrading a Source for 8510XF

Chapter 3 Making 8510XF Adjustments

• Vertical Alignment Adjustment

• Degaussing the Display

• 8360 Series Sources Full User CAL

• Power Level Calibration

❍ Detector Gain Cal

❍ Conversion Loss Cal

Chapter 4 Performance Verification

Chapter 5 System Level Servicing and Troubleshooting

• Theory of Operation

• Troubleshooting Block Diagrams

8510XF Service Quick Reference Guide

iii

Warranty

Certification

DOCUMENTATION WARRANTY

Agilent Technologies certifies that this product met its published

specifications at the time of shipment from the factory. Agilent Technologies

further certifies that its calibration measurements are traceable to the United

States National Institute of Standards and Technology (NIST, formerly

NBS), to the extent allowed by the Institute’s calibration facility, and to the

calibration facilities of other International Standards Organization members.

THE MATERIAL CONTAINED IN THIS DOCUMENT IS

PROVIDED "AS IS," AND IS SUBJECT TO BEING CHANGED,

WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER, TO

THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW,

AGILENT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS

OR IMPLIED WITH REGARD TO THIS MANUAL AND ANY

INFORMATIONCONTAINEDHEREIN,INCLUDINGBUTNOT

LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. AGILENT SHALL NOT BE LIABLE FOR ERRORS

OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH THE FURNISHING, USE, OR

PERFORMANCE OF THIS DOCUMENT OR ANY

INFORMATION CONTAINED HEREIN. SHOULD AGILENT

AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS COVERING THE MATERIAL IN

THIS DOCUMENT THAT CONFLICT WITH THESE TERMS,

THE WARRANTY TERMS IN THE SEPARATE AGREEMENT

WILL CONTROL.

Assistance Product maintenance agreements and other customer assistance agreements

are available for Agilent Technologies products.

For assistance, call your local Agilent Technologies office (refer to

“Contacting Agilent” on page v).

iv

8510XF Service Quick Reference Guide

Contacting Agilent

Online assistance: www.agilent.com/find/assist

United States

(tel) 1 800 452 4844

New Zealand

(tel) 0 800 738 378

(fax) (+64) 4 495 8950

Malaysia

(tel) 1 800 828 848

(fax) 1 800 801 664

Taiwan

(tel) 0800-047-866

(fax) (886) 2 25456723

Latin America

(tel) (305) 269 7500

(fax) (305) 269 7599

Japan

(tel) (+81) 426 56 7832

(fax) (+81) 426 56 7840

Philippines

(tel) (632) 8426802

(tel) (

PLDT subscriber only):

1 800 16510170

(fax) (632) 8426809

(fax) (

PLDT subscriber only):

1 800 16510288

People’s Republic of

China

(tel) (preferred):

800-810-0189

(tel) (alternate):

10800-650-0021

(fax) 10800-650-0121

Canada

(tel) 1 877 894 4414

(fax) (905) 282-6495

Australia

(tel) 1 800 629 485

(fax) (+61) 3 9210 5947

Thailand

(tel) outside Bangkok:

(088) 226 008

(tel) within Bangkok:

(662) 661 3999

(fax) (66) 1 661 3714

India

(tel) 1-600-11-2929

(fax) 000-800-650-1101

Europe

(tel) (+31) 20 547 2323

(fax) (+31) 20 547 2390

Singapore

(tel) 1 800 375 8100

(fax) (65) 836 0252

Hong Kong

(tel) 800 930 871

(fax) (852) 2506 9233

8510XF Service Quick Reference Guide

v

Safety and Regulatory Information

Review this product and related documentation to familiarize yourself with

safety markings and instructions before you operate the instrument. This

product has been designed and tested in accordance with international

standards.

WARNING The WARNING notice denotes a hazard. It calls attention to a

procedure, practice, or the like, that, if not correctly performed

or adhered to, could result in personal injury. Do not proceed

beyond a WARNING notice until the indicated conditions are

fully understood and met.

CAUTION The CAUTION notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like, which, if not correctly performed or adhered

to, could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

Instrument Markings

When you see this symbol on your instrument, you should refer to the

instrument’s instruction manual for important information.

!

This symbol indicates hazardous voltages.

The laser radiation symbol is marked on products that have a laser

output.

This symbol indicates that the instrument requires alternating current

(ac) input.

The CE mark is a registered trademark of the European Community.

If it is accompanied by a year, it indicates the year the design was

proven.

The C-Tick mark is a registered trademark of the Australian Spectrum Agency.

The CSA mark is a registered trademark of the Canadian Standards

Association.

vi

8510XF Service Quick Reference Guide

1SM1-A This text indicates that the instrument is an Industrial Scientific and

Medical Group 1 Class A product (CISPER 11, Clause 4).

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme a la norme NMB du Canada.

This symbol indicates that the power line switch is ON.

This symbol indicates that the power line switch is OFF or in

STANDBY position.

Safety Earth Ground

This is a Safety Class I product (provided with a protective earthing

terminal). An uninterruptible safety earth ground must be provided from the

main power source to the product input wiring terminals, power cord, or

supplied power cord set. Whenever it is likely that the protection has been

impaired, the product must be made inoperative and secured against any

unintended operation.

BeforeApplying Power Verify that the product is configured to match the available main power

source as described in the input power configuration instructions in this

manual. If this product is to be powered by autotransformer, make sure the

common terminal is connected to the neutral (grounded) side of the ac power

supply.

8510XF Service Quick Reference Guide

vii

Typeface Conventions

Typeface Conventions

Italics

• Used to emphasize important information:

Use this software

only

with the xxxxxX system.

• Used for the title of a publication:

Refer to the

xxxxxX System-Level User’s Guide

.

• Used to indicate a variable:

Type

LOAD BIN

Instrument Display • Used to show on-screen prompts and messages that you will see on the

display of an instrument:

The xxxxxX will display the message

[Keycap] • Used for labeled keys on the front panel of an instrument or on a

computer keyboard:

Press

[Return].

{Softkey} • Used for simulated keys that appear on an instrument display:

Press

{Prior Menu}.

User Entry • Used to indicate text that you will enter using the computer keyboard;

text shown in this typeface must be typed

Type

LOAD PARMFILE

filename

.

CAL1 SAVED.

exactly

as printed:

Path Name

Computer Display

• Used for examples of programming code:

#endif // ifndef NO_CLASS

• Used for a subdirectory name or file path:

Edit the file

usr/local/bin/sample.txt

• Used to show messages, prompts, and window labels that appear on a

computer monitor:

The

Edit Parameterswindow will appear on the screen.

• Used for menus, lists, dialog boxes, and button boxes on a computer

monitor from which you make selections using the mouse or keyboard:

Double-click

EXIT to quit the program.

viii

8510XF Service Quick Reference Guide

Contents

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

What You’ll Find in This Manual… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

DOCUMENTATION WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Contacting Agilent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Safety Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Before Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Typeface Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

1. Installation “Preflight” Checkout

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Rack Diagram Configured for Coaxial Measurements . . . . . . . . . . 1-2

Rack Diagram Configured for Wafer-Probe Measurements . . . . . . . 1-3

Front View Cabling Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Rear View Cabling (rack mounted source) . . . . . . . . . . . . . . . . . . . . 1-5

Rear View Cabling (table mounted source) . . . . . . . . . . . . . . . . . . . 1-6

8510XF Option 006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2. Upgrading a Source for 8510XF

3. Making 8510XF Adjustments

Procedure 1. Vertical Alignment Adjustment . . . . . . . . . . . . . . . . . . 3-3

Procedure 2. DeGaussing (Demagnetizing) the Display . . . . . . . . . 3-4

Procedure 3. 8360 Series Sources Full User CAL . . . . . . . . . . . . . . 3-5

Procedure 3A. 8360 Series Sources Modulator Offset and Gain

Adjustment (8510XF RF source only) . . . . . . . . . . . . . . . . . . . . 3-5

Procedure 4. Power Level Calibration . . . . . . . . . . . . . . . . . . . . . . . 3-6

4. Performance Verification

Verification Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

When to Verify . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Materials Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Calibration and Frequency Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Verification Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

General Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Verification Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Low Band Verification (< 50 GHz) . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

8510XF Service Quick Reference Guide Contents ix

High Band Verification (> 50 GHz) . . . . . . . . . . . . . . . . . . . . . . . . 4-10

CW Frequency Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Materials Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

5. System Level Servicing & Troubleshooting

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Millimeter Wave Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Frequency Bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

8510XF Firmware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Hardware States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Instrument States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Power Level Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Test Plots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

x 8510XF Service Quick Reference Guide

1 Installation “Preflight” Checkout

System Overview The 8510XF network analyzer system has been designed to measure

broadband devices to 110 GHz, on-wafer or coax, fully calibrated, in a

single frequency sweep.

Single RF connection to 110 GHz

The 8510XF system provides frequency coverage from 45 MHz to 110 GHz

in a single sweep with a single connection.

Millimeter-wave measurements in 1.0 mm coax

With a single connection, fully error-corrected measurements to 110 GHz

are made in 1.0 mm coax. Making millimeter-wave measurements in

1.0 mm coax delivers uncompromised performance and improved

productivity compared to waveguide.

Convenient millimeter-wave on-wafer measurements

The 8510XF system is designed for convenient on-wafer measurements

using the 1.0 mm coax connector to interface with the 1.0 mm wafer probe.

Broadband calibration with built-in firmware

The built-in firmware of the 8510XF system enables you to perform a single

calibration from 45 MHz to 110 GHz, either in coax or on-wafer.

8510XF Service Quick Reference Guide

1-1

Rack Diagram

Configured for

Coaxial Measurements

Installation “Preflight” Checkout

System Diagrams

System Diagrams

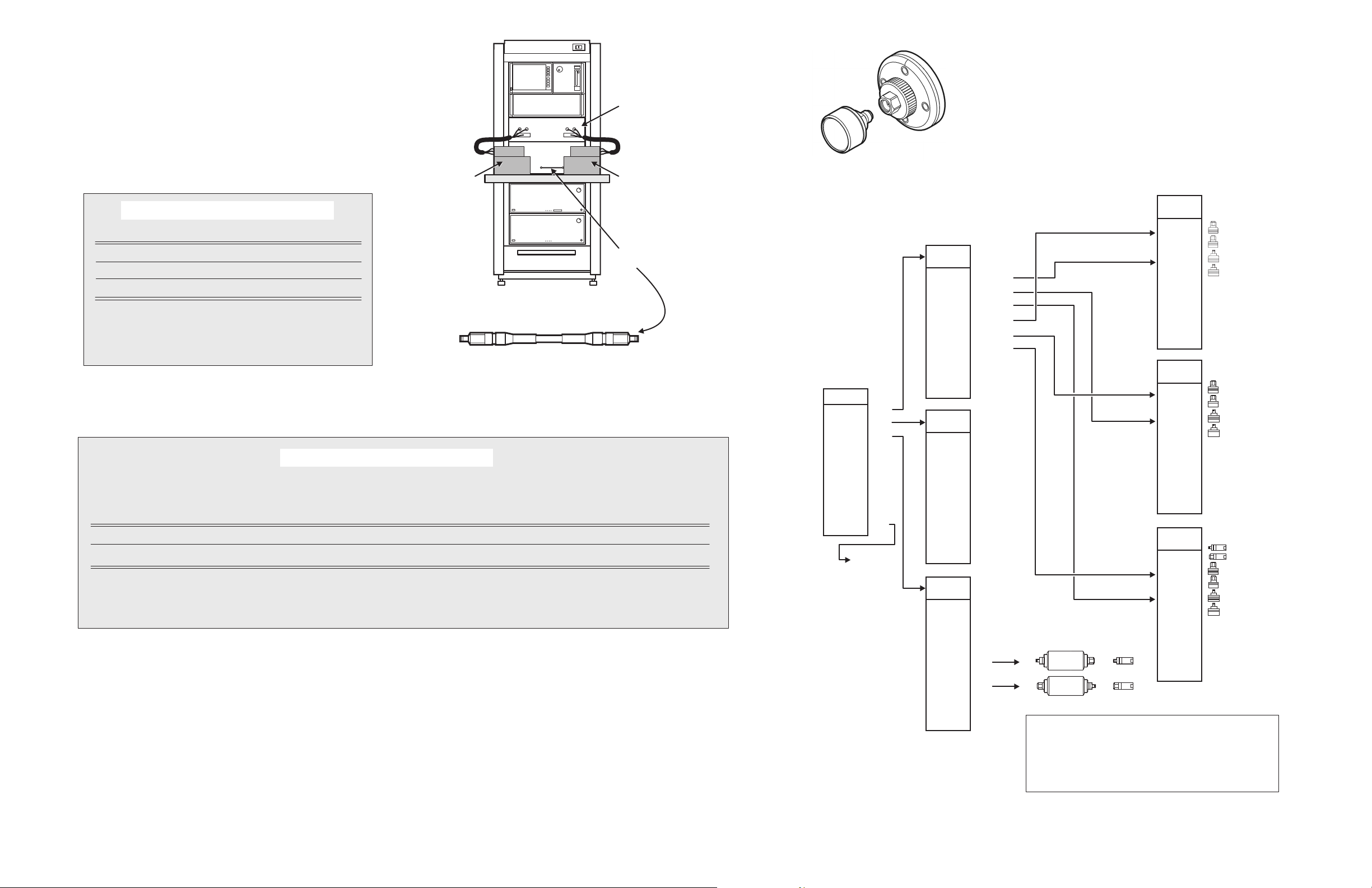

Figure 1-1 Rack diagram configured for coaxial measurements

1-2

8510XF Service Quick Reference Guide

Rack Diagram

Configured for

Wafer-Probe

Measurements

Installation “Preflight” Checkout

System Diagrams

Figure 1-2 Rack diagram configured for wafer-probe measurements

8510XF Service Quick Reference Guide

1-3

Front View Cabling Diagram

Installation “Preflight” Checkout

System Diagrams

3.5 mm

Figure 1-3 Front view wiring diagram

Figure 1-4 Test head connectors

1-4

8510XF Service Quick Reference Guide

2.4 mm

SMA

testhead.cdr

Rear View Cabling (rack mounted source)

Installation “Preflight” Checkout

System Diagrams

Figure 1-5 Rear view wiring diagram (rack mounted source)

8510XF Service Quick Reference Guide

1-5

Rear View Cabling (table mounted source)

Installation “Preflight” Checkout

System Diagrams

Figure 1-6 Rear view wiring diagram (table mounted source)

1-6

8510XF Service Quick Reference Guide

Installation “Preflight” Checkout

8510XF Option 006

8510XF Option 006

8510XF Option 006 provides the capability to add an additional 8510 series

test set provided Option 001 is installed in the test set. Option 006 includes:

• Coupler and amplifier added to millimeter-wave controller

• 2.4 mm termination added to rear panel

Figure 1-7 8510XF Option 006

The configuration for the 8510XF Option 006 is as shown in Figure 1-8.

Figure 1-8 Multiple test set example application

8510XF Service Quick Reference Guide

1-7

Installation “Preflight” Checkout

8510XF Option 006

1-8

8510XF Service Quick Reference Guide

2 Upgrading a Source for 8510XF

All 8360 series sources are compatible, but only the 83621A/B or 83651A/B

are recommended in order to insure full functionality of the 8510XF.

Table 2-1 shows the upgrade options required.

NOTE 83651/21A and 83650/20A/B will also work for upgraded 8510XF systems

as long as it has test port flatness correction modification or capability, rear

panel output (Option 004), and 1 Hz frequency resolution (Option 008)

installed.

Table 2-1 Source Upgrades

Model

83620B/21B

83650A/B

83651A/B

83621A

83631A

83620A

83623A

83624A

83630A

83640A

1. Fully compatible at time of shipment.

2. Can be used for 8510XF LO source when upgraded and includes Options 004 and 008.

3. Includes installation.

4. 83623L, 30L, 40L and 50L, with Option 004 and 008, will also work as LO source, but do not have

2

2

2

24

2

2

2

modulation capability (83623L maximum power at highest frequency is + 15 dBm).

Maximum Power at

Highest Frequency

+ 13 dBm

+ 2.5 dBm

+ 2.5 dBm

+13 dBm

+ 10 dBm

+ 13 dBm

+ 17 dBm

+ 20 dBm

+ 10 dBm

+ 26 dBm

Serial Prefix

All No modification required.

< 3103A

3103A

3104A to 3111A

≥ 3112A

≤ 3103A

3104A to 3111A

≥ 3112A

≥ 3145A

Required for Test Port

Flatness Correction

83601A upgrade kit.

08360-60167 firmware kit

08360-60201 firmware kit

No modification required.

08360-60167 firmware kit

08360-60201 firmware kit

No modification required.

No modification required.

3

1

1

1

1

8510XF Service Quick Reference Guide

2-1

Upgrading a Source for 8510XF

2-2

8510XF Service Quick Reference Guide

3 Making 8510XF Adjustments

NOTE This chapter covers both the CRT and LCD displays. Some display-related

adjustments apply only to instruments with CRT display.

The following table provides adjustments most frequently needed for

8510XF system service. Most of the 8510XF is self-adjusting except for the

following:

Table 3-1 Frequently used 8510XF adjustments

Procedure

1 Vertical Alignment Adjustment

2 Degausing (Demagnetizing) the 85101

3 8360 Series Sources Full User CAL

4 Power Level Calibration Insures level power at the test ports Leveling DAC/ EEPROM, A16,

1. Reference subsequent sections in this document.

2. These adjustments apply to a CRT-based display only.

1

Title Adjustment Function Assembly Adjusted

display

2

2

Aligns softkey labels and mechanical

softkey buttons.

Demagnetize the display.

A11

and Leveling Compensation

Board, A7

8510XF Service Quick Reference Guide

3-1

Making 8510XF Adjustments

Table 3-2 Equipment required for 8510XF adjustments

Equipment Recommended Model Substitute

CRT demagnetizer or bulk tape

1

eraser

Radio Shack Model 44-233 Techno Tool (USA) or

Nietronix (Europe) 692PR022

1 to 2 amp pencil sharpening motor (base held

near CRT with motor on), or electric drill

Flat-head screwdriver (small) At least 2 inches long, non-conductive none

10 dB pad 8493C 8360 series source with built-in attenuator

85102A/B and test set adjust software Part Number 08510-10024 Rev. A.01.10

Power Meter 437B power meter 438A or EPM-441A power meter

Power Sensors:

N/A

N/A

Only available as a special

N/A

50 GHz

V band

W band

8481A or 8482A

8487A power sensor

V8486A power sensor

W8486A power sensor

Adapter, 2.4 to 1.0 mm (f-f) 85059A K01

Adapter, V-band to 1.0 mm (f-f) V281C

Adapter, W-band to 1.0 mm (f-f) W281C

Laptop, personal computer or

controller

2, 3

8510XF port power level calibration

9000 series 200 or larger

08510-100xx

check software

BASIC 6.3 or higher

4

E2060B

Agilent VEE 4.0 Installation E2120-13605

1. These adjustments apply to a CRT based display only.

2. Minimum 4 megabytes of available memory after BASIC has been loaded.

3. With BASIC for Windows and PCMCIA-GPIB card.

4. Includes language extensions and drivers.

3-2

8510XF Service Quick Reference Guide

Making 8510XF Adjustments

Procedure 1. Vertical Alignment Adjustment

NOTE This procedure applies to a CRT based display only.

NOTE The vertical alignment can be affected by magnetic interference. Before

adjusting the vertical position, be sure the analyzer is in a non-magnetic

environment and the CRT is degaussed.

Perform the following steps to adjust the vertical alignment.

1. Switch on the system and allow it to warm up for 60 minutes.

2. Remove the side panel nearest the display to access the vertical position

and focus controls. See Figure 3-1.

3. Insert a narrow, non-conductive, flathead screwdriver (2 or more inches

long) into the vertical position hole.

4. Adjust the control until the softkey labels align with the softkeys.

Figure 3-1 Vertical adjustment location

8510XF Service Quick Reference Guide

3-3

Making 8510XF Adjustments

Procedure 2. DeGaussing (Demagnetizing) the Display

NOTE This procedure applies to a CRT based display only.

Use any CRT demagnetizer or bulk tape eraser for this procedure. The color

monitor display is very susceptible to external magnetic fields, such as metal

frame tables, welded cabinets, the earth, unshielded motors, and other

sources. The usual symptom is discoloration or slight dimming of the

display (usually near a top corner of the CRT). In extreme cases, a total color

shift may be observed. For example, a trace that was red may shift to green.

This shift does not suggest a problem with the display. It is characteristic of

color displays needing demagnetizing. In countries using 50 Hz, some 10 Hz

jitter may be observed. If this problem is observed, remove the device

causing the magnetic field.

If the display becomes magnetized or if color purity is a problem, cycle the

power several times. Leave the instrument off for at least 15 seconds before

switching power on. This will trigger the automatic degaussing circuit in the

display. If this is insufficient to restore color purity, use a commercially

available demagnetizer (either a CRTdemagnetizer or a bulk tape eraser). In

an emergency, you can use a running electric drill or a pencil sharpener that

draws 1/2 to 2 amps through its AC motor winding. Follow the

manufacturer’s instructions keeping in mind that it is imperative when

demagnetizing a display that the degausser is kept farther than 4 inches

(10 cm) from the face of the CRT.Generally, degaussing is done with a slow

rotary motion of the degausser, moving it in a circle of increasing radius

while simultaneously moving away from the CRT. The following figure

illustrates the motion for degaussing the display.

CAUTION Applying an excessively strong magnetic field to the CRT face can

permanently destroy the CRT.

Figure 3-2 Using a Degausser on the display

3-4

8510XF Service Quick Reference Guide

Making 8510XF Adjustments

Procedure 3. 8360 Series Sources Full User CAL

NOTE If the 8360 series source does not have a front panel, use the 8360 source

Full User CAL initiates a full synthesizer calibration. The calibration

performed is instrument state dependent. For example, if the synthesizer is

in ramp sweep mode, a sweep span and an auto track calibration are

performed. If the synthesizer has amplitude modulation active on an SW

signal, then RF peaking and AM bandwidth calibrations are performed. For

8510XF purposes, only ramp-sweep mode is needed.

Perform the following calibration procedure:

1. On the 8360, press

2. Select {Full User CAL}. Wait for the calibration to complete (usually less

than a minute).

Attenuation needed

If the 8360 series source does not have a built-in attenuator, you will be

prompted to connect a 10 dB attenuator to the 8360 series RF output port.

Auto track is done as part of Full User CAL.

front panel emulator in the 8510C network analyzer (refer to the “Service

Program” section in the 8510C On-Site Service Manual). For the RF source

calibration, the front-panel emulator will default to GPIB address 19. For the

LO source calibration, change the GPIB address in the front panel emulator

to 18.

[PRESET] [USER CAL].

Procedure 3A.

8360 Series Sources

Modulator Offset and

Gain Adjustment

(8510XF

RF source only)

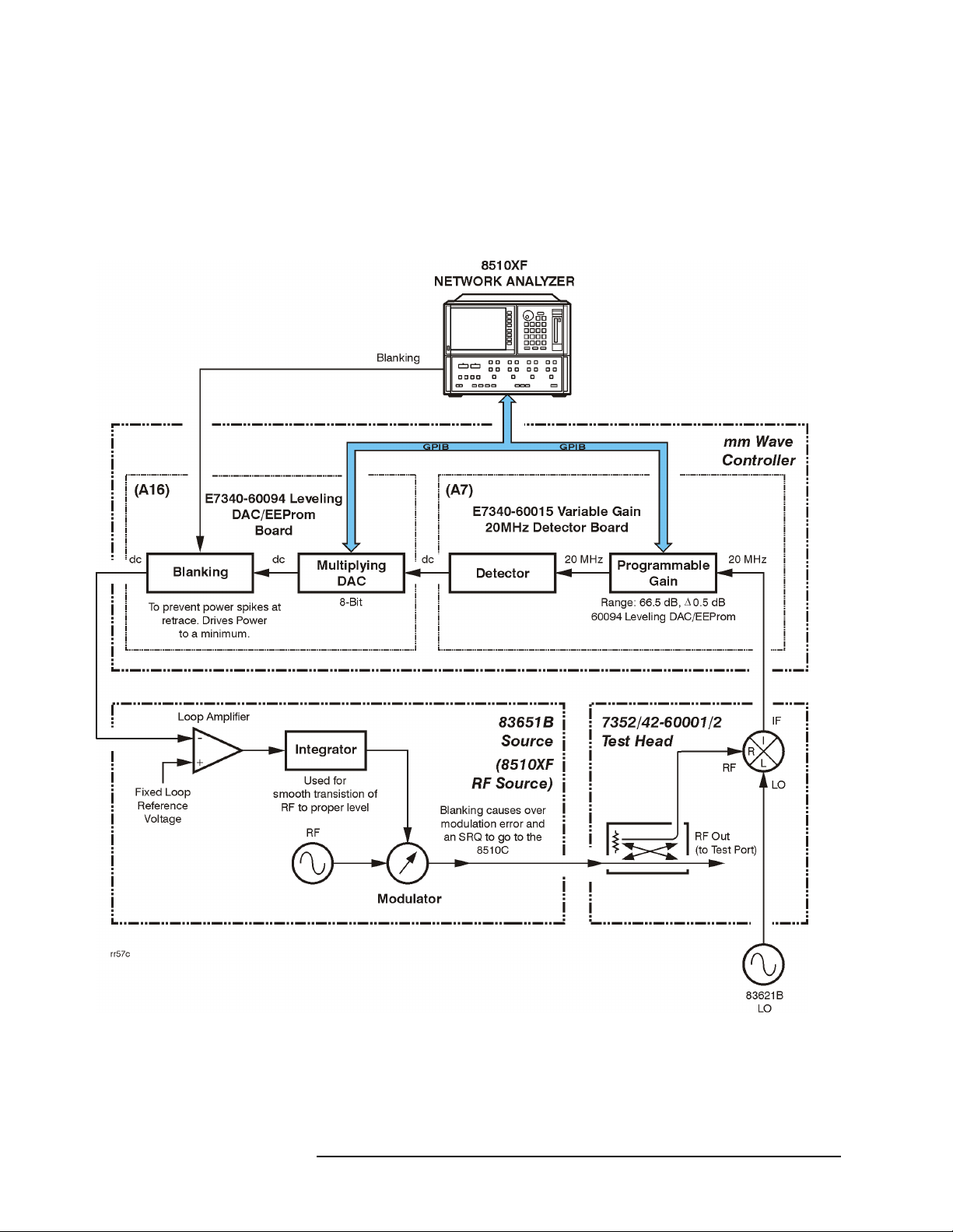

Modulator offset and gain adjustment optimizes the modulator in the 8360

series source for maximum performance. This is necessary since the RF

source is part of the 8510XF level control (refer to Figure 3-3 on page 3-6).

This should be done before the conversion loss calibration is performed on

systems with older sources or sources which may be out of calibration.

Adjust the RF source using the procedure “Modulator Offset and Gain

Adjustment” in the 8360 Series Synthesized Sweeper Service Guide’s

“Adjustments” chapter.

8510XF Service Quick Reference Guide

3-5

Making 8510XF Adjustments

Procedure 4. Power Level Calibration

Power level calibration insures leveled power at ports 1 and 2. To level the

power, we sense the IF signal which correlates to RF level. Since the

translation function is frequency dependent, we need to measure the

translation function using the conversion loss calibration procedure. The

power level calibration is accomplished using IF leveling as shown in the

following circuit.

Figure 3-3 8510XF level control

3-6

8510XF Service Quick Reference Guide

Making 8510XF Adjustments

Detector Gain Cal Before we begin the conversion loss calibration, we must perform a detector

gain calibration to compensate for the imprecision of the detector board

(E7340-60015 A7). Perform the following procedure for the detector gain

calibration:

1. Under the

2. Press

3. Press

4. Press

5. Press

Auxiliary Menus, press [System] hard key.

{More} softkey.

{RF Power Config} softkey.

{More} softkey.

{Reset Det Gain Cal} softkey.

6. Follow the on-screen instructions until cal is completed.

CAUTION If the operating system is reloaded, it is necessary to perform the detector

gain calibration.

NOTE It is recommended that this 5-minute calibration be performed once a month.

Additionally, a CW frequency accuracy test should be performed prior to

doing the conversion loss and power level flatness calibrations. Refer to

“CW Frequency Accuracy Test” on page 12.

Conversion Loss

Calibration

After performing a detector gain cal, you will be ready to perform the RF to

IF conversion loss calibration. This calibration provides the absolute power

level information at 25/50 MHz intervals over the entire frequency range of

the E7340/50A to compensate for conversion losses in the E7340/50A so

that ports 1 and 2 will be power leveled.

a. The external controller with its software changes the 8510XF CW

frequency and reads the power meter.

b. The entire frequency range is stepped in 25/50 MHz increments at

approximately 2200 points per port (25 MHz steps from 45 MHz to

18 GHz, and 50 MHz steps from 18 GHz to 110 GHz).

c. The result is stored in the millimeter controller EEPROM memory

board (A16) after all bands and heads are measured and should be

valid for one year or until a test head is repaired or replaced.

8510XF Service Quick Reference Guide

3-7

Making 8510XF Adjustments

To perform the conversion loss calibration:

Use the following procedure to perform the conversion loss calibration.

1. Load the BASIC, version 6.3 or greater.

2. Calibrate and zero the power sensor, and enter all cal factors versus

frequency of the 3 or 4 sensors into the text file of the conversion loss

calibration program.

3. Connect the power sensor to the left or right test head and press

[ENTER].

4. Create a power sensor cal factor test file. Using MS Windows Notepad,

enter the following values in the respective columns:

Column Entry

First Frequency (GHz)

Second Cal Factor

Third Sensor #3

Save this file as

XFPWRCAL.PMC, and in the same directory as your

conversion loss cal program.

5. Load

6. Press

xfpwcal.bas, and press [ENTER].

{Run}.

7. Select one of the following frequency ranges:

Selection Frequency Range

1 0.045 to 110 GHz

2 2 to 110 GHz

3 0.045 to 85 GHz

4 2 to 85 GHz

8. Select (1) for the left test-head, or (2) for the right test-head.

9. Enter the serial number of the test head up to eight digits.

10. Approximately 20 frequencies will be used to check the 8510XF power

control. These frequencies and the corresponding levels will be

displayed if all is okay. If not, the display will have an error message

which indicates that the 8510XF leveling loop must be corrected.

NOTE Refer to Performance Verification, page 4-1, for details on the types of

computers and software needed to run the Performance Verification and

conversion loss calibration programs.

3-8

8510XF Service Quick Reference Guide

4 Performance Verification

Verification Overview

NOTE The verification procedures in this chapter work for all 8510 and 8510XF

hardware configurations by substituting the proper 8510 source, test set,

accessories, and millimeter wave controller.

Performance verification software Rev. A.05.00 or greater will be available

only in DOS format, and will work with laptops or PCs that have the

required accessories installed. Refer to “Materials Required” on page 4-2.

When to Verify After installation of the system is complete, a performance verification is

necessary to assure proper system operation. This initial verification is

included with the installation.

After the initial verification, the verification should be repeated once a year.

This recommended interval assumes that Agilent cables are used with the

system.

If non-Agilent cables, adaptors, or other fixtures are used, the verification

schedule must be determined by the user, as the characteristics of these

devices are unknown. In establishing a verification schedule, the following

factors should be considered:

• Frequency of use

• Amount of cable movement

• Amount of drift occurring between prior verifications

NOTE Performance verification of a system performed at long intervals is not to be

confused with measurement calibration. Measurement calibration typically

is performed on a daily basis, or when measurement setup or conditions have

changed.

8510XF Service Quick Reference Guide

4-1

Performance Verification

Materials Required The following materials are required to run the tests:

• 8510XF system with accessories

• 85059A 1.0 mm Precision Calibration and Verification Kit

• PC-based, 8510 Specification and Performance Verification Software

(Rev. A.05.00 or greater; p/n 08510-10033)

• Laptop or PC running BASIC for Windows (3.1/95/NT)

(Rev. 6.3 or greater)

• GPIB Card for PCs (National Instruments or HP)

• PCMCIA Card for Omnibook or laptop

• GPIB cable from PC to 8510XF

Calibration and Frequency Ranges

Table 4-1 Calibration storage locations

The 8510XF requires separate verifications for frequencies below and above

50 GHz (see on “Frequency ranges” on page 4-3).

A special two-band calibration procedure is required for the performance

verification of the 8510XF system (a measurement calibration is not

sufficient). There are up to three different calibrations and corresponding

frequency ranges required, which are stored in suggested locations in the

8510 analyzer (Refer to Table 4-1). For more information refer to the section

on “Frequency ranges” on page 4-3. The parameters for these calibrations

are set up automatically on the analyzer by the performance verification

software.

File Location Name:

Cal Set 1 1-50 GHz

Cal Set 2 45 MHz

Cal Set 3 50-110 GHz

1. This calibration is for Option 005 systems only.

2. The frequency for standard systems is 2-50 GHz.

3. The frequency range shown is for the E7352A system only. The E7342A

system’s frequency range will be: 50-85 GHz.

Frequency Range of Data

Stored:

1

(2-50 GHz)

1

3

2

4-2

8510XF Service Quick Reference Guide

Performance Verification

Frequency ranges

For most of the menu items in the software, there are two or more selections

that pertain to the 8510XF. These menu selections are differentiated by:

A. The frequency range of the millimeter wave subsystem

❍ E7352A: 110 GHz subsystem

❍ E7342A: 85 GHz subsystem

❍ Option 005: 45 MHz to 2 GHz

B. The portion of the subsystem’s frequency range that is being verified (the

ranges above and below 50 GHz are verified separately).

The menu selections are broken down in Tables 4-2 and 4-3, below.

Table 4-2 System hardware configuration (E7352A -- 110 GHz System)

Hardware Selection (<50 GHz Range) Selection (>50 GHz Range)

Network Analyzer 8510C -- Vector Network Analyzer 8510C -- Vector Network Analyzer

Test Set E7352A -- 1.0 mm Subsystem (2-50 GHz)

E7352A005 -- 1.0 mm Subsystem (45MHz-50GHz)

Source 8365xXF -- Synthesizer (45 MHz-50 GHz) 836xxXF -- Multiplied Synth. (above 50 GHz)

Calibration Kit

Calibration

Technique

Test Port Cables DIRECTXF -- for 8510XF verification (1.0 mm-1.0 mm) DIRECTXF -- for 8510XF verification (1.0 mm-1.0 mm)

Verification Kit 85059AOV -- 1.0 mm (45 MHz-50 GHz) 85059AOV110 -- 1.0 mm (above 50 GHz)

1. The 85059A --1.0 mm (45MHz-50GHz) [Use w/ 8517A/B] selection is not used for the 8510XF Performance Verification.

1

85059A -- 1.0 mm (45 MHz-50 GHz) [Use w/

E7342A/52A]

BL -- Broadband Load Cal OS -- Offset Short Cal

E7352A110 -- 1.0 mm (50 GHz-110 GHz)

85059A110 -- 1.0 mm (50 GHz-110 GHz)

Table 4-3 System hardware configuration (E7342A -- 85 GHz System)

Hardware Selection (<50 GHz Range) Selection (>50 GHz Range)

Network Analyzer 8510C -- Vector Network Analyzer 8510C -- Vector Network Analyzer

Test Set E7342A -- 1.0 mm Subsystem (2-50 GHz)

E7342A005 -- 1.0 mm Subsystem (45 MHz-50GHz)

Source 8365xXF -- Synthesizer (45 MHz-50 GHz) 836xxXF --

Calibration Kit

1

85059A -- 1.0 mm (45 MHz-50 GHz) [Use w/

E7342A/52A]

E7342A85 -- 1.0 mm (50 GHz-85 GHz)

Synth. (above 50 GHz)

85059A85 -- 1.0 mm (50 GHz-85 GHz)

Calibration

Technique

Test Port Cables DIRECTXF -- for 8510XF verification (1.0 mm-1.0 mm) DIRECTXF -- for 8510XF verification (1.0 mm-1.0 mm)

Verification Kit 85059AOV -- 1.0 mm (45 MHz-50 GHz) 85059AOV110 -- 1.0 mm (above 50 GHz)

1. The 85059A --1.0 mm (45MHz-50GHz) [Use w/ 8517A/B] selection is not used for the 8510XF Performance Verification.

BL -- Broadband Load Cal OS -- Offset Short Cal

8510XF Service Quick Reference Guide

4-3

Performance Verification

Verification Setup

Verification Setup

General Preparation Prepare for performance verification by completing the following steps:

1. Measure the environment temperature and humidity. The temperature

must be between +20

cannot vary by more than 1

2. Perform a good installation “preflight” checkout on the 8510XF system.

3. Power on the system components in the following order:

a. Sources

b. Millimeter wave controller

c. 8510XF

°C and +26 °C. Additionally, the temperature

°C after calibration.

d. Controller (PC or laptop)

4. Remember to allow at least one hour for warm up of the components.

Software Installation In order to verify performance, you must first install BASIC for Windows

and the 8510C Specification and Performance Verification software on a PC

(or controller).

NOTE This manual documents the use of the verification software on a PC. Use of

the software on a controller is not documented.

The PC must have an INTEL 486 processor or higher,and must have at least

eight megabytes of memory available. The PC must also have an GPIB card

in order to communicate with the 8510XF.

1. Install BASIC for Windows (Revision 6.3 or later) on the PC following

the instructions on the first BASIC disk. The program will guide you

through the installation process. (For more detailed information, refer to

BASIC for Windows, Installing and Using Guide.) If you are installing

Revision 7.1 or later, install the Legacy Version.

2. Install the specification and performance verification software by

following the instructions on the disk label. The installation program

will lead you through the installation. In the process, a new program

group will be created, which includes the “Spec8510” icon.

4-4

8510XF Service Quick Reference Guide

Performance Verification

Verification Setup

NOTE Rev. A.05.00 or greater of the performance verification software is

backwards compatible. So, it is acceptable to replace the older version you

have on the PC.

3. Run the program by clicking on the “Spec8510” icon or selecting:

Programs, 8510, Spec8510. The following warning messages will be

displayed:

A validBasicfor Windows GPIBdriverfor your board (if any)has not been loaded. You can

run the Specifications and Uncertainty portions of the 8510 software but can not run the

Verification portion as this requires communication. Press CONTINUE to load and run the

8510 software without GPIB or:

To load the correct driver EDIT this program and Remove the “!” from in front of the LOAD

statement for your GPIB board.

After editing, type RE-STORE “AUTOST” to store the modified program. Then, close this

window and re-select the Specifications and Verification icon to re-run the program. The

8510 software should now load and run.

4. Edit the AUTOST program according to the instructions in the warning

message. (However, if you do not want to run the verification portion of

the software, you can skip this step by selecting

CONTINUE.)

NOTE For additional information on running the system specifications, system

uncertainty, and edit system specifications portions of the program, refer to

the “Performance Verification and Specifications” chapter in the 8510C

On-Site Service Manual.

Start,

5. After editing and storing the

AUTOST file, exit the program by closing the

window and then restart the 8510 Specification and Performance

Verification Program.

Software

Configuration

NOTE Once the Specifications and Verification Software is running, there is no

functional difference between operation on a PC and operation on a

controller.

1. Verify the GPIB cable is connected from the PC to the GPIB bus (also

referred to as the public bus) on the analyzer.

2. After the program is started, the program title (8510 Specifications and

Performance Verification Software) and copyright notices are displayed.

Select

RESUME.

8510XF Service Quick Reference Guide

4-5

Performance Verification

Verification Setup

3. A screen prompt will give you the opportunity to set the date and time.

Press the

[Y] key on the PC to skip this step, or press [N] to set the date

and time.

4. The program loads the System Configuration file, and displays the

System Hardware Configuration Menu. Use this menu to specify the

equipment you are using, and the frequency range you are verifying

(refer to “Frequency ranges” on page 4-3).

To set up for the first performance verification, select the proper

hardware setup for Low Band Verification (< 50 GHz) using Table 4-2

on page 4-3 for the E7352A 110 GHz system, or Table 4-3 on page 4-3

for the E7342A 85 GHz system.

a. Select

menu item.

b. Use the up and down arrow keys on the PC to advance from one

menu item to another.

c. Select

5. The main menu is displayed (see Table 4-4).

Table 4-4 Main menu

Softkey Description

System Config System Hardware and Software Configuration Menu

System Specs System Spec Table Menu

System Uncert System Uncertainty & Dynamic Accuracy Plot/Table Menu

Edit Specs Edit the System Specifications

Verify System System Performance Verification Menu

Quit Progam Quit this Program

NEXT or PREVIOUS to step through the list of selections for each

DONE when you have made a selection for each menu item.

4-6

8510XF Service Quick Reference Guide

Printer selection

1. From the Main Menu (choosing printer options):

Performance Verification

Verification Setup

a. Select

b. Select

c. Select

System config.

Software Config.

Printer Connected to:

2. Select printer output choice (refer to Table 4-5)

Table 4-5 Printer table of selections

Printer Connected To:

GPIB

WIN Printer

LPT1

LPT2

2

File

1. Windows default printer

2. Under Printer Redirection (File): Verify directory path exists

before entering name of path

1

3. Select

Done and Previous Menu to return to Main Menu.

8510XF Service Quick Reference Guide

4-7

Performance Verification

Verification Procedures

Verification Procedures

Low Band Verification

(< 50 GHz)

The following steps assume the hardware configuration has been previously

setup for Low Band Verification (< 50 GHz) in step 4 on page 4-6 under

Software Configuration.

1. From the Main Menu select

Verification Menu.

2. Select

3. Select

for frequencies <50 GHz. See Table 4-1 on page 4-2 for the calibrations

required and suggested calibration storage locations (also refer to the

“Two-Band Calibration Procedure for 8510XF Performance

Verification” art foldout at the end of this chapter).

a. Install the 1.0 mm female to female cable (8.8 cm, part number

b. A full two-port calibration is required. A table of calibration

Serial Numbers to enter serial numbers of system and components.

System Cal and follow the program prompts to calibrate the system

11500-60001) onto the right test head (port 2) prior to calibration.

This cable is part of the 85059A 1.0 mm Precision Calibration and

Verification Kit and is considered to be a test port cable.

standards required for each frequency range can be found in the

85059A 1.0 mm precision calibration and verification kit manual, or

on the art foldout at the end of this chapter.

VerifySystem to go to the System Performance

CAUTION Do not remove this test port cable once the Calibration/Verification process

has begun. If the test port cable becomes loose or is removed during the

calibration/verification process, the calibration is invalid.

CAUTION Do not pull on the connectors on the ends of the test port cable—this will

damage the cable. Avoid damaging the cable once it is connected to port 2

by carefully making the thru connection between the two test heads. This is

best done by placing the two test heads on a smooth surface and gently

sliding the right test head (port 2) towards the left test head (port 1).

4-8

8510XF Service Quick Reference Guide

Performance Verification

Verification Procedures

c. To make the thru connection, gently slide the right test (port 2)

towards the left test head (port 1) a little bit at a time, while turning

the threaded ring on the left head test port connector by hand onto

the cable attached to the right test head. Do not use the threaded ring

on the test port connector to pull the cable into the connector. Repeat

this process until the cable is firmly seated into port 1, then make the

threaded ring barely finger tight. Finally use the torque wrench on

the port 1 threaded ring and a backup wrench on the cable to tighten

the connection.

4. Select

Select Standard to go to the Standard Selection Menu.

5. To verify the system, use the Verification Standards provided with the

85059A 1.0 mm Precision Calibration and Verification Kit (refer to

Table 4-6). Using the menu select the verification standard and enter the

standard’sserial number. The verification standards may be measured in

any order.

Table 4-6 Verification standards from 1.0 mm calibration and verification kit

Type of Standard Part Number

Mismatched Thru Adapter 85059-60016

Match Thru Adapter 85059-60017

NOTE It is recommended to connect the Verification Standards to the cable on

port 2 prior to attempting to connect to port 1. Then follow the

recommended procedure for making a thru connection outlined under step 3

above to avoid damaging the cable.

6. Use defaults for

Measurement (If Required): 2

7. If your system has Option 005, verify that

Required)

8. Select

9. Select

is set to Yes. Otherwise, set to No.

Done and follow the program prompts.

Measure Data to measure the verification standards. Follow the

Cal Set for Broadband Measurement: 1 and Cal Set for 45 MHz

in the Standard Menu.

Cal Set for 45 MHz Measurement (If

program prompts.

10. When verification has been completed view the data, then print or save

(if required). If needed the verification standard can be remeasured by

selecting

Repeat Measure.

8510XF Service Quick Reference Guide

4-9

Performance Verification

Verification Procedures

11. Select Select Standard to return to the Standard Selection Menu. Repeat

steps 5 through 10 above for the other verification standard (refer to

Table 4-6 on page 4-9).

12. Select

Prior Menu until the Main Menu appears.

HighBandVerification

(> 50 GHz)

NOTE Before verification of the high band frequencies it is necessary to:

1) select new hardware for the system, and

2) perform a calibration (for the frequency band > 50 GHz).

1. From the Main Menu select

2. Select the proper hardware setup for High Band Verification (> 50 GHz)

using Table 4-2 on page 4-3 for the E7352A 110 GHz System or

Table 4-3 on page 4-3 for the E7342A 85 GHz System.

3. Select

4. Select

5. Select

Done and Prior Menu to return to Main Menu.

Verify System to go to the System Performance Verification Menu.

System Cal and follow the program prompts to calibrate the system

for frequencies >50 GHz. See Table 4-1 on page 4-2 for the calibrations

required and suggested calibration storage locations (refer to step 3 on

page 4-8).

System Config then Hardware Config.

6. Select

Select Standard to go to the Standard Selection Menu.

7. To verify the system use the Verification Standards provided with the

85059A 1.0 mm Precision Calibration and Verification Kit (refer to

Table 4-6 on page 4-9). Using the menu select the verification standard

and enter the standard’s serial number. The verification standards may

be measured in any order.

NOTE It is recommended to connect the Verification Standards to the cable on

port 2 prior to attempting to connect to port 1. Then follow the

recommended procedure for making a thru connection outlined under step 3

on page 4-8 to avoid damaging the cable.

8. Change default for

Cal Set for Broadband Measurement from 1 to 3.

NOTE It is suggested that the High Band Calibration be stored in Cal Set 3 (Refer

to Table 4-1 on page 4-2).

4-10

8510XF Service Quick Reference Guide

Performance Verification

Verification Procedures

9. Verify Cal Set for 45 MHz Measurement (If Required) is set to No.

10. Select

11. Select

Done and follow the program prompts.

Measure Data to measure the verification standards. Follow the

program prompts.

12. When verification has been completed view the data, then print or save

(if required). If needed the verification standard can be remeasured by

selecting:

13. Select

Repeat Measure.

Select Standard to return to the Standard Selection Menu. Repeat

steps 7 through 12 above for the other verification standard (refer to

Table 4-6 on page 4-9).

14. Select

15. Select

Prior Menu until the Main Menu appears.

Quit Program to exit the program, then close the program window to

finish.

8510XF Service Quick Reference Guide

4-11

Performance Verification

CW Frequency Accuracy Test

CW Frequency Accuracy Test

NOTE The CW frequency accuracy test should be performed prior to doing the

conversion loss calibration adjustment or detector gain calibration.

Source frequency accuracy is tested across the entire sweep range for 8360

sources. The CW frequency accuracy is measured with a frequency counter.

Materials Required The following materials are required to run the tests:

• 5343 Option 001, 10 MHz to 26.5 GHz frequency counter

• 10 dB pad

NOTE If the source and test set operate below 500 MHz, connect the test set output

to the 10 Hz to 500 MHz BNC connector on the frequency counter. The

input switch on the frequency counter must also be in the 10 Hz to 500 MHz

position.

Procedure 1. Connect the equipment as shown in Figure 4-1.

Figure 4-1 CW frequency accuracy equipment setup

2. To preset the instruments, press

{FACTORY PRESET}

4-12

8510XF Service Quick Reference Guide

. Disregard any error messages.

INSTRUMENT STATE [RECALL] {MORE}

Performance Verification

CW Frequency Accuracy Test

3. To set the frequency using the analyzer front panel, press STIMULUS

[CENTER] [MENU] {SINGLE POINT}

.

Enter the start frequency of the source.

4. Measure RF and LO frequencies with the counter, and record these

values on the test record at the end of this section.

5. From the analyzer front panel, enter the frequency per the tables at the

end of this section.

NOTE Be sure to connect RF and LO output to the 500 MHz to 26.5 GHz input on

the frequency counter. Also set the input switch to the 500 MHz to 26.5 GHz

position.

6. Measure the frequency with the counter,then record the value on the test

record at the end of this section.

In Case of Difficulty If the measured values do not meet the specifications listed on the test

record, refer to your source manual for adjustment and troubleshooting

instructions.

8510XF Service Quick Reference Guide

4-13

Performance Verification

CW Frequency Accuracy Test

Performance Test Record

Record the measured frequencies for RF source readings on Table 4-7, and

for LO source on Table 4-8.

Table 4-7 Performance test record for CW frequency accuracy test (RF source)

Instrument Model: _________________ Report Number: __________________________ Date: _______

Frequency Minimum Specification Recorded Results Maximum Specification Uncertainty

45 MHz 44.999955 MHz 45.000045 MHz 10 Hz

2 MHz 1.999998 GHz 2.000002 GHz 10 Hz

2

20 GHz

26 GHz 26.4999735 GHz 26.5000256 GHz 5 kHz

1. The measurement uncertainty is quoted for these performance tests using only the recommended models specified in Table 8-1 of the “Equipment

Required” chapter of the On-Site Service Manual. The quoted uncertainty represents limits of 3 times the equivalent standard deviation (3s) and is

intended to represent 90% confidence level.

2. For 83620A/B or 83621A/B only.

19.99998 GHz 20.00002 GHz 4 kHz

1

Table 4-8 Performance test record for CW frequency accuracy test (LO source)

Instrument Model: _________________ Report Number: __________________________ Date: _______

Frequency Minimum Specification Recorded Results Maximum Specification Uncertainty

1

45 MHz 44.999955 MHz 45.000045 MHz 10 Hz

2 MHz 1.999998 GHz 2.000002 GHz 10 Hz

2

20 GHz

1. The measurement uncertainty is quoted for these performance tests using only the recommended models specified in Table 8-1 of the “Equipment

Required” chapter of the On-Site Service Manual. The quoted uncertainty represents limits of 3 times the equivalent standard deviation (3s) and is

intended to represent 90% confidence level.

2. For 83620A/B or 83621A/B only.

19.99998 GHz 20.00002 GHz 4 kHz

4-14

8510XF Service Quick Reference Guide

Two-Band Calibration Procedure for

8510XF Performance Verification

The 8510XF requires separate verifications for frequencies below

and above 50 GHz (see "Frequency Ranges" in this same chapter).

A special two-band calibration procedure is required for the

performance verification of the 8510XF System (a single full-band

measurement calibration is equivalent).not

There are up to three different full 2-port calibrations and

corresponding frequency ranges required, which are stored

in suggested locations in the 8510 analyzer.

(E7352L or

Calibration Storage Locations

File Location Name:

Cal Set 1

Cal Set 2 45 MHz

Cal Set 3 50–110 GHz

1. This calibration is for Option 005 systems only.

2. The frequency for standard systems is 2–50 GHz.

3. The frequency range shown is for the E7352A system only.

The E7342A system's frequency range will be: 50–85 GHz

F

or more information refer to the section on "Frequency Ranges"

in this same chapter. The parameters for these calibrations are set up

automatically on the analyzer by the performance verification software.

Frequency Range of Data Stored:

1–50 GHz (2–50 GHz)

12

1

3

Calibration Techniques and Standards

Calibration Kit Label:

Frequency

Range

DC–50 GHz

3

Calibration

Technique

1

SOLT

"Open" Standard

(Reflection)

Open

Disk File Name:

"Short" Standard

CK_MMKA1A

(Reflection)

Short 3

50–110 GHz Offset Shorts Short 3 Short 1

1. SOLT = Short, Open, Load and Thru standards

2. The broadband load is a combination of a lossy delay line plus a 50 GHz load.

3. Also used for 45 MHz frequency point.

Calibration Techniques:

A variety of calibration techniques can be used with the 8510XF, including the following:

(Short-Open-Load-Thru) Used for performance verification 45 MHz to 50 GHz.

•

SOLT

•

Offset Shorts

TRL

(Thru-Reflect-Line)**

•

TRM

(Thru-Reflect-Match)**

•

** Note: Not used for performance verification

The calibration technique used depends in part on the type of calibration kit used. The 1.0 mm

calibration kit (85059A) was designed specifically for the 8510XF, and uses a combination of

two calibration techniques: SOLT calibration for frequencies up to 50 GHz, and offset shorts

calibration for frequencies above 50 GHz. This combination of techniques provides the best

possible calibration results on the 8510XF.

(Shorts with different offset lengths) Used for performance verification 50 GHz

to 110 GHz.

E7342L)

1.00mmA.1A

s1

8510C

MM Controller

Left

Test

Head

Full 2-port calibration system configuration

for performance verification in 1.0 mm coax.

"Load" Standard

(Reflection)

50 GHz Load Thru

Short 4

Short 2

83651B

83621B

Cable F-F (8.8 cm) 11500-60001

From 85059A calibration verification kit

"Thru" Standard

(not used for

1-port cal)

Thru Load BB

E7341A

(Std. or

Opt. 005)

Right

Test

Head

(E7352R or

E7342R)

Cable

F-F (8.8 cm)

"Isolation"

Standard

50 GHz Load

Clarifying Connector Sex:

The calibration standard labels that appear in the 8510XF softkey

calibration menus specify connector sex as "(M)" or "(F)". The sex designator

refers to the sex of the test port connector to which the calibration standard

is connected ( the sex of the calibration standard connector).not

Offset Shorts:

Male Test Port

The "OPEN" category is therefore renamed "OPEN/SHORT," and the "LOAD"

category is renamed "LOAD/SHORT" on the calibration menu softkey labels.

Female Calibration Standard

Offset shorts are used in the place of opens and loads

Full 2-Port

Reflection

Cal Menu

(S11):

SHORTS

(S22):

SHORTS

DONE

THRU

THRU

THRU

THRU

TRANS.

DONE

OMIT

LOAD

LOAD

DONE

CLASS11A

CLASS11B

CLASS11C

CLASS22A

CLASS22B

CLASS22C

REFD

FWDT

FWDM

REVT

REVM

TRAD

OMII

FWDI

REVI

ISOD

(F)

(M)

Lossy Delay Line

(M) (F)

(F) (M)

50 GHz Load

"FWD/REV ISOL'N LOAD"

OPEN/SHORT

LOAD/SHORT

OPEN/SHORT

LOAD/SHORT

Full 2-Port

Cal Menu

REFLECT'N

ISOLATION

2-PORT CAL

2

TRANS-

MISSION

SAVE

Cal

Cal Set

Select Menu

REFL

TRAN

ISOL

SAV2

REFLECT'N

Full 2-Port

Transmission

Cal Menu

FWD. TRANS

FWD. MATCH

REV.TRANS.

REV. MATCH

Full 2-Port

Isolation

Cal Menu

ISOLATION

FWD ISOL'N

REV ISOL'N

ISOLATION

For: < 50 GHz use a 50 GHz load only.

For: > 50 GHz a lossy delay line is required in addition

to a 50 GHz load.*

*

Note: If you use a 50 GHz load only, a bad calibration will

result due to reflection from the load above 50 GHz.

at frequencies above 50 GHz.

Open/Short

(F) OPEN

(F) SHORT3

(M) OPEN

(M) SHORT3

DONE

OPEN/SHORT

Shorts Menu

(F) SHORT3

(F) SHORT1

(M) SHORT3

(M) SHORT1

DONE

SHORTS

Load/Short

Menu

50 GHz LOAD

(F) SHORT4

(F) SHORT2

(M) SHORT4

(M) SHORT2

DONE

LOAD/SHORT

(M)

(M)

(F)

(F)

DONE

(M)

(M)

(F)

(F)

DONE

(F)

(M)

(M)

(M)

(F)

(F)

DONE

rr51c

8510XF Full 2-Port Calibration Menus

5 System Level Servicing & Troubleshooting

This chapter describes the basic servicing and troubleshooting techniques for

the 8510XF system.

8510XF Service Quick Reference Guide

5-1

System Level Servicing & Troubleshooting

Theory of Operation

Theory of Operation

The 8510XF applies RF test signals to the DUT, and compares these incident

signals to whatever is reflected from (or transmitted through) the DUT. The

incident, reflected, and transmitted signals are separated out by means of

directional couplers, and mixed down to create a set of four IF inputs to the

analyzer, as illustrated below.

Figure 5-1 Basic operation of the system

5-2

8510XF Service Quick Reference Guide

System Level Servicing & Troubleshooting

Theory of Operation

At this simplified level of description, system operation does not differ from

that of other 8510-based systems. What makes the 8510XF unique is the

means by which it covers its extremely wide frequency range.

Figure 5-2 shows how the 8510XF test set is divided into frequency bands.

For the sake of simplicity, this figure only shows half of the test set. An

actual test set, with two base units and two test heads, would include twice

as many mixers. Note that all bands make use of the same output/input

paths, the same connection to the DUT, and the same directional couplers.

Figure 5-2 Modules of the 7352A test set

8510XF Service Quick Reference Guide

5-3

System Level Servicing & Troubleshooting

Theory of Operation

Millimeter Wave Controller

The controller has more functions than are illustrated in Figure 5-2 on

page 5-3. It controls the switching of RF paths in the microwave subheads

and test heads at different points in the system’s frequency range. It also

collects together the IFs generated by all mixers in the microwave subhead,

the millimeter test heads, and the controller itself, and uses a multiplexer to

furnish the appropriate IFs to the network analyzer at each moment in time.

Frequency Bands Each frequency band uses its own set of mixers. The bands are as follows.

Band Included In

.045 to 2 GHz 8510XF systems with Option 005

2 to 50 GHz All 8510XF systems

50 to 85 GHz

50 to 75 GHz

75 to 110 GHZ E7350A systems/E7352A subsystems

Frequency Multiplication The frequency range of the system greatly exceeds that of the system’s RF

source (the 83651B has a maximum frequency of 50 GHz). Frequencies

above 50 GHz are generated through harmonic multiplication of the RF

source. The signals from the LO source are also multiplied, in the sense that

the mixers in certain ranges are designed to use a harmonic of the LO input,

rather than the fundamental input. The details for each band are discussed

below.

E7340A systems/E7342A subsystems

E7350A systems/E7352A subsystems

75 to 110 GHz Band In the 75 to 110 GHz range, the signal from the RF source is applied to a

frequency tripler in the test head. The mixers for this range are located in the

test head, and designed to use the 18th harmonic of the LO input frequency.

This applies to E7350A systems and E7352A subsystems only.

50 to 85 GHz or

50 to 75 GHz Band

In the 50 to 85 GHz range, the signal from the RF source is applied to a

frequency doubler in the test head. The mixers for this range are located in

the test head, and designed to use the 14th harmonic of the LO input

frequency. For E7350A systems and E7352A subsystems, this band covers

the 50 to 75 GHz range.

2 to 50 GHz Band In the 2 to 50 GHz range, the signal from the RF is not multiplied; it is

applied directly to the mixers. The mixers for this range are located in the

microwave subhead. In a portion of this range (from 18 to 50 GHz) the

mixers use the third harmonic of the LO input frequency. In the remainder of

this range (from 2 to 18 GHz), the mixers use the fundamental of the LO

input frequency.

5-4

8510XF Service Quick Reference Guide

System Level Servicing & Troubleshooting

Theory of Operation

0.045 to 2 GHz Band In the .045 to 2 GHz range, the signal from the RF source is not multiplied; it

is applied directly to the mixers. The mixers for this range are located in the

millimeter wave controller, and are designed to use the fundamental of the

LO input frequency. This applies to 8510XF systems equipped with

Option 005 only.

8510XF Service Quick Reference Guide

5-5

System Level Servicing & Troubleshooting

8510XF Firmware Specifications

8510XF Firmware Specifications

Operating Parameters Frequency Limits: 45 MHz to 85 GHz (E7340A/E7342A with Option 005)

or 45 MHz to 110 GHz (E7350A/E7352A with Option 005)

Band Crossings:

Table 5-1 Band crossings (45 MHz- 85 GHz)

RF Frequency RF Harm LO Harm Band

45 MHz - 2 GHz 1 1 0

2 - 18 GHz 1 1 1

18 - 50 GHz 1 3 1

50 - 64.2 GHz 2 12 2

64.2 - 85 GHz 2 14 2

Table 5-2 Band crossings (45 MHz- 110 GHz)

RF Frequency RF Harm LO Harm Band

45 MHz - 2 GHz 1 1 0

2 - 18 GHz 1 1 1

18 - 50 GHz 1 3 1

50 - 64.2 GHz 2 12 2

64.2 - 75 GHz 2 14 2

75 - 85.5 GHz 3 14 3

85.5 - 97.7 GHz 3 16 3

97.7 - 110 GHz 3 18 3

Step Mode Internally implemented as frequency list mode.

• 51 points

• 101 points

• 201 points

• 401 points

• 801 points

List Mode Up to 801 points.

5-6

8510XF Service Quick Reference Guide

System Level Servicing & Troubleshooting

8510XF Firmware Specifications

Sweep Time Similar to 8510C.

Hardware States The hardware states specific to the 8510XF are as shown in Table 5-3.

Table 5-3 Hardware States Specific to 8510XF

System Parameter

System Phaselock

Multi Source

Leveling Source #1 (RF)

Leveling Source #2

1. These menus are integrated into the firmware and are not available as softkeys.

2. Source leveling is set to system for normal (default) 8510XF operation. The source will indicate

external leveling for the RF source and internal leveling for the LO source.

1

1

2

2

Frequency Range

(45 MHz to 50 GHz)

None None

On On

System (External) System (External)

System (Internal) System (Internal)

Frequency Range

(50 to 85 GHz, or 50 to 110 GHz)

Receiver: Constant frequency = 0.020000000 GHz

Instrument States Table 5-4 shows the instrument states specific to the 8510XF system.

Table 5-4 Instrument states specific to the 8510XF system

System Parameter

RF Power source #1

LO Power source #2

Z

o

Delay Coaxial Coaxial

1,2

1,2

Frequency Range

(45 MHz to 50 GHz)

−10 dBm −10 dBm

+10 dBm +10 dBm

50 ohm 50 ohm

Frequency Range

(50 to 85 GHz or

50 to 110 GHz)

3

1. The 8510XF normally operates in step mode (ramp mode is not available).

2. Source power is set/read with internal source leveling selected. Normal (default) operation of the 8510XF is with

system source leveling selected.

3. Zo is normally set to one Ohm for calibrations/measurements using waveguide test port connectors.

8510XF Service Quick Reference Guide

5-7

System Level Servicing & Troubleshooting

Power Level Check

Power Level Check

A quick operational check may be performed by measuring the power levels

of the 8510XF user parameters a

levels listed in Table 5-5 on page 5-9 gives the user a high level of

confidence that the system is operating properly. For complete system

verification, see Performance Verification, page 4-1.

, b1, a2, and b2. Observing the appropriate

1

1. If needed, save the current instrument state by pressing

[SAVE]

and selecting 1-8. Press INSTRUMENT STATE [RECALL], {MORE}, {FACTORY

PRESET}

to restore the default factory instrument state. Change the

INSTRUMENTSTATE

instrument settings as indicated under “Power level check (low RF

power)” on page 5-10.

2. Connect a short to test port 1. Press

PARAMETER [MENU], then {USER 1 a1}.

The forward reference signal path power level is displayed. The power

level should be approximately as indicated in Table 5-5 and Figure 5-3

on page 5-11.

3. Select

{USER 4 b1}. The forward reflection signal path power level is

displayed. The power level should be approximately as indicated in

Table 5-5 and Figure 5-6 on page 5-12.

4. Connect a short to test port 1. In order to measure the reverse reference

signal path, the parameter must be redefined. Press:

{USER 3 a2}

{REDEFINE PARAMETERS}

{DRIVE} {DRIVE:PORT2}

{REDEFINE DONE}

The reverse reference signal path signal level is displayed. The power

level should be approximately as indicated in Table 5-5 and Figure 5-5

on page 5-12.

5. In order to measure the reverse reflection signal path, the parameter

must be redefined. Press:

{USER 2 b2}

{REDEFINE PARAMETERS}

{DRIVE} {DRIVE:PORT2}

{REDEFINE DONE}

The reverse reflection signal path power level is displayed. The power

level should be approximately as indicated in Table 5-5 and Figure 5-4

on page 5-11.

5-8

8510XF Service Quick Reference Guide

System Level Servicing & Troubleshooting

Power Level Check

6. Connect Port 1 and Port 2 together. Select {USER 2 b2} {REDEFINE

PARAMETERS} {DRIVE} {DRIVE:PORT1}

. The forward transmission signal path

power level is displayed. The power level should be approximately 2 dB

less than what was measured with a short on each test port.

NOTE The following measurements show the approximate RF signal levels

incident at the first frequency conversion stage and are given in dBm even

though the marker value is read out in dB.

NOTE Figures 5-3 through 5-6 are typical graphs from which the data in Table 5-5

was derived. These graphs are typical 8510XF user channel traces with

offset shorts connected to Port 1 and Port 2. The RF source power level must

be set so that it does not activate the IF OVERLOAD running error message.

Table 5-5 Typical power levels for power level check (low RF power) of the mm-wave

sub-system

Raw Channel Power

Frequency Range (GHz)

75-110 (E7350A/E7352A only)

a

1 (USER 1)

b

1 (USER 4)

a

2 (USER 3)

b

2 (USER 2)

Frequency Range (GHz)

0.045 to 50

−5 to −35 −30 to −50 −35 to−50

−5 to −35 −30 to −50 −35 to−50

−5 to −35 −30 to −50 −35 to−50

−5 to −35 −30 to −50 −35 to−50

Frequency Range (GHz)

50 to 85 (E7340A/E7342A)

50 to 75 (E7350A/E7352A)

NOTE 0.1 dB compression, −8 dBm; typical, −10 dBm maximum; damage,

+15 dBm.

If any of the power levels shown in Table 5-5 and Figures 5-3 through 5-6

are not observed (within approximately

±5 dB), consult the “Service and

Troubleshooting” paragraphs in this Quick Reference Guide. An Agilent

Customer Engineer may be contacted for service assistance (see “Contacting

Agilent” on page v).

Additional graphs—for help with troubleshooting—are provided in the

following sections:

• “Power level check (high RF power)” on page 5-13

• “Operator’s check (normal operating condition)” on page 5-16

8510XF Service Quick Reference Guide

5-9

System Level Servicing & Troubleshooting

Power Level Check

Test Plots Power level check (low RF power)

The RF source power level must be set so that the IF OVERLOAD running

error message is not activated when obtaining these graphs. The graphs

Figures 5-3 through 5-6 were obtained with the following settings:

1. Factory preset

2. Shorts connected to Ports 1 and 2

3. RF Source leveling: internal (no conversion loss calibration)

4. Disconnect the BNC cable from the millimeter-wave controller ALC

output to the RF Source ALC input.

5. LO Source leveling: system (default)

6. RF Source power: −10 dBm (default)

NOTE In order for no IF OVERLOAD running error message to occur, it may be

necessary to set the RF Source power level lower.

7. LO Source power: +10 dBm (default)

8. Response reference value: 0 dB (default)

9. Response reference position: 8 Div

5-10

8510XF Service Quick Reference Guide

System Level Servicing & Troubleshooting

Power Level Check

Figure 5-3 User 1 (a1)

Figure 5-4 User 2 (b2)

8510XF Service Quick Reference Guide

5-11

System Level Servicing & Troubleshooting

Power Level Check

Figure 5-5 User 3 (a2)

Figure 5-6 User 4 (b1)

5-12

8510XF Service Quick Reference Guide

System Level Servicing & Troubleshooting

Power Level Check

Power level check (high RF power)

The IF OVERLOAD running error message is normal when obtaining these

graphs. A power level of +10 dBm will over drive the 8510XF so you can

see the intermodulation leveling differences. The graphs Figures 5-7 through

5-10 were obtained with the following settings:

1. Factory preset

2. Shorts connected to Ports 1 and 2

3. RF Source leveling: internal (no conversion loss calibration)

4. Disconnect the BNC cable from the millimeter-wave controller ALC

output to the RF Source ALC input.

5. LO Source leveling: system (default)

6. RF Source power: +10 dBm

NOTE Disregard IF OVERLOAD running error message.

7. LO Source power: +10 dBm (default)

8. Response reference value: 0 dB (default)

9. Response reference position: 8 Div

8510XF Service Quick Reference Guide

5-13

System Level Servicing & Troubleshooting

Power Level Check

Figure 5-7 User 1 (a1)

Figure 5-8 User 2 (b2)

5-14

8510XF Service Quick Reference Guide

System Level Servicing & Troubleshooting

Power Level Check

Figure 5-9 User 3 (a2)

Figure 5-10 User 4 (b1)

8510XF Service Quick Reference Guide

5-15

System Level Servicing & Troubleshooting

Power Level Check

Operator’s check (normal operating condition)

The graphs Figures 5-11 through 5-14 were obtained with the following

settings (normal default settings) after performing a factory preset:

1. Shorts connected to Ports 1 and 2

2. RF Source leveling: system (default—with conversion loss calibration)

3. BNC cable connected from millimeter-wave controller ALC output to

the RF source ALC input (default).

4. LO Source leveling: system (default)

5. Port 1 and Port 2 power level: −15 dBm (default)

6. Response reference value: −20 dB

7. Response reference position: 5 Div (default)

NOTE For additional information on normal operating conditions, refer to the

“System Operation Test” section in the “Installation” chapter of the 8510XF

Operating and Service Manual.

5-16

8510XF Service Quick Reference Guide

System Level Servicing & Troubleshooting

Power Level Check

Figure 5-11 User 1 (a1)

Figure 5-12 User 2 (b2)

8510XF Service Quick Reference Guide