Page 1

Agilent Technologies

8510C Network Analyzer System

Operating and Programming Manual

For use with Firmware Revision C.07.XX with CRT display

For use with Firmware Revision C.08.XX or greater with LCD

Serial Numbers

This manual applies directly to instruments with

this serial prefix number or above: 3031A.

Part Number: 08510-90281

Printed in USA

May 2001

Edition 3.0

Supersedes January 31, 1994

© Copyright Agilent Technologies 1989, 1994, 2001

Page 2

Certification

Agilent Technologies certies that this product met its publishedspecications at the time

of shipment from the factory. Agilent further certies that its calibration measurements

aretraceable to the United States National Institute of Standards and Technology, to the

extent allowed by the Institute's calibration facility, and to the calibration facilities of other

International Standards Organization members.

Warranty

This Agilent instrument product is warranted against defects in material and workmanship for

a period of one year from date of delivery. During the warranty perio d, Agilent will, at its

option, either repair or replace products which prove to be defective.

For warranty service or repair, this pro duct must b e returned to a service facility designated

by AgilentTechnologies. Buyer shall prepay shipping charges to Agilent and Agilent shall

pay shipping charges to return the product to Buyer. However, Buyer shall pay all shipping

charges, duties, and taxes for pro ducts returned to Agilen

t from another country.

Agilentwarrants that its software and rmware designated by Agilent for use with an

instrument will execute its programming instructions when properly installed on that

instrument. Agilent do es not warrant that the operation of the instrument, or software, or

rmware will be uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate

maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modication or

misuse, operation outside of the environmental specications for the product, or improper site

preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE REMEDIES. Agilent SHALL

NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

c

Copyright AgilentTechnologies, Inc., 1989, 1994, 2001 All rights reserved. 1400

FountaingroveParkway, Santa Rosa, CA 95403 U.S.A.

Page 3

Safety and Regulatory Information

Review this product and related documentation to familiarize yourself with safety markings

and instructions before you operate this instrument.

This product has been designed and tested in accordance with the standards listed on the

Manufacturer's Declaration of Conformity, and has been supplied in a safe condition. The

documentation contains information and warnings that must be followed by the user to ensure

safe operation and to maintain the pro duct in a safe condition.

Caution

Warning

The CAUTION notice denotes a hazard. It calls attention to a pro cedure

which, if not correctly p erformed or adhered to, could result in damage to or

destruction of the instrument. Do not pro ceed beyond a

caution

sign until the

indicated conditions are fully understood and met.

The WARNING notice denotes a hazard. It calls attention to a procedure which,

if not correctly performed or adhered to, could result in injury or loss of life. Do

not proceed beyondaWARNING sign until the indicated conditions are fully

understood and met.

When you see this symbol on your instrument, you should refer to the

instrument's instruction manual for important information.

The CSA mark is the Canadian Standards Association safet

The CE mark is a registered trademark of the European Communit

y mark.

y.Ifitis

accompanied byayear, it indicates the year the design was proven.

This symbol indicates that the instrument requires alternating current (ac) input.

This symbol is used to mark the STANDBY/OFF position of the power line

switch.

This symbol is used to mark the ON position of the p o

wer line switch.

This text indicates that the instrument is an industrial Scientic and Medical

Group 1 Class A product (CISPER 11, Clause 4).

The C-tick mark is a registered trademark of the Sp ectrum Management Agency

of Australia. This signies compliance with the Australian EMC Framework

regulations under the terms of Radio communications Act of 1992.

iii

Page 4

General Safety Considerations

Warning

Caution

This is a Safety Class 1 Product (provided with a protective earthing ground

incorporated in the power cord). The mains plug shall only be inserted in a

socket outlet provided with a protective earth contact. Any interruption of the

protective conductor inside or outside of the product is likely to make the

product dangerous. Intentional interruption is prohibited.

Before applying power, verify that the product is configured to match the

available main power source as described in the input power configuration

instructions. If this product is to be powered by autotransformer, make sure

the common terminal is connected to the neutral (grounded) side of the ac

power supply.

If this product is not used as specified, the protection provided by the

equipment could be impaired. This product must be used in a normal

condition (in which all means for protection are intact) only.

Always use the three-prong ACpower cord supplied with this product.

Failure to ensure adequate earth grounding by not using this cord may cause

product damage.

Ventilation Requirements: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum op erating

temperature of the product by4

for every 100 watts dissipated in the

cabinet. If the total power dissipated in the cabinet is greater than 800

watts forced convection must be used.

This product is designed for use in Installation Category II and P

Degree 2 per IEC 1010 and 664 respectiv

ely.

ollution

iv

Page 5

Acoustic Noise Emissions Declaration

This is to declare that this instrument is in conformance with the German Regulation on

Noise Declaration for Machines (Laermangab e nach der Maschinenlaermrerordnung03.

GSGV Deutschland).

Acoustic Noise Emission/Geraeuschemission

LpA<70 dB LpA<70 dB

Operator p osition am Arbeitsplatz

normal operation normaler Betrieb

Per ISO 7779 nach DIN 45635 t. 19

By internet, phone, or fax, get assistance with all your test & measurement needs.

Table 0-1. Contacting Agilent

Online Assistance:

United States

(tel) 1 800 452 4844

www.agilent.com/find/assist

Japan

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

New Zealand

(tel) 0 800 738 378

(fax) 64 4 495 8950

Canada

(tel) 1 877 894 4414

(fax) (905) 206 4120

Europe

(tel) (31 20) 547 2323

(fax) (31 20) 547 2390

Latin America

(tel) (305) 269 7500

(fax) (305) 269 7599

Australia

(tel) 1 800 629 485

(fax) (61 3) 9210 5947

Asia Pacic

(tel) (852) 3197 7777

(fax) (852) 2506 9284

v

Page 6

Introduction

This

8510C Operating and Programming Manual

comprehensive tutorial material to help you learn typical applications and op erating details of

the Agilent 8510 network analyzer system.

is designed to provide you with

A companion volume, the

8510 front-panel hardkeys, menu softkeys, and programming mnemonics. Eachentry also

includes information about how to use the function in programmed op eration.

Note

Note

The original 8510C incorporated a cathode ray tube (CRT) based display. The

current design incorp orates a liquid crystal display (LCD). In this manual

references to either CRT or LCD apply to both display designs unless noted

otherwise.

Systems with a CRT based display in the 85101C use rmware revision

C.07.XX or greater.

Systems with an LCD require rmware revision C.08.00 or greater.

In this manual, the terms GPIB (General Purpose Interface Bus) and

HP-IB (Hewlett-Packard Interface Bus) refer to the same proto col.

Instrument softkeys for HP-IB related functions use \HP-IB", for example,

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

HP-IB ADDRESSES

8510 Keyword Dictionary

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

or

HP-IB CONFIGURE

provides a complete alphab etical list of

.

vi

Page 7

vii

Page 8

Typeface Conventions

The following conventions are used in the

Keyword Dictionary

Italics

Italic type is used for emphasis, and for titles of manuals and other publications. It is also

used to designate a variable entry value.

Computer

Computer type is used for information displayed on the instrument and to designate a

programming command or series of commands.

4

Hardkeys

Instrumentkeys are represented in \key cap." You are instructed to

W

WWWWWWWWWWWWWWWWWWWWWWWWWWW

Softkeys

Softkeys are located along side of the displa

display. These keys are represented in \softkey." You are instructed to

5

.

8510C Operating and Programming Manual

press

a hardkey.

y, and their functions depend on the current

select

a softkey.

and the

viii

Page 9

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name: Agilent Technologies, Inc.

Manufacturer’s Address: 1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799

USA

Declares that the product:

Product Name: Network Analyzer

Model Number: 8510C

Product Options: This declaration covers all options of the above product.

Conforms to the following product specifications:

EMC: IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011-1991 (Group 1, Class A)

IEC 61000-4-2:1995+A1998 / EN 61000-4-2:1995 (4 kV CD, 8 kV AD)

IEC 61000-4-3:1995 / EN 61000-4-3:1995 (3 V/m, 80 - 1000 MHz)

IEC 61000-4-4:1995 / EN 61000-4-4:1995 (0.5 kV sig. lines, 1 kV power lines)

IEC 61000-4-5:1995 / EN 61000-4-5:1996 (0.5 kV L-L, 1 kV L-G)

IEC 61000-4-6:1996 / EN 61000-4-6:1998 (3 V, 0.15 – 80 MHz)

IEC 61000-4-11:1994 / EN 61000-4-11:1998 (1 cycle, 100%)

Safety: IEC 61010-1:1990 + A1:1992 + A2:1995 / EN 61010-1:1993 +A2:1995

CAN/CSA-C22.2 No. 1010.1-92

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the

EMC Directive 89/336/EEC and carries the CE-marking accordingly.

Santa Rosa, CA, USA 28 February, 2001

Greg Pfeiffer/Quality Engineering Manager

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

Page 10

Contents

1. Introduction to the 8510C Network Analyzer System

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

8510 Network Analyzer System Description . . . . . . . . . . . . . . 1-1

FrontPanel Controls . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Display Modes and Annotation Areas . . . . . . . . . . . . . . . . . . 1-3

Channel/Parameter Identication Area . . . . . . . . . . . . . . . . 1-4

Stimulus Values Area . . . . . . . . . . . . . . . . . . . . . . . . 1-4

ActiveEntry Area . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Knowing When a Function Is Selected . . . . . . . . . . . . . . . . 1-5

Recognizing Mutually-Exclusive Functions . . . . . . . . . . . . . . 1-5

Title Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

System Messages Area . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Enhancement Annotation Area . . . . . . . . . . . . . . . . . . . . 1-6

Softkey Menu and Marker List Display Area . . . . . . . . . . . . . . 1-6

Using ENTRY Blo ck Keys . . . . . . . . . . . . . . . . . . . . . . . 1-7

Uparrow(

4

5

) and Downarrow(

8

4

5

) Keys . . . . . . . . . . . . . . . 1-7

9

Using Numeric Keys . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Using Units Terminator Keys . . . . . . . . . . . . . . . . . . . . . 1-8

Using the Prior Menu Key . . . . . . . . . . . . . . . . . . . . . 1-8

Using the Backspace Key . . . . . . . . . . . . . . . . . . . . . 1-8

Using the

4

=MARKER

5

Key . . . . . . . . . . . . . . . . . . . . . 1-8

Using ACTIVE CHANNEL Block Keys . . . . . . . . . . . . . . . . . 1-9

Coupling Channels . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Coupling Conditions . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Using MENUS Block Keys . . . . . . . . . . . . . . . . . . . . . . . 1-10

Using STIMULUS, PARAMETER, FORMAT, and RESPONSE Blocks Keys . 1-11

Using INSTRUMENT STATE Keys . . . . . . . . . . . . . . . . . . . 1-12

Using AUXILIARY MODE Keys . . . . . . . . . . . . . . . . . . . . 1-12

Using MEASUREMENT Block Key . . . . . . . . . . . . . . . . . . . 1-12

Using the Menus, Examples . . . . . . . . . . . . . . . . . . . . . . 1-13

To Create, Edit, or Delete a Title . . . . . . . . . . . . . . . . . . . 1-13

To Adjust the Date/Time Clo ck . . . . . . . . . . . . . . . . . . . 1-13

The Analyzer Remembers Previous Settings (Limited Instrument State) . 1-14

INSTRUMENT STATE Blo ck . . . . . . . . . . . . . . . . . . . . 1-15

4

USER PRESET

5

Key . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Saving and Recalling Complete Instrument States . . . . . . . . . . . 1-15

4

5

LOCAL

Key . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1

Page 11

2. Introductory Measurement Sequence

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Verifying the System Setup . . . . . . . . . . . . . . . . . . . . . . 2-1

If some instruments do not resp ond at power-up . . . . . . . . . . . 2-2

Turning on system power, the sequence . . . . . . . . . . . . . . . 2-2

Waiting for self-test and initialization . . . . . . . . . . . . . . . . 2-3

Measurement Sequence Example 1: Frequency Domain Measurement . . . . 2-3

1. Setting Up the Measurement. . . . . . . . . . . . . . . . . . . . 2-4

Making Connections . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Factory Preset State . . . . . . . . . . . . . . . . . . . . . . . 2-5

Set Stimulus, Parameter, Format, Response . . . . . . . . . . . . . 2-5

2. Performing the Measurement Calibration . . . . . . . . . . . . . . 2-7

Making a reection frequency response calibration . . . . . . . . . . 2-7

To Identify, Create, and Store S11Measurement Calibration Data . . . 2-7

Reading the displayed response . . . . . . . . . . . . . . . . . . 2-8

Making a transmission frequency response calibration . . . . . . . . . 2-8

To Identify, Create, and Store S21Measurement Calibration Data . . . 2-8

3. Making a Measurement . . . . . . . . . . . . . . . . . . . . . . 2-9

To measure return loss (S11) in LOG MAG format (frequency domain

measurements) . . . . . . . . . . . . . . . . . . . . . . . . 2-9

To measure the insertion loss (S

4. Saving Data and Getting an Output of the Results

) in LOG MAG format . . . . . . . . 2-10

21

. . . . . . . . . . 2-11

Plotting Advantages . . . . . . . . . . . . . . . . . . . . . . . . 2-11

To set up the plotter . . . . . . . . . . . . . . . . . . . . . . . 2-11

Plotting the Current Display . . . . . . . . . . . . . . . . . . . . 2-12

To plot selected areas of the results display. . . . . . . . . . . . . . 2-12

Measurement Sequence Example 2: Time Domain . . . . . . . . . . . . . 2-13

3. Principles of Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Basic Principles of Network Measurements . . . . . . . . . . . . . . . . 3-1

System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . 3-3

Description of the 8510 Network Analyzer . . . . . . . . . . . . . . . 3-3

How the 8510 Makes Measurements . . . . . . . . . . . . . . . . . 3-4

Test and Measurement Input Channels . . . . . . . . . . . . . . . 3-4

Ratio Measurements and Sampling Details . . . . . . . . . . . . . . 3-4

Digital Signal Processing . . . . . . . . . . . . . . . . . . . . . . . 3-5

CPU and Memory Description . . . . . . . . . . . . . . . . . . . 3-5

Data Processing Steps . . . . . . . . . . . . . . . . . . . . . . . 3-5

Button Push Detection . . . . . . . . . . . . . . . . . . . . . . . 3-6

Test Signal Sources . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Sources in ramp-sweep mode . . . . . . . . . . . . . . . . . . . . 3-7

Sources in step-sweep mo de . . . . . . . . . . . . . . . . . . . . 3-7

Test Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Coaxial Test Set Information . . . . . . . . . . . . . . . . . . . . 3-7

Reection/Transmission Test Sets . . . . . . . . . . . . . . . . . . 3-8

S-Parameter Test Sets . . . . . . . . . . . . . . . . . . . . . . . 3-9

Customized Test Sets . . . . . . . . . . . . . . . . . . . . . . . 3-10

Measurement Accessories . . . . . . . . . . . . . . . . . . . . . . 3-11

Source Output-to-Test-Set Input Signal Cable . . . . . . . . . . . . 3-11

Test Port Return Cables . . . . . . . . . . . . . . . . . . . . . . 3-11

2

Page 12

Extension Lines . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Adapters (To Protect Test Ports from Wear) . . . . . . . . . . . . . 3-13

Proper Connector Care and Use . . . . . . . . . . . . . . . . . . 3-13

Calibration Kits . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Verication Kits . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Automatic Recall of Instrument Settings . . . . . . . . . . . . . . . . . 3-15

The Added Benet of the SAVE/RECALL Feature . . . . . . . . . . . 3-15

Factory Preset State . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Hardware State . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

4. Measurement Controls

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Display Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Dual Channel Display Modes . . . . . . . . . . . . . . . . . . . . 4-3

Single Channel, Four Parameter Display Modes . . . . . . . . . . . . 4-5

Adjust Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Intensity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Background Intensity (CRT only) . . . . . . . . . . . . . . . . . . . 4-6

Modify colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Default Colors . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

External Video (CRT only) . . . . . . . . . . . . . . . . . . . . . 4-9

External Video (LCD only) . . . . . . . . . . . . . . . . . . . . . 4-10

Limits: Limit Lines and Limit Points Measurements . . . . . . . . . . . . 4-11

Types of Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Limit Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Limit Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Creating a Limit Test . . . . . . . . . . . . . . . . . . . . . . . . 4-12

To Set Up the Measurement . . . . . . . . . . . . . . . . . . . . 4-12

To Set the Limit Test Values . . . . . . . . . . . . . . . . . . . . 4-13

To Dene the Maximum Limit . . . . . . . . . . . . . . . . . . . 4-13

To Dene Minimum Limit Lines . . . . . . . . . . . . . . . . . . 4-15

Editing Limits in the Limits Table . . . . . . . . . . . . . . . . . . 4-16

Trace Memory Op erations . . . . . . . . . . . . . . . . . . . . . . . 4-17

Storing Trace Data in Memory . . . . . . . . . . . . . . . . . . . . 4-17

To Display a Stored Trace . . . . . . . . . . . . . . . . . . . . . 4-17

Settings that can and cannot b e changed . . . . . . . . . . . . . . 4-17

To Display Data and Memory Simultaneously . . . . . . . . . . . . 4-17

Settings that can and cannot b e changed . . . . . . . . . . . . . . 4-17

To Select the Default Memory . . . . . . . . . . . . . . . . . . . 4-18

Which memory lo cations are volatile, which are not . . . . . . . . . 4-20

What is the operational life of non-volatile memory . . . . . . . . . 4-20

Trace Math Operations . . . . . . . . . . . . . . . . . . . . . . . 4-20

Data from Channel 1 and Data from Channel 2 . . . . . . . . . . . . . 4-22

Domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Automatic Memory of Domain Settings . . . . . . . . . . . . . . . . 4-24

Applicable Calibration Types for Each Domain Mo de . . . . . . . . . . 4-24

Auxiliary Voltage Domain Example . . . . . . . . . . . . . . . . . . 4-24

FORMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Cartesian Formats . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Smith Chart Formats . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Polar Display Formats . . . . . . . . . . . . . . . . . . . . . . . . 4-25

3

Page 13

Format Keys Available on the FrontPanel . . . . . . . . . . . . . . . 4-25

Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Using the Markers . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Select the Active Marker . . . . . . . . . . . . . . . . . . . . . . 4-29

Marker Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Continuous and Discrete . . . . . . . . . . . . . . . . . . . . . . 4-31

Marker List Displays . . . . . . . . . . . . . . . . . . . . . . . 4-31

Delta Mode Markers . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Marker Search Modes . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Search Right and Search Left . . . . . . . . . . . . . . . . . . . . 4-35

Delta Mode Operation . . . . . . . . . . . . . . . . . . . . . . . 4-36

Marker Familiarization Sequence . . . . . . . . . . . . . . . . . . . 4-36

Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Basic Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

S-Parameter Denitions and Conventions . . . . . . . . . . . . . . . 4-38

Parameter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

User Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Redene Parameter . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Redene Basic Parameters . . . . . . . . . . . . . . . . . . . . . 4-42

Redene User Parameters . . . . . . . . . . . . . . . . . . . . . 4-44

Measuring Power (dBm) . . . . . . . . . . . . . . . . . . . . . . . 4-44

Dynamic Range Considerations . . . . . . . . . . . . . . . . . . . . 4-46

Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Changing Display Scale and Reference . . . . . . . . . . . . . . . . . 4-48

Setting Scale and Reference Values Automatically . . . . . . . . . . . 4-48

Changing Display Scale Manually . . . . . . . . . . . . . . . . . . 4-48

Changing the Position of the Reference Line Manually . . . . . . . . . 4-48

Changing the Value of the Reference Line Manually . . . . . . . . . . 4-49

Automatic Recall of Previous Display Settings . . . . . . . . . . . . 4-49

Hierarchy of the Automatic Memory . . . . . . . . . . . . . . . . 4-49

The automatic memory does not include Stim

ulus settings . . . . . . 4-50

Other options for control of Stimulus settings . . . . . . . . . . . . 4-50

The Eect of Factory Preset on Display Settings . . . . . . . . . . . 4-50

Response Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Trace Averaging and Smoothing . . . . . . . . . . . . . . . . . . . 4-50

Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

Averaging Details . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

Notication when averaging is nished . . . . . . . . . . . . . . . 4-51

Averaging Factor Recommendations . . . . . . . . . . . . . . . . . 4-51

Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Electrical Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Using Electrical Delay. . . . . . . . . . . . . . . . . . . . . . . 4-53

DelayFeatures . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Coaxial Delay . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Waveguide Delay . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Table Delay . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Selecting Velo cityFactor . . . . . . . . . . . . . . . . . . . . . 4-54

Auto Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Phase Oset . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Magnitude Slope and Magnitude Oset . . . . . . . . . . . . . . . . 4-55

Stimulus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

4

Page 14

Set Frequency Sweep . . . . . . . . . . . . . . . . . . . . . . . . 4-56

Set Sweep Using Markers . . . . . . . . . . . . . . . . . . . . . . 4-57

Set Stimulus Power . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

Setting and Monitoring Signal Levels . . . . . . . . . . . . . . . . 4-57

Set Source RF Output Level . . . . . . . . . . . . . . . . . . . 4-58

Power Slop e On/O . . . . . . . . . . . . . . . . . . . . . . . 4-59

Attenuator Port: 1 and Attenuator Port: 2 . . . . . . . . . . . . . 4-59

Setting power for passive devices, or devices with gain . . . . . . . . 4-59

Source Power and Flatness Correction Calibration . . . . . . . . . . . 4-60

Selecting the Number of Points to Measure . . . . . . . . . . . . . . . 4-61

Source Sweep Mo des . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Speed of Step and Frequency vs. Ramp Modes . . . . . . . . . . . . 4-63

Measurement Hint . . . . . . . . . . . . . . . . . . . . . . . . 4-63

Entering Ramp, Step, and Single Point Stimulus Values . . . . . . . . 4-63

Sweep Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

Example: Eects of Sweep Time . . . . . . . . . . . . . . . . . . . 4-64

Sweep Execution, Hold/Single/Numb er of Groups/Continual . . . . . . . 4-65

Why Use Number of Groups? . . . . . . . . . . . . . . . . . . . . 4-66

Coupled/Uncoupled Channels . . . . . . . . . . . . . . . . . . . 4-66

How to tell if a function is coupled . . . . . . . . . . . . . . . . 4-67

Dual Channel . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

Uncoupled Stimulus Settings and Dual Channel Displays . . . . . . . 4-67

Trigger Mo des . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

Creating a Frequency List . . . . . . . . . . . . . . . . . . . . . . 4-69

Entering the First Segment. . . . . . . . . . . . . . . . . . . . . 4-69

Add Segments . . . . . . . . . . . . . . . . . . . . . . . . . . 4-70

Editing the Frequency List . . . . . . . . . . . . . . . . . . . . . 4-70

Changing a Segment . . . . . . . . . . . . . . . . . . . . . . 4-70

Deleting a Segment . . . . . . . . . . . . . . . . . . . . . . . 4-71

Adding a Segment . . . . . . . . . . . . . . . . . . . . . . . 4-71

To Duplicate Points . . . . . . . . . . . . . . . . . . . . . . . . 4-71

Frequency List Save and Recall . . . . . . . . . . . . . . . . . . . 4-71

Selecting All Segments or a Single Segment. . . . . . . . . . . . . 4-71

To Exit Frequency List . . . . . . . . . . . . . . . . . . . . . . 4-72

5. Using System Functions

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

System Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Controls that Aect the Network Analyzer . . . . . . . . . . . . . . . . 5-3

Phaselock Controls . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

LockType . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Step Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Normal Step . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Quick Step Mode . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Lock Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Warning Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

IF Calibration and Correction . . . . . . . . . . . . . . . . . . . . 5-5

IF Calibration Controls . . . . . . . . . . . . . . . . . . . . . . 5-5

DisplayFunctions . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Creating a Title . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Deleting a Title . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5

Page 15

Adjusting the Date/Time Clock . . . . . . . . . . . . . . . . . . 5-6

Using SecurityFeatures in the System

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

DISPLAY FUNCTIONS

Menu . . . 5-7

Controls that Aect Input/Output . . . . . . . . . . . . . . . . . . . 5-8

GPIB Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

GPIB Congure . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Edit Multiple Source . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Power Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Controlling Multiple Sources . . . . . . . . . . . . . . . . . . . . . . 5-11

Using the Multiple Source Menu . . . . . . . . . . . . . . . . . . . 5-12

HowtoEnter the Example Conguration . . . . . . . . . . . . . . 5-13

Nowsave the conguration . . . . . . . . . . . . . . . . . . . . 5-14

Millimeter Wave Mixers . . . . . . . . . . . . . . . . . . . . . . 5-15

Uses for the SOURCE 1 and RECEIVER Formulas . . . . . . . . . . . 5-15

SOURCE 1 Formula Use . . . . . . . . . . . . . . . . . . . . . . 5-15

Receiver Formula Use . . . . . . . . . . . . . . . . . . . . . . . 5-15

Why are these settings used? . . . . . . . . . . . . . . . . . . . 5-16

Service Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Test Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Disc Commands . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

System Bus Softkeys . . . . . . . . . . . . . . . . . . . . . . . . 5-19

IF Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Why Use Manual Control . . . . . . . . . . . . . . . . . . . . . 5-20

Why the problem o ccurs . . . . . . . . . . . . . . . . . . . . . 5-20

How to Use Manual IF Gain Controls Properly . . . . . . . . . . . . 5-22

Peek and Poke . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Purpose of Peek and Poke . . . . . . . . . . . . . . . . . . . . . 5-23

6. COPY Printing and Plotting

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . 6-2

Supported Interfaces . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Connecting a GPIB Printer or Plotter . . . . . . . . . . . . . . . . . 6-2

Connecting an RS-232 Printer or Plotter . . . . . . . . . . . . . . . . 6-2

Selecting the GPIB (System Bus) or RS-232 Ports . . . . . . . . . . . 6-2

RS-232 Print/Plot Buers . . . . . . . . . . . . . . . . . . . . . . . 6-3

Adding Custom Annotations to the Screen . . . . . . . . . . . . . . . . 6-3

Using a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Printing Features . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

What Is Printed? . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Installing a Printer . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Selecting the Output Port . . . . . . . . . . . . . . . . . . . . . . 6-4

Printer and the 8510C Conguration . . . . . . . . . . . . . . . . . . 6-5

Using a Laser Printer . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Conguring the Laser Printer . . . . . . . . . . . . . . . . . . . . . 6-6

Using the Standard Conguration . . . . . . . . . . . . . . . . . . . 6-6

Using Other Laser Printer Settings . . . . . . . . . . . . . . . . . 6-6

Conguring the Network Analyzer . . . . . . . . . . . . . . . . . 6-6

Selecting Printer Resolution . . . . . . . . . . . . . . . . . . . . 6-6

Using the High Speed Conguration . . . . . . . . . . . . . . . . . . 6-7

Why is it faster? . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6

Page 16

My printer has built-in HP-GL. Do I still need the cartridge? . . . . . . 6-7

Ordering the Cartridge . . . . . . . . . . . . . . . . . . . . . . 6-7

Having Enough Printer Memory . . . . . . . . . . . . . . . . . . 6-8

Setting the Printer Up . . . . . . . . . . . . . . . . . . . . . . . 6-8

Using Other Laser Printer Settings . . . . . . . . . . . . . . . . . 6-8

Conguring the Network Analyzer . . . . . . . . . . . . . . . . . 6-8

Switching Between Real Plotters and HP-GL-emulating Laser Printers . . 6-9

Using an HP DeskJet, DeskJet Plus, or DeskJet 500 or 550 Series Printer . . 6-10

Using Serial Setup . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Setting the Serial DIP Switch . . . . . . . . . . . . . . . . . . . 6-10

Preparing the Printer for Use . . . . . . . . . . . . . . . . . . . . 6-10

Conguring the Network Analyzer . . . . . . . . . . . . . . . . . . 6-10

Selecting Printer Resolution . . . . . . . . . . . . . . . . . . . . 6-10

Using the HP DeskJet 500C or 550C Additional Steps Required . . . . 6-10

Using an HP QuietJet, QuietJet Plus, PaintJet, or PaintJet XL Printer . . . 6-11

Using Serial Setup . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Setting the Serial DIP Switch . . . . . . . . . . . . . . . . . . . 6-11

Setting Up GPIB . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Setting the GPIB Address DIP Switch. . . . . . . . . . . . . . . . 6-12

Preparing the Printer for Use . . . . . . . . . . . . . . . . . . . . . 6-12

Conguring the Network Analyzer . . . . . . . . . . . . . . . . . . 6-12

Selecting Printer Resolution (HP QuietJet and QuietJet Plus Printers) . 6-12

Selecting Printer Resolution (HP PaintJet and PaintJet XL Printers) . . 6-13

Printing In Color . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Using an HP ThinkJet Printer . . . . . . . . . . . . . . . . . . . . . 6-13

Using Serial Setup . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Setting the Serial DIP Switch . . . . . . . . . . . . . . . . . . . 6-13

Setting Up for GPIB . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Setting the GPIB Address DIP Switch. . . . . . . . . . . . . . . . 6-13

Preparing the Printer for Use . . . . . . . . . . . . . . . . . . . . 6-14

Conguring the Network Analyzer . . . . . . . . . . . . . . . . . . 6-14

Selecting Printer Resolution . . . . . . . . . . . . . . . . . . . . 6-14

Using Non-HP Printers . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Using Serial Setup . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Setting the Serial DIP Switch . . . . . . . . . . . . . . . . . . . 6-15

Setting Up for GPIB . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Setting the GPIB Address DIP Switch. . . . . . . . . . . . . . . . 6-15

Pre-Printing Check-Out . . . . . . . . . . . . . . . . . . . . . . . 6-15

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Printing Orientation: Either Landscape or Portrait . . . . . . . . . . . 6-16

Printing One Snapshot p er Page (Portrait or Landscape) . . . . . . . . . 6-17

Printing Two Snapshots per Page . . . . . . . . . . . . . . . . . . . 6-17

Printing Tabular Measurement Data . . . . . . . . . . . . . . . . . 6-18

Changing the Tabular Data Format . . . . . . . . . . . . . . . . . 6-19

Printing Instrument Settings and System Conguration . . . . . . . . . 6-20

Using a Plotter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Plotting Features . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

What Is Plotted? . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Installing a Plotter . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Selecting the Output Port . . . . . . . . . . . . . . . . . . . . . . 6-22

Connecting the HP 7550, Special Instructions .

. . . . . . . . . . . . . 6-23

7

Page 17

Using HP 7550B and HP 7550 Plus Plotters . . . . . . . . . . . . . 6-23

Plotting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Selecting Plotter Pen Color . . . . . . . . . . . . . . . . . . . . . 6-23

Plotting with a Single Pen Color . . . . . . . . . . . . . . . . . . . 6-24

Plotting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Plotting One Snapshot per Page . . . . . . . . . . . . . . . . . . . 6-26

Plotting Individual Display Comp onents . . . . . . . . . . . . . . . . 6-26

Plotting a Selected QuadrantFour Snapshots per Page . . . . . . . . . 6-26

7. Disk Drive Op eration

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Compatible Disk Types, Disk Storage Capacity. . . . . . . . . . . . . . 7-1

DOS Subdirectories . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Disk Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

ASCII and Binary File Types . . . . . . . . . . . . . . . . . . . . . . 7-2

Changing between DOS and LIF Discs . . . . . . . . . . . . . . . . . . 7-3

Initializing Discs . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Storing Disk Files . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Loading Disk Files . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Loading a File . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Viewing a Directory of Files . . . . . . . . . . . . . . . . . . . . . . 7-7

Deleting Disk Files . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Un-Deleting Disk Files . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Using an External Disk Drive . . . . . . . . . . . . . . . . . . . . . . 7-8

Compatible Disk Drives . . . . . . . . . . . . . . . . . . . . . . . 7-8

Disk Unit Number and Disk Volume . . . . . . . . . . . . . . . . . . 7-8

Connections and Conguration Settings . . . . . . . . . . . . . . . . 7-8

Initializing a Hard Disc . . . . . . . . . . . . . . . . . . . . . . . 7-9

Guide to Saving Data . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Sharing a System . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Saving Everything . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Viewing or Plotting Old Data . . . . . . . . . . . . . . . . . . . . 7-12

8. Calibrating for System Measurements

What Is a Measurement Calibration? . . . . . . . . . . . . . . . . . . 8-1

What Is Vector Accuracy Enhancement? . . . . . . . . . . . . . . . . 8-1

How the 8510 Corrects Measurement Data . . . . . . . . . . . . . . . 8-2

Calibration Requirements . . . . . . . . . . . . . . . . . . . . . . 8-2

Use the Same Stimulus and Parameter Settings in the Measurement. . . 8-2

Settings that should not be changed . . . . . . . . . . . . . . . . 8-2

Use the Same Equipment Setup in the Measurement. . . . . . . . . . 8-3

Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Coupled/Uncoupled Channels . . . . . . . . . . . . . . . . . . . . 8-3

Cal Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Turning On an Existing Cal Set . . . . . . . . . . . . . . . . . . 8-4

Performing a Measurement Calibration . . . . . . . . . . . . . . . . . 8-5

Calibration Process Synopsis . . . . . . . . . . . . . . . . . . . . . 8-5

Exiting and Resuming a Calibration Procedure .

Time LowPass Frequencies . . . . . . . . . . . . . . . . . . . . . 8-6

Step 1. Select a Calibration Kit . . . . . . . . . . . . . . . . . . . 8-6

What is a \Class" and what is a \Standard?"

8

. . . . . . . . . . . . 8-5

. . . . . . . . . . . . 8-6

Page 18

Step 2. Select the Type of Cal You Need . . . . . . . . . . . . . . . . 8-6

What a Response Calibration Provides . . . . . . . . . . . . . . . 8-7

What a Response and Isolation Calibration Provides . . . . . . . . . 8-7

What a 1-Port Calibration Provides . . . . . . . . . . . . . . . . . 8-7

What a Full 2-Port Calibration Provides . . . . . . . . . . . . . . . 8-7

8510 Measurement Specications and Calibration . . . . . . . . . . . 8-7

Non-Insertable Devices . . . . . . . . . . . . . . . . . . . . . . 8-7

Step 3. Measure all Required Standards . . . . . . . . . . . . . . . . 8-9

Connecting Standards . . . . . . . . . . . . . . . . . . . . . . . 8-9

When You Are Finished Connecting Standards . . . . . . . . . . . . 8-9

If you are using averaging . . . . . . . . . . . . . . . . . . . . 8-9

Standards Required for a Response Calibration . . . . . . . . . . . . 8-9

Standards Required for a S111-Port Calibration . . . . . . . . . . . 8-10

Standards Required for a Full 2-Port Calibration . . . . . . . . . . . 8-12

Measurement order is not imp ortant . . . . . . . . . . . . . . . . 8-12

Standards Required for a TRL 2-Port Calibration . . . . . . . . . . . 8-14

Step 4. Saving the Cal Set to Memory . . . . . . . . . . . . . . . . . 8-14

Calibration Save Registers and Storage Capacity . . . . . . . . . . . 8-14

How to tell if a register already has a Cal Set in it.

What to do if all registers are full .

. . . . . . . . . . . . . . . . . 8-15

. . . . . . . . . . 8-14

Cal Set Limited Instrument State . . . . . . . . . . . . . . . . . . 8-15

S-Parameter Test Set (Two-Path) Calibration Error Mo dels . . . . . . . . 8-15

Frequency Response Calibrations . . . . . . . . . . . . . . . . . . . . 8-16

One-Port Device: S

Two-Port Device: S

Two-Port Device: S

Two-Port Device: S

Two-Port Device: S

Frequency Response Calibration . . . . . . . . . . 8-16

11

Frequency Response Calibration . . . . . . . . . 8-17

11

Frequency Response Calibration . . . . . . . . . 8-17

21

Frequency Response Calibration . . . . . . . . . 8-17

12

Frequency Response Calibration . . . . . . . . . 8-18

22

Response and Isolation Calibration . . . . . . . . . . . . . . . . . . 8-18

1-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

One-Port Device: S

1-Port Correction . . . . . . . . . . . . . . . . 8-19

11

One-Port Device: S221-Port Correction . . . . . . . . . . . . . . . . 8-20

Two-Port Device: Combining Error Models . . . . . . . . . . . . . . 8-20

Full 2-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . 8-22

TRL 2-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . 8-24

R/T Test Set (One-Path) Calibration Error Models . . . . . . . . . . . . 8-25

Response and 1-Port . . . . . . . . . . . . . . . . . . . . . . . . 8-25

One-Path 2-Port . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Storing Calibration Data to Disc . . . . . . . . . . . . . . . . . . . 8-27

Principles and Care of Calibration Standards . . . . . . . . . . . . . . . 8-27

Calibration Standards Require Careful Handling . . . . . . . . . . . . 8-27

Proper Inspection, Cleaning, and Connection . . . . . . . . . . . . . . 8-27

Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . 8-27

Quality of the Standards Aects Accuracy . . . . . . . . . . . . . . 8-28

Standard Models Dier Depending on Connector Type . . . . . . . . 8-28

Specications, Modifying a Cal Kit . . . . . . . . . . . . . . . . . 8-28

Common Problems . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Verifying Calibration Data . . . . . . . . . . . . . . . . . . . . . . . 8-29

Adjusting Trim Sweep . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

Using Agilent 834x Series Sources . . . . . . . . . . . . . . . . . . . 8-30

Using 835x Series Sources . . . . . . . . . . . . . . . . . . . . . . 8-30

9

Page 19

Modifying a Calibration Kit . . . . . . . . . . . . . . . . . . . . . . 8-31

Modifying a Calibration Set . . . . . . . . . . . . . . . . . . . . . . 8-32

Reducing the Number of Points After Calibration . . . . . . . . . . . . 8-32

Eects in Step Sweep Mo de . . . . . . . . . . . . . . . . . . . . 8-33

Eects in Ramp Sweep Mo de . . . . . . . . . . . . . . . . . . . . 8-33

Dening a Frequency Subset . . . . . . . . . . . . . . . . . . . . . 8-34

Create and Save the Frequency Subset . . . . . . . . . . . . . . . . 8-34

Eects in Ramp Sweep Mo de . . . . . . . . . . . . . . . . . . . 8-35

Changing the Calibration Type . . . . . . . . . . . . . . . . . . . . 8-36

Modifying a Cal Set with Connector Compensation . . . . . . . . . . . 8-36

Using Connector Compensation . . . . . . . . . . . . . . . . . . . 8-38

9. Transmission Measurements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Measuring Two-Port Devices . . . . . . . . . . . . . . . . . . . . . 9-1

Using Test Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Setting Up for Transmission Tests . . . . . . . . . . . . . . . . . . . 9-3

Transmission Measurement Calibration Choices . . . . . . . . . . . . 9-3

Setting up for Response Calibration . . . . . . . . . . . . . . . . . . 9-4

Response and Isolation Calibration . . . . . . . . . . . . . . . . . 9-4

One-Path 2-Port Calibration . . . . . . . . . . . . . . . . . . . . 9-4

Full 2-Port and TRL Calibrations . . . . . . . . . . . . . . . . . . 9-4

Measurement Calibration for Noninsertable Devices . . . . . . . . . . . 9-4

Making an Adapter Removal Measurement. . . . . . . . . . . . . . 9-5

Insertion Loss/Gain Measurement. . . . . . . . . . . . . . . . . . . 9-6

Measuring 3 dB Frequencies . . . . . . . . . . . . . . . . . . . . 9-6

Measuring Maximum and Minimum Values . . . . . . . . . . . . . . 9-7

Making Insertion Phase Measurement . . . . . . . . . . . . . . . . . 9-8

Measuring S-Parameters . . . . . . . . . . . . . . . . . . . . . . . 9-9

Making Group Delay Measurements . . . . . . . . . . . . . . . . . . 9-10

Measuring Group Delay Aperture . . . . . . . . . . . . . . . . . . 9-11

Comparing aperture, resolution, and noise . . . . . . . . . . . . . 9-12

Measuring aperture and phase slope . . . . . . . . . . . . . . . . 9-12

Using aperture and smoothing . . . . . . . . . . . . . . . . . . 9-12

Measuring Deviation from Linear Phase Measurement.. . . . . . . . . 9-12

10. Reection Measurements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Reection Test Setups . . . . . . . . . . . . . . . . . . . . . . . . 10-1

One-Port Devices . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Two-Port Devices . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Reection Measurement Calibration Choices . . . . . . . . . . . . . . 10-1

Response and Response-and-Isolation Calibrations . . . . . . . . . . 10-1

1-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . 10-1

One-Path 2-Port Calibration . . . . . . . . . . . . . . . . . . . . 10-2

2-Port Calibrations . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Return Loss Measurement . . . . . . . . . . . . . . . . . . . . . . 10-3

SWR Measurement . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

S-Parameter Measurement . . . . . . . . . . . . . . . . . . . . . . 10-4

Impedance Measurement. . . . . . . . . . . . . . . . . . . . . . . 10-5

Admittance Measurement . . . . . . . . . . . . . . . . . . . . . . 10-5

10

Page 20

11. Introduction to Time Domain Measurements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Using FrontPanel Controls in Time Domain Mo de . . . . . . . . . . . 11-1

General Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Time Domain Modes . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Reection Measurements Using Time Band Pass . . . . . . . . . . . . 11-4

Interpreting the Time Band Pass Reection Response Horizontal Axis . . 11-5

Interpreting the Time Band Pass Reection Response Vertical Axis . . . 11-5

Fault Location Measurements Using Time Band Pass . . . . . . . . . . 11-5

Transmission Measurements Using Time Band Pass . . . . . . . . . . . 11-6

Interpreting the Time Band Pass Transmission Response Horizontal Axis 11-7

Interpreting the Time Band Pass Transmission Response Vertical Axis . . 11-7

Time Domain LowPass . . . . . . . . . . . . . . . . . . . . . . . . 11-8

LowPass Mode Requirements . . . . . . . . . . . . . . . . . . . . 11-8

Setting Frequency Range for Time LowPass . . . . . . . . . . . . . . 11-8

Avoiding Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Analyzing Time LowPass Reections . . . . . . . . . . . . . . . . . 11-9

Reection Measurements using Time LowPass . . . . . . . . . . . . . 11-9

Interpreting the Time LowPass Reection Response Horizontal Axis . . 11-10

Interpreting the Time LowPass Reection Response Vertical Axis . . . 11-10

Trace Bounce . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Time Domain Concepts . . . . . . . . . . . . . . . . . . . . . . . . 11-14

Masking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

Windowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-17

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-18

Response Resolution . . . . . . . . . . . . . . . . . . . . . . . 11-18

Range Resolution . . . . . . . . . . . . . . . . . . . . . . . . . 11-19

Gating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-19

Setting the Gate . . . . . . . . . . . . . . . . . . . . . . . . . 11-20

Select Gate Shape . . . . . . . . . . . . . . . . . . . . . . . . . 11-21

Measurement Recommendations . . . . . . . . . . . . . . . . . . . 11-22

Source Considerations . . . . . . . . . . . . . . . . . . . . . . . 11-23

Test Set Considerations . . . . . . . . . . . . . . . . . . . . . . 11-23

12. Power Domain Measurements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

What Is Power Domain? . . . . . . . . . . . . . . . . . . . . . . . 12-1

What Is Receiver Cal? . . . . . . . . . . . . . . . . . . . . . . . . 12-2

Making a Power Domain Measurement . . . . . . . . . . . . . . . . . 12-3

Performing a Receiver Calibration . . . . . . . . . . . . . . . . . . . . 12-4

The Flatness Calibration Must Be Completed . . . . . . . . . . . . . 12-4

Swept-Frequency Gain Compression Measurement Exercise . . . . . . . . . 12-6

Swept-Power Gain Compression Measurement Exercise . . . . . . . . . . 12-7

11

Page 21

13. GPIB Programming

What's in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . 13-1

What You Can Do with Remote Programming . . . . . . . . . . . . . . 13-2

GPIB Command Information . . . . . . . . . . . . . . . . . . . . . . 13-2

Programming Command Sequence . . . . . . . . . . . . . . . . . . 13-2

Syntax Requirements . . . . . . . . . . . . . . . . . . . . . . . . 13-2

Entering Mnemonics . . . . . . . . . . . . . . . . . . . . . . . 13-2

Using Numeric Entries and Units . . . . . . . . . . . . . . . . . . 13-3

\Next Menu" Commands Are Unnecessary . . . . . . . . . . . . . . 13-3

Timing Considerations . . . . . . . . . . . . . . . . . . . . . . . . 13-3

Overview of Computer-Controlled Measurements . . . . . . . . . . . . . 13-4

Setting Up the System . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

Connect the External Computer . . . . . . . . . . . . . . . . . . . 13-4

Address Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

Set Up the Measurement Using GPIB Commands . . . . . . . . . . . . 13-5

Transferring Data out of the Network Analyzer . . . . . . . . . . . . . . 13-5

Sending Data to the Computer . . . . . . . . . . . . . . . . . . . . 13-5

What Types of Data Are Available from the 8510C? . . . . . . . . . . . 13-5

Data Arrays Read by an External Computer . . . . . . . . . . . . . . 13-6

Raw Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-6

Corrected Data Array . . . . . . . . . . . . . . . . . . . . . . . 13-6

Formatted Data Array. . . . . . . . . . . . . . . . . . . . . . . 13-7

Data Always Comes from the Active Channel . . . . . . . . . . . . . . 13-8

Available Data Transfer Formats . . . . . . . . . . . . . . . . . . . 13-8

How Much Data Is Transferred? . . . . . . . . . . . . . . . . . . 13-9

Preparing the Computer to Transmit or Receive Data . . . . . . . . . . 13-9

Setting up the I/O Path . . . . . . . . . . . . . . . . . . . . . . 13-9

Size of the Preamble, Size Blo ck, and Data Blo cks . . . . . . . . . . 13-10

Setting Up Variables . . . . . . . . . . . . . . . . . . . . . . . 13-10

Dynamic Array Allocation . . . . . . . . . . . . . . . . . . . . . 13-10

Performing the Actual Transfer . . . . . . . . . . . . . . . . . . . . 13-11

An Example of a Data Transfer . . . . . . . . . . . . . . . . . . . 13-11

Using the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-13

Preprocessing FORM1 Data . . . . . . . . . . . . . . . . . . . . . 13-13

Using Real/Imaginary Format for Vector Math . . . . . . . . . . . . . 13-13

Converting Real/Imaginary Data to Magnitude and Phase Data . . . . . 13-13

Transferring Data into the Network Analyzer . . . . . . . . . . . . . . . 13-14

Raw, Corrected, Formatted Arrays . . . . . . . . . . . . . . . . . . 13-14

Trace Memories . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-15

FORM4 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-15

Commonly-Used Queries . . . . . . . . . . . . . . . . . . . . . . . . 13-16

Marker Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-16

ActiveFunction Value . . . . . . . . . . . . . . . . . . . . . . . . 13-16

Query System State . . . . . . . . . . . . . . . . . . . . . . . . . 13-16

System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-16

Where to Find Other Query Commands . . . . . . . . . . . . . . . . 13-17

Local Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-17

Program Debugging Aids . . . . . . . . . . . . . . . . . . . . . . . 13-17

Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . 13-18

Example 1: Syntax Familiarization . . . . . . . . . . . . . . . . . . 13-18

Example 2: ActiveFunction Output . . . . . . . . . . . . . . . . . . 13-19

12

Page 22

Example 3: Marker Output . . . . . . . . . . . . . . . . . . . . . 13-20

Example 4: Marker Operations . . . . . . . . . . . . . . . . . . . . 13-21

Example 5: Single- and Dual-Channel Displays . . . . . . . . . . . . . 13-22

Example 6: Trace Data Output/Input . . . . . . . . . . . . . . . . . 13-22

Example 7: FORM1 Data Conversion . . . . . . . . . . . . . . . . . 13-22

Example 8: S11 1-Port and S21 Response Cals . . . . . . . . . . . . . 13-22

Selecting the Calibration Type . . . . . . . . . . . . . . . . . . . 13-22

Select the Standard Class . . . . . . . . . . . . . . . . . . . . . 13-23

Select Calibration Standards in Class . . . . . . . . . . . . . . . . 13-24

Save the Cal Set . . . . . . . . . . . . . . . . . . . . . . . . . 13-24

Example 9: Modify Cal Kit . . . . . . . . . . . . . . . . . . . . . 13-25

Example 10: Simulated Standard Measurement. . . . . . . . . . . . . 13-25

Example 11: Using the Drive Disk . . . . . . . . . . . . . . . . . . 13-25

Using the Internal Disk . . . . . . . . . . . . . . . . . . . . . . 13-25

File Name Prexes . . . . . . . . . . . . . . . . . . . . . . . . 13-26

Printing Your Own Messages on the Network Analyzer Display . . . . . . 13-26

Example 12: Making Plots Using COPY . . . . . . . . . . . . . . . . 13-26

Example 13: List Trace Values . . . . . . . . . . . . . . . . . . . . 13-27

Example 14: Print to Printer on 8510C System Bus . . . . . . . . . . . 13-27

General Input/Output . . . . . . . . . . . . . . . . . . . . . . . 13-27

Passing Commands through the Network Analyzer Devices on the System

Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-27

How to send pass-through commands . . . . . . . . . . . . . . . 13-27

How pass-through works . . . . . . . . . . . . . . . . . . . . . 13-28

Pass-Through to a Printer . . . . . . . . . . . . . . . . . . . . . 13-29

Output to a Plotter . . . . . . . . . . . . . . . . . . . . . . . . 13-29

User Display Graphics . . . . . . . . . . . . . . . . . . . . . . . . 13-29

Example 15: Plot User Graphics . . . . . . . . . . . . . . . . . . 13-29

Example 16: Plot Using BASIC HP-GL . . . . . . . . . . . . . . . 13-29

Vector Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . 13-29

Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-30

Select Pen Colors . . . . . . . . . . . . . . . . . . . . . . . . . 13-31

Using the Internal Disk to Store the User Displa y . . . . . . . . . . . 13-31

Summary of User Graphics Statements . . . . . . . . . . . . . . . 13-31

Summary of User Display Instructions . . . . . . . . . . . . . . . . 13-32

Example 17: Redene Parameter . . . . . . . . . . . . . . . . . . . 13-32

Example 18: Read and Output Caution/Tell Message . . . . . . . . . . 13-32

Example 19: Read and Output Status Bytes . . . . . . . . . . . . . . 13-32

Read Status Bytes . . . . . . . . . . . . . . . . . . . . . . . . 13-33

Setting the Service Request Mask . . . . . . . . . . . . . . . . . . 13-33

Example 20: Output Key Code . . . . . . . . . . . . . . . . . . . . 13-34

Example 21: Triggered Data Acquisition . . . . . . . . . . . . . . . . 13-34

Example 22: Wait Required . . . . . . . . . . . . . . . . . . . . . 13-34

Example 23: Wait Not Required . . . . . . . . . . . . . . . . . . . 13-34

Example 24: Frequency List . . . . . . . . . . . . . . . . . . . . . 13-34

Example 25: Output/Learn String . . . . . . . . . . . . . . . . . . 13-35

Example 26: Input and Display ASCII Trace . . . . . . . . . . . . . . 13-35

Example 27: DelayTable Operations . . . . . . . . . . . . . . . . . 13-36

Example 28: Fast CW Data Acquisition . . . . . . . . . . . . . . . . 13-36

Example 29: Test Port Power Flatness Cal . . . . . . . . . . . . . . . 13-36

Example 30: Receiver Power Cal/Power Domain . . . . . . . . . . . . 13-36

13

Page 23

Example 31: Disk Store and Load Using Cal Sets . . . . . . . . . . . . 13-37

General GPIB Programming . . . . . . . . . . . . . . . . . . . . . . 13-38

Interface Functions . . . . . . . . . . . . . . . . . . . . . . . . . 13-38

Response to GPIB Universal Commands . . . . . . . . . . . . . . . . 13-39

Response to GPIB Addressed Commands . . . . . . . . . . . . . . . 13-39

Example Program Listing . . . . . . . . . . . . . . . . . . . . . . . 13-40

Example Programs in

14. Operator's Check and Routine Maintenance

Operator's Check . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Agilent 8510 Self-Test . . . . . . . . . . . . . . . . . . . . . . . . 1

S-Parameter Test Set Check . . . . . . . . . . . . . . . . . . . . . 2

In Case of Diculty . . . . . . . . . . . . . . . . . . . . . . . . . 2

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 3

Maintain Proper Air Flow . . . . . . . . . . . . . . . . . . . . . . 3

Inspect and Clean Connectors . . . . . . . . . . . . . . . . . . . . 3

Cleaning the Test Set Rear-Panel Extensions . . . . . . . . . . . . . 4

Cleaning the Glass Filter and CRT . . . . . . . . . . . . . . . . . . 4

Cleaning the LCD . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Deguass (Demagnetize) the Display (CRT Only) . . . . . . . . . . . . 5

Inspect the Error Terms . . . . . . . . . . . . . . . . . . . . . . . 5

Index

EX_8510

. . . . . . . . . . . . . . . . . . . . 13-40

14

Page 24

Figures

1-1. Typical 8510 Network Analyzer System . . . . . . . . . . . . . . . . 1-2

1-2. 8510C Network Analyzer Front-Panel Key Blo cks . . . . . . . . . . . . 1-3

1-3. Annotation Areas for Single Parameter, or Dual Channel Display Mode . . 1-4

1-4. ENTRY Block Keys . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-5. Channel 1 and Channel 2 Selection Keys . . . . . . . . . . . . . . . . 1-9

1-6. Uncoupled Channels Showing Alternate Frequency Sweep . . . . . . . . 1-9

1-7. Stimulus, Parameter, Format, and Response Keys . . . . . . . . . . . . 1-11

1-8. Measurement RESTART Key . . . . . . . . . . . . . . . . . . . . . 1-12

1-9. INSTRUMENT STATE Block . . . . . . . . . . . . . . . . . . . . 1-15

2-1. Network Analyzer System Interconnections . . . . . . . . . . . . . . . 2-2

2-2. Measurement Sequence 1, Test Setup . . . . . . . . . . . . . . . . . 2-5

2-3. Initial Display Showing a Thru Connection . . . . . . . . . . . . . . . 2-6

2-4. Display with Open Circuit Connected . . . . . . . . . . . . . . . . . 2-9

2-5. Display with S

2-6. Display with Thru Connected (S

2-7. Display with S

Response Calibration ON . . . . . . . . . . . . . . . 2-9

11

Calibration) . . . . . . . . . . . . . 2-9

21

Response Calibration ON . . . . . . . . . . . . . . . 2-9

21

2-8. Return Loss: S11LOG MAG. . . . . . . . . . . . . . . . . . . . . 2-10

2-9. Insertion Loss: S21LOG MAG . . . . . . . . . . . . . . . . . . . . 2-10

2-10. Time Domain Re Response Short Circuit: S11TIME BANDPASS . . . . 2-13

2-11. Time Domain Reection Response of an Air Line and Short Circuit .

. . . 2-14

2-12. Time Domain Reection Response of a Thru: S21. . . . . . . . . . . . 2-15

2-13. Time Domain Reection Response of an Air Line: S21. . . . . . . . . . 2-15

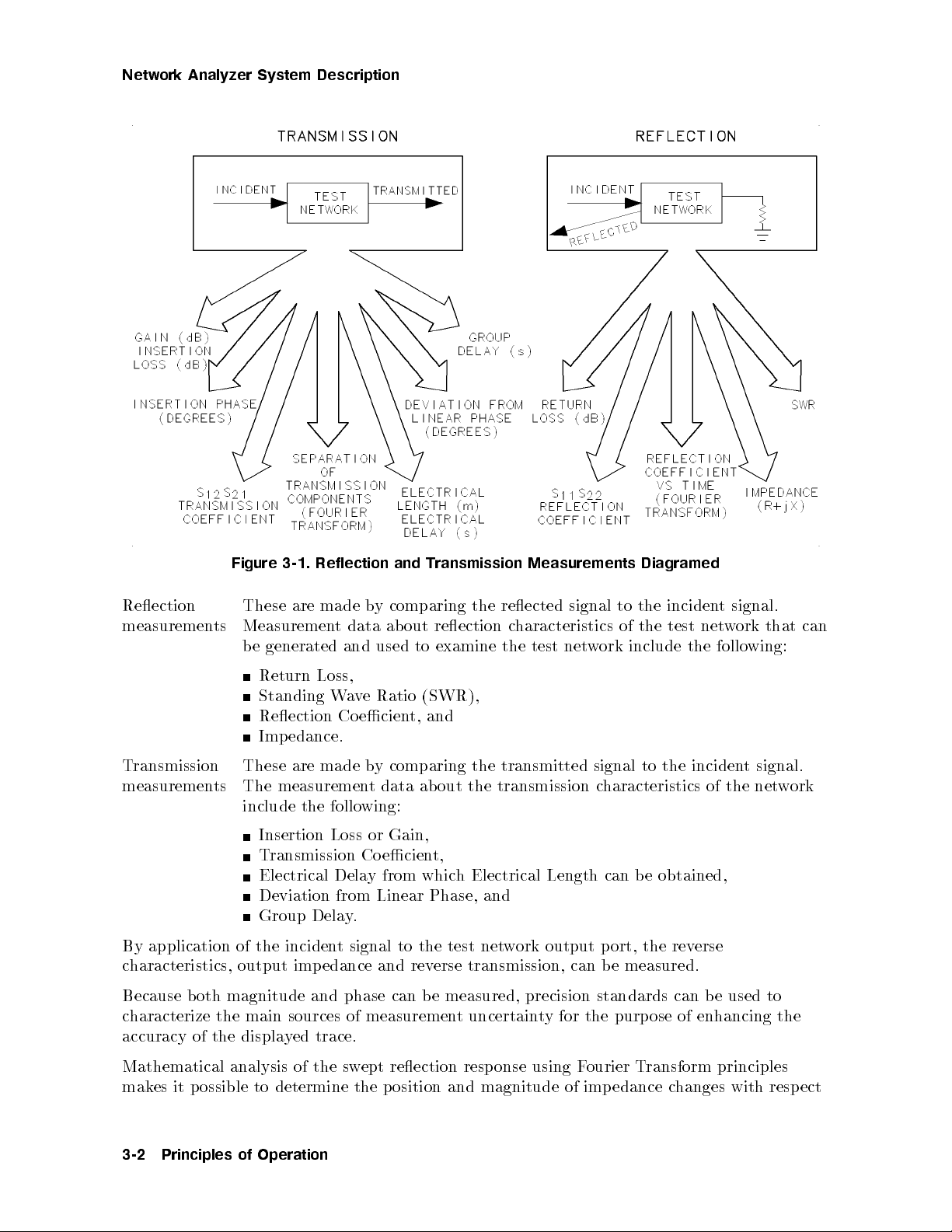

3-1. Reection and Transmission Measurements Diagramed . . . . . . . . . 3-2

3-2. Simplied System Block Diagram . . . . . . . . . . . . . . . . . . . 3-3

3-3. Digital Signal Processing . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-4. Reection/Transmission Test Set Signal Flow. . . . . . . . . . . . . . 3-8

3-5. S-Parameter Test Set Signal Flow. . . . . . . . . . . . . . . . . . . 3-9

3-6. 8511A Frequency Converter Signal Flow . . . . . . . . . . . . . . . . 3-10

3-7. Recommended Typical Test Setups . . . . . . . . . . . . . . . . . . 3-12

4-1. Display and Display Mo de Menus . . . . . . . . . . . . . . . . . . . 4-2

4-2. Annotation Areas for Single Parameter or Dual Channel DisplayMode . . 4-2

4-3. Annotation Areas for Four Parameter Split DisplayMode . . . . . . . . 4-3

4-4. Dual Channel Overlay and Split Displays . . . . . . . . . . . . . . . 4-4

4-5. Adjust Display Menu . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-6. External Video Menu . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4-7. Example of a Limit Test using Limit Lines . . . . . . . . . . . . . . . 4-12

4-8. Limit Test Example Using Limit Lines and Limit Points . . . . . . . . . 4-16

4-9. Display Menu Showing Trace Memory Lo cations Menu . . . . . . . . . 4-19

4-10. Trace Math Operations Menu Structure . . . . . . . . . . . . . . . . 4-21

4-11. Domain Main Menu Structure . . . . . . . . . . . . . . . . . . . . 4-23

4-12. Format Function Block and Format Menu . . . . . . . . . . . . . . . 4-26

4-13. Format Selections (1 of 2) . . . . . . . . . . . . . . . . . . . . . . 4-27

15

Page 25

4-14. Format Selections (2 of 2) . . . . . . . . . . . . . . . . . . . . . . 4-28

4-15. MARKER Key and Marker Menus . . . . . . . . . . . . . . . . . . 4-29

4-16. Markers on Trace . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

4-17. Marker and 1 Mode Menus . . . . . . . . . . . . . . . . . . . . . 4-33

4-18. 1 Mode Markers on Trace . . . . . . . . . . . . . . . . . . . . . . 4-34

4-19. Marker Search Mo des . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4-20. 1 Mode Marker to Target . . . . . . . . . . . . . . . . . . . . . . 4-36

4-21. Parameter Function Blo ck . . . . . . . . . . . . . . . . . . . . . . 4-38

4-22. S-Parameter Flowgraphs . . . . . . . . . . . . . . . . . . . . . . . 4-39

4-23. Parameter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

4-24. Typical User 1, a1Measurement . . . . . . . . . . . . . . . . . . . 4-40

4-25. Redene Parameter Menu Structure . . . . . . . . . . . . . . . . . . 4-43

4-26. Dynamic Range Considerations . . . . . . . . . . . . . . . . . . . . 4-47

4-27. Response Function Blo ck . . . . . . . . . . . . . . . . . . . . . . 4-48

4-28. Response Menu Structure . . . . . . . . . . . . . . . . . . . . . . 4-50

4-29. Results of Averaging . . . . . . . . . . . . . . . . . . . . . . . . 4-52

4-30. Smoothing Operation . . . . . . . . . . . . . . . . . . . . . . . . 4-52

4-31. Results of Smoothing . . . . . . . . . . . . . . . . . . . . . . . . 4-53

4-32. STIMULUS Function Block . . . . . . . . . . . . . . . . . . . . . 4-56

4-33. Source Power Menu.. . . . . . . . . . . . . . . . . . . . . . . . 4-58

4-34. Number of Points Menu . . . . . . . . . . . . . . . . . . . . . . . 4-61

4-35. Narrowband Responses . . . . . . . . . . . . . . . . . . . . . . . 4-62

4-36. Sweep Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

4-37. Eects of Sweep Time . . . . . . . . . . . . . . . . . . . . . . . . 4-65

4-38. Hold, Single, Number of Groups, Continual . . . . . . . . . . . . . . . 4-65

4-39. Trigger Mode Menu. . . . . . . . . . . . . . . . . . . . . . . . . 4-68

4-40. Frequency List Menu Structure . . . . . . . . . . . . . . . . . . . . 4-69

4-41. Enter the First Segment . . . . . . . . . . . . . . . . . . . . . . . 4-70

4-42. Frequency List, Display of Single Segment . . . . . . . . . . . . . . . 4-72

5-1. Main System Menu and Part of the Display Functions Menu . . . . . . . 5-2

5-2. System Phaselock Menu . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-3. Date/Time Functions Menu . . . . . . . . . . . . . . . . . . . . . 5-6

5-4. System Power Leveling Menu. . . . . . . . . . . . . . . . . . . . . 5-10

5-5. Actual LO Frequency Required by a Harmonic Mixer . . . . . . . . . . 5-11

5-6. Edit Multiple Source Menu. . . . . . . . . . . . . . . . . . . . . . 5-12

5-7. Source 2 Modied for Third Harmonic Mixer System . . . . . . . . . . 5-13

5-8. Finished Multi-Source Conguration, LO Source and 3rd Harmonic Mixers . 5-14

5-9. Module Testing Example . . . . . . . . . . . . . . . . . . . . . . . 5-16

5-10. Finished Multiple Source Conguration for Hypothetical Module

. . . . . 5-17

5-11. Service Functions Menu . . . . . . . . . . . . . . . . . . . . . . . 5-18

5-12. Simplied Block Diagram of the Agilent 8510C Network Analyzer . . . . . 5-21

5-13. Gain Stages in the IF section . . . . . . . . . . . . . . . . . . . . . 5-22

6-1. Dene Print Menu . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-2. HP QuietJet and PaintJet (Family) Printer Serial Switch Settings . . . . . 6-11

6-3. HP QuietJet and PaintJet (Family) Printer GPIB Switch Settings . . . . 6-12

6-4. HP ThinkJet Printer GPIB Switch Settings . . . . . . . . . . . . . . 6-14

6-5. Landscape Printer Orientation . . . . . . . . . . . . . . . . . . . . 6-16

6-6. Portrait Printer Orientation . . . . . . . . . . . . . . . . . . . . . 6-17

6-7. Dene List Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6-8. System/Operating Parameters Menu . . . . . . . . . . . . . . . . . 6-20

6-9. Dene Plot and Plot to Plotter Men

u Structure . . . . . . . . . . . . . 6-25

16

Page 26

6-10. Four-Quadrant Plot Example . . . . . . . . . . . . . . . . . . . . . 6-27

7-1. Disk Menu, Data Type Select Menu, Setup Disk Menu, and Initialize Disk

Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

8-1. Cal and Cal Type Menus . . . . . . . . . . . . . . . . . . . . . . 8-4

8-2. Cal Type Selections . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

8-3. Response Cal Menu.. . . . . . . . . . . . . . . . . . . . . . . . 8-10

8-4. S111-Port Cal Menu . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8-5. LOADS Frequency Ranges . . . . . . . . . . . . . . . . . . . . . . 8-12

8-6. Full 2-Port Reection, Transmission, and Isolation Cal Menus . . . . . . 8-13

8-7. TRL 2-Port Cal Menu. . . . . . . . . . . . . . . . . . . . . . . . 8-14

8-8. S-Parameter Test Set Frequency Response Calibrations . . . . . . . . . 8-16

8-9. S-Parameter Test Set 1-Port Calibrations . . . . . . . . . . . . . . . 8-19

8-10. S-Parameter Test Set Full 2-Port Calibration . . . . . . . . . . . . . . 8-22

8-11. Reection/Transmission Test Set One-Path 2-Port Calibration . . . . . . 8-26

8-12. Reduced Number of Points After Calibration . . . . . . . . . . . . . . 8-33

8-13. Modify Cal Set, Frequency Subset Menu. . . . . . . . . . . . . . . . 8-34

8-14. Dening a Frequency Subset . . . . . . . . . . . . . . . . . . . . . 8-35

8-15. Connector Compensation Menu Keys . . . . . . . . . . . . . . . . . 8-37

9-1. Two-Port Device Types . . . . . . . . . . . . . . . . . . . . . . . 9-1

9-2. Transmission Test Setups . . . . . . . . . . . . . . . . . . . . . . 9-3

9-3. Adapter Removal Calibration Sequence . . . . . . . . . . . . . . . . 9-5

9-4. Typical Insertion Loss Display . . . . . . . . . . . . . . . . . . . . 9-6

9-5. Measuring 3 dB Points . . . . . . . . . . . . . . . . . . . . . . . 9-7

9-6. Measuring Minimum and Maximum Insertion Loss . . . . . . . . . . . 9-8

9-7. Typical Insertion Phase Display . . . . . . . . . . . . . . . . . . . . 9-9

9-8. Typical S-Parameter Display . . . . . . . . . . . . . . . . . . . . . 9-9

9-9. Group Delay Denition . . . . . . . . . . . . . . . . . . . . . . . 9-10

9-10. Group Delay Aperture . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9-11. Typical Group Delay Display . . . . . . . . . . . . . . . . . . . . . 9-11

9-12. Changing the Group Delay Measurement Aperture . . . . . . . . . . . 9-11

9-13. Group Delay Plots with Dierent Aperture Selections . . . . . . . . . . 9-12

9-14. Typical Group Delay and Deviation from Ideal Phase Displays . . . . . . 9-14

10-1. Typical Measurement Setup . . . . . . . . . . . . . . . . . . . . . 10-2

10-2. Typical Return Loss Display . . . . . . . . . . . . . . . . . . . . . 10-3

10-3. Typical SWR Display . . . . . . . . . . . . . . . . . . . . . . . . 10-4

10-4. Typical S-Parameter Display . . . . . . . . . . . . . . . . . . . . . 10-4

10-5. Typical Impedance Display. . . . . . . . . . . . . . . . . . . . . . 10-5

10-6. Typical Admittance Display . . . . . . . . . . . . . . . . . . . . . 10-5

11-1. Frequency Domain and Time Domain Measurements . . . . . . . . . . 11-2

11-2. Measurement of a Sliding Load . . . . . . . . . . . . . . . . . . . . 11-4

11-3. Cable Fault Location Measurement Using Time Band Pass . . . . . . . . 11-6

11-4. Transmission Measurement in Time Band Pass . . . . . . . . . . . . . 11-7

11-5. Time LowPass Step and Impulse Resp onses . . . . . . . . . . . . . . 11-11

11-6. Time LowPass Step Response of a 25 Airline and Fixed Load . . . . . 11-12

11-7. Step Response of a 30 cm Airline and Fixed Load . . . . . . . . . . . . 11-13

11-8. Masking Example: 3 dB Pad and Short Circuit . . . . . . . . . . . . . 11-14

11-9. Time Domain Window Characteristics . . . . . . . . . . . . . . . . . 11-16

11-10. Approximate Formulas for Step Rise Time and Impulse Width

11-11. Eect of Windowing on Time Domain Responses of a Short Circuit

. . . . . . 11-16

. . . . 11-17

11-12. Time Domain Measurement Showing Response Repetitions . . . . . . . . 11-18

11-13. Resolution in Time Domain . . . . . . . . . . . . . . . . . . . . . 11-19

17

Page 27

11-14. Typical Gate Shape . . . . . . . . . . . . . . . . . . . . . . . . . 11-20

11-15. Reection Measurement of 7-mm to 3.5-mm Adapter, Airline, and Load . . 11-20

11-16. Gated Responses of the 7-mm to 3.5-mm Adapter . . . . . . . . . . . . 11-21

11-17. Gate Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 11-22

12-1. Domain Menu with Power Domain Function Keys . . . . . . . . . . . . 12-1

12-2. Receiver Calibration Menu. . . . . . . . . . . . . . . . . . . . . . 12-2

13-1. Data Processing Stages in the Network Analyzer . . . . . . . . . . . . 13-6

13-2. PAVector Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . 13-30

13-3. Text Character Cell . . . . . . . . . . . . . . . . . . . . . . . . . 13-31

14-1. Typical Preset State Display . . . . . . . . . . . . . . . . . . . . . 1

14-2. Removing the Glass Filter . . . . . . . . . . . . . . . . . . . . . . 4

14-3. Motion for Degaussing the Display . . . . . . . . . . . . . . . . . . 5

18

Page 28

Tables

0-1. Contacting Agilent . . . . . . . . . . . . . . . . . . . . . . . . . v

1-1. ENTRY Key Terminator Denitions . . . . . . . . . . . . . . . . . . 1-8

2-1. To MatchPen Colors to Display Default Colors . . . . . . . . . . . . . 2-12

2-2. Plot Category Key Choices . . . . . . . . . . . . . . . . . . . . . . 2-12

3-1. Factory Preset Conditions for the 8510C . . . . . . . . . . . . . . . . 3-16

3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

4-1. Default Settings for Display Elements . . . . . . . . . . . . . . . . . 4-8

4-2. External Display Cable Connections . . . . . . . . . . . . . . . . . . 4-10

4-3. Marker Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4-4. Standard PARAMETER Denitions . . . . . . . . . . . . . . . . . . 4-41

4-5. Measuring Power (dBm) at First Frequency Converter . . . . . . . . . . 4-45

4-6. Approximate Insertion Losses in Test Sets (dB) . . . . . . . . . . . . . 4-45

4-7. Approximate Insertion Losses in Test Sets (dB) . . . . . . . . . . . . . 4-46

4-8. Typical Test Port Power Ranges for Source or Test Set Congurations . . . 4-60

5-1. Test Menu.. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

6-1. Serial Printer Settings for Other Printers . . . . . . . . . . . . . . . . 6-15

6-2. Default Pen Numbers . . . . . . . . . . . . . . . . . . . . . . . . 6-24

7-1. Disk Storage Capacities . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2. Information You Can Store to Disc, and HowitIs Saved . . . . . . . . . 7-3

7-3. File Types and Prexes . . . . . . . . . . . . . . . . . . . . . . . 7-7

11-1. Useful Time Band Pass Formats . . . . . . . . . . . . . . . . . . . 11-5

11-2. Maximum Frequency Ranges for Time LowPass . . . . . . . . . . . . 11-8

11-3. Useful Time LowPass Formats . . . . . . . . . . . . . . . . . . . . 11-12

13-1. Marker Units for All displayFormats . . . . . . . . . . . . . . . . . 13-20

19

Page 29

Page 30

1

Introduction to the 8510C

Network Analyzer System

Introduction