Notice

Hewlett-Packard to Agilent Technologies Transition

This documentation supports a product that previously shipped under the HewlettPackard company brand name. The brand name has now been changed to Agilent

Technologies. The two products are functionally identical, only our name has changed. The

document still includes references to Hewlett-Packard products, some of which have been

transitioned to Agilent Technologies.

Printed in USA March 2000

User's Guide

HP 8510 Pulsed-RF Network Analyzer

ABCDE

08510{90505

No.

Part

HP

Printed

in

USA

March

1995

Notice

The information contained in this document is sub ject to change without notice.

Hewlett-Packard makes no warrantyofany kind with regard to this material, including,

but not limited to, the implied warranties of merchantability and tness for a particular

purpose. Hewlett-Packard shall not b e liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material.

Restricted Rights Legend.

Use, duplication, or disclosure by the U.S. Government is sub ject to restrictions as set forth

in subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software clause

at DFARS 252.227-7013 for DOD agencies, and subparagraphs (c) (1) and (c) (2) of the

Commercial Computer Software Restricted Rights clause at FAR 52.227-19 for other agencies.

c

Cop

yrigh

t

adaptation, or

cop

ta

the

Rosa

Systems

under

San

Hewlett-P

1988

translation

la

t

yrigh

Division,

ws.

ard

ack

without

1400

Compan

prior

oun

F

.

y

written

taingro

Righ

All

ermission

p

Pkwy,

e

v

ts

San

Reserv

prohibited,

is

ta

ed.

Rosa,

Repro

CA

duction,

except

as

95403-1799

allo

ed

w

CERTIFICATION

Hewlett-Packard Company certies that this product met its publishedspecications at the

time of shipment from the factory. Hew lett-Packard further certies that its calibration

measurements aretraceable to the United States National Institue of Standards and Technology

(NIST, formerly NBS), to the extent al lowed by the institute's calibration facility, and to the

calibration facilities of other International Standards Organization members.

WARRANTY

This Hewlett-Packard instrument product is warranted against defects in material and

workmanship for a p eriod of one year from date of delivery. During the warranty p eriod,

Hewlett-Packard Company will, at its option, either repair or replace pro ducts whichproveto

be defective.

For warranty service or repair, this product must be returned to a service facilit y designated

byHP.Buyer shall prepay shipping charges to HP and HP shall payshippingcharges to

return the product to Buyer. However, Buyer shall pay all shipping charges, duties, and taxes

for products returned to HP from another country.

HP warrants that its software and rmware designated by HP for use with an instrument

will

es

do

unin

execute

arrant

not w

terrupted

programming

its

that the

error

or

operation

free.

instructions

the

of

LIMIT

prop

when

instrumen

ATIONS

erly

t,

OF

or

W

installed

are,

w

soft

ARRANTY

on that

rm

or

instrument.

will

are

w

HP

e

b

y

eration

op

b

or

foregoing

The

Buy

er,

Buy

the

outside

main

NO

of

tenance.

OTHER

DISCLAIMS

AR

P

A

OR

F

arrant

w

er-supplied

vironmen

en

ARRANTY

W

IMPLIED W

THE

TICULAR

not

shall

y

are

w

soft

sp

tal

IS

PURPOSE.

defects

to

apply

terfacing,

in

or

ecications

EXPRESSED

for

OR

ARRANTIES OR

CLUSIVE

EX

resulting

unauthorized

duct,

pro

the

IMPLIED.

CHANT

MER

REMEDIES

improp

from

dication

mo

improp

or

SPECIFICALLY

HP

ABILITY

er

or

er site

tenance

main

misuse,

preparation

FITNESS

AND

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE

REMEDIES. HP SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT,

TORT, OR ANY OTHER LEGAL THEORY.

ANCE

customer

e

assistanc

e agr

d Sales and Servic

ements

available

e

ar

eOc

e. A

for

ddresses

maintenanc

duct

o

Pr

Hewlett-Packar

dPr

For any assistanc

eprovided at the b

ar

ements

e

agr

e

oducts.

ontact your ne

e, c

ack of this manual.

ASSIST

other

and

arest Hewlett-Packar

iii

Contents

1. Introduction

Organization of This Do cument. . . . . . . . . . . . . . . . . . . . . 1-1

System Description . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Principles of Pulsed-RF Network Measurements . . . . . . . . . . . . . 1-1

Pulse Measurements Overview . . . . . . . . . . . . . . . . . . . . 1-1

Operating the HP 8510 for Pulsed-RF Measurements . . . . . . . . . . 1-1

Frequency Domain Point-in-Pulse Measurements . . . . . . . . . . . . 1-2

Pulse Prole Domain Measurements . . . . . . . . . . . . . . . . . . 1-2

General Timing Information . . . . . . . . . . . . . . . . . . . . . 1-2

Using External Triggering and Pulse Mo dulation . . . . . . . . . . . . 1-2

High P

Reference

er Measuremen

ow

Data

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ts .

.

.

.

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1-2

1-2

System

2.

Who

Principles

3.

Pulse

Pulse

Dut

Pulse

Rise/F

Trigger Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Pulse Prole Measurement Resolution Period . . . . . . . . . . . . . . . 3-3

4. Pulse Measurements Overview

Pulsed-RF S-parameters versus Frequency . . . . . . . . . . . . . . . . 4-1

Pulse

Op

5.

System Connections

Turn On System P

Operator's Chec

Description

.

.

.

.

.

.

.

.

.

.

.

.

.

ts?

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ts

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

Measuremen

. . . . . . . . . . . . . . . . . . 5-3

t State Files

. . . . . . . . . . . . . . . . . 5-5

.

.

.

.

ts

. . . . . . . . . 5-3

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

w

Net

PRP

PRF

,

.

.

. .

.

.

.

.

Pulsed-RF

for

k

Measuremen

.

.

.

. .

.

.

Measuremen

ork

.

.

.

.

.

.

. .

.

.

.

. .

.

.

.

.

.

Pulsed-RF

e

of

Set

etition

etition

Mak

eration

Op

w

Signal

of

the

T

Flo

Pulsed-RF

eriod,

P

requency

F

.

.

.

.

.

.

. .

.

.

.

.

. .

. .

Domain

HP

Hardware State and Instrumen

k . . . . . . . . . .

riggering

.

8510

. . . . . . . . . . . . . . . . . . . . . . . . .

ower . . . . . .

Chec

Should

Theory

est

T

Rep

Rep

Cycle

y

Width

all Time

Prole

erating

Load Pulse

Pulse Prole Domain Check . . . . . . . . . . . . . . . . . . . . . 5-5

Frequency Domain Check . . . . . . . . . . . . . . . . . . . . . . 5-7

External

.

.

.

.

.

.

.

. 3-2

.

. 5-1

.

2-1

2-2

2-3

3-1

3-1

3-2

3-2

4-3

5-9

Contents-1

6. Frequency Domain Point-in-Pulse Measurements

Measurement Calibration for Point-in-Pulse . . . . . . . . . . . . . . . 6-1

Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Set Pulse Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Set Pulse Width . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Set Duty Cycle Limit . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Set Trigger Delay.. . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Connect the Device Under Test . . . . . . . . . . . . . . . . . . . . 6-2

7. Pulse Prole Domain Measurements

Measurement Calibration for Pulse Prole . . . . . . . . . . . . . . . . 7-1

Pulse Prole Domain . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Frequency Domain Using Frequency List . . . . . . . . . . . . . . . . 7-2

Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Set Pulse Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Set Pulse Width . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Set Duty Cycle Limit . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Set Measurement Time Span . . . . . . . . . . . . . . . . . . . . . 7-5

.

.

.

. .

. .

. .

.

.

.

.

.

.

.

.

d

erio

Set

Connect

Switc

Measuremen

Device

the

hing Bet

ween

Resolution

t

under

Frequency

P

.

.

est

T

Domain and

. .

. .

Pulse

. .

Prole

. .

.

.

.

Domain

.

.

.

.

.

.

.

.

.

.

.

.

.

.

7-5

7-5

7-7

Information

Cycle

Measuremen

Time

Cycle

t

.

Time

Width

Cycle

y

Prole

Characteristics

el

external

P

a30dBAmplier .

ort 1 and P

User Parameters and Set A

Memories

Normalized

Appropriate

.

. .

.

Limit

Domain

Domain

and

d

erio

P

and Stop

signal

Measuremen

er

w

o

ort 2 A

ttenuators . . . . . . . .

P

and

t

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Time

Stop

rigger

T

Sweep

conditioning .

.

arameters

Measuremen

Measurement

Dela

y Cycle

Dut

Signals

.

.

.

ts

. . . . . . . . . . . . . . . . . . . .

ttenuators .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

y

.

.

.

.

.

.

Considerations .

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

. . . .

els .

. . . . . . . . . . . . .

. . . . . . . . . . . . . 10-5

ttenuators . . . . . . . . . . . . . 10-5

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Calibration

t

Sequence

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

. . . . . . . . . 10-4

. . . 10-5

.

. .

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

ork

w

Rep

Sw

Pulse

Dut

Pulse

requency

F

Lev

the P

the

Timing

Analyzer

eep

etition

Trigger

High

race

T

the

Calibration

General

8.

Net

Measuremen

Pulse

External

9. Using External Triggering and Pulse Modulation

Connect the Pulse Generator . . . . . . . . . . . . . . . . . . . . . . 9-1

10. High Power Measurements

Signal

Connecting

Example

Measure

Measure an Amplier with High Input Lev

Using

Controlling the A

Measure

Changing Signal Path After Calibration . . . . . . . . . . . . . . . . . 10-6

Set the Attenuators . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Store

View

Selecting

General

. 8-1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 8-5

.

.

.

.

.

.

. 10-3

.

.

.

.

.

.

.

.

8-3

8-3

8-3

8-3

8-3

8-3

8-4

10-1

10-2

10-3

10-6

10-7

10-7

10-9

Contents-2

General Calibration and Measurement Sequence Using Display Math . . . . 10-9

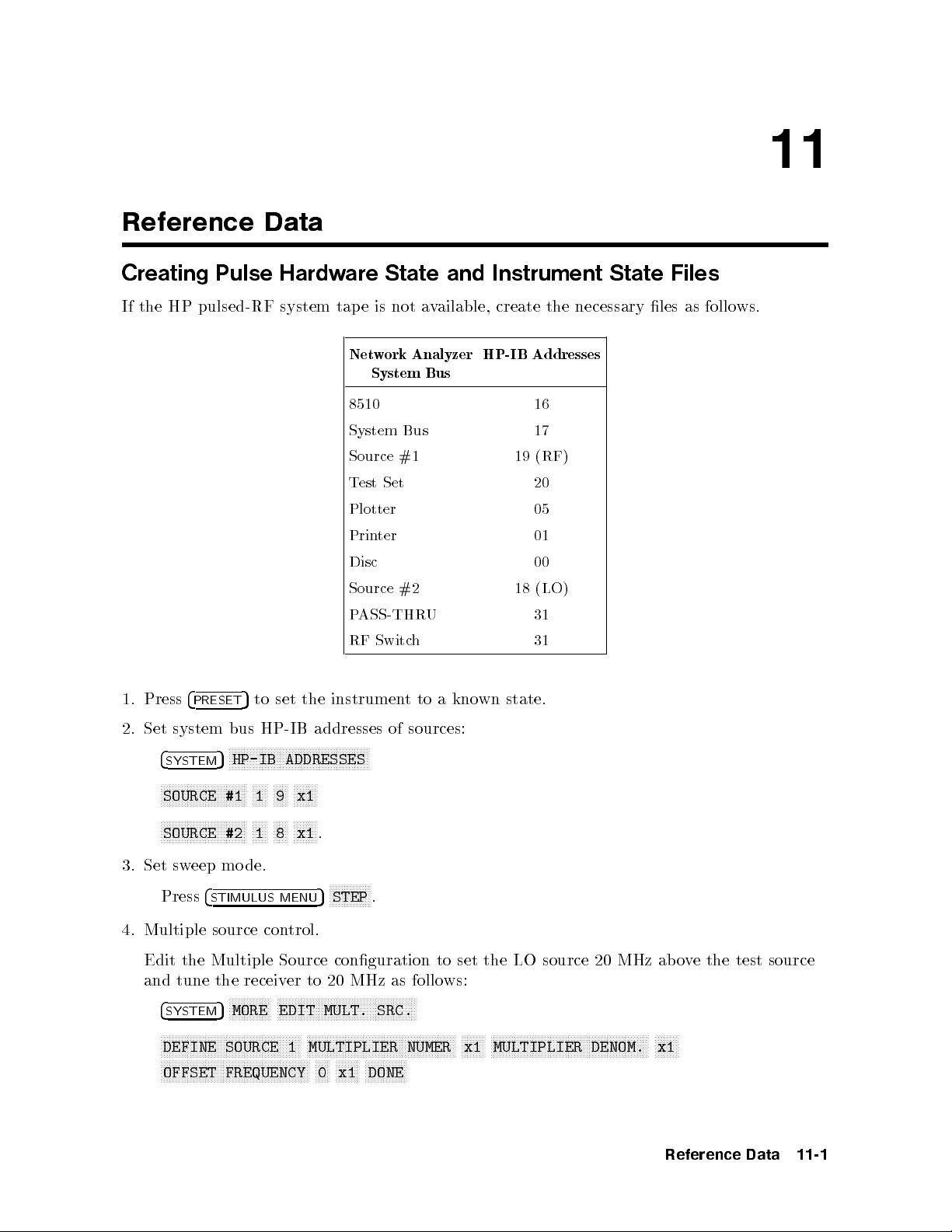

11. Reference Data

Creating Pulse Hardware State and Instrument State Files . . . . . . . . . 11-1

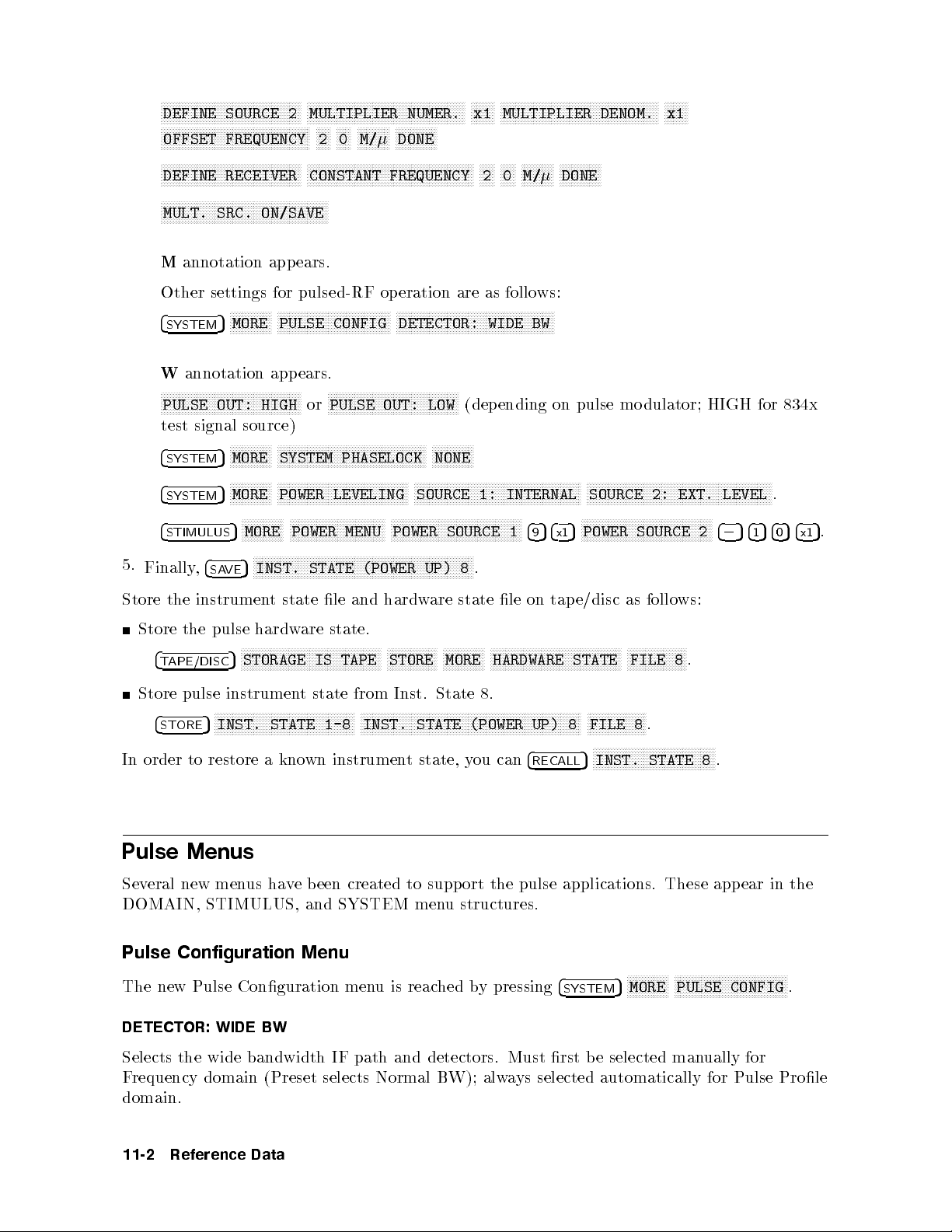

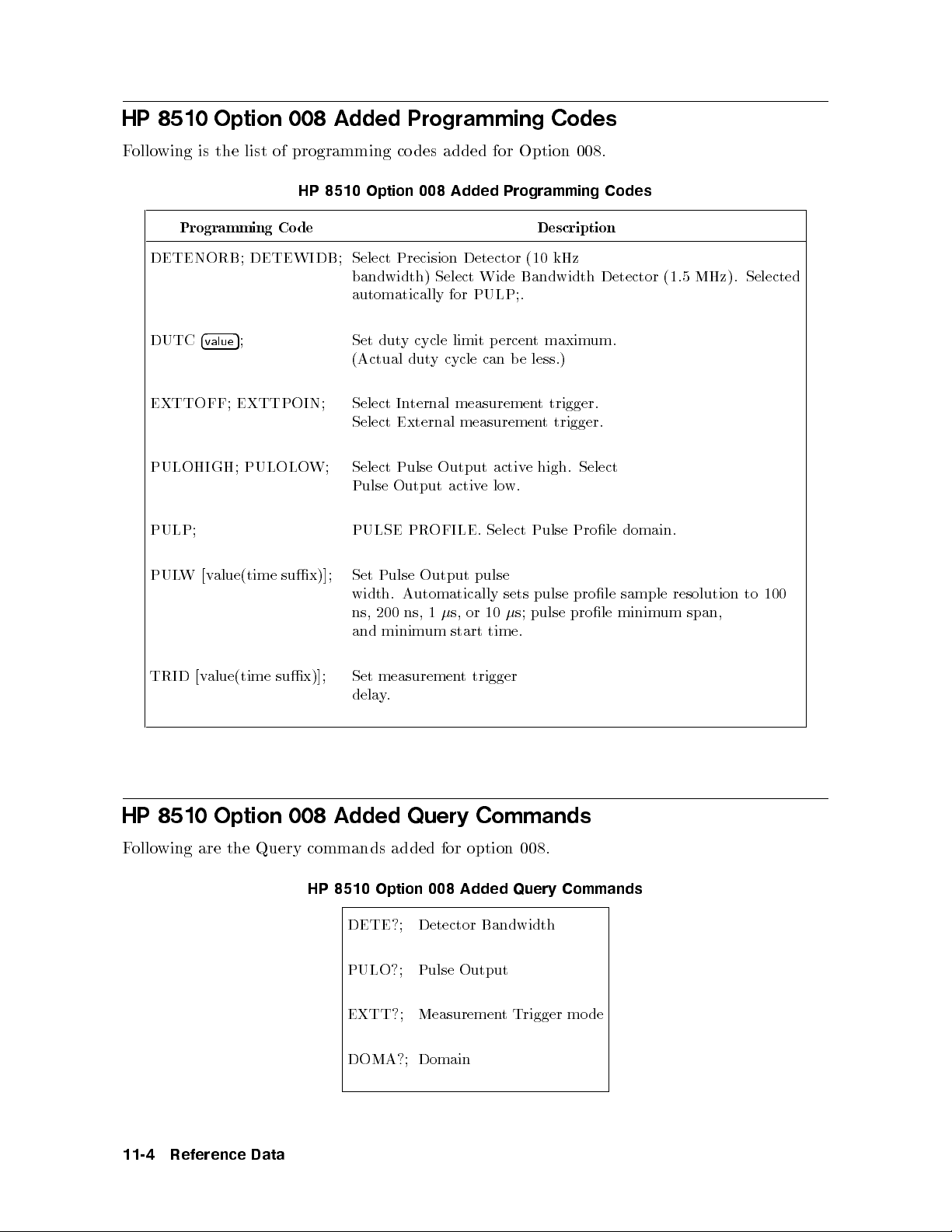

Pulse Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Pulse Conguration Menu . . . . . . . . . . . . . . . . . . . . . . 11-2

DETECTOR: WIDE BW . . . . . . . . . . . . . . . . . . . . . 11-2

DETECTOR: NORMAL BW . . . . . . . . . . . . . . . . . . . 11-3

PULSE WIDTH . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

DUTY CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

PULSE OUT: HIGH . . . . . . . . . . . . . . . . . . . . . . . 11-3

PULSE OUT: LOW. . . . . . . . . . . . . . . . . . . . . . . . 11-3

TRIGGER DELAY . . . . . . . . . . . . . . . . . . . . . . . . 11-3

TRIG MODE: INTERNAL . . . . . . . . . . . . . . . . . . . . 11-3

TRIG MODE: EXTERNAL . . . . . . . . . . . . . . . . . . . . 11-3

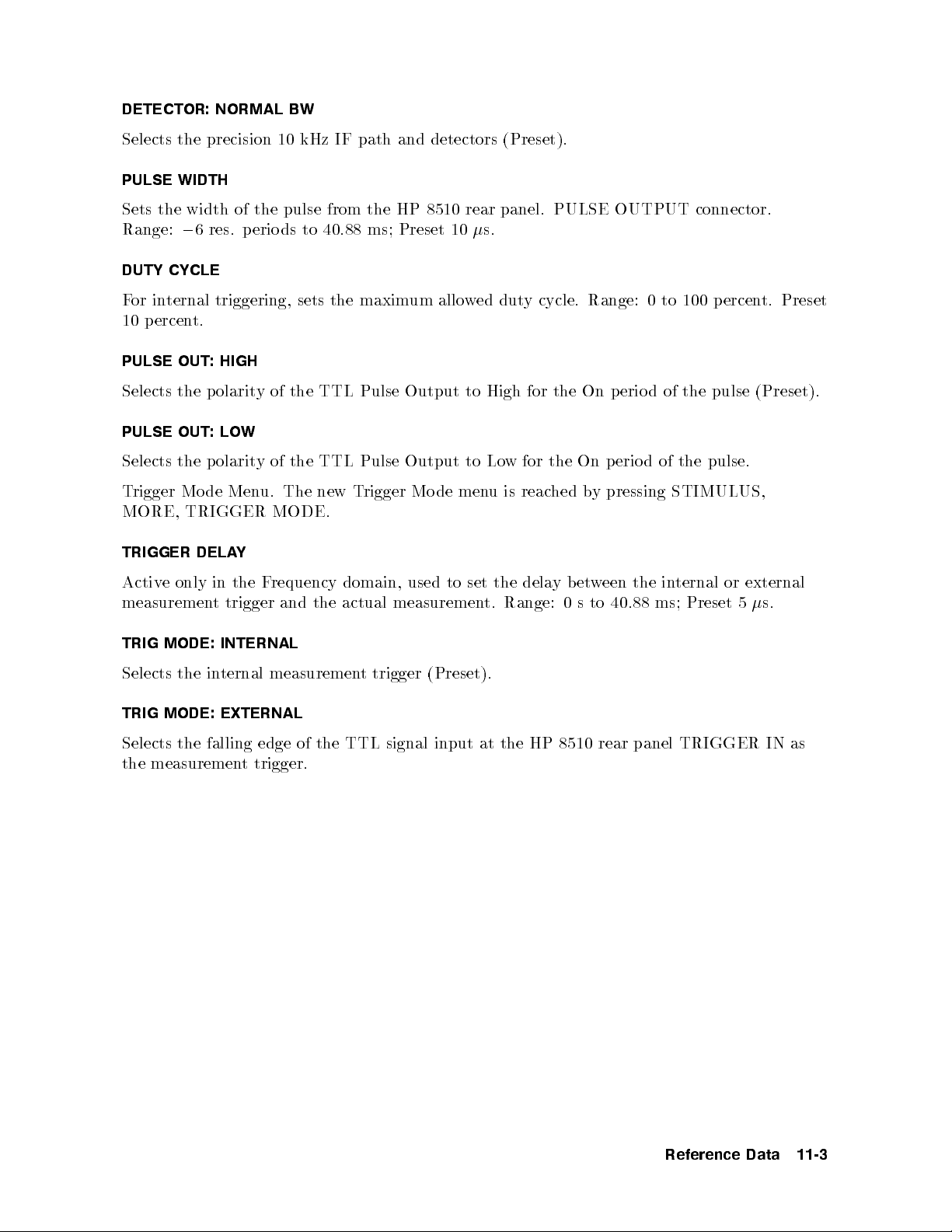

HP 8510 Option 008 Added Programming Co des . . . . . . . . . . . . . 11-4

HP 8510 Option 008 Added Query Commands . . . . . . . . . . . . . . 11-4

Contents-3

Figures

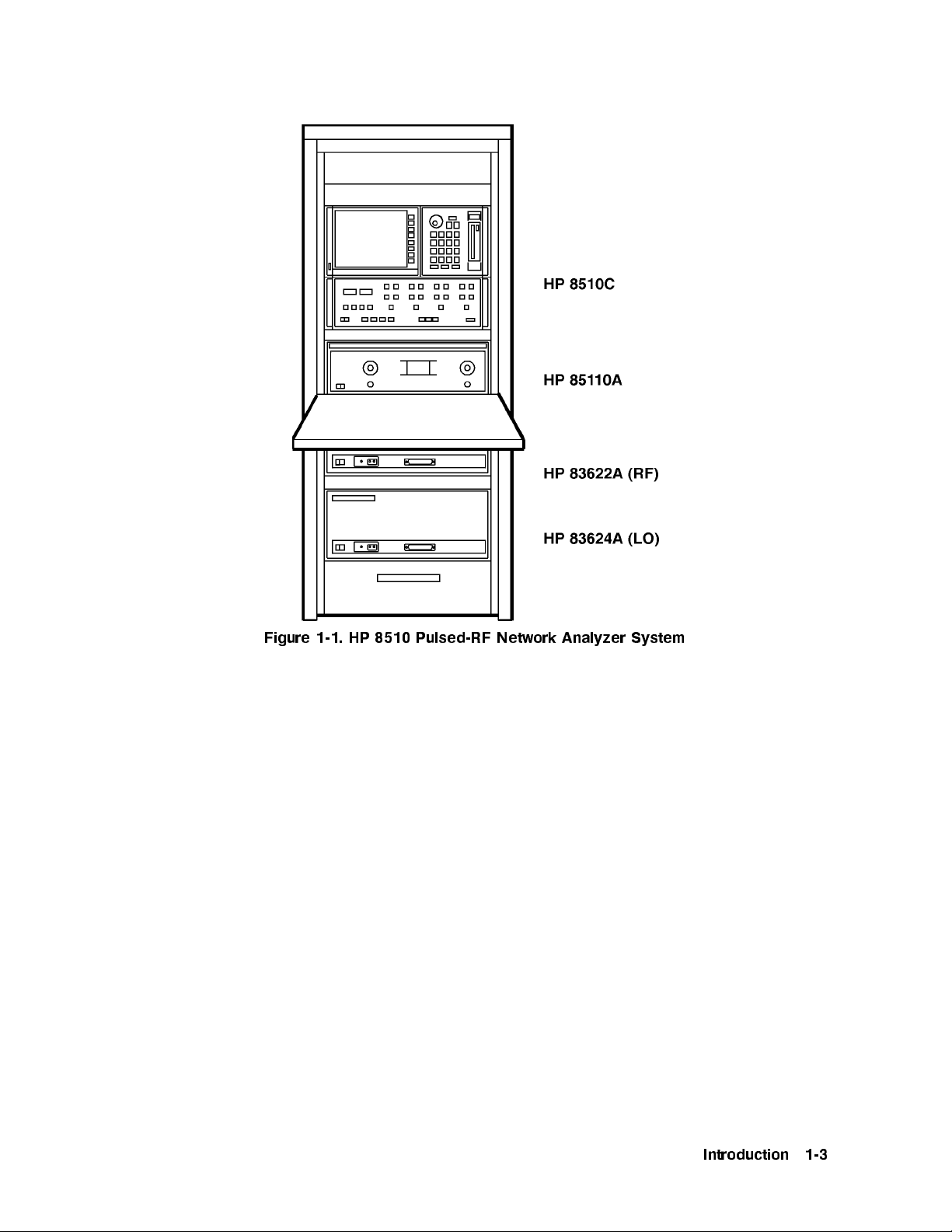

1-1. HP 8510 Pulsed-RF Network Analyzer System . . . . . . . . . . . . . 1-3

2-1. Simplied Pulsed-RF Network Analyzer Block Diagram . . . . . . . . . 2-2

2-2. HP 85110A S-Parameter Test Set Signal Flow . . . . . . . . . . . . . 2-4

3-1. Pulse Terms and Denitions . . . . . . . . . . . . . . . . . . . . . 3-3

4-1. Pulsed-RF S-Parameters versus Frequency (Frequency Domain Point-in-Pulse) 4-2

4-2. Pulsed-RF S-Parameters versus Time (Pulse Prole Domain) Measurement

Internal Pulse Output and Internal MeasurementTrigger . . . . . . . 4-4

5-1. System Cable Connections . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2. Typical Response After Recall, Inst. State 8, Frequency, Detector: WB, Mult.

Srce. On . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

. .

er

Prole,

Domain,

5-3.

Pulse Prole,

5-4.

Pulse

5-5.

S

5-6.

11

S

5-7.

11

Amplier

6-1.

Frequency

7-1.

Pulse

7-2.

S

7-3.

21

Minim

7-4.

7-5. S11, Smith

Net

8-1.

Example

8-2.

8-3. External

9-1. External Control of PRP and Duty Cycle . . . . . . . . . . . . . . . 9-2

9-2. Using External Trigger and External Mo dulation PRP = 10 microseconds,

10-1. Test Set Maximum Signal Levels . . . . . . . . . . . . . . . . . . . 10-2

10-2. Measuring a 30 dB gain Amplier . . . . . . . . . . . . . . . . . . . 10-3

Measuring

10-3.

Option

11-1.

Pulse

User1 a1,

Prole,

requency

F

,

requency

F

,

Prole,

Pulse

,

um

ork

w

Duty Cycle = 50% . . . . . . . . . . . . . . . . . . . . . . . . 9-3

008

S

11

Domain,

Domain,

Gain,

Displa

List

requency

F

Prole,

Time

Chart

Analyzer

ternal

In

Trigger

Amplier

an

Domain,

F

Span,

Mark

Marker

.

.

.

.

Pulse

Pulse

requency

During

y

List

Thru

.

Measuremen

Pulse

and Stop

.

Resolution P

.

.

.

Output

with

ulus,

Stim

.

.

.

Width

Width

Domain

Measuremen

Segmen

.

.

.

.

.

.

Cycle

t

PRP

Sweep

High

and

.

.

.

.

.

.

10

10

t-in-Pulse .

oin

P

Num

t

.

.

.

d

erio

.

.

.

.

and Dut

Timing

Input Lev

System

.

.

.

.

.

.

rigger

s,T

rigger

s,T

Calibration

t

er

b

. .

.

100

=

.

.

.

.

.

.

y Cycle

Diagram

els

Men

1

ns

us

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

s .

5

y

Dela

.

.

.

.

. .

s

15

y

Dela

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

5-4

5-6

5-6

5-7

5-8

6-3

7-3

7-3

7-4

7-6

7-6

8-2

8-4

8-5

10-4

11-5

Contents-4

1

Introduction

This documentisintended for use with the HP 8510B/C Option 008 Network Analyzer

and is a supplement to the HP 8510B/C Operating and Programming manual. It contains

descriptions of the pulsed-RF network analyzer system features for measurements in the

frequency domain and in the pulse prole domain. With resp ect to the standard, swept CW

system, operation of the pulsed-RF system is identical except that the measurement is made

at a specic, known time during each pulse. For information ab out network analysis, please

refer to HP Pro duct Note 8510-10, HP 8510B Introductory User's Guide, for an intro duction

to using the front panel for measurement setup, measurement calibration, and basic network

measurements.

Organization

section

This

ts

ten

con

System

duces

tro

In

Principles

of

list

A

con

h

eac

of

Description

HP 8510B/C

the

Pulsed-RF

of

terms

the

of

tains

hapter.

c

and

This

a

Document

hapters

c

the

of

list

Option

Netw

008

ork

denitions used

cumen

do

this

in

Pulsed-RF

measuremen

Measurements

in pulsed-RF

netw

description

brief

a

and

t

capabilit

t

ork measuremen

y

ts.

the

of

.

Pulse Measurements Overview

A description of how the network analyzer measures pulsed-RF S-parameters versus frequency

and versus time.

Operating

Describes the setup, measuremen

the

t calibration, and measuremen

Pulsed-RF

for

8510

HP

system and making pulsed-RF measuremen

Measurements

t process for setting up the

ts.

Introduction

1-1

Frequency Domain Point-in-Pulse Measurements

This chapter contains measurement calibration and measurement procedures to display the

pulsed-RF S-parameters versus frequency.

Pulse Profile Domain Measurements

This chapter contains measurement calibration and measurement procedures to display the

pulsed-RF S-parameters versus time.

General Timing Information

Descriptions of the internal timing to show the system's internal pulse repetition p eriod and

duty cycle capabilities.

Using External Triggering and Pulse Modulation

This section contains information to help you determine if your application requires external

tain

t.

accuracy

mo

pulse

P

High

Discusses

making

when

dulating

er

w

o

the

equipmen

t,

Measurements

considerations

ecial

sp

at

measuremen

ts

instructions

and

high

required

o

p

RF

wer

for

protect

to

lev

connecting

the

els.

the

test

external

system

equipmen

main

and

Reference

option

all

ws

Sho

Data

008

men

structures

u

and

denitions,

ey

k

including

programming

co

des.

1-2

Introduction

Figure

1-1.

HP

8510

Pulsed-RF

Netw

ork

Analyzer

System

Introduction

1-3

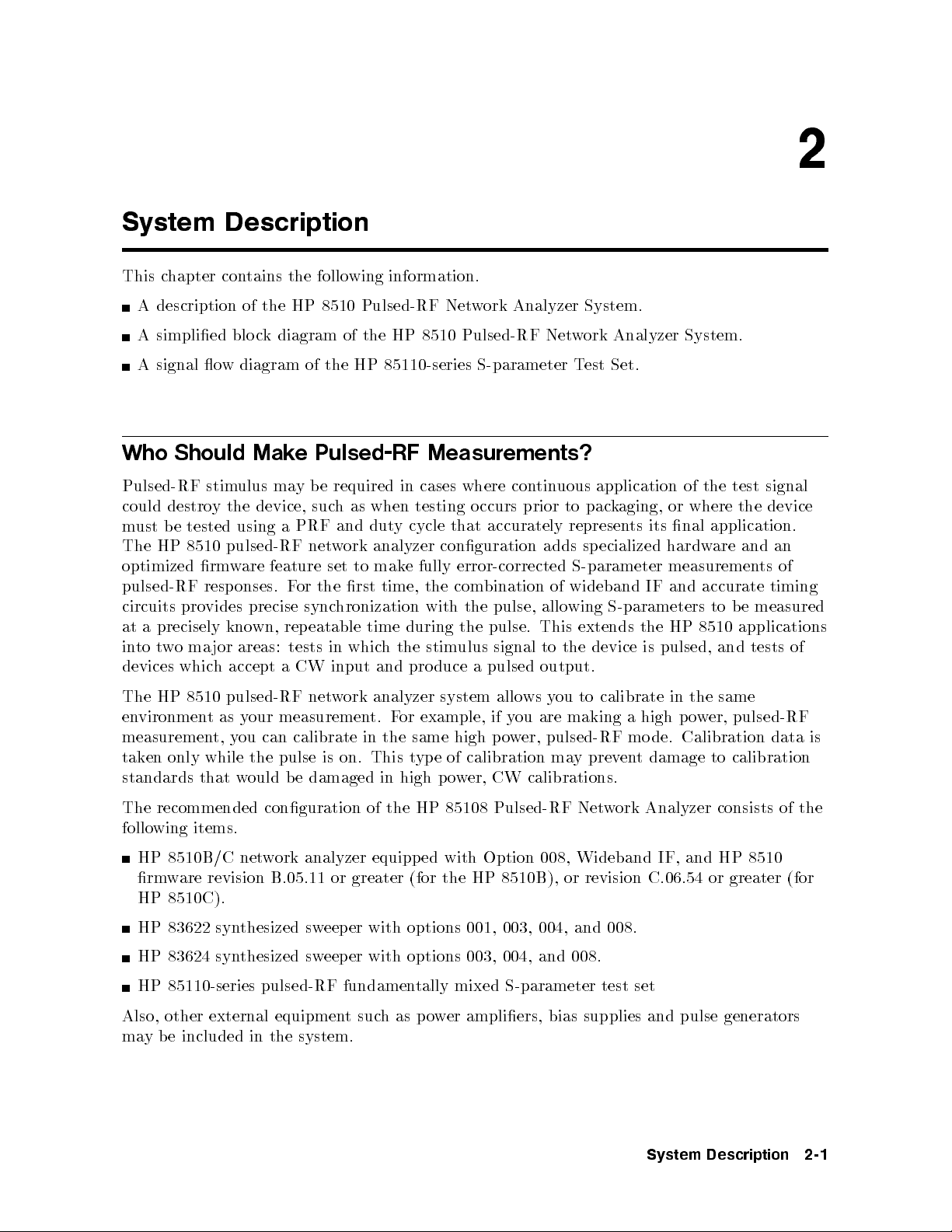

System Description

This chapter contains the following information.

A description of the HP 8510 Pulsed-RF Network Analyzer System.

A simplied block diagram of the HP 8510 Pulsed-RF Network Analyzer System.

A signal ow diagram of the HP 85110-series S-parameter Test Set.

Who Should Make Pulsed-RF Measurements?

Pulsed-RF stim

the

y

destro

could

tested

e

b

ust

m

8510 pulsed-RF

HP

The

optimized

pulsed-RF

circuits

a

at

to

in

devices

rm

resp

vides

pro

precisely

ma

o

tw

whic

kno

jor

h

ulus ma

device,

using

are

w

onses.

precise

wn,

areas:

accept

y

PRF

a

netw

feature

or

F

sync

eatable

rep

tests

CW

a

required

e

b

as

h

suc

and

ork

to

set

rst

the

hronization

whic

in

input

in

when

duty

analyzer

e

mak

time,

during

time

the

h

and

where

cases

testing

cycle that

conguration

error-corrected

fully

com

the

the

with

the pulse.

ulus

stim

duce

pro

con

ccurs

o

accurately

bination

pulse, allo

signal

pulsed

a

tin

prior

adds

This

to

output.

application

uous

pack

to

represen

ecialized

sp

S-parameter

wideband

of

wing

extends

device

the

aging, or

ts

S-parameters

of

where the

nal

its

hardw

measuremen

and

IF

HP

the

pulsed,

is

8510

2

signal

test

the

device

application.

an

and

are

of

ts

accurate timing

measured

e

b

to

applications

of

tests

and

same

the

high p

mo

in

ow

Calibration

de.

pulsed-RF

er,

data

is

8510

HP

The

vironmen

en

measuremen

pulsed-RF

our

y

as

t

ou

y

t,

net

measuremen

calibrate

can

w

ork

analyzer

or

F

t.

in the

system

example,

same high

allo

if

po

ws

ou are

y

wer,

calibrate

to

ou

y

making a

pulsed-RF

taken only while the pulse is on. This type of calibration mayprevent damage to calibration

standards that would be damaged in high power, CW calibrations.

The recommended conguration of the HP 85108 Pulsed-RF Network Analyzer consists of the

following items.

HP

rm

8510B/C

revision

are

w

net

work

B.05.11

analyzer

greater

or

equipp

ed

(for

Option

with

HP 8510B),

the

008,

or

Wideband

revision

IF,

C.06.54

or

greater

(for

8510

HP

and

HP 8510C).

HP 83622 syn

HP 83624

synthesized sweeper with options 003, 004, and 008.

thesized sw

eeper with options 001, 003, 004, and

HP 85110-series pulsed-RF fundamen

tally mixed S-parameter test set

008.

Also, other external equipmentsuchaspower ampliers, bias supplies and pulse generators

system.

ma

e

b

y

included in

the

System

Description

2-1

The pulsed-RF network analyzer system allows you to select either the normal precision 10

kHz IF bandwidth or the new wideband 3 MHz IF bandwidth. The wide IF and detection

bandwidth allows testing using pulses as short as 1 microsecond but with accuracy comparable

to traditional non-pulsed measurements.

These system components may be rack-mounted or arranged on a desktop.

Theory of Operation

A simplied block diagram of the system is shown in Figure 2-1. One synthesizer provides

the test signal stimulus to the RF input of the test set and the other provides the LO signal

to the four frequency converters (only two are shown). The LO source is always tuned 20

MHz above the test signal source. The standard internal phaselocktechnique is not used;

instead, a common 10 MHz frequency reference is used for both of these sources and the

internal sample selection and timing logic in the HP 8510. These sources are considered to be

coherent, thus generating the correct 20 MHz rst IF and the correct clock frequency for the

reference and test synchronous detectors. This eliminates the need to use the reference signal

for receiver phaselock and allows all reference and test signals to b e pulsed, therebymaking

fully error-corrected 2-port, pulsed-RF S-parameter measurements possible.

Figure 2-1. Simplified Pulsed-RF Network Analyzer Block Diagram

detectors

exible

y the HP 8510

and

in

accurate

Using

erate

op

wider

a

at

bandwidth

MHz,

20

of device response during the

oth the

b

reference

measuremen

and

sample

t

timing

circuits

sync

IF,

test

the

pulse. With the sources and test set con

hronous

allow

trolled b

over the 8510 system bus, and with all necessary pulse generation and measuremen

signals generated in

ternally from a common

pulsed-RF stimulus/response test system. One pulse of a

each data poin

t and the measuremen

t is sync

10 MHz reference, the HP 85108 is a complete

user-specied width is measured at

hronized so that it is made at a certain kno

that

analysis

t timing

wn

time in the pulse. The stimulus duty cycle can be predicted for a given instrument state,

but the actual pulse rep etition p eriod depends upon the current domain, cal type, averaging,

y

dut

to

eep

sw

cycle,

2-2

time,

refer

System

pulse

and

to General

Description

width

Timing

selections.

Information.

this reason,

or

F

sensitiv

device

our

y

if

is

e

Either the internal logic, the TTL Trigger Input, or the HP-IB Group Execute Trigger from

an external controller can initiate a measurement cycle. When control of the pulse rep etition

period and duty cycle is required, the HP 8510 can use the trigger input to synchronize with

the internal or an external pulse mo dulator. The HP 8510 Stop Sweep output can be used as

a gating signal to tell when the analyzer is ready for the next measurement. The measurement

is made with 100 nanosecond resolution and about 200 picosecond uncertainty with respect to

the internally- or externally-generated measurement trigger.

Test Set Signal Flow

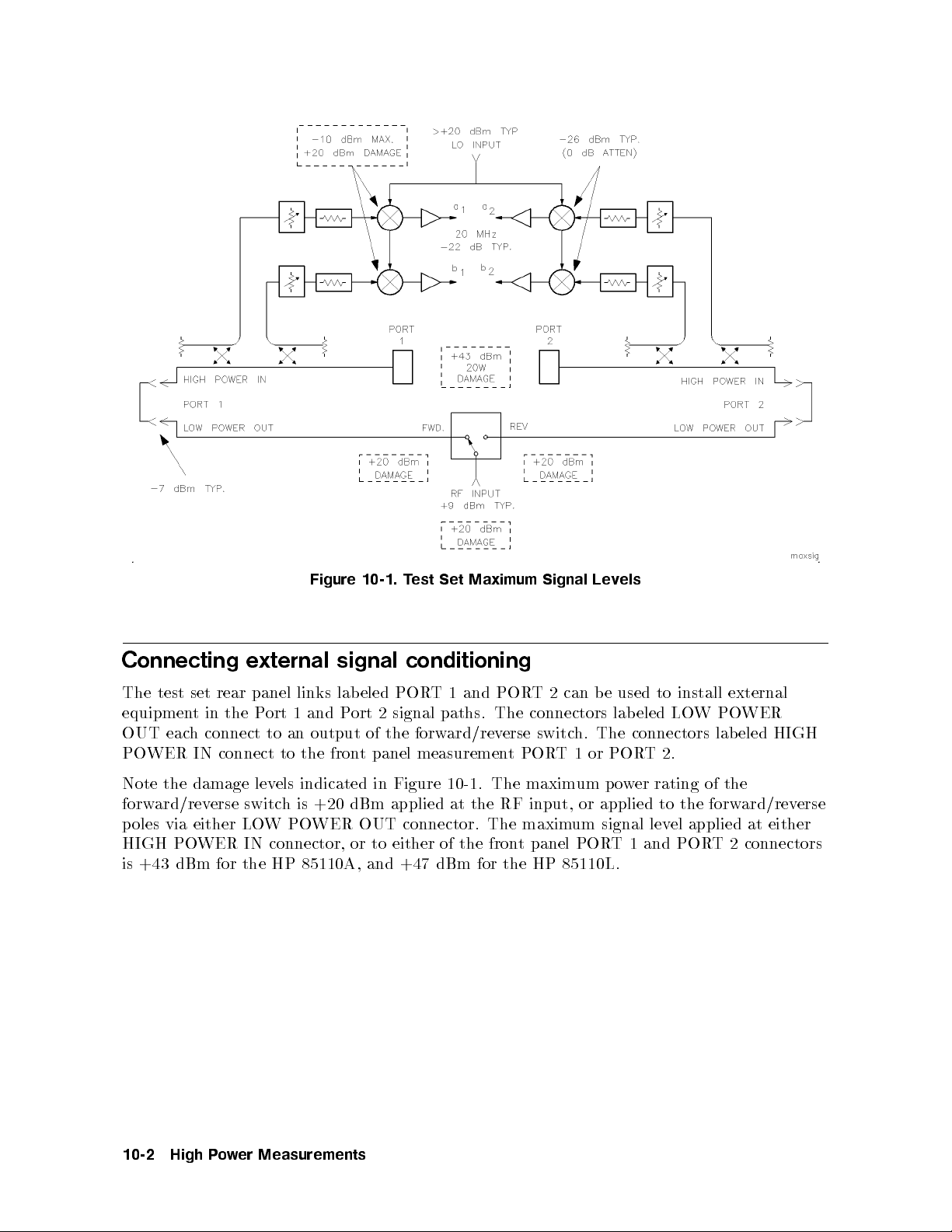

Figure 2-2 shows a detailed diagram of the HP 85110-series test set signal separation, signal

routing, and frequency conversion. This is a fundamentally mixed test set, providing four 20

MHz outputs to the network analyzer. Placement of a 0 to 90 db (10 dB/step) attenuator

before each mixer provides control of the signal levels into the mixers while allowing operation

at high PORT 1 and PORT 2 signal levels necessary in many pulsed-RF applications.

The test set has rear panel access links to allow integration of additional test and signal

conditioning equipment in the low-loss main signal paths to the test p orts. If your device

exhibits more than about 20 dB of gain, or higher p ort signal levels are required, refer to the

chapter.

include

test

IF

and

ts

mixing

set.

detectors.

and

detectors.

the HP

IF

This

and

sets

test

8514, 8515,

85110

HP

There

HP

The

erform

p

designed to

are

and

fundamen

applications

are

85104

pulse

the

work

coaxial

8516

mixing

tal

millimeter

measuremen

with the

whic

in

test sets

sets;

test

test

the

h

can

functions

t

normal 10

and

is

set

HP

e

b

describ

HP

the

designed

can

85110

congured

ed

kHz

to

IF

85104

w

e

b

to

here.

ork

w

o

P

High

Hewlett-P

detectors.

and

millimeter

the

with

with

used

with

erate

op

Measuremen

er

ard

k

ac

These

eguide

v

a

w

wideband

normal

the wideband

harmonic

IF

All

Test

four

coaxial

HP

Sets,

coaxial

so

a

test

sets

test

system

sets

can

and

can b

a

equipp

e

e

b

equipp

ed

millimeter-w

ed

for

a

v

to

a

e

include

wide

set.

test

Option

range

001,

applications

of

IF

Switc

hing

including

y

b

for

Multiple

to

up

System

Description

2-3

Figure

2-2.

HP

85110A

arameter

S-P

T

est

Signal Flo

Set

w

2-4

System

Description

3

Principles of Pulsed-RF Network Measurements

This chapter contains a list of terms used to describe the pulsed-RF stimulus and response.

Figure 3-1 shows a typical envelope of the pulsed-RF waveform output by the RF signal

source. For internal measurement triggering, the RF frequency and the ON time of the pulse

is controlled by the HP 8510 so that there is one pulse per measurement.

Pulse Repetition Period, PRP

The time from the 50 percentpoint on the rising edge of one pulse to the 50 percentpointon

pulse.

next

the

of

edge

rising

the

eration

ternal

in

or

F

ypically

T

and

time

for

width

the

is

The

the

frequency

ab

pulse.

up

pulse

In

PRP

making the

millisecond

calibration

PRP

the

If

triggering

is

there

measuremen

the

time

measuremen

next

and

30

out

maxim

during

e,

yp

t

con

is

op

pulse

one

tis

next

the

til

un

cycle

y

dut

domain,

when

milliseconds. In

PRP

um

of

part

width,

pulse

trolled

externally

the analyzer with the pulse.

Pulse

Repetition

Frequency,

the

measuremen

er

p

made at

pulse

and

t

limit.

the

out

ab

measuremen

the

dut

system

some

consists

second,

analyzer

Pulse

the

milliseconds.

3

y cycle,

HP

the

,

PRF

PRF

PRP

The

t.

user-sp

rst

necessary

if

tuned

is

Prole

Other

t.

and pulse

external trigger

8510

=

PRP

up

ends

dep

time

aiting

w

the

a

time

eraging,

v

turned ON

next

the

whic

pulse is

ecied

the

of

,

to

domain,

With

factors

prole domain

1

the

on

relativ

required

satisfy

to

frequency,

frequency

the

aect

h

stop time.

input is

instrumen

user-sp

a

for

the

to

e

the

for

user-sp

the

the

es

do

can

PRP

system

the

used to

t state.

ecied

of

start

analyzer

ecied

maxim

hange,

c

not

ab

e

b

PRP

sync

the

set

to

um

1

out

are

hronize

Principles

Pulsed-RF

of

Netw

Measurements

ork

3-1

Duty Cycle

The ratio of the time that the pulse is ON to the total Pulse Repetition Period. If the pulse

ON and OFF times are equal, the Duty Cycle is 50 percent.

For internal operation, the maximum duty cycle percent limit can be specied, but the actual

duty cycle may be less, depending upon the user-specifed pulse width and the time it takes for

the analyzer to set up for the next measurement.

Pulse Width

The ON time from the 50 p ercent p oint on the rising edge to the 50 p ercentpointon the

falling edge.

The internally-generated Pulse Width can be set from less than 100 nanoseconds to 40.88

milliseconds.

Time

Rise/F

all

time

es

for

time:

the

pulse

to

rise

from

the

10

The

tr

The

=

pulse

pulse

time

transition

rise

tak

it

condition.

time

fall

pulse

=

tf

90

the

from

fall

to

pulse

the

for

es

tak

it

time

The

condition.

The

normal

IF

resp

onds

rise/fall

to

times

out 75

ab

of

to rise/fall times of about 300 nanoseconds.

y

Trigger

time

The

In the F

Dela

the

that

ON

pulse

after

requency domain, the T

measuremen

rigger Dela

t

y can b e set from do

(internal) or +3 resolution perio ds (external) and

Prole domain the trigger dela

width,

and number of p oin

y is automatic depending upon the displa

ts.

ON

t

ercen

p

ON

t

ercen

p

microseconds; the

actually made.

is

condition

condition to

to

the 10

wideband IF

90 p

the

wn to -6 resolution p erio

up to 40.88 milliseconds. In the Pulse

y time span, pulse

ercen

ercen

p

ON

t

ON

t

responds

ds

3-2

Principles

Pulsed-RF

of

Netw

Measurements

ork

Pulse Profile Measurement Resolution Period

The time between adjacent Pulse Prole domain data p oints. The minimum is 100

nanoseconds. This is set by an algorithm depending upon the Pulse Prole stop time, pulse

width, and number of time points.

Figure

3-1.

Pulse

erms

T

Definitions

and

Principles

Pulsed-RF

of

Netw

Measurements

ork

3-3

4

Pulse Measurements Overview

This chapter contains information ab out how the HP 8510 pulsed-RF network analyzer system

measures pulsed-RF S-parameters versus frequency and versus time.

The pulsed-RF conguration allows use of vector network analysis techniques for twotypes of

measurements:

Pulsed-RF S-Parameters versus Frequency

. The measurementissynchronized with the

pulse so that the measurement result is the S-parameter at a sp ecic user-specied pointin

the pulse at each frequency of the sweep

Pulse Prole

. The system is tuned to a single frequency and the measurementis

synchronized with the pulse so that the measurement result is the S-parameter as a function

of time

during the

Pulsed-RF

with

the

p

of

oin

tests

pulse.

t

t-in-pulse"

t

the

Pulsed-RF

cess

pro

during

measuremen

domain

measuremen

onse

resp

external

or

F

the

is

trigger. F

trigger

pulse.

S-parameters

frequency domain

the

in

the

that

so

pulse

frequency

h

eac

t

A

certain

a

after

made

measuremen

ternal

or in

pulsed

the

mo

to

de,

eac

h

device

ersus

v

measuremen

the

,

dela

using

t

trigger

stim

oin

p

data

Frequency

accomplished

are

is

t

Figure

in

the

de,

at

the trace

are

ternal pulse

eac

the

sources

.

y

mo

ulus

tof

made

tuned,

4-1

data

h

same

sync

y

b

single,

a

at

the

an

ws

sho

output and

oin

p

terv

in

represents

hronizing

user-sp

is turned

RF

example

the

of

t

after

al

the resp

of this

the

trace

the

onse

measuremen

the

ecied

then

on,

\frequency

ternal

in

represen

pulse is

of

time

the

the

ts

turned on.

device

the

the pulsed stimulus after the falling edge of the externally-generated measurementtrigger.

t

to

Measurements

Pulse

Ov

erview

4-1

Figure 4-1. Pulsed-RF S-Parameters versus Frequency (Frequency Domain Point-in-Pulse)

erview

4-2

Pulse

Measurements

Ov

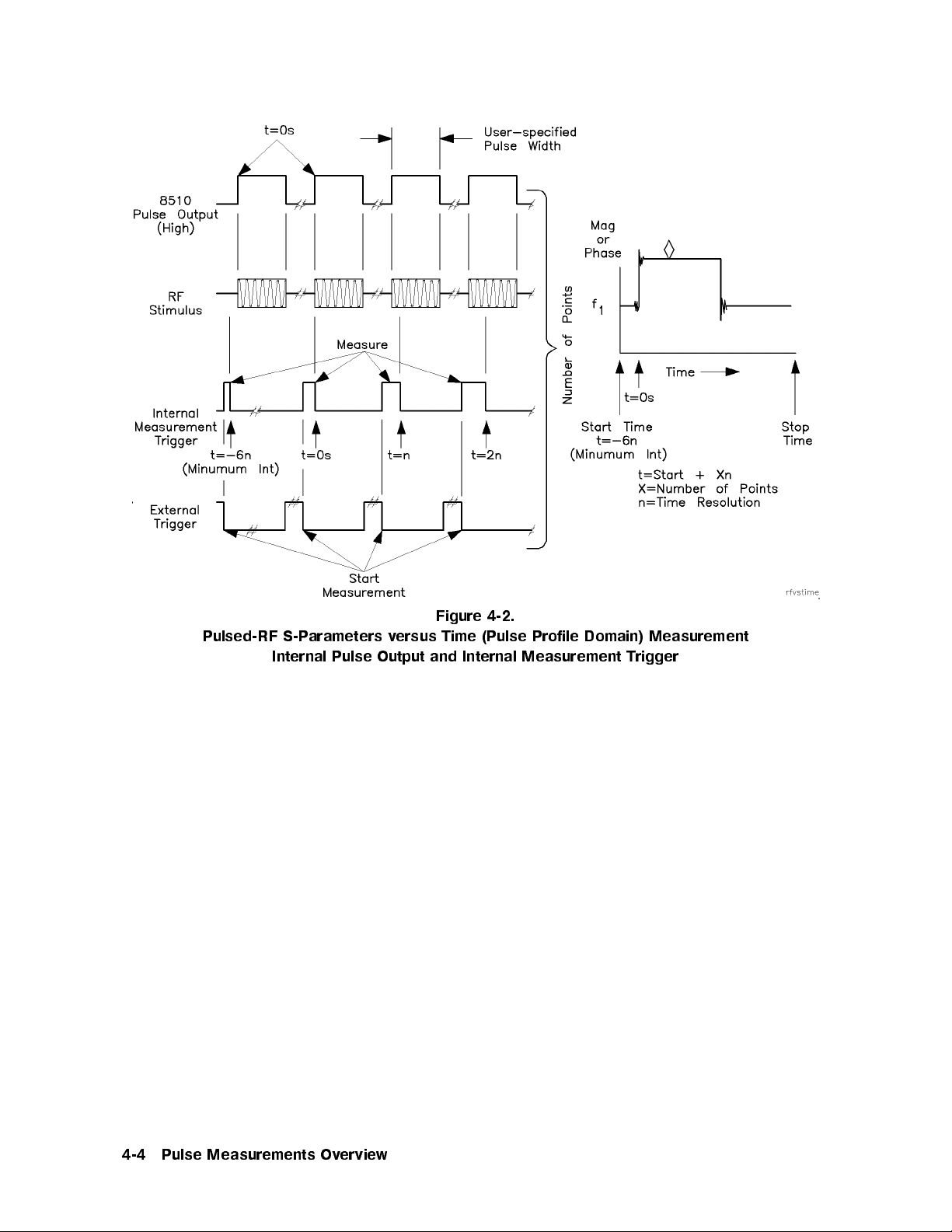

Pulse Profile Domain

Measurements in the Pulse Prole domain create a plot of the resp onse as a function of

time in synchronization with the internal or the external measurement trigger. A rep etitive

sampling technique is used, in which the data is reconstructed from samples taken from a

series of pulses. This allows display of the S-parameters versus time during the pulse. Figure

6 is an example of this pro cess showing a timing diagram using the internal pulse mo dulation

and internal measurement trigger. For each pulse, a single point in the pulse is measured. A

prole of the pulse is made by measuring the rst pulse at the user-specied Start time, then

increasing the measurement trigger delayby a certain time increment for each pulse until the

specied number of points is measured.

Time zero is the leading edge of the internally-generated pulse output waveform, or the falling

edge of the externally-generated measurement trigger waveform. The HP 8510 automatically

controls the time incrementbetween samples, called the measurement resolution perio d,

using an algorithm that depends up on the greater of the user-specied pulse width or stop

time. This automatic selection of the time resolution can be seen bychanging the number

of points and the time span. For narrow pulses and small time spans, the measurement

spans,

time

large

d

erio

resolution

can

it

rst

the

p

increase to

sample

can b

external triggering,

ds

erio

resolution

p

e

b

can

multiples

etak

external

the

time

after

as

en up

100

as

small

microseconds. With

of 10

resolution

to 6

trigger

sets

zero.

nanoseconds;

erio

p

zero

time

the

ds

for

prior

and

wide

ternal

in

the

pulses

to

rst

and

measuremen

zero.

time

sample

t

When

can

trigger,

using

tak

e

b

en

three

Measurements

Pulse

Ov

erview

4-3

Pulsed-RF

S-Parameters

Internal

Pulse

ersus

v

Output

Figure

Time

and

4-2.

(Pulse

Internal

Profile

Measurement

Domain)

Measurement

Trigger

4-4

Measurements

Pulse

Ov

erview

5

Operating the HP 8510 for Pulsed-RF Measurements

This chapter describes the setup, measurement calibration, and measurement process for

conguring the system and making frequency domain p oint-in-pulse measurements and

pulse prole domain measurements. These pro cedures use the internal pulse modulation and

internal measurement trigger capabilities of the HP 8510 Option 008. Familiarize yourself

with these capabilities before setting up measurements that use external triggering techniques.

For more detailed information on the standard features of the HP 8510, refer to the HP 8510

Operating and Programming manual.

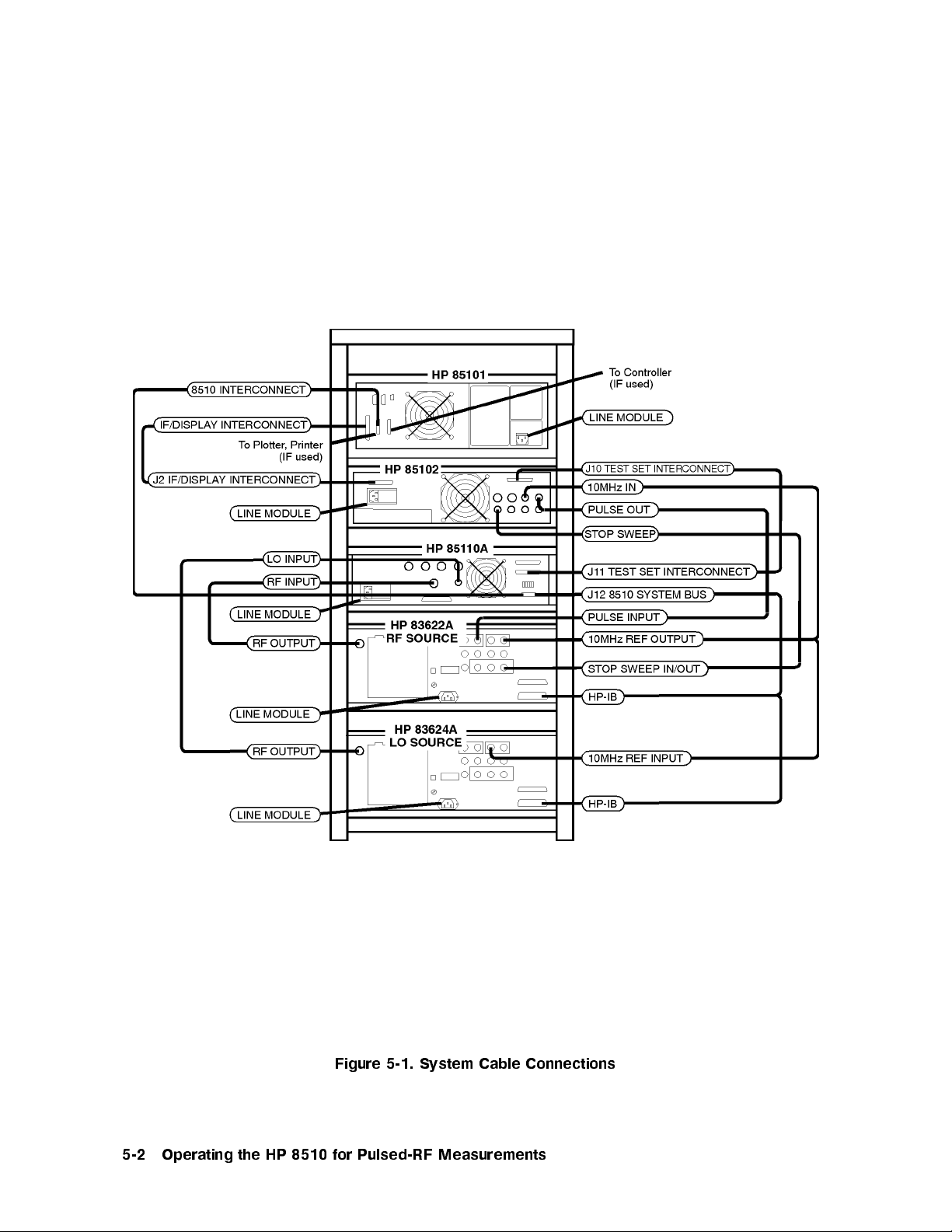

System

Figure

Notice

the

5-1

that

reference

supplies,

dulators,

mo

equipmen

other

Connections

ws the

sho

the

can

ampliers

and a

cable connections

source

RF

the

e

b

connected

computer.

ma

that

t

LO

y

serv

b

as

es

source

the

to

erify

V

connected

e

the

or

test

these

for

the

10

to

recommended

the

MHz

8510.

HP

rear

set

basic

system.

the

frequency

y

Man

links, external

panel

connections

85108

HP

reference

for

applications

familiarize

and

pulse

the

will

pulse

conguration.

system,

although

also include

generators

ourself

y

with

bias

and

Operating

the

HP

8510

Pulsed-RF

for

Measurements

5-1

Figure

5-1.

System

Cable

Connections

5-2

Operating

the

HP

8510

Pulsed-RF

for

Measurements

Turn On System Power

Turn on rackpower, line power to the sources, test set, and other equipment, and then the HP

8510. Depending upon the contents of HP 8510 Instrument State 8 and the current HP 8510

Hardware State, the system may not be fully op erational immediately after initial power up.

Messages to the operator may appear on the screen and b eep sounds may be heard. If so, load

the pulse instrument state and hardware state as described below. The rmware revision will

be displayed on the screen. It should be B.05.11 or later for HP 8510B, and C.06.54 or later

for HP 8510C.

Load Pulse Hardware State and Instrument State Files

The pulsed-RF conguration les are supplied with the option 008 equipment. Use the

following pro cedure to load the hardware state le 8 and the instrument state all le 8 into

HP 8510 memory.

1. Load the conguration tap e/disk.

Press

4

TAPE/DISC

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

STORAGE IS TAPE/DISC

.

Load pulse

2.

Press

M

The

the

that

Load

3.

Press

4.

After

Recalling

the

If

shows

This

HP 8510 rear panel PULSE OUTPUT connector is activated. Select the wideband IF by

pressing the following keys.

5.

Press

Note

hardware

N

N

N

N

N

N

N

N

N

N

N

N

N

N

LOAD

enhancemen

HP

pulsed-RF

N

N

N

N

N

N

N

N

LOAD

loading the

wideband IF

4

SYSTEM

N

N

N

N

N

N

N

N

MORE

8510

N

N

N

N

N

N

N

N

N

N

N

N

N

N

INST.

instrumen

that

5

,

Preset

state.

N

N

N

N

N

N

N

N

NNNNNNNNNNNNNN

N

N

N

N

N

N

N

N

N

N

HARDWARE

annotation

t

op

is

instrumen

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

N

STATE

les,

t state

is selected,

wideband

the

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MORE

PULSE CONFIG

alw

NN

NN

NN

N

N

N

N

N

N

N

erating

t

N

N

N

N

N

N

N

N

N

N

N

N

N

8

press

8sets

selects

ys

a

N

N

N

N

N

N

N

N

N

N

N

N

NN

STATE

should

the

in

state in

N

N

N

N

N

N

N

N

N

N

N

N

FILE

N

N

N

N

N

N

N

N

N

N

N

N

RECALL

a

W

IF

NN

N

N

N

N

N

N

N

N

N

FILE

m

to

N

N

N

N

N

N

N

N

N

N

.

8

N

N

N

N

N

N

NN

N

N

N

INST.

correct

the

annotation will

detectors

and

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

N

NN

N

N

N

N

N

N

N

N

DETECTOR:

N

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

inst.

N

DETECTOR: WIDE BW

N

8

ear

app

ultiple

N

N

NN

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

.

at

source

state

N

N

N

N

N

N

N

N

N

N

N

N

STATE 8

instrumen

are

N

NN

N

N

N

N

N

N

N

N

N

NORMAL

the

8.

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

left

mode.

N

N

NN

N

.

state

t

ear

app

selected

N

N

N

N

N

N

N

N

N

N

N

NN

N

N

BW

side

at

.

.

for

the

and

of

the

pulse

left

that

screen.

eration.

op

side

TTL

the

of

This

the

signal

screen.

sho

ws

at

the

If these les are not a

as described in the Creating Pulse Hardw

vailable, create

the correct hardw

Operating

are state le and instrumen

are and Instrumen

8510

HP

the

t States c

Pulsed-RF

for

hapter.

Measurements

t state le

5-3

Typical Response

After

Recall,

Inst.

Figure

State

5-2.

Frequency

8,

Detector:

,

WB,

Mult.

Srce.

On

5-4

Operating

the

HP

Figure 5-3. Domain, Pulse Profile,

8510

Pulsed-RF

for

Measurements

Marker

Operator's Check

After loading the pulse instrument state and hardware state les, then recalling instrument

state 8, check operation of the pulsed-RF network analyzer (using internal triggering) by

performing the following basic tests. Refer to the menu diagrams on the last pages of this

document.

Pulse Profile Domain Check

1. Connect a short circuit to p ort 1 of the test set.

2.

Press

4

PARAMETER

NNNNNNNNNNNNNN

5

MENU

NNNNNNNNNNNNNNNNNNNNNNN

USER a1

.You are viewing the unratio ed value of the a1

reference signal.

3.

Press

4

DOMAIN

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

PULSE PROFILE

. The signal level is high when the pulse is On and low

when the pulse is O.

4. Press

5.

Press

Change

6.

oin

p

7.

Press

cycle

of

eac

Press

8.

the

9.

Press

pulse c

10.

Press

t,

long

data

h

stop

4

MARKER

4

SYSTEM

the

measuremen

the

N

N

N

N

N

N

N

N

N

N

N

N

N

N

DUTY

ercen

p

pulse

p

4

5

STOP

time to

4

SYSTEM

hanges.

N

N

N

NN

NN

NN

NN

N

N

N

PULSE

5

then move the marker to various points on the trace.

NNNNNNNNNNNNNN

5

pulse

N

N

N

N

N

N

NN

NN

CYCLE

t allo

width

t.

oin

then

,

N

5

N

N

N

N

N

N

N

N

N

N

OUT:

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MORE

PULSE CONFIG

width

t time

N

N

N

N

N

N

N

N

then c

,

y

b

wed

and

hange

c

e

hiev

ac

N

NN

NN

N

N

N

N

N

N

N

N

MORE

N

N

N

N

N

N

N

PULSE

N

N

N

N

N

N

N

NN

NN

NN

NN

N

HIGH

N

N

N

N

alue.

v

the

lo

the

NN

N

N

N

N

N

.

for eac

hange

in

ercen

p

w

the

desired

N

N

N

N

N

N

N

N

NN

CONFIG

Notice

the

ternal

Stop

N

N

N

N

N

N

N

N

N

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

PULSE WIDTH

that

h data

dut

the

measuremen

cycle

y

dut

t

Adjust

time.

displa

NN

NN

N

N

N

N

NN

NN

N

N

N

N

N

N

N

N

N

PULSE

as

poin

.

y

N

N

N

cycle

y

N

N

N

N

N

N

OUT:

.

increase the

ou

y

will

t

limit.

timing

t

increase

will

the pulse

NN

NN

N

N

N

N

N

N

N

N

N

N

N

N

LOW

increase.

This

logic.

N

N

N

N

N

N

Notice

.

pulse width

sets

measuremen

the

width,

that

the

Notice

um

n

the

maxim

that

er

b

p

past a

com

t

p

of

olarit

certain

dut

um

binations

time

ts,

oin

of

y

y

for

and

the

Operating

the

HP

8510

Pulsed-RF

for

Measurements

5-5

1.

Press

and noisy

On

a1,

that the

trace

is

pulse

the

when

at

is

t.

User1

Notice

Profile,

Pulse

ed

pulse

5-4.

measuremen

O.

is

Figure

S

11

to

view

when

the

ratio

the

er

Mark

5-6

Operating

the

HP

8510

Figure

Pulsed-RF

for

Pulse

5-5.

Measurements

Profile,

S

11

This occurs because when the pulse is O, the network analyzer is measuring the ratio of

noise to noise, and since the noise is approximately equal in the reference and test signal

paths, the result is near 0 dB with respect to the On perio d of the pulse. Also, in this

measurement, some large spikes may be seen in the noisy part of the trace. If the noise in the

reference channel instantaneously go es to a very small value, the ratio will increase to a very

large value.

Note

In the Pulse Prole domain:

Without averaging, pulse width and duty cycle settings resulting in less than

about 3 milliseconds PRP will not change the actual system PRP.

With averaging, pulse width and duty cycle settings resulting in less than

about 1 millisecond PRP will not change the actual system PRP.

Also, the PRP and duty cycle can vary during the sweep. To learn more ab out

control of these values, refer to the General Timing Information chapter.

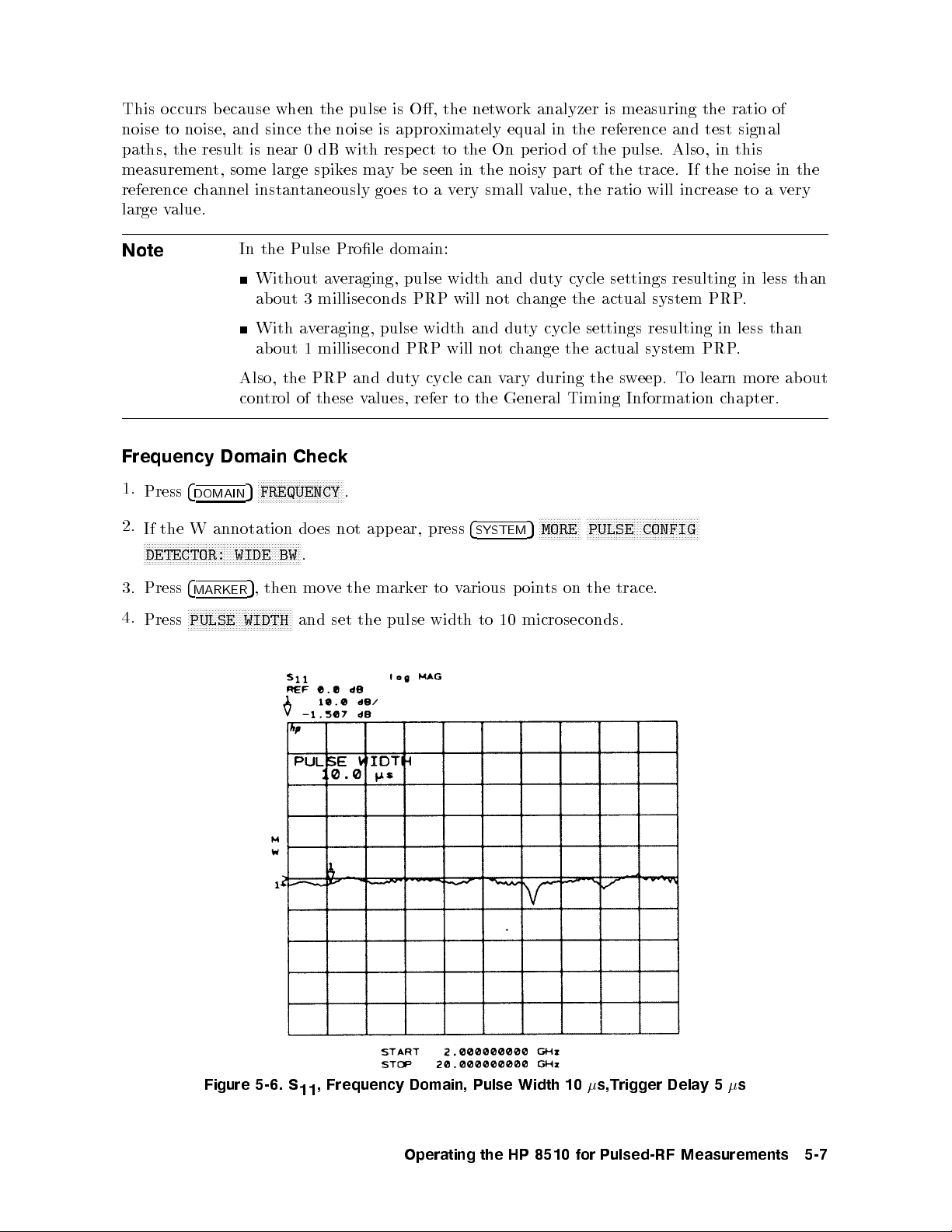

Frequency Domain Check

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

NN

NN

N

N

N

N

N

1.

Press

2.

the

If

N

N

N

N

N

N

N

N

DETECTOR:

3.

Press

4.

Press

N

N

N

N

N

N

4

DOMAIN

W

NN

N

N

N

N

N

N

N

N

4

MARKER

N

N

N

N

N

N

N

N

PULSE

N

5

FREQUENCY

annotation do

N

N

N

N

N

N

N

N

N

N

N

NN

WIDE

5

N

N

N

N

NN

N

N

N

N

N

N

N

N

WIDTH

N

N

N

N

,

N

N

N

N

NN

N

N

N

N

N

N

BW

then

N

N

N

N

N

N

N

N

N

NN

N

and

N

.

mo

es not

e

v

set the

N

N

.

the

app

mark

ear,

pulse

press

er to

width

4

SYSTEM

arious

v

to

N

N

N

N

N

N

N

N

N

5

MORE

on

ts

oin

p

microseconds.

10

N

N

N

N

N

N

N

N

N

PULSE

the

N

N

N

N

N

NN

N

N

N

N

N

N

N

trace.

N

N

N

N

N

N

N

N

N

N

N

N

NN

CONFIG

N

N

N

N

N

N

Figure

5-6.

S

11

Frequency

,

Domain,

Operating

Pulse

the

Width

HP

8510

10

for

s,Trigger

Pulsed-RF

s

5

y

Dela

Measurements

5-7

1.

Press

4

STIMULUS MENU

NNNNNNNNNNNNNN

5

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MORE

TRIGGER MODE

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

TRIGGER DELAY

.

Change the trigger delay and notice that when the trigger delay is greater than the pulse

width, the trace level decreases to the noise o or b ecause the measurement is being made

after the pulse has turned O.

s

15

y

1.

2.

Press

that as

p

data

Press

Figure 5-7.

N

4

SYSTEM

you

oin

NN

NN

NN

N

N

N

5

MORE

increase the

increase.

will

t

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

DUTY CYCLE

s,Trigger

N

N

N

N

. Change

t,

oin

p

10

the

the

measuremen

S

, Frequency

11

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

PULSE CONFIG

N

NN

NN

N

N

N

N

N

N

N

N

N

N

NN

NN

N

N

N

N

N

N

N

N

N

pulse width

Domain,

N

N

N

N

N

N

N

N

N

N

N

N

past

N

Pulse

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

N

N

N

N

N

N

N

N

N

N

N

N

PULSE WIDTH

certain

a

Width

N

N

. Change the the duty cycle limit. This changes the maximum duty

pulse

Dela

width

t

v

time

alue.

for

cycle percent allowed by the internal measurement timing logic. Notice that combinations

of long pulse width and low percentduty cycle will increase the measurement time for each

data point.

Cycle

y

Note

requency

F

the

In

Without a

Domain

requency

F

veraging, pulse

System

domain:

about 30 milliseconds PRP will not c

With a

veraging, pulse width

Dut

width and dut

y cycle settings resulting in less than

hange the actual system PRP

and duty cycle settings resulting in less than

.

about 1 millisecond PRP will not change the actual system PRP.

To learn more ab out control of these values, refer to the General Timing

hapter.

Information

c

Notice

h

eac

5-8

Operating

the

HP

8510

Pulsed-RF

for

Measurements

External Triggering Check

Connect the output of the external pulse generator to the HP 8510 rear panel TRIGGER IN

connector and to the RF source PULSE MODULATION INPUT (Figure 9-1). Set the pulse

generator to deliver a continuous TTL pulse train, going low for at least 100 nanoseconds at

any pulse repetition period less than about 1 millisecond. Activate the pulse generator pulse

output.

Press

4

STIMULUS MENU

NNNNNNNNNNNNNN

5

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MORE

TRIGGER MODE

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

TRIGGERING EXTERNAL

.

The network analyzer should sweep normally in either the frequency domain or the pulse

prole domain. The analyzer is not aected by excess trigger inputs.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

4

DOMAIN

5

PULSE PROFILE

. The trace represents the signal at the RF source Pulse

Modulation Input. The signal level is high when the pulse is On and low when the pulse is

O.

Press

4

MARKER

5

then move the marker to various points on the trace.

Adjust the time span and number of points for the desired display. Notice that the

measurement resolution period is set by the pulse width, stop time, and number of points.

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

NN

NN

N

Press

NN

NN

NN

N

N

N

N

PULSE

Press

4

DOMAIN

N

N

N

N

N

N

NN

4

MARKER

NN

N

N

N

N

N

N

N

N

N

N

N

CONFIG

N

N

N

N

N

5

FREQUENCY

N

NN

NN

NN

NN

N

N

N

N

DETECTOR:

5

then

4

press

ear,

app

not

es

p

do

oin

ts

on

the

trace.

SYSTEM

5

.

NN

NN

NN

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

NN

WIDE

the

e

v

mo

N

N

N

N

N

N

N

N

N

mark

N

N

BW

N

N

N

N

N

.

arious

v

to

er

annotation

W

the

If

NN

N

N

N

N

N

N

MORE

NN

NN

NN

the

In

desired

ma

ou

Y

high

es

go

rigger

T

of

Pulse Output

8510

frequency domain,

falling

the

after

time

y

also

to

In

monitor

indicate

and

the

that

Pulse

is not

adjust

rear

the

dulation

Mo

activ

edge

panel

HP

e

trigger

the

trigger

of

8510

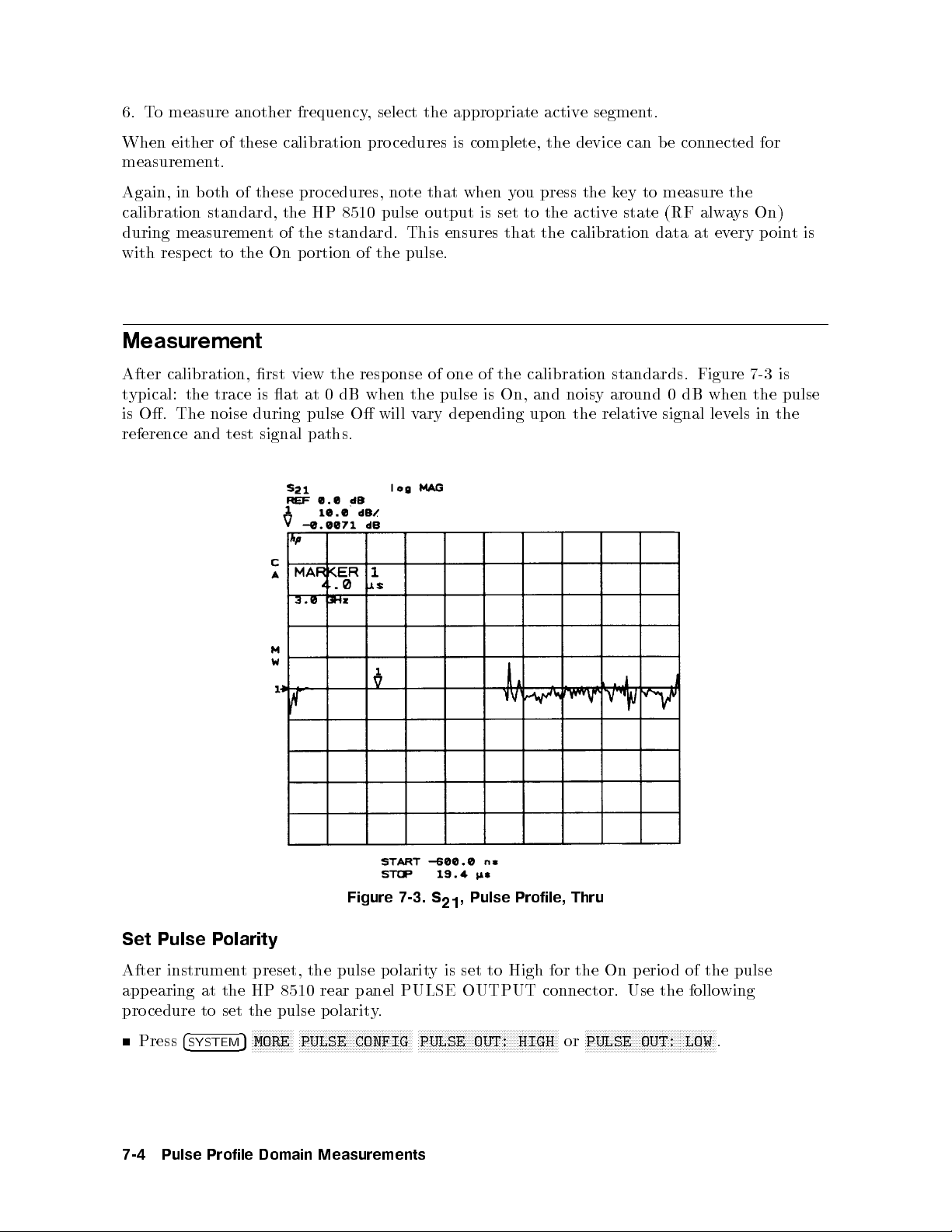

Input and

when

STOP

ready

is

external

so

y

dela

in.

SWEEP

to

notice the

triggering

that

output

mak

measuremen

the

with

measurement.

the

e

timing

selected.

is

of

an

the

tak

t

oscillosop

Change

Sw

Stop

es

e.

eep.

place

Stop

the

The

at

Sw

p

the

eep

erio

HP

d

Operating

the

HP

8510

Pulsed-RF

for

Measurements

5-9

6

Frequency Domain Point-in-Pulse Measurements

This chapter contains measurement calibration and measurement procedures to displaythe

pulsed-RF S-parameters versus frequency.

Measurement Calibration for Point-in-Pulse

Measurement calibration for point-in-pulse is accomplished in exactly the same way as for the

standard HP 8510.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

not

1. Press

displa

N

N

N

N

N

N

N

N

N

N

DETECTOR:

4

DOMAIN

ed, select

y

NN

NN

NN

NN

N

N

N

frequency

5

FREQUENCY

the wideband

N

N

N

N

N

N

N

NN

NN

NN

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

WIDE

BW

.

to

select

the

detector b

y pressing

domain.

4

SYSTEM

If

5

N

N

N

N

N

N

N

MORE

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

PULSE

NN

NN

N

N

N

N

N

annotation

W

the

N

N

N

N

N

N

N

N

N

N

NN

NN

CONFIG

is

N

N

N

N

N

2.

Select

the

appropriate

in

for

Note

pulse

8510

HP

standard.

the

indep

pulse

external

for

Note

measuremen

during

the

maxim

ternal

enden

t.

pulse for

um

measuremen

triggering,

assures

of

t

signal

the

output

This

triggering,

ust

m

ou

Y

calibration, then

calibration.

t

when

is set

that

trigger

ou

y

the

set

the

dela

trigger

of

er

b

um

n

Measurement

olarity

Pulse

Set

After instrumen

appearing

P

t preset, the pulse polarity is set to High for the

at the HP 8510 rear panel PULSE OUTPUT connector. Use the follo

procedure to set the pulse polarit y

NNNNNNNNNNNNNN

Press:

4

SYSTEM

5

MORE

NNNNNNNNNNNNNNNNNNNNN

PULSE CONFIG

oin

p

press

ou

y

the

to

calibration

.

y

trol

con

not c

.

NNNNNNNNNNNNNNNNN

k

state

e

is

pulse

to mak

for

to measure

ey

made

width

ethe

during

NNNNNNNNNNNNNNNNNNNNNNNNN

required

ts

the

activ

the

delay

hange it

NNNNNNNNNNNNNNNNNNNNN

PULSE OUT: HIGH

the measuremen

calibration

the

On)

ys

a

alw

(RF

ect

resp

with

cycle

y

dut

and

measurement

measuremen

the

On perio d of the pulse

N

NNNNNNNNNNNNNNNNNNNNN

or

PULSE OUT: LOW

t, then

during

the

to

during

at

NNNNNNNNNNNNNNNNNNNNNNN

erform

p

standard,

measuremen

ortion

p

On

calibration

correct

the

t.

wing

.

the

of

time

the

t

the

and

of

Frequency

Domain

oint-in-Pulse

P

Measurements

6-1

Set Pulse Width

After instrument preset, the pulse width is set to 10 microseconds. Use the following

procedure to set a dierent pulse width.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

PULSE WIDTH

. Use the knob, step keys, or numeric entry to set the desired pulse

width.

Set Duty Cycle Limit

After instrument preset, the duty cycle limit is set to 10%. This means that the maximum

duty cycle will never be allowed to be greater than 10 percent regardless of the pulse width.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

To set the duty cycle limit, press

DUTY CYCLE

on the Pulse Conguration menu. Use the

knob, step keys, or numeric entry to set the desired maximum duty cycle limit. Note that

the actual duty cycle may be less.

Set Trigger Delay

frequency

the

zero.

N

N

N

,

on

then

that

Time

the

use

equals

pulse

the

mo

knob,

seconds

zero

dulator.

step

k

After

domain

is when

the

Use

Press

n

or

Preset,

the

measuremen

the HP

wing

follo

4

STIMULUS

umeric

en

trigger

8510

pro

MENU

try

will tak

t

pulse

cedure

set

to

5

dela

output

NN

N

N

N

N

N

N

MORE

the

is

y

e place

set

to

N

N

N

N

NN

N

N

TRIGGER

desired

5

to

set

5 microseconds

to

es

go

trigger

the

N