Page 1

Page 2

Page 3

Safety Summary

When you notice any of the unusual conditions listed below, immediately

terminate operation and disconnect the power cable.

Contact your local Agilent Technologies sales representative or

authorized service company for repair of the instrument. If you continue

to operate without repairing the instrument, there is a potential fire or

shock hazard for the operator.

n Instrument operates abnormally.

n Instrument emits abnormal noise, smell, smoke or a spark-like light

during the operation.

n Instrument generates high temperature or electrical shock during

operation.

n Power cable, plug, or receptacle on instrument is damaged.

n Foreign substance or liquid has fallen into the instrument.

Page 4

Page 5

Page 6

Page 7

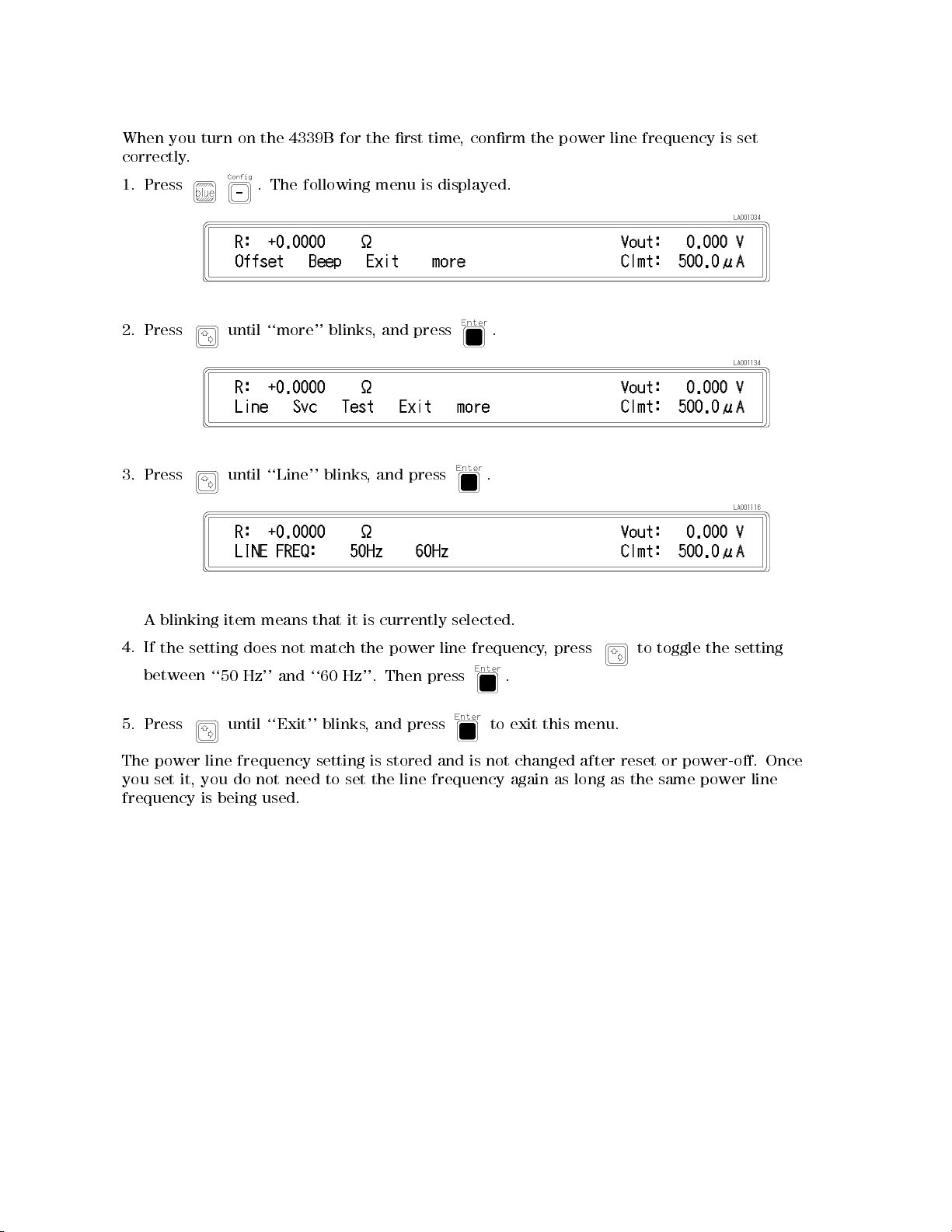

When

you

correctly

.

turn

on

the 4339B

for the

rst time

, conrm

the power

line frequency

is set

1. Press

2.

Press

3.

Press

A

blinking

until

until

item

. The

following menu

``more''

``Line''

means

blinks

blinks

that

,

,

it

is

is displayed.

and

press

and press

currently

.

.

selected.

4.

If

the

setting

between

5.

Press

The power

you set

it, you

frequency is

does

``50

Hz''

until

line

frequency

do

not

being used.

not

and

``Exit''

need

match

``60

blinks,

setting

to

the

Hz''.

set

power

Then

and press

is

stored

the

line

line

frequency

press

and

is

frequency

.

to

not

,

exit

this menu.

changed

again

press

as

long

after

reset

as

to

the

toggle

or

power-o.

same

the

power

setting

Once

line

Page 8

Page 9

Agilent

4339B High

Resistance

Operation Manual

Meter

This

number

F

manual

or

additional

numbers

applies

prex

,

read

SERIAL

directly

JP1KD

,

important

\Serial

NUMBERS

to

instruments

or

rmware

information

Number"

revision

about

in

Appendix

with

serial

serial

1.04.

A.

Agilent Part No. 04339-90060

Printed in Japan March 2003

Ninth Edition

Page 10

Notice

The

information

This

document

reserved.

language

contains

No

part

without

contained

proprietary

of

this

the

prior

in

this

document

written

document

information

may

be

consent

is

subject

that

is

photocopied,

of

the

Agilent T

to

change

protected

reproduced,

echnologies.

without

by

copyright.

or

notice

.

All

translated

rights

are

to another

Agilent

T

echnologies

Component

1-3-2,

Murotani,

Hyogo

,

651-2241

T

est

Japan,

PGU-Kobe

Nishi-ku,

Japan

Ltd.

Kobe-shi,

c

1996, 1998, 1999, 2000, 2001, 2002, 2003 Agilent Technologies Japan, Ltd.

Page 11

4339B

Manual Printing

March

December

June

A

July

March

January

September

March

ugust

1999

1996

1998

1998

2000

2003

1996

:

:

2001

2002

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

:

:

:

:

:

::

::

:

:

:

:

:

::

:

:

:

:

:

:

:

::

::

::

History

::

::

::

::

::

::

::

::

::

::

::

::

::

::

::

::

::

::

::

:

:

::

::

:

:

:

:

::

::

::

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

First

Edition (part

::

::

::

:

:

:

:

:

:

:

:

:

:

:

::

::

::

Second Edition

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

::

::

:

Third

Edition

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

:

F

ourth

Edition

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

:

Fifth

Edition

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

Sixth

Edition

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

:

Seventh

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

Eighth Edition

:

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

Ninth

Edition

Edition

number: 04339-90010)

(part number:

(part

number:

(part

number:

(part

number:

(part

number:

(part

number:

(part

number:

(part

number:

04339-90020)

04339-90030)

04339-90040)

04339-90050)

04339-90050)

04339-90050)

04339-90050)

04339-90060)

iii

Page 12

Safety Summary

The

following

service

W

ARNINGS

In

addition

,

and

elsewhere

it

general

repair

violates

safety

of this

in

safety standards

instrument.

The

A

gilent

requirements

T

echnologies assumes

.

precautions must

instrument. F

this manual

no liability

be observed

ailure to

may impair

of design,

for the

during all

comply with

the protection

manufacture,

customer's failure

phases of

these precautions

provided by

and intended

the equipment.

use of

to

comply

operation,

or with

the

with

4339B

specic

these

Note

4339B

61010-1

4339B

Note

LEDs

CLASS

Ground

T

o

avoid

safety

DO

Do

not

electrical

Keep

earth

NOT

operate

A

way

The

Instrument

electric

shock

ground

Operate

the

instrument

From

Operating personnel

adjustments

with

the

with

the

circuits

power

power

before

must

cable

cable

touching

be

is

designed

and

is

an

INDOOR

in

4339B

1

LED

hazard,

by

the

supplied

In

An

instrument

in

such

Live

must

not

made

by

connected.

removed.

them.

for

use

POLLUTION

USE

are

Class

PRODUCT

the

instrument

power

Explosive

in

the

presence

an

environment

Circuits

remove

instrument

qualied

Under

T

o

avoid

in

INST

ALLA

DEGREE

product.

1

in

accordance

chassis

cable

with

Atmosphere

of

ammable

constitutes

covers

maintenance

certain

injuries

conditions

,

always

TION

1

according

with

and

earth

a

.

Component

personnel.

,

disconnect

CA

TEGORY

to

IEC60825-1.

cabinet

blade

.

gasses

denite

Do

dangerous

II

IEC

61010-1

must

be

or

fumes

safety

replacement

not

replace

voltages

power

according

and

connected

.

Operation

hazard.

components

may

and

discharge

IEC

and

exist

to

IEC

60664-1.

to

a

of

internal

even

any

DO

NOT

Service

Or

A

djust

Alone

Do not attempt internal service or adjustment unless another person, capable of rendering rst

aid and resuscitation, is present.

DO NOT Substitute P

Because of the danger of introducing additional hazards

arts Or Modify Instrument

, do not install substitute parts or

perform unauthorized modications to the instrument. Return the instrument to a Agilent

T

echnologies Sales and Service Oce for service and repair to ensure that safety features are

maintained.

iv

Page 13

4339B

Dangerous

W

arnings

this

W

arning

,

manual.

Procedure

such

as

the

example

Instructions

contained

Dangerous voltages

instrument. Use

this instrument.

W

arnings

below

in

, capable

extreme caution

,

precede

the

warnings must

potentially dangerous

be followed.

of

causing

death,

when handling,

procedures throughout

are

present

testing,

in

and

this

adjusting

v

Page 14

Certication

4339B

Agilent

of

T

echnologies

shipment

measurements

T

echnology

facilities

W

arranty

This

of

Agilent

,

to

other

workmanship

certain

specied

repair

F

or

Agilent

T

echnologies

pay

another

Agilent

T

echnologies

property

of

components

or

warranty

Technologies

all

shipping

country

T

echnologies

the

instrument,

period.

replace

installed

certies

from

the

are

traceable

the extent

International

T

echnologies

for

a

period

listed

During

products

service

.Buyer

shall

pay

charges

.

warrants

for

use

with

on

or

factory.

to

allowed by

instrument

of

in

General

the warranty

that

or

repair

shall

shipping

,

duties

an

instrument

that

instrument.

software

that this

Agilent T

the United

product met

echnologies further

States National

the Institution's

Standards Organization

one

year

product

from the

is

warranted against

date of

Information

period, Agilent

prove to

,

this

prepay

charges

,

and

that

,

or

be defective

product

shipping

to

taxes

its

software

will

Agilent

rmware

must

return

for

products

execute

T

will

and

echnologies

be

its published

certies that

Institute of

calibration facility

members.

shipment, except

of

this manual,

Technologies

.

be returned

charges

the

to

product

Agilent

returned

rmware

its

programming

does

uninterrupted

specications at

its calibration

Standards and

,or

defects in

the

warranty

will,

at

to

a

service

T

echnologies

to

Buyer

.

However

to

Agilent

designated

instruction

not

warrant

or

error

to the

material and

that

in

its

option,

facility

T

echnologies

by

Agilent

that

free.

the time

calibration

the

case

of

shall

be

for

either

designated

and

Agilent

,

Buyer

shall

from

when

the operation

the

by

Limitation

The

foregoing

maintenance

misuse

,

preparation

No

other

implied

by

operation

or

warranty

warranties

Of

W

arranty

warranty

Buyer

shall

,

Buyer-supplied

outside

maintenance

is

expressed

of

merchantability

not

apply

the

environmental

.

or

to

defects

software

implied.

and

resulting

or

interfacing,

specications

A

gilent

tness

T

echnologies

for a

from

improper

or

unauthorized

for

the

product,

specically

particular purpose

inadequate

modication

or

improper

disclaims

.

or

site

the

vi

Page 15

4339B

Exclusive Remedies

The

remedies

shall

not

whether

be

liable

based

provided

for any

on

contract,

herein

direct, indirect,

Assistance

are buyer's

tort, or

sole and

special, incidental,

any other

exclusive remedies

legal theory

or consequential

.

.A

gilent T

echnologies

damages,

Product

Agilent

F

or

any

A

ddresses

maintenance

T

echnologies

assistance

are

,

provided

agreements

products

contact

at

and

.

your

nearest Agilent

the

back

other

of this

customer

Technologies

manual.

assistance

Sales and

agreements

Service

are

available for

Oce

.

vii

Page 16

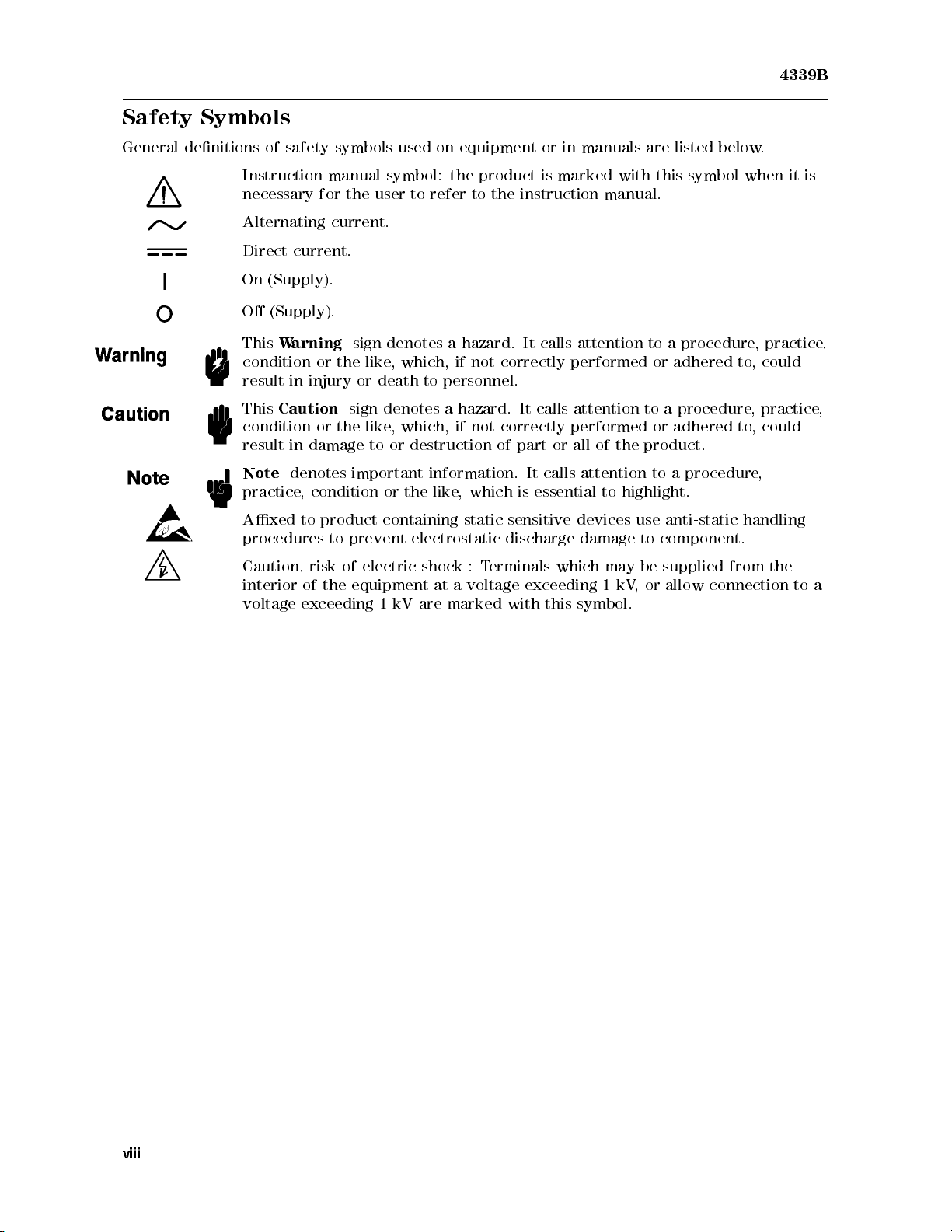

Safety Symbols

4339B

General

denitions

Instruction

necessary

Alternating

Direct

On

O

This

condition

result

This

condition

result

Note

practice

Axed

procedures

Caution,

interior

voltage

of

safety

symbols used

manual

for

the

current.

current.

(Supply).

(Supply).

W

arning

in

Caution

in

or

the

injury

sign

or

the

damage

sign

or

denotes important

, condition

to

product

to

prevent

risk

of

of

the

equipment

exceeding

symbol:

user

denotes

like

,

which,

death

denotes

like

,which,

to

or

or the

containing

electric

1

kV

on equipment

the

product is

to refer

to the

a

hazard. It

if not

to

personnel.

a

hazard.

if not

destruction

information.

like

,

which

static

electrostatic

shock

:

T

at

a

voltage

are

marked

or in

manuals are

marked with

instruction manual.

calls attention

correctly performed

It calls

correctly

of

part

It

is

sensitive

discharge

erminals

exceeding

with

attention to

performed

or

all of

calls

attention

essential

devices

damage

which

this

symbol.

to

may

1

this symbol

to a

or adhered

a procedure

or

the

product.

to

highlight.

use

anti-static

to

component.

be

supplied

kV

,

or

allow

listed below

when it

procedure

to

adhered

a

procedure

to

handling

from

connection

.

is

,

practice

,

could

, practice

,

could

,

the

to

,

,

a

viii

Page 17

4339B

Herstellerbescheinigung

GERSCHEMISSION

LpA

<

70

dB

am

Arbeitsplatz

normaler

nach

DIN

Betrieb

45635

T

.19

Manufacturer's Declaration

A

COUSTIC

LpA

<

NOISE

70 dB

EMISSION

operator position

normal

per

operation

ISO

7779

ix

Page 18

4339B

Contents of

Chapter

Provides

4339B

Chapter

Shows

learn

Chapter

Describes

the

functions

Chapter

Shows how

the

should

how

about

1

product overview

read

2

to

operate

operations

3

all

functions

of

4

to remotely

the procedures

Chapter

5

this Manual

this

chapter

the

4339B

using

of this

the front

and rear

operate

for remotely

operating the

and basic

measurement procedure

rst.

from

its

front

the

front

panel

instrument. Refer

panel keys

the

4339B

.

4339B

panel.

keys

and

Refer

.

to this

terminals

to

this

via

the

Refer

chapter

chapter

GPIB

to

. First

this

when

time users

chapter

you

when

wish

to

of the

you

learn

wish

about

to

.

when

you

wish

to

learn

about

.

Contains

chapter

system,

Chapter

Provides

Chapter

Provides

complete information

when

you

wish

to

learn

and

data

transmission

6

a

measurement example

7

information for

eective operations

on

remotely

about

format.

using the

the

Chapter 8

Provides

specications

,

reference

data,

and

Chapter 9

Describes how to verify the specications

operating

GPIB

4339B

.

other

.

the

commands

.

general

4339B

,

status

via

the

reporting

information.

GPIB

.

mechanism,

Refer

to

this

trigger

x

Page 19

4339B

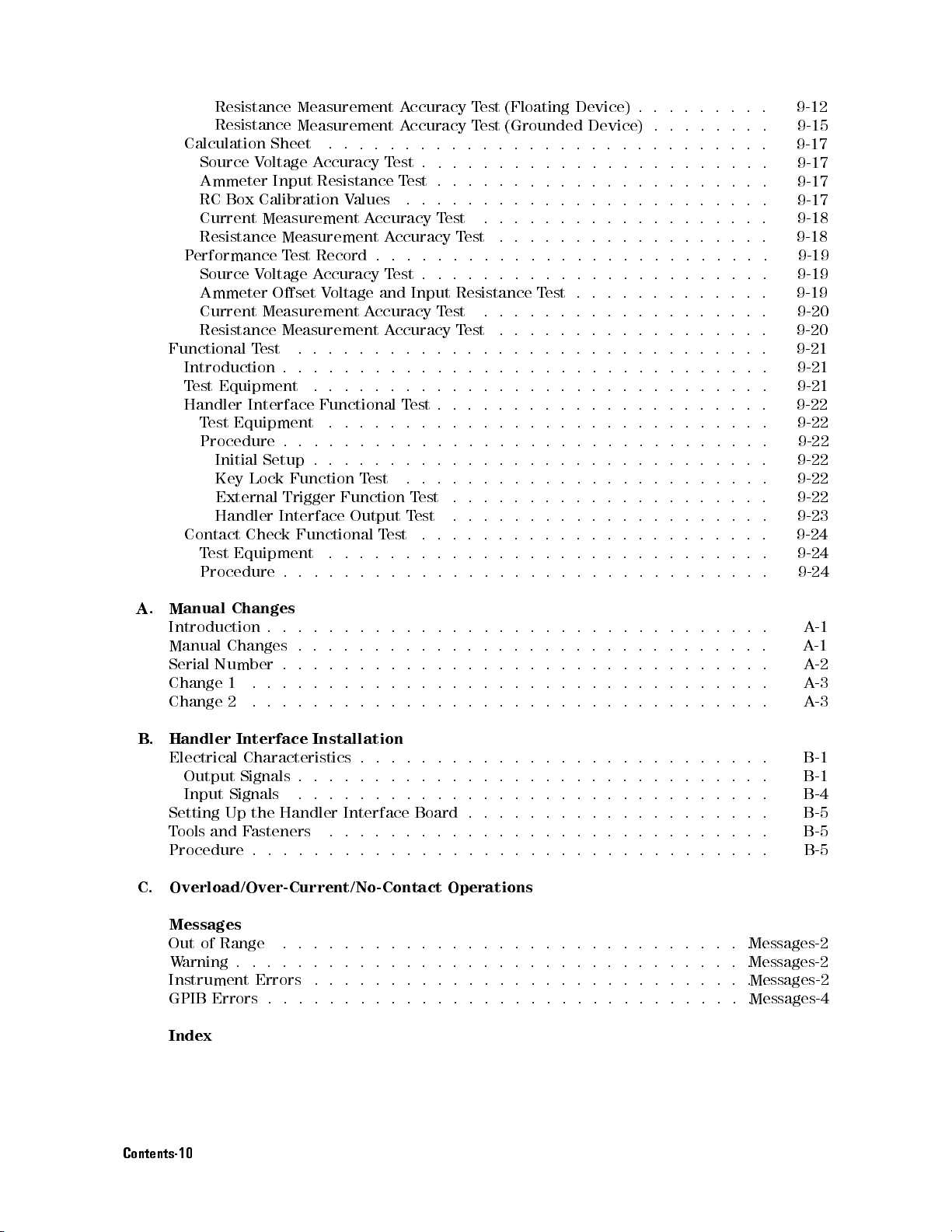

Appendix

Contains

information

printed.

Appendix

Contains

handler

information which

interface,

Appendix

The

summary

current

limit),

A

B

C

of

operations

or

N.C.

on

using

read this

(No-Contact).

the

4339B

is required

appendix

when

the

s

for

and

4339B

which

using

set

the

detects

were

manufactured

the

handler

handler

O

VLD

interface

interface

(Overload),

before this

.

Before

input/output

Over-Current

manual was

using

the

signal.

(exceeding

xi

Page 20

Page 21

Contents

1.

Getting

Introduction

Overview

F

A

Front

Display

Rear

Initial

Providing

Instruction for

P

ower

Preparation

P

Started

eatures

ccessories

P

P

anel

Inspection

Cable

ower

Fuse

.

.

.

.

.

.

.

.

.

.

.

.

.

A

vailable

anel

.

.

.

.

.

.

.

.

.

.

.

.

.

clearance

.

for

Requirements

.

to

Cleaning .

.

.

.

Use

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

dissipate

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

heat

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

at

installation

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

.

.

.

.

..

..

.

.

.

.

..

.

.

.

.

.

.

..

..

..

.

.

.

..

..

..

.

..

.

.

..

..

.

.

.

.

..

..

..

.

.

..

.

.

..

site

.

.

.

.

..

.

..

.

.

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

..

..

.

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

.

.

.

1-1

.

1-2

.

1-2

.

1-3

.

1-4

.

1-6

.

1-7

.

1-8

.

1-8

.

1-9

.

1-10

.

1-12

.

1-12

. 1-12

Turning

P

ower-On

Using

Front

Direct

T

Selection

V

Basic

Floating DUT Measurement . . . . . . . . . .

Grounded DUT Measurement . . . . . . . . . .

Resetting 4339B . . . . . . . . . . . . . . . . . . . . .

Performing Calibration . . . . . . . . . . . . . . . . . . . . .

Setting T

Selecting Measurement P

Selecting Measurement Range ........................ 1-23

Auto Range mode ...... ...... ...... ...... ..... 1-23

Hold Range mode ............................. 1-23

Execution

oggle

Type

alue

Setup

V

alue Setup

V

alue Setup

V

alue Setup

V

alue Change

Operation .

Connecting

est Voltage ....................

Performing OPEN Correction

Changing the Range in Hold Range mode ................. 1-23

ON

the

Self

T

est

P

anel

Keys

Type

Keys

Type

Keys

Type

Keys

Using Numeric

Using Maximum

Using Down

Using Back

..

T

est

4339B

.

Keys

.

.

.

..

Fixture

arameter ...... ..... ...

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

and Up

Space Key

..

..

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

Keys .

and Minimum

.

.

.

.

.

.

.

.

.

.

Keys

.

.

.

Arrow

.

.

.

.

...... ...... ...... ....

Keys

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

...... ...... ...

..............

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

...... ....

...... .

.........

........

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 1-16

.

.

.

.

.

.

. 1-18

.

.

1-13

1-14

1-15

1-15

1-15

1-15

1-16

1-17

1-17

1-17

1-19

1-19

1-19

1-20

1-20

1-21

1-22

1-23

Applying Test Voltage........ ...... ...... ...... 1-24

Contents-1

Page 22

2.

Operating

Introduction

Measurement

Selecting

Setting

Setting

Setting

Making

Triggering

Using

Displaying

Using

Turning

the

the

the

the

Entering

Setting

a

Measurement

the

Setting

Selecting

the

Selecting

Setting

Setting

OFF

T

est

V

oltage

4339B

.

.

.

.

.

.

.

Conguration

the

Measurement

A

veraging

Trigger

P

arameters

Thickness

the

Electrode

a

Measurement

Comparator

Deviation

the

Reference

the

Measurement

the Measurement

the Measurement

Time

Display

Rate

Delay

for

of

.

Function

Data

Deviation

Function

the

Size

.

Value

Sequence

.

.

.

.

.

..

..

..

.

.

.

..

Time

Mode

.

.

.

.

..

Time

Display

.

.

.

Resistivity

DUT

..

.

..

..

..

..

..

.

.

.

.

..

.

.

.

.

.

.

.

..

..

..

Mode

Function

Sequence Mode

Sequence Mode

.

.

.

.

..

..

..

..

..

..

..

..

.

.

.

.

..

..

..

..

.

..

..

..

Measurement

..

..

..

..

..

.

..

.

.

.

.

..

..

.

..

..

..

..

..

.

.

.

.

.

.

..

..

.

.

.

.

.

.

P

arameters

.

.

.

.

.

.

..

..

..

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

.

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 2-5

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1-24

2-1

2-2

2-2

2-2

2-2

2-3

2-3

2-3

2-5

2-5

2-7

2-7

2-8

2-9

2-9

2-9

2-10

Starting

Aborting

Setting

Setting

Setting

Setting

Setting

Changing

Saving

Locking

Selecting

Setting

Printing

Setting

T

esting

Performing a Self-T

Testing the Front P

If Y

If the Display is Blank and the 4339B Appears

If an Error Message is Displayed

If the 4339B does not A

If the Indicated V

If Y

Contact

Reading

Reading

Current

Current

Beeper

Display

and Recalling

Out the

Local Mode

the

Measurement

the

the

4339B

ou Have a Problem . .

ou Find Y

Measurement

Measurement

Check

the

Limit

Data of

the

Capacitance

Limit

Monitor

Mode

Measurement

GPIB

Oset-Error

ourself Lost When Operating the 4339B . . . . . . . . . .

.

Mode

and

Instrument

Front

P

.

A

ddress

Data

.

.

.

est ..................

anel Key's Functionality

ccept Any Key Input

alue is not Stable

Sequence

Sequence

.

.

.

Contact

Data

.

.

..

.

.

.

..

Display

Settings

anel

Keys

.

.

.

.

.

.

.

Canceling

.

.

.

.........................

.

.

at DUT

.

..

..

Display

Settings

.

.

.

.

.

.

..

.

.

.

.

.

Check

.

.

.

.

.

.

.

.

.

F

ormat

.

.

.

.

.

.

.

.

.

.

.

Function

.

.

...

...

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Function

Measurement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Mode

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

...... ..... ....

Dead.............

...................

................

...... ...... ......

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

..

..

..

.

.

.

.

..

..

.

.

.

..

..

..

.

..

.

.

.

.........

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

..

.

.

.

.

.

..

.

.

...

.

.

.

.

.

.

..

.

.

.

..

.

..

.

2-11

.

2-11

.

2-12

.

2-13

.

2-13

.

2-14

.

2-14

. 2-14

. 2-16

.

2-17

. 2-18

2-18

.

2-18

.

2-19

.

2-19

2-19

.

2-20

2-20

2-21

. 2-22

2-22

2-22

2-22

2-22

2-22

Contents-2

Page 23

3.

Function Reference

Introduction

Front

Panel

Display

LINE

Switch .

Interlock

..

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

Connector .

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

.

3-1

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

.

.

.

3-2

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

.

.

3-2

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

.

3-3

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

3-3

UNKNOWN

High

V

oltage

V

Output

V Output

Source V

Current Limit

Measurement Time

A

verage

Measurement

Single

Continuous

Program

Time

Measurement

Electrode

Show

Current

oltage key

key

Mode

Display

Setting

Monitor

Key

Indicator .

Key

Sequence

..

mode

Key

Function

P

arameter

Size

Key

Key

Key

T

erminals

Indicator

..

key

Mode Key

..

..

.

.

.

.

..

.

..

.

.

Key

.

.

.

.

.

..

.

.

..

..

.

.

..

..

.

.

.

.

.

.

.

.

.

.

..

.

.

..

..

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

..

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

. 3-5

.

.

.

. 3-5

.

.

.

.

..

.

. 3-6

.

.

.

.

.

.

.

.

.

.

.

3-4

3-4

3-4

3-5

3-5

3-5

3-6

3-6

3-7

3-8

3-8

3-8

3-10

3-10

A

uto/Hold

Range

Sequence

Local

Address

Trigger Mode Key ...... ..... .

Delay Key .............

Recall Key

Save Key .........................

Comparator

Left/Down and Right/Up Arrow Keys ............... 3-13

0, . . . , 9, .(point),0(minus) Keys ... ...... ... 3-13

Shift Key ......... ..... ...... ...... .... 3-13

Exponential Key ........................... 3-13

Range

Setup

Trigger

Abort

Key

Key

Key

Key

.

.

..

Key

Key

.

...... ...... ...... ......

Limit Keys .

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

.

.

..

.... ...... ...... ...... ..

..............

..............

....................

.

.

..

..

..

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

..

......

...

.

.

.

.

.

.

.

.

. 3-11

3-10

3-10

3-11

3-11

3-11

3-12

3-12

3-12

3-12

3-12

Contents-3

Page 24

Back

Space Key

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

. 3-13

Enter

Key

Minimum

Maximum

Open

Key

Calibration

Comparator

Contact

Display

Key

Lock

Reset

Key

Conguration

Rear

P

anel

External

LINE

Fuse

LINE

V

oltage

P

ower

Cord

P

ower

Serial

Number

Handler

Specications

GPIB

Interface

Theory

of

Overall

Overall

Grounded

.

..

Key .

Key

Key

On/O

Check

Mode

Key

.

.

Trigger

Holder

Receptacle

Cord

Interface

Operation

Measurement

Block

and

Key

Key

Key

Key

.

.

..

.

.

.

Selector

.

.

.

Plate

.

.

.

.

.

.

Diagram

Ungrounded

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Theory

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

DUT

Measurement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

..

.

.

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

..

.

.

..

.

.

.

..

.

.

.

.

.

.

.

Conguration

..

.

.

..

..

..

.

.

.

..

..

..

.

.

.

.

.

.

.

.

..

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

.

..

..

..

.

.

.

.

.

.

.

.

.

.

..

..

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3-13

3-13

3-13

3-14

3-14

3-14

3-15

3-16

3-16

3-17

3-18

3-20

3-20

3-21

3-21

3-21

3-21

3-21

3-22

3-22

3-25

3-26

3-26

3-27

3-28

4.

Remote

Introduction .

Getting Started

Contents-4

Operation

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

Input/Output Statements

Reading the

Sending a

Returning

Query Commands

Getting Data from the

To Control the 4339B

To Set Up the 4339B

To Reset the 4339B

To Set the P

To Select the Measurement P

To Set the T

ToSettheCurrentLimit ....... ...... ..... ...... . 4-6

To Select Measurement Time Mode .. ...... ...... ...... 4-6

ToPerform Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

ToPerform OPEN Correction . . . . . . . . . . . . . . . . . . . . . . . 4-7

To Select the Measurement Range . . . . . . . . . . . . . . . . . . . . . 4-7

GPIB A

Remote Command

to

Local Mode

ower LINE Frequency

est V

oltage . . . . . . . . . .

To Apply the Test Voltage . . . . . . . . . . . . . . . . . . . . . . 4-6

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ddress .

.

.........................

4339B . . . . . . . . . . . . . . . . . . . . . . . .

from an External Computer

...... ...... ...... ...... .

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..............

.........................

...... ..

arameter . . . . . . . . . .

................

............

.........

.

..

..

..

.

..

...

...

. 4-2

. 4-2

. 4-2

.

. 4-5

4-1

4-2

4-2

4-3

4-3

4-4

4-5

4-5

4-5

4-5

Page 25

T

o Set

T

o Set

T

o Set

T

o Set

T

o Lock

T

o Check

T

o

Use

T

o

Display

T

o

Set

T

o

T

o

Get

T

o

Save

T

o

Trigger

W

aiting

Sample

Reading

Reading

Reading

Data

T

o

Retrieve

T

o

Use

Other

F

T

o

T

est

T

o

Read

T

o

Report

the A

Trigger

the

Beeper

Out

Contact

the

Comparator

a

the

Oset-Error

W

ait

Until

the

Current

and

a

Measurement

F

or

Completion

program

Out

Measured

out

out

Retrieval

Data

Data

T

o

P

erform

eatures

the

4339B

the

the

veraging

Delay

P

arameters

Mode

the

Front

Integrity

Deviation

Previously

Instrument

Recall

measured

measured

Buer

Error

Instrument

.

.

Result

.

.

.

Eciently

.

a

Measurement

.

.

.

.

Queue

Instrument's

Rate

Time

Function

Measurement

Canceling

Of

.

result

result

.

.

.

.

.

.

for

Resistivity

.

.

.

.

P

anel

Keys

at

Sent

Settings

Settings

.

.

.

Measurement

.

.

.

.

.

.

using

using

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

Status

.

.

.

.

.

.

.

.

.

.

Measurements

.

.

.

.

.

.

.

the

T

est

Fixture

.

.

.

.

.

.

Function

Commands

.

.

.

.

..

..

(detecting

.

.

.

..

.

.

.

.

.

*TRG

:FETC?

.

.

.

.

.

.

.

.

.

.

..

..

.

Sequence

.

.

..

..

.

..

..

.

.

.

.

.

.

..

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

are

Completed

.

.

.

.

.

.

..

..

..

..

.

..

command

command

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

..

..

..

..

.

.

..

..

..

..

..

.

.

.

.

..

.

..

..

.

.

..

.

.

.

.

.

.

..

..

..

..

.

.

.

completion

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

..

..

..

..

..

..

..

..

..

..

..

..

..

.

.

.

.

..

..

..

.

.

.

.

.

.

of

measurement)

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

.

..

..

..

..

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

..

..

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 4-8

.

.

.

. 4-8

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4-7

4-7

4-8

4-8

4-9

4-9

4-9

4-9

4-10

4-10

4-11

4-12

4-13

4-14

4-15

4-19

4-23

4-24

4-24

4-25

4-26

4-26

4-26

4-26

Sample

If Y

ou

Have

If

the

5.

GPIB

Reference

Introduction

GPIB

Commands

Common

Subsystem

Sybsystem

Program

Command

Case ....................

Program Message T

Common Command Syntax . . . . . . . . . . . . . . . . . . . .

Subsystem Command Syntax . . . . . . . . . . . . . . . . . . . . .

Parameters .... ...... ...... ......

Parameter Types . . . . . .

Multiple Messages

Query and Response Message Syntax

Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Notations ................................. 5-6

ABORt Command .............................. 5-7

:ABORt .................................. 5-7

ARMSubsystem ....... ...... ..... ...... ...... . 5-8

:ARM[:SEQuence1][:LAYer]:DELay<numeric value>[MSjS] ......... 5-9

:ARM[:SEQuence1][:LAYer]:SOURcefBUSjEXTernaljMANualjIMMediateg... 5-9

Program

a

Problem

4339B

Hangs

.

.

Commands

Commands

Command

Message

Abbreviations

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Up

When

Y

ou

Send

the

ABORt

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

..

..

Tree

Syntax

erminator .... ..... ...... ...

........

.

.

.

.

.

.

..

.

.

.

.

..

..

..

.

.

.

.

..

.

.

.

...... ...... ...... .....

.....................

......

Command

..

..

..

.

.

..

..

..

..

.

.

.

.

.

..

..

.

.

..

..

..

.

..

..

..

.

.

.

.

.

.

.

...... ...... ...

...... ...... ..

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

......

.....

...

..........

.

4-28

.

4-30

4-30

.

5-1

.

5-1

.

5-1

.

5-1

.

5-1

.

5-2

.

5-2

5-3

5-3

5-3

5-3

5-3

5-3

5-4

5-5

Contents-5

Page 26

CALCulate

:CALCulate1:FORMat

:CALCulate1:LIMit:BEEP

:CALCulate1:LIMit:BEEP

:CALCulate1:LIMit:CLEar

:CALCulate1:LIMit:F

:CALCulate1:LIMit:LOW

:CALCulate1:LIMit:LOW

:CALCulate1:LIMit:ST

:CALCulate1:LIMit:UPP

:CALCulate1:LIMit:UPP

:CALCulate1:MA

:CALCulate1:MA

:CALCulate1:MA

:CALCulate1:P

:CALCulate1:RESistivity:EARea

:CALCulate1:RESistivity:EPERimeter

:CALCulate1:RESistivity:GLENgth

:CALCulate1:RESistivity:STHickness

:CALCulate2:MA

:CALCulate3:FORMat

:CALCulate3:MA

:CALCulate3:DIRECtion

:CALCulate3:BEEP

CALibration

:CALibration[:ALL]?

:CALibration:A

D

A

T

A

:D

A

:D

A

:D

AT

:D

AT

:D

AT

:D

A

:D

A

DISPlay

:DISPlay[:WINDow][:ST

:DISPlay[:WINDow]:TEXT1:DIGit

:DISPlay[:WINDow]:TEXT1:P

:DISPlay[:WINDow]:TEXT1:PREFix

:DISPlay[:WINDow]:TEXT2:PAGEf1j2j3

FETCh? Query

:FETCh? ...........

FORMat Subsystem

:FORMat[:DATA]fASCiijREAL[,64]

INITiate Subsystem .....................

:INITiate[:IMMediate] .......... ...... ...... .

:INITiate:CONTinuousfONjOFFj1j0g...............

Subsystem .

TH:EXPRession:CA

TH:EXPRession:NAME

TH:ST

A

TH?

TH:ST

TH:ST

Subsystem

UTO

Subsystem

T

A[:D

A

T

A[:D

A

A[:D

A

A[:D

A

A:FEED

T

A:FEED:CONTrol

T

A:POINts

Subsystem

.

.

T

A]

REF

T

A]?

DBUF

T

A]?

IMON

T

A]?

TMON

DBUF

DBUF

.

..... ....

..

.

.

.

.

.

.

f

REAL

AIL? .

er[:D

er:ST

A

T

er[:D

er:ST

A

T

.

.

A

T

f

SEC

A

T

er

f

ON

.

.

.

f

ON

.

.

.

,

<

numeric

.

.

.

,

<

data

DBUF

,

<

numeric

.

.

.

A

...........

j

SRESistivity

er:CONDition

er[:STA

e

e

e

e

f

j

OFF

T

..

.

A

A

f

ON

A

A

f

ON

.

.

f

ON

j

TPCNT

f

ON

UP

j

DOWN

j

OFF

..

.

.

j

.

.

.

.

.

.

.

.

handle

,

f

.

.

e]

f

ON

A

T

e]

.

.

.

.

.

T

A]

<

T

e

f

j

OFF

T

A]

<

T

e

f

ON

j

OFF

.

.

.

<

numeric

j

OFF

j

OFF

j

1

j

0

g

..

.

..

.

1

j

0

g

.

.

.

.

value

.

.

.

.

.

.

.

.

.

>

AL

W

value

.

.

.

j

OFF

f

GE

f

...... ...... ...... ....

......................

f

f

ON

.

.

.

.

numeric

ON

j

j

1

numeric

j

T

alog?

j

.

.

<

<

numeric

<

numeric

j

1

j

0

g

.

.

j

1

j

0

g

.

.

.

.

.

.

.

.

.

.

.

>

.

.

.

.

.

.

.

.

.

ays

>

.

.

j

1

j

3

j

4

j

5

1

j

2

g

f

ON

g

.

.

.

.

.

.

.

..

..

..

..

j

VRESistivity

P

ASS

j

F

AIL

j

OFF

j

1

j

0

.

.

.

.

.

.

.

.

.

.

.

..

value

>

OFF

j

1

j

0

g

j

0

g

.

..

value

>

OFF

j

1

j

0

g

.

.

.

.

.

f

DEV

j

PCNT

1

j

0

g

..

..

..

..

..

value

>

.

.

.

.

.

.

.

.

.

value

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

er

.

.

.

..

.

.

.

.

..

j

1

j

0

value

value

.

.

.

.

.

.

.

.

.

.

.

.

g

.

..

.

..

g

>

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

.

.

numeric

g

.

.

..

g

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

j

NEV

.

.

0

g

g

..

j

OFF

j

4j5j6g...... ...... ....

...... ...... ......

.............

g

g

.

..

..

..

.

g

.

.

>

>

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

..

.

.

.

..

..

..

.

.

..

..

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

.

..

.

.

..

.

.

..

..

.

.

..

.

.

g

.

.

.

.

.

.

.

..

..

..

..

..

..

..

..

..

..

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

..

..

..

..

..

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

..

..

.

.

.

.

.

.

.

.

..

......

...... ..

..

.

.

..

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

..

.

.

.

.

.

....

...

.

..

..

..

..

.

.

.

.

.

.

..

.

.

.

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5-10

. 5-11

. 5-11

5-11

5-11

5-12

.

5-12

.

5-12

.

5-12

.

5-12

.

5-12

.

5-13

5-13

.

5-13

.

5-13

. 5-13

. 5-13

5-14

.

5-14

.

5-14

.

5-14

.

5-14

.

5-14

5-15

. 5-16

.

5-16

.

5-16

.

5-17

.

5-17

.

5-17

.

5-18

.

5-18

.

5-18

.

5-18

. 5-18

.

5-19

.

5-19

.

5-19

.

5-19

.

5-19

5-20

5-21

5-21

5-22

5-22

5-23

5-23

5-23

SENSe Subsystem .............................. 5-25

Contents-6

OUTPutSubsystem........................... 5-24

:OUTPut[:STATe]fONjOFFj1j0g...... ...... ...... .. 5-24

[:SENSe]:AVERage:COUNt<numeric value>................ 5-25

[:SENSe]:AVERage[:STATe]fONjOFFj1j0g................ 5-25

[:SENSe]:CONTact:DATA?.......................... 5-26

Page 27

[:SENSe]:CONT

[:SENSe]:CONT

[:SENSe]:CONT

[:SENSe]:CORRection:COLLect[:A