Page 1

New Technologies for Wide Impedance

Range Measurements to 1.8 GHz

Product Note 4291-1

HP 4291B RF Impedance/

Material Analyzer

Introduction

With the current trends in the

communications and data

processing industries requiring

higher performance, smaller

physical size, lower cost, and

higher reliability, accurate and

efficient electronic component

characterization is an increasingly

important part of product design.

Many of these advanced products

are operating at frequency in the

RF range.

Older low-frequency or indirect

methods of component evaluation

are often not able to provide the

high quality impedance parameter

information required for

HP 4291B RF Impedance/Material Analyzer with SMD fixtures

understanding component

performance under actual

operating conditions in the RF

range. This product note

describes new impedance

measurement techniques and

innovations contained in the

HP 4291B RF Impedance/

Material Analyzer that allow

accurate and efficient direct

impedance measurement and

analysis from 1 MHz to 1.8 GHz.

Five general topics will be

discussed:

Limitations of traditional

methods of impedance analysis.

Extending the frequency range

and impedance magnitude

range, while maintaining high

accuracy.

1

Making high accuracy Quality

Factor (Q) and Dissipation Factor

(D) measurements at RF.

Increasing test flexibility by

extending the device-under-test

(DUT) location 1.8 meters from

the instrument while maintaining

accuracy.

Eliminating fixture errors

critical issues for accurate RF

measurements.

Limitations of traditional

impedance measurement

solutions

Most conventional measuring

instruments such as traditional

LCR meters and impedance

analyzers are limited to lower

frequency analysis where the

4-terminal pair method can

provide very high accuracy. For

higher frequencies a vector

network analysis approach is

often used by first measuring the

reflection coefficient, then

calculating impedance values.

This indirect method may be

useful for impedance values near

50 Ω, but can be inaccurate for

impedance values significantly

higher or lower than 50 Ω. In

addition, calibration and removal

of test fixturing errors can be a

tedious procedure and in some

cases, not possible. The issue of

fixturing at RF can be a major

Page 2

source of error and expense. In

general, impedance measurements

in the RF range in the past have

been very difficult and often

yield widely varying results with

questionable accuracy. For

today's RF component or circuit

designer, a new solution is

needed to provide the accuracy

and test efficiency required for

complete RF impedance

characterization of circuit

elements.

Hewlett-Packard now offers a

new analyzer dedicated to the

direct measurement of

impedance and material

parameters from 1 MHz to 1.8 GHz

that overcomes many of the

limitations of previous approaches.

The HP 4291B provides highly

accurate RF impedance

measurements and offers a

family of surface mount device

(SMD) test fixtures. With a color

display and powerful firmware,

up to 15 impedance parameters

as well as equivalent circuit

models and more are easily

measured and displayed. The

following topics describe this

new analyzer's capabilities and

measurement technology.

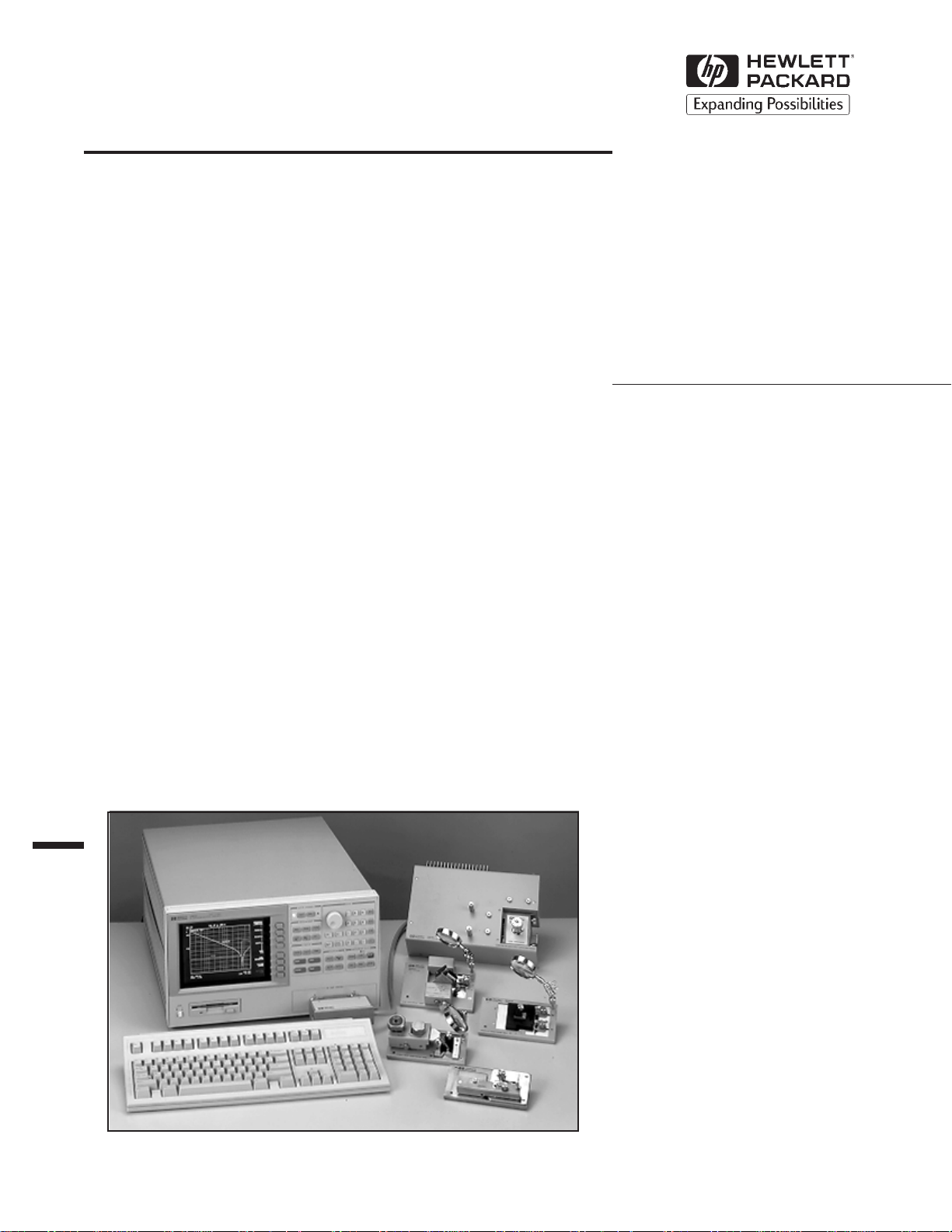

Figure 1. Ranges of impedance

measurement (Accuracy of

measurement: 10%)

The HP 4291B achieves its

accuracy over these wide

impedance ranges using tow new

techniques:

Direct impedance using

the RF I-V method

The analyzer uses a new method

to measurement impedance; the

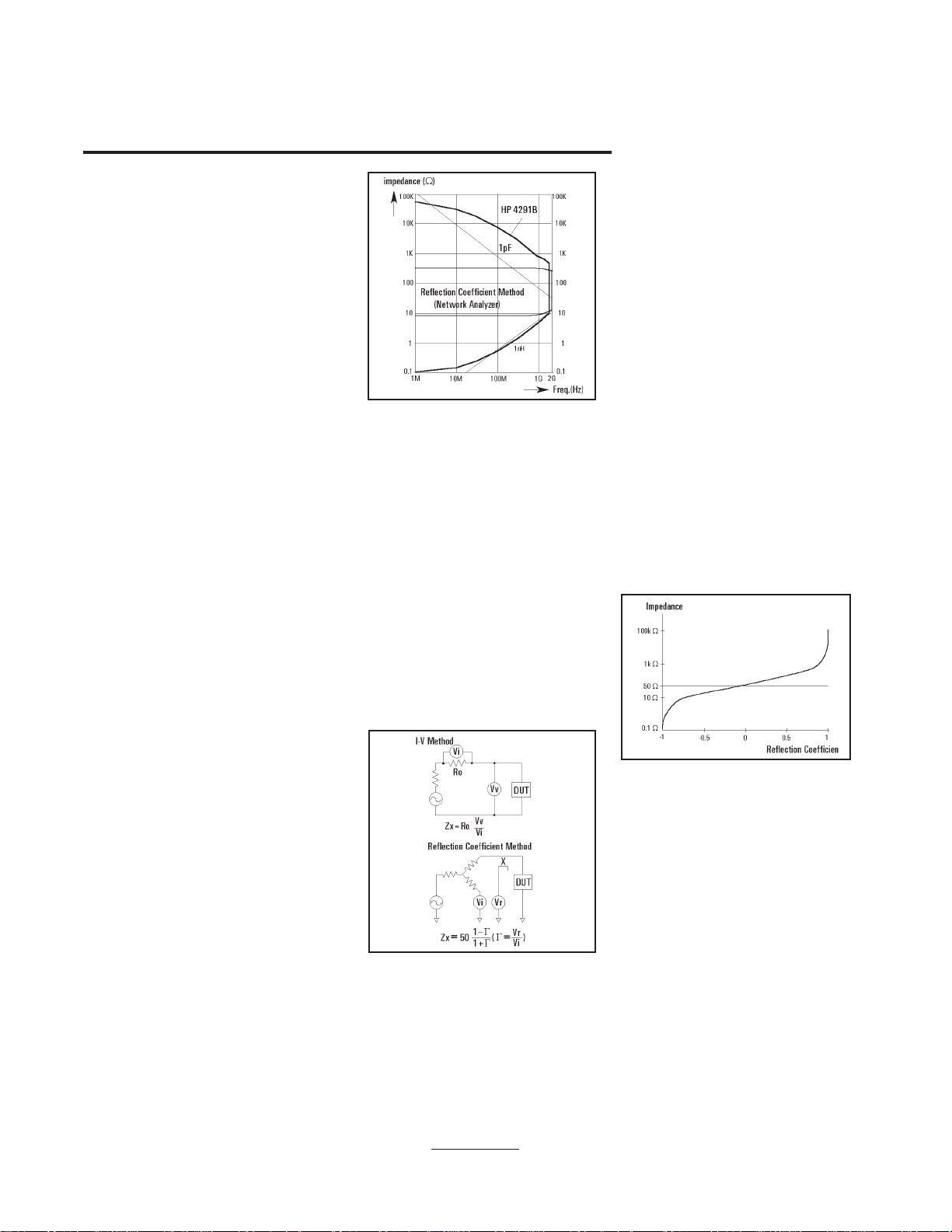

RF I-V method. Figure 2 shows

the basic principles of the RF I-V

method and reflection coefficient

method (conventional method

using a vector network analyzer).

and reflection coefficient

methods, the impedance is given

by ratios of the readings of the

two voltmeters. Therefore one

would expect that the accuracy

of both methods would be similar.

However, the reflection

coefficient method magnifies the

measurement error when

converting reflection coefficient

to impedance. As impedance

goes away from 50 Ω, Figure 3

shows that a small changes in

reflection coefficient value

produces a large change in

impedance. In other words, a

small error in the reflection

coefficient leads to a large error

in impedance. (For example, for

an impedance of 2 kΩ, a 1 % error

of reflection coefficient results

in a 24 % error in impedance.)

Figure 3. Relationship between

impedance and reflection coefficient

Expanding the range of

impedance magnitudes

As shown in Figure 1, the

HP 4291B provides an

exceptionally wide range of

impedance measurements. It is

the ideal instrument for measuring

very small capacitance (1 pF)

and inductance (1 nH) values in

the RF range.

Figure 2. I-V method and reflection

coefficient impedance method

As can be seen from the equations

in Figure 2, the RF I-V method

measures impedance directly,

while the reflection coefficient

method measures reflection

coefficient and concerts it to

impedance. In both the RF I-V

2

The RF I-V method measures

impedance directly from a ratio

of voltage and current, without

converting the measured data.

Therefore, the RF I-V technique

maintains consistent accuracy

even if the impedance is

significantly larger or smaller

than 50 Ω. Thus for measuring

non-50 Ω components, the

HP 4291B using the RF I-V

technique is recommended.

Page 3

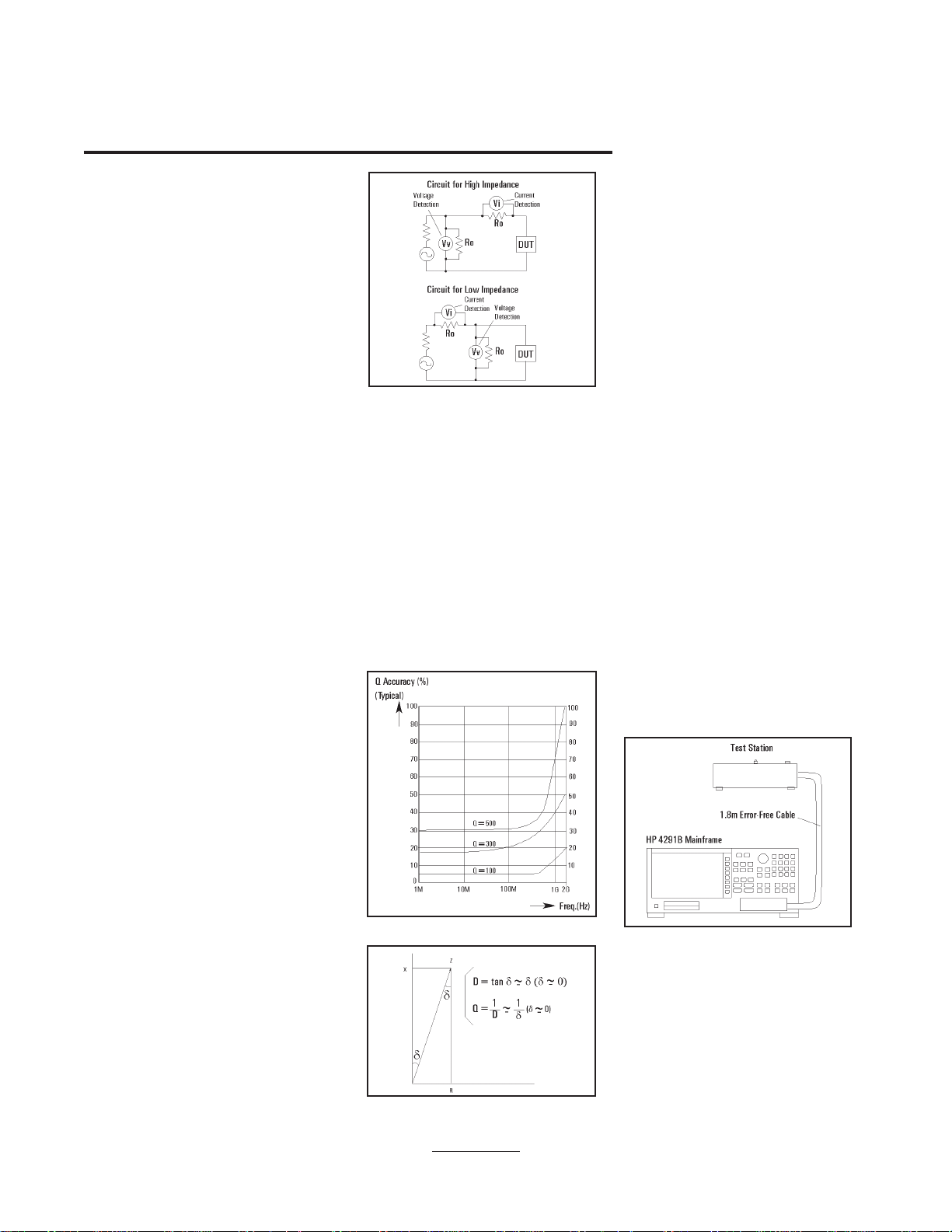

High/Low impedance circuit

The HP 4291B employs highimpedance and low-impedance

circuits, as shown in Figure 4, to

expand the range of impedance

measurements. When measuring

a high-impedance device,

accurate measurement of the

DUT current is most critical. The

high-impedance circuit solves

this problem by connecting the

current detection circuit directly

in series with the DUT, ensuring

accurate DUT current

measurement and not measuring

current flowing in the voltage

sensing circuit.

On the other hand, when

measuring a low-impedance

device, the voltage across the

DUT is most critical. In this case,

the low-impedance circuit

connects the voltage detection

circuit directly to the DUT,

ensuring accurate voltage

measurement and not measuring

the voltage drop from the current

sensing impedance. By using the

right measuring circuit for the

impedance being measured, it is

possible to extend the range of

impedance magnitudes measured

for a given accuracy.

Figure 4. High-impedance and lowimpedance measuring circuits

High Accuracy Q and D

measurements

As shown in Figure 5,

the HP 4291B is capable of

evaluating a sample with Q = 100

within ±15 % accuracy at 1 GHz.

This capability is targeted for

evaluating the loss of low-loss

components at RF. The accuracy

of Q and D measurements depend

on the accuracy of phase

measurement. See Figure 6.

The HP 4291B improves the

accuracy of phase measurements

by requiring an additional phase

calibration step. (Conventional

one-port calibration uses open,

short, and 50 Ω load standards.)

This type of one-port calibration

does not provide satisfactory

accuracy for phase measurements

because of the phase uncertainty

of the 50 Ω standard. By using a

low-loss air capacitor as a phase

standard, the HP 4291B lowers

the phase uncertainty to 1 mrad or

less (corresponding to D = 0.001),

ensuring improved accuracy for

Q and D measurements.

Error-free 1.8m cable

extension

The cable connecting the main

body of the HP 4291B to the test

station has been extended to

1.8 meters without adding

additional errors. See Figure 7.

The long cable allows easy

access to remote DUT locations.

This temperature chamber,

scanner/handler, or custom test

setup, for example.

These two measuring circuits are

implemented as two different test

heads in the HP 4291B, so users

can select and switch the circuits

easily to optimize the measurement

range and accuracy to best

match the DUT impedance.

Figure 5. Q measurement accuracy

Figure 6. Q and D measurement and

phase measurement

3

Figure 7. Extended test cable

Normally, extending the cable

increases measurement error

due to increased noise,

temperature differentials, cable

resistance, etc. However, as

illustrated in Figure 8, the

HP 4291B measures the current

and voltage signals using the

same circuit and alternates the

measurement with fast timedivision multiplexing.

Page 4

Since the measurements are

made at an alternating interval of

several milliseconds, the same

cable-induced errors occur in

both the current and voltage

measurement data. These errors

are then canceled out when the

impedance is obtain from the

ratio of voltage to current.

Furthermore, by measuring

current and voltage with the same

circuit, errors in the measuring

instrument caused by temperature

changes are offset in the same

manner, resulting in significant

temperature characteristic

improvement.

Figure 8. Time-division multiplexing

of cuurent/voltage measurement

Test fixtures have a large impact

on measurement accuracy,

especially at higher test

frequencies. An important factor

in getting accurate measurements

is eliminating errors introduced

by the DUT fixturing. Calibration

insures high accuracy at the plane

of calibration (measurement point

where the standards are applied),

but in actual practice, the test

fixture can add additional error

terms beyond the calibration

plane. This is why fixture error

compensation is so important.

Electrical properties of the test

fixture (which occur after the

calibration point), consist of a

phase rotation due to the

physical length of the electrodes

and other unwanted stray

parasitics between electrodes.

Both of these can cause significant

measurement errors in the RF

band. Conventional measuring

instruments often have no

convenient method to eliminate

them effectively. The HP 4291B

uses electrical length

compensation to remove the

errors caused by phase rotation

and OPEN/SHORT compensation

(at the DUT location in the fixture)

for removing fixture parasitic

impedance.

Conclusion

The HP 4291B RF impedance

and material analyzer provides

highly accurate impedance and

material measurements by

incorporating new technologies

and offering an integrated

package including a family of

SMD and material fixtures. The

analyzer overcomes many

limitations of conventional

impedance analysis and, for the

first time, provides an efficient

and accurate measurement

solution for passive component

analysis over the RF range.

For detailed technical information

of the HP 4291B RF impedance

and material analyzer, refer the

HP 4291B Technical Information

in page 5.

For more information, request

following literatures from your

local HP representative:

HP4291B 1.8 GHz impedance/Material

Analyzer Product Overview P/N 59661501E

HP 4291B Technical Specifications P/N

5966-1543E

Highly Accurate Evaluation of Chip

Capacitors using the HP 4291B

Application Note 1300-1 P/N 59661850E

Evaluating Chip Inductors using the HP

4291B Application Note 1300-2 P/N

5966-1848E

Permittivity Measurements of PC Board

and Substrate Materials using the HP

4291B and HP 16453A

Application Note 1300-3 P/N 59661847E

Permeability Measurements using the

HP 4291B and HP 16454A Application

Note 1300-4 P/N 5966-1844E

Electronic Characterization of IC

Package Application Note 1300-5 P/N

5966-1849E

Impedance Characterization of

Magneto-Resistive Disk Heads Using

the HP 4291B Impedance/Material

Analyzer Application Note 1300-6 P/N

5966-1096E

On-Chip Semiconductor Device

Impedance Mesurements Using the HP

4291B Application Note 1300-7

P/N 5966-1845E

Evaluating Temperature Characteristics

using a Temperature Chamber and the

HP 4291B Product Note

4291-2 P/N 5966-1927E

Impedance Measurements Using the HP

4291B and the Cascade Microtech

Prober Product Note 4291-3 P/N

5966-1928E

Dielectric Comnstant Evaluation of

Rough Surfaced Materials Product Note

4291-5 P/N 5966-1926E

4

Page 5

Appendix.

New Technologies used in the High Frequency

Impedance Analyzer

HP 4291B RF Impedance/Material Analyzer

Technical information

Abstract

A new one-port impedance analyzer has been

developed for analysis of high frequency devices

and materials up to 1.8 GHz.

Traditionally, impedances near 50 Ω have been

measured accurately by the null method using a

directional bridge. However, this new analyzer

uses a voltmeter/ammeter method and offers

precise measurement capability over a wide

impedance range. Furthermore, a special

calibration method using a low-loss capacitor

realizes an accurate high-Q device measurement.

This paper describes the advantages of these

techniques. Impedance traceability of the

instrument will also be discussed.

Finally, many types of test fixtures are introduced,

because they are a key element in any test system.

1. Introduction

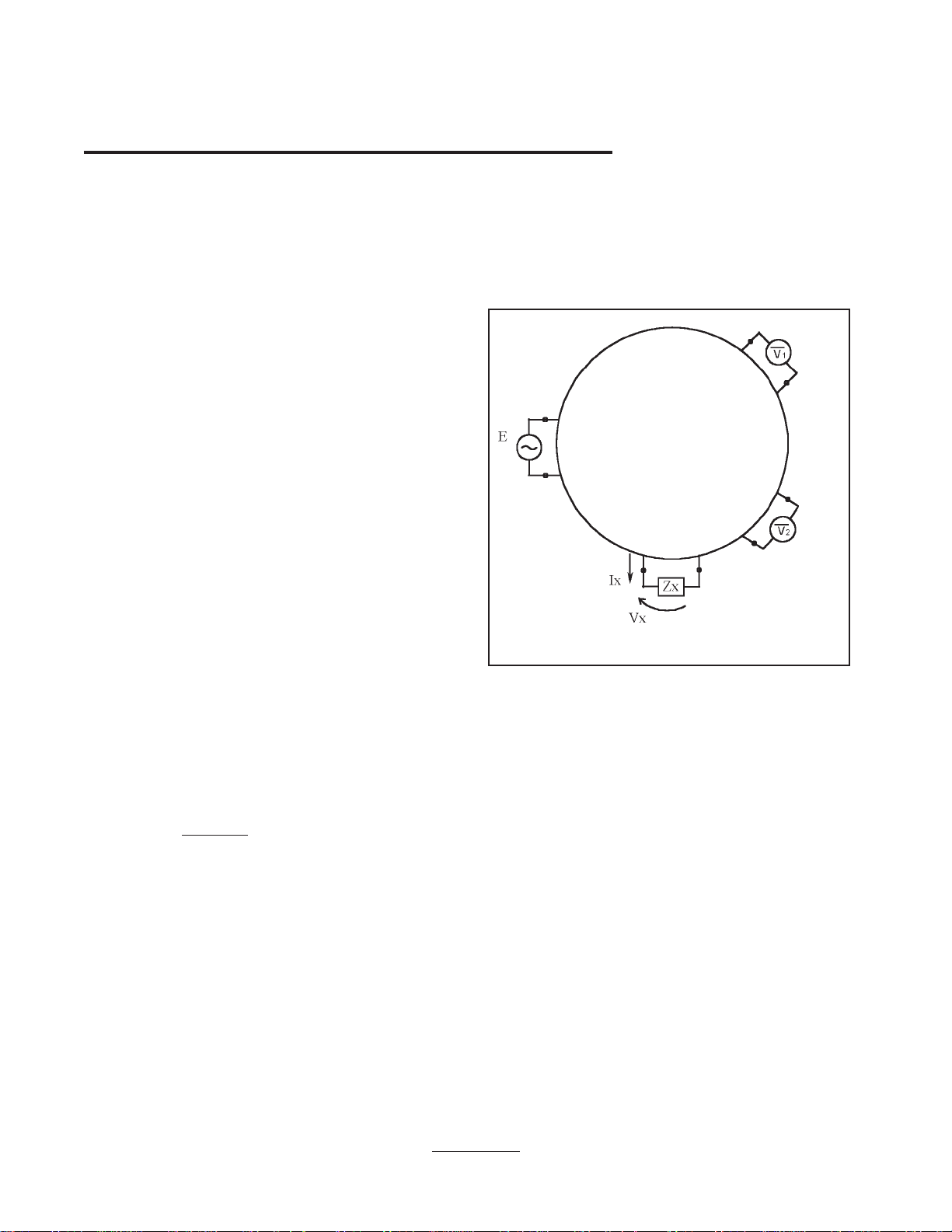

A general impedance measurement schematic

using two vector voltmeters is shown in Fig. 1. In

this case, the true impedance (Zx) of a device under

test (DUT) is determined by measuring the voltages

of any two different sets of points in a linear circuit.

Zx = K1 × (1)

where

K1, K2, K3 : complex constant

In the process of deriving the equation above,

linearity is assumed but reciprocity is not assumed.

Therefore, the existence of active devices in the

circuitry is not prohibited.

There are at most three unknown parameters

related to the circuit in the equation (1). Once we

know these parameters, we can calculate any

impedance of the DUT from the measured voltage

K2+Vr

1+K3×Vr

Vr : voltage ratio

E: signal source V1: vector voltmeter1

V2: vector voltmeter2 Zx: DUT

Figure 1. General schematic for impedance measurement

using two vector voltmeters

ratio (Vr). The procedure that estimates these

circuit parameters is called "calibration" and one

method is "Open-Short-Load (OSL) calibration."

Calculation of Zx from the measured voltage ratio

(Vr) according to equation (1) is called

"correction."

2. Transducer

We call a linear circuit such as the one in Fig. 1

(one that relates a signal source, two vector

voltmeters and a DUT) a "transducer."

Transducers are the key element in impedance

measurement. For example, two types of

transducers, the "directional bridge" and the

transducer in a "voltmeter/ammeter (V-I) method,"

are compared in terms of sensitivity to the gain

variance.

2-1. Directional bridge type

Directional bridges (see Fig. 2-1) are used in many

network analyzers.

5

Page 6

In this case, the bilinear transformation is

1+

Zx = −R

Γ

× (2)

0

1−

Γ

where

(Z

−

R0)

Γ

Vr = = (− ) ×

R

x

= : reflection coefficient

(Z

+

R0)

x

V

2

V

1

= 50Ω : characteristic impedance

0

1

Γ

8

Parameters corresponding to those in equation (1)

are

K1 = - Ro, K2 = 1, K3 = - 1

E: signal source V1: vector voltmeter1

V2: vector voltmeter2 Zx: DUT

R@ Ro = 50 Ω

Ro: characteristic impedance

Figure 2-1. Directional bridge circuit

2-2. V-I method

Fig. 2-2 shows the simplest transducer in the V-I

method. The bilinear transformation in this case is

Zx = R

× Vr (3)

0

where

R

= 50Ω : resistor that converts DUT current

0

to a voltage

V

Vr =

2

V

1

Parameters corresponding to those in equation (1)

are

E: signal source V1: vector voltmeter1

V2: vector voltmeter2 Zx: DUT

R: resistor converting DUT current to a voltage

R@ Ro = 50 Ω

Figure 2-2. V-I method

2-3. Sensitivity to gain variance

In this section we discuss the relationship between

the impedance measurement error and the gain

variance of the vector voltmeters.

2-3-1. Directional bridge type

We assume that the vector voltmeters in Fig. 2-1

are not ideal but have some gain variance. In this

situation, the measured voltages (V1 and V2) and

the calculated impedance (Zx) are:

V

= E ×

1

V2 =

Zx = −R

α

1

( − )

8

×

0

1

× E × Γ ×

1+

Γ

1−

Γ

α

2

where

α

: gain of the vector voltmeter1

1

α

: gain of the vector voltmeter2

2

Γ

=

−

8 × Vr ×

V

2

Vr = : voltage ratio

V

1

α

2

α

= : ratio of voltmeter gains

2

α

α

: measured reflection coefficient

r

1

K1 = R, K2 = 0, K3 = 0

6

Page 7

We define the calculated impedance sensitivity (S)

to the voltmeters' gain variance as follows:

δZ

x

Z

S = (4)

x

δ

α

r

α

r

This sensitivity can be considered as the inverse of

the "magnification on gain variance." The smaller S

is, the smaller the error of the calculated

impedance is. In this case, equation (4) is given as

follows:

δ

Z

δΓ

S = × ×

x

δΓ

1

= ( ) ×

2

δα

Z

r

2

− R

x

Zx × R

α

r

Z

x

2

o

o

1

(− ) × ( ) for |Z

2

R

o

Z

x

| << Ro

x

= 0 for |Zx| = Ro

1

( ) × ( ) for |Z

2

Z

x

R

o

| >> Ro

x

This implies

1) This type of transducer has little sensitivity to

the voltmeter gain variance when the DUT

impedance is near Ro (50 Ω).

2) The gain variance of the voltmeters behaves as

the offset impedance with a magnitude of

(1/2)*Ro*| ∆α r/α r | when the DUT impedance is

far smaller than Ro.

3) The gain variance of the voltmeters behaves as

the offset admittance with a magnitude of

(1/2)*Go*| ∆α r/ α r| when the DUT impedance is

far larger than Ro.

where

∆αr: change in gain ratio α

r

Go : 1 / Ro

Fig. 2-3 shows this characteristic.

Figure 2-3. Sensitivity to the voltmeter gain variance

2-3-2. V-I method

We also assume that there is some gain variance in

the vector voltmeters in Fig. 2-2. The relationship

among measured voltages (V1 and V2) and the

calculated impedance (Zx) are:

R

V1 = E ×

V2 = E ×

Zx = Ro × Vr

o

Zx + R

Z

x

Zx + R

× α

r

× α

1

o

× α

2

o

where

α

: gain of the vector voltmeter1

1

α

: gain of the vector voltmeter2

2

V

Vr = : voltage ratio

α

2

V

1

α

1

= : ratio of voltmeter gains

r

α

2

In this case, the sensitivity is given by the following:

The error ratio (∆Zx/Zx) is always constant and

equal to unity. For example, if the voltmeter gain

7

Page 8

ratio ar changes 1%, an impedance error of 1% is

caused for any DUT.

δZ

x

Z

x

S = = 1

δ

α

r

α

r

3.Schematic of new RF impedance

analyzer

From the discussion in section 2, we find that the

voltmeter gain variance is neither suppressed nor

magnified for all DUT impedances in a "V-I method

type transducer." This characteristic is desirable

for wide impedance measuring capability.

Therefore we adopted this type of transducer for

our new one-port RF impedance meter.

3-1. Basic transducer circuit

Fig. 3-1 shows the basic circuit of the transducer in

New RF Impedance Meter which is modified from

Fig. 2-2. The high impedance configuration realizes

perfect OPEN and imperfect SHORT conditions. On

the other hand the low impedance configuration

realizes imperfect OPEN and perfect SHORT

conditions.

Moreover, this circuit has the following

characteristic:

3-2. Actual transducer circuit

Actual transducer circuits are shown in Fig. 3-2 (a)

and Fig. 3-2 (b).

We took the following things into account when

designing the actual transducer circuits:

(a) for high impedance measurement

* the output impedance at the DUT port is always Ro in

either switch position

E: signal source V1: vector voltmeter1

V2: vector voltmeter2 Zx: DUT

R@ Ro: characteristic impedance

switch: ON for high impedance measurement

switch: OFF for low impedance measurement

Figure 3-1. Basic transducer circuit in New RF

impedance Analyzer

(b) for low impedance measurement

E: signal source V1: vector voltmeter1

V2: vector voltmeter2 Zx: DUT

R@Ro

Ro: characteristic impedance

Figure 3-2. The actual transducer circuit

1) Because a wideband switch with small nonlinearity and with small transients over a

wide signal range is not easily realized, we

divided the circuit in Fig. 3-1 into two separate

circuits.

2) Because the minimum frequency of the new

meter is 1 MHz, the floating voltmeter (V1),

8

Page 9

which corresponds to the current meter, is easily

realized by using a balun.

3) In order to prevent the error caused by by-pass

current we adopted a circuit in which the exciting

impedance of the balun is parallel connected not

to the current meter (V1) but to the signal source

(E).

3-3. Simplified block diagram of new impedance

analyzer

The followings are other key features of the

instrument:

1) time division multiplex

Two voltmeters are obtained by time division

multiplexing one voltmeter. The multiplexing

eriod is 2msec. This ensures that the slow drift

of the voltmeter gain does not affect the

impedance measurement. The signal path

after the multiplexer can be extended. This

instrument uses a 1.8m cable between the

transducer and the instrument main frame.

This allows wide flexibility in constructing a

test system using automatic device handlers.

Good temperature characteristics are also

derived even with an extended cable by the

single path configuration.

Figure 3-5. (a) Typical errors for impedance magnitude

with the transducer for high impedance

Figure 3-5. (b) Typical errors for impedance magnitude

with the transducer for low impedance

4. A special calibration for high Q measurement

Normally the accuracy requirement for the

impedance phase is greater than that of the

impedance magnitude. Our New Impedance Meter

has a special, but easy-to-use, calibration for high

Q (quality factor) device measurements. We

discuss this calibration technique in this section.

(2) impedance ranging

At frequencies below 200 MHz there exists an

"expand range." In the expand range there is a

gain difference between the voltage channel

and the current channel in the earlier stage of

the multiplexer. This impedance ranging offers

stable measurements for DUTs with

impedances that differ greatly from 50 Ω.

Fig.3-3 (a), Fig. 3-3 (b) shows the typical

measurement errors for impedanceof the

instrument. The errors mainly consist of the

uncertainties for standards (STDs) used in the

calibration, non-repeatabilities in connections,

temperature coefficients, noise and errors in the

interpolations. The impedance phase errors can be

reduced by using a special calibration (see Section

4).

4.1 Outline of the special calibration

Even if the stability of the instrument is good

enough, accurate Q measurements are not

performed without correct markings on the phase

scale of the instrument. For instance, if we want to

measure the Q factor with 10% uncertainty for a

DUT whose Q value is almost 100, the uncertainty

for phase scaling must be smaller than 1E-3. The

phase accuracy of the instrument is determined

almost entirely by the uncertainty of the 50Ω LOAD

STD used in the OSL calibration. One method to

improve phase measurement accuracy is to use a

phase calibrated LOAD STD. However, it is not

ensured that phase uncertainty for a calibrated

50Ω LOAD is smaller than 1E-3 at high frequencies

(such as 1 GHz).

In addition to the normal OPEN-SHORT-LOAD

STDs, using a low-loss air-capacitor as the second

LOAD (LOAD2), whose dissipation factor (D) is

kept below 1E-3 at around 1 GHz, offers the

following feature:

9

Page 10

* the uncertainty for the measured phase is

decreased from the phase uncertainty of the 50Ω

LOAD (LOAD1) to the uncertainty of

D of the low-loss capacitor (LOAD2) for almost

all DUT impedances.

4.2 Details of the modified OSL calibration

using an additional load

We want to have the calibration method which

reduces the error in phase measurement in spite of

the existence of phase error for the 50Ω LOAD.

Consider the case that we have the 50Ω LOAD STD

whose impedance phase is not known but

impedance magnitude is known. In this situation

how about adding another LOAD (LOAD2) whose

impedance magnitude is not known but impedance

phase is known? We use a low-loss capacitor as the

second LOAD. The number of unknown circuit

parameters are still three at most. However, two

more unknowns related to STDs are added. Let us

define the problem. There are eight real unknown

parameters:

1) circuit parameter K1 (two real parameters)

2) circuit parameter K2 (two real parameters)

3) circuit parameter K3 (two real parameters)

Zlmi : measured impedance for LOAD STD

(i = 1 : LOAD1, i = 2 : LOAD2)

Zlsi : true impedance for LOAD STD

(i = 1 : LOAD1, i = 2 : LOAD2)

Zls

= Zabs_ls1*EXP(j*θls1)

1

Zls

= Zabs_ls2*EXP(j*θls2)

2

θls1 = θ2 - θ1 + θls2

Zabs_ls2 = A1/A2*Zabs_ls1

Zabs_ls1 : impedance magnitude for LOAD1

(50Ω) : known

θls2 : impedance phase for LOAD2

(low-loss capacitor) : known

θ1 = arg((1 - Zlm

θ2 = arg((1 - Zlm

*Yom)/(Zlm1 - Zsm))

1

*Yom)/(Zlm2 - Zsm))

2

A1 = |(1 - Zlm1 *Yom)/(Zlm1 - Zsm)|

A2 = |(1 - Zlm2 *Yom)/(Zlm2 - Zsm)|

For the actual cases these circuit parameters are

expressed by far more complicated equations.

Therefore

we adopted a simpler procedure consisting of two

steps:

4) impedance phase qls1 of the 50Ω LOAD

(one real parameter)

5) impedance magnitude Zabs_ls2 of the low-loss

capacitor LOAD2 (one real parameter)

We solved this problem analytically. For the

simplest case where both the OPEN and the SHORT

STD are ideal, the three circuit parameters are

found as follows :

K1 = A × Zls × R

−

Z

K2 =

K3 = −Ysm x R

sm

R

o

o

o

(5)

where

Ro : characteristic impedance

A = (1 - Zlmi *Yom)/(Zlmi - Zsm)

Yom : measured admittance for OPEN STD

Zsm : measured impedance for SHORT STD

1) step 1

*Regard the impedance of the 50Ω LOAD as

Zls1 = 50+j*0 (that is, the phase of LOAD1 is

zero).

*Find the circuit parameters K1, K2, and K3 by

normal OSL calibration using the LOAD value

(Zls1).

*Execute correction for LOAD2 and get the

corrected impedance (Zcorr2).

*Calculate the phase difference (∆θ) between the

phase of Zcorr2 and the true phase of LOAD2

2) step 2

*Modify the impedance of LOAD1 to Zls1'

whose phase is -∆θ and whose impedance

magnitude is still 50 Ω

*Calculate the circuit parameters again by

normal OSL calibration using modified

LOAD impedance Zls1'.

10

Page 11

Although this is an approximate method, actually

just performing the two steps is accurate enough

for our purpose. We call this method the "modified

OSL calibration."

4.3 Phase measurement error using modified

OSL calibration

We considered the following error factors during

phase measurement in the modified OSL

calibration:

1) uncertainty for impedance magnitude of

LOAD1

For example, the relationship between the phase

measurement error and the uncertainty for the

impedance phase of LOAD2 (∆θls2) is shown in

Fig. 4-1. Fig. 4-2 shows the relationship between

the phase measurement error and the uncertainty

for admittance magnitude of OPEN (∆Yopen).

From the above discussion the phase measurement

error when using the modified OSL calibration is

mainly determined by

* uncertainty for the impedance phase of LOAD2

* uncertainty for the admittance magnitude of

OPEN

2) impedance phase of LOAD1

3) impedance magnitude of LOAD2

4) uncertainty for impedance phase of LOAD2

5) uncertainty for admittance magnitude of OPEN

Notice that factor 2 and factor 3 do not cause any

error if we use the analytical solution. By

computer simulations the phase error is shown to

behave as follows:

1) Sensitivity of phase measurement error due to

the uncertainty of impedance magnitude for

LOAD1 is small.

2) Sensitivity of phase measurement error due to

the impedance phase of LOAD1 is small.

3) Sensitivity of phase measurement error due to

the impedance magnitude of LOAD2 is small.

4) Uncertainty for the impedance phase of LOAD2

directly affects the phase measurement error.

5) Sensitivity of the phase measurement error due

to the uncertainty for admittance magnitude of

OPEN (| ∆Yopen|) is reduced to

|Ro*∆Yopen|*(Copen/Cls2) in the case of

reactive DUT. In the case of resistive DUTs, the

sensitivity is the same as in the normal OSL

calibration.

where

Ro : characteristic impedance = 50 Ω

Copen : capacitance of OPEN STD

Cls2 : capacitance of LOAD2 (low-loss

capacitor)

Now we evaluate these two items. The D factor for

the capacitor (3pF) used in the calibration can be

small because its dimensions are small and the

space between the inner and outer conductors is

filled almost completely with air. The D value is

verified as 500E-6 at 1GHz from the residual

resistance measurement at the series resonant

frequency. The D factor is in proportion to Freq

due to the skin effect. By using zero as the D value

for the capacitor during calibration a phase

measurement error of 500E-6 is realized at 1 GHz.

On the other hand, the uncertainty for the OPEN

capacitance is +/-5fF at most.

This leads to a phase measurement error less than

+/-100E-6 at 1 GHz. In all, a phase measurement

uncertainty of 500E-6 is realized by using the

modified OSL calibration.

5. Impedance tracability

For an impedance performance check using the

top-down method [1] we set up a kit traceable to the

National Standards. This kit is calibrated annually

at our standard laboratory. Two major items in the

kit are the 50Ω LOAD and 10 cm long, 50Ω

beadless air line. The 50Ω LOAD is desirable

because its frequency characteristic for

impedance is very flat. The structure of the air line

is very simple. Therefore, it is easy to predict its

frequency characteristic and it is convenient to

realize various impedances by changing

frequencies with the OPEN or SHORT terminated.

The traceability path for the kit is shown in Fig. 5.

The impedance characteristic of OPEN ended and

SHORT ended air lines can be calculated

theoretically from their dimensions and resistivity.

11

1.5

Page 12

[2] However, it is not easy to design the syst offring

calibrated dimensions with the individual kit.

Freq. = 1GHz

|Zopen| : impedance of OPEN STD @ 2 kΩ

Dqls2: uncertainty for impedance phase of LOAD2 (low-loss

capacitor) = 500E-6

Figure 4-1. Relationship between the phase measurement

error and the uncertainty for the impedance phase of

LOAD2

Therefore, the periodical calibration of dimensions

is performed only to the reference air line of the

standard laboratory. Calibration for the individual

air line is executed by the network analyzer

calibrated from the reference air line. The 50Ω

LOAD calibration is done mainly by the quarter

wave impedance method and DCR measurement.

The OPEN termination is calibrated by a

capacitance bridge at low frequencies and by the

network analyzer at high frequencies. The SHORT

termination is treated as an ideal one.

Uncertainties for it consists of the skin effect and

non-repeatabilities.

Freq. = 1GHz

Ro: characteristic impedance = 50 Ω

|Zopen| : impedance of OPEN STD @ 2kΩ

Dq1 = |Ro*DYopen|*Copen/Cls2

|DYopen| : uncertainty for admittance magintude of OPEN = 30mS

Copen = 82 fF, Cls2 = 3pF

Figure 4-2. Relationship between the phase measurement

error

6. Test fixtures

In the actual measurement test fixtures

corresponding to different shaped DUTs are

needed. As the frequency range goes up higher,

people need fixtures that are able to handle smaller

devices. We have developed four types of

fixtures:

* a fixture for surface mount devices (SMDs) with

bottom electrodes

* a fixture for SMDs with side electrodes

* a fixture for very small SMDs

* a fixture for lead components

To reduce the error at the fixture terminal it is

necessary to minimize the length from the

reference APC-7 plane to the fixture terminal and

to minimize the connection non-repeatability.

The new fixtures improved repeatability by almost

five times compared with our old ones.The typical

non-repeatability of the SMD fixtures is

12

Page 13

* +/-50 pH, +/- 30 mΩ for SHORT measurement

* +/- 5 fF, +/- 2 µS for OPEN measurement

Furthermore, we installed "fixture compensations"

in the firmware which corresponds to the

corrections at the reference plane. This reduces the

errors generated in the circuit between the

reference plane and the fixture terminal. The best

choice for the compensation is the OSL. However, it

is not easy to prepare a LOAD having excellent

frequency characteristics. As the more realistic

way we prepare the following compensation

functions:

* fixture port extension

* OPEN-SHORT correction at the fixture plane

Fig. 6 shows the typical additional error when using

the above corrections at the same time. These

values are almost three times better than the errors

for our former type of fixtures.

Figure 6. Typical additional errors after fixture

compensations

7. Conclusion

Selection of "transducers" is important for accurate

impedance measurement . A new type of

transducers, which are based on the voltmeter/

ammeter method and have wide impedance

measuring capability, are proposed. By adopting

these transducers the New RF Impedance Analyzer

has been developed. We also proposed a new

phase calibration technique modified from the OSL

calibration. It utilizes a low-loss capacitor as the

second LOAD. This calibration enables accurate Q

measurements.

References

[1] Hewlett Packard, "Traceability and the HP8510

Network Analyzer," Nov. 1 1985

[2] Robert E. Nelson, Marlene R. Coryell,

"Electrical Parameters of Precision, Coaxial,

Air-Dielectric Transmission Lines," NBS

Monograph96, June 30 1966

13

Page 14

For more information about HewlettPackard test & measurement products,

applications, services, and for a current

sales office listing, visit our web site,

http://www.hp.com/go/tmdir. You can

also contact one of the following

centers and ask for a test and measurement sales representative.

United States:

Hewlett-Packard Company

Test and Measurement Call Center

P.O. Box 4026

Englewood, CO 80155-4026

1 800 452 4844

Canada:

Hewlett-Packard Canada Ltd.

5150 Spectrum Way

Mississauga, Ontario

L4W 5G1

(905) 206 4725

Europe:

Hewlett-Packard

European Marketing Centre

P.O. Box 999

1180 AZ Amstelveen

The Netherlands

(31 20) 547 9900

Japan:

Hewlett-Packard Japan Ltd.

Measurement Assistance Center

9-1, Takakura-Cho, Hachioji-Shi,

Tokyo 192, Japan

Tel: (81) 426 56 7832

Fax:(81) 426 56 7840

APC-7 ® is a U.S. registered trademark

of the Bunker Ramo Corporation.

14

Latin America:

Hewlett-Packard

Latin American Region Headquarters

5200 Blue Lagoon Drive

9th Floor

Miami, Florida 33126

U.S.A.

Tel: (305) 267-4245

(305) 267-4220

Fax:(305) 267-4288

Australia/New Zealand:

Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

Australia

Tel: 1 800 629 485 (Australia)

0800 738 378 (New Zealand)

Fax:(61 3) 9210 5489

Asia Pacific:

Hewlett-Packard Asia Pacific Ltd.

17-21/F Shell Tower, Times Square,

1 Matheson Street, Causeway Bay,

Hong Kong

Tel: (852) 2599 7777

Fax:(852) 2506 9285

Copyright © 1998

Hewlett-Packard Company

Printed in U.S.A. 10/98

5966-2046E

Loading...

Loading...