Page 1

HP 4291B RF Impedance/Material Analyzer

Programming Manual

SERIAL NUMBERS

This manual applies directly to instruments with serial number

prex \JP1KE" and above, or whose rmware is version 1.0.

For additional important information about serial numbers,

read \Serial Number" in Appendix A of this Manual.

HP Part No. 04291-90037

Printed in JAPAN March 1998

Second Edition

Page 2

Notice

The information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All rights are

reserved. No part of this document may be photocopied, reproduced, or translated to another

language without the prior written consent of the Hewlett-Packard Company.

Hewlett-Packard Japan, LTD.

Kobe Instrument Division

1-3-2, Murotani, Nishi-ku, Kobe-shi,

Hyogo, 651-2241 Japan

The customer shall have the personal, non-transferable rights to use

PROGRAMS in this manual for the Customer's internal operations

, copy, or modify SAMPLE

. The customer shall use the

SAMPLE PROGRAMS solely and exclusively for their own purpose and shall not license, lease,

market, or distribute the SAMPLE PROGRAMS or modication of any part thereof.

HP shall not be liable for the quality, performance, or behavior of the SAMPLE PROGRAMS. HP

especially disclaims that the operation of the SAMPLE PROGRAMS shall be uninterrupted or

error free. The SAMPLE PROGRAMS are provided AS IS.

HP DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

HP shall not be liable for any infringement of any patent, trademark, copyright, or other

proprietary rights by the SAMPLE PROGRAMS or their use. HP does not warrant that the

SAMPLE PROGRAMS are free from infringements of such rights of third parties. However,HP

will not knowingly infringe or deliver software that infringes the patent, trademark, copyright,

or other proprietary right of a third party.

R

MS-DOS

c

is a U.S. registered trademark of Microsoft Corporation.

Copyright 1997,1998 Hewlett-Packard Japan, LTD.

Page 3

Manual Printing History

The manual printing date and part number indicate its current edition. The printing date

changes when a new edition is printed. (Minor corrections and updates that are incorporated

at reprint do not cause the date to change.) The manual part number changes when extensive

technical changes are incorporated.

December 1997

March 1998

::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::

::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::

Second Edition

First Edition

iii

Page 4

Typeface Conventions

Bold

Boldface type is used when a term is dened. For example:

icons

symbols.

Italics

Italic type is used for emphasis and for titles of manuals and other

publications.

Italic type is also used for keyboard entries when a name or a variable

Computer

4

HARDKEYS

NNNNNNNNNNNNNNNNNNNNNNNNNN

SOFTKEYS

must be typed in place of the words in italics.For example:

lename

type the name of a le such as

means to type the word

file1

copy

, to type a space, and then to

.

Computer font is used for on-screen prompts and messages.

5

Labeled keys on the instrument front panel are enclosed in45.

Softkeys located to the right of the LCD are enclosed in

copy

NNNNN

.

Related Documentation Information

You can obtain more detailed information than provided by this manual by referring to the

following documents.

The following manuals are provided with the HP 4291B :

HP 4291B HP-IB Command Reference

for the complete HP-IB command list of the analyzer

are

.

HP 4291B Quick Start Guide

for learning about the analyzer itself and its front panel key

operation.

HP Instrument BASIC User's Handbook & its supplement for the HP 4291B

BASIC information.

The following documents also provide related information:

HP BASIC Programming Guide

for learning HP BASIC programming. (Furnished with the HP

BASIC system.)

Tutorial Description of the Hewlett-Packard Interface Bus

for an overview of the HP-IB and

IEEE 488 standard (HP literature no. 5952-0156).

Beginner's Guide to SCPI

for learning about a generic SCPI standard command set and its use

(HP part no. H2325-90001).

for Instrument

iv

Page 5

Contents

1. Introduction

How to Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Target Reader .... ...... ...... ...... ..... .... 1-1

What's in This Manual? ........................... 1-1

How to Use the Program Modules . . . . . . . . . . . . . . . . . . . . . . . 1-3

Building a Working Program Using Program Modules . . . . . . . . . . . . . 1-3

Initializing Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Example ................................ 1-4

HP-IB Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Device Selector ...... ...... ...... ...... ......

HP-IB Commands ..............................

Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Control Commands .......................

Simple Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Message Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper and Lower Cases ..........................

Program Message Terminator . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Messages .............................

Query and Response Message Syntax .. ...... ...... ......

Parameters ...... ...... ...... ...... ..... ...

Variable Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Tree and Compound Header Usage .................

Preparation for Operation ..........................

Using Instrument BASIC for Controller ........ ...... .....

1. Connecting the HP-IB Cables ..................... 1-13

2. Setting the HP-IB Address . . . . . . . . . . . . . . . . . . . . . . . 1-13

3. Preparing Instrument BASIC . . . . . . . . . . . . . . . . . . . . . . 1-13

Using an External Controller . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1. Connecting the HP-IB Cables ..................... 1-14

2. Setting the HP-IB Address . . . . . . . . . . . . . . . . . . . . . . .

3. Preparing HP BASIC ...... ...... ...... ..... ..

Sample Program Disk ............................

Loading a Program from Disk . . . . . . . . . . . . . . . . . . . . . . . .

1-6

1-7

1-7

1-7

1-7

1-8

1-8

1-8

1-8

1-9

1-9

1-9

1-9

1-11

1-13

1-13

1-14

1-14

1-15

1-15

Contents-1

Page 6

2. Setup and Measurement Program

Overview of HP-IB Control . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Sending HP-IB Commands ......................... 2-1

Reducing Keystrokes by Eliminating Node Repetition ........... 2-2

Sending a Query and Reading the Response ................. 2-2

Automating the Impedance Measurement Procedure . . . . . . . . . . . . . . 2-3

1. Setting the Active Channel ........ ...... ...... ... 2-3

2. Setting Stimulus ............................ 2-4

Setting Frequency Sweep Range and Level .. ...... ..... ... 2-4

Setting OSC Level Sweep . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Setting dc Voltage Sweep (Option 001 Only) . . . . . . . . . . . . . . . . 2-5

Setting dc Current Sweep (Option 001 Only) . . . . . . . . . . . . . . . . 2-5

3. Performing Calibration ......................... 2-6

Checking Calibration State . . . . . . . . . . . . . . . . . . . . . . . . 2-6

4. Setting Port Extension and Electrical Length .. ...... ...... . 2-7

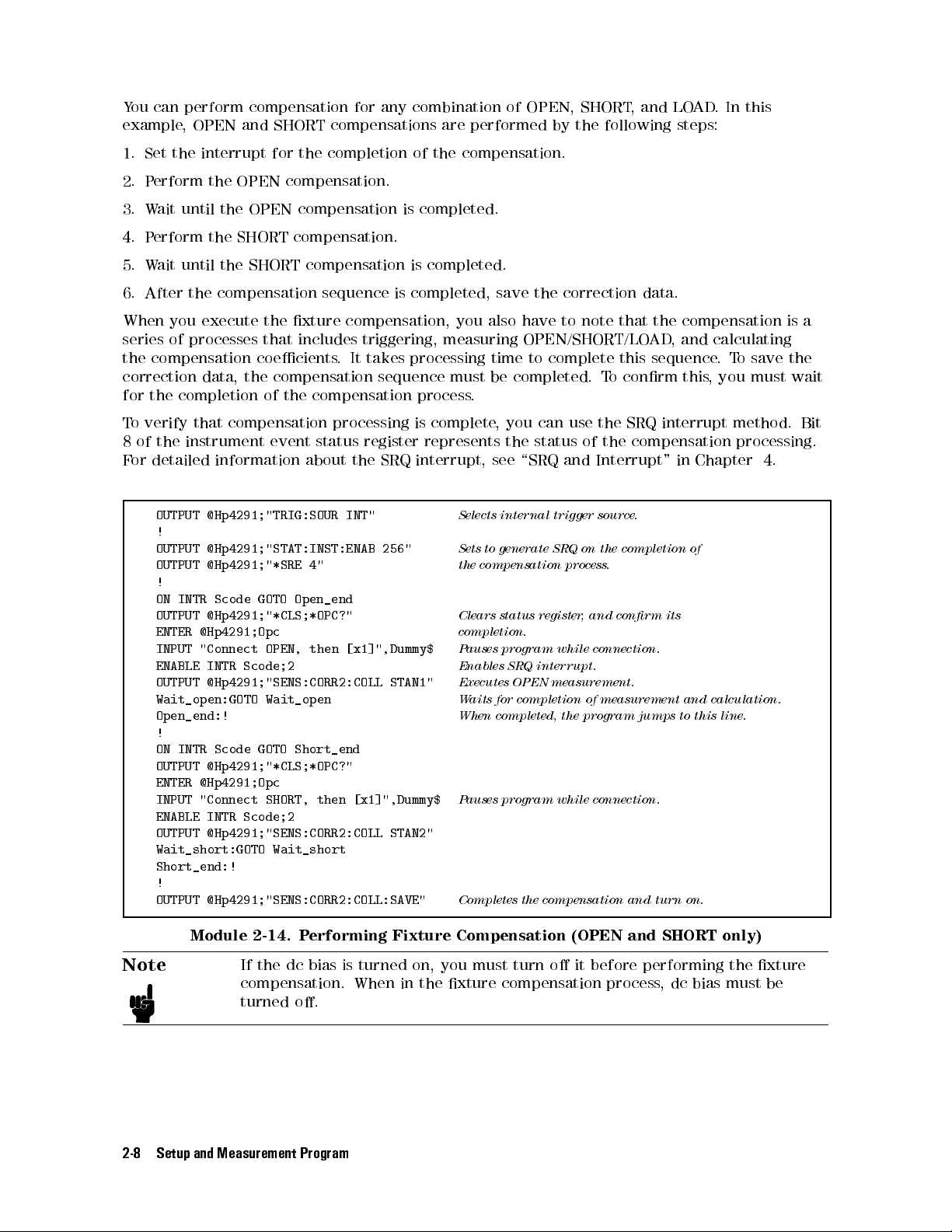

5. Performing Fixture Compensation .................... 2-7

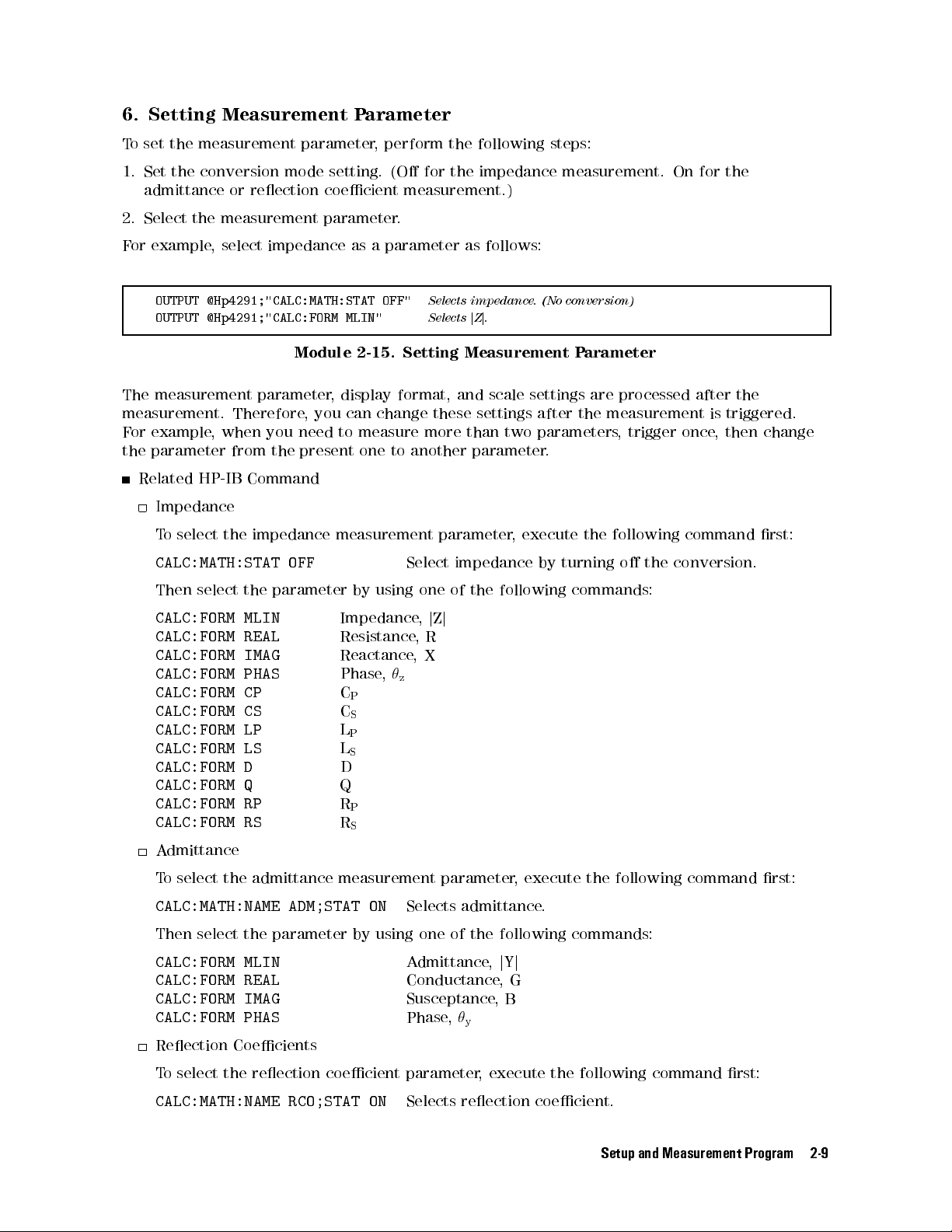

6. Setting Measurement Parameter ..................... 2-9

7. Setting Display Format ......................... 2-10

8. Setting dc Bias (Option 001 Only) .. ...... ...... ...... 2-11

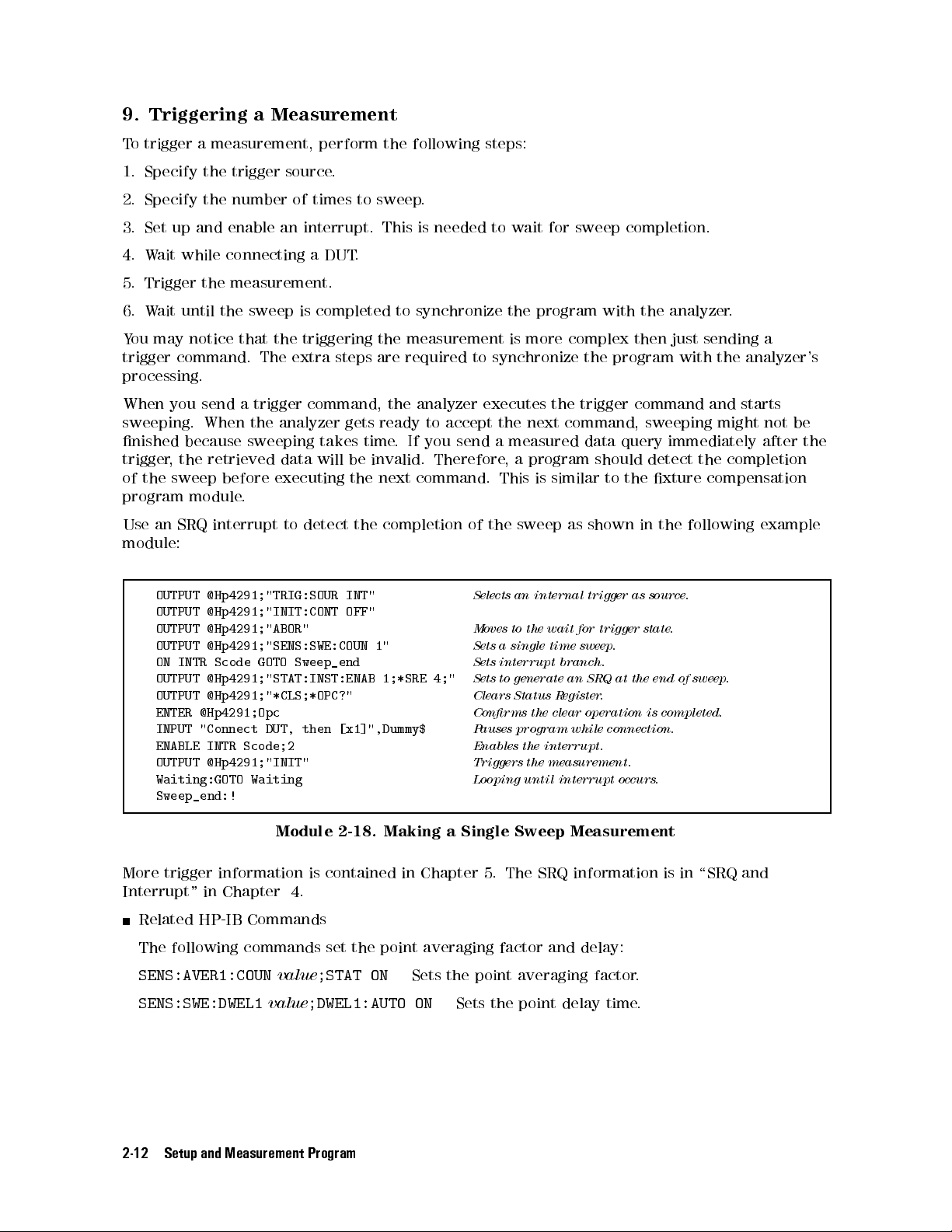

9. Triggering a Measurement . . . . . . . . . . . . . . . . . . . . . . . . 2-12

10. Setting Scale and Reference ......................

11. Getting Measured Data to the Controller ...... ...... ....

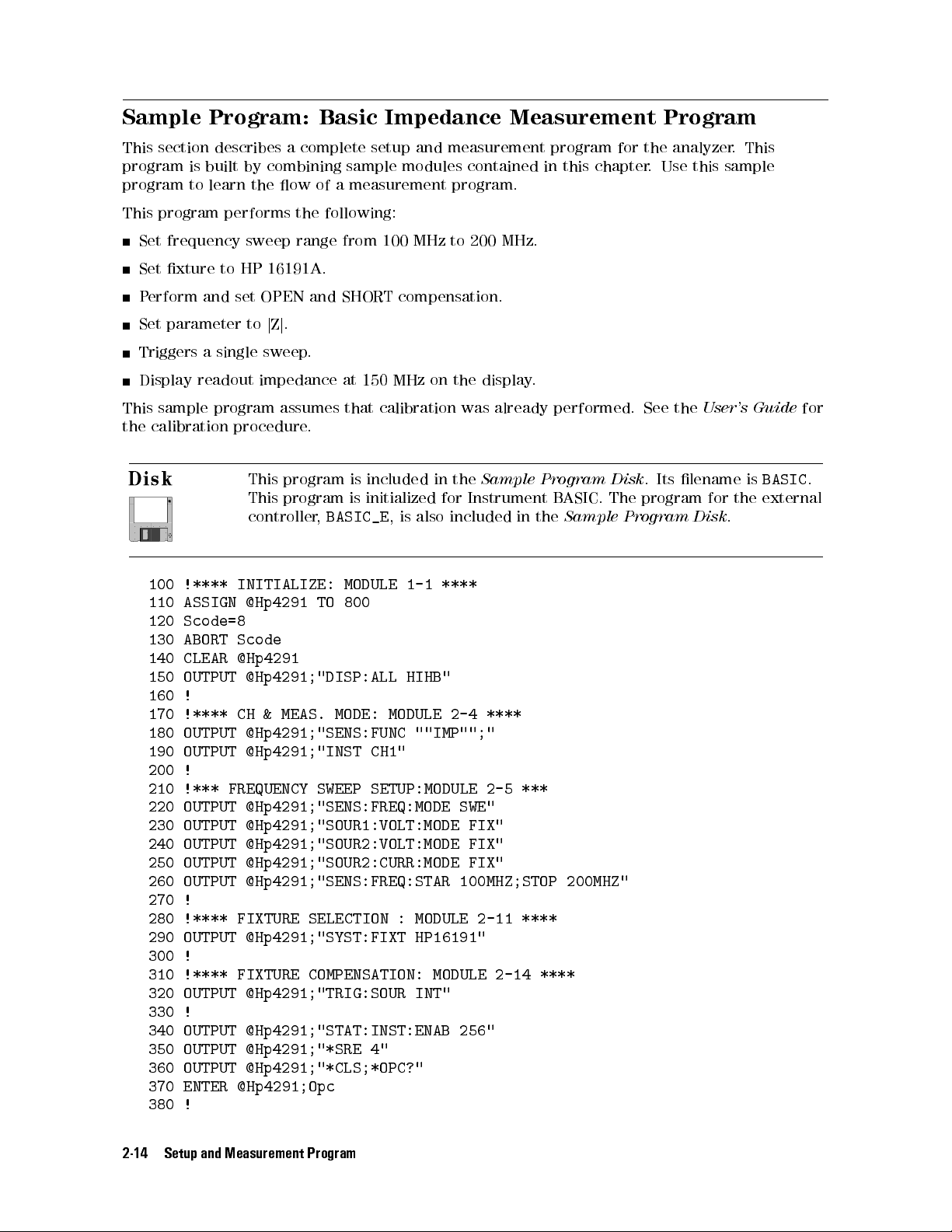

Sample Program: Basic Impedance Measurement Program ...........

Automating the Permittivity Measurement (Option 002 Only) . . . . . . . . . .

4. Selecting Fixture ............ ...... ..... .....

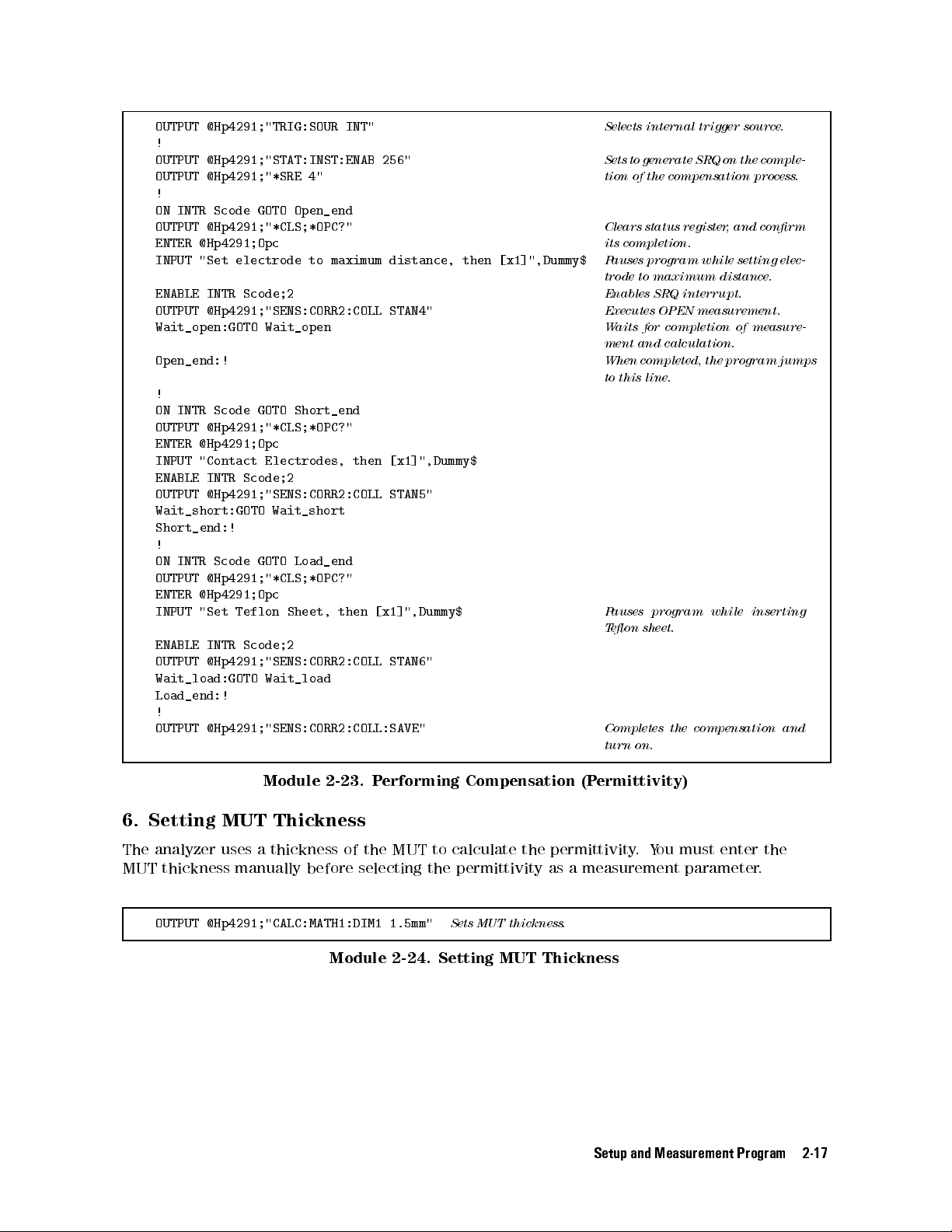

5. Performing Fixture Compensation ....................

6. Setting MUT Thickness .........................

7. Setting Measurement Parameter .....................

Cole-Cole Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

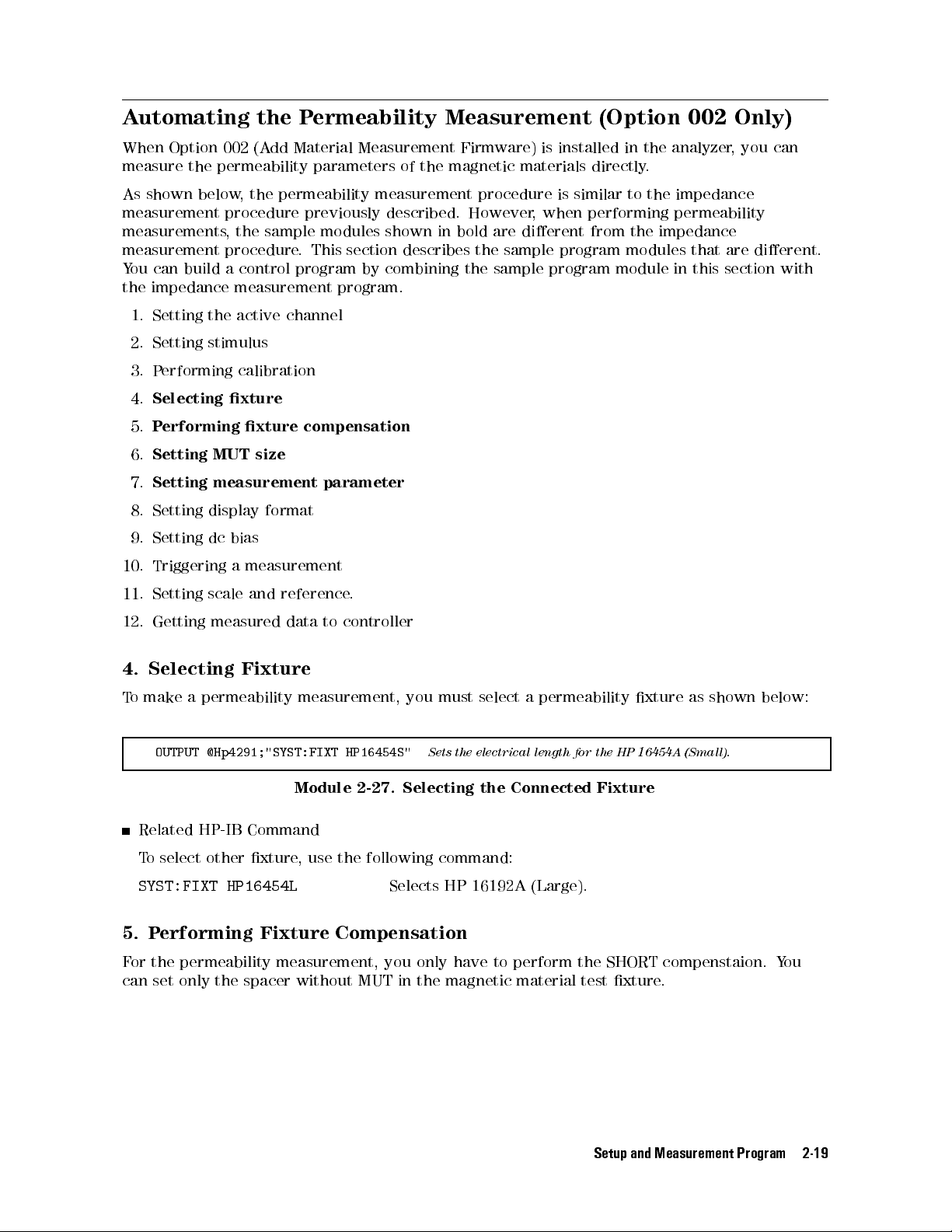

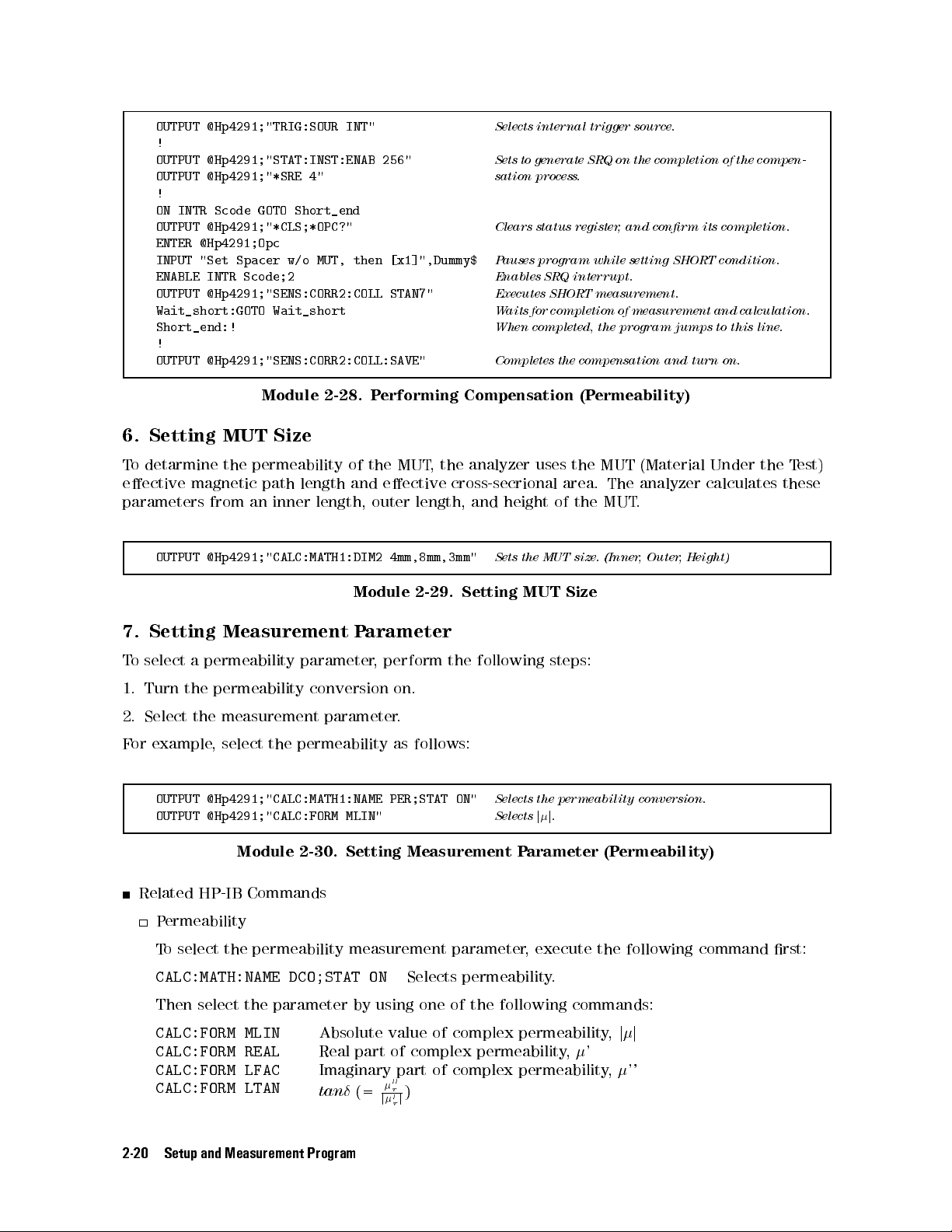

Automating the Permeability Measurement (Option 002 Only) . . . . . . . . . .

4. Selecting Fixture ............ ...... ..... .....

5. Performing Fixture Compensation ....................

6. Setting MUT Size .. ...... ...... ..... ...... ...

7. Setting Measurement Parameter .....................

2-13

2-13

2-14

2-16

2-16

2-16

2-17

2-18

2-18

2-19

2-19

2-19

2-20

2-20

3. Data Processing and Transfer

Data Arrays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Raw Data Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Data Array ................................ 3-2

Data Trace Array ...... ...... ...... ...... ..... 3-2

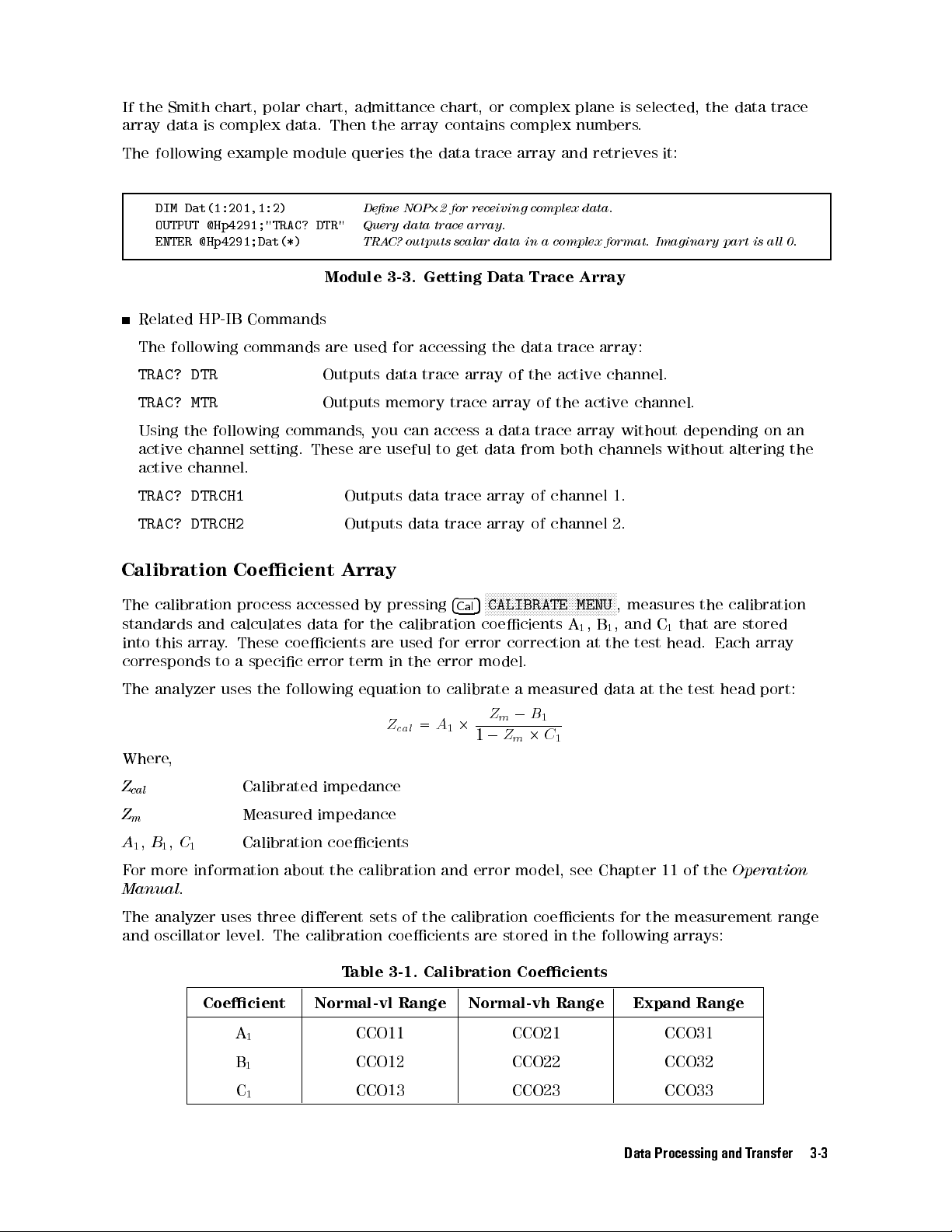

Calibration Coecient Array . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Arrays ............................

Compensation Coecient Array ...... ...... ...... ....

Accessing Arrays ............................

Monitor Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stimulus Array ..............................

Arrays for Memory Trace . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Memory Array . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Memory Trace Array . . . . . . . . . . . . . . . . . . . . . . 3-6

Data Transfer Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

ASCII Transfer ..............................

Binary Transfer ..............................

Data Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Data from Analyzer .. ...... ...... ..... ....

Sample Programs: Compensation Data Transfer ................

Contents-2

3-3

3-4

3-4

3-4

3-5

3-5

3-6

3-6

3-7

3-8

3-9

3-10

3-11

Page 7

Storing Compensation Data to Disk (CMP STOR) . . . . . . . . . . . . . . . 3-11

Loading Compensation Data from Disk (CMP LOAD).... ...... ... 3-13

4. Using Status Reporting System

General Status Register Model ........................ 4-1

Event Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Enable Register .............................. 4-2

Status Byte Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Transition Filter and Condition Register . . . . . . . . . . . . . . . . . . . 4-3

Status Register Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

How to Use the Status Registers in a Program . . . . . . . . . . . . . . . . . 4-8

Reading an Event Register Directly . . . . . . . . . . . . . . . . . . . . . 4-8

SRQ and Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Sample Program: Performing Calibration ................... 4-11

5. Using the Trigger System

Trigger System ............................... 5-2

Idle State ...... ...... ...... ..... ...... .... 5-2

Wait for Trigger State ........................... 5-2

Measurement State ............................ 5-3

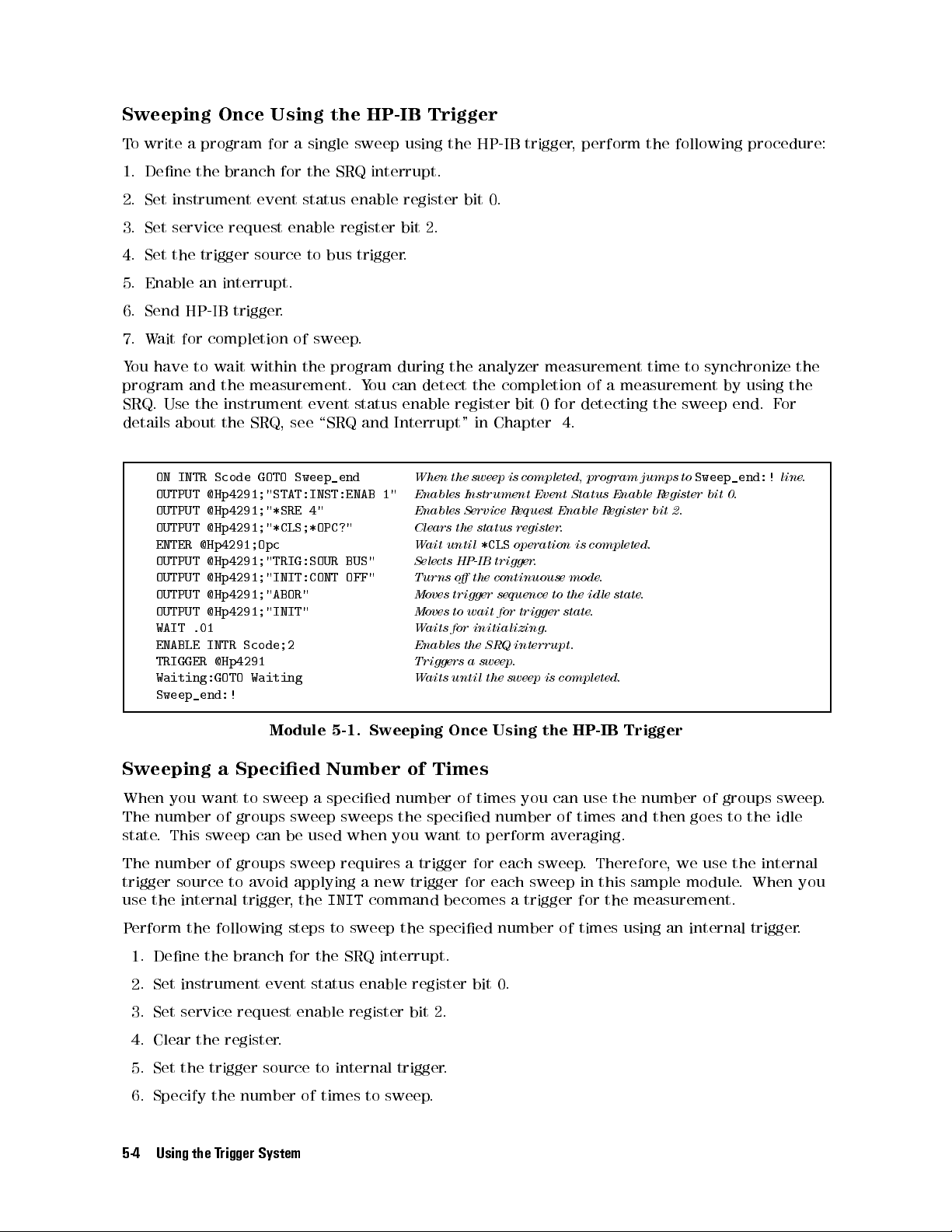

Sweeping Once Using the HP-IB Trigger . . . . . . . . . . . . . . . . . . .

Sweeping a Specied Number of Times ...................

Triggering on Each Point Using the Manual Trigger . . . . . . . . . . . . . .

6. Using the I/O Port

I/O Port Pin Assignment ...........................

Accessing I/O Port ..............................

Access I/O Port from the External Controller .... ...... ......

Sample Program: BIN Sorting Using the I/O Port...... ...... ....

5-4

5-4

5-5

6-1

6-2

6-2

6-3

7. Using the User Traces

What's the User Trace? ...........................

Using a User Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting A Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Data Train for The Trace .. ...... ...... ...... ..

Turning ON the User Trace . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Using the Marker on a User Trace . . . . . . . . . . . . . . . . . . . . . . 7-4

Clearing a User Trace .... ...... ...... ...... ..... 7-4

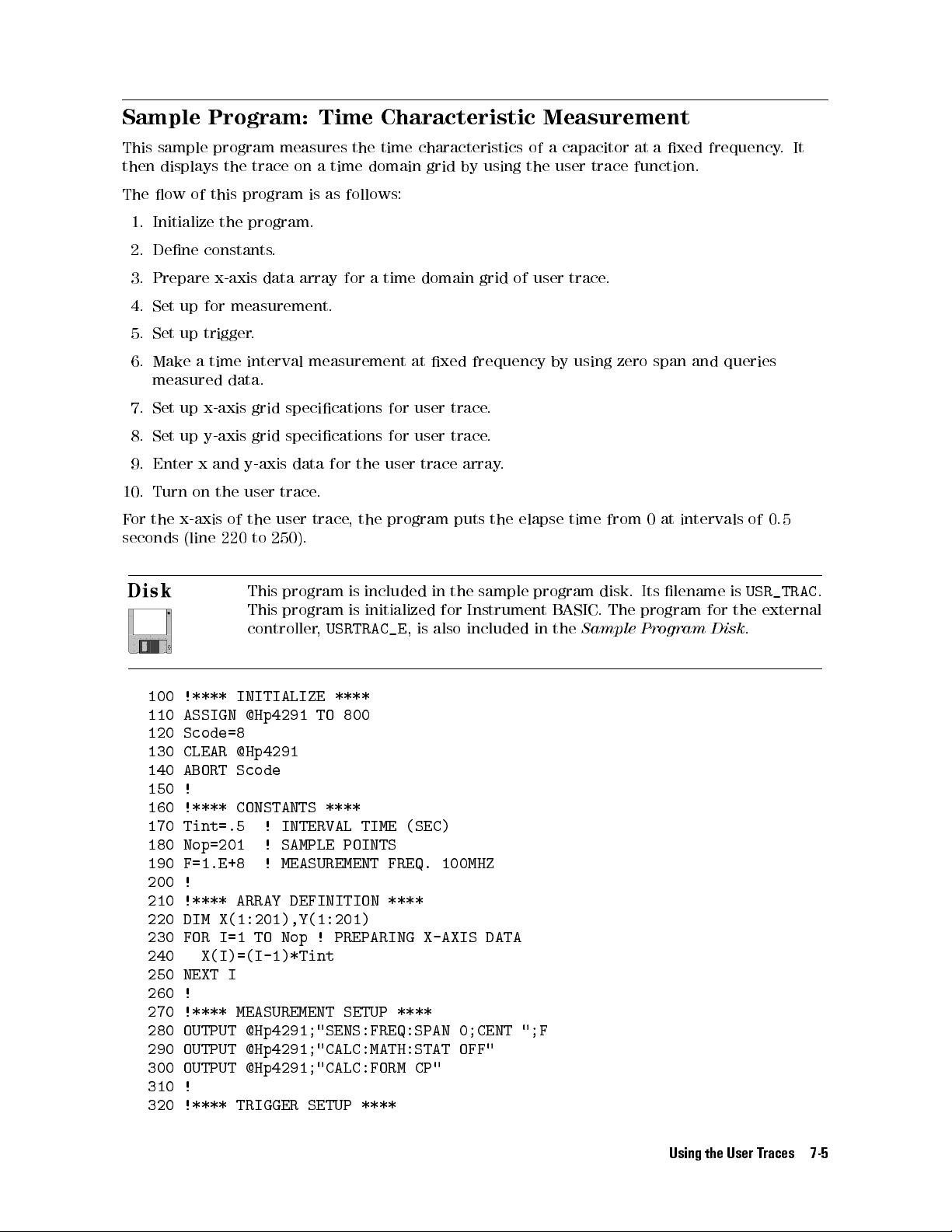

Sample Program: Time Characteristic Measurement .............. 7-5

8. Programming Miscellaneous

Using Disks .................................

Saving the Analyzer Status . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Trace Data From the Disk into a Program Variable ......... 8-2

Sample Program: Making HP CITIle .....................

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Print Analyzer Display .........................

Printer Preparation .... ...... ...... ..... ......

Execute Print ........ ...... ..... ...... ..... 8-5

To Observe Printing ............................ 8-5

Controlling Instrument BASIC from an External Controller . . . . . . . . . . .

Reading or Putting the Variable Data .......... ...... ....

Reading Numeric Variable ........................

Putting Numeric Variable . . . . . . . . . . . . . . . . . . . . . . . . .

Reading String Variable .... ...... ...... ...... ...

7-1

7-2

7-3

7-3

8-1

8-1

8-3

8-5

8-5

8-5

8-6

8-6

8-6

8-6

8-7

Contents-3

Page 8

Putting String Variable . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Simultaneously Running Instrument BASIC and External Controller Programs . 8-8

Controlling Instrument BASIC Execution Status .............. 8-8

Determining Instrument BASIC Execution State ...... ...... .. 8-8

Transferring Program Source . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Uploading a Program from Controller to Instrument BASIC . . . . . . . . . 8-10

Downloading a program from Instrument BASIC to the Controller . . . . . . 8-10

Debugging Program ............................. 8-11

Processing Time Measurement .... ...... ...... ...... .. 8-12

Key Sequence Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Generating Equivalent Program For Empty Editor . . . . . . . . . . . . . . 8-13

Inserting Equivalent Codes into Your Program . . . . . . . . . . . . . . . . 8-13

Limitations ................................ 8-14

File Transfer Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

File Transfer from HP 4291B to External Controller .......... ... 8-16

File Transfer from External Controller to HP 4291B .......... ... 8-18

Displaying List of Files in Current Directory . . . . . . . . . . . . . . . . . 8-20

9. Facilitating Program Execution and Utilizing Storage Devices

How to Save Programs of Instrument BASIC . . . . . . . . . . . . . . . . . . 9-1

The Procedure to Save Programs ......................

Running a Program through the Softkey Interface . . . . . . . . . . . . . . .

Automatically Starting a Program at Power-ON (AUTOST) ...........

About

AUTOREC

...... ...... ...... ...... ......

Using Storage Devices ............................

BASIC Commands for Setting up the Storage Devices . . . . . . . . . . . . .

Floppy Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Disk ...............................

Transfering Data between Floppy Disk and Memory Disk . . . . . . . . . . .

9-1

9-2

9-3

9-3

9-4

9-4

9-4

9-4

9-4

10. Introducing HP Instrument BASIC System

Overview of HP Instrument BASIC ......................

Controlling the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using HP Instrument BASIC for the First Time . . . . . . . . . . . . . . . . .

Allocating Screen Area for HP Instrument BASIC .... ...... ....

Entering BASIC Statements from the Front Panel Keys . . . . . . . . . . . . . 10-3

Getting into/out of the EDIT Mode ...................... 10-3

Getting into the EDIT Mode ........................ 10-3

Entering the EDIT Mode from the Keyboard . . . . . . . . . . . . . . . . . 10-3

Getting Out of the EDIT Mode ...... ...... ..... ...... 10-3

Editing Programs in the EDIT Mode . . . . . . . . . . . . . . . . . . . . . .

Deleting Characters .... ...... ...... ...... ......

Back Space .......... ...... ...... ..... ....

Deleting Characters ...........................

Inserting Characters ........ ...... ...... ...... ..

Moving the Cursor . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scrolling Lines and Pages . . . . . . . . . . . . . . . . . . . . . . . . . .

Scrolling Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scrolling Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Jumping from the Current Line . . . . . . . . . . . . . . . . . . . . . . . 10-5

Jumping to a Specied Line .......................

Jumping to the Top/Bottom of a Program .................

Inserting/Deleting/Recalling Lines . . . . . . . . . . . . . . . . . . . . . .

Clearing Line ...............................

Renumbering Program Line Numbers ...... ...... ...... ...

10-1

10-2

10-2

10-2

10-4

10-4

10-4

10-4

10-4

10-4

10-4

10-4

10-5

10-5

10-5

10-5

10-5

Contents-4

Page 9

Listing Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Listing on the Screen .... ...... ...... ...... ..... 10-6

Listing to the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Saving Programs (SAVE) .... ...... ...... ...... ..... 10-6

Listing File Names (CAT).... ...... ...... ...... ..... 10-7

Listing to Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Listing to Printer .... ...... ...... ...... ...... . 10-8

Getting Programs (GET) ........................... 10-8

On Key Label Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

Pass Control Between the External Controller . . . . . . . . . . . . . . . . . 10-9

Pass Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

To Execute an HP Instrument BASIC Command from the External Controller . 10-10

To Load an Array in an HP Instrument BASIC Program to the External Controller 10-11

Available I/O Interfaces and Select Codes .......... ...... ... 10-11

External RUN/CONTinue Connector . . . . . . . . . . . . . . . . . . . . . . 10-11

Graphics .................................. 10-12

HP Instrument BASIC Graphics Commands ................. 10-12

Hard Copies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

Initial settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

Example of Graphics Programming ..................... 10-13

Drawing a Straight Line .... ...... ...... ...... ...

Drawing a Circle . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character Entry Keys .. ...... ...... ..... ...... ..

Cursor-Control and Display-Control Keys ........ ...... ....

Numeric Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Keys .. ...... ...... ...... ...... .....

Program Control Keys .... ...... ...... ...... .....

System Control Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Softkeys and Softkey Control . . . . . . . . . . . . . . . . . . . . . . . .

Softkey Control Keys ...........................

Softkeys .................................

Softkeys Accessed form

Using

4

5

Key in Edit Mode ........ ...... ..... .....

CTRL

4

5

Key........ ...... ..... ...

F10

Run Light Indications ...........................

10-13

10-13

10-14

10-14

10-14

10-14

10-15

10-15

10-15

10-16

10-16

10-16

10-16

10-17

10-17

BASIC Commands Specic to HP 4291B . . . . . . . . . . . . . . . . . . . . 10-18

DATE................................... 10-18

DATE$ .... ...... ...... ...... ...... ...... 10-18

READIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

SET TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

SET TIMEDATE ..............................

TIME ...................................

TIME$ .. ...... ...... ...... ...... ...... ..

WRITEIO .................................

10-19

10-19

10-19

10-20

11. Command Reference

Conventions and Denitions .........................

ABORt .... ...... ...... ...... ..... ...... ..

BLIGHTfOFFjONj0j1g............................ 11-3

CALCulate Subsystem ............................ 11-4

CALCulate:EVALuate Subsystem .. ...... ...... ..... ...

:BAND:FULL[:STATe]fOFFjONj0j1g...... ...... ...... .

:BAND:SPAN DMARker . . . . . . . . . . . . . . . . . . . . . . . . .

:BAND:STARt MARKer .. ...... ...... ..... ......

:BAND:STOP MARKer .... ...... ...... ..... ....

11-1

11-2

11-4

11-4

11-4

11-4

11-5

Contents-5

Page 10

:COUPlefOFFjONj0j1g......................... 11-5

:EFFect:ONf1j2g............................ 11-5

:EPARameters ............................. 11-6

:EPARameters:CIRCuitfAjBjCjDjEg................... 11-6

:EPARameters:SIMulation .. ...... ...... ...... .... 11-6

:INTerpolatefOFFjONj0j1g....................... 11-6

:MSTatisticsfOFFjONj0j1g...... ...... ...... ...... 11-6

:MSTatistics:DATA? ........................... 11-7

:MSTatistics[:STATe]fOFFjONj0j1g.................... 11-7

:ON[1] \TRf1-21g" .. ...... ...... ...... ..... .. 11-7

:ON2f\OFF"j\ACV"j\ACC"j\DCV"j\DCC"g................ 11-8

:PEAK:EXCursionf<

:PEAK:EXCursion:Xf<

:PEAK:EXCursion[:Y]f<

numeric>j

numeric>j

numeric>j

DMARkerg................ 11-8

DMARkerg...... ..... .... 11-8

DMARkerg.............. 11-9

:PEAK:POLarityfPOSitivejNEGativeg.................. 11-9

:PEAK:THResholdf<

numeric>j

MARKerg................. 11-9

:PEAK:THReshold:STATefOFFjONj0j1g.................. 11-10

:R:FORMatfRIMaginaryjMLIPhasejMLOPhasejRXjGBjSWRPhaseg..... 11-10

:REFerence:DATA? ........................... 11-10

:REFerence:X<numeric>........................ 11-11

:REFerence:Y[1]<numeric

>

......................

:REFerence:Y2<numeric>.......................

:WIDTh:DATA? .............................

:WIDTh:STATefOFFjONj0j1g...... ...... ..... .....

:WIDTh:XPOSition:IN ...... ...... ...... ...... ..

:WIDTh:XPOSition:OUT .... ...... ...... ...... ...

:WIDTh:YfDIVS2jMULS2jDIV2jFIXed[,<numeric>]g...... .....

:Yf1-8g:DATA? [CH1jCH2] . . . . . . . . . . . . . . . . . . . . . . . .

:Yf1-8g:VALuef1j2g? [CH1jCH2] . . . . . . . . . . . . . . . . . . . . .

:Yf1-8g:XPOSition<numeric>......................

:Y[1]:XPOSition:LPEak .........................

:Y[1]:XPOSition:LTARget . . . . . . . . . . . . . . . . . . . . . . . . .

:Y[1]:XPOSition:MAXimum .. ...... ...... ...... ...

:Y[1]:XPOSition:MINimum . . . . . . . . . . . . . . . . . . . . . . . .

:Y[1]:XPOSition:NPEak ........ ...... ...... .....

11-11

11-11

11-12

11-12

11-12

11-12

11-13

11-13

11-14

11-14

11-14

11-15

11-15

11-15

11-15

:Y[1]:XPOSition:PEAK . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

:Yf1-8g:XPOSition:POINt<numeric>.................. 11-15

:Y[1]:XPOSition:RPEak ......................... 11-16

:Y[1]:XPOSition:RTARget ........................ 11-16

:Y[1]:XPOSition:TARGet<numeric>...... ...... ..... .. 11-16

:Y[1]:XPOSition:TRACkfMAXimumjMINimumjTARGetjPEAKjOFFg.... 11-16

CALCulate:FORMatfMLINearjPHASejUPHasejREALjIMAGinaryjLFACtor

j

LTANgentjCPjCSjLPjLSjDjQjRPjRSjCOMPlexg...... ...... ...

11-17

CALCulate:FORMat:UNIT:ANGLefDEGjRADg............... 11-18

CALCulate:LIMit Subsystem ........................

:BEEPerfOFFjONj0j1g.........................

:BEEPer:CONDitionfPASSjFAILg...... ...... ...... ..

:BEEPer[:STATe]fOFFjONj0j1g......................

11-18

11-18

11-18

11-18

:CLEar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-19

:CONTrol:OFFSet<numeric>...... ...... ...... .... 11-19

:LINEfOFFjONj0j1g...... ...... ...... ..... ...

:OFFSetf<

numeric>j

MARKerg.....................

:SAVE .................................

:SEGMent<numeric

>

...... ...... ..... ...... ..

:SEGMent:ADD . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-19

11-20

11-20

11-20

11-21

Contents-6

Page 11

:SEGMent:CONTrol[:DATA]<numeric>...... ...... ..... 11-21

:SEGMent:DELete . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-21

:SEGMent:DELTa<numeric>...................... 11-21

:SEGMent:EDIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-22

:SEGMent:LOWer<numeric>...................... 11-22

:SEGMent:MIDDlef<

numeric>j

MARKerg...... ...... .... 11-22

:SEGMent:SAVE............................. 11-22

:SEGMent:UPPer<numeric

>

...................... 11-23

:STATefOFFjONj0j1g.......................... 11-23

CALCulate:MATH1 Subsystem ...... ...... ...... ..... 11-23

:CATalog? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-23

:DIMension1<numeric>...... ...... ...... ...... 11-24

:DIMension2<numeric(in)>,<numeric(out)>,<numeric(hei)>....... 11-24

[:EXPRession]:CATalog? ......................... 11-24

[:EXPRession]:NAMEfADMjDCOjPERjRCOg............... 11-24

:STATefOFFjONj0j1g.......................... 11-25

CALCulate:MATH2 Subsystem ...... ...... ...... ..... 11-25

[:EXPRession]:CATalog? ......................... 11-25

[:EXPRession]:NAMEfSUBjADDjDIVjMULg...... ...... .... 11-26

:STATefOFFjONj0j1g.......................... 11-26

CENT<numeric>, CHANf1j2g, CLEM, CONT . . . . . . . . . . . . . . . .

DATA Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATA[:DATA]fAOFFjGAINjMZAPg,<numeric>...............

DATA[:DATA] OFFS,f<

DATA[:DATA]<array>,f<

n2>g

.................................

numeric>j

MARKerg.................

block>j<numeric11>,<numeric12>, ... ,<numeric

DATA[:DATA]fEQC0jEQC1jEQL1jEQR1g,<numeric>.............

DATA[:DATA]? LFA ............................

DATA[:DATA]? LLIS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATA[:DATA]? LMAR ...........................

DATA[:DATA]?MEM............................

DATA[:DATA]? SPAR............................

DATA[:DATA]:VALue?fSPARjDATAjMEMjMONg,<numeric>.........

DATA:DEFinefOADMjSIMPjLIMPg,f<

numeric>j

DATAjDTRjTR1g....... 11-31

DATA:DELetefOADMjSIMPjLIMPg.....................

11-27

11-27

11-27

11-28

11-28

11-29

11-29

11-29

11-30

11-30

11-30

11-30

11-31

DATA:POINt? LFA............................. 11-31

DATMEM .................................. 11-32

DIAGnostic Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-32

DIAGnostic:EREFerence:STATe?............ ...... ..... 11-32

DIAGnostic:FREVision? .......................... 11-32

DIAGnostic:INIT:RESult? . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGnostic:SERVice Subsystem . . . . . . . . . . . . . . . . . . . . . . .

DIAGnostic:TEST Subsystem ........................

DFLT, DISPfDATAjMEMOjDATMg......................

11-32

11-33

11-33

11-34

DISPlay Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . ..... 11-34

DISPlay:ANNotation:FREQuencyfOFFjONj0j1g............... 11-34

DISPlay:BACKlightfOFFjONj0j1g...... ...... ...... ....

DISPlay:BRIGhtness<numeric>...... ...... ...... ....

11-34

11-35

DISPlay:CMAP Subsystem ......................... 11-36

:COLorf1-14g:DEFault . . . . . . . . . . . . . . . . . . . . . . . . . . 11-36

:COLorf1-14g:HSL<numeric(Hue)>,<numeric(Sat)>,<numeric(Lum)>... 11-36

:DEFault ................................

:LOAD .................................

:STORe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPlay:CONTrast<numeric>.......................

11-37

11-37

11-37

11-37

Contents-7

Page 12

DISPlay[:WINDow]:ALLocationfINSTrumentjHIHBjBASicjBSTatusg...... 11-37

DISPlay[:WINDow]:FORMatfFBACkjULOWerg............... 11-38

DISPlay[:WINDow]:GRAPhics:STATefOFFjONj0j1g............. 11-38

DISPlay[:WINDow]:TEXTf1-40gSubsystem ...... ...... ..... 11-38

:CLEar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-39

:COLor<numeric>........................... 11-39

[:DATA]<string>...... ...... ...... ...... .... 11-39

:LOCate<numeric(x)>[,<numeric(y)>] ................. 11-40

:PAGEfUPjDOWNj<

numeric>g

..................... 11-40

:STATefOFFjONj0j1g.......................... 11-41

DISPlay[:WINDow]:TRACef1-21gSubsystem . . . . . . . . . . . . . . . . . 11-41

:CLEar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-41

:GRATicule:AXIS:COUPlefOFFjONj0j1g.................. 11-42

:GRATicule:FORMatfRECTanglejPOLarjSMIThjADMittancejCPLaneg.... 11-42

:GRATicule:GRID[:STATe]fOFFjONj0j1g.................. 11-43

:MARKer[1]:ALL DEFault . . . . . . . . . . . . . . . . . . . . . . . . 11-43

:MARKer[1]:ALL:STATefOFFjONj0j1g...... ...... ...... 11-43

:MARKer[1]:RELativefOFFjONj0j1g...... ...... ..... .. 11-43

:MARKer[1]:RELative:REFerencefFIXedjMARKerjTRACkedg....... 11-44

:MARKerf2-8g:STATefOFFjONj0j1g................... 11-44

:MARKerf1-8g:UNITfSPARameterjTIMEjIOMegag............

:STATefOFFjONj0j1g..........................

:X[:SCALe]:LEFT<numeric>...... ...... ...... ....

:X[:SCALe]:RIGHt<numeric>......................

:X[:SCALe]:RLEVel<numeric>.....................

:X:SPACingfLINearjLOGarithmicjOBASeg................

:X:UNIT<string

>

...... ...... ...... ..... ....

:Y[:SCALe]:AUTO ONCE .. ...... ...... ...... ....

:Y[:SCALe]:BOTTom<numeric>.....................

:Y[:SCALe]:COUPlefOFFjONj0j1g....................

:Y[:SCALe]:PDIVision<numeric>...... ...... ...... ..

:Y[:SCALe]:RLEVelf<

numeric>j

MARKerg................

:Y[:SCALe]:RPOSition<numeric>...... ...... ...... ..

:Y[:SCALe]:TOP<numeric>.......................

:Y:SPACingfLOGarithmicjLINearg...... ...... ...... ..

11-45

11-45

11-46

11-46

11-46

11-47

11-47

11-48

11-48

11-48

11-49

11-49

11-50

11-50

11-50

:Y:UNIT<string>...... ...... ...... ..... ..... 11-51

DISSMEMOfOFFjONj0j1g,DUACfOFFjONj0j1g............... 11-52

DPI<numeric>...... ...... ...... ...... ...... . 11-52

DUAMfIMPHjIRIMjAPPHjARIMjLSQjLPQjCSDjCPDjDMPHjDRIMjPMPHjPRIMg. 11-52

FMTfLINYjLOGYjPOLjSMITjADMjCOMPg................... 11-52

FORMat Subsystem .............................

FORMat[:DATA]fASCiijREAL,32jREAL,64jPACKed,32g...........

FREO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FORMFEEDfOFFjONj0j1g..........................

HCOPy Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HCOPy ..................................

HCOPy:ABORt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HCOPy:DEFault ..............................

11-52

11-52

11-54

11-54

11-54

11-54

11-54

11-54

HCOPy:DEVice:CMAP:COLorfFIXedjVARiableg............... 11-55

HCOPy:DEVice:COLorfOFFjONj0j1g...... ...... ...... .. 11-55

HCOPy:DEVice:DPI<numeric>......................

HCOPy:DEVice:FORMFeedfOFFjONj0j1g...... ...... ......

HCOPy:DEVice:LANDScapefOFFjONj0j1g.................

HCOPy:DEVice:LEFTMarg<numeric>...... ...... ..... ..

HCOPy:DEVice:SKEYfOFFjONj0j1g...... ...... ..... ...

11-55

11-56

11-56

11-56

11-57

Contents-8

Page 13

HCOPy:DEVice:TOPMarg<numeric>.................... 11-57

HCOPy[:IMMediate] ............................ 11-57

HCOPy:ITEM Subsystem .......................... 11-57

:TDSTamp:STATefOFFjONj0j1g..................... 11-58

HOLD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-59

INITiate Subsystem ...... ...... ...... ..... ...... 11-59

INITiate:CONTinuousfOFFjONj0j1g...... ...... ...... .. 11-59

INITiate[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-59

INITiate[:IMMediate]:AGAin:ALL . . . . . . . . . . . . . . . . . . . . . . 11-60

INSTrument Subsystem ........................... 11-61

INSTrumentfCH1jCH2g.......................... 11-61

INSTrument:COUPlefALLjNONEg..................... 11-61

INSTrument:NSELectf1j2g........................ 11-61

INSTrument[:SELect]fCH1jCH2g...... ...... ...... .... 11-62

INSTrument:STATefOFFjONj0j1g...................... 11-62

LANDSCAPEfOFFjONj0j1g, LISDfFBASjOBASg, LMARG<numeric>..... 11-63

MARDCENT, MARDSPAN, MARKfOFFjONj0j1g, MARKCENT, MARKREF

MARKSTAR, MARKSTOP, MARZ ..................... 11-63

MATHfDATAjDMNMjDPLMjDDVMjDMLMg.................. 11-63

MEASfIMAGjIPHjIREjIIMjAMAGjAPHjAREjAIMjRCMjRCPH

RCRjRCIMjDCMjDCPHjDCRjDCIMjPHMAjPPHjPREjPIMjCPjCSjLP

LSjDjQjRPjRSg...... ...... ...... ...... ......

MMEMory Subsystem ............................

MMEMory:CDIRectory [<string>] .....................

MMEMory:COPYf<

string(s)>,<string(m s)>,<string(d)>,<string(m d)>g

MMEMory:CREate:DIRectory<string>...... ...... ...... .

MMEMory:DELete<string(le name)>[,<string(m)>] .... ...... ..

MMEMory:INITialize<string>,fLIFjDOSg...... ..... ...... .

MMEMory:LOAD Subsystem ........................

:STATe<string(le name)>[,<string(m)>] ................

:TRACe SEL,<string(le name)>[,<string(m)>]......... .....

MMEMory:STORe Subsystem ........................

:DINTerchange:TIFF<string(le name)>[,<string(m)>]..... .....

j

j

11-63

11-63

11-63

.. 11-64

11-64

11-64

11-65

11-65

11-65

11-65

11-66

11-66

:DINTerchange:TRACe SEL,<string(le name)>[,<string(m)>]....... 11-66

:ITEM:TRACe:CATalog? ...... ...... ...... ...... .

11-66

:ITEM:TRACe:DELetefCCOjDATAjDTRjUTRjMEMjMTRjRAWg...... . 11-67

:ITEM:TRACe:SELectfCCOjDATAjDTRjUTRjMEMjMTRjRAWg....... 11-67

:STATe<string(le name)>[,<string(m)>] ................ 11-68

:TRACe SEL,<string(le name)>[,<string(m)>]......... ..... 11-68

NUMG<numeric>............................. 11-69

PROGram Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROGram:CATalog? ............................

PROGram[:SELected] Subsystem .... ...... ...... ......

:DEFine<block>...... ...... ...... ...... ....

:DELete[:SELected] . . . . . . . . . . . . . . . . . . . . . . . . . . .

:DELete:ALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

:EXECute<string>...........................

:MALLocatef<

numeric>j

DEFaultg...... ...... ...... .

11-69

11-69

11-69

11-69

11-70

11-70

11-70

11-71

:NAME<string>............................ 11-71

:NUMBer<var>,<numeric1>,<numeric2>, ... ,<numeric n>...... 11-71

:STATefRUNjPAUSejSTOPjCONTinueg...... ..... ...... .

:STRing<var>,<string1>,<string2>, ... ,<string n>...... .....

:WAIT .... ...... ...... ...... ...... .....

PROGram:EXPLicit Subsystem .......... ...... ...... .

:DEFine \PROG",<block

>

...... ...... ...... .....

11-72

11-72

11-72

11-73

11-73

Contents-9

Page 14

:DELete \PROG" . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-73

:EXECute \PROG",<string>....................... 11-73

:MALLocate \PROG",f<

numeric>j

DEFaultg............... 11-73

:NAME \PROG",<string>........................ 11-73

:NUMBer \PROG",<var>,<numeric1>,<numeric2>, ... ,<numeric n>.. 11-74

:STATe \PROG",fRUNjPAUSejSTOPjCONTinueg...... ...... .. 11-74

:STRing \PROG",<var>,<string1>,<string2>, ... ,<string n

>

...... 11-74

:WAIT \PROG" ............................. 11-74

PEAKCENT, POIDTIME<numeric>, PRSOFTfOFFjONj0j1g, SELM<numeric>11-75

SAVDSTAC<string>,SAVDTIF<string>, STODfDISKjMEMOg, STORMDISK .. 11-75

SENSe Subsystem .............................. 11-75

SENSe:AVERage1:COUNt<numeric>...... ...... ...... .. 11-75

SENSe:AVERage1[:STATe]fOFFjONj0j1g...... ...... ...... 11-75

SENSe:AVERage2:CLEar . . . . . . . . . . . . . . . . . . . . . . . . . . 11-76

SENSe:AVERage2:COUNt<numeric>...... ...... ...... .. 11-76

SENSe:AVERage2[:STATe]fOFFjONj0j1g...... ...... ...... 11-76

SENSe:CORRection1 Subsystem . . . . . . . . . . . . . . . . . . . . . . . 11-76

:CKITfAPC7jUDEFinedg........................ 11-77

:CKIT:LABel<string>......................... 11-77

:CKIT:SAVE............................... 11-77

:CKIT:STANdard1:C<numeric>...... ...... ...... ...

:CKIT:STANdard1:G<numeric>.....................

:CKIT:STANdard2:L<numeric>.....................

:CKIT:STANdard2:R<numeric>...... ...... ...... ...

:CKIT:STANdard3:R<numeric>...... ...... ...... ...

:CKIT:STANdard3:X<numeric>.....................

11-77

11-78

11-78

11-78

11-78

11-79

:COLLect[:ACQuire]fSTANdard1jSTANdard2jSTANdard3jSTANdard4g... 11-79

:COLLect:FPOintsfFIXedjUSERg.....................

:COLLect:SAVE .............................

:EDELay:STATefOFFjONj0j1g......................

:EDELay[:TIME]<numeric>.......................

[:STATe]? ................................

SENSe:CORRection2 Subsystem . . . . . . . . . . . . . . . . . . . . . . .

:CKIT[1]:LABel<string>...... ...... ..... ...... .

:CKIT[1]:SAVE .... ...... ...... ..... ...... ..

11-79

11-80

11-80

11-80

11-81

11-82

11-82

11-82

:CKIT[1]:STANdard1:C<numeric>...... ...... ...... .. 11-82

:CKIT[1]:STANdard1:G<numeric

>

...... ...... ...... . 11-82

:CKIT[1]:STANdard1[:SELect]fLISTjLPARameterg............ 11-83

:CKIT[1]:STANdard2:L<numeric>.................... 11-83

:CKIT[1]:STANdard2:R<numeric>...... ...... ...... .. 11-83

:CKIT[1]:STANdard2[:SELect]fLISTjLPARameterg............

:CKIT[1]:STANdard3:L<numeric>....................

:CKIT[1]:STANdard3:R<numeric>...... ...... ...... ..

11-83

11-84

11-84

:CKIT[1]:STANdard3[:SELect]fLISTjLPARameterg............ 11-84

:CKIT2fTEFLonjUDEFinedg......................

:CKIT2:LABel<string>.........................

:CKIT2:SAVE ..............................

:CKIT2:STANdard6:PREal<numeric>...... ...... ......

11-84

11-85

11-85

11-85

:CKIT2:STANdard6:PLFactor<numeric>................. 11-85

:CKIT2:STANdard6:THICkness<numeric>...... ...... .... 11-86

:COLLect[:ACQuire] STANdardf1-7g...... ...... ...... .

:COLLect:FPOintsfFIXedjUSERg....................

:COLLect:SAVE.............................

:OPEN[:STATe]fOFFjONj0j1g......................

:SHORt[:STATe]fOFFjONj0j1g......................

11-86

11-86

11-87

11-87

11-87

Contents-10

Page 15

:LOAD[:STATe]fOFFjONj0j1g...................... 11-87

SENSe:FREQuency Subsystem ....................... 11-88

:CENTerf<

numeric>j

DMARkerjMARKerjTPEakg............. 11-88

:MODEfFIXedjLISTjSWEepg...................... 11-88

:SPANf<

:STARtf<

:STOPf<

numeric>j

numeric>j

numeric>j

DMARkerjMZAPertureg............... 11-89

MARKerg...................... 11-89

MARKerg...................... 11-89

SENSe:LIST Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-90

:CLEar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-90

:SAVE ................................. 11-90

:SEGMent<numeric>.......................... 11-90

:SEGMent:ADD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-90

:SEGMent:AVERage:COUNt<numeric>................. 11-90

:SEGMent:CURRent<numeric>...... ...... ...... ... 11-91

:SEGMent:DELete . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-91

:SEGMent:EDIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-91

:SEGMent:FREQuency:CENTer<numeric>...... ...... .... 11-91

:SEGMent:FREQuency:SPAN<numeric>...... ...... ..... 11-92

:SEGMent:FREQuency:STARtf<

:SEGMent:FREQuency:STOPf<

numeric>j

numeric>j

MARKerg........... 11-92

MARKerg........... 11-92

:SEGMent:POINts<numeric>......................

:SEGMent:POWer<numeric>......................

:SEGMent:QUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

:SEGMent:SAVE.............................

:SEGMent:VOLTage<numeric>.....................

SENSe:SWEep:COUNt<numeric>.....................

SENSe:SWEep:DWELlf1j2g<

numeric>...... ...... ...... .

SENSe:SWEep:DWELlf1j2g:AUTOfOFFjONj0j1g..............

SENSe:SWEep:POINts<numeric>.....................

SENSe:SWEep:SPACingfLINearjLOGarithmicg...............

SENSe:SWEep:TIME<numeric>......................

SENSe:SWEep:TIME:AUTOfOFFjONj0j1g..................

SING .......... ...... ...... ..... ...... ...

SOURce Subsystem .............................

SOURce1:FREQuency[:CWj:FIXed]<numeric>...............

SOURce1:fCURRentjPOWerg[:LEVel][:IMMediate][:AMPLitude]<numeric>.. 11-97

SOURce1:SWEep:DIRectionfUPjDOWNg.................. 11-98

SOURce1:SWEep:SPACingfLINearjLOGarithmicg............... 11-98

SOURce1:VOLTage Subsystem . . . . . . . . . . . . . . . . . . . . . . . . 11-98

:CENTerf<

numeric>j

DMARkerjMARKerjTPEakg...... ...... 11-98

[:LEVel][:IMMediate][:AMPLitude]<numeric>...... ...... ..

:MODEfFIXedjLISTjSWEepg......................

:SPANf<

:STARtf<

:STOPf<

numeric>j

numeric>j

numeric>j

DMARkerjMZAPertureg...............

MARKerg......................

MARKerg......................

SOURce2:fCURRentjVOLTagegSubsystem ..................

:ALC[:STATe]fOFFjONj0j1g.......................

:CENTerf<

numeric>j

DMARkerjMARKerjTPEakg............. 11-101

11-100

11-100

11-100

11-101

11-101

[:LEVel][:IMMediate][:AMPLitude]<numeric>...... ...... .. 11-101

:LIMit[:AMPlitude]<numeric>...... ...... ...... ... 11-102

:MODEfFIXedjSWEepg...... ...... ...... ...... .

:SPANf<

:STARtf<

numeric>j

numeric>j

DMARkerjMZAPertureg...............

MARKerg......................

:STATefOFFjONj0j1g..........................

:STOPf<

numeric>j

MARKerg......................

11-102

11-103

11-103

11-103

11-104

11-93

11-93

11-93

11-93

11-94

11-94

11-94

11-95

11-95

11-95

11-96

11-96

11-97

11-97

11-97

11-99

11-99

Contents-11

Page 16

SOURce2:SWEep:DIRectionfUPjDOWNg...... ...... ...... 11-104

SOURce2:SWEep:SPACingfLINearjLOGarithmicg............... 11-104

SPAN<numeric>,STAR<numeric>.................... 11-105

STATus Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-105

STATus:INSTrument Subsystem . . . . . . . . . . . . . . . . . . . . . . . 11-105

:ENABle<numeric>...... ...... ...... ...... .. 11-105

[:EVENt]? ............................... 11-105

STATus:OPERation Subsystem .. ...... ...... ...... ... 11-106

:CONDition? .............................. 11-106

:ENABle<numeric>...... ...... ...... ...... .. 11-106

[:EVENt]? ............................... 11-106

:NTRansition<numeric>........................ 11-107

:PTRansition<numeric>...... ...... ...... ...... 11-107

STATus:PRESet .. ...... ...... ...... ...... .... 11-107

STATus:QUEStionable Subsystem .... ...... ...... ...... 11-108

:CONDition? .............................. 11-108

:ENABle<numeric>.......................... 11-108

[:EVENt]? ............................... 11-108

STOP<numeric>.............................. 11-109

STYPEfLINjLOGjLISTg, SWEDfUPjDOWNg, SWEDTIME<numeric>,

SWESfFREQjOLEVjDCVjDCIg......................

SYSTem Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTem:BEEPerf1j2g:STATefOFFjONj0j1g.................

SYSTem:COMMunicate:GPIB Subsystem . . . . . . . . . . . . . . . . . . .

:CONTroller:ADDRess<numeric>....................

SYSTem:COMMunicate:PARallel Subsystem .................

[:RECeive]:DATA?.... ...... ...... ...... ......

:TRANsmit:DATA<numeric>...... ...... ...... ....

SYSTem:DATE<numeric(year)>,<numeric(month)>,<numeric(day)

>

.... 11-111

SYSTem:DATE:MODEfMDYjDMYg.....................

SYSTem:ERRor? ..............................

SYSTem:FIXTurefNONEjHP16191jHP16192jHP16193jHP16194jHP16453

j

HP16454SjHP16454LjUDEFinedg....................

SYSTem:FIXTure:DISTance<numeric>...................

SYSTem:FIXTure:LABel<string

>

.....................

11-109

11-109

11-109

11-109

11-110

11-110

11-110

11-110

11-111

11-111

11-111

11-112

11-112

SYSTem:FIXTure:SAVE...... ...... ...... ...... ... 11-112

SYSTem:KEY<numeric>...... ...... ...... ..... .. 11-112

SYSTem:KLOCkfOFFjONj0j1g....................... 11-113

SYSTem:PRESet .............................. 11-114

SYSTem:SECurity[:STATe]fONj1g...................... 11-114

SYSTem:TIME<numeric(hour)>,<numeric(min)>,<numeric(sec)>...... 11-114

SYSTem:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMARG<numeric>...... ...... ...... ...... .....

TRACe Subsystem ..............................

TRACe:COPY TRf2-17g,TR1 ........................

TRACe:COPY TRf18-21g,TRf1-17g...... ...... ...... ...

TRACe[:DATA]<trace>,f<

n2>g

.................................

TRACe[:DATA]fTRXf18-21gjTRYf18-21gg,f<

<

numeric2>, ... ,<numeric n>g

block>j<numeric11>,<numeric12>, ... ,<numeric

block>j<numeric1>,

...... ...... ...... .. 11-117

TRACe[:DATA]:VALue?<trace>,<numeric>................

TRACe:POINts TRf18-21g[,<numeric>]......... ...... ....

TRIGger Subsystem .............................

TRIGger:EVENt:TYPEfPOINtjSWEepg...................

TRIGger:SLOPefPOSitivejNEGativeg....................

11-115

11-116

11-116

11-116

11-116

11-116

11-117

11-118

11-119

11-119

11-119

Contents-12

Page 17

TRIGger:SOURcefBUSjEXTernaljINTernaljMANualg...... ...... . 11-119

USKEY ................................... 11-121

Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-121

3

CLS ........ ...... ...... ...... ...... ... 11-121

3

ESE<numeric>............................. 11-121

3

ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-121

3

IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-121

3

OPC ...... ...... ...... ...... ...... ..... 11-122

3

OPT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-122

3

PCB<numeric>...... ...... ...... ...... ..... 11-122

3

RST ........ ...... ...... ...... ...... ... 11-123

3

SRE<numeric>...... ...... ...... ..... ...... 11-123

3

STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-123

3

TRG ...... ...... ...... ...... ...... ..... 11-123

3

TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-123

3

WAI .... ...... ...... ...... ...... ...... . 11-124

Simple Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-125

BLIGHTfOFFjONj0j1g...... ...... ...... ...... ... 11-125

CENT<numeric>............................. 11-125

CHAN1 .................................. 11-125

CHAN2 ..................................

CLEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLOSE ........ ...... ...... ...... ..... ...

CONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CWD? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATMEM .................................

DFLT ...................................

DISPfDATAjMEMOjDATMg........................

DISSMEMOfOFFjONj0j1g...... ...... ..... ...... ..

DPI<numeric>..............................

DUACfOFFjONj0j1g...... ...... ...... ...... ....

11-126

11-126

11-126

11-126

11-126

11-126

11-127

11-127

11-127

11-128

11-128

DUAMfIMPHjIRIMjAMPHjARIMjLSQjLPQjCSDjCPDjDRLFjDRLTjDLFLT

j

DMLTjPRLFjPRCLTjPLFLTjPMLTg...... ...... ...... ..

FMTfLINYjLOGYjPOLjSMITjADMjCOMPg...... ...... ......

FNAME?<numeric>...... ...... ..... ...... .....

11-128

11-129

11-130

FNUM? .................................. 11-130

FORMFEEDfOFFjONj0j1g...... ...... ...... ..... .. 11-130

FREO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-130

FSIZE?<string>.............................. 11-131

HOLD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-131

LANDSCAPEfOFFjONj0j1g........................

LMARG<numeric>............................

LISDfFBASjOBASg...... ...... ...... ...... ....

MARDCENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MARDSPAN................................

MARKfOFFjONj0j1g...........................

MARKCENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MARKREF ................................

11-131

11-131

11-132

11-132

11-132

11-132

11-133

11-133

MARKSTAR ................................ 11-133

MARKSTOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-133

MARZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MATHfDATAjDMNMjDPLMjDDVMjDMLMg...... ...... .....

11-133

11-133

MEASfIMAGjIPHjIREjIIMjAMAGjAPHjAREjAIMjRCMjRCPHjRCRjRCIM

j

DCRjDCLFjDCLTjDCMjPREjPLFjPLTjPMAGjCPjCSjLPjLSjDjQjRPjRSg.... 11-134

NUMG<numeric>............................

11-135

Contents-13

Page 18

PEAKCENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-135

POIDTIME<numeric>........................... 11-135

PRSOFTfOFFjONj0j1g........................... 11-135

READ? .................................. 11-136

ROPEN<string

>

...... ...... ...... ...... ..... 11-136

RESTMDISK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-137

SAVDSTAC<string>...... ...... ...... ...... .... 11-137

SAVDTIF<string>...... ...... ...... ..... ..... 11-137

SELM<numeric>............................. 11-138

SING ................................... 11-138

SPAN<numeric>............................. 11-138

STAR<numeric>...... ...... ..... ...... ...... 11-138

STODfDISKjMEMOg............................ 11-139

STOP<numeric>...... ...... ...... ...... ..... 11-139

STORMDISK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-139

STYPEfLINjLOGjLISTg.......................... 11-139

SWEDfUPjDOWNg...... ...... ...... ...... .... 11-140

SWEDTIME<numeric>.......................... 11-140

SWESfFREQjOLEVjDCVjDCIg...... ...... ...... ..... 11-140

TMARG<numeric>............................ 11-141

USKEY ..................................

WOPEN<string>[,<numeric>]....... ...... ...... ....

WRITE<block>..............................

A. Manual Changes

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change 1 .......... ...... ...... ...... ..... .

11-141

11-141

11-142

A-1

A-1

A-2

A-3

B. Complex Operation Sub Program

Complex Opearation Sub Program . . . . . . . . . . . . . . . . . . . . . . .

Sample Program: Using Complex Operation Sub Program . . . . . . . . . . .

C. HP-IB Command List by Function

Front Panel Key List with Equivalent HP-IB Commands ............ C-2

HP-IB Only Functions and the HP-IB Commands . . . . . . . . . . . . . . . . C-33

D. SCPI Conformance Information

SCPI Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

HP-IB Commands Compatible to SCPI . . . . . . . . . . . . . . . . . . . . .

Simple Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. Measurement Parameter Settings Using HP-IB Commands

Messages

Index

B-1

B-2

D-1

D-14

Contents-14

Page 19

Figures

1-1. HP-IB Device and Address ......................... 1-6

1-2. Program Message Terminators ...... ...... ...... ..... 1-8

1-3. Command Tree and Compound Header Usage ................ 1-12

2-1. Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3-1. Simplied Data Processing Flow ...................... 3-1

3-2. Simplied Internal Process of ASCII and Binary Transfer . . . . . . . . . . . 3-7

3-3. IEEE 64-bit oating point format . . . . . . . . . . . . . . . . . . . . . . 3-8

3-4. IEEE 32-bit oating point format . . . . . . . . . . . . . . . . . . . . . . 3-9

3-5. Binary Data Header ............................ 3-9

4-1. General Status Register Model ........ ...... ..... .... 4-1

4-2. Transition Filter and Condition Register . . . . . . . . . . . . . . . . . . . 4-3

4-3. Status Register Structure . . . . . . . . . . . . . . . . . . . . . . . . . .

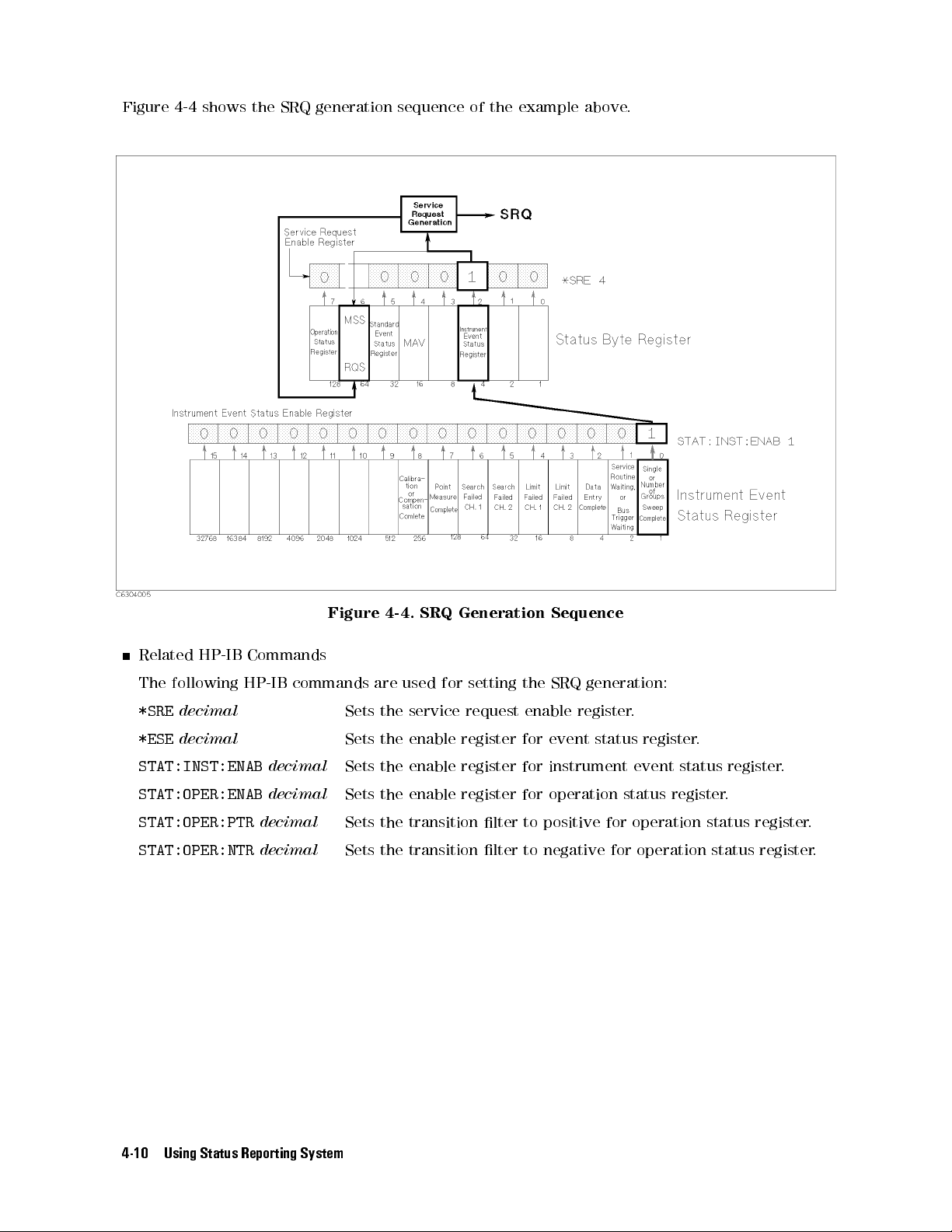

4-4. SRQ Generation Sequence .........................

5-1. Simplied Trigger System .... ...... ...... ...... ...

6-1. I/O Port Pin Assignment ...... ...... ...... ...... ..

6-2. Connecting I/O Port ............................

6-3. Timing Chart ...... ...... ...... ...... ..... ..

7-1. User Trace ........ ...... ...... ..... ...... .

8-1. Example of HP CITIle . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2. Sample Program : To Observe Printing ...................

10-1. Sample Program : To Transfer the Program to IBASIC (on External Controller) 10-10

10-2. Sample Program : To Load HP Instrument BASIC Program Array (on External

Controller) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-3. Screen Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-1. Key Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-2. Fixed length block format .........................

11-113

11-136

11-3. Procedure of executing commands to read/write data ............ 11-137

A-1. Serial Number Plate ...... ...... ...... ...... .... A-2

E-1. Data Formatting Inside HP 4291B . . . . . . . . . . . . . . . . . . . . . . E-1

4-4

4-10

5-2

6-1

6-3

6-4

7-2

8-3

8-5

10-11

10-12

Contents-15

Page 20

Tables

3-1. Calibration Coecients . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

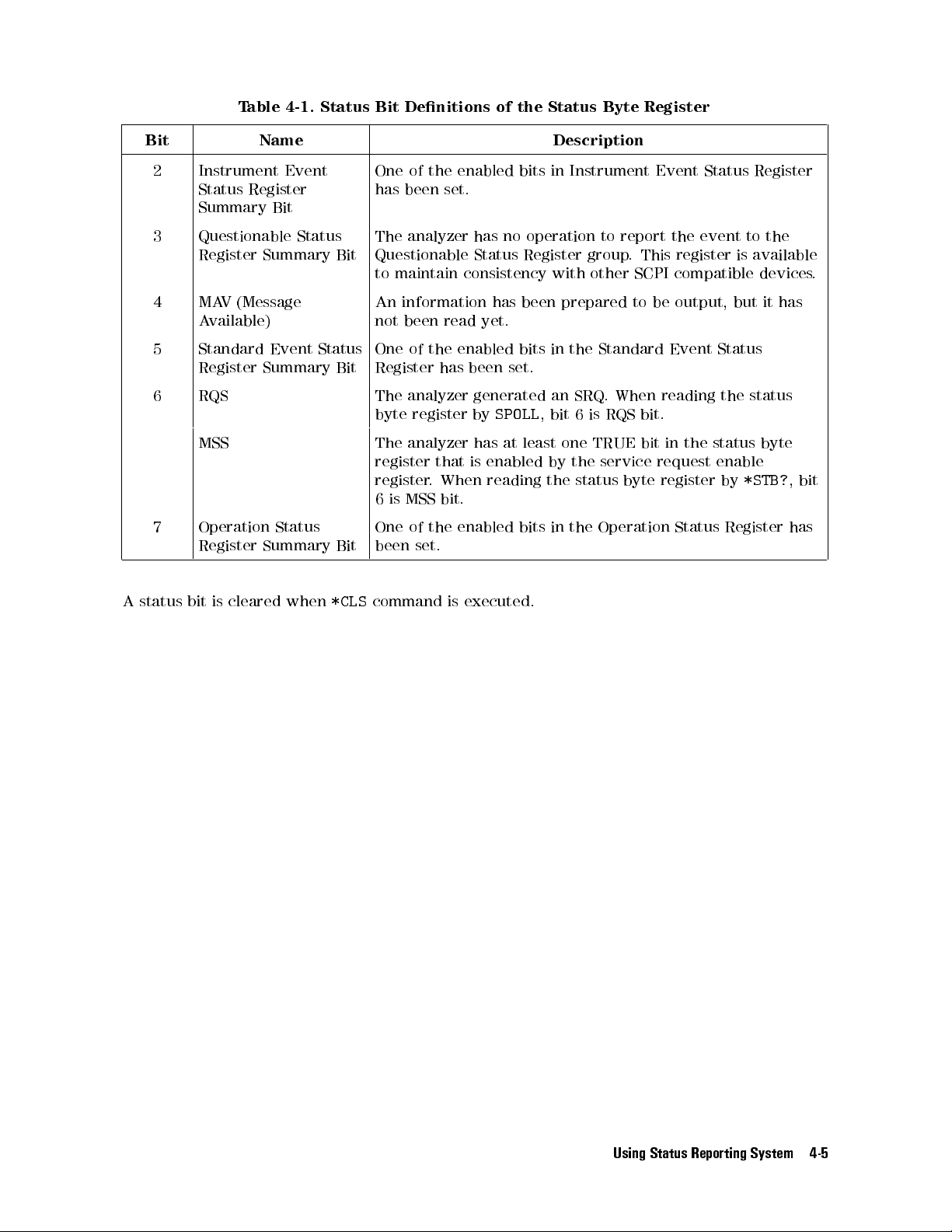

4-1. Status Bit Denitions of the Status Byte Register .............. 4-5

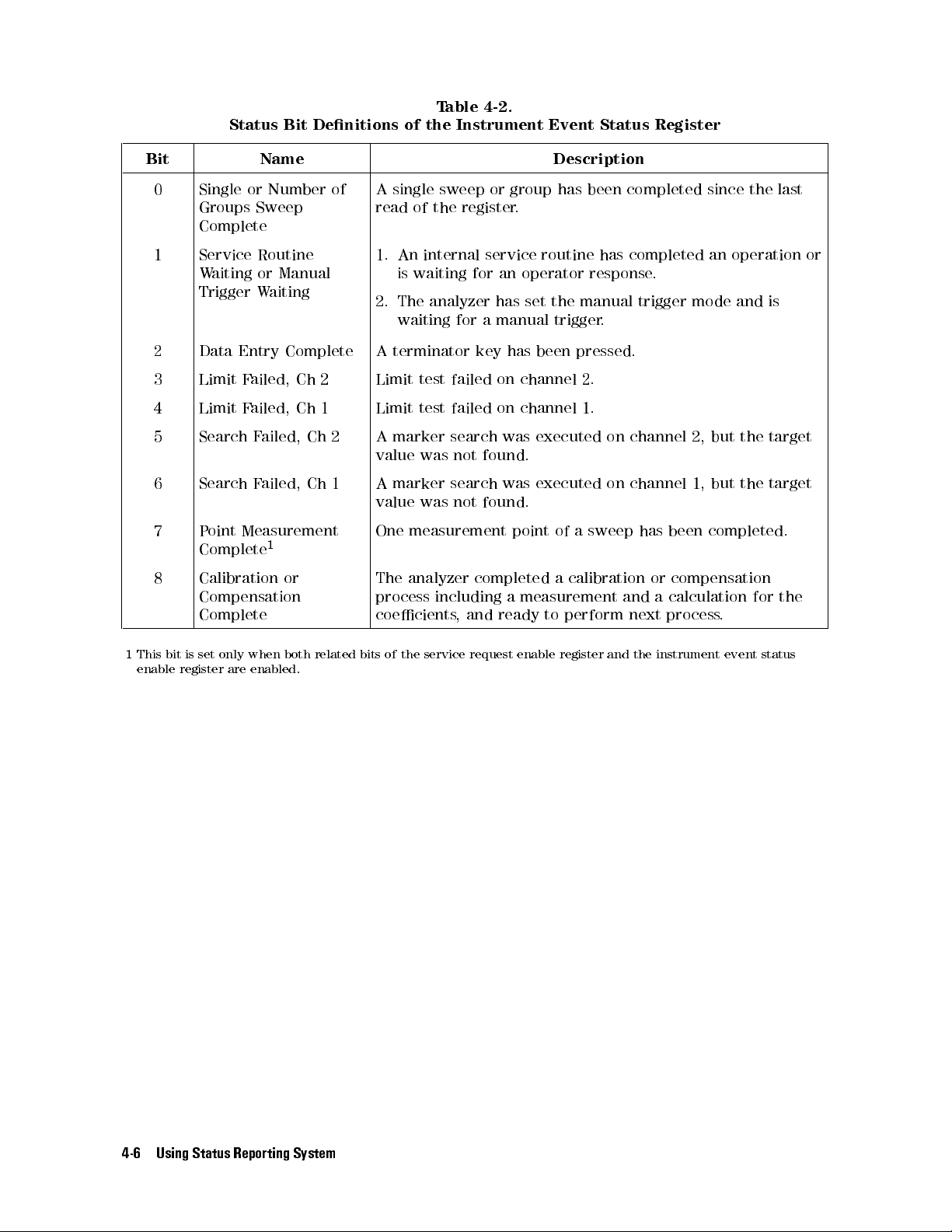

4-2. Status Bit Denitions of the Instrument Event Status Register .... .... 4-6

4-3. Status Bit Denitions of the Standard Event Status Register ...... ... 4-7

4-4. Status Bit Denitions of the Operation Status Register ............ 4-7

7-1. HP-IB Commands for User Trace 1 to 4 .... ...... ...... ... 7-2

A-1. Manual Changes by Serial Number .... ...... ...... ..... A-1

A-2. Manual Changes by Firmware Version . . . . . . . . . . . . . . . . . . . . A-1

D-1. IEEE 488.2 Common Commands ...................... D-1

D-2. Instrument Control Commands ....................... D-2

D-3. Simple Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-14

E-1. HP-IB Commands Setting Measurement Parameters (1/2) . . . . . . . . . . .

E-2. HP-IB Commands Setting Measurement Parameters (2/2) . . . . . . . . . . .

E-2

E-3

Contents-16

Page 21

1

Introduction

How to Use This Manual

This manual introduces HP-IB programming for the HP 4291B. It provides additional

information on how to write programs that might be dicult to understand when using only

the HP-IB Command Reference. It also provides information, techniques, and examples of how

to eectively control HP-IB instruments.

To use this manual eectively, you need one of the following HP-IB controllers:

HP Instrument BASIC. That is an internal HP-IB controller in the HP 4291B.

HP Vectra PC (or IBM compatible PC) with HP BASIC for Windows. An HP 9000 Series 700

(200 or 300) UNIX computer that has BASIC/UX.

This manual helps you to learn how to write programs that control the HP 4291B. T

o help you

learn quickly, many sample modules and programs are provided.

Target Reader

A target reader of this manual is a programmer who wants to control the HP 4291B through

the HP-IB interface.

This manual explains HP-IB programming using HP BASIC. Therefore, you should have some

experience using BASIC. If you have never written a program in B

ASIC, review the applicable

documentation listed at the end of this chapter before starting this manual. This manual does

not require extensive knowledge of BASIC programming.

This manual assumes you understand the operations and features of the HP 4291B. If you

have never operated the HP 4291B, read the

Quick Start Guide

to learn how to operate the

HP 4291B.

What's in This Manual?

The following chapters are provided in this manual:

Chapter 1 \Introduction" provides an introduction to this manual, how to use a sample

program, an HP-IB overview, hardware preparation, and a description of the sample program

disk. This chapter provides important information that is used throughout this manual. You

should read this chapter rst.

Chapter 2 \Setup and Measurement Program" provides HP-IB command basics. It also shows

how to build a measurement program including setups, compensating, triggering, and getting

data. If you want to build an automated measurement program, read this chapter.

Chapter 3 \Data Processing and Transfer" shows the data processing ow and the arrays

of the analyzer, describes how to access an internal data array (including trace data or

calibration data). If you want to get measured trace data from the analyzer

, read this

chapter.

Introduction 1-1

Page 22

Chapter 4 \Using Status Reporting System" describes the status reporting system of the

analyzer and how to use it. This chapter also describes an SRQ interrupt. If you want to

obtain the analyzer's status using a BASIC program, read this chapter.

Chapter 5 \Using the Trigger System" describes the SCPI trigger system and the procedures

for using several types of sweeps and triggers. Read this chapter to learn how to use single

or multiple sweeps.

Chapter 6 \Using the I/O Port" provides information on how to use the I/O port on the rear

panel. If you want to use the I/O port for communicating with an external instrument (such

as a handler), read this chapter.

Chapter 7 \Using the User Traces" describes how to use a user trace.

Chapter 8 \Programming Miscellaneous" provides information not directly concerned with

measurements, but useful for programming. This includes disk access, controlling Instrument

BASIC, or debugging a program.

Chapter 9 \Facilitating Program Execution and Utilizing Storage Devices" provides

information on how to execute instrument BASIC programs easily, and on strage system

relation to this function.

Chapter 10 \Introducing HP Intrument B

ASIC System" explains how to use HP 4291B's

Instrument BASIC function.

Chapter 11 explains all the HP-IB command functions and their syntax.

Appendix A \Manual Changes" shows revision information for this manual.

Appendix B provides the complex operation subprogram for the instrument B

ASIC which

does not has the complex operation function.

Appendix C lists all the HP-IB commands sorted by function (key label). This list helps you to

nd the commands that are functionally equivalent to the key operations

. Functions that are

only available from HP-IB and corresponding commands are also listed.

Appendix D provides the Standard Commands for Programmable Instruments (SCPI)

conformance information. All commands implemented in the analyzer are listed in this

chapter.

Appendix E helps you to understand about the measurement parameter setting commands by

explaining the theory of the data formatting inside the analyzer.

Error Messages lists all error messages with an explanation for each error.

1-2 Introduction

Page 23

How to Use the Program Modules

This manual provides many sample program modules that are not in a complete program

style.You can easily understand the module's objective because the program module does

not includes unnecessary code.You can use these modules to build your own program by

combining them.

The program modules are provided in the following style and typeface:

THIS IS A SAMPLE CODE.

As shown in the example above, a module has no line number, no initializing part, and no

This is a comment for a sample code.

END

statement. All these are required for an executable BASIC program.

Building a Working Program Using Program Modules

To make a program that uses sample program modules, perform the following steps:

1. Add an initializing module at the beginning of your program.

2. Arrange the program modules.

3. Add an

The line numbers are added automatically by the B

END

statement on the last line executed by your program.

ASIC editor.

Initializing Module

The initializing module denes a hardware identier as a variable to eliminate the dierence

between Instrument BASIC and HP BASIC. Usually, you can use the same program for

Instrument BASIC and HP BASIC by changing the initializing module. The initializing module

also intializes an HP-IB.

The following are the initializing modules for a program:

ASSIGN @Hp4291 TO 800

Scode=8

ABORT Scode

CLEAR @Hp4291

Assigning HP-IB address to 800.

Assigning interface select code to 8.

Get active control.

Preset the interface.

Module 1-1. Initialize Module for Instrument BASIC

ASSIGN @Hp4291 TO 717

Scode=7

ABORT Scode

CLEAR @Hp4291

Assigning HP-IB address to 717.

Assigning interface select code to 7.

Get active control.

Preset the interface.

Module 1-2. Initialize Module for the External Controller

Each module of this manual assumes that one of the initializing modules exists at the beginning

of the program, and uses the following variables without notice:

800

@Hp4291

Represents the device selector of the HP 4291B.

and

717

is for the external controller.

is for Instrument BASIC

Introduction 1-3

Page 24

Scode

Example

For example, a complete program using Module 2-2 in Chapter 2 and Instrument BASIC, is

shown below:

10 ASSIGN @Hp4291 TO 800 !

20 Scode=8 ! Module 1-1

30 ABORT Scode !

40 CLEAR @Hp4291 !

50 !

60 OUTPUT @Hp4291;"SYST:PRES;:INST CH2" ! Module 2-2

70 !

80 END

Represents the interface select code to which the HP 4291B is connected.8is

for Instrument BASIC and7is for the external controller.

1-4 Introduction

Page 25

HP-IB Overview

The HP-IB is a general purpose digital interface system that is used to integrate the controller,

measurement instruments, and peripherals into a system. HP-IB is Hewlett-Packard's

implementation of the IEEE 488 Bus.

Controller

The controller is a device that can address an HP-IB device to talk (output data) or listen

(receive data).

The active controller can control the other devices on the bus at that time (when multiple

controllers are connected). Only one controller can be active at a time. The active controller

can pass control to another controller by using the

Only one controller can be a system controller on the same bus. The system controller is

the active controller when the system is turned on. When another controller is the active

controller, the system controller can become the active controller at any time by executing

ABORT

select-code

.

PASS CONTROL

command.

Introduction 1-5

Page 26

Device Selector

HP-IB device control is accomplished by sending commands from the active controller. The

active controller can select the target device for the commands by specifying the device

selector.

Figure 1-1. HP-IB Device and Address

Figure 1-1 shows the relationship between the HP-IB address and the device selector

example, the device selector of the printer on HP-IB with an address of \1," is \701" on the

HP-IB.

HP Instrument BASIC is connected in the HP 4291B internally by the internal interface. The

interface select code of the internal interface is \8" to distinguish it from the external select

code of \7."

You can use any address from \00" to \30" to specify the internally connected analyzer from

Instrument BASIC, because only the analyzer is connected on the internal interface

manual uses address \00," thus the device selector is \800."

.For

. This

1-6 Introduction

Page 27

HP-IB Commands

The analyzer is equipped with the Hewlett-Packard Interface Bus (HP-IB) remote programming

digital interface. The HP-IB is Hewlett-Packard's hardware, software, documentation, and

support for the IEEE 488.1, IEC-625, IEEE 488.2, and JIS-C1901 worldwide standards for

interfacing instruments.

The HP-IB commands implemented in the HP 4291B are divided into the following three

categories: common commands, instrument control commands, and simple commands.

The HP 4291B's HP-IB commands conform to the Standard Commands for Programmable

Instruments (SCPI). SCPI is the new instrument command language for controlling instruments

that goes beyond IEEE 488.2 to address a variety of instrument functions in a standard

manner.

Common Commands

Common commands are dened by the IEEE 488.2 standard. All common commands begin

with an asterisk (3).

For example,

3

CLS

Instrument Control Commands

Instrument control commands are dened by SCPI, and include all measurement functions

and some general purpose functions. Instrument control commands consist of subsystems.

Each subsystem is a set of commands that roughly corresponds to a functional block inside the

instrument.

Instrument control commands have a hierarchical structure, called a

command tree,

that

consists of several nodes separated by colons.

For example,

CALCulate:EVALuate:BAND:FULL

Simple Commands

Simple commands are analyzer-specic commands that conform to IEEE 488.2. Each simple

command controls some measurement function that is normally programmed by sending

multiple instrument control commands.To reduce the number of program lines and make the

program simpler, these functions can also be executed by using a simple command instead of

the multiple instrument control commands.

Note

All HP-IB commands implemented the analyzer are listed in Chapter 11.

Introduction 1-7

Page 28

Program Message Syntax

This section explains the construction of program messages.A

program message

is the

message that you send from a computer to an instrument. Program messages consist of

commands combined with appropriate punctuation and program message terminators.

Command Abbreviations

Many instrument control commands have a long and a short form. The short form is obtained

by deleting the lower case letters. The analyzer accepts both forms.

For example, the short form of

(The analyzer does

not

accept anything in between, such as

:INITiateis:INIT

and the long form of it is

:INITIA

.)

:INITIATE

Some commands have a numerical sux. The numerical sux can be omitted, and the

analyzer recognizes that a numerical sux of1is implied in this command.

For example in

DISP:CMAP:COL

DISPlay:CMAP:COLor{1-14}

, it is recognized as

DISP:CMAP:COL1

, the numerical sux is

(the 1 is implied).

{1-14}

. If you send

Upper and Lower Cases

Letter cases (upper and lower) are ignored.

Program Message Terminator

A program message must end with the

program message terminators

.

.

Figure 1-2. Program Message Terminators

<^END>

means that End of Identify (EOI) is asserted on the HP-IB interface at the same time

the preceding data byte is sent.

The HP BASIC

OUTPUT

statement automatically sends program message terminators after the

last data byte.

1-8 Introduction

Page 29

Multiple Messages

To send more than one command in the same message, you must separate them with a

semicolon(;):

SENS:FREQ:STAR 100MAHZ;STOP 1GHZ

For more information, see \Command Tree and Compound Header Usage", later in this chapter.

Query and Response Message Syntax

All commands can be queried except the commands described as \no query" in the command

reference.To send a query message, add?after the last command mnemonic.

SENS:FREQ:STAR?

A query response indicates the current setting of the analyzer. A response message may

contain both commas and semicolons as separators. When a single query command returns

multiple values, a comma is used to separate each data item. When multiple queries are sent

in the same message, the group of data items corresponding to each query are separated by

a semicolon. For example, the ctitious query

QUERY1?;QUERY2?

might return a response

message of:

<data1>,<data1>;<data2>,<data2>

After the message,

<New Line><^END>

is always sent as a response message terminator.

Parameters

There must be a

<white space>

example below) and the rst parameter (

3

between the last command mnemonic (

100MAHZ

, in the example below).

SOUR:FREQ

, in the

SOUR:FREQ 100MAHZ

If you send more than one parameter with a single command, each parameter must be

separated by a comma.

DATA AOFF,2

Each command reference contains information about the parameters available for the

individual commands. There are parameters that are spelled out (for example OFF, ON, \TR1")

or parameters shown as a word enclosed in

3

<white space>

is a white space character (ASCII-encoded byte in the range of 00-09, 0B-20

<>

, that represents some value.

(0-9, 11-32 decimal) ) or a series of the white space characters.

Variable Types

The variable parameters used in HP-IB commands are of three types:<numeric>,<string>,

and<block>.

<

numeric>represents numeric parameters as follows:

100

100.0

1.0E6

100.

0

1.23,+235

0

7.89e001

.5

integer

xed decimal point

oating decimal point

fractional digits optional

leading signs allowed

use either E or e in exponentials

digits to the left of the decimal point are optional

Introduction 1-9

Page 30

The analyzer accepts<numeric>parameters in various formats and responds to a particular

query in a predened and xed format.

3

The analyzer setting programmed with a numeric parameter can assume a nite number of

values, so the analyzer automatically rounds o the parameter.For example, if you specied

the OSC level as

3

The<numeric>whose absolute value is less than 1000000 is returned in the xed decimal point format (If

501MV

, it would be rounded o to

500MV

.

the value is integer, the return format is integer).

The<numeric>whose absolute value is, or more than 1000000 is returned in the oating decimal point

format.

Sux

When a command has a specied sux, the sux multiplier and sux units can be used

with parameters as follows (the sux multiplier must be used with the sux unit):

Parameter Sux Unit Available Multipliers

Frequency

Power

Voltage

Current

Impedance

Admittance

Inductance

Capacitance

Time

Phase

distance

1

2

A

SIE

DEG

RAD

HZ

(Hz)

DBM

(dBm)

V

(Volt)

(Ampere)

OHM

()

(Siemens)

H

(henry)

F

(farad)

S

(second)

(

; default),

(radian)

M

(meter)

G

MA

K

M

U

N

P

F

: G ( giga;2109)

: M ( mega;2106)

: k ( kilo;210

: m ( milli;210

:( micro;210

: n ( nano;210

: p ( pico;210

: f ( femto;210

3

)

0

3

0

0

9

0

12

0

)

6

)

)

)

15

)

1

Resistance and reactance are the same

2

Conductance or susceptance are the same

The sux is optional and can be omitted. If you omit it, the analyzer assumes that the

default sux is sent.

<