Page 1

HP 4286A RF LCR meter

User's Guide

SERIAL NUMBERS

This manual applies directly to instruments with serial number prex JP3KC and

above, or whose rmware is version 2.0. For additional important information

about serial numbers, read \Serial Number" in Appendix A of this manual.

HP Part No. 04286-90031

Printed in JAPAN April 1999

Forth Edition

Page 2

Notice

The information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All rights are

reserved. No part of this document may be photocopied, reproduced, or translated to another

language without the prior written consent of the Hewlett-Packard Company.

Hewlett-Packard Japan, LTD.

Kobe Instrument Division

1-3-2, Murotani, Nishi-ku, Kobe-shi,

Hyogo, 651-2241 Japan

R

MS-DOS

APC-7

is a U.S. registered trademark of Microsoft Corporation.

R

is a U.S. registered trademark of Bunker Ramo Corporation.

c

Copyright 1995, 1998, 1999 Hewlett-Packard Japan, LTD.

Page 3

Manual Printing History

The manual printing date and part number indicate its current edition. The printing date

changes when a new edition is printed. (Minor corrections and updates that are incorporated

at reprint do not cause the date to change.) The manual part number changes when extensive

technical changes are incorporated.

June 1995

July 1995

September 1998

April 1999

::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::

::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: :

:::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: :

Second Edition

::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: :::

First Edition

Third Edition

Forth Edition

iii

Page 4

Safety Summary

The following general safety precautions must be observed during all phases of operation,

service, and repair of this instrument. Failure to comply with these precautions or with specic

WARNINGS

elsewhere in this manual may impair the protection provided by the equipment.

In addition it violates safety standards of design, manufacture, and intended use of the

instrument.

The Hewlett-Packard Company assumes no liability for the customer's failure to comply with

these requirements.

Note

HP 4286A is designed for use in INSTALLATION CATEGORY II according to IEC

61010-1 and POLLUTION DEGREE 1 according to IEC 61010-1 and IEC 60664-1.

HP 4286A is an INDOOR USE product.

Note

LEDs in HP 4286A are Class 1 in accordance with IEC60825-1.

CLASS 1 LED PRODUCT

Ground The Instrument

To avoid electric shock hazard, the instrument chassis and cabinet must be connected to a

safety earth ground by the supplied power cable with earth blade

.

DO NOT Operate In An Explosive Atmosphere

Do not operate the instrument in the presence of ammable gasses or fumes

. Operation of any

electrical instrument in such an environment constitutes a denite safety hazard.

Keep Away From Live Circuits

Operating personnel must not remove instrument covers. Component replacement and internal

adjustments must be made by qualied maintenance personnel. Do not replace components

with the power cable connected. Under certain conditions, dangerous voltages may exist even

with the power cable removed. To avoid injuries, always disconnect power and discharge

circuits before touching them.

DO NOT Service Or Adjust Alone

Do not attempt internal service or adjustment unless another person, capable of rendering rst

aid and resuscitation, is present.

DO NOT Substitute Parts Or Modify Instrument

Because of the danger of introducing additional hazards, do not install substitute parts

or perform unauthorized modications to the instrument. Return the instrument to a

Hewlett-Packard Sales and Service Oce for service and repair to ensure that safety features

are maintained.

iv

Page 5

Dangerous Procedure Warnings

Warnings

, such as the example below, precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed.

Warning

Dangerous voltages, capable of causing death, are present in this

instrument. Use extreme caution when handling, testing, and adjusting

this instrument.

v

Page 6

Typeface Conventions

Bold

Boldface type is used when a term is dened. For example:

icons

are

symbols.

Italics

Italic type is used for emphasis and for titles of manuals and other

publications.

Italic type is also used for keyboard entries when a name or a variable

Computer

4

HARDKEYS

NNNNNNNNNNNNNNNNNNNNNNNNNN

SOFTKEYS

must be typed in place of the words in italics.For example:

lename

type the name of a le such as

means to type the word

file1

copy

, to type a space, and then to

.

Computer font is used for on-screen prompts and messages.

5

Labeled keys on the instrument front panel are enclosed in45.

Softkeys located to the right of the CRT are enclosed in

copy

NNNNN

.

Assistance

Product maintenance agreements and other customer assistance agreements are available for

Hewlett-Packard products.

For any assistance, contact your nearest Hewlett-Packard Sales and Service Oce.Addresses

are provided at the back of this manual.

Safety Symbols

General denitions of safety symbols used on equipment or in manuals are listed below

Instruction manual symbol: the product is marked with this symbol when it is

necessary for the user to refer to the instruction manual.

Alternating current.

Direct current.

On (Supply).

O (Supply).

This

Warning

sign denotes a hazard. It calls attention to a procedure

condition or the like, which, if not correctly performed or adhered to, could

result in injury or death to personnel.

This

Caution

sign denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, could

result in damage to or destruction of part or all of the product.

Note

denotes important information. It calls attention to a procedure,

practice, condition or the like, which is essential to highlight.

Axed to product containing static sensitive devices use anti-static handling

procedures to prevent electrostatic discharge damage to component.

.

, practice,

vi

Page 7

Contents

1. Brief Description of the HP 4286A

Front and Rear Panels ............................ 1-2

2. Installation and Set Up Guide

Incoming Inspection ............................. 2-1

Rack Mounting .............................. 2-3

Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Instruction for Cleaning ...... ...... ...... ...... ... 2-7

Connecting the Connector Box ........................

2-7

Connecting the Test Head . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Test Head with L-type Coaxial Adapter (Option 022 only) . . 2-9

Connecting the APC-3.5 to 7mm Adapter ...................

Connecting a Keyboard (Option 1C2 Only) . . . . . . . . . . . . . . . . . . .

3. Basic Measurement Procedures

Measurement Outline ............................

Basic Measurement Flow . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Power ON ................................

Line Input Receptacle ...........................

Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steps to turn on the power . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

2. Setting up the HP 4286A ......................... 3-5

2-1. Setting up for Ls-Q Frequency Characteristics Measurements . . . . . . . 3-5

2-2. Creating a sweep table ........................ 3-5

2-3. Setting the OSC level .... ...... ...... ...... ... 3-5

3. Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Procedure ...........................

4. Connecting the Test Fixture ........................

Selecting a Test Fixture ..........................

Connecting the Test Fixture to the Test Head ................ 3-12

5. Setting the Electrical Length of the Test Fixture ...... ...... .. 3-14

6. Fixture Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing SHORT Compensation . . . . . . . . . . . . . . . . . . . . . .

SHORT Compensation Key Sequence ................... 3-17

Performing OPEN Compensation ...... ...... ..... ..... 3-18

OPEN Compensation Key Sequence . . . . . . . . . . . . . . . . . . . .

7. Connecting the DUT to the Test Fixture ...... ...... ......

8. Measuring the DUT ............................

2-9

2-10

2-11

3-2

3-2

3-3

3-4

3-4

3-4

3-7

3-7

3-12

3-12

3-15

3-15

3-18

3-19

3-20

Contents-1

Page 8

4. HP 4286A with Chip Handler

Dierentiation of DUTs through BIN Sorting . . . . . . . . . . . . . . . . . . 4-2

Editing BIN Table ............................. 4-2

Setting up Handler Interface . . . . . . . . . . . . . . . . . . . . . . . . 4-3

BIN Sorting ...... ...... ...... ...... ...... .. 4-3

GO/NO-GO Test with Limit Test Function ................... 4-4

Editing Limit Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Setting up Handler Interface . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Limit Test................................. 4-6

Contact Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Setting up Beeper .............................. 4-8

Display Updating ON/OFF .......................... 4-9

Setup Linking HP 4286A and Chip Handler .................. 4-10

Setting up Handler Interface Board . . . . . . . . . . . . . . . . . . . . . . 4-11

Checking Default Settings .. ...... ...... ...... ..... 4-11

Selecting Settings ............................. 4-12

Changing Settings ............................. 4-13

Removing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Setting up Control Output Signal and DC Isolated Input Signal ....... 4-13

Using External Power Source . . . . . . . . . . . . . . . . . . . . . . 4-14

Using Internal Power Source .. ...... ...... ...... ..

Setting up the Internal Power Source . . . . . . . . . . . . . . . . . . .

Mounting the Top Cover .......... ...... ...... ...

Mounting a Pull-up Resistor ...... ...... ...... ......

Pull-up Resistor for Comparator Signals . . . . . . . . . . . . . . . . . .

Pull-up Resistor for Control Output Signal . . . . . . . . . . . . . . . . .

Setting up Output Signal Pattern ......................

HP 4286A Measurement Time ...... ...... ...... ......

Electrical Specication of Handler Interface . . . . . . . . . . . . . . . . . .

Signal Output Mode ............................

Signal Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pin Assignment and Signal Denitions (Mode 1) ...............

Pin Assignment and Signal Denitions (Mode 2) ...............

Electrical Characteristics of Signals . . . . . . . . . . . . . . . . . . . . .

DC Isolated Output Signals . . . . . . . . . . . . . . . . . . . . . . . .

DC Isolated Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Handler Interface Board Switches ...... ...... ..... .... 4-37

Top Cover Removal ............................ 4-37

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Top Cover Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing Calibration with Working Standard (only with option 004) . . . . . .

Measuring the Working Standard Value ...................

Calibration with Working Standard .....................

Restoring Settings After Power Interruption . . . . . . . . . . . . . . . . . .

4-14

4-14

4-14

4-15

4-15

4-15

4-16

4-19

4-21

4-22

4-22

4-23

4-27

4-33

4-33

4-37

4-37

4-39

4-39

4-39

4-41

Contents-2

Page 9

5. Typical Functions

Point Delay and Sweep Delay . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Making a Point Delay Measurement . . . . . . . . . . . . . . . . . . . . . 5-2

Making a Sweep Delay Measurement .. ...... ..... ...... . 5-2

Delay Description ............................. 5-2

Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Further Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

OSC Level Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Entering Titles on the Screen . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Title Entry Procedure ...... ...... ...... ...... ... 5-5

Saving and Recalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Saving HP 4286A Setting and Measurement Trace .............. 5-6

Recalling a Saved HP 4286A Setting and Measurement Trace . . . . . . . . . 5-6

Saving a Display Image to an HP-GL File .................. 5-7

Saving Measured Data for a Spreadsheet .................. 5-7

Purging a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Initializing a Disk/RAM Disk for Use .................... 5-7

Printing or Plotting .. ...... ...... ...... ...... ... 5-9

Printing or Plotting a Display Image . . . . . . . . . . . . . . . . . . . . . 5-9

Using a Dierent HP-IB Address for the Printer/Plotter .... ...... . 5-9

Logging the Key Sequence into a Program (Option 1C2 Only) . . . . . . . . . .

Resetting the HP 4286A ...........................

A. Manual Changes

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-10

5-11

A-1

A-1

A-2

B. Maintenance

Performance Verication . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair .. ...... ...... ...... ...... ...... ...

Possible Problems and Their Solution ....................

Replacement of Center Conductor Collet ...................

Changing the Line Voltage Setting ...... ...... ...... ....

Replacing the Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Fixture Compensation Procedures for the HP 16191A and HP 16193A

HP 16191A ...... ...... ...... ...... ...... ... C-1

SHORT Compensation ........................... C-1

SHORT Compensation Key Sequence ...................

OPEN Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPEN Compensation Key Sequence . . . . . . . . . . . . . . . . . . . .

Connecting DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP 16193A ...... ...... ...... ...... ...... ...

SHORT Compensation ...........................

SHORT Compensation Key Sequence ...................

OPEN Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPEN Compensation Key Sequence . . . . . . . . . . . . . . . . . . . . C-8

Connecting DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Index

B-1

B-1

B-1

B-2

B-4

B-6

C-3

C-3

C-4

C-4

C-6

C-6

C-7

C-7

Contents-3

Page 10

Figures

1-1. HP 4286A Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2. HP 4286A Rear Panel ........ ...... ...... ..... .. 1-2

2-1. Contents of Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-2. Power Cable Supplied ........................... 2-6

2-3. Connecting the Connector Box to the Mainframe .............. 2-8

2-4. Connecting a Keyboard .......................... 2-11

3-1. Basic Flow for Impedance Measurements .................. 3-2

3-2. Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-3. Line Input Receptacle and Fuse . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-4. Calibration ................................ 3-7

3-5. ...................................... 3-8

3-6. ......................................

3-7. ......................................

3-8. ......................................

3-9. ......................................

3-10. ......................................

3-11. ......................................

3-12. ......................................

3-13. ......................................

3-14. ......................................

3-15. Connecting the Test Fixtures (HP 16192A) . . . . . . . . . . . . . . . . . .

3-16. Fixture Compensation ...........................

4-1. Example of BIN Table ...........................

4-2. Basic Flow of Handler Interface Setting . . . . . . . . . . . . . . . . . . .

4-3. BIN Sorting .... ...... ...... ...... ...... ....

4-4. Limit Test.................................

4-5. Timing Diagram (Mode 1) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4-6. BIN Sorting .... ...... ...... ...... ...... .... 4-28

4-7. Limit Test................................. 4-28

4-8. Timing Diagram (mode 2: On Sweep Mode) .. ...... ...... ... 4-32

4-9. Timing Diagram (mode 2: On Point Mode) . . . . . . . . . . . . . . . . . . 4-32

4-10. Circuit Conguration of Comparator Output Signals .............

4-11. Circuit Conguration of Control Output Signals ...............

4-12. Circuit Conguration of Handler Interface Input Signals ...........

4-13. Handler Interface Board Switches ...... ...... ..... ....

5-1. Point Delay and Sweep Delay . . . . . . . . . . . . . . . . . . . . . . . .

5-2. Point Averaging .......... ...... ...... ..... ...

5-3. Level Monitor Function ..........................

5-4. Label Function ..............................

A-1. Serial Number Plate .. ...... ...... ...... ..... ... A-2

3-8

3-8

3-9

3-9

3-9

3-10

3-10

3-13

3-13

3-13

3-15

4-2

4-17

4-23

4-23

4-34

4-35

4-36

4-37

5-2

5-3

5-4

5-5

Contents-4

Page 11

Tables

2-1. Contents .... ...... ...... ..... ...... ...... 2-2

2-2. Rack Mount Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3-1. Example of Measurement Conditions .................... 3-5

3-2. Test Fixture Specication . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-3. Dimension of Shorting Devices ...... ...... ...... ..... 3-15

3-4. Dimension of Shorting Devices ...... ...... ...... ..... 3-16

4-1. Example of limit setting .......................... 4-4

4-2. Handler Interface Board Setup Worksheet . . . . . . . . . . . . . . . . . . 4-12

4-3. SW1 Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4-4. SW2 Setting (External power source:1) .. ...... ...... ..... 4-14

4-5. SW2 Setting (External Power Source:2) ................... 4-14

4-6. SW2 Setting(Internal Power Source) . . . . . . . . . . . . . . . . . . . . .

4-7. Typical Pull-up Resistance for Comparator Signals . . . . . . . . . . . . . .

4-8. Typical Pull-up Resistance for DC Isolated Input Signal . . . . . . . . . . . .

4-9. Pin Assignment of Handler Interface Connector (Mode 1) . . . . . . . . . . .

4-10. Signal Denition (Mode 1) .........................

4-11. Handler Interface Connector Pin Assignment (Mode 2) . . . . . . . . . . . .

4-12. Signal Denition (Mode 2) .........................

4-13. Electrical Characteristics of DC Isolated Output Signals ...... .....

4-14. Electrical Characteristics of DC Isolated Input Signals .... ...... ..

4-15. Typical Values of Working Standard (with option 004) ...... ......

A-1. Manual Changes by Serial Number .....................

A-2. Manual Changes by Firmware Version . . . . . . . . . . . . . . . . . . . .

B-1. Line Voltage Ranges .......... ...... ...... ..... .

4-14

4-15

4-15

4-24

4-25

4-29

4-30

4-33

4-36

4-40

A-1

A-1

B-4

Contents-5

Page 12

Page 13

Brief Description of the HP 4286A

Key specication assuring high accuracy impedance measurement in the RF region

Measurement frequency: 1 MHz to 1 GHz

Basic measurement accuracy: 1%

Impedance measurement range: 200 m to 3 k

High accuracy Q factor measurement(6%, @Q=100, 100 Mhz)

Features simplifying integration to your system

HP-IB, Handler Interface

HP Instrument BASIC(Option 1C2)

1 m / 3 m selectable measurement cable

Test head with APC 3.5 connector

Capabilities allowing high throughput testing

High-speed measurement(15 ms)

Comparator function

Contact checking function

List sweep

1

Brief Description of the HP 4286A 1-1

Page 14

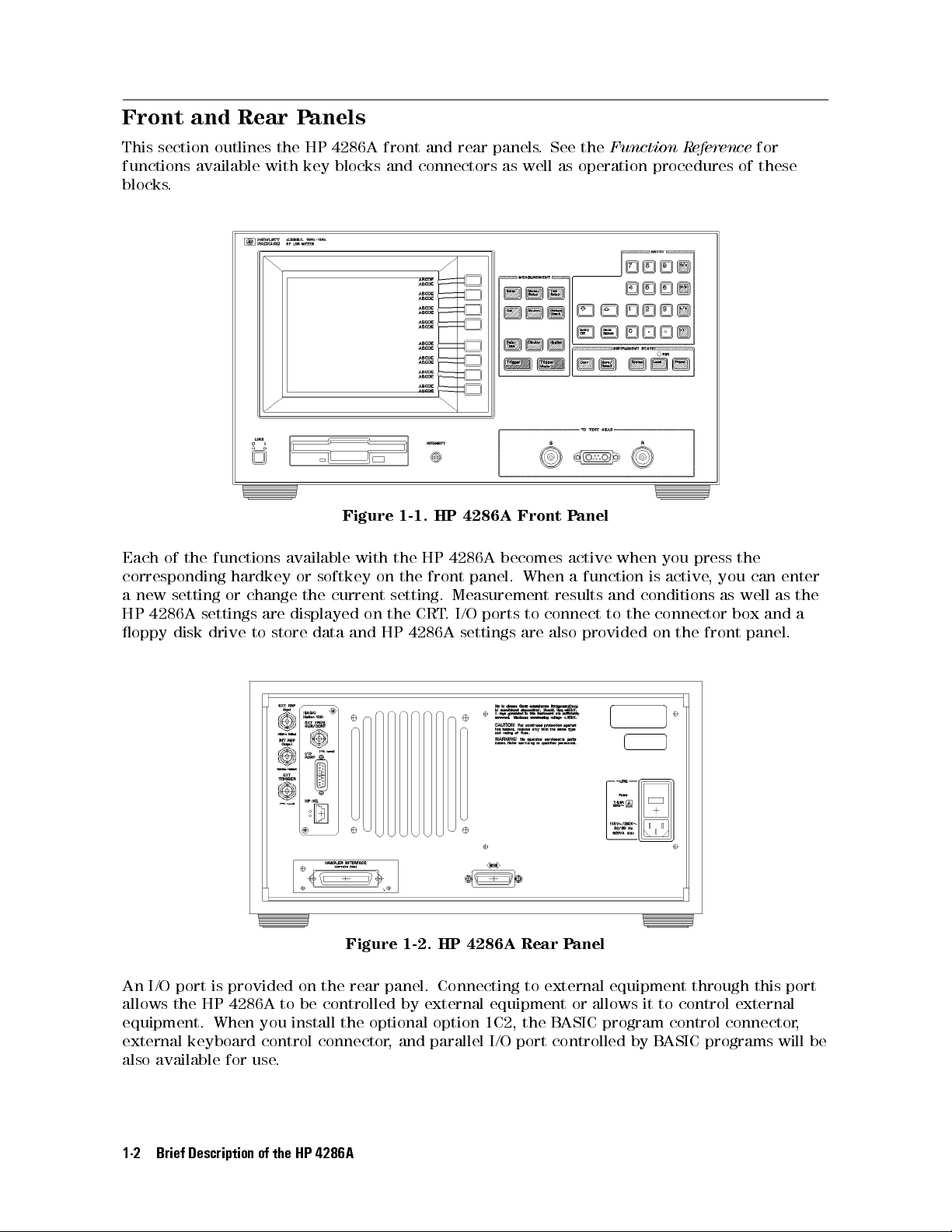

Front and Rear Panels

This section outlines the HP 4286A front and rear panels. See the

functions available with key blocks and connectors as well as operation procedures of these

blocks.

Figure 1-1. HP 4286A Front Panel

Each of the functions available with the HP 4286A becomes active when you press the

corresponding hardkey or softkey on the front panel. When a function is active

a new setting or change the current setting. Measurement results and conditions as well as the

HP 4286A settings are displayed on the CRT. I/O ports to connect to the connector box and a

oppy disk drive to store data and HP 4286A settings are also provided on the front panel.

Function Reference

, you can enter

for

Figure 1-2. HP 4286A Rear Panel

An I/O port is provided on the rear panel. Connecting to external equipment through this port

allows the HP 4286A to be controlled by external equipment or allows it to control external

equipment. When you install the optional option 1C2, the BASIC program control connector,

external keyboard control connector, and parallel I/O port controlled by B

also available for use.

1-2 Brief Description of the HP 4286A

ASIC programs will be

Page 15

Installation and Set Up Guide

This chapter provides the information necessary for performing an incoming inspection and

setting up your HP 4286A.

Incoming Inspection

2

Warning

Inspect the shipping container for damage. If the shipping container or cushioning material

is damaged, it should be kept until the contents of the shipment have been checked for

completeness and the HP 4286A has been checked mechanically and electrically

of the shipment should be as listed in T

mechanical damage or defect, or if the HP 4286A does not pass the power-on selftests

the nearest Hewlett Packard oce. If the shipping container is damaged, or the cushioning

material shows signs of unusual stress, notify the carrier as well as the Hewlett P

Keep the shipping materials for the carrier's inspection.

The line voltage selector is set at the factory to correspond to the most commonly used line

voltage of the country of destination. If you want to change the line voltage

the Line Voltage Setting" in Appendix B.

To avoid hazardous electrical shock, do not turn on the HP 4286A when

there are signs of shipping damage to any portion of the outer enclosure

(for example, covers, panel, or display)

. The contents

able 2-1 . If the contents are incomplete, if there is

, notify

ackard oce.

, see \Changing

Installation and Set Up Guide 2-1

Page 16

Table 2-1. Contents

Description HP Part Number

RF LCR meter HP 4286A

Mainframe

Fixture Stand

1

Right Angle Type Test Head with

1-m cable

Documents

User's Guide

Function Reference

Programming Manual

2

3

4

4

4

04286-90001

04286-90002

04291-90007

APC-3.5 to 7mm Adapter 1250-1746

Power Cable

Calibration Kit

4

8120-4753 (See Fig in Spec.)

5

0STermination 04186-85302

0Termination 04186-85300

50 Termination 04286-65006

LOW-LOSS Capacitor 04291-60042

Carrying Case

4

04291-60041

Option 021 only

Straight Angle Type Test Head

04286-60121

with 1-m cable

L-type Coaxial Adapter 1250-1249

Option 022 only

Straight Angle Type Test Head

with 3-m cable

L-type Coaxial Adapter 1250-1249

Option 032 only

Right Angle Type Test Head with

3-m cable

1

Not included when Option 002 is ordered.

2

Not included when Option 031 is ordered.

3

Not included when Option 0B0 is ordered.

4

Accessories are not shown in Figure 2-1 .

5

Not included when Option 001 is ordered.

2-2 Installation and Set Up Guide

04286-60122

04286-60132

Page 17

Description HP Part Number

Option 004 only

Shorting Device

1.020.5 mm 16191-29005

1.620.8 mm 16191-29006

2.021.25 mm 16191-29007

3.221.6 16191-29008

51 Chip Resistor

1.020.5 mm 5182-0433

1.620.8 mm 5182-0434

2.021.25 mm 5182-0435

3.221.6 mm 5182-0436

Device Case 1540-0692

Option 0BW only

Service Manual

Table 2-1. Contents (continued)

1

04291-90101

Option 1C2 only

Keyboard Template

HP-HIL Keyboard

Keyboard Cable

HP Instrument BASIC User's

Handbook

1

HP Instrument BASIC User's

1

1

1

08751-87111

HP 46021C Option ABA

46020-60001

E2083-90000

04286-90005

Handbook Supplement

1

This item is not shown in Figure 2-1.

Rack Mounting

Rack mounting information is provided with the rack mount kit. If the kit was not ordered

with the HP 4286A as an option, it may be ordered through the nearest Hewlett P

ackard oce.

The part numbers of the rack mount kit are shown in Table 2-2 .

Table 2-2. Rack Mount Kits

Option Description HP Part Number

1CN Handle Kit 5062-3991

1CM Rack Flange Kit 5062-3979

1CP Rack Mount & Handle Kit 5062-3985

Installation and Set Up Guide 2-3

Page 18

2-4 Installation and Set Up Guide

Figure 2-1. Contents of Package

Page 19

Power Cable

In accordance with international safety standards, this instrument is equipped with a

three-wire power cable. When connected to an appropriate ac power outlet, this cable grounds

the instrument frame. The type of power cable shipped with each instrument depends on the

country of destination. Refer to Figure 2-2 for the part numbers of the power cables available.

Warning

For protection from electrical shock, the power cable ground must not be

defeated.

The power plug must be plugged into an outlet that provides a protective

earth ground connection.

Installation and Set Up Guide 2-5

Page 20

2-6 Installation and Set Up Guide

Figure 2-2. Power Cable Supplied

Page 21

Power Requirements

HP 4286A requires a following power source:

Voltage : 90 to 132 Vac, 198 to 264 Vac

Frequency : 47 to 66 Hz

Power : 500 VA maximum

Ventilation Requirements

To ensure adequate ventilation, make sure that there is adequate clearance of at least 180 mm

behind, 60 mm sides and 15 mm above and below.

Instruction for Cleaning

For cleaning, wipe with soft cloth that is soaked with water and wrung tightly without undue

pressure.

Connecting the Connector Box

The HP 4286A consists of the mainframe, the test head, and the test xture stand. The

test head has a connector box that connects to the mainframe

Figure 2-3. While you connect the connector box to the mainframe

. This connection is shown in

, turn o the HP 4286A.

Installation and Set Up Guide 2-7

Page 22

Figure 2-3. Connecting the Connector Box to the Mainframe

1. Engage the two type-N connectors (labeledSandR, respectively) and the center connector.

2. Turn the two type-N connectors to tighten the connection.

2-8 Installation and Set Up Guide

Page 23

Connecting the Test Head

When you connect or replace the test head, turn o the HP 4286A.

1.

Place the test xture stand on a level surface. At this time, make sure that the

hexagonal hole on top of the stand is located in front of the two mounting posts as you look

at the stand. Then, lay the stand on its side.

2.

Allow the test head to pass under the xture stand from the side opposite to yours.

3.

Position the test head such that the connectors of the test head and holes on top of the

xture stand are aligned.

4.

Slightly tighten the two screws on the bottom surface of the xture stand to ensure

that the test head is suciently stable. Press screws to check for correct engagement of

their thread.

5.

Further tighten the screws while holding the test head with your hand to completely

secure the head in place.

6.

Place the xture stand with its bottom surface down.

Connecting the Test Head with L-type Coaxial Adapter

(Option 022 only)

When you connect or replace the test head, turn o the HP 4286A.

1.

Connect Connecting L-type Coaxial Adapter to the Test Head.

2.

Place the test xture stand on a level surface. At this time, make sure that the

hexagonal hole on top of the stand is located in front of the two mounting posts as you look

at the stand. Then, lay the stand on its side

.

3.

Allow the test head to pass under the xture stand from the side opposite to yours.

4.

Position the test head such that the connectors of the L-type Coaxial adapter and holes

on top of the xture stand are aligned.

5.

Slightly tighten the two screws on the bottom surface of the xture stand to ensure

that the test head is suciently stable. Press screws to check for correct engagement of

their thread.

Installation and Set Up Guide 2-9

Page 24

6.

Further tighten the screws while holding the test head with your hand to completely

secure the head in place.

7.

Place the xture stand with its bottom surface down.

Connecting the APC-3.5 to 7mm Adapter

1. Check that the connector sleeve is fully extended.

2. Connect APC-3.5 to 7mm adapter to the test head connector through the hole on top of the

xture stand.

3. Tighten the adapter nut to secure this adapter in place.

2-10 Installation and Set Up Guide

Page 25

Connecting a Keyboard (Option 1C2 Only)

When Option 1C2 is installed, an HP-HIL keyboard can be connected to the HP-HIL connector

on the rear panel of the HP 4286A. The HP-HIL keyboard provides an easier way to enter

characters for the le names, display titles, and Instrument BASIC programs. It can also access

the HP 4286A softkey functions by using keyboard function keys.For more information on the

HP-HIL keyboard, see the

HP Instrument BASIC User's Handbook Supplement

that is included

in Option 1C2.

Figure 2-4. Connecting a Keyboard

Installation and Set Up Guide 2-11

Page 26

Page 27

Basic Measurement Procedures

This chapter provides a quick start guide of the HP 4286A. New users can quickly become

familiar with the HP 4286A by following these procedures. In this chapter, to help you learn

how to use the HP 4286A, impedance of inductors are measured as examples.

At the end of the quick start procedures, you will have learned how to get the following

measurement results:

Calibration

Setting electrical length of test xture

Correction of test xture

List sweep

3

Basic Measurement Procedures 3-1

Page 28

Measurement Outline

This chapter describes how to measure the impedance of a 100 nH inductor as an example.

Measurement items and conditions are shown below.

Parameter Ls-Q

Frequency 1, 2, 5, 10, 20, 50, 100, 200, 500, 1000 MHz

OSC level 10 mA

Basic Measurement Flow

Figure 3-1 shows the basic ow for an impedance measurement.

Figure 3-1. Basic Flow for Impedance Measurements

3-2 Basic Measurement Procedures

Page 29

Required Equipment

To perform all the steps in this quick start, the following equipment is required:

HP 4286A RF LCR meter

Test Head

Fixture Stand

Calibration Kit

Test Fixture

HP 16191A Side Electrode SMD Test Fixture,or

HP 16192A Parallel Electrode SMD Test Fixture,or

HP 16193A Small Side Electrode SMD Test Fixture

Shorting Device Set (Included with HP 16191A, HP 16192A, HP 16193A, and Option 004

Working Standard Set)

Tweezers (Included with HP 16191A, HP 16192A, and HP 16193A)

Device Under Test (DUT) (A chip inductor is used in this guide.)

Figure 3-2. Required Equipment

Basic Measurement Procedures 3-3

Page 30

1. Power ON

Verify the connector box and the test head are correctly set up before turning ON the

HP 4286A. If they have not been set up, see Chapter 2.

Line Input Receptacle

ACPower cable is connected to this receptacle.

Figure 3-3. Line Input Receptacle and Fuse

Fuse

Use the following fuse:

HP Part Number : 2110-0917

(UL/CSA type, Semi Time Lag, 6.3 A 250 V)

If you need this fuse, contact your nearest Hewlett-Packard Sales and Service Oce.

Steps to turn on the power

1. Verify the power line setting is correct before you turning ON the meter. If necessary, see

\Changing the Line Voltage Setting" in Appendix B.

2. Connect AC power cable to the line input receptacle.

3. Press the LINE switch.

After the power-on self-test (approximately 10 seconds), the installed options and the

connected test head information are displayed.

Note

Only option numbers 1C2 and 001 are displayed at power-on (if they are

installed). Other installed option numbers are listed on the rear panel.

A 30 minute-warm-up period is required to stabilize the HP 4286A after it has been turned ON.

This ensures the HP 4286A its specied measurement accuracy

3-4 Basic Measurement Procedures

.

Page 31

2. Setting up the HP 4286A

Before you start the measurement, you must set up the HP 4286A to t your measurement

requirements. This section provides the set up procedures for Ls-Q frequency characteristics

measurements.

To set up the HP 4286A, press the front panel keys as shown below. All keys necessary for this

set up procedures are available on the MEASUREMENT Block.

2-1. Setting up for Ls-Q Frequency Characteristics Measurements

Table 3-1. Example of Measurement Conditions

Range

1MHz, 2MHz, 5MHz, 10MHz,

20MHz, 50MHz, 100MHz, 200MHz,

500MHz, 1GHz

OSC Level

10 mA

Select parameters to satisfy the conditions above.Follow the procedures below.

1. Press

2.

Press

4

Meas

NNNNNNNNNNNNNN

Ls-Q

5

.

. The

NNNNNNNNNNNNNN

Ls-Q

softkey label becomes underlined, showing that

NNNNNNNNNNNNNN

Ls-Q

has been

selected.

2-2. Creating a sweep table

Create a sweep table to set list sweep conditions

1. Press

2.

3. Press

4.

4

Sweep Setup

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

EDIT LIST

4

5

2

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

SEGMENT DONE

, then

5

.

NNNNNNNNNNN

ADD

to create an additional segment.

4

5

to set the measurement frequency of the additional segment to 2 MHz.

M/

to complete the segment setting.

.Follow the procedures below.

5. Repeat steps 2 through 4 to create 8 additional segments. Set the frequency of each of these

segments to 5, 10, 20, 50, 100, 200, 500, and 1000 (=1G) MHz, respectively. (The frequency

of a segment available at power-on has automatically been set to 1 MHz.)

Press

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

LIST DONE

to complete the table creation step.

6.

2-3. Setting the OSC level

Set the OSC signal level applied to the DUT.Follow the procedures below.

Press

4

5

.

Source

NNNNNNNNNNNNNNNNNNNN

Press

Press

Hints

AMPERE

415,405

to set the OSC level as current.

, and then

Use

4

5

k/m

4*5or4+5

to set the OSC level to 10 mA.

to quickly increase or decrease the value to be entered. The

value changes in steps of 1, 2, 5, and 10 with these keys

Basic Measurement Procedures 3-5

.

Page 32

To delete the value you have entered, simply press

pressed

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

SEGMENT DONE

To start the segment condition setting all over again, rst press

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

SEGMENT QUIT

number using numeric keys and

4

5

, or enter a new value if you have already pressed

M/

.

NNNNNNNNNNNNNNNNNNNNNNN

and then

SEGMENT

4x15

. Next, specify the desired segment

. Finally, press

4

Back Space

NNNNNNNNNNNNNN

EDIT

5

if you have not

4

M/

and then

NNNNNNNNNNNNNNNNNNNNNNN

SEGMENT

You are now ready to specify the frequency for the selected segment.

5

but not

.

3-6 Basic Measurement Procedures

Page 33

3. Calibration

R

Calibration denes the measurement accuracy for the contact surface of the APC-7

on

the APC-3.5 to 7mm adapter which is connected to the test head. The calibration must be

performed when the HP 4286A is turned ON. After the calibration, the HP 4286A can measure

within its specied measurement accuracy.

The 0 S, 0 , and 50 terminations and low-loss capacitor in the calibration kit are required.

Figure 3-4. Calibration

Calibration Procedure

1. Press

2.

3.

4

5

Cal

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

N

Press

CALIBRATE MENU

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

CAL POINTS

.

.

to set the frequency for the Calibration

NNNNNNNNNNNNNNNNN

When you modify the measurement frequency, select

FIXED

.

NNNNNNNNNNNNNN

When you do not modify the measurement frequency, select

USER

.

NNNNNNNNNNNNNNNNN

See

Function Reference

NNNNNNNNNNNNNN

USER

(user-dened point calibration).

4. Turn the APC-7

R

for details on

FIXED

(xed point calibration) and

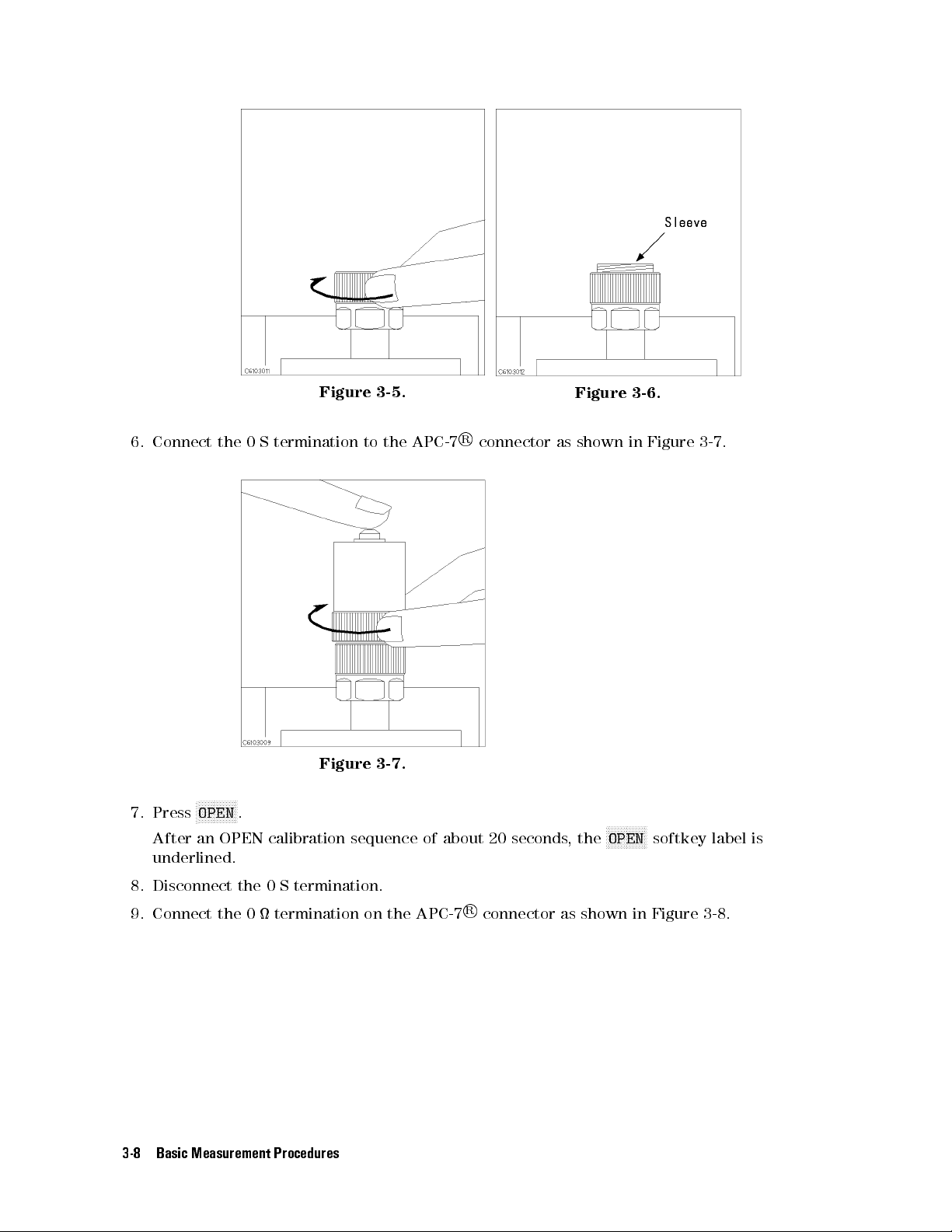

connector on the test head as shown in Figure 3-5.

5. Verify that the connector sleeve is extended fully as shown in Figure 3-6.

Basic Measurement Procedures 3-7

Page 34

Figure 3-5.

R

6. Connect the 0 S termination to the APC-7

Figure 3-7.

NNNNNNNNNNNNN

7. Press

N

OPEN

.

After an OPEN calibration sequence of about 20 seconds, the

underlined.

connector as shown in Figure 3-7.

Figure 3-6.

NNNNNNNNNNNNNN

OPEN

softkey label is

8. Disconnect the 0 S termination.

9. Connect the 0 termination on the APC-7

3-8 Basic Measurement Procedures

R

connector as shown in Figure 3-8.

Page 35

Figure 3-8.

10. Press

11. Disconnect the 0 termination.

12. Turn only the APC-7

13. Verify that the connector sleeve is retracted fully as shown in Figure 3-10.

NNNNNNNNNNNNNNNNN

SHORT

After a SHORT calibration sequence of about 20 seconds

underlined.

.

R

connector nut of the 50 termination as shown in Figure 3-9.

, the

NNNNNNNNNNNNNNNNN

SHORT

softkey label is

Figure 3-9. Figure 3-10.

14. Connect the 50 termination on the APC-7

R

connector as shown in Figure 3-11 .

Basic Measurement Procedures 3-9

Page 36

Figure 3-11.

15. Press

LOAD

.

After a LOAD calibration sequence of about 20 seconds, the

underlined.

16. Disconnect the 50 termination.

NNNNNNNNNNNNNN

R

17. Connect the low-loss capacitor to the APC-7

connector as shown in Figure 3-12.

Figure 3-12.

NNNNNNNNNNNNNN

LOAD

softkey label is

18. Press

LOW-LOSS CAPACITOR

After a low-loss capacitor calibration sequence of about 20 seconds, the

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

LOW-LOSS CAPACITOR

.

softkey label is underlined.

19. Disconnect low-loss capacitor.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

20.

21.

NNNNNNNNNNNNNNNNNNNNNNNNNN

Press

DONE:CAL

Verify that \

NNNNNNNNNNNNNN

(

USER

) is displayed on the left of the screen.

.

CO+

" (when you have selected

NNNNNNNNNNNNNNNNN

FIXED

)or\

Co+

" (when you have selected

The calibration data is erased when the HP 4286A is turned o.

3-10 Basic Measurement Procedures

Page 37

Note

R

Handling and Storage of the APC-7

Connector:

Keep connectors clean.

Do not touch the mating plane surfaces.

Do not set connectors contact-end down.

Before storing, extend the sleeve or connector nut.

Use end caps over the mating plane surfaces.

Never store connectors loose in a box or a drawer.

Basic Measurement Procedures 3-11

Page 38

4. Connecting the Test Fixture

Selecting a Test Fixture

Hewlett-Packard provides the test xtures listed in Table 3-2 for dierent sizes of surface

mounted device (SMD) measurements. These xtures provide high stability and repeatability

measurements.

Table 3-2. Test Fixture Specication

HP 16191A HP 16192A HP 16193A

Mountable

DUT size

Length

(mm)

2.0 to 12.0 1.0 to 20.0

1

0.5 to 3.2

Width (mm) 0.5 to 5 0.5 to 5 3 or less

Height

0.5 to 5 0.5 to 5 3 or less

(mm)

Electrodes in contact

with DUT (shown with

8

)

1

See chapter 2 of the

Service Manual

HP 16192A Parallel Electrode SMD Test Fixture Operation and

for the electrodes' conguration when measuring a DUT of more

than 5 mm long.

This user's guide explains how to use these test xtures

.

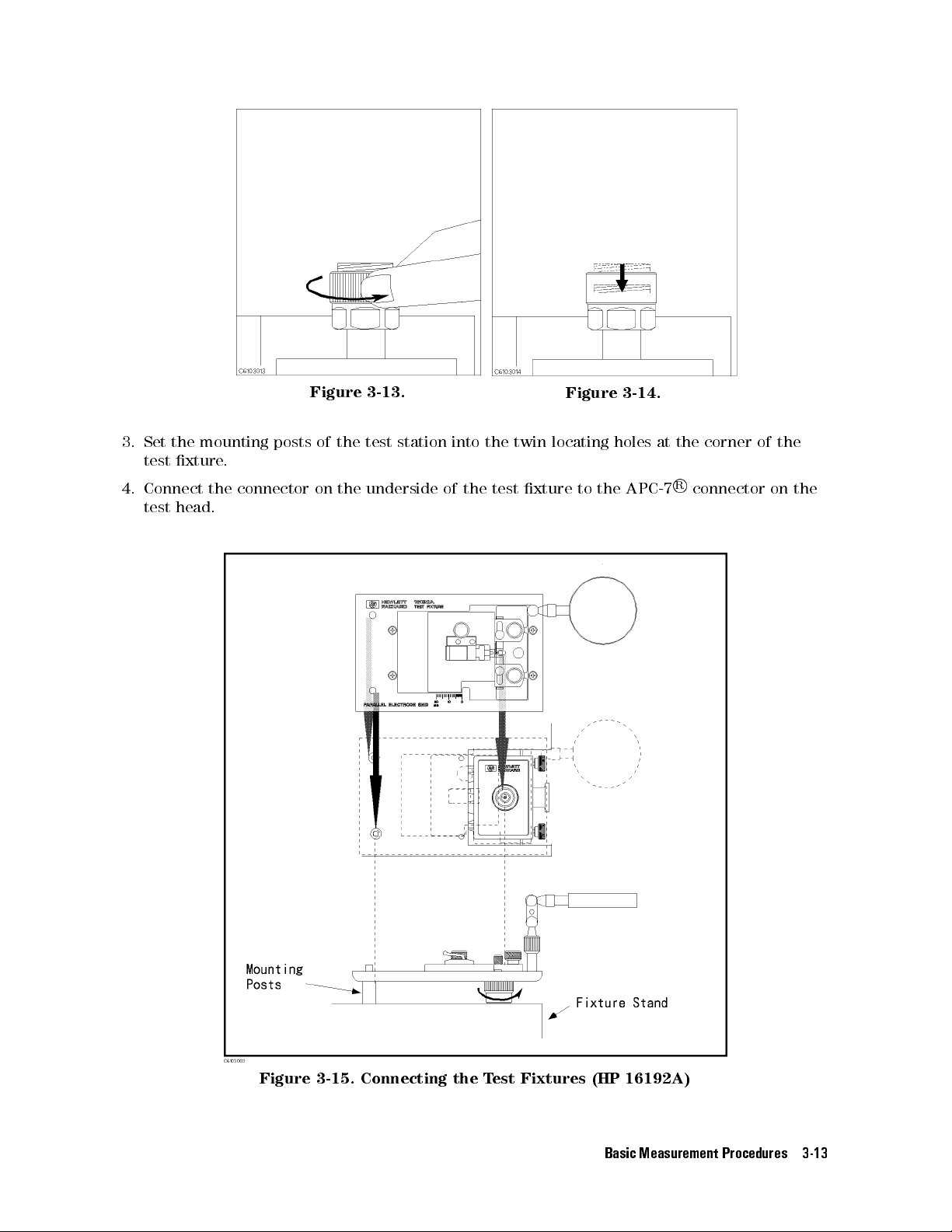

Connecting the Test Fixture to the Test Head

To connect your xture to the Test Head, perform the steps listed below. (Figure 3-15 shows

the connection for HP 16192A as an example.)

R

1. Turn the APC-7

connector on the test head as shown in Figure 3-13.

2. Verify that the connector sleeve is retracted fully as shown in Figure 3-14.

3-12 Basic Measurement Procedures

Page 39

Figure 3-13.

Figure 3-14.

3. Set the mounting posts of the test station into the twin locating holes at the corner of the

test xture.

R

4. Connect the connector on the underside of the test xture to the APC-7

connector on the

test head.

Figure 3-15. Connecting the Test Fixtures (HP 16192A)

Basic Measurement Procedures 3-13

Page 40

5. Setting the Electrical Length of the Test Fixture

In the RF region, the wavelengths are short and are not negligible compared to the physical

transmission line length of the test xture. This causes a phase shift error. The phase shift

error is compensated by the electrical length parameter for the test xture. Because the

electrical length values for the Hewlett Packard test xtures are stored in the HP 4286A, you

can set the electrical length parameter by selecting the xture model number.

Setting Procedure

1. Press

2.

3. Select the xture model number that you are using.

4.

5. Verify that \

Press

Press

4

5

.

Cal

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

FIXTURE[]

NNNNNNNNNNNNNNNNNNNN

RETURN

.

Del

and then

" appears on the left of the display.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

SELECT FIXTURE

.

3-14 Basic Measurement Procedures

Page 41

6. Fixture Compensation

Fixture compensation reduces the parasitic error existing between the test xture electrode

and the test head APC-7

compensation consists of OPEN, SHORT and LOAD compensations.For basic measurements, the

OPEN and SHORT compensations are required.

R

connector (where the measurement accuracy is specied). Fixture

Figure 3-16. Fixture Compensation

Performing SHORT Compensation

SHORT Compensation compensates for the residual impedance due to the test xture

When you use a shorting device supplied with the HP 4286A (with option 004) or xture (with

option option 010), be sure to select the device of the same size as or at least closest to that of

the DUT. The dimensions for each shorting device are shown in Table 3-3.

Table 3-3. Dimension of Shorting Devices

Dimension (mm) HP Part Number

1.020.520.5 16191-29005

1.620.820.8 16191-29006

2.021.2520.8 16191-29007

3.221.620.8 16191-29008

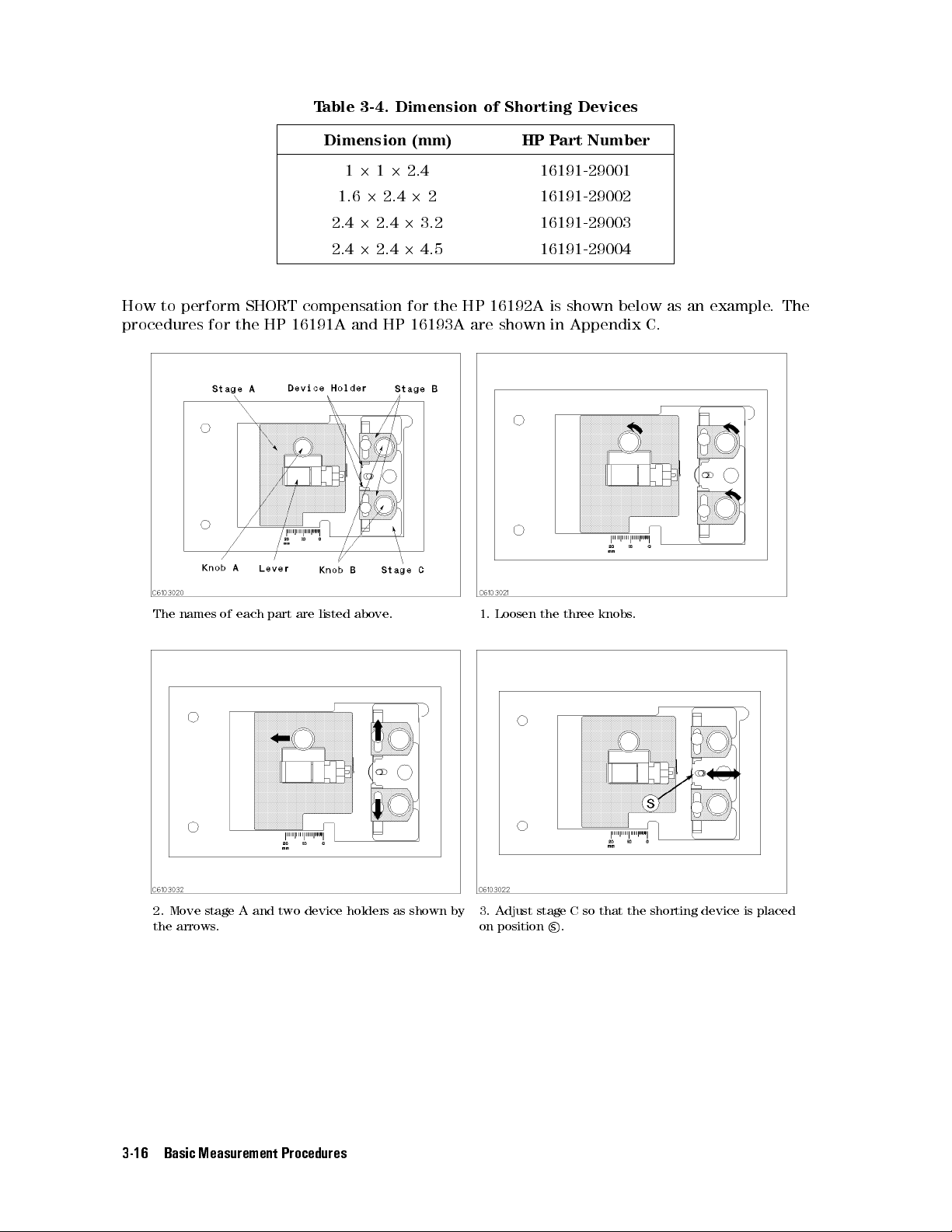

Four shorting divices of dierent dimensions are supplied with each xture. The shorting

device that is closest to the size of the DUT should be used. The dimensions for each shorting

device are shown in Table 3-4.

.

Basic Measurement Procedures 3-15

Page 42

Table 3-4. Dimension of Shorting Devices

Dimension (mm) HP Part Number

12122.4 16191-29001

1.622.422 16191-29002

2.422.423.2 16191-29003

2.422.424.5 16191-29004

How to perform SHORT compensation for the HP 16192A is shown below as an example. The

procedures for the HP 16191A and HP 16193A are shown in Appendix C.

The names of each part are listed above. 1. Loosen the three knobs.

2. Move stage A and two device holders as shown by

the arrows.

3. Adjust stage C so that the shorting device is placed

on positions

.

3-16 Basic Measurement Procedures

Page 43

4. Place the shorting device so that it contacts the

electrode.

5. Adjust the two B stages and the two device holders

to hold the shorting device.

6. Tighten the two B knobs to x the B stages and the

device holders.

8. Tighten knob A while pushing the lever. 9. Release the lever to hold the shorting device.

SHORT Compensation Key Sequence

When the test xture is ready for the SHORT compensation sequence

panel keys:

7.1

Push the lever.2

the lever until the electrode on the stage A slightly

contacts the shorting device.

Slide stage A while pushing

, press the following front

Basic Measurement Procedures 3-17

Page 44

1.

Press

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

4

5

FIXTURE COMPEN

Cal

After the SHORT compensation sequence is done, the

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

COMPEN MENU

NNNNNNNNNNNNNNNNN

SHORT

.

NNNNNNNNNNNNNNNNN

SHORT

softkey label is underlined.

Performing OPEN Compensation

OPEN Compensation corrects for stray admittance due to the test xture. How to perform an

OPEN compensation sequence for the HP 16192A is described as an example. The procedures

for the HP 16191A and HP 16193A are shown in Appendix C.

1. Set the DUT on the test xture just as you set the

2. Push the black lever and remove the DUT

shorting device in the SHORT compensation.

OPEN Compensation Key Sequence

When the test xture is ready for the OPEN compensation sequence

procedure:

1.

2.

3. Verify that \

Note

NNNNNNNNNNNNNN

Press

OPEN

.

After the OPEN compensation sequence is done, the

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

DONE: COMPEN

Cmp

" appears on the left of the display.

You can perform the desired xture compensation individually.To do this,

press

4

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

FIXTURE COMPEN

Cal

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

RESUME CAL SEQUENCE

NNNNNNNNNNNNNN

OPEN

softkey label is underlined.

desired compensation.

.

, perform the following

and then the key for the

3-18 Basic Measurement Procedures

Page 45

7. Connecting the DUT to the Test Fixture

How to connect the DUT to the HP 16192A is shown in below as an example. The procedures

for the HP 16191A and HP 16193A are shown in Appendix C.

1. Push the lever and place the DUT on the electrode. 2. Release the lever to hold the DUT.

Caution

Protect the instrument from ESD damage by wearing a grounding strap

that provides a high resistance path to ground. Alternatively, ground yourself

to discharge any static charge built-up by touching the outer shell of any

grounded instrument chassis before touching the test port connectors

.

Basic Measurement Procedures 3-19

Page 46

8. Measuring the DUT

After you place the DUT on the test xture, the measured result is displayed.

3-20 Basic Measurement Procedures

Page 47

4

HP 4286A with Chip Handler

This chapter describes the functions available with the HP 4286A and operation procedures for

each of those functions when the HP 4286A is used with a chip handler.

Dierentiation of DUTs through BIN Sorting

GO/NO-GO Test with Limit Test Function

Contact Check

Enabling Beeper

Display Updating ON/OFF

Setup Linking HP 4286A and Chip Handler

Setting up Handler Interface Board

This chapter also includes the technical information for using HP 4286A with automatic

selection system in the production line.

HP 4286A Measurement Time

Electrical Specication of Handler Interface

Performing Calibration with Working Standard

Restoring Settings After Power Interruption

Note

When you use the HP 4286A together with a chip handler

interface board before performing limit test or BIN sorting. See \Setting up

Handler Interface Board" for details.

, be sure to set up the

HP 4286A with Chip Handler 4-1

Page 48

Dierentiation of DUTs through BIN Sorting

You can dierentiate DUTs by checking which BINs DUTs are classied into.To do this,

you need to set several combinations of upper and lower limits for a specic frequency as

measurement parameters.

Editing BIN Table

This section describes how to edit a BIN table as shown in Figure 4-1.

Figure 4-1. Example of BIN Table

1.

Press

4

Test Setup

5

, and then

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

BIN SORT MENU

.

2. Set desired frequency points for BIN sorting. Select frequency points for BIN sorting from

the segment of list table which is set by

4

Sweep Setup

5

. (The HP 4286A has been initially set to

segment 1 of the frequency point for BIN sorting.)

NNNNNNNNNNNNNNNNNNNNNNNNNN

Press

TEST SEG

Enter the desired segment number for BIN sorting, then press

.

4

5

.

x1

3. Primary Parameters

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

EDIT BIN SORT

.

NNNNNNNNNNN

Press

ADD

to create BIN1.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

UPPER LIMIT

Enter valueA

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

N

LOWER LIMIT

Press

Enter valueB

.

.

.

.

NNNNNNNNNNNNNN

Press

DONE

to complete the creation of BIN1.

4-2 HP 4286A with Chip Handler

Page 49

Repeat the steps above to create BIN2 through BIN9.

4. Secondary Parameters

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

SEC REJECT MENU

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

UPPER LIMIT

.

Enter valuea

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

LOWER LIMIT

Enter valueb

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

SEC REJECT on OFF

.

.

NNNNNNNNNNNNNNNNNNNN

to toggle it

ON off

.

NNNNNNNNNNNNNNNNNNNN

Press

5.

Press

RETURN

NNNNNNNNNNNNNN

DONE

to complete the secondary parameter setting.

to complete the creation of BIN table.

Setting up Handler Interface

1. Set up the handler interface board. See \Setting up Handler Interface Board" for details

abount the mode.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

2. Press

3.

Select

4

Test Setup

NNNNNNNNNNNNNNNNNNNN

MODE 1

5

, and then

NNNNNNNNNNNNNNNNNNNN

or

MODE 2

N

HANDLER IF

.

.

The pattern of output signals for BIN sorting can be selected from either Mode 1 or Mode 2.

Denitions in output signals for handler interface vary depending on the mode used. See

\Setting up Handler Interface Board" for details about the mode

Press

NNNNNNNNNNNNNNNNNNNN

RETURN

.

4.

.

BIN Sorting

1.

2.

Press

4

Test Setup

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

BIN SORT on OFF

5

and then,

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

BIN SORT MENU

NNNNNNNNNNNNNNNNNNNN

to toggle it

ON off

.

.

When the BIN sort key is ON, measured data outside the limits are output and displayed as

follows:

On-screen Message Showing Corresponding BIN or BIN OUT (if outside preset limits)

Beeper (ON/OFF selectable)

HP-IB Command

:DATA? BIN

Handler Interface Output

HP 4286A with Chip Handler 4-3

Page 50

GO/NO-GO Test with Limit Test Function

Use the limit test function to perform GO/NO-GO test. This function sets the upper and lower

limits to determine whether DUTs are acceptable. The limit dierentiation function compares

the measured data with preset limits and shows through its output and on-screen message

whether the DUT is within the limits.

Editing Limit Table

This section describes how to edit the limit table of primary parameters and secondary

parameters, as shown in Table 4-1.

Table 4-1. Example of limit setting

Segment Stimulus Value Primary Parameter Secondary Parameter

Lower limit Upper limit Lower limit Upper limit

1 1MHz 10nH 12nH 100.0 1G

2 10MHz 12nH 14nH 100.0 1G

3 100MHz 10nH 14nH 100.0 1G

1

Testing function is not actually performed.

1

1

1

Note

If you do not want to perform testing function for upper or lower limits

of secondary parameters, specify suciently large value for upper limit or

suciently small value for lower limit.

1. Press

2.

4

Test Setup

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

EDIT PRI LIMIT

5

, and then

3. Segment 1

Press

NNNNNNNNNNNNNN

EDIT

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

and

STIMULUS VALUE

Enter Stimulus (1MHz).

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

LOWER LIMIT

Enter lower limit value (10nH).

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

UPPER LIMIT

Enter upper limit value (12nH).

NNNNNNNNNNNNNN

Press

DONE

to complete the editing of this segment.

4. Segment 2

NNNNNNNNNNN

Press

ADD

to edit the new segment.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

STIMULUS VALUE

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

LIMIT TEST MENU

.

.

.

.

.

.

Enter Stimulus (10MHz).

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

LOWER LIMIT

.

Enter lower limit value (12nH).

4-4 HP 4286A with Chip Handler

Page 51

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

UPPER LIMIT

.

Enter upper limit value (14nH).

NNNNNNNNNNNNNN

Press

DONE

to complete the editing of this segment.

5. Segment 3

NNNNNNNNNNN

Press

ADD

to edit the new segment.

Enter stimulus, lower limit, and upper limit values in the same manner above.

NNNNNNNNNNNNNN

Press

DONE

to complete the editing of this segment.

Press

NNNNNNNNNNNNNN

DONE

to complete the editing of the primary parameter limit table.

6.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Then, press

EDIT SEC LIMIT

to edit the secondary parameter limit table.

1. Segment 1

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

LOWER LIMIT

.

Enter lower limit value (100.0).

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

UPPER LIMIT

.

Enter upper limit value (1G).

NNNNNNNNNNNNNN

Press

DONE

to complete the editing of this segment.

2. Segment 2,3

NNNNNNNNNNNNNN

Enter lower and upper limit values and press

DONE

to complete the editing of this

segment in the same manner as segment 1.

Setting up Handler Interface

1. Set up the handler interface board. See \Setting up Handler Interface Board" for the set up

procedure.

2.

3.

Press

Press

4

Test Setup

NNNNNNNNNNNNNNNNNNNN

MODE 1

5

, and then

NNNNNNNNNNNNNNNNNNNN

or

MODE 2

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

HANDLER IF

.

.

When you perform limit test, select the signal pattern from either Mode 1 or Mode 2. The

output for the interface varies depending the mode used as follows.

NNNNNNNNNNNNNNNNNNNN

MODE 1

NNNNNNNNNNNNNNNNNNNN

MODE 2

Outputs overall results of comparison for limit test.

Outputs results for each segment.

See \Setting up Handler Interface Board" for details abount the mode.

Press

NNNNNNNNNNNNNNNNNNNN

RETURN

.

4.

HP 4286A with Chip Handler 4-5

Page 52

Limit Test

You can perform limit test for only primary or secondary parameters.

1.

Press

2.

4

Test Setup

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

PRI LIMIT on OFF

5

, and then

parameters) to toggle it

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

LIMIT TEST MENU

(primary parameters) or

NNNNNNNNNNNNNNNNNNNN

ON off

.

.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

SEC LIMIT on OFF

(secondary

When either of the limit test keys is ON, measured data outside the limits are output and

displayed as follows:

On-screen FAIL Message

Beeper (ON/OFF selectable)

HP-IB Command

Note

:DATA? LFA,:DATA? LLIS,:DATA? LMAR

The frequency (stimulus value) of limit table for setting limits can be set

independently of the frequency set in the list table.

If the frequency of the limit table does not equal to the measurement

frequency of list table, limit tests for all measurements can be performed using

interpolation of the limit values.

For example, if only one point is dened in limit table

with the constant upper limit and lower limit for all measurements

, limit test is performed

.

4-6 HP 4286A with Chip Handler

Page 53

Contact Check

Contact check is used to check the electrical contact between the test head and DUT. This

check consists of measuring dc resistance between the two and determining whether the

resistance is within the preset limits.

Follow the procedure below.

1. Press

4

Contact Check

5

.

2. Set the upper and lower limits for dc resistance between the test head and DUT.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

RDC UPPER LIMIT

and enter the upper limit.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

3.

RDC LOWER LIMIT

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

RDC MEAS on OFF

and enter the lower limit.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

to toggle it

RDC MEAS ON off

.

Then, the measured dc resistance will be displayed on the screen.

4.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Press

RDC LIMIT on OFF

to toggle it

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

RDC LIMIT ON off

.

Whether the measured resistance is within the limits will be displayed on the screen.

Contact check results will be output and displayed as follows:

On-screen FAIL Message

Handler Interface

HP-IB Command

HP 4286A with Chip Handler 4-7

Page 54

Setting up Beeper

Beepers can be used to announce results of limit test and BIN sorting.

The beeper can be set to sound when both of BIN sorting and limit test passed or both of them

failed.

Follow the procedure below.

1.

Press

4

Test Setup

2.

If you wish to sound the beeper when both of BIN sorting and limit test passed, press

If you wish to sound it when both of BIN sorting and limit test failed, press

NNNNNNNNNNN

OFF

when you do not wish to sound the beeper regardless of test results. In other words,if

5

, and then

NNNNNNNNNNNNNN

BEEP

.

NNNNNNNNNNNNNN

NNNNNNNNNNNNNN

FAIL

PASS

. Press

either of BIN sorting or limit test failed, the beeper does not sound for any settings.

Press

NNNNNNNNNNNNNNNNNNNN

RETURN

.

3.

.

4-8 HP 4286A with Chip Handler

Page 55

Display Updating ON/OFF

You can select whether to display new measurement results on the screen by switching the

display updating function ON and OFF. Switch this function OFF to more quickly determine

whether the DUT is acceptable or not.

Switching display updating OFF gains 3ms + 6ms/point.

This updating function can be switched ON and OFF at any time.

Follow the procedure below.

1. Press

2.

Press

4

5

.

Display

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MEAS DISP ON off

to switch the updating function ON and OFF.

HP 4286A with Chip Handler 4-9

Page 56

Setup Linking HP 4286A and Chip Handler

The HP 4286A can be set up to read initial settings from exible disk during startup. This

setup allows the HP 4286A to run exclusively for your particular purpuse, the chip handler for

instance, from the moment of startup.

Follow the procedure below.

1. Set up the HP 4286A for use with the handler.

2. Insert a 3.5-inch LIF or DOS-formatted disk into the built-in disk drive.

3. Press

4.

Press

4

Save/Recall

NNNNNNNNNNNNNNNNNNNNNNNNN

N

STOR DEV

5

.

to switch it to

NNNNNNNNNNNNNNNNNNN

N

[DISK]

. This species the built-in disk drive as the storage

destination.

NNNNNNNNNNNNNNNNN

5. Press

6.

Enter

Before turning on the HP 4286A, insert the disk containing the \

STATE

.

AUTOREC

as the lename and press

NNNNNNNNNNNNNN

DONE

.

AUTOREC

" le into the built-in

disk drive. Each time you turn on HP 4286A, it recalls settings in the le to operate exclusively

for the handler from the moment of startup

.

4-10 HP 4286A with Chip Handler

Page 57

Setting up Handler Interface Board

This section describes the steps necessary to use the handler interface board.

There are 3 major steps as follows:

Mounting Pull-up Resistor

Mount a pull-up resistor to the handler. Where to mount a resistor and what resistance the

resistor needs to have depends on the signal I/O format.

Note

A pull-up resistor must be mounted to the handler for comparator signals.

Setting up Handler Interface

Set up the handler interface signal pattern that suits the HP 4286A operation mode. Set it up

on the HP 4286A.

The following step is required when the power supplies for I/O or COMMON setting should be

modied.

Changing Signal I/O Format

Change the switch setting on the handler interface board to change its signal I/O format.

This is necessary when you need the I/O format that requires the switch settings dierent

from the default settings.

Checking Default Settings

The handler interface board has been set as follows before shipment.

Signals Settings

Comparator Signal This signal is opto-isolated and is output through open-collector

COM1 is used as COMMON that is isolated from HP 4286A's

chassis ground. Pull-up resistors are mounted to the handler

.

Output voltage is supplied from an external power source (5 to

24V) on the handler.

Control Output Signal This signal is opto-isolated and is output through open-collector

COM2 is used as COMMON that is isolated from HP 4286A's

chassis ground. Pull-up resistors are mounted to the handler.

Output voltage is supplied from an external power source (5 to

15V) on the handler.

DC isolated Input Signal This signal is opto-isolated from the internal circuits of

HP 4286A. Driving voltage is supplied from an external power

source (5 to 7V) through EXT.DCV2. This signal turns \TRUE" if

input signal is connected to the COMMON of the external power

source.

Internal power source (5V) Not used.

.

.

See \Handler Interface Board Switches" for default switch settings.

Warning

Be sure to check the procedures in \Removing the Top Cover" before

removing the HP 4286A top cover.

HP 4286A with Chip Handler 4-11

Page 58

Selecting Settings

Select the desired settings according to the table below.

Table 4-2. Handler Interface Board Setup Worksheet

Item Selection Default Power Source Pull-up

Comparator

Signal

Control

Output

Signal

A Default

External(COM1) Mount to the

Setting

B Internal(+5V)

C Default

External

2

Setting

D External

2

handler

1

Mount to the

handler

Use internal

pull-up

resistors(4.64k).

E Internal

3

Mount to the

handler

F Internal

3

Use internal

pull-up

resistors(4.64k).

DC Isolated

Input

Signal

G Default

Setting

External257V Use internal

pull-up resistors.

H External2715V Isolated Set SW2(6) and SW2(8) OFF.

I Internal

3

Resistor

Opt-

Modication to Default

isolation

Isolated

Not

isolated

Supply an internal power

source(+5V) to pull-up

resistors on the handler. Set

SW2(5) ON.

Isolated

Isolated Set SW2(1) through SW2(3)

ON.

Not

isolated

Not

isolated

Turn SW1

Internal(+5V)

side.

Set SW2(4) ON.

Set SW2(1)

through SW2(3)

and SW2(4) ON.

Isolated

Not

isolated

Turn SW1

Internal(+5V)

Set SW2(4) ON.

side.

1

Chassis grounding is used.

2

Supply through EXT.DCV2. COM2 is used as COMMON.

3

Set voltage +5V.

Follow the combination logic shown below according to power sources.

Comparator

Control Output Signal DC Isolated Input Signal

Signal

Select A or B. For external power source . . . Select C or D.

For internal power source . . . Select E or F.

Note

Review the check items below before selecting your settings.

For C or D . . . Select G or H.

For E or F . . . Select I.

You must use the same power source for control output signal and DC

isolated input signal.

If you select COM1 for COMMON and use internal power source output,

comparator signals will not be opto-isolated.

If you select COM2 for COMMON and choose to use internal power source

output, comparator signals will not be opto-isolated.

4-12 HP 4286A with Chip Handler

Page 59

When you use the internal pull-up resistor and apply voltage to the control

output signal from an external power source, the permissible voltage range is

between 5 and 15V.

If your current settings are default settings or if you wish to change your settings, follow the

steps below.

Changing Settings

You need to change your settings depending on the signal output format (open-collector,

internal voltage output, or external voltage output) of your handler interface. Two switches

are provided for changing settings. The setting of both switches can be changed on the top

shield. (See \Handler Interface Board Switches".)

See \Electrical Specication of Handler Interface" rst to become familiar with electrical

characteristics of each signal and operations of the interface board and I/O circuits before

changing your settings.

Also, check the default settings in \Checking Default Settings". If you need to change the

default setting, follow the steps below.

Removing the Top Cover

1. Turn OFF the HP 4286A, disconnect the power cable

, and wait for a few minutes to allow

capacitors in the HP 4286A to discharge.

Warning

The HP 4286A internal circuits carry high voltage during operation and

immediately after it has been turned OFF.To prevent injuries due to

electrical shocks, be sure to wait for at least few minutes before removing

the cover to make sure that capacitors in the HP 4286A discharge

completely .

2. Remove 4 back legs that hold the top cover and rear panel together

3. Fully loosen the screw behind the top cover

.

.

4. Slide the top cover backward and lift it up to remove it. Find the top shield, which shows

the locations and default settings of SW1 and SW2.

Setting up Control Output Signal and DC Isolated Input Signal

Select either external or internal power source for supplying voltage to the control output and

DC isolated input signals.

Set SW1 as follows:

Table 4-3. SW1 Setting

Power Source SW1

External Source Switch it over toward the rear panel.

Internal Source Switch it over toward the front panel.

HP 4286A with Chip Handler 4-13

Page 60

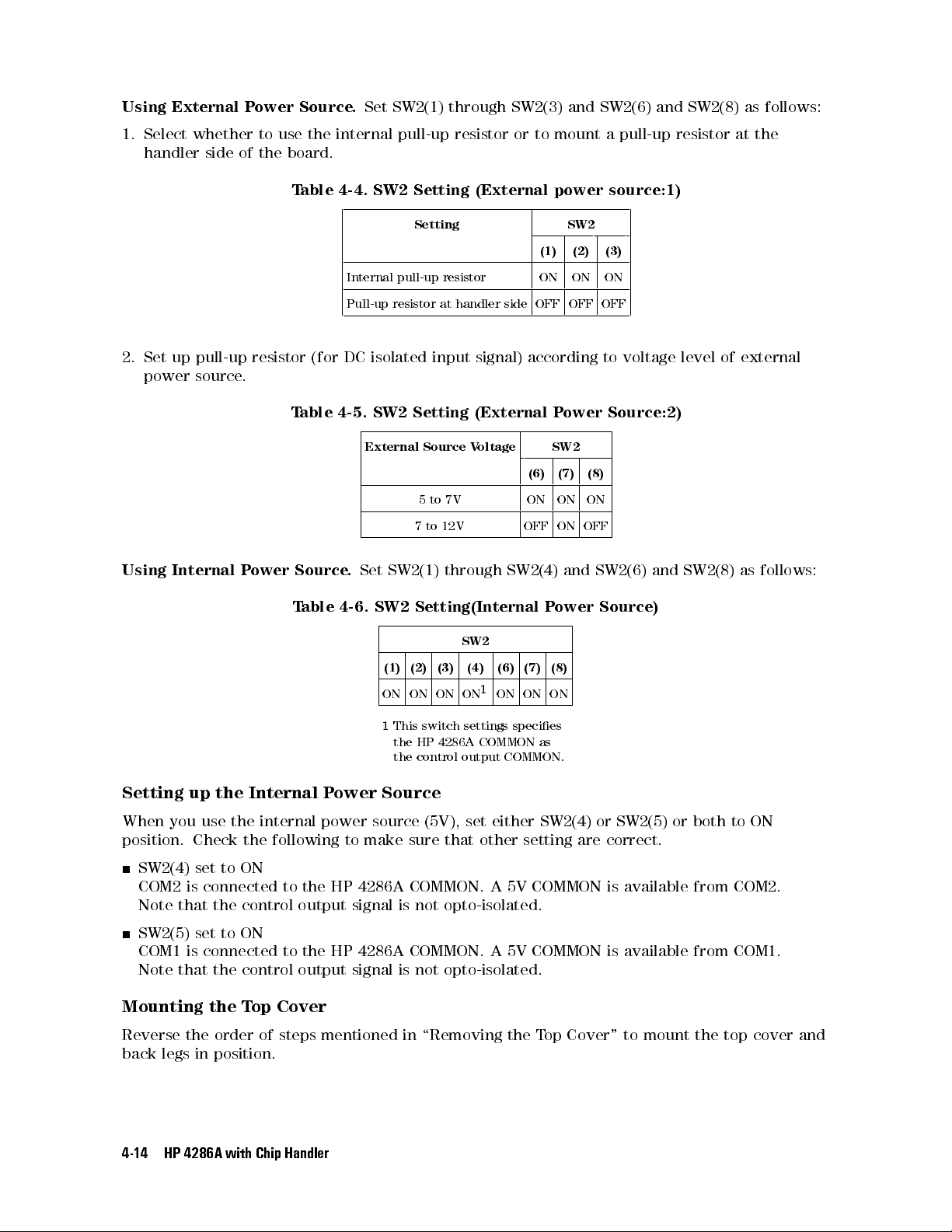

Using External Power Source.

Set SW2(1) through SW2(3) and SW2(6) and SW2(8) as follows:

1. Select whether to use the internal pull-up resistor or to mount a pull-up resistor at the

handler side of the board.

Table 4-4. SW2 Setting (External power source:1)

Setting SW2

(1) (2) (3)

Internal pull-up resistor ON ON ON

Pull-up resistor at handler side OFF OFF OFF

2. Set up pull-up resistor (for DC isolated input signal) according to voltage level of external

power source.

Table 4-5. SW2 Setting (External Power Source:2)

External Source Voltage SW2

(6) (7) (8)

5to 7V ON ON ON

7 to 12V OFF ON OFF

Using Internal Power Source.

Set SW2(1) through SW2(4) and SW2(6) and SW2(8) as follows:

Table 4-6. SW2 Setting(Internal Power Source)

SW2

(1) (2) (3) (4) (6) (7) (8)

ON ON ON ON1ON ON ON

1

This switch settings species

the HP 4286A COMMON as

the control output COMMON.

Setting up the Internal Power Source

When you use the internal power source (5V), set either SW2(4) or SW2(5) or both to ON

position. Check the following to make sure that other setting are correct.

SW2(4) set to ON

COM2 is connected to the HP 4286A COMMON. A 5V COMMON is available from COM2.

Note that the control output signal is not opto-isolated.

SW2(5) set to ON

COM1 is connected to the HP 4286A COMMON. A 5V COMMON is available from COM1.

Note that the control output signal is not opto-isolated.

Mounting the Top Cover

Reverse the order of steps mentioned in \Removing the T

back legs in position.

4-14 HP 4286A with Chip Handler

op Cover" to mount the top cover and

Page 61

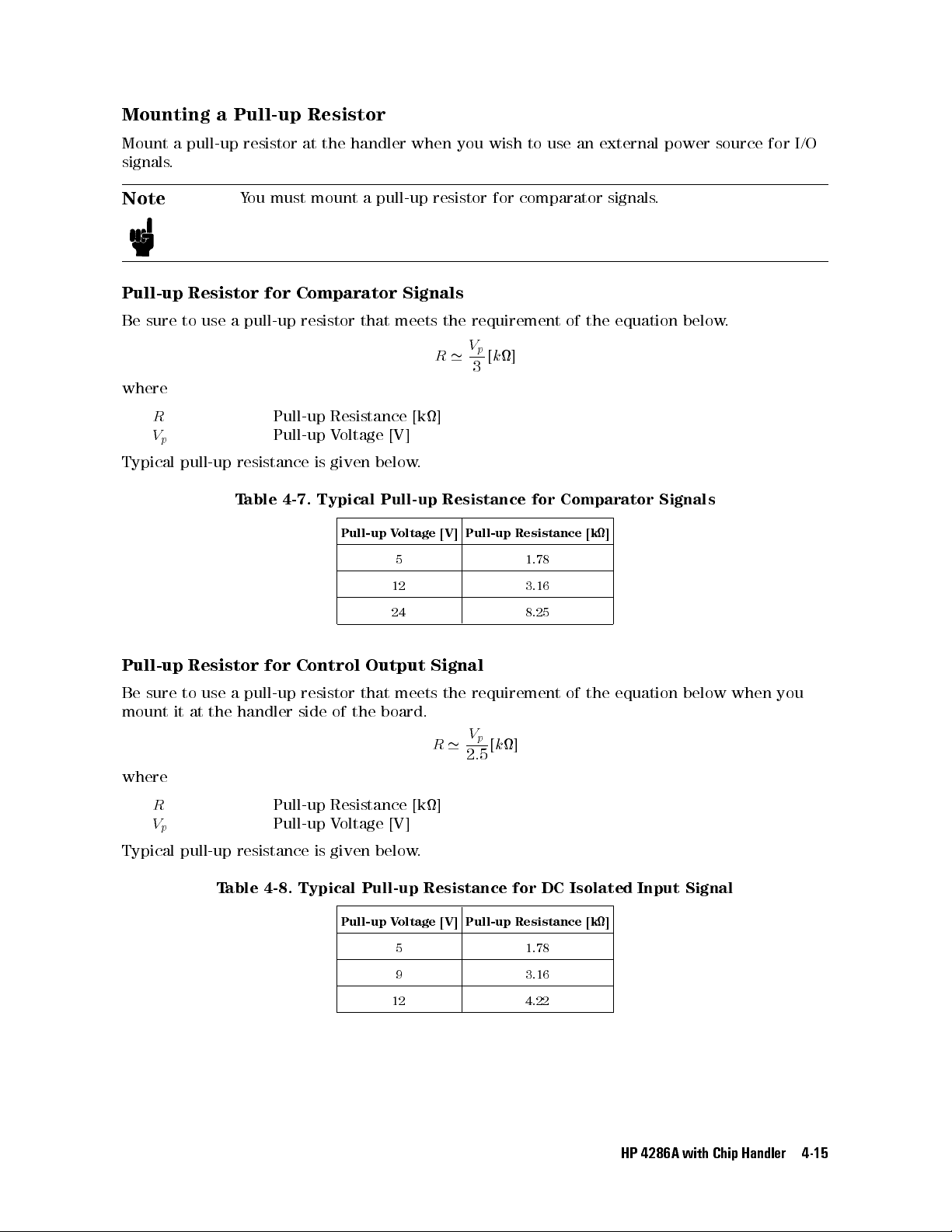

Mounting a Pull-up Resistor

Mount a pull-up resistor at the handler when you wish to use an external power source for I/O

signals.

Note

You must mount a pull-up resistor for comparator signals.

Pull-up Resistor for Comparator Signals

Be sure to use a pull-up resistor that meets the requirement of the equation below.

V

p

R

'

[k]

3

where

R

V

p

Typical pull-up resistance is given below

Pull-up Resistance [k]

Pull-up Voltage [V]

.

Table 4-7. Typical Pull-up Resistance for Comparator Signals

Pull-up Voltage [V] Pull-up Resistance [k]

5 1.78

12 3.16

24 8.25

Pull-up Resistor for Control Output Signal

Be sure to use a pull-up resistor that meets the requirement of the equation below when you

mount it at the handler side of the board.

V

p

R

'

[k]

2:5

where

R

V

p

Pull-up Resistance [k]

Pull-up Voltage [V]

Typical pull-up resistance is given below.

Table 4-8. Typical Pull-up Resistance for DC Isolated Input Signal

Pull-up Voltage [V] Pull-up Resistance [k]

5 1.78

9 3.16

12 4.22

HP 4286A with Chip Handler 4-15

Page 62

Setting up Output Signal Pattern

Set up the signal pattern for the handler interface. Settings vary depending on the HP 4286A

operation mode.

NNNNNNNNNNNNNNNNNNNN

Mode 1(

MODE 1

)

BIN sorting is performed on one of the segments dened in the frequency list table. DUTs are

classied into 9 BINs maximum based on the results for the specied segment. For the other

segments, limit test is performed.

Output signal appears on the corresponding connector pin, indicating the BIN which DUT

falls into. The limit test result is output as overall results of comparison for all specied

segments.

NNNNNNNNNNNNNNNNNNNN

Mode 2(

MODE 2

)

Outputs overall results of comparison for all specied segments. Also, outputs results of

comparison and BIN sorting for each segment. The BIN sorting results are output as 4 bit

code.

Mode 2 can be further divided into

On Sweep Mode

and

On Point Mode

, depending on the

type of triggering used. Denitions of some output signals are dierent between the two