Page 1

MANUAL CHANGES

Agilent 4285A

Precision LCR Meter

Operation Manual

This supplement contains information for correcting manual errors and for adapting the manual to newer instruments that contains

improvements or modifications not doc umented in the existing manual.

To use this supplement

1. Make all ERRATA corrections

2. Make all appropriate serial-num ber-rel ated changes listed below

SERIAL PREFIX OR NUMBER MAKE MANUAL

CHANGES

All 1

New Item

K

SERIAL PREFIX OR NUMBER MAKE MANUAL

CHANGES

MANUAL IDENTIFICATION

Model Number: 4285A

Date Printed: March 2000

Part Number: 04285-90010

ERRATA

CHANGES 1

CHANGE 1 contains the information needed to adapt the 4285A’s manual.

Changed the company name from YOKOGAWA-HEWLETT-PACKARD, LTD., or its abbreviation YHP to Agilent

Technologies Japan, Ltd.

Manual change supplement are revised as often as nec essary to keep manuals as current and acc urate as possible. Agilent Technol ogies

recommends that you peri odi cally request the latest edition of this supplement. Free copies are available from al l Agilent Technologies offi ces.

When requesting copies , quote the m anual ident ific ation inform ation from your supplem ent, or the model number and print date f rom t he titl e

page of the manual.

Date/Div: March 2000/33

Page 1 of 3

PRINTED IN JAPAN

NOTE

Page 2

The pink sheet titled “CAUTION ON OPERATION”

Change the page title as follows.

CAUTION ON OPERATION

3.HANDLER INTERFACE BOARD (OPTION 201)

Add the following information.

Fuse: Non Time Delay 0.5A 125V

If you need this fuse,contact your nearest Agilent Technologies Sales and Service Office.

MODEL 4284A PRECISION LCR METER OPTION 201 HANDLER INTERFACE

OPERATION NOTE

Page 2-16 Warning

Change the procedure 1 and warning as follows:

1. Disconnect the 4284A’s power cord and allow 1 minute for the internal supply filter capacitors to

discharge.

Dangerous energy/voltage exists when the 4284A is in operation,and for a time after it is

powered down. Allow 1 minute for the internal capacitors to discharge.

Page 2-16

Add the following CAUTION after the procedure 7.

The interface board contains electronic components that can be damaged by static

electricity through electrostatic discharge(ESD).To prevent ESD damage,maintain frequent

contact with any bare sheet metal surface on the chassis. A grounding wrist strap (or similar

device) is useful for this purpose. Handle the board car efully at all times. Avoid touching

electronic components or circuit paths.

MODEL 4284A PRECISION LCR METER OPTION 202 HANDLER INTERFACE

OPERATION NOTE

Page 3-4 Warning

Change the procedure 1 and warning as follows:

1. Disconnect the 4284A’s power cord and allow 1 minute for the internal supply filter capacitors to

discharge.

Dangerous energy/voltage exists when the 4284A is in operation,and for a time after it is

powered down. Allow 1 minute for the internal capacitors to discharge.

Page 3

Page 3-4

Add the following CAUTION after the procedure 6.

The interface board contains electronic components that can be damaged by static

electricity through electrostatic discharge(ESD).To prevent ESD damage,maintain frequent

contact with any bare sheet metal surface on the chassis. A grounding wrist strap (or similar

device) is useful for this purpose. Handle the board car efully at all times. Avoid touching

electronic components or circuit paths.

MODEL 4284A PRECISION LCR METER OPTION 301 SCANNER INTERFACE

OPERATION NOTE

Page 2-11 Warning

Change the procedure 1 and warning as follows:

Disconnect the power cable from the 4284A and allow 1 minute for the internal capacitors to

discharge.

Dangerous energy/voltage exists when the 4284A is in operation,and for a time after it is

powered down. Allow 1 minute for the internal capacitors to discharge.

Page 4

Page 5

MANUAL CHANGES

Agilent 4285A

Precision LCR Meter

Operation Manual

This supplement contains information for correcting manual errors and for adapting the manual to newer instruments that contains

improvements or modifications not doc umented in the existing manual.

To use this supplement

1. Make all ERRATA corrections

2. Make all appropriate serial-num ber-rel ated changes listed below

SERIAL PREFIX OR NUMBER MAKE MANUAL

CHANGES

3041J00276 1

New Item

K

SERIAL PREFIX OR NUMBER MAKE MANUAL

CHANGES

MANUAL IDENTIFICATION

Model Number: 4285A

Date Printed: March 2000

Part Number: 04285-90010

ERRATA

CHANGES 1

When used with the 42851A Precision Q Adapter, make the following changes:

Two system messages are added.

"Warning, Cannot find resonance" (when the tuning capacitor cannot resonate with the DUT)

"Waiting for trigger" (when the 4285A is not triggered)

On the Q CORRECTION page, the SHORT correction function is always set to ON.

On the Q CORRECTION page, the Q-MODE field is added to select between EFFECTIVE Q mode and CIRCUIT

Q mode.

Manual change supplement are revised as often as nec essary to keep manuals as current and acc urate as possible. Agilent Technol ogies

recommends that you peri odi cally request the latest edition of this supplement. Free copies are available from al l Agilent Technologies offi ces.

When requesting copies , quote the m anual ident ific ation inform ation from your supplem ent, or the model number and print date f rom t he titl e

page of the manual.

Date/Div: March 2000/33

Page 1 of 1

PRINTED IN JAPAN

NOTE

Page 6

Page 7

CAUTIONS ON OPERATION

1. UNKNOWN (MEASUREMENT) TERMINA LS

Do NOT

NOT apply DC voltage or current to the UNKNOWN terminals. Doing so will damage

NOTNOT

the 4285A. Before you measure a capacitor, be sure the capacitor is fully discharged.

2. MEMORY CARD

Use Agilent Technologies-specified memory cards containing 4285A-specific data only. If

other memory cards are used, the 4285A may be damaged. Non 4285A-specific data

contained on a memory card is not guaranteed, and data may be lost.

To insert a memory card into the MEMORY

facing upward and with the contacts at the slot opening. Insert the card into the slot until

it "clicks" in place.

To remove a memory card from the 4285A, press the UNLOCK button and remove the

card.

Do NOT remove a memory card while LOADing or STORing d ata. Doing so may damage

the memory card and any data stored in the memory card may be lost.

Store memory cards in their furnished card cases when not in use. The card case protects

memory cards from contamination and electrostatic discharge.

Also, store memory cards under the following environmental conditions.

Storage Temperature Range: -30 ℃ to +70 ℃

Storage Humidity Range: 30%. to 85%. (@ +50 ℃)

MEMORY card slot, hold the memory card with the label

MEMORYMEMORY

Do NOT shock or stress memory cards.

When storing or moving your 4285A, be sure the memory card slot is empty (no memory

card inserted).

Do NOT touch the connector contact surface of a memory card and do NOT use chemical

liquids to clean the contacts.

Page 8

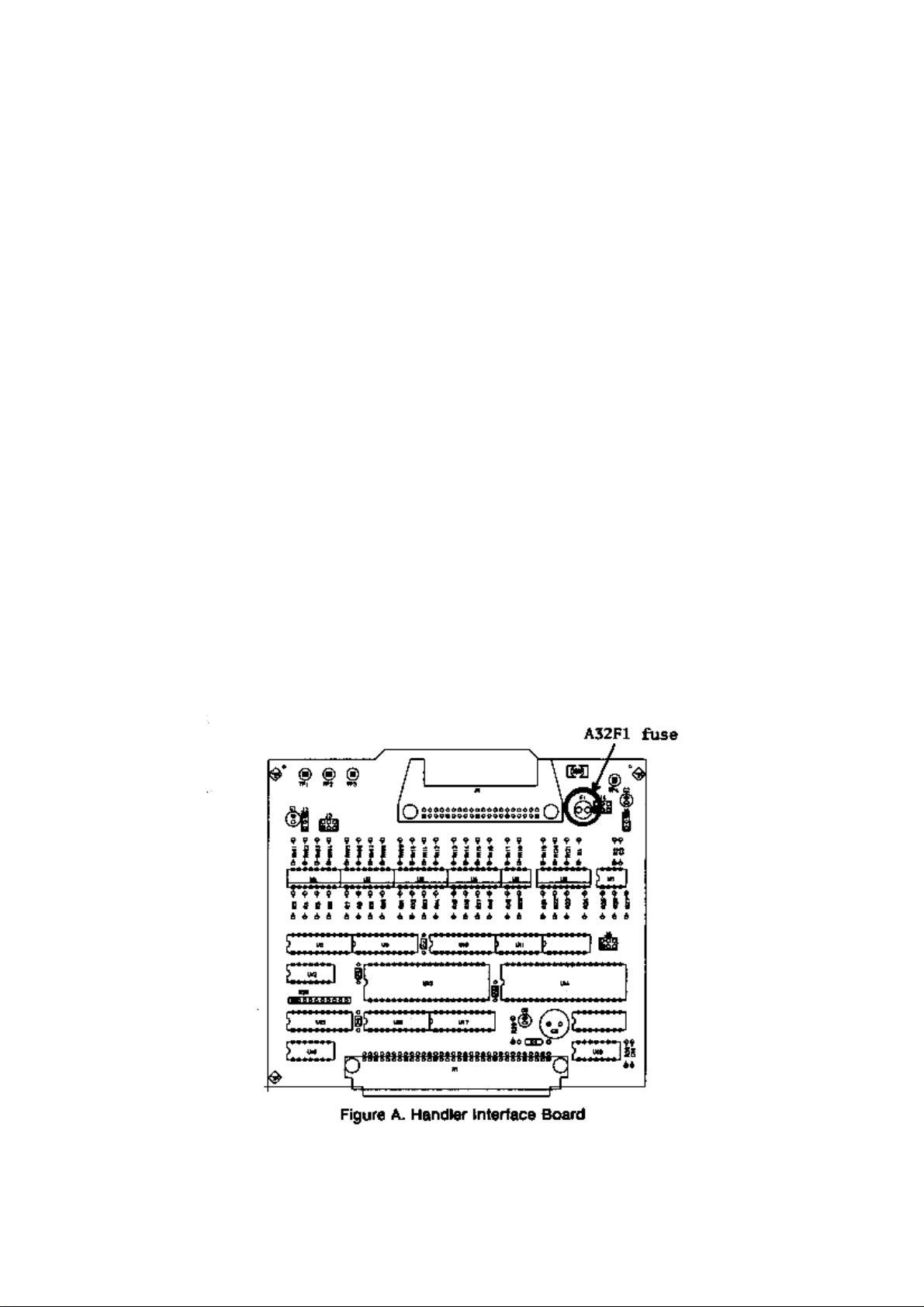

3. HANDLER INTERFACE BOARD (0PTION 201)

If the +5V internal voltage

output

output , a fuse on the handler interface board (A32F1) has blown and must be replaced.

outputoutput

Two replacement fuses are furnished with the 4285A option 201. Additional fuses are

available from Agilent Technologies. Order PN 2110-0046.

Fuse: Mpm Time Delay 0.5A 12.5V

If you need this fuse, contact your nearest Agilent Technologies S ales and S e rv ice O f f ice.

To replace A32F1 , perform the following procedure.

1. To remove the handler interface board (A32), perform proc edu re I th roug h 7

2. Remove A32F1 (indicated in Figure A) from socket and carefully insert the new fuse.

3. Replace the handler interface board, top shield plate, rear feet, and top cover.

+5V internal voltage (pin 16, 17 or 18 of the handler interface connector) is not

+5V internal voltage+5V internal voltage

procedure I through 7 on page

procedure I through 7procedure I through 7

10-26

10-26.

10-2610-26

is not

is notis not

page

pagepage

If the handler interface continues not to output +5V after A32F1 has been replaced,

contact the nearest Agilent Technologies office.

Page 9

Page 10

Page 11

Safety Summary

When you notice any of the unusual conditions listed below, immediately

terminate operation and disconnect the power cable.

Contact your local Agilent Technologies sales representative or

authorized service company for repair of the instrument. If you continue

to operate without repairing the instrument, there is a potential fire or

shock hazard for the operator.

n Instrument operates abnormally.

n Instrument emits abnormal noise, smell, smoke or a spark-like light

during the operation.

n Instrument generates high temperature or electrical shock during

operation.

n Power cable, plug, or receptacle on instrument is damaged.

n Foreign substance or liquid has fallen into the instrument.

Page 12

Page 13

Page 14

Page 15

Agilent 4285A

PRECISION

LCR

METER

OPERA

SERIAL

This

3009J

read

NUMBERS

manual

.

F

or

\Serial

applies

additional

Number"

TION MANU

directly

important

in

Chapter

to

instruments

information about

1

of this

with serial

Operation Manual.

AL

number prex

serial numbers

,

Agilent Part No. 04285-90010

Printed in JAPAN January 2001

Sixth Edition

Page 16

Notice

The

information

without

This

notice

document

copyright.

photocopied,

the

prior

written

contained

.

contains

All

rights

reproduced,

consent

in

proprietary

are

reserved.

or

of

this

document

No

translated

the

Agilent

is

information

part

of this

to

another

Technologies

subject to

which

is

document may

language

.

change

protected by

be

without

Agilent

T

echnologies

Component

1-3-2,

Murotani,

Hyogo

,

651-2241

T

est

Japan, Ltd.

PGU-Kobe

Nishi-ku,

Japan

Kobe-shi,

c

Copyright 1990, 1992, 1996, 1997, 2000, 2001

Agilent Technologies Japan, Ltd.

Page 17

Manual

History

Printing

The

manual printing

edition.

(Minor

not

The printing

corrections

cause the

extensive

June

1990

June

1992

date and

date changes

and

updates which

date to

change.)

technical changes

:

::

::

::

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

part number

when a

are incorporated

The manual

are incorporated.

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

::

::

indicate its

new edition

part number

::

:

:

:

:

:

:

:

:

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

current

is printed.

at reprint

changes

:

:

:

First

:

Second

do

when

Edition

Edition

December

September

March

January

2000

2001

1996

1997

:

::

:

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

Third

Edition

:

::

::

:

:

:

:

F

ourth

Edition

::

:

:

:

:

:

:

:

:

:

:

Fifth

Edition

:

:

:

:

:

:

:

:

:

:

:

:

:

Sixth

Edition

(part

(part

(part

number:

number:

number:

04285-90010)

04285-90010)

04285-90010)

iii

Page 18

Safety

Summary

The

following general

phases

comply

in

In

intended

The

failure

of operation,

with

this manual

addition it

use of

Agilent

to

comply

safety precautions

service,

these

precautions or

may impair

violates safety

the instrument.

Technologies

with these

and repair

with specic

the protection

standards of

assumes no

requirements.

must be

of this

observed during

instrument. F

WARNINGS

provided by

design, manufacture

liability for

the

all

ailure to

elsewhere

the equipment.

,and

customer's

DO

NOT

Explosive

Keep

DO

A

way

NOT

Note

Note

Ground

Instrument

Operate

In

Atmosphere

From

Circuits

Service

A

djust

Alone

The

An

Live

Or

4285A

DEGREE

LEDs

CLASS

T

must

cable

Do

fumes

o

avoid

complies

in

be

with

not

.

2

this

1

LED

electric

connected

operate

Operation

constitutes

Operating

personnel must

replacement

maintenance

cable

connected.

exist

even

with

disconnect

Do

not

attempt

capable

of

rendering

with

in

IEC1010-1.

product

PRODUCT

shock

earth

blade

the

of

a

denite

and internal

personnel.

Under

the

power

and

internal

INST

ALLA

4285A

are

Class

hazard,

to

a

safety

.

instrument

any

electrical

safety

hazard.

not

adjustments

Do

not

certain

power

cable

discharge

service or

rst

aid and

TION

CA

TEGORY

is

INDOOR

1

in

accordance with

the

instrument

earth

ground

in

the

presence

instrument

remove

instrument

must

replace

components

conditions

removed.

circuits

before

adjustment unless

resuscitation, is

USE

product.

chassis

by

the

of

in

such

be

made

,

dangerous

T

o

avoid

touching

II

and

POLLUTION

IEC825-1.

and

cabinet

supplied

ammable

an

environment

covers

by

with

.

qualied

Component

the

voltages

injuries

,

them.

another person,

present.

power

gasses

power

may

always

or

DO

NOT

Parts

Substitute

Or Modify

Instrument

Dangerous Procedure

Warnings

Warning

iv

Because

install

instrument. Return

of

the

substitute

danger

parts

the

of

introducing

or

perform

instrument

additional

unauthorized

to

a

Agilent

hazards

,

do

modications

T

echnologies

not

to

Sales

the

and

Service Oce for service and repair to ensure that safety features are

maintained.

Warnings

procedures throughout this manual. Instructions contained

, such as

the example below

, precede potentially dangerous

in the

warnings must be followed.

Dangerous voltages, capable of causing death, are present in this

instrument. Use extreme caution when handling, testing, and

adjusting this instrument.

Page 19

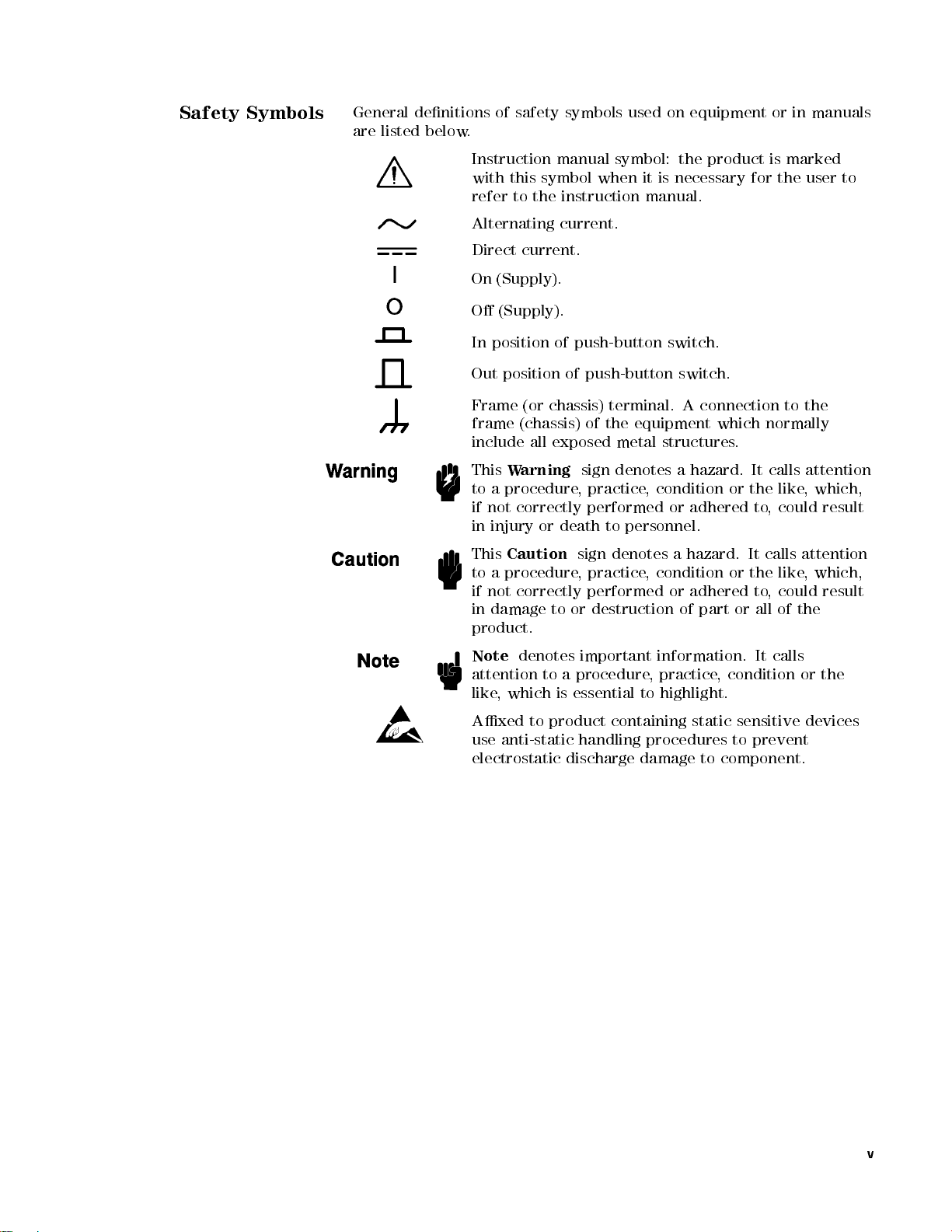

Safety Symbols

General

are

listed below

denitions

.

of

safety symbols

used on

equipment or

in manuals

Instruction

with

this symbol

refer

Alternating

Direct

On

(Supply).

O

(Supply).

In position

Out

position

Frame

frame

include

This

W

to

a

procedure,

if

not

in

injury

This

Caution

to

a

procedure

if

not

in

damage

manual symbol:

to the

instruction manual.

current.

current.

of push-button

(or chassis)

(chassis)

all

exposed

arning

correctly performed

or

death

correctly

to

product.

when it

of

push-button

terminal.

of

the

metal

sign

denotes a

practice,

to

sign

denotes

,

practice

performed

or

destruction

the product

is necessary

switch.

switch.

A

equipment

structures

condition or

or adhered

personnel.

a

hazard.

,

condition

or

of

connection

which

.

hazard. It

the like

It

or

the

adhered

part

or

is marked

for the

to

normally

calls

to,

could result

calls

like

to

,

could

all

of

the

user to

the

attention

,

which,

attention

,

which,

result

Note

denotes

attention

like

Axed

use

to

,

which

to

anti-static

electrostatic

important

a

procedure

is

essential

product

handling

discharge

information.

,

practice

to

highlight.

containing

procedures

damage

,

condition

static

sensitive

to

to

component.

It

calls

prevent

or

the

devices

v

Page 20

4285A

LCR

Precision

Meter

Documentation

Map

The

documentation for

manuals

purpose

.F

ollowing is

.

The

system

basic

the 4285A

a brief

4285A Getting

setup

and

measurements

has been

description of

Started Guide

initial

power-up

and

explains

separated into

each manual

walks

,

shows

you

how

commonly

several

and its

through

to

make

used

features

.

The

4285A

04285-90010)

GPIB

OPERA

provides

programming

TION

MANU

general

information,

AL

(Agilent

information,

and

in

depth

P

art Number

specications

reference

information.

The

4285A

MAINTENANCE

MANU

AL

(Agilent

P

art

Number 04285-90030) explains how to verify conformance

to published specications

.

,

The

4285A SERVICE MANUAL

(Agilent Part Number

04285-90031) explains how to adjust, troubleshoot, and

repair the instrument. (Furnished Option 915 only.)

vi

Page 21

How

T

Manual

o

Use

This

This

is the

Operation Manual

This

manual contains

characteristics

control

reference

commands in

.

specications,

,

installation,

nine chapters

for the

4285A Precision

supplemental performance

conguration, operation,

.Use

this manual

LCR Meter

and remote

for the

function

.

General

Information

Product

DISPLA

MEAS

CA

T

ALOG/SYSTEM

CONFIGURA

Chapter

Chapter

1

2

Installation

Chapter 3

Overview

Chapter

Y

FORMA

Chapter

4

T

5

SETUP

Chapter

6

TION

Chapter

1

provides

characteristics

Chapter

kit

know

Chapter

Chapter

and

menukey

Chapter 5

2

provides

installation,

and

do

3

provides

4

provides

measurement

.

provides

condition setup

Chapter

memory

to

the

6

provides

and

system

4

CA

T

ALOG/SYSTEM

the

,

and

other

unpacking,

and

preparation

before

applying

information

detailed

function,

detailed

,

corresponding

detailed

conguration

5

specications

general

information on

initial

information

A

C

power

including

information

corresponding

information

to

the

information

catalog

menukey

.

, supplemental

the 4285A.

inspection,

rack

necessary

.

a

product

for

the

display

to

the

4

for

the

measurement

4

MEAS

for

of

5

SETUP

the

internal/external

the

4285A, corresponding

performance

mount/handle

for

you

overview

format

DISPLA

Y

FORMA

menukey

to

.

5

T

.

Chapter

Measurement

Chapter

Remote

Chapter

Control

7

Basics

8

9

Command Reference

Appendix A

Manual Changes

Chapter

impedance

Chapter

interface

Chapter

7

provides

theory

8

provides

.

9

provides

the

basic

and

measurement

information

detailed

measurement

techniques

to

control

information for

procedure

.

the

4285A using

each

of

the

with

4285A

the

general

the GPIB

GPIB

commands.

Appendix A contains Manual Changes and provides information for

using this manual with an 4285As manufactured before the printing

date

of the manual.

vii

Page 22

Error

Appendix B

and W

arning

Messages

Appendix

descriptions

B lists

the 4285A's

and solutions

.

error and

warning messages

with brief

Appendix C

Initial

Settings

System

Appendix

Write

Protection

Typeface

Conventions

and

Memory

D

Appendix

status

is

stored

Appendix D

stored data

memory.

Bold

Italics

Computer

C

lists

provides

in

the

the

in

internal

4285A's

4285A's

system

the

procedure

memory

Boldface

F

or

Italic

of

manuals

Italic

when

place

copy

to

type

a

le

Computer

and

initial

memory

type

example:

type

is

type

is

a

name

of

the

lename

a

space

such

as

font

messages

settings

for

write

card

and

is

used

icons

used

and

other

also

or

a

words

means

,

and

file1

is

.

and

.

protecting

internal

when

are

for

emphasis

publications

used

for

variable

in

italics

to

then

.

used

for

functions

EEPROM

a

term

symbols

keyboard

must

.

F

or

type

the

to

type

on-screen

whose

all

of

is

.

and

for

.

entries

be

typed

example:

word

the

prompts

the

dened.

titles

in

copy

name

of

,

Certication

4

HARDKEYS

N

NN

NN

N

N

N

N

SOFTKEYS

5

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

Labeled

are

enclosed

Softkeys

Crystal

keys

in

located

Display

on

the

5

.

4

to

(LCD)

instrument

the

right

are

enclosed

front

of the

panel

Liquid

N

N

in

Agilent Technologies certies that this product met its published

specications at the

Technologies further certies

traceable to the United States

Technology (

nist

facility, or to the calibration

Organization members

time of shipment from the factory

. Agilent

that its calibration measurements are

National Institute of Standards and

), to

the extent allowed by the Institute's calibration

facilities of other International Standards

.

N

N

N

.

viii

Page 23

W

arranty

This

Agilent T

defects

the

listed

manual,

warranty

or

F

or warranty

service

shipping

shall

Buyer

returned

in material

date

of

shipment, except

in \Components

the warranty

period, Agilent

replace products

facility designated

charges to

pay shipping

shall pay

to Agilent

echnologies instrument

and workmanship

that in

not Covered

shall be

for the

Technologies

which prove

service or

repair

,

to be

this

by Agilent

Agilent T

charges to

all shipping

Technologies

echnologies

return the

charges,

from another

product is

for a

period of

the case

by W

of certain

arranty" in

specied period.

will, at

its option,

defective.

product

T

must

echnologies

and

Agilent

product

duties

,

and

country

warranted against

one year

from

components

Chapter 1

of

During the

be

.

Buyer

to

Buyer

taxes

returned

either

T

echnologies

.

for

repair

to

shall

prepay

However

products

.

this

a

,

Limitation

W

arranty

Exclusive

Remedies

of

Agilent

designated

execute

instrument.

of

error

The

improper

software

operation

or

No

specically

tness

The

remedies

Technologies

by Agilent

its

programming

Agilent

the

instrument,

free

.

foregoing

warranty

or

inadequate

or

interfacing,

outside

improper

other

site

preparation

warranty

disclaims

for

a

particular

remedies provided

.

A

gilent

warrants

T

echnologies

that

instruction

T

echnologies does

or

software

shall

,

not

maintenance

unauthorized

of

the

environmental

or

is

expressed

the

implied

purpose

herein are

T

echnologies shall

its

software

for

use

when

not

or

rmware

apply

to

defects

by

Buyer

modication

specications

maintenance

or

implied.

warranties

.

buyer's

not

be

with

property

warrant

will

.

sole

liable

indirect, special, incidental, or consequential

on contract, tort, or any other legal theory

.

and

rmware

an

instrument

installed

that

be

uninterrupted

resulting

,

Buyer-supplied

or

misuse

for

Agilent

of

Technologies

merchantability

and

exclusive

for

any

the

on

operation

from

,

the

product,

direct,

will

that

damages, whether based

or

and

Assistance

Product maintenance agreements and other customer assistance

agreements are available for Agilent T

echnologies products

.

For any assistance, contact your nearest Agilent Technologies Sales

and Service Oce.Addresses are provided at the back of this manual.

ix

Page 24

Page 25

Contents

1.

General

Introduction

Components not

Serial Number

Specications .

Measurement Functions

T

Display

Measurement

Measurement Accuracy Calculation Example . . . . . 1-15

Correction Functions ................ 1-17

Information

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Covered

.

.

.

Measurement

Combinations

Mathematical

Equivalent

Ranging .

Trigger

Delay

Time

Measurement

T

est

Cable

Integration

A

veraging

est

Signal

Frequency

Frequency

Signal

Signal

Output

T

j

D

Q

GA

RpAccuracy ...................

RsAccuracy ...................

Basic

N

Cable Length

Temperature F

Example of Ls-Q Accuracy Calculation . . . . . . . 1-15

Zero Open ............ ...... .. 1-17

Zero Short .... ...... ...... .... 1-17

Modes

Normal

Constant

Level

Impedance

est

Signal

Range

Z

j

,

j

Y

j

,

Accuracy

A

ccuracy

Accuracy . . . . . . . . . . .

ccuracy ...........

Accuracy Equations . . . . . . . . . . . . .

Accuracy F

Determine inductance measurement accuracy Ae. 1-15

Determine Q measurement accuracy Qe..... 1-17

P

arameters

of

Functions

Measurement

..

.

.

.

.

.

.

T

erminals

Length

Time

.

.

.

.

.

.

.

A

ccuracy

.

.

.

.

.

.

Level

.

Accuracy

L,

C,

R,

..

.

.

actors . . . . . . . . . . . . . . . .

Factor ...... ...... ...

actor . . . . . . . .

by

W

arranty

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Measurement

.

.

Circuit

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

..

.

.

.

..

Monitor

.

.

X,

G,

..

.

.

.

.

.

..

and

..

.

.

..

..

B

..

..

.

.

.

.

.

.

.

.

.

.

.

P

arameters

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

..

.

..

.

..

..

.

.

A

ccuracy

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

..

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.........

...... ..

.... ....

..

.

.

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

. 1-1

.

1-1

. 1-1

1-3

.

1-3

. 1-3

.

1-3

.

1-3

.

1-3

.

1-3

1-3

. 1-3

.

1-4

. 1-4

.

1-4

. 1-4

.

1-4

.

1-4

.

1-4

.

1-4

.

1-4

.

1-4

.

1-4

.

1-5

.

1-5

.

1-6

.

1-6

.

1-9

.

1-9

1-9

1-9

1-10

1-10

1-10

1-10

1-12

1-15

1-15

Contents-1

Page 26

Load

..

..

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

List

Sweep .

Comparator

Sorting

Sequential

T

olerance Mode

Bin

Count

List

Sweep

Other

Functions

Store/Load

GPIB

GPIB

Self

T

est

Option

Other

Furnished

A

Power

Operating

Dimensions

W

Display

Supplemental P

Stability ...... ....

Temperature Coecient . . . . . . . . .

Settling Time . . . . . . . . . . .

Input Protection

Measurement Time . . . . . . . . . . . . . . . . . 1-23

Option 001 (Internal DC Bias) .. ...... .... 1-23

DC Bias Settling Time . . . . . . . . . . . . . . . . 1-23

001

DC

Bias

DC

Bias

Options

ccessories

T

est

Fixture

DC

Bias

Memory

GPIB

Handler

201

Scanner

301

Requirements

Line

Voltage

Line

Frequency .

P

ower Consumption

T

emperature .

Humidity

Altitude

eight

.

Capable

Number

Frequency (fm)....... ...... .....

Test Signal Level

Measurement Range

Display Time . . . . . . . . . . . . . . . . . . . 1-23

GPIB Data Output Time . . . . . . . . . . . . . . 1-23

.

.

.

.

.

.

.

.

.

.

.

..

Function .

Modes .

mode .

.

.

Comparator

.

.

.

.

.

.

Interface

Level

Monitor

A

Source

Card

Interconnection

Interface

.

Interface

.

Environment .

.

.

of

of

Functions

.

.

.

(Internal

.

ccessories

A

vailable

/

T

est

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Displaying

Display

erformance Characteristics . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

DC

Bias)

.

.

.

T

erminal

.

.

.

.

Leads

.

.

.

.

.

.

Cables

Connector

..

..

Connector

.

.

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Digits

.................

..... ..... ...... ..

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

..

..

.

.

..

for

Mating

.

.

.

.

.

.

.

for

Mating

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

..

.

............

...... ...

...... ...... ...

..

..

..

.

.

.

..

.

.

.

..

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

..

.

.

.

..

.

.

..

..

..

..

..

.

.

.

..

..

.

.

.

.

..

..

..

..

..

.

..

..

..

..

..

..

.

.

.

.

.

..

.

.

.

.

.

..

.

.

..

..

..

.

.

.

with Option

.

.

.

.

.

with

Option

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

..

.

.

.

..

..

..

..

.

.

..

..

..

..

.

.

.

.

.

......

. 1-17

..

..

..

..

..

. 1-18

..

. 1-18

.

..

.

.

. 1-18

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

. 1-21

. 1-21

..

.

.

. 1-22

1-17

1-18

1-18

1-18

1-18

1-18

1-18

1-18

1-18

1-18

1-18

1-19

1-19

1-20

1-20

1-20

1-20

1-20

1-20

1-21

1-21

1-21

1-21

1-21

1-21

1-21

1-21

1-21

1-21

1-21

1-21

1-21

1-22

1-22

1-22

1-22

1-22

1-22

1-22

Contents-2

Page 27

2.

Installation

Incoming

P

ower Requirements

P

ower Cable

Line

Voltage

Line

Voltage

Inspection .

.

.

.

and

Fuse

Selection

.

.

.

.

.

.

.

.

.

.

.

Selection

.

.

.

.

.

.

.

.

.

.

..

..

. 2-1

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

2-3

. 2-3

2-5

. 2-5

Fuse Selection

Operation

Electromagnetic

V

entilation Requirements

Instruction

Rack/Handle

Option

Option

Option

3.

Overview

Introduction .

Product

Front

Environment .

907 Handle

Handle

908 Rack

Rack

Mounting

909

Handle

Introduction

P

anel

1

LINE

2

LCD

3

SOFTKEYs

4

MENU

5

CURSOR

6

ENTRY

7

GPIB

8

5

4

LCL

9

4

TRIGGER

A

MEMORY

B

4

DC

BIAS

C

CONTRAST

for Cleaning

Installation .

and

P

Key

..

Compatibility .

.

Installation .

Kit

Flange

.

.

.

Rack

Flange

Rack

Mounting

.

.

.

.

.

.

.

Description

On/O

anel

Keys

Status

Keys

Keys

5

Key

Card

5

Key

.

.

.

.

.

.

.

.

.

.

.

.

Indicator

.

.

.

.

Slot

.

Control

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

Kit

.

.

&

Handle

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

and

.

.

Knob

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Kit

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

UNLOCK

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

Button .

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

..

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

.

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

. 3-1

.

.

.

.

.

. 3-2

.

. 3-2

.

.

.

.

.

.

.

.

.

. 3-3

..

.

.

. 3-3

.

.

.

.

2-5

2-6

2-6

2-7

2-7

2-7

2-7

2-7

2-7

2-7

2-8

2-8

3-1

3-2

3-2

3-2

3-3

3-3

3-3

3-3

3-3

3-3

D

E

Rear

1GPIB Interface Connector

2Interface Connectors . . . . . . . . . . . . . .

3

4EXT TRIGGER Connector . . . . . .

5

6

7

Display .. ...... ...... ..... .... 3-7

Display Area Denition . . . . . . . . . . . . . . . 3-7

Display Page Format Field . . . . . . . . . . . . . 3-7

System Menu Field . . . . . . . . . . . . . . . . 3-7

Comment Field . . . . . . . . . . . . . . . . . . 3-7

Softkey Area . . . . . . . . . . . . . . . . . . . 3-8

Measurement Data/Conditions Area ........ 3-8

UNKNOWN T

FRAME T

P

anel Description

INT DC BIAS MONITOR Connector

LINE Input Receptacle

LINE VOLTAGE SELECTOR . . . . . . . . . .

erminal

LINE Fuse Holder . . . . . . . . . . . .

erminals .

.

.

.

.

.

.

.

.

.

.....

..

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

..

.

...........

..... ..

......

.......

.

.

..

.

.

Contents-3

3-4

3-4

3-5

3-5

3-5

3-5

3-5

3-6

3-6

3-6

Page 28

Input

Line Area

System

MENU

4

DISPLA

4

MEAS

4

CA

TALOG/SYSTEM

Summary

MEAS

BIN

BIN

LIST

MEAS

CORRECTION

LIMIT

LIST

CA

SYSTEM

CABLE

SELF

Basic

4.

DISPLA

Introduction

MEAS

SYS

N

N

N

N

LOAD

Storing

Loading

N

N

N

N

D.P.

Setting

N

N

N

N

PRINT

Dumping

Printing

NN

N

N

KEY

Locking

BIN

No

COMP

Setting

SYS

Loading

Printing the Measurement Result

Locking Out the Front P

BIN COUNT DISPLA

SYS MENU Field

N

NNNNNNNNNNNNNNNNNNNNNNNNN

COUNT ON

Setting the

Loading or

Printing the Measurement Result ......... 4-17

Locking Out the Front Panel ........... 4-18

LIST SWEEP DISPLAYPage.............. 4-19

MODE Field .................... 4-21

Setting the List Sweep Measurement Mode . . . . . 4-21

SYS MENU Field .................. 4-21

Storing the Control Settings . . . . . . . . . . . . 4-22

Message Area

Keys and

YF

ORMAT

5

SETUP

of

DISPLA

No

.

DISPLA

COUNT

SWEEP

SETUP

T

ABLE

SWEEP

T

ALOG

CONFIG

CORRECTION

TEST

Operation

Y

FORMA

DISPLA

MENU

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

.

MENU

N

N

N

N

N

N

NN

NN

N

STORE

/

the

NN

N

N

N

N

N

N

N

N

N

N

N

FIX

the

N

N

N

N

N

N

N

N

N

N

N

N

N

DISP

N

N

N

N

N

N

N

N

N

N

N

NN

LOCK

Out

DISPLA

Field

the

Field

N

N

N

the

N

N

N

N

the

out

NN

Field

or

P

ages

(under

.

Y

NN

NN

N

Control

N

N

N

N

N

N

A

Fixed

N

N

N

N

N

N

NN

Softkey

Comparator

Storing

N

NNNNNNNNNNNNNNNNNNNNNNNNN

COUNT OFF

/

Bin Counter ON or OFF

Storing the Control Settings

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Display

5

..

..

.

5

..

Y

(under

Y

DISPLA

DISPLA

(under

(under

SETUP

SETUP

(under

.

.

T

Menu

.

.

.

P

age

.

N

N

N

Softkeys

Control

N

N

N

N

N

N

N

N

N

D.P.FIX

/

N

N

N

N

N

N

N

N

N

PRINT

/

LCD

the

the

Y

P

age

.

.

.

.

YP

...............

P

age

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4

DISPLA

Y

F

ORMA

(under

4

CA

(under

4

.

..

..

.

N

N

NN

N

N

N

Decimal

NN

N

N

N

N

N

Screen

Measurement

Front

.

.

the

age ........ ...

4

DISPLA

Y

F

ORMA

Y

(under

Y

(under

4

MEAS

4

MEAS

(under

(under

T

ALOG/SYSTEM

(under

CA

T

ALOG/SYSTEM

.

.

..

..

..

Settings

Settings

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

DATA

.

.

P

.

.

.

.

.

..

Control

NNN

4

DISPLA

Y

4

DISPLA

Y

5

)

SETUP

SETUP

4

MEAS

4

MEAS

4

CA

T

ALOG/SYSTEM

4

CA

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

N

Softkeys

P

oint

N

N

N

N

Softkeys

to

the

.

.

.

.

.

..

..

.

.

.

.

.

..

Settings

N

N

N

N

B

N

N

N

N

.

anel

..

Function

anel ...........

Softkeys . . . . . . . . . .

.

5

)

.

SETUP

SETUP

5

)

.

T

ALOG/SYSTEM

5

)

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

Function

..

Printer

.

.

.

.

.

.

.

.

.

.

.

.

..

..

to

ON

..

...

........

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

..

..

5

)

.

T

5

)

.

T

F

F

5

ORMA

T

ORMA

T

.

.

.

.

.

.

5

)

.

5

)

.

.

.

.

5

)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

or

OFF

..

..

..

......

......

.

.

..

..

.

..

..

.

..

..

.

.

.

.

)

.

5

)

.

.

.

.

.

.

.

.

.

.

.

.

5

)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

..

..

.

.

...

...

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

3-8

3-8

3-8

. 3-9

. 3-9

. 3-10

. 3-11

.

3-11

.

3-11

.

3-11

.

3-11

.

3-11

.

3-11

.

3-11

.

3-12

.

3-12

.

3-12

.

3-12

.

3-12

.

3-16

.

4-1

.

4-1

.

4-4

.

4-4

.

4-5

.

4-5

.

4-6

.

4-6

.

4-6

.

4-8

.

4-8

4-9

. 4-9

.

4-10

.

4-12

. 4-12

.

4-13

.

4-13

4-13

4-14

4-15

4-16

4-16

4-16

4-17

Contents-4

Page 29

Loading

Printing

Locking

5.

MEAS SETUP

Introduction

MEAS

FUNC

Choosing

RANGE

N

N

N

N

N

N

AUTO

N

N

N

N

N

N

HOLD

N

N

N

N

N

N

INCR

N

N

N

N

N

N

DECR

Setting

FREQ

N

N

N

N

N

N

INCR

N

N

N

N

N

N

INCR

N

N

N

N

N

N

DECR

N

NN

NN

NN

DECR

N

N

N

N

N

N

kHz

N

N

N

N

N

N

1kHz

Setting

LEVEL

N

N

N

N

N

N

INCR

N

N

N

N

N

NN

mV

Setting

BIAS

N

N

N

N

N

N

INCR

N

N

N

N

N

N

mV

Setting

INTEG

N

N

N

N

N

N

SHORT

NN

NN

NN

MED

NN

NN

N

N

LONG

Setting the

Comment Field .

NNNNNNNNNNN

COM-MENT

NNNNNNNNNNNNN

[!]

NNNNNNNNNNNNNN

CLEAR LINE

NNN

NNNNNNNNNNNNNNNNNNNNNNNNN

ABORT& EXIT

NNNNNNNNNNNNNNNNN

END INPUT

Entering Comments . . . . . . . . . . . . . . . . 5-14

TRIG Field . . . . . . . . . . . . . . . . . . . . . 5-14

NNNNNNNNNNN

INT

NNNNNNNNNNN

MAN

NNNNNNNNNN

N

EXT

Setting the Trigger Mode .. ...... ..... 5-15

the Control

the Measurement

Out the

Menu

..

.

SETUP

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

NN

NN

NN

N

N

N

N

N

N

N

N

N

N

N

N

NN

N

,

Field

N

N

N

N

N

N

,

NN

NN

NN

N

N

N

N

N

N

P

age

Field

N

N

N

N

N

N

N

N

N

N

NN

NN

NN

Field

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

MHz

/

N

N

N

N

N

N

N

N

N

N

V

N

N

N

N

N

N

N

V

Field

NN

N

N

N

Softkey

N

N

N

N

NNNNNNNNNNNNNNN

Softkey................... 5-14

Softkey................... 5-14

Softkey................... 5-14

.

the

Measurement

Field

.

.

Softkey

Softkey

NN

NN

NN

*

Softkey

NN

N

N

N

+

Softkey

the

Measurement

.

.

NN

NN

N

*

N

N

N

NN

1Hz

N

N

N

N

N

1Hz

N

N

N

N

N

+

N

N

N

N

N

N

N

N

N

N

1MHz

/

the

Field

N

N

N

N

N

*

N

N

,

the

N

N

N

N

N

*

N

N

,

the

N

N

N

Softkey

Softkey

Softkey ..............

NNNNNNNNNNNNNNNNNN

NNNNNNNNNNNN

.

N

Softkey

N

N

N

N

N

N

N

Softkey

N

N

N

N

N

N

N

Softkey

N

Softkey

N

N

N

N

Softkeys

N

N

N

N

N

N

N

N

N

N

Softkeys

T

est

.

.

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

DECR

/

N

N

N

N

N

NN

N

A

,

and

Oscillator

.

.

.

N

N

N

N

DECR

and

N

N

N

N

N

N

N

N

N

N

N

N

mA

A

,

DC Bias

..

Integration Time . . . . . . . . . . . .

Softkey . .

Softkey . . . .

NNNNNNN

Softkey .......

Settings .

Result

Front

P

anel

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Range

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

Frequency

.

..

.

N

N

N

N

N

N

+

Softkeys

N

N

N

N

mA

.

.

N

N

N

N

N

N

N

N

N

N

N

N

N

N

,

and

..

..

..

.

.

.

...... ...... ..... .

Softkey ..............

.

N

NN

N

Softkeys .

Level

.

.

.

N

N

N

N

N

N

N

+

Softkeys

N

N

N

N

N

A

Softkeys

..

..

..

.

..

..

.

.

.

.

.

.

..............

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

..

.

.

.

.

.

..

..

Function

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

..

.

..

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

...... .....

........

.

.

.

..

..

..

.

..

..

..

.

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

....

.

.

.

.

..

..

..

..

.

.

..

..

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

..

.

4-22

.

4-22

. 4-24

5-1

5-1

5-4

.

5-4

5-5

5-6

. 5-6

.

5-6

.

5-6

.

5-6

5-7

.

5-7

.

5-7

.

5-7

.

5-7

.

5-7

.

5-8

.

5-8

.

5-9

.

5-9

.

5-9

.

5-9

.

5-10

.

5-11

5-11

.

5-11

.

5-12

.

5-12

.

5-12

. 5-12

5-12

5-13

5-13

5-13

5-13

5-13

5-13

Contents-5

Page 30

ALC

Field .

Setting

MON

Field .

N

NN

NN

N

N

N

N

N

N

N

N

N

N

V

BIAS

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

I

BIAS

Setting the

AVG

Field .

NN

NN

NN

NN

N

N

N

N

N

N

N

INCR

Setting

DELA

Y

Field

N

N

N

N

N

N

N

N

N

N

NN

NN

msec

Setting

Vm/Im

DEV

REF

SYS

CORRECTION

OPEN

SHORT Field . . . . . . . .

FREQ1{7 Fields

Fields

Setting

A/B

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

1

ABS

N

N

N

N

N

N

N

N

N

N

N

1

%

Softkey

N

N

N

N

N

N

N

N

N

N

N

OFF

Softkey

A/B

N

N

N

N

N

N

N

N

N

N

NN

NN

NN

MEA-SURE

P

erforming the

MENU Field

N

N

N

NN

NN

N

N

N

N

N

N

N

LOAD

/

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

CLEAR

Resetting

P

age

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

PRINT

Dumping

N

N

N

N

N

N

N

N

N

N

N

N

NN

N

SYSTEM

Resetting

Field .

N

NN

NN

NN

N

ON

Softkey .

N

NN

N

N

N

N

N

N

N

N

OFF

Softkey

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

MEAS

N

N

N

N

N

N

N

N

N

N

NN

NN

NN

ABORT

P

erforming

NNNNNNNN

ON

Softkey .... ....

NNNNNNN

NNNN

OFF

Softkey . . . . . . . . . . . . . . . . . . .

NNNNNNNNNNNNNNNNNNNNN

MEAS SHORT

NNNNNNNNNN

NNNNNNN

ABORT

Performing the SHORT Correction . . . . .

NNNNNNNN

ON

Softkey .... ...... ...... ... 5-34

NNNNNNNNNNN

OFF

Softkey . . . . . . . . . . . . . . . . . . . 5-34

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MEAS OPEN

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MEAS SHORT

NNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MEAS LOAD

the A

N

NN

NN

Softkey

NN

NN

N

Softkey

N

N

N

N

N

*

and

the

and

the

the

Fields

NN

Softkey

Fields

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

N

N

N

STORE

N

N

N

N

N

N

N

NN

NN

SETUP

the

.

N

N

N

N

N

N

N

N

N

DISP

the

N

N

N

N

N

N

N

N

N

N

RESET

the

N

NN

NN

NN

NN

N

OPEN

N

Softkey

NNNNNNNNNNN

Softkey

..

..

.

.

.

.

.

.

.

utomatic

.

.

DC Bias

..

NN

NN

NN

NN

DECR

A

veraging

.

.

N

N

N

N

N

N

N

N

N

N

N

sec

Softkeys

Delay

.

.

T

est

Signal

.

.

.

N

Softkey

Deviation Measurement

N

N

N

N

N

N

N

Softkeys .

N

N

N

N

N

N

N

N

N

Softkey

Control

.

.

N

N

N

N

N

N

N

Softkey

MEAS

N

N

N

N

N

N

N

N

N

N

N

N

N

4285A

P

age

..

.

N

N

N

N

Softkey

the

OPEN

Softkey..........

Softkey ........ ...... . 5-34

Softkey............... 5-34

Softkey ........ ...... . 5-35

Level

Control

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Monitor Mode

.

.

.

.

.

.

.

.

N

N

N

N

N

N

N

N

N

N

N

N

+

Softkeys .

Rate

.

.

.

..

..

Time

.

.

.

.

.

.

.

.

Softkey

.

..

.

.

..................

.........

.

.

.

Level

.

.

.

.

.

.

.

.

.