Page 1

Specifications

The complete Agilent Technologies 4284A specifications are listed in this data sheet. These specifications are the performance standards or limits

against which the instrument is tested. When

shipped from the factory, the Agilent 4284A meets

the specifications listed here.

Measurement Functions

Measurement parameters

|Z| = Absolute value of impedance

|Y| = Absolute value of admittance

L = Inductance

C = Capacitance

R = Resistance

G = Conductance

D = Dissipation factor

Q = Quality factor

Rs= Equivalent series resistance

Rp= Parallel resistance

X = Reactance

B = Susceptance

q = Phase angle

Combinations of measurement parameters

|Z|, |Y| L, C R G

q (deg), q (rad) D, Q, Rs, Rp, G X B

Mathematical functions

The deviation and the percent of deviation of

measurement values from a programmable

reference value.

Equivalent measurement circuit

Parallel and series

Ranging

Auto and manual (hold/up/down)

Trigger

Internal, external, BUS (GPIB), and manual

Delay time

Programmable delay from the trigger command to

the start of the measurement, 0 to 60.000 s in 1 ms

steps.

Measurement terminals

Four-terminal pair

Test cable length

Standard 0 m and 1 m selectable

With Option 4284A-006 0 m, 1 m, 2 m, and 4 m selectable

Integration time

Short, medium, and long (see Supplemental

Performance Characteristics for the measurement

time)

Averaging

1 to 256, programmable

Agilent 4284A

Precision LCR Meter

Data Sheet

Page 2

Test Signal

Frequency

20 Hz to 1 MHz, 8610 selectable frequencies

Accuracy

±0.01%

Signal modes

Normal (non-constant) – Program selected voltage or

current at the measurement terminals when they

are opened or shorted, respectively.

Constant – Maintains selected voltage or current at

the device under test (DUT) independent of

changes in the device’s impedance.

Signal level

Mode Range Setting accuracy

Voltage Non-constant 5 mV

rms

to 2 V

rms

±(10% + 1 mV

rms

)

Constant

1

10 mV

rms

to 1 V

rms

±(6% + 1 mV

rms

)

Current Non-constant 50 µA

rms

to 20 mA

rms

±(10% + 10 µA

rms

)

Constant

1

100 µA

rms

to 10 mA

rms

±(6 % + 10 µA

rms

)

1. Automatic Level Control Function is set to ON.

Output impedance

100 Ω, ±3%

Test signal level monitor

Mode Range Accuracy

Voltage

1

5 mV

rms

to 2 V

rms

±(3% of reading + 0.5 mV

rms

)

0.01 mV

rms

to 5 mV

rms

±(11% of reading + 0.1 mV

rms

)

Current

2

50 µA

rms

to 20 mA

rms

±(3% of reading + 5 µA

rms

)

0.001 µA

rms

to 50 µA

rms

±(11% of reading) + 1 µA

rms

)

1. Add the impedance measurement accuracy [%] to the voltage level monitor

accuracy when the DUT’s impedance is < 100 Ω.

2. Add the impedance measurement accuracy [%] to the current level monitor

accuracy when the DUT’s impedance is ≥ 100 Ω.

Accuracies apply when test cable length is 0 m or 1 m. The additional error when test

cable length is 2 m or 4 m is given as

fm x L[%]

2

where:

fm = Test frequency [MHz]

L = Test cable length [m]

For example,

DUT’s impedance: 50 Ω

Test signal level: 0.1 V

rms

Measurement accuracy: 0.1%

Cable length: 0 m

Then, voltage level monitor accuracy is

±(3.1% of reading + 0.5 mV

rms

)

Display Range

Parameter Range

|Z|, R, X 0.01 mΩ to 99.9999 MΩ

|Y|, G, B 0.01 nS to 99.9999 S

C 0.01 fF to 9.99999 F

L 0.01 nH to 99.9999 kH

D 0.000001 to 9.99999

Q 0.01 to 99999.9

q –180.000° to 180.000°

∆ –999.999% to 999.999%

2

Page 3

Absolute Accuracy

Absolute accuracy is given as the sum of the

relative accuracy plus the calibration accuracy.

|Z|, |Y|, L, C, R, X, G, and B accuracy

|Z|, |Y|, L, C, R, X, G, and B accuracy is given as

Ae+ A

cal

[%]

where:

Ae= Relative accuracy

A

cal

= Calibration accuracy

L, C, X, and B accuracies apply when Dx(measured

D value) ≤ 0.1. R and G accuracies apply when Q

x

(measured Q value) ≤ 0.1. G accuracy described in

this paragraph applies to the G-B combination only.

D accuracy

D accuracy is given as

De+ q

cal

where:

Deis the relative D accuracy

q

cal

is the calibration accuracy [radian]

Accuracy applies when Dx(measured D value) ≤ 0.1.

Q accuracy

Q accuracy Qeis given as

Q

2

xxDa

Qe= ±

1 Q

xxDa

where:

Qx= Measured Q value

Da= D accuracy

Q accuracy applies when Qxx Da< 1.

q accuracy

q accuracy is given as

q

e

+ q

cal

[deg]

where:

qe= Relative q accuracy [deg]

q

cal

= Calibration accuracy [deg]

G accuracy

When Dx(measured D value) ≤ 0.1

G accuracy is given as

where:

Bx= Measured B value [S]

Cx= Measured C value [F]

Lx= Measured L value [H]

Da= Absolute D accuracy

f = Test frequency [Hz]

G accuracy described in this paragraph applies to

the Cp-G and Lp-G combinations only.

Rpaccuracy

When Dx(measured D value) ≤ 0.1

Rpaccuracy is given as

RpxxD

a

Rp=±

DxD

a

[Ω]

where:

Rpx= Measured Rpvalue [Ω]

Dx= Measured D value

Da= Absolute D accuracy

3

–

+

–

+

Page 4

4

Rsaccuracy

When Dx( measured D value) ≤ 0.1

Rsaccuracy is given as

where:

Xx= Measured X value [Ω]

Cx= Measured C value [F]

Lx= Measured L value [H]

Da= Absolute D accuracy

f = Test frequency [Hz]

Relative Accuracy

Relative accuracy includes stability, temperature

coefficient, linearity, repeatability, and calibration

interpolation error. Relative accuracy is specified

when all of the following conditions are satisfied:

1. Warm-up time: ≥ 30 minutes

2. Test cable length: 0 m, 1 m, 2 m, or 4 m

(Agilent 16048 A/B/D/E)

For 2 m or 4 m cable length operation, test signal

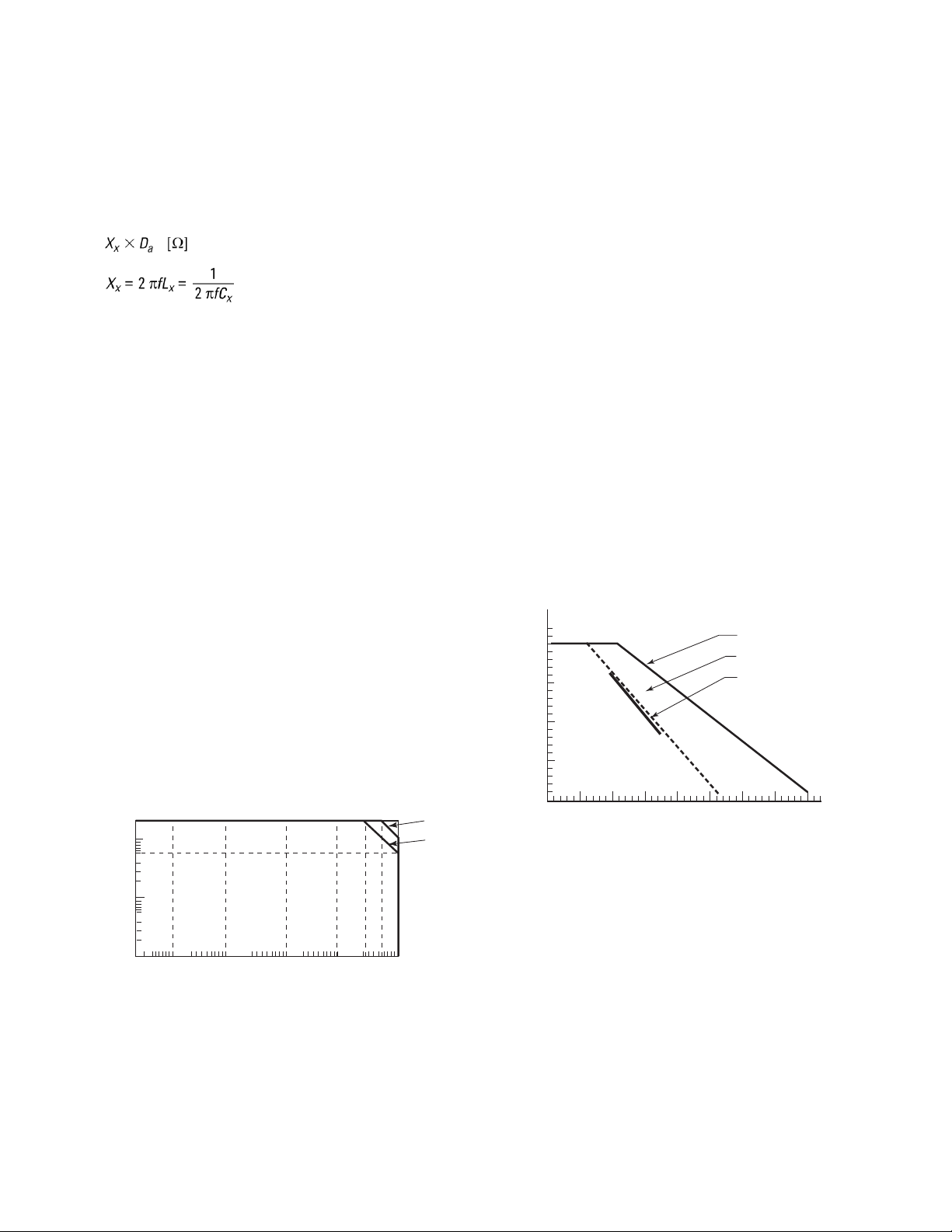

voltage and test frequency are set according to

Figure 1-1. (2 m and 4 m cable can only be used

when Option 4284A-006 is installed.)

3. OPEN and SHORT corrections have been

performed.

4. Bias current isolation: Off

(For accuracy with bias current isolation, refer to

supplemental performance characteristics.)

5. Test signal voltage and DC bias voltage are set

according to Figure 1-2.

6. The optimum measurement range is selected

by matching the DUT’s impedance to the effective

measuring range. (For example, if the DUT’s

impedance is 50 kΩ, the optimum range is the

30 kΩ range.)

Range 1: Relative accuracy can apply.

Range 2: The limits applied for relative accuracy

differ according to the DUT’s DC resistance. Three

dotted lines show the upper limits when the DC

resistance is 10 Ω, 100 Ω and 1 kΩ.

Figure 1-1. Test signal voltage and test frequency upper

limits to apply relative accuracy to 2 m and 4 m cable

length operation

20 100 1k

1

1M100k10k

10

20

Test signal voltage (Vrms)

Frequency Hz

2m cable

4m cable

Figure 1-2. Test signal voltage and DC bias voltage upper

limits apply for relative accuracy

Test signal voltage (Vrms)

5302520151004035

DC bias voltage setting (V)

5

0

10

15

20

DC resistance = 1 kΩ

DC resistance = 10 Ω

DC resistance = 100 Ω

Range 1 Range 3Range 2

Page 5

5

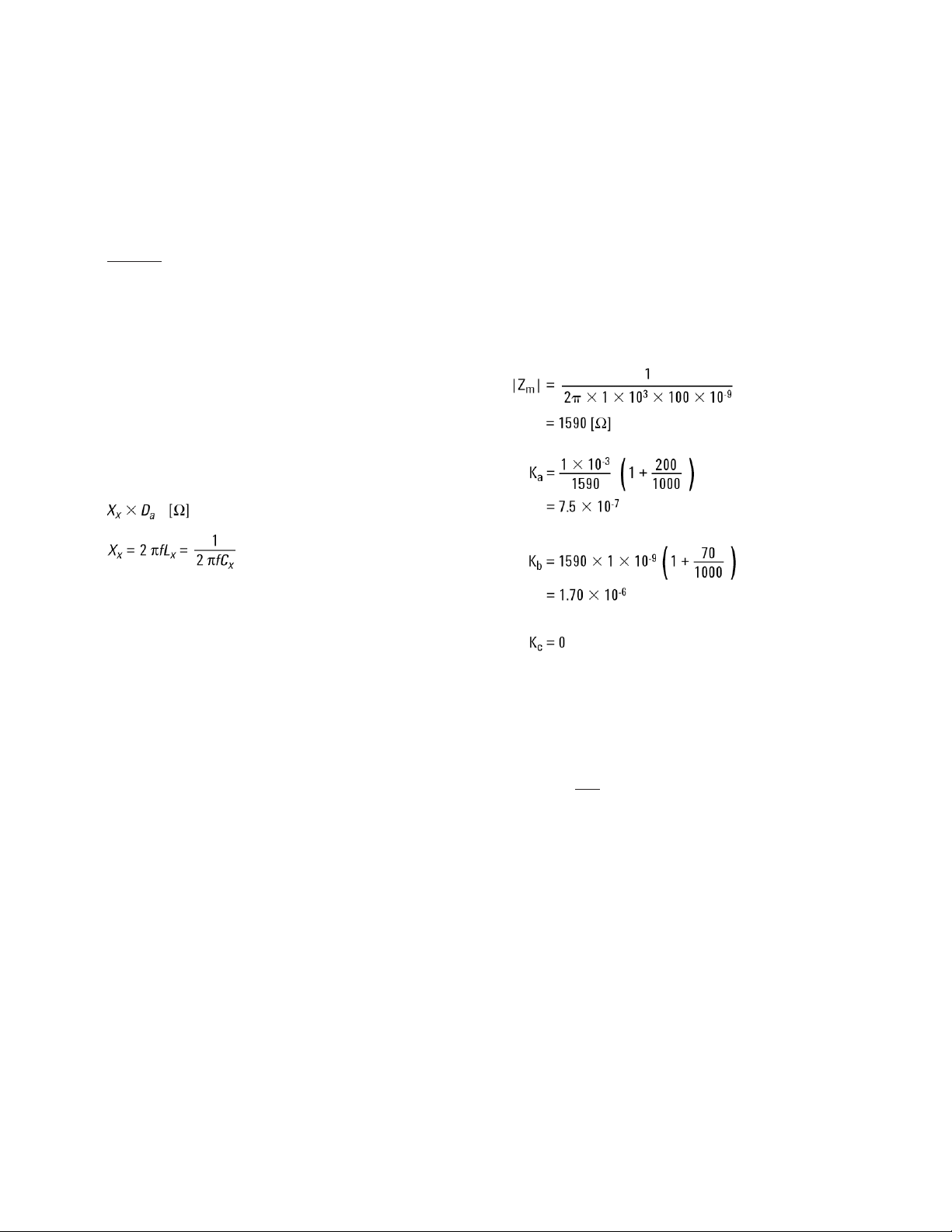

|Z|, |Y|, L, C, R, X, G, and B accuracy

|Z|, |Y|, L, C, R, X, G, and B accuracy Aeis given as

Ae= ± [A + (Ka+ Kaa+ KbxKbb+ Kc) x 100 + Kd] xKe[%]

A = Basic accuracy (refer to Figure 1-3 and 1-4)

Ka= Impedance proportional factor (refer to

Table 1-1)

Kaa= Cable length factor (refer to Table 1-2)

Kb= Impedance proportional factor (refer to

Table 1-1)

Kbb= Cable length factor (refer to Table 1-3)

Kc= Calibration interpolation factor (refer to

Table 1-4)

Kd= Cable length factor (refer to Table 1-6)

Ke= Temperature factor (refer to Figure 1-5)

L, C, X, and B accuracies apply when Dx(measured

D value) ≤ 0.1.

R and G accuracies apply when Qx(measured

Q value) ≤ 0.1.

When Dx≥ 0.1, multiply Aeby 1 + D

x

2

for L, C,

X, and B accuracies

When Qx≥ 0.1, multiply Aeby 1 + Q

x

2

for R and

G accuracies.

G accuracy described in this paragraph applies to

the G-B combination only.

D accuracy

D accuracy Deis given as

De= ±

A

e

100

Accuracy applies when Dx(measured D value) ≤ 0.1.

When Dx> 0.1, multiply Deby (1 + Dx).

Q accuracy

Q accuracy is given as

Q

2

xxDe

±

1 QxxD

e

where:

Qx= Measured Q value

De= Relative D accuracy

Accuracy applies when Qxx De< 1.

q accuracy

q accuracy is given as

180 xA

e

π x 100

[deg]

G accuracy

When Dx(measured D value) ≤ 0.1

G accuracy is given as

where:

Bx= Measured B value [S]

Cx= Measured C value [F]

Lx= Measured L value [H]

De= Relative D accuracy

f = Test frequency [Hz]

G accuracy described in this paragraph applies to

the Cp-G and Lp-G combinations only.

–

+

Page 6

6

Rpaccuracy

When Dx(measured D value) ≤ 0.1

Rpaccuracy is given as

RpxxD

e

±

DxD

e

[Ω]

where:

Rpx= Measured Rpvalue [Ω]

Dx= Measured D value

De= Relative D accuracy

Rsaccuracy

When Dx(measured D value) ≤ 0.1

Rsaccuracy is given as

where:

Xx= Measured X value [Ω]

Cx= Measured C value [F]

Lx= Measured L value [H]

De= Relative D accuracy

f = Test frequency [Hz]

Example of C-D Accuracy Calculation

Measurement conditions

Frequency: 1 kHz

C measured: 100 nF

Test signal voltage: 1 V

rms

Integration time: MEDIUM

Cable length: 0 m

Then:

A = 0.05

Therefore,

C

accuracy

= ±[0.05 + (7.5 x 10-7+ 1.70 x 10-6) x 100]

≈ ±0.05 [%]

D

accuracy

=±

0.05

100

= ±0.0005

–

+

Page 7

7

On boundary line apply the better value.

Example of how to find the A value:

0.05 = A value when 0.3 V

rms

≤ Vs≤ 1 V

rms

and

integration time is MEDIUM and LONG.

(0.1) = A value when 0.3 V

rms

≤ Vs≤ 1 V

rms

and

integration time is SHORT.

A1= A value when Vs< 0.3 V

rms

or Vs> 1 V

rms

.

To find the value of A1, A2, A3, and A4refer

to the following table.

where:

Vs= Test signal voltage

100M

10n

100n

1µ

10µ

100µ

1m

10m

100m

1

10

100

100k

32k

10k

320k

1M

10M

1

15

10

100

1k

10m

100m

1

0

0

p

F

1

n

F

1

0

n

F

1

0

0

n

F

1

µ

F

1

0

0

µ

F

1

m

F

1

0

0

m

F

1

0

m

F

20 30 100 1k 10k 100k

30k 300k

1M [Hz]

[S]

|Y| G.B

|Z| R.X

1

0

µ

F

10 H

1 H

100 mH

10 mH

1 mH

100 µH

10 µH

1 µH

100 nH

10 nH

1

0

p

F

1

p

F

1

0

0

f

P

1

0

f

P

100 H

1 kH

10 kH

100 kH

0.1

(0.15)

A4

0.1

(0.2)

A2

0.25

(0.3)

A3

0.05

(0.1)

A1

0.25

(0.3)

A3

0.1

(0.2)

A2

Test Frequency

[Ω]

Specification Charts and Tables

Figure 1-3. Basic accuracy A (1 of 2)

Test frequency

Page 8

8

The following table lists the value of A1, A2, A3, and

A4. When Atl is indicated find the Atl value using

Figure 1-4.

* Multiply the A values as follows, when the test

frequency is less than 300 Hz.

100 Hz ≤ fm<300 Hz: Multiply the A values by 2.

fm< 100 Hz: Multiply the A values by 2.5.

** Add 0.15 to the A values when all of the follow-

ing measurement conditions are satisfied.

Test frequency: 300 kHz < fm≤ 1 MHz

Test signal voltage: 5 V

rms

< Vs≤ 20 V

rms

DUT: Inductor, |Zm| <200 Ω (|Zm|: impedance

of DUT)

A1 = Atl

A

2 = Atl

A

3 = Atl

A

4 = Atl

A

1 = Atl

A

2 = Atl

A

3 = 0.25

A

4 = Atl

A

1 = Atl

A

2 = Atl

A

3 = 0.25

A

4 = Atl

A

1 = Atl

A

2 = 0.1

A

3 = 0.25

A

4 = 0.1

A

1 = Atl

A

2 = Atl

A

3 = 0.25

A

4 = Atl

A

1 = Atl

A

2 = Atl

A

3 = 0.25

A

4 = Atl

A

1 = Atl

A

2 = Atl

A

3 = Atl

A

4 = Atl

A

1 = Atl

A

2 = Atl

A

3 = 0.3

A

4 = Atl

A1 = Atl

A

2 = 0.2

A

3 = 0.3

A

4 = 0.5 X Alt+0.1

A1 = Atl

A

2 = Atl

A

3 = 0.3

A

4 = Atl

A

1 = Atl

A

2 = Atl

A

3 = 0.3

A

4 = Atl

Medium/

long

Short

*

*

**

**

5m 12m 0.1 0.15 0.3 1 2 5 20 [Vrms]

5m 33m 0.15 1 2 5 20 [Vrms]

2.0

1.5

1.0

0.5

0.2

0.1

0.15

0.05

0.02

0.01

5m 10m 20m 50m 100m 200m 500m 1 2 5 10 20 [Vrms]

At1

INTEG TIME

SHORT

MEDIUM

and

LONG

Figure 1-4. Basic accuracy A (2 of 2)

Test signal voltage

Test signal voltage

Page 9

9

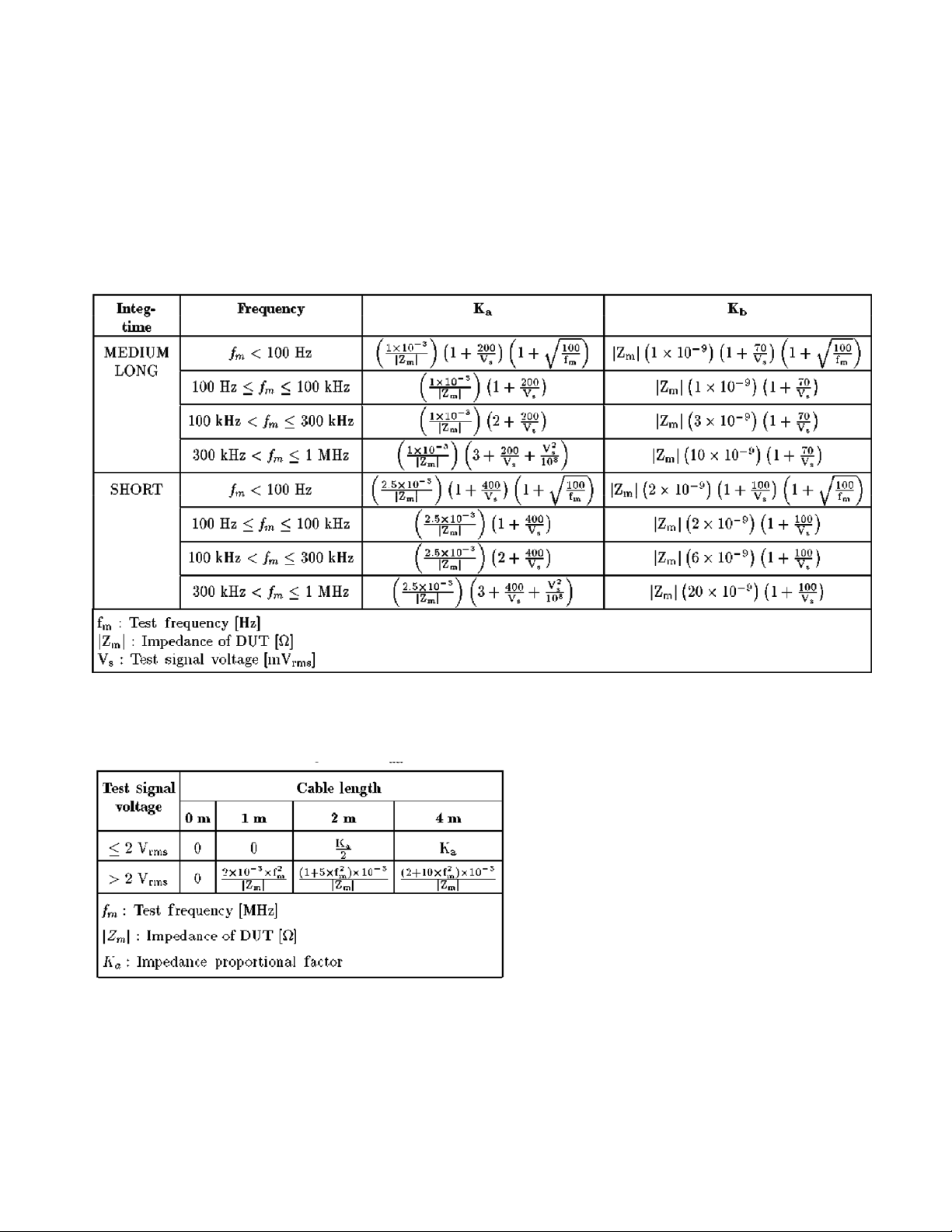

Kaand Kbvalues are the incremental factors in

low impedance and high impedance measurements,

respectively. Kais practically negligible for impedances above 500 Ω, and Kbis negligible for impedances below 500 Ω.

Table 1-1. Impedance proportional factors Kaand K

b

Kaais practically negligible for impedances above 500 Ω.

Table 1-2. Cable length factor K

aa

Page 10

10

Table 1-3. Cable length factor K

bb

Cable length

Frequency 0 m 1 m 2 m 4 m

fm≤ 100 kHz 1 1 + 5 xf

m

1 + 10 xfm1 + 20 xf

m

100 kHz < fm≤ 300 kHz 1 1 + 2 xf

m

1 + 4 xfm1 + 8 xf

m

300 kHz < fm≤ 1 MHz 1 1 + 0.5 xfm1 + 1 xfm1 + 2 xf

m

fm: Test Frequency [MHz]

Table 1-4. Calibration interpolation factor K

c

Test frequency K

c

Direct calibration frequencies 0

Other frequencies 0.0003

Direct calibration frequencies are the following

forty-eight frequencies.

Table 1-5. Preset calibration frequencies

20 25 30 40 50 60 80 [Hz]

100 120 150 200 250 300 400 500 600 800 [Hz]

1 1.2 1.5 2 2.5 3 4 5 6 8 [kHz]

10 12 15 20 25 30 40 50 60 80 [kHz]

100 120 150 200 250 300 400 500 600 800 [kHz]

1 [MHz]

Table 1-6. Cable length factor K

d

Test

signal Cable length

level 1 m 2 m 4 m

≤ 2 V

rms

2.5 x 10–4(1 + 50 xfm)5 x 10–4(1 + 50 x fm)1x 10–3(1 + 50 x fm)

> 2 V

rms

2.5 x 10–3(1 + 16 xfm)5x 10–3(1 + 16 x fm)1x 10–2(1 + 16 xfm)

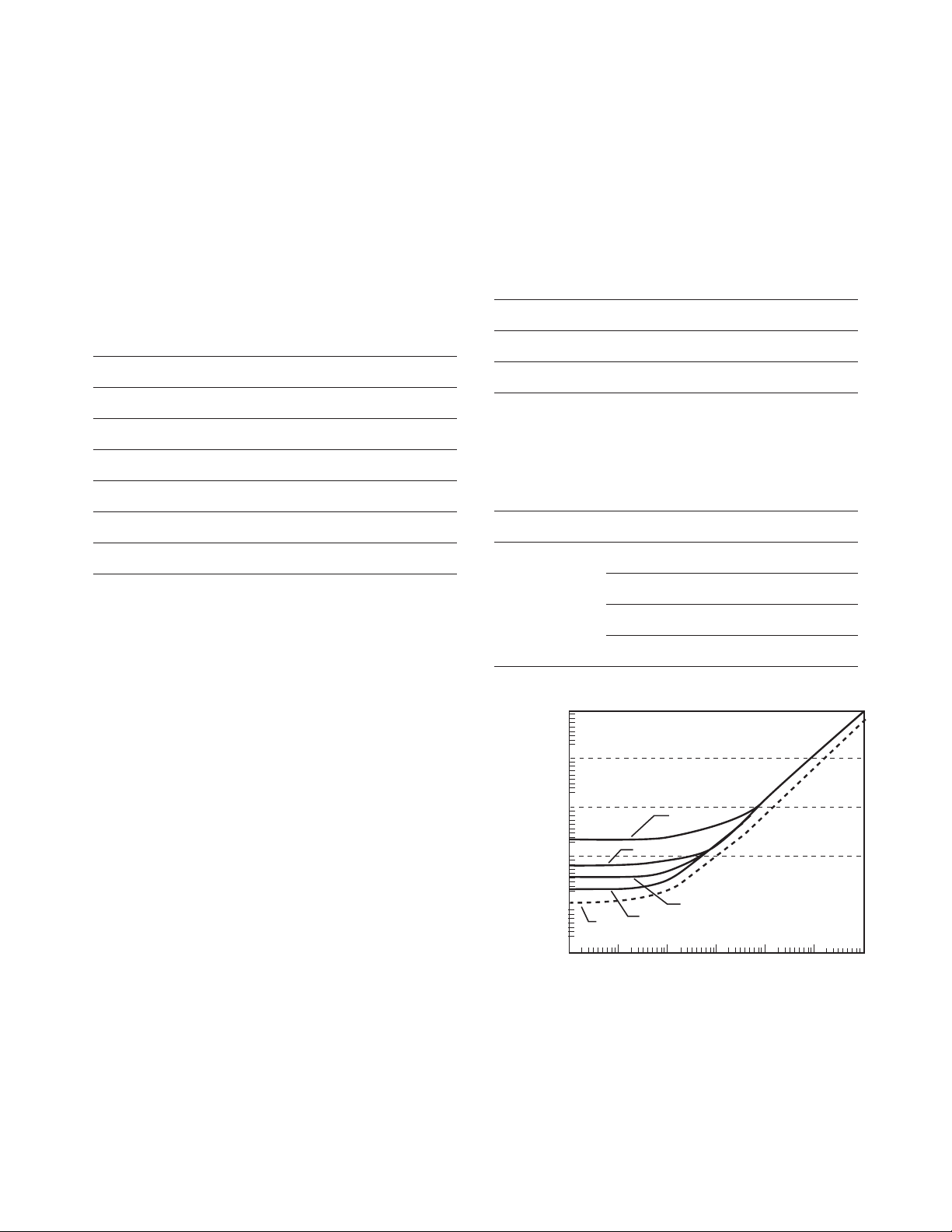

Temperature [°C]

Ke

5 8 18 28 38 45

42124

Figure 1-5. Temperature factor K

e

Page 11

11

Agilent 4284A Calibration Accuracy

Calibration accuracy is shown in the following figure:

fm = test frequency [kHz]

On boundary line apply the better value:

Upper value (A

cal

) is |Z|,|Y|, L, C, R, X, G, and B

calibration accuracy [%]

Lower value (q

cal

) is phase calibration accuracy

in radians.

* A

cal

= 0.1% when Hi-PW mode is on.

** A

cal

= (300 + fm) x 10–6[rad] when Hi-PW mode

is on.

Phase calibration accuracy in degree, q

cal

[deg]

is given as,

q

cal

[deg] = [rad]

180

π x q

cal

100M

10n

100n

1µ

10µ

100µ

1m

10m

100m

1

10

100

100k

32k

10k

320k

1M

10M

1

15

10

100

1k

10m

100m

1

0

0

p

F

1

n

F

1

0

n

F

1

0

0

n

F

1

µ

F

1

0

0

µ

F

1

m

F

1

0

0

m

F

1

0

m

F

20 30 100 1k 10k 100k

30k 300k

1M [Hz]

[S]

|Y| . G . B

|Z| . R . X

1

0

µ

F

10 H

1 H

100 mH

10 mH

1 mH

100 µH

10 µH

1 µH

100 nH

10 nH

1

0

p

F

1

p

F

1

0

0

f

P

1

0

f

P

100 H

1 kH

10 kH

100 kH

Acal = 0.03+1 x

10-3 fm

[Ω]

qcal = (100+20fm) x 10-6

0.03+1 x

10-4 fm

(100+20fm) x 10

-6

1 x 10-4

0.03

3 x 10-4

0.05

2 x 10-4

0.05

1 x 10-4

0.03*

2 x 10-4

0.05*

3 x 10-4

0.05*

0.05+5 x

10

-5

fm*

3 x 10

-4

+ 2 x 10

-7

fm**

0.05+5 x 10

-5

fm

3 x 10

-4

2.5fm

Test frequency

Page 12

12

Additional Specifications

When measured value < 10 mΩ, |Z|, R, and X accuracy Ae, which is described on page 5, is given as

following equation.

|Z|, R, and X accuracy:

Ae= ±[(Ka+ Kaa+ Kc) x 100 + Kd] x Ke(%)

Where

• Ka: Impedance proportional factor (refer to

Table 1-1)

• Kaa: Cable length factor (refer to Table 1-2)

• Kc: Calibration interpolation factor (refer to

Tables 1-4 and 1-5)

• Kd: Cable length factor (refer to Table 1-6)

• Ke: Temperature factor (refer to Figure 1-5)

• X accuracy apply when Dx(measured D

value) ≤ 0.1

• R accuracy apply when Qx(measured Q

value) ≤ 0.1

• When Dx> 0.1, multiply Aeby

for X accuracy.

• When Qx> 0.1, multiply Aeby

for R accuracy.

When measured value < 10 mΩ, calibration accu-

racy A

cal

, which is described on page 11, is given as

follows.

Calibration accuracy:

• When 20 Hz ≤ fm ≤ 1 kHz, calibration

accuracy is 0.03 [%]*.

• When 1 kHz < fm ≤ 100 kHz, calibration

accuracy is 0.05 [%]*.

• When 100 kHz < fm ≤ 1 MHz, calibration

accuracy is 0.05 + 5 x 10-5fm [%]*.

• fm: test frequency [kHz]

•*A

cal

= 0.1% when Hi-PW mode is on.

Correction Functions

Zero open

Eliminates measurement errors due to parasitic

stray impedances of the test fixture.

Zero short

Eliminates measurement errors due to parasitic

residual impedances of the test fixture.

Load

Improves the measurement accuracy by using a

working standard (calibrated device) as a reference.

List Sweep

A maximum of 10 frequencies or test signal levels

can be programmed. Single or sequential test can

be performed. When Option 4284A-001 is installed,

DC bias voltages can also be programmed.

Comparator Function

Ten bin sorting for the primary measurement

parameter, and IN/OUT decision output for the

secondary measurement parameter.

Sorting modes

Sequential mode. Sorting into unnested bins with

absolute upper and lower limits

Tolerance mode. Sorting into nested bins with

absolute or percent limits

Bin count

0 to 999,999

List sweep comparator

HIGH/IN/LOW decision output for each point

in the list sweep table.

DC Bias

0 V, 1.5 V, and 2 V selectable

Setting accuracy

±5% (1.5 V, 2 V )

(1 + D

x

2

)

(1 + Q

x

2

)

Page 13

13

Other Functions

Store/load

Ten instrument control settings, including

comparator limits and list sweep programs, can

be stored and loaded from and into the internal

non-volatile memory. Ten additional settings can

also be stored and loaded from each removable

memory card.

GPIB

All control settings, measured values, comparator

limits, list sweep program. ASCII and 64-bit binary

format. GPIB buffer memory can store measured

values for a maximum of 128 measurements and

output packed data over the GPIB bus. Complies

with IEEE-488.1 and 488.2. The programming

language is SCPI.

Interface functions

SH1, AH1, T5, L4, SR1, RL1, DC1, DT1, C0, E1

Self test

Softkey controllable. Provides a means to confirm

proper operation.

Options

Option 4284A-001 (power amp/DC bias)

Increases test signal level and adds the variable

DC bias voltage function.

Test signal level

Mode Range Setting accuracy

Voltage Non-constant 5 mV to 20 Vrms ±(10% + 1 mV)

Constant

1

10 mV to 10 Vrms ±(10% + 1 mV)

Current Non-constant 50 µA to 200 mArms ±(10% + 10 µA)

Constant

1

100 µA to 100 mArms ±(10% + 10 µA)

1. Automatic level control function is set to on.

Output impedance

100 Ω, ±6%

Test signal level monitor

Mode Range Accuracy

Voltage

1

> 2 V

rms

±(3% of reading + 5 mV)

5 mV to 2 V

rms

±(3% of reading + 0.5 mV)

0.01 mV to 5 mV

rms

±(11% of reading + 0.1 mV)

Current

2

> 20 mArms ±(3% of reading + 50 µA)

50 µA to 20 mArms ±(3% of reading + 5 µA)

0.001 µA to 50 µArms ±(11% of reading + 1 µA)

1. Add the impedance measurement accuracy [%] to the voltage level monitor

accuracy when the DUT’s impedance is < 100 Ω

2. Add the impedance measurement accuracy [%] to the current level monitor

accuracy when the DUT’s impedance is ≥ 100 Ω.

Accuracies apply when test cable length is 0 m or 1 m.

Additional error for 2 m or 4 m test cable length

is given as:

fmx [%]

where:

fmis test frequency [MHz]

L is test cable length [m]

DC bias level

The following DC bias level accuracy is specified

for an ambient temperature range of 23 °C ±5 °C.

Multiply the temperature induced setting error

listed in Figure 1-5 for the temperature range of

O °C to 55 °C.

Test signal level ≤ 2 V

rms

Voltage range Resolution Setting accuracy

±(0.000 to 4.000) V 1 mV ±(0.1% of setting + 1 mV)

±(4.002 to 8.000) V 2 mV ±(0.1% of setting + 2 mV)

±(8.005 to 20.000) V 5 mV ±(0.1% of setting + 5 mV)

±(20.01 to 40.00) V 10 mV ±(0.1% of setting + 10 mV)

L

2

Page 14

14

Test signal level > 2 V

rms

Voltage range Resolution Setting accuracy

±(0.000 to 4.000 ) V 1 mV ±(0.1% of setting + 3 mV)

±(4.002 to 8.000) V 2 mV ±(0.1% of setting + 4 mV)

±(8.005 to 20.000) V 5 mV ±(0.1% of setting + 7 mV)

±(20.01 to 40.00) V 10 mV ±(0.1% of setting + 12 mV)

Setting accuracies apply when the bias current isolation function is set to OFF. When the bias current

isolation function is set to on, add ±20 mV to each

accuracy value (DC bias current ≤ 1 µA).

Bias current isolation function

A maximum DC bias current of 100 mA (typical

value) can be applied to the DUT.

DC bias monitor terminal

Rear panel BNC connector

Other Options

Option 4284A-700 Standard power

(2 V, 20 mA, 2 V DC bias)

Option 4284A-001 Power amplifier/DC bias

Option 4284A-002 Bias current interface

Allows the 4284A to control the

42841A bias current source.

Option 4284A-004 Memory card

Option 4284A-006 2 m/4 m cable length operation

Option 4284A-201 Handler interface

Option 4284A-202 Handler interface

Option 4284A-301 Scanner interface

Option 4284A-710 Blank panel

Option 4284A-907 Front handle kit

Option 4284A-908 Rack mount kit

Option 4284A-909 Rack f lange and handle kit

Option 4284A-915 Add service manual

Option 4284A-ABJ Add Japanese manual

Option 4284A-ABA Add English manual

Furnished Accessories

Power cable Depends on the country

where the 4284A is being

used.

Fuse Only for Option 4284A-201,

Part number 2110-0046, 2 each

Power Requirements

Line voltage

100, 120, 220 Vac ±10%, 240 Vac +5% – 10%

Line frequency

47 to 66 Hz

Power consumption

200 VA max

Operating Environment

Temperature

0 °C to 55 °C

Humidity

≤ 95% R.H. at 40 °C

Dimensions

426 (W) by 177 (H) by 498 (D) (mm)

Weight

Approximately 15 kg (33 lb., standard)

Display

LCD dot-matrix display

Capable of displaying

Measured values

Control settings

Comparator limits and decisions

List sweep tables

Self test message and annunciations

Number of display digits

6 digits, maximum display count 999,999

Page 15

15

Supplemental Performance Characteristics

The 4284A supplemental performance characteristics are not specifications but are typical characteristics included as supplemental information for

the operator.

Stability

MEDIUM integration time and operating temperature at 23 °C ±5 °C

|Z|, |Y| L, C, R, < 0.01%/day

D < 0.0001/day

Temperature Coefficient

MEDIUM integration time and operating temperature at 23 °C ±5 °C

Test signal level |Z|, |Y|, L, C, R D

≥ 20 mV

rms

< 0.0025%/°C < 0.000025/°C

< 20 mV

rrns

< 0.0075%/°C < 0.000075/°C

Settling Time

Frequency (fm)

< 70 ms (fm≥ 1 kHz)

< 120 ms (100 Hz ≤ fm < 1 kHz)

< 160 ms (fm< 100 Hz)

Test signal level

< 120 ms

Measurement range

< 50 ms/range shift (fm≥ 1 kHz)

Input Protection

Internal circuit protection, when a charged capacitor is connected to the UNKNOWN terminals.

The maximum capacitor voltage is:

V

max

= [V]

where:

V

max

≤ 200 V,

C is in Farads

Measurement Time

Typical measurement times from the trigger to

the output of EOM at the handler interface.

(EOM: end of measurement)

Integration Test frequency

time 100 Hz 1 kHz 10 kHz 1 MHz

SHORT 270 ms 40 ms 30 ms 30 ms

MEDIUM 400 ms 190 ms 180 ms 180 ms

LONG 1040 ms 830 ms 820 ms 820 ms

Display time

Display time for each display format is given as

MEAS DISPLAY page Approx. 8 ms

BIN No. DISPLAY page Approx. 5 ms

BIN COUNT DISPLAY page Approx. 0.5 ms

GPIB data output time

Internal GPIB data processing time from EOM

output to measurement data output on GPIB lines

(excluding display time).

Approx. 10 ms

DC Bias (1.5 V/2 V)

Output current.: 20 mA max.

2000

1000

200

400

600

10

20

40

60

80

20 Hz 100 Hz

Measurement time [ms]

Test frequency

1 kHz 10 kHz 100 kHz 1 MHz

MEDIUM

LONG

SHORT

1

C

Page 16

16

V

b

100 + R

dc

Measurement range 10 Ω 100 Ω 300 Ω 1 kΩ 3 kΩ 10 kΩ 30 kΩ 100 kΩ

Bias current isolation On 100 mA 100 mA 100 mA 100 mA 100 mA 100 mA 100 mA 100 mA

Off 2 mA 2 mA 2 mA 1 mA 300 µA 100 µA 30 µA 10 µA

N = P x

x

x

[%] x

10

-4

n

DUT

impedance

[Ω]

1

Measurement range

[Ω]

DC

bias current

[mA]

Test signal level

[Vrms

]

√

Option 4284A-001 (Power Amp/DC Bias)

DC bias voltage

DC bias voltage applied to DUT (V

dut

) is given as

V

dut

= Vb– 100 x I

b

[V]

Where, Vbis DC bias setting voltage [V]

Ibis DC bias current [A]

DC bias current

DC bias current applied to DUT (I

dut

) is given as

I

dut

= [A]

where: Vbis DC bias setting voltage [V]

Rdcis the DUT’s DC resistance [Ω]

Maximum DC bias current when the normal

measurement can be performed is as follows.

Relative accuracy with bias current isolation

When the bias current isolation function is set to

on, add the display fluctuation (N) given in the

following equation to the Aeof relative accuracy.

(Refer to “relative accuracy” of specification.)

The following equation is specified when all of

the following conditions are satisfied.

DUT impedance ≥ 100 Ω

Test signal level setting ≤ 1 V

rms

DC bias current ≥ 1 mA

Integration time : MEDIUM

where:

P is the coefficient listed on Table 1-7.

n is the number of averaging.

Page 17

17

When the DC bias current is less than 1 mA, apply

N value at 1 mA. When integration time is set to

SHORT, multiply N value by 5. When integration

time is set to LONG, multiply N value by 0.5.

Table 1-7. Coefficient related to test frequency and

measurement range

Meas. Test frequency fm[Hz]

range 20 ≤f

m

100 ≤ f

m

1 k ≤ f

m

10 k ≤ f

m

< 100 < 1 k < 10 k ≤ 1 M

100 Ω 0.75 0.225 0.045 0.015

300 Ω 2.5 0.75 0.15 0.05

1 kΩ 7.5 2.25 0.45 0.15

3 kΩ 25 7.5 1.5 0.5

10 kΩ 75 22.5 4.5 1.5

30 kΩ 250 75 15 5

100 kΩ 750 225 45 15

Calculation Example

Measurement conditions

DUT: 100 pF

Test signal level: 20 mVrms

Test frequency: 10 kHz

Integration time: MEDIUM

Then:

DUT’s impedance = 1/(2π x 104x100 x10

–12

) = 159 kΩ

Measurement range is 100 kΩ

DC bias current << 1 mA

P = 15 (according to Table 1-7)

Aeof relative accuracy without bias current isola-

tion is ±0.22 [%]. (Refer to “relative accuracy” of

specification.)

Then, N = 15 x (159 x 103)/(100 x 103) x 1/

(20 x 10–3) x 10–4= 0.12 [%]

Therefore, relative capacitance accuracy is:

±(0.22 + 0.12) = ±0.34 [%]

DC Bias Settling Time

When DC bias is set to on, add the settling time

listed in the following table to the measurement

time. This settling time does not include the DUT

charge time.

Bias current isolation

Test frequency (fm)On Off

20 Hz ≤ fm< 1 kHz 210 ms 20 ms

1 kHz ≤ fm< 10 kHz 70 ms 20 ms

10 kHz ≤ fm≤ 1 MHz 30 ms 20 ms

Sum of DC bias settling time plus DUT (capacitor)

charge time is shown in the following figure.

Bias source Bias current isolation Test frequency (fm)

(1) Standard On/Off 20 Hz ≤ fm≤ 1 MHz

(2) Option 4284A-001 Off 20 Hz ≤ fm≤ 1 MHz

(3) On 10 kHz ≤ fm≤ 1 MHz

(4) On 1 kHz ≤ fm< 10 kHz

(5) On 20 Hz ≤ fm< 1 kHz

100sec

10sec

1 sec

210msec

100msec

70msec

30msec

20msec

12msec

10msec

Setting time

1 mF 10 mF 100 mF1 µF 10 µF 100 µF

(1)

(2)

(3)

(5)

(4)

Capacitance

Figure 1-6. Measurement time

Page 18

18

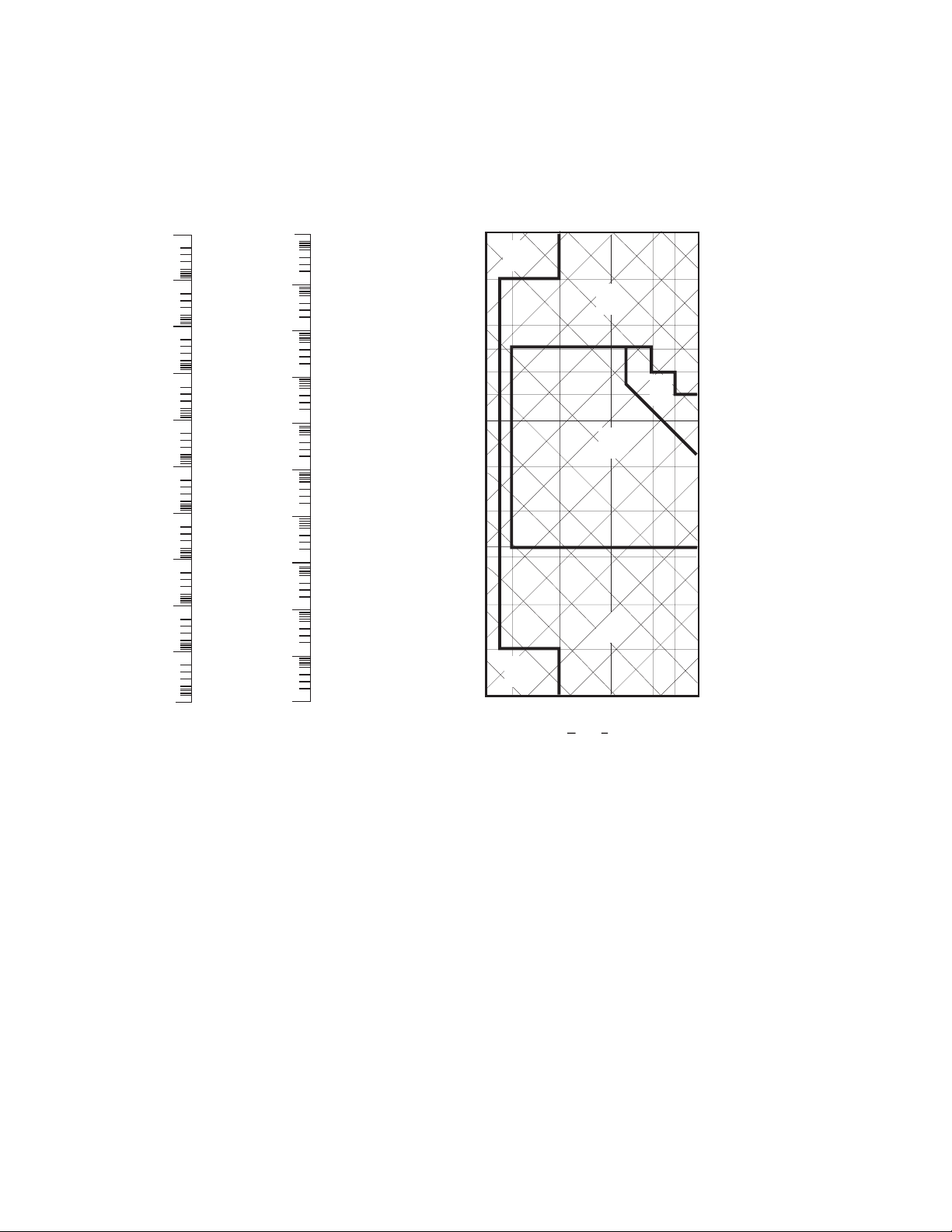

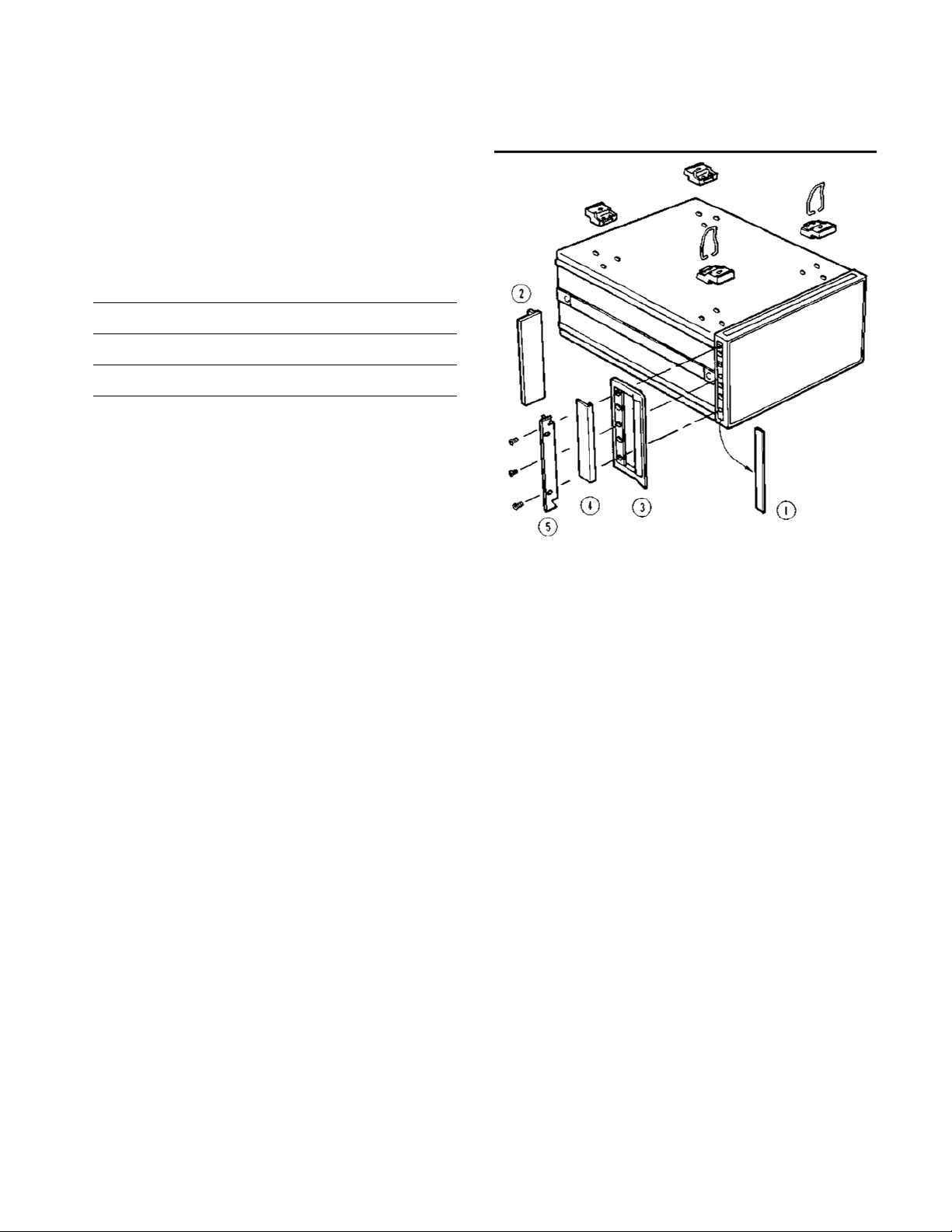

Rack/Handle Installation

The Agilent 4284A can be rack mounted and used

as a component of a measurement system. The following figure shows how to rack mount the 4284A.

Table 1-8. Rack mount kits

Option Description Kit part number

4284A-907 Handle kit 5061-9690

4284A-908 Rack flange kit 5061-9678

4284A-909 Rack flange and handle kit 5061-9684

Figure 1-7. Rack mount kits installation

1. Remove the adhesive-backed trim strips (1) from the left and

right front sides of the 4284A.

2. HANDLE INSTALLATION: Attach the front handles (3) to the

sides using the screws provided and attach the trim strip (4) to the

handle.

3. RACK MOUNTING: Attach the rack mount flange (2) to the left

and right front sides of the 4284A using the screws provided.

4. HANDLE AND RACK MOUNTING: Attach the front handle (3)

and the rack mount flange (5) together on the left and right front

sides of the 4284A using the screws provided.

5. When rack mounting the 4284A (3 and 4 above), remove all

four feet (lift bar on the inner side of the foot and slide the foot

toward the bar).

Page 19

19

Storage and repacking

This section describes the environment for storing

or shipping the Agilent 4284A, and how to repackage the 4284A far shipment when necessary.

Environment

The 4284A should be stored in a clean, dry environment. The following environmental limitations

apply for both storage and shipment

Temperature: –20 °C to 60 °C

Humidity: ≤ 95% RH (at 40 °C)

To prevent condensation from taking place on the

inside of the 4284A, protect the instrument against

temperature extremes.

Original packaging

Containers and packing materials identical to

those used in factory packaging are available

through your closest Agilent sales office. If the

instrument is being returned to Agilent for servicing, attach a tag indicating the service required,

the return address, the model number, and the full

serial number. Mark the container FRAGILE to

help ensure careful handling. In any correspondence, refer to the instrument by model number

and its full serial number.

Other packaging

The following general instructions should be

used when repacking with commercially available

materials:

1. Wrap the 4284A in heavy paper or plastic. When

shipping to an Agilent sales office or service

center, attach a tag indicating the service

required, return address, model number, and

the full serial number.

2. Use a strong shipping container. A doublewalled carton made of at least 350 pound test

material is adequate.

3. Use enough shock absorbing material (3- to

4-inch layer) around all sides of the instrument

to provide a firm cushion and to prevent movement inside the container. Use cardboard to

protect the front panel.

4. Securely seal the shipping container.

5. Mark the shipping container FRAGILE to help

ensure careful handling.

6. In any correspondence, refer to the 4284A by

model number and by its full serial number.

Caution

The memory card should be removed before

packing the 4284A.

Page 20

Agilent Technologies’ Test and Measurement Support, Services, and Assistance

Agilent Technologies aims to maximize the value you receive, while minimizing your

risk and problems. We strive to ensure that you get the test and measurement

capabilities you paid for and obtain the support you need. Our extensive support

resources and services can help you choose the right Agilent products for your

applications and apply them successfully. Every instrument and system we sell has

a global warranty. Support is available for at least five years beyond the production life

of the product. Two concepts underlie Agilent’s overall support policy: “Our Promise”

and “Your Advantage.”

Our Promise

Our Promise means your Agilent test and measurement equipment will meet its

advertised performance and functionality. When you are choosing new equipment, we will help you with product information, including realistic performance

specifications and practical recommendations from experienced test engineers.

When you receive your new Agilent equipment, we can help verify that it works

properly and help with initial product operation.

Your Advantage

Your Advantage means that Agilent offers a wide range of additional expert test

and measurement services, which you can purchase according to your unique technical and business needs. Solve problems efficiently and gain a competitive edge

by contracting with us for calibration, extra-cost upgrades, out-of-warranty repairs,

and onsite education and training, as well as design, system integration, project

management, and other professional engineering services. Experienced Agilent

engineers and technicians worldwide can help you maximize your productivity, optimize the return on investment of your Agilent instruments and systems, and obtain

dependable measurement accuracy for the life of those products.

www.agilent.com/find/emailupdates

Get the latest information on the products and applications you select.

Agilent T&M Software and Connectivity

Agilent’s Test and Measurement software and connectivity products, solutions and

developer network allows you to take time out of connecting your instruments to

your computer with tools based on PC standards, so you can focus on your tasks,

not on your connections. Visit

www.agilent.com/find/connectivity

for more information.

For more information on Agilent Technologies’ products, applications or services,

please contact your local Agilent office. The complete list is available at:

www.agilent.com/find/contactus

Product specifications and descriptions in this document subject to change

without notice.

© Agilent Technologies, Inc. 2004, 2003, 2002

Printed in USA, September 21, 2004

5963-5390E

Phone or Fax

United States:

(tel) 800 829 4444

(fax) 800 829 4433

Canada:

(tel) 877 894 4414

(fax) 800 746 4866

China:

(tel) 800 810 0189

(fax) 800 820 2816

Europe:

(tel) 31 20 547 2111

Japan:

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

Korea:

(tel) (080) 769 0800

(fax) (080)769 0900

Latin America:

(tel) (305) 269 7500

Ta iw a n :

(tel) 0800 047 866

(fax) 0800 286 331

Other Asia Pacific Countries:

(tel) (65) 6375 8100

(fax) (65) 6755 0042

Email: tm_ap@agilent.com

Agilent Email Updates

Loading...

Loading...