Page 1

HP 41802A 1 M Input Adapter

Operation Note

SERIAL NUMBERS

This manual applies directly to HP 41802As with serial number prex 3103J.For additional

important information about serial numbers, read \Serial Number" in Chapter 1.

ABCDE

HP Part No. 41802-90000

Printed in Japan February, 1999

2nd Edition

Page 2

c

Copyright 1991,1999 Hewlett-Packard Japan, LTD.

Page 3

Certication

Hewlett-Packard Company certies that this product met its published specications at the

time of shipment from the factory. Hewlett-Packard further certies that its calibration

measurements are traceable to the United States National Institute for Standards and

Technology, to the extent allowed by the Institution's calibration facility, or to the calibration

facilities of other International Standards Organization members.

Warranty and Assistance

All Hewlett-Packard products are warranted against defects in materials and workmanship.

This warranty applies for one year from the date of delivery,or, in the case of certain

major components listed in the operating manual, for the specied period. We will repair or

replace products which prove to be defective during the warranty period provided they are

returned to Hewlett-Packard. No other warranty is expressed or implied. We are not liable for

consequential damages.

For any assistance, contact your nearest Hewlett-Packard Sales and Service Oce.Addresses

are provided at the back of this manual.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or adequate

maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modication or

misuse, operation outside of the environment specications for the product, or improper site

preparation or maintenance.

No other warranty is expressed or implied. HP specically disclaims the implied warranties

of merchantability and tness for a particular purpose.

iii

Page 4

Caution

The HP 41802A is sensitive to electrostatic discharge (ESD). The followings

must be adhered to when using the HP 41802A.

Do

NOT

touch the center conductor of the BNC connector of the HP

41802A.

Do

NOT

touch the pin of the probe which is connected to the HP 41802A.

Eliminate ESD on your body.

Eliminate ESD on the work surface.

Do

NOT

introduce ESD into the DUT, while the HP 41802A and the probe is

in use.

iv

Page 5

Contents

1. General Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Compatible Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Compatible Instruments .......................... 1-2

Compatible Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Specications ................................ 1-4

Supplemental Performance Characteristics ...... ...... ...... 1-5

2. Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mating Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . .

3. Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Precautions ............................

Anti-static Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Allowable Level . . . . . . . . . . . . . . . . . . . . . . . . .

Discharging the Probe .. ...... ...... ...... ...... .

Probe Power Plug .. ...... ...... ...... ...... ...

Preparation for Use .............................

Operating Check Using a Network Analyzer . . . . . . . . . . . . . . . . .

Using an HP 8751A or HP 3577A/B Network Analyzer . . . . . . . . . . .

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Using HP 8753A/B/C Network Analyzer . . . . . . . . . . . . . . . . . . 3-5

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Operating Check Using a Spectrum Analyzer .. ...... ...... ..

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Check Using a Network/Spectrum Analyzer ............ 3-7

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Probe ............................

Using a Network Analyzer ...... ...... ...... ..... .

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Using a Spectrum Analyzer . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Measurement Setups .... ...... ...... ...... ...

Network Measurements ..........................

2-1

2-2

2-3

2-3

2-4

3-1

3-2

3-2

3-3

3-3

3-3

3-3

3-4

3-4

3-6

3-6

3-6

3-7

3-7

3-8

3-8

3-10

3-10

3-10

3-11

3-12

Contents-1

Page 6

Using One HP 41802A .......................... 3-12

Using One HP 41802A with a Transmission/Reection Test Set ....... 3-13

Using Two HP 41802As ......................... 3-14

Spectrum Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Using HP 41802A with instruments which have BNC connectors ....... 3-16

4. Performance Test

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Calibration Cycle .............................. 4-2

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Gain Accuracy/Flatness Tests . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Description ................................ 4-3

Specications ............................... 4-3

Test Equipment .............................. 4-3

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Gain Accuracy/Flatness Tests . . . . . . . . . . . . . . . . . . . . . . . . 4-6

5. Adjustment

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gain Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description ................................

Equipment ................................

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1

5-1

5-1

5-2

5-2

5-2

5-2

6. Replaceable Parts

Replaceable Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. Manual Changes

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

A-1

A-1

Contents-2

Page 7

Figures

1-1. Serial Number Plate .... ...... ...... ...... ...... 1-3

1-2. Specications ........ ...... ...... ...... ..... 1-4

1-3. Supplemental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2-1. Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2. Probe Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3-1. Operating Check Setup Using HP 8751A or HP 3577A/B Network Analyzer .. 3-4

3-2. Operating Check Setup Using HP 8753A/B/C Network Analyzer . . . . . . . . 3-5

3-3. Operating Check Setup Using Spectrum Analyzer ........ ...... 3-6

3-4. Operating Check Setup Using Network/Spectrum Analyzer . . . . . . . . . . 3-7

3-5. Probe Adjustment Setup Using a Network Analyzer|1 . . . . . . . . . . . . 3-8

3-6. Probe Adjustment Setup Using a Network Analyzer|2 . . . . . . . . . . . . 3-9

3-7. Probe Adjustment Setup Using Spectrum Analyzer . . . . . . . . . . . . . .

3-8. Network Measurement Setup Example (Using One HP 41802A) . . . . . . . .

3-9. Network Measurement Setup Example (Using with a Transmission/Reection Set)

3-10. Network Measurement Setup Example (Using Two HP 41802As) ....... 3-14

3-11. Spectrum Measurement Setup Example . . . . . . . . . . . . . . . . . . .

3-12. Measurement Setup Example (BNC input connector) . . . . . . . . . . . . .

4-1. Test Setup 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2. Test Setup 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1. Adjustment Setup 1 ............................

5-2. Adjustment Setup 2 ............................

5-3. Adjustment Setup 3 ............................

6-1. Replaceable Parts (1 of 2) .........................

6-2. Replaceable Parts (2 of 2) .........................

3-10

3-12

3-13

3-15

3-16

4-3

4-4

5-2

5-3

5-4

6-2

6-4

Tables

2-1. Probe Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3-1. Anti-static Products Available .......................

4-1. Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . .

6-1. Component Manufactures ...... ...... ...... ...... .

6-2. Replaceable Parts (2 of 2) .........................

6-3. Replaceable Parts (2 of 2) .........................

A-1. Manual Changes by Serial Number .....................

3-2

4-1

6-1

6-3

6-4

A-1

Contents-3

Page 8

Page 9

1

General Information

Introduction

The HP 41802A 1 M Input Adapter is used with high impedance passive probes for circuit

signal analysis using network and spectrum analyzers.

This is an operation note for the HP 41802A, containing information on installation, operation,

and service in the following chapters.

Chapter 1, General Information

Provides the specications and the information necessary for preparing the HP 41802A for

use.

Chapter 2, Installation

Provides the installation information, including initial inspection, power requirements

mating connectors, and environmental requirements.

Chapter 3, Operation

Provides the information for preparation and typical measurement setups

on use.

Chapter 4, Performance Test

Provides performance test procedures to ensure that the HP 41802A is within specications

Chapter 5, Adjustment

Provides the adjustment procedure to bring it within specications

the performance test or it has been repaired.

Chapter 6, Replaceable Parts

Provides the replaceable parts information to service the HP 41802A.

, if the HP 41802A failed

, including cautions

,

.

General Information 1-1

Page 10

Compatible Equipment

Compatible Instruments

Instruments compatible with the HP 41802A are network and spectrum analyzers which meet

the following conditions.

Measurement frequency range includes 5 Hz to 100 MHz.

Input resistance is 50 .

Probe power supplies are furnished.

The following HP network and spectrum analyzers are compatible with the HP 41802A.

Network Analyzers: HP 8751A, HP 8753A/B/C, HP 3577A/B

Spectrum Analyzers: HP 3585A/B, HP 8568B

Network/Spectrum Analyzer: HP 4195A

If the instrument does not have a probe power supply, use a separate power supply which

meets the requirements described in \Power Requirements" in Chapter 2.

Compatible Probes

Compatible probes with the HP 41802A are high impedance passive probes which meet the

following conditions.

Input resistance is 1 M.

Compensates oscilloscope input capacitance includes 12 pF.

The following HP Oscilloscope Probes are compatible with the HP 41802A.

HP 10432A, HP 10433A, HP 10435A, HP 10440A

HP 10017A, HP 10018A, HP 10080A, HP 10081A

Refer to \Adjusting the Probe" in Chapter 3 how to adjust the probe which is connected to a

network analyzer or a spectrum analyzer.

1-2 General Information

Page 11

Serial Number

Hewlett-Packard uses a two-part, nine character serial number which is stamped on the serial

number plate (see Figure 1-1 ) attached to the instrument's rear panel. The rst four digits

and a letter are the prex, and the last ve digits are the sux of the serial number. The

letter in the serial number identies the country where the instrument was manufactured.

The prex is same for all identical instruments; it changes only when a change is made to the

instrument. The sux, however, is assigned sequentially and is dierent for each instrument.

This operation note applies to instruments with the serial number prexes listed under SERIAL

NUMBERS on the title page.

Figure 1-1. Serial Number Plate

Units manufactured after this operation note was printed may have a serial number prex that

is not listed on the title page. An unlisted serial number prex indicates that the instrument

may be dierent from those described in this operation note

instruments may be accompanied by a yellow Manual Supplement page or have a dierent

manual part number. This supplement contains \Change Information" explaining how to adapt

this operation note to the newer instruments.

In addition to change information, the supplement may contain information for correcting

errors (Errata) in the previous operation notes.To keep this manual as current and accurate as

possible, Hewlett-Packard recommends that you periodically request the latest Manual Changes

supplements. The supplement for this operation note is identied by the Print Date and HP

Part No., both of which appear on the operation note's title page.

For information concerning the serial number prex not listed on the title page or in the

Manual Change supplements, contact your nearest Hewlett-Packard oce.

. Operation notes for new

General Information 1-3

Page 12

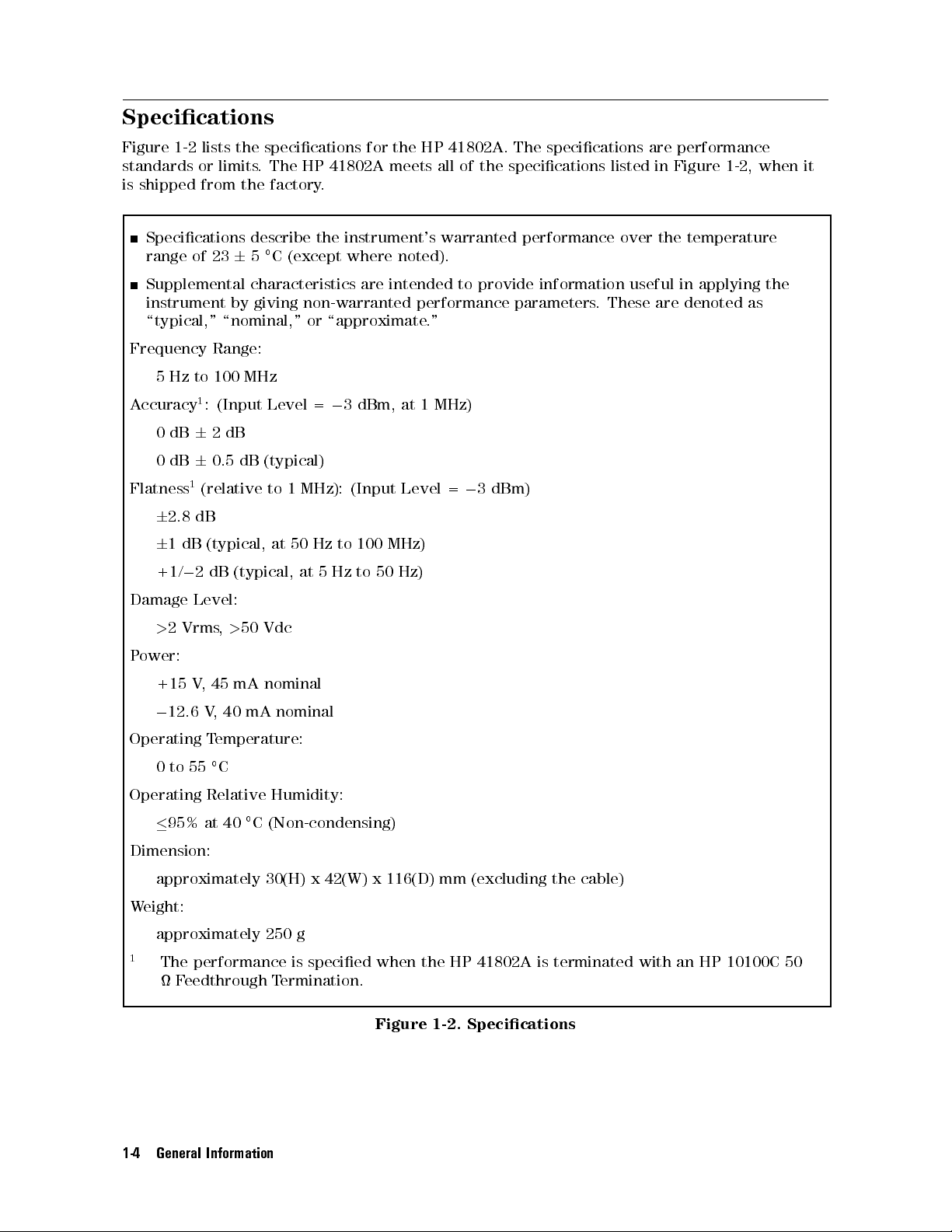

Specications

Figure 1-2 lists the specications for the HP 41802A. The specications are performance

standards or limits. The HP 41802A meets all of the specications listed in Figure 1-2, when it

is shipped from the factory.

Specications describe the instrument's warranted performance over the temperature

range of 2365C (except where noted).

Supplemental characteristics are intended to provide information useful in applying the

instrument by giving non-warranted performance parameters. These are denoted as

\typical," \nominal," or \approximate."

Frequency Range:

5 Hz to 100 MHz

Accuracy1: (Input Level =03 dBm, at 1 MHz)

0dB62dB

0dB60.5 dB (typical)

Flatness1(relative to 1 MHz): (Input Level =03 dBm)

6

2.8 dB

6

1 dB (typical, at 50 Hz to 100 MHz)

+1/02 dB (typical, at 5 Hz to 50 Hz)

Damage Level:

>

2 Vrms,>50 Vdc

Power:

+15 V, 45 mA nominal

0

12.6 V, 40 mA nominal

Operating Temperature:

0to55C

Operating Relative Humidity:

95% at 40C (Non-condensing)

Dimension:

approximately 30(H) x 42(W) x 116(D) mm (excluding the cable)

Weight:

approximately 250 g

1

The performance is specied when the HP 41802A is terminated with an HP 10100C 50

Feedthrough Termination.

1-4 General Information

Figure 1-2. Specications

Page 13

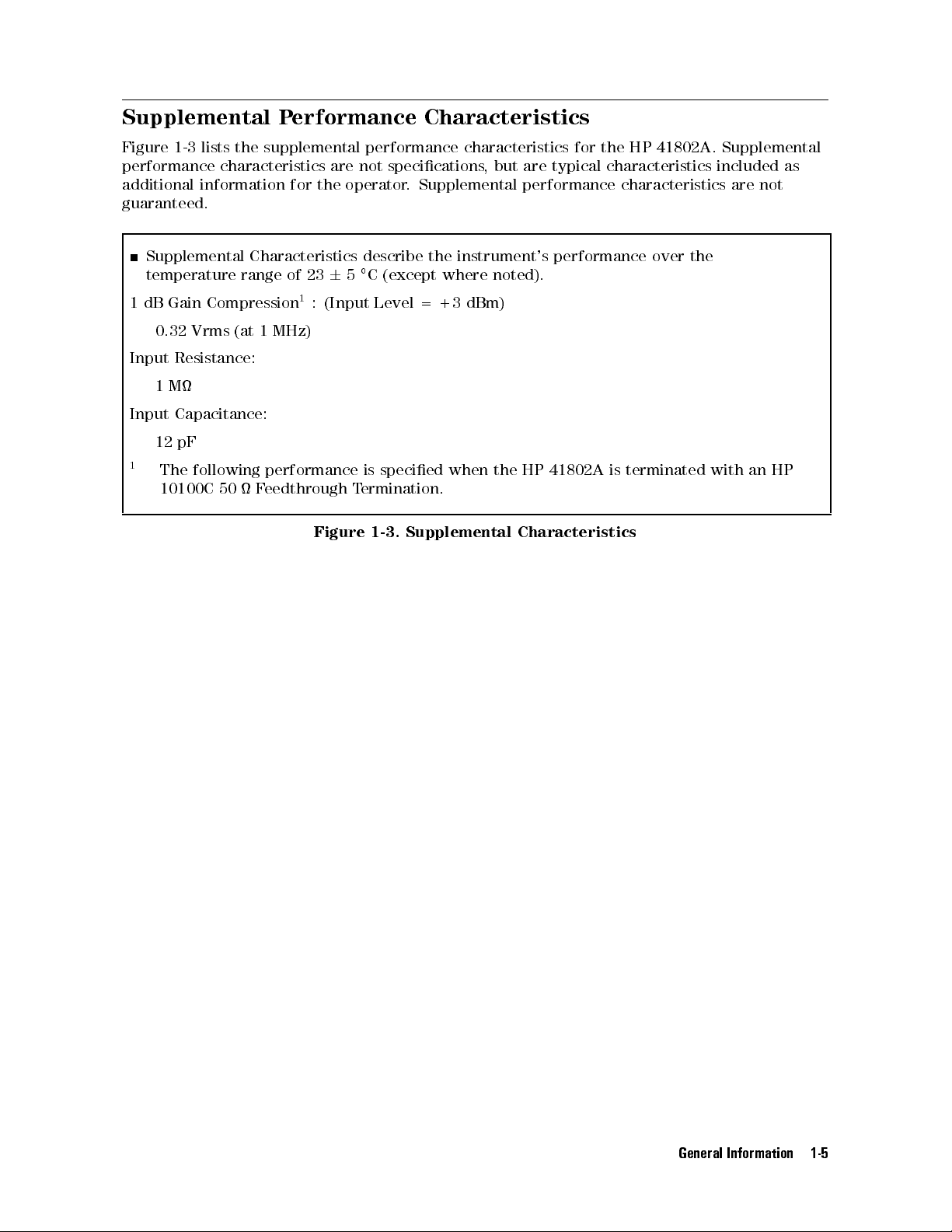

Supplemental Performance Characteristics

Figure 1-3 lists the supplemental performance characteristics for the HP 41802A. Supplemental

performance characteristics are not specications, but are typical characteristics included as

additional information for the operator. Supplemental performance characteristics are not

guaranteed.

Supplemental Characteristics describe the instrument's performance over the

temperature range of 2365C (except where noted).

1 dB Gain Compression1: (Input Level = +3 dBm)

0.32 Vrms (at 1 MHz)

Input Resistance:

1M

Input Capacitance:

12 pF

1

The following performance is specied when the HP 41802A is terminated with an HP

10100C 50 Feedthrough Termination.

Figure 1-3. Supplemental Characteristics

General Information 1-5

Page 14

Page 15

Installation

Introduction

This chapter contains the following information.

Initial inspection

Power Requirements

Mating connector

Environmental requirements

2

Installation 2-1

Page 16

Initial Inspection

Caution

The HP 41802A meets all of the specications listed in Figure 1-2. Upon receipt, inspect

the shipping container for damage. If the shipping container or the cushioning has been

damaged, keep the container and packing material until the contents have been checked

for completeness and the HP 41802A has been mechanically and electrically checked out.

Figure 2-1 shows the product overview of the HP 41802A. The procedures for checking the

general electrical operation are given in Chapter 4.

If anything is damaged (scratches, dents, broken connectors, etc.), or if performance does not

meet the specied performance test limits, notify the nearest HP sales oce (see the list at

the back of this operation note). The HP sales oce will immediately arrange for repair or

replacement without waiting for a claim settlement.

Electrostatic Discharge (ESD) can damage the HP 41802A's highly sensitive

input amplier.Do

the HP 41802A.

NOT

touch the center conductor of the BNC connector of

2-2 Installation

Figure 2-1. Product Overview

Page 17

Power Requirements

Power for the HP 41802A is supplied by the compatible instruments described in \Compatible

Instruments" in Chapter 1 by connecting the HP 41802A's power plug to the probe power jack

on the instrument. If the instrument used with the HP 41802A does not have a probe power

supply, use a separate power supply which meets the requirements listed in Table 2-1. The HP

1122A and HP 11899A Probe Power Supply meets these requirements and it accepts the HP

41802A's probe power plug directly.

Figure 2-2. Probe Power Requirements

Table 2-1. Probe Power Requirements

Pin Voltage Current

1012.6 V610% 40 mA

2 Ground

3 +15 V66% 45 mA

Mating Connectors

The output connector of the HP 41802A is a 50 N-type male connector

Note

Caution

Keep the N-type output connector clean.

Trying to mate this 50 N-type connector to a 75 N-type connector will

result in damage to both connectors.

.

Installation 2-3

Page 18

Environmental Requirements

The HP 41802A may be stored or shipped under the following environmental conditions.

Temperature:040C to +70C

Humidity:95% at 40C (Non-condensing)

The unit must be protected from temperature extremes which can cause condensation.

2-4 Installation

Page 19

Operation

Introduction

This chapter provides the following information.

Operating precautions

Preparation for use

Typical measurement setups

3

Operation 3-1

Page 20

Operating Precautions

This paragraph describes precautions for using the HP 41802A to prevent from damage on the

HP 41802A and your device under test (DUT).

Anti-static Precautions

Caution

The HP 41802A is sensitive to electrostatic discharge (ESD). The following must

be adhered to when using the HP 41802A.

Do

NOT

touch the center conductor of the BNC connector of the HP

41802A.

Do

NOT

touch the pin of the probe which is connected to the HP 41802A.

The probe input circuit is highly susceptible to damage by ESD introduced

through the input connector.

Eliminate ESD on your body.

Wear a snug-tting ground strap that is connected to earth ground through a

high resistance.Table 3-1 lists the available anti-static products.

Eliminate ESD on the work surface.

A grounded anti-static bench mat is recommended. Optional oor mats

provide an extra measure of protection, especially in areas with oor carpet.

Do

NOT

use the HP 41802A on a carpeted work surface

Do

NOT

introduce ESD into the DUT while the probe is in use

If an unprotected person touches a part of the DUT

.

.

, a static surge could

damage the DUT as well as the probe.

Table 3-1. Anti-static Products Available

Description HP Part Number

3-2 Operation

Liquid Anti-static Agent 8550-3397

Static Control Table Mat with Ground Cord 9300-0797

Small Wrist Strap with Ground Cord 9300-1099

Medium Wrist Strap with Ground Cord 9300-1117

Large Wrist Strap with Ground Cord 9300-1242

Page 21

Maximum Allowable Level

Caution

Discharging the Probe

Caution

Probe Power Plug

Note

Preparation for Use

Maximum allowable level (ac+dc) to the probe is650 V.

Measuring a node having a dc voltage potential charges the blocking capacitors

inside the HP 41802A. Ground the probe pin after measuring such nodes to

discharge probe capacitor.Failure to do this could result in damage to sensitive

circuits in the DUT, especially if it is an active device.

Connect the probe power plug, before connecting the N-type connector.

This paragraph provides the HP 41802A operating check procedure and the probe adjustment

procedure.

The HP 41802A operating check procedure checks the adapter gain using a network analyzer

a spectrum analyzer, or a network/spectrum analyzer. These operating check procedures are

only intended to ensure that the HP 41802A is functional. If the HP 41802A fails this check,

it should be repaired. To verify that the HP 41802A meets its specications

performance test described in Chapter 4.

The probe adjustment procedure is for frequency compensation. For the best measurement

results, always adjust the probe.

, perform the

,

Operation 3-3

Page 22

Operating Check Using a Network Analyzer

Using an HP 8751A or HP 3577A/B Network Analyzer

This section provides the HP 41802A operating check procedure using the HP 8751A or the HP

3577A/B network analyzer.

Equipment Required.

Network Analyzer: HP 8751A or HP 3577A/B

BNC(m)-BNC(m) Cable, 30 cm: PN 8120-1838

Adapters: as necessary

Procedure.

1. Connect the equipment as shown in Figure 3-1. Note that the probe power plug must be

connected before connecting the HP 41802A's N-type connector.

Figure 3-1. Operating Check Setup Using HP 8751A or HP 3577A/B Network Analyzer

2. Set the network analyzer as follows:

Measurement Mode: B(, A, or R) (absolute amplitude measurement)

Center Frequency: 1 MHz

Frequency Span: 0Hz

Output Level:

3. Conrm that the signal level is `04dB65dB.'

Note

3-4 Operation

If the signal level is lower than the limit, conrm that the power trip function

is set to OFF.

0

10 dBm

Page 23

Using HP 8753A/B/C Network Analyzer

This section provides the HP 41802A operating check procedure using the HP 8753A/B/C

network analyzer.

Equipment Required.

Network Analyzer: HP 8753A/B/C

50 Feedthrough: HP 10100C

BNC(m)-BNC(m) Cable, 30 cm: PN 8120-1838

Adapters: as necessary

Procedure.

1. Connect the equipment as shown in Figure 3-2. Note that the probe power plug must be

connected before connecting the HP 41802A's N-type connector.

Figure 3-2. Operating Check Setup Using HP 8753A/B/C Network Analyzer

2. Set the network analyzer as follows:

Measurement Mode: R (absolute amplitude measurement)

Center Frequency: 1 MHz

Frequency Span: 0Hz

Output Level:

3. Conrm that the signal level is `05dB65dB.'

Note

If the signal level is lower than the limit, conrm that the power trip function

is set to OFF.

0

5 dBm

Operation 3-5

Page 24

Operating Check Using a Spectrum Analyzer

This section provides the HP 41802A operating check procedure using a spectrum analyzer.

Equipment Required

Spectrum Analyzer: Any Compatible Spectrum Analyzer

BNC(m)-BNC(m) Cable, 61 cm: PN 8120-1839

50 Feedthrough: HP 10100C

Adapters: as necessary

Procedure

1. Connect the equipment as shown in Figure 3-3. Note that the probe power plug must be

connected before the HP 41802A's N-type connector.

Note

If the spectrum analyzer has a tracking generator output, use the tracking

generator output connector instead of the calibration output connector. Then

set the output level to010 dBm.

Figure 3-3. Operating Check Setup Using Spectrum Analyzer

2. Setup the spectrum analyzer as follows:

Center Frequency: Same as Calibration Output frequency.

Frequency Span: 0 Hz.

Attenuation: 40 dB.

3. Conrm that the signal level is `calibration output level

3-6 Operation

6

5dB.'

Page 25

Operating Check Using a Network/Spectrum Analyzer

This section provides the HP 41802A operating check procedure using the HP 4195A

network/spectrum analyzer.

Equipment Required

Network/Spectrum Analyzer: HP 4195A

BNC(m)-BNC(m) Cable, 30 cm: PN 8120-1838

Adapters: as necessary

Procedure

1. Connect the equipment as shown in Figure 3-4. Note that the probe power plug must be

connected before the HP 41802A's N-type connector.

Figure 3-4. Operating Check Setup Using Network/Spectrum Analyzer

2. Set up the Network/Spectrum analyzer as follows:

Conguration: Spectrum

Center Frequency: 1 MHz

Frequency Span: 0Hz

Port Select: Source Channel 1 on

Amplitude (S1):

Ref Attenuator (R1): 10 dB

3. Conrm that the signal level is `020 dB65dB.'

0

26 dBm

Operation 3-7

Page 26

Adjusting the Probe

Using a Network Analyzer

This section provides the probe adjustment procedure using a network analyzer.

Equipment Required.

Network Analyzer: Any Compatible Network Analyzer

Power Splitter: HP 11667A

N(m)-N(m) Adapter: PN 1250-0778

N(m)-BNC(m) Adapter: PN 1250-0780, 2 ea.

50 Feedthrough: HP 10100C

N(m)-N(m) Cable: HP 11500B

BNC(m)-BNC(m) Cable: PN 8120-1838

Procedure.

1. Connect the equipment as shown in Figure 3-5.

Figure 3-5. Probe Adjustment Setup Using a Network Analyzer|1

2. Setup the network analyzer as follows:

Measurement Mode: B/R

Start Frequency: 5Hz

Stop Frequency: 100 MHz

Sweep Type: Log Frequency

Source Power:

IF BW: 2Hz

3. Perform a response calibration.

3-8 Operation

0

5 dBm

Page 27

4. Change the connection as shown in Figure 3-6. Connect the ground lead rmly to provide

good electrical bond.

Figure 3-6. Probe Adjustment Setup Using a Network Analyzer|2

5. Touch the center pin of the feedthrough with the probe tip

.

6. Adjust the trimmer component (through opening in probe assembly cover) until the trace is

as close to020 dB as possible.

Note

Only the mid-frequency range is adjustable. (The low frequency and high

frequency range are not adjustable.) The adjustable range depends on the

probe you use.

Operation 3-9

Page 28

Using a Spectrum Analyzer

This section provides the probe adjustment procedure using a spectrum analyzer.

Equipment Required.

Spectrum Analyzer: Any Compatible Spectrum Analyzer

50 Feedthrough: HP 10100C

Adapters: as necessary

Procedure.

1. Connect the equipment as shown in Figure 3-7. Note that the probe power plug must be

connected before the HP 41802A's N-type connector. Connect the ground lead rmly to

provide good electrical bond.

Note

If the spectrum analyzer has a tracking generator output, use the tracking

generator output connector instead of the calibration output connector. Then

set the output level to010 dBm.

Figure 3-7. Probe Adjustment Setup Using Spectrum Analyzer

2. Setup the spectrum analyzer as follows:

Center Frequency: Same as Calibration Output frequency.

Frequency Span: 50 kHz.

Attenuation: 10 dB.

3. Touch the center conductor of the feedthrough with the probe tip.

4. Adjust the trimmer component (through opening in probe assembly cover) until the peak

0

signal level is as close to `calibration output level

3-10 Operation

20 dB' as possible.

Page 29

Typical Measurement Setups

This paragraph provides typical measurement setups using the HP 41802A. The following

setups are described.

Network Measurement Setups

Using one HP 41802A

Using one HP 41802A with a transmission/reection test set

Using two HP 41802As

Spectrum Measurement Setups

Using the HP 41802A with instruments which have BNC connectors

Caution

Note

Electrostatic discharge (ESD) can damage the HP 41802A's highly sensitive

input amplier.

Do

NOT

touch the center conductor of the BNC connector of the HP

41802A.

Do

NOT

touch the pin of the probe which is connected to the HP 41802A.

Do not apply a ac+dc level which exceeds650 V to the probe.

Do not mate the output connector of the probe assembly (50 type-N

connector) to 75 type-N connectors or damage may results

Connect the probe power plug before connecting the N-type connector

.

.

Operation 3-11

Page 30

Network Measurements

Using One HP 41802A

Figure 3-8 shows a typical measurement setup for the network measurements. Place the probe

tip as close to the input of the device under test, and perform a normalize (through) calibration

to compensate the frequency response error.

Figure 3-8. Network Measurement Setup Example (Using One HP 41802A)

3-12 Operation

Page 31

Using One HP 41802A with a Transmission/Reection Test Set

Figure 3-9 shows typical measurement setup for the network measurements using with a

transmission/reection test set. Place the probe tip as close to the input of the device under

test, and perform a normalize (through) calibration to compensate the frequency response

error.

Figure 3-9.

Network Measurement Setup Example (Using with a Transmission/Reection Set)

Operation 3-13

Page 32

Using Two HP 41802As

Figure 3-10 shows typical measurement setup for network measurements using two probes.

Place the probe tip as close as possible to the input of the device under test, and perform a

normalize (through) calibration to compensate the frequency response error.

Figure 3-10. Network Measurement Setup Example (Using Two HP 41802As)

Note

3-14 Operation

Use Input R and Input B to reduce cross talk.

If you want to set two HP 41802As side by side:

Set the HP 41802As vertically in the same direction.

Set the HP 41802As parallel and do not let them touch each other.

Page 33

Spectrum Measurements

Figure 3-11 shows typical measurement setup using a spectrum analyzer.

Figure 3-11. Spectrum Measurement Setup Example

Operation 3-15

Page 34

Using HP 41802A with instruments which have BNC connectors

Figure 3-12 shows typical measurement setup using a instrument which has a BNC input

connector. A BNC(m) cable and N(f)-BNC(m) adapter are recommended to use for connecting

the HP 41802A to the instrument. Do not use an inexible adapter such as a BNC(m)-N(f)

adapter instead of the cable and N(f)-BNC(f) adapter, otherwise the overweight caused by the

HP 41802A may damage the instrument's connector.

3-16 Operation

Figure 3-12. Measurement Setup Example (BNC input connector)

Page 35

Performance Test

Introduction

This chapter provides performance test procedure to ensure that the HP 41802A meets the

specications listed in Figure 1-2 . The performance test can be performed without accessing

the interior of the HP 41802A.

The test results should be recorded into the Performance Test Record which is located at the

end of this chapter.

Equipment Required

4

The equipment required for performance testing is listed in T

able 4-1 . Substitutions can

be made if the substitution equipment meets or exceeds the specications listed in the

Requirements column.

Table 4-1. Recommended Test Equipment

Equipment Critical Specications Recommended Model Qty.

Network Analyzer No substitute HP 8751A or HP

4195A

Power Splitter Frequency: 10 Hz to 100 MHz,

HP 11667A 1

Equivalent Output SWR:1.1

(@100 MHz)

Adapter 50 , N(m)-N(m) PN 1250-0778 1

50 , N(m)-BNC(f) PN 1250-0780 2

Attenuator Pad ATT 10 dB,

HP 8491A Opt. 010 1

Impedance 50 , N(m)-N(f)

ATT 20 dB, SWR:1.2,

HP 8491A Opt. 020 1

Impedance 50 , N(m)-N(f)

Cables 50 , N(m)-N(m) HP 11500B 1

50 , BNC(m)-BNC(m), 30cm PN 8120-1838 1

1

Coaxial Load 50 Feed through, BNC(m)-BNC(f),

VSWR:1.1 (@100 MHz)

HP 10100C 1

Performance Test 4-1

Page 36

Calibration Cycle

The HP 41802A requires periodic performance verication. The HP 41802A should be checked

out using the performance test at least once a year or more depending on its frequency of use.

Preparation

This paragraph provides the information which you should know and the steps that you should

perform before starting the performance test.

1. Allow the HP 41802A and the test equipment to warm up and stabilize for at least 30

minutes before you execute any of the performance tests.

2. Perform all performance tests in an ambient temperature of 23C65C.

4-2 Performance Test

Page 37

Gain Accuracy/Flatness Tests

Description

This test checks the gain at 1 MHz, and the atness (relative to 1 MHz).

Specications

Gain Accuracy: 0dB62 dB at 1 MHz

Flatness:

Test Equipment

Network Analyzer: HP 8751A

Power Splitter: HP 11667A

10 dB Attenuator Pad: HP 8491A Opt. 010

20 dB Attenuator Pad: HP 8491A Opt. 020

N(m)-N(m) Adapter: PN 1250-0778

N(m)-BNC(f) Adapter: PN 1250-0780, 2 ea.

50 Feed through: HP 10100C

N(m)-N(m) Cable: HP 11500B

BNC(m)-BNC(m) Cable: PN 8120-1838

Procedure

6

2.8 dB relative to 1 MHz

1. Connect the equipment as shown in Figure 4-1.

Figure 4-1. Test Setup 1

Performance Test 4-3

Page 38

2. Setup the HP 8751A as follows:

Control Settings Key Strokes

Preset

Start Freq. = 10 Hz

Stop Freq. = 100 MHz

Meas. Cong: B/R

Number of Points: 8

Sweep Type: LOG FREQ

IF BW = 2 Hz

Source Power = +3 dBm

Marker: Discrete

4

PRESET

4

START54154054x1

4

STOP54154054054M/

4

MEAS

4

MENU

4

MENU

4

AVG

4

MENU

4

MKR

5

NNNNNNNNNNN

5

B/R

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

NUMBER of POINTS

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

N

5

SWEEP TYPE MENU

NNNNNNNNNNNNNNNNN

5

IF BW

4254x15

NNNNNNNNNNNNNNNNN

5

POWER

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

MARKER MODE MENU

4354x15

5

5

3. Perform the following key strokes to do a response calibration.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

4

5

CALIBRATE MENU

CAL

NNNNNNNNNNNNNNNNNNNNNNNNNN

RESPONSE

NNNNNNNNNNNNNN

THRU

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

DONE:RESPONSE

4. Change the connection as shown in Figure 4-2

4854x15

NNNNNNNNNNNNNNNNNNNNNNNNNN

LOG FREQ

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MARKERS: DISCRETE

Figure 4-2. Test Setup 2

5. Perform the following key strokes for a single measurement.

4

MENU

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

N

TRIGGER MENU

5

NNNNNNNNNNNNNNNNNNNN

SINGLE

6. Rotate the RPG knob, and move the marker to the measurement result at 1 MHz. Record the

results on the Performance Test Record.

4-4 Performance Test

Page 39

7. Rotate the RPG knob, and move the marker according to the following table. Then record

the results on the Performance Test Record, and use the equation given on the Performance

Test Record to calculate the test results.

Test Frequency

10 Hz

100 Hz

1 kHz

10 kHz

100 kHz

10 MHz

100 MHz

Performance Test 4-5

Page 40

Performance Test Record

HP 41802A 1 M Input Adapter

Date:

Temperature:

Humidity:

Serial No.:

Tested by:

Gain Accuracy/Flatness Tests

Gain Accuracy (at 1 MHz, 0 dBm)

Minimum Limit Test Result

0

2.0 dB +2.0 dB

Flatness (relative to 0 dBm at 1 MHz)

Frequency Reading

Minimum

[b]

10 Hz

100 Hz

1 kHz

10 kHz

100 kHz

10 MHz

100 MHz

0

0

0

0

0

0

0

Maximum Limit Measurement

[a]

Limit

Test Result

[0a+b]

Maximum

Limit

2.8 dB +2.8 dB

2.8 dB +2.8 dB

2.8 dB +2.8 dB

2.8 dB +2.8 dB

2.8 dB +2.8 dB

2.8 dB +2.8 dB

2.8 dB +2.8 dB

Uncertainty

6

0.48 dB

Measurement

Uncertainty

6

0.70 dB

6

0.70 dB

6

0.70 dB

6

0.70 dB

6

0.70 dB

6

0.70 dB

6

0.70 dB

4-6 Performance Test

Page 41

5

Adjustment

Introduction

This chapter describes the adjustments required to return the HP 41802A to a condition to

meet the specications listed in Figure 1-2, if the HP 41802A failed the performance test, or

after it has been repaired. If proper performance cannot be achieved after these adjustments,

refer to Chapter 6.

Equipment Required

Table 4-1 lists the equipment required for adjustment.

Preparation

This paragraph provides the information which you should know

must perform before starting the adjustments.

1. Allow the HP 41802A and the test equipment to warm up and stabilize for at least 30

minutes before you execute the adjustments.

2. Perform the adjustments in an ambient temperature of 23

, and the procedures that you

C65

C.

Adjustment 5-1

Page 42

Gain Adjustment

Description

This adjustment adjust the HP 41802A's gain.

Equipment

Network Analyzer: HP 8751A

Power Splitter: HP 11667A

10 dB Attenuator Pad: HP 8491A Opt. 010

20 dB Attenuator Pad: HP 8491A Opt. 020

N(m)-N(m) Adapter: PN 1250-0778

N(m)-BNC(f) Adapter: PN 1250-0780, 2 ea.

50 Feed through: HP 10100C

N(m)-N(m) Cable: HP 11500B

BNC(m)-BNC(m) Cable: PN 8120-1838

Procedure

1. Remove the bottom plate of the HP 41802A.

2. Connect the equipment as shown in Figure 5-1.

5-2 Adjustment

Figure 5-1. Adjustment Setup 1

Page 43

3. Setup the HP 8751A as follows:

Control Settings Key Strokes

Preset

CENTER Freq. = 1 MHz

SPAN Freq. = 0 Hz

Meas. Cong: B/R

Number of Points: 2

IF BW = 200 Hz

Source Power = +3 dBm

Marker: Discrete

Scale: 0.1 dB/div

4

PRESET

4

CENTER54154M/

4

SPAN54054x1

4

MEAS

4

MENU

4

AVG

4

MENU

4

MKR

4

SCALE REF54.54154x1

5

5

NNNNNNNNNNN

5

B/R

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

NUMBER of POINTS

NNNNNNNNNNNNNNNN

N

5

IF BW

4254054054x15

NNNNNNNNNNNNNNNNN

5

POWER

4354x15

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

5

MARKER MODE MENU

5

5

4. Perform the following key strokes to do a response calibration.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

4

5

CALIBRATE MENU

CAL

NNNNNNNNNNNNNNNNNNNNNNNNNN

RESPONSE

NNNNNNNNNNNNNN

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

THRU

DONE:RESPONSE

5. Change the connection as shown in Figure 5-2.

4254x15

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

MARKER DESCRETE

Figure 5-2. Adjustment Setup 2

Adjustment 5-3

Page 44

6. Adjust A1R5 until the marker reading is 0 dB60.1 dB, and is as close as possible to 0 dB.

Figure 5-3. Adjustment Setup 3

5-4 Adjustment

Page 45

6

Replaceable Parts

This chapter provides information about the replaceable parts.

Replaceable Parts Lists

Accompanying each replaceable parts illustration is a replaceable parts list. Each list is

arranged in alpha-numerical order by reference designator. The reference designator keys the

part listed to the illustration. The rst part number listed is HP's part number and may dier

from the manufacturer's part number. The check digit serves as an error check of the part

number and should be used when ordering a part. Quantity refers to the quantity of the part

in the accompanying illustration. The description is a brief written description of the part and

may be used for ordering purposes. The manufacturer's code is a ve digit number assigned to

each manufacturer as listed in Table 6-1. The manufacturer part number may or may not be

the same as the HP part number.

Table 6-1. Component Manufactures

Mfr # Name Location Zipcode

28480 HEWLETT-PACKARD CO CORPORATE HQ PALO ALTO CA US 94304

78189 ILLINOIS TOOL WORKS INC SHAKEPROOF ELGIN IL US 60126

Replaceable Parts 6-1

Page 46

6-2 Replaceable Parts

Figure 6-1. Replaceable Parts (1 of 2)

Page 47

Table 6-2. Replaceable Parts (2 of 2)

RD Part No. CDQty. Description Mfr. Mfr.Part No.

1 41802-87112 9 1 LABEL 28480 41802-87112

2 2950-0035 8 1 NUT-HEX-DBL-CHAM 28480 2950-0035

3 41802-24003 5 1 SPACER 28480 41802-24003

4 2190-0102 8 1 WSHR-LK INTL T 78189 1922-01

5 41802-07001 7 1 KEEPER 28480 41802-07001

6 1250-1579 2 1 CONN-RF BNC 28480 1250-1579

7 41802-20001 5 1 HOUSING DIVIDER 28480 41802-20001

8 41802-66501 6 1 A1 HI Z ADAPTER 28480 41802-66501

9 41802-04001 1 1 COVER HOUSING 28480 41802-04001

10 0515-1873 0 2 SCREW METRIC 28480 0515-1873

11 5080-3324 2 1 LABEL (Serial No. Plate) 28480 5080-3324

12 0515-0976 2 3 SCR MACH M2X0.4 28480 0515-0976

13 2190-0654 5 3 WASHER LK HLCL 2 28480 2190-0654

14 41802-87113 0 1 LABEL 28480 41802-87113

15 0515-0914 8 2 SCR-MACH M3X0.5 28480 0515-0914

16 1250-2229 1 1 CONN N-PR-237 28480 1250-2229

17 0515-0914 8 2 SCR-MACH M3X0.5 28480 0515-0914

18 41802-87111 8 1 LABEL 28480 41802-87111

19 41802-61601 7 1 CABLE ASSY 28480 41802-61601

20 0515-1873 0 4 SCREW METRIC 28480 0515-1873

Replaceable Parts 6-3

Page 48

Figure 6-2. Replaceable Parts (2 of 2)

Table 6-3. Replaceable Parts (2 of 2)

RD Part No. CDQty. Description Mfr. Mfr.Part No.

1 41802-64901 6 1 HI Z ADAPTER (w/o Serial No. Plate) 28480 41802-64901

6-4 Replaceable Parts

Page 49

A

Manual Changes

Introduction

This appendix contains the information required to adapt this operation note to earlier

versions or congurations of the HP 41802A than the current printing date of this manual. The

information in this operation note applies directly to HP 41802A whose serial number prex is

listed on the title page of this operation note.

Manual Changes

To adapt this operation note to your HP 41802A, refer to T

changes listed opposite your instrument's serial number.

Instruments manufactured after the printing of this manual may be dierent than those

documented in this operation note. Later instrument versions will be documented in a manual

changes supplement that will accompany the operation note shipped with that instrument. If

your instrument serial number is not listed on the title page of this manual or in T

may be documented in a yellow

on serial number coverage, refer to \Serial Number" in Chapter 1.

Table A-1. Manual Changes by Serial Number

Serial Prex

or Number

There are no earlier congurations than the printing date of this operation note

MANUAL CHANGES

Make Manual Changes

able A-1, and make all of the manual

able A-1, it

supplement. For additional information

.

Manual Changes A-1

Page 50

Loading...

Loading...