Page 1

User’s Guide

Volume 2

Measurement and Analysis

Agilent 4155C Semiconductor Parameter Analyzer

Agilent 4156C Precision Semiconductor Parameter Analyzer

Agilent Part No. 04156-90020

Printed in Japan January 2001

Edition 1

Page 2

Legal Notice

The information contained in this document is subject to change without notice.

Copyright © 2001 Agilent Technologies

This document contains information which is protected by copyright. All rights are

reserved. Reproduction, adaptation, or translation without prior written permission

is prohibited, except as allowed under the copyright laws.

• Product Warranty

Agilent Technologies warrants Agilent Technologies hardware, accessories and

supplies against defects in materials and workmanship for the period of one year

from the warranty start date specified below. If Agilent Technologies receives

notice of such defects during the warranty period, Agilent Technologies will, at

its option, either repair or replace products which prove to be defective.

Replacement products may be either new or like-new.

Warranty service of this product will be performed at Agilent Technologies.

Buyer shall prepay shipping charges to Agilent Technologies and Agilent

Technologies shall pay shipping charges to return the product to Buyer.

However, Buyer shall pay all shipping charges, duties, and taxes for products

returned to Agilent Technologies from another country.

Agilent Technologies does not warrant that the operation of Agilent

Technologies products will be uninterrupted or error free. If Agilent

Technologies is unable, within a reasonable time, to repair or replace any

product to a condition as warranted, customer will be entitled to a refund of the

purchase price upon prompt return of the product.

The Agilent Technologies products may contain remanufactured parts

equivalent to new in performance or may have been subject to incidental use.

The warranty period begins on the date of delivery or on the date of installation

if installed by Agilent Technologies. If customer schedules or delays Agilent

Technologies installation more than 30 days after delivery, warranty begins on

the 31st day from delivery.

Warranty does not apply to defects resulting from (a) improper or inadequate

maintenance or calibration, (b) software, interfacing, parts or supplies not

supplied by Agilent Technologies, (c) unauthorized modification or misuse, (d)

operation outside of the published environmental specifications for the product,

or (e) improper site preparation or maintenance.

2 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 3

To the extent allowed by local law, the above warranties are exclusive and no

other warranty or condition, whether written or oral, is expressed or implied and

Agilent Technologies specifically disclaims any implied warranties or

conditions of merchantability, satisfactory quality, and fitness for a particular

purpose.

Agilent Technologies will be liable for damage to tangible property per incident

up to the greater of $300,000 or the actual amount paid for the product that is the

subject of the claim, and for damages for bodily injury or death, to the extent

that all such damages are determined by a court of competent jurisdiction to

have been directly caused by a defective Agilent Technologies product.

To the extent allowed by local law, the remedies in this warranty statement are

customer’s sole and exclusive remedies. Expect as indicated above, in no event

will Agilent Technologies or its suppliers be liable for loss of date or for direct,

special, incidental, consequential (including lost profit or date), or other damage,

whether based in contract, tort, or otherwise.

For consumer transactions in Australia and New Zealand: the warranty terms

contained in this statement, except to the extent lawfully permitted, do not

exclude, restrict or modify and are in addition to the mandatory statutory rights

applicable to the sale of this product to you.

• Assistance

Product maintenance agreements and other customer assistance agreements are

available for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales Office.

• Certification

Agilent Technologies, Inc. certifies that this product met its published

specifications at the time of shipment from the factory. Agilent Technologies

further certifies that its calibration measurements are traceable to the National

Institute of Standards and Technology (NIST), to the extent allowed by the

Institute’s calibration facility, and to the calibration facilities of other

International Standards Organization members.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 3

Page 4

• Safety Summary

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to comply with these

precautions or with specific warnings elsewhere in this manual may impair the

protections provided by the equipment. In addition, it violates safety standards

of design, manufacture, and intended use of the instrument. Agilent

Technologies, Inc. assumes no liability for customer’s failure to comply with

these requirements.

NOTE Agilent 4155C/4156C/41501B comply with INSTALLATION CATEGORY II for

mains input and INSTALLATION CATEGORY I for measurement input terminals,

and POLLUTION DEGREE 2 defined in IEC 1010-1.

Agilent 4155C/4156C/41501B are INDOOR USE products.

NOTE LEDs in Agilent 4155C/4156C/41501B are Class 1 in accordance with IEC 825-1.

CLASS 1 LED PRODUCT.

• GROUND THE INSTRUMENT

This is Safety Class I instrument. To minimize shock hazard, the instrument

chassis and cabinet must be connected to an electrical ground. The power

terminal and the power cable must meet International Electrotechnical

Commission (IEC) safety standards.

• DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

• KEEP AWAY FROM LIVE CIRCUITS

Operation personnel must not remove instrument covers. Component

replacement and internal adjustments must be made by qualified

maintenance personnel. Do not replace components with power cable

connected. Under certain conditions, dangerous voltages may exist even

with the power cable removed. To avoid injuries, always disconnect power

and discharge circuits before touching them.

• DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another person, capable

of rendering first aid and resuscitation, is present.

4 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 5

• DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Because of the danger of introducing additional hazards, do not install

substitute parts or perform any unauthorized modification to the instrument.

Return the instrument to a Agilent Technologies Sales and Service Office for

services and repair to ensure that safety features are maintained.

• DANGEROUS PROCEDURE WARNINGS

Warnings, such as example below, precede potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be

followed.

WARNING Dangerous Voltage, capable of causing death, are present in this instrument.

Use extreme caution when handling, testing, and adjusting.

• Safety Symbols

The general definitions of safety symbols used on equipment or in manuals are

listed below.

Instruction manual symbol: the product will be marked with this symbol when it

is necessary for the user to refer to the instruction manual in order to protect

against damage to the instrument.

Indicates dangerous voltage and potential for electrical shock. Do not touch

terminals that have this symbol when instrument is on.

Protective conductor terminal. For protection against electrical shock in case of

a fault. Used with field wiring terminals to indicate the terminal which must be

connected to ground before operating equipment.

Frame or chassis terminal. A connection to the frame (chassis) of the equipment

which normally includes all exposed metal structures.

Indicates earth (ground) terminal.

Alternating current.

Direct current.

ON (Supply).

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 5

Page 6

OFF (Supply).

STANDBY (Supply).

CAT 1

Means INSTALLATION CATEGORY I. Measurement terminals on the rear

panel comply with INSTALLATION CATEGORY I.

WARNING The warning sign denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, could result in

injury or death to personal.

CAUTION The caution sign denotes a hazard. It calls attention to an operating procedure,

practice, condition or the like, which, if not correctly performed or adhered to, could

result in damage to or destruction of part or all of the product.

• Herstellerbescheinigung

GEÄUSCHEMISSION

Lpa < 70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 T. 19

• Manufacturer’s Declaration

ACOUSTIC NOISE EMISSION

Lpa < 70dB

operator position

normal operation

per ISO 7779

6 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 7

Printing History

Edition 1: January 2001

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 7

Page 8

In This Manual

This manual provides information for measurement and analysis functions of

Agilent 4155C/4156C, and consists of the following chapters:

• Sweep Measurements

Describes how to perform sweep measurements.

• Knob Sweep Measurements

Describes how to perform knob sweep measurements.

• Sampling Measurements

Describes how to perform sampling measurements.

• Quasi-static C-V Measurements

Describes how to perform quasi-static C-V measurements.

• Stress Force

Describes how to perform stress force. Stress function is effective for the

reliability testing of semiconductor devices.

• Analyzing Measurement Results

Describes how to analyze measurement results manually and automatically.

• Measurement Units and Functions

Provides information about measurement units and measurement functions.

• Measurement Support Functions

Provides information about several functions which support measurements.

• Built-in Functions

Provides information about the built-in mathematical functions and read out

functions.

• Connecting Measurement Devices

Explains how to connect the measurement devices to the instrument.

8 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 9

Contents

1. Sweep Measurements

Measurement Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Basic Sweep Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Subordinate Sweep Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Synchronous Sweep Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Pulse Sweep Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Defining Measurement Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

To Define Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

To Set up Primary Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

To Set up Secondary Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

To Set up Synchronous Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

To Set up Constant Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

To Set up SMU Pulsed Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

To Set up PGU Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

To Set up Stop Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

To Display Graphics Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

To Display List Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

To Execute or Stop Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Making a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Step 1. Prepare for the measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Step 2. Mount your DUT on the test fixture . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Step 3. Define the channel assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Step 4. Define the user functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Step 5. Set up the measurement parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

Step 6. Set up the results display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

Step 7. Execute the measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-43

2. Knob Sweep Measurements

Measurement Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Available units and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 Contents - 1

Page 10

Contents

Normal Sweep and Knob Sweep Measurements . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Features of Knob Sweep Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

KNOB SWEEP screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Analysis of the Knob Sweep Measurement Results . . . . . . . . . . . . . . . . . . . . . 2-9

Executing Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

To Define Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

To Execute Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

To Stop Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

To Change Measurement Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

3. Sampling Measurements

Measurement Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Available Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Sampling Interval and Measurement Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Sampling Measurement Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Sampling Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Source Output Sequence and Time Origin. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Linear Sampling Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

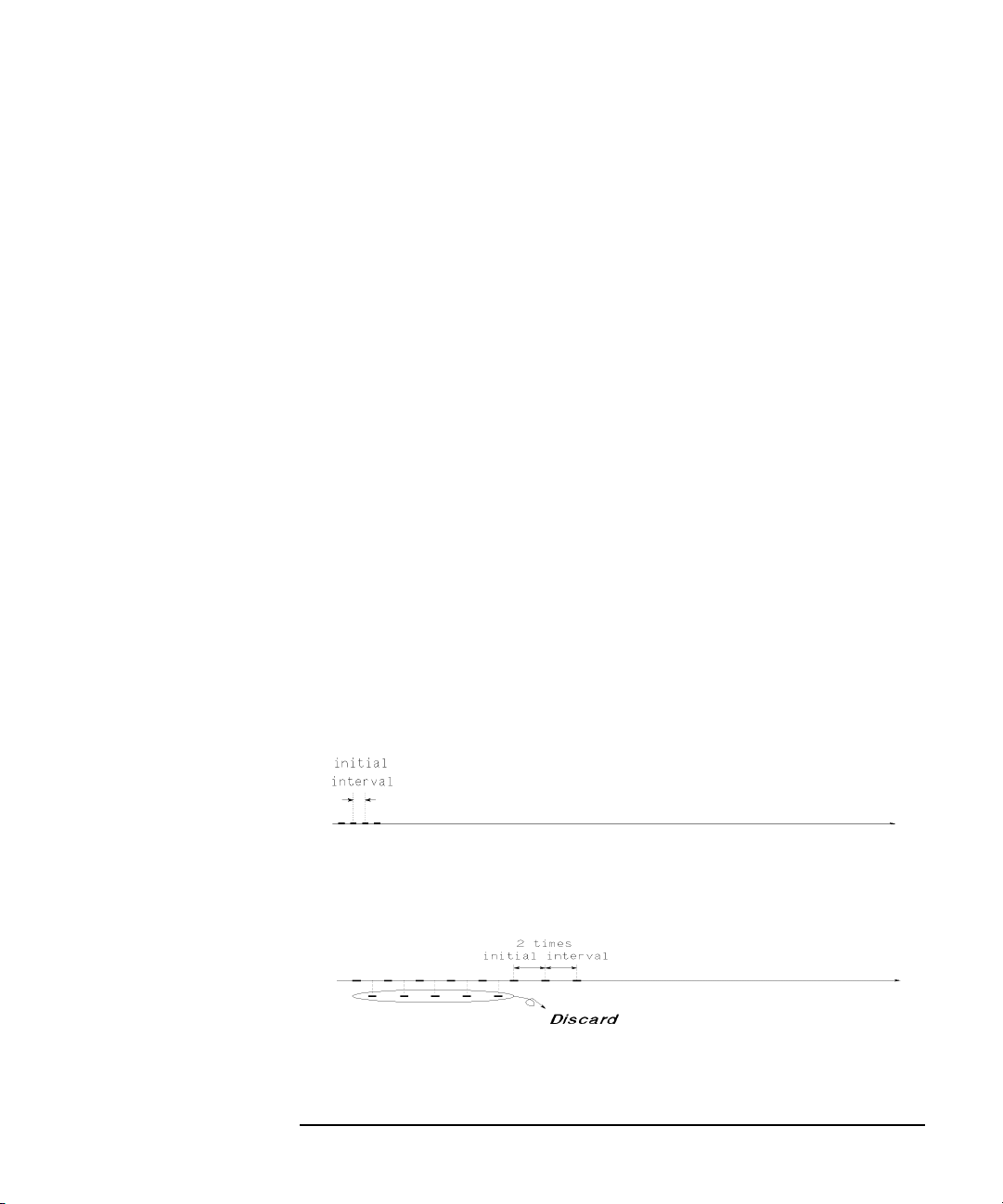

Thinned-out Sampling Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Logarithmic Sampling Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Defining Measurement Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

To Define Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

To Set up Sampling Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

To Set up Constant Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

To Set up PGU Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

To Define Stop Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

To Display Graphics Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

To Display List Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

To Execute or Stop Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Making a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Contents - 2 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 11

Contents

Step 1. Prepare for the measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Step 2. Mount your DUT on the test fixture . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Step 3. Define the channel assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Step 4. Set up the measurement parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Step 5. Set up the results display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Step 6. Execute the measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

4. Quasi-static C-V Measurements

Measurement Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Available Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Capacitance Data Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Defining Measurement Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

To Define Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

To Set up QSCV Sweep Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

To Set up Stop Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

To Set up Constant Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

To Set up PGU Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

To Define Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

To Display Graphics Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

To Display List Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

To Execute or Stop Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Making a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Step 1. Prepare for measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Step 2. Mount your DUT on the test fixture . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Step 3. Define the channel assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Step 4. Set up the source parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Step 5. Set up the measurement parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Step 6. Set up the results display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Step 7. Execute the measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 Contents - 3

Page 12

Contents

Maximum Measurement Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Considering Measurement Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

5. Stress Force

Stress Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Stress Output Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Stress Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Stress Force Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Stress Stop Function at Abnormal Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Defining Stress Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

To Set up Stress Source Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

To Set up Stress Condition/Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

To Set up ac (Pulse) Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

To Set up dc Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

To Force Stress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

6. Analyzing Measurement Results

Analysis Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Marker on the GRAPH/LIST: GRAPHICS screen . . . . . . . . . . . . . . . . . . . . . . 6-4

Marker on the GRAPH/LIST: LIST screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Cursor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Line Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Scaling Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Overlay Display Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Automatic Analysis Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Manual Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

To Specify a Measurement Point on Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

To Specify between Measurement Points on Curve . . . . . . . . . . . . . . . . . . . . 6-16

To Display or Move Cursor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

To Adjust Display Range to Measurement Curve Automatically . . . . . . . . . . 6-19

Contents - 4 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 13

Contents

To Zoom the Display Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

To Center Display at Cursor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

To Draw Line through Two Specified Points . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

To Draw Line through Specified Point with Specified Gradient . . . . . . . . . . 6-22

To Draw Tangent to Specified Point of Measurement Curve . . . . . . . . . . . . . 6-24

To Draw Regression Line for Specified Region . . . . . . . . . . . . . . . . . . . . . . . 6-26

To Display and Select a Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

To Display Grid on the Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

To Change Data Variable on Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

To Change Range of X or Y Axis Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

To Change Variable Assigned to X, Y1, or Y2 Axis . . . . . . . . . . . . . . . . . . . . 6-31

To Overlay an Internal Memory Measurement Curve onto Plotting Area . . . 6-32

To Scroll the LIST screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

To Display or Move Marker on LIST screen . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

To Change Variables of LIST screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

Automatic Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

To Draw Line by Specifying Two Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

To Draw Line by Specifying Gradient and One Point . . . . . . . . . . . . . . . . . . 6-40

To Draw Tangent to Specified Measurement Point . . . . . . . . . . . . . . . . . . . . . 6-42

To Draw Regression Line by Specifying Two Points . . . . . . . . . . . . . . . . . . . 6-44

To Display Marker at Specified Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

7. Measurement Units and Functions

Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

GNDU - Ground Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

SMU - Source Monitor Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

VSU - Voltage Source Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

VMU - Voltage Monitor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

PGU - Pulse Generator Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Voltage and Current Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 Contents - 5

Page 14

Contents

Power Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Measurement Ranging Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Auto Ranging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Limited Auto Ranging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Compliance Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Fixed Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Measurement Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

Integration Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

Overhead Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

To Specify Source Output Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

SMU Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

Self-calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Zero Offset Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

To Measure Offset Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

To Perform Offset Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

QSCV Zero Offset Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

To Measure Offset Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

To Perform Offset Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Operation States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

Idle State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

Measurement State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

Stress Force State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

Standby State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

Changing among Operation States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

Output Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Sequential Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

Simultaneous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

Contents - 6 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 15

Contents

8. Support Functions

User Function and User Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Output or Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

User Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

User Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Syntax of Data Variable Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Expression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Standby Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Standby Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Standby State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Available Units and Output Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Output Values of non-Standby Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Output Sequence of Standby Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

When Getting Setup File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

To Use Standby Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

R-BOX Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Resistance Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

To Use R-Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

SMU/PG Selector Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Setup and Switching Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Restrictions using Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

To Use Selector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

Switching Matrix Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

To Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

To Control Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-36

To Use Matrix Setup File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 Contents - 7

Page 16

Contents

Trigger Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-41

Trigger Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-43

Trigger Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

9. Built-in Functions

Built-in Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

AT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

AVG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

COND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

DELTA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

DIFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

EXP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

INTEG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

LGT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

MAVG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

MAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

MIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

SQRT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Read Out Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

@CX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

@CY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

@CY1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

@CY2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

@IX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

@IY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

@IY1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

@IY2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

@L1CO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

@L1G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Contents - 8 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 17

Contents

@L1G1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

@L1G2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

@L1X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

@L1Y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

@L1Y1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

@L1Y2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

@L2CO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

@L2G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

@L2G1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

@L2G2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

@L2X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

@L2Y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

@L2Y1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

@L2Y2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

@MI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

@MX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

@MY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

@MY1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

@MY2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

10. Connecting Measurement Devices

Using Test Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Using Connector Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

To Reduce Leakage Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

To Measure Low Resistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 Contents - 9

Page 18

Contents

Contents - 10 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 19

1 Sweep Measurements

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 20

Sweep Measurements

This chapter consists of the following sections which describes how to execute a

sweep measurement:

•“Measurement Functions”

•“Defining Measurement Conditions”

•“Making a Measurement”

For details about the measurement setup screens, see Setup Screen Reference

manual.

1-2 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 21

Sweep Measurements

Measurement Functions

Measurement Functions

For sweep measurements, the sweep source channels perform staircase sweep

output of voltage or current, while the monitor channels measure voltage or current

for each sweep step.

The 4155C/4156C provides three types of sweep measurement:

•“Basic Sweep Measurement”

One sweep source (VAR1) is used.

•“Subordinate Sweep Measurement”

A primary (VAR1) and secondary sweep source (VAR2) are used.

•“Synchronous Sweep Measurement”

A primary (VAR1) and synchronous sweep source (VAR1') are used.

Also, you can set up a combined subordinate and synchronous sweep measurement.

Available Units SMUs and VSUs can be sweep sources (VAR1, VAR2, and VAR1'). A sweep or

constant source SMU can be set to the pulsed source to prevent thermal drift of the

DUT.

Output Range Sweep source units use the following output range:

• minimum range covers all sweep output values in Linear sweep.

• minimum range covers all sweep output values in Log voltage sweep.

• optimum range for output value every sweep step in Log current sweep.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-3

Page 22

Sweep Measurements

Measurement Functions

Basic Sweep Measurement

Basic sweep measurement uses one sweep source (VAR1).

The following sweep types are available:

• LIN/LOG

• Linear staircase

• Logarithmic staircase

• SWEEP MODE

• Single Source channel sweeps the output from user specified start value to

stop value.

• Double Source channel sweeps the output from user specified start value to

stop value, then from stop value to start value.

You can select any combination of LIN/LOG and SWEEP MODE as shown in the

following table:

1-4 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 23

Figure 1-1 Basic Sweep Measurement

Sweep Measurements

Measurement Functions

To set up basic sweep measurement, select VAR1 function for desired SMU or VSU

on CHANNELS: CHANNEL DEFINITION screen.

Parameters

Also, specify the following parameters for VAR1 on MEASURE: SWEEP SETUP

screen.

Parameter Description

sweep mode Single or double sweep.

linear/log Linear or logarithmic sweep. For logarithmic sweep, select the

number steps in one decade as follows:

LOG10 10 steps in one decade.

LOG25 25 steps in one decade.

LOG50 50 steps in one decade.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-5

Page 24

Sweep Measurements

Measurement Functions

start Start value of sweep. For logarithmic sweep, start must not be

zero. Allowable range of start depends on output range of

sweep source. For output range of each measurement channel,

refer to Chapter 7.

stop Stop value of single sweep or turning back value of double

sweep. For logarithmic sweep, stop must have same polarity as

start, and must not be zero. Allowable range of stop depends on

output range of sweep source. For output range of each

measurement channel, refer to Chapter 7.

step • For linear sweep, step is step increment of sweep. Number

of sweep steps is calculated from start, stop, and step.

Calculated number of steps must be in range: 2 to 1001.

• For logarithmic sweep, step is invalid. Number of sweep

steps is calculated from start, stop, and number of steps in

one decade, which is specified by log parameter. Calculated

number of steps must be in range: 2 to 1001.

compliance Compliance value of sweep source. This parameter applies to

SMU only. Allowable range of compliance depends on the

compliance range of sweep source. For the compliance range of

each measurement channel, refer to Chapter 7.

power compliance (Optional) Power compliance value of sweep source. This

parameter applies to SMU only. Allowable range depends on

power compliance range of sweep source. For details, refer to

Chapter 7.

hold time Time required for DUT to settle after forcing start value.

Allowable range is 0 to 655.35s. Resolution: 10 ms.

delay time Time required for DUT to settle after stepping the output.

Allowable range: 0 to 65.535 s. Resolution: 100 ms

Refer to Setup Screen Reference for setting up these parameters.

1-6 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 25

Subordinate Sweep Measurement

For subordinate sweep measurement, you set up a secondary sweep source (VAR2)

in addition to a primary sweep source (VAR1). After primary sweep is completed,

the output of secondary sweep source is incremented or decremented by the

specified step value, then the primary sweep source is swept again.

Figure 1-2 Subordinate Sweep Measurement

Sweep Measurements

Measurement Functions

To set up the subordinate sweep measurement, select the following on CHANNELS:

CHANNEL DEFINITION screen:

• VAR1 function for desired primary sweep source (SMU or VSU).

• VAR2 function for desired secondary sweep source (SMU or VSU).

Subordinate sweep measurement has the following restriction:

• For the secondary sweep source, only single sweep mode and linear staircase

mode are available.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-7

Page 26

Sweep Measurements

Measurement Functions

Parameters

The parameters for primary sweep source (VAR1) are same as the parameters for

sweep source of basic sweep measurement. For secondary sweep source (VAR2),

specify the following parameters on MEASURE: SWEEP SETUP screen.

Parameter Description

start Start value of secondary sweep. Allowable range of start

step Step increment of secondary sweep.

number of steps Number of secondary sweep steps.Allowable range: 1 to 128.

NOTE Stop value

Stop value of secondary sweep is calculated from start, step, and number of steps.

Allowable range of stop depends on the output range of secondary sweep source.

For the output range of each measurement channel, refer to Chapter 7.

compliance Compliance value of secondary sweep source. This parameter

depends on the output range of secondary sweep source. For the

output range of each measurement channel, refer to Chapter 7.

applies to SMU only. Allowable range of compliance depends

on the compliance range of secondary sweep source. For the

compliance range of each measurement channel, refer to

Chapter 7.

power compliance (Optional) Power compliance value of secondary sweep source.

This parameter applies to SMU only. Allowable range of power

compliance depends on the power compliance range of sweep

source. For details, refer to Chapter 7.

1-8 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 27

Synchronous Sweep Measurement

For synchronous sweep measurement, you set up a synchronous sweep source

(VAR1') in addition to a primary sweep source (VAR1). The output of the

synchronous sweep source is swept synchronously with the output of the primary

sweep source at a constant offset value and ratio.

Figure 1-3 Synchronous Sweep Measurement

Sweep Measurements

Measurement Functions

To set up synchronous sweep measurement, select the following on CHANNELS:

CHANNEL DEFINITION screen:

• VAR1 function for desired primary sweep source (SMU or VSU).

• VAR1' function for desired synchronous sweep source (SMU or VSU).

Synchronous sweep mode has the following restrictions:

• For the following, VAR1' is always set to the same mode as VAR1:

• linear/log staircase

• single/double sweep mode

• VAR1 and VAR1' must be same V/I output mode. For example, if VAR1 is set to

V mode, then VAR1' must be set to V or VPULSE mode.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-9

Page 28

Sweep Measurements

Measurement Functions

Parameters

The parameters for primary sweep source (VAR1) are same as the parameters for

sweep source of basic sweep measurement. For synchronous sweep source (VAR1'),

specify the following parameters on MEASURE: SWEEP SETUP screen.

Parameter Description

offset Offset between outputs of primary and synchronous sweep

sources.

ratio Ratio between outputs of primary and synchronous sweep

sources.

compliance Compliance value of synchronous sweep source. This

parameter applies to SMU only. Allowable range of compliance

depends on the compliance range of synchronous sweep source.

For the compliance range of each measurement channel, refer to

Chapter 7.

power compliance (Optional) Power compliance value of synchronous sweep

source. This parameter applies to SMU only. Allowable range

of power compliance depends on the power compliance range

of synchronous sweep source. For details, refer to Chapter 7.

The relationship between the output of primary and synchronous sweep sources is

determined by the following equation:

synchronous output = primary output ´ ratio + offset

The synchronous output determined by above equation must not exceed the output

range of synchronous sweep source.

1-10 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 29

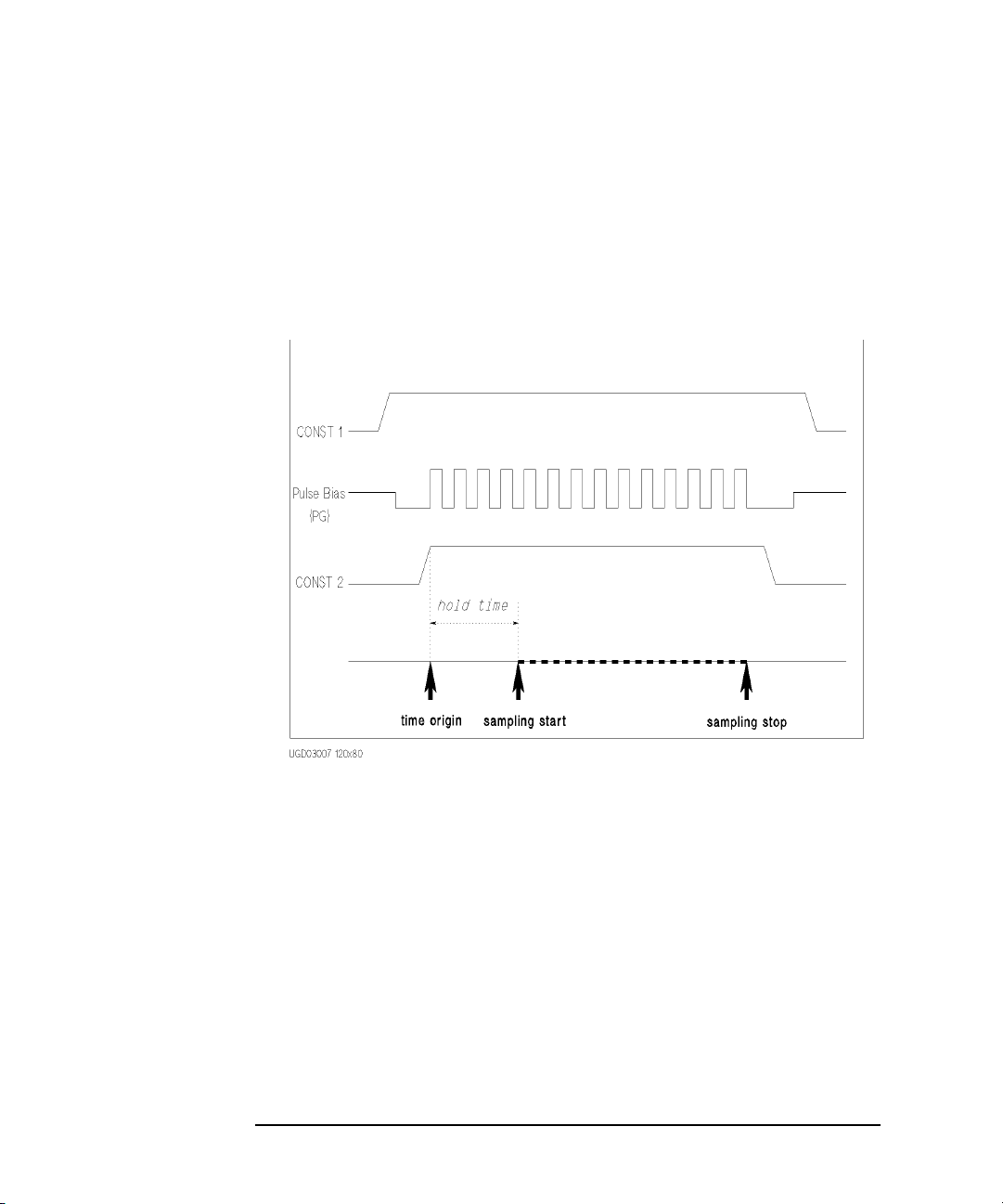

Pulse Sweep Measurement

For a sweep measurement, a sweep or constant source SMU can be a pulse source.

But only one SMU can be a pulse source. Figure 1-4 shows the relationship between

pulse source and other sources.

Figure 1-4 Pulse Source and Other Sources

Sweep Measurements

Measurement Functions

For the pulse sweep measurement, the delay time of the primary sweep source is

ignored, and each step of the primary sweep source is synchronized with output of

the SMU pulse source. Measurements are made during the pulse output.

The pulse output of PGU is not synchronized with any other source.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-11

Page 30

Sweep Measurements

Measurement Functions

Figure 1-5 SMU Pulse

Parameters

Specify SMU pulse parameters (MEASURE: SWEEP SETUP):

Parameter Description

pulse period SMU forces the next pulse after specified pulse period.

Allowable range: 5 ms to 1 s. Resolution: 100 ms.

pulse width Time from when SMU output starts to change from base value

to time when SMU starts to return from peak value.

Measurements are made while the peak value is output.

Allowable range: 0.5 ms to 100 ms. Resolution: 100 ms.

base value The base output value of the SMU pulse.

Be aware that if any of following are true, pulsed SMU channel may not output the

pulse period and pulse width you specified:

• Measurement range differs from compliance range (lowest range that includes

compliance).

• Ranging mode is set to auto range or limited auto range.

• Multi-channel measurement is set.

1-12 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 31

NOTE Pulse width

If the measurement settings do not meet the following conditions, pulse width

setting of SMU may be insufficient to make measurement. If so, the pulse width is

automatically changed to be appropriate.

Number of Meas. Channels: 1

Integration Time: Short

Ranging Mode: Fixed

Sweep Measurements

Measurement Functions

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-13

Page 32

Sweep Measurements

Defining Measurement Conditions

Defining Measurement Conditions

This section describes the sweep measurement tasks.

The basic procedure to test your DUT is as follows:

1 Connecting your DUT to the 4155C/

4156C. See Chapter 10 for procedures.

2 Defining measurement mode and

CHANNELS: CHANNEL DEFINITION 01JAN29 10:57AM

*MEASUREMENT MODE

SWEEP

*CHANNELS

UNIT VNAME INAME MODE FCTN RESISTANCE

SMU1:HR VS IS COMMON CONST 0 ohm

SMU2:HR VG IG V VAR1'

SMU3:HR VD ID V VAR1

SMU4:HR

SMU5:HP 0 ohm

VSU1 -------

VSU2 -------

VMU1 ------- ----- ---- DISCHARGE

VMU2 ------- ----- ---- ON

PGU1 -------

PGU2 -------

GNDU ------- ----

SWEEP

Select Measurement Mode with softkey or rotary knob.

CHANNEL

DEF

MEASURE STBY SERIES

USER

USER

FCTN

VAR

E5250A

S

PROP

B

SWEEP

SAM-

QSCV

DEFAULT

MEASURE

SETUP

MEM1 M

B-Tr

VCE-IC

MEM2 M

FET

VDS-ID

MORE

1/2

NEXT

PAGE

measurement units that you use to make

measurement.

PLING

See “To Define Measurement Units” on

page 1-16. Also see Chapter 8 for the user

function, standby function, and R-box

control.

3 Setting the source parameters of the units.

MEASURE: SWEEP SETUP 01JAN29 10:58AM

*VARIABLE VAR1 VAR2 VAR1'

UNIT SMU3:HR UNIT SMU2:HR

NAME VD NAME VG

SWEEP MODE SINGLE OFFSET 0.0000 V

LIN/LOG LINEAR RATIO 1.000

START 0.0000 V COMPLIANCE 100.00mA

STOP 2.0000 V POWER COMP OFF

STEP 20.0mV

NO OF STEP 101

COMPLIANCE 100.00mA

POWER COMP OFF

*TIMING

HOLD TIME 0.0000 s

DELAY TIME 0.0000 s *SWEEP STOP AT ANY ABNORM Status

*CONSTANT

UNIT

NAME

MODE

SOURCE --------- --------- --------- ---------

COMPLIANCE --------- --------- --------- ---------

SINGLE

Select Sweep Mode with softkey or rotary knob.

SWEEP

SETUP

MEASURE

SETUP

OUTPUT

SEQ

S

PREV

PAGE

SINGLE

DOUBLE

B

NEXT

PAGE

See following in this section:

•“To Set up Primary Sweep”

•“To Set up Secondary Sweep”

•“To Set up Synchronous Sweep”

•“To Set up Constant Output”

•“To Set up SMU Pulsed Output”

•“To Set up PGU Output”

•“To Set up Stop Condition”

1-14 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 33

Sweep Measurements

Defining Measurement Conditions

4 Setting the display mode to show

DISPLAY: DISPLAY SETUP 01JAN29 10:58AM

*DISPLAY MODE

GRAPHICS

*GRAPHICS

Xaxis Y1axis Y2axis

NAME VD SQID DSQID

SCALE LINEAR LINEAR LINEAR

MIN 0.000000000 V 0.0000000000 0.0000000000

MAX 2.0000000 V 100.00000000m 100.00000000m

*GRID *LINE PARAMETER

ON ON

*DATA VARIABLES *DATA DISPLAY RESOLUTION

NORMAL

GRAPH-

LIST

measurement results.

ICS

See following in this section:

•“To Display Graphics Results”

•“To Display List Results”

GRAPHICS

Select Display Mode with softkey or rotary knob.

DISPLAY

SETUP

ANLYSIS

SETUP

S

PREV

PAGE

B

NEXT

PAGE

5 Executing the measurement.

See “To Execute or Stop Measurement” on

page 1-29. Also see Chapter 7 for

executing self-calibration and zero offset

cancel.

6 Results.

GRAPH/LIST: GRAPHICS SHORT 01JAN29 10:59AM

() ()

100.m 100.m

SQID DSQID

10.0m 10.0m

/div /div

0.00 0.00

0.00 VD (V) 200 .m /div 2.00

AXISY1MARKER/

LINE SCALING DISPLAY

CURSOR

SWEEP

SETUP

TIMING

SETUP

S

SETUP

B

MARKER

MARKER

MIN/MAX

INTER-

MARKER

SKIP

AUTO

ANALY-

CURSOR

For example, displayed graphically.

OFF

POLATE

OFF

SIS

OFF

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-15

Page 34

Sweep Measurements

Defining Measurement Conditions

To Define Measurement Units

Press Chan front-panel key to define the measurement units. CHANNELS:

CHANNEL DEFINITION screen is displayed.

1. MEASUREMENT MODE:

Select SWEEP secondary softkey for sweep measurement.

2. VNAME:

Enter a unique name for voltage variable. For example, enter Vce for

collector-emitter voltage. If channel does neither V force nor V measurement,

you can omit VNAME.

3. INAME:

Enter a unique name for current variable. For example, enter Ic for collector

current. If channel does neither I force nor I measurement, you can omit

INAME.

4. MODE:

Select one of the following softkeys:

• V : Voltage output (for SMU, VSU, and PGU).

V : Grounded mode voltage measurement (for VMU).

• I : Current output (for SMU).

• VPULSE : Pulsed voltage output (for SMU and PGU).

• IPULSE : Pulsed current output (for SMU).

• COMMON : Circuit common (for SMU and GNDU).

• DVOLT : Differential mode voltage measurement (for VMU).

5. FCTN:

Select one of the following softkeys to set the output function:

• CONST : Constant output function (for SMU, VSU, and PGU).

• VAR1 : Primary sweep output function (for SMU and VSU).

• VAR2 : Secondary sweep output function (for SMU and VSU).

• VAR1' : Synchronous sweep output function (for SMU and VSU).

1-16 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 35

Sweep Measurements

Defining Measurement Conditions

6. DISCHARGE:

Select ON secondary softkey to connect the discharge resistor to VMU input, or

OFF to disconnect the resistor. The discharge resistor is used to prevent the

VMU inputs from charge up in the idle state.

When DISCHARGE is ON, the discharge resistor is automatically connected to

the VMU input, and disconnected from the input in the measurement state.

VNAME and INAME

You can use VNAME and INAME names in user function definitions or for analysis

on the GRAPHICS/LIST screens. These names must be 6 or less alphanumeric

characters. First character must be alphabet character.

To disable a unit

Select DELETE ROW softkey. The settings for the unit are deleted.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-17

Page 36

Sweep Measurements

Defining Measurement Conditions

To Set up Primary Sweep

Primary sweep source is the measurement unit defined as VAR1 in the

CHANNELS: CHANNEL DEFINITION screen. To set up the primary sweep

source, press

displayed.

1. VAR1 : SWEEP MODE

Select one of the following softkeys to set the sweep mode:

• SINGLE : single sweep mode.

• DOUBLE : double sweep mode.

2. VAR1 : LIN/LOG

Select one of the following softkeys to set the sweep step mode:

• LINEAR : linear step mode.

• LOG XX : logarithmic step mode. XX specifies the number of steps per

3. VAR1 : START

Meas front-panel key. The MEASURE: SWEEP SETUP screen is

decade. XX is 10, 25, or 50.

Enter the sweep start value.

4. VAR1 : STOP

Enter the sweep stop value.

If you select LOG sweep step mode, the polarity of stop value must be same as

the polarity of start value.

5. VAR1 : STEP

If you select LINEAR sweep step mode, enter the sweep step value. This field is

not available for the LOG mode.

6. VAR1 : COMPLIANCE, POWER COMPLIANCE

Only for SMU. Enter the compliance value, and power compliance (ON or OFF)

for the primary sweep source.

NO OF STEP is automatically calculated from START, STOP, and STEP values.

You cannot change UNIT and NAME in this screen. To change the values, go to the

CHANNELS: CHANNEL DEFINITION screen.

1-18 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 37

Sweep Measurements

Defining Measurement Conditions

To Set up Secondary Sweep

Secondary sweep source is the measurement unit defined as VAR2 in the

CHANNELS: CHANNEL DEFINITION screen. On the MEASURE: SWEEP

SETUP screen, set up the primary sweep source (VAR1), then do following:

1. VAR2: START

Enter the secondary sweep start value.

2. VAR2: STEP

Enter the secondary sweep step value.

3. VAR2: NO OF STEP

Enter the number of steps for the secondary sweep.

4. VAR2 : COMPLIANCE, POWER COMPLIANCE

Only for SMU. Enter the compliance value, and power compliance (ON or OFF)

for the secondary sweep source.

SWEEP MODE and LIN/LOG are automatically set to SINGLE and LINEAR,

respectively. You cannot change the settings.

The STOP value is automatically calculated from START, STEP, and NO OF STEP

values.

You cannot change UNIT and NAME in this screen. To change the values, go to the

CHANNELS: CHANNEL DEFINITION screen.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-19

Page 38

Sweep Measurements

Defining Measurement Conditions

To Set up Synchronous Sweep

Synchronous sweep source is the measurement unit defined as VAR1’ in the

CHANNELS: CHANNEL DEFINITION screen. VAR1’ is available for the

measurement units set to the output mode same as the VAR1 output mode. The

output value of VAR1' is calculated by the following equation:

VA R1 ' = VAR 1 ´ RATIO + OFFSET

On the MEASURE: SWEEP SETUP screen, set up the primary sweep source

(VAR1), then do following:

1. VAR1’ : OFFSET

Enter the offset value of the VAR1’ output against the VAR1 output.

2. VAR1’ : RATIO

Enter the ratio value of the VAR1’ output against the VAR1 output.

3. VAR1’ : COMPLIANCE, POWER COMPLIANCE

Only for SMU. Enter the compliance value, and power compliance (ON or OFF)

for the synchronous sweep source.

You cannot change UNIT and NAME in this screen. To change the values, go to the

CHANNELS: CHANNEL DEFINITION screen.

1-20 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 39

Sweep Measurements

Defining Measurement Conditions

To Set up Constant Output

Constant voltage/current source is the measurement unit defined as CONST in the

CHANNELS: CHANNEL DEFINITION screen. To set up the constant output

source, press

displayed.

1. CONSTANT : SOURCE

Enter the desired output value of the constant source.

2. CONSTANT : COMPLIANCE

Only for SMU. Enter the compliance value for the constant source.

You cannot change UNIT, NAME, and MODE in this screen. To change the values,

go to the CHANNELS: CHANNEL DEFINITION screen.

Meas front-panel key. The MEASURE: SWEEP SETUP screen is

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-21

Page 40

Sweep Measurements

Defining Measurement Conditions

To Set up SMU Pulsed Output

SMU pulse output source is the measurement unit defined as VPULSE or IPULSE

in the CHANNELS: CHANNEL DEFINITION screen. For pulsed sweep source, set

the function (FCTN) to VAR1, VAR2, or VAR1’. For pulsed constant source, set the

function to CONST. To set up the SMU pulse output source, press

key. The MEASURE: SWEEP SETUP screen is displayed.

1. Set the source output parameters:

• For VAR1, refer to “To Set up Primary Sweep” on page 1-18.

• For VAR2, refer to “To Set up Secondary Sweep” on page 1-19.

• For VAR1’, refer to “To Set up Synchronous Sweep” on page 1-20.

• For CONST, refer to “To Set up Constant Output” on page 1-21.

2. SMU PULSE: PERIOD

Enter the pulse period value.

3. SMU PULSE: WIDTH

Enter the pulse width value.

Meas front-panel

4. SMU PULSE: BASE

Enter the pulse base value.

You cannot change UNIT and NAME in this screen. To change the values, go to the

CHANNELS: CHANNEL DEFINITION screen.

1-22 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 41

Sweep Measurements

Defining Measurement Conditions

Pulse Parameters

The relation between the PERIOD, WIDTH, and BASE values are as shown in the

following figures.

SMU outputs the pulses as shown in figure (a) or figure (b).

• Figure (a)

When the function (FCTN) is set to VAR1, VAR2, or VAR1’.

The pulse peak values are the sweep output values calculated from the sweep

start, stop, step values, and so on.

• Figure (b)

When the function (FCTN) is set to CONST.

The pulse peak value is the output value of the constant output source.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-23

Page 42

Sweep Measurements

Defining Measurement Conditions

To Set up PGU Output

1. Define PGU to be VPULSE and CONST as described in “To Define

Measurement Units” on page 1-16.

2. Press

3. Select PGU SETUP primary softkey.

4. In the PERIOD field of PGU1, enter the pulse period value.

5. In the WIDTH field of desired PGU column, enter the pulse width value.

6. In the DELAY TIME field of desired PGU column, enter delay time value.

7. In the PEAK VALUE field of desired PGU column, enter pulse peak value.

8. In the BASE VALUE field of desired PGU column, enter pulse base value.

9. In the LEADING TIME field of desired PGU column, enter the leading-edge

10. In the TRAILING TIME field of desired PGU column, enter the trailing-edge

11. In the IMPEDANCE field of desired PGU column, select:

12. In the PULSE COUNT field, do one of the following:

Meas key in the PAGE CONTROL key group.

transition time.

transition time.

• LOW secondary softkey for approximately zero ohm output impedance.

• 50 ohm secondary softkey for 50 ohm output impedance.

• Select FREE RUN secondary softkey to force the pulse continuously.

• Or enter the number of pulses to output (for sampling measurement only).

For the pulse period and pulse count values, the values you set for PGU1 are also

used for PGU2. The following figure shows the relation between pulse waveform

and setup parameters.

1-24 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 43

Sweep Measurements

Defining Measurement Conditions

To modify the UNIT and NAME fields

Modify the UNIT and NAME fields on the CHANNELS: CHANNEL

DEFINITION screen.

Using PGUs as constant voltage source

To use a PGU as a constant voltage source, set the desired PGU as follows:

• V in MODE column on the CHANNEL DEFINITION screen

• Desired output voltage value in SOURCE field on MEASURE: PGU SETUP

screen.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-25

Page 44

Sweep Measurements

Defining Measurement Conditions

To Set up Stop Condition

1. Press Meas key in the PAGE CONTROL key group.

2. Move field pointer to SWEEP Status field.

3. Select one of the following softkeys:

CONT AT ANY Sweep will continue even if an abnormal status occurs. If

power compliance is set for an SMU, this softkey is not

displayed.

STOP AT ANY

ABNORM Sweep will stop if any abnormal status occurs.

STOP AT

COMPLIANCE Sweep will stop only if SMU reaches its compliance setting.

This is automatically set when power compliance is set for

SMUs, or when 10k ohm, 100k ohm, or 1M ohm is

selected in the SERIES RESISTANCE field.

Abnormal status means the following:

• SMU reaches its compliance setting.

• Current of VSU exceeds approximately ±100 mA.

• SMU or VSU oscillates.

• A/D converter overflow occurs.

• Average current of PGU exceeds ±100 mA.

1-26 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 45

Sweep Measurements

Defining Measurement Conditions

To Display Graphics Results

1. Press Display key in the PAGE CONTROL key group.

2. Select DISPLAY SETUP primary softkey.

3. In the DISPLAY MODE field, select GRAPHICS secondary softkey.

4. In the X axis column, enter variable name, select axis scale, and enter minimum

and maximum values.

5. In the Y1 axis column, enter variable name, select axis scale, and enter

minimum and maximum values.

6. If you use Y2 axis, enter variable name, select axis scale, and enter minimum

and maximum values in Y2 axis column.

When the pointer is in the NAME row, the allowable variable names appear in the

secondary softkey area. To set a variable name, select the desired secondary softkey.

The allowable names are names that you already set up on the CHANNEL

DEFINITION, USER FUNCTION, and USER VARIABLE screens.

To display a grid on the plotting area

In the GRID field, select ON to display or OFF to not display.

To display line parameters on the plotting area

In the LINE PARAMETER field, select ON to display or OFF to not display. Line

parameters are the X and Y intercepts and gradient of the analysis lines.

To display variables on the data variable area

In the DATA VARIABLES fields, select secondary softkey for desired variable. Up

to 2 variables can be displayed on the data variable area which is located between

the graph area and the marker area.

To change resolution of the data to be displayed

In the DATA DISPLAY RESOLUTION field, select NORMAL for the resolution

shown in the specifications, or EXTEND for the ADC full scale resolution. For

example, the data display resolution is 1 fA in NORMAL mode, and 10 aA in

EXTEND mode for 10 pA measurement range.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-27

Page 46

Sweep Measurements

Defining Measurement Conditions

To Display List Results

1. Press Display key in the PAGE CONTROL key group.

2. Select DISPLAY SETUP primary softkey.

3. In the DISPLAY MODE field, select LIST secondary softkey.

4. In the LIST area, select the secondary softkey of the variables for which you

want to list the measurement results.

When the pointer is in the NAME row, the allowable variable names appear in the

secondary softkey area. To set a variable name, select the desired secondary softkey.

The allowable names are names that you already set up on CHANNEL

DEFINITION, USER FUNCTION, and USER VARIABLE screens.

To display variables on the data variable area

In the DATA VARIABLES fields, select secondary softkey for desired variable. Up

to 2 variables can be displayed on the data variable area which is located below the

list area.

To change resolution of the data to be displayed

In the DATA DISPLAY RESOLUTION field, select NORMAL for the resolution

shown in the specifications, or EXTEND for the ADC full scale resolution. For

example, the data display resolution is 1 fA in NORMAL mode, and 10 aA in

EXTEND mode for 10 pA measurement range.

1-28 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 47

Sweep Measurements

Defining Measurement Conditions

To Execute or Stop Measurement

• To execute a measurement, press:

Single key in the MEASUREMENT key group for single measurement.

•

•

Repeat key in the MEASUREMENT key group for repeat measurement.

•

Append key in the MEASUREMENT key group for append measurement.

• To stop a measurement, press

Sto p key in the MEASUREMENT key group.

Single, Repeat, and Append Measurement

There are three measurement execution modes as follows:

Single

measurement Clears GRAPHICS or LIST screen, then executes measurement

one time. Measurement results are displayed on GRAPHICS or

LIST screen.

Repeat

measurement Executes measurements continuously. Before each

measurement is executed, the GRAPHICS or LIST screen is

cleared. Most recent measurement results are displayed on

GRAPHICS or LIST screen.

Append

measurement Executes measurement one time. Does not clear GRAPHICS or

LIST screen. That is, measurement results are added to the

existing results.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-29

Page 48

Sweep Measurements

Making a Measurement

Making a Measurement

In this section, you learn how to execute the measurements with an 4155C/4156C

and to display the measurement results graphically. Id-Vg measurement of a MOS

FET is provided as an example. You learn step-by-step how to perform this

measurement.

You measure the device under test (DUT) by using the measurement circuit as

shown in the following diagram. SMU2 and SMU3 sweep the same voltage to the

gate and drain. SMU3 measures the drain current (Id). The source and substrate are

connected to circuit common.

You should get result similar to the following figure. Gate voltage Vg (swept from

0 V to 2 V) is assigned to X axis, ÖId

assigned to Y2 axis.

is assigned to Y1 axis, and ¶ÖId / ¶Vg is

NOTE For accurate measurements, allow the 4155C/4156C to warm-up for a minimum of

40 minutes after you turn on the instrument, and then execute calibration. For the

self-calibration, see Chapter 7.

1-30 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 49

Sweep Measurements

Making a Measurement

Step 1. Prepare for the measurement

Before executing measurement, configure the 4155C/4156C and accessories.

1. Make sure that the 4155C/4156C is off.

2. Connect the 16442A test fixture to the 4155C/4156C. See figure below.

3. If you use the keyboard, connect it to the 4155C/4156C.

Connection between 4156C and 16442A:

16442A

Kelvin Triaxial Cables

Coaxial Cables

Interlock/LED Cable

4156

4156C cable 16442A 4156C cable 16442A

Intlk

SMU 1

SMU 2

SMU 3

Interlock/LED

Kelvin triaxial

Kelvin triaxial

Kelvin triaxial

a

Intlk VSU 1

c

SMU 1 VSU 2

c

SMU 2 VMU 1

c

SMU 3 VMU 2

Coaxial

Coaxial

Coaxial

Coaxial

b

VSU 1

b

VSU 2

b

VMU 1

b

VMU 2

a. Interlock/LED cable: Agilent 16493J

b. Coaxial cable: Agilent 16493B. You do not need to connect VSUs and

VMUs for this measurement.

c. Kelvin triaxial cable: Agilent 16493K

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-31

Page 50

Sweep Measurements

Making a Measurement

Connection between 4155C and 16442A:

Triaxial Cables

16442A

Coaxial Cables

Interlock/LED Cable

4155

4155C cable 16442A 4155C cable 16442A

a

Intlk

SMU 1

Interlock/LED

Triaxial

b

Intlk

SMU 1

VSU 1

Coaxial

c

VSU 1

(blue label)

SMU 2

Triaxial

b

SMU 2

VSU 2

Coaxial

c

VSU 2

(blue label)

SMU 3

Triaxial

b

SMU 3

VMU 1

Coaxial

c

VMU 1

(blue label)

SMU 4

Triaxial

b

SMU 4

VMU 2

Coaxial

c

VMU 2

(blue label)

a. Interlock/LED cable: Agilent 16493J

b. Triaxial cable: Agilent 16493C. You do not need to connect SMU4 for

this measurement.

c. Coaxial cable: Agilent 16493B. You do not need to connect VSUs and

VMUs for this measurement.

1-32 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 51

Sweep Measurements

Making a Measurement

Step 2. Mount your DUT on the test fixture

1. Select a suitable socket module for your DUT.

2. Mount the socket module on the test fixture.

3. Mount your DUT on the socket module.

4. Make connections with four connection cables (miniature banana to pin plug).

You make the following connections:

• Source to SMU1

• Gate to SMU2

• Drain to SMU3

• Substrate to SMU1

Both the source and substrate terminals are connected to SMU1.

5. After finishing connections, shut the lid of the test fixture.

Agilent 4155C/4156C User’s Guide Vol.2, Edition 1 1-33

Page 52

Sweep Measurements

Making a Measurement

Wiring for the 4156C

For this measurement, non-Kelvin connections are used. So, connect only the force

terminals as shown in the following figure:

Wiring for the 4155C

1-34 Agilent 4155C/4156C User’s Guide Vol.2, Edition 1

Page 53

Sweep Measurements

Making a Measurement