GPIB Command Reference

Agilent 4155C Semiconductor Parameter Analyzer

Agilent 4156C Precision Semiconductor Parameter Analyzer

Agilent Part No. 04156-90050

Printed in Japan January 2001

Edition 1

Legal Notice

The information contained in this document is subject to change without notice.

Copyright © 2001 Agilent Technologies

This document contains information which is protected by copyright. All rights are

reserved. Reproduction, adaptation, or translation without prior written permission

is prohibited, except as allowed under the copyright laws.

• Product Warranty

Agilent Technologies warrant Agilent Technologies hardware, accessories and

supplies against defects in materials and workmanship for the period of one year

from the warranty start date specified below. If Agilent Technologies receive

notice of such defects during the warranty period, Agilent Technologies will, at

its option, either repair or replace products which prove to be defective.

Replacement products may be either new or like-new.

Warranty service of this product will be performed at Agilent Technologies.

Buyer shall prepay shipping charges to Agilent Technologies and Agilent

Technologies shall pay shipping charges to return the product to Buyer.

However, Buyer shall pay all shipping charges, duties, and taxes for products

returned to Agilent Technologies from another country.

Agilent Technologies do not warrant that the operation of Agilent Technologies

products will be uninterrupted or error free. If Agilent is unable, within a

reasonable time, to repair or replace any product to a condition as warranted,

customer will be entitled to a refund of the purchase price upon prompt return of

the product.

The Agilent Technologies products may contain remanufactured parts

equivalent to new in performance or may have been subject to incidental use.

The warranty period begins on the date of delivery or on the date of installation

if installed by Agilent Technologies. If customer schedules or delays Agilent

Technologies installation more than 30 days after delivery, warranty begins on

the 31st day from delivery.

Warranty does not apply to defects resulting from (a) improper or inadequate

maintenance or calibration, (b) software, interfacing, parts or supplies not

supplied by Agilent Technologies, (c) unauthorized modification or misuse, (d)

operation outside of the published environmental specifications for the product,

or (e) improper site preparation or maintenance.

2 Agilent 4155C/4156C GPIB Command Reference, Edition 1

To the extent allowed by local law, the above warranties are exclusive and no

other warranty or condition, whether written or oral, is expressed or implied and

Agilent Technologies specifically disclaim any implied warranties or conditions

of merchantability, satisfactory quality, and fitness for a particular purpose.

Agilent Technologies will be liable for damage to tangible property per incident

up to the greater of $300,000 or the actual amount paid for the product that is the

subject of the claim, and for damages for bodily injury or death, to the extent

that all such damages are determined by a court of competent jurisdiction to

have been directly caused by a defective Agilent Technologies product.

To the extent allowed by local law, the remedies in this warranty statement are

customer’s sole and exclusive remedies. Expect as indicated above, in no event

will Agilent Technologies or its suppliers be liable for loss of date or for direct,

special, incidental, consequential (including lost profit or date), or other damage,

whether based in contract, tort, or otherwise.

For consumer transactions in Australia and New Zealand: the warranty terms

contained in this statement, except to the extent lawfully permitted, do not

exclude, restrict or modify and are in addition to the mandatory statutory rights

applicable to the sale of this product to you.

• Assistance

Product maintenance agreements and other customer assistance agreements are

available for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales Office.

• Certification

Agilent Technologies Inc. certifies that this product met its published

specifications at the time of shipment from the factory. Agilent further certifies

that its calibration measurements are traceable to the National Institute of

Standards and Technology (NIST), to the extent allowed by the Institute’s

calibration facility, and to the calibration facilities of other International

Standards Organization members.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 3

Printing History

Edition 1: January 2001

Microsoft, Windows, MS-DOS and Excel are registered trademarks of Microsoft Corporation.

NFS is a trademark of Sun Microsystems, Inc.

4 Agilent 4155C/4156C GPIB Command Reference, Edition 1

In This Manual

Agilent 4155C/4156C provides three command modes to control the 4155C/4156C

via GPIB interface. You can control the 4155C/4156C using one of the following

command modes.

• 4155/4156 SCPI command mode

SCPI means Standard Commands for Programmable Instruments. This mode is

the default mode of the 4155C/4156C, and allows you to control the 4155C/

4156C functions except for the timestamp, search, and the enhanced stop

condition the FLEX mode supports.

• 4155/4156 FLEX command mode

FLEX means Fast Language for EXecution. This mode allows you to control

measurement functions of the 4155C/4156C. Command execution is faster than

the SCPI command mode.

• 4145 syntax command mode

This mode allows you to execute the 4145A/B programs on the 4155C/4156C

directly with little or no modification. In this command mode, you cannot

control all functions of the 4155C/4156C.

To confirm the present control mode, see the language mode indicator on the screen,

or enter the CMD? command.

Language indicator The indicator is located between the fourth primary softkey and

the fifth primary softkey, and next to the screen lock indicator.

The meaning of the indicator is as follows:

S: SCPI command mode

F: FLEX command mode

4: 4145 syntax command mode

CMD? command This query command returns the present command mode. The

response is as follows:

0: SCPI command mode

1: FLEX command mode

2: 4145 syntax command mode

This command is effective for all command mode.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 5

This manual describes about the 4155C/4156C FLEX command set and the 4145

syntax command set, and consists of the following chapters:

• 4155C/4156C FLEX Commands

Lists the 4155C/4156C FLEX commands, and provides description, command

syntax, example statements, and so on. Also provides the command input

format, data output format, status byte information and error messages.

• 4145B Syntax Commmand Set

Lists the 4145 Syntax commands, and provides description, command syntax,

example statements, and so on. Also provides the general conventions,

differences from the 4145A/B commands and status byte information.

For information about the 4155C/4156C SCPI command set, refer to SCPI

Command Reference.

See User's Guide Measurement and Analysis and User's Guide General Information

for information about the 4155C/4156C itself.

Refer to Programmer's Guide to make a program and use built-in Instrument

BASIC controller.

NOTE 4155C/4156C FLEX command set

The 4155C/4156C FLEX command set includes some commands which have the

same name as the GPIB command of Agilent 4142B DC Source/Monitor. This is

useful for you who create the 4155C/4156C measurement program by modifying

the program created to control the 4142B.

However the 4155C/4156C commands are not fully compatible with the 4142B

commands. So you need to do some modifications on the measurement program for

the 4142B.

6 Agilent 4155C/4156C GPIB Command Reference, Edition 1

Contents

1. 4155C/4156C FLEX Commands

Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

US/US42 Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

To Quit FLEX Command Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

To Use 4142B Measurement Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Command Input Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Header. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Numeric Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Special Terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Data Output Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Time Stamp Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

ASCII Format in US Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Binary Format in US Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

ASCII Format in US42 Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Binary Format in US42 Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Status Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

AB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-48

ACH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-50

AV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-52

AZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-53

BC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-54

BGI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-55

BGV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

BSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-61

BSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-64

BSSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-66

BSSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-68

Agilent 4155C/4156C GPIB Command Reference, Edition 1 Contents-1

Contents

BST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-70

BSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-71

BSVM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-74

CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-75

*CAL? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-76

CL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-77

CLOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-79

*CLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-80

CM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-81

CMD?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-82

CMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-83

CN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-84

DI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-86

DO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-89

DV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-90

DZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-93

END . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-95

ERR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-96

ESC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-97

*ESE(?) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-100

*ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-102

FL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-103

FMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-104

GOC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-106

*IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-108

IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-109

LGI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-111

LGV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-113

LOP? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-115

*LRN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-118

LSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-125

LSSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-128

Contents-2 Agilent 4155C/4156C GPIB Command Reference, Edition 1

Contents

LSSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-130

LST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-132

LSTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-134

LSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-135

LSVM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-138

MCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-139

MI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-140

MM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-143

MP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-146

MSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-149

MT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-151

MV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-152

NUB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-155

*OPC(?) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-156

OPEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-157

*OPT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-158

OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-159

PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-160

PI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-161

POR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-164

PRN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-165

PT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-166

PV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-168

PWI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-171

PWV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-175

QSL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-179

QSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-180

QSR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-182

QST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-183

QSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-185

QSZ/QSZ? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-191

RBC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-192

Agilent 4155C/4156C GPIB Command Reference, Edition 1 Contents-3

Contents

RCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-193

RD? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-194

RI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-195

RMD? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-201

*RST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-202

RU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-203

RV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-204

RZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-209

SCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-210

SDSK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-211

SIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-212

SLI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-213

SOC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-214

SPG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-215

SPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-218

SPP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-219

SPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-220

*SRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-221

*SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-222

SRP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-223

SSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-224

ST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-225

*STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-227

STC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-228

STG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-229

STI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-230

STM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-234

STP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-235

STT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-238

STV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-240

:SYST:ERR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-243

TDI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-244

Contents-4 Agilent 4155C/4156C GPIB Command Reference, Edition 1

Contents

TDV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-248

TI/TI? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-251

TM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-253

TSC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-254

TSQ?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-255

TSR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-256

*TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-257

TTI/TTI? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-259

TTV/TTV? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-262

TV/TV? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-265

UNT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-267

VM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-268

VMD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-269

*WAI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-270

WI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-271

WM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-275

WNU? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-277

WR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-278

WS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-279

WSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-280

WSV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-283

WT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-286

WV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-287

XE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-291

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-292

2. 4145B Syntax Command Set

General Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Command Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Changing the Command Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Command and Screens for System Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Agilent 4155C/4156C GPIB Command Reference, Edition 1 Contents-5

Contents

Parameter Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

String Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Real Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Semicolons and <whitespace>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Invalid Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

4145B Syntax Mode Status Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Differences from 4145A/B Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Non-supported Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Differences on Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Running 4145A/B Program Directly on 4155C/4156C . . . . . . . . . . . . . . . . . . . 2-11

Spot Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Sweep Steps in Logarithmic Step Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

System Mode Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

AS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

CH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

DE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

DM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

DO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

DT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

GL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

GT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

HT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

IR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

LI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

MD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Contents-6 Agilent 4155C/4156C GPIB Command Reference, Edition 1

Contents

ME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

MX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

NR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

PR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

RT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

SC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

SH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

SM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

SS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

SV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

VC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

VM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

VP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

VR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

VS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

WT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

XN, YA, YB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

XT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

User Mode Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

DI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

DS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

DV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

GL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

TI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

TV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

HP-GL Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

Common Mode Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

BC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

CMD? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

Agilent 4155C/4156C GPIB Command Reference, Edition 1 Contents-7

Contents

DL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

DP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

DR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

EI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

IT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

PF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-72

PL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-73

SF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

Contents-8 Agilent 4155C/4156C GPIB Command Reference, Edition 1

1 4155C/4156C FLEX Commands

Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

This chapter provides the following information:

•“Control Mode”

•“Command Input Format”

•“Data Output Format”

•“Status Byte”

•“Command Reference”

•“Error Messages”

1-2 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

Control Mode

To use the 4155C/4156C FLEX commands, enter the US or US42 command when

the 4155C/4156C is in one of the following state. This command causes the

4155C/4156C control mode transition.

• Power on state

• Interactive operation mode (normal operation mode, which is not GPIB control

mode)

• 4155C/4156C SCPI command control mode

The control mode transition resets the 4155C/4156C settings. For the initial settings

in the FLEX command control mode, see the *RST command in the “Command

Reference” section in this chapter.

In the FLEX command control mode, you can use the all commands described in

this chapter, and the SCPI commands and the 4145A/B syntax commands are not

available.

If you use the built-in IBASIC controller, use the full IBASIC screen. All front panel

keys except for the following keys are available.

• MEASUREMENT key group

•

Plot/Print key

•

Save and Get keys

• IBASIC

Display key

If you use an external controller, the screen and front panel keys on the

4155C/4156C front panel are not available. Only the LOCAL secondary softkey is

available. This softkey is used to release the remote control state of the

4155C/4156C.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1- 3

4155C/4156C FLEX Commands

US/US42 Command

US/US42 Command

Syntax, command parameters, and example statements for the US and US42

command are shown below.

Difference between US command and US42 command is that the US42 command

provides the 4142B DC Source/Monitor-like response for the following items:

• Output data format

• Query response

• Status code (status byte)

Syntax Syntax of US command:

US

Syntax of US42 command:

US42[level]

Parameters level Support level for the 4142B-like response. Must be an integer. Refer to

the following table. If you do not specify this parameter, level is set to

255 (1+2+4+8+16+32+64+128). This means all levels are selected.

Example

Statements

If you select multiple levels, enter a value that is the sum of the desired

level values. For example, if you select levels 1, 2 and 4, enter 7

(1+2+4) as the level value.

OUTPUT @Hp4156;"US"

OUTPUT @Hp4156;"US42"

OUTPUT @Hp4156;"US42 15"

1-4 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

To Quit FLEX Command Mode

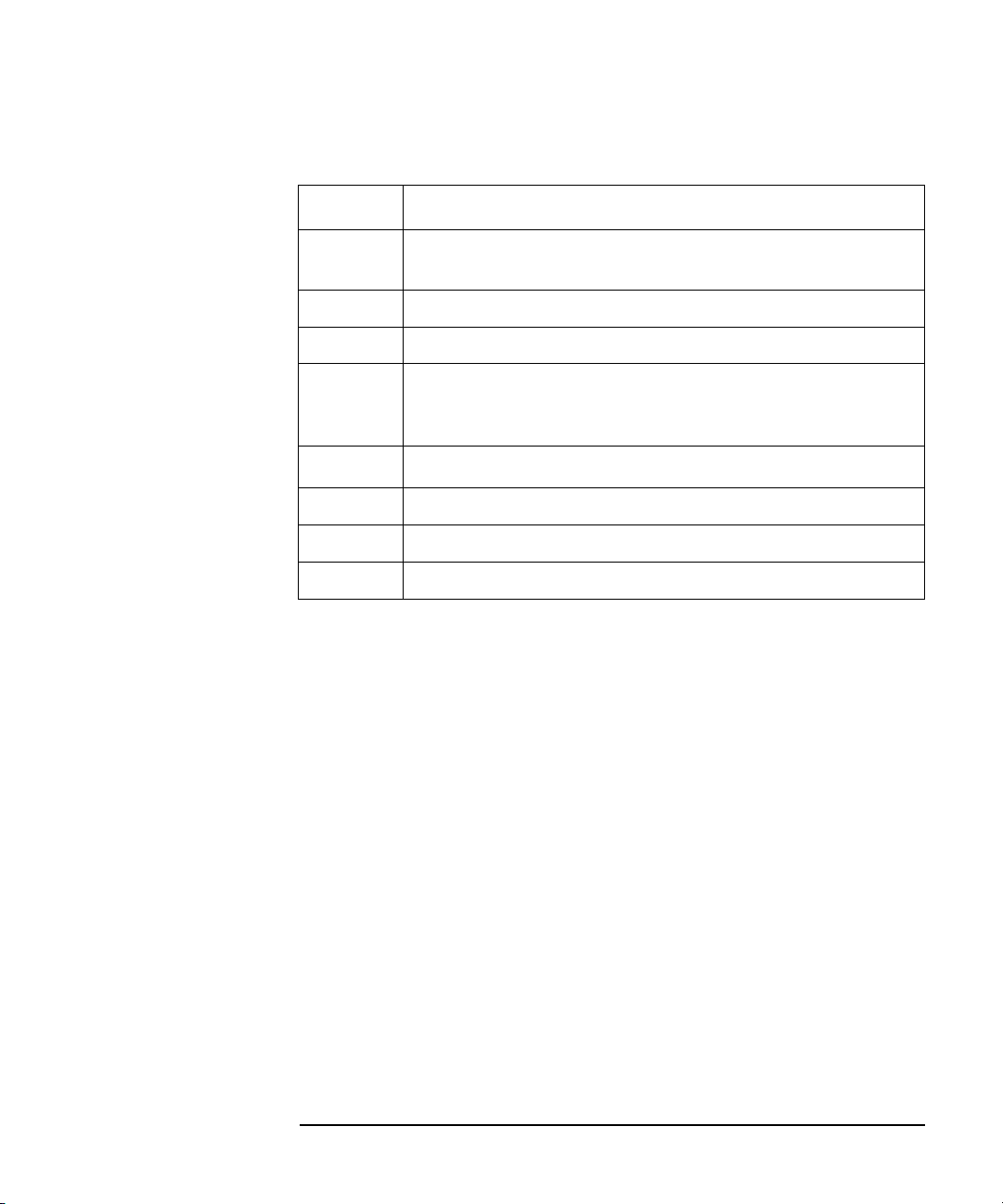

level Description

1 Supports the 4142B-like data output format. (FMT command

allows you to select data output format.)

2 Supports the 4142B-like status code (status byte).

4 Supports the 4142B-like query response.

8 Supports the 4142B-like GNDU, VMU output switch setting.

(GNDU and VMU output switches are set to ON after executing

the CL command without specifying channel number.)

16

32 Not defined.

64 Not defined.

128 Not defined.

a. Without level=16, you need to enter the RMD? command before enter-

ing the command (ex; ENTER (HP BASIC) command) to read the output data. If you select level=16, you do not need the RMD? command.

But you cannot read the output data correctly if both output data and

query response are in the 4155C/4156C output buffer.

Reads output data without RMD? command.

a

To Quit FLEX Command Mode

To quit the FLEX command control mode, do one of the following:

• Enter the :PAGE command (ex: OUTPUT @Hp415x;":PAGE")

• Enter the LOCAL (HP BASIC) command

• If you use an external controller: Select the LOCAL secondary softkey

displayed on the 4155C/4156C screen.

• If you use the built-in IBASIC controller: Press any key in the PAGE

CONTROL key group.

The control mode transition resets the 4155C/4156C settings except for the auto

calibration mode setting. Auto calibration is set to OFF forcibly.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1- 5

4155C/4156C FLEX Commands

To Use 4142B Measurement Program

To Use 4142B Measurement Program

If you want to use the measurement program created to control Agilent 4142B

Modular DC Source/Monitor, remember the following precautions. You need to

modify the measurement program.

• Command syntax:

The 4155C/4156C FLEX commands need a space between the command and its

command parameter. The 4142B commands do not need a space.

Add a space between the command and the first command parameter as shown

in the following example:

• For 4142B:

OUTPUT @Hp4142;"DV1,0,20" !Applies 20V

• For 4155C/4156C:

OUTPUT @Hp4156;"DV 1,0,20" !Applies 20V

• Reading output data:

To read the 4155C/4156C output data after a measurement, use the RMD?

command as shown in the following example:

• For 4142B:

OUTPUT @Hp4142;"XE" !Executes measurements

ENTER @Hp4142;A$ !Reads measurement data

• For 4155C/4156C:

OUTPUT @Hp4156;"XE" !Executes measurements

OUTPUT @Hp4156;"RMD?" !Puts data on the output buffer

ENTER @Hp4156;A$ !Reads measurement data

If you select level=16 for the US42 command parameter, you do not need the

RMD? command before the ENTER command on this example. But you cannot

read the output data correctly if both output data and query response are in the

4155C/4156C output buffer.

1-6 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

To Use 4142B Measurement Program

• Command parameters:

For the 4155C/4156C FLEX commands which have the same name as the

4142B commands, such as DV and DI, the meaning and order of most

parameters are the same as the 4142B commands. However, the values available

for the command parameter will be different from the 4142B control command

because of the difference in measurement performance. Also, some optional

command parameters may be added.

Confirm the command parameters and the available values.

• Measurement unit channel numbers:

The channel numbers of the measurement units must be changed. To change the

channel numbers, use the ACH command. The ACH command translates the

channel numbers for the 4142B to the channel numbers for the 4155C/4156C.

For details, see the ACH command in the “Command Reference” section in this

chapter.

• Unsupported commands:

The following 4142B commands are not supported by the 4155C/4156C.

AIV, ASM, ASV, AVI, BDM, BDT, BDV, ERC,

PDI, PDM, PDV, POL

• Multiple command strings

The 4155C/4156C FLEX command mode does not support the multiple

command strings such as the following example. Do not enter the multiple

command strings.

OUTPUT @Hp415x;"CN 1;DV 1,0,5;MM 1,1"

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1- 7

4155C/4156C FLEX Commands

Header

Command Input Format

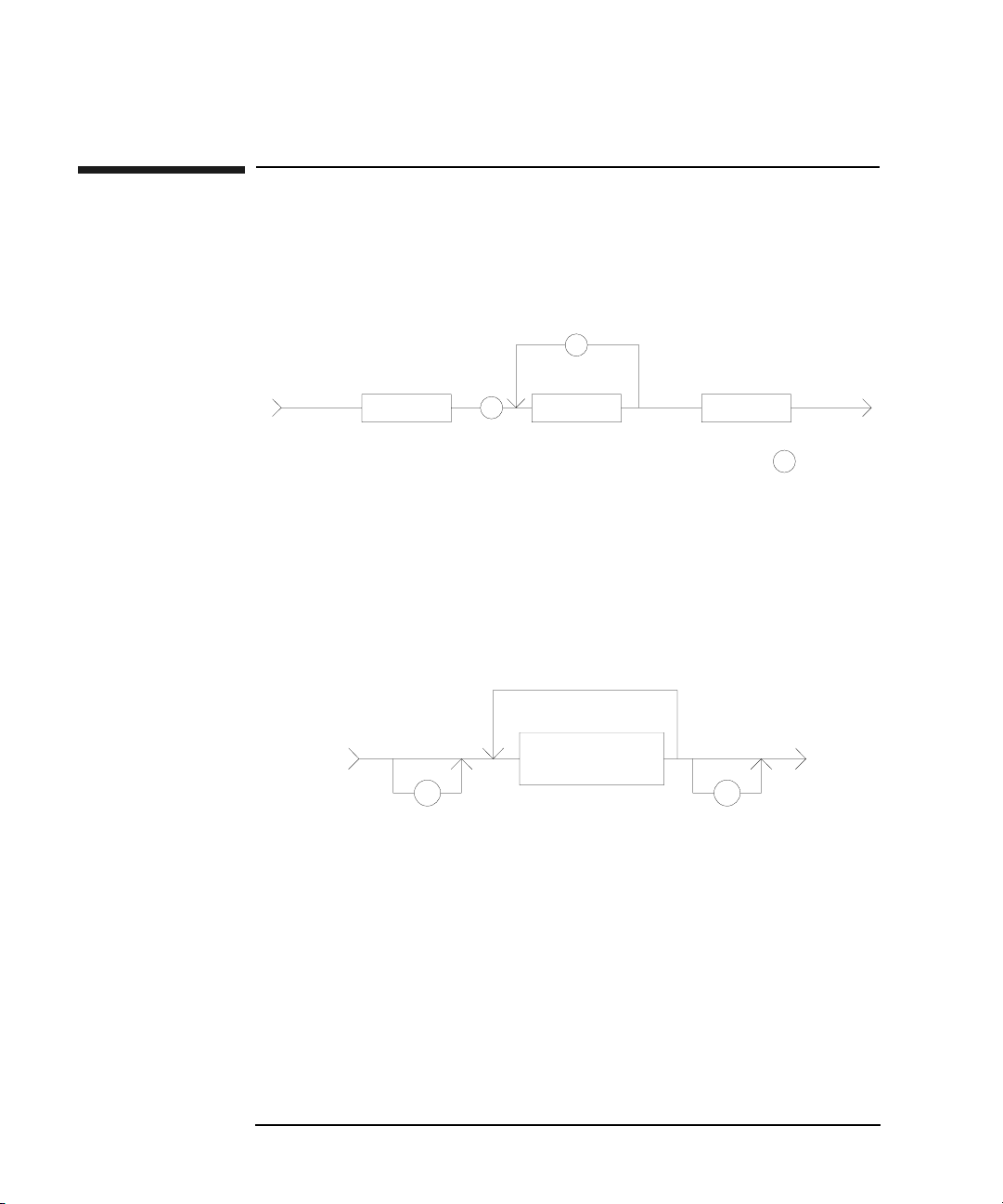

The 4155C/4156C FLEX commands are composed of a header, numeric data, and

terminator, as shown in the syntax diagram in the following figure.

4155C/4156C Control Command Syntax Diagram

Header

The header is the command name, always contains alpha characters, and is not

upper or lowercase sensitive. Some command names also contain an asterisk (*) or

question mark (?). The following figure shows the syntax diagram for a header.

Header Syntax Diagram

1-8 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

Numeric Data

Numeric Data

Numeric data is the command parameters. You need to insert a space between the

header and the command parameters (numeric data). Some parameters require

integer data. The following figure shows the syntax diagram for numeric data.

Numeric Data Syntax Diagram

The following 3 figures show the syntax diagrams for integer, fixed point, and

floating point data, respectively.

Integer Data Syntax Diagram

Fixed Point Data Syntax Diagram

Floating Point Data Syntax Diagram

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1- 9

4155C/4156C FLEX Commands

Terminator

Terminator

The terminator completes the GPIB command entry and starts command execution.

The following figure shows the terminator syntax diagram.

Terminator Syntax Diagram

%4

.(

.(

'1+

(

Special Terminator

If a semicolon (;) is inserted before the terminator, as shown in the following figure,

the preceding commands are not executed until the next command line is input and

another terminator is input, without a preceding semicolon. The command lines are

then executed together.

Special Terminator

%4

.(

.(

'1+

@

1-10 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

Conventions

Data Output Format

This section describes the data output formats of the 4155C/4156C. The

4155C/4156C provides the following four types of data output formats:

•“ASCII Format in US Mode”

•“Binary Format in US Mode”

•“ASCII Format in US42 Mode”

•“Binary Format in US42 Mode”

You can select the data output format using the FMT command. See the FMT

command for more information.

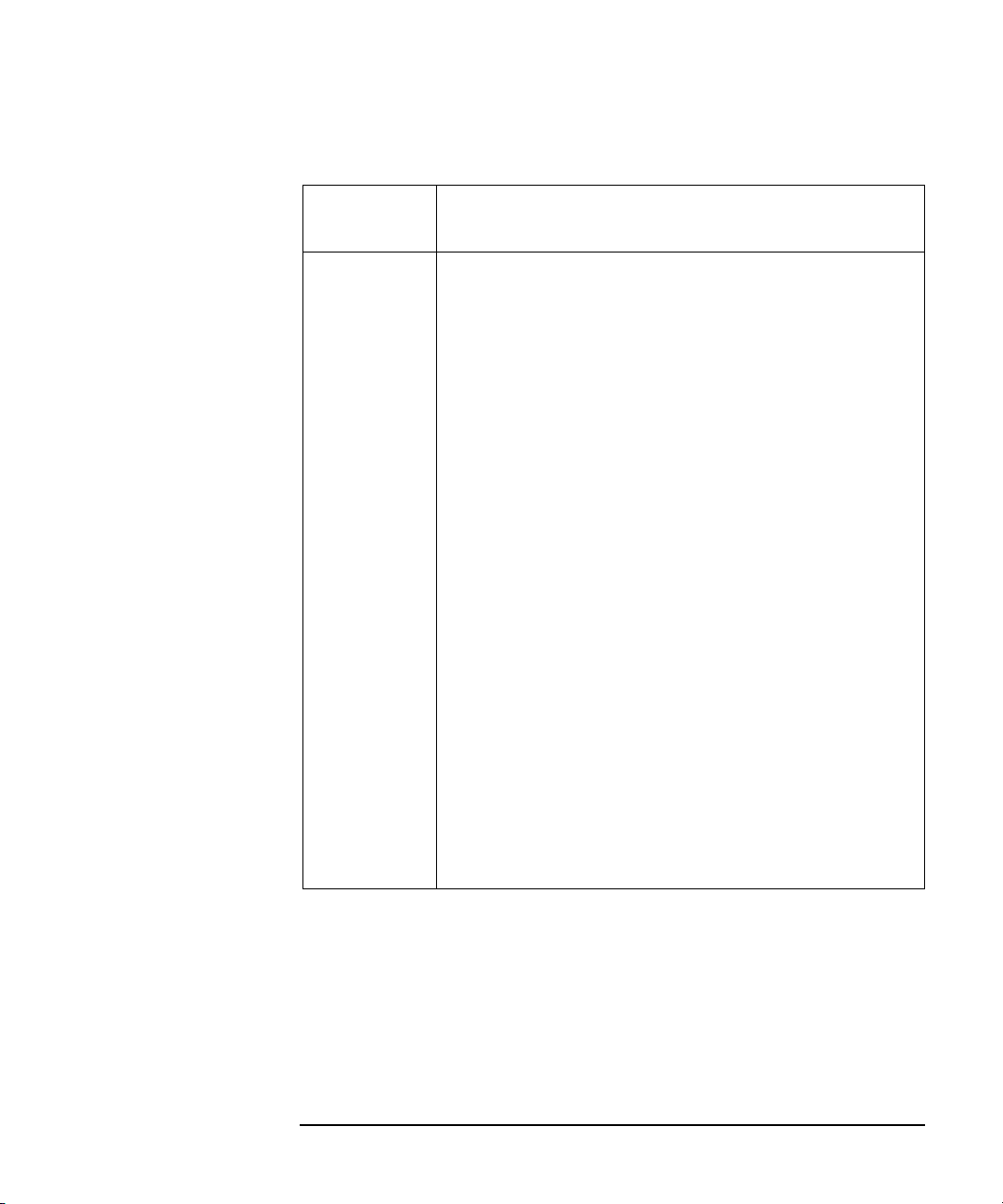

Conventions

The following conventions are used in the data output format tables (Table 1-1

through Table 1-4).

Data Output data that the 4155C/4156C sends after a measurement.

[Data] Optional output data that is sent when there are multiple output

data. See FMT command. For example, after the sampling

measurements when the sampling point index output is

specified by the FMT command.

Time Stamp Function

The time stamp function is used to record the start time of the measurement. When

this function is enabled, the 4155C/4156C output data includes the time data (Time).

For example, in the staircase sweep measurements, the output data will be as

follows:

Block1 [,Block2] . . . . <terminator>

where, BlockN (N: integer) = Time1,Data1 [,Time2,Data2] ... [,Source_data]

TimeN (N: integer) is the time from the point the count is cleared until the start of the

DataN measurement.

The time stamp function is not available for the quasi-static CV measurements,

linear search measurements, and binary search measurements in the US control

mode. It is not available for any measurement in the US42 control mode.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-11

4155C/4156C FLEX Commands

ASCII Format in US Mode

ASCII Format in US Mode

Table 1-1 shows the ASCII data output format in control mode set by the US

command. The format used depends on the measurement mode selected.

Table 1-1 ASCII Data Output Format in US Control Mode

Measurement Mode Output Format

Stress Force

High Speed Spot

Spot

1ch Pulsed Spot

Staircase Sweep,

Pulsed Sweep,

Staircase Sweep with

Pulsed Bias

Status <terminator>

a

Status is the status information sent after a stress force.

Data <terminator>

a

Data is the data measured by the measurement unit

specified for the high speed spot measurement using the

MM command.

Data1 [,Data2] . . . . <terminator>

a

DataN (N: integer) is the data measured by one unit.

The order of Data is specified by the MM command.

Data <terminator>

a

Data is the data measured by the measurement unit

specified for the pulsed spot measurement using the

MM command.

Block1 [,Block2] ....<terminator>

a

Block1 is the block of data measured at the first sweep

step. Block2 is the block of data measured at the second

sweep step.

where Block consists of the following data:

Data1 [,Data2]....[,Source_data]

DataN (N: integer) is the data measured by one unit.

The order of Data is specified by the MM command.

Source_data is the source data at the sweep step.

a. Terminator. <LF^EOI> or <,^EOI>, depending on the FMT command

parameter. See FMT command.

1-12 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

ASCII Format in US Mode

Measurement

Mode

Sampling

Output Format

Block1 [,Block2] . . . . <terminator>

a

Block1 is the block of the data measured at the first sampling

point.

Block2 is the block of the data measured at the second

sampling point.

where Block consists of the following data:

[Sampling_no,] Data1 [,Data2] . . . .

Sampling_no is the sampling point index. This value depends

on the sampling interval setting and the measurement time.

If the measurement time is shorter than the sampling interval,

Sampling_no will be N of BlockN (N: 1, 2, 3 . . . ).

If the measurement time is longer than the sampling interval,

Sampling_no is not N of BlockN.

For example, if the measurement time is longer than the

sampling interval and shorter than twice the sampling interval,

then the Sampling_no is 2 for Block1, and 4 for Block2.

The measurement time depends on the settings of the AV, AZ,

SIT and SLI commands.

DataN (N: integer) is the data measured by one unit. The order

of Data is specified by the MM command.

The Sampling_no and Data values can be discarded when the

range changes in the auto or limited auto ranging mode.

a. Terminator. <LF^EOI> or <,^EOI>, depending on the FMT command

parameter. See FMT command.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-13

4155C/4156C FLEX Commands

ASCII Format in US Mode

Measurement Mode Output Format

Quasi-static CV

Linear search,

Binary search

Block1 [,Block2] ....<terminator>

a

Block1 is the data of the first measurement point.

Block2 is the data of the second point.

where Block consists of the following data:

[DataL,] DataC [,Source_data]

DataL is the leakage current measurement data.

DataC is the capacitance measurement data.

Source_data is the source output voltage.

DataL is set by the QSL command.

[D1,D2 . . . ,] Search,Source_data,Data <terminator>

Search is the search status. Source_data is the source

output data of the search target.

Data is the measurement data of the search target.

D1 is the data of the first measurement point.

D2 is the data of the second point.

where Dn (n: integer) consists of the following data:

Source_data,Data

Source_data is the source output data.

Data is the measurement data.

a

Dn is set by the BSVM command for the binary search,

or LSVM command for the linear search.

a. Terminator. <LF^EOI> or <,^EOI>, depending on the FMT command

parameter. See FMT command.

1-14 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

ASCII Format in US Mode

Output Data The 4155C/4156C sends the measurement data (Data), source output data

(Source_data), sampling point index (Sampling_no), time data (Time) or status

information (Search or Status) in the format specified by the FMT 1, FMT 2, or

FMT 5 command.

• ASCII format with header (output by FMT 1 or FMT 5):

AAABCDDDDDDDDDDDDD

• ASCII format without header (output by FMT 2):

DDDDDDDDDDDDD

where,

A: Status.

B: Channel number.

C: Data type.

D: Data.

NOTE For Sampling_no, ignore B.

For Time, ignore A.

For Search, ignore A and B.

For Status, ignore B and D.

They are not valid for the output data.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-15

4155C/4156C FLEX Commands

ASCII Format in US Mode

The A, B, C, and D values are explained below.

A : Status; 3 digits.

• Status for Source_data:

AAA Explanation

W Data is for the first or intermediate sweep step.

E Data is for the last sweep step.

• Status for Data, Sampling_no, or Status:

AAA Explanation

1 A/D converter overflowed.

2 One or more units are oscillating.

4 Another unit reached its compliance setting.

8 This unit reached its compliance setting.

Integration time too short for capacitance measurement.

16 The PGU reached its compliance setting.

32 The sweep measurement was stopped by the ESC stop

condition. Returned data is effective.

64 Invalid data is returned. D is not used.

128 EOD (End of Data).

If multiple status conditions are found, the sum of the AAA values is

returned. For example, if an A/D converter overflow occurred, and

an SMU was oscillating during the measurements, the returned AAA

value is 3 (1 + 2).

1-16 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

ASCII Format in US Mode

B : Channel number of the measurement/source unit; 1 digit.

B Explanation

A Channel number 1, SMU1.

B Channel number 2, SMU2.

C Channel number 3, SMU3.

D Channel number 4, SMU4.

E Channel number 5, SMU5 (in 41501A/B).

F Channel number 6, SMU6 (in 41501A/B).

Q Channel number 21, VSU1.

R Channel number 22, VSU2.

S Channel number 23, VMU1.

T Channel number 24, VMU2.

V Channel number 26, GNDU (in 41501A/B).

W Channel number 27, PGU1 (in 41501A/B).

X Channel number 28, PGU2 (in 41501A/B).

Z Returned D value is not measurement data.

C : Data type; 1 digit.

C Explanation

V Voltage measurement data (Data).

v Voltage source setup data (Setup_data).

I Current measurement data (Data).

i Current source setup data (Setup_data).

C Capacitance measurement data (Data).

p Sampling point index (Sampling_no).

T Time data (Time).

S Status information (Search or Status).

Z Invalid data is returned.

z

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-17

4155C/4156C FLEX Commands

ASCII Format in US Mode

D : Data; 13 digits.

Value of Data, Source_data, Sampling_no, and Time may be one of the

following:

• sn.nnnnnnEsnn

• snn.nnnnnEsnn

• snnn.nnnnEsnn

where,

s: Sign, + or -.

n: Digit, 0 to 9.

E: Exponent symbol.

Value of Search:

D Description

0 No error.

1 Measurement aborted, but cannot specify the reason. Ignore

Source_data and Data.

10 No target found in the specified search range of the binary

search. Data at the start or stop near the target value is set to

Source_data and Data.

11 No target found in the limit mode binary search. The last

search data is set to Source_data and Data.

12 Over-range at the synchronous output channel in the binary

search. Ignore Source_data and Data.

20 No target found in the linear search. Ignore Source_data

and Data.

21 Over-range at the synchronous output channel in the linear

search. Ignore Source_data and Data.

22 Abort condition occurred in the linear search. Ignore

Source_data and Data. The status of the Data is AAA=192.

In all data output modes (LSVM 1), the status code is set to

the status of the last measurement data.

The abort condition is set by the WM command.

1-18 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

Binary Format in US Mode

Table 1-2 shows the binary data output format in control mode set by the US

command. The format used depends on the measurement mode selected.

Table 1-2 Binary Data Output Format in US Control Mode

Measurement Mode Output Format

Binary Format in US Mode

Stress Force

High Speed Spot

Spot

1ch Pulsed Spot

Staircase Sweep,

Pulsed Sweep,

Staircase Sweep with

Pulsed Bias

Status <terminator>

a

Status is the status information sent after a stress force.

Data <terminator>

a

Data is the data measured by the measurement unit

specified for the high speed spot measurement using

the MM command.

Data1 [Data2] . . . . <terminator>

a

DataN (N: integer) is the data measured by one unit.

The order of Data is specified by the MM command.

Data <terminator>

a

Data is the data measured by the measurement unit

specified for the pulsed spot measurement using the

MM command.

Block1 [Block2] . . . . <terminator>

a

Block1 is the block of data measured at the first sweep

step. Block2 is the block of data measured at the second

sweep step.

where Block consists of the following data:

Data1 [Data2] . . . . [Source_data]

DataN (N: integer) is the data measured by one unit.

The order of Data is specified by the MM command.

Source_data is the source data at the sweep step.

a. Terminator. <LF^EOI> or <,^EOI>, depending on the FMT command

parameter. See FMT command.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-19

4155C/4156C FLEX Commands

Binary Format in US Mode

Measurement Mode Output Format

Sampling

Block1 [Block2] . . . . <terminator>

a

Block1 is the block of the data measured at the first

sampling point.

Block2 is the block of the data measured at the second

sampling point.

where Block consists of the following data:

[Sampling_no] Data1 [Data2] . . . .

Sampling_no is the sampling point index. This value

depends on the sampling interval setting and the

measurement time.

If the measurement time is shorter than the sampling

interval, Sampling_no will be N of BlockN (N: 1, 2, 3

. . . ).

If the measurement time is longer than the sampling

interval, Sampling_no is not N of BlockN.

For example, if the measurement time is longer than

the sampling interval and shorter than twice the

sampling interval, then the Sampling_no is 2 for

Block1, and 4 for Block2.

The measurement time depends on the settings of the

AV, AZ, SIT and SLI commands.

DataN (N: integer) is the data measured by one unit.

The order of Data is specified by the MM command.

The Sampling_no and Data values can be discarded

when the range changes in the auto or limited auto

ranging mode.

a. Terminator. <LF^EOI> or <,^EOI>, depending on the FMT command

parameter. See FMT command.

1-20 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

Binary Format in US Mode

Measurement Mode Output Format

Quasi-static CV

Linear search,

Binary search

Block1 [Block2] . . . . <terminator>

a

Block1 is the data of the first measurement point.

Block2 is the data of the second point.

where Block consists of the following data:

[DataL,] DataC [,Source_data]

DataL is the leakage current measurement data.

DataC is the capacitance measurement data.

Source_data is the source output voltage.

DataL is set by the QSL command.

[D1 D2 . . . ] Search Source_data Data <terminator>

Search is the search status. Source_data is the source

output data of the search target.

Data is the measurement data of the search target.

D1 is the data of the first measurement point.

D2 is the data of the second point.

where Dn (n: integer) consists of the following data:

Source_data Data

Source_data is the source output data.

Data is the measurement data.

a

Dn is set by the BSVM command for the binary search,

or LSVM command for the linear search.

a. Terminator. <LF^EOI> or <,^EOI>, depending on the FMT command

parameter. See FMT command.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-21

4155C/4156C FLEX Commands

Binary Format in US Mode

Output Data The 4155C/4156C sends the measurement data (Data), source output data

(Source_data), sampling point index (Sampling_no), time data (Time), or status

information (Search or Status) in the format specified by the FMT 3 or FMT 4

command.

The binary data is six (6) bytes long, and consists of some blocks as shown below:

For Data, Source_data, Sampling_no, Search, Status:

Byte1

65432107 65432107 65432107 65432107 65432107 65432107

BC D E F

A

Byte 2

Byte 3

Byte 4

Byte 5

For Time:

Byte1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

65432107 65432107 65432107 65432107 65432107 65432107

AB G F

where,

A: Measurement or source output data type.

B: Data type.

C: Measurement or output range.

D: Data.

E: Status.

F: Channel number.

G: Time data.

NOTE For Sampling_no, ignore A, C, and F.

Byte 6

For Search, ignore A, C, E and F.

For Status, ignore A, C, D, and F.

For Time, ignore A.

They are not valid for the output data.

1-22 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

Binary Format in US Mode

The A, B, C, D, E, F, and G values are explained below.

A : Measurement or source output data type; one bit.

A Explanation

0 Source output data.

1 Measurement data.

B : Data type; three bits.

B Explanation

000 Voltage data.

001 Current data.

010 Capacitance data.

011 Time data.

110 Sampling point index.

111 Status information.

C : Measurement or output range; five bits.

C Explanation

01001 10 pA or 10 pF

01010 0.2 V or 100 pA or 100 pF

01011 2 V or 1 nA or 1 nF

01100 20 V or 10 nA or 10 nF

01101 40 V or 100 nA or 100nF

01110 100 V or 1 mA or 1 mF

01111 200 V or 10 mA or 10 mF

10000 100 mA or 100 mF

10001 1 mA or 1 mF

10010 10 mA or 10 mF

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-23

4155C/4156C FLEX Commands

Binary Format in US Mode

C Explanation

10011 100 mA or 100 mF

10100 1 A or 1 F

11111 Invalid data is returned.

D : Value of Data, Source_data, or Sampling_no; 26 bits.

This value is expressed as 26-bit binary data. It is used to calculate the

measurement data or source output data, using the equations shown

below. For Sampling_no, this value is the binary expression of the

value. You do not need the following equations.

Equations:

Measurement data = Count ´ Range /1000000

Source output data = Count ´ Range /20000

where, Count is the decimal value of D, and Range is the value

indicated by C.

If the top bit of the 26-bit binary data is 0, the Count is positive and

equal to the decimal value of the 25-bit binary data that follows the top

bit.

If the top bit is 1, the measurement data is negative. Calculate the Count

by subtracting 33554432 (10000000000000000000000000 in binary)

from the decimal value of the 25-bit binary data.

Example:

If the output binary data is:

100101010000000000000000110000001001000000000001

then,

Data type: Current measurement data (A=1, B=001)

Range: 100 pA (C=01010)

Count: 1540 (D=00000000000000011000000100)

Statu s: EOD (E=10000000)

Channel: SMU1 (channel number 1) (F=00001)

Measurement data = 1540

´ 100E–12/1E+6 = 154 fA

1-24 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

Binary Format in US Mode

Value of Search; 26 bits. The following table shows lower 5 bits.

D Description

00000 No error.

00001 Measurement aborted, but cannot specify the reason.

Ignore Source_data and Data.

01010 No target found in the specified search range of the

binary search.

Data at the start or stop near the target value is set to

Source_data and Data.

01011 No target found in the limit mode binary search.

The last search data is set to Source_data and Data.

01100 Over-range at the synchronous output channel in the

binary search.

Ignore Source_data and Data.

10100 No target found in the linear search.

Ignore Source_data and Data.

10101 Over-range at the synchronous output channel in the

linear search.

Ignore Source_data and Data.

10110 Abort condition occurred in the linear search.

Ignore Source_data and Data.

Status of Data is E=11000000.

In all data output modes (LSVM 1), the status code is set

to the status of the last measurement data.

An abort condition is set by the WM command.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-25

4155C/4156C FLEX Commands

Binary Format in US Mode

E : Status; eight bits.

• Status for Source_data:

E Explanation

00000001 Data is for the first or intermediate sweep step.

00000010 Data is for the last sweep step.

• Status for Data, Sampling_no, or Status:

E Explanation

00000001 A/D converter overflowed.

00000010 One or more units are oscillating.

00000100 Another unit reached its compliance setting.

00001000 This unit reached its compliance setting.

Integration time too short for capacitance

measurement.

00010000 The PGU reached its compliance setting.

00100000 Sweep measurement was stopped by the ESC stop

condition. The returned data is effective.

01000000 Invalid data is returned. D is not valid.

10000000 EOD (End of Data).

If multiple status conditions are found, the sum of the status values

is returned. For example, if an A/D converter overflow occurred

and an SMU was oscillating during the measurements, the returned

value is 00000011 (00000001+00000010).

F : Channel number of the measurement/source unit; five bits.

F Explanation

00001 Channel number 1, SMU1.

00010 Channel number 2, SMU2.

00011 Channel number 3, SMU3.

00100 Channel number 4, SMU4.

1-26 Agilent 4155C/4156C GPIB Command Reference, Edition 1

F Explanation

00101 Channel number 5, SMU5 (in 41501A/B).

00110 Channel number 6, SMU6 (in 41501A/B).

10101 Channel number 21, VSU1.

10110 Channel number 22, VSU2.

10111 Channel number 23, VMU1.

11000 Channel number 24, VMU2.

11010 Channel number 26, GNDU (in 41501A/B).

11011 Channel number 27, PGU1 (in 41501A/B).

11100 Channel number 28, PGU2 (in 41501A/B).

11111 Invalid data is returned.

G : Value of Ti m e; 39 bits.

4155C/4156C FLEX Commands

Binary Format in US Mode

This value is expressed in 39-bit binary data. It is used to calculate the

time data, using the equations shown below.

Equations:

Time data = Count ´ 100 ms

where, Count is the decimal value of G.

Example:

If the output binary data is:

001100000000000000000000100100100111110000000001

then,

Data type: Time data (A=0, B=011)

Count: 300000 (D=1001001001111100000)

Channel: SMU1 (channel number 1) (F=00001)

Measurement data = 300000

´ 100E–6 = 30 s

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-27

4155C/4156C FLEX Commands

ASCII Format in US42 Mode

ASCII Format in US42 Mode

Table 1-3 shows the ASCII data output format in control mode set by the US42

command. The format used depends on the measurement mode selected.

Table 1-3 ASCII Data Output Format in US42 Control Mode

Measurement Mode Output Format

Stress Force

High Speed Spot

Spot

1ch Pulsed Spot

Staircase Sweep

a

Status <terminator>

Status is the status information sent after a stress force.

Data <terminator>

a

Data is the data measured by the measurement unit

specified for the high speed spot measurement using

the MM command.

Data1 [,Data2] . . . . <terminator>

a

DataN (N: integer) is the data measured by one unit.

The order of Data is specified by the MM command.

Data <terminator>

a

Data is the data measured by the measurement unit

specified for the pulsed spot measurement using the

MM command.

Block1 [,Block2] . . . . <terminator>

a

Block1 is the block of data measured at the first sweep

step. Block2 is the block of data measured at the second

sweep step.

where Block consists of the following data:

Data1 [,Data2] . . . . [,Source_data]

DataN (N: integer) is the data measured by one unit.

The order of Data is specified by the MM command.

Source_data is the source data at the sweep step.

a. Terminator. <CR/LF^EOI>, <^EOI> or , (comma), depending on the

FMT command parameter. See FMT command.

1-28 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

ASCII Format in US42 Mode

Measurement Mode Output Format

Pulsed Sweep,

Block1 [,Block2] . . . . <terminator>

Staircase Sweep with

Pulsed Bias

Block1 is the block of data measured at the first sweep

step. Block2 is the block of data measured at the second

sweep step.

where Block consists of the following data:

Data [,Source_data]

Data is the measurement data. Source_data is the

source data at the sweep step.

Sampling

Block1 [,Block2] . . . . <terminator>

Block1 is the block of the data measured at the first

sampling point. Block2 is the block of the data

measured at the second sampling point.

where Block consists of the following data:

[Sampling_no,] Data1 [,Data2] . . . .

Sampling_no is the sampling point index. This value

depends on the sampling interval setting and the

measurement time.

a

a

If the measurement time is shorter than the sampling

interval, the Sampling_no will be N of BlockN (N: 1, 2,

3 . . . ). If the measurement time is longer than the

sampling interval, the Sampling_no is not N of BlockN.

For example, if the measurement time is longer than

the sampling interval and shorter than twice the

sampling interval, then the Sampling_no is 2 for

Block1, and 4 for Block2.

The measurement time depends on the settings of the

AV, AZ, SIT and SLI commands.

DataN (N: integer) is the data measured by one unit.

The order of Data is specified by the MM command.

The Sampling_no and Data values can be discarded

when the range changes in the auto or limited auto

ranging mode.

a. Terminator. <CR/LF^EOI>, <^EOI> or , (comma), depending on the

FMT command parameter. See FMT command.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-29

4155C/4156C FLEX Commands

ASCII Format in US42 Mode

Output Data The 4155C/4156C sends the measurement data (Data), source output data

(Source_data), sampling point index (Sampling_no), or stress status information

(Status) in the format specified by the FMT 1, FMT 2, or FMT 5 command.

• ASCII format with header (output by FMT 1 or FMT 5):

ABCDDDDDDDDDDDD

where no space is included between the parameters.

• ASCII format without header (output by FMT 2):

DDDDDDDDDDDD

where,

A: Status.

B: Channel number.

C: Data type.

D: Data.

NOTE If the output data is Sampling_no, ignore B.

If the output data is Status, ignore B and D.

They are not valid for the output data.

The A, B, C, and D values are explained below.

A : Status; 1 digit.

• Status for Data, Sampling_no, or Status:

A Explanation

N No status error occurred.

T Another unit reached its compliance setting.

C This unit reached its compliance setting.

V Measurement data is over the measurement range.

X One or more units are oscillating.

1-30 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

ASCII Format in US42 Mode

• Status for Source_data:

A Explanation

W Data is for the first or intermediate sweep step.

E Data is for the last sweep step.

B : Channel number of the measurement/source unit; 1 digit.

B Explanation

A Channel number 1, SMU1.

B Channel number 2, SMU2.

C Channel number 3, SMU3.

D Channel number 4, SMU4.

E Channel number 5, SMU5 (in 41501A/B).

F Channel number 6, SMU6 (in 41501A/B).

Q Channel number 21, VSU1.

R Channel number 22, VSU2.

S Channel number 23, VMU1.

T Channel number 24, VMU2.

V Channel number 26, GNDU (in 41501A/B).

W Channel number 27, PGU1 (in 41501A/B).

X Channel number 28, PGU2 (in 41501A/B).

Z Returned D value is not measurement data.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-31

4155C/4156C FLEX Commands

ASCII Format in US42 Mode

C : Data type; 1 digit.

C Explanation

V Voltage measurement data.

v Voltage source setup data.

I Current measurement data.

i Current source setup data.

p Sampling point index.

S Status information.

Z Invalid data is returned.

z

D Value of Data, Source_data, or Sampling_no; 12 digits, which may be

one of the following:

• sn.nnnnnEsnn

• snn.nnnnEsnn

• snnn.nnnEsnn

where,

s: Sign, + or -.

n: Digit, 0 to 9.

E: Exponent symbol.

1-32 Agilent 4155C/4156C GPIB Command Reference, Edition 1

4155C/4156C FLEX Commands

Binary Format in US42 Mode

Binary Format in US42 Mode

Table 1-4 shows the binary data output format in control mode set by the US42

command. The format used depends on the measurement mode selected.

Table 1-4 Binary Data Output Format in US42 Control Mode

Measurement Mode Output Format

Stress Force

High Speed Spot

Spot

1ch Pulsed Spot

Staircase Sweep

a

Status <terminator>

Status is the status information sent after a stress force.

Data <terminator>

a

Data is the data measured by the measurement unit

specified for the high speed spot measurement using the

MM command.

Data1 [Data2] . . . . <terminator>

a

DataN (N: integer) is the data measured by one unit.

The order of Data is specified by the MM command.

Data <terminator>

a

Data is the data measured by the measurement unit

specified for the pulsed spot measurement using the

MM command.

Block1 [Block2] . . . . <terminator>

a

Block1 is the block of data measured at the first sweep

step. Block2 is the block of data measured at the second

sweep step.

where Block consists of the following data:

Data1 [Data2] . . . . [Source_data]

DataN (N: integer) is the data measured by one unit.

The order of Data is specified by the MM command.

Source_data is the source data at the sweep step.

a. Terminator. <CR/LF^EOI>, <^EOI> or , (comma), depending on the

FMT command parameter. See FMT command.

Agilent 4155C/4156C GPIB Command Reference, Edition 1 1-33

4155C/4156C FLEX Commands

Binary Format in US42 Mode

Measurement Mode Output Format

Pulse Sweep,

Block1 [Block2] . . . . <terminator>

Staircase Sweep with

Pulsed Bias

Block1 is the block of data measured at the first sweep

step. Block2 is the block of data measured at the second

sweep step.

where Block consists of the following data:

Data [Source_data]

Data is the measurement data. Source_data is the

source data at the sweep step.

Sampling

Block1 [Block2] . . . . <terminator>

Block1 is the block of the data measured at the first

sampling point. Block2 is the block of the data

measured at the second sampling point.

where Block consists of the following data:

[Sampling_no] Data1 [Data2] . . . .

Sampling_no is the sampling point index. This value

depends on the sampling interval setting and the

measurement time.

a

a

If the measurement time is shorter than the sampling

interval, then the Sampling_no will be N of BlockN (N:

1, 2, 3 . . . ). If the measurement time is longer than the

sampling interval, then the Sampling_no is not N of