Page 1

Agilent 4155C Semiconductor

Parameter Analyzer

Agilent 4156C Precision Semiconductor

Parameter Analyzer

Data Sheet

S

Introduction

Agilent 4155C and 4156C

Basic Functions

• Set measurement and/or stress

conditions

• Control measurement and/or stress

execution

• Perform arithmetic calculations

• Display measured and calculated

results on the LCD display

• Perform graphical analysis

• Store and recall measurement

setups, and measurement and

graphical display data

• Dump to printers or plotters for

hardcopy output

• Perform measurement and analysis

with built-in instrument BASIC

• Self test, Auto calibration

Configuration

The 4155C and 4156C both come

standard with I/CV 2.1 Lite

automation software. A PC-based

instrument controller with I/CV Lite

preinstalled and an Agilent 82357A

USB/GPIB interface are also included

with the standard configuration. You

have the option of deleting the

controller and cable from your order,

but I/CV Lite is always included with

both instruments. If you want the full

version of I/CV 2.1, you can request

the E5240BU upgrade kit when you

order a 4155C or 4156C. For more

information about the differences

between I/CV 2.1 Lite and I/CV 2.1,

please refer to the Agilent I/CV 2.1

Technical Overview, publication

number 5988-8474EN.

4155C

4xMPSMU

2xVMU 2xVMU

2xVSU 2xVSU

I/CV 2.1 Lite I/CV 2.1 Lite

Standard PC-based controller

and USB/GPIB interface

41501B (Optional)

GNDU

4156C

4xHRSMU

2xPGU (Option)

HPSMU (Option) or

2xMPSMU (Option)

1

SMU: Source Monitor Unit

Display resolution: 6 digits at each

current range (0.01fA display resolu tion at 10pA range)

HRSMU: High Resolution SMU

(1fA/2µV to 100mA/100V)

MPSMU: Medium Power SMU

(10fA/2µV to 100mA/100V)

HPSMU: High Power SMU

(10fA/2µV to 1A/200V)

VMU: Voltage Monitor Unit

(0.2µV resolution in differential

mode)

VSU: Voltage Source Unit

PGU: Pulse Generator Unit (1 channel)

GNDU: Ground Unit

1

Minimum number of installable MPSMU or

PGU is two.

2

Accuracy not guaranteed. Minimum

guaranteedresolution is 1fA at 10pA range.

1

2

S1

Page 2

Hardware

Specification Condition

The “supplemental” information and

“typical” entries in the following specifications are not warranted, but provide

useful information about the functions

and performance of the instruments.

The measurement and output accuracy

are specified at the rear panel connector terminals when referenced to the

Zero Check terminal under the following con-ditions:

1. 23° C ±5° C (double between 5° C to

18° C, and 28° C to 40° C if not noted

otherwise)

3. Ambient temperature change less

than ±1° C after auto calibration

execution.

4. Integration time: medium or long

5. Filter: ON (for SMUs)

6. Kelvin connection (for HRSMU,

HPSMU, and GNDU)

7. Calibration period: 1 year

2. After 40 minutes warm-up

Agilent 4156C Precision Semiconductor Parameter Analyzer

HRSMU (High Resolution SMU) Specifications

Voltage Range, Resolution, and Accuracy (HRSMU)

Voltage Set. Set. Meas. Meas. Max.

Range Reso. Accuracy Reso. Accuracy Current

±2V 100µV ±(0.02%+400µV) 2µV ±(0.01%+200µV) 100mA

±20V 1mV ±(0.02%+3mV) 20µV ±(0.01%+1mV) 100mA

±40V 2mV ±(0.025%+6mV) 40µV ±(0.015%+2mV)

±100V 5mV ±(0.03%+15mV) 100µV ±(0.02%+5mV)

1

100mA (Vout £20V), 50mA (20V<Vout£40V)

2

100mA (Vout £20V), 50mA (20V<Vout£40V), 20mA (40V<Vout£100V)

Current Range, Resolution, and Accuracy (HRSMU)

Current Set. Set. Meas. Meas. Max.

Range Reso. Accuracy Reso. Accuracy V

±10pA 10fA ±(4%+400fA)

±100pA 10fA ±(4%+400fA)

±1nA 100fA ±(0.5%+0.7pA+1fA×Vout)

±10nA 1pA ±(0.5%+4pA+10fA×Vout) 10fA ±(0.5%+2pA+10fA×Vout) 100V

±100nA 10pA ±(0.12%+40pA+100fA×Vout) 100fA ±(0.1%+20pA+100fA×Vout) 100V

±1µA 100pA ±(0.12%+400pA+1pA×Vout) 1pA ±(0.1%+200pA+1pA×Vout) 100V

±10µA 1nA ±(0.07%+4nA+10pA×Vout) 10pA ±(0.05%+2nA+10pA×Vout) 100V

±100µA 10nA ±(0.07%+40nA+100pA×Vout) 100pA ±(0.05%+20nA+100pA×Vout) 100V

±1mA 100nA ±(0.06%+400nA+1nA×Vout) 1nA ±(0.04%+200nA+1nA×Vout) 100V

±10mA 1µA ±(0.06%+4µA+10nA×Vout) 10nA ±(0.04%+2µA+10nA×Vout) 100V

±100mA 10µA ±(0.12%+40µA+100nA×Vout) 100nA ±(0.1%+20µA+100nA×Vout)

1

The accur acy is applicable when offset cancellation has been performed.

2

The offset current specification is multiplied by one of the following

factors depending upon the ambient temperature and humidity

(RH = Relative Humidity):

Temperature 5 - 60 60 - 80

5° C to 18° C ×2 ×2

18° C to 28° C ×1 ×2

28° C to 40° C ×2 ×5

3

100V (Iout£20mA) 40V (20mA<Iout£50mA) 20V (50mA<Iout£100mA)

Vout is the output voltage in volts. Iout is the output current in amps.

For example, accuracy specifications are given as ±% of set/measured

value (0.04%) plus offset value (200nA+1nA×Vout) for the 1mA range.

The offset value consists of a fixed part determined by the set/measure ment range and a proportional part that is multiplied by Vout or Vout/100.

Humidity % RH

1, 2

1, 2

1fA ±(4%+20fA+1fA×Vout/100)

1fA ±(4%+40fA+10fA×Vout/100)

2

10fA ±(0.5%+0.4pA+1fA×Vout)

1

2

1, 2

100V

1, 2

100V

2

100V

100

-

Output terminal/connection:

Dual triaxial connectors, Kelvin

(remote sensing)

Voltage/Current Compliance

(Limiting):

The SMU can limit output voltage or

current to prevent damaging the device

under test.

Voltage: 0 V to ±100 V

Current: ±100 fA to ±100 mA

Compliance Accuracy: Same as the

current (voltage) settling accuracy.

HRSMU Supplemental Information:

Maximum allowable cable resistance

when using Kelvin connection (Force,

Sense): 10

Typical voltage source output

resistance (Force line/non-Kelvin

connection): 0.2

Voltage measurement input resist ance/

current source output resistance:

15

³10

W (10 pA range)

Current compliance setting accuracy for

opposite polarity:

3

10 pA to 10 nA range: V/I setting

accuracy ±12% of range

100 nA to 100 mA range: V/I setting

accuracy ±2.5% of range

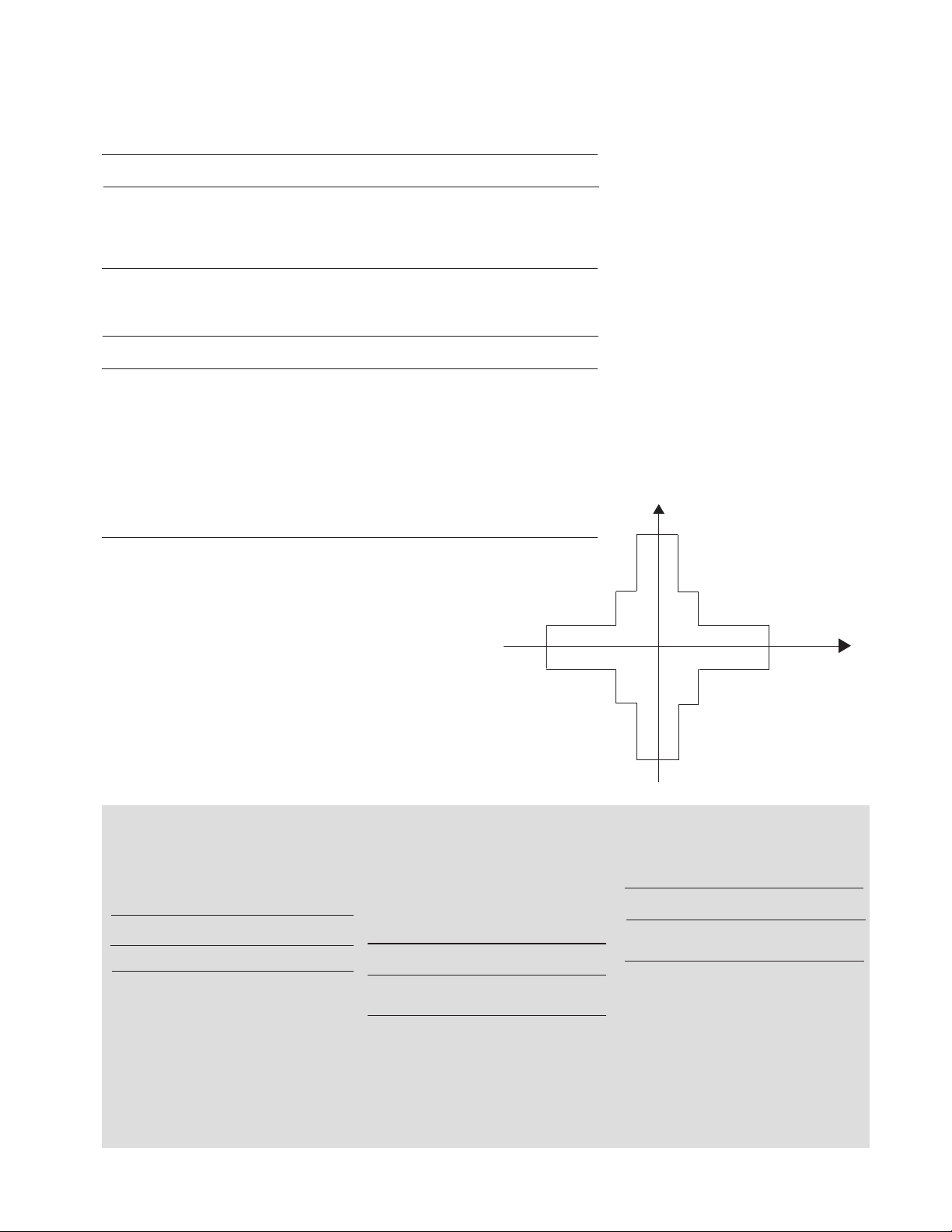

Current (mA)

100

50

20

20 40 100

20

-40-

20

-

W

W

HRSMU Measurement

and Output Range

Voltage (V)

50

-

100

-

2

Page 3

Agilent 4155C Semiconductor Parameter Analyzer

MPSMU (Medium Power SMU) Specifications

Voltage Range, Resolution, and Accuracy (MPSMU)

Voltage Set. Set. Meas. Meas. Max.

Range Reso. Accuracy Reso. Accuracy Current

±2V 100µV ±(0.03%+900µV+0.3×Iout) 2µV ±(0.02%+700µV+0.3×Iout) 100mA

±20V 1mV ±(0.03%+4mV+0.3×Iout) 20µV ±(0.02%+2mV+0.3×Iout) 100mA

±40V 2mV ±(0.03%+7mV+0.3×Iout) 40µV ±(0.02%+3mV+0.3×Iout)

±100V 5mV ±(0.04%+15mV+0.3×Iout) 100µV ±(0.03%+5mV+0.3×Iout)

1

100mA (Vout £20V), 50mA (20V<Vout £40V)

2

100mA (Vout £20V), 50mA (20V<Vout £40V), 20mA (40V<Vout£100V)

Current Range, Resolution, and Accuracy (MPSMU)

Current Set. Set. Meas. Meas. Max.

Range Reso. Accuracy Reso. Accuracy V

±1nA 100fA ±(0.5%+3pA+2fA×Vout) 10fA ±(0.5%+3pA+2fA×Vout) 100V

±10nA 1pA ±(0.5%+7pA+20fA×Vout) 10fA ±(0.5%+5pA+20fA×Vout) 100V

±100nA 10pA ±(0.12%+50pA+200fA×Vout) 100fA ±(0.1%+30pA+200fA×Vout) 100V

±1µA 100pA ±(0.12%+400pA+2pA×Vout) 1pA ±(0.1%+200pA+2pA×Vout) 100V

±10µA 1nA ±(0.12%+5nA+20pA×Vout) 10pA ±(0.1%+3nA+20pA×Vout) 100V

±100µA 10nA ±(0.12%+40nA+200pA×Vout) 100pA ±(0.1%+20nA+200pA×Vout 100V

±1mA 100nA ±(0.12%+500nA+2nA×Vout) 1nA ±(0.1%+300nA+2nA×Vout) 100V

±10mA 1µA ±(0.12%+4µA+20nA×Vout) 10nA ±(0.1%+2µA+20nA×Vout) 100V

±100mA 10µA ±(0.12%+50µA+200nA×Vout) 100nA ±(0.1%+30µA+200nA×Vout)

1

100V (Iout £20V), 40V (20mA<Iout£50mA), 20V (50mA<Iout£100mA)

Vout is the output voltage in volts. Iout is the output current in amps.

For example, accuracy specifications are given as ±% of set/measured

value (0.1%) plus offset value (30pA+200fA×Vout) for the 100nA range.

The offset value consists of a fixed part determined by the set/

measurement range and a proportional part that is multiplied by Vout.

1

2

1

Output terminal/connection:

Single triaxial connector, non-Kelvin

(no remote sensing)

Voltage/Current Compliance (Limiting):

The SMU can limit output voltage or

current to prevent damaging the device

under test.

Voltage: 0 V to ±100 V

Current: ±1 pA to ±100 mA

Compliance Accuracy: Same as the

current (voltage) settling accuracy.

MPSMU Supplemental Information:

Typical voltage source output

resistance: 0.3

W

Voltage measurement input resistance/

current source output resistance:

13

³10

W (1 nA range)

Current compliance setting accuracy

foropposite polarity:

1nA to 10 nA range: V/I setting

accuracy ±12% of range

100 nA to 100 mA range: V/I setting

accuracy ±2.5% of range

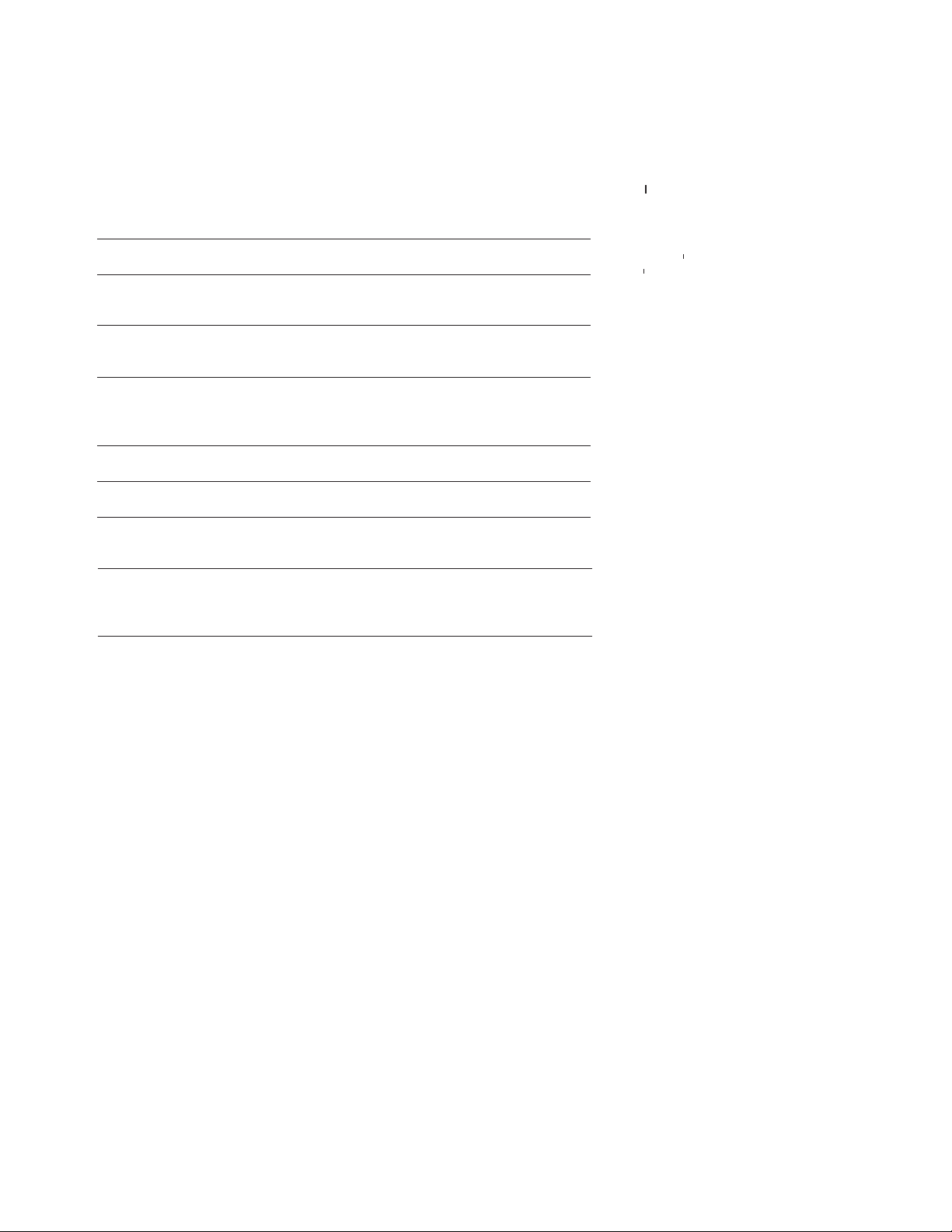

Current (mA)

100

MPSMU Measurement

and Output Range

50

20

VSU and VMU specifications are common to both the 4155C and 4156C

VSU (Voltage Source Unit)

Specifications

VSU Output Range:

Voltage Meas. Meas.

Range Reso. Accuracy

±20V 1mV ± (0.05% of setting +10mV)

1

Specification is applicable under no load

current. Max. Output Current: 100mA

VSU Supplemental Information:

Output resistance: 0.2 W (typical)

Maximum load capacitance: 10 µF

Maximum slew rate: 0.2 V/µs

Current limit: 120 mA (typical)

Output Noise: 1 mV rms (typical)

100

-

VMU (Voltage Monitor Unit)

Specifications

VMU Differential Mode Range,

Resolution, and Accuracy:

1

Diff V Meas. Meas.

Range Reso. Accuracy

±0.2V 0.2µV ±(0.03%+10µV+0.3µV×Vi)

±2V 2µV ±(0.02%+100µV+3µV×Vi)

Max. Common Mode Voltage: ± 20V

Note: Vi is the input voltage of VMU2 in volts.

For example, accuracy specifications are

given as ±% of set/measured value (0.02%)

plus offset value (100µV+3µV×Vi) for the 2V

range. The differential mode offset value

consists of a fixed part determined by the

measurement range and a proportional part

that is multiplied by Vi.

20

-40-

20 40 100

20

-

50

-

100

-

VMU Measurement Range, Resolution,

and Accuracy:

Voltage Meas. Meas.

Range Reso. Accuracy

±2V 2µV ±(0.02%+200µV)

±20V 20µV ± (0.02%+1mV)

VMU Supplemental Information:

Input Impedance: ³1G W

Input leakage current (@0 V): £500 pA

Measurement noise: 0.01% of range

(p-p) (typical) when integration time

is 10 PLC

Differential mode measurement noise:

0.005% of range (p-p) (typical) when

integration time is short.

Voltage (V)

3

Page 4

Agilent 41501B SMU and Pulse Generator Expander

HPSMU (High Power SMU) Specifications

Voltage Range, Resolution, and Accuracy (HPSMU)

Voltage Set. Set. Meas. Meas. Max.

Range Reso. Accuracy Reso. Accuracy Current

± 2V 100µV ±(0.03%+900µV) 2µV ±(0.02%+700µV) 1A

± 20V 1mV ±(0.03%+4mV) 20µV ±(0.02%+2mV) 1A

± 40V 2mV ±(0.03%+7mV) 40µV ±(0.02%+3mV) 500mA

±100V 5mV ±(0.04%+15mV) 100µV ±(0.03%+5mV) 125mA

±200V 10mV ±(0.045%+30mV) 200µV ±(0.035%+10mV) 50mA

Current Range, Resolution, and Accuracy (HPSMU)

Current Set. Set. Meas. Meas. Max.

Range Reso. Accuracy Reso. Accuracy V

±1nA 100fA ±(0.5%+3pA+2fA×Vout) 10fA ±(0.5%+3pA+2fA×Vout) 200V

±10nA 1pA ±(0.5%+7pA+20fA

±100nA 10pA ±(0.12%+50pA+200fA×Vout) 100fA ±(0.1%+30pA+200fA×Vout 200V

±1µA 100pA ±(0.12%+400pA+2pA

±10µA 1nA ±(0.12%+5nA+20pA×Vout) 10pA ±(0.1%+3nA+20pA×Vout) 200V

±100µA 10nA ±(0.12%+40nA+200pA

±1mA 100nA ±(0.12%+500nA+2nA×Vout) 1nA ±(0.1%+300nA+2nA×Vout) 200V

±10mA 1µA ±(0.12%+4µA+20nA

±100mA 10µA ±(0.12%+50µA+200nA×Vout) 100nA ±(0.1%+30µA+200nA×Vout) 1

±1A 100µA ±(0.5%+500µA+2µA×Vout) 1µA ±(0.5%+300µA+2µA×Vout) 2

1

200V (Iout £50mA), 100V (50mA<Iout£100mA)

2

200V (Iout £50mA), 100V (50mA<Iout£125mA), 40V (125mA<Iout£500mA), 20V (500mA<Iout£1mA)

Vout is the output voltage in volts. Iout is the output current in amps. For example, accuracy

specifications are given as ±% of set/measured value (0.1%) plus offset value (30pA+200fA

for the 100nA range. The offset value consists of a fixed part determined by the set/measurement

range and a proportional part that is multiplied by Vout.

×Vout) 10fA ±(0.5%+5pA+20fA×Vout) 200V

×Vout) 1pA ±(0.1%+200pA+2pA×Vout) 200V

×Vout) 100pA ±(0.1%+20nA+200pA×Vout 200V

×Vout) 10nA ±(0.1%+2µA+20nA×Vout) 200V

×Vout)

Output terminal/connection:

Dual triaxial connectors, Kelvin

(remote sensing)

Voltage/Current Compliance

(Limiting):

Voltage: 0V to ±200V

Current: ±1pA to ±1A

Compliance Accuracy: Same as

the current (voltage) settling

accuracy.

HPSMU Supplemental

Information:

Maximum allowable cable

resistance when using Kelvin

connection:

Force: 0.7W (100mA to 1A)

Force: 10W (£100mA)

Sense: 10W

Typical voltage source output

resistance (Force line/non-Kelvin

connection): 0.2W

Voltage measurement input

resistance/current source output

resistance:

13

³10

W (1nA range)

Current compliance setting

accuracy foropposite polarity:

1nA to 10nA range: V/I setting

accuracy ±12% of range

100nA to 1A range: V/I setting

accuracy ±2.5% of range

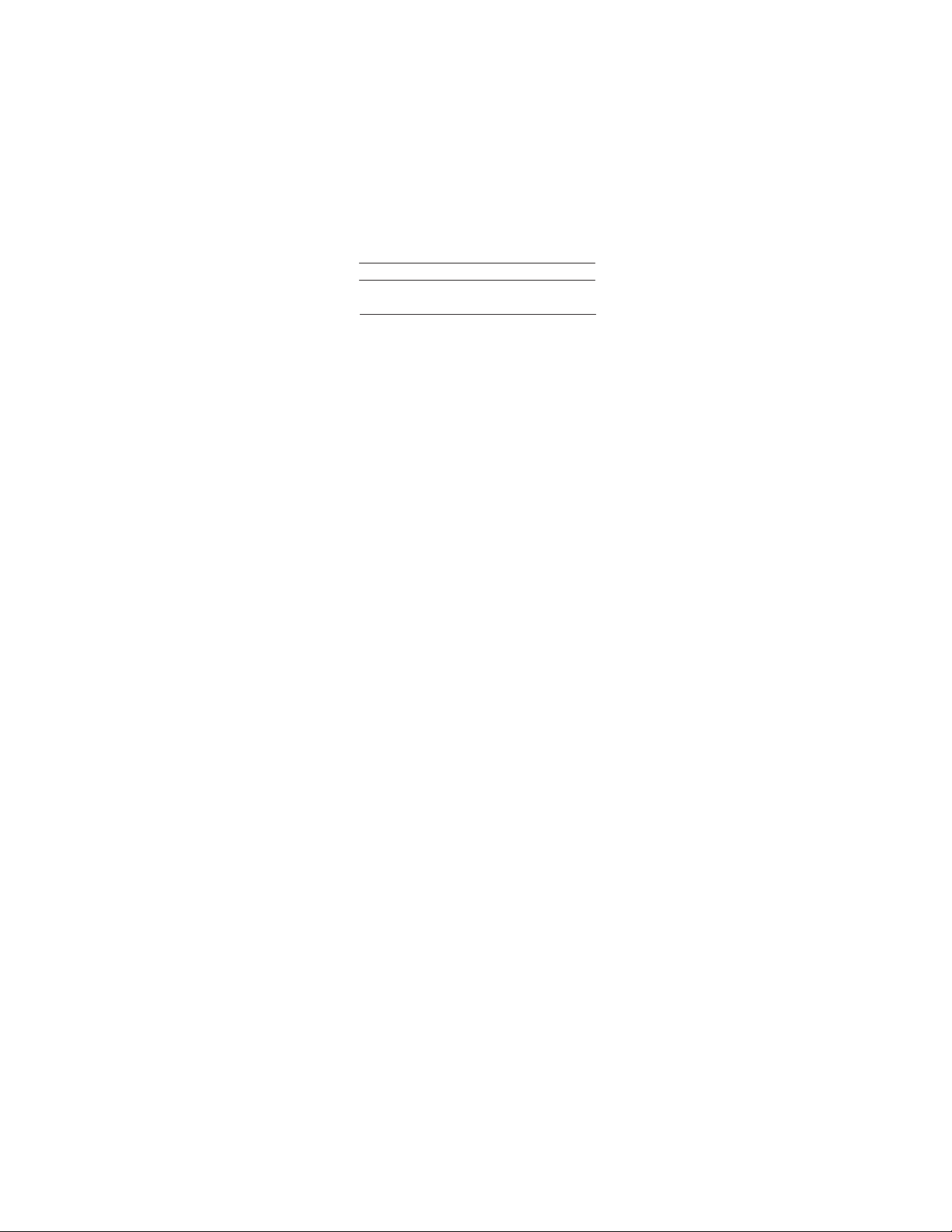

HPSMU Measurement

and Output Range

-200

-100 -40 -20

1000

500

125

50

-50

-125

-500

-1000

Current (mA)

Voltage (V)

100 20 40

200

4

Page 5

PGU (Pulse Generator Unit)

Specifications

Modes: Pulse or constant

Amplitude: 0Vp-p to 40Vp-p

Window: -40.0V to +40.0V

Maximum current:

±100mA

±200mA (pulse width: £1ms, average

current 100mA)

Pulse width: 1.0µs to 9.99s

Minimum resolution: 100ns

Pulse period: 2.0µs to 10.0s

Minimum resolution: 100ns

Delay: 0s to 10s

Minimum resolution: 100ns

Transition time: 100ns to 10ms

Minimum resolution: 1ns

Output impedance: 50W or low

impedance (£1W)

Burst count range: 1 – 65535

Pulse parameter accuracy:

Period: ±(2% +2ns)

Width: ±(3% +2ns)

Delay: ±(2% +40ns)

Transition time: ±(5% +10ns)

Trigger output:

Level: TTL

Timing: Same timing and width as

PGU1 pulse output

PGU Supplemental Information:

Overshoot: £±5% of amplitude ±10mV

(50W output impedance to 50W load)

Pulse width jitter: 0.2% + 100ps

Pulse period jitter: 0.2% + 100ps

Maximum slew rate: 100V/µs (50W

output impedance to 50W load)

Noise: 0.2% of range (@ DC output)

MPSMU Specifications

Same as 4155C MPSMU.

Pulse/DC Output Voltage and Accuracy (PGU)

Set Voltage

Parameter Range Resolution Accuracy

Base ±20V 4mV ±(1% of Base +50mV +1% of Pulse)

±40V 8mV ±(1% of Base +50mV +1% of Pulse)

Pulse ±20V 4mV ±(3% of Base +50mV)

±40V 8mV ±(3% of Base +50mV)

Note: DC output is performed by the Base Parameter.

1

Accuracy is specified at leading edge - trailing edge = 1µs

1

Pulse Range and Pulse Parameter (PGU)

Range Period Width Delay Set resolution

1 2µs -100µs 1µs - 99.9µs 0 - 100µs 0.1µs

2 100µs - 1000µs 1µs - 999µs 0 - 1000µs 1µs

3 1ms - 10ms 0.01ms - 9.99ms 0 - 10ms 10µs

4 10ms - 100ms 0.1ms - 99.9ms 0 - 100ms 100µs

5 100ms - 1000ms 1ms - 999ms 0 - 1000ms 1ms

6 1s - 10s 0.01s - 9.99s 0 - 10s 10ms

Note: Pulse width is defined when leading time is equal to trailing time. PGU2 must be set in the

same range as PGU1.

GNDU (Ground Unit)

Specifications:

Output Voltage: 0V ±100µV

Maximum sink current: 1.6A

Output terminal/connection:

Single triaxial connector,

Kelvin (remote sensing)

GNDU Supplemental Information

Load Capacitance: £1µF

Cable resistance:

Force £1W

Sense £10W

HRSMU, MPSMU, HPSMU

Supplemental Information

Maximum capacitive load: 1000pF

Maximum guard capacitance: 900pF

Maximum shield capacitance: 5000pF

Maximum guard offset voltage: ±1mV

Noise characteristics (typical, Filter: ON):

Voltage source noise: 0.01% of V

range (rms)

Current source noise: 0.1% of I range

(rms)

Voltage monitor noise: 0.02% of V

range (p-p)

Current monitor noise: 0.2% of I

Output overshoot (typical, Filter: ON):

Voltage source: 0.03% of V range

Current source: 1% of I range

Range switching transient noise

(typical, Filter: ON):

Voltage ranging: 250mV

Current ranging: 10mV

Maximum slew rate: 0.2V/µs

Leading/Trailing Edge Times (PGU)

Range Set Resolution` Accuracy

100ns - 1000ns 1ns ±(5% + 10ns)

0.5µs - 10µs 10ns ±(5% + 10ns)

5.0µs - 100µs 100ns ±(5% + 10ns)

50µs - 1000µs 1µs ±(5% + 10ns)

0.5ms - 10ms 10µs ±(5% + 10ns)

Restrictions:

Pulse width < Pulse Period, Delay time < Pulse period, Leading time < Pulse width ´ 0.8

Trailing time < (Pulse period - Pulse width) ´ 0.8

Period, width, and delay of PGU1 and PGU2 must be in the same range. Leading time and trailing

timefor a PGU must be in the same range.

5

Page 6

Capacitance Calculation Accuracy (Supplemental Data)

Accuracy is derived from the current range, voltage range, capacitance measurement and leakage current measurement integration times, and the guard capacitance of cabling and step voltage. The information in the chart below is based on

the following conditions: Voltage Range ±20V; Voltage Step: 100mV; Guard

Capacitance : 100pF; Equivalent parallel resistance of DUT: 1 ´ 1015W. The ratio

of integration times for capacitance measurement and leakage current measurement is 1:1.

HRSMU

Current Integration Max. Meas. Accuracy

Range Time Value Resolution Reading % Offset

10pA/

100pA

1nA 0.5sec 4.5nF 40fF 0.85 280fF

10nA

0.5sec 100pF/1pF 5fF 4.2 70fF

1sec 2pF/20pF 10fF 4.3 90fF

2sec 76pF/760pF 20fF 4.3 130fF

0.1sec 700pF 10fF 0.84 160fF

2sec 18nF 200fF 0.93 740fF

0.1sec 7nF 10fF 0.84 200fF

0.5sec 45nF 40fF 0.85 440fF

2sec 180nF 200fF 0.93 1.4pF

10sec 940nF 1pF 1.3 6.2pF

MPSMU

Integration Max. Meas. Accuracy

Current Time Value Resolution Reading % Offset

0.1sec 700pF 10fF 0.91 170fF

1nA 0.5sec 4.5nF 40fF 0.94 340fF

2sec 18nF 200fF 1.0 1pF

0.1sec 7nF 10fF 0.91 180fF

10nA 0.5sec 45nF 40fF 0.94 480fF

2sec 180nF 200fF 1.0 1.6pF

10sec 940nF 1pF 1.6 7.6pF

Current complicance must be smaller than the current range. The capacitance of

the DUT and measurement path must be smaller than the maximum measurement

value.

Functions

Measurement Setup

Setting

Fill-in-the-blanks using front-panel or

•

full-size external keyboard

Load settings from floppy disk or via

•

the LAN port

Program using internal Instrument

•

BASIC or via GPIB

HELP Function

•

Library: Default measure setup, Vce-

•

Ic, Vds-Id, Vgs-Id, and Vf-If are predefined softkeys

User-defined measurement setup

•

library

Auto file load function on power-up

•

Measurement

The 4155C and 4156C can

perform dc or pulsed force/measure,

and stress force. For dc, voltage/

current sweep and sampling (time

domain) measurements are available.

6

Voltage/Current Sweep

Measurement Characteristics

Each SMU and VSU can sweep using

VAR1 (primary sweep), VAR2

(subordinate sweep), or VAR1

(synchronous sweep).

VAR1

Primary sweep controls the staircase

(dc or pulsed) voltage or current

sweep.

Maximum number of steps: 1001 for

one VAR1 sweep.

Sweep type: linear or logarithmic

Sweep direction: Single or double sweep

Hold time: Initial wait time or wait

time after VAR2 is set: 0 to 655.35s

with 10ms resolution

Delay time: Wait time from VAR1 step

to the start of the measurement: 0 to

65.535s with 100µs resolution

VAR2

Subordinate linear staircase or linear

pulsed sweep. After primary sweep is

completed, the VAR2 unit output is

incremented.

Maximum number of steps: 128

VAR1

Staircase or pulse sweep synchronized

with the VAR1 sweep. Sweep is made

with a user specified ratio and offset

value. VAR1 output is calculated as

VAR1 = a ´ VAR1 + b, where “a” is the

user specified ratio and “b” is the user

specified offset value.

CONSTANT

A source unit can be set as a constant

voltage or current source depending on

the unit.

PULSE

One of the SMUs can be set as a pulse

source.

Pulse width: 0.5ms to 100ms, 100µs

resolution.

Pulse period: 5ms to 1s (³pulse width +

4ms), 100µs resolution.

SMU pulse setting accuracy (supplemental information, at fixed range

measurement except multichannel

measurement):

Width: 0.5% + 50µs

Period: 0.5% + 100µs

Trigger output delay for pulsed

measurement: 0 - 32.7ms with 100µs

resolution (< pulse width).

Sampling (Time Domain)

Measurement Characteristics

Displays the time sampled voltage/

current data versus time.

Max. sampling points: 10,001 (linear)

Sampling mode: linear, log, and

thinned-out

Note: The thinned-out mode is similar to

reverse-log sampling. Sampling measurement

continues by thinning out older data until the

sampling completion condition is satisfied.

Sampling interval range and resolution:

Linear scale (auto mode):

60µs to 480µs range: 20µs resolution

480µs to 1s range: 80µs resolution

1s to 65.535s range: 2ms resolution

Linear scale (no limit mode), log

scale, and thinned-out modes:

560µs (720µs at thinned-out mode)

to 1s range: 80µs resolution

1s to 65.535s range: 2ms resolution

Note: The following conditions must be set when

initial interval is less than 2ms.

Number of measurement channels: 1

•

Measurement ranging: fixed range

•

Stop condition: disable

•

Hold time:

Initial wait time: 0.03s to 655.35s,

100µs resolution

Sampling measurement stop condition:

Page 7

A condition to stop the sampling can

be defined.

Sampling interval setting accuracy

(supplemental data):

0.5% + 10µs (sampling interval £480µs)

0.5% + 10µs (480µs £sampling

interval <2ms)

0.5% + 100µs (2ms £sampling interval)

C-V Measurement

Characteristics

Capacitance is a calculated value

derived from the following equation:

DQ

C =

DV

DQ is the change in charge when DV,

the step voltage, is applied by the SMU;

DQ is derived from the measurement

current (amps) and the integration time

(seconds).

Maximum Measurable Value

Maximum measurable value depends

on thecurrent range, integration time,

and step voltage (refer to the chart in

supplemental data).

Capacitance Calculation Accuracy

Accuracy is dependent on accuracy of

the current measurement and voltage

measurement and the stray capacitance

and leakage current of measurement

path, etc. (Refer to the chart in supplemental data).

Zero Offset

Cancels stray capacitance of the

fixtures and test leads.

Leakage Current Compensation

Cancels the inf luence of the leakage

current to the capacitance measurement.

Stress Force Characteristics

SMU, VSU, and PGU output can be

forced for the user specified period.

Stress time set range: 500µs to

31,536,000s (365 days)

Resolution:

100µs (500µs £stress time £10s)

10ms (10s <stress time £31,536,000s)

Burst pulse count: 1 - 65,535 (PGU only)

Trigger: The 4155C and 4156C output a

gate trigger while stress channels are

forcing stress.

Knob Sweep

In knob sweep mode, sweep range is

controlled instantaneously with the

front-panel rotary knob. Only the

Channel Definition page need be defined.

Standby Mode

SMUs in “Standby” remain programmed

to their specified output value even

as other units are reset for the next

measurement.

Other Characteristics

Measurement Control: Single, append,

repeat, and stop

Stress Control: Stress force and stop

SMU Setting Capabilities: Limited auto ranging, voltage/current compliance,

power compliance, automatic sweep

abort functions, self-test, and self calibration.

Arithmetic and Analysis

Functions

Arithmetic Functions

User Functions

Up to six USER FUNCTIONS can be

defined using arithmetic expressions.

Measured data and analyzed variables

from graphics analysis (marker, cursor,

and line data) can be used in the

computation. The results can be

displayed on the LCD.

Arithmetic Operators

+, -, *, /, ^, LGT (logarithm, base 10),

LOG (logarithm, base e), EXP

(exponent), DELTA, DIFF (differential),

INTEG (integration), MAVG (moving

average), SQRT, ABS (absolute value),

MAX, MIN, AVG (averaging), COND

(conditional evaluation).

Physical Constants

Keyboard constants are stored in

memory as follows:

q:Electron Charge, 1.602177 E-19 C

k:Boltzman’s Constant, 1.380658 E-23

e (e): Dielectric Constant of Vacuum,

8.854188 E-12

Engineering Units

The following unit symbols are also

available on the keyboard: f (10

-12

p (10

m (10

), n (10-9 ), u or m (10-6 ),

-3

), K (103 ), M (10

Analysis Capabilities

Overlay Graph Comparison

A graphics plot can be stored and later

recalled as an overlay plane. Four overlay planes can be stored. One plane can

be overlaid onto the current data.

Marker

Marker to min/max, interpolation,

direct marker, and marker slip

Cursor

Long and short, direct cursor.

Line

Two lines, normal mode, grad mode,

tangent mode, and regression mode.

Scaling

Auto scale and zoom.

Data Variable Display

Up to two user defined parameters can

be displayed on the graphics screen.

Read Out Function

The read out functions are built-in

functions for reading various values

related to the marker, cursor, or line.

6

), G (10

-15

),

9

)

Automatic Analysis Function

On a graphics plot, the markers and

lines can be automatically located using

the auto analysis setup. Parameters can

be automatically determined using

automatic analysis, user function, and

read out functions.

User Variable

Display the data on the LCD via GPIB

or instrument BASIC.

Output

Display

Display Modes

Graphics and list.

Graphics Display

X-Y or X-Y1/Y2 plot of source current/

voltage, measured current/voltage, time,

or calculated USER FUNCTION data.

List Display

Measurement data and calculated

USER FUNCTION data are listed in

conjunction with VAR1 step number or

time domain sampling step number. Up

to eight data sets can be displayed.

Display

8.4-inch diagonal color active matrix

LCD, 640 dot (H) ´ 480 dot (V). More

than 99.99% of the pixels on an LCD

are active.

Hard Copy Functions

Graphics Hard Copy

Measured data and all data appearing

on the LCD can be output via GPIB,

parallel printer port, or network

interface to supported HP plotters or

printers. PCL, HR PCL (high-resolution

PCL), and HP-GL formats are supported (selectable).

Text Hard Copy

Print out setup information or measured data list as ASCII text via GPIB,

parallel printer port, or network

interface to supported HP plotters or

printers. PCL, HR PCL, and HP GL

formats are supported (selectable).

Hard Copy File

Hard copy output can be stored to an

internal or external mass storage

device instead of sending it to a printer

or plotter. The data can be stored in

PCL, HR PCL, TIFF, HR TIFF (highresolution TIFF), or HP GL formats.

Hard Copy via Network Interface

The network interface has lpr client

capability.

High-Resolution (HR) Mode

This file mode is available for cases

where an extremely clean print-out or

plot is desired.

Note: High-resolution mode takes significantly

greater CPU time to generate, so its use is

recommended for final reports only.

7

Page 8

Data Storage

Mass storage device:

Built-in 3.5-inch floppy disk drive

Media: 3.5-inch 2HD or 2DD diskette

Format type: HP LIF and DOS

User area: 1.44Mbyte (2HD) or

720Kbyte (2DD)

File types:

Auto start program file, initial setup

file, measurement setup file, mea

surement setup/result file, stress

setup file, customize file, hard copy

data file, and Instrument BASIC

program and data file.

Format of data made by the HP BASIC

program:

Data made by the HP BASIC program

and data made by the Instrument

BASIC program are compatible.

Network mass storage device:

An NFS mountable mass storage device

File types:

Auto start program file, initial setup

file, measurement setup file, measure ment setup/result file, stresS setup

file, customize file, and hard copy

data file.

Maximum number of files allowed per

directory on network mass storage

device: 199

Data storage (supplemental data):

2HD DOS format:

Available bytes: 1457K (byte)

File size:

Measurement setup: 3843 (byte)

Stress setup: 601 (byte)

Measurement setup/result

(Typical data): 15387 (byte)

(VAR1: 101, VAR2: 5)

Customized system setup: 1661 (byte)

Hardcopy data: 30317 (byte)

(Monochrome PCL 75DPI file)

Hardcopy data: 38702 (byte)

(monochrome TIFF file)

Note: For LIF format, the total number of files is

limited to 199.

Repeating and Automating

Test

Instrument Control

Agilent 4155C and 4156C function

control:

Internal or external computer controls

the 4155C and 4156C functions via

the GPIB interface

Command sets:

SCPI command set

Agilent FLEX command set

Agilent 4145B command set

Program Memory:

Using the Agilent FLEX command set,

the user can store program code in

the 4155C or the 4156C. The maximum

number of subprograms is 255 (8 bit).

External instrument remote control:

Control external equipment via the

GPIB interface.

8

Instrument BASIC

Instrument BASIC is a subset of

HP BASIC.

Functions:

Arithmetic operation, binary opera

tion, string manipulation, logical

operation, array operation, program

flow control, event-initiated branch

ing, program editing and debugging

support, mass storage operation,

instrument control, real-time clock,

softkey operation, and graphics.

Agilent 4145B automatic sequence

program (ASP) typing aid:

4145B ASP-like syntax softkeys are

available in instrument BASIC. A

4145B ASP file cannot be read by

the 4155C or 4156C.

Remote control:

Instrument BASIC is remote

controllable from an external

computer via the GPIB interface.

Instrument BASIC memory area

(supplemental data):

Program (text) area: 16K (byte)

Variable/stack area: 500K (byte)

Common variable area: 600K (byte)

Note: The memory size for common variable is

decreased when hard copy or disk operation is

performed.

Trigger

Input:

External trigger input starts a sweep

or sampling measurement or can be

used as a trigger input for continuing

an Instrument BASIC program.

Input Level:

TTL level, negative or positive edge

trigger

Output:

External edge trigger outputs can

be generated by the start of a sweep

measurement, the start of each

sweep step in a staircase sweep, the

start of each pulse leading edge for

an SMU in pulse mode, and the

issuance of an an IBASIC trigger out

command execution. In addition, you

can set the trigger signal to be active

during the Stress Force State. If you

have a 41501A/B with PGU option,

you can output a synchronized

trigger output through the 41501A/B

trigger output.

Output Level:

TTL level, negative or positive logic

4145B Data Compatibility

and Syntax Commands

Setup and data file

Measurement setup and data from the

4145B can be loaded.

GPIB program

GPIB programs for the 4145B can be

used when the 4145B command set is

selected.

Note: There is a possibility that GPIB programs

for the 4145B will need to be modified.

Interfaces

GPIB interface:

SH1, AH1, T6, L4, SR1, RL1, PP0,

DC1, DT1, C1, C2, C3, C4, C11, E2

Parallel interface: Centronics

RJ45:

Ethernet IEEE 802.3 10BASE-T for a

10Mbps CSMA/CD local area network

External keyboard:

Compatible PC-style 101-key

keyboard (mini DIN connector)

Interlock and LED connector R-BOX

control connector

Trigger in/out

SMU/PGU selector control connector

(41501B)

Sample Application

Programs

Flash EEPROM test

TDDB

Constant I (Electromigration test)

V-Ramp test

J-Ramp test

SWEAT

GO/NO-GO test

HCI degradation test

Charging pump test

Sample VEE Program

Vth measurement using the 4155C or

4156C, the E5250A, and a wafer prober.

VXI plug&play Drivers

VXI plug&play drivers for the

4155C and 4156C

Supported VXI plug&play operating

systems:

Microsoft Windows 95, 98, NT, 2000

Professional, and XP Professional

Format

Tree-structured function panel.

Panel mode for hardware configuration and manual parameter setting.

Parameter mode for variable definition

and I/O configuration.

General Specifications

Temperature range

Operating:

+10°C to +40°C (if using floppy

disk drive)

+5°C to +40°C (if not using floppy

disk drive)

Storage: -22°C to +60°C

Humidity range

Operating:

20% to 80% RH, non-condensing and

wet bulb temperature £29°C (if using

floppy disk drive)

15% to 80% RH, non-condensing and

wet bulb temperature £29°C (if not

using floppy disk drive)

Storage: 5% to 90% RH , non-condensing

and wet bulb temperature £39°C

Page 9

Altitude

Operating: 0 to 2,000 m (6,561 ft)

Storage: 0 to 4,600 m (15,091 ft)

Power requirement

90V to 264V, 47 to 63 Hz

Maximum VA

4155C and 4156C: 450VA

41501B: 350 VA

Regulatory Compliance

EMC: EN 61326-1:+A1, AS/NZS 2064.1

Safety:

CSA C22.2 NO.1010.1 (1992),

IEC 61010-1:+A2/EN 61010-1:+A2

UL3111-1:1994

Certification:

CE, CSA, NRTL/C, C-Tick

Dimensions

4155C and 4156C: 235mm H ´

426mm W ´ 600mm D

41501B: 190mm H ´

426mm W ´ 600mm D

Weight (approx.)

4155C and 4156C: 21kg

41501B: 16kg (option 412,

HPSMU + 2 ´ PGU)

4155C and 4156C

Furnished Accessories

Triaxial cable, 4 ea. (4155C)

Kelvin triaxial cable, 4 ea. (4156C)

Coaxial cable, 4 ea.

Interlock cable, 1 ea.

Keyboard, 1 ea.

User manual, 1 set

Sample application program disk, 1 ea.

Sample VEE program disk, 1 ea.

VXIplug&play drivers disk for the

4155C and 4156C, 1 ea.

VXIplug&play drivers disk for the

E5250A, 1 ea.

LAN Interface Test Adapter, 1 ea.

Accessory

Specifications

Specification Condition

The “supplemental information” and

“typical”entries in the following specifications are not warranted, but provide

useful information about the functions

and performance of the instruments

(23°C ±5°, 50% RH).

16440A SMU/Pulse Generator

Selector

The 16440A switches either an SMU

or PGU to the associated output port.

You can expand to 4 channels by

adding an additional 16440A. The

channel 1 PGU port provides a “PGU

OPEN” function, which can disconnect

the PGU by opening a semiconductor

relay. The 16440A cannot work without

two pulse generator units of the

41501A/B (SMU and Pulse Generator

Expander).

Channel configurations:

Two channels (CH1, CH2)

CH1: INPUT ports: 2

(SMU and PGU, PGU port has

additional series semiconductor relay)

OUTPUT port: 1

CH2: INPUT ports: 2 (SMU and PGU)

OUTPUT port: 1

Voltage and Current Range

Input port Max. V Max. I

SMU 200V 1.0A

PGU 40V 0.2A (AC Peak)

Supplemental Information

(at 23°C ± 5°C, 50%RH)

SMU port leakage current:

< 100fA @100V

SMU port residual resistance (typical):

0.2W

SMU port stray capacitance (typical

@1MHz):

Force « Common: 0.3pF

Force « Guard: 15pF

Guard « Common: 130pF

PGU port residual resistance: 3.4W

PGU port OFF capacitance (typical): 5pF

PGU port OPEN capacitance (typical):

700pF (@ 1MHz, Vin - Vout = 0V)

PGU port signal transfer characteristics

Overshoot: < 5% of pulse amplitude

(@20ns leading and trailing time, 50W

pulse generator source impedance,

50pF and 1MW in parallel load).

General Specifications

Dimensions:

50mm H ´ 250mm W ´ 275mm D

Approximate weight: 1.1kg

16441A R-BOX

The 16441A R-BOX adds a selectable

series resistor to the SMU output. You

can select the resistor from the setup

page, and the voltage drop due to the

series resistor is automaticallycompensated for in the measurement result.

Measurement limitations with the

4155C and 4156C and R-BOX:

If you measure device characteristics

including negative resistance over

1MW with the 4155C/4156C and

R-BOX, there is a possibility that

they cannot be measured. There is a

possibility that the 4155C and 4156C

cannot perform measurements

because of DUT oscillations even with

the R-BOX. Whether oscillation occurs

or not depends upon the DUT and

measurement conditions.

Number of SMU channels that can add

a resistor: 2

Resistor values:

1MW, 100kW, 10kW, 0W (each

channel)

Resistance accuracy:

0.3% (at 23°C ±5°C, between input output terminal)

Maximum voltage: 200V

Maximum current: 1A (0W selected)

Kelvin connection: Kelvin connection

is effective only when 0W is selected.

Supplemental Information

(at 23°C ± 5°C, 50%RH)

Leakage current: <100fA @ 100V

General Specifications

Dimensions:

72mm H ´ 250mm W ´ 270mm D

Approximate weight: 1.6kg

16442A Test Fixture

Channel Information

SMU:

6 channels (1 triaxial connector

per channel)

3 channels (1 Kelvin triaxial connector

per channel)

VSU:

2 channels (1 BNC connector per

channel)

VMU:

2 channels (1 BNC connector per

channel)

PGU:

2 channels (1 BNC connector per

channel)

GNDU:

1 channel (1 triaxial connector)

INTLK: 6-pin connector

Supplemental Information

(at 23°C ± 5°C, 50% RH)

SMU channel:

Leakage current: 10pA max @200V

(Force or Sense « Common)

Stray capacitance: 15pF max

(Force or Sense « Common)

Stray capacitance: 3pF typical

(Force or Sense « Other SMU)

Residual resistance: 60mW typical

(Force, Sense)

Guard capacitance: 70pF max

(Force or Sense « Guard)

VSU channel residual resistance:

60mW typical

VMU channel residual resistance:

60mW typical

PGU channel characteristic impedance:

50mW typical

GNDU channel residual resistance:

40mW typical (Force, Sense)

General Specifications

Temperature range:

Operating: +5°C to +40°C

Storage: -40°C to +70°C

Humidity range;

Operating: 5% to 80% RH

(no condensation)

Storage: 5% to 90% RH at 65°C

(no condensation)

Dimensions:

140 mm H ´ 260 mm W ´ 260 mm D

Weight (approx.): 2.5kg

9

Page 10

Automation Software

I/CV 2.1 Lite

Overview

Agilent I/CV 2.1 Lite provides

automated test solutions for semiconductor characterization. It supports the Agilent 4155C and 4156C,

the Agilent E5270 Series, the

Agilent E5250A Low Leakage

Switch, the Keithley 707 Switching Matrix, the Agilent 4284A and

4294A LCR meters, and many popular semiautomatic wafer probers.

I/CV 2.1 Lite also provides wizardbased test development, test execution, and sequencing along with

data logging and post- analysis

tools on Microsoft® Windows.®

10

Software Functions

Interactive Measurements

I/CV 2.1 Lite includes Agilent ICS

as the default measurement tool.

ICS provides point-and-click

measurements, intuitive matrix

control, and graphical analysis

capabilities for semiconductor

parametric measurements.

Created setups can be used as

measurement algorithms in the

script editor.

Script Editor

The script editor provides a

wizard-based interface for building test scripts used in the execution of automated tests. It allows

access to libraries of built- in

software components that support functions for creating test

plans. Components include:

• Automated sub-die prober

movement

• Switch connection execution

• Test algorithm execution

• Pass/Fail determination and

processing

• Conditional branching: IF,

ELSE

• Looping: FOR, WHILE

• User variable creation

• User prompts

• Message displays

• Test script commenting

Wafer Prober Navigation

I/CV 2.1 Lite provides support

for popular semiautomatic probers as well as several automatic

probers. Probe plans can be

defined that include sub-die

movement for performing automated test of multiple modules

or individual devices across a

wafer. Interactive prober control

can also be implemented for

analytical applications.

Page 11

Test Execution

Test scripts can be executed for

either manual or automated

tests. Manual tests are used for

single devices or single modules

(which can include several

devices) on a manual prober.

Automated tests are used for

wafer tests combing semiautomatic

prober control with die or module

test scripts. Test wizards provide

step-by-step instructions for

entering runtime information,

selection of wafer navigation plans,

selection of test plans, and

starting a test.

Auto-Analysis and Test Reporting

Parametric quantities from test

data can be extracted and

standard reports and graphs can

be generated. Supported graphs

and reports include:

• Color wafer maps

• Histograms

• Parameter statistics

• Parametric values vs. die

location

• Tables of I-V or C-V curve data

Software Measurement

Tool Support

Test algorithms can be created

using the following tools:

• Agilent ICS

• Microsoft VBScript (resident

in the script editor)

Computer System Requirements

Operating System

Microsoft Windows 2000

Professional or XP Professional

with Service Pack 1

CPU

300 MHz Pentium II-class

(500 MHz Pentium III-class or

faster recommended)

Hard Disk

5 GB available space

(20 GB recommended)

Memory

128 MB for Windows 2000

Professional

(256 MB recommended)

256 MB for Windows XP

Professional

Disk Drive

CD-ROM

Software Security

Parallel or USB port required

to attach security key

Control I/F

Supported GPIB card (see

requirements below)

GPIB Card Support

Agilent

Card

82341C (ISA)

82357A

(USB/GPIB)

Agilent I/O Library L.02.01 required

National Instruments

Card

PCI-GPIB

GPIB-USB-A

Windows 2000 Windows XP Pro.

Professional (Service Pack 1)

X –

X X

Windows 2000 Windows XP Pro.

Professional (Service Pack 1)

X X

X X

Prober Support

Cascade Microtech

S 300 with Nucleus version 2.1

or 2.5

Summit 12k with Nucleus version

2.1 or 2.5

Electroglas

2001 and 408X

SUSS MicroTec

All SUSS MicroTec probe stations

using Prober Bench NT v4.2

Vector Semiconductor

AX-2000 / VX-3000, Version 3.2

or later

Supported Measurement

Instruments

• E5270 Series of Parametric

Measurement Solutions

• 4155A/B/C Semiconductor

Parameter Analyzer

• 4156A/B/C Precision Semicon ductor Parameter Analyzer

• 4284A Precision LCR Meter

• 4294A Impedance Analyzer*

• E5250A Low Leakage Switch

Mainframe

• Keithley 707 Switch

* VBScript libraries are supplied.

11

Page 12

For more information about Agilent and its

products, go to www.agilent.com.

For more information about Agilent Technologies

semiconductor test products, applications, and

services, visit our website: www.agilent.com/

go/semiconductor or you can call one of the

centers listed and ask to speak with a

semiconductor test sales representative.

Americas

Brazil (11) 4197-3600

Canada (French) 1 877 894-4414

Canada (English) 1 800 447-8378

Mexico 33 134-5841

United States 1 800 447-8378

Asia/Asia Pacific

Australia 1 800 629-485

China 1 800 276-3059

Hong Kong 852 2599 7889

India 91/11 690-6156

Japan 0120 421-345

Malaysia 1 800 880-780

New Zealand 0 800 738 378

Philippines 1 800 1651-0135

Singapore 1 800 276-3059

South Korea 080 778-0011

Taiwan 0 800 047-662

Thailand 1 800 2758-5822

Europe

Austria (01) 25 125-7183

Belgium (0) 2 404-9380

Denmark 080301040

Finland 20 547-9999

France (0) 825 010710

Germany (0) 18 05 24-63 34

Greece 20 547-9999

Ireland 016158393

Italy 02 92 60 8333

Luxembourg (0) 2 404-9340

Netherlands (0) 20 547-9999

Poland 20 547-9999

Russia 20 547-9999

Spain 91 631 3383

Sweden 020 120-9975

Switzerland (Italian) (0) 2 92 60 8484

Switzerland (German) (0) 1 735-9300

Switzerland (French) (0) 825 010 700

United Kingdom (0) 7004 222-222

Middle East

Israel 20 547-9999

Technical data subject to change without notice.

Microsoft and Windows are U.S. registered

trademarks of Microsoft Corporation.

© Copyright 2002 Agilent Technologies

Printed in USA April 21, 2003

5988-9238EN

S1

Loading...

Loading...