Page 1

Mechanical Contents

Contents

Color Printer...................................................................................................................1.1

General ...............................................................................................................1.1

Tools.......................................................................................................1.1

Lens Carrier ........................................................................................................1.2

Changing the Zoom................................................................................1.2

Focusing.................................................................................................1.2

Adjustment of the Zoom position............................................................1.3

Adjustment of the fixed focus lens position............................................1.4

Dismounting the lens carrier ..................................................................1.4

Changing the gas pressure spring.........................................................1.4

Shutter.................................................................................................................1.6

Dismounting the shutter .........................................................................1.6

Paddle height .........................................................................................1.7

Shutter adjustment.................................................................................1.7

Color Printer, Scanner Area..........................................................................................2.1

General ...............................................................................................................2.1

Tools.......................................................................................................2.1

Removing the Covers..........................................................................................2.2

Feeder....................................................................................................2.2

Computer ...............................................................................................2.2

Negative carrier......................................................................................2.2

Dismounting the Display Holder..........................................................................2.3

Filter Unit.............................................................................................................2.4

Replacing the cold light mirror................................................................2.4

Replacing the IR filter.............................................................................2.4

Dismounting the filter unit.......................................................................2.4

Dismounting the lamp switch .................................................................2.5

Replacing the filter paddles and the solenoids.......................................2.6

Film Supply .........................................................................................................2.7

Dismounting the film supply...................................................................2.7

Changing the rubber rollers....................................................................2.7

Changing the flap...................................................................................2.8

Replacing the motors .............................................................................2.9

Replacing the lifting magnet.................................................................2.10

Adjustment of the light sensors............................................................2.11

Film Feeder.......................................................................................................2.13

Dismounting the Film Feeder...............................................................2.13

Tension of the drive belt.......................................................................2.13

Rough adjustment of the film guide......................................................2.13

Mounting the Film Feeder....................................................................2.14

Adjustment of the film guide.................................................................2.15

Adjustment of the channel width scanning...........................................2.15

AGFA MSC 101 26.10.95 1

Page 2

Contents Mechanical

Negative Carrier................................................................................................2.17

Dismounting the negative carrier..........................................................2.17

Active Film Output: Dismounting or changing the toothed belt ............2.17

Changing the lifting magnet, toothed belt, auxiliary drive shaft............2.18

Working on the rockers ........................................................................2.19

Changing the light sensors for the negative coding..............................2.22

Replacing the negative carrier lock......................................................2.22

Scanner.............................................................................................................2.23

PC Holder..........................................................................................................2.24

Dismounting the holder.........................................................................2.24

Replacing the hard disk and/or the disk drive ......................................2.24

Film Processor...............................................................................................................3.1

General................................................................................................................3.1

Tools.......................................................................................................3.1

Dryer Block..........................................................................................................3.1

Removing the covers..............................................................................3.1

Changing the Leader Cutter...................................................................3.2

Heater.....................................................................................................3.2

Changing the dryer rack.........................................................................3.4

2 26.10.95 AGFA MSC 101

Page 3

Mechanical Color Printer

Color Printer

General

It is not mentioned in particular that the connecting lines must be disconnected for the

removal of a unit.

- Never touch screws secured with red lacquer, except when required in the manual.

Tools

The following tools and auxiliary means are needed:

- Gauge 135 from the set of gauges for the film plane

printing)

- Paper gauge for exposure table (standard accessory)

1 Centre point hole

(Part number not known at the moment of

#Lehre2

AGFA MSC 101 26.10.95 1.1

Page 4

Color Printer Mechanical

Lens Carrier

Attention! Do not unscrew screws on the lens carrier or on the Zoom lens without

specific reason!

Only the screws indicated in the manual may be unscrewed without

causing damage!

Changing the Zoom

- Push back the lens carrier (= single lens position)

- Unscrew screws A (3 screws)

Attention! The Zoom comes down

- Take out the Zoom

- Installation in reverse order

Attention! Do not open the Zoom! Replace it only as a complete unit.

Focusing

- Set the configuration to the maximum Zoom enlargement (10.58) and select this

configuration

- Go to menu "Edit\Printer\Parameter\Justify\Zoom Offset\Base Offset\Basic Zoom

Offset"

- Expose a focusing test series (seven Prints):

* Select test ±X; X gives the step width of an exposure test series.

* The MSC101 jumps into the Reprint mode:

Print a suitable frame for focus assessment (if a single frame is used, there must be

enough film on the left and right side so that it is fully pressed down by the film

pressure flap).

After leaving the Reprint mode, the MSC101 returns to the Basic Offset menu.

- Assess the prints and enter the Offset value of the best print as Basic Zoom Offset.

Example: Basic Zoom Offset: 30. Select test ±

following Zoom Offsets: 15, 20, 25, 30, 35, 40, 45

Best print with an Offset of 20, i.e. 20 is entered for the Basic Zoom Offset.

Now print a test series with 14, 16, 18, 20, 22, 24, 26 with test ±2 , select again the

best print result etc.

If none of the prints is sharp, the Basic Offset must be modified. Proceed as follows to

find the Basic Offset:

5 for the first test series. Print a series with the

- Keep on exposing test series with test ±5 until an increase in sharpness is visible in

one test series.

Make focusing test series with the following Basic Offsets:

15, 50, 85, -20, -55, -90

1.2 26.10.95 AGFA MSC 101

Page 5

Mechanical Color Printer

Adjustment of the Zoom position

y-direction (direction of movement of the Zoom lens):

- Set the configuration to the minimum Zoom enlargement (3.25) and select this

configuration

- Put the paper gauge on the exposure table

- Push the gauge 135 on the exposure table from the right side (centre point hole about

in the middle of the window). While pushing in the gauge, lift the rubber roller by

pressing on the rocker.

#Sclehin1

- Project the gauge 135 on the exposure table (Test Mode: Focusing)

- Turn screw B until the projected centre point is on the horizontal middle line of the

paper gauge

- Tighten the lock nut of screw B again

x-direction (paper advance direction):

- No adjustment required!

z-direction (direction of the light path):

- No adjustment required.

A shift in z-direction only shifts the focus point. The focus is adjusted electromechanically (see "Focusing").

#Objtrae1

1 Zoom

AGFA MSC 101 26.10.95 1.3

Page 6

Color Printer Mechanical

Adjustment of the fixed focus lens position

Prerequisite for the adjustment of the position is that the lenses have been focused

before (see the instructions attached to the fixed focus lenses)

- Push back the lens carrier (= single lens position)

- Put the paper gauge on the exposure table

- Push the gauge 135 on the exposure table from the right side (centre point hole about

in the middle of the window). While pushing in the gauge, lift the rubber roller by

pressing on the rocker.

#Sclehin1

- Project the gauge on the exposure table (Test Modus: Focusing)

- Unscrew the screws D

- Put in the lens

- Shift the lens until the projected centre point of the gauge is in the middle of the

graticule of the paper gauge

- Tighten the screws D

Dismounting the lens carrier

- Dismount the Zoom (see "Changing the Zoom")

- Remove the cover in the Scanner range (see "Removing the covers" in chapter "Color

Printer, Scanner area")

- Unscrew the screws C

Attention! The lens carrier comes down!

- Installation in reverse order

Changing the gas pressure spring

- Dismount the lens carrier (see "Dismounting the lens carrier")

- Take out the two marked lock washers

- Pull the spring and holder off the lens carrier

- Installation in reverse order

- Check the adjustment of the Zoom (see above)

1.4 26.10.95 AGFA MSC 101

Page 7

Mechanical Color Printer

1 Zoom 2 Gas pressure spring

#Objtrae2

AGFA MSC 101 26.10.95 1.5

Page 8

Color Printer Mechanical

Shutter

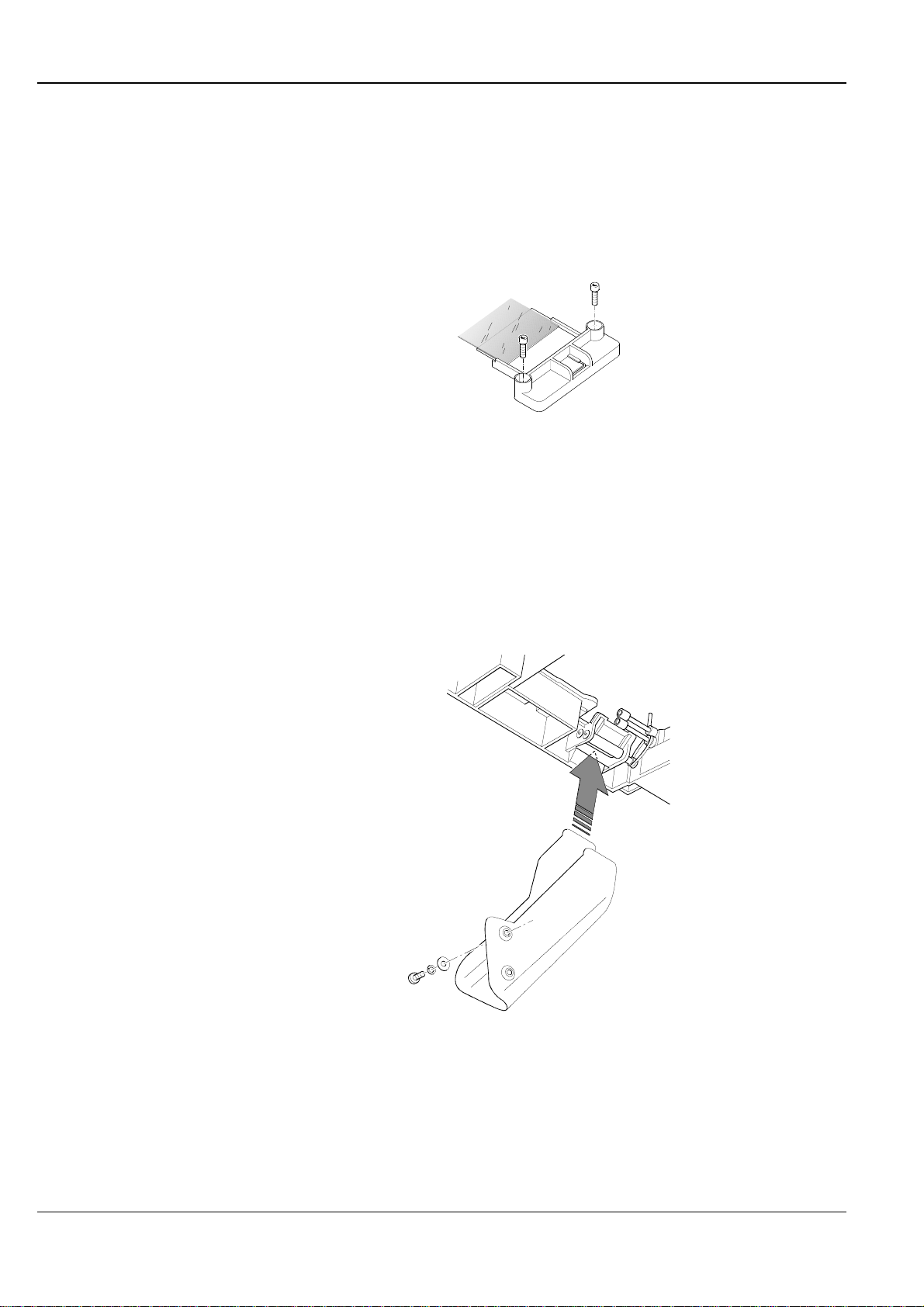

Dismounting the shutter

- Remove the negative carrier

- Push the Scanner to the right up to the stop

- Dismount the mirror (two screws)

#Spiegel01

- Fold up the dryer of the Film Processor

- Take out the last STB rack

- Unscrew the film supply (see "Flim supply, dismounting the film supply")

- Unscrew the top film chute (2 screws)

Note: Mind the correct position of the chute before pulling it out.

The left top edge of the chute is between the negative carrier and the active film output

#Frtsch01

- Pull out the film chute towards the bottom

- Push up the solenoid

The shutter is held on the darkroom housing only by magnetic force

1.6 26.10.95 AGFA MSC 101

Page 9

Mechanical Color Printer

- Pull out the shutter

- Installation in reverse order

Mind the correct position of the chute and the shutter (the shutter must lock in safely)

Note: If it is difficult to install the chute, don’t despair, this is normal! Make only sure that the

active film output is not damaged.

Paddle height

Adjust the height of the paddle with D-Cut shims so that the smallest distance between

the paddle and the housing is 0.1mm...0.5mm (over the entire swivel area of the paddle)

when it is turned (solenoid up). In normal position (solenoid down), the paddle may rub

slightly on the friction rib on the housing.

The paddle must not touch the metal cover when the latter is in place.

Note: At least one D-Cut shim is required

Shutter adjustment

Turn the solenoid in the 3 oblong adjusting holes until the bouncing and the noise at both

stops is minimised.

#Shutter

1 Oblong adjusting holes 2 D-Cut shim(s)

AGFA MSC 101 26.10.95 1.7

Page 10

Mechanical Color Printer

Color Printer, Scanner Area

General

It is not mentioned in particular that the connecting lines must be disconnected for the

removal of a unit.

Attention! Never touch screws secured with red lacquer, except when required in the manual.

Tools

The following tools and auxiliary means are needed:

- Expansion pliers for retaining rings

- Set of gauges for the film plane

1 Gauge 135 2 Zero position gauge

(Part number unknown at the moment of printing)

#Lehre2

AGFA MSC 101 26.10.95 2.1

Page 11

Color Printer Mechanical

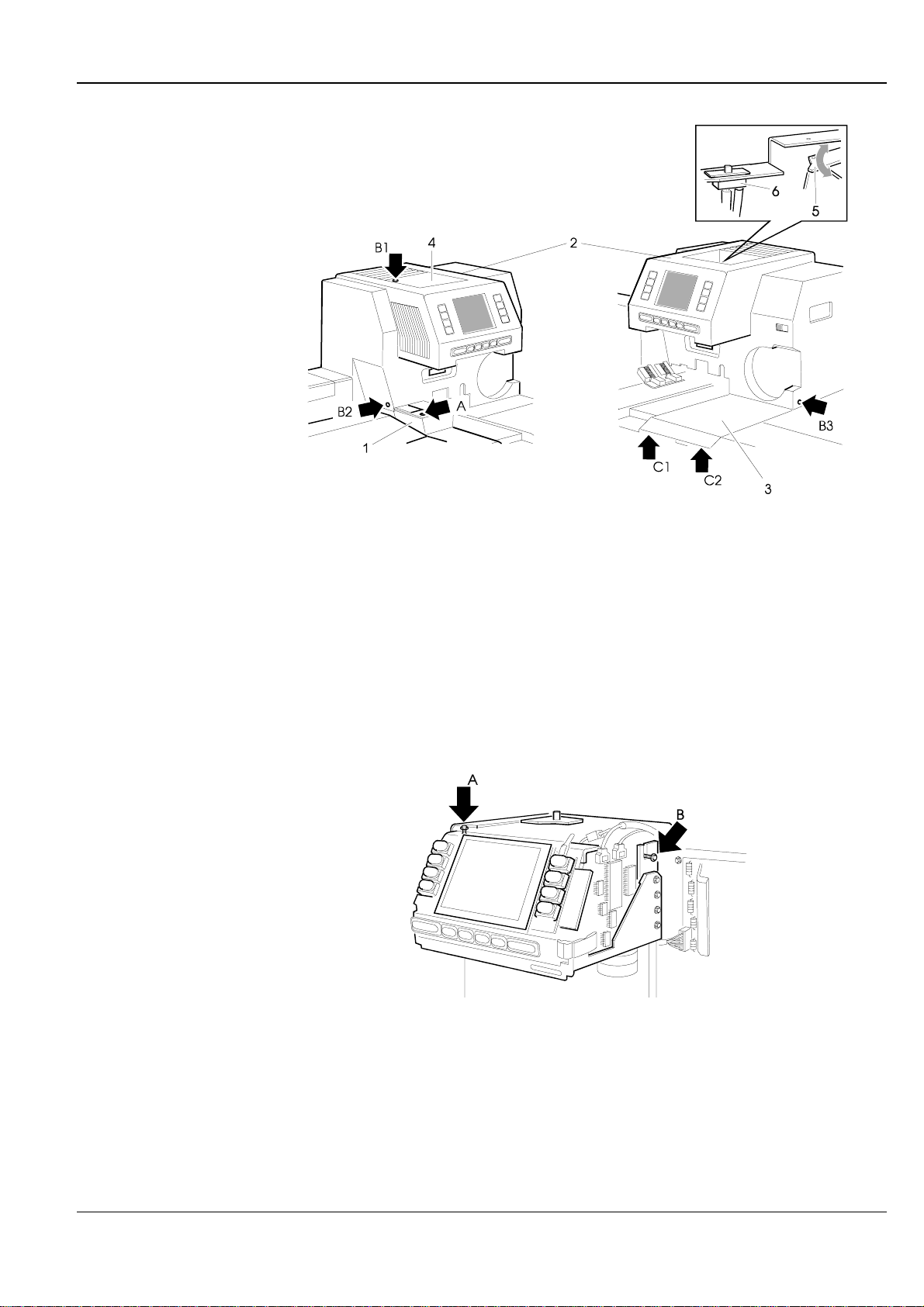

Removing the Covers

- Take out the mirror box

- Dismount the film take up

- Fold up the dryer of the Film Processor and open the cover of the Paper Processor

Feeder

- Unscrew screw A

- Take off the cover

Computer

- Take off the lamphouse cover

* Open the cover

* Separate the cover from the reflector bracket (the cover simply snaps on the

bracket)

The reflector unit moves up.

Attention! Never operate or jumper the lamp switch while the reflector unit is out! The heat of

Attention! In normal operating position (computer cover and lamphouse cover put on), the

Negative carrier

the lamp would immediately destroy the filters.

- Move the reflector back in and hold it down with the reflector pressure part.

reflector unit must not be held down by the pressure part !

- Unscrew the screws B1, B2, B3 d

- Pull out the cover towards the front

- Unscrew the screws C1 and C2

after having opened the Printer and lane distributor door

- Pull the cover out towards the front and lift it off

2.2 26.10.95 AGFA MSC 101

Page 12

Mechanical Color Printer

1 Feeder cover 4 Lamphouse cover

2 Computer cover 5 Reflector pressure part

3 Negative carrier cover 6 Lamp switch

Dismounting the Display Holder

- Unscrew screw A

- Slacken screw B

- Pull the unit out and up

#Agfacove

#Displ

AGFA MSC 101 26.10.95 2.3

Page 13

Color Printer Mechanical

Filter Unit

Replacing the cold light mirror

- Dismount the display holder (see there)

- Unscrew the marked screws

- Remove the cover

- Remove the holding spring

- Take out the mirror

- Installation in reverse order

Attention! The coated side of the mirror must point to the lamp!

Replacing the IR filter

Attention! The marked side (ring on the edge) must point to the lamp!

Dismounting the filter unit

#Kaltlich

1 Cover 3 Cold light mirror

2 Holding spring

The IR filter is located under the cold light mirror

- Take out the cold light mirror (see "Replacing the cold light mirror")

- Take out the holding spring

- Replace the filter

- Dismount the display holder (see there)

- Open the reflector pressure part (= move the pressure part in Home position)

- Unscrew the three marked screws

- If necessary, move in the filter paddle by hand

(If the filters are out, they may get damaged when the filter unit is dismounted).

2.4 26.10.95 AGFA MSC 101

Page 14

Mechanical Color Printer

- Dismount the filter unit

* Lift the unit a little and pull it out towards the front until it comes free

* Carefully press on the solenoids from below and tilt the unit towards the front

Attention! Do not reach into the light path opening or press on the filters!

* Pull out the unit towards the front

- Installation in reverse order

Make sure that all lines are installed and fastened again correctly so that they do not

hinder the filters.

Dismounting the lamp switch

Illustration see above

- Dismount the fan

- Strip the cable lugs off the switch

- Press on the switch locks (1) and pull the switch up (2)

#Filt_uni

1 Solenoids 3 Lamp switch

2 Reflector pressure part

AGFA MSC 101 26.10.95 2.5

Page 15

Color Printer Mechanical

Replacing the filter paddles and the solenoids

- Dismount the filter unit (see there)

Filter paddle:

- Remove the retaining ring

Note: The retaining ring is clamped directly on the (grooveless) solenoid shaft.

- Lift the paddles

Very stiff!

- Installation in reverse order

* It should not be necessary to adjust the paddle height.

This may only be necessary by inserting or removing D-Cut shims when a paddle

grinds. One D-Cut shim must remain on the shaft.

* Push the paddles on the shaft up to the stop

* Press the retaining ring firmly on the paddles

Solenoids:

Note: Mark the position of the solenoids (facilitates the reinsertion of the solenoids later on)

- Unscrew the fastening screws (3 screw each)

The screws of the Y, M, C solenoids are accessible from above, those of the mask

filter and light attenuator solenoids from below.

- Take out the solenoid

- Installation in reverse order

No adjustment required

#Filtpadd

1 Retaining ring 3 D-Cut shim

2 Filter paddle

2.6 26.10.95 AGFA MSC 101

Page 16

Mechanical Color Printer

Film Supply

Work on the film supply is performed in dismounted condition

Dismounting the film supply

- Dismount the film supply (2 screws)

Changing the rubber rollers

Note: The shaft can only be pushed in when its chamfer is in alignment with the chamfer of

#Flmsupl4

Top roller:

- Take off the lock washer and thrust out the shaft

- Replace the roller

- Assembly in reverse order

the shaft holder bores.

- Check the light sensors for correct triggering; readjust them, if necessary (see

"Adjustment of the light sensors")

#Fsobroll

1 Top rubber roller 3 Shaft

2 Lock washer 4 Shaft holder

AGFA MSC 101 26.10.95 2.7

Page 17

Color Printer Mechanical

Bottom roller:

- Remove all four lock washers from the shaft

- Pull out the shaft a little and thrust out the driver pin

- Pull out the shaft

Mind the washers (note their location)

- Push the roller off the shaft

- Assembly in reverse order

Attention! The roller turns only in one direction! Push the roller on the shaft so that it turns

in film drive direction when the shaft is held tight!

- Check the light sensors for correct triggering; readjust them, if necessary

(see "Adjustment of the light sensors")

#Flmsupl1

Free running direction when the shaft is held tight

1 Shaft 3 Driver pin

2 Roller 4 Lock washer

Changing the flap

- Pull out the shaft of the bottom rubber roller (see "Changing the rubber rollers")

- Hang out the leg spring

Note: For the assembly later on, it is useful to mark the contact point of the spring on the

eccentric of the flap.

- Unscrew the film guide plate

2.8 26.10.95 AGFA MSC 101

Page 18

Mechanical Color Printer

- Remove the connecting rod from the eccentric of the flap

- Remove the holding bracket

- Take out the flap

- Installation in reverse order

- Check the light sensors for correct triggering; readjust them, if necessary

(see "Adjustment of the light sensors")

#Flmsupl2

Free running direction when the shaft is held tight

1 Flap 4 Holding bracket

2 Film guide plate 5 Leg spring

3 Connecting rod

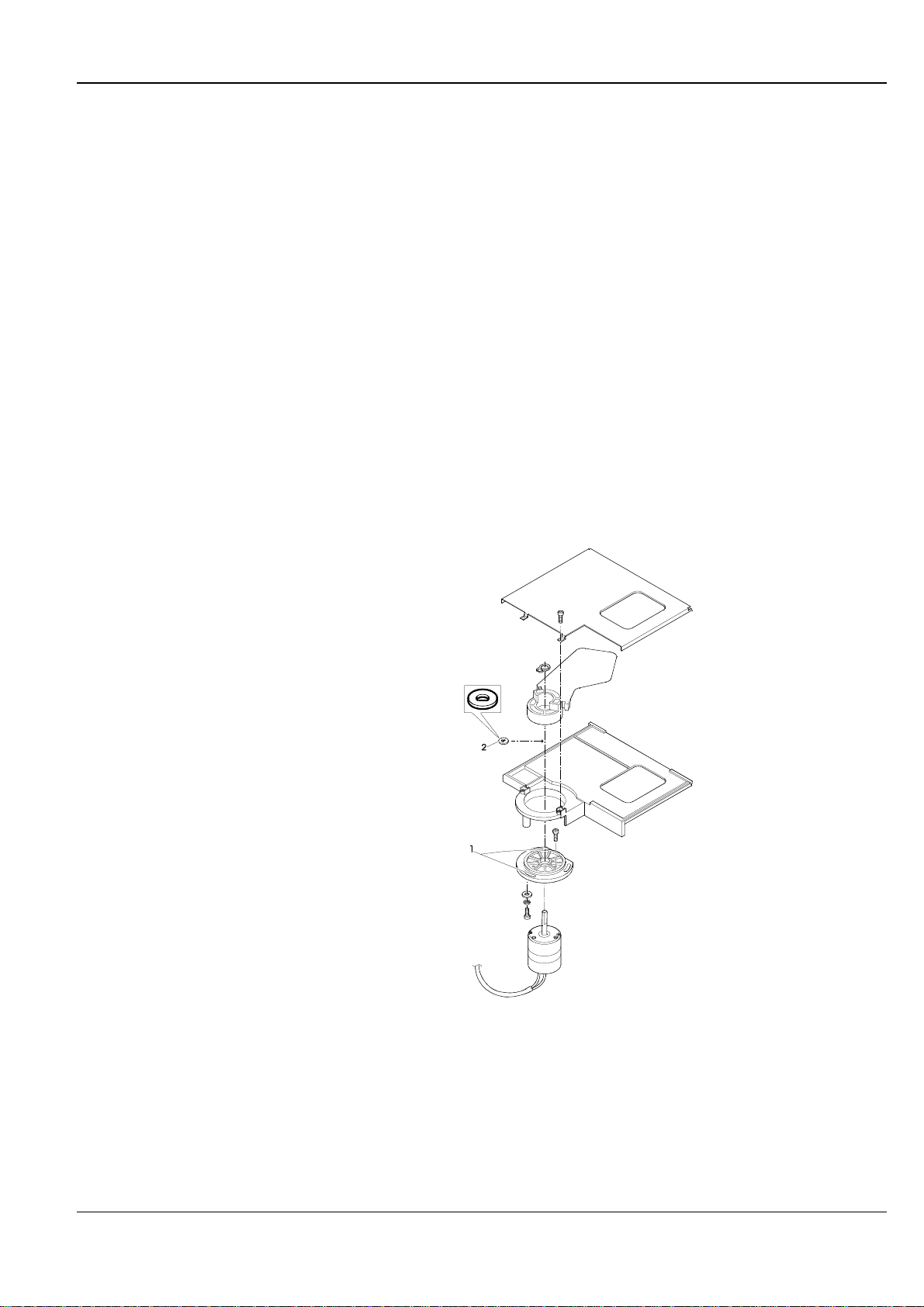

Replacing the motors

The motors are held in the motor holder only by brackets

- Remove the holder bracket (2 screws)

- Pull out the motor

- Installation in reverse order

Be careful when tightening the screws; the plastic thread gets easily damaged.

AGFA MSC 101 26.10.95 2.9

Page 19

Color Printer Mechanical

Replacing the lifting magnet

- Unscrew the light sensors

- Remove the lock washer

- Remove the cover plate (3 screws)

- Lift the light sensor actuator

- Thrust out the driver pin

- Lift out the magnet

Make sure that the second driver pin does not get lost when the shaft is moved

- Installation in reverse order

- Check the light sensors for correct triggering; readjust them, if necessary

(see "Adjustment of the light sensors")

#Flmsupl3

1 Light sensors 4 Driver pin

2 Cover plate 5 Magnet

3 Light sensor actuator

2.10 26.10.95 AGFA MSC 101

Page 20

Mechanical Color Printer

Adjustment of the light sensors

The adjustment can be performed while the film supply is dismounted. Only the light

sensors need to be connected. Check the light sensors in the test mode of the MSC 101.

The light sensors are relocated together.

Note: The indications "horizontal" and "vertical" refer to the mounting position of the film supply

Horizontal position of the flap:

- Put a 1mm spacing piece (e.g. twist drill) under the film guide plate

* Put it in in such a way that it is jammed between the film guide plate and the goose

pimple(s) of the flap when the latter is horizontal.

1 Film guide plate 3 Spacer 1mm

2 Flap

- Move the flap in horizontal position in the test mode

- If the light sensor for the horizontal position does not respond:

* Slacken both fastening screws

* Shift the light sensors until the light sensor for the horizontal position responds.

The light sensor for the vertical position must not send a signal

- Tighten the screws

- Move the flap in vertical position

- Move the flap several times in vertical and in horizontal position.

The light sensor for the horizontal position must respond each time, if not, the

adjustment must be repeated.

Attention! The actuator must not rub on the light sensors !

If necessary, slacken the fastening screws one by one, bend the jammed light sensor in a

better position, check its correct triggering, and tighten the screws again.

#101skiz

AGFA MSC 101 26.10.95 2.11

Page 21

Color Printer Mechanical

Vertical position of the flap:

- Let the flap drop in vertical position

- Check the light sensor for correct triggering

Only the light sensor for the vertical position may send a signal.

If the light sensor does not respond, slacken the fastening screw again and bend the

light sensor until it is triggered.

Attention! The actuator must not rub on the light sensors !

If necessary, slacken the fastening screw, bend the jammed light sensor in a better

position, check its correct triggering, and tighten the screws again.

2.12 26.10.95 AGFA MSC 101

Page 22

Mechanical Color Printer

Film Feeder

Dismounting the Film Feeder

Attention! Dismount and mount the Feeder only while the film supply is dismounted (see also

"Dismounting the film supply"), otherwise the Feeder or the film supply may get

damaged.

The Feeder is fastened to the negative carrier from above by means of two screws.

- Unscrew the fastening screws

- Lift off the Feeder

Once the Feeder has been removed, all units are accessible without problems; for this

reason, there is no need for detailed assembly/disassembly instructions for the single

parts.

The Feeder adjustment is more difficult. It is described on the following pages.

Tension of the drive belt

The belt tension can be adjusted by relocating the motor (4 screws).

Rough adjustment of the film guide

Adjustment becomes necessary when the gears are relocated on the shafts (e.g. after

replacement of the toothed belt).

- Unscrew the cover plate

- Dismount gear B and

turn the stop ring to the right end of shaft B

- Undo the connection between skid A ↔ shaft A (grub screw)

- Hold shaft A and screw in gear A until the threadless end of the shaft stands out of the

associated bush about 2mm

The shoulder on gear A should not slip out of its hole!

- Push skid A to the middle up to the stop

#101skiz

- Fasten skid A on shaft A again

- Turn gear A about half a turn in ccw direction

- Undo the connection between skid B ↔ shaft B (grub screw)

- Push skit B to the outside up to the stop

- Shift shaft B so that the threadless end of the shaft stands out of the associated bush

about 2mm.

AGFA MSC 101 26.10.95 2.13

Page 23

Color Printer Mechanical

- Fasten skid B on shaft B again

after having ascertained that

* there are still 2mm standing out and

* the skid is on the extreme outside.

- Push skid B against skid A and hold it tight

- Turn in the stop ring until skid B starts moving to the right

- Put on gear B

- Screw on the cover plate

- Move the Feeder in position 120 and in zero position in the test mode:

The threadless end of a shaft must not penetrate into the associated bush in neither of

the two positions (projection 0.5mm ... 1.8mm). Repeat the rough adjustment, if

necessary.

Mounting the Film Feeder

Attention! Be sure to dismount the film supply before installing the Feeder

#Feeder

1A Skid A 1B Skid B

2A Shaft A 2B Shaft B

3A Gear A 3B Gear B

4Stop ring 6 Lug

5Cover plate

If the film supply is not dismounted, the Feeder or the film supply may get damaged

- Dismount the film supply (see "Dismounting the film supply"); the cables need not be

disconnected

- Lift the top film transport roller

- Put the Feeder on the negative carrier diagonally from above,

inserting the film exit flap between the top and bottom film transport roller

- Screw the Feeder back on

2.14 26.10.95 AGFA MSC 101

Page 24

Mechanical Color Printer

Adjustment of the film guide

Adjustment is with the Feeder in place (see "Mounting the Feeder")

- Open the Feeder skids by hand (turn the toothed belt gear) until the gauge 135 just fits

Attention! Never move the skids towards the gauge because in this case they would not be

symmetric with the optical axis!

- Push in the gauge until it reaches into the film guide of the negative mask 135F

If it is impossible to push in the gauge, or too much backlash (max. 0.3mm):

* Unscrew the skids from the shaft (one grub screw each) and shift them as

appropriate

- Move the Feeder in position 120 and in zero position in the test mode:

The threadless end of a shaft must not penetrate into the associated bush in neither of

the two positions (projection 0.5mm ... 1.8mm). Repeat the rough adjustment, if

necessary (see "Rough adjustment of the film guide").

1 Gauge 3 Negative mask

2 Feeder skids

Adjustment of the channel width scanning

Adjustment is with the Feeder in place (see "Mounting the Feeder")

- Put in the zero position gauge

- Close the Feeder manually (turn the toothed belt gear) until the gauge is jammed (zero

position)

- Release the light sensor actuator and pull it out of the light sensor

- Push the actuator back into the light sensor until the latter is triggered (check in the test

mode of the MSC 101)

- Fasten the actuator again

#101skiz

AGFA MSC 101 26.10.95 2.15

Page 25

Color Printer Mechanical

- Open the skids for film size 120 (via the test mode)

- Move the skids back to zero position (via the test mode)

- The gauge must fit again with a backlash of ±0.1mm, if necessary, correct or repeat

the adjustment

Note In zero position, the skids are not symmetric with the optical axis.

#Feedkuf

1 Light sensor actuator

2.16 26.10.95 AGFA MSC 101

Page 26

Mechanical Color Printer

Negative Carrier

Some parts (e.g. film drive motors, rocker motors) are only accessible after the negative

carrier has been dismounted

Dismounting the negative carrier

- Unscrew the film supply (2 screws)

Attention! Never unscrew banjo screws secured with red lacquer!

- Unscrew the marked screws

- Lift out the negative carrier

Active Film Output: Dismounting or changing the toothed belt

The film output must be dismounted or at least slackened to change the toothed belt.

The film output is fastened under the negative carrier with two screws. It is accessible

without problems after the negative carrier has been removed.

#Negcar01

1 Banjo screw. Do not touch! 2 Active film output

AGFA MSC 101 26.10.95 2.17

Page 27

Color Printer Mechanical

Changing the lifting magnet, toothed belt, auxiliary drive shaft

Lifting magnet:

- Unscrew the marked screws (grub screws)

- Pull off the magnet

Belt:

- Pull off the additional gear (incl. armature plate)

- Change the belt

Auxiliary drive shaft:

- Unscrew the holder (3 screws)

- Pull out the shaft

The bearings can be taken off after removing the lock washer.

- Mind the correct position of the holder upon reassembly (see illustration).

#filmantri

1 Magnet 4 Holder

2 Armature plate 5 Single print drive shaft

3 Gear 6 Lock washer

2.18 26.10.95 AGFA MSC 101

Page 28

Mechanical Color Printer

Working on the rockers

Rocker motor(s) and eccentric blocks:

Since the assembly/disassembly of both rocker motors and eccentric blocks are identical,

the procedure is described only for one motor.

- Unscrew the cover plate (incl. light sensor)

- Pull out the motor

- Remove the lock washer on the eccentric block

Attention! Do not dismantle the eccentric block, but replace it as a complete unit!

- Pull out the eccentric block

To pull out eccentric block A, the gear in front of it need not be removed. It is sufficient

to pull out rocker shaft A a little.

Rocker disassembly:

- Remove the lock washer on the rocker eccentric

- Pull out rocker shaft B. Mind the washers, note their location !

- Remove the lock washer in the rocker

Attention! Do not try to detach the eccentric from the rocker.

- Strip off the rocker with the eccentric

AGFA MSC 101 26.10.95 2.19

Page 29

Color Printer Mechanical

#Wippe01

1a Cover plate A 1b Cover plate B

2a Motor A 2b Motor B

3a Eccentric block A 3b Eccentric block B

4a Rocker shaft A 4b Rocker shaft B

5a Rocker 5b Rocker eccentric

Rocker assembly:

- Remove the plates

- Dismount the bottom rubber roller

* Lock the shaft: Push the pin (or an Allan key) through the hole in the motor shaft

2.20 26.10.95 AGFA MSC 101

Page 30

Mechanical Color Printer

* Unscrew the marked screw

* Strip off the roller

- Push the rocker a few mm on the shaft with the spring inserted

(Spring position in the rocker, see illustration below)

- Turn the rocker until it rests on the motor shaft

(The eccentric hangs down)

- Turn the spring until its long leg rests on the rocker

(The leg moves away from the rubber roller, in direction of the motor shaft)

- Push the rocker and spring fully on the shaft

The short leg of the spring slides in the recess on the shaft.

- Turn the rocker in opposite direction to the spring tension until it rests on the negative

carrier. (The eccentric rests on the negative carrier as well)

- Fasten the bottom rubber roller on the motor shaft again

- Put the lock washer back into the rocker

- Screw the plates back on the negative carrier

#Wippe02

1 Plates 3 Bottom rubber roller

2 Motor shaft 4 Rocker

AGFA MSC 101 26.10.95 2.21

Page 31

Color Printer Mechanical

Changing the light sensors for the negative coding

- Slightly press down the quick-action locks of the light sensor holder and push the unit

to the back

- Lift the light sensor

1 Light sensor holder with sensor 3 Locking button

2 Cover plate

Replacing the negative carrier lock

See the above illustration.

- Unscrew the cover plate (2 screws)

- Take out the lock

Attention! Change only the complete lock!

- Installation: Mind the correct position of the locking button (see illustration above)

#Negcar02

2.22 26.10.95 AGFA MSC 101

Page 32

Mechanical Color Printer

Scanner

The slide motor is directly accessible, the toothed belt and the Scanner slide, after

removal of the negative carrier (see "Negative carrier, dismounting the negative carrier")

Reference value for the toothed belt tension: Slack of 3mm at approx. 2.5N.

All measuring cells are located directly on the Scanner board. It can be removed from the

Scanner slide and reinserted without problems.

1 Scanner tray 4 Scanner slide

2 Slide motor 5 Scanner board

3 Toothed belt

#Scan01

AGFA MSC 101 26.10.95 2.23

Page 33

Color Printer Mechanical

PC Holder

Dismounting the holder

- Unscrew the screws A (2 screws)

- Lift the holder up and off

Replacing the hard disk and/or the disk drive

Hard disk:

- Unscrew screw B

- Push the hard disk to the back

- Lift out the hard disk

- Installation in reverse order

Disk drive:

- Dismount the hard disk (see above)

- Take out the filter power drive board

- Unscrew the screws C (4 screws)

- Take out the disk drive

- Installation in reverse order

#Pc_traeg

1 Hard disk 3 Disk drive

2 Filter Power Drive Board

2.24 26.10.95 AGFA MSC 101

Page 34

Mechanical Film Processor

Film Processor

General

It is not mentioned in particular that the connecting lines must be disconnected for the

removal of a unit.

- Never touch screws secured with red lacquer, except when required in the manual.

Tools

The following tools and auxiliary means are needed:

- No special tools required

Dryer Block

The dryer block is composed of the following units

- Film feeder block

Removing the covers

Note: The Film Processor may not heat up when the cover is open, even not when the dryer is

- Film dryer block and

- Leader Cutter.

- Remove the cover of the emergency film removal

- Fold up the dryer

- Unscrew the fastening screws (6 screws at the bottom edge)

- Strip off the cover

Provide the dryer rack and the heater with an additional cover:

- Unscrew the fastening screws (2 screws at the crossover dryer block ↔film feeder

block)

down and correctly locked. Reason: There are other control switches on the rear side

next to the Reed switch on the locking button (not visible from above). Without the cover,

the dryer location is slightly different. For reason of manufacturing tolerances, the control

switches may not be actuated in this case.

AGFA MSC 101 26.10.95 3.1

Page 35

Film Processor Mechanical

Changing the Leader Cutter

The Leader cutter should not be touched. Since its adjustment, removal and reinstallation

would be too time-consuming, the Leader cutter is replaced only as a whole block.

- Unscrew the marked screws (on the dryer underside)

- Pull the Leader Cutter towards the front and lift it out

Heater

#Lc01

Attention! Switch off the current on the main switch!

Remove the bimetal fuse strip:

Remove the fuse only if it does not switch through when the red touch-contact key is

pressed.

- Remove the cover (screws A)

- Unscrew the fuse (screws B)

Dismount the heater element:

- Remove the cover (screws A)

- Remove screw C

- Lift out the heater element

Change the thermofuse:

The thermofuse is easily accessible after the heater element has been removed (see

above).

3.2 26.10.95 AGFA MSC 101

Page 36

Mechanical Film Processor

Dismount the heater fan:

- Dismount the heater element (see above)

- Unscrew the screws D

- Lift out the fan

#Ftrock01

1a Cover 3 Heater element

2a Bimetal fuse strip 4 Heater fan

2a Touch-contact key

AGFA MSC 101 26.10.95 3.3

Page 37

Film Processor Mechanical

Changing the dryer rack

- Dismount the Leader Cutter (see "Changing the Leader Cutter")

- Dismount the heater fan (see above)

Note: Dismounting the heater fan is not absolutely necessary but simplifies the removal of

the dryer rack.

- Unscrew the marked screws

- Take out the rack

- Installation in reverse order

Make sure that the ball bearing sits correctly in the holder on the drive shaft.

#Ftrock02

1 Dryer rack 4a Drive shaft

2 Leader Cutter 4b Holder

3 Heater fan

■

3.4 26.10.95 AGFA MSC 101

Loading...

Loading...