Page 1

Add-on for Microsoft

BroncoBronco

Flight Simulator

Manual

Page 2

Bronco X

Concept Mathijs Kok (Aerosoft)

Models/Textures: Stefan Hoffman (Aerosoft)

XML/ gauges: Finn Jacobsen (Aerosoft) /

Frank Wiesmann (Aerosoft)

Flight mechanics: John Cagle

Project Management: Mathijs Kok (Aerosoft)

Manual, documentation: Finn Jacobsen (Aerosoft),

Mathijs Kok (Aerosoft)

Sounds: William Lennox (Aerosoft)

Images: Nick Churchill

Installer: Andreas Mügge (Aerosoft)

Testing: Several good folks who will

all be getting a free copy

A special thanks to the OV-10 Bronco Association, German Wing, very cool

people (Tony DeBruyn, Thomas Viertbauer, Tom Houquet, Michael Vaeremans,

Peter Junior, Heinz-Dieter Rheinländer, Ela Gedl, Markus Rheinländer) who fly a

very cool aircraft. Without their help this aircraft would not be half as good.

Copyright: © 2012/ Aerosoft GmbH

Airport Paderborn/Lippstadt

D-33142 Bueren, Germany

Tel: +49 (0) 29 55 / 76 03-10

Fax: +49 (0) 29 55 / 76 03-33

E-Mail: info@aerosoft.de

Internet: www.aerosoft.de

www.aerosoft.com

All trademarks and brand names are trademarks or registered of their

respective owners. All rights reserved.

2 3

Aerosoft GmbH 2012

Page 3

BroncoX

Manual

Add-on for

Microsoft Flight Simulator X

Page 4

Bronco X

Content

Introduction ...............................................................6

System Requirements .......................................................... 7

Contact Support ................................................................... 8

Specifications(OV-10A) ........................................................ 9

FSX Limitations and Settings ............................................ 10

Flying the Bronco .....................................................13

The Garrett Turboprop Engine .......................................... 16

Failures ...................................................................... 18

Accumulative Engine Wear ........................................ 19

Electrical System ................................................................ 22

Battery Busses ........................................................... 22

Engineer Station Gauge............................................. 24

Fuel System ........................................................................ 26

Hydraulic Power System ................................................... 27

Oil System .......................................................................... 27

Power Levers/ Condition Levers ....................................... 28

Landing Gear ...................................................................... 29

Nosewheel Steering .................................................. 29

Wheelbrakes/ Parking Brakes ..................................... 29

Flight Control Systems ...................................................... 30

Trims ......................................................................... 30

Wing Flaps ................................................................ 30

Aerosoft GPS Unit .............................................................. 31

Map Mode ................................................................ 31

Direct To Mode .......................................................... 32

Cursor Mode ............................................................. 33

HSI Page ................................................................... 35

Becker BXP 6401 Transponder .......................................... 38

Tacan Receiver .................................................................... 40

Becker AR 4201

Communication Radio ....................................................... 41

Interactive Checklist Gauge .............................................. 42

Panels ................................................................................. 46

Aerosoft GmbH 2012

4 5

Page 5

Main Panel ......................................................................... 47

Right Side Main Panel ....................................................... 48

Left Rear Side Panel ........................................................... 49

Left Forward Side Panel .................................................... 51

Throttle Quadrat ................................................................ 52

Overhead Panel ................................................................. 53

Right Forward Side Panel .................................................. 54

Right Rear Side Panel ........................................................ 55

Right Sidewall Switches .................................................... 56

Checklist ............................................................................. 57

Normal Checklist ....................................................... 57

EMERGENCY CHECKLIST........................................... 68

Appendix A: Landing Pattern ........................................... 79

Appendix B: The Making Of ............................................. 80

Page 6

Bronco X

Introduction

Almost all aircraft designed for a COIN (counter-insurgency) are great

fun to fly. They have to be sturdy and have loads of power to get out

of trouble and they also have got to be agile and easy to fly low to the

ground. So they are all the opposite of airliners that draw straight lines

high in the sky, they feel most at ease when the hug the ground and

pull G. The OV-10 Bronco is perhaps the finest example of this class of

aircraft.

The Bronco has its roots deep in the 1960s when most military aircraft

were getting bigger, more complex and way faster. These aircraft did

not work well in harsh conditions found in jungles and even on carrier

decks. The concept of a rugged close air support aircraft that would

be ideal to operate in limited scale conflicts and operate from improvised airfields was proven by the Cambodia and Vietnam conflicts that

were developing at the time. The North American (later Rockwell)

developed the concept into prototypes that were soon in service with

the U.S. Marines Corps, U.S. Air Force and the U.S. Navy. In Vietnam

the aircraft was introduced in a Forward Air Control role, guiding large

attack aircraft onto targets but soon the Bronco’s went into battle with

a large array of ground attack weapons. Medium bombs, rocket and

gun pods all proven to be effective and even Sidewinders against air

targets were used. To increase loiter time over ‘Indian’ country external

fuel tanks were added. All this additional weight and drag caused the

aircraft to feel underpowered, even though it has ample power when

it is flown without external stores.

The Bronco has a small fuselage but if comfort was not important and

the backseat removed it could carry 5 passengers. In fact the Bronco

was soon used in every possible role. It was one of those aircraft that

seemed to grow in potential over time, and as can be seen with other

aircraft (the A10 Warthog for example) it seems hard to find a modern

replacement. That’s why there are still plans to build a updated version

using the same basic design. When the Bronco was pulled from front

line duty it was still in demand in military and civil roles.

Aerosoft GmbH 2012

6 7

Page 7

Countries like Colombia, Indonesia, Philippines, Thailand, Venezuela,

Lebanon and Germany used them for many tasks including drug

interdiction, firefighting and target tugs. Many are still flying and they

are welcome guests at airshows with their distinct shape and sound.

Our standard version is based on the OV-10B that was last in service in

Germany as a target tug (dragging air targets for other fighters) and

now fly as part of the German Wing of the OV10 Bronco Association

(GWOBA). That organization and especially its founder Tony De Bruyn

and press Officer Markus Rheinländer cannot be thanked enough. Do

visit their website at http://www.germanwing.de/Start.htm.

System Requirements

• Windows XP, Vista, 7 (fully updated)

• Microsoft Flight Simulator FSX (with SP2 or Acceleration Pack)

• Dual Core CPU

• 2 GB RAM internal memory

• 512 MB graphic card

• Adobe Acrobat® Reader 8 minimal to read and print the

manual (1)

(1) Available for free, download at: http://www.adobe.com/prodindex/

acrobat/readstep.html

Page 8

Bronco X

Contact Support

Support for this product is offered by Aerosoft. We prefer to have a

support forum for the simple reason that it is fast and efficient

because customers help customers when we are sleeping.

There are special forums for this product at: http://forum.aerosoft.

com/index.php/forum/474-ov10-bronco/

We feel strongly about support. Buying one of our products gives you

the right to waste our time with questions you feel might be silly. They

are not.

Versions

The Broncos came in various variants:

• OV-10A - Original production version

• OV-10B - German broncos used as target tugs (the Aerosoft

Bronco cockpit is based on this version)

• OV-10C – Export version for Thailand

• OV-10E – Export version for Venezuela

• OV-10F – Export version for Indonesia

• OV-10D – Second generation Bronco with modernized systems

Aerosoft GmbH 2012

8 9

Page 9

Specifications(OV-10A)

Crew: 2

Length: 41 ft 7 in (12.67 m)

Wingspan: 40 ft 0 in (12.19 m)

Height: 15 ft 2 in (4.62 m)

Wing area: 290.95 ft² (27.03 m²)

Empty weight: 6,893 lb (3,127 kg)

Max takeoff weight: 14,444 lb (6,552 kg)

Powerplant: 2 × Garrett T76-G-410/412 turboprop,

715 hp (533 kW) each

Performance

Maximum speed: 281 mph (452 km/h)

Range: 576 mi (927 km)

Service ceiling: 24,000 ft (7,315 m) even though

18.000 ft seemed always more accurate

Armament

Guns: 4 × 7.62x51mm M60C machine guns

Hard points: 5 fuselage and 2 under wing and

provisions to carry combinations of:

Rockets: 7- or 19-tube launchers for 2.75” FFARs or

2- or 4-tube launchers for 5” FFARs

Missiles: AIM-9 Sidewinder (Wing pylons only)

Bombs: Up to 500 lb

Other: SUU-11/A or Mk 4 Mod 0 gun pods

Page 10

Bronco X

FSX Limitations and Settings

Unfortunately FSX has some limitations that are hard to overcome, it

also has some bugs that that are simply not possible to avoid. Some

limitations (like Landing Lights and the complete Electrical System)

have been circumvented by replacing what FSX has to offer and

writing our own code, but some other things are not so easy. We like

to mention them.

Almost all lights are not very solid in FSX. They always seem to wander

around the airframe. Even stranger, this effect depends on where you

are on the globe. We have avoided this effect in some cases by not

using effects but modeled ‘balls’ of light. These are not easy to see at

long distances but look better close up.

The sound is a special problematic area for this project because FSX

does not know this type of engine. When we would have used the

standard turboprop sound the startup would be rather unrealistic as

the propellers would be heard while they would not be moving. So we

are using a combination of FSX sounds and some played by our own

sound module. We even switch off the default FSX sound during

start-up otherwise it would be even more problematic. So don’t worry

if you see the SOUND OFF message appear for a moment.

Aerosoft GmbH 2012

10 11

Page 11

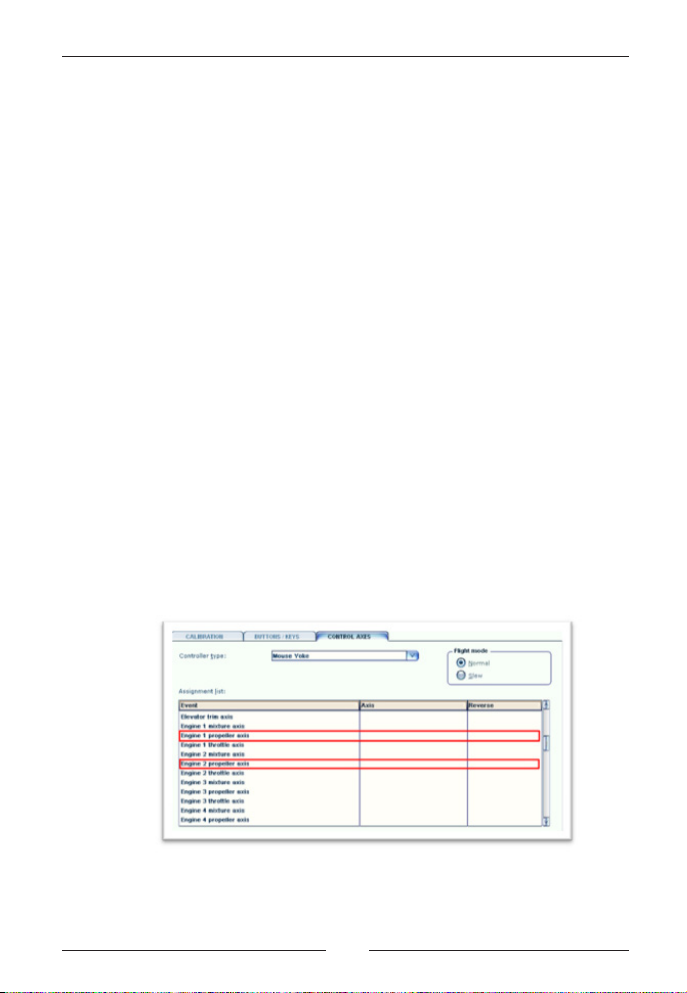

The OV-10 Bronco does use special coding to handle the props and

the Engine 1 propeller axis and Engine 2 propeller axis should be left

unassigned in FSX. If you do have hardware assigned on those axis

leave the levers fully forward when using the Bronco.

We decided not to model the back seat as it really is useless in FSX.

You can’t fly the aircraft from there as visibility is almost zero. Note

that the aircraft is now mostly flown with just the pilot. The Bronco

does not have an Autopilot but we left the standard FSX Autopilot key

commands on so when you do need to make a long flight you can use

it. We strongly recommend FSX REALISM settings as shown in the

image. If you prefer to fly without rudder activating the Autorudder is

an acceptable option.

Because this aircraft is modeled with detailed system using a nonstandard startup situation could cause some systems to be in an

incorrect initialization state. We provided a startup situation called

Aerosoft - OV10 Bronco that places the aircraft at the airport where it

is normally found (Wevelgem Belgium) with all FSX settings as they

should be. Feel free to change the weather and location but do not

change any of the other settings.

Page 12

Bronco X

To handle some of the more complex systems we need to overwrite

certain parameters in FSX. This causes the standard select engine and

select doors commands to be less reliable. We added a small panel

that can be called up with [SHIFT] + [4] that makes these functions

easy to access.

The Bronco does not have a standard spoiler system so we took advantage of this

to include an invisible spoiler that makes ground maneuvering and STALL landings far more realistic. If you notice that you are not able to reach sufficient speed

in flight (at least 200 knots without any problem) check if there is you have the

spoiler assignment handled by FSUIPC or have it linked to a hardware button. In

the air the code will set the spoilers to retracted a few times every second.

Aerosoft GmbH 2012

12 13

Page 13

Flying the Bronco

You will find that the Bronco is an amazingly easy aircraft to fly; it has

almost no nasty features you should be aware of. There are however a

few things that are special. For starters the very wide speed range, it

has been clocked at 400 knots (okay that is over the 350 knots red

limit and in a dive) and with full flaps it will land at 44 knots (!)

without problems. It will basically feel very happy at any speed

between 100 and 300 knots. If you consider the role of the aircraft it

makes sense. It needs to get somewhere fast and then loiter for as

long as possible. That loitering was often done at low altitudes and

between the trees and hills where the aircraft seems to be happy. As

long as you keep in mind the engines need a bit of time to spool up

(and the aircraft is not loaded up with weapons) you will have ample

power to get out of tricky situation.

The German OV10 Bronco we used as our base model flies at many

airshows and it used to fly this demo in 2010:

1. Take off360° climb

2. High speed pass followed by a 45° steep climb

3. Slow speed pass with landing gear down

4. Top side pass

5. Horizontal 360° turn

6. Bottom pass

7. Wing waggle

8. Stoll Landing

Page 14

Bronco X

Don’t be afraid to pull some G in the Bronco, it loves tight turns. It

also loves steep dives. As one Bronco driver told us:

“…very much a pilot’s aircraft. Named after a type of horse and that

makes a lot of sense. You sit in it like you sit on a horse, in a very high

seating position with great visibility all around and it seems to

understand what you want to do. A good Bronco driver can put her

anywhere he likes in any attitude. It’s a shame they are getting old

now and the pilots have now got more sense than we did. We pulled

stuff you will never see at airshows now and most of my friends

landed after all that. If you lose an engine though, better be prepared

to bail out because things get out of hand real fast.“

Tony de Bruyn, who has to be one of the current Bronco pilots with

the most experience, sent us this when we asked about what it is like

to fly this aircraft:

“Flying the Bronco is like feeling to be on top of the world, such is the

fantastic view all around, the responsiveness on the controls, the

speed range and its versatility. There seem to be no limits in where you

want the aircraft to take you and it does it in such a way that you are

continuously wondering whether the airplane is reading your mind

rather than you making control inputs. It flies with such magnificent

ease that one soon feels very privileged in handling the thoroughbred

and bring the very best out. Some additional personal comments/

thoughts. The people at NAA were probably at the pinnacle of

airplane development at the time when the Bronco was conceived in

the mid 1960’s:

• The engineering is out right brilliant - no doubt building on a

long and highly successful legacy (just to name a few: AT6

Texan, P51 Mustang, B25 Mitchell, F86 Sabre, X15, etc...)

• The flying characteristics are just magnificent; unbelievably well

harmonized and light controls throughout the full speed range

from 70 to 350 KIAS (note: KIAS), very direct and snappy

response to control inputs make it very well liked by everyone

who ever got their hands on it.

Aerosoft GmbH 2012

14 15

Page 15

• Operationally the Bronco is incredibly versatile feeling at home

in and out of any environment - jungle to dessert, unprepared

dirt strips, carrier deck, you name it, it has been there...

• Maintainability; it was designed to be maintained out in the

field with just a standard tool set at hand, no special tools are

required.

• Even when it came to giving the airplane a name, they

absolutely got it right: bronco: A wild or half-tamed horse, esp.

of the western U.S. From Spanish, literally ‘rough, rude.’ The

Bronco is not too large, just as the wild horses out on the

prairies. It’s got a little way of it’s own, but in a good natured

way; you will need to keep it in control - tame it - all the time

but this is easily done.

• It’s got a purposeful rough appearance, some say it’s beautiful

others think differently. It definitely has got CHARACTER and it

shows!

A very likable airplane altogether and I have never come across anyone

who has expressed any dislike or displeasure about the OV10 Bronco,

which is probably also unique and a good indication of its quality.”

If you want to get an idea how the Bronco should be flown, check out

this video: http://player.vimeo.com/video/28244509. It shows the

Bronco in its element, flying low and fast, twisting and turning.

What ever you do, don’t be hung up on charts and speeds. The

Bronco will tell you when it is about to stall (keep an eye on the

airspeed indicator, before the stall happens the buffeting airstream will

make it jitter) and when it wants to fly. One mistake however that is

easy to make is to lose too much speed at landing, although you can

fly at very low speeds it is strongly advised to stay over 100 knots. See

the landing chart that is added at appendix A. Also listen to the

aircraft, you hear the airframe groan when you put G-load on it, the

wind noise will give you good indications on the speed.

Page 16

Bronco X

The Garrett Turboprop Engine

The turboprop model in FSX is poorly modeled, the same is true for

torque and EGT readouts from FSX. Air-starting the engines by wind

milling is not featured by FSX, but through coding around the FSX

“engine”, we managed to correct all these deficiencies.

The turboprop available in FSX is based on the Pratt and Whitney PT6

type of engines. The PT6 is a free turbine engine. This means that the

core engine - the gas producer is a self-sustained gas turbine. The

propeller is driven through a gearbox connected to a separate turbine

placed after the gas producer. This means that the gas producer is

allowed to start and spool up independently of the propeller and it´s

turbine. Since propeller blade pitch angle is controlled via a hydraulic

governor, which uses engine oil pressure, the propeller will move into

feathered position when engine oil pressure is lost or if the condition

lever is moved fully back into the SHUTDOWN and FEATHER position.

A feathered propeller needs a huge amount of torque to overcome the

drag when spinning. Since a free turbine turboprop allows the gas

producer to spool up without turning the prop, sufficient engine oil

pressure will build up to un-feather the propeller.

The turboprop engines used on the Rockwell OV-10A Bronco are the

Garret T-76 types of engines. They are known as single shaft geared

turboprop, in which there is no separate turbine for the propeller. This

means that the propeller is directly linked to the gas producer via the

gearbox. With a feathered propeller, the engine starter will have to

both turn the gas producer as well as the propeller up to speed during

start up. As explained, a feathered propeller needs a lot of torque to

overcome the drag induced when the propeller starts spinning. This is

not desirable. To prevent this, a mechanism called Start latches are

built into the propeller. The start latches locks the propeller blades in

their beta range so with flat pitch position (between full fine and

reverse). In that position the propeller blades produce very little drag,

but also no forward thrust - or at least very little.

Aerosoft GmbH 2012

16 17

Page 17

To engage the start latches, the pilot needs to pull the throttles into

the reverse range right after shutdown of the engines but before Ng

RPM drops below approximately 50%. This will keep the propeller

blades in the beta range enabling the start latches to “snap in” and

lock the blades. To disengage the start latches, the pilot only need to

move the throttle into reverse range after engine startup has occurred

and Ng RPM is above approximately 60%. Throttling up with start

latches engaged will be noticed because of the lack of forward thrust

and little torque readout on the gauges.

In the case where the pilot fails to move the throttles into reverse

range, the propeller will feather, just like on the free turbine types of

engine. In such cases the propellers will need to be un-feathered. This

is done via the Airstart switches. The airstart switches have 3 positions

CRANK, AUTO, ON. AUTO is the normal position and will automatically control fuel and ignition in accordance to the engine RPM sensing

switches. CRANK will turn on a pump called the un-feather pump. This

pump supplies oil pressure to the propeller governor forcing the

propeller blades towards full fine and beta range - no fuel or ignition is

introduced. Crank is somewhat misleading - it won´t crank the engine

by the Starter, but merely points to the fact that in air, the un-feathering of the propeller will cause these to start wind-milling. ON means

that the un-feather pump as well as fuel and ignition is introduced for

an air-start. After un-feathering / air-start the Airstart switch must be

returned to AUTO. Note the Bronco has two additional ignition

switches for continuous ignition.

The description might sound complex, but is actually very straight

forward. For starting the engines on the Bronco follow this procedure:

• Power levers: GROUND IDLE

• Condition levers: SHUT OFF (NOT SHUT OFF & FEATHER)

• Primary DC bus: POWERED (BATT DISC & BATT MAIN

SWITCHES ON OR GRND PWR ON)

Page 18

Bronco X

If propellers not feathered:

• Start switch: ON

• At 10% Ng RPM : CONDITION LEVER NORMAL FLIGHT

If propellers feathered:

• Power levers: MOVE INTO REVERSE RANGE

• Airstart switch: CRANK

• Prop at flat pitch set

Airstart switch: AUTO

• Power Levers: GROUND IDLE

• Start switch: ON

• At 10% Ng RPM: CONDITION LEVER

NORMAL FLIGHT

Failures

The engines in the Aerosoft OV-10 Bronco will fail if they are not

treated with respect. They are very well maintained but they are a few

decades old, so be nice to them. All failures can be switched off in the

checklist configurator.

• Engine flameouts might occur when flying in icing conditions

without having switched on the continuous ignition switches.

• Starter motors will fail if run too long with feathered propellers

due to over torque.

• Continuous torque should be limited to 1875 foot/lb and only

exceeded for short amounts of time. When this limit is

exceeded the chance of a failure increases dramatically. Keep in

mind the overtorque warning light will only be lit at 2200 foot/

lb so do not wait for them to light up.

Aerosoft GmbH 2012

18 19

Page 19

• Another source for engine failure is overheating. To monitor

engine temperatures there is a EGT gauge for each engine.

During startup they show EGT (Exhaust Gas Temperature), but

when Ng (RPM) passes 50% they shift to read TIT (Turbine Inlet

Temperature). EGT is measured with a probe in the exhaust

gas, while TIT is calculated from EGT, since no probe would last

very long at the TIT temperature. The TIT is further altered by

the SRL computer (Single Red-Line) also called the “Pilot Lier”,

since the temperature shown is different from the real TIT.

Under ISA conditions the T76 engines are limited by torque

until approximately 17.000 feet where Max Allowable EGT

normally is reached). With higher OAT this altitude becomes

lower. To be honest, the Bronco is not happy when flown that

high, it’s an aircraft designed to be flown low. Max Allowable

EGT is not a fixed value, but is a function of Ng (RPM), OAT,

Altitude and Airspeed. Using EGT to determine if you are

running the right temperatures is complex and involves many

tables and charts. That’s where TIT with the SRL correction

comes is, Max allowable TIT, compensated by the SRL, is always

approximately 1000 °C , so the pilot only needs to verify that the

needles don´t get higher than that. The TIT Warn lights are also

set to light at 996 °C. Some Broncos (the German OV-10B’s for

example) were later changed to always display EGT, but still have

the TIT warn lights that will light when the temperatures are too

high. Keep an eye on these lights. They are important.

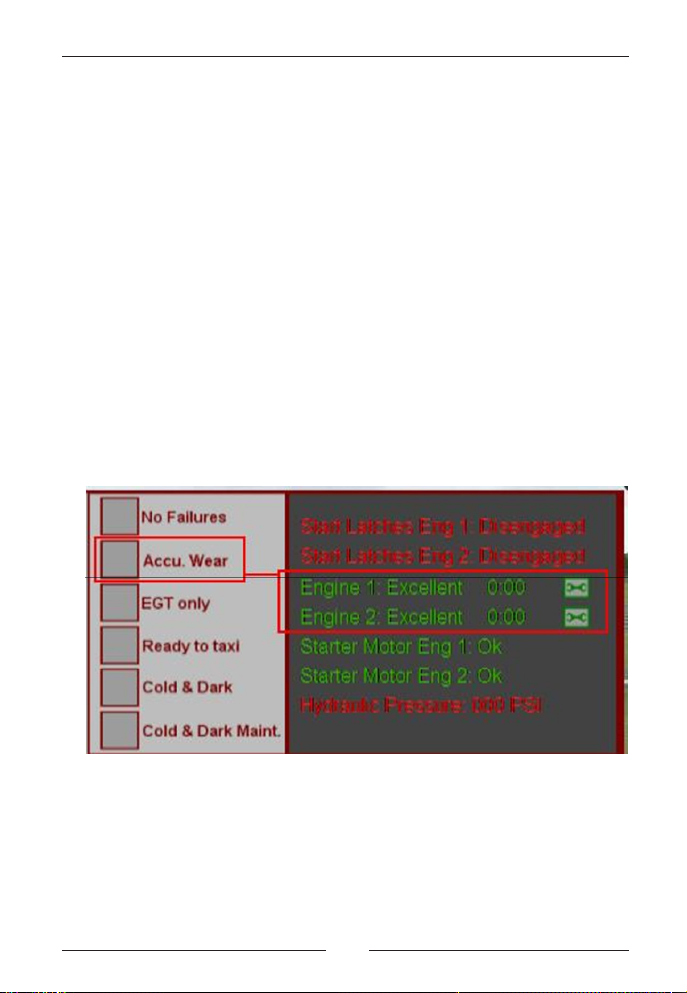

Accumulative Engine Wear

If this option is enabled the engines will start to wear. They will

degrade over time by this schedule:

• 0-80 hours = Excellent

• 80-120 hours = Good

• 120-140 hours = Ok

• 140-160 hours = Poor

• 160 -> hours = INOP (not functional)

Page 20

Bronco X

This schedule only holds true if the engines are operated within their

limits. This means that the engines won´t be over torqued or overheated! If they are being run outside their limits the degradation happens

faster as a function of how much and how long they have been run

above their limits. With increased degradation the engines will start to

run hotter over time until INOP state is reached, then they will stop

running and cannot be started.

The real Bronco has a time between overhaul at 1600 hours (Some

even extended to 3400 hours). Since no flightsimmer ever well reach

that figure this time has been reduced to 1/10 of this i.e 160 hours.

This is still a lot of flight simming time, and since degradation happens

exponentially you won´t see any change before reaching 80 hours.

For those who want to speed up degradation further the option has

been added to decrease this time even further by selecting 2x or 4x

this rate. This option is disabled by default. To enable – click to cycle

between disabled, 1x, 2x & 4x.

On the above figure the selection box labelled “Accu. Wear” can be

seen. It is disabled. Engine health state can be seen to the right

together with their operating time Hours:Minutes. Clicking on the

small “Wrench” symbol for each engine will overhaul it and reset the

timer. The Wrench symbol will also repair the engine(s) if they have

failed and reset the fire extinguishing system for the affected engine.

20 21

Aerosoft GmbH 2012

Page 21

When the “No failures” checkbox is checked the engines will not stop

running and can still be started, but the EGT gauge will still show the

increased operating temperature due to degradation. When clicking

the “Accu. Wear” checkbox the following symbols will appear instead

of a checkmark:

Symbol for normal wear (0-160 hours)

Symbol for 2x wear (0-80 hours)

Symbol for 4x wear (0-40 hours)

When you use the engines correctly you should be able to reach the

160 (or 80 or 40) hours without much problems. Your mechanics will

love you.

Page 22

Bronco X

Electrical System

One of the most important systems of an aircraft is the electrical

system as most parts of an aircraft rely on electrical supply, such as fuel

pumps, hydraulic pump, engine controllers, various instruments and

radios as well as lighting. The electrical system has faithfully been

simulated in the Aerosoft OV-10 Bronco. The default FSX electrical

system has been scrapped and replaced by our custom coded system.

Everything that depends on electricity, down to the smallest light bulb,

will add a load to the system.

The main type of electrical power supply on the Bronco is 24VDC. This

is supplied from the two batteries, the two generators or ground

power. The generators also act as engine starter motors. To manage

the power distribution, the electrical system is divided into several

busses (busbars). This is also done to preserve electrical power in the

event of generator failures. For example the secondary bus, supplying

non-essential systems as lights and radios will be turned off if both

generators fail. The generators, which also act as starter motors, and

can fail if not used right.

Some equipment requires 115VAC. This is made available by converting 24VDC into 115VAC through the inverters. The Bronco has two

inverters, one primary and a backup inverter. Both are powered under

normal conditions though.

Battery Busses

Primary DC bus 24 VDC:

• Startignitionadvisorylight

• Enginerewarnsys

• Fuelboostpumps

• Hydraulicpump

• Gear/Flapindicator

• Alternateaps

• Unfeatherpumps

• Pitotheat

• Windshieldwiper

Aerosoft GmbH 2012

22 23

Page 23

• Smokegenerator

• Trimmotors

• Trimindicator

• Warnandcautionlights

• TurnandSlipindicator

Start Control DC bus 24 VDC:

• Engine1Utilities

• Engine2Utilities

• Engine1Starter

• Engine2Starter

• Engine1ignition

• Engine2ignition

• Fuelshutoffvalves

Secondary DC bus 24 VDC:

• Landinglights

• Taxilights

• Formationlights

• Positionlights

• Anti-collisionlights

• Panellights

• Communicationradio

• Navradio

• ADFradio

• Transponder

Monitored DC bus 24 VDC:

• Yawdamper

Primary AC bus 115 VAC:

• Attitudeindicator

• StandbyAttitudeindicator

• Fuelquantityindicator

• Engine1EGTindicator

• Engine2EGTindicator

Page 24

Bronco X

Monitored AC 1 bus 115 VAC:

• TACAN

• Strikecamera

Monitored AC 2 bus 115 VAC:

• TACAN(Altpwr)

Instrument AC bus 26 VAC:

• VOR/ILSindicator

• DirectionalGyro/VOR/ADFind.

• Markerbeacon

• Engine1torqueindicator

• Engine2torqueindicator

• Oilpressureindicator

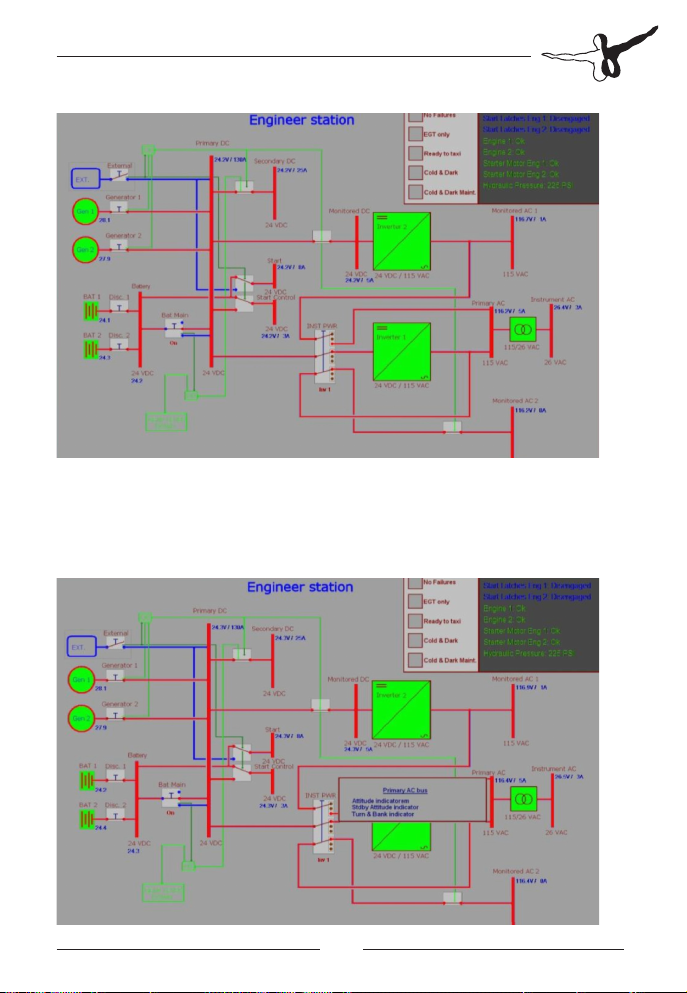

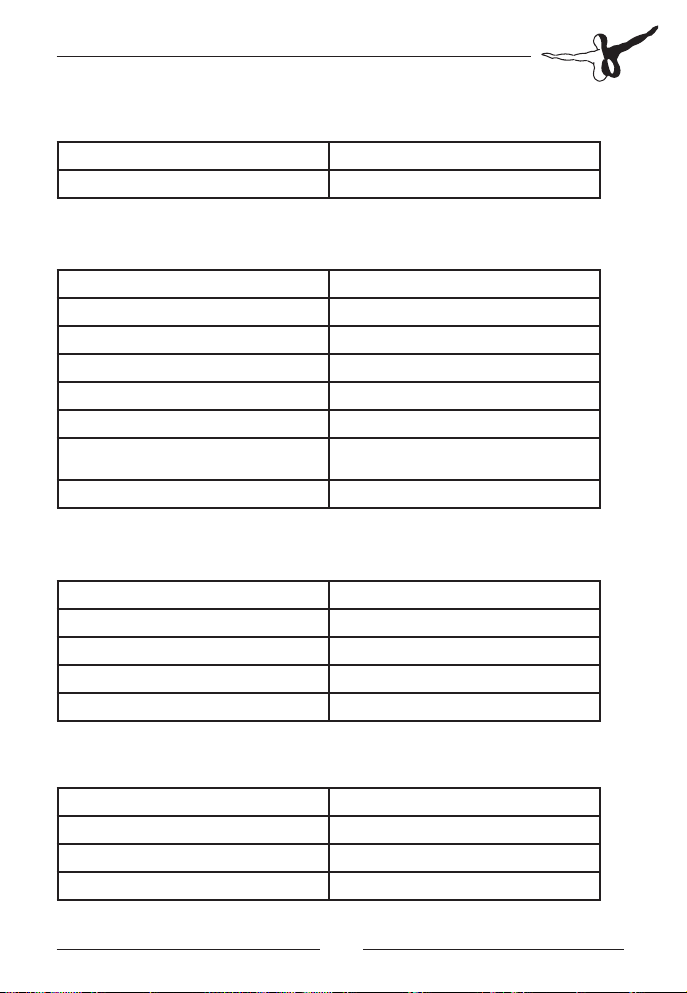

Engineer Station Gauge

During the development of the Bronco it was hard to understand

exactly how the system interacted so the systems coder Finn decided

to make a simple schematic instrument that shows how it works. We

have gotten so used to it we decided to keep it in the released code.

We even decided not to make it look refined so you get an idea of

how we code these complex systems. You can open it with [SHIFT]-[3]

and when you move your mouse over the switches and busses you will

see where you can click. Most switches can be operated (sometimes

with left and right mouse buttons) and when you click on a bus

(vertical thick red line) you will see what’s connected to it. When a bus

or supply “string” is unpowered it is blue, while being red when

powered. Actual voltage and ampere load can be read for each bus as

well as batteries and generators.The best way to see it in action is to

open it, select Cold & Dark and then select ready to taxi. The aircraft

will go through the whole startup sequence and you see the generators and busses come online. When all is running, start disconnecting

things and see how the systems are affected. The real Bronco drivers

would have loved something like this!

Aerosoft GmbH 2012

24 25

Page 25

In the upper right corner various engine related items can be checked for their

state. There are also checkboxes for setting aircraft state and user preferences

like found in the Interactive Checklist gauge. When clicking on the various bus

bars a list with the equipment that it supplies will be shown as long as the mouse

button is pressed.

Page 26

Bronco X

Fuel System

The fuel system consists of two inboard, two outboard tanks and one

center tank plus an optional external fuel tank. Fuel from the outboard

tanks flows to the inner tanks and then both inner tanks feed the

center tank all by gravity. From the center tank is pumped by the

engine driven boost to the low/high pressure fuel pumps. These supply

the fuel control units that feed the engines. Fuel from the optional

external tank is pumped with an electrical transfer pump to the centre

tank. The external fuel transfer switch operates the transfer pump at

about 845 pound an hour. When all internal tanks are full and the

transfer pump is used the fuel is dumped via the wing tank vents.

Normally the transfer pump is started when the wing tanks are

partially emptied and then used for half an hour. Do not forget to

switch it off, there is no indication about the quantity of fuel in the

external tank!

CAUTION: As part of the system uses gravity it has only limited

inverted capacity.

The fuel quantity indicator indicates the weight of the fuel in pounds x

100 in part of the fuel tanks depending on the setting of the fuel

gauge select switch. In the FEED position it shows the weight of the

fuel in the centre feed tank. At INT setting the weight of the fuel in

the internal wing tanks is shown Note the 230 gallon external tank

does NOT have any indication so the EXT setting will show zero., the

EXT setting on the fuel gauge does not function with this tank. The

fuel gauge test button will rotate the needle fully clockwise and

counter clockwise to indicate full freedom of movement.

TANK CAPACITY USABLE

GALLONS POUNDS GALLONS POUNDS

WING OUTBOARD 75.3 489 72.4 471

WING INBOARD 134.5 874 130.6 849

CENTER / FEED 37.1 241 36.0 234

EXTERNAL 230 1494 220 1427

TOTAL 476.9 3098 459 2981

Aerosoft GmbH 2012

26 27

Page 27

The FUEL EMERGENCY SHUT-OFF switches cut the fuel flow (and the

fire T-handles) cut all fuel flow to an engine. The engine might operate

for up to a minute on the fuel remaining in the feed lines.

The FUEL LOW caution light illuminates when the centre tank holds

less than 220 pounds. The FUEL FEED warning light will illuminate

when there is less the 50 pound left in the centre tank.

Hydraulic Power System

Hydraulic power is used to power the landing gear, nose wheel

steering and the flaps. It is supplied on demand by the electrical

hydraulic pump. The pump does not provide enough pressure to

operate flaps and gear at the same time at normal rate.

CAUTION: The hydraulic pump needs a 3 minute cool down period

after extensive use (5 minutes of nosewheel steering or three consecutive gear or flap cycles.

A green hydraulic indicator light on the center pedestal will be lit

when the hydraulic pump is activated. An amber warning light

illuminates when pressure is too low for normal operation.

Oil System

Each engine has its own independent dry sump oil system. The oil

system will provide engine lubrication, provide pressure for the

propeller control system and will serve as an additional cooling system

using a ram-air cooler. When the gear is extended the oil cooler doors

are mechanically opened to provide greater cooling capacity during

ground operations.

Page 28

Bronco X

Power Levers/ Condition Levers

The power levers control the thrust output of the engines and are

marked into 4 sections:

• FULL REVERSE: provide maximum reverse thrust. Selection of

reversed thrust in flight is prevented by a switch linked to the

gear. Only when the gear is compressed can reverse be

selected.

• GROUND START: give minimal torque at idle RPM because the

propeller will be set flat pitch position.

• FLIGHT IDLE: sets the engine and propeller to inflight minimum

fuel flow and torque.

• MILITARY: provides maximum torque.

The condition levers control the fuel flow to the engines and are

marked in 4 sections:

• FEATHER AND FUEL SHUT-OFF (normally referred to as FEATH-

ER): will feather the propellers and cut the fuel to the engine.

• FUEL SHUT-OFF: fuel is shut off but the propeller control

systems stay pressurized and propellers will NOT feather.

• NORMAL FLIGHT: open fuel flow to the engines and sets

minimal engine RPM (on ground 60%, inflight 70%).

• T.O./LAND: open fuel flow to the engine and sets minimal

engine RPM (on ground 94%, inflight 96%). These higher

settings allow the rapid response to commands given via the

power levers.

CAUTION: if the condition lever is set to Normal Flight with the engine

not running fuel WILL be injected into the combustion chambers. This

can result in an engine fire when the engine is hot!

Propeller control is automated and controlled as a function of the

power levers and condition levers.

Aerosoft GmbH 2012

28 29

Page 29

Landing Gear

The tricycle-type landing gear of the OV-10 Bronco is hydraulically

operated with the main gear retracting backwards and the nose gear

forward. When on the ground the Ground Safety Switch will deactivate the pitot heater, stall warning, and store emergency release

systems. IFF hold feature, nose wheel steering will be activated.

The landing gear unsafe light will be illuminated if the gear is not

locked in the position of the gear handle. The landing gear position

indicator (integrated with the flaps position indicator) shows the

position of the gear. A red wheels warning light will warn the pilot of

a possible unsafe gear position when the gear is not extended and the

power levers are retarded, engine condition lever is at T.O./LAND and

the flaps are extended 30 degrees or more. An audible warning horn

will sound when the wheels warning light is illuminated.

CAUTION: There is NO protection against retraction of the gear using

a ground safety switch. The gear WILL retract when the gear lever is

operated on the ground and the aircraft is powered up.

Nosewheel Steering

The nosewheel can move 55 degrees left or right using a hydraulic

nose wheel steer-damping system. As soon as the landing gear carries

any weight the nose wheel steering is operational. In the real Bronco

the pilot has to keep a button on the stick pressed, this is not needed

in the simulated version.

Wheelbrakes/ Parking Brakes

The wheel brakes are operated by a separate manually operated

hydraulic system on each wheel. Using the rudder pedals the pilot can

apply the brakes on each wheel separately. When the park brake

handle is pulled and when the brakes are applied the pressure is

trapped in the system. To release parking brakes the pilot just needs to

apply the brakes

Page 30

Bronco X

Flight Control Systems

The elevator and aileron/spoiler are operated by a balanced mechanical

system using boost tabs. The rudders are mechanically linked directly

to the rudder pedals. Trim surfaces are moved by electrically operated

trim bungees.

• Pitch is controlled with a horizontal stabilizer and tab-boosted

elevator.

• Yaw is controlled by two vertical stabilizers, twin rudders and a

yaw damping system. The yaw damper, powered by the d-c

bus, prevents unwanted tail oscillations and is operated with a

three position switch. ON, OFF, TEST. In test mode the deactivation of the systems on the ground is bypassed for ground tests.

• Roll control uses ailerons and is augmented by 4 spoiler plates

inn each wing. These spoilers rotate upwards and create

additional drag and remove lift that will lower the wing.

The control stick includes a roll/pitch trim switch, the nose wheel

steering button, bomb release button and gun trigger. None of these

are functional in the simulated model as they are near impossible to

use in the simulator.

Trims

The flaps / trim panel hold the controls for aileron, elevator and rudder

trim. When trims are in neutral green, press -to-test, lights will be

illuminated.

Wing Flaps

There are two slotted wing flap sections on each wing, normally

operated by hydraulic power, and an electrical backup system is

available. The flaps are controlled by the flap handle and can be set to

any position between 0 degrees and 40 degrees. This is not possible in

FSX and therefore we decided to default to 0, 20 and 40 degrees. The

flaps position Indicator will show the flaps setting and movement.

Aerosoft GmbH 2012

30 31

Page 31

Aerosoft GPS Unit

The GPS instrument has its own internal battery so it can be used

when the Master switch is still off. It’s charged by the Primary DC

electrical bus when the Battery master switch is on. To turn the GPS

on, press the button with the red logo and the start-up screen will be

displayed.

CAUTION: The framerate of the sim is affected by the amount of

details shown!

Map Mode

After initialization the GPS will be in Map Mode showing an aircraft

symbol in the centre of a map. North is always up. In the four corners

of the display, current ground speed, distance to next waypoint,

estimated time to next waypoint and a pointer depicting relative

bearing to the next waypoint are shown. If the pointer points up, the

aircraft is heading straight towards the next waypoint.

Page 32

Bronco X

Use the IN / OUT buttons to zoom the map in or out. The GPS can

show Airports, VOR’s, NDB’s, Intersections and Airspace boundaries. To

toggle the display of these items press the MENU button and use the

UP / DOWN cursor key (the large button) to highlight the Class

(Airport, VORs, NDBs, Intersection or Airspace). Use the LEFT / RIGHT

cursor key to toggle the display of these items. Use the QUIT button to

return to the MAP page.

Standard FSX flight plans can be loaded via the normal FSX dialog and

will be automatically displayed on the MAP page.

Direct To Mode

Using the GOTO button will allow the input of a DIRECT TO location.

Use the UP / DOWN cursor keys to change the character on the

blinking field. Use the LEFT / RIGHT cursor key to move to the next or

previous field. Enter an ICAO identifier for airport, VOR or NDB.

Aerosoft GmbH 2012

32 33

Page 33

NOTE: Intersections are not supported in the GOTO mode.

Once an identifier is recognized, it will show facility name and nearby city – if

possible. Press ENTER and the GPS will return to the Map mode with the flight

plan leg from the current aircraft position to the selected identifier. As everywhere using the QUIT button will halt the action and return to the MAP screen.

Cursor Mode

Another option to make a DIRECT-TO flight plan, is with the help of

the “Cursor Mode”. When the GPS is in map mode, pressing either

the UP / DOWN / LEFT or RIGHT cursor key, will put the GPS into

“Cursor mode”. A small cursor (blinking circle) will appear instead of

the aircraft symbol. Using the cursor keys the circle can be moved on

the map and the map will centre on the cursor position. A line will be

drawn from the current aircraft position to the cursor.

Page 34

Bronco X

Press ENTER to select the cursor position as a Direct-To flight plan. If

the ENTER button is not pressed within a few seconds or by pressing

QUIT, cursor mode will be suspended and the GPS will return to Map

mode. By using the cursor mode any global position can be selected as

a waypoint. This is the easiest way to make a very simple flight plan,

certainly if the desired waypoint isn´t too far away. In cursor mode

finer adjustments can be made by zooming in on the map first.

Nearest Station

Using the NRST button will open

the NEAREST STATION list and the

LEFT / RIGHT cursor keys will

change between Airports, VORs,

NDBs and Intersections. Use the

UP / DOWN cursor keys to

highlight an identifier and press

ENTER to select it as DIRECT-TO, or

press QUIT to cancel the selection.

Aerosoft GmbH 2012

34 35

Page 35

HSI Page

Pressing the ENTER key while being in Map mode will bring up the HSI

page. The HSI page shows:

• Compass rose, showing ground track, which is the true track

over ground, taking crosswinds and sideslip into account. It

does NOT show magnetic nor true heading, like a normal gyro

based HSI.

• Course Needle, showing the active flight plan leg bearing.

• Course deviation indicator bar (middle part of the Course

needle), showing the cross track error. Each dot represents 1

nautical mile.

• TO/FROM flag showing the position relative from the active

flight plan leg.

Right part of the screen shows Ground speed, Distance to next

waypoint, Ground track (same as Compass rose) and next waypoint

bearing.

Page 36

Bronco X

If the Ground track value and the Bearing value are equal, this

indicates that the aircraft is heading straight towards the next

waypoint, but not necessarily following the flight plan leg.

HSI Samples:

On track direct towards the active waypoint, TO / FROM flag shows

TO:

Correct heading but 3 miles to the left of the flight plan leg:

Aerosoft GmbH 2012

36 37

Page 37

Still 3 miles left of the flight plan leg, but on an intercept heading of 40°:

Flight plan leg behind the aircraft, note the TO/FROM flag has changed

to FROM:

Page 38

Bronco X

Becker BXP 6401 Transponder

The Becker BXP 6401 transponder is a Mode

S transponder which enables ATC to locate,

identify and track the aircraft by responding

to ATC radar interrogations. In Mode S it will

conduct altitude reporting, used by other aircrafts TCAS systems for collision warnings.

Remember to turn the Transponder to STDBY after landing when leaving the runway.

The transponder is turned on by rotating the

left knob to STDBY. In STDBY mode the transponder will be on, but it will not respond to

ATC interrogations. STDBY is normally used

until the aircraft is ready for runway line-up.

There is a short self-test on start up. Turning

the knob to ON will make the transponder

start to respond, but without altitude reporting. The blinking R symbol, indicating that

the unit responds. When the knob is at either STDBY or ON the bottom line will show

the aircraft identification number.

Turning the knob to ALT will make the transponder respond with altitude reporting

when inquired. Current flight level will be

displayed. Flight level is altitude in 100th of

feet with the standard setting at 1013 mb.

(1013,2 hpa)

To change the transponder code left click on

the right button and the first digit will start

to blink. Use the mouse wheel to change the

value. Left click the right button again and

the next digit will blink. Left click the right

button when the last digit has been set.

When all digits have not been set, the transponder code will NOT be changed. Press the

VFR button to set the transponder code to

the normal European VFR transponder code,

7000.

Aerosoft GmbH 2012

38 39

Page 39

These are standard codes, otherwise set to the squawk code assigned by FSX’s

ATC:

• 0000: Military intercept code mode C or other SSR failure.

• 0033: Parachute dropping in progress (UK).

• 0041 to 0057: In Belgium assigned for VFR traffic under Flight

Information Services

• 0100: In Australia: flights operating at aerodromes

• 1000: Instrument Flight Rules (IFR) flight below 18,000’ when

no other code has been assigned (Canada). Non-discrete mode

A code reserved use in Mode S radar / ADS-B environment

where the aircraft identification will be used to correlate the

flight plan instead of the mode A code.

• 1200: Visual flight rules (VFR) flight, this is the standard

squawk code used in North American airspace when no other

has been assigned. In Australia civil VFR flights in class E or G

airspace.

• 1201: Visual flight rules (VFR) glider flight, this is the standard

squawk code used in United States airspace for transponder

equipped gliders when no other has been assigned.

• 1400: VFR flight above 12,500’ASL when no other code has

been assigned (Canada).

• 2000: The code to be squawked when entering a secondary

surveillance radar (SSR) area from a non-SSR area used as

Uncontrolled IFR flight squawk code in ICAO countries. In

Canada for uncontrolled IFR at or above 18,000. In Australia:

civil IFR flights in Class G airspace.

• 2100: Australia: Ground testing by aircraft maintenance staff.

• 3000: Australia: Civil flights in classes A, C and D airspace, or

IFR flights in Class E airspace.

• 4000: Aircraft on a VFR Military Training Route or requiring

frequent or rapid changes in altitude (US).

Page 40

Bronco X

• 4400 to 4477: Reserved for use by SR-71, YF-12, U-2 and

B-57, pressure suit flights, and aircraft operations above FL600

(USA only).

• 5000: Aircraft in Military Operations.

• 6000: Australia: Military flights in Class G airspace.

• 7000: VFR standard squawk code when no other code has

been assigned (ICAO). UK: this code does not imply VFR; 7000

is used as a general squawk.

• 7001: Sudden military climb out from low-level operations (UK)

• 7004: Aerobatic and display code in some countries.

• 7010: VFR circuit traffic code in the UK.

• 707X: Paradrop activities in France (7070, 7071, 7072...).

• 7615: Australia: civil flights engaged in littoral surveillance.

• 7777: Military interception Emergency codes:

• 7500: Unlawful Interference i.e., Aircraft hijacking (“seven fife,

man with knife”)

• 7600: Lost Communications.

• 7700: General Emergency (“seven, seven, goes to heaven”)

Tacan Receiver

TACAN is a VOR like navigation

system that uses transmitters

that are mainly placed on or

close to military airfields. Where

you tune a VOR using a

frequency, a TACAN is identified by a channel.

Aerosoft GmbH 2012

40 41

Page 41

The navigation database of FSX is not fully accurate or complete in

regards to TACAN, for some countries all stations seem to be there, in

some other countries there are none. You will find them on your

charts marked with something like CH41X.

Setting the channel is done with the rotary control on the front and the

larger rotary control hiding behind the front plate. Just move your mouse

to the edge of the instrument and you will find the click zone. The smaller

rotary control is used to power the radio on. In any setting except OFF the

radio is activated. The volume control toggles the audio ident.

Becker AR 4201

Communication Radio

The Becker AR 4201 Coms radio is a

basic two way radio for voice communication. It is turned on with the ON/OFF/

VOL knob and will display a test pattern

when started. The upper (large) digits

show the active frequency, while the

lower (smaller) show the standby

frequency. Turning the lower right knob

will change the frequency number

before the decimal sign, while turning

the right upper knob changes the

numbers after the decimal sign. To

swap the standby frequency with the

active, press the swap button (double

arrow button). Pressing the mode

button (MDE) will display the supply

voltage instead of the standby frequency. In this mode the swap button will

toggle the display of Supply voltage,

Outside temperature in °C and Outside

temperature in °F.

Coms radio is seen as COMS 2 in FSX.

The Becker AR 4201

Page 42

Bronco X

Interactive Checklist Gauge

The Aerosoft Bronco X comes equipped with a highly innovative

interactive checklist gauge. The checklist can be opened with [SHIFT] +

[2].

When opened the left page has options for configuring the Bronco

systems and to select prefabricated settings of all aircraft systems. The

upper three “radio” buttons are for setting up the panel state.

• Cold & Dark Normal state: engines are shut down the panels

reflects how a pilot normally will find it for the first flight of the

day.

• Cold & Dark Maintenance State: engines are shut down,

propellers are feathered and generators, fuel shut off valves

and battery disconnect switches are off.

• Ready for Taxi state: engines are running and all systems are

ready for taxi

The lower three check boxes are for setting your preferences.

• EGT gauges showing EGT only: will make the EGT gauge

display EGT and not shift to TiT. Please refer to the chapters on

the engine to understand the difference.

• Play sounds for checklist items: will disable the voice over in the

checklist.

• No failures: will disable all failures that are not standard FSX

failures.

The next pages contain the actual checklists.

Aerosoft GmbH 2012

42 43

Page 43

Click the checklist header (like “COCKPIT CHECK”) and a red checkmark will indicate that the checklist has been started, but not finished

correctly yet. Now click each checklist item and a checkmark will

indicate whether it is set correctly or not. If it has been set correctly a

green checkmark will be shown and a voice will also confirm the item

is checked (or the action performed) and the item is completed. If the

checkmark is red you have two options. Either you can manually

correct the issue or right click the checklist item to have it done for

you. This is especially useful if you have not yet fully mastered the

aircraft and find it hard to find all the switches.

The moment the checklist has been completed the checkmark at the

top will turn green and the voice will tell you the checklist is completed. If you like to start over, use the CLEAR CHECKLIST option.

Page 44

Bronco X

It is possible to go from a cold and dark aircraft to a fully configured,

ready for taxi with engines running state by just right clicking on the

checklist items!

A few additional comments;

• Because some systems are mentioned more than one time in

the checklist it could be a system that is set to ON in one

location and has to be switched OFF further in the checklist.

The first occurrence of those conflicting states will then be

shown in grey instead of green or red.

• The checkmark might blink between red and green when a

control is in the progress of being set

• Where right click options are not possible (like throttle control,

setting of certain speeds etc) the checkmark turns green when

correct settings are detected.

Aerosoft GmbH 2012

44 45

Page 45

• Where there are Left engine / Right engine controls, You will

see a selector at the top of the Checklist section labeled L / R.

CAUTION: The “Unfeathering Propellers” and “Engine Motoring”

should only be executed when required.

The last part of the checklist contains the emergency checklist. This

works exactly like the normal checklist, but don´t have voice overs.

Page 46

Bronco X

Panels

The cockpit of the OV-10 Bronco is rather strange. It’s rather cramped

in the lower sections with all gauges and controls seemingly randomly

placed very close together and above that all is a very roomy glass

section with near perfect visibility. In its role as reconnoiter and spotter

aircraft this visibility was very usable, but it also means that you will

have to look down to see the panel and instruments. As the aircraft is

intended for VFR flights this is not problematic. In FSX it is a bit of a

problem for people who do not use a tracking system that pans the

view around as you move your head. When needed zoom out a bit [-]

and lower the seat [CONTR] + [ENTER].

Aerosoft GmbH 2012

46 47

Page 47

Main Panel

1. Left battery Hot warning light

2. Left over torque warning light

3. Left TiT/EGT high warning light

4. Gyro VOR needle / ILS source selector switch VOR / TACAN

5. Left & Right Continuous ignition switches

6. Standby artificial horizon

7. G-meter

8. Clock / stopwatch

9. Wheel up warning light

10. Alternate TACAN power switch

11. Fire detector / warning lights test switch

12. ADF radio

13. Landing gear lever

14. Landing gear and flaps indicator

15. Elevator trim indicator

Page 48

Bronco X

16. Rudder trim neutral light

17. Aileron trim neutral light

18. Airspeed indicator

19. Altimeter

20. Artificial horizon

21. Gyro compass with VOR/TACAN & ADF needle

22. TACAN radio

Right Side Main Panel

1. Right TiT/EGT high warning light

2. Right over torque warning light

3. Right battery hot warning light

4. Fire extinguisher

5. Fire handles

6. Turn & Bank indicator

7. Vertical speed indicator

Aerosoft GmbH 2012

48 49

Page 49

8. ILS gauge

9. Engine torque indicators

10. Turbine RPM (Ng)

11. TiT/EGT indicators

12. Oil pressure indicator

13. Fuel quantity indicator

14. Fuel qty indicator selector switch

15. External fuel transfer switch

16. Emergency fuel shut off switches

Left Rear Side Panel

1. COM radios transmit select (VHF1 / VHF2)

2. ADF ident sound to speaker

3. COM1 (VHF1) sound to speaker

Page 50

Bronco X

4. COM2 (VHF2) sound to speaker

5. VOR ident (NAV1) sound to speaker

6. External light / Landing light switch

7. Flaps lever

8. Aileron trim / Alternate elevator trim switch

9. Alternate trim select

10. Alternate rudder trim switch

11. Normal rudder trim switch

12. Alternate flaps setting switch

13. Yaw damper

14. Voltmeter / Generator 1 or 2 ampere meter

15. Outside air temperature indicator

Aerosoft GmbH 2012

50 51

Page 51

Left Forward Side Panel

1. Ignition and unfeather switches

2. Starter switches

3. Generator switches

4. Instrument power switch (Inverters)

5. Battery switch

6. Parking brake lever

Page 52

Bronco X

Throttle Quadrat

1. Power levers

2. Condition levers

3. Friction lock for power and condition levers

(move forward to lock)

Aerosoft GmbH 2012

52 53

Page 53

Overhead Panel

1. Whiskey compass

2. Smoke generator switch

3. Camera power switch

4. Camera power on light

5. End of film warning light

6. Film select switch

7. Gun sight dimmer

Page 54

Bronco X

Right Forward Side Panel

1. Pitot heat switch

2. Cockpit defroster

3. Cockpit temperature adjustment

4. Ram air adjustment

5. Windscreen wiper power switch

6. Windscreen wiper speed switch

7. Anti collision lights

8. Formation lights

9. Wing and tail lights (position lights)

10. IFF/Transponder reply light

11. IFF/Transponder test light

12. IFF/Transponder mode selector

13. IFF/Transponder code and selectors

14. Batteries disconnect switches

Aerosoft GmbH 2012

54 55

Page 55

Right Rear Side Panel

1. Gyro compass drift index

2. Gyrocompass source

3. Gyro compass alignment knob

4. Marker beacon ident sound switch

5. Marker beacon Hi/Lo selector switch

6. Marker beacon power/test switch

7. COM1 radio frequency

8. COM1 radio power switch (Lower knob)

9. COM1 radio whole Mhz selector (Upper knob)

10. COM1 radio fractional Mhz selector

11. NAV1radio frequency

Page 56

Bronco X

12. NAV1 radio power switch (Lower knob)

13. NAV1 radio whole Mhz selector

14. NAV1 radio ident switch

15. NAV1 radio fractional Mhz selector

16. “Becker” COM2 radio

17. “Becker” Transponder 2

18. Panel lights

Right Sidewall Switches

1. Bleed-air switches

2. Generator 1 & 2 ampere meter selector switch

3. Canopy open

Aerosoft GmbH 2012

56 57

Page 57

Checklist

The following checklists are taken directly from the real aircraft as

flown right now. Please note that the checklist gauge build into the

aircraft is much easier and much more powerful than this simple list.

In the checklist the sections that have no function in FSX are shown as

light grey. Just skip those.

Normal Checklist

SAFETY CHECK

1. FORM 781

2. CANOPY

3. THRUSTER SAFETY PIN

4. EJECTION “D” RING SAFETY PIN

5. SPEED SENSOR CONNECTIONS

6. EJECTION SEAT QUICK-DISCON

7. PARACHUTE DEPL STATIC LINE

8. CATAPULT-ROCKET RET BOLT

9. DEPLOYMENT STATIC LINE

10. SEAT-MAN SEPARATOR LINK

11. OXYGEN QUANTITY

12. MASTER ARM

13. GEAR HANDLE

CHECK

OPEN

INSTALLED

INSTALLED

SECURE

SECURE

SECURE

SECURE

SECURE IN LINE CUTTER

SECURE IN PLACE

CHECK MINIMUM

OFF

DOWN

Page 58

Bronco X

EXTERIOR INSPECTION

1. FRONT COCKPIT CANOPY

2. REAR COCKPIT

3. UPPER WING

4. RIGHT PROPELLER

5. RIGHT ENGINE

6. RIGHT WING

7. RIGHT MAIN GEAR

8. RIGHT SPONSON

9. EXTERNAL PWR RECEPTACLE

DOOR

10. CARGO BAY

11. TAIL BOOM, TAIL SURFACES

12. LEFT SPONSON

13. ARMT SAFETY DISABLE

14. LEFT MAIN GEAR

15. LEFT WING

16. LEFT ENGINE

17. LEFT PROPELLER

18. ANGLE-OF-ATTACK PROBE

19. NOSE OF AIRCRAFT

20. NOSE GEAR

CHECKED

SECURE (SOLO)

CHECKED

CHECKED

CHECKED

CHECKED

CHECKED

CHECKED

SECURE (IF NOT USED)

CHECKED

CHECKED

CHECKED

NORM

CHECKED

CHECKED

CHECKED

CHECKED

CHECKED

CHECKED

CHECKED

Aerosoft GmbH 2012

58 59

Page 59

COCKPIT CHECK

1. GUST LOCK

2. THRUSTER SAFETY PIN

3. SURVIVAL KIT

4. RISER ATTACH FITTINGS

5. LAP BELT

6. PERSONAL LEADS

7. HF COMM

8. COMPASS

9. VHF/FM COMM-

10. FLAPS

11. EXT LIGHTS MASTER

12. POWER LEVERS

13. CONDITION LEVERS

14. BATTERY

15. GENERATORS

16. INST PWR

17. AIR START

18. GEAR HANDLE

19. UHF COMM

20. ARM MASTER

21. CLOCK

22. SIGHT FIL SEL

23. SIGHT RETICLE BRIGHTNESS

KNOB

24. ALTERNATE TACAN POWER

25. TACAN-

26. FIRE PULL HANDLES

27. EXT FUEL TRANS

REMOVED

REMOVED

ATTACHED

SECURED

SECURED

CONNECTED

OFF

SLAVED

OFF

UP

EXT LIGHTS

FLIGHT IDLE

FUEL SHUT-OFF

OFF

ON

OFF

AUTO.

DOWN

OFF

NORM²

SET

NO 1.

OFF²

NO. 1 MSL

OFF

IN

OFF

Page 60

Bronco X

28. FUEL EMERG SHUT OFF

29. PITOT HEAT-

30. WINDSHIELD WIPER

31. WING & TAIL LIGHTS

32. FORM LIGHTS

33. OXYGEN SYSTEM

34. EMERG IFF

35. IFF

36. ADF

37. ICS

38. BLEED AIR

39. VHF COMM

40. INTERIOR LIGHTS

41. CIRCUIT BREAKERS

NORM

OFF

OFF

BRT

AS REQUIRED

CHECKED

NORMAL

OFF

OFF

SET

AS REQUIRED

OFF

AS REQUIRED

CHECKED

1)Aircraft having TCTO 1L-1OA-510 incorporated

2) Aircraft 66-13552 through 67-14650 not having TCTO 1L-1OA-503

3) Aircraft 67-14651 and subs and aircraft having TCTO 1L-1OA-503

Aerosoft GmbH 2012

60 61

Page 61

BEFORE STARTING ENGINES

1. BATTERY-

2. ICS

3. SEAT ADJ

4. RUDDER PEDALS

5. FLIGHT CONTROLS

6. FIRE DET

7. EXTERNAL POWER

8. INST PWR

9. FIRE DETECTOR/WARNING

LIGHTS

10. RADIO

11. ATTITUDE INDICATOR

12. FUEL QUANTITY INDICATOR

ON

CHECKED

ADJUSTED

ADJUSTED

CHECKED

CHECKED

IF REQUIRED

INV NO. 1

CHECKED

ON

CHECKED

CHECKED

UNFEATHERING

13. POWER LEVER

14. AIR START

15. POWER LEVER

FULL REVERSE

CRANK

FLIGHT IDLE

Never try to start the engines with propeller blades feathered, the

starter motor might get damaged, hung start can happen, and

batteries might get overheated due to the excessive torque. Never

move condition levers from FUEL SHUTOFF with Ng below 10.0%, a

hung or hot start might evolve. Never start both engines simultaneously, always start them one at the time or the batteries might overheat.

Use ground power if available.

Page 62

Bronco X

STARTING ENGINES

1. BRAKES

2. PROPELLER

3. STARTER

4. START IGNITION LIGHT ON

5. CONDITION LEVER

SET

CLEAR

START

CHECK

NORM FLT 10% RPM

IF NO LIGHT-OFF WITHIN 15 SECONDS, ABORT START MONITOR

EGT (815°C MAXIMUM) AND RPM AT 50% TO 53% RPM CHECK:

6. OIL PRESSURE INDICATION

7. START IGNITION LIGHT OUT

8. EGT/T. I. T. SHIFT

9. FUEL BOOST LIGHT OUT

10. RPM

11. PROPELLER

CHECK

CHECK

CHECK

CHECK

STABILIZE APPR. 85%

UNLOCK

SMOOTHLY RETARD POWER LEVER TO REVERSE RANGE AND

NOTE INCREASE IN TORQUE, THEN RETURN TO GROUND START

12. RPM

13. OIL PRESSURE

STABILIZED APPR. 67%

50 PSI MINIMUM

PRIOR TO START 2ND ENGINE, CHECK VOLT FOR <75 AMPS

14. REPEAT STEPS 2 THROUGH 7 FOR OTHER ENGINE

AFTER BOTH ENGINES ARE STARTED:

15. EXTERNAL POWER

16. GENERATOR CAUTION LIGHTS

DISCONNECT (IF APPL.)

OUT

62 63

Aerosoft GmbH 2012

Page 63

GROUND SHUTDOWN ABORTED/HUNG START

17. CONDITION LEVER

18. STARTER

FUEL SHUT-OFF

ABORT

BEFORE TAXI

1. INST PWR

2. TRIM-

3. COMPASS-

4. RADIOS AND NAV EQUIPMENT

5. ALTIMETER-

6. IFF-

7. EJEC SEAT “D” RING SAFETY

PIN

8. CHOCKS

CHECKED

CHECKED

SET

ON, AS REQUIRED

SET

STBY

REMOVED AND STOWED

REMOVED

TAXI CHECK

1. BRAKES

2. NOSE WHEEL STEERING

3. FLIGHT INSTRUMENTS

4. YAW DAMPER

5. NAVIGATION AIDS

CHECKED

CHECKED

CHECKED

CHECKED

CHECKED

BEFORE TAKE-OFF

1. TRIM

2. FLAPS

3. NAVIGATION AIDS

4. SHOULDER HARNESS

SET

SET

SET FOR DEPARTURE

AS REQUIRED

Page 64

Bronco X

5. PITOT HEAT

6. IFF

7. ANTI COLLISION LIGHT

8. FEED TANK

9. FLIGHT CONTROLS

10. CANOPY

11. CANOPY DOOR LOCK

INDICATORS

ON, AS REQUIRED

AS REQUIRED

ON

CHECK 260 TO 280 LBS

CHECK

CLOSED, LOCKED

CHECK²

1) Aircraft having tcto 1l-10a-563 incorporated

LINE-UP CHECK

1. FLIGHT INSTRUMENTS

2. CONDITION LEVERS

3. POWER LEVERS

CHECK

T.O./LAND

ADVANCE

AFTER TAKE-OFF

1. GEAR

2. FLAPS

UP

UP

CLIMB

1. CONDITION LEVERS

2. OXYGEN

3. YAW DAMPER

4. EXT FUEL TRANS

AS REQUIRED

AS REQUIRED

AS REQUIRED

ON, AS APPLICABLE

CRUISE

1. CONDITION LEVERS NORMAL FLIGHT

2. POWER LEVERS AS REQUIRED

64 65

Aerosoft GmbH 2012

Page 65

DESCENT

1. APPROACH PROCEDURES

2. CKPT AIR/DEFR

3. ALTIMETER

4. POWER LEVERS

BEFORE LANDING

1. CONDITION LEVERS

2. SHOULDER HARNESS

3. YAW DAMPER

4. HYDRAULIC SYSTEM

5. GEAR

6. FLAPS

GO-AROUND

1. POWER LEVERS

2. GEAR

3. FLAPS

TOUCH-AND-GO LANDING

1. FLAP

2. POWER LEVERS

3. FLAP

4. GEAR

5. BEFORE LANDING, PERFORM

BEFORE LANDING

REVIEW, AS REQUIRED

AS REQUIRED

SET

AS REQUIRED

T.O./LAND

AS REQUIRED

OFF

CHECK

DOWN

AS REQUIRED

ADVANCE, AS REQUIRED

UP, AS REQUIRED

UP, AS REQUIRED

T/O

MILITARY

UP, AT 110 KIAS

UP, AS REQUIRED

CHECK

Page 66

Bronco X

AFTER LANDING

1. FLAPS

2. CONDITION LEVERS

3. IFF

4. ANTI COLLISION LIGHT

5. EXT FUEL TRANS

6. TRIM

7. EJECT SEAT “D” RING SAFETY

PIN

SHUTDOWN

1. PARK BRAKE

2. RADIO AND NAV EQUIPMENT

3. POWER LEVERS

4. CONDITION LEVERS

5. POWER LEVERS

6. INST PWR

7. NAVIGATION LIGHTS

8. BATTERY

9. CONTROL GUST LOCK

10. THRUSTER SAFETY PIN

UP

NORMAL FLIGHT

OFF

OFF

OFF

NEUTRAL

INSTALLED

SET

OFF

GROUND START

FUEL SHUT-OFF

FULL REVERSE

OFF

OFF

OFF

INSTALLED

INSTALLED

Aerosoft GmbH 2012

66 67

Page 67

BEFORE LEAVING AIRCRAFT

1. CHOCKS

2. PARK BRAKE

3. OXYGEN

4. CANOPY

5. FORM 781

IN PLACE

RELEASED, AS REQUIRED

100% AND OFF

CLOSED, AS REQUIRED

COMPLETE

Note:

Some Broncos were changed to always read EGT on the EGT/TIT

gauge. This option is available on the Aerosoft OV-10 Bronco too

through the Checklist/Config gauge .

When set to EGT readout only, the pilot is required to determine max

allowable EGT with the help of EGT charts.

The TIT warn lights are hardcoded to 996°C and will not warn for any

EGT over temperature situation since EGT is much lower than TIT.

TIT is not a measured value, since no temperature probe type is able to

withstand the temperatures at the turbine inlet. Instead TIT is calculated and “tweaked” by the SRL computer to read a TIT value giving a

single red-line value- i.e EGT is converted to TIT and this value is again

compensated for Ng, OAT, Altitude and Airspeed in order to make the

gauge needle read 996°C when reaching max allowable TIT, which

again will lit the TIT warn light.

Options:

Included are the following:

• Set Cold & dark state.

• Set Cold & dark Maintenance.

• Set Ready for Take-Off state.

• Select EGT/TIT readout.

• Failure enable/disable.

Page 68

Bronco X

Emergency Checklist

ENGINE OR NACELLE FIRE DURING START / HOT START

1. CONDITION LEVER

2. FIRE LIGHT

3. AIR START

HOLD SWITCH TO SHUT OFF FUEL ENRICHMENT AND IGNITION

ALLOW STARTER TO CONTINUE ROTATING ENGINE.

FUEL SHUT-OFF

PULL

CRANK

4. START SWITCH

ABORT

IF FIRE PERSISTS OR LIGHT ILLUMINATED:

5. FIRE EXT

6. EXTERNAL POWER

7. BATTERY

AGENT

DISCONNECT, IF USED

OFF

ENGINE FIRE AFTER SHUTDOWN

1. BATTERY

2. START SWITCH

3. POWER LEVER

ON

TO CONT ROTATE ENG

GROUND START

TWO-ENGINE ABORT

1. POWER LEVERS

2. BRAKES

RETARD

AS REQUIRED

Aerosoft GmbH 2012

68 69

Page 69

ENGINE FAILURE AFTER LIFT-OFF (TAKE-OFF CONTINUED)

1. GEAR

2. STORES

3. FAILED ENG COND. LEVER

4. FLAPS

5. FAILED ENGINE POWER LEVER

UP

JETTISON

FEATHER & FUEL

UP (ABOVE 110 KIAS)

FLIGHT IDLE

ENGINE FIRE AFTER LIFT-OFF

1. GEAR

2. STORES

3. FAILED ENG COND. LEVER

4. FIRE LIGHT

5. FIRE EXT

6. FAILED ENGINE POWER LEVER

7. FLAPS

8. FAILED ENGINE FUEL EMERG

S.O

9. IF STILL ON FIRE

UP

JETTISON

FEATHER & FUEL

SHUT-OFF

PULL

AGENT

FLIGHT IDLE

UP (WHEN ABOVE 110 KIAS)

SHUT OFF

ENGINE FAILURE DURING FLIGHT

1. FAILED ENG COND. LEVER

2. OPERATIVE ENGINE POWER

LEVER

3. GEAR

4. FLAPS

FEATHER & FUEL

ADVANCE, AS REQUIRED

UP

UP

Page 70

Bronco X

MAINTAIN MINIMUM SINGLE-ENGLNE SPEED OR ABOVE

5. STORES

6. FAILED ENGINE POWER LEVER

7. FAILED ENGINE FUEL

EMERG S.O

JETTISON, AS REQUIRED

FLIGHT IDLE

SHUT OFF

FAILURE OF BOTH ENGINES IN FLIGHT

1. MAINTAIN

2. FUEL QUANTITY

130 KIAS

CHECK

ENGINE AIR START

1. CONDITION LEVER

2. POWER LEVER

3. AIR START

4. CONDITION LEVER

5. AIR START

FUEL SHUT-OFF

HALFWAY BETWEEN FLIGHT IDLE

AND MILITARY

ON

NORMAL FLIGHT AT 10% RPM

AUTO

UNSUCCESSFUL AIR START

1. CONDITION LEVER

2. AIR START

3. STORES

4. FAILED ENGINE POWER LEVER

FEATHER & FUEL

AUTO

JETTISON, AS REQUIRED

FLIGHT IDLE

Aerosoft GmbH 2012

70 71

Page 71

ENGINE FIRE DURING FLIGHT

1. AFF. ENG COND. LEVER

2. FIRE LIGHT

3. FIRE EXT

4. IF STILL ON FIRE

5. FAILED ENGINE FUEL

EMERG S.O

ELECTRICAL FIRE

1. GENERATORS

2. BATTERY

3. RAM AIR KNOB

4. ALL ELECTRICAL EQUIPMENT

5. BATTERY

6. GENERATORS

7. VOLTAMMETER

8. DEFECTIVE EQUIPMENT

SMOKE OR FUMES ELIMINATION

1. BLEED AIR

2. RAM AIR KNOB

3. COCKPIT AIR VENTS

4. CKPT AIR/DEFR

FEATHER & FUEL SHUT-OFF

PULL

AGENT

EJECT OR LAND IMMEDIATELY

SHUT OFF

OFF

OFF

PULL FULL OUT

OFF

ON

RESET

CHECK

ISOLATE

EMERG OFF

PULL, AS DESIRED

OPEN

FULL IN

IF ELECTRICAL FIRE IS SUSPECTED, FOLLOW ELECTRICAL FIRE PROCEDURE

Page 72

Bronco X

GENERATORS FAILURE

1. REDUCE ELECTRICAL LOAD

2. APPLICABLE GENERATOR

3. IF GENERATOR WILL NOT RESET

RESET

TURN OFF GENERATOR AND LAND

BOTH GENERATORS OUT

1. ALL ELECTRICAL EQUIP

2. GENERATORS

OFF

RESET

IF NEITHER GENERATOR WILL RESET, TURN OFF BOTH GENERATORS

AND LAND AS SOON AS POSSIBLE

3. BATTERY EMERG, AS REQUIRED