Page 1

Model 8314-X IM-477

IM-477

Operation & Installation Manual

Model 8314-X

WLAN Simulator Subsystem

(P/N 193-8132-X)

This documentation may not be reproduced in any form, for any

purpose unless authorized in writing by Aeroflex / Weinschel, Inc.

© Aeroflex / Weinschel, Inc.

Frederick, Maryland

2008

Manual Rev. 4-2-08

Aeroflex / Weinschel 1

Firmware V2.0

Page 2

SAFETY SUMMARY

SAFETY SUMMARY

DEFINITIONS.

The following definitions apply to WARNINGS,

CAUTIONS, and NOTES found throughout this manual.

WARNING

An operating or maintenance procedure, practice,

statement, condition, etc., which, if not strictly

observed, could result in injury and/or death of

personnel. Do not proceed beyond a WARNING

symbol until all the indicated conditions have been

fully understood and/or met.

CAUTION

An operating or maintenance procedure, practice,

statement, condition, etc., which, if not strictly

observed, could result in damage or destruction of the

equipment or long-term health hazards to personnel.

Do not proceed beyond a CAUTION symbol until all

the indicated conditions have been fully understood

and/or met.

NOTE

An essential operating or maintenance procedure,

condition, or statement that must be highlighted.

•

To minimize shock hazard, the instrument chassis

must be connected to an electrical ground. Using

the supplied three-conductor power cable ensures

that the instrument can be firmly connected to the

ac power source and electrical ground at a

grounded power outlet. If using a 3-2 wire

adapter be sure to connect the ground lead to earth

ground.

•

Use the buddy system any time work involving

active high voltage components is required. Turn

OFF the power before making/breaking any

electrical connection. Regard any exposed

connector, terminal board, or circuit board as a

possible shock hazard. DO NOT replace any

component or module with power applied.

•

If test conditions to live equipment are required,

ground the test equipment before probing the

voltage or signal to be tested.

•

Personnel working with or near high voltage

should be familiar with modern methods of

resuscitation.

•

DO NOT wear jewelry (rings, bracelets, metal

watches, and/or neck chains) while working on

exposed equipment. Be very cautious about

using hand tools near exposed backplanes, bus

bars, and/or power supply terminals. Use

properly insulated tools. When making test

connections to the power supply terminals and

bus bars, use only insulated probe tips.

•

Verify that the instrument is set to match the

available line voltage and the correct fuse is

installed.

GENERAL PRECAUTIONS.

The following are general precautions that are not related

to any specific procedure and, therefore, do not appear

elsewhere in this publication. These are precautions that

personnel must understand and apply during various phases of

instrument operation or service.

WARNING

•

Potentially lethal voltages are present in this

instrument. Serious shock hazards from voltages

above 70 volts may exist in any connector,

chassis, or circuit board. Observe the following

precautions:

•

DO NOT install substitute parts or perform any

unauthorized modification to this instrument.

Contact Weinschel Corporation to acquire any

information on replacement parts or returning

the instrument for repair. Unauthorized

modification can cause injury to personnel and/or

destruction of the instrument.

•

Operating personnel must not remove instrument

covers. Component replacement or adjustments

MUST BE performed by qualified service

personnel.

•

DO NOT operate the instrument near or in the

presence of flammable gases or fumes.

DETAILED PRECAUTIONS.

The following WARNINGS, CAUTIONS and NOTES

appear throughout the text of this manual and are repeated here

for emphasis.

i

Page 3

SAFETY SUMMARY

•

All procedures and/or steps identified as

must be followed exactly as written and

according to industry accepted ESDS device

handling procedures. Failure to comply WILL

RESULT in ESDS damage.

•

DO NOT use a nylon bristle brush in the solvent

as the bristles may dissolve and cause damage to

the circuit card or component.

•

DO NOT use ultrasonic cleaning on parts or

assemblies containing electrical or electronic

components.

•

DO NOT bend pins of electrical connectors

when using fiber-bristle brush.

•

Compressed air used for cleaning and/or drying

can create airborne particles that may enter the

eye. Goggles/faceshields should be worn. DO

NOT direct air stream towards self or other

personnel. Pressure should be restricted to a

maximum of 15 psi to avoid personal injury.

•

Under no circumstances should a wire brush, steel

wool, or abrasive compound be used on any

surface. Using these items will cause extensive

damage to the instruments surface.

NOTE

CAUTION

DO NOT return any instrument or component to

Weinschel Corporation without receiving prior

factory authorization.

SAFETY SYMBOLS.

The following symbols are used to identify safety hazards

found throughout this publication and/or located on the

instrument.

CAUTION

HIGH VOLTAGE

WARNING

HIGH

VOLTAGE

ii

Page 4

Model 8314-X IM-477

TABLE OF CONTENTS

1. GENERAL INFORMATION ................................................................................................................................................. 4-7

1-1. PURPOSE ........................................................................................................................................................................................... 4

1-2. SCOPE ............................................................................................................................................................................................... 4

1-3. EQUIPMENT DESCRIPTION .......................................................................................................................................................... 4

1-4. UNPACKING AND INSPECTION ................................................................................................................................................... 4

1-5. RESHIPMENT INSTRUCTIONS ..................................................................................................................................................... 5

1-6. STORAGE INSTRUCTIONS ............................................................................................................................................................ 5

1-7. RELATED MANUALS ..................................................................................................................................................................... 6

1-8. ELECTROSTATIC DISCHARGE SENSITIVE ................................................................................................................................ 6

1-9. SAFETY CONSIDERATIONS .......................................................................................................................................................... 6

1-10. POWER REQUIREMENTS ............................................................................................................................................................ 6

2. FRONT & REAR PANEL CONNECTORS & INDICATORS .......................................................................................... 7-11

2-1. POWER ENTRY MODULE ASSEMBLY ..................................................................................................................................... 7-8

2-2. MOBILE & BASE STATION PORT CONNECTORS ..................................................................................................................... 8

2-3. FRONT PANEL LEDS ...................................................................................................................................................................... 8

2-4. EXTERNAL CONTROLS (REAR-PANEL BNC) ........................................................................................................................... 8

2-5. ETHERNET CONTROLLER LEDS & HARDWARE SETTINGS ............................................................................................ 8-11

2-5-1. STATUS LEDS ................................................................................................................................................................... 8

2-5.2. HARDWARE CONFIGURATION SWITCH SETTINGS ............................................................................................ 9-10

2-5.3. CONNECTOR PINOUTS ................................................................................................................................................. 11

3. COMMUNICATIONS ........................................................................................................................................................... 12

4. SIMULATION PARAMETERS & OVERVIEW .............................................................................................................. 13-14

5. PROGRAMMING .............................................................................................................................................................. 15-23

5.1. SIMULATION PARAMETERS ............................................................................................................................................. 15-17

5-2. SIMULATION CONTROL ..................................................................................................................................................... 18-19

5-3. SIMULATION DATA/DIRECT IO ........................................................................................................................................ 20-24

5-4. NETWORK CONTROL .......................................................................................................................................................... 24-25

5-5. HARDWARE CONTROL ............................................................................................................................................................ 25

5-6. DATA STORAGE ........................................................................................................................................................................ 26

6. MAINTENCE ..................................................................................................................................................................... 28-30

6-1. INSPECTION ................................................................................................................................................................................... 28

6.2. PREVENTIVE MAINTENANCE .................................................................................................................................................... 28

6.3. SPECIAL CLEANING INSTRUCTIONS ....................................................................................................................................... 28

6-3.1. MICROWAVE COAXIAL CABLE ASSEMBLIES ............................................................................................................ 28

6-3.2. CIRCUIT CARDS AND MODULES ................................................................................................................................... 28

6-3.3. MACHINED SURFACES AND HARDWARE ................................................................................................................... 29

6-3.4. CHASIS CLEANING ............................................................................................................................................................ 29

6-3.5. CONNECTOR CLEANING .................................................................................................................................................. 29

6.4. LINE VOLTAGE FUSE REPLACEMENT ..................................................................................................................................... 30

Aeroflex / Weinschel 2

Page 5

Model 8314-X IM-477

7. REPLACABLE PARTS LIST ................................................................................................................................................. 31

7-1. UNDERSTANDING REFERENCE DESIGNATORS .................................................................................................................... 31

7-2. ORDERING INFORMATION ......................................................................................................................................................... 31

7-3. DRAWING NUMBER ..................................................................................................................................................................... 31

7-4. REPLACABLE PARTS LIST .......................................................................................................................................................... 31

7-4.1. REFERENCE DESIGNATOR .......................................................................................................................................... 31

7-4.2. DESCRIPTION ................................................................................................................................................................. 31

7-4.3. PART NUMBER ............................................................................................................................................................... 31

7-4.4. VENDOR PART NUMBER ............................................................................................................................................. 31

7-5.5. CAGE CODE .................................................................................................................................................................... 31

7-4.6. ASSEMBLY AND COMPPONET LOCATION .............................................................................................................. 31

8314-1 WLAN SIMULATOR SUBSYSTEM REPLACEABLE PARTS LIST (P/N 93-8132-1) ...................................................... 32-33

8314-2 WLAN SIMULATOR SUBSYSTEM REPLACEABLE PARTS LIST (P/N 93-8132-2) ...................................................... 34-35

8. CONTACTING AEROFLEX / WEINSCHEL. ..................................................................................................................... 36

9. AEROFLEX / WEINSCHEL WARRANTY ........................................................................................................................ 36

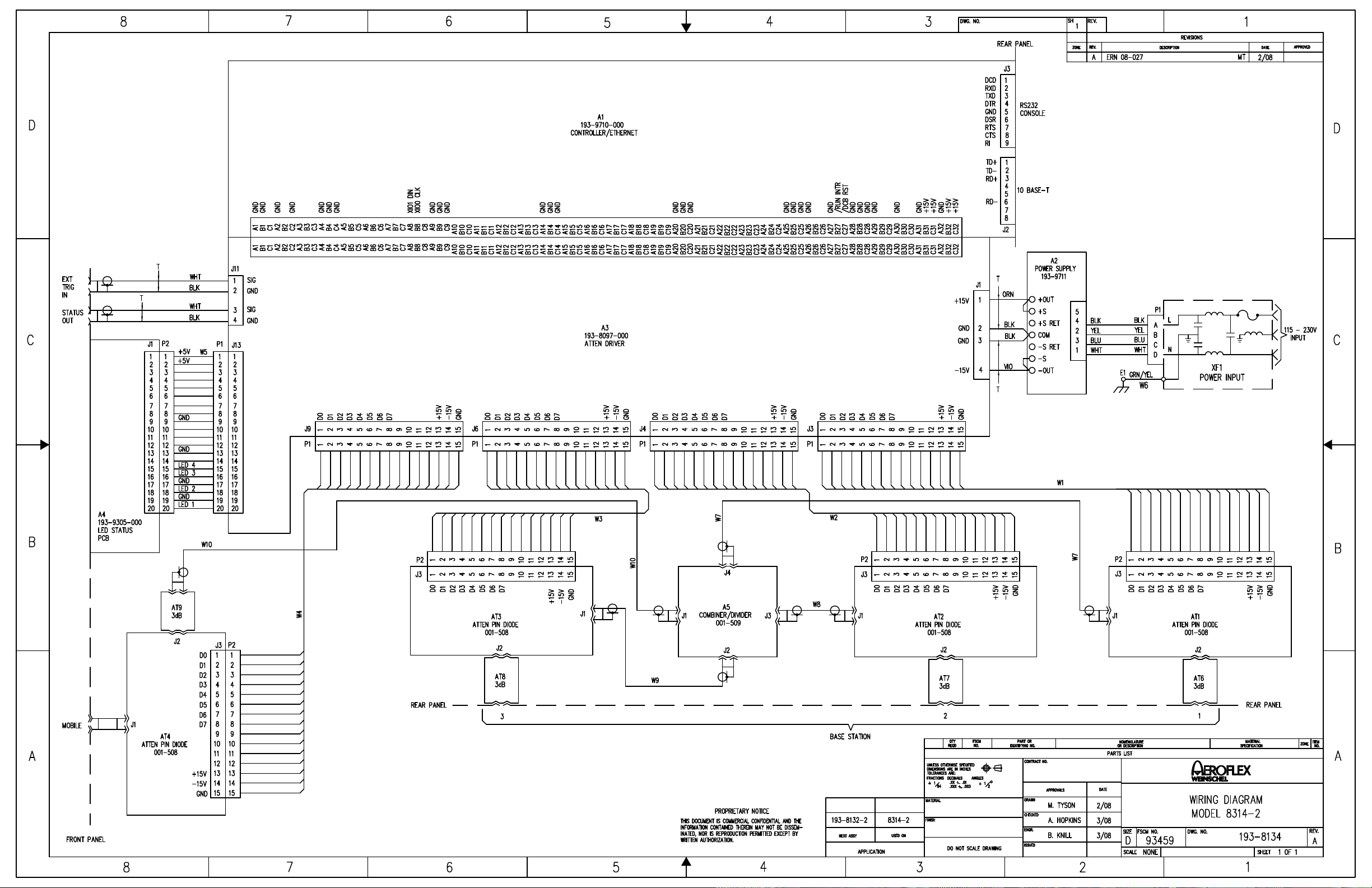

10. ASSEMBLY/WIRING DIAGRAMS

MODEL 8314-1 ASSEMBLY DRAWING ............................................................................................................................... 193-8132-1

MODEL 8314-2 ASSEMBLY DRAWING ............................................................................................................................... 193-8132-2

MODEL 8314-1 WIRING DIAGRAM ........................................................................................................................................ 193-8133

MODEL 8314-2 WIRING DIAGRAM ........................................................................................................................................ 193-8134

MODEL 8314-1 INTERFACE CONTROL DRAWING (SPECFICATIONS) ............................................................................ 089-4037

MODEL 8314-2 INTERFACE CONTROL DRAWING (SPECIFICATIONS) ......................................................................... 089-4038

Aeroflex / Weinschel 3

Page 6

Model 8314-X IM-477

1. GENERAL INFORMATION:

1-1 PURPOSE: This manual contains setup and operation information for the Aeroflex / Weinschel’s 8314 WLAN

Simulator Subsystem (P/N 193-8132-X). The manual also provides component location, reference designators, part

numbers, and nomenclature to identify all the assemblies and sub-assemblies of the WLAN Simulator Subsystem.

1-2 SCOPE: This manual is to be used in conjunction with the operation and maintenance of a 8314 WLAN Simulator

Subsystem. The manual also provides a description of each assembly; assembly parts list; block diagrams: and

general maintenance procedures to maintain the instrument.

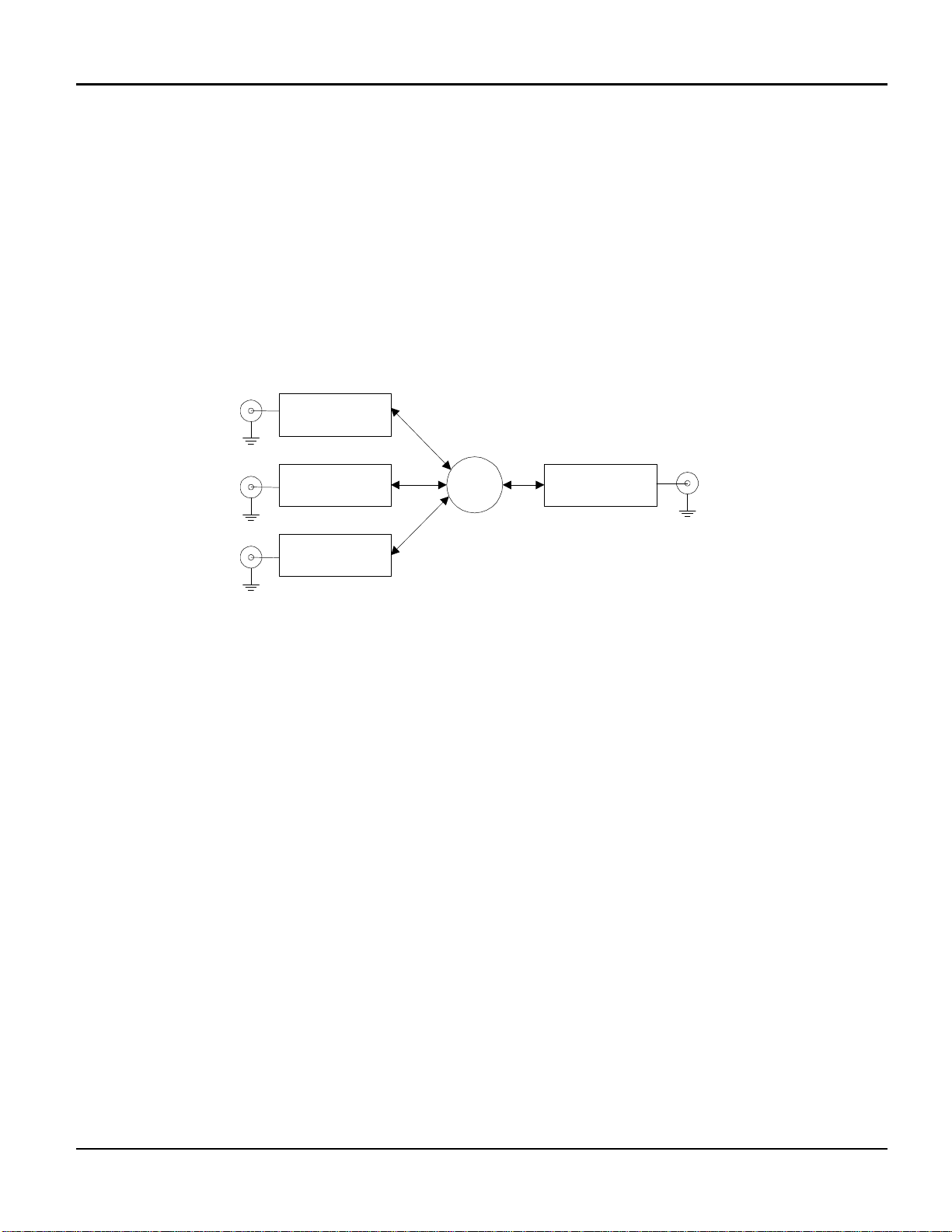

1-3 EQUIPMENT DESCRIPTION: The WLAN Simulator Subsystem (8314) is available in two frequency ranges and

is used to simulate the connectivity between a mobile running along a line of 3 base stations. Each of the three base

stations have an individually controlled attenuator, which are then combined, and passed thru a fourth attenuator used

to set the offset level. The attenuators are digitally controlled pin-diode absorptive attenuators, with a range of 0-63.75

dB in 0.25 dB steps. Refer to the RF Block Diagram below:

BS1

BS2

BS3

ATTN 1

(0-63dB )

ATTN 2

(0-63dB )

ATTN 3

(0-63dB )

3:1

ATTN 4

(0-63dB)

MOBILE

1-4. UNPACKING AND INSPECTION: Upon unpacking the equipment, retain the shipping container and packing

material for future shipment for recalibration. Perform the following initial inspection:

a. Carefully look at the outside of the shipping container for discoloration, stains, charring, or other signs of

exposure to excessive heat, moisture, or liquid chemicals. Check for any physical damage to the shipping

container such as dents, snags, rips, crushed sections or areas, or similar signs of excessive shoc k or

careless handling.

b. With the equipment and any accessory package removed from the shipping container, check each item

against the packing list or Items Supplied List. If any items are missing, contact the Aeroflex / Weinschel

Corporation Customer Service Department.

c. Carefully inspect the equipment looking for dents, deep scratches, damaged or loose connector, or any other

d. signs of physical abuse or careless handling. If damage is found, forward an immediate request to the

delivering carrier to perform an inspection and prepare a concealed-damag e report. DO NOT destroy any

packing material until it has been examined by an agent of the carrier. Concurrently, report the nature and

extent of damage to Weinschel Corporation, giving equipment model and serial numbers, so that necessary

action can be taken. Under U.S. shipping regulations, damage claims must be collected by the consignee;

DO NOT return the equipment to Aeroflex / Weinschel, Inc. until a claim for damages has been established.

Aeroflex / Weinschel 4

Page 7

Model 8314-X IM-477

1-5. RESHIPMENT: Use the best packaging materials available to protect the unit during storage or reshipment.

When possible, use the original packing container and cushioning material. If the original packing materials are not

available, use the following procedure:

a. Wrap the storage cases in sturdy paper or plastic;

b. Place the wrapped storage cases in a strong shipping container and place a layer of shock-absorbing material

(3/4 inch minimum thickness) around all sides of the unit to provide a firm cushion and to prevent movement

inside the container.

c. If shipping the unit for service, attach a tag to indicate:

1. model and serial numbers

2. service required

3. description of malfunction

4. return address

5. authorization to conduct repairs

6. return authorization number

d. Thoroughly seal the shipping container and mark it FRAGILE. Ship to:

Aeroflex / Weinschel, Inc.

Attn: Customer Service Department

5305 Spectrum Drive

Frederick, MD 21703-7362

or to an authorized sales representative.

1-6. STORAGE: Storage of the Model 8314 WLAN Simulator Subsystem is possible for extended periods without

incurring damage to internal circuitry if the 8314 Series is packaged according to the instructions above. The safe

limits for storage environment are as follows:

Temperature: 67° to +167 °F (-55° to +75 °C)

Humidity: less than 95% without condensation

Altitude: Up to 40,000 feet

1-7. RELATED MANUALS: The following manuals contain information that may be used in conjunction with this

manual to operate, service, or calibrate this instrument.

Manua

l Title

H4-1 and H4-2 Federal Supply Code for Manufacturers Cataloging Handbook

Aeroflex / Weinschel 5

Page 8

Model 8314-X IM-477

1-8. ELECTROSTATIC DISCHARGE SENSITIVE: The equipment documented in this manual contains certain

Electrostatic Discharge Sensitive (ESDS) components or parts. Therefore, certain procedures/steps are identified by

the use of the symbol . . This symbol is used in two ways:

CAUTION

All procedures and/or steps identified as must be followed exactly as written and according to

accepted ESDS device handling procedures. Failure to comply WILL RESULT in ESDS damage.

a. When the ESDS symbol is placed between a paragraph number and title , all of that

paragraph, including all subparagraphs, is considered ESDS device ha ndling procedure.

b. When the ESDS symbol is placed between a procedure/step number and the text , all of

that procedure is considered an ESDS device handling procedure.

1-9. SAFETY CONSIDERATIONS: The WLAN Simulator Subsystem and all related documentation must be reviewed

for familiarization with safety markings and procedures before any operation and/or service. Refer to the SAFETY

SUMMARY located at the beginning of this manual for a summary of safety information and procedures. Following

these simple safety precautions will ensure safe operation and service of the WLAN Simulator Subsystem.

1-10. POWER REQUIREMENTS: Aeroflex / Weinschel supplies a detachable power cable (P/N 068-21) to connect

an 100 to 240 Vac power source with a frequency between 50 to 60 H

Z to the WLAN Simulator Subsystem. To

minimize shock hazard, the instrument chassis must be connected to an electrical ground. Using the supplied threeconductor power cable ensures that the instrument can be firmly connected to the ac power source and electrical

ground (safety ground) at a grounded power outlet. Refer to paragraph 4-2 (Initial Setup) before applying any power

to the instrument.

Aeroflex / Weinschel 6

Page 9

Model 8314-X IM-477

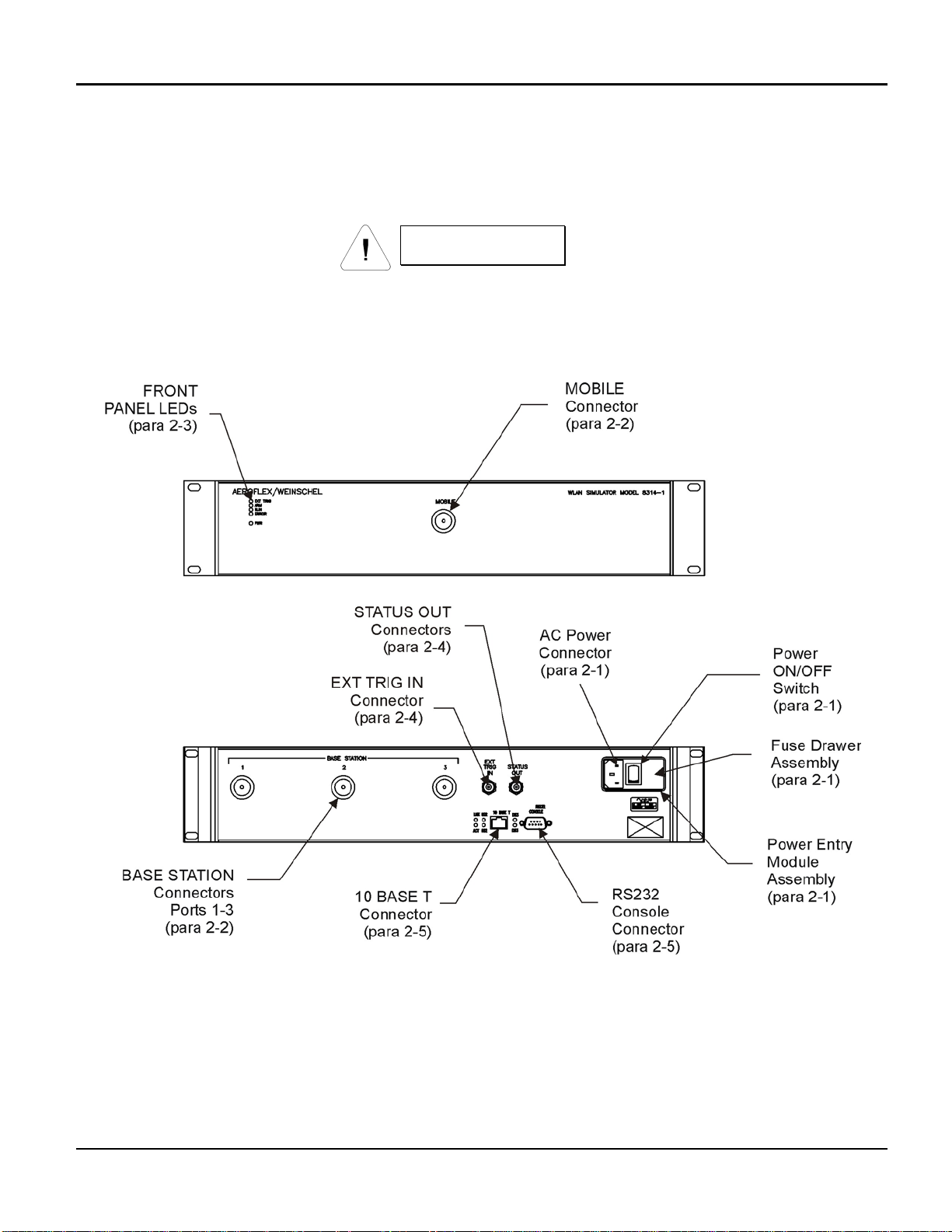

2. FRONT & REAR PANEL CONTROLS & INDICATORS:

The following paragraphs provide a description of the connections that can be made to the 8314 WLAN Simulator

Subsystem. Figure 1 shows the location of these connectors.

WARNING

Sufficient power levels are present at the Power Input Assembly to cause personal injury.

Ensure that the instrument power cord is DISCONNECTED before attempting to change

fuses.

Figure 1. Front & Rear Panel Connectors & Indicators

2-1 POWER ENTRY MODULE ASSEMBLY: The Power Entry Module Assembly located on the rear panel contains a

three-prong ac power input connector and a fuse drawer assembly (Figure 1). The Fuse Drawer Assembly contains

the line voltage fuse (Aeroflex / Weinschel P/N 052-1-1.5). The Model 8314 uses a T 1.5A, 250 Vac fuse which is 5 x

20 mm in size. Refer to paragraph 8-XXX for replacement of the fuse.

Aeroflex / Weinschel 7

Page 10

Model 8314-X IM-477

The AC Power Connector, located on the left side of XF1 (Figure 1), is a plug-type, prong insert connector with three

conductors for connection of the power cord (P/N 068-21) to the Power Supply Assembly located within the WLAN

Simulator Subsystem. This connector also grounds the chassis of the WLAN Simulator Subsystem when the the ac

power cord is connected to a grounded wall outlet. If necessary, use a three prong to two prong adapter and connect

the adapter’s ground lead to the outlet plate retaining screw.

The Power ON/OFF Switch is located on the rear panel and in part of the Power Entry Module Assembly. Placing the

POWER ON/OFF switch in the ON position applies power to the instrument.

CAUTION

When applying an RF signal to the RF INPUT connector, DO NOT exceed the maximum allowable

power level specifications of the Model 8314.

2-2. MOBILE & BASE STATION PORT CONNECTORS: There are three BASE STATION Ports location on

the rear panel and a Mobile Port on the front panel. These Type N female connectors provide a input and

output ports where RF signals can be applied to the devices internally mounted in the Model 8314.

2-3. FRONT PANEL LEDS: There are four leds plus a PWR indicator which are shown on the front panel:

FP LED FUNCTION

EXT TRIG When on, the trig mode is set to external. When off, trig mode is internal.

ARM When on, the system is awaiting a trigger event. Goes off when trig received.

RUN System has been triggered and is running. Goes out when sweep ends.

ERROR One or more of the setup parameters is invalid, and unable to run.

PWR Indicates that external power is applied to the unit.

2-4. EXTERNAL CONTROL CONECTORS: These BNC female connectors are located on the rear panel. The table

below outlines each connector’s parameters:

CONTROL CONNECTOR PARAMETERS

EXT TRIG INPUT TTL/CMOS compatible schmitt-trigger

Max input voltage range: -0.5V to +5.5V

High-level input voltage VIH: +2.1V minimum

Low-level input voltage VIL: +0.5V maximum

Internal 10 KΩ resistive pullup to +5V

ESD and current limit protected

Programmable polarity

STATUS OUTPUT

(simulation RUN state)

Aeroflex / Weinschel 8

High-level output voltage VOH +4.8V @ IOH=-50µA (RUNNING)

+3.2V @ IOH=-5mA

Low-level output voltage VOL +0.2V @ IOL=50µA (STOPPED)

+1.4V @ IOL=5mA

ESD and current limit protected

Page 11

Model 8314-X IM-477

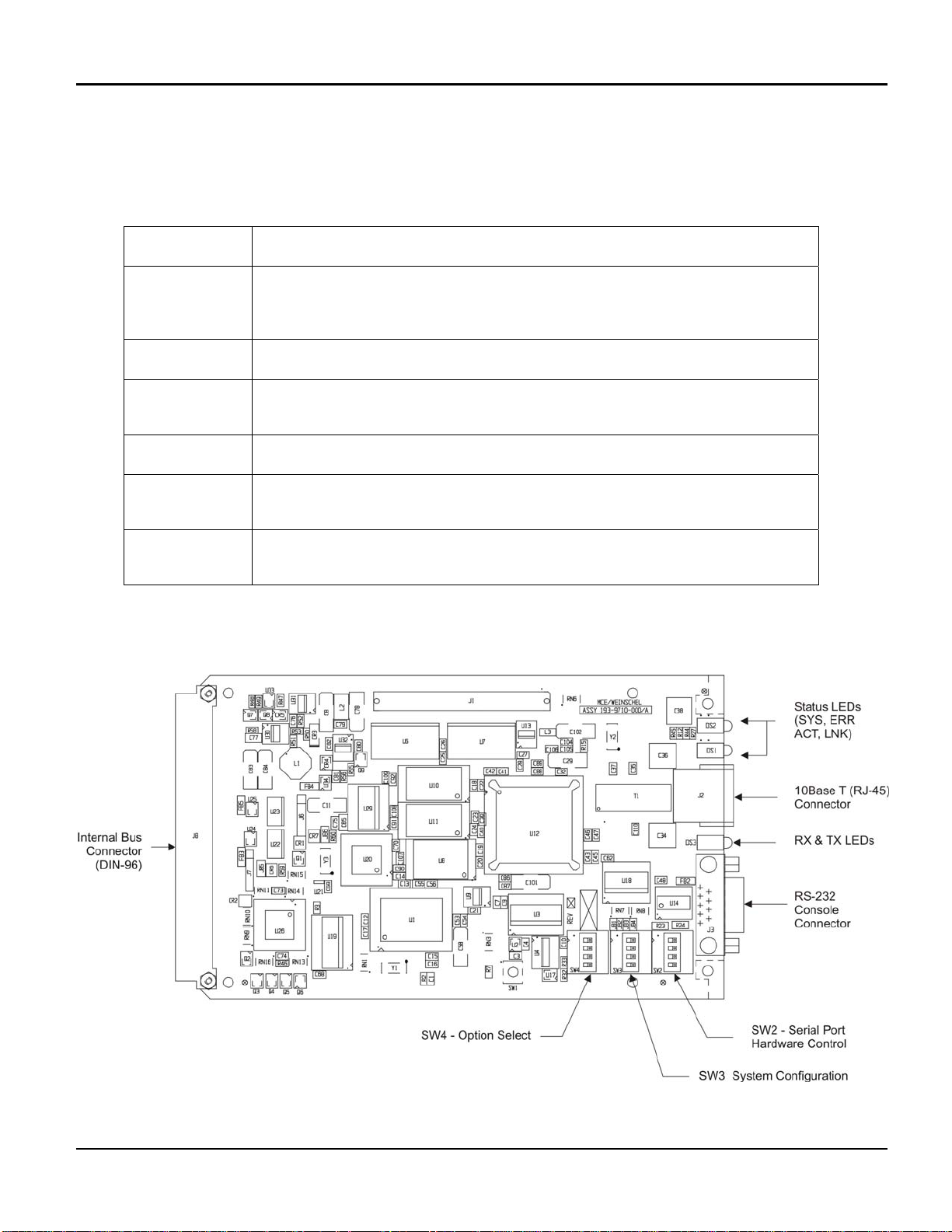

2-5. ETHERNET CONTROLLER LED’s & HARDWARE SETTINGS: The following paragraphs provide a descri ption

for each of the rear panel Ethernet LEDs, hardware settings for the internal Ethernet controller card and signal – pin

locations for the 10BaseT and RS232 connectors. Figure 1 shows the location of these connectors.

2-5.1 STATUS LEDs:

LED FUNCTION

SYS Indicates that the Ethernet controller is enabled for operation in the system.

This LED flashes during boot and remains on during normal operation of the

switch.

ERR Indicates that a serious error has occurred during system boot.

ACT Indicates that activity is occurring over the 10BaseT Ethernet RJ-45 interface.

This LED flashes as transmit/receive activity occurs.

LINK Indicates that the Ethernet port has established a valid link with the network.

TX This LED flashes as the Ethernet Controller transmits data via the RS232

Console port.

RX This LED flashes as the Ethernet Controller receives data via the RS232

Console port

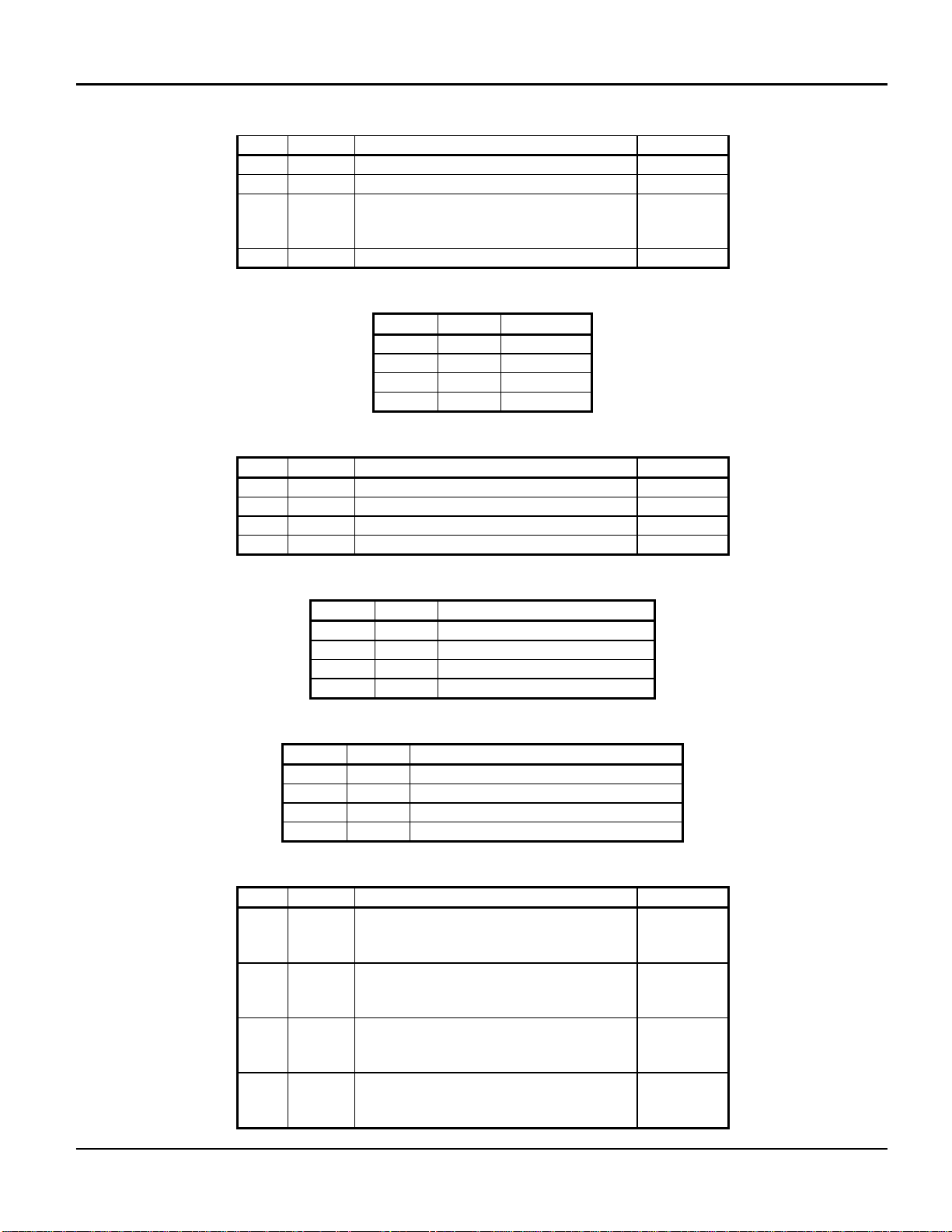

2-5.2. Hardware Configuration Switch Settings: Figure 2 is provided for component locatio n for the switches,

LEDs, connectors on the Ethernet controller card.

Figure 2. Ethernet Controller Card Switch/LED/Connector locations

Aeroflex / Weinschel 9

Page 12

Model 8314-X IM-477

SW4 – Option Select

Name Description Default

1 --- unused off

2 --- unused off

3 BR1 Baud Rate Select

off

(see below)

BR0 Baud Rate Select off

Baud Rate Select

BR0 BR1 Rate

0 0 9600

1 0 19200

0 1 38400

1 1 57600

SW3 – System Configuration

Name Description Default

1 MS1 Memory Select off

2 MS2 Memory Select off

3 LS2 Load Sequence Overrid e (see below) off

4 LS1 Load Sequence Overrid e off

Memory Select

MS1 MS2 Description

0 0 Normal

1 0 External ROM card

0 1 Emulation mode (reserved)

1 1 Emulation mode (reserved)

Load Sequence Override

LS1 LS2 Description

0 0 Normal sequence

1 0 run RomMon w/WDOG disabled

0 1 run SysLoader

1 1 Normal sequence w/WDOG disabled

SW2 – Serial Port Hardware Control

Name Description Default

1 CTST RS422 Mode CTS Termination

off

Off – no termination

On – 120 ohm termination

2 RXDT RS422 Mode RXD Termination

off

Off – no termination

On – 120 ohm termination

3 RTSS RS422 Mode RTS line

off

Off – RTS+ not connected

On – RTS+ connected

4 MODE Serial Port Mode

off

Off – RS232

On – RS422

Aeroflex / Weinschel 10

Page 13

Model 8314-X IM-477

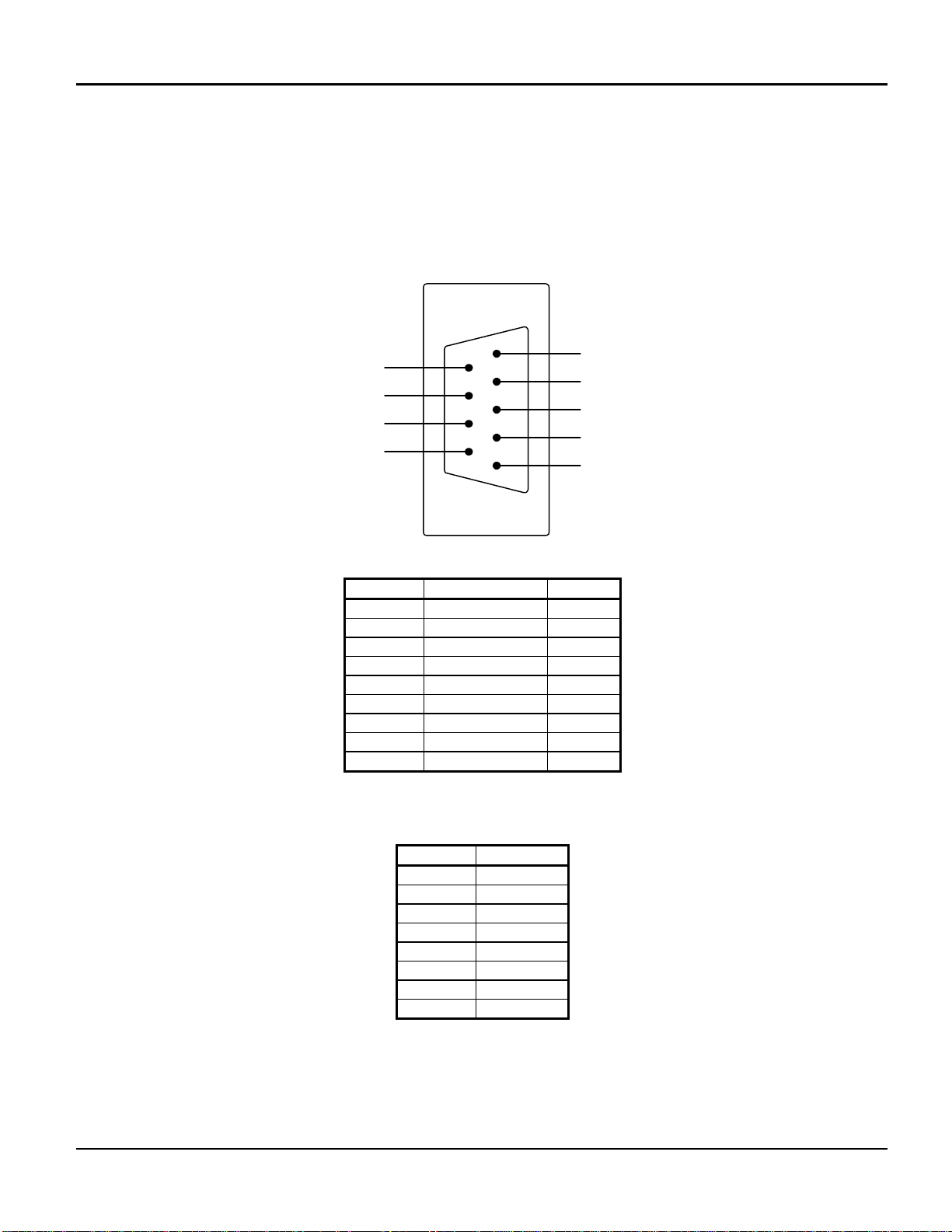

2-5.3 Connector Pinouts: The Ethernet controller card contains a 10BaseT (RJ-45) and a RS232 (DB9M) Console

connector that are mounted to the rear panel. There is also a table included for Internal Bus Connector, J8 located on

the Ethernet Controller card (DIN-96). Pin-outs for these connectors are as follows:

Serial Port Connector (DB9M)

RS232

9-pin DB9

Pinout

1

DSR

RTS

CTS

RI

6

7

8

9

DCD

2

RxD

3

TxD

4

DTR

5

GND

PIN NO RS232 RS422

1 DCD (unused) RXD+

2 RXD RXD3 TXD TXD4 DTR TXD+

5 GND GND

6 DSR (unused) CTS+

7 RTS RTS8 CTS CTS9 RI (unused) RTS+

10Base-T Ethernet Port (RJ-45)

PIN NO 10Base-T

1 TD+

2 TD3 RD+

4 Unused**

5 Unused**

6 RD7 Unused**

8 Unused**

** Unused pins on the RJ-45 have 75Ω/0.01µF to chassis to reduce noise.

Aeroflex / Weinschel 11

Page 14

Model 8314-X IM-477

3. COMMUNICATIONS:

The system provides both RS-232 serial port and 10BaseT Ethernet operation.

The RS-232 port can operate at 9600, 19200, 38400, or 57600 baud rates, selectable via internal DIP switch.

Default format is 9600N81. The serial port uses a standard DB9 DTE connector pinout. Connection to a standard

PC’s serial port requires the use of a “null-modem” type cable to swap the transmit and receive data pair (pins 2 and

3). A command-line interface (CLI) will be provided for interactive use w/ a terminal emulator. The CLI can be disabled

to facilitate use of the serial port as a programming interface. The CLI provides user prompts and supports simple line

editing (via the BS key) , last command recall (Ctrl-P), and a simple help facility. Help can be accessed from the main

command prompt using either the HELP or simply ‘?’. Additional help for many commands is available by specifying

the main command followed by a ‘?’. For example, “SET ?” provides a list of the SET commands, and “SET FREQ ?”

provides detailed info on the set frequency command.

Many commands and keywords allow abbreviated forms. Command abbreviations can be displayed using the

‘CMD ?’ help command. Also, there are some system level configuration/diagnostic commands, such as PING, that

can be listed using ‘SYS ?’ help command. Many of these require system-level password access.

10BaseT Ethernet will provide TELNET access (port 23) to the CLI for operation over a network. In addition,

TFTP client will also be supported for performing code updates to the flash memory. Network parameters (IP address,

subnet mask, TFTP host address, etc) can be set and stored/recalled from non-volatile memory. TFTP transfer is also

used to support the download/upload of the raw data tables, due to the potential volume of information to be

transferred. By default, the unit is configured for an IP address of 10.0.0.1, with a subnet mask of 255.255.255.0.

A NOTE ON PASSWORDS

Passwords are/can be used to prevent inadvertent configuration/switch changes. Password

protection is, generally, weak, in that a user can see the current password using the ‘SHOW CONFIG’

command. In addition, there is a fixed password (the word SYSTEM) that can be used that will grant

system-level access to many commands normally reserved for system testing/configuration.

Aeroflex / Weinschel 12

Page 15

Model 8314-X IM-477

λ

4. SIMULATION PARAMETERS AND OVERVIEW:

gain

xpos

BS1

ypos

gain

BS2

ypos

xpos

xpos

BS3

ypos

gain

2

⎞

⎟

⎟

⎠

22

GtGr

MOBILE

velocity

freq

gain

= wavelength

distance

stoppos

(origin)

startpos

The above diagram shows the user-entered parameters. When a simulation is initiated, the parameters are validated,

and the system builds its tables of attenuation setting vs time using the following relationship (Friis Transmission

Equation)

⎛

λ

LinkLoss

where

The system allocates a maximum of 10,000 data points for each attenuator for use over the entire simulation

time, for a total of 30,000 data points. The data tables are pre-built prior to the start of the simulation run, and typically

takes 3-4 seconds to complete.

When computing the data tables, the system notes the maximum signal level computed over the course of the

simulation, which will occur when the mobile position is at Xpos1, Xpos2, or Xpos3, depending on the basestation

gain and Ypos settings. This level, along with the nominal insertion loss of the unit, is used to set the Offset Attenuator

(ATTN4), whose value will not be changed over the course of the simulation. This offset will be subtracted from the

loss calculations of the three base station attenuators ATTN1-ATTN3, allowing the full range of these attenuators to

be used for the simulation in most cases. For basestation positions that are located far from the track, the Offset

Attenuator alone may not provide the reqd amount of attenuation, and this must be taken into account. For example,

for f=2000MHz, ypos=100m, the loss is 78dB. Since there’s only 63dB range in ATTN4, the remaining 78-63=15dB

will have to provided by the BS attenuator.

⎜

=

⎜

R

4

π

⎝

xposyposR += and

Simulation time is controlled via a 16-bit hardware timer/counter with 100nsec resolution , which provides a

max count time of 6.5536ms, with no pre/post-scaling.The actual required update rate is a function of the simulation

distance, mobile velocity, and the maximum number of allocated data points. The distance and velocity determine the

total simulation time:

Time =

mdistance

)/()(smvelocity

The system enforces a maximum update rate of 1msec. If Time is less than 10 secs (10,000pts * 1ms/pt),

then the update rate is fixed at 1msec, and the array size is reduced to cover the required time. If Time is greater than

10 secs, the entire 10,000 points are used, and the update rate is adjusted to cover the total simulation time.

Aeroflex / Weinschel 13

Page 16

Model 8314-X IM-477

The system also supports a “raw data mode”, in which the data tables are filled via external file download. This

allows the unit to support any arbitrary attenuation profile.

Operational Notes:

- set trigger mode

triggering can be set for INTernal or EXTernal. Ext trig is indicated on front-panel led.

- set trig polarity

external trig polarity can be set for active high (1) or active low (0) logic levels. Triggering is levelsensitive. Note that the EXT TRIG input is pulled high via a resistive pullup.

- set sweep mode

the simulation sweep can be set for SINgle or CONtinuous operation. In SINGLE mode, the

simulation will be run one time when a trigger event occurs, and will then stop. In CONT mode, when

the end of a simulation is reached, the simulation will be automatically restarted from the beginning,

depending on the current trigger mode. If the system is set for external triggering, then the triggering

subsystem is re-armed, and will wait for a new trigger event before continuing.

- set/show parameters

All parameters will have commands to set and query their current setting, as well as to be able to

restore the default settings. Summary commands will also be available to view multiple related

settings.

- run/stop simulation control

The RUN command initiates a simulation sweep. It performs the following:

1). All parameters are reviewed for validity. Note that while all the values are range-checked when

they are entered, some parameter values are coupled, and cannot be validated until all parameters

are entered. An example of this is the mobile position vs mobile distance. If the parameter values

result in an invalid simulation, the run is aborted and the front-panel ERROR led is illuminated.

2). Assuming the parameters are valid, the attenuation vs time profile data is computed, and stored in

internal tables. The triggering subsystem goes from the IDLE to the ARMED state, in which it waits for

a trigger event to occur. The front-panel ARM led is illuminated.

3). If the trig mode is set to INTernal, the triggering subsystem automatically transitions from the

ARMED to the RUNNING state. For external triggering, the ARMED to RUNNING state transition

occurs when the system detects the external trigger event. The front-panel RUN led is illuminated,

and the external STATUS output is asserted high.

4). Simulation runs, with the basestation attenuators (1-3) being updated periodically over the course

of the simulation.

5). When the end of the simulation is reached, if the sweep mode is SINGLE, then the simulation

ends, the RUN led goes off, and the external STATUS output is low. Otherwise the triggering is

rearmed, and the simulation goes to step 3. In the CONTinuous sweep mode, the simulation will be

re-run until the STOP command is given.

Aeroflex / Weinschel 14

Page 17

Model 8314-X IM-477

5. PROGRAMMING:

5-1. Simulation Parameters: In general, parameter ranges have been set to cover most real-world (and some

not so real) conditions. The simulation can be run over a 20km total distance (12.4 miles), at speeds up to 320km/hr

(approx 200mph). The system will not attempt to limit the selection of parameters, with the exception that the mobile

and basestation positions must be within the MOBILE DISTANCE (total simulation distance) setting. This allows the

maximum flexibility, but note that it also allows the user to set up scenarios that are not very realistic, or that could

result in extremely long simulation runs.

SET BASESTATION POSITION

Syntax

SET BASESTATION POSITION <select> <xpos> <ypos>

SET? BASESTATION POSITION <select>

Parameters

<select> basestation select (1-3)

<xpos> x-axis distance from the origin, in meters (0-20000)

<ypos> y-axis distance from the track, in meters (1-100)

Description

Sets the position of the selected basestation. The position along the X axis should be <= the MOBILE

DISTANCE setting. There are no restrictions on the order or positioning between the three ba se stations.

Example

SET BASESTATION POSITION 1 2500 50

sets the position of basestation 1 to 2500 meters from the start, at an offset

of 50 meters

SET BASESTATION GAIN

Syntax

SET BASESTATION GAIN <select> <gain>

SET? BASESTATION GAIN <select>

Parameters

<select> basestation select (1-3)

<gain> gain factor, in dB (-10.0 to +10.0)

Description

Sets the antenna gain factor, in dB, for the specified basestation.

Example

SET BASESTATION GAIN 1 -1.5

sets the gain of basestation 1 to -1.5dB, providing loss

Aeroflex / Weinschel 15

Page 18

Model 8314-X IM-477

SET MOBILE DISTANCE

Syntax

SET MOBILE DISTANCE <dist>

SET? MOBILE DISTANCE

Parameters

<dist> simulation distance, in meters (1-20000)

Description

Sets the total distance travelled for the simulation. Setting this parameter will automatically reset the

MOBILE POSITION to cover the distance specified

Example

SET MOBILE DISTANCE 10000

sets the distance to 10000 meters

SET MOBILE VELOCITY

Syntax

SET MOBILE VELOCITY <vel>

SET? MOBILE VELOCITY

Parameters

<vel> velocity, in km/hr (1-320)

Description

Sets the speed of the mobile, in kilometers/hr

SET MOBILE GAIN

Syntax

SET MOBILE GAIN <gain>

SET? MOBILE GAIN

Parameters

<gain> gain factor, in dB (-10.0 to +10.0)

Description

Sets the antenna gain factor, in dB, for the mobile.

Example

SET MOBILE GAIN -1.5

sets the gain of mobile to -1.5dB, providing loss

Aeroflex / Weinschel 16

Page 19

Model 8314-X IM-477

SET MOBILE POSITION

Syntax

SET MOBILE POSITION <startpos> <stoppos>

SET? MOBILE POSITION

Parameters

<startpos> x-axis starting distance from the origin, in meters (0-20000)

<stoppos> x-axis stopping distance, in meters

Description

Sets the mobile start and stop position, relative to the origin. Normally, these values would be set

to cover the MOBILE DISTANCE setting. This command allows the user to travel over a portion of

the total simulation distance. Note that changing this setting has no effect on the actual simulation

data or update rate, as the data is based on the entire distance.

SET FREQ

Syntax

SET FREQ <mhz>

SET? FREQ

Parameters

<mhz> frequency, in MHz (2000-6000)

Description

Sets the current operating frequency for use by the loss calculations.

SHOW PARAM

Syntax

SHOW PARAM

Description

Displays the current setting of all the user-entered simulation parameters.

SAVE PARAM

Syntax

SAVE PARAM

Description

Saves the current setting of all the user-entered simulation parameters into non-volatile memory .

These settings will be recalled during next system bootup.

Aeroflex / Weinschel 17

Page 20

Model 8314-X IM-477

5-2. Simulation Control

SET TRIGGER MODE

Syntax

SET TRIGGER MODE <mode>

SET? TRIGGER MODE

Parameters

<mode> trigger mode, INT or EXT

Description

Selects internal or external triggering for the simulation. With internal triggering, the simulation runs

automatically after a RUN command is received. When external triggering is selected, the simulation

will wait for an external trigger event before the simulation starts.

SET TRIGGER POLARITY

Syntax

SET TRIGGER POLARITY <pol>

SET? TRIGGER POLARITY

Parameters

<pol> active level, 0 or 1

Description

Sets the external trigger polarity level. Setting <pol>=0 sets an active-low external trigger, while a

<pol> of 1 sets an active-high trigger level. The external trigger input has a resistive pull-up, so that

if trigger input is left unconnected it will default to a high level.

SET SWEEP MODE

Syntax

SET SWEEP MODE <mode>

SET? SWEEP MODE

Parameters

<mode> sweep mode, CONT or SINgle

Description

Sets the simulation sweep mode. In SINGLE mode, once a simulation is triggered the simulation

will run once and then stop. If the sweep is set for CONTinuous operation, when the simulation

reaches the end it will return to the armed state and await another trigger event.

RUN

Syntax

RUN [CALC]

Description

Initiates/computes a simulation run. In its basic form, the RUN command computes the

attenuator data tables based on the entered parameters, and places the triggering subsystem in

the armed state, awaiting a trigger event. If the optional CALC switch is specified, the command

will only perform the calculations, and will not arm the trigger. This is useful if the user desires to

view the simulation results prior to actually running the simulation.

Aeroflex / Weinschel 18

Page 21

Model 8314-X IM-477

STOP

Syntax

STOP

Description

Stops a running simulation.

SHOW CALC

Syntax

SHOW CALC

Description

Displays various results of the simulation calculations, including total

time, max levels, update rate, etc

SHOW STATUS

Syntax

SHOW STATUS

Description

Displays the current state of a simulation.

Sets the simulation sweep mode. In SINGLE mode, once a simulation is triggered the simulation will run once

and then stop. If the sweep is set for CONTinuous operation, when the simulation reaches the end it will

return to the armed state and await another trigger event.

Aeroflex / Weinschel 19

Page 22

Model 8314-X IM-477

5-3. Simulation Data/Direct IO

These commands provide access to the raw simulation data and control, and can be used to override or view the

internal calculation data.

SET DATA CALC

Syntax

SET DATA CALC <mode>

Parameters

<mode> calc mode 0 or OFF, 1 or ON

Description

This command can be used to enable/disable the loss calculations. With calc off, the system allows

the data tables to be filled with arbitrary data using the SET DATA, SET DATA TIMER, and SET

DATA POINTS commands.

NOTE: this is not a new command, but it now allows use of the parameters ON and OFF instead of just 0/1

SET DATA POINTS

Syntax

SET DATA POINTS <numofpts>

Parameters

<numofpts> number of data points (1-10000)

Description

Sets the number of data points to use for a simulation run in table mode. Each point must be filled

using the SET DATA command

SET DATA

Syntax

SET DATA <pt> <attn1> <attn2> <attn3>

Parameters

<pt> data point number (0-10000)

<attn1> attenuator 1 setting, in dB

<attn2> attenuator 2 setting, in dB

<attn3> attenuator 3 setting, in dB

Description

Sets a data point for use in table mode (DATA CALC 0). Data point 0 is the initial setting at time

0. The range of the attn setting is dependant on the attenuator configuration, but is typically 0 to

63.75 in 0.25dB steps. Note: Control of the Offset Attn (Attn4) setting may be done using the

ATTN command

Aeroflex / Weinschel 20

Page 23

Model 8314-X IM-477

SET DATA TIMER

Syntax

SET DATA TIMER <secs>

Parameters

<secs> simulation update rate, in secs (0.001-60.000)

Description

Sets the attenuator update rate in table mode. The total simulation time is

determined from DATA TIMER * DATA POINTS

SHOW DATA

Syntax

SHOW DATA <startidx> <endidx> [FMT]

Parameters

<startidx> starting data array index (0-10000)

<endidx> ending data array index (0-10000)

[FMT] optional formatting flag

Description

Displays the simulation data array. The response shows the point number, and the data for each

of the three attenuators at that point. The default format for the attenuation data is the integer

programming word (0-255), which can be changed to display attenuation by using the optional FMT

specifier

ATTN

Syntax

ATTN <select> <setting>

ATTN? <select>

Parameters

<select> attenuator select (1-4)

<setting> attenuation value, in dB (0-63.75)

Description

Directly sets an attenuator setting. This command is useful for testing and diagnostics.

SET OFFSET ATTN

Syntax

SET OFFSET ATTN <setting>

SET? OFFSET ATTN

Parameters

<setting> attenuation value, in dB (0-63.75)

Description

Sets the Offset Attenuator value. The dB value specified in <setting> will be rounded to the resolution of the

attenuator. This command is useful for setting an offset while using Data Table mode, and is equivalent to the

'ATTN 4 xx' command.

Aeroflex / Weinschel 21

Page 24

Model 8314-X IM-477

FILL DATA

Syntax

FILL DATA <setting>

Parameters

<setting> attenuation value, in dB (0-63.75)

Description

Fills the data tables with the specified db value.

SHOW TIME

Description

Shows current system time in hrs:min:secs.msec and elapsed time since last invocation. Useful for timing

script execution.

SHOW ERROR COUNT

Description

Shows count of total errors since last invocation. Useful for script debugging.

SHOW FILE

Syntax

SHOW FILE [DATAFLASH:]

Description

This command can be used to display the status and contents of the dataflash: storage area

(including the name and size) if the optional 'DATAFLASH:' or 'DF: ' parameter is specified.

Otherwise, it displays the status of both the flash: and dataflash: file storage areas, including header

information, crc's, version, date, size, etc.

The first line of each section contains status information for each copy in the form 'Status (backup copy,

working copy)'. A status of 0 indicates the file is valid, while <0 indicates an error was detected in the copy.

The remaining

info is from the copy that is/will be in use. For example, flash: Status(-252, 0) indicates that there is a CRC

error

in the backup copy, while the working copy is ok.

EXECUTE SCRIPT

Syntax

EXECUTE SCRIPT [ECHO]

Description

This command executes the command script file stored in the dataflash: (df:) device. If the optional 'ECHO'

keyword is provided, then the command will display the script on the current console device as it is executed.

The command script file may contain any executable command supported by the CLI. Lines are limited to

128 chars in length, and should end with an ascii CR (0x0d), LF (0x0a), or any combination of the two.

Comment lines are optional, and if usedmust begin with either an ascii single-quote character (0x27), or an

ascii '/' char (0x2f).

Script files are stored into the dataflash: using the COPY TFTP command, and are limited to a maximum

total length of 512K bytes. The current contents of the dataflash: can be viewed using the SHOW FILE DF:

command.

Aeroflex / Weinschel 22

Page 25

Model 8314-X IM-477

COPY source destination

Syntax

COPY TFTP:<url-filename> {FLASH: | DATAFLASH:}

COPY {FLASH: | DATAFLASH:} TFTP:<url-filename>

Access-level : password

Description

Copies remote file identified by <url-filename> via TFTP to/from application flash: or dataflash: memory. The

first argument is the source, the second is the destination. It allows the user to download an image from the

network and save in flash, or upload an image from flash to the network server. By default, the transfer uses

the host IP address specified by SET TFTPHOST. However, if the <url-filename> contains an IP address, the

transfer will use this address instead.

For example, 'copy tftp://10.0.0.10/file.bin flash:' would attempt to download the file from the specified

address of 10.0.0.10, ignoring the current TFTPHOST setting, if any.

Each of the data storage devices only reserve space for a single file, so any downloads will overwrite the

current contents. As such, any filename parameters for the fl: and df: destinations are used strictly as

placeholders.

The command accepts the abbreviations of 'FL:' and 'DF:' for the flash: and dataflash: devices, respectively.

ENABLE

ENABLE PASSWORD

DISABLE

Syntax

ENABLE

ENABLE <plain-text>

ENABLE PASSWORD <plain-text>

NO ENABLE PASSWORD

DISABLE

RECOVER PASSWORD

SHOW PASSWORD\0

see also: SET ACCESS SYSTEM

Access-level : all

Description

The mrs software provides two levels of access to commands: user and privileged. The unprivileged user

mode is called 'user exec' mode. The privileged mode is called 'privileged exec' mode and normally req uires

entry via a password. The commands available in 'user exec' mode are a subset of the commands available

in 'privileged

exec' mode.

The ENABLE and DISABLE commands are used to enter and leave privileged exec mode, respectively. If a

password has been set, the user will be prompted to enter in the password. Once entered, the prompt

changes to 'mrs#' to show the current mode. You may bypass the 'password:' prompt by including the

password along

with the ENABLE keyword on the command line.

To set an access-level password, use the 'ENABLE PASSWORD <plain-text>' command, where <plain-text>

specifies the desired password, and may be up to 11 chars in length. The password is stored in nvram. The

command 'NO ENABLE PASSWORD' deletes the password and removes it from nvram storage, as long as

you are in privileged mode.

Aeroflex / Weinschel 23

Page 26

Model 8314-X IM-477

There is a password recovery feature that allows the user to view/erase the current password without being

in privileged mode. This can be accessed only via a local serial port connection to the console, and will not

work over a telnet connection.

To erase the password, you must first send an RS232 BREAK signal. You should see the console respond

with the message '**BREAK** detected. Password recovery enabled'. Once password recovery is enabled,

you can use the 'SHOW PASSWORD' command to display the current password, or you can send

'RECOVER PASSWORD', which will erase the current password setting. If successful, you will get the

message 'Password reset'. Password recovery mode is automatically terminated after receipt of any two CLI

commands, after which you will get an 'Access denied' error, and have to repeat the steps.

5-4. Network Configuration

SHOW NETWORK CONFIG

Syntax

SHOW NETWORK CONFIG

Description

Displays the current setting of the configuration parameters, including MAC and IP addresses, tftp

host, password, etc.

SET IP ADDRESS

Syntax

SET IP ADDRESS <ip-addr> [<subnet-mask>]

Access-level : password

Description

Sets the IP address of the ethernet interface to <ip-addr> with a network mask <subnet-mask>, if

supplied. Both <ip-addr> and <subnet-mask> are in the form of A.B.C.D.

By default, the IP address is 10.0.0.1, with a subnet mask of 255.255.255.0

SET IP GATEWAY

Syntax

SET IP GATEWAY <ip-addr>

Access-level : password

Description

Sets the IP address of the default gateway used to access addresses outside the local subnet.

The <ip-addr> parameter is in the form of A.B.C.D.

Changes made to this parameter will not take effect until the system is rebooted (see RELOAD).

SET TELNET TIMEOUT

Syntax

SET TELNET TIMEOUT <secs>

Description

Sets the inactivity timeout for TELNET sessions, in secs. <secs> can be in the range of 30 to

1800 (30 mins). The default timeout is 600 secs (10 mins).

Aeroflex / Weinschel 24

Page 27

Model 8314-X IM-477

SET TFTPHOST

Syntax

SET TFTPHOST <ip-addr>

Description

Sets the IP address for a remote TFTP server, which is used by the COPY cmd.

PING

Syntax

PING <ip-addr>

Description

Sends ICMP ECHO packets to <ip-addr>, and reports the results. The packets are 32 bytes in length.

COPY source destination

Syntax

COPY TFTP:<url-filename> {FLASH: | BOOTFLASH:}

COPY {FLASH: | BOOTFLASH:} TFTP:<url-filename>

Description

Copies remote file identified by <url-filename> via TFTP to/from application flash: or sysloader

bootflash: memory. The first argument is the source, the second is the destination. It allows the

user to download an image from the network and save in flash, or upload an image from flash to the

network server. By default, the transfer uses the host IP address specified by SET TFTPHOST.

However, if the <url-filename> contains an address, the transfer will use this address instead. For

example, 'copy tftp://10.0.0.10/file.bin flash:' would attempt to download the file from the specified

address of 10.0.0.10, ignoring the current TFTPHOST setting, if any.

RELOAD

Syntax

RELOAD

Description

Reboots the system, performing the boot-up sequence as if from power-up.

5-5. Hardware Configuration

CONFIG commands are typically used during system mfg and set up, and should not normally be

changed by the user, unless instructed to do so. These commands require system-l evel access.

CONFIG ATTN <maxdb> <stepdb>

Sets the attenuator max setting and stepsize, in dB

CONFIG FREQ <minf> <maxf>

Sets the min and max freq range, in MHz

CONFIG LOSS <minl> <maxl>

Sets the insertion loss min and max (at min/max freq), in dB

SAVE CONFIG

SHOW CONFIG

Aeroflex / Weinschel 25

Page 28

Model 8314-X IM-477

5-6. Data Storage

The MRS has a new logical storage device referred to as the dataflash: ( or DF: ). While the dataflash: cannot

be used to directly store the simulation data tables, the dataflash: can be loaded with a text script file that can be used

for a variety of purposes. The script file can contain any sequence of commands that are recognized from the CLI,

and can be executed on command much like a batch file. The dataflash: script file is loaded via downloading the file

from a network TFTP server connection. Once copied, the file is stored in non-volatile memory on the controller and is

automatically saved for future execution. The script file can then be executed via a CLI command. While the script file

can contain any sequence, it is particularly useful for setting up the simulation data tables.

While the data tables can be loaded via cli commands, it can take a long time to send the sequence via the serial port

or even a network telnet connection, especially for a large number of data points. Also, without the dataflash:, the data

points are lost upon power-down. The dataflash: fixes these issues.

To use the dataflash:, you must create an ASCII text file that has the desired sequence of commands. The

lines of the file should be limited to 128 characters in length, and terminated with an ASCII CR (0x0D) , LF (0x0A) or

both. The file can contain empty (blank) lines for readability, and can also contain comments lines. Comment lines are

those lines that begin with either a single slash character (0x2F) , a double slash, or a single quote (0x27) character.

Examples are shown below:

/ THIS IS A COMMENT

set data 1 12.45 13.45 13.45

// also a comment

set data 2 1.2 2.2 3.2

' YET ANOTHER COMMENT

There are no formal limits on the number of lines contained in a script file, but the file size must be limited to a

maximum of 512K bytes to fit into the dataflash: storage area ( a typical 10,000 point data script file is roughly 324K

in size). An example 10-point data file might look like:

// setup general simulation params

// turn off calculations (sets table mode)

set data calc off

// number of points

set data points 10

// update rate of 1ms per point

set data timer 0.001

// init the offset attn (#4)

set offset attn 10.5

// fill table with 0dB

fill data 0

// data points

set data 0 0.25 0.5 0.75

set data 1 1.25 2.25 3.25

set data 2 2.5 4.5 6.5

set data 3 3.75 6.75 9.75

set data 4 5 9 13

set data 5 6.25 11.25 16.25

set data 6 7.5 13.5 19.5

set data 7 8.75 15.75 22.75

set data 8 10 18 26

set data 9 11.25 20.25 29.25

set data 10 12.5 22.5 32.5

// comment end of file

Aeroflex / Weinschel 26

Page 29

Model 8314-X IM-477

Once the file has been created, the next step is to transfer it to the MRS. This is done via the network using

the TFTP file transfer protocol. Place the file on a PC running a TFTP server that the MRS can communicate with. If

you do not have a TFTP server, there are several freeware/open source packages available on the internet, such as

tftpd32 (available at http://tftpd32.jounin.net/

from the CLI. Use the COPY command to perform the download to the MRS’s dataflash: device. For example, if the

tftp server is at address 10.100.103.100, and the file is named “example.txt” you could use the command:

). The MRS contains a TFTP client that can be used to initiate the transfer

mrs> copy tftp://10.100.103.100/example.txt df:

This should initiate the transfer, download, and store the file into the dataflash: device. Note: as shown above,

the target name for the file in the dataflash: is optional. Since the dataflash: can only hold a single file, the name is

used for information purposes only. The name, if provided, will be displayed via the

Once succesfully transferred, the script file can be executed from the command line via the EXECUTE

SCRIPT command, which will parse and execute the series of commands from the file, after which a short summary is

displayed. If you would like to see the script as it executes, you can use EXECUTE SCRIPT ECHO, which is useful for

finding errors in the script. You can display the contents of the dataflash: to the console using the command SHOW

FILE DF: Once executed, the data table will contain the desired attenuation profile, and the simulation can be

controlled via the normal RUN, STOP, etc commands.

Using the dataflash: to store the script is most useful for large data sets. After all, since the script file consists

puely of executable commands, you could just send the contents of the script file via telnet for direct execution by the

MRS, and this works fine for small data sets. It can be, in fact, faster to do this than to use COPY TFTP: and

EXECUTE SCRIPT. Once the data set becomes larger, it’s more efficient to transfer the file to the dataflash:. Some

typical times vs file sizes are shown below

Data

points

100 2.2 sec 4 sec / 0.4 sec = 4.4 sec

500 9.1 sec 4.9 sec / 1.7 sec = 6.6 sec

1000 17.8 sec 5.9 sec / 3.3 sec = 9.2 sec

5000 88.2 sec 14.5 sec / 16.3 sec = 30.8 sec

10000 176.3 sec 26.4 sec / 32.5 sec = 58.9 sec

Also, once the file has been stored in the dataflash:, it can be used again the next time the unit is powered up

simply by using the EXECUTE SCRIPT command, saving the time required to re-download the file.

You can also retreive the contents of the dataflash: storage. The following command would create a file

named “example.txt” on the TFTP server, and copy the contents of the dataflash: to it.

Telnet

transfer

Tftp transfer/execute

mrs> copy df: tftp://10.100.103.100/example.txt

Aeroflex / Weinschel 27

Page 30

Model 8314-X IM-477

6. MAINTENANCE:

The following paragraphs provide general inspection and maintena nce guide lines for the Model 8314 WLAN

Simulator Subsystem.

6-1. INSPECTION: Perform a visual inspection in conjunction with the maintenance activities schedule when a

malfunction is suspected, or whenever an assembly is removed or replaced.

6-2. PREVENTIVE MAINTENANCE: While the 8314 requires very little preventive maintenance, it should not be

subjected to physical abuse, severe mechanical shock, high humidity, or operating temperatures outside the

specification range. The instrument should be kept free of excessive dirt and dust, since these can interfere with

connector functions and with normal heat dissipation. For cleaning instructions refer to paragraph 6-3 (special

cleaning instructions). The following paragraphs provide the preventive maintenance that is to be performed on the

Unit.

Care should be taken to prevent strain on the interconnecting cables, since damage here may not always be

apparent. Occasionally check the external cables and connectors for signs of cracked insulation and/or bent or worn

pins. Tests show that connectors must be clean for accuracy and stability. This requires an inspection and cleaning of

each connector immediately before use. For connector cleaning instructions, refer to paragraph 6-3. When cleaning

precautions are observed regularly, connectors can maintain their stability for over several thousand connection

cycles. Refer to Appendix A for more information about cables and connectors.

6-3. SPECIAL CLEANING INSTRUCTIONS: The cleaning procedures for 8314 are divided into five general groups:

microwave coaxial cable assemblies, circuit card and modules; machined surfaces and hardware, chassis cleaning,

and connector cleaning.

6-3.1. MICROWAVE COAXIAL CABLE ASSEMBLIES: Appendix A (located at the end of this manual) provides all

the necessary procedures for care, cleaning, and handling of microwave coaxial cable assemblies.

6-3.2 CIRCUIT CARDS AND MODULES: A protective coating is applied to circuit cards for protection from moisture,

arcing, short-circuiting, and abrasion. To remove light dirt from circuit cards and modules proceed as follows:

CAUTION

• DO NOT use a nylon bristle brush in the solvent as the bristles may dissolve and cause

damage to the circuit card or component.

• DO NOT use ultrasonic cleaning on parts or assemblies containi ng electrical or electronic

components.

• DO NOT bend pins of electrical connectors when using fiber-bristle bru sh.

a. Briskly brush isopropyl alcohol onto area to be cleaned with fiber-bristle brush.

b. Carefully remove residue with a clean lint-free cloth and repeat step "a" as a rinse.

WARNING

Compressed air used for cleaning and/or drying can create airborne particle s that may

enter the eye. Goggles/ faceshields should be worn. DO NOT direct air stream to wards

self or other personnel. Pressure should be restricted to a maximum 15 psi to avoid

personal injury.

c. When parts are thoroughly clean, dry parts using 5 psi of clean moisture free compressed air or

preferably dry nitrogen (pressurized spray will work well).

Aeroflex / Weinschel 28

Page 31

Model 8314-X IM-477

6-3.3 MACHINED SURFACES AND HARDWARE: To remove light dirt and dust from mechanical parts such as

castings, covers and other hardware proceed as follows:

WARNING

Compressed air used for cleaning and/or drying can create airborne particle s that may

enter the eye. Goggles/ faceshields should be worn. DO NOT direct air stream to wards

self or other personnel. Pressure should be restricted to a maximum 15 psi to avoid

personal injury.

CAUTION

• Under no circumstances use a wire brush, steel wool, or abrasive compound. Using

these items will cause extensive damage to the instrument's surface.

• DO NOT use a nylon bristle brush in solvent as the bristles may dissolve and cause

damage to the circuit card or component.

a. Use 5 psi of clean, moisture-free compressed air or preferably dry nitrogen to blow loose dirt and dust

from surface of item.

b. Briskly brush isopropyl alcohol onto area to be cleaned with a fiber-bristle brush.

c. Remove residue with lint-free cloth and repeat step "b" as a rinse.

d. When parts are thoroughly clean, dry parts using 5 psi of clean, moisture-free compressed air or

preferably dry nitrogen.

e. Clean smaller mechanical parts or hardware by dipping into a container of isopropyl alcohol. Remove dirt

by brushing with fiber-bristle brush after parts have been immersed for several hours.

f. Remove parts from isopropyl alcohol and rinse by immersing into a different container of isopropyl

alcohol.

g. When parts are thoroughly cleaned, dry parts using 5 psi of clean, moisture-free compressed air or

preferably dry nitrogen.

6-3.4 CHASSIS CLEANING: Clean chassis using a lint-free cloth moistened with water and mild detergent. For

harder to clean areas, such as inside corners of chassis, use a vacuum cleaner.

6-3.5 CONNECTOR CLEANING: Where small amounts of rust, corrosion, and/or oxide deposits are present on

connectors, clean externally with a soft-bristle brush, aluminum wool, or internally with an acid brush; then wa sh with

a non-corrosive solvent. MIL-C-83112 is recommended. Exercise care to ensure no metal filing or resid ue remains

inside the connector and the connector is thoroughly dry. Where rust, corrosion, and/or oxide depo sits are present in

large quantities, replace the connector.

Aeroflex / Weinschel 29

Page 32

Model 8314-X IM-477

6-4. LINE VOLTAGE FUSE REPLACEMENT: The following steps provide procedures to replace the line voltage

Fuse Assembly. This unit accepts a F1.5A, 250 Vac fuse for 115 Vac.

WARNING

Sufficient power levels are present at the Power Input Assembly to cause personal injury.

Ensure that the instrument power cord is DISCONNECTED before attempting to change

fuses.

CAUTION

DO NOT connect or apply power to this instrument until the Power Entry Module

Assembly has been adjusted to the operational line voltage.

a. Disconnect the power cord from the Power Entry Module Assembly.

b. Use a small screwdriver to carefully open the Fuse Drawer.

c. Slide out Fuse Drawer located in the center of the Power Entry Module Assembly.

d. Remove defective fuse and replace with the correct fuse (Refer to applicable parts list for

fuse part number).

e. Snap the Fuse Drawer shut and re-connect ac power cord.

Aeroflex / Weinschel 30

Page 33

Model 8314-X IM-477

7. REPLACEABLE PARTS LIST:

This section lists and describes the parts located in the Model 8314 WLAN Simulator Subsystem (P/N 1938132-X). The Replaceable Parts Lists (RPL) are intended for use in identifying, locating, and requisitioning

assemblies and components for the Model 8314.

7-1 UNDERSTANDING REFERENCE DESIGNATORS: All assemblies and electrical parts are identified by standard

reference designators (resistors R1, for example). Reference designators are used in parts lists and on parts

identification drawings. The title of a parts list or drawing contains the reference designator or the assembly or

subassembly to which it applies. The designators in the parts list, as a prefix, but omitted from the list to make it

easier to locate a specific part. To complete a reference designator in a parts list, precede the designator for the

specific part (DS1, for example) with the designator in the title (A6, for example) to form a complete reference

designator for the part (in this case, A6DS1).

7-2 ORDERING INFORMATION: When ordering parts from Ae roflex / Weinschel, please include the following

information:

• Aeroflex / Weinschel part number.

• Description of the component or part.

• Model and serial number of the instrument.

• Assembly number and assembly revision (if any) from the assembly

(this information is on the component side of the PCB).

7-3 DRAWING NUMBER: The Aeroflex / We insch el par t numb er cons is ts of a ba s ic numb er wi th a d ash numb er. T he

basic number should cross reference to a drawing number for most of the items. For those items that do not have a

drawing number, the manufacturers part number is provided.

7-4 REPLACEABLE PARTS LIST (RPL): This RPL contains a breakdown of the instrument into its major assemblies

and detailed parts. The following paragraphs describe the contents of each column of the RPL.

7-4.1 REFERENCE DESIGNATOR: This column contains refere nce designations arranged in alphanumerical

sequence. The letters A thru Z have precedence, followed by numerals 0 thru 9. In addition to the reference

designators that are listed, some mechanical parts are also listed. These items lack reference designators and are

included because they are considered subject to wear and/or breakage, or because they are custom (non-standard)

hardware or parts that might become lost or damaged. This column contains the word N/A for those items or parts not

having a reference designator.

7-4.2 DESCRIPTION: This column contains the nomenclature located in the title block of the engineering drawin g by

the designing activity. The noun name is listed first, followed by modifiers and descriptive information to completely

identify the part or assembly.

7-4.3 PART NUMBER: This column contains the Weinschel part number assign ed to an assembly, sub-assembly, or

detailed part. This also includes Weinschel numbers for specification control, source control, and altered items

drawings.

7-4.4 VENDOR PART NO.: This column contains manufacturers part numbers for those parts Weinschel purchases,

as off the shelf items and assigns Weinschel part numbers for internal control only. These parts may be ordered

through the manufacturer or through Weinschel by the Weinschel part number.

7-4.5 CAGE CODE: This column provides the Commercial and Government Entity (CAGE) code on the same lin e as

the applicable part number. Codes, names, and addresses of venders with an assigned CA GE are listed in Cataloging

Handbook H4-1 and H4-2. Vendors that have not been assigned CAGE codes by the govern ment are identified by the

word NONE in this column. The names and addresses of these venders can be obtained from Weinschel. Part

numbers that have no CAGE numbers listed are manufactured or altered by Weinschel.

7-4.6 ASSEMBLY AND COMPONENT LOCATION: The assembly/component location and schematic dia grams for

the 8314 series models are located in rear of this manual by the drawing number. Drawing find numbers have also

been included to help locate components or hardware.

Aeroflex / Weinschel 31

Page 34

Model 8314-X IM-477

Model 8314-1, WLAN Simulator Subsystem Assembly Replaceable Parts List (P/N 193 -8132-1):

Find Part Number Description Quantity Reference CAGE Vendor

No. Used Designator Code Part Number

1 193-970 1-3 ENCLOSURE , MODIFI ED 1 NA

2 193-9700 CHASSIS 1 NA

3 193-9702 MOUNTING PLATE, AT TENUAT OR 4 NA

5 074-912 KIT, RACK MOUNTING W/O HANDLE S 3. 5 H 1 NA 24803 K2RMX-001A

7 193-971 0-000 ASSY, PCB, CO NTROLLER/ETHE RNET 1 A1

8 193-9711 ASS Y, POWER SUPP LY 1 A2

9 193-809 7- 000 ASSY, PCB, ATTEN DRIVER 1 A3

10 193-9305-000 ASSY, PCB,LED ST ATUS 1 A4

12 001-508 ATT EN P RGM PIN 60 dB, 2-6 GHz, 8 BIT 4 AT1 - AT4 56 A6P-48N-4MD

13 001-683-16 PWR DIV / COMBINER, 3-WAY 2-4 GHz SMA-F 1 A5 2242 4 803-2-3.00 0

14 3T- 3 ATTEN FXD 2 AT5, AT9

15 3T- 8 ATTEN FXD 3 AT6 - AT8

17 051-40 FUSE HOLDER, POWER INPUT, W/SWITCH 1 XF1 5245 PSOSXSS6B

18 052-1-1 /2 FUSE 1/ 2 A MP 1 F1 75915 312-500

20 052-1-1 FUSE 1 A MP 250V 1 F1 75915 312001

21 063-165-1 ADAPTER, TYPE N FE M ALE TO SMA MA LE 4 NA 64671 5207-067

BULKHEAD DC TO 6GH z

22 063-279 CONNECTOR, BNC, FEMAL E BULKHEAD 2 NA 1VY65 CP-1094-AST

WITH GND TAB

25 068-32-5/0 COAXIAL CABLE ASSY, SMA M/ M, 1 W7 93459 B068-32-5/0

CONFORMABLE, DC TO 18 GHz

26 068-32-4/0 COAXIAL CABLE ASSY, SMA M/M, 1 W8 B068-32-4/0

CONFORMABLE, DC TO 18 GHz

27 068-32-6/0 COAXIAL CABLE ASSY, SMA M/M, 1 NA B068-32-6/0

CONFORMABLE, DC TO 18 GHz

28 068-32-8/0 COAXIAL CABLE ASSY, SMA M/M, 1 NA B068-32-8/0

CONFORMABLE, DC TO 18 GHz

29 193-9159 ASSY , CABLE, GND 1 W6

32 193-9193 ASSY, CABLE, CONTRO LLER TO FRONT 1 W5

PANEL DISPLAY

33 193-9704-1 AS S Y, CABLE, RIBBON, 15 PIN FEMALE 1 W1

TO FEMALE

34 193-9704-2 AS S Y, CABLE, RIBBON, 15 PIN FEMALE 1 W2

TO FEMALE

35 193-9704-3 AS S Y, CABLE, RIBBON, 15 PIN FEMALE 1 W3

TO FEMALE

36 193-9704-4 AS S Y, CABLE, RIBBON, 15 PIN FEMALE 1 W4

TO FEMALE

37 068-51 CORD PWR 3-CONDUCTOR 1 NA 16428 17506

DTCH 6.7FT 10A-125V

NEMA5-15P/IEC320-C13

38 074-170-5 CABLE TIE, #4-40 TI E D OWN 1 NA 5650 1 TY-33M

39 074- 3- 30 GRO MMET, NYLON , FOR SHT THK .08 5 - .128 1 NA 6915 MGS-3-01

CATAPILLAR TYPE

40 062-184-5 CONN SCR EW LOCK FEM A LE 2 NA 7146 8 D20418-2

51 079-147-10 WIRE #22 BLACK TEFLO N 1 NA 0 A079-147-10

53 079-147 -9 WIRE #2 2 WHITE T EFLON 1 NA 0 A079-147- 9

54 MS35649-244 NU T H EX #4 9 NA

56 MS51957-19 SCR PAN HD 4-40 X 3/4 LG 2 NA

57 MS51957-31 SCR PAN HD 6-32 X 5/8 LG 4 NA

58 MS24693-C4 SCR FLAT HD 4- 40 X 3/8 LG 100 6 NA

59 MS24693-C10 SCR FLAT HD 4-40 X 1 LG 100 8 NA

Aeroflex / Weinschel 32

Page 35

Model 8314-X IM-477