Page 1

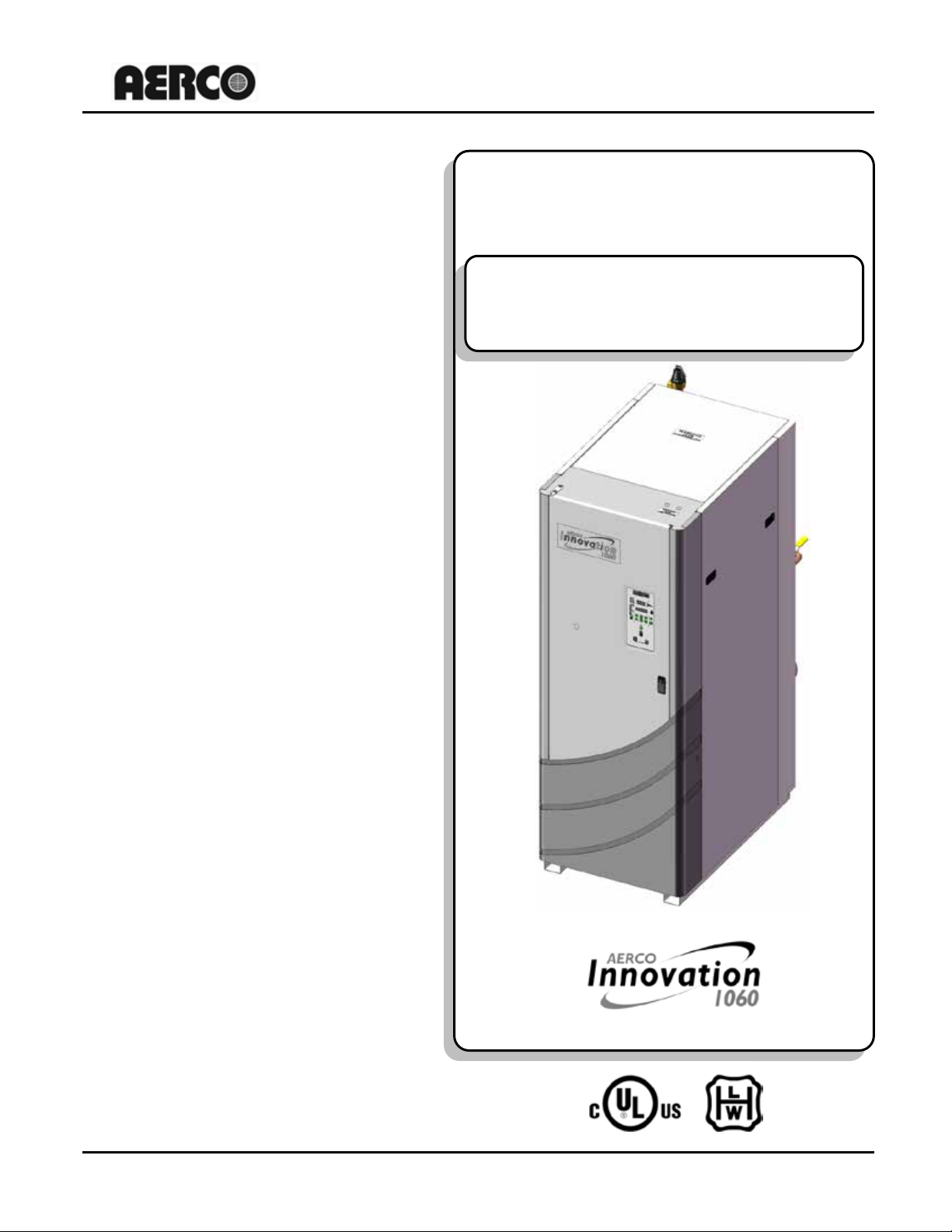

GF-128

OMM-0079_0B

INNOVATION Series

Gas-Fired Water Heaters

Installation, Operation, and Maintenance

Natural Gas Modulating,

Condensing Water Heater

Models:

• INN600

• INN800

• INN1060

Applicable to Serial Numbers

G-10-1350 to G-11-0563

Other documents for this product

include:

• GF-5030 INN Gas Supply Guide

• GF-5050 INN Venting Guide

• GF-5060 INN Elect. Power Guide

• GF-5080 INN Sizing Guide

Copies of these documents are

included in Appendices J thru M

of this Manual

Released: 07/21/2011

USER MANUAL

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 2

GF-128 Innovation Series Water He aters

Technical Support:

OMM-0079_0B USER MANUAL

(Mon–Fri, 8am-5pm EST)

1-800-526-0288

www.aerco.com

The information containe d in this manual is subject to c hange without notice from AERCO Inter national,

Inc. AERCO makes no warranty of any kind with respect to this material, including but not limited to

implied warranties of merchantability and fitness f or a particular application. AE RCO International is not

liable for errors appearing in this manual. Nor for incidental or consequential damages occurring in

connection with the furnishing, performance, or use of this material.

Page 2 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Disclaimer

Page 3

Innovation Series Water Heaters GF-128

Table of Contents USER MANUAL OMM-0079_0B

TABLE OF CONTENTS

FOREWORD ................................................................................................................... 7

CHAPTER 1. SAFETY PRECAUTIONS .................................................................. 9

1.1 WARNINGS & CAUTIONS ................................................................................................. 9

1.2 EMERGENCY SHUTDOWN ............................................................................................. 10

1.3 PROLONGED SHUTDOWN ............................................................................................. 10

CHAPTER 2. INSTALLATION ............................................................................... 13

2.1 INTRODUCTION ............................................................................................................... 13

2.2 RECEIVING THE UNIT ..................................................................................................... 13

2.3 UNPACKING .................................................................................................................... 13

2.4 SITE PREPARATION ....................................................................................................... 13

2.4.1 Installation Clearances ..............................................................................................14

2.4.2 Setting the Unit ..........................................................................................................15

2.5 WATER INLET AND OUTLET PIPING ............................................................................. 15

2.6 TEST HOSE BIB CONNECTION ...................................................................................... 16

2.7 PRESSURE & TEMPERATURE RELIEF VALVE INSTALLATION .................................. 17

2.8 SYSTEM RECIRCULATION LOOP .................................................................................. 17

2.9 CONDENSATE DRAIN & PIPING .................................................................................... 17

2.10 GAS SUPPLY PIPING .................................................................................................... 19

2.10.1 Gas Supply Specifications. ........................................................................................20

2.10.2 Manual Gas Shutoff Valve .........................................................................................20

2.10.3 External Gas Supply Regulator ..................................................................................20

2.11 AC ELECTRICAL POWER WIRING ............................................................................... 21

2.11.1 Electrical Power Requirements ..................................................................................21

2.12 FIELD CONTROL WIRING ............................................................................................. 22

2.12.1 Outdoor Air Sensor ....................................................................................................23

2.12.2 AUX SENSOR IN ......................................................................................................23

2.12.3 ANALOG IN ...............................................................................................................23

2.12.4 B.M.S. (PWM) IN .......................................................................................................24

2.12.5 SHIELD .....................................................................................................................24

2.12.6 mA OUT ....................................................................................................................24

2.12.7 EXHAUST SENSOR IN .............................................................................................24

2.12.8 INTERLOCKS............................................................................................................24

2.12.9 FAULT RELAY ..........................................................................................................25

2.12.10 AUXILIARY RELAY CONTACTS.............................................................................25

2.13 FLUE GAS VENT INSTALLATION ................................................................................. 25

2.14 COMBUSTION AIR ......................................................................................................... 25

2.14.1 Combustion From Outside the Building .....................................................................26

2.14.2 Combustion Air from Inside the Building ....................................................................26

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 3 of 200

Page 4

GF-128 Innovation Series Water He aters

OMM-0079_0B USER MANUAL Table of Contents

2.15 SEALED COMBUSTION ................................................................................................. 26

CHAPTER 3. OPERATION .................................................................................... 27

3.1 INTRODUCTION ............................................................................................................... 27

3.2 CONTROL PANEL DESCRIPTION .................................................................................. 27

3.3 CONTROL PANEL MENUS .............................................................................................. 31

3.3.1 Menu Processing Procedure ......................................................................................31

3.4 OPERATING MENU ......................................................................................................... 32

3.5 SETUP MENU ................................................................................................................... 33

3.6 CONFIGURATION MENU ................................................................................................. 34

3.7 TUNING MENU ................................................................................................................. 35

3.8 START SEQUENCE ......................................................................................................... 36

3.9 START/STOP LEVELS ..................................................................................................... 38

CHAPTER 4. INITIAL START-UP ......................................................................... 41

4.1 INITIAL STAR T-UP REQUIREM ENTS ............................................................................. 41

4.2 TOOLS AND INSTRUMENTATION FOR COMBUSTION CALIBRATION ....................... 41

4.2.1 Required Tools & Instrumentation..............................................................................41

4.2.2 Installing Gas Supply Manometer ..............................................................................42

4.2.3 Accessing the Analyzer Probe Port ............................................................................42

4.3 NATURAL GAS COMBUST ION CALIBRATION .............................................................. 43

4.4 REASSEMBLY ................................................................................................................. 45

4.5 TEMPERATURE CONTROL CALIBRATION ................................................................... 45

4.5.1 Setting the Outlet Water Temperature Setpoint .........................................................45

4.5.2 Minimum Load Adjustment ........................................................................................46

4.5.3 Maximum Load Adjustment .......................................................................................46

4.6 OVER-TEMPERATURE LIMIT SWITCHES ...................................................................... 47

CHAPTER 5. SAFETY DEVICE TESTING ............................................................ 49

5.1 TESTING OF SAFETY DEVICES ..................................................................................... 49

5.2 LOW GAS PRESSURE FAULT TEST .............................................................................. 49

5.3 HIGH GAS PRESSURE TEST .......................................................................................... 50

5.4 LOW WATER LEVEL FAULT TEST ................................................................................. 50

5.5 WATER TEMPERATURE FAULT TEST .......................................................................... 51

5.6 INTERLOCK TESTS ......................................................................................................... 52

5.6.1 Remote Interlock .......................................................................................................52

5.6.2 Delayed Interlock .......................................................................................................53

5.7 FLAME FAULT TESTS ..................................................................................................... 53

5.8 AIR FLO W FAULT TESTS ............................................................................................... 54

Page 4 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 5

Innovation Series Water Heaters GF-128

Table of Contents USER MANUAL OMM-0079_0B

5.9 SSOV PROOF OF CLOSURE SWITCH ........................................................................... 56

5.10 PURGE SWITCH OPEN DURING PURGE ..................................................................... 56

5.11 IGNITION SWITCH OPEN DURING IGNITION ............................................................... 57

5.12 SAFETY PRESSURE RELIEF VALVE TEST .................................................................. 58

CHAPTER 6. MAINTENANCE .............................................................................. 59

6.1 MAINTENANCE SCHEDULE ........................................................................................... 59

6.2 IGNITER-INJECTOR ........................................................................................................ 60

6.3 FLAME DETECTOR ......................................................................................................... 61

6.4 COMBUSTION CALIBRATION ........................................................................................ 62

6.5 SAFETY DEVICE TESTING ............................................................................................. 62

6.6 FIRESIDE INSPECTION ................................................................................................... 62

6.7 WATERSIDE INSPECTION .............................................................................................. 65

6.8 HEAT EXCHANGER CLEANING ..................................................................................... 67

6.8.1 Pumping System Set-Up Instructions ........................................................................67

6.8.2 Cleaning Procedure ...................................................................................................68

6.8.3 Testing HydroSkrub Effectiveness .............................................................................69

6.9 CONDENSATE DRAIN TRAP .......................................................................................... 69

6.10 AIR FILTER REPLACEMENT .......................................................................................... 70

6.11 SHUTTING THE WATER HEATER DOW N FO R AN EXTENDED PERI OD OF TIME ...... 71

6.12 PLACING THE HEATER BACK IN SERVICE AFTER A PROLONGED SHUTDOWN .... 71

CHAPTER 7. TROUBLESHOOTING GUIDE ........................................................ 73

7.1 INTRODUCTION ............................................................................................................... 73

7.2 ADDITIONAL FAULTS WITHOUT SPECIF IC FAULT MESSAGES ................................. 84

CHAPTER 8. RS232 COMMUNIC ATION .............................................................. 87

8.1 INTRODUCTION ............................................................................................................... 87

8.2 RS232 COMMUNICATION SETUP .................................................................................. 87

8.3 MENU PROCESSING UTILIZING RS232 COMMUNI CATION ......................................... 87

8.4 DATA LOGGING .............................................................................................................. 88

8.4.1 Fault Log ...................................................................................................................88

8.4.2 Operation Time Log ...................................................................................................89

8.4.3 Sensor Log ................................................................................................................89

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 5 of 200

Page 6

GF-128 Innovation Series Water He aters

OMM-0079_0B USER MANUAL Table of Contents

APPENDIX A: WATER HEATER MENU ITEM DESCRIPTIONS ............................... 91

APPENDIX B: STARTUP, STATUS AND FAULT MESSAGES ................................. 95

APPENDIX C 99TEMPERATURE SENSOR RESISTANCE/VOLTAGE CHART ........ 99

APPENDIX D: WATER HEATER DEFAULT SETTINGS .......................................... 101

APPENDIX E: PARTS LIST DRAWINGS .................................................................. 103

APPENDIX F: PIPING DRAWINGS ........................................................................... 113

APPENDIX G: C-MORE CONTROL PANEL VIEWS ................................................ 127

APPENDIX H: C-MORE WIRING DIAGRAMS .......................................................... 129

APPENDIX I: RECOMMENDED SPARES ................................................................ 137

APPENDIX J: GF-5030: GAS COMPONENTS & SUPPLY DESIGN GUIDE .......... 139

APPENDIX K: GF-5050: VENTING & COMBUSTION AIR GUIDE ......................... 151

APPENDIX L: GF-5060: ELECTRICAL POWER GUIDE ......................................... 175

APPENDIX M: GF-5080: COMMERCIAL LAUNDRY SIZING GUIDE ..................... 183

APPENDIX N: LIMITED WARRANTY ....................................................................... 195

Page 6 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 7

Innovation Series Water Heaters GF-128

Foreword USER MANUAL OMM-0079_0B

FOREWORD

The AERCO Innovation Series Water Heaters are modulating units which represent a true

industry advance that meets the needs of today's energy efficiency and environmental

concerns. Designed for use in any domestic water heating system, each Innovation model

provides precisely-controlled potable water within ±2°F of setpoint, regardless of flow rate.

Innovation’s compact size and varied venting capabilities allow maximum installation flexibility.

The Innovation Series Heaters, with their load tracking controls modulate over a 20:1 turn down

ratio to match the system demand and yield high thermal efficiencies.

When installed and operated on natural gas in accordance with this Instruction Manual, the

Innovation Series Models covered herein comply with the NOx emission standards outlined in:

• South Coast Air Quality Management District (SCAQMD), Rule 1146.2

• Texas Commission on Environmental Quality (TCEQ), Title 30, Chapter 117,

Rule 117.465

Whether used in singular or modular arrangements, the Innovation Heaters offer the maximum

flexibility in venting with minimum installation space requirements. Innovation’s advanced

electronic controls offer simplified integration with today’s Energy Management Systems.

For service or parts, contact your local sales representative or AERCO INTERNATIONAL.

NAME:

ORGANIZATION:

ADDRESS:

TELEPHONE:

INST ALLATION DATE: ___________________________________________________

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 7 of 200

Page 8

GF-128 Innovation Series Water He aters

OMM-0079_0B USER MANUAL Foreword

This P age Is Intentionally Blank

Page 8 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 9

Chapter 1 Innovation Series Water He ate rs GF-128

Safety Precautions USER MANUAL OMM-0079_0B

CHAPTER 1. SAFETY PRECAUTIONS

1.1 WARNINGS & CAUTIONS

Installers and operating personnel MUST, at all times, observe all safety regulations. The following

warnings and cautions are gener al and m ust be given the same attention as spec ific precautio ns included

in these instructions. In addition to all the requirements inc luded in this AERCO Instruction Manu al, the

installation of units MUST conform with local building codes, or, in the absence of local codes, ANSI

Z223.1 (National Fuel G as C ode Pub lica tio n No. NFPA-54) for gas-fired heaters and ANSI/ NFP AS B f or LP

gas-fired heaters. Where applicable, the equipment shall be installed in accordance with the current

Installation Code for Gas Burning Appliances and Equipment, CSA B149.1, and applicable Provincial

regulations for the class; which should be carefully followed in all cases. Authorities having jurisdiction

should be consulted before installations are made.

See pages 11 and 1 2 for important inf ormation re garding installation of units wit hin the Com monwealth of

Massachusetts.

IMPORTANT

This Instruction Manual is an integral part of the product and must be maintained

in legible condition. It must be given to the user by the installer and kept in a safe

place for future reference.

IMPORTANT

Read the following restrictions prior to installing the water heater:

1. The water heater can only be used for applications where the chlorine

concentrations Do Not Exceed 4 mg/L which is the Environmental Protection

Agency limit for chlorine concentrations in drinking water.

2. Do Not use this heater for a pool heating application.

WARNING

DO NOT USE MATCHES, CANDLES, FLAMES, OR OTHER SOURCES OF

IGNITION TO CHECK FOR GAS LEAKS.

WARNING

FLUIDS UNDER PRESSURE MAY CAUSE INJURY TO PERSONNEL OR

DAMAGE TO EQUIPMENT WHEN RELEASED. BE SURE TO SHUT OFF ALL

INCOMING AND OUTGOING WATER SHUTOFF VALVES. CAREFULLY

DECREASE ALL TRAPPED PRESSURES TO ZERO BEFORE PERFORMING

MAINTENANCE.

WARNING

ELECTRICAL VOLTAGES UP TO 120 VAC MAY BE USED IN THIS

EQUIPMENT. THEREFORE THE COVER ON THE UNIT’S POWER BOX

(LOCATED BEHIND THE FRONT PANEL DOOR) MUST BE INST ALL ED AT ALL

TIMES, EXCEPT DURING MAINT E NANCE AND SE RVICING.

WARNING

A DOUBLE-POLE SWITCH MUST BE INSTALLED ON THE ELECTRICAL

SUPPLY LINE OF THE UNIT. THE SWITCH MUST BE INSTALLED IN AN

EASILY ACCESSIBLE POSITION TO QUICKLY AND SAFELY DISCONNECT

ELECTRICAL SERVICE. DO NOT AFFIX SWITCH TO UNIT SHEET METAL

ENCLOSURES.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 9 of 200

Page 10

GF-128 Innovation Series Water He aters Chapter 1

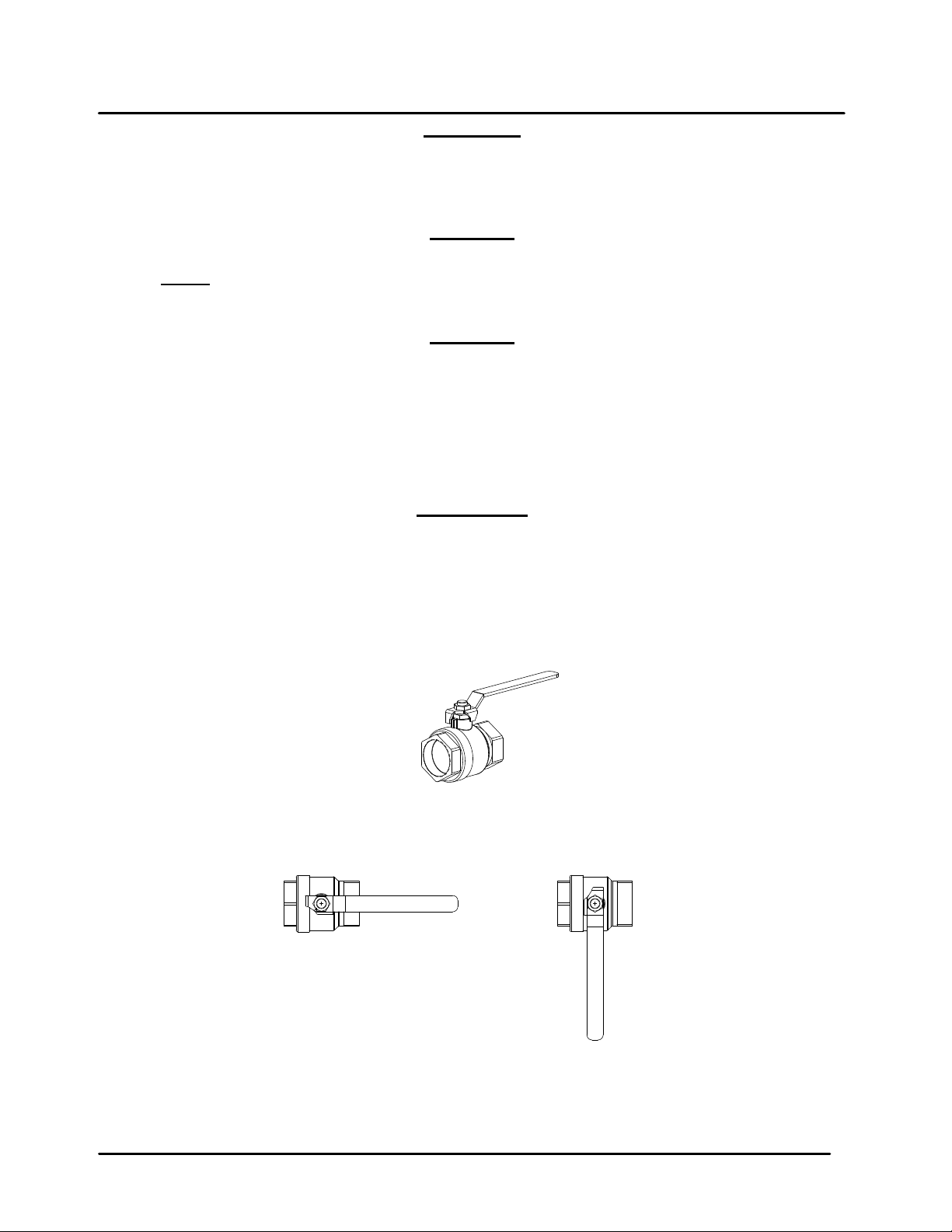

MANUAL GAS SHUTOFF VALVE

VALVE OPEN

VALVE CLOSED

OMM-0079_0B USER MANUAL Safety Precautions

CAUTIONS

Must be observed to prevent equipment damage or loss of operating

effectiveness.

CAUTION

Many soaps used for gas pipe leak testing are corrosive to metals. The piping

must

completed.

DO NOT use this heater if any part has been under water. Call a qualified service

technician to inspect and replace any part that has been under water.

1.2 EM ERGENCY SHUTDOWN

If overheati ng occurs or the gas suppl y fails to shut of f, close the manual gas shutof f valve (Figure 1-1)

located external to the unit.

The Installer mus t identify and indicate the locat ion of the emergency shutdo wn manual

gas valve to operating personnel.

be rinsed thoroughly with clean water after leak checks have been

CAUTION

IMPORTANT

1.3 PRO L ONGED SHUTDOWN

After prolonged shutdown, it is recommended that the startup procedures in Chapter 4 and the safety

device test procedures in Chapter 6 of this manual be performed, to verify all system-operating

parameters. If ther e is an em ergency, turn of f the ele ctrical power suppl y to the AERC O heater and close

the manual gas valve located upstream the unit. The installer must identify the emergency shut-off device.

Page 10 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Figure 1-1. Manual Gas Shutoff Valve

Page 11

Chapter 1 Innovation Series Water He ate rs GF-128

Safety Precautions USER MANUAL OMM-0079_0B

IMPORTANT – FOR MASSACHUSETTS I NSTALLATIONS

Water heater Installations within the Commonwealth of Massachusetts must

conform to the following requirements:

• Heater must be installed by a plumber or a gas fitter who is licensed within the

Commonwealth of Massachusetts.

• Prior to unit operation, the complete gas train and all connections must be leak

tested using a non-corrosive soap.

• The vent termination must be located a minimum of 4 feet above grade level.

If side-wall venting is used, the installation must conform to the following

requirements extracted from 248 CMR 5.08 (2):

(a) For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or

structure used in whole or in part for residential purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet above finished

grade in the are a of the ventin g, inclu ding b ut not l im ited to deck s and porches , the f ollo wing requir em ents

shall be satisfied:

1. INSTALLAT ION OF CARBON MONOXID E DETECTORS

horizontal vented gas f ueled equipment, the installing plum ber or gasfitter sha ll observe that a har d wired

carbon monoxide detector with an alarm and battery back-up is installe d on the floor level where the gas

equipment is to be installed. In addition, the installing plumber or gasfitter shall observe that a battery

operated or hard wired car bon monox ide detec tor w ith an alar m is ins talled on each ad ditiona l level of the

dwelling, building or s tructure served by the sid e wall horizontal vented g as fueled equipment. It s hall be

the responsibility of the pr operty owner to secure the services of qual ified licensed professionals for the

installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas f ueled equipment is installed in a crawl

space or an attic, the har d wired carbon monoxide d etector with alarm and batter y back-up may be

installed on the next adjacent floor level.

b. In the event that the re quirements of this subdivision can not b e met at the tim e of completion of

installation, the owner shall have a period of thirt y (30) da ys to compl y with the abov e requirem ents;

provided, however, that during said thirty (30) day period, a battery operated carbon monoxide

detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS.

accordance with the a bove provisions sha ll comply with NFPA 72 0 and be ANSI/UL 2034 listed and IAS

certified.

3. SIGNAGE

building at a minim um height of eight (8) f eet abo ve grade d irectl y in line with the exhaus t vent t erm inal for

the horizontally vented gas fueled heating appliance or equipment. The sign shall read, in print size no less

than one-half (1/2) inch in size, "GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS".

. A metal or plastic identif ication plate shall be permanently mount ed to the exterior of the

. At the time of installation of the side wall

Each carbon monoxide detector as required in

4. INSPECTION

equipment shall not approve the installation unless, upon inspection, the inspector observes carbon

monoxide detectors and signage installed in accordance with the provisions of 248 CMR 5.08(2)(a)1

through 4.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 11 of 200

. The state or local gas inspector of the side wall horizontally vented gas fueled

Page 12

GF-128 Innovation Series Water He aters Chapter 1

OMM-0079_0B USER MANUAL Safety Precautions

(b) EXEMPTIONS

1. The equipment listed in Chapter 10 ent itled "Equipm ent Not Required To Be Vented" in the m ost

current edition of NFPA 54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or

structure separate from the dwelling, building or structure used in whole or in part for residential

purposes.

(c) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VEN TING SYSTE M PROVIDED.

manufacturer of Produc t Approved side wall horizonta lly vented gas eq uipment provi des a venting system

design or venting s ystem components with the equipm ent, the instructions provided b y the manufacturer

for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system

components; and

2. A complete parts list for the venting system design or venting system.

(d) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufact urer of a Product Approved si de wall horizontally vented ga s fueled equipment does

not provide the parts for venting the flue gases, but identifies "special venting systems", the following

requirements shall be satisfied by the manufacturer:

1. The referenced "special venting system" instructions shall be included with the appliance or

equipment installation instructions; and

: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

When the

2. The "special vent in g s ys tems" shall be Product Ap p roved by the Board, and the ins truc t ions f or th at

system shall include a parts list and detailed installation instructions.

(e) A copy of all ins tallation instr uctions for all Pr oduct Approved s ide wall horiz ontally vented g as fueled

equipment, all venting instructions, all parts lists for venting instructions, and/or all venting design

instructions shall remain with the appliance or equipment at the completion of the installation.

______________________________________

[End of Extracted Information From 248 CMR 5.08 (2)]

Page 12 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 13

Chapter 2 Innovation Series Water Heater s GF-128

Installation USER MANUAL OMM-0079_0B

CHAPTER 2. INSTALLATION

2.1 INTRODUCTION

This Chapter provides the descriptions and proc edures necess ary to unpack, inspec t and install AERCO

Innovation Water Heater Models INN 600, INN 800 and INN 1060.

2.2 RECEIVING THE UNIT

Each Innovation Water Heating System is shipped as a single crated unit. The shipping weight is

approximately 1200 pounds. The unit m ust be moved with the proper rigg ing equipment f or safety and to

avoid equipment dam age. T he unit should b e com pletely inspected f or evidenc e of s hipping dam age and

shipment completeness at the time of receipt from the carrier and before

NOTE

AERCO is not responsible for lost or damaged freight. Each unit has a Tip-N-Tell

indicator on the outside of the crate. This indicates if the unit has been turned on

its side during shipment. If the Tip-N-Tell indicator is tripped, do not sign for the

shipment. Note the information on the carrier’s paperwork and request a freight

claim and inspection by a claims adjuster before proceeding. Any other visual

damage to the packaging mater ials should also be made clear to the delivering

carrier.

the bill of lading is signed.

2.3 UNPACKING

Carefully unpack the unit taking care not to damage the unit enclosure when cutting away packaging

materials

After unpacking, a close inspection of the unit sh ould be made to ensure that there is no evidence of

damage not indicated b y the Tip-N-T ell indicator. The f reight carrier shou ld be notified imm ediately if an y

damage is detected.

The following access ories come standard with each un it and ar e e ith er packed separately within the unit’s

shipping container or are factory installed on the unit:

• Pressure/Temperature Gauge

• Spare Spark Igniter-Injector

• Spare Flame Detector

• ASME Pressure Relief Valve

• Condensate Drain Trap

• 1-1/2” Gas Supply Shutoff Valve

When optional access ories are order ed, they may be pack ed within the unit ’s shipping container , factory

installed on the unit, or pac ked and shipped in a separate c onta in er . Any standard or optional acces s ories

shipped loose should be identified and stored in a safe place until ready for installation or use.

2.4 SITE PREPARATION

Ensure that the site selected for installation of the Innovation Water Heater includes:

• Access to AC Input Power at 120 VAC, Single-Phase, 60 Hz @ 20 Amps.

• Access to Natural Gas line at a minimum pressure of 4 inches W.C.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 13 of 200

Page 14

GF-128 Innovation Series Water He aters Chapter 2

OMM-0079_0B USER MANUAL Installation

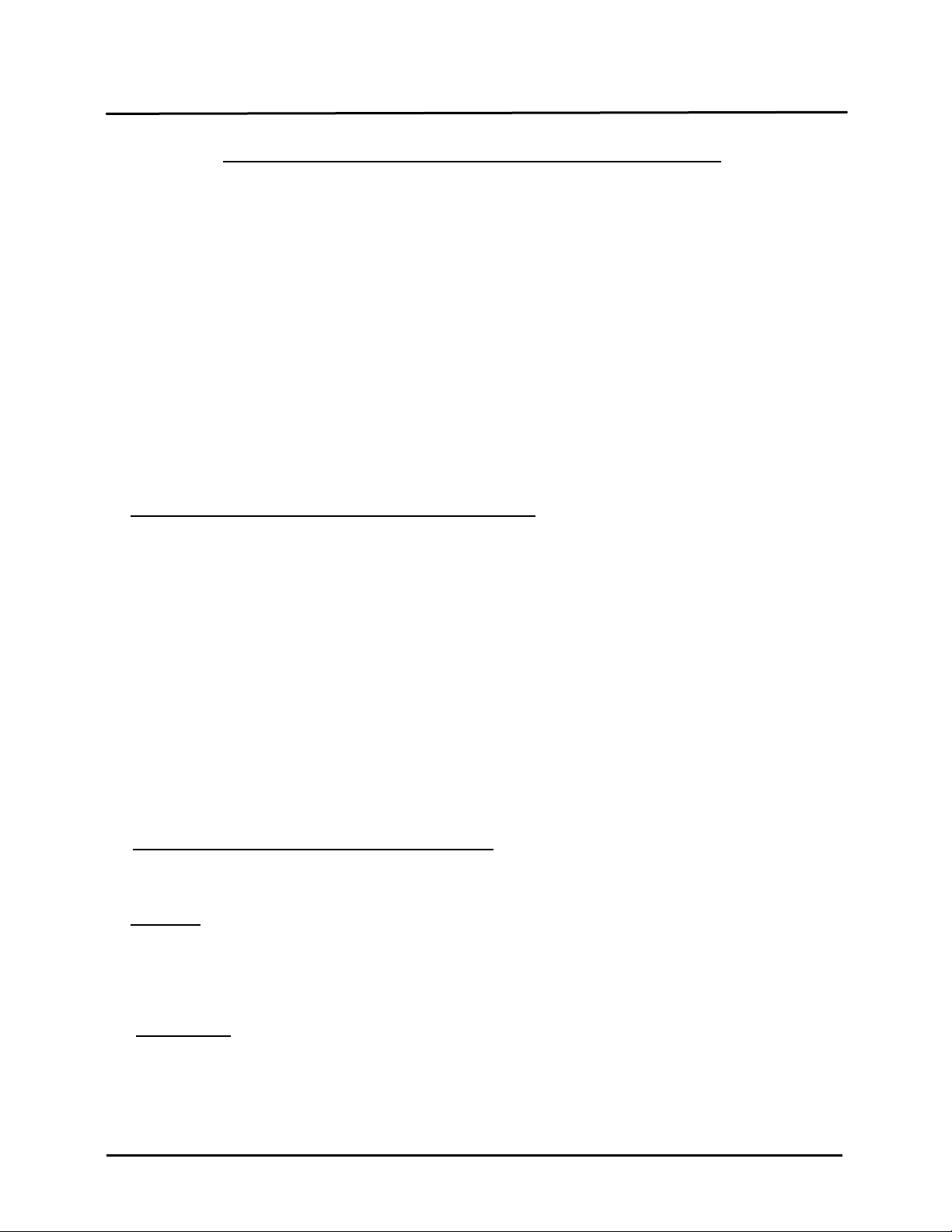

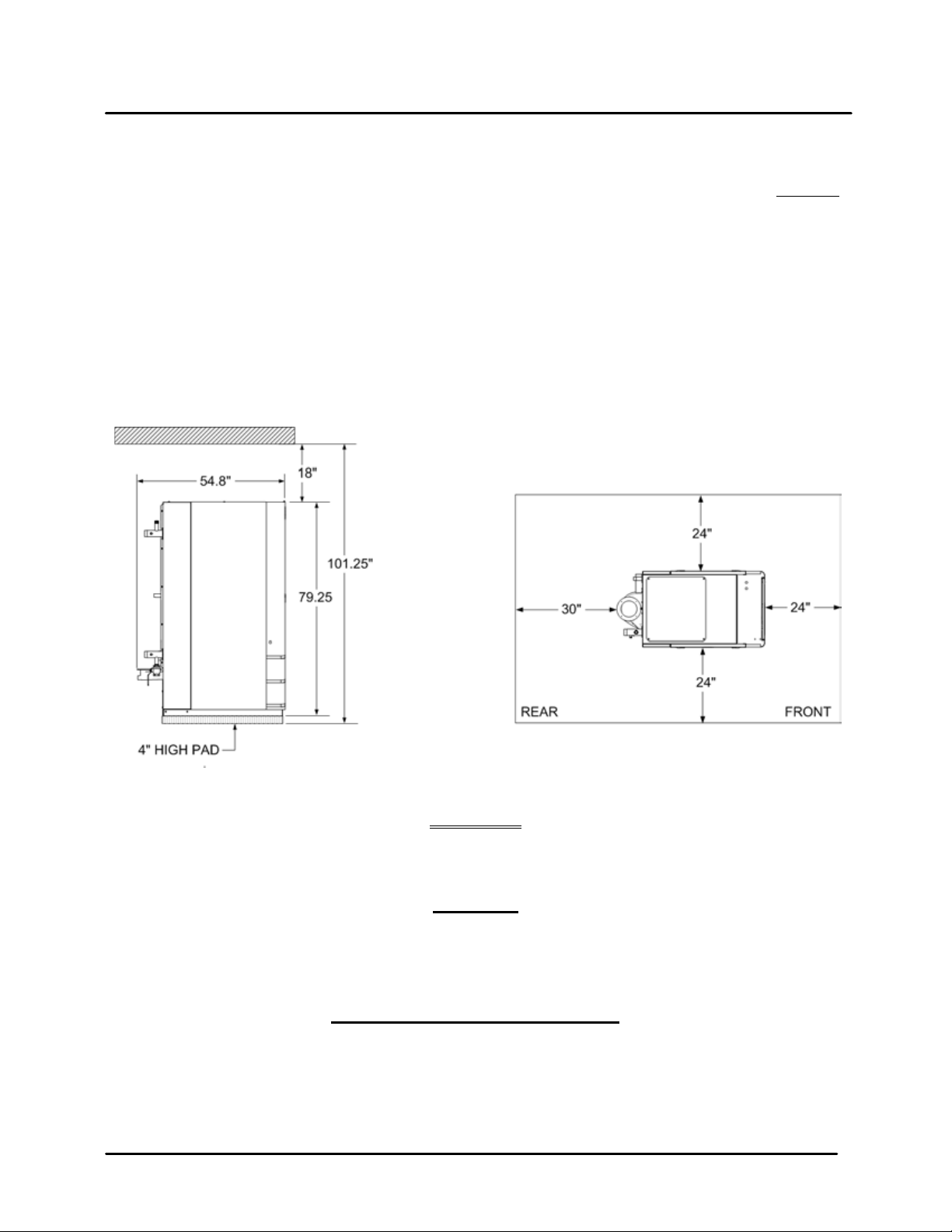

2.4.1 Installation Clearances

Innovation Models 790 and 1060 are packaged in enclosur es having identical exterior dim ensions. The

unit must be installed with the prescribed clearances for service as shown in Figure 2-1. The minimum

clearance dimens ions, required by AERCO, are liste d below. However, if Local Building Codes require

additional clearances, these codes shall supersede AERCO’s requirements. Minimum acceptable

clearances required are as follows:

• Sides: 24 inches

• Front : 24 inches

• Rear: 30 inches

• Top: 18 inches

All gas piping, water pi ping and electric al conduit or c able must be ar ranged so that th ey do not interf ere

with the removal of any panels, or inhibit service or maintenance of the unit.

Figure 2-1 Innovation Water Heater Clearances

WARNING

KEEP THE UNIT AREA CLEAR AND FREE FROM ALL COMBUSTIBLE

MATERIALS AND FLAMMABLE VAPORS OR LIQUIDS

.

CAUTION

While packaged in the shipping container, the unit must be moved by pallet jack

or forklift from the FRONT ONLY.

FOR MASSACHUSSETTS ONLY:

For Massachusetts installations, the unit must be installed by a plumber or gasfitter who is licensed within the Commonwealth of Massachusetts. In addition, the

installation must comply with all requirements specified in Chapter 1 (Safety

Precautions), pages 11 and 12.

Page 14 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 15

Chapter 2 Innovation Series Water Heater s GF-128

Installation USER MANUAL OMM-0079_0B

2.4.2 Setting the Unit

The unit must be instal le d on a 4 inch to 6 inch h ous e k eeping p ad t o ensure proper condensate drainage.

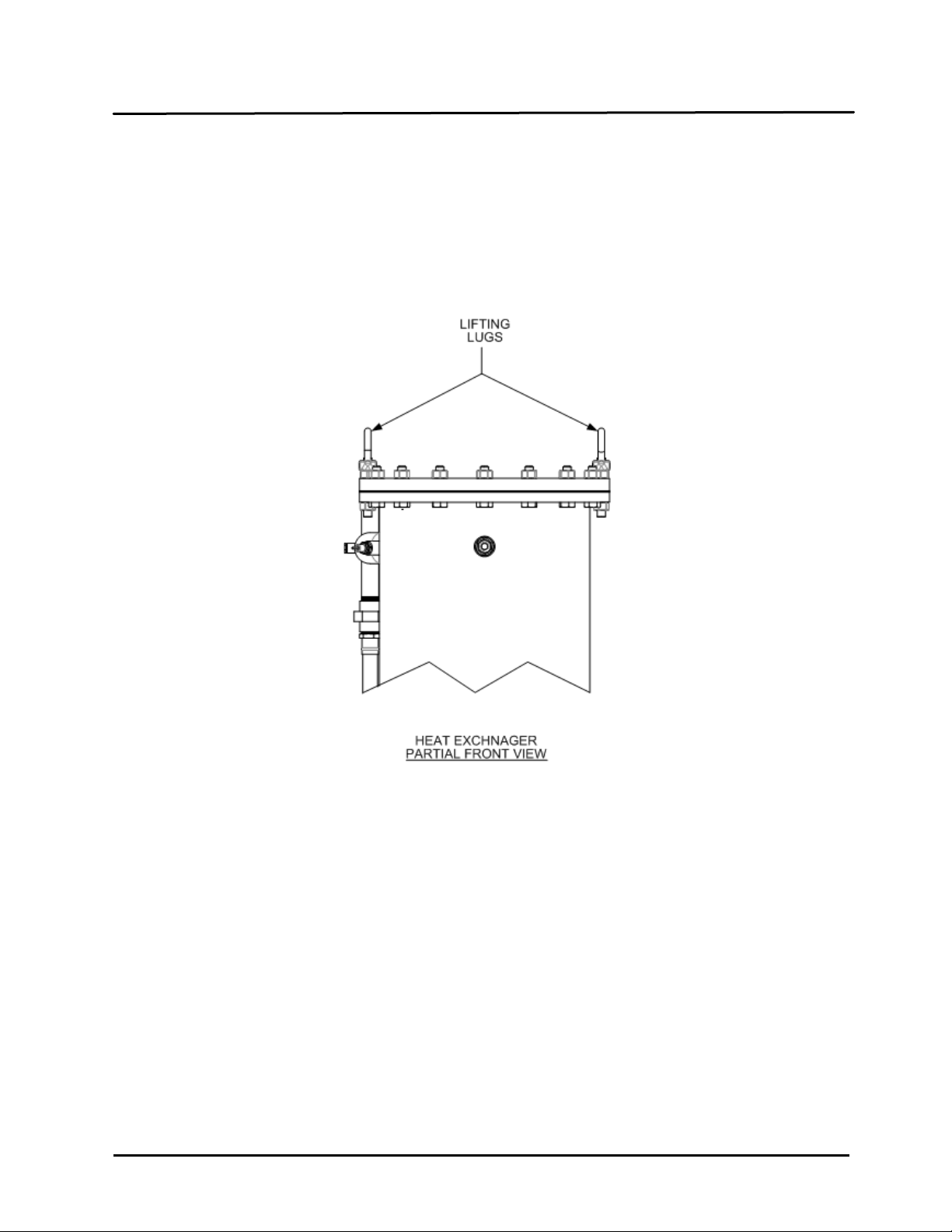

If anchoring the unit, r ef er to the dimensional drawings in Appendix F f or anc hor l ocatio ns. Two lifting lugs

are provided at the top of the heat exchan ger as sho wn in Figure 2-2. USE THESE TWO LUGS T O LIFT

AND MOVE THE UNIT. Rem ove the top pane l from the unit to provide acc ess to the lif ting lugs. Rem ove

the four (4) lag screws s ecuring the unit to the s h ipp ing s kid. Lift the unit off the s hip ping s kid and position

it on the 4 inch to 6 inch housekeeping concrete pad (required) in the desired location.

Figure 2-2

Partial Top View Showing Lifting Tab Location

In multiple unit installations , it is im por tant to plan the position of each unit in advance. Sufficient space for

piping connections and fut ure service/maintenance requirem ents must also be taken into consideration.

All piping must include ample provisions for expansion.

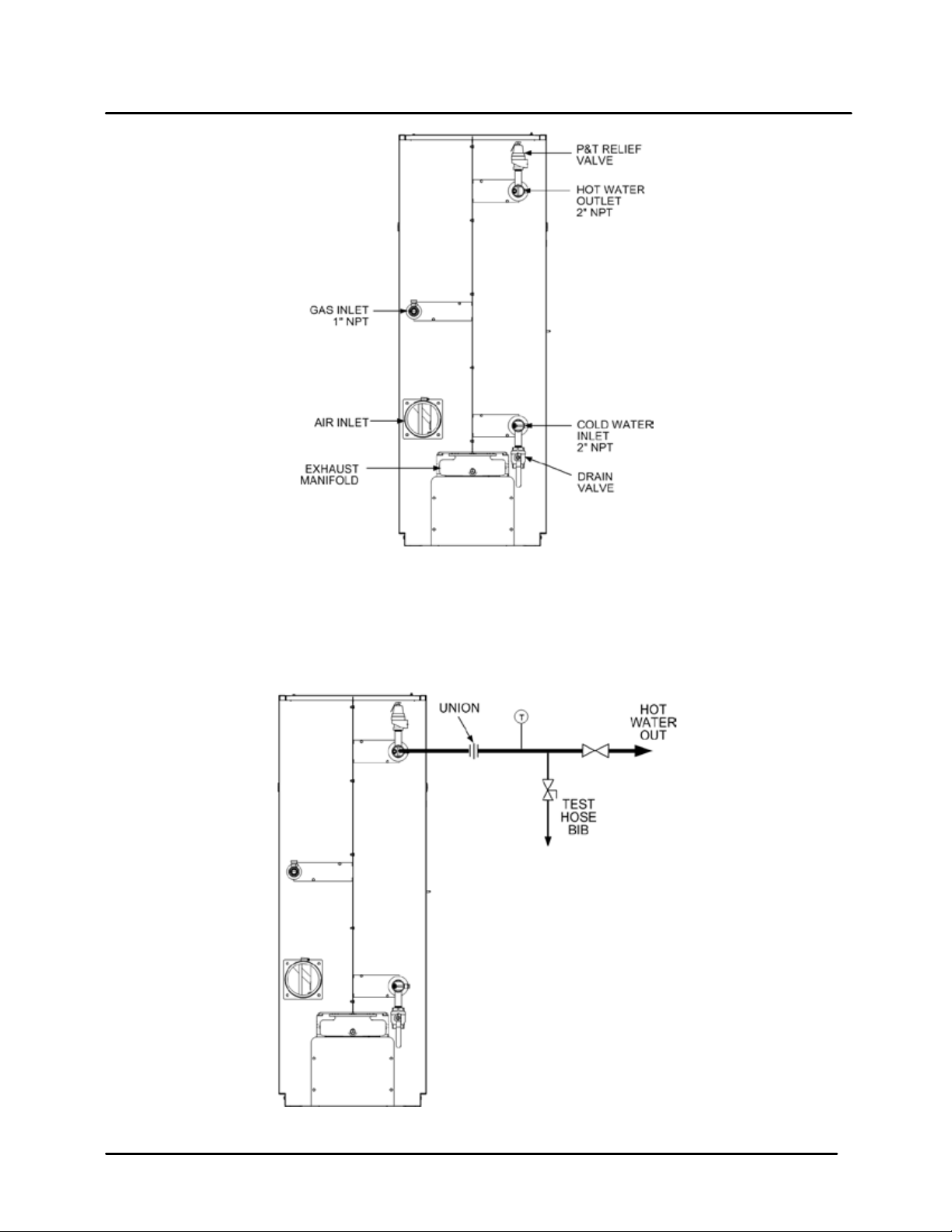

2.5 WATER INLET AND OUTLET PIPING

The locations of the 2" NPT cold water inlet and hot water outlet p iping connections ar e shown in Figure

2-3. Flow rates through the unit are limited to 30 gpm continuous and 40 gpm intermittent.

Shut-off valves and union connections must be installed in the inlet and outlet lines for

maintenance. The use of dielectric unions is recommended.

NOTE:

All piping must be arranged so that it does not interfere with removal of any covers, inhibit

service or maintenance, or prevent access between the unit and walls, or another unit.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 15 of 200

Page 16

GF-128 Innovation Series Water He aters Chapter 2

OMM-0079_0B USER MANUAL Installation

Figure 2-3. Water Inlet & Outlet Locations

2.6 TEST HOS E BIB CONNECTION

A Test Hose Bib connecti on, upstream of the s hut off valve on the hot water out let, is requir ed for star tup

and testing (Figure 2-4) . The pipe d iameter should be a m inimum of 3/4". The Test Hose Bib cannot be

omitted.

Figure 2-4. Test Hose Bib Location

Page 16 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 17

Chapter 2 Innovation Series Water Heater s GF-128

Installation USER MANUAL OMM-0079_0B

NOTE:

The maximum working pre ssure f or installations within t he Province of Alberta is 87 psig.

Therefore, a pressure & temperature relief valve with a setting of 75 psig/210°F is

supplied with Alberta shipments. See Drawing AP-A-863 in Appendix E.

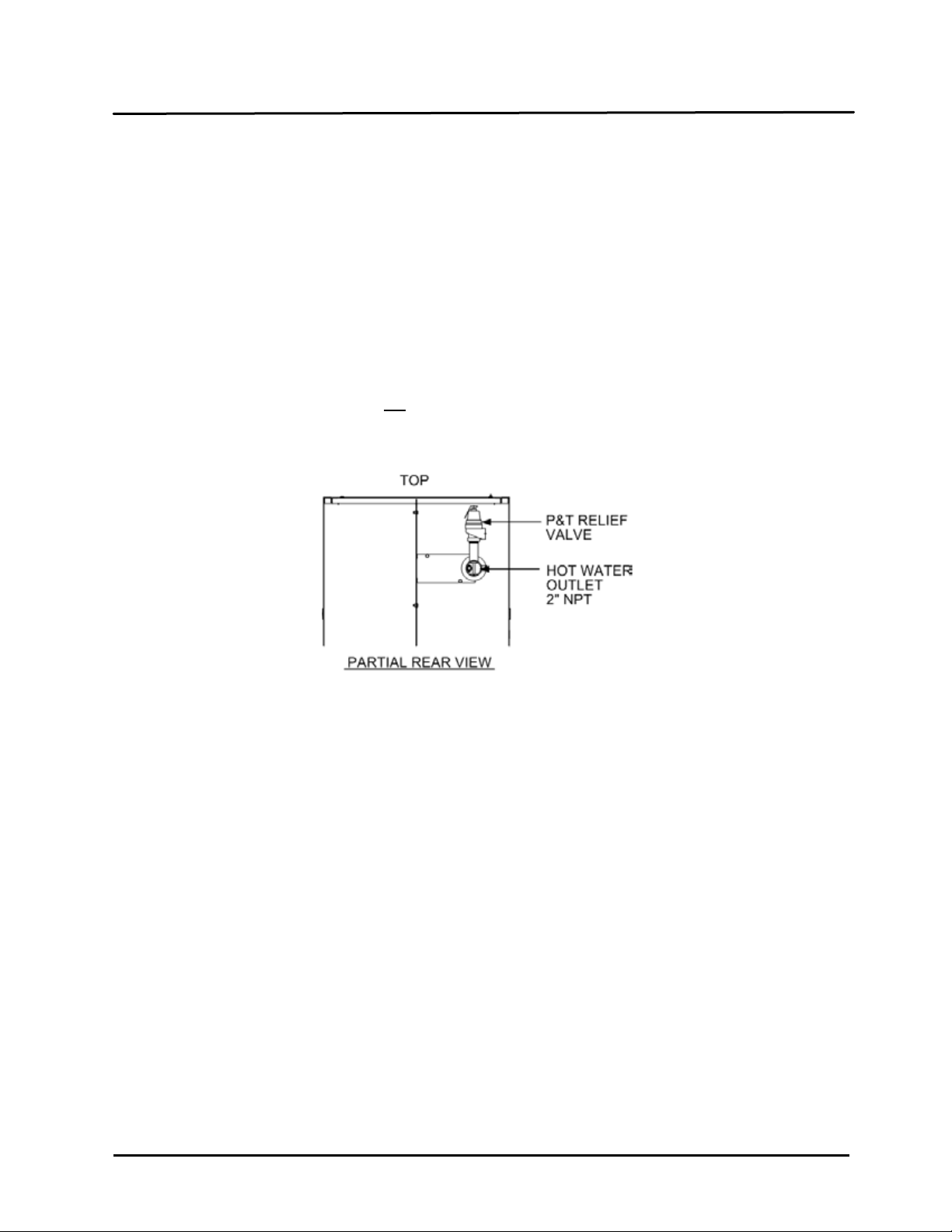

2.7 PRESSURE & TEMPERATURE RELIEF VALVE INSTALLATION

An ASME rated Pressure & Temperature (P&T) Relief Valve is supplied with each Innovation Water

Heater. With the exc eption of Alberta insta llations (see above Note) , the v alve s etpoi nt is 150 psi g/210°F.

The P&T Relief V al ve is installed at the to p of th e R ec i r culati on Loo p As sembly as shown in F i gure 2-5. A

suitable pipe joint com pound should be used on the threaded c onnections. Any excess should be wiped

off to avoid getting an y into the valve body. The reli ef valve should be piped to within 12 inches of the

floor to prevent injury in the event of a discharge. The relief piping must be full size, 1-1/2”, without

reduction. No valves , restrictions, or other blockages are allowed in the discharge line. In m ultiple unit

installations the discharge lines must not

suitable discharge location.

be manifolded together. Each must be individually run to a

Figure 2-5. P&T Relief Valve Location

2.8 SYSTEM RECIRCULATION LOOP

The System Recirculati on Loop Assembly is located at the rear of the unit as shown in Fi gure 2-5. This

assembly contains a rec irculator pum p which c on nec t s bet ween the upper hot wat er o utl et and l o wer c o ld

water inlet of the unit’s heat exchanger. The purpose of this loop is to provide feed-forward (FFWD)

temperature control by mixing a portion of the hot water outlet with the cold water inlet of the unit.

Temperature sensors located in the hot water outlet and c old water inlet provide temperatur e data to t he

C-More Control System . The Control System utilizes this data to m odulate the fire rate (Air/Fuel Valve

position) to precisely maintain the hot water outlet temperature at the selected setpoint temperature.

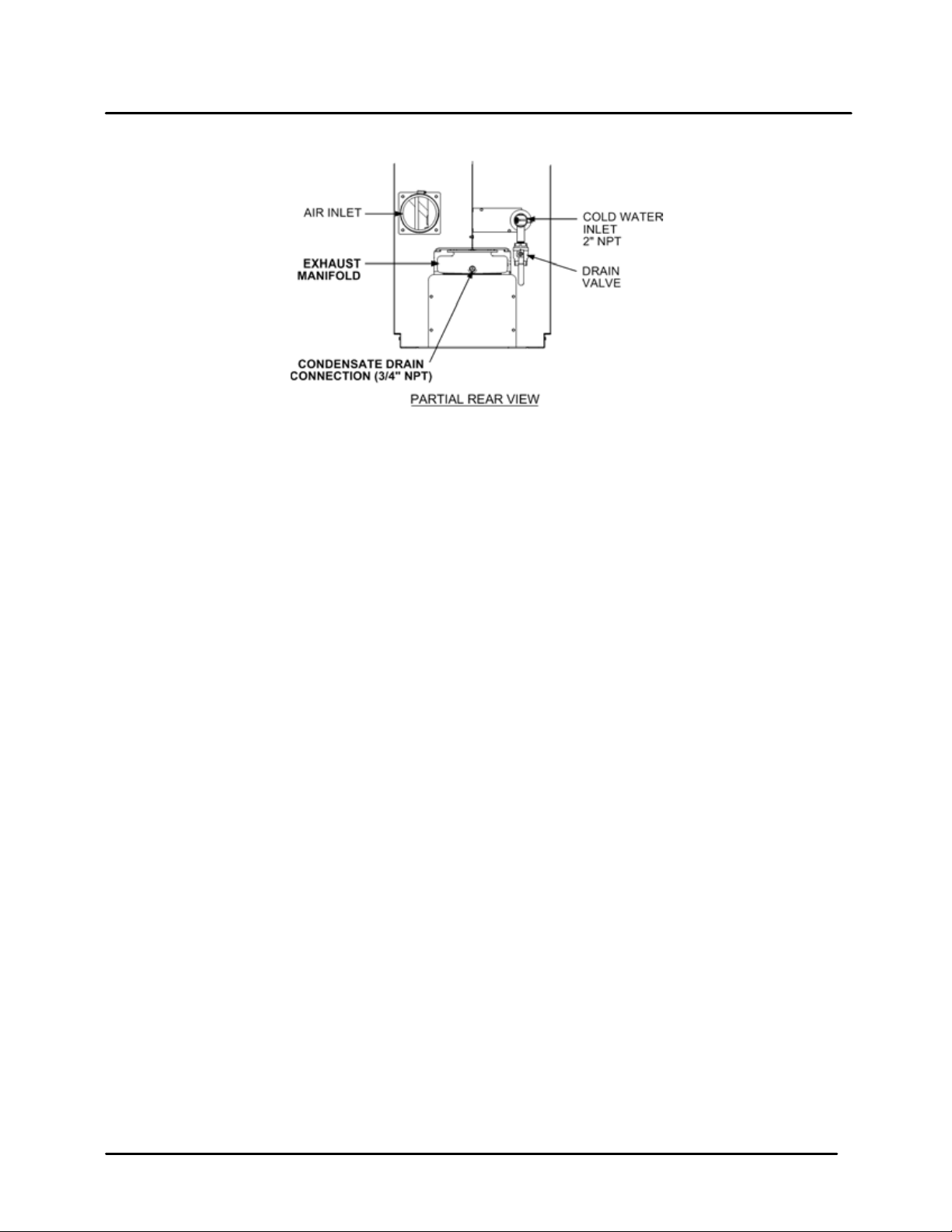

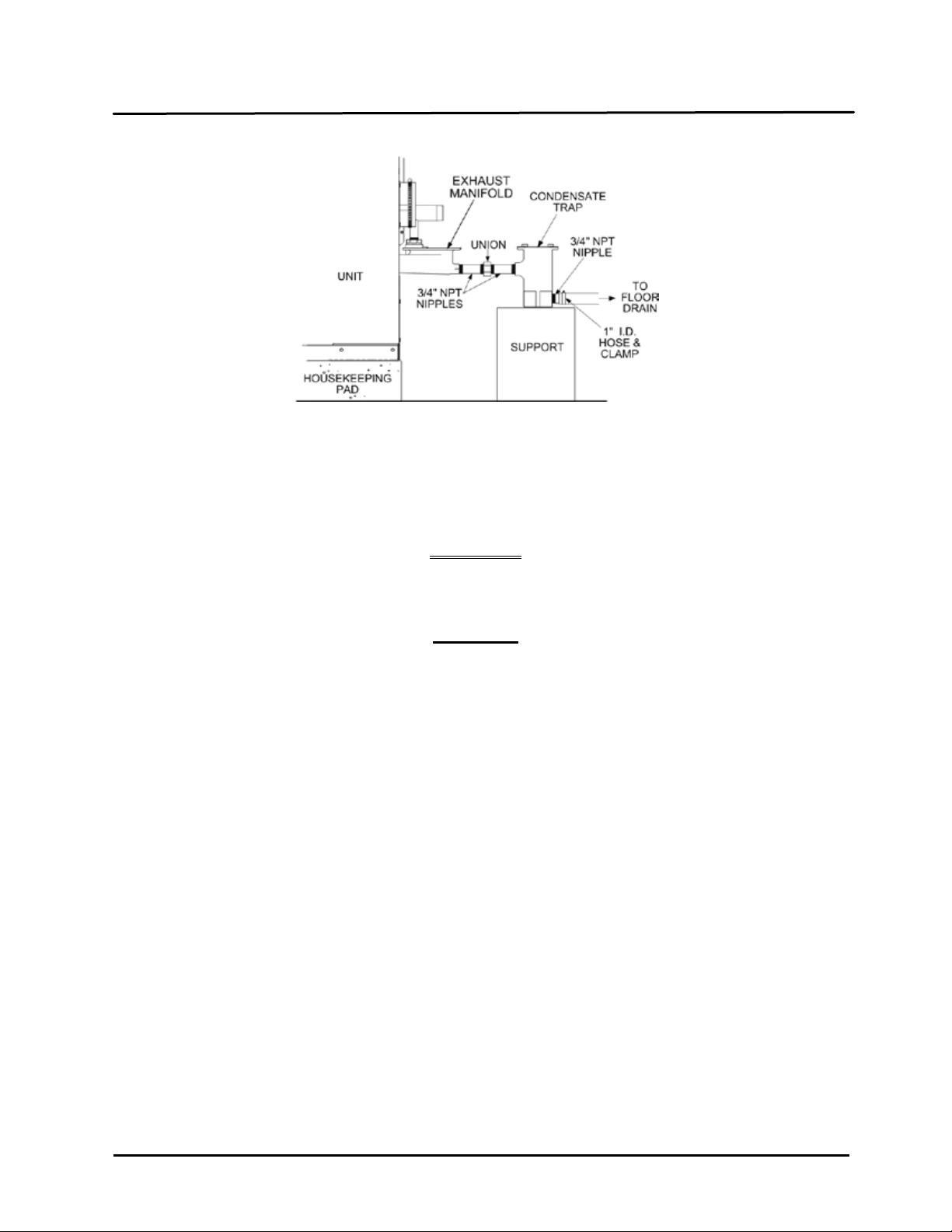

2.9 CONDENSATE DRAIN & PIPING

The Innovation Water Heater is des igned t o condens e wat er vapor f rom the flue produc ts. T heref ore, the

installation must have provisions for suitable condensate drainage or collection.

The condensate drai n port, is located on the exhaust manifold at the rear of the unit (Figure 2-6). This

drain port must be connected t o the C ondensate T rap (part n o. 240 60) which is pack ed separate ly with in

the unit’s shipping conta iner. The Condensat e Trap inlet and o utlet connectio ns contain tappe d 3/4” NPT

ports.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 17 of 200

Page 18

GF-128 Innovation Series Water He aters Chapter 2

OMM-0079_0B USER MANUAL Installation

Figure 2-6. Condensate Drain Connection Location

A sample Condensate T rap inst allation is shown in Figure 2-7. However, the actual insta llation details f or

the trap will var y depend ing on the avai lable c learanc es , housek eepin g pad heig ht/ dim ens ions and other

prevailing conditions at the site. the following general guidelines must be observed to ensure proper

condensate drainage:

• The condensate trap inl et (Figure 2-6) must be level with, or lower than the exhaust m anifold drain

port.

• The base of the condensate trap must be supported to ensure that it is level (horizontal).

• The trap must be rem ovable for routine maintenance. AERCO rec ommends that a union be utilized

between the exhaust manifold condensate drain port and the trap inlet port.

While observing the above guidelines, install the condensate trap as follows,

1. Connect the condensate trap inlet to the exhaust manifold drain connection using the appropriate

piping components (nipples, reducers, elbows, etc.) for the heater installation site.

2. At the condensate trap outlet, install a 3/4” NPT nipple.

3. Connect a length of 1” I.D polypropylene hose to the trap outlet and secure with a hose clamp.

4. Route the hose on the trap outlet to a nearby floor drain.

If a floor drain is not a vailable, a condens ate pum p can be used to rem ove the c ondensate to drain . The

maximum condensate flow rate is 20 G PH. The condensate drain trap, associat ed fittings and dra in line

must be removable for routine maintenance.

Page 18 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 19

Chapter 2 Innovation Series Water Heater s GF-128

Installation USER MANUAL OMM-0079_0B

Figure 2-7. Sample Condensate Trap Installation

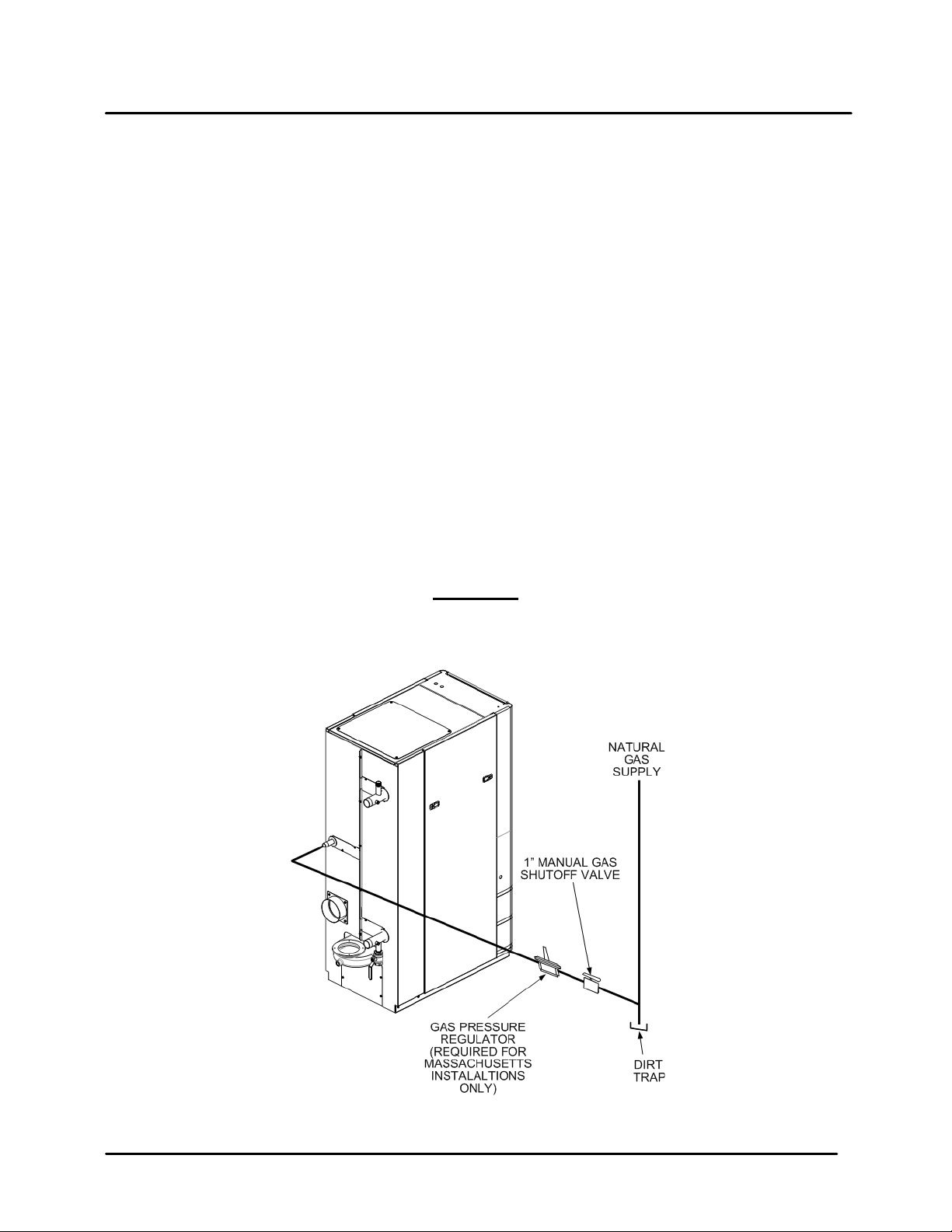

2.10 GAS SUPPLY PIPING

The AERCO Innovat ion Gas Com ponents and S upply Design Gu ide, GF-5030 (see Append ix J) must be

consulted prior to designing or installing any gas supply piping.

WARNING

NEVER USE MATCHES, CANDLES, FLAMES OR OTHER SOURCES OF

IGNITION TO CHECK FOR GAS LEAKS

.

CAUTION

Many soaps used for gas pipe leak testing are corrosive to metals. Therefore,

piping must be rinsed thoroughly with clean water after leak checks have been

completed.

All gas piping must be arranged so that it does not interfere with removal of any

covers, inhibit service/maintenance, or restrict access between the unit and

walls, or another unit.

Innovation units contain a 1 inch NPT gas inlet connection on the rear of the unit as shown in Figure 2-3.

NOTE

Prior to installation, all pip es should be d e-bur red an d inter nall y clear ed of an y scale, m etal ch ips or ot her

foreign particles. Do Not install any flexible connectors or unapproved gas fittings. Piping must be

supported from the floor, ceiling or walls only and must not be supported by the unit.

A suitable piping com pound, approved for use with natural gas, should be used. Any excess must be

wiped off to prevent clogging of components.

To avoid unit damage when pres s ure t esti ng gas p ip in g, isol ate t he u nit f r om the gas supply piping. A t no

time should the gas press u re applied to the unit exceed 14” W.C.. Leak tes t all e xter nal p ip ing thor o ugh ly

using a soap and water s olution or suitable equivalent. The gas piping used must meet all appl icable

codes.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 19 of 200

Page 20

GF-128 Innovation Series Water He aters Chapter 2

OMM-0079_0B USER MANUAL Installation

2.10.1 Gas Supply Specifications.

The gas supply input specifications to the unit for Natural Gas are as follows:

The maximum static pressure to the unit mus t not exceed 14” W .C. The gas supply pressur e to the unit

must be of suff icient capaci ty to pro vide 1060 cfh while m aintain ing the gas pressur e at 7 inches W .C. f or

FM gas trains.

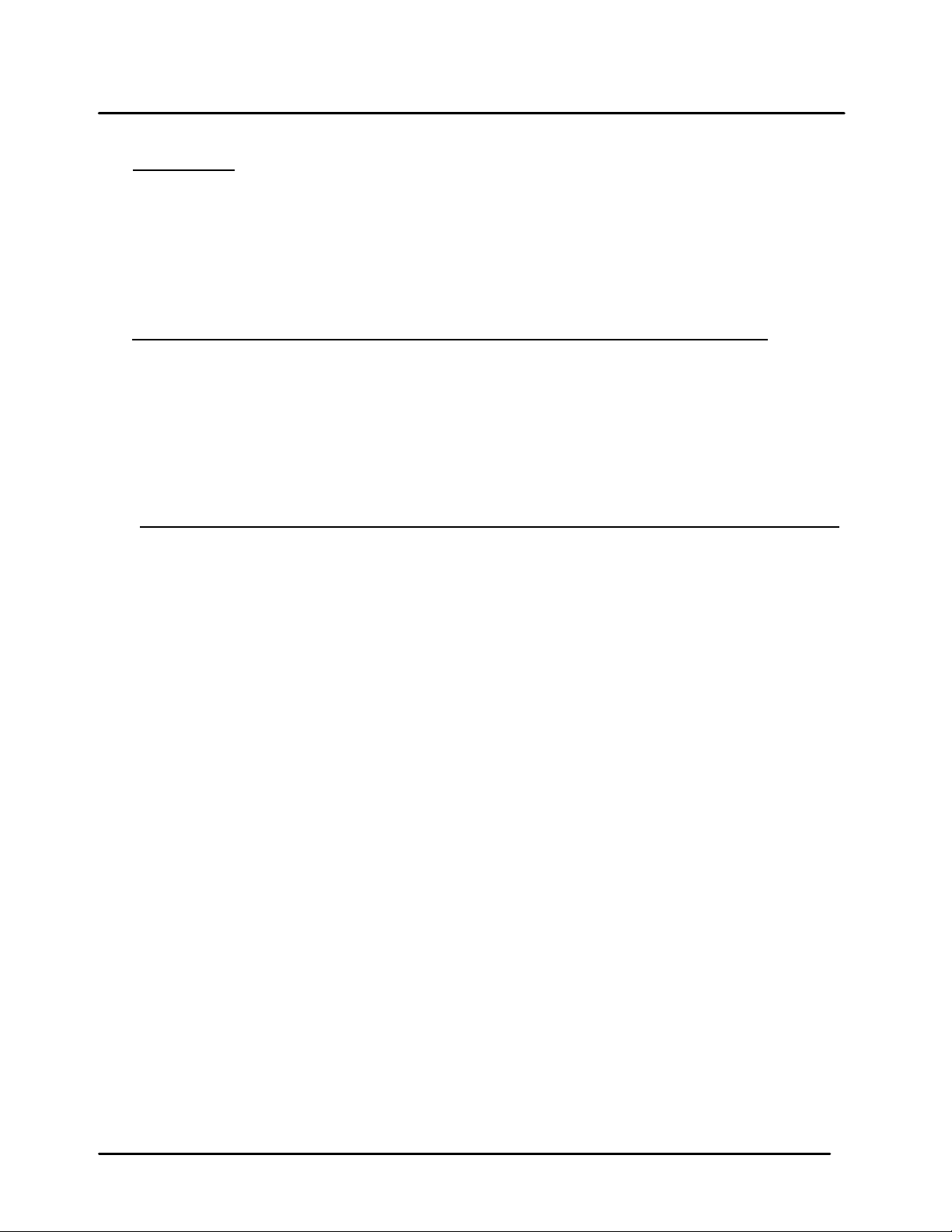

2.10.2 Manual Gas Shutoff Valve

A manual shut-off valve must be installed in the gas supply line upstream of the Heater as shown in

Figure 2-8. Maximum allowable gas pressure to the Heater is 14” W.C.

NOTE

Paragraph 2.10.3 appl ies only to water heater install ations within the Commonweal th of

Massachusetts.

2.10.3 External Gas Supply Regulator

For Massachusetts ins tallations, a m andator y externa l gas supp ly regulator m ust be pos itioned as shown

in Figure 2-6. The gas suppl y re gulator must be pr operly vented to outdoor s. Consult the loca l gas utility

for detailed requirements concerning venting of the the supply gas regulator.

NOTE

The external regulator must be capable of regulating 40,000 – 1,060,000 BTU/HR of

natural gas while maintaining a gas pressure of 7.0” W.C. to the unit.

CAUTION

A lock-up style regulator MUST be used when gas supply pressure will exceed

14” W.C.

Figure 2-8. Manual Gas Shut-Off Valve Location

Page 20 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 21

Chapter 2 Innovation Series Water Heater s GF-128

Installation USER MANUAL OMM-0079_0B

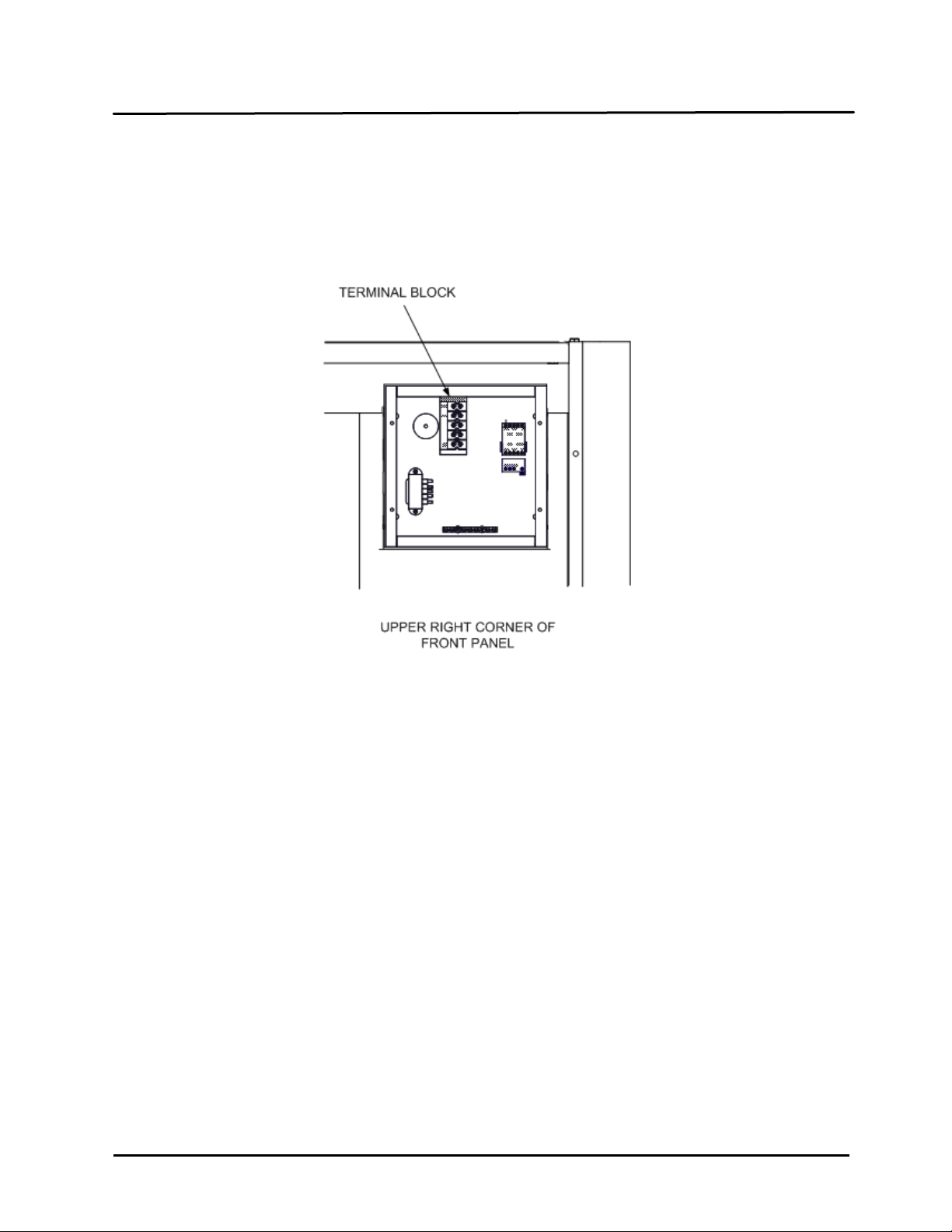

2.11 AC ELECTRICAL POWER WIRING

The AERCO Innovation Electrical Power Wiring Guide, GF-5060 (see Appen dix L), must be consulted

prior to connecting an y AC po wer wiri ng to t he un it. E xternal AC po wer c onnec tions ar e m ade to t he un it

inside the Power Box on t he front panel of the un it. Remove the front do or of the unit to ac ces s the Po wer

Box mounted directly abov e the Contr ol Box. Loos en the f our Power Box cover screws and r em ove cover

to access the AC terminal connections inside the Power Box (Figure 2-9).

Figure 2-9. Power Box With Cover Removed

NOTE

All electrical condu it and hard ware must be ins talled so that it does not i nterfere with th e

removal of any unit covers , inhibit service/maintenance, or prev ent access between the

unit and walls or another unit.

2.11.1 Electrical Power Requirements

The AERCO Innovation He ater acc epts 120 V AC, s in g le-ph as e, 60 H z @ 20 A. The Power Box contains a

terminal block as shown in Figure 2-8. In addition, a wiring diagram showing the required AC power

connections is provided on the front cover of the Power Box.

Each unit must be connected t o a dedicated electrical circuit. NO OTHER DE VICES SHOULD BE ON

THE SAME ELECTRICAL CIRCUIT AS THE HEATER.

A double-pole switch must be installed on the electrical supply line in an easily accessible location to

quickly and safely discon nect electrical servic e. DO NOT attach the switch t o sheet metal enclosures of

the unit.

After placing the unit in s ervice, the ignit ion safety shutof f device must be tested. If an external elec trical

power source is used, the insta lled boiler must be electrically bonded to gro und in accordance with the

requirements of the authority having jurisdiction. In the absence of such requirements, the installation

shall conform to National Electrical Code (NEC), ANSI/NFPA 70 and/or the Canadian Electrical Code

(CEC) Part I, CSA C22.1 Electrical Code.

For electrical power wiring diagrams, see the AERCO Innovation Electrical Power Wiring Guide, (GF-

5060).

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 21 of 200

Page 22

GF-128 Innovation Series Water He aters Chapter 2

OMM-0079_0B USER MANUAL Installation

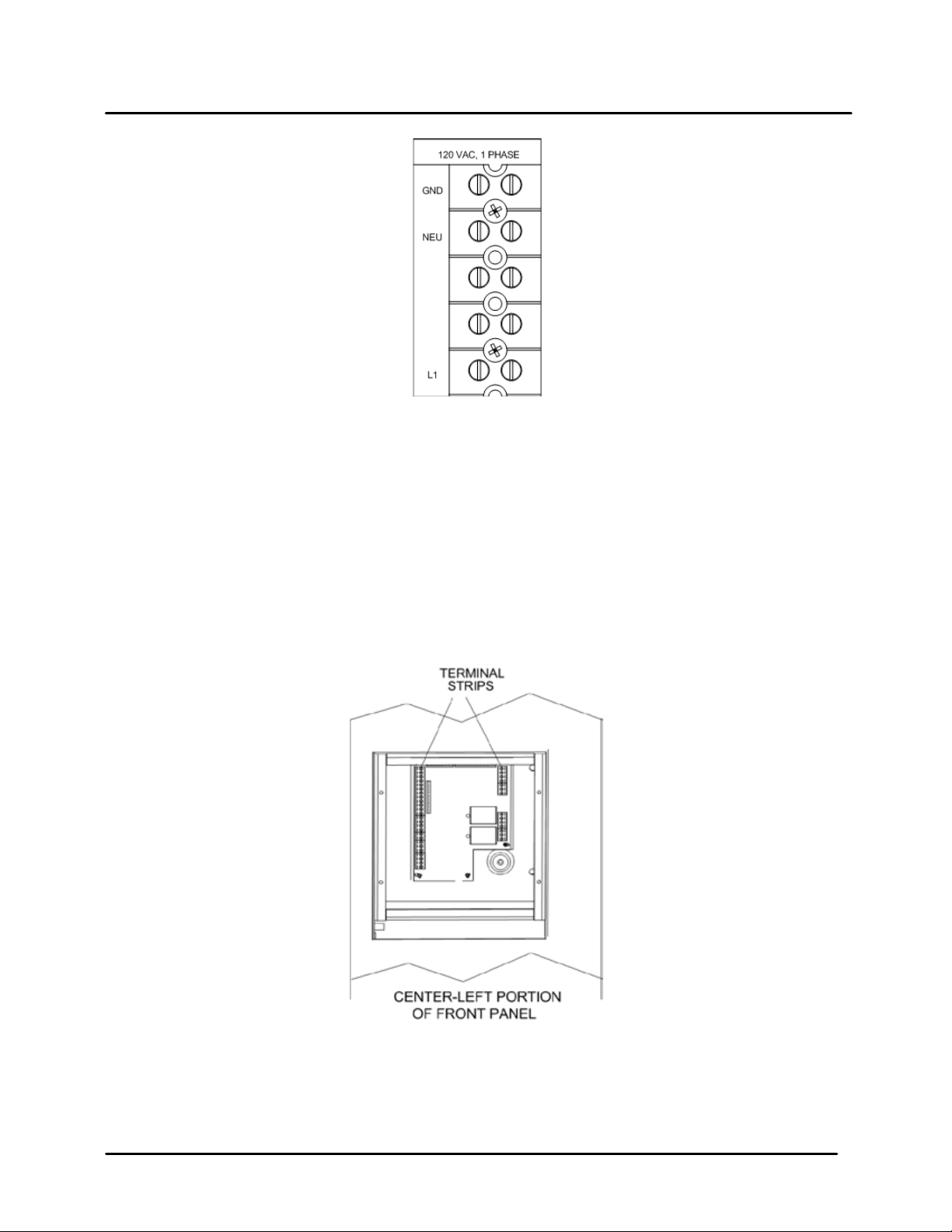

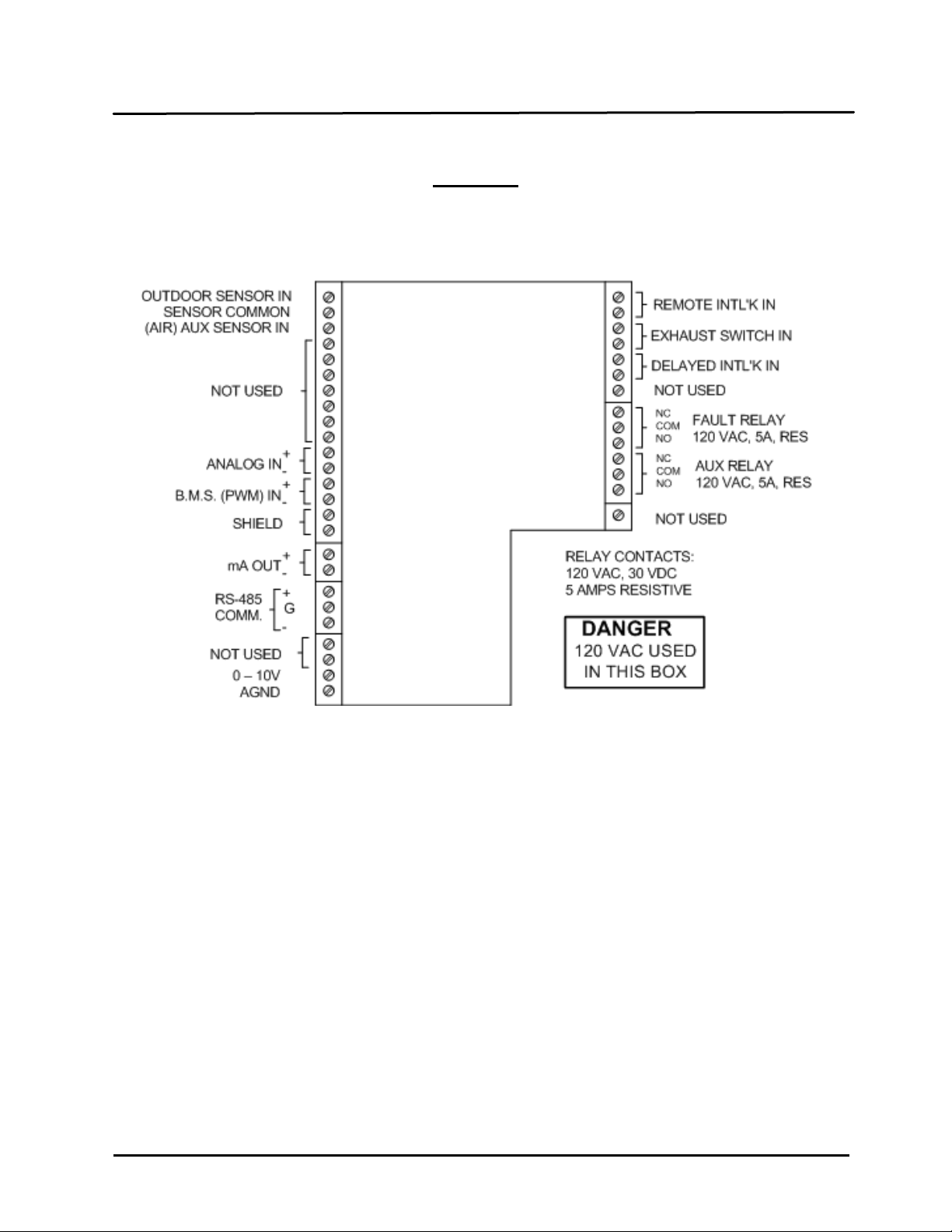

2.12 FIELD CONTROL WIRING

Each unit is fully wired f rom the f actor y with an i ntern al operat ing co ntrol s ystem . No f ield contr ol wiri ng is

required for normal operation. Howe ver, th e C -More control s ystem us ed with all Innovation H eater s does

allow for some c ontrol and monitoring features. Wir ing connections f or these features are made in the

Input/Output (I/O) Box. T he I/O Box is located on the upper -left portion of the unit f ront panel (Figure 2-

11) behind the rem ovable front panel door. To acces s the I/O Box terminal strips shown in Figure 2-11,

loosen the four cover screws and rem ove the cover. All field wiring is ins talled from the rear of the panel

by routing the wires through one of the four bushings provided.

Figure 2-10. AC Terminal Block Configurations

Refer to the wiring diagra m provided on the cover of the I/O Box (F igure 2-12) when making all wiring

connections.

Figure 2-11. Input/Output (I/O) Box Location

Since identical I/O Boxes are used with both AERCO gas-fired boilers and water heater s, some of the

input and output connectio ns apply only to boilers while oth ers are common to both boilers and heaters.

These I/O Box connections are noted in the following paragraphs.

Page 22 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 23

Chapter 2 Innovation Series Water Heater s GF-128

Installation USER MANUAL OMM-0079_0B

CAUTION

DO NOT make any connections to the I/O Box terminals labeled “NOT USED”.

Attempting to do so may cause equipment damage.

Figure 2-12. I/O Box Terminal Strips

2.12.1 Outdoor Air Sensor

Not Applicable to Water Heaters.

2.12.2 AUX SENSOR IN

The AUX SENSOR IN terminals can be used to add an additional temperature sensor for monitoring

purposes. This input is always enabled and is a view onl y input that can be seen in the o perating menu.

The sensor must be wired to the AUX SENSOR IN and SENSOR COMMON and must be similar to

AERCO BALCO wire sensor P/N 12449. A resistance chart for this sensor is located in APPENDIX C.

2.12.3 ANALOG IN

The ANALOG IN + and – terminals are used when an external signal is used to change the setpoint

(Remote Setpoint Mode) of the heater.

Either a 4 to 20 mA /1 to 5 VDC or a 0 to 20 m A/ 0 to 5 VDC signal ma y be used to vary the setpoint or

air/fuel valve posi tion. The factory default setting is for 4 to 20 mA / 1 to 5 VD C, however this may be

changed to 0 to 20 mA / 0 to 5 VDC using the Configuration Menu described in Chapter 3.

If voltage rather than current is selected as the drive signal, a DIP s witch must be set on the PMC Board

located inside the Control Box. Contact the AERCO factory for information on setting DIP switches.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 23 of 200

Page 24

GF-128 Innovation Series Water He aters Chapter 2

OMM-0079_0B USER MANUAL Installation

All supplied signals must be floating (unground-ed) signals. Connections between the source and the

Heater’s I/O Box mus t be made using tw isted shielded pa ir of 18–2 2 AW G wire such as Belde n 9841(see

Figure 2-12). Polarit y must be maintai ned and the shield m ust be connecte d only at the source end and

must be left floating (not connected) at the Heater’s I/O Box.

Whether using voltage or current f or the drive si gnal, the y are linearl y mapped to a 40°F to 240°F setpoint

or a 0% to 100% air/fuel valve position. No scaling for these signals is provided

2.12.4 B.M.S. (PWM) IN

Not Applicable to Water Heaters

2.12.5 SHIELD

The SHIELD terminals are used to terminate any shields used on sensor wires connected to the unit.

Shields must only be connected to these terminals.

2.12.6 mA OUT

These terminals prov ide a 4 to 20 m A output that c an be used to m onitor setpoi nt ( 40°F to 24 0°F), outlet

temperature (30°F to 240°F), or air/f uel valve positio n (0% to 100% o pen). This function is enabled in the

Configuration Menu (Chapter 3, Table 3-4).

2.12.7 EXHAUST SENSOR IN

These terminals permit an exhaust sensor to be connected to the exhaust manifold of the heater.

2.12.8 INTERLOCKS

The unit offers two interlock circuits for interfacing with Energy Management Systems and auxiliary

equipment such as pumps or louvers or other accessories. These interlocks are called the Remote

Interlock and Dela yed Interlock (Figure 2-12). T he wiring terminals for these interlocks ar e located inside

the I/O Box on the left side of the unit. The I/O Box cover contains a wiring diagram which shows the

terminal strip locations for these interlocks (REMOTE INTL’K IN and DELAYED INTL’K IN). Both

interlocks, described below, are factory wired in the closed position.

NOTE:

Both the Delayed Interloc k and Remote Interlock must be in the clos ed pos iti on for the unit

to fire.

2.12.8.1 REMOTE INTERLOCK IN

The remote interlock circuit is provided to remotely start (enable) and stop (disable) the unit if desired. The

circuit is l abeled REMOTE INT L’K IN and is located inside t he I/O Box on the left s ide of the unit. The

circuit is 24 VAC and comes factory pre-wired closed (jumped).

2.12.8.2 DELAYED INTERLOCK IN

The delayed interlock is typically used in conjunction with the auxiliary relay described in paragraph

2.12.10. This interloc k circuit is located in t he purge sec tion of the star t string. It can be connec ted to the

proving device (end switch, flow switch etc.) of an auxiliary piece of equipment started by the unit’s

auxiliary relay. The delayed interlock must be closed for the heater to fire. If the delayed interlock is

connected to a proving device that requires time to close (make), a time delay (Aux Start O n Dly) that

holds the start sequence of the unit long enough for a proving switch to make (close) can be programmed.

Should the proving switch not prove within the programm ed time frame, the unit will shut down. T he Aux

Start On Dly can be programm ed from 0 to 120 seconds. This option is locate in the Configuration Men u

(Chapter 3).

Page 24 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 25

Chapter 2 Innovation Series Water He ate rs GF-128

Installation USER MANUAL OMM-0079_0B

2.12.9 FAUL T RELAY

The fault relay is a single p ole double thr ow (SPDT ) relay having a nor mall y open and norm ally closed set

of relay contacts that are r ated for 5 amps at 120 VAC and 5 am ps at 30 VDC. T he relay energi zes when

any fault condition occurs and remains energized until the fault is cleared and the CLEAR button is

depressed. The fault relay connections are shown in Figure 2-12.

2.12.10 AU XILIARY RELAY CONT ACTS

Each unit is equipped with a single pole double throw (SPDT) relay that is energized when there is a

demand for heat a nd de-energized after the dem and for heat is satisfied. The relay is provided for the

control of auxiliary eq uipment, such as pumps and louvers, or c an be used as a unit status ind ictor (fir ing

or not firing). Its contacts are rated for 120 VAC @ 5 amps. Refer to Figure 2-12 to locate the AUX RELAY

terminals for wiring connections.

2.13 FLUE GAS VENT INSTALLATION

AERCO Gas Fired Venting and Combustion Air Guide, GF-5050 (see Appendix K) must be consulted

before any flue or combustion air venting is designed or installed. Suitable, U/L approved, positive

pressure, watertight vent materials MUST be used for safety and UL certification. Because the unit is

capable of dischargi ng low temperature exha ust gases, the flue must be p itched back towards the u nit a

minimum of 1/4" per foot to avoid any condensate pooling and to allow for proper drainage.

While there is a positive flue pressure during operation, the combined pressure drop of vent and

combustion air systems must not exceed 140 equiva lent feet of 1.9” W.C. Fittings as well as pipe lengt hs

must be calculated as part of the equivalent length. For a natural draft installation the draft must not

exceed - 0.10” W .C. These factors must be planned into the vent installation. If the m aximum allowable

equivalent lengths of piping are exceeded, the unit will not operate properly or reliably.

For Massachusetts installations, the Heatfab Division of the Selkirk Corporation provides vent systems

which conform to all applicabl e requirem ents for installations within the Comm onwealth of Mass achusetts.

Contact information for this supplier is as follows:

Selkirk Corporation

Heatfab Division

130 Industrial Blvd.

Turners Falls, MA 01376

Phone: 1-800-772-0739

www.heat-fab.com

2.14 COMBUSTION AIR

The AERCO Gas-Fired He ater Venting and Combustion Air Guide , GF-5050 MUST be consulted before

any flue or inlet air venting is designed or installed. Air supply is a direct requirement of ANSI 223.1,

NFPA-54, CSA B149. 1 and local codes. These codes should be consulted before a perm anent design is

determined.

The combustion air must be free of chlorine, halogenated hydrocarbons or other chemicals that can

become hazardous when used in gas-fired equipment. Common sources of these compounds are

swimming pools, degreas ing compounds, plast ic processing, and ref rigerants. Whene ver the environm ent

contains these t ypes of chemicals, com bustion air MUST be su pplied from a clean area outdoors for the

protection and longevity of the equipment and warranty validation.

The more common methods of combustion air supply are outlined in the following paragraphs. For

combustion air suppl y from ducting, cons ult the AERC O GF-5050, Gas F ired Ven ting and Combus tion Air

Guide.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 25 of 200

Page 26

GF-128 Innovation Series Water He aters Chapter 2

OMM-0079_0B USER MANUAL Installation

2.14.1 Combustion From Outside the Building

Air supplied from outside the building must be provid ed through two permanent openin gs. For each unit

these two openings m ust have a free area of not less than one squar e inch for each 4000 BTUs input of

the equipment or 250 s qu ar e inch es of f r ee area. T he f r ee area must take into account r es tr ic tio ns s uc h a s

louvers and bird sc reens. For Canada i nstallations , refer to the requirem ents specified in CSA B149.1-10,

8.4.1 and 8.4.3.

2.14.2 Combustion Air from Inside the Building

When combustion air is provided from within the building, it must be supplied through two permanent

openings in an interior wall. Each opening must have a free area of not less than one square inch per 1000

BTUH of total input or 1000 square inches of free area. The free area must take into account any

restrictions, such as louvers.

2.15 SEALED COMBUSTION

The AERCO Innovation Water Heater is UL listed for 100%-sealed combustion. For sealed combustion

installations, the screen inlet air ductwork must then be attached direc t l y to the unit’s air inlet.

In a sealed combustion air application, the combustion air ducting pressure losses must be taken into

account when calculat ing the total maximum allowable v enting run. See the AERCO Innov ation Venting

and Combustion Air Gui de, GF-5050. When using the heater in a sealed c ombustion air configuration,

each unit must have a minimum 6 inch diameter connection at the unit.

Page 26 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 27

Chapter 3 Innovation Series Water Heater s GF-128

Operation USER MANUAL OMM-0079_0B

CHAPTER 3. OPERATION

3.1 INTRODUCTION

The information in this Chapter provides a guide to the operation of the Innovation Water Heater using the

Control Panel mounted on the front of the unit. It is imperative that the initial startup of this unit be

performed by factor y trained personnel. Oper ation prior to initial startu p by factor y trained personnel will

void the equipment w arr ant y. In ad dit io n, th e f oll o wing WARNINGS and CAUT ION S must be observed at

all times.

CAUTION

All of the installation procedures in Chapter 2 must be completed before

attempting to start the unit.

WARNING

ELECTRICAL VOLTAGES IN THIS SYSTEM INCLUDE 120 AND 24 VOLTS AC.

IT MUST BE SERVICED ONLY BY FACTORY CERTIFIED SERVICE

TECHNICIANS

WARNING

DO NOT ATTEMPT TO DRY FIRE THE UNIT. STARTING THE UNIT

WITHOUT A FULL WATER LEVEL CAN SERIOUSLY DA MAGE THE UNIT AND

MAY RESULT IN INJURY TO PERSONNEL OR PROPERTY DAMAGE. THIS

SITUATION WILL VOID ANY WARRANTY.

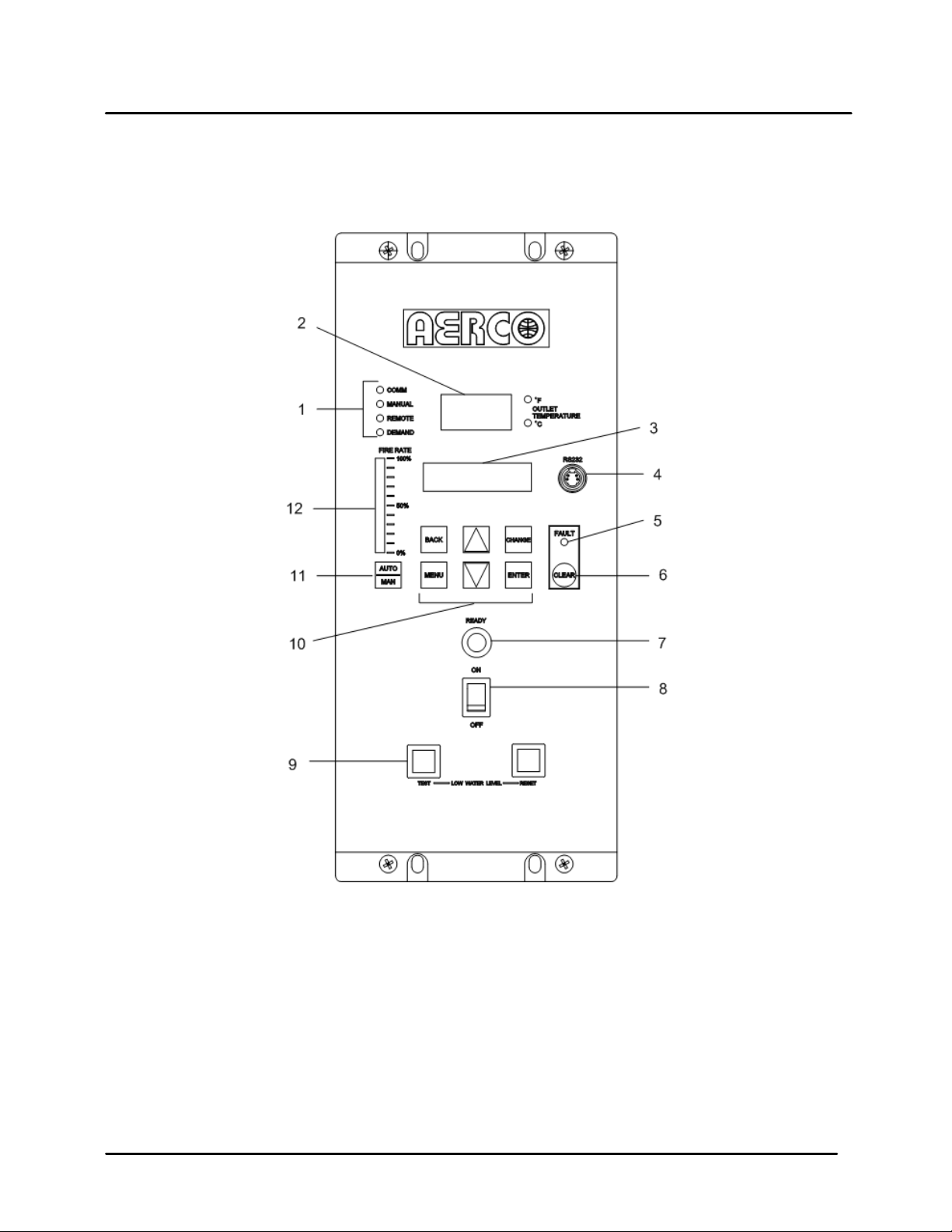

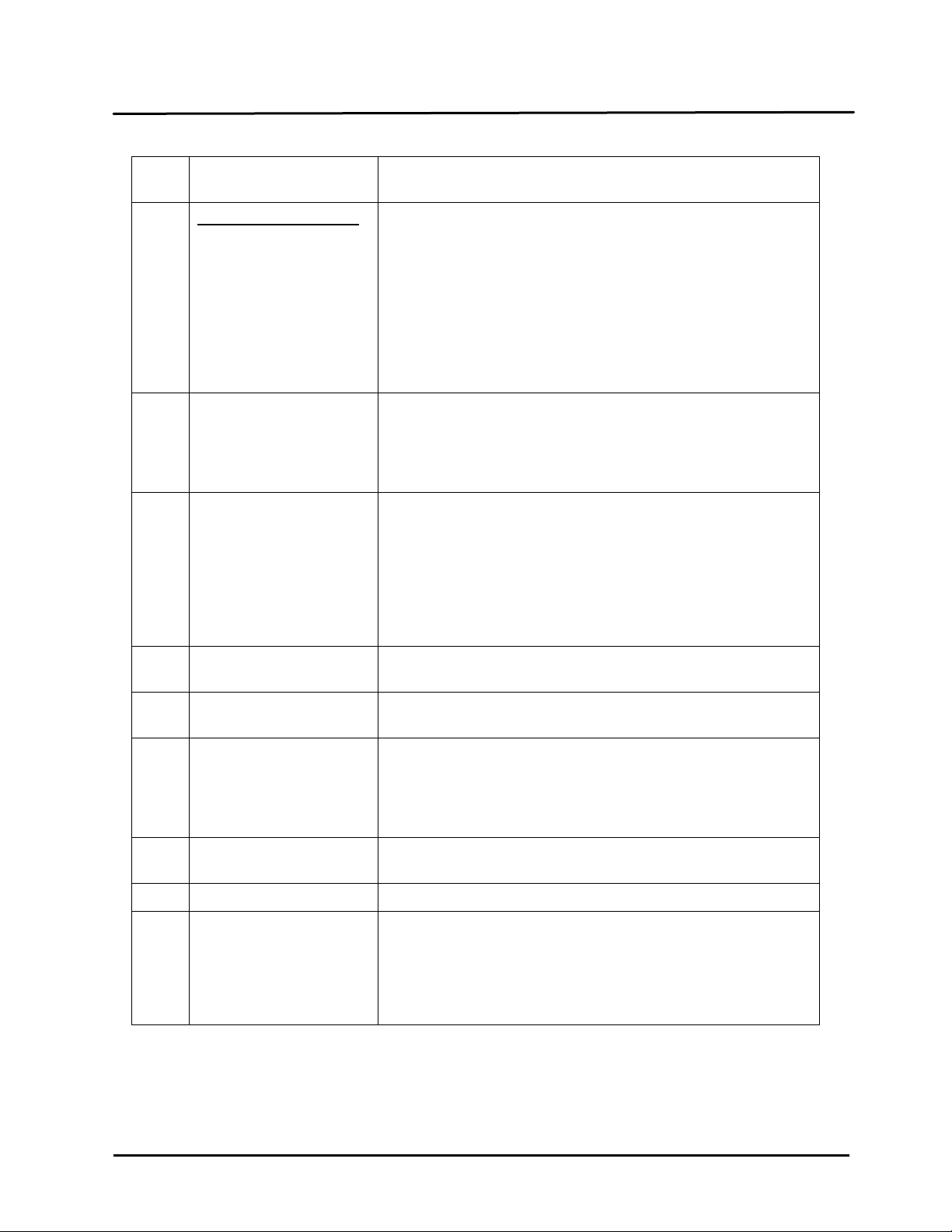

3.2 CO NTROL PANEL DESCRIPTION

The Innovation Control Panel shown in Figure 3-1 contains all of the controls, indicators and displays

necessary to opera te, adjust and troubleshoot the I nnovation Water Heater. T hese operating controls,

indicators and displays are listed and described in Table 3-1. Additional information on these items is

provided in the individual operating procedures provided in this Chapter.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 27 of 200

Page 28

GF-128 Innovation Series Water He aters Chapter 3

OMM-0079_0B USER MANUAL Operation

Figure 3-1. Control Panel Front View

Page 28 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 29

Chapter 3 Innovation Series Water Heater s GF-128

FUNCTION

Operation USER MANUAL OMM-0079_0B

Table 3-1 Operating Controls, Indicators and Displays

ITEM

NO.

CONTROL, INDICATOR

OR DISPLAY

LED Status Indicators

1

COMM

MANUAL

REMOTE

DEMAND

OUTLET

2

TEMPERATURE

Display

3 VFD Display Vacuum Fluorescent Display (VFD) consists of 2 lines each

Four Status LEDs indicate the current operating status as

follows:

Lights when RS-232 communication is occurring

Lights when the unit is being controlled using the front panel

keypad.

Lights when the unit is being controlled by an external signal

from an Energy Management System

Lights when there is a demand for heat.

3–Digit, 7–Segment LED display continuously displays the

outlet water temperature. The °F or °C LED next to the

display lights to indicate whether the displayed temperature is

in degrees Fahrenheit or degrees Celsius. The °F or °C blinks

when operating in the Deadband Mode.

capable of displaying up to 16 alphanumeric characters. The

information displayed includes:

Startup Messages

Fault Messages

Operating Status Messages

Menu Selection

RS-232 Port

4

FAULT Indicator Red FAULT LED indicator lights when a heater alarm

5

CLEAR Key Turns off the FAULT indicator and clears the alarm message

6

READY Indicator

7

ON/OFF Switch

8

LOW WATER LEVEL

9

TEST/RESET Switches

Port permits a Laptop Computer or External Modem to be

connected to the unit’s Control Panel.

condition occurs. An alarm message will appear in the VFD.

if the alarm is no longer valid. Lockout type alarms will be

latched and cannot be cleared by simply pressing this key.

Troubleshooting may be required to clear these types of

alarms.

Lights ON/OFF switch is set to ON and all Pre-Purge

conditions have been satisfied.

Enables and disables heater operation.

Allows operator to test operation of the water level monitor.

Pressing TEST opens the water level probe circuit and

simulates a Low Water Level alarm.

Pressing RESET resets the water level monitor circuit.

Pressing the CLEAR key (item 6) resets the display.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 29 of 200

Page 30

GF-128 Innovation Series Water He aters Chapter 3

FUNCTION

OMM-0079_0B USER MANUAL Operation

Table 3-1 Operating Controls, Indicators and Displays – Continued

ITEM

NO.

CONTROL, INDICATOR

OR DISPLAY

10

MENU Keypad

MENU

BACK

▲ (UP) Arrow When in one of the main menu categories (Figure 3-2),

▼ (DOWN) Arrow When in one of the main menu categories (Figure 3-2),

CHANGE

Consists of 6 keys which provide the following functions for

the Control Panel Menus:

Steps through the main menu categories shown in Figure 3-

2. The Menu categories wrap around in the order shown.

Allows you to go back to the previous menu level without

changing any information. Continuously pressing this key

will bring you back to the default status display in the VFD.

Also, this key allows you to go back to the top of a main

menu category.

pressing the ▲ arrow key will select the displayed menu

category. If the CHANGE key was pressed and the menu

item is flashing, pressing the ▲ arrow key will increment the

selected setting.

pressing this key will select the displayed menu category. If

the CHANGE key was pressed and the menu item is

flashing, pressing the ▼ arrow key will decrement the

selected setting.

Permits a setting to be changed (edited). When the

CHANGE key is pressed, the displayed menu item will begin

to flash. Pressing the ▲ or ▼ arrow key when the item is

flashing will increment or decrement the displayed setting.

ENTER

11

12

AUTO/MAN Switch

VALVE POSITIO N

Bargraph

Saves the modified menu settings in memory. The display

will stop flashing.

This switch toggles the heater between the Automatic and

Manual modes of operation. When in the Manual (MAN)

mode, the front panel controls are enabled and the

MANUAL status LED lights.

When in the Automatic (AUTO) mode, the MANUAL status

LED will be off and the front panel controls disabled.

20 segment red LED bargraph continuously shows the

Air/Fuel Valve position in 5% increments from 0 to 100%

Page 30 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 31

Chapter 3 Innovation Series Water Heater s GF-128

Operation USER MANUAL OMM-0079_0B

3.3 CO NTROL PANEL MENUS

The Control Panel incorpo rates an extensive menu structure which p ermits the operator to set up, and

configure the unit. The m enu str ucture c onsists of f ive major menu categor ies w hich ar e applica ble to th is

manual. These categori es are shown in Figure 3-2. Each of the menus shown, contain options which

permit operating param eters to be viewed or chan ged. The menus are protected by a password l evels to

prevent unauthorized use.

Prior to entering th e correct password, the options contai ned in the Operat ion, Setup, Configurat ion and

Tuning Menu categories can be viewed. However, with the exception of Int ernal Setpoint Temperature

(Configuration Menu), none of the viewable menu options can be changed.

Once the valid level 1 password (159) is entered, the options listed in the Setup. Configuration and

Tuning Menus can be viewed and changed, if desired.

3.3.1 Menu Processing Procedure

Accessing and initiating ea ch menu and option is accomplished us ing the Menu Ke ys shown in Figure 3-

1. Therefore, it is imperative that you be thoroughly familiar with the following basic steps before

attempting to perform specific menu procedures.

1. The Control Panel will nor mally be in the Operating Menu and the VF D will display the current unit

status. Pressing the ▲ or ▼ arrow key will display the other available data items in the Operating

Menu.

2. Press the MENU k ey. The displa y will show the Setup Men u, whic h is th e nex t menu c ateg ory sh own

in Figure 3-2. This m enu contains th e Passwor d option which mus t be entered if other m enu options

will be changed.

3. Continue pressing the MENU key until the desired menu is displayed.

4. With the desired menu displayed, press the ▲ or ▼ arrow key. The first option in the selected menu

will be displayed.

5. Continue to press the ▲ or ▼ arrow key until the desired menu option is displayed. Pressing the ▲

arrow key will displa y the available m enu options in the Top-Down sequence. Pressing the ▼ arrow

key will displa y the options in the Bottom -Up sequence. T he menu optio ns will wr ap-around after the

first or last available option is reached.

6. To change the value or set ting of a displayed menu option, pres s the CHANGE key. The displa yed

option will begin to flash. Press the ▲ or ▼ arrow key to scroll through the available menu option

choices for the option to be changed. The menu option choices do not wrap around.

7. To select and store a changed menu item, press the ENTER key.

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 31 of 200

Page 32

GF-128 Innovation Series Water He aters Chapter 3

OPERATING

SETUP

CONFIGURATION

TUNING

LEVEL 1 PWD

OMM-0079_0B USER MANUAL Operation

Figure 3-2. Menu Structure

NOTE

The following paragraphs provide brief descriptions of the options contained in each

menu. Refer to Appendix A for detailed descriptions of each menu option. Refer to

Appendix B for listings and descriptions of displayed startup, status and error messages.

3.4 O PERATING MENU

The Operating Menu displa ys a number of key operating parameters f or the unit as listed in Table 3-2.

This menu is “R ead-Only” and does not allow person nel to change or adjust any displa yed items. Since

this menu is “Read-Only”, it can be viewed at any time without entering a password. Pressing the ▲

arrow key to display the menu items in the order listed (Top-Down). Pressing the ▼ arrow k e y wil l display

the menu items in reverse order (Bottom-Up).

Page 32 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 33

Chapter 3 Innovation Series Water Heater s GF-128

Available Choices or Limits

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Default

Operation USER MANUAL OMM-0079_0B

3.5 SETUP M ENU

The Setup Menu (Table 3-3) permits the operator to enter the u nit password (159) which is required to

change the menu options. To prevent unauthorized use, the password will time-out after 1 hour.

Therefore, the correc t password must be reentered when re quired. In addition to permitting passw ord

entries, the Setup Menu is also used to enter date and time, units of tem perature measurements and

entries required for external communication and control of the unit via the RS-232 port. A view-only

software version display is also provided to indicate the current Control Box software version.

NOTE

The Outdoor Temp displa y item shown with an asteris k in Table 3-2 will not be displa yed

unless the Outdoor Sens or function has been e nabled in the Configur ation Menu (Table

3-4).

Table 3-2. Operating Menu

Menu Item Display Minimum Maximum Default

Status Message

Active Setpoint 40°F 240°F

Inlet Temp 40°F 140°F

AIR Temp -70°F 245°F

Outdoor Temp* -70°F 130°F

Valve Position In 0% 100%

Valve Position Out 0% 100%

FFWD Temp 80°F 160°F

Flame Strength 0% 100%

Run Cycles 0 999,999,999

Run Hours 0 999,999,999

Fault Log 0 19 0

Table 3-3. Setup Menu

Passsword

0

9999 0

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 33 of 200

Language English English

Time 12:00 am 11:59 pm

Date 01/01/00 12/31/99

Unit of Temp Fahrenheit or Celsius Fahrenheit

Comm Address 0 127 0

Baud Rate 2400, 4800, 9600, 19.2K 9600

Software Ver 0.00 Ver 9.99

Page 34

GF-128 Innovation Series Water He aters Chapter 3

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Default

OMM-0079_0B USER MANUAL Operation

3.6 CO NF IG URATION MENU

The Configuration Menu shown in Table 3-4 permits adjustment of the Internal Setpoint (Setpt)

temperature regardles s of wheth er the valid password has been e ntere d. Se tpt is r equire d f or operati on i n

the Constant Setpoint mode. The remaining options in this menu require the valid password to be

entered, prior to chang ing existing entries. This m enu contains a number of other configuration settings

which may or may not be displayed, depending on the current operating mode setting.

NOTE

The Configuration Men u settings shown in Table 3-4 are Fac tory-Set in accordan ce with

the requirements spec ified for each individual order. T herefore, under normal operating

conditions, no changes will be required.

Table 3-4. Configuration Menu

Internal Setpt

Unit Type

Unit Size

Fuel Type

Water Heater Mode

Remote Signal

(If Mode = Remote

Setpoint, Direct Drive

or Combination)

Bldg Ref Temp

(If Mode = Outdoor

Reset)

Reset Ratio

(If Mode = Outdoor

Reset)

Outdoor Sensor

Lo Temp

Hi Temp Limit 130°F

Limit

KC Boiler, KC Boiler LN,

BMK Boiler, BMK Boiler LN,

BMK Boiler Dual, KC Water

Heater, KC Water Heater LN,

INN

0.5 MBTU, 1.0 MBTU

1.5 MBTU, 2.0 MBTU

3.0 MBTU, 3.5 MBTU

4.0 MBTU, 5.0 MBTU

6.0 MBTU

Natural Gas, Propane Natural Gas

Constant Setpoint,

Remote Setpoint,

4 – 20 mA/1 – 5V

1.0 MBTU

Constant

Setpoint

4 – 20 mA,

0 -20 mA/0 – 5V

PWM Input (BMS)

Network

40°F 230°F 70°F

0.1 9.9 1.2

Enabled or Disabled Disabled

INN

1-5V

Page 34 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

System Start Tmp

(If Outdoor Sensor =

Enabled)

30°F 100°F 60°F

Page 35

Chapter 3 Innovation Series Water Heater s GF-128

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Default

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Default

Operation USER MANUAL OMM-0079_0B

Table 3-4. Configuration Menu - Continued

Setpt Lo Limit

Setpt Hi Limit

Temp Hi Limit

Max Valve Position

Pump Delay Timer

Aux Start On Dly

Failsafe Mode Shutdown or Constant Setpt Shutdown

*Analog Output

(See CAUTION at

end of Table 3-4 )

Low Fire Timer 2 sec. 600 sec. 2 sec.

Setpt Limiting Enabled or Disabled Disabled

Setpt Limit Band 0°F 10°F 0

Network Timeout 5 Sec 999 Sec 30 Sec

HI DB Setpt EN 0% 100% 30%

Demand Offsert 0 25 0

Deadband High 0 25 0

40°F Setpt Hi Limit 60°F

Setpt Lo Limit 220°F 140°F

40°F 240°F 160°F

40% 100% 100%

0 min. 30 min. 0 min.

0 sec. 120 sec. 0 sec.

Off, Setpoint, Outlet Temp,

Valve Position 4-20 mA,

Valve Position 0-10V

*Valve

Position

0-10V

Deadband Low 0 25 0

*CAUTION:

DO NOT CHANGE the Analog Output Menu Item from its Default setting

(Valve Position 0-10V

3.7 TUNING MENU

The Tuning Menu item s in T able 3-5 ar e Factor y set for eac h indi vidual uni t. Do not c hange t hese m enu

entries unless specifically requested to do so by Factory-Trained personnel.

Prop Band

Integral Gain 0.00 2.00 1.6

Derivative Time 0.0 min 2.00 min 0.10 min

Reset Defaults? Yes, No, Are You Sure? No

).

Table 3-5. Tuning Menu

1°F

120°F 8°F

07/21/11 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 35 of 200

Page 36

GF-128 Innovation Series Water He aters Chapter 3

OMM-0079_0B USER MANUAL Operation

3.8 START SEQUENCE

When the Control B ox ON/OFF switch is set to the O N pos ition, it chec k s all pre -pur ge saf et y switches to

ensure they are closed. These switches include:

• Safety Shut-Off Valve Proof of Closure (POC) switch

• Low Water Level switch

• High Water Temperature switch

• High Gas Pressure switch

• Low Gas Pressure switch

• Blower Proof switch

If all of the above switches ar e closed, the READY light above t he ON/OFF swit ch will light and the unit

will be in the Standby mode.

When there is a demand for hot water, the following events will occur:

NOTE

If any of the Pre-Purge safety dev ice switches are open, the appropriate fault mes sage

will be displayed. Also, the appropriate mes sages will be displayed thr oughout the star t

sequence, if the required conditions are not observed.

1. The DEMAND LED status indicator will light.

2. The unit checks to ensur e that the Proof of Clos ure (POC) s witch in the downstream Safety Shut-Off

Valve (SSOV) is closed. See Figure 3-3 for SSOV location.

Figure 3-3. SSOV Location

3. With all required safet y devic e sw itches c losed, a p ur g e cycle will be initiated and the f ollo win g event s

will occur:

(a) The Blower relay energizes and turns on blower.

(b) The Air/Fuel Valve rotates to th e full-open p urge position an d closes purge p osition switc h. The

dial on the Air/Fuel Valve (Figure 3-4) will read 100 to indicate that it is full-open (100%).

(c) The VALVE POSITION bargraph will show 100%.

Page 36 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 07/21/11

Page 37

Chapter 3 Innovation Series Water Heater s GF-128

Operation USER MANUAL OMM-0079_0B

Figure 3-4.

Air/Fuel Valve In Purge Position

4. Next, the blower proof switch on the Air/Fuel Valve (Figure 3-5) closes. The display will show Purging

and indicate the elapsed time of the purge cycle in seconds.

Figure 3-5. Blower Proof Switch

5. Upon completion of the purge cycle, the Control Box initiates an ignition cycle and the following

events occur:

(a) The Air/Fuel Valve rotates t o the l o w-f ire ig nit io n p os ition a nd c l os es the ignition switch. The dial