Page 1

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C

HE-110

USER MANUAL

Revised: 07/26/2013

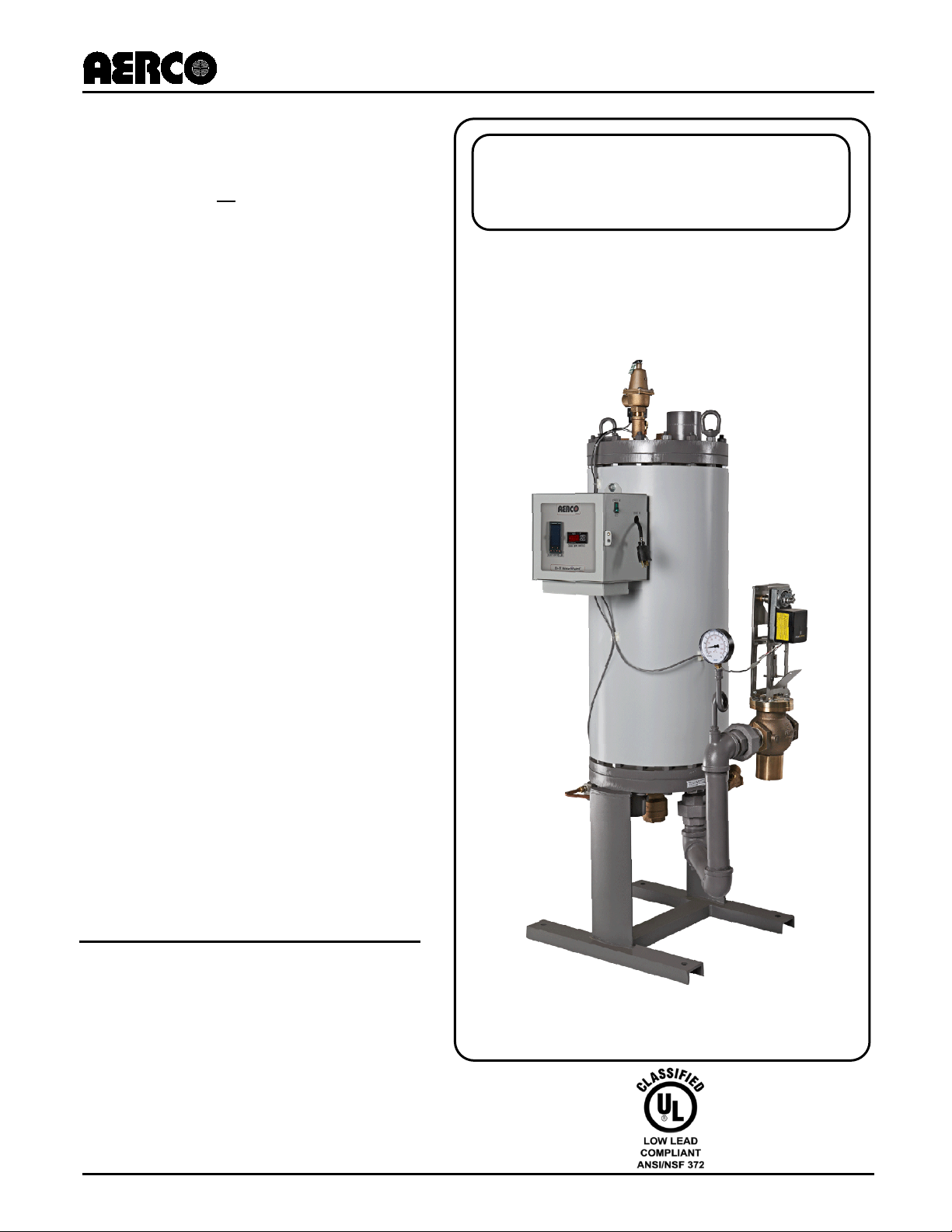

Water Wizard

SW1B+II Packaged Water Heater with

Pneumatically Controlled Valve (CXT-P)

Installation, Operation, and Maintenance

Covers all 1B+ II models

Other applicable documentation includes:

including units with

pneumatically controlled valve

(Type CXT-P) or with an

Electronic Control System (ECS)

and electronically controlled

valve (CXT-E):

• B+03

• B+04

• B+05

• B+06

• B+07

• B+08

• B+09

• B+10

• B+11

• B+12

• B+13

• B+14

• B+15

Note: Number indicates number of

heating coils used (3 to 15).

Water Heaters

1B+ II

SB-2006-02: ECS Retrofit Instructions

AC-105: Electronic Controls System (ECS) Manual

AC-103: Pneumatic Temperature Controller Manual

Page 2

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Technical Support:

1-800-526-0288

www.aerco.com

OMM-0063_0C Installation, Operation & Maintenance Manual

(Mon–Fri, 8am-5pm EST)

Disclaimer

The information containe d in this manual is subject to c hange without notice from AERCO Inter national,

Inc. AERCO makes no warranty of any kind with respect to this material, including but not limited to

implied warranties of merchantability and fitness f or a particular application. AE RCO International is not

liable for errors appearing in this manual. Nor for incidental or consequential damages occurring in

connection with the furnishing, performance, or use of this material.

Page 2 of 50 MC2: 07/26/13

Page 3

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

TABLE OF CONTEN TS

CHAPTER 1. SAFETY PRECAUTIONS ...................................................................................................... 5

CHAPTER 2. GENERAL INFORMATION.................................................................................................... 6

2.1. MODEL NAMES .......................................................................................................................... 6

2.2. HEAT EXCHANGER CONFIGURATIONS .................................................................................. 6

2.3. ACCESSORIES ........................................................................................................................... 6

2.4. ALL OTHER ITEMS ..................................................................................................................... 7

CHAPTER 3. INSTALLATION ................................................................................................................... 12

3.1. INSTALLING THE WATER WIZARD ......................................................................................... 12

CHAPTER 4. PRINCIPLE OF OPERATION .............................................................................................. 17

4.1. HEAT EXCHANGER OPERATION WITH PNEUMATIC CONTROL ......................................... 17

4.2. HEAT EXCHANGER OPERATION WITH ELECTRONIC CONTROL SYSTEM (ECS) ............ 18

CHAPTER 5. OPERATING PROCEDURES .............................................................................................. 19

CHAPTER 6. ROUTINE MAINTENANCE .................................................................................................. 22

6.1. DRAINING THE HEATER .......................................................................................................... 22

6.2. CHECKING THE DRAINED WATER ......................................................................................... 22

6.3. CHECKING THE TEMPERATURE CONTROL ......................................................................... 22

CHAPTER 7. TROUBLESHOOTING ......................................................................................................... 23

CHAPTER 8. CORRECITVE MAINTENANCE .......................................................................................... 24

CHAPTER 9. DE-SCALING BY THERMAL SHOCK METHOD ................................................................ 26

CHAPTER 10. MAINTENANCE DISASSEMBLY ...................................................................................... 27

10.1. TOOLS AND EQUIPMENT ........................................................................................................ 27

1.1.1. Common Tools and Equipment ............................................................................................. 27

1.1.2. Special Tools and Equipment Required: ............................................................................... 27

10.2. ISOLATING THE HEATER ........................................................................................................ 29

10.3. DISCONNECTING THE HEATER FROM THE FACILITY ......................................................... 30

10.4. ANTICIPATOR CHECK VALVE DISASSEMBLY ...................................................................... 31

11.5.1. Special Tools Required ..................................................................................................... 31

10.5. PREPARING TO REMOVE THE HEATER SHELL.................................................................... 32

10.6. REMOVING THE HEATER SHELL ........................................................................................... 33

10.7. REMOVING COILS AND RISERS ............................................................................................. 33

CHAPTER 11. CLEANING AND INSPECTION ......................................................................................... 34

11.1. PREPARATION OF BOTTOM HEAD ........................................................................................ 34

11.2. PREPARATION OF RISER AND RETURN ............................................................................... 34

11.3. PREPARATION OF COIL ASSEMBLIES .................................................................................. 35

11.4. PREPARATION OF COIL GASKETS ........................................................................................ 37

CHAPTER 12. MAINTENANCE REASSEMBLY ....................................................................................... 38

MC2: 07/26/13 Page 3 of 50

Page 4

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

12.1. REASSEMBLY OF RISERS, SUB-COOLING COIL, AND STEAM COILS ............................... 38

12.2. SUB-COOLING COIL INSTALLATION ...................................................................................... 40

12.3. STEAM COIL INSTALLATION ................................................................................................... 40

12.4. HYDROSTATICALLY TESTING COILS & RISERS ............................................................................... 42

12.5. ANTICIPATOR CHECK VALVE REASSEMBLY .................................................................................... 42

12.6. REASSEMBLY OF SHELL ................................................................................................................ 43

12.7. REINSTALLING HEATER I N FACILITY ............................................................................................... 43

12.8. STARTUP PROCEDURE ................................................................................................................. 43

CHAPTER 13. RECOMMENDED SPARE PARTS .................................................................................... 44

Page 4 of 50 MC2: 07/26/13

Page 5

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

! ! !

!

Installation, Operation & Maintenance Manual OMM-0063_0C

CHAPTER 1. SAFETY PRECAUTIONS

Installing or operat ing pers onnel m ust, at al l times , observe all safet y regulat ions. T he followin g warni ngs

are general and must be given the same attention as specific precautions included in the instructions.

WARNING

FLUIDS UNDER PRESSURE MAY CAUSE INJURY TO PERSONNEL OR

DAMAGE TO EQUIPMENT WHEN RELEASED.

SHUT OFF ALL INCOMING AND OUTGOING STEAM AND HOT WATER STOP VALVES AND

CAREFULLY DECREASE ALL TRAPPED TRESSURES TO ZERO (see SHUTDOWN IN

OPERATERING PROCEDURES) BEFORE PERFORMING ANY MAINTENANCE.

WARNING

LIVE STEAM CAN CAUSE SEVERE BURNS.

NEVER SEARCH FOR LEAKAGE IN A LIVE STEAM LINE BY SIGHT ALONE OR BY “FEEL.” USE A

MIRROR OR OTHER SUITIBLE POLISHED OBJECT. ALSO, ALWAYS WEAR GLOVES AND LONG

SLEEVES.

MC2: 07/26/13 Page 5 of 50

Page 6

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

This instruction covers the AERCO Helitherm Model B+ WATER WIZARD Steam to Water

Heat Exchangers. STEAM is the PRIMARY or TUBE SIDE FLUID. The WATER BEING

HEATED is the Heat Exchanger (service or domestic water or other fluid) is the SECONDARY

or SHELL SIDE FLUID.

2.1. MODEL NAMES

The number of coils in a particular Heat Exchanger is denoted by the two digits following the

“B+” in the Heat Exchanger Model Number. That is: B+03 = 3 coils, B=07 = 7 coils, B+11 = 11

coils, and B+15 = 15 coils.

The Style designation for a Heat Exchanger denotes materials of construction for the various

components of the assembly. If this information is required for a specific Heat Exchanger,

contact the nearest AERCO Sales Representative.

2.2. HEAT EXCHANGER CONFIGURATIONS

There are three basic heat exchanger configurations; those with a pneumatically controlled

valve (CXT-P), those with Electronic Control System (ECS) with an electronically controlled

valve (CXT-E), and a “bare” heat exchanger without controls or valve. See separate ECS

Controls manual, AC-105, for information about the Electronic controls System and

electronically operated CXT-E valve. See Section 3 for available accessories.

2.3. ACCESSORIES

CHAPTER 2. GENERAL INFORMATION

Accessories included in the AERCO B+ Heater Package Assembly (See Figures 1a, 1b, 1c,

21, 22, and 23) include:

• Steam Flow Control Valve – either Air-Operated or Self-Contained as ordered and

furnished, sized as required for the service.

• Temperature Controller – installed in the Control Box when an Air Operat ed Control Valve is

furnished (See Fig. 20, Item 134).

• Over-Temperature Limit System, including the following:

• Temperature Switch – installed in the Control Box (Figure 20, Item 126).

• Solenoid Valves:

o Water – installed in the Heater Top Head.

o Air – installed in the Control Box when an Air Operated Control Valve is furnished

(Fig. 20, Item 135).

o Steam – installed on the Self-Contained Control Valve when such valve is furnished.

o Indicator Lights: “Power On” and “Tripped” – installed in the Control Box (Figure 20,

Items 129 and 130).

• Steam Compound Pressure Gage – mounted below the Control Box (Figure 20, Item 133).

• Shell Hot Water Outlet Temperature Gage – mounted below the Control Box (Figure 20,

Item 1 32).

• Pressure & Temperature Relief Valves – size and number furnished as required in

accordance with the design BTU output of the heater – first two located in the heater Top

Page 6 of 50 MC2: 07/26/13

Page 7

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

Head as shown in Figure 1a, 1b, 1c, and 1d. The third, if furnished, to be installed in the hot

water outlet piping by the user as shown in Figure 2.

• Union Orifice – located in the Condensate Outlet (Figure 12, Item 55) – required in place of

a steam trap to ensure complete condensation of the steam within the heater.

• Check Valve – located in the Condensate Outlet (Figure 12, Item 53).

2.4. ALL OTHER ITEMS

Stop valves, check valves, strainers, unions or flanges, and other piping and f ittings as s hown in

Figures 3 through 6 – are to be furnished by USER.

NOTE:

This instruction covers only the heat exchanger portion of the model B+

packaged heater assembly. Separate instructions are included in this package

covering steam control valve, the over-temperature limit system and its

components, and other accessories included in the heater package.

NOTE:

The AERCO Helitherm heat exchanger carries the standard AERCO warranty

against defective material and workmanship. However, AERCO cannot honor its

warranty if the installer or user deviates in any way from the instructions and

precautions included herein and/or make any alteration of the equipment from

that furnished without the written approval of AERCO.

MC2: 07/26/13 Page 7 of 50

Page 8

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

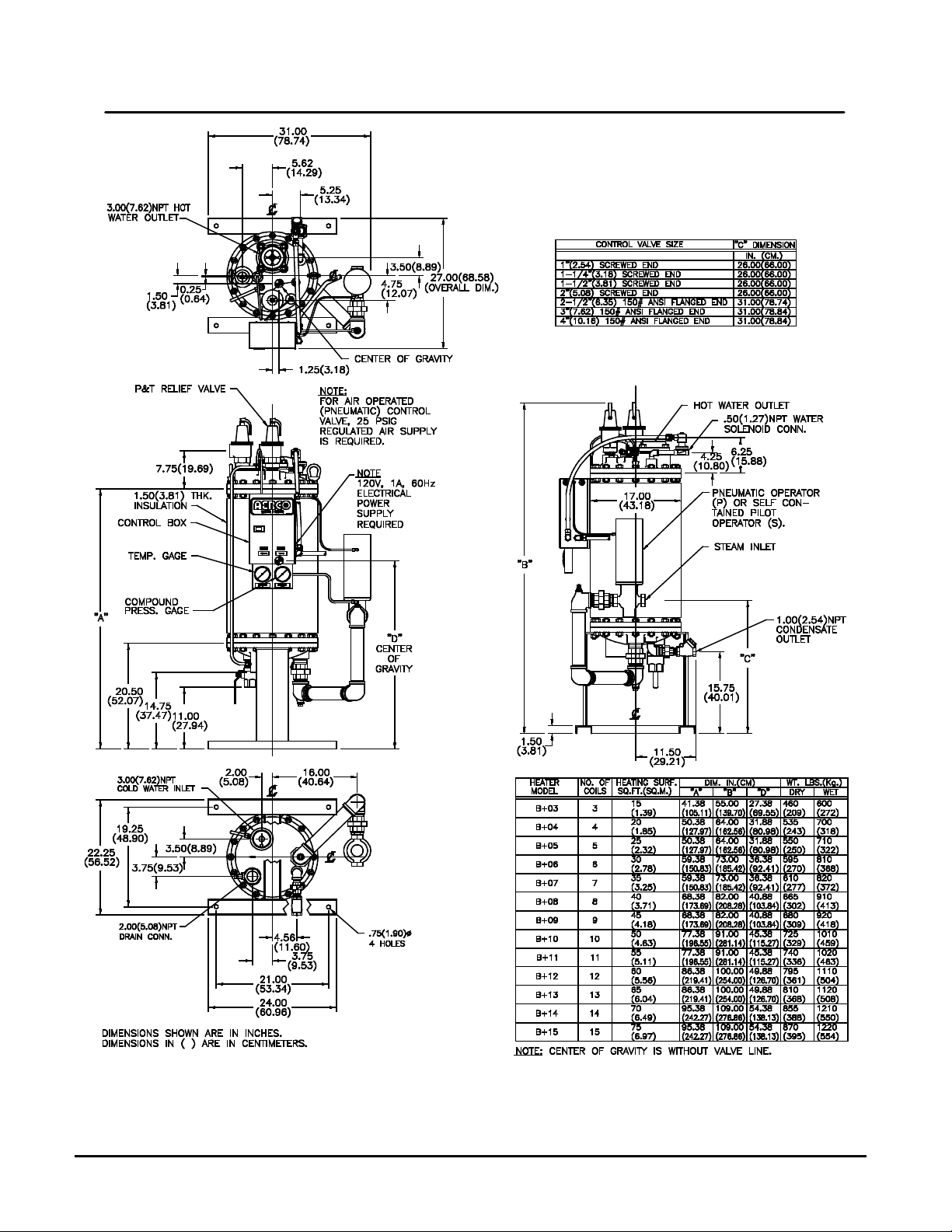

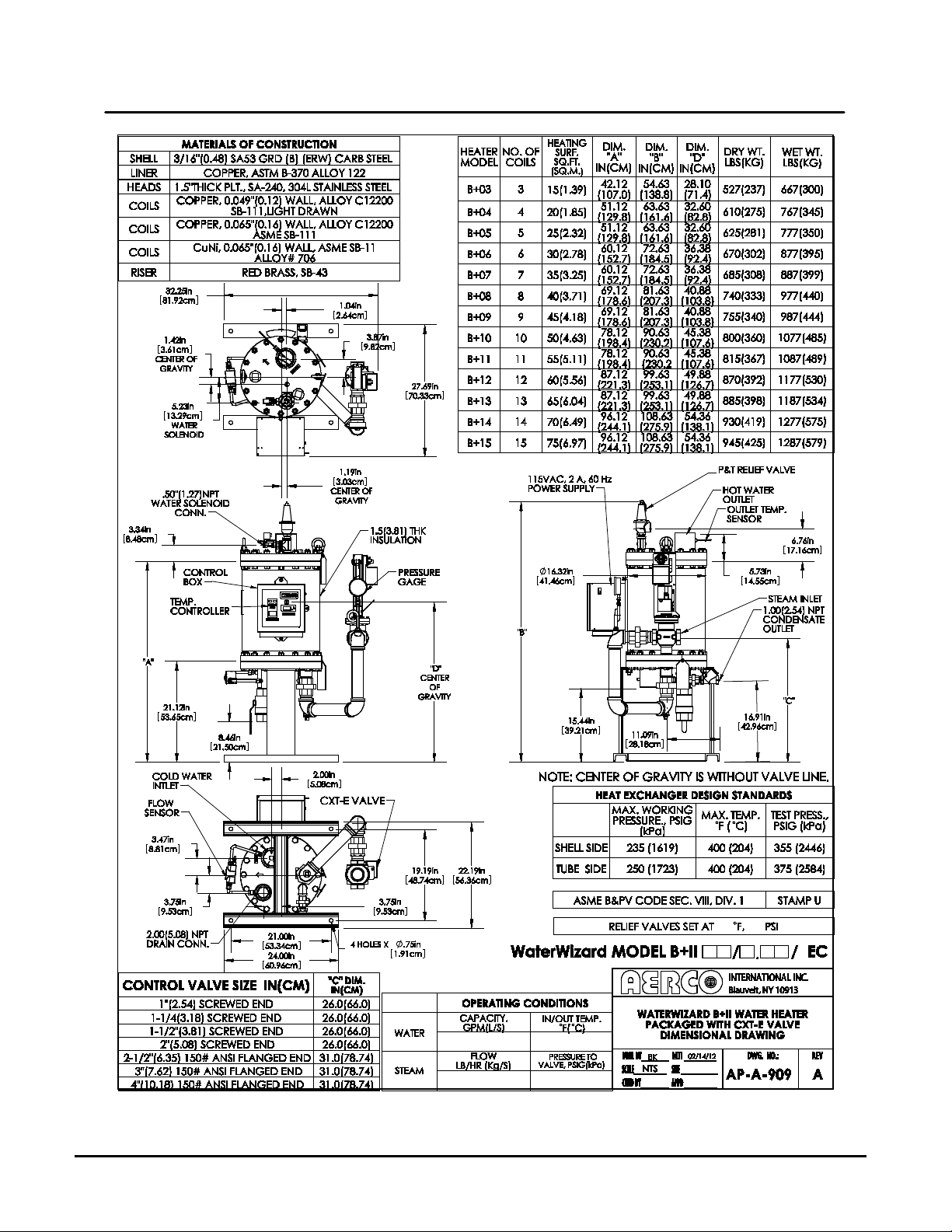

Chapter 2

OMM-0063_0C Installation, Operation & Maintenance Manual

General Information

Figure 1a – Dimensions for AERCO Helitherm Heat Exchanger (Packaged Water Heater),

Model Water Wizard SW1B+II with Pneumatic CXT-P Valve

Page 8 of 50 MC2: 07/26/13

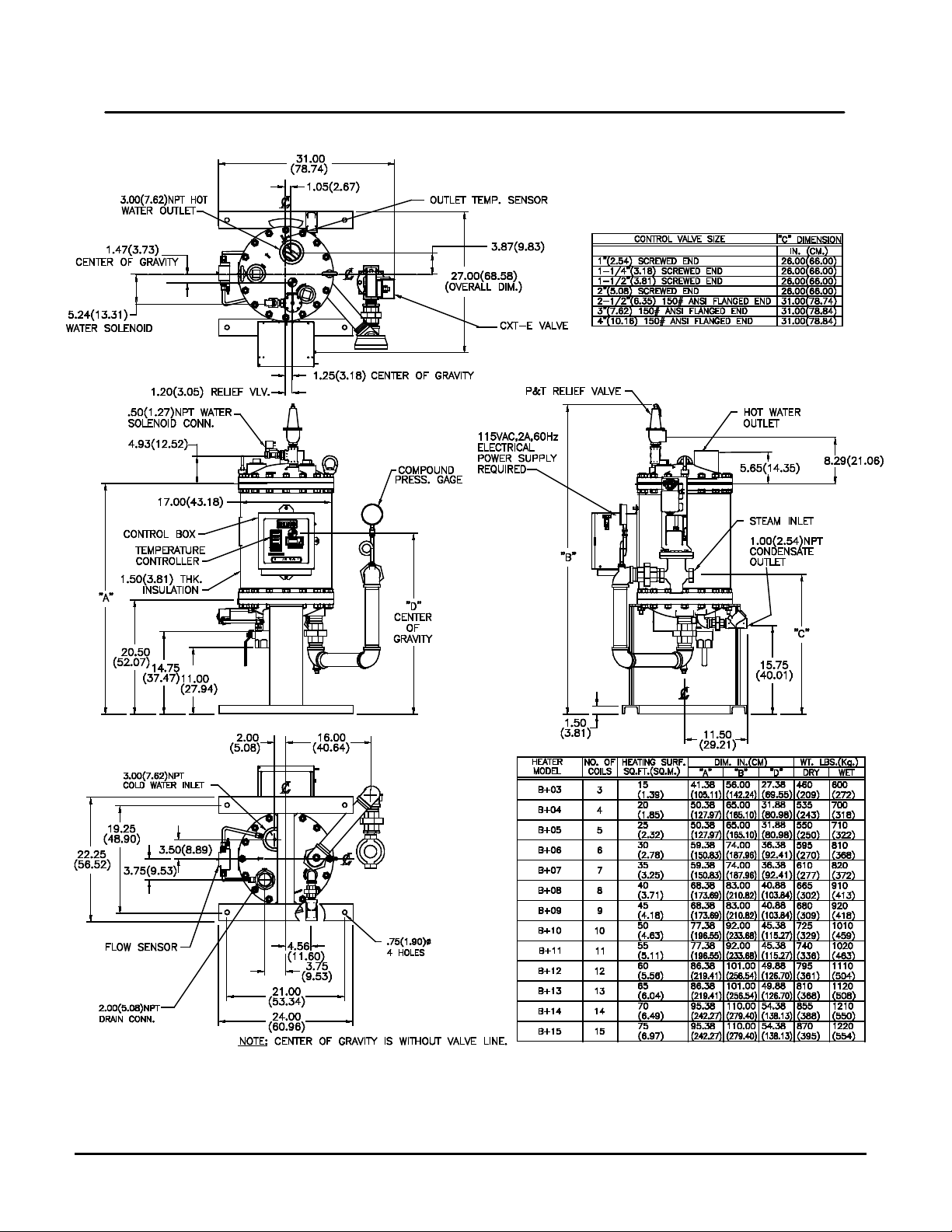

Page 9

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

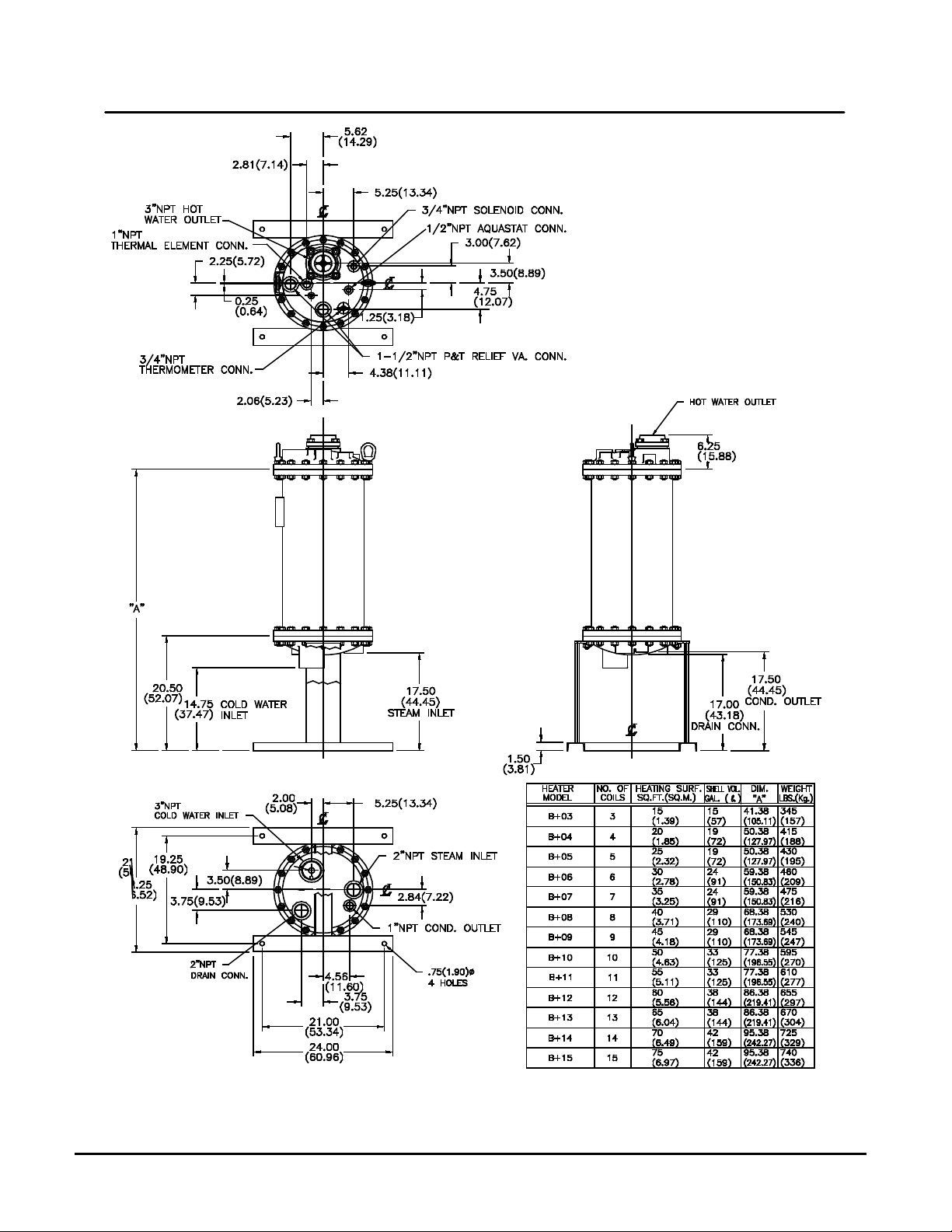

Figure 1b – Dimensions for AERCO Helitherm Heat Exchanger (Packaged Water Heater),

Model Water Wizard SW1B+II with Bronze Heads, ECS, and CTX-E Valve

MC2: 07/26/13 Page 9 of 50

Page 10

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

Figure 1c – Dimensions for AERCO Helitherm Heat Exchanger (Packaged Water Heater),

Model Water Wizard SW1B+II with Stainless Steel Heads, ECS, and CTX-E Valve

Page 10 of 50 MC2: 07/26/13

Page 11

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Chapter 3

Installation, Operation & Maintenance Manual OMM-0063_0C

Installation

Figure 1d – Dimensions for AERCO Bare Helitherm Replacement Heat Exchanger for

Model Water Wizard SW1B+II

MC2: 07/26/13 Page 11 of 50

Page 12

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

CHAPTER 3. INSTALLATION

3.1. INSTALLING THE WATER WIZARD

To install the Water Wizard SW1B+II water Heater, follow the steps below:

Installing the Water Wizar d H eat er Instructions

1) Dimensions for three versions of AERCO Model SW1B+II are shown in Figures 1a, 1b, and

1c.

2) Uncrate the Heater carefully. Set the Heater upright by using a block and tackle or hoist

attached to the lifting lug on the top of the Heater (the eye-bolt s s hown in Fig ur e 15). Always

use the lifting lugs to lift and/or move the Heater.

3) If possible, for easy in-place maintenance, locate the Heater where there is at least 2 feet

clearance all around the Heater and where the head room clearance from the top of

dimension B in Figure 1 is at least equal to dimension A for the Heater Model, less 24

inches.

4) It is suggested that the Heater stand assembly be secured to the floor, however, any other

means for securing the Heater may be used. If piping is used to secure the Heater, the

piping must include ample provision for expansion.

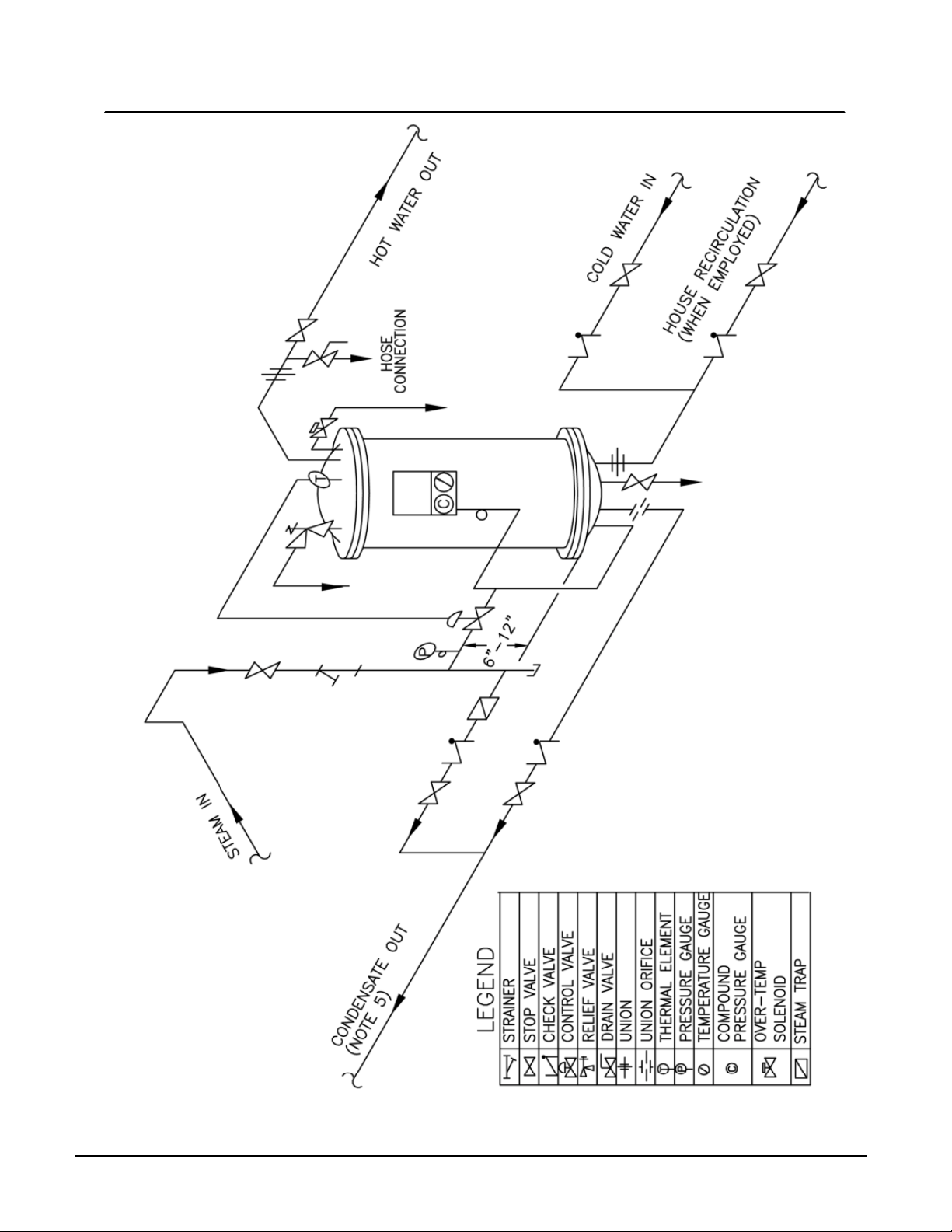

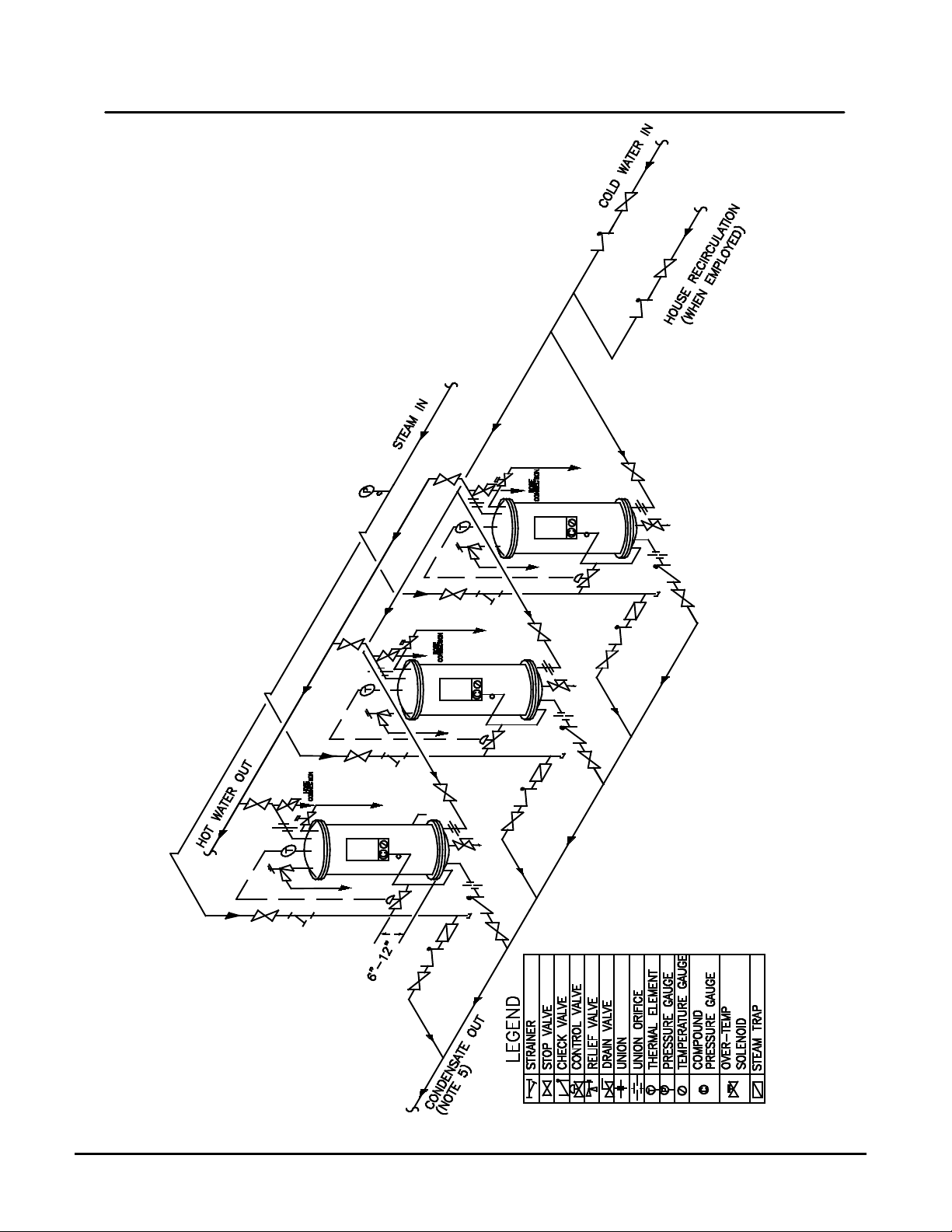

5) Make all piping connections as instructed in Step 6 below and per the appropriate Figures

shown:

a) Single Heater – Figure 3

b) Parallel Heaters – Figure 4

c) Single Heater used with an Accumulator – Figure 5

d) Single Heater used with a Stratified Storage Tank – Figure 6

or with any specific piping diagram which may have been furnished by AERCO for this

installation.

6) For the best Heater performance, OBSERVE THE FOLLOWING VERY CAREFULLY in

making the piping installation:

a) Do not use cement or red lead in making up pipe joints

b) For Heater connection types, sizes, and exact locations, see Figure 1.

c) All piping to the Heater top head should be provide with unions or flanges which are

LOCATED BEYOND THE OUTSIDE DIAMETER OF THE HEATER HEAD to permit

removal of the head and shell for in-place maintenance.

d) Include all of the stop valves, check valves, steam traps, and other elements in the

piping as shown in Figure 3, 4, 5, or 6, or as separately specified by AERCO. Note

that the check valve shown at the Heater in the Condensate return line is furnished in

the piping package assembly by AERCO.

e) The Condensate return piping MUST be arranged to permit Condensate to drain

freely by gravity from the Heater Bottom Head. Failure to do so may result in

improper Heater operation and/or in damage to the Heater Steam/Condensate

system.

(Continued)

Page 12 of 50 MC2: 07/26/13

Page 13

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

Installing the Water Wizar d H eat er I nst ructions (Cont.)

f) All drain discharges – relief valve(s) in the Top Head of the Heater, outlet of the

Water Solenoid Valve in the top head of the Heater, and Drain Valve in the Bottom

Head of the Heater – should be piped directly to a convenient floor drain.

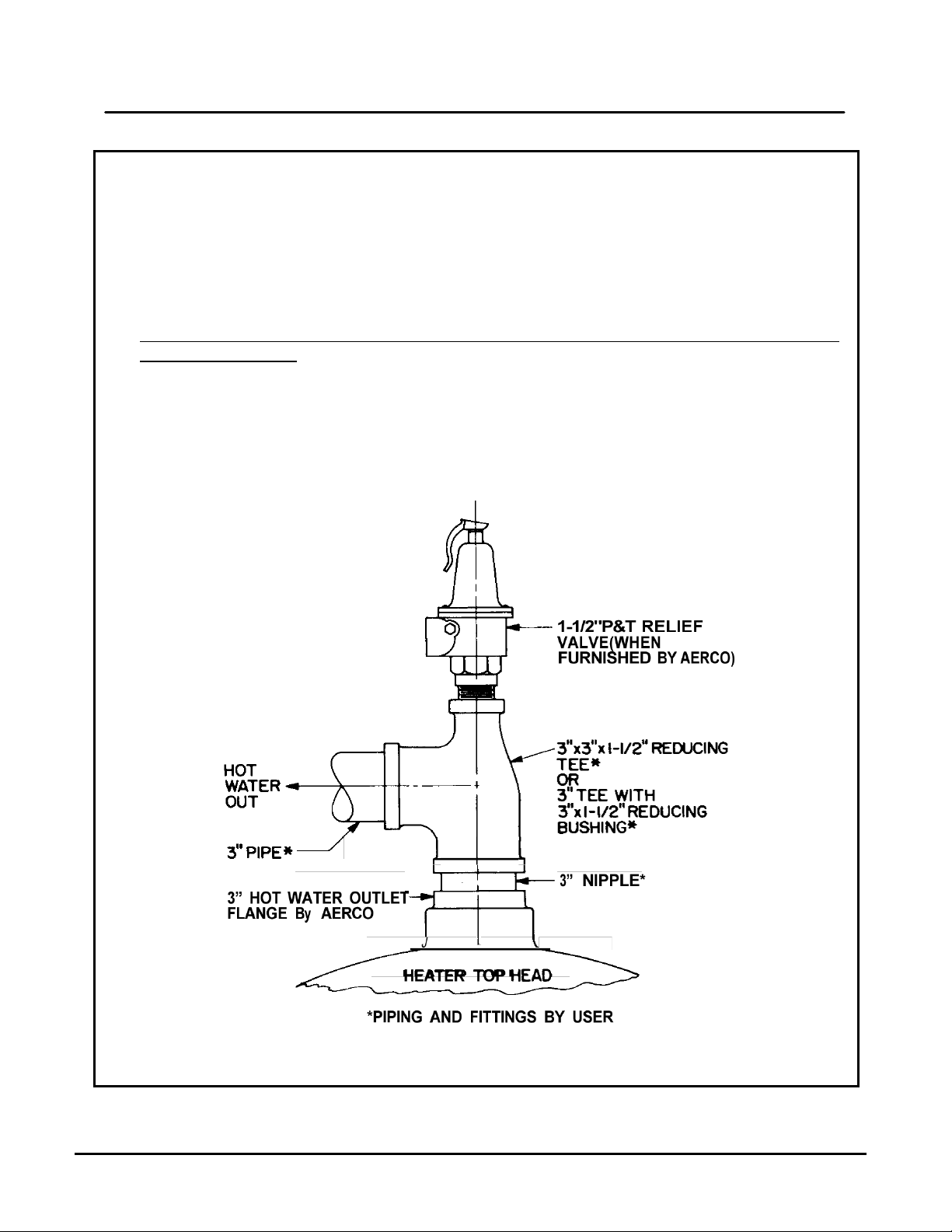

7) When a third P&T Relief Valve is furnished with the Heater (the first two furnished have

been assembled in the top head of the Heater by AERCO), the t hird Valve is to be installed

in the Heater hot water outlet piping, by the user, as illustrated in Figure 2.

8) Before making final piping connections to and from the Heater and Cont rol Valve, blow out

all piping thoroughly.

9) If an air-operated Control Valve is furnished in the Heater package, make the necessary

supply air connection to the connector through the side of the Control Box (see Figure 20,

Item 136). The supply air pressure must be maintained at 20 PSIG.

10) Connect 110 volt 60 Hz power supply wiring through the side of the Control Box to the

electrical Junction Box (see Figure 20, Item 127).

Figure 2 – P&T Relief Valve Located in the Heater Hot Water Outlet Piping

MC2: 07/26/13 Page 13 of 50

Page 14

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

Figure 3 – Piping Connections for a Single Heater

Page 14 of 50 MC2: 07/26/13

Page 15

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

MC2: 07/26/13 Page 15 of 50

Page 16

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Chapter 4

OMM-0063_0C Installation, Operation & Maintenance Manual

Figure 4 – Piping Connections for Parallel Heaters

Figure 5 – Piping Connections for a Single Heater used with an Accumulator

Principal of Operation

Figure 6 – Piping Connections for a Single Heater used with a Stratified Storage Tank

Page 16 of 50 MC2: 07/26/13

Page 17

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0B Installation, Operation & Maintenance Manual

CHAPTER 4. PRINCIPLE OF OPERATION

The AERCO Helitherm Heat Exchanger (Heater) consists of three parts (see Figure 7);

1. Shell with Top and Bottom Heads

2. Coils assembled to Steam Riser and Condensate Return

3. Integral Demand Anticipator Temperature Control Unit

Cold Water (or other liquid) enters the heater through the inlet connection and Orifice in the

Bottom Head and strikes the Deflector. The Orifice serves to divert some Cold Water into the

Shut Tube, whereas the Deflector disperses the incoming Cold Water evenly into the bottom of

the Shell. The Cold Water in the Shell, then, flow upward among the Coils (heating surfaces)

and, heated, is discharged through the Check Valve and Hot Water Outlet Connection in the

Top Head.

Steam enters through the Control Valve and the Steam inlet connection in t he Heater Bottom

and is fed through the Steam Riser to the inlet of each Heat Exchanger Coil unit as shown in

Figure 7. The Steam flows through these Coils units simultaneously in parallel and enters the

Condensate Return as Condensate. The Condensate is fed through the Sub-Cooling Coil unit

and leaves the Heater through the Condensate outlet connection in the Bottom Head of the

Heater. The Sub-Cooling Coil unit is included in the assembly to provide the maximum possible

condensing of the Steam, thus providing the greatest amount of heat transfer, the lowest

Condensate outlet temperature, and the greatest reduction in energy loss from flash steam.

As noted above, the Cold Water being heated flows through the Heater from bottom to top. In

addition, Heater Water, being of less density than Cold Water, migrates to the top of the Shell

by convection. These actions result in the hottest Water always being at the top of the Heater –

at the Heater outlet and at the How Water inlet to the Anticipator Temperature Sensing Tube –

See Figure 7.

Hot Water from the top of the Heater Shell enters the open end of the Sensing Tube and Cold

Water enters the Sensing Tube from the Shunt Tube at a r ate proportional to the load (call for

Hot Water) on the Heater. The mixture of Hot and Cold W ater in the Sensing Tube creates an

average temperature which necessarily will be cooler than t he temperature of the Hot Water in

the top of the Heater Shell.

4.1. HEAT EXCHANGER OPERATION WITH PNEUMATIC CONTROL

The Temperature Sensing Element “reads” the average temperature of the Water in the

Sensing Tube at any given moment and signals the Water in the Sensing Tube at any given

moment and signals the Steam Control Valve to modulate between full open or closed as

necessary to maintain the req uired Heater Hot Water outlet temperature. With no demand or

load on the Heater, the Temperature Sensing Element reads only the temperature of the W ater

in the top of the Heater and at the Heater outlet. If that Water is at the required outlet

temperature or above, the Sensing Element signals the Steam Control Valve to close.

However, the moment that there is a demand for Hot Water, Cold Water flows from the Shunt

Tube to mix with the Hot Water I the Sensing Tube, cooling the Sensing Element so that is

signals the Steam Control Valve to open. The need for Steam (heat) to the Coils is satisfied at

once, the incoming Cold Water passing over the Coils is heated, and the Hot Water outlet

temperature does not fall below that required.

The Demand Anticipator Temperature Control Unit, as its name implies, is constantly alert to

lead conditions and changes, as well as to changes in the temperature of the incoming Cold

Page 18

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

Water, and provides FEED-FORWARD temperature control at all times.

Figure 7 – Schematic of AERCO Model B+II Water Heater showing Anticipator

Temperature Control

4.2. HEAT EXCHANGER OPERATION WITH ELECTRO NIC CONTROL SYSTEM

(ECS)

The Electronic Control System (ECS) available for the Water Wizard SW1B+II offers

features and functions not described in this manual. Refer to the separate manual, AC105, for detailed descriptions of the function and operation of the ECS and electr onically

operated valve, type CXT-E.

Page 18 of 50 MC2: 07/26/13

Page 19

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

CHAPTER 5. OPERATING PROCEDURES

Water Wizard Operating Procedure Instructions

1) W ith the installation entirely completed, including:

1) All piping connections have been made,

2) All connecting piping has been cleaned (blown) out,

3) All connections per Steps 8 and 9 under INSTALLATION have been made,

Open the stop valve in the Cold Water inlet line and hold the relief valve (or any one of the

relief valves) in the Heater top head open to allow air to come out (otherwise an air pocket

will be built up and the Heater will not fill). When water flows out of the relief valve, the

Heater is full.

2) Temporarily set the Over-Temperature Limit System Temperature Switch in the Control Box

(Figure 20, Item 126) to its high temperature limit.

3) If the Steam Control Valve furnished is air operated and there is a Temperature Controller in

the Control Box (see Figure 8), set the Controller at t he temperature desired to be held at

the Heater Hot Water outlet.

4) Open the stop valve in the Hot Water outlet line. Open a Hot Water faucet or faucets in the

building or process to insure a flow of water thr ough t he heater. For best results in adjusting

the temperature control, a water flow of 10% to 25% of heater rating is desirable. Slowly

open all stop valves in the Steam inlet and condensate outlet lines.

5) Slowly open all stop valves in the Steam inlet and Condensate outlet lines.

6) Follow the instructions furnished with the air -operated Temperature Controller and Control

Valve or with self-contained Temperature Regulator Valve, and:

a) Introduce Steam to the Heater.

b) Adjust the air-operated Temperature Controller OR self-contained Temperature

Regulator Valve until the Heater hot water outlet temperature is being held steady at

the desired temperature. If the hot water outlet temperature is erratic, see Step 7

below.

c) Close the hot water faucet or faucets opened in Step 4.

7) Open any stop valves in the building recirculation system if such is included in the Heater

installation.

8) If the hot water outlet temperature is erratic especially during load changes:

a) Put a load on the Heater, by opening a hot water faucet or faucets in the building or

process, as quickly as possible.

b) Adjust the Temperature Controller of Temperature Regulator to provide best

response on load changes. See the instruction furnished with the Controller or

Regulator.

9) Adjust the Over-Temperature Limit System Temperature Switch in the Control Box to its

proper setting in accordance with the instructions furnished which cover the OverTemperature Limit System – usually 15°F to 20°F higher than the desired hot water outlet

temperature.

(Continued)

MC2: 07/26/13 Page 19 of 50

Page 20

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

Water Wizard Operating Procedure Instructions (Cont.)

10) The Heater installation is now set for operation. No further operation procedure is

necessary unless or until further temperature control adjustments may be required. If so,

repeat Steps 4, 5, 6, 7, and, if necessary, Step 8.

11) To SHUT DOWN the System:

a) Close all stop valves in the Steam inlet and Condensate outlet lines.

b) In this order, close the stop valves in

i. the hot water outlet line,

ii. the recirculation line, if any, and

iii. t he c old water inlet line (see Step 11c, which follows).

c) If the system includes an accumulator or stratified storage tank, DO NOT SHUT O FF

THE COLD WATER UNTIL T HE HEATER HAS COOLED DOWN. If the system is

allowed to cool while the cold water is shut off, the Heater liner may collapse

because of formation a vacuum in the Heater.

12) For DRAINING THE HEATER, see the instruction included under ROUTINE

MAINTENANCE, Chapter 6, Section 6.1.

13) To START UP again, with the shell filled per Step 1 above, open the stop valves in the

following order:

1) stop valve in the Cold Water inlet line,

2) any stop valve in the recirculation line, if any,

3) stop valve in the Hot Water outlet line, and

4) stop valves in the Steam inlet line and Condensate outlet lines.

14) After each startup, check the temperature control. If necessary, make adjustments per

Steps 4 through 9.

Page 20 of 50 MC2: 07/26/13

Page 21

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

Figure 8 – Model B+II Heater Control Box

Figure 9 – Over-Temperature Limit System Wiring Diagram

MC2: 07/26/13 Page 21 of 50

Page 22

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

CHAPTER 6. ROUTINE MAINTENANCE

6.1. DRAINING THE HEATER

The constant flexure of the Heater coils under varying load conditions automatically provides a

de-scaling action and prevents a buildup of brittle scale. A periodic blowdown (draining) is

required to remove accumulated solids.

After the first 3 months of initial operation, drain the Heater as follows:

(1) Close all stop valves in the Steam inlet and Condensate outlet lines.

(2) In this order, close the stop valves in

a) the hot water outlet line,

b) the recirculation line, if any, and

c) the cold water inlet line.

(3) Carefully open the relief valve (or one of the relief valves) in the Heater top head to relieve

pressure in the Heater shell. If water continues to flow fr om the relief valve one of the stop

valves either leaks or is not shut off t ight. This must be rem edied until there is no mor e f low

through the relief valve.

(4) With the relief valve being held open, (to prevent creating a vacuum in the shell) open the

drain valve and drain the Heater completely.

(5) To refill the Heater and place it back into operation, close the drain valve and proceed

through Steps 1, 12, and 13 under OPERATING PROCEDURES, Chapter 5.

6.2. CHECKING THE DRAINED W ATER

The constant flexure of the Heater coils under varying load conditions automatically provides a

de-scaling action and prevents a buildup of brittle scale. A periodic blowdown (draining) is

required to remove accumulated solids.

After the first 3 months of initial operation, drain the Heater as outlined below. Examine the

water being drained.

(a) If the amount of solids appears to be heavy, set a schedule to drain the Heater every 3

months.

(b) If the amount of solids appears to be light, set a schedule to drain the Heater every 6

months.

(c) Even if the amount of solids appears to be very light, set a schedule to drain the Heater

at least once each year.

(d) Also see TROUBLESHOOTING, Chapter 7 and CORRECTIVE MAINTENANCE,

Chapter 8. If de-scaling by thermal shock is required, schedule that procedure in your

ROUTINE MAINTENANCE, Chapter 9.

6.3. CHECKING THE TEMPERATURE CONTROL

Check the t emperature control at least once every 3 months. Make any necessary adjustments

per Steps 4 through 8 under OPERATING PROCEDURES, Chapter 5.

Page 22 of 50 MC2: 07/26/13

Page 23

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

PROBABLE CAUSE & REMEDY

Installation, Operation & Maintenance Manual OMM-0063_0C

CHAPTER 7. TROUBLESHOOTING

SYMPTOM

Heater does not maintain required temperature at rated

capacity.

Heater overheats.

Hot Water outlet temperature fluctuates widely.

Insufficient Water through or from Heater.

Excess or insufficient Condensate being returned from

Heater.

Steam being discharged into Condensate drain,

Pressure/Temperature Relief Valve pops.

Heater shuts down below, at, or too near above required

Hot Water temperature.

Loud banging in heater or in Steam or Condensate piping

(not to be confused with normal clicking noise).

“CORRECTIVE MAINTENANCE” ITEM NO.

1, 2, 6, 12, 14, 17, 18, 19

1, 5, 6, 8, 11, 13, 14

2, 6, 11-14, 17, 19

3, 15

6, 7

18, 19

4-6, 8-11, 13, 14, 16

16

6, 7, 9, 10

MC2: 07/26/13 Page 23 of 50

Page 24

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

CHAPTER 8. CORRECITVE MAINTENANCE

Refer to table in TROUBLESHOOTING, Chapter 7 for a description of problematic symptoms.

The following are probable causes and remedies for improper function of the Heater.

1. The temperature gage or steam pressure gage, or the Steam supply pressure gage

ahead of the Control Valve, may be wrong. Check each with a gage which is known to

be correct.

2. Steam pressure is too low. Check the steam supply pressure gage ahead of the

Control Valve. If the reading is low, adjust the steam supply pressure to that which is

required. If there is a restriction in the steam supply line, the gage reading will drop

excessively when the Heater calls for full steam even though the pressure appears to be

normal when the load is light. If the steam supply pressure is correct, the steam gage

(below the Control Box) reading should reach design pressure for steam in the coils as the

Heater temperature drops. If it does not, check the operation of the Control Valve.

3. Cold Water pressure is low. Check and correct, if necessary, the Water pressure to the

Heater.

4. Static pressure of the Cold Water is too high. Make the necessary corrections to bring

the Water pressure below that for which the Relief Valve(s) is set.

5. Water to be heated is preheated too hot. Reduce the preheating to a temperature at least

10°F under the desired Heater hot water outlet temperature.

6. Condensate return piping has not been installed so that the Condensate drains freely

by gravity and/or the Condensate check valve leaks or has failed. If necessary,

rearrange the Condensate return piping per Step 6e under INSTALLATIION, Chapter 3.

Inspect the check valve and replace it if it is leaking or has failed. Also, check to make sure

there is no restriction in the Condensate drain line.

7. Steam supply line is not properly trapped. Install trap as indicated in Figure 2, 3, 4, or 5.

8. Leaking stop valve in bypass line, if any, around the Steam Control Valve. Maintain

the stop valve to shut tight.

9. Lack of expansion tank in the hot water system. Install an expansion tank in the outlet

hot water line close to the heater.

10. I nsufficient shock absorbers. Insert shock absorbers (water hammer arresters) in both

the cold and hot water systems as needed to eliminate shock waves.

11. The Steam Control Valve does not close. Check the instructions covering the Valve.

12. The Steam Control Valve does not open. Check the instructions covering the Valve.

13. The temperature control thermal element (connected to the air-operated

Temperature Controller or the self-contained Control Valve and located in the Heater

top head) has failed. Refer to the instructions covering the Temperature Controller or

Control Valve.

14. The Anticipator Unit system is not operating properly. Check to make sure that the

temperature sensing element has not failed (see Item 13, above), that the shunt tube ( item

Page 24 of 50 MC2: 07/26/13

Page 25

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

87 in Figures 17 and 18) has not become clogged, and that the check valve at the hot

eater outlet is working properly (see Item 15, below). Make any necessary corrections.

15. The Anticipator Check Valves at the Heater hot water outlet is not worki ng properly.

Disassemble and inspect the Check Valve, clean the Valve, and repair or replace any parts

as necessary per Steps 1 through 5 under DISASSEMBLY, Chapter 10, Section 10.4.1.

16. The Over-Temperat ure Limit System is out of adjustment of some component of the

system has failed. Check out the systems setting per Step 8 under OPERATING

PROCEDURES, Chapter 5. Inspect and repair or replace each component as necessary.

17. There is a l eak i n t he Heater coil(s), steam riser, or condensate return, causing water

from the shell to leak into the heating coil system, or steam or condensate from the

coil system to the shell. To verify such a leak, shut off the steam supply and break a

connection in the Condensate Line – CAREFULLY to avoid being burned. Condensate will

drain from the coil system initially, but the flow should stop after a minute or two. If the flow

continues, water is leaking from the pressurized shell side to the tube side of the Heater.

Disassemble, inspect, repair (if possible), replace, and reassemble the Heater as outlined

below under DISASSEMBLY, Chapter 10, and REASSEMBLY, Chapter 12.

18. The Heater coils are scaled up. De-scale the Heater by thermal shock in the manner

outlined below under DESCALING BY THERMAL SHOCK METHOD, Chapter 9.

19. The Heater is being utilized at a rate higher than its design capacity. Contact the

nearest AERCO Representative for advice in remedying this problem.

MC2: 07/26/13 Page 25 of 50

Page 26

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

De-Scaling by Thermal Shock Instructions

consult the nearest AERCO Representative for advice.

OMM-0063_0C Installation, Operation & Maintenance Manual

CHAPTER 9. DE-SCALING BY THERM AL SHOCK ME THO D

Where, under certain conditions of continuous steady usage, the Cold Water is so hard or

alkaline that normal flexure of the Heater coils (see Routine Maintenance) and routine blow

down (draining the Heater shell) will not remove scale buildup on the coils, the heating surfaces

(coils) may be thermally shocked, without damage to any part of the Heater, to dislodge scale

solids.

1) Drain the Heater per steps 1 through 4, Chapter 6, ROUTINE MAINTENANCE, Chapter 6.

However, instead of holding the relief valve open in step 4, remove the relief valve, shown as

Item 73(A) in Figure 17 or 18 from the Heater top head.

2) Open the Heater drain valve. Leave the drain valve open until step 8 below.

3) Connect a source of cold water (for example, a hose from a cold water faucet) to the open

relief valve connection.

4) Open all shutoff valves in the Steam inlet line and the Condensate outlet line to allow Steam

to the Heater. After about 30 seconds, or until Steam is blowing out of the Condensate drain

line, close the stop valve in the Condensate outlet line. Leave the Steam inlet line open for

about two minutes longer, and then close all Steam inlet stop valves.

5) Inject a flow of cold wate r t hrough the relief valve connection for about two minutes. Then shut

off the cold water flow and open the Condensate line stop valve to drain off all Condensate.

6) Repeat steps 4 and 5 several times until the water coming from the Heater drain appears to

be relatively free of solids.

7) Remove the cold water source from the relief valve connection. Open the stop valve in the

main Cold Water inlet line and allow a complete flushing of the Heater shell.

8) After the Heater shell has been completely drained, close the Heater drain valve, and place

the Heater back into operation per steps 1, 12, and 13 under OPERATING PROCEDURES,

Chapter 5.

9) If Cold W ater conditions are so severe that thermal shocking does not remove scale deposits,

Page 26 of 50 MC2: 07/26/13

Page 27

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

CHAPTER 10. M AINTEN ANCE DI SASSEMBLY

10.1. TOOLS AND EQUIPMENT

The following common and special tools and equipment are required to perform the instructions

contained in this chapter:

10.1.1. Common Tools and Equipment

• Combination Wrenches: 7/16”, 5/8”, 13/16”, 1-1/16”, 1-1/8”

• Pipe Wrenches: 12” and 24”

• Chain Hoist

• Voltmeter:

• Brass Wire Brush

• Needle-Nose Pliers

• Gasket Removal Tool

• Carpenter’s Square

• Teflon Tape

• Orange Citric Cleaner

• Black Marker

10.1.2. SPECIAL TOOLS AND EQUIPMENT REQUIRED:

• Hydrostatic Pressure Pump: Range= Up to 235 psig

• Torque Wrench, 75 ft.-lbs. With 1-1/4” , 1-5/16” & 1-1/2” Open-End Spanners

(1-1/4” Open-End Spanner required for “A” Heater Only)

• Coil Retaining Tool (Figure 1)

• Coil Spacing Tool (Figure 1)

• Short-Length Wrenches: 1-1 /4” , 1-5/16”, 1-1/2”

(Overall wrench lengths should be approx. 6 inches or less)

MC2: 07/26/13 Page 27 of 50

Page 28

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

Figure 10: Tool Fabrication Details: Coil Spacing and Retaining Tools

Recommended Material: 1018 steel

Page 28 of 50 MC2: 07/26/13

Page 29

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Isolating the Heater Instructions

Installation, Operation & Maintenance Manual OMM-0063_0C

NOTE:

The procedures in the following paragraphs are arranged to isolate, disconnect

and disassemble the unit to the extent necessary to repair or replace defective

items. These procedures should be performed in the order specified to minimize

repair time.

10.2. ISOLATING THE HEATER

To isolate the Heater from all facility energy sources (steam, water, electrical, etc.), proceed as

follows:

1) Disconnect and Lock-Out/Tag-Out external AC power supplied to the Control Box and any

other devices connected to the Heater.

2) Using a voltmeter, check to ensure that all incoming voltage readings are zero Before

continuing.

3) If the Heat er is equipped with a Pneumatic Steam Valve, close the valve supplying air inlet

pressure to the Pneumatic Controller.

4) Close all stop valves in the Steam Inlet and Condensate Outlet lines

5) On the water-side, close the stop valves in the following order:

6) Carefully open the Relief Valve located on the T op Head to relieve pressure in the Heater

7) W hile holding the Relief Valve open to prevent creating a vacuum in the Shell, open the

• Hot water outlet line

• Recirculation line

• Cold water inlet line

Shell. Water should stop flowing from the valve within one minute. If water continues to

flow from the Relief Valve, one of the water stop valves is not securely closed.

Drain Valve in the Bottom Head on the Heater. Completely drain the potable water from the

Heater.

MC2: 07/26/13 Page 29 of 50

Page 30

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Disconnecting the Heater from the Facility Instructions

OMM-0063_0C Installation, Operation & Maintenance Manual

10.3. DISCONNECTING THE HEATER FROM THE FACILITY

To disconnect the Heater from the facility piping and wiring connections, proceed as follows:

1) First, check the ceiling height to determine if the Heater Shell and Top Head can be hoisted

up with the Heater remaining in position.

2) If there is sufficient ceiling clearance to permit safe elevation of the Shell assembly, skip to

step 8. If there is insufficient clearance, proceed to step 3 to remove the Heater from its

current location.

3) Using a 5/8” c ombination wrench, remove the Steam Pressure Line from the Steam Line and

Pressu re Gaug e.

4) Disconnect the Steam line from the Valve and Bottom Head.

5) Disconnect the water inlet from the Bottom Head.

6) Disconnect the drain line from the Bottom Head.

7) Disconnect the Condensate Drain piping from the Bottom Head.

8) Disconnect all electrical wires to the Control Box. Also, disconnect all wiring between the

Control Box and any external Solenoid Valve(s).

9) Using a 5/8” combination wrench, remove the Steam Pressure line from the Steam Line and

Pressure Gauge, if it was not performed in step 3.

10) Remove the water outlet piping from the Top Head.

11) Remove the pipe drain(s) from the Pressure Relief Valve(s).

12) Disconnect the pipe drain from the Water Solenoid Relief Valve.

13) Using a 13/16” combination wrench, disconnect the compression fittings on the Cold Water

Feed Tube from the Top Head and Bottom Head.

14) If controlled by a Pneumatic Valve, disconnect the incoming air supply to the Control Box and

Steam Valve.

15) If controlled by a Self-contained Valve, remove the thermal well from the Top Head that is

attached to the Valve.

Page 30 of 50 MC2: 07/26/13

Page 31

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Anticipator Check Valve Disassembly Instructions

Installation, Operation & Maintenance Manual OMM-0063_0C

10.4. ANTICIPATOR CHECK VALVE DISASSEMBLY

To disassemble the Anticipator Check Valve, proceed as follows:

10.4.1. Special Tools Required

• Torque wrench for 5/8” nuts.

• A block and tackle or ratchet hoist is recommended for lifting off the Heater top head and

shell, or for lifting and moving the Heater.

1) Shut down the Heater in accordance with Step 10 under OPERATING PROCEDURES.

2) Disconnect the union in the Hot water outlet piping (the one located beyond the outside

3) Separ at ely, lift the Spring Plate Assembly (33), the Gasket (32), the Spring (34), the Washer

4) Clean all parts and gasket surfaces thoroughly, and repair or replace any part necessary to

Manually (and carefully) open a relief valve to relieve any pressure in the Heater shell.

Figure 11 – Model B+II Heater Control Box

diameter of the Heater top head). Then remove the Nuts (51) and the Outlet Flange (31) and

outlet piping.

(35), and the Valve Plug (35).

make the Check Valve operate properly (open on water flow through the Heater).

MC2: 07/26/13 Page 31 of 50

Page 32

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Preparation for Heater Shell Removal Instructions

OMM-0063_0C Installation, Operation & Maintenance Manual

10.5. PREPARING TO REMOVE THE HEATER SHELL

Note that all part item numbers are given in parentheses ( ) in the instructions below refer to

those shown in Figures 14, 15, 16, 17, or 18.

Also, Note that it is not necessary to disassemble or remove the Check valve Assembly (see

above) in order to remove the Heater Shell.

1. Shut down and drain the Heater in accordance with Steps 1 through 4 in ROUTINE

MAINTENANCE, Chapter 6.

2. If a self-contained Control Valve is being used, remove the Valve’s Temperature Control

Thermal Element from the Thermal Well Bushing (62) in the Heater Top Head. Be careful not

to damage the Element or its capillary.

3. Disconnect ALL external piping from the Heater Top Head, including that to the Relief Valve(s)

(67) and the Water Solenoid Valve (73). Disconnect the Hot Water outlet piping at the union or

flange located beyond the outside diameter of the Heater Top Head.

4. Disconnect the power supply wiring to the Control Box and all wiring between the Control Box

and any outside Solenoid Valve(s).

5. Disconnect the Pressure Gage pressure line Compression Fitting (60).

6. Disconnect the Compression Fitting (59), located at the bottom of the Shunt Tubing (69) from

the Heater Bottom Head.

Figure 12: Part Reference for Heater Shell Removal

Page 32 of 50 MC2: 07/26/13

Page 33

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Heater Shell Removal Instructions

Removal of Coils and Risers Instructions

Installation, Operation & Maintenance Manual OMM-0063_0C

10.6. REMOVING THE HEATER SHELL

Remove the Heater Shell as follows:

1) Using a black marker, mark the edge of the Heater Bott om Head flange and Shell flange in ord er to

indicate their correc t relative positions upon reas semble. The Top Head can r emain attached to the

Shell.

2) Using the 1-1/16” c ombination wr ench, unbolt the sixteen stu ds and nuts around the bottom r ing of the

Shell. The two nuts loca ted in-line with the m ounting skid legs are to be removed with the s tud left in

place.

3) Attach a chain h oist to the two lifting lu gs on the Top Head. Lif t the Shell up to clear t he internal coil

bundle.

4) Using a light source, visually inspect the inside of the Heater Shell for evidence of damage to the

Copper Shell Liner. If any area of the Copper Liner is dam aged, replace t he Shell down on t he Bottom

Head and contact your local AERCO Representative to process return of the Heater to AERCO for

repair.

5) Move the heat exchanger bundle a few feet to the side so that the Shell can be lowered to t he floor.

Set the Shell on clean surface. Use care to avoid damaging the bottom edge of the Copper Shell Liner.

10.7. REMOVING COILS AND RISERS

The Coil Assemblies, Riser and Condensate Return are removed as follows:

1) Using the proper size open-end wrench, loosen the two Union Nuts securing the Coils to the

2) Using a pipe wrench, remove the Steam Riser and Condensate Return from the Bottom Head.

Steam Riser and Condensate Return.

MC2: 07/26/13 Page 33 of 50

Page 34

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Preparation of Bottom Head Instructions

Preparation of Riser and Return Instructions

Visually inspect all Steam Riser and Condensate Return Spuds, (Figure 2) threads and

!

!

OMM-0063_0C Installation, Operation & Maintenance Manual

CHAPTER 11. CLE ANING AND INSPECTION

Prior to reassembling Heater components, the Bottom Head, Steam Riser, Condensate Return

and Coils must be cleaned, inspected and prepared as described in the following paragraphs:

10.8. PREPARATION OF BOTTOM HEAD

The Bottom Head of the Heater must be cleaned, inspected and prepared for reassembly

as follows:

1) Clean off all debris from the topside of the Bottom Head.

2) Visually inspect the internal pipe threads where the Risers ar e connected. The overall depth

3) If the threads are less than the required depth, use the appropriate 1” or 2” NPT tap to clean

4) Using the g asket removal tool, remove the Shell Gasket from the Bottom Head. Use care t o

5) Apply pipe dope to the internal NPT threads in the Bottom Head.

of threads should measure, (1-1/8” for 2” NPT and 1” for 1” NPT)

out the threads.

avoid creating scratches or indents in the Bottom Head casting’s gasket surface area. Any

linear scratches can potentially create a leak.

10.9. PREPARATION OF RISER AND RETURN

The Riser and Return piping of the Heater must be cleaned, inspected and prepared for

reassembly as follows:

1)

2) Using a brass wire brus h, clean the threads of the Spuds. Use care to avoid scrat ching the

3) Using a brass wire brush, clean the pipe threads on the Riser. After cleaning, wipe with a

4) W rap two layers of Teflon tape around the Riser NPT threads.

sealing surfaces for damage, scratches, braze material and cleaning deposits. If defects are

found with the Spud threads or sealing surfaces, contact your AERCO Representative for

instruction to return the defective Riser.

sealing surfaces of the Spuds. Scratches can cause a leak pat h under the Coil Gasket. After

brush cleaning, wipe with a clean lint-free cloth.

clean lint-free cloth.

CAUTION

The use of Teflon tape or any lubricant on the threads of the spuds is

prohibited and may void the warranty.

Page 34 of 50 MC2: 07/26/13

Page 35

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

SPUD

THREADS

SEALING

SURFACE

STEAM RISER OR

CONDENSATE RETURN

SPUD

Preparation of Coil Assemblies Instructions

d evidence of damage.

Installation, Operation & Maintenance Manual OMM-0063_0C

Figure 13: Preparation of Riser/Return Spuds

10.10. PREP ARATION OF COIL ASSEMBLIES

The Coil Assem b lies of the Heater must be cleaned, inspected and prepared for

reassembly as follows:

1) Visually inspect all Tail Piece sealing surfaces for cleanliness an

(Figure 14).

2) Pull the Union Nut forward against the seating surface of the Tail Piece and rotate the Union Nut

several turns to check for any obstructions around the perimeter of the seating surface. (Figure

14).

3) Contact your local AERCO Representative f or replacement of the Coil if obstr uctions prohibit the

rotation of the Union Nut.

4) Using a brass wire brush, clean the internal threads of the Union Nut.

5) Using a citric orange cleaner, spray the area between the Union Nut and Tail Piece. While

pulling the Union Nut forward against the seating surface of the Tail Piece, rotate the Nut to

remove any residue that can cause unneeded friction between the two surfaces.

6) Form the Coil by creating a 1/8” minimum gap between the individual tubes and a 1/8” to 1/4”

gap between the four layers of tubes as shown in Figure 15. Maintain a flat surface on t he top

and bottom tube surface of the Coil.

MC2: 07/26/13 Page 35 of 50

Page 36

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

SEE

DETAIL ‘A’

0

DETAIL ‘A’

TAILPIECE

SEATING

SURFACE

UNION

NUT

SEALING

SURFACE

BOX

HEADER

OMM-0063_0C Installation, Operation & Maintenance Manual

Figure 14: Coil Assembly Preparation

Page 36 of 50 MC2: 07/26/13

Page 37

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

TOP VIEW

1/8" MINIMUM

1/8" TO 1/4"

1/8" TO 1/4"

SIDE VIEW

1/8" MINIMUM

2 - 3°

Preparation of Coil Gaskets

Installation, Operation & Maintenance Manual OMM-0063_0C

Figure 15: Coil Assembly Spacing

10.11. PREP ARATION OF COIL GASKETS

Two 6-t ab gaskets are provided with each replacement Coil Assembly. Proceed as

follows:

1) Form the Gasket into a round shape

2) Using Needle-Nose Pliers, form the 6 tabs on each Coil Gasket by bending each tab outward

2 to 3 degrees as shown in Figure 16. This will secure the Gasket into the Spud’s inside

diameter.

Figure 16: Coil Gasket Preparation

MC2: 07/26/13 Page 37 of 50

Page 38

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Riser Installation Instructions

hreaded stud

OMM-0063_0C Installation, Operation & Maintenance Manual

CHAPTER 12. M AINTEN ANCE R EASSEMBLY

12.1. REASSEMBLY OF RISERS, SUB-COOLING COIL, AND STEAM COILS

Following preparation of all Heater components as described in ROUTINE MAINTENANCE,

Chapter 6, the Heater is ready for reassembly as described in the following instructions.

12.1.1. Riser Installation

Install the Risers as follows:

1) Thread the Steam Riser into the Bottom Head.

2) Tighten the Riser until the center of the Spud is visually lined up to the cast notch on the

3) Thread the Condensate Riser into the Bottom Head.

4) Tighten the Riser until the center of the Spud is visually lined up to the cast notch on the

5) If this is a B+ I I Water Wizard, thread the Sub-Cooling Coil onto the Condensate Riser, hand

6) Measure the distance between the outside diameter of the Coil to the t

7) Position the Condensate Riser to create an equal distance between both measurements

8) Remove the Sub-Cooling Co il.

9) Thread a Steam Coil onto the Steam Riser, hand tight.

10) Position the Steam Riser so that the Condensate Tailpiece is aligned with the Spud on the

11) Remove the Steam Coil.

12) Insert the properly formed Coil Gaskets into each Spud. Ensure that the Coil Gasket snaps

13) If the Coil Gasket is loose in the Spud, remove it and reform the six tabs to create a positive

Bottom Head.

Bottom Head.

tight (ref. paragraph 7.2). If this is not a B+ II Wizard Bundle assembly, proceed to step 9.

protruding through the Bottom Head on both sides of the Coil (Figure 6).

shown in Figure 6.

Condensate Riser.

into the Spud (Fig. 7).

connection into the Spud.

Page 38 of 50 MC2: 07/26/13

Page 39

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

STEAM RISER OR

CONDENSATE RETURN

UNION NUT

COIL GASKET

BOX

HEADER

SPUD

Installation, Operation & Maintenance Manual OMM-0063_0C

Figure 17: Sub-Cooling Coil Alignment

MC2: 07/26/13 Page 39 of 50

Figure 18: Assembly of Coil to Steam Riser or Condensate Return

Page 40

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Sub-cooling Coil Installation Instructions

Steam Coil Installation Instructions

OMM-0063_0C Installation, Operation & Maintenance Manual

12.2. SUB-COOLING COIL INSTALLATION

Install the Sub-cooling Coil as follows:

1) For Wizard Sub-cooling Coil, align the Union Nuts with the two Spuds on the Condensate

2) Hand thread the Unions Nuts down to the seating surface.

3) Position the Coil to a level position.

4) Using the 75 ft/lb torque wrench, tighten the Union Nuts.

5) If the Union Nuts do not seat properly, remove the Sub-cooling Coil and re-clean all surfaces

Riser.

and threads on the Riser Spuds.

12.3. STEAM COIL INSTALLATION

Install the Steam Coil as follows:

1) W hile holding the Steam Coil horizontally with the Union Nuts facing the Riser Spuds, hand

2) Hand t hr ead the Condensate Union Nut onto the Spud.

3) Posit ion the Coil horizontally.

4) Using a Carpenter’s Square, check the vertical alignment to ensure that the Coil is installed

5) If needed, use the appropriate Short-Length wrench to tighten the Union Nuts to a seating

6) I ns ert the Coil Retaining tool through the first lower section of the Coil tubing. (Figure 8).

7) Using a Torque Wrench set for 75 ft-lbs, insert the wrench in the proper torque direction on

8) Apply pressure to the Coil Retaining tool in the opposite direction of the pressure being

9) When the Torque Wrench setting “clicks”, remove the Coil Retaining Tool.

10) Slowly reapply the pressure to the Torque Wrench holding the Coil by hand until the setting

11) Once again, reapply the pressure to the Torque Wrench without holding the Coil until the

12) Repeat step 11 until the Torque Wrench setting “clicks” without rotating the Union Nut or

13) Using the Coil Spacing Tool, perform a final spacing check of the Coil tubing by creating

14) Recheck all Union Nuts for the 75 ft/lbs setting without holding the Coil.

15) If a Union Nut or Coil rotates during this step, repeat steps 10 and 11.

thread the Steam Union Nuts onto the Spud. (Figure 7).

inside the perimeter of the Shell. It is important that all coils in the bundle line up vertically

and are positioned to ensure that they will not rub against the Liner of the Heater Shell.

condition.

the Union Nut (Figure 8).

applied to the Torque Wrench and tighten the Union Nut.

“clicks”. If the Coil rotates during this operation, reinsert t he Coil Retaining Tool and caref ully

apply a little more torque.

setting “clicks”.

twisting the Coil.

uniformed gaps between the Coil tubes (see Figure 4). Chec k for spacing between the Box

Header and Return Bend. If the Return Bend is touching the Box Header, use the Coil

Spacing Tool to separate the two components. Check for spacing between the Coil tubes

above and below the Box Header. Create clearance using the Coil Spacing Tool.

Page 40 of 50 MC2: 07/26/13

Page 41

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

COIL RETAINING

TOOL

BOX HEADER

RISER

UNION

NUT

INSERT COIL RETAINING

TOOL HERE

BOX

HEADER

RISER

TOP VIEW (PARTIAL CUT-AWAY)

SIDE VIEW

COIL

ASSEMBLY

COIL

ASSEMBLY

Installation, Operation & Maintenance Manual OMM-0063_0C

Figure 19: Positioning of Coil Retaining Tool

MC2: 07/26/13 Page 41 of 50

Page 42

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Hydrostatically Testing Coils & Risers

Anticipator Check Valve Reassembly

OMM-0063_0C Installation, Operation & Maintenance Manual

12.4. Hydrostatically Testing Coils & Risers

Test the Coils and Risers hydrostatically as follows:

1) Install fittings into the inlet and outlet of the Bottom for the Risers that can supply a hydrostatic

pressure source.

2) One fitting should have a valve for the release of internal air pressure.

3) The other fitting should be attached to a source to apply the maximum allowable working

pressure, (MAWP) to the internal Coil and Riser Bundle.

4) Apply MAWP to the Coil Bundle.

5) Close off bot h inlet and outlet valves to retain the internal pressure for 20 minutes.

6) If leaks are detected, remove the internal pressure.

7) Remove the leaking Coil and inspect for causes for leak.

8) If the leak is due to debris, clean the Coil and reinstall.

9) If there are damages to any surfaces, contact your AERCO Representative for instruction for

returning the failed Coil.

12.5. Anticipator Check Valve Reassembly

Reassemble the Anticipator Check Valve assembly as follows:

1) Insert the Valve Plug (36), the Washer (35), the Spring (34), and the Gasket (32). AERCO

recommends that a new Gasket (32) be use whenever the Check Valve is reassembled.

2) Insert the Spring Plate Assembly (33), taking care to center it as closely as possible.

3) Line up the Outlet Flange (31) on the Studs (50) in the Heater top head, making sure that the

Spring Plate Assembly (33) is centered in its groove in the bottom of the Outlet Flange (31).

4) Replace the Nuts (51) and tighten the Outlet Flange (31) leak-tight to the Heater top head.

5) If this is the only reassembly operation, reconnect the hot water outlet piping union and place

the Heater back into operation in accordance with Steps 1, 12, and 13 under OPERATING

PROCEDURES above.

Page 42 of 50 MC2: 07/26/13

Page 43

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Reassembly of Shell Instructions

Installation, Operation & Maintenance Manual OMM-0063_0C

12.6. Reassembly of Shell

Reassemble the Heater Shell assembly as follows:

1) Install fittings into the inlet and outlet of the Bottom for the Risers that can supply a hydrostatic

pressure source.

2) One fitting should have a valve for the release of internal air pressure.

3) The other fitting should be attached to a source to apply the maximum allowable working

pressure, (MAWP) to the internal Coil and Riser Bundle.

4) Apply MAWP to the Coil Bundle.

5) Close off both inlet and outlet valves to retain the internal pressure for 20 minutes.

6) If leaks are detected, remove the internal pressure.

7) Remove the leaking Coil and inspect for causes for leak.

8) If the leak is due to debris, clean the Coil and reinstall.

9) If there are damages to any surfaces, contact your AERCO Representative for instruction for

returning the failed Coil.

12.7. Reinstalling Heater in Facility

Reassemble all components that were disconnected in paragraph 5.2. When re-installing the Thermal

Element into the Thermal Well Bushing in the Top Head, be careful not to damage the Element against

the internal Coils. Straighten the Element before inserting.

12.8. Startup Procedure

Follow the operating procedures in Chapter X, OPERATING USING PNEUMATIC CONTROLS. If you are

using electronic controls, refer to document AC-105, Electronic Controls System (ECS) Manual.

MC2: 07/26/13 Page 43 of 50

Page 44

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Quantity Per Heater

Part Name

Item No.

Shown in Figure No.

1

Dial Thermometer

3

15

1

Temperature Switch

5

15

1

Compound Pressure Gage

12

15

1

Green Indicator Light

24

15

1

Red Indicator Light

25

15

2

Outlet Flange Gasket

32

16

4

Head Gasket

54

16

*

Coil Assembly

56

16

**

Conical Coil Gasket

57

16

** 2 per Space Coil Assembly, Item 56, plus 2

List A above plus:

Quantity Per Heater

Part Name

Item No.

Shown in Figure No.

1

Temperature Controller

2

15

1

Air Solenoid Valve

11

15

1

P&T Relief Valve***

73

17

1

Water Solenoid Valve

79

17

2

Asbestos Flange Gasket****

97

17

OMM-0063_0C Installation, Operation & Maintenance Manual

CHAPTER 13. RECOMMENDED SPARE PARTS

LIS T A – For Any Model B+II Water Wizard Heater

* Minimum of 2 to a maximum of the number in your largest Heater

LIST B – For Model B+II Water Wizard with Pneumatic-Operated Control Valve

Page 44 of 50 MC2: 07/26/13

Page 45

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

Figure 20 – AERCO Model SW1B+II Control Box Assembly and Parts List

MC2: 07/26/13 Page 45 of 50

Page 46

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

Figure 21 – AERCO Model B+II Water Heater w/Pneumatic Valve - Assembly and Parts List

Page 46 of 50 MC2: 07/26/13

Page 47

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Figure 22 – AERCO Model SW1B+II Water Heater with ECS – Assembly and Parts List

Installation, Operation & Maintenance Manual OMM-0063_0C

MC2: 07/26/13 Page 47 of 50

Page 48

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Figure 23 – AERCO Bare Replacement Heat Exchanger for Model SW1B+II – Assembly and Parts List

OMM-0063_0C Installation, Operation & Maintenance Manual

Page 48 of 50 MC2: 07/26/13

Page 49

1B+ I I Wa t er Wiza rd Water Heaters HE-110

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Installation, Operation & Maintenance Manual OMM-0063_0C

NOTES:

MC2: 07/26/13 Page 49 of 50

Page 50

HE-110 1B+ II Water Wizard Water Heat er s

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

OMM-0063_0C Installation, Operation & Maintenance Manual

© AERCO International, Inc., 2011

Page 50 of 50 MC2: 07/26/13

Loading...

Loading...