Page 1

Installation, Operation, and Maintenance

For Interfacing AERCO Equipment to Building

ProtoNode-LER

ProtoNode-RER

P/N 64084)

AERCO/ProtoNode

GF-129

OMM-0080_0D

Gateway

USER MANUAL

(Serial Ethernet,

BACnet MS/TP, BACnet/IP, N2, or LonWorks

Automation Systems Utilizing:

Protocols

(LonWorks,

P/N 64085)

Revised: 01/17/2012

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 2

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

Technical Support:

www.aerco.com

(Mon–Fri, 8am-5pm EST)

1-800-526-0288

GF-129

The information contained in this manual is subject to change without notice from AERCO International,

Inc. AERCO makes no warranty of any kind with respect to this material, including but not limited to

implied warranties of merchantability and fitness for a particular application. AERCO International is not

liable for errors appearing in this manual. Nor for incidental or consequential damages occurring in

connection with the furnishing, performance, or use of this material.

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Disclaimer

Page 2 of 64

Page 3

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

TABLE OF CONTENTS

1. Introduction ............................................................................................................................ 5

2. Bacnet/LONWorks Setup through Protocessor Protonode RER/LER ............................... 7

2.1 Installation Steps For The Customer ........................................................ 7

2.2 Record Identification Data ...................................................................... 7

2.3 Configure the DIP Switches ..................................................................... 7

2.3.1 Setting the Node/ID Device Instance (DIP Switch A0 – A7) for BACnet MS/TP,

BACnet/IP, and Metasys N2 ................................................................................................ 7

2.3.2 Setting the Serial Baud Rate (DIP Switch B0 – B3) for BACnet MS/TP & Metasys N2 .... ..7

2.3.3 Using S0 – S3 bank of DIP Switches to select and load Configuration Files ............ 8

3. Interfacing the ProtoNode to The AERCO Control System (ACS, BMS II, or BMS) ....... 11

3.1 ProtoNode RER and LER showing connection ports ................................ 11

3.2 ACS/BMS II/BMS Wiring Connections to ProtoNode RER and LER ........... 11

3.3 Modulex BCM ...................................................................................... 13

3.4 ECS .................................................................................................... 13

3.5 C-MORE .............................................................................................. 14

4. Connection from ProtoNode RER to BACnet MS/TP and Metasys N2 networks ......... 15

4.1 Wiring the ProtoNode RER to RS-485 Field Protoc ol ............................ 15

4.2 Wiring the ProtoNode LER Field Port to a LonWorks network ............... 15

4.3 Power-Up the ProtoNode RER or LER ................................................ 15

4.4 Commisioning the ProtoNode LER on a Lonworks network ................... 16

4.5 Sending Write Val ues ........................................................................ 16

5. Install and Run the Utility Software to Setup ip Address for bacnet/IP.......................... 17

5.1 Connect the PC to the ProtoNode via the Ethernet port ......................... 17

5.2 Connect to the ProtoNode using RUI (Ruinet) ........................................ 18

5.3 Set IP Address for BACnet/IP ............................................................... 18

Appendix A. Troubleshooting Tips ......................................................................................... 20

A.1 - LED Diagnostics for Modbus RTU Communications Between the Protonode

and AERCO’s Boiler Controllers ................................................................... 20

A.1.1 - ProtoNode LER - LED Locations and Functions .................................................... 20

A.1.2 - ProtoNode RER - LED Locations and Functions .................................................. 22

A.2 - Troubleshooting Procedu res for Connection Problems .......................... 23

Appendix B. Reference ............................................................................................................. 25

B.1 Specifications ...................................................................................... 25

B.1.1 Compliance with UL Regulations ............................................................................. 25

B.2 Address DIP Switch Settings ................................................................ 26

Appendix C. Configuration Information ................................................................................. 33

C.1 Default Modbus RTU COM Settings for AERCO Control lers ..................... 33

C.2 BACnet/IP, BACnet MS/TP, Metasys N2, and LonWorks Points List ......... 34

C.2.1 - Four C-Mores and One ACS/BMS II/BMS ............................................................. 34

C.2.2 - Eight C-Mores and One ACS/BMS II/BMS ............................................................ 36

C.2.3 - Twelve C-Mores and One ACS/BMS II/BMS ......................................................... 40

C.2.4 - MLX and One ACS/BMS II/BMS ............................................................................ 45

C.2.5 – ECS…………………………………………………………………………………...….47

C.2.6 - Twelve C-Mores, Six ECS/SP, Four Modulex and Two ACS/BMS II/BMS ............ 48

Appendix D. Limited 2 year Warranty .....................................................................................

63

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 3 of 64

Page 4

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

(This page left intentionally blank)

GF-129

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 4 of 64

Page 5

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

1. INTRODUCTION

GF-129

ProtoNode is an external, high performance, Building Automation multi-protocol gateway that has been

preprogrammed for AERCO’s equipment to support BACnet®

TCP, and LonWorks®

the ProtoNode and are selectable via DIP switches for fast and easy installation. There is no need to download any

configuration files to support the required applications.

This provides the necessary information to assist the Installers of the boilers/heaters with the installation of the

ProtoNode RER on BACnet MS/TP, BACnet/IP, and Metasys N2 by JCI networks and installation of the ProtoNode

LER on a LonWorks network.

BACnet International BTL certification is the highest level of BACnet conformance tests that a product can be

subjected to.

• The ProtoNode RER is BACnet BTL Certified.

• The ProtoNode LER is LonMark Certified.

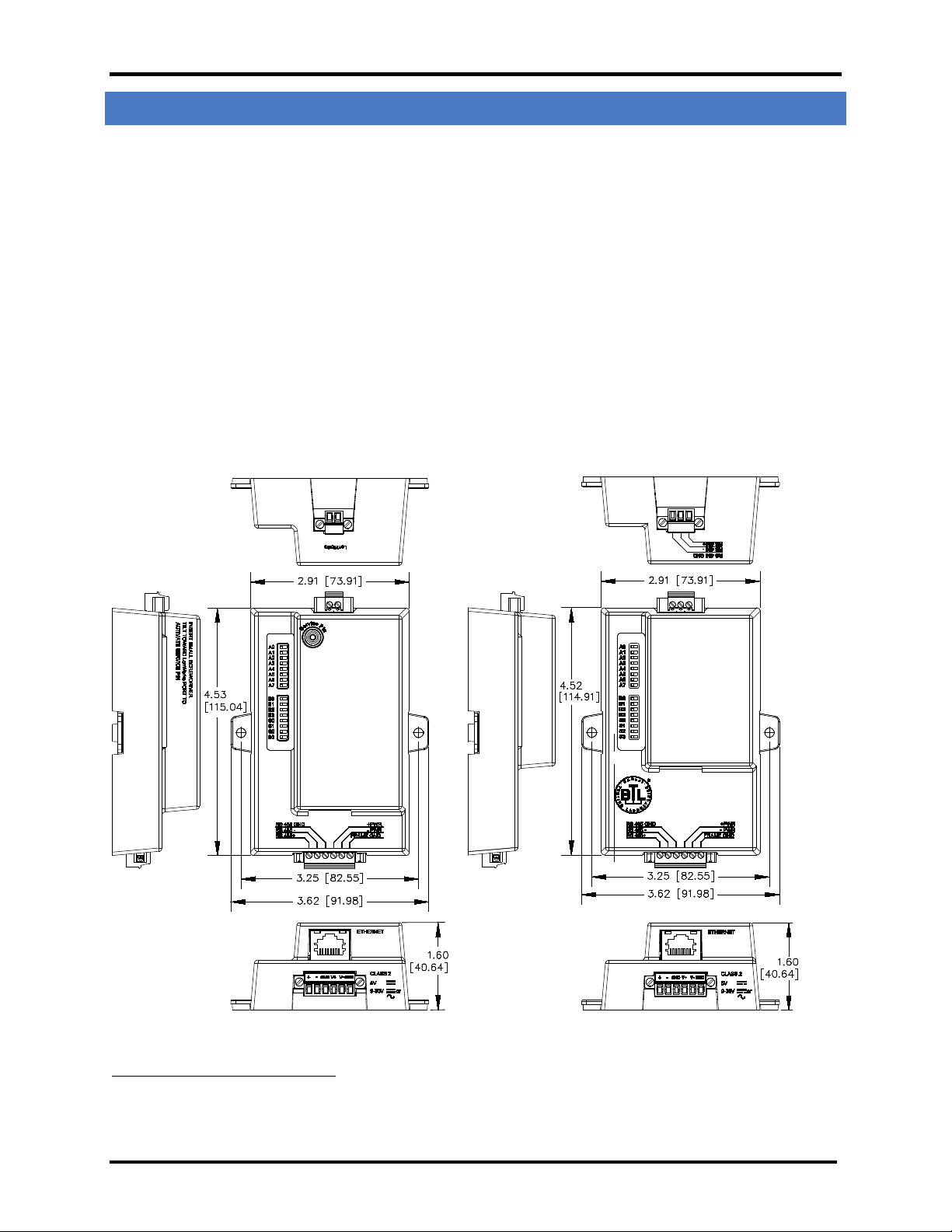

The ProtoNode units feature a very small form factor, as indicated in the dimensional illustration below:

3

. All the different AERCO C-More configurations for the various protocols are stored within

1

MS/TP, BACnet/IP, Metasys®2 N2 by JCI, Modbus

Dimensions for ProtoNode LER (left) and ProtoNode RER (right)

1

BACnet is a registered trademark of ASHRAE

2

Metasys is a registered trademark of Johnson Controls Inc.

3

LonMark is a registered trademark of LonMark International

4

LonWorks is a registered trademark of Echelon Corporation

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 5 of 64

Page 6

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

(This page left intentionally blank)

GF-129

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 6 of 64

Page 7

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

2. BACNET/LONWORKS SETUP THROUGH PROTOCESSOR PROTONODE RER/LER

2.1 Installation Steps For The Customer

1. Set the A, B, and S DIP Switch banks for field protocol baud rate, Node-ID/Device Instance, and proper

configuration. See Section 2.3.

2. Connect the ProtoNode to the Field protocol port and AERCO’s Control System/Boiler Management

System – RS-232 or RS-485 interface. See Section 3.

3. Power up the ProtoNode RER or LER. After power up, the device is installed on BACnet MS/TP, Metasys

N2, or LonWorks for the LER.

4. Where the Field protocol is BACnet/IP, refer to Section 5 to run the Ruinet utility program to change the

IP address. No changes to the configuration file are necessary.

2.2 Record Identification Data

Each ProtoNode has a unique serial number located on the underside of the unit. The number format is FPC-N3XXXX-XXX-XXXX. This number should be recorded as it may be required for technical support. The AERCO part

numbers and model numbers are shown in the table below:

ProtoNode Model AERCO P/N Model Number

RER 64084 FPC-N34-103-126-0645

LER 64085 FPC-N35-103-401-0646

2.3 Configure the DIP Switches

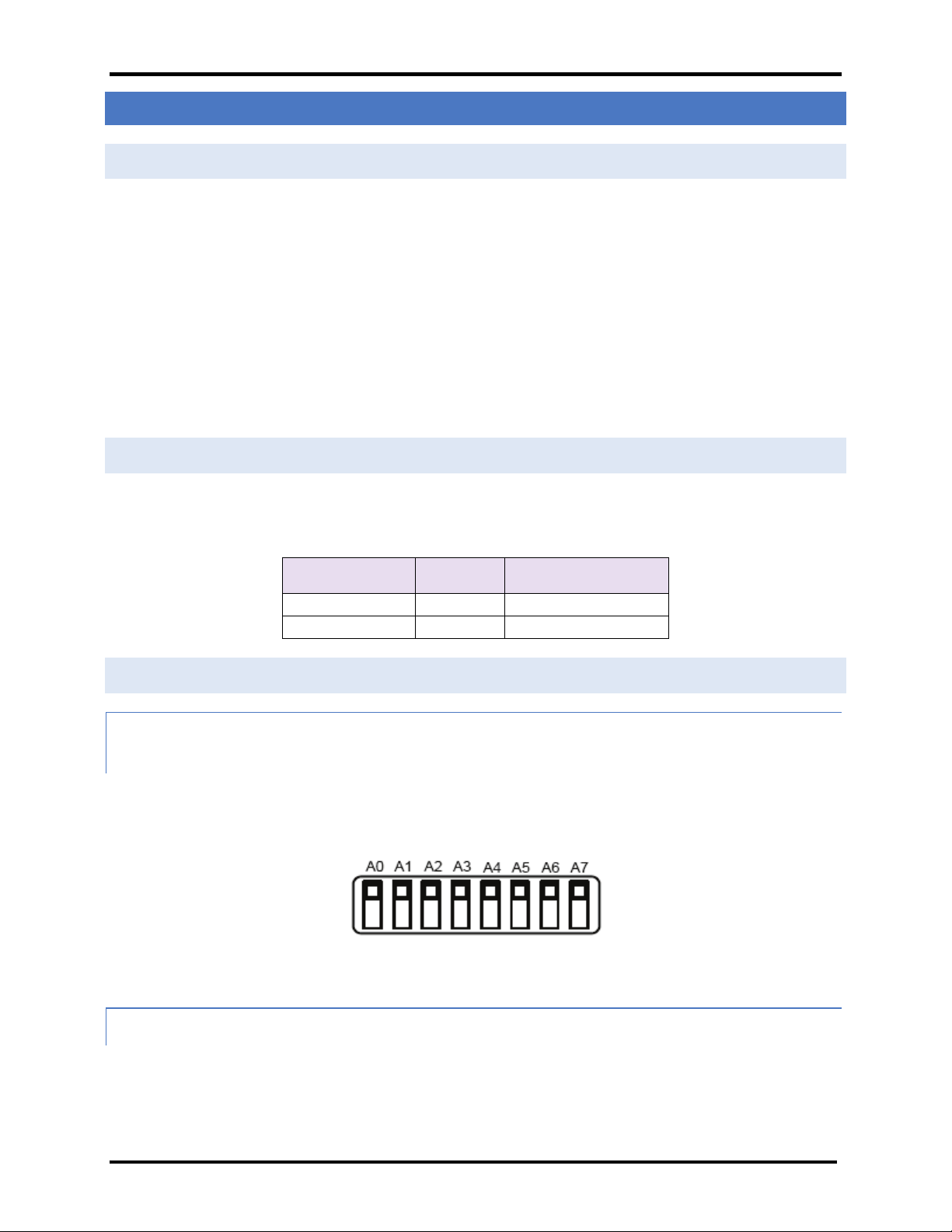

2.3.1 Setting the Node/ID Device Instance (DIP Switch A0 – A7) for BACnet MS/TP, BACnet/IP, and Metasys N2

• The A Bank DIP switches on the ProtoNode RER-R allow users to set the Node-ID/Device Instance

on the Field RS-485.

• DIP switches A0 – A7 can also be used to set the MAC Address for BACnet MS/TP and BACnet/IP

Figure 1. A0 – A7 DIP Switches

• Please refer to Appendix B.2 for the full range of addresses to set Nod-ID/Device Instance..

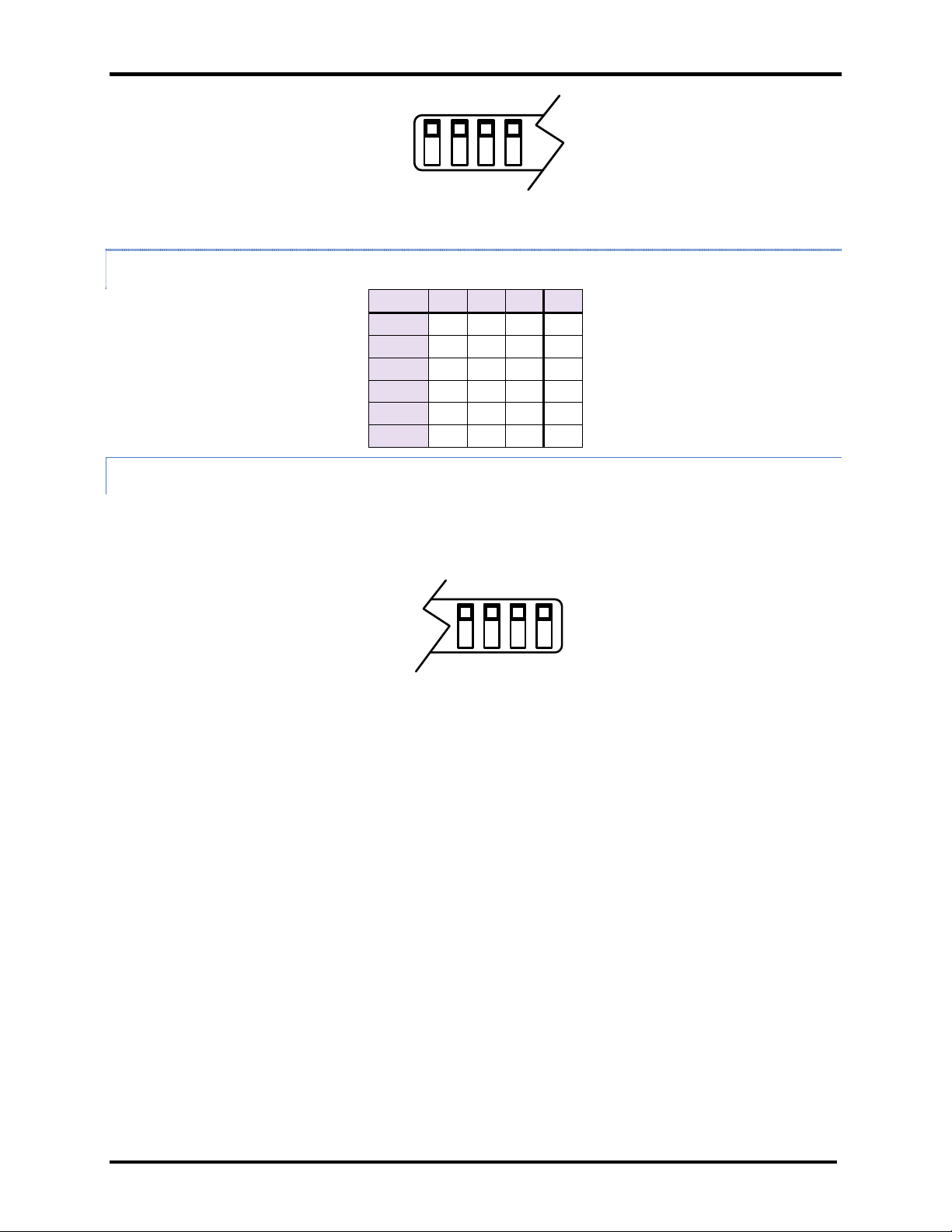

2.3.2 Setting the Serial Baud Rate (DIP Switch B0 – B3) for BACnet MS/TP & Metasys N2

• Setting the serial baud rate to match the baud rate provided by the Building Management

System can be done through DIP Switches B0 – B3 for BACnet MS/TP.

• Metasys N2 is always defaulted to 9600 baud and the B bank is disabled.

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 7 of 64

Page 8

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

B0 B1 B2 B3

Auto

Off

Off

Off

Off

9600

On

On

On

Off

19200

Off

Off

Off

On

38400

On

On

Off

On

57600

Off

Off

On

On

76800

On

Off

On

On

S0 S1 S2 S3

Figure 2. B0 – B3 DIP Switches

2.3.2.1 Baud Rate DIP Switch Selection

Baud B0 B1 B2 B3

2.3.3 Using S0 – S3 bank of DIP Switches to select and load Configuration Files

• The S bank of DIP switches, S0 - S3 is used to select and load a configuration file from a group of

pretested/preloaded configuration files which are stored in the ProtoNode RER (BACnet MS/TP,

BACnet/IP, Modbus TCP and/or Metasys N2) and LER (LonWorks).

Figure 3. S0 – S3 DIP Switches

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 8 of 64

Page 9

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

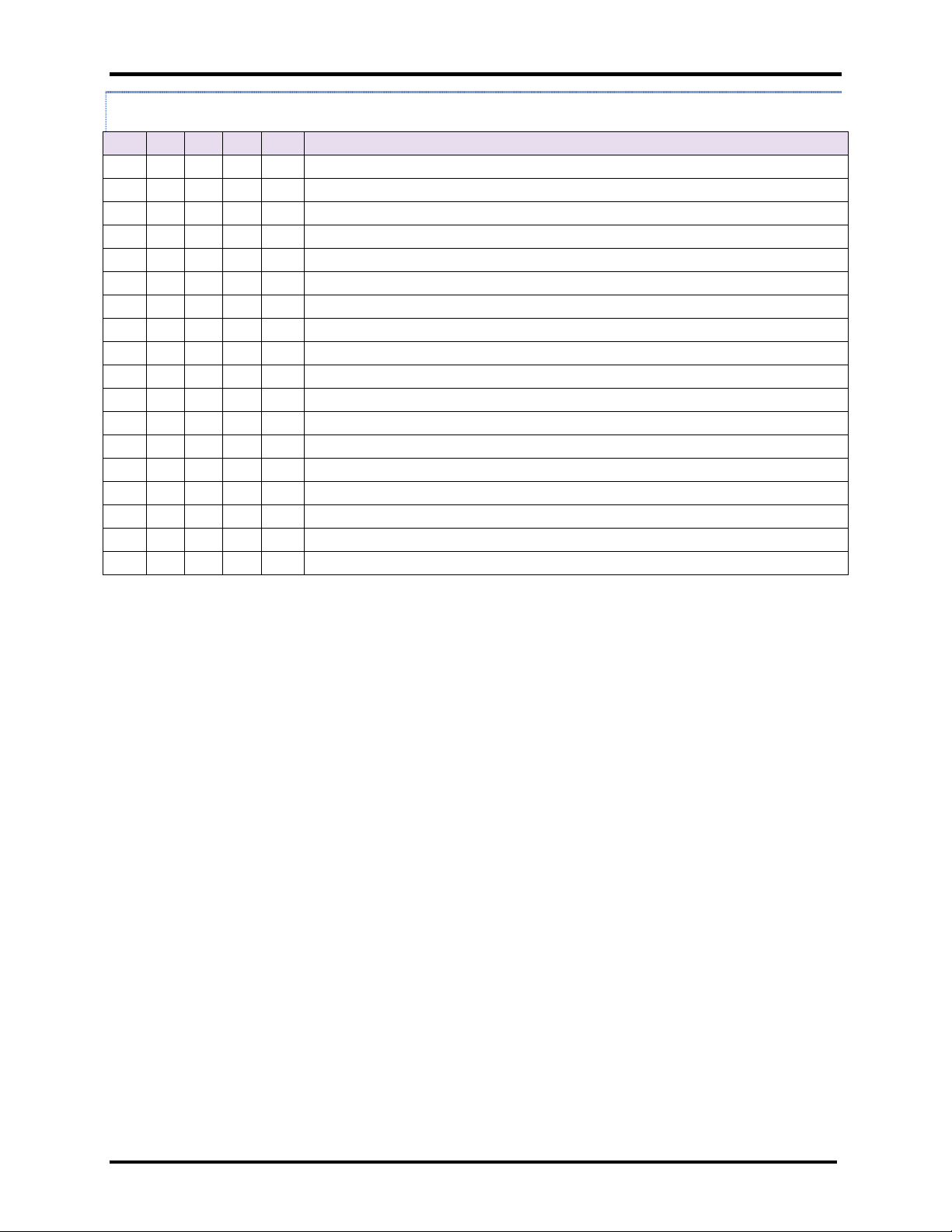

2.3.3.1 ProtoNode RER: S0 – S3 (and A1*) DIP Switch Configuration Settings

S0 S1 S2 S3 A1* Profile

Off Off Off Off Off BACnet/IP/BACnet MS/TP, 1 ACS/BMS II/BMS, 4 C-More Controlled Boilers

Off Off Off Off BACnet/IP/BACnet MS/TP, 1 ACS/BMS II/BMS, 8 C-More Controlled Boilers

On

Off

On On

Off Off

On

Off

On On On

Off Off Off

On

Off

On On

Off Off

On

Off

On On On On

Off Off Off Off

On

Off Off Off BACnet/IP/BACnet MS/TP, 1 ACS/BMS II/BMS, 12 C-More Controlled Boilers

On

Off Off Off BACnet/IP/BACnet MS/TP, 1 ACS/BMS II, 4 Modulex Boilers With BCMs

Off Off BACnet/IP/BACnet MS/TP, 4 ECS/SP Systems

On

Off

On On

Off Off

On

Off

On On On

Off Off Off

Off Off BACnet/IP/BACnet MS/TP, 12 C-More, 6 ECS/SP, 4 Modulex and 2 ACS/BMS II

On

Off Off Metasys N2, 1 ACS/BMS II/BMS, 4 C-More Controlled Boi l ers

Off Off Metasys N2, 1 ACS/BMS II/BMS, 8 C-More Controlled B oi l ers

Off Metasys N2, 1 ACS/BMS II/BMS CS, 12 C-More Controlled Boilers

On

Off Metasys N2, 1 ACS/BMS II, 4 Modulex Boilers with BCMs

On

Off

Off

On On

On On

Off Metasys N2, 4 ECS/SP Systems

On

Off Metasys N2, 12 C-More, 6 ECS/SP, 4 Modulex and 2 ACS/BMS II

On

Off Modbus TCP, 1 ACS/BMS II/BMS, 4 C-More Controlled Boilers

Off Modbus TCP, 1 ACS/BMS II/BMS, 8 C-More Controlled Boilers

Off Modbus TCP, 1 ACS/BMS II/BMS, 12 C-More Controlled Boilers

Off Modbus TCP, 1 ACS/BMS II, 4 Modulex Boilers With BCMs

Modbus TCP, 4 ECS/SP Systems

On

Modbus TCP, 12 C-More, 6 ECS/SP, 4 Modulex an d 2 ACS/BMS II

On

*NOTE:

The first sixteen profiles in the chart above (Section 2.3.3.1) require that DIP

switches A1 through A8 be set to OFF, which is the default setting, so those

switches do not need to be accessed for those configurations (and so are not

shown in the above chart). However, the last two profiles do require that DIP

switch A1 be set to ON, so for those two profiles, DIP Switch A1 needs to be

changed to ON (A2 through A8 remain in the OFF position).

A photograph showing the DIP switch locations inside the unit is on the next page.

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 9 of 64

Page 10

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

Off

Off

Off

Off

1 ACS/BMS II/BMS, 4 C-More Controlled Boilers

On

Off

Off

Off

1 ACS/BMS II/BMS, 8 C-More Controlled Boilers

Off

On

Off

Off

1 ACS/BMS II/BMS, 12 C-More Controlled Boilers

On

On

Off

Off

1 ACS/BMS II, 4 Modulex Boilers With BCMs

Off

Off

On

Off

4 ECS/SP Systems

On

Off

On

Off

12 C-More, 6 ECS/SP, 4 Modulex and 2 ACS/BMS II

A1 - A8 DIP

S-Bank DIP

ON

OFF

ON

OFF

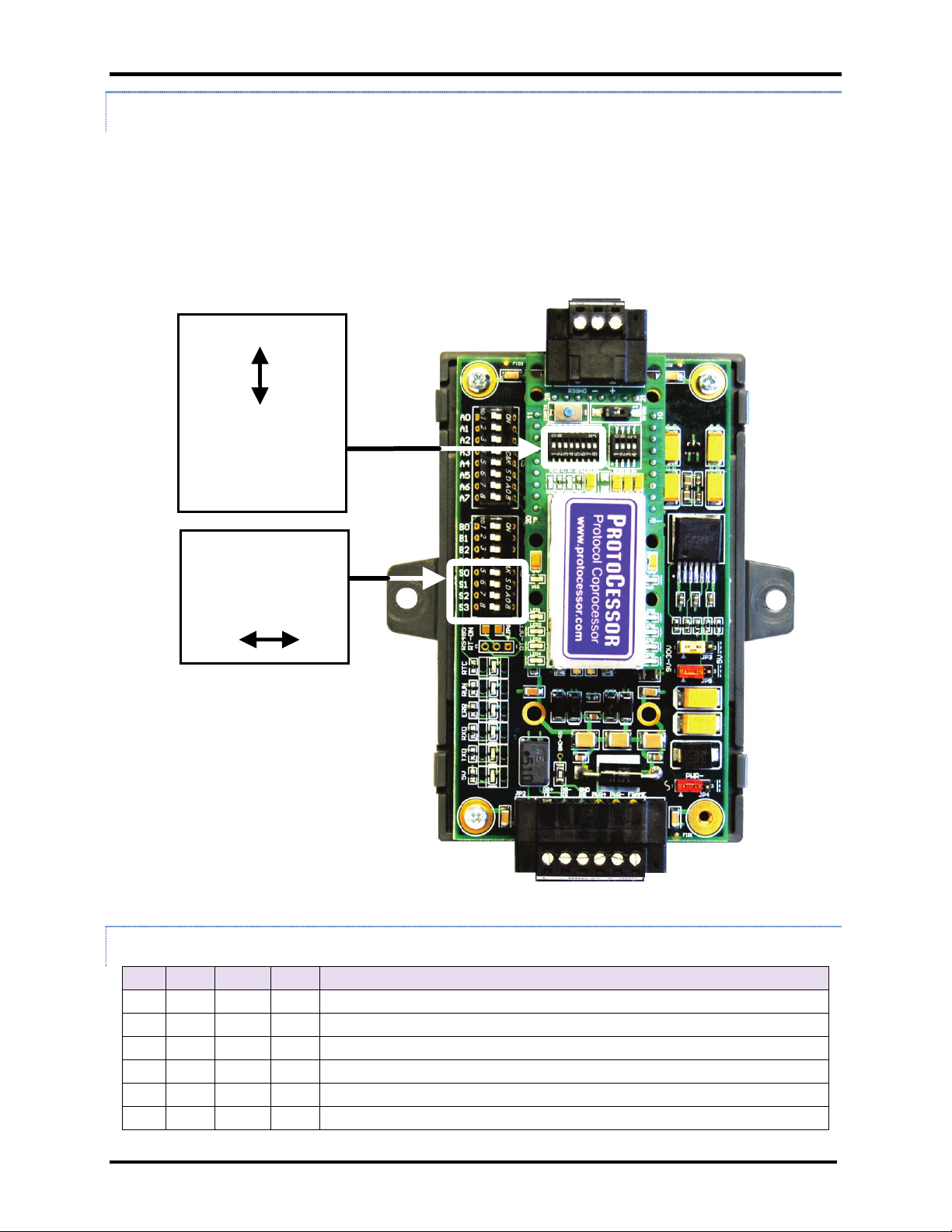

2.3.3.2 ProtoNode RER: S0 – S3 and A1-A8 DIP Switch Locations

The S-Bank DIP switches are accessible through the top cover. However, the cover must be

removed to access the A1 through A8 switches. To remove the cover, pull it from the unit while

holding onto the 6 pin Phoenix connector.

IMPORTANT!

Do not hold the wall mount tabs when removing the cover as these

are designed to break off if not required!

Switches

Switches

(S0, S1, S2, S3)

Location of DIP Switches S0 – S3 and A1-A8

2.3.3.3 ProtoNode LER: S0 – S3 DIP Switch Configuration Settings

S0 S1 S2 S3 Profile

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 10 of 64

Page 11

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

LonWorks

LonWorks

OEM connection

10/100

10/100

Power +/- and FG

Power +/- and FG

3. INTERFACING THE PROTONODE TO THE AERCO CONTROL SYSTEM (ACS, BMS II, OR

BMS)

3.1 ProtoNode RER and LER showing connection ports

RS-485 Port for Serial

Field Protocol

Service Pin

Port

Base T

RS-485 Port

Base T

(Frame Ground)

9-30 VDC, 12-24 VAC

OEM

Connection

RS-485 Port

(Frame Ground)

9-30 VDC, 12-24 VAC

Figure 4. ProtoNode BACnet RER (left) and LonWorks LER (right)

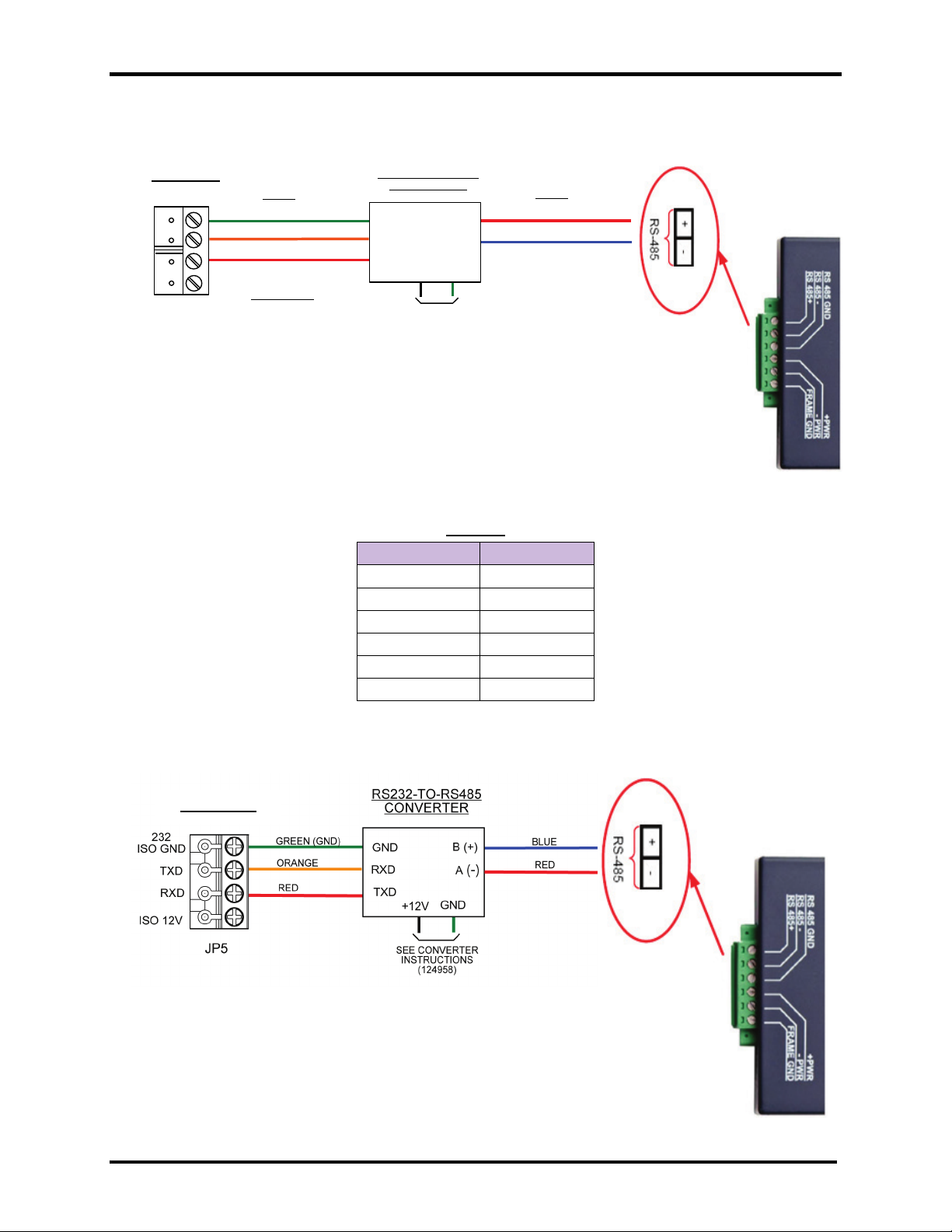

3.2 ACS/BMS II/BMS Wiring Connections to ProtoNode RER and LER

• When an ACS, BMS II, or BMS is being used, an RS-485-to-RS-232 converter will be required to

connect it to the ProtoNode’s RS485 port (green 6-pin Phoenix connector).

• Refer to Figures 5 and 6 to locate the internal RS-232 connector JP12 (BMS) or JP5 (BMS II/ACS) inside

the wiring area of the ACS/BMS II/BMS.

• If the AERCO RS232-to-RS485 Converter (part no. 124943) is used, the RS-232 side of the converter

contains a connector that plugs directly into header connector JP12 (BMS) or JP5 (BMS II/ACS).

• If a third party converter is used, connect the RS-232 Receive (RxD) and Transmit (TxD) wire leads to

the internal RS-232 connector (JP12 or JP5) as shown in Figures 5 and 6. DO NOT connect the wire

shield on this side of the converter.

NOTE

If a third-party RS232-to-RS485 Converter is used, consult the manufacturer’s instruction manual for signal

polarity.

• On the RS-485 side of the converter (Figure 5 to Figure 7), connect the wire leads as follows:

o Connect the TD B (+) terminal to the ProtoNode’s RS485+ Port.

o Connect the TD A (-) terminal to the ProtoNode’s RS485- Port.

o Connect the GND terminal to the ProtoNode’s RS485 Frame GND Port.

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 11 of 64

Page 12

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

RXD

TXD

GND

RS232

JP12

RS232-TO-RS485

CONVERTER

TXD

RXD

GND

GND

B (+)

A

(-)

RED (+)

BLUE (-)

GREEN (GND)

RED

ORANGE

IMPORTANT

CHECK INPUT & OUTPUT

POLARITY ON CONVERTER

BEING USED

BMS

RS232

RS485

+12V

SEE CONVERTER

INSTRUCTIONS

(124958)

ACS /BMS

Figure 5. RS-232 Connection to ACS/BMS

GF-129

ACS/BMS II

Pinouts

ProtoNode Pin # Pin assignment

Pin 1 RS-485 +

Pin 2 RS-485 -

Pin 3 RS-485 GND

Pin 4 V +

Pin 5 V -

Pin 6 FRAME GND

Figure 6. RS-232 Connection to ACS/BMS II

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 12 of 64

Page 13

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

TERMINATE SHIELD

TIE TOGETHER WITH

TIE TOGETHER WITH

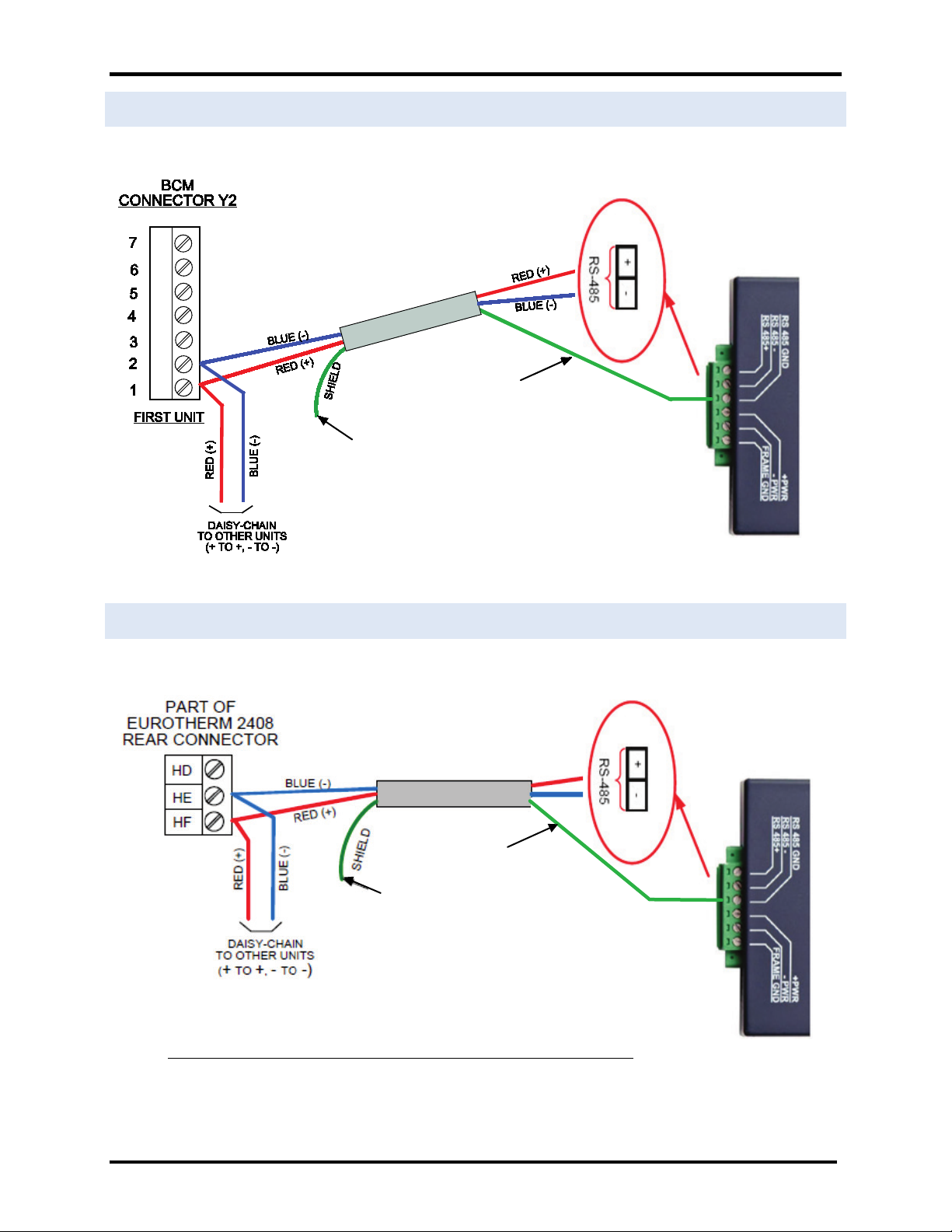

3.3 Modulex BCM

GF-129

3.4 ECS

SHIELDS OF OTHER

FLOAT AT END OF

TO SIGNAL GROUND

UNITS AND

LINE (INSULATE)

Figure 7. RS-485 Connection to BCM

SHIELDS OF OTHER

FLOAT AT END OF

LINE (INSULATE)

Figure 8. RS-485 Connection to ECS

Connect ECS terminals HE and HF to XPC Port 1a (Figures 5-7) as follows:

• Connect the “HF” terminal to the ProtoNode’s “RS485 +” port

• Connect the “HE” terminal to the ProtoNode’s “RS485 -” port

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

TERMINATE SHIELD

TO SIGNAL GROUND

UNITS AND

Page 13 of 64

Page 14

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

If an Oxygen Sensor is attached to the C-

ENABLE

DISABLE

BIAS2

TERM

BIAS1

R1

S2

RS485

TIE TOGETHER WITH

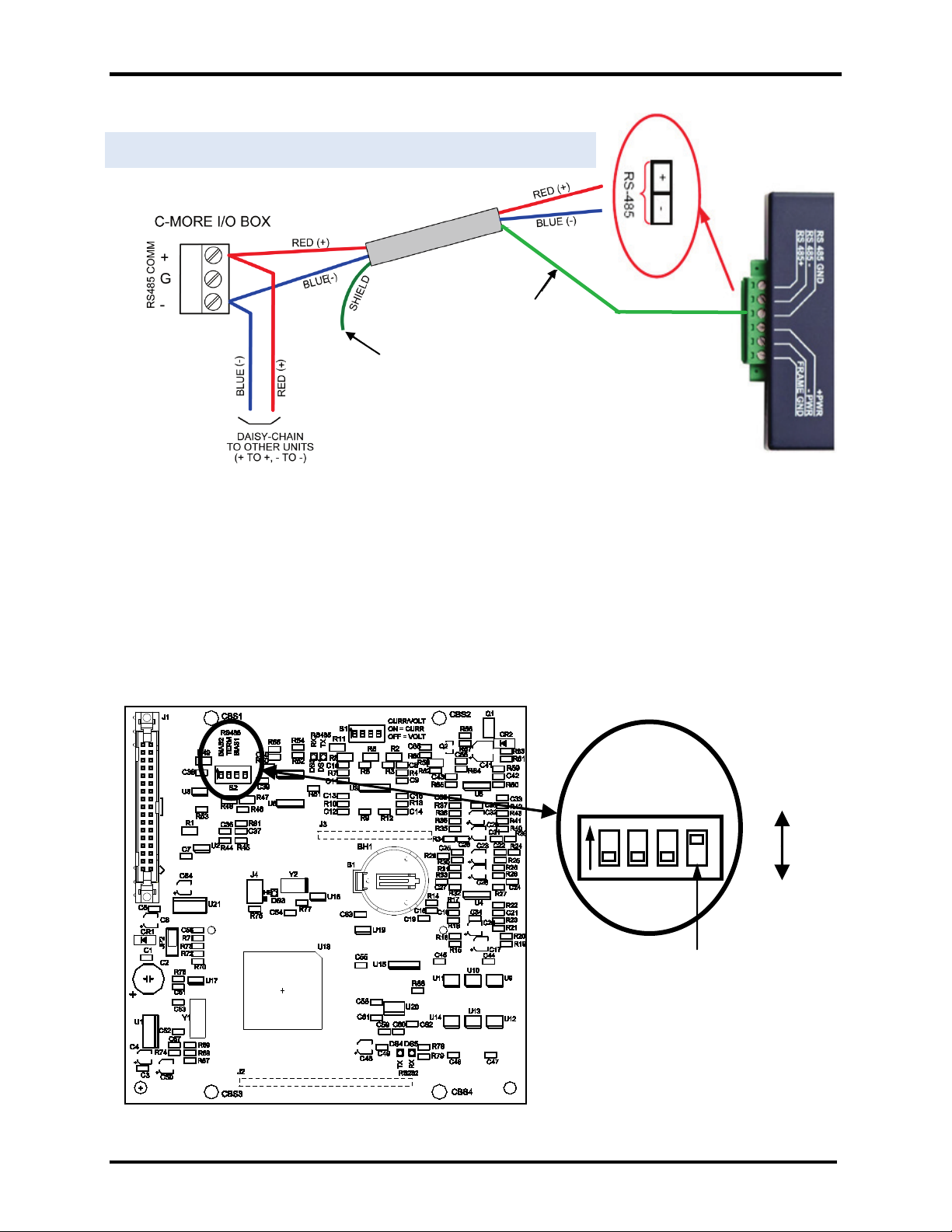

.5 C-MORE

TERMINATE SHIELD

TO SIGNAL GROUND

SHIELDS OF OTHER

UNITS AND

FLOAT AT END OF

LINE (INSULATE)

Figure 8a. RS-485 Connection to C-MORE (RS-485)

GF-129

TERMINATE SHIELD

TO SIGNAL GROUND

IMPORTANT NOTE

The 4-position RS485 DIP Switch (S2) on the PMC PCB of the C-More Controller must be set as

follows:

1) The termination (TERM) and bias (BIAS1 & BIAS2) DIP Switches of S2 must be set to DISABLE.

2) If an Oxygen Sensor is connected to the C-More Controller, switch R1 (see below) should be set

to DISABLED (down). If an Oxygen Sensor is NOT connected to the C-More Controller, it should

be set to ENABLED (up). Improper setting of R1 may result in erro r m essages.

Instructions for accessing the PMC PCB and this DIP Switch can be found in Section 4.3 of ModBus

manual GF-114.

R1

More Controller, set R1 to DISABLED

(down). If an Oxygen Sensor is NOT used,

set R1 to ENABLED (up). Factory default

setting is ENABLED.

C-More Controller PMC PCB

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 14 of 64

Page 15

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

G

-

+

4. CONNECTION FROM PROTONODE RER TO BACNET MS/TP AND METASYS N2

NETWORKS

4.1 Wiring the ProtoNode RER to RS-485 Field Protocol

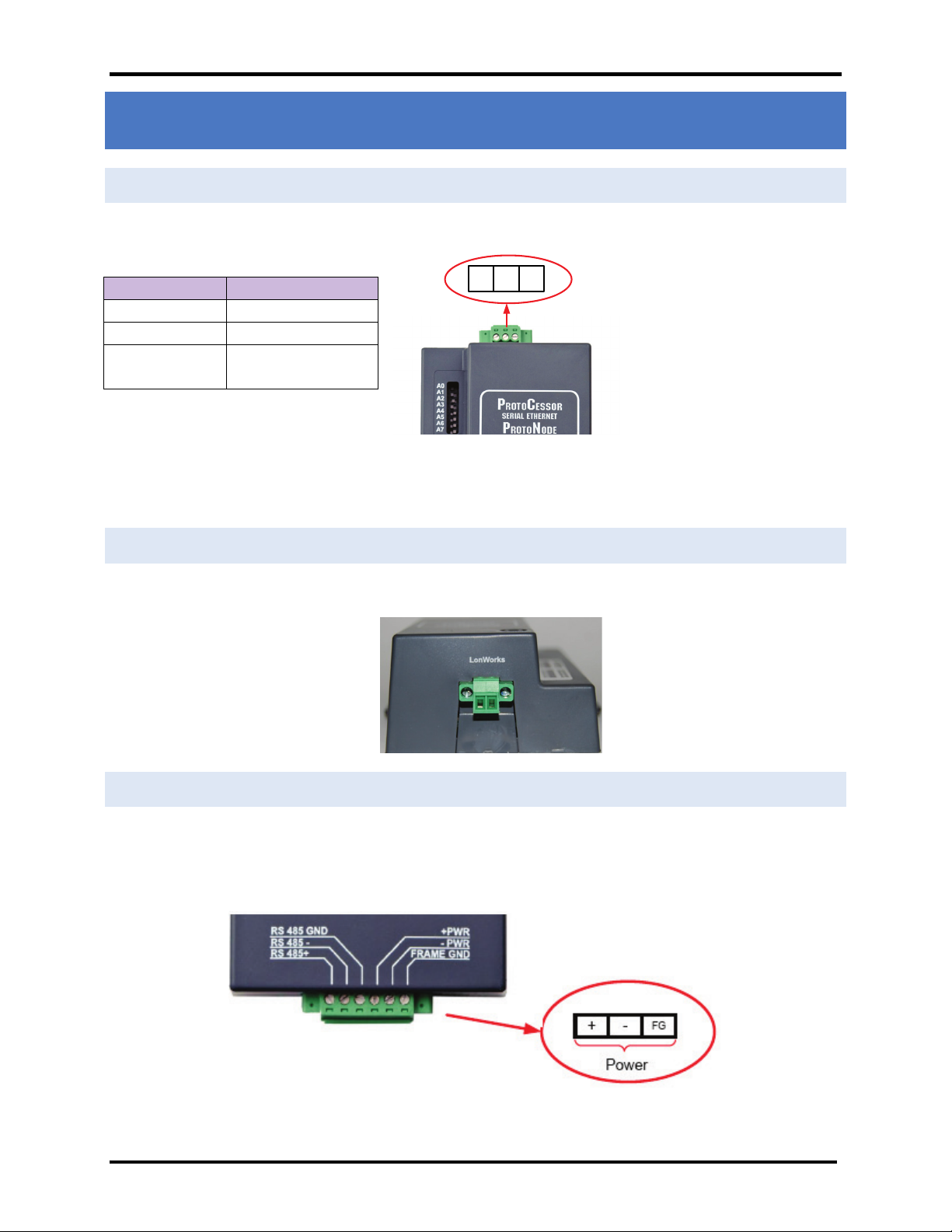

The Field Protocol can be connected to the 3-pin connector on the ProtoNode RER as shown:

GF-129

ProtoNode Pin # Pin assignment

Pin 1 RS-485 +

Pin 2 RS-485 -

Pin 3 RS-485 SIGNAL GND,

MS/TP or N2

Figure 9. Connection from ProtoNode to RS-485 Field Protocol –BACnet MS/TP or Metasys N2

NOTE: For information on connecting the ProtoNode RER to a BACnet/IP network, see Section 5.

4.2 Wiring the ProtoNode LER Field Port to a LonWorks network

• Connect the ProtoNode to the field network with the LonWorks terminal using a twisted pair non-

shielded cable. LonWorks has no polarity

4.3 Power-Up the ProtoNode RER or LER

Apply power to the device. Ensure that the power supply used complies with the specifications provided in

Appendix B. Ensure that the cable is grounded using the “Frame-GND” terminal.

The ProtoNode features a multi-mode power input and accepts either 9-30 VDC or 12-24 VAC.

Figure 10. Supply Voltage to ProtoNode

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 15 of 64

Page 16

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

Pinouts

ProtoNode Pin # Pin assignment

Pin 1 RS-485 +

Pin 2 RS-485 -

Pin 3 RS-485 GND

Pin 4 V +

Pin 5 V -

Pin 6 FRAME GND

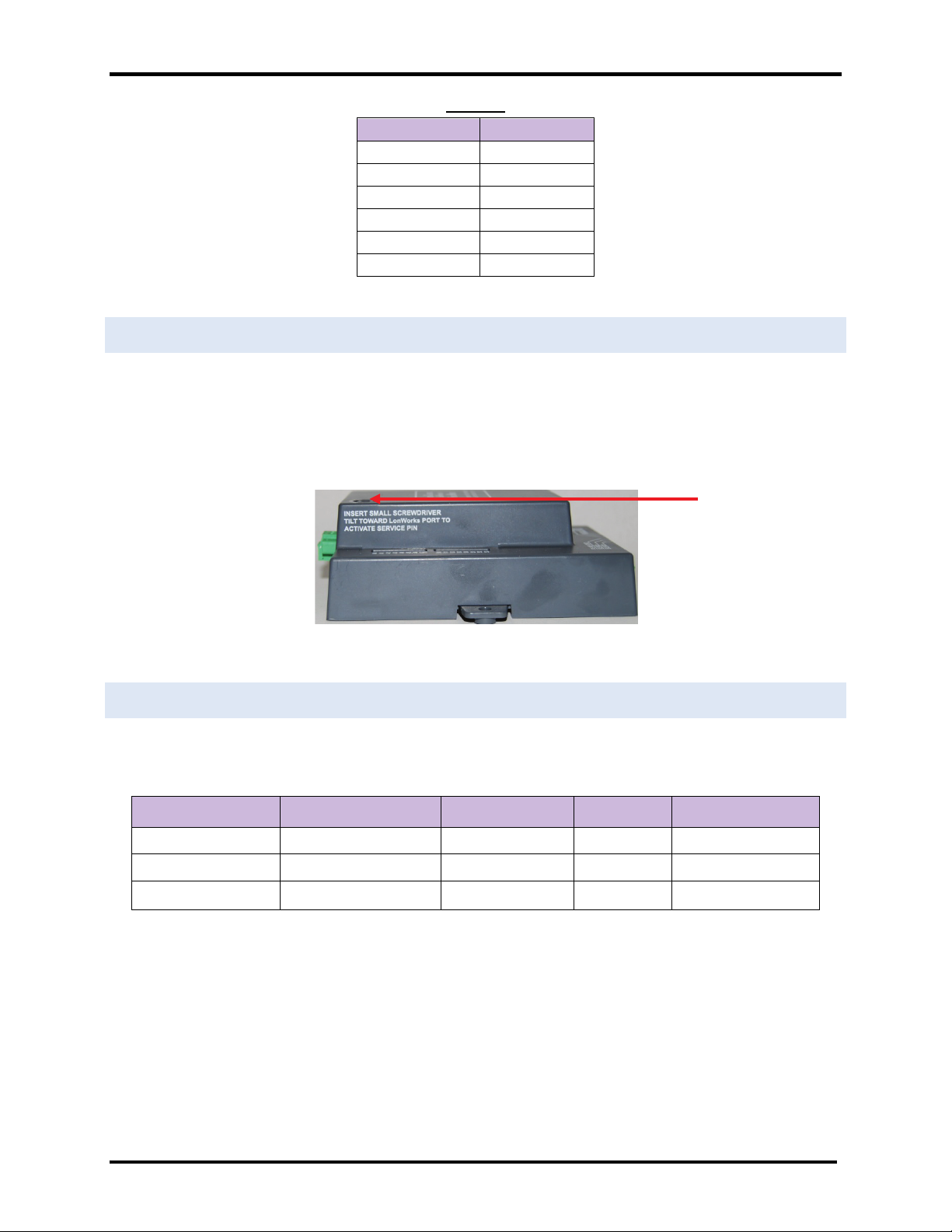

4.4 Commissioning the ProtoNode LER on a Lonworks network

Commissioning may only be performed by the LonWorks administrator.

To commission the ProtoNode LER LonWorks port, insert a small screwdriver in the commissioning hole

on the face of the LER’s enclosure to access the Service Pin. See the illustration on the ProtoNode LER as

to which way to toggle the screw driver during commissioning.

GF-129

4.5 Sending Write Values

The administrator must setup their host management system to write through the gateway to the CMore, ACS or BMS II three or four times within the timeout value.

AERCO Device Parameter Default Value Range Menu

BMS II

C-More

ACS

Network Timeout 30 s 5 to 240 s RS-232

Network Timeout 30 s 5 to 999 s Configuration

Network Timeout 30 s 5 to 240 s RS-232

Refer to GF-112, GF-124, and GF-131 for more information.

LonWorks Service Pin

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 16 of 64

Page 17

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

5. INSTALL AND RUN THE UTILITY SOFTWARE TO SETUP IP ADDRESS FOR BACNET/IP

• Download the RUINET Utilities from the ProtoCessor web site (under Tech Support – Utilities –

Utilities Software – Install.zip) or access the page at:

http://www.protocessor.com/tech_support/Design_Documents.html#US

• Run Install.zip and follow the installation instructions

• Once installed, the FieldServer Utilities can be located in the Windows Start menu as a desktop icon

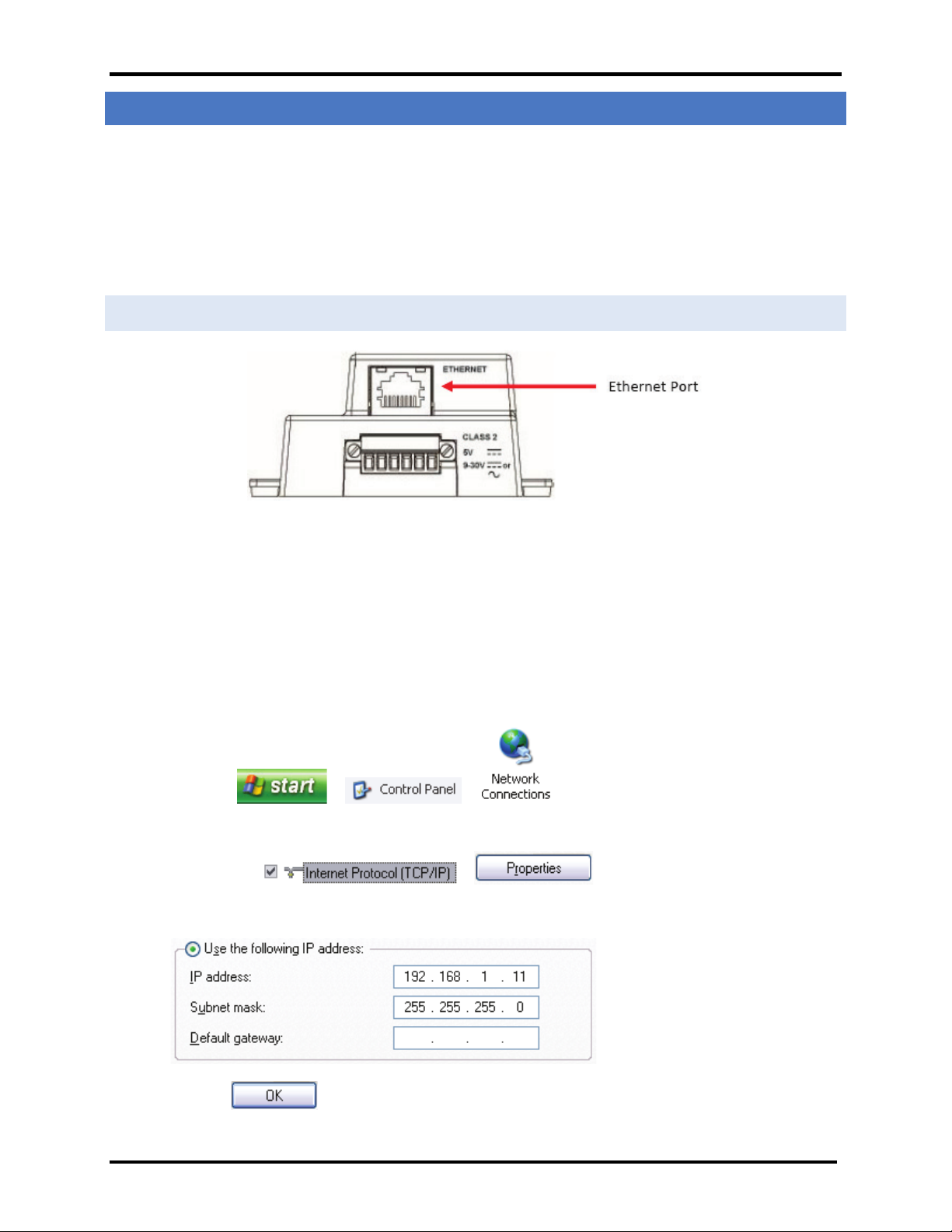

5.1 Connect the PC to the ProtoNode via the Ethernet port

Figure 11. Ethernet port location of ProtoNode

• Disable any wireless Ethernet adapters on the PC/Laptop

• Disable firewall and virus protection software

• Connect a standard cat5 Ethernet cable between the PC and ProtoNode.

• The Default IP Address of the ProtoNode is 192.168.1.24, Subnet Mask is 255.255.255.0. If the PC and

the ProtoNode are on different IP Networks, assign a static IP Address to the PC on the 192.168.1.xxx

network.

• Go to > >

• Right-click on Local Area Connection > Properties

• Highlight >

• Select: Use the following IP address

• Click twice

• Go to Start > Programs > Field Server Utilities > Ruiping Utility

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 17 of 64

Page 18

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

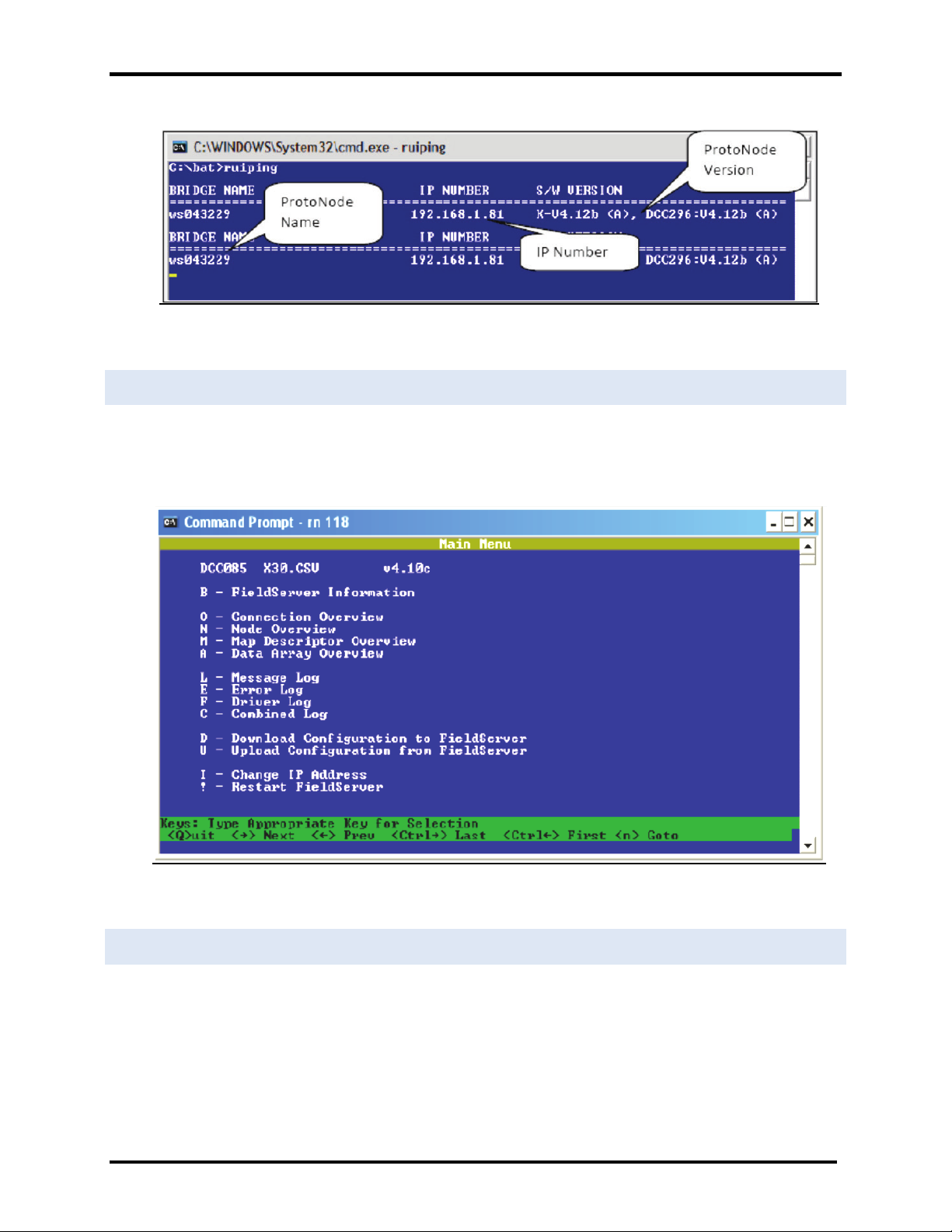

• If the IP Address of the ProtoNode module appears on the screen, the ProtoNode is running.

Figure 12. RUIPING screen

5.2 Connect to the ProtoNode using RUI (Ruinet)

• Double click on the debugging utility, “RUINET” (Remote User Interface). The following screen will

appear: (if Ruinet does not automatically display the main menu, select the ProtoNode by typing the

2-digit number to the left of the title name).

GF-129

5.3 Set IP Address for BACnet/IP

• From the main menu, press “I” to enter the Edit IP Address Settings menu

• Press “1” to modify the IP address of the Ethernet adapter

• Type in a new IP address in the format 192.168.2.X and press <Enter>

• If necessary, press “2” to and change the netmask

• Type in a new Subnet Mask and press <Enter>

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Figure 13. RUINET screen

Page 18 of 64

Page 19

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

• If necessary, press “3” to and change the IP Gateway

• Type in a new IP Gateway and press <Enter>

• Note: If the ProtoNode is connected to a router, the IP Gateway of the ProtoNode should be set to

the IP address of the router that it is connected to

• Unplug Ethernet cable from PC and do not connect to network hub or router.

GF-129

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 19 of 64

Page 20

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

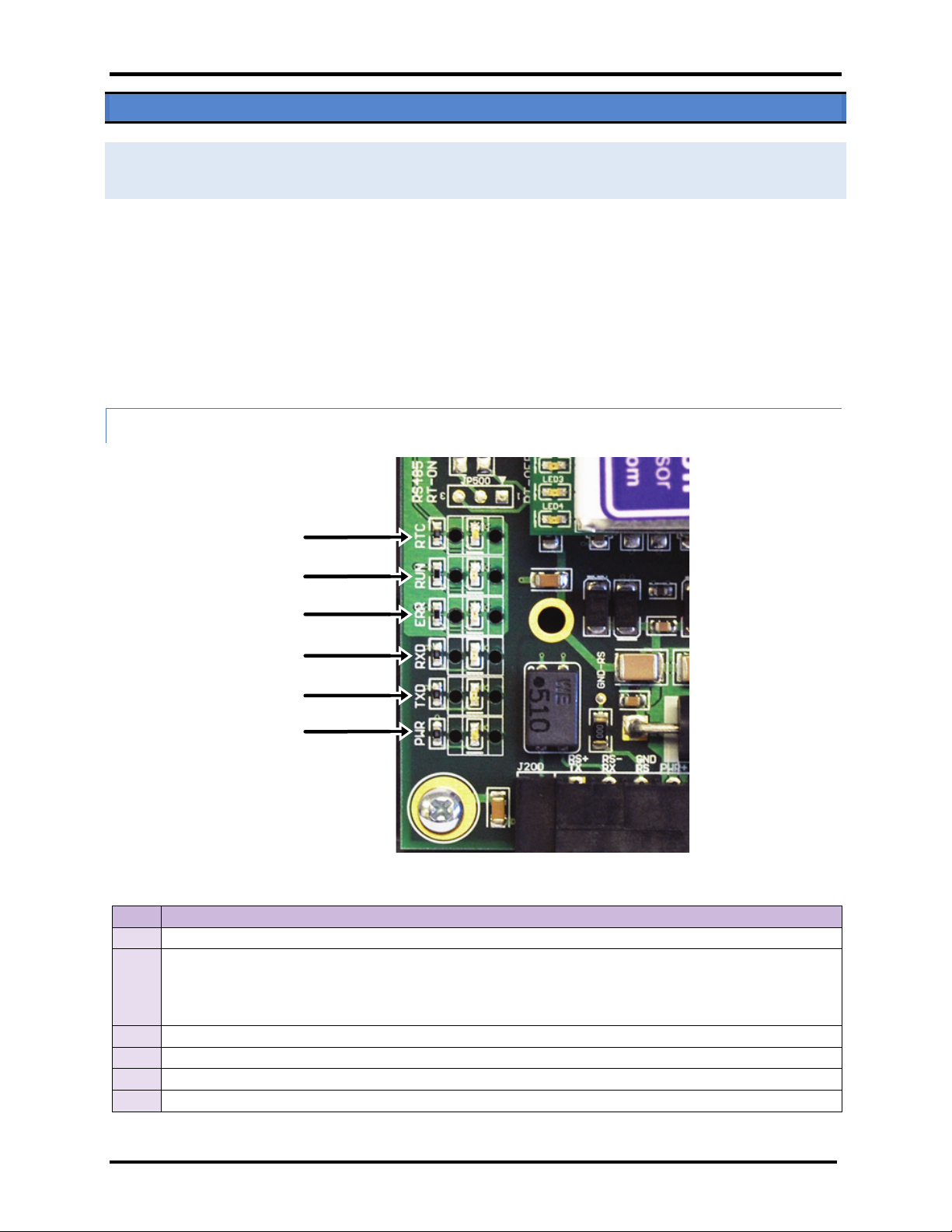

PWR

TX

RX

ERR

RUN

RTC

Appendix A. TROUBLESHOOTING TIPS

A.1 - LED Diagnostics for Modbus RTU Communications Between the Protonode and AERCO’s Boiler

Controllers

The AERCO/ProtoNode Gateway units feature status LEDs that indicate a number of possible activities. The

ollowing shows how to open the unit and interpret the activity of the indication LEDs.

The lid on top of the AERCO/ProtoNode Gateway must be removed in order to see the LED’s. Pull on the lid while

holding onto the 6 pin Phoenix connector.

IMPORTANT!

Do not hold the wall mount tabs when removi n g the co ver as these are

designed to break off if not required!

LED locations and function descriptions for LER and RER versions are shown in the following two subsections.

A.1.1 - ProtoNode LER - LED Locations and Functions

Figure 14. AERCO/ProtoNode Gateway LER Main Board Indication LED Locations

LED DESCRIPTION

RUN

ERR

RX

TX

PWR

RTC

The RUN LED will start flashing 20 seconds after power up, indicating normal operation.

The SYS ERR LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. A steady red

light will indicate there is a system error on the ProtoNode LER. If this occurs, immediately report the

related “system error” shown in the error screen of the RUI interface to AERCO International for

evaluation.

The RX LED will flash when a message is received on the socket port.

The TX LED will flash when a message is sent on the socket port.

This is the power light and should show steady green at all times when the ProtoNode LER is powered.

Unused

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 20 of 64

Page 21

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

The SYS ERR LED will flash once on power up and flash once 15 seconds after power up. A

steady red light will indicate a communication error has occurred. To establish the cause of

On normal operation of ProtoNode LER, the RX LED will flash when a message is received on

ProtoNode is configured for implicit addressing and not

LON TX

LON RX

LON-SRV

Config. Error

System Error

Unused

Unused

Power

Figure 15. AERCO/ProtoNode Gateway LER ProtoCessor Board Indication LED Locations

Run (PIO)

LED DESCRIPTION

Power

System

Error

Comm.

Error

Config.

Error

Node

Offline

RUN

(PIO)

PIC Run

PIC

This is the power light and should show steady green at all times when the ProtoNode LER is

powered.

steady red light will indicate there is a system error on the ProtoNode LER. If this occurs,

immediately report the related “system error” shown in the error screen of the RUI interface

to AERCO International for evaluation.

The COMM ERR LED will flash once on power up and flash once 15 seconds after power up. A

the error, go to the error screen of the RUI interface.

The Config ERR LED will flash once on power up and flash once 15 seconds after power up. A

steady amber light will indicate a configuration error exists in the active configuration. See the

Error Screen in the Remote User Interface for a description of the configuration error.

The Node Offline LED will flash once on power up and flash once 15 seconds after power up. If

the Node Offline LED stays on solid, a Node Offline condition has occurred.

The RUN LED will start flashing 20 seconds after power indicating normal operation. The

ProtoNode LER will be able to access RUINET once this LED starts flashing.

The PIC RUN LED will flash indicating normal operation.

The PIC ERR LED will go on solid indicating there is a PIC error.

Error

LON-TX

LON-RX

LON-

SRV

On normal operation of ProtoNode LER, the TX LED will flash when a message is sent on the

Lon port of the ProtoNode.

the Lon port of the ProtoNode.

The LON-SRV LED will flash if the

commissioned. LED will be off if the ProtoNode is configured for implicit addressing and

commissioned or if it is configured for explicit addressing.

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 21 of 64

Page 22

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

Unused

Power

Power

Node

Offline

Config.

Error

Comm.

Error

System

Error

TX

RX

Run

A.1.2 - ProtoNode RER - LED Locations and Functions

Figure 16. AERCO/ProtoNode Gateway RER Indication LED Locations

GF-129

LED DESCRIPTION

PWR

System

Error

Comm.

Error

Config.

Error

Node

Offline

Unused

RX

TX

This is the power light and should show steady green at all times when the ProtoNode RER is

powered.

The SYS ERR LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. A steady

red light will indicate there is a system error on the ProtoCessor. If this occurs, immediately report the

related “system error” shown in the error screen of the RUI interface to AERCO International for

evaluation.

COMM ERR LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. A steady

red light will indicate the communications problem if there is a configured node connected to the

ProtoCessor that is offline. To establish the cause of the error, go to the error screen of the RUI

interface.

Config ERR LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. A steady

amber light will indicate a configuration error exists in the active configuration. See the Error Screen

in the Remote User Interface for a description of the configuration error.

Node Offline LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. If the

Node Offline LED stays on solid, a node offline condition has occurred.

15 seconds after powering up the 4 unused LEDs will turn on solid for 5 seconds, then turn off.

On normal operation of FPC-FD2, the RX LED will flash when a message is received on the field port of

the ProtoCessor.

On normal operation of FPC-FD2, the TX LED will flash when a message is sent on the field port of the

ProtoCessor

Run

RUN LED will flash 20 seconds after power up, signifying normal operation. The ProtoNode RER will be

able to access RUINET once this LED starts flashing. During the first 20 seconds, the LED should be off

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 22 of 64

Page 23

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

Appendix A.2 - Troubleshooting Procedures for Connection Problems

• Confirm that the network cabling is correct

• Confirm that the computer network card is operational and correctly configured

• Confirm that there is an Ethernet adapter installed in the PC’s Device Manager List, and that it is configured

to run the TCP/IP protocol.

• Check that the IP netmask of the PC matches the ProtoNode. The Default IP Address of the ProtoNode is

192.168.1.24, Subnet Mask is 255.255.255.0

o Go to Start > Run

o Type in “ipconfig”

o The account settings should be displayed

o Ensure that the IP address is 192.168.1.xxx and the netmask 255.255.255.0

• Ensure that the PC and ProtoNode are on the same IP Network, or assign a Static IP Address to the PC on the

192.168.1.0 network using the Remote User Interface Utility.

• If Using Windows XP, ensure that the firewall is disabled

• Ensure that all other Ethernet cards active on the PC, especially wireless adapters are disabled

• Refer to the Field Server Troubleshooting Guide which can be found at www/protocessor.com/downloads/

under documentation

• Confirm that the network cabling is correct

• If write values are lost from time to time, check that the timeout values for the ACS, BMS II, C-More and the

host system are compatible. Refer to Section 4.5 in this manual for more information.

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 23 of 64

Page 24

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

(This page left intentionally blank)

GF-129

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 24 of 64

Page 25

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

Appendix B. REFERENCE

B.1 Specifications

ProtoNode RER ProtoNode LER

One 6-pin Phoenix connector, one RS-485

+/- ground port, power +/- frame ground

Electrical

Connections

Approvals:

Power

Requirements

Physical

Dimensions

Weight: 0.2 kg (0.4 lbs)

Operating

Temperature:

Surge Suppression EN61000-4-2 ESD EN61000-4-3 EMC EN61000-4-4 EFT

Humidity: 5 - 90% RH (non-condensing)

(Specifications subject to change without notice)

port

One 3-pin RS-485 Phoenix connector, one

RS-485 +/- ground port

One Ethernet-10/100 Ethernet port

CE (EN55022;EN55024; EN60950), UL916, FCC Class A Part 15, DNP3 Conformance Tested,

OPC Self-tested for Compliance, RoHS Compliant, CSA 205 Approved

BTL Marked LonMark Certified

Multi-mode power adapter: 9-30 VDC, 12-24 VAC

11.5 cm L x 8.3 cm W x 4.1 cm H (4.5 x 3.2 x 1.6 in.)

-40°C to 75°C (-40°F to167°F)

One 6-pin Phoenix connector, one RS-485

+/- ground port, power +/- frame ground

port

One Ethernet 10/100 BaseT port

One FTT-10 LonWorks port

GF-129

B.1.1 Compliance with UL Regulations

For UL compliance, the following instructions must be met when operating the ProtoNode.

The units shall be powered by listed LPS or Class 2 power supply suited to the expected operating temperature

range.

The interconnecting power connector and power cable shall:

• Comply with local electrical code.

• Be suited to the expected operating temperature range.

• Meet the current and voltage rating for the ProtoNode/Net

Furthermore, the interconnecting power cable shall:

• not exceed 3.05m (118.3”) in length.

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 25 of 64

Page 26

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

Off

Off

Off

Off

Off

Off

Off

Off

On

Off

Off

Off

Off

Off

Off

Off

Off

On

Off

Off

Off

Off

Off

Off

On

On

Off

Off

Off

Off

Off

Off

Off

Off

On

Off

Off

Off

Off

Off

On

Off

On

Off

Off

Off

Off

Off

Off

On

On

Off

Off

Off

Off

Off

On

On

On

Off

Off

Off

Off

Off

Off

Off

Off

On

Off

Off

Off

Off

On

Off

Off

On

Off

Off

Off

Off

Off

On

Off

On

Off

Off

Off

Off

On

On

Off

On

Off

Off

Off

Off

12

Off

Off

On

On

Off

Off

Off

Off

On

Off

On

On

Off

Off

Off

Off

Off

On

On

On

Off

Off

Off

Off

On

On

On

On

Off

Off

Off

Off

Off

Off

Off

Off

On

Off

Off

Off

On

Off

Off

Off

On

Off

Off

Off

Off

On

Off

Off

On

Off

Off

Off

On

On

Off

Off

On

Off

Off

Off

Off

Off

On

Off

On

Off

Off

Off

On

Off

On

Off

On

Off

Off

Off

Off

On

On

Off

On

Off

Off

Off

On

On

On

Off

On

Off

Off

Off

Off

Off

Off

On

On

Off

Off

Off

25

On

Off

Off

On

On

Off

Off

Off

Off

On

Off

On

On

Off

Off

Off

27

On

On

Off

On

On

Off

Off

Off

Off

Off

On

On

On

Off

Off

Off

On

Off

On

On

On

Off

Off

Off

Off

On

On

On

On

Off

Off

Off

On

On

On

On

On

Off

Off

Off

Off

Off

Off

Off

Off

On

Off

Off

On

Off

Off

Off

Off

On

Off

Off

Off

On

Off

Off

Off

On

Off

Off

On

On

Off

Off

Off

On

Off

Off

Off

Off

On

Off

Off

On

Off

Off

• Be constructed of materials rated VW-1 or FT-1 or better.

• If the unit is to be installed in an operating environment with a temperature above 65 °C, it should be

installed in a Restricted Access Area requiring a key or a special tool to gain access

• This device must not be connected to a LAN segment with outdoor wiring.

B.2 Address DIP Switch Settings

Address

0

1

2

3

4

5

6

7

8

9

10

11

13

14

15

16

17

18

19

20

21

22

23

24

A0 A1 A2 A3 A4 A5 A6 A7

26

28

29

30

31

32

33

34

35

36

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 26 of 64

Page 27

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

On

Off

On

Off

Off

On

Off

Off

Off

On

On

Off

Off

On

Off

Off

On

On

On

Off

Off

On

Off

Off

40

Off

Off

Off

On

Off

On

Off

Off

On

Off

Off

On

Off

On

Off

Off

42

Off

On

Off

On

Off

On

Off

Off

On

On

Off

On

Off

On

Off

Off

Off

Off

On

On

Off

On

Off

Off

On

Off

On

On

Off

On

Off

Off

Off

On

On

On

Off

On

Off

Off

On

On

On

On

Off

On

Off

Off

Off

Off

Off

Off

On

On

Off

Off

On

Off

Off

Off

On

On

Off

Off

Off

On

Off

Off

On

On

Off

Off

On

On

Off

Off

On

On

Off

Off

Off

Off

On

Off

On

On

Off

Off

53

On

Off

On

Off

On

On

Off

Off

Off

On

On

Off

On

On

Off

Off

55

On

On

On

Off

On

On

Off

Off

Off

Off

Off

On

On

On

Off

Off

On

Off

Off

On

On

On

Off

Off

Off

On

Off

On

On

On

Off

Off

On

On

Off

On

On

On

Off

Off

Off

Off

On

On

On

On

Off

Off

On

Off

On

On

On

On

Off

Off

Off

On

On

On

On

On

Off

Off

On

On

On

On

On

On

Off

Off

Off

Off

Off

Off

Off

Off

On

Off

On

Off

Off

Off

Off

Off

On

Off

66

Off

On

Off

Off

Off

Off

On

Off

On

On

Off

Off

Off

Off

On

Off

68

Off

Off

On

Off

Off

Off

On

Off

On

Off

On

Off

Off

Off

On

Off

Off

On

On

Off

Off

Off

On

Off

On

On

On

Off

Off

Off

On

Off

Off

Off

Off

On

Off

Off

On

Off

On

Off

Off

On

Off

Off

On

Off

Off

On

Off

On

Off

Off

On

Off

On

On

Off

On

Off

Off

On

Off

Off

Off

On

On

Off

Off

On

Off

On

Off

On

On

Off

Off

On

Off

Off

On

On

On

Off

Off

On

Off

79

On

On

On

On

Off

Off

On

Off

Off

Off

Off

Off

On

Off

On

Off

81

On

Off

Off

Off

On

Off

On

Off

GF-129

Address

37

38

39

41

43

44

45

46

47

48

49

50

51

52

54

A0 A1 A2 A3 A4 A5 A6 A7

56

57

58

59

60

61

62

63

64

65

67

69

70

71

72

73

74

75

76

77

78

80

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 27 of 64

Page 28

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

Off

On

Off

Off

On

Off

On

Off

On

On

Off

Off

On

Off

On

Off

Off

Off

On

Off

On

Off

On

Off

85

On

Off

On

Off

On

Off

On

Off

Off

On

On

Off

On

Off

On

Off

87

On

On

On

Off

On

Off

On

Off

Off

Off

Off

On

On

Off

On

Off

On

Off

Off

On

On

Off

On

Off

Off

On

Off

On

On

Off

On

Off

On

On

Off

On

On

Off

On

Off

Off

Off

On

On

On

Off

On

Off

On

Off

On

On

On

Off

On

Off

Off

On

On

On

On

Off

On

Off

On

On

On

On

On

Off

On

Off

Off

Off

Off

Off

Off

On

On

Off

On

Off

Off

Off

Off

On

On

Off

98

Off

On

Off

Off

Off

On

On

Off

On

On

Off

Off

Off

On

On

Off

100

Off

Off

On

Off

Off

On

On

Off

On

Off

On

Off

Off

On

On

Off

Off

On

On

Off

Off

On

On

Off

On

On

On

Off

Off

On

On

Off

Off

Off

Off

On

Off

On

On

Off

On

Off

Off

On

Off

On

On

Off

Off

On

Off

On

Off

On

On

Off

On

On

Off

On

Off

On

On

Off

Off

Off

On

On

Off

On

On

Off

On

Off

On

On

Off

On

On

Off

Off

On

On

On

Off

On

On

Off

111

On

On

On

On

Off

On

On

Off

Off

Off

Off

Off

On

On

On

Off

113

On

Off

Off

Off

On

On

On

Off

Off

On

Off

Off

On

On

On

Off

On

On

Off

Off

On

On

On

Off

Off

Off

On

Off

On

On

On

Off

On

Off

On

Off

On

On

On

Off

Off

On

On

Off

On

On

On

Off

On

On

On

Off

On

On

On

Off

Off

Off

Off

On

On

On

On

Off

On

Off

Off

On

On

On

On

Off

Off

On

Off

On

On

On

On

Off

On

On

Off

On

On

On

On

Off

124

Off

Off

On

On

On

On

On

Off

On

Off

On

On

On

On

On

Off

126

Off

On

On

On

On

On

On

Off

GF-129

Address

82

83

84

86

88

89

90

91

92

93

94

95

96

97

99

A0 A1 A2 A3 A4 A5 A6 A7

101

102

103

104

105

106

107

108

109

110

112

114

115

116

117

118

119

120

121

122

123

125

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 28 of 64

Page 29

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

On

On

On

On

On

On

On

Off

Off

Off

Off

Off

Off

Off

Off

On

On

Off

Off

Off

Off

Off

Off

On

130

Off

On

Off

Off

Off

Off

Off

On

On

On

Off

Off

Off

Off

Off

On

132

Off

Off

On

Off

Off

Off

Off

On

On

Off

On

Off

Off

Off

Off

On

Off

On

On

Off

Off

Off

Off

On

On

On

On

Off

Off

Off

Off

On

Off

Off

Off

On

Off

Off

Off

On

On

Off

Off

On

Off

Off

Off

On

Off

On

Off

On

Off

Off

Off

On

On

On

Off

On

Off

Off

Off

On

Off

Off

On

On

Off

Off

Off

On

On

Off

On

On

Off

Off

Off

On

Off

On

On

On

Off

Off

Off

On

143

On

On

On

On

Off

Off

Off

On

Off

Off

Off

Off

On

Off

Off

On

145

On

Off

Off

Off

On

Off

Off

On

Off

On

Off

Off

On

Off

Off

On

On

On

Off

Off

On

Off

Off

On

Off

Off

On

Off

On

Off

Off

On

On

Off

On

Off

On

Off

Off

On

Off

On

On

Off

On

Off

Off

On

On

On

On

Off

On

Off

Off

On

Off

Off

Off

On

On

Off

Off

On

On

Off

Off

On

On

Off

Off

On

Off

On

Off

On

On

Off

Off

On

On

On

Off

On

On

Off

Off

On

156

Off

Off

On

On

On

Off

Off

On

On

Off

On

On

On

Off

Off

On

158

Off

On

On

On

On

Off

Off

On

On

On

On

On

On

Off

Off

On

Off

Off

Off

Off

Off

On

Off

On

On

Off

Off

Off

Off

On

Off

On

Off

On

Off

Off

Off

On

Off

On

On

On

Off

Off

Off

On

Off

On

Off

Off

On

Off

Off

On

Off

On

On

Off

On

Off

Off

On

Off

On

Off

On

On

Off

Off

On

Off

On

On

On

On

Off

Off

On

Off

On

Off

Off

Off

On

Off

On

Off

On

169

On

Off

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

171

On

On

Off

On

Off

On

Off

On

GF-129

Address

127

128

129

131

133

134

135

136

137

138

139

140

141

142

144

A0 A1 A2 A3 A4 A5 A6 A7

146

147

148

149

150

151

152

153

154

155

157

159

160

161

162

163

164

165

166

167

168

170

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 29 of 64

Page 30

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

Off

Off

On

On

Off

On

Off

On

On

Off

On

On

Off

On

Off

On

Off

On

On

On

Off

On

Off

On

175

On

On

On

On

Off

On

Off

On

Off

Off

Off

Off

On

On

Off

On

177

On

Off

Off

Off

On

On

Off

On

Off

On

Off

Off

On

On

Off

On

On

On

Off

Off

On

On

Off

On

Off

Off

On

Off

On

On

Off

On

On

Off

On

Off

On

On

Off

On

Off

On

On

Off

On

On

Off

On

On

On

On

Off

On

On

Off

On

Off

Off

Off

On

On

On

Off

On

On

Off

Off

On

On

On

Off

On

Off

On

Off

On

On

On

Off

On

On

On

Off

On

On

On

Off

On

188

Off

Off

On

On

On

On

Off

On

On

Off

On

On

On

On

Off

On

190

Off

On

On

On

On

On

Off

On

On

On

On

On

On

On

Off

On

Off

Off

Off

Off

Off

Off

On

On

On

Off

Off

Off

Off

Off

On

On

Off

On

Off

Off

Off

Off

On

On

On

On

Off

Off

Off

Off

On

On

Off

Off

On

Off

Off

Off

On

On

On

Off

On

Off

Off

Off

On

On

Off

On

On

Off

Off

Off

On

On

On

On

On

Off

Off

Off

On

On

Off

Off

Off

On

Off

Off

On

On

201

On

Off

Off

On

Off

Off

On

On

Off

On

Off

On

Off

Off

On

On

203

On

On

Off

On

Off

Off

On

On

Off

Off

On

On

Off

Off

On

On

On

Off

On

On

Off

Off

On

On

Off

On

On

On

Off

Off

On

On

On

On

On

On

Off

Off

On

On

Off

Off

Off

Off

On

Off

On

On

On

Off

Off

Off

On

Off

On

On

Off

On

Off

Off

On

Off

On

On

On

On

Off

Off

On

Off

On

On

Off

Off

On

Off

On

Off

On

On

On

Off

On

Off

On

Off

On

On

214

Off

On

On

Off

On

Off

On

On

On

On

On

Off

On

Off

On

On

216

Off

Off

Off

On

On

Off

On

On

GF-129

Address

172

173

174

176

178

179

180

181

182

183

184

185

186

187

189

A0 A1 A2 A3 A4 A5 A6 A7

191

192

193

194

195

196

197

198

199

200

202

204

205

206

207

208

209

210

211

212

213

215

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 30 of 64

Page 31

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

On

Off

Off

On

On

Off

On

On

Off

On

Off

On

On

Off

On

On

On

On

Off

On

On

Off

On

On

220

Off

Off

On

On

On

Off

On

On

On

Off

On

On

On

Off

On

On

222

Off

On

On

On

On

Off

On

On

On

On

On

On

On

Off

On

On

Off

Off

Off

Off

Off

On

On

On

On

Off

Off

Off

Off

On

On

On

Off

On

Off

Off

Off

On

On

On

On

On

Off

Off

Off

On

On

On

Off

Off

On

Off

Off

On

On

On

On

Off

On

Off

Off

On

On

On

Off

On

On

Off

Off

On

On

On

On

On

On

Off

Off

On

On

On

Off

Off

Off

On

Off

On

On

On

233

On

Off

Off

On

Off

On

On

On

Off

On

Off

On

Off

On

On

On

235

On

On

Off

On

Off

On

On

On

Off

Off

On

On

Off

On

On

On

On

Off

On

On

Off

On

On

On

Off

On

On

On

Off

On

On

On

On

On

On

On

Off

On

On

On

Off

Off

Off

Off

On

On

On

On

On

Off

Off

Off

On

On

On

On

Off

On

Off

Off

On

On

On

On

On

On

Off

Off

On

On

On

On

Off

Off

On

Off

On

On

On

On

On

Off

On

Off

On

On

On

On

246

Off

On

On

Off

On

On

On

On

On

On

On

Off

On

On

On

On

248

Off

Off

Off

On

On

On

On

On

On

Off

Off

On

On

On

On

On

Off

On

Off

On

On

On

On

On

On

On

Off

On

On

On

On

On

Off

Off

On

On

On

On

On

On

On

Off

On

On

On

On

On

On

Off

On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

GF-129

Address

217

218

219

221

223

224

225

226

227

228

229

230

231

232

234

A0 A1 A2 A3 A4 A5 A6 A7

236

237

238

239

240

241

242

243

244

245

247

249

250

251

252

253

254

255

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 31 of 64

Page 32

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

(This page left intentionally blank)

GF-129

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

Page 32 of 64

Page 33

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

C-more 1

1

C-more 2

2

C-more 3

3

C-more 5

5

C-more 6

6

C-more 7

7

C-more 8

8

C-more 9

9

C-more 11

11

C-more 12

12

ACS /BMS II/BMS

128

Modulex 1

1

Modulex 3

3

Modulex 4

4

ACS /BMS II/BMS

128

ECS 1

29

30

ECS 3

31

ECS 4

32

ECS 1

17

ECS 2

18

ECS 3

19

ECS 4

20

ECS 5

21

22

Appendix C. CONFIGURATION INFORMATION

C.1 Default Modbus RTU COM Settings for AERCO Controllers

GF-129

Serial Port Setting ACS, BMS II, BMS ECS/SP

BCM

(Modulex)

Baud Rate ≤19200 ≤38.4 9600 9600

Data Bits 8 8 8 8

Stop Bits 1 1 1 1

Parity None None None None

Configuration Controllers

C-more 4

12

C-More

Controllers

&

1 ACS/BMS II/BMS

C-more 10

4

Modulex

Controllers

&

1 ACS/BMS II

Modulex 2

Modbus Default

Address

4

10

2

C-More

4

ECS/SP

ECS 2

For Profiles defined in Section C.2.6, the ECS/SP Modbus default point addresses are defined below.

Configuration Controllers

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 VD2:011712

6

ECS/SP

ECS 6

Modbus Default

Address

Page 33 of 64

Page 34

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

03-Net Remote Setpt

setpt_1 AV:24

data float

3

nviSetpt1

inc count (9)

Input (non-polling)

05-Fire Rate In

boilerload_1

AV:28

data float

5

nvoBlrLoad1

inc count (9)

Output (non-polled)

06-Outlet Temp

localsuptemp_1

AV:29

data float

6

nvoLocSupTmp1

inc count (9)

Output (non-polled)

30012-30013/1

30014-30015/1

30009/2

30017/2

40001/2

30018/2

30003/2

30001/2

30002/2

30012-30013/2

30014-30015/2

30009/3

30017/3

40001/3

30018/3

C.2 BACnet/IP, BACnet MS/TP, Metasys N2, and LonWorks Points List

C.2.1 - Four C- M ores and One ACS/BMS II/BMS

Equipment Point Name Name Read Only BACnet Type:ID N2 Type N2 ID Lon SNVT NAME Lon SNVT Lon Direction ModBus/Unit Addr.

Blr Addr 1

01-Fire Rate Out boilerstate_1

02-Active Setpoint effectsetpt_1

07-Display Code dispcode_1

08-Unit Status unitstat_1

09-Run Cycles runcycles_1

10-Run Hours runhours_1

Blr Addr 2

01-Fire Rate Out boilerstate_2

02-Active Setpoint effectsetpt_2

03-Net Remote Setpt setpt_2 AV:47 data float 13 nviSetpt2 inc count (9) Input (non-polling)

05-Fire Rate In boilerload_2

06-Outlet Temp localsuptemp_2

07-Display Code dispcode_2

08-Unit Status unitstat_2

09-Run Cycles runcycles_2

10-Run Hours runhours_2

Blr Addr 3

01-Fire Rate Out boilerstate_3

02-Active Setpoint effectsetpt_3

03-Net Remote Setpt setpt_3 AV:56 data float 23 nviSetpt3 inc count (9) Input (non-polling)

05-Fire Rate In boilerload_3

AV:26 data float 1 nvoBlrState1 inc count (9) Output (non-polled)

AV:27 data float 2 nvoEffSetpt1 inc count (9) Output (non-polled)

AV:22 data float 7 nvoDispCode1 inc count (9) Output (non-polled)

AV:23 data float 8 nvoUnitStat1 inc count (9) Output (non-polled)

AV:42 data float 9 nvoRunCycles1 51 Output (non-polled)

AV:43 data float 10 nvoRunHours1 51 Output (non-polled)

AV:30 data float 11 nvoBlrState2 inc count (9) Output (non-polled)

AV:46 data float 12 nvoEffSetpt2 inc count (9) Output (non-polled)

AV:50 data float 15 nvoBlrLoad2 inc count (9) Output (non-polled)

AV:51 data float

16 nvoLocSupTmp2 inc count (9) Output (non-polled)

AV:52 data float 17 nvoDispCode2 inc count (9) Output (non-polled)

AV:53 data float 18 nvoUnitStat2 inc count (9) Output (non-polled)

AV:44 data float 19 nvoRunCycles2 51 Output (non-polled)

AV:45 data float 20 nvoRunHours2 51 Output (non-polled)

AV:54 data float 21 nvoBlrState3 inc count (9) Output (non-polled)

AV:55 data float 22 nvoEffSetpt3 inc count (9) Output (non-polled)

AV:60 data float 25 nvoBlrLoad3 inc count (9) Output (non-polled)

30009/1

30017/1

40001/1

30018/1

30003/1

30001/1

30002/1

VD2:011712

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 34 of 64

Page 35

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

30003/3

30001/3

30002/3

30012-30013/3

30014-30015/3

30009/4

30017/4

05-Fire Rate In

boilerload_4

AV:73

data float

35

nvoBlrLoad4

inc count (9)

Output (non-polled)

06-Outlet Temp

localsuptemp_4

AV:65

data float

36

nvoLocSupTmp4

inc count (9)

Output (non-polled)

30012-30013/4

30014-30015/4

30005/128

30006/128

Net Header Set

40005/128

30002/128

30003/128

30011/128

30008/128

30009/128

30017/128

30018/128

30019/128

30020/128

30021/128

C.2.1 - Four C-Mores and One ACS/BMS II/BMS (Cont.)

Equipment Point Name Name Read Only BACnet Type:ID N2 Type N2 ID Lon SNVT NAME Lon SNVT Lon Direction ModBus/Unit Addr.

06-Outlet Temp localsuptemp_3

07-Display Code dispcode_3

08-Unit Status unitstat_3

09-Run Cycles runcycles_3

10-Run Hours runhours_3

Blr Addr 4

01-Fire Rate Out boilerstate_4

02-Active Setpoint effectsetpt_4

03-Net Remote Setpt setpt_4 AV:72 data float 33 nviSetpt4 inc count (9) Input (non-polling)

07-Display Code dispcode_4

08-Unit Status unitstat_4

09-Run Cycles runcycles_4

10-Run Hours runhours_4

BMS Addr 128

01-Fire Rate Out boilerstate_5

02-Header Set Temp effectsetpt_5

03Temp setpt_5

04-Header Temp localsuptemp_5

05-Outside Air Temp localoatemp_5

06-Display Code dispcode_5

07-Num Boilers Fired blrfired_5

08-Num Boilers Online blronline_5

09-Last Blr Fired blrlast_5

10-Boiler 1 Status blr1stat_5

11-Boiler 2 Status blr2stat_5

12-Boiler 3 Status blr3stat_5

13-Boiler 4 Status blr4stat_5

AV:33

AV:61 data float

26 nvoLocSupTmp3 inc count (9) Output (non-polled)

AV:62 data float 27 nvoDispCode3 inc count (9) Output (non-polled)

AV:63 data float 28 nvoUnitStat3 inc count (9) Output (non-polled)

AV:58 data float 29 nvoRunCycles3 51 Output (non-polled)

AV:59 data float 30 nvoRunHours3 51 Output (non-polled)

AV:70 data float 31 nvoBlrState4 inc count (9) Output (non-polled)

AV:71 data float 32 nvoEffSetpt4 inc count (9) Output (non-polled)

AV:66 data float 37 nvoDispCode4 inc count (9) Output (non-polled)

AV:67 data float 38 nvoUnitStat4 inc count (9) Output (non-polled)

AV:68 data float 39 nvoRunCycles4 51 Output (non-polled)

AV:69 data float 40 nvoRunHours4 51 Output (non-polled)

AV:31 data float 41 nvoBlrState inc count (9) Output (non-polled)

AV:32 data float 42 nvoEffSetpt inc count (9) Output (non-polled)

data float

AV:34 data float

43

nviSetpt inc count (9)

Input (non-polling)

44 nvoLocSupTmp inc count (9) Output (non-polled)

AV:35 data float 45 nvoLocOATmp inc count (9) Output (non-polled)

AV:36 data float 46 nvoDispCode inc count (9) Output (non-polled)

AV:37 data float 47 nvoBlrsFired inc count (9) Output (non-polled)

AV:38 data float 48 nvoBlrsOnline inc count (9) Output (non-polled)

AV:39 data float 49 nvoLastBlrFired inc count (9) Output (non-polled)

AV:40 data float 50 nvoBlr1Stat inc count (9) Output (non-polled)

AV:41 data float 51 nvoBlr2Stat inc count (9) Output (non-polled)

AV:48 data float 52 nvoBlr3Stat inc count (9) Output (non-polled)

AV:1 data float 53 nvoBlr4Stat inc count (9) Output (non-polled)

40001/4

30018/4

30003/4

30001/4

30002/4

VD2:011712

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 35 of 64

Page 36

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

GF-129

30022/128

30023/128

30024/128

30025/128

30026/128

30027/128

30028/128

30029/128

Only

Address

30009/1

30017/1

40001/1

30018/1

30003/1

30001/1

30002/1

30012-30013/1

30014-30015/1

30009/2

30017/2

40001/2

30018/2

30003/2

30001/2

30002/2

30012-30013/2

C.2.1 - Four C-Mores and One ACS/BMS II/BMS (Cont.)

Equipment Point Name Name Read Only BACnet Type:ID N2 Type N2 ID Lon SNVT NAME Lon SNVT Lon Direction ModBus/Unit Addr.

14-Boiler 5 Status blr5stat_5

15-Boiler 6 Status blr6stat_5

16-Boiler 7 Status blr7stat_5

17-Boiler 8 Status blr8stat_5

18-Net Blr 1 Status blr9stat_5

19-Net Blr 2 Status blr10stat_5

20-Net Blr 3 Status blr11stat_5

21-Net Blr 4 Status blr12stat_5

C.2.2 - Eight C - Mores and One ACS/BMS II/BMS

AV:2 data float 54 nvoBlr5Stat inc count (9) Output (non-polled)

AV:3 data float 55 nvoBlr6Stat inc count (9) Output (non-polled)

AV:4 data float 56 nvoBlr7Stat inc count (9) Output (non-polled)

AV:5 data float 57 nvoBlr8Stat inc count (9) Output (non-polled)

AV:6 data float 58 nvoNetBlr1Stat inc count (9) Output (non-polled)

AV:7 data float 59 nvoNetBlr2Stat inc count (9) Output (non-polled)

AV:8 data float 60 nvoNetBlr3Stat inc count (9) Output (non-polled)

AV:9 data float 61 nvoNetBlr4Stat inc count (9) Output (non-polled)

Equipment Point Name Name

Blr Addr 1

Blr Addr 2

01-Fire Rate Out boilerstate_1

02-Active Setpoint effectsetpt_1

03-Net Remote Setpt setpt_1 AV:24 data float 3 nviSetpt1 inc count (9) Input (non-polling)

05-Fire Rate In boilerload_1

06-Outlet Temp localsuptemp_1

07-Display Code dispcode_1

08-Unit Status unitstat_1

09-Run Cycles runcycles_1

10-Run Hours runhours_1

01-Fire Rate Out boilerstate_2

02-Active Setpoint effectsetpt_2

03-Net Remote Setpt setpt_2 AV:47 data float 13 nviSetpt2 inc count (9) Input (non-polling)

05-Fire Rate In boilerload_2

06-Outlet Temp localsuptemp_2

07-Display Code dispcode_2

08-Unit Status unitstat_2

09-Run Cycles runcycles_2

Read

BACnet Type:ID N2 Type N2 ID Lon SNVT NAME Lon SNVT Lon Direction

AV:26 data float 1 nvoBlrState1 inc count (9) Output (non-polled)

AV:27 data float 2 nvoEffSetpt1 inc count (9) Output (non-polled)

AV:28 data float 5 nvoBlrLoad1 inc count (9) Output (non -polled)

AV:29 data float 6 nvoLocSupTmp1 inc count (9) Output (non-polled)

AV:22 data float 7 nvoDispCode1 inc count (9) Output (non -polled)

AV:23 data float 8 nvoUnitStat1 inc count (9) Output (non-polled)

AV:42 data float 9 nvoRunCycles1 51 Output (non-polled)

AV:43 data float 10 nvoRunHours1 51 Output (non-polled)

AV:30 data float 11 nvoBlrState2 inc count (9) Output (non-polled)

AV:46 data float 12 nvoEffSetpt2 inc count (9) Output (non-polled)

AV:50 data float 15 nvoBlrLoad2 inc count (9) Output (non -polled)

AV:51 data float 16 nvoLocSupTmp2 inc count (9) Output (non-polled)

AV:52 data float 17 nvoDispCode2 inc count (9) Output (non -polled)

AV:53 data float 18 nvoUnitStat2 inc count (9) Output (non-polled)

AV:44 data float 19 nvoRunCycles2 51 Output (non-polled)

ModBus/Unit

VD2:011712

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 36 of 64

Page 37

USER MANUAL

AERCO/ProtoNode Gateway

OMM-0080_0D

Only

Address

30014-30015/2

30009/3

40001/3

30003/3

30002/3

30014-30015/3

30009/4

40001/4

30003/4

30002/4

30014-30015/4

30009/5

40001/5

30003/5

30002/5

30014-30015/5

30009/6

C.2.2 - Eight C-Mores and One ACS/BMS II/BMS (Cont.)

Equipment Point Name Name

Blr Addr 3

Blr Addr 4

Blr Addr 5

Blr Addr 6

10-Run Hours runhours_2

01-Fire Rate Out boilerstate_3

02-Active Setpoint effectsetpt_3

03-Net Remote Setpt setpt_3 AV:56 data float 23 nviSetpt3 inc count (9) Input (non-polling)

05-Fire Rate In boilerload_3

06-Outlet Temp localsuptemp_3

07-Display Code dispcode_3

08-Unit Status unitstat_3

09-Run Cycles runcycles_3

10-Run Hours runhours_3

01-Fire Rate Out boilerstate_4

02-Active Setpoint effectsetpt_4

03-Net Remote Setpt setpt_4 AV:72 data float 33 nviSetpt4 inc count (9) Input (non-polling)

05-Fire Rate In boilerload_4

06-Outlet Temp localsuptemp_4

07-Display Code dispcode_4

08-Unit Status unitstat_4

09-Run Cycles runcycles_4

10-Run Hours runhours_4

01-Fire Rate Out boilerstate_5

02-Active Setpoint effectsetpt_5

03-Net Remote Setpt setpt_5 AV:82 data float 43 nviSetpt5 inc count (9) Input (non-polling)

05-Fire Rate In boilerload_5

06-Outlet Temp localsuptemp_5

07-Display Code dispcode_5

08-Unit Status unitstat_5

09-Run Cycles runcycles_5

10-Run Hours runhours_5

01-Fire Rate Out boilerstate_6

Read

GF-129

BACnet Type:ID N2 Type N2 ID Lon SNVT NAME Lon SNVT Lon Direction

AV:45 data float 20 nvoRunHours2 51 Output (non-polled)

AV:54 data float 21 nvoBlrState3 inc count (9) Output (non-polled)

AV:55 data float 22 nvoEffSetpt3 inc count (9) Output (non-polled)

AV:60 data float 25 nvoBlrLoad3 inc count (9) Output (non-polled)

AV:61 data float 26 nvoLocSupTmp3 inc count (9) Output (non-polled)

AV:62 data float 27 nvoDispCode3 inc count (9) Output (non-polled)